Page 1

LP GAS CONVERSION INSTRUCTIONS

For Thermador Professional® Cooktops and Dual Fuel Ranges

INSTRUCTIONS DE

CONVERSION DE GAZ LP

Pour toutes les cuisinières mixtes

Thermador Professional

®

INSTRUCCIONES DE

Model/

Modèle /

Modelo:

PALPKITHC

CONVERSION DE GAS LP

Para Parillas y Estufas de Todo Tipo de Gas

Thermador Professional

®

Page 2

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table 1: Conversion Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2: LP Orifice Conversion Chart (by Model Number) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Replacing Burner Orifices in Cooktop / Rangetop . . . . . . . . . . . . . . . . . . . . . . . . 3

Accessing the Gas Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Converting the Gas Regulator to LP Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

®

Setting Manual Valve Screws for the Star

Check for Gas Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Burner Testing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Burners . . . . . . . . . . . . . . . . . . . . . . . 7

Final Step—Placement of LP Conversion Label . . . . . . . . . . . . . . . . . . . . . . . . . 11

This Thermador Appliance is made by

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 3

Safety

Important Safety Instructions

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING

Natural Gas to Propane (LP) Gas Conver sion Kit for

Thermador Professional

Ranges

FOR RESIDENTIAL USE ONLY

IMPORTANT:

Only a qualified service technician or installer should make

this conversion.

INSTALLER:

Please leave these Conversion Instructions with this unit

for the owner.

OWNER:

Please retain these instructions for future reference.

®

Cooktops and Dual Fuel

WARNING:

This conversion kit shall be

installed by a qualified service

agency in accordance with the

manufacturer’s instructions and all

applicable codes and requirements

of the authority having jurisdiction.

If the information in these

instructions is not followed exactly ,

a fire, explosion or production of

carbon monoxide may result

causing property damage,

personal injury or loss of life. The

qualified service agency is

responsible for the proper

installation of this kit. The

installation is not proper and

complete until the operation of the

converted appliance is checked as

specified in the manufacturer’s

instructions supplied with the kit.

®

Contains Star

Propane Gas operation for all burners in cooktop or

rangetop section of the following series models.

Save the natural gas parts for possible conversion from LP

back to the natural gas in the future.

This kit is used to convert Thermador Professional

Cooktops and PRO-HARMONY™ Dual-Fuel Ranges from

natural gas to Propane (LP) Gas operation. This kit cannot

be used to convert older models of Thermador Professional

cooktops or ranges (see TABLE 2

to convert Thermador Professional

burners, or any other brand of appliance.

Burner orifices for proper conversion to

®

). This kit cannot be used

®

All Gas Ranges, oven

CAUTION:

Disconnect gas and electric power before

making conversion. Before turning power ON,

be sure that all controls are in the OFF position.

To the Service Agent:

It is important that you know the following BEFORE you

begin the gas conversion of the appliance.

• Confirm that the Propane (LP) Gas supply system is

available and ready to use. This is particularly

important for new construction.

• You must plan for sufficient time and resources to

perform the LP conversion process properly and

completely before leaving the job site. Every step

described in these instructions must be performed to

safely convert the appliance for proper operation on

Propane Gas. INCOMPLETE OR INADEQUATE GAS

CONVERSION OF THE APPLIANCE CAN CREATE A

SAFETY HAZARD.

English 1

Page 4

California Safe Drinking Water and Toxic Enforcement Act (Proposition 65) Notice:

WARNING:

This product contains or, through ordinary use

for its intended purpose, facilitates emission of a

chemical or chemicals known to the State of

California to cause cancer and/or birth defects

or other reproductive harm. To minimize

exposure to these chemicals:

Conversion Instructions

1. Perform the LP conversion according to the instructions in this manual.

2. The conversion and adjustment to the burners should be done by a certified installer or agency to ensure proper combustion.

3. Always operate the unit according to the instructions provided with your Range or Cooktop.

4. Ensure proper ventilation with an open window or use a ventilation fan or hood when cooking with Gas.

Before You Begin

CAUTION:

Before proceeding with the conversion, shut off

the gas supply to the appliance prior to

disconnecting the electrical power.

Tools Needed:

• Scissors

• 7mm -or- 9/32” socket with 1/4” driver & extension

• T-30 -or- T-27 Torx driver

• 4mm hex Allen wrench

• Large, slotted screwdriver, 0.40” X .050” blade

• Extra large, slotted screwdriver, 0.60” X .060” blade

• 7/8” wrench -or- 7/8” socket & drive

• T-20 Torx driver

• Precision screwdriver, 1/8” X .020” blade

• Soap & water mixture -or- leak-check solution

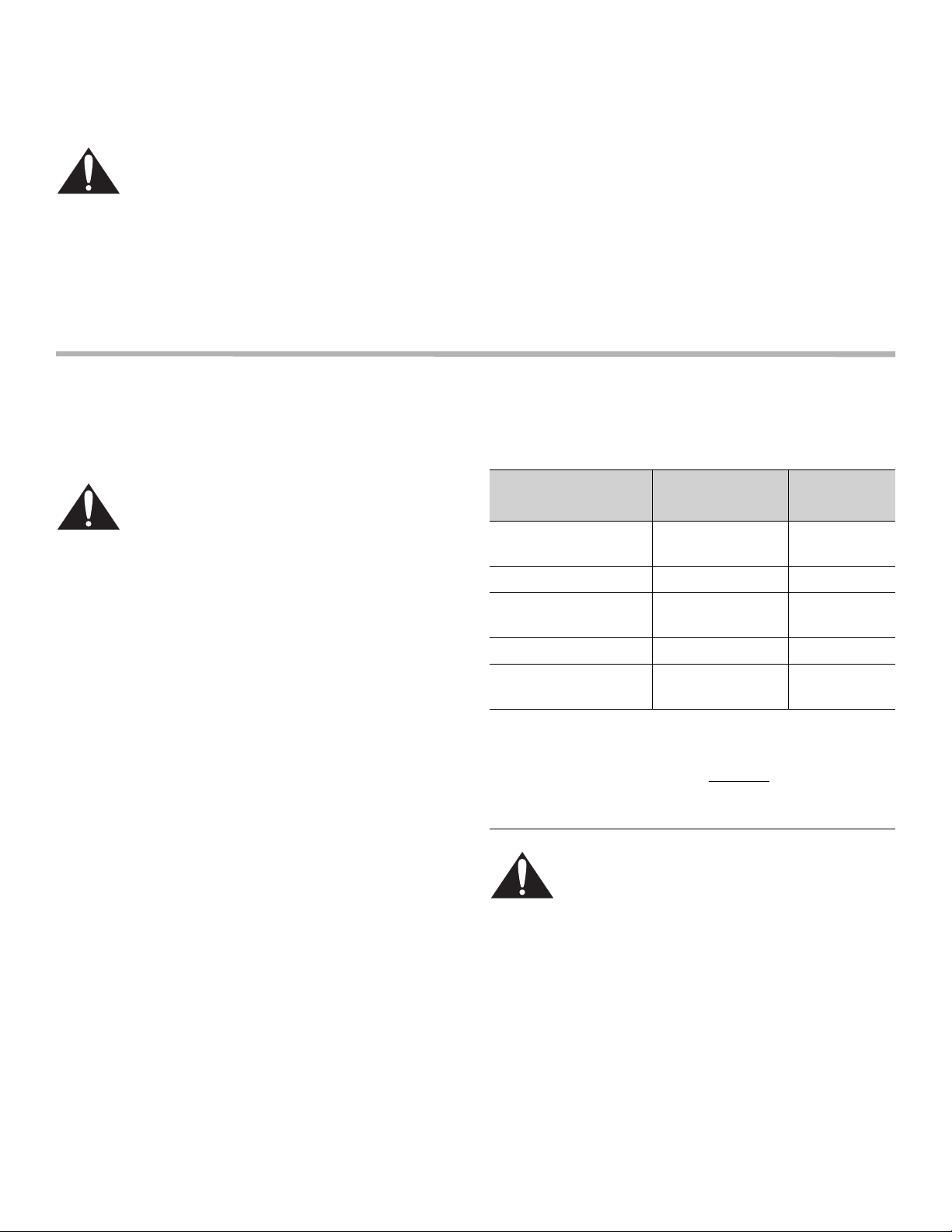

Table 1: Conversion Kit Contents

Description

PALPKITHC

Instructions

Foam Tape, 1” piece 418145 1 Propane Conversion

Label Plastic Bag 418148 1 Star Burner Jet

Orifice

This Propane Conversion Kit contains the quantities of

parts indicated above; however , some orifices will not be

used depending upon the size of the appliance being

converted to LP Gas. Refer to TABLE 2

appropriate quantity of orifices to be used for each

model.

Service

Number

553122 1

418146 1

617163 6

Quantity

for a list of

CAUTION:

When connecting the unit to propane gas, make

certain the propane gas t ank is equippe d with its

own high pressure regulator. The maximum gas

pressure to this appliance is not to exceed 14.0

inches water column from the propane gas tank

regulator.

English 2

Page 5

When properly converted using the prescribed LP orifices,

the burners will operate at the following flow rates using

Propane (LP) Gas:

Replacing Burner Orifices in Cooktop / Rangetop

•Star

®

Burners — 15,000 BTU/hr. [4.3 9 kW] each, using

1.15mm orifices.

WARNING:

NEVER leave the gas conversion partially

completed. If the appliance is operated wh ile the

gas conversion is incomplete, high levels of

carbon monoxide may be emitted, or a fire or

explosion may occur .

WARNING:

If the Natural Gas orifices are left in place while

attempting to operate the appliance using

Propane (LP) Gas, at the higher pressure

setting for LP Gas, the burners will produce

large flames which may emit high levels of

carbon monoxide into the room, or a fire or

explosion may occur .

Table 2: LP Orifice Conversion Chart (by Model Number)

NOTICE:

After the replacement of each orifice, and before

reassembly of the burner, perform a brief gas leakage

check of the orifice and associated fittings, per the "Check

for Gas Leaks" section of these instructions.

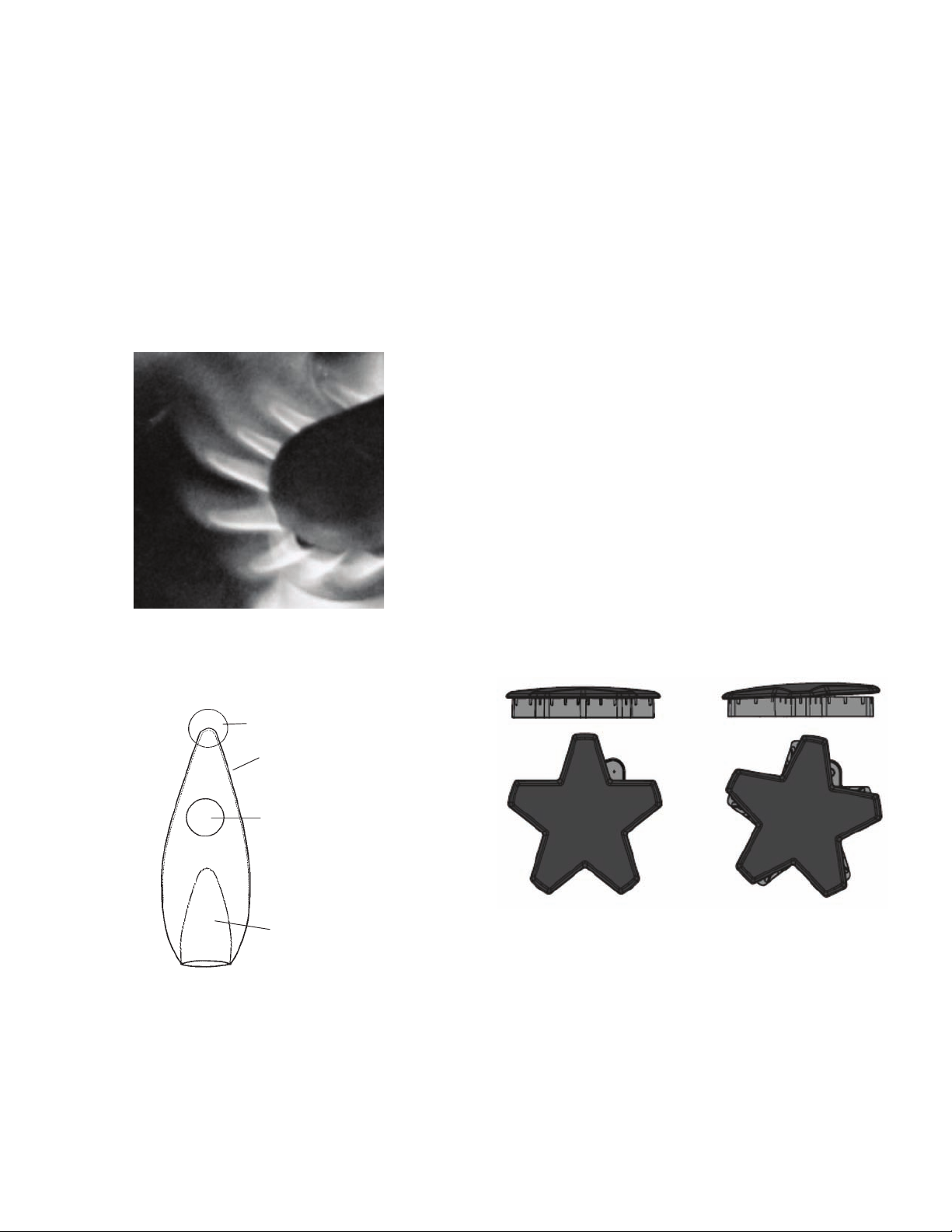

Replace the Star® Burner orifices—all models:

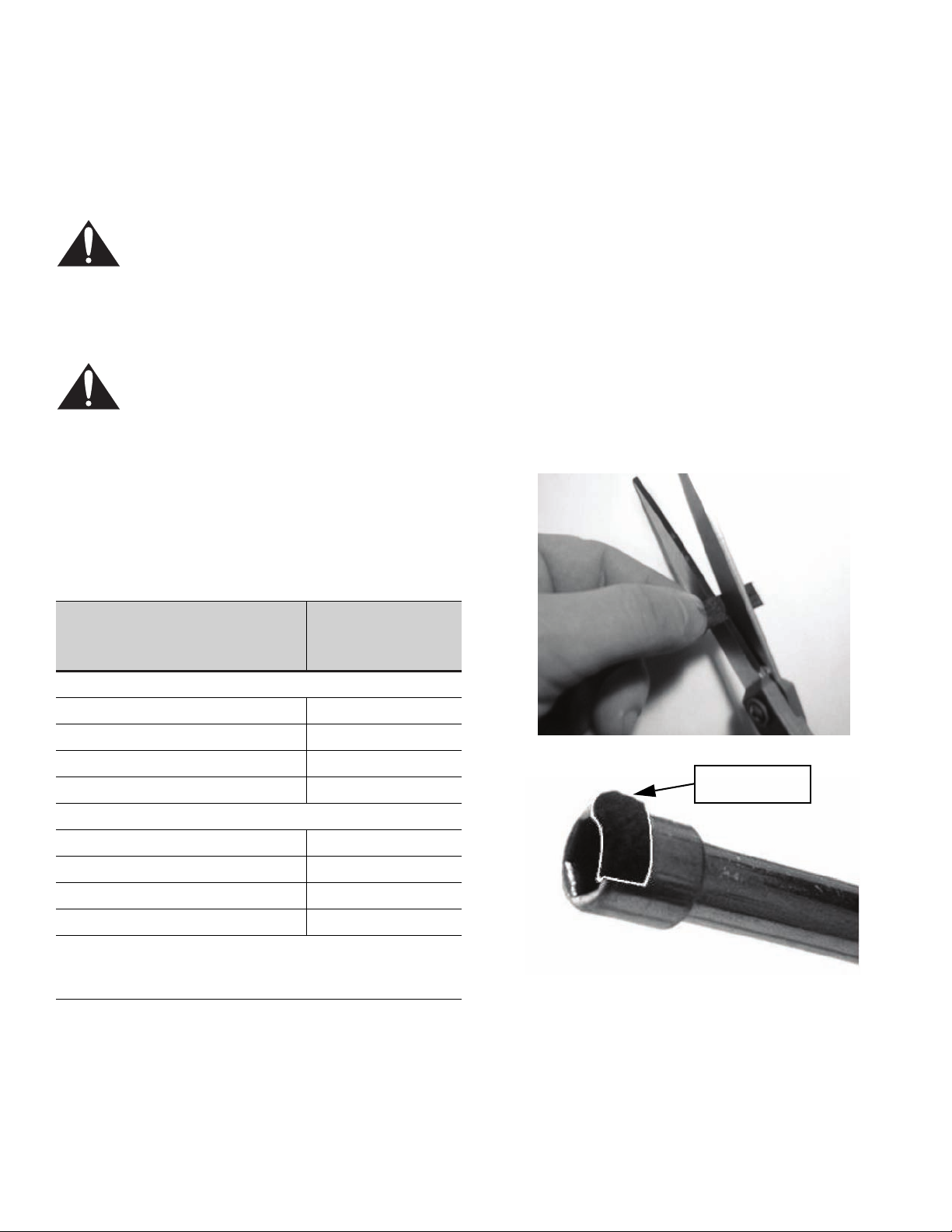

• Cut a 3/8” long piece of the adhesive foam strip

supplied in the kit and place over the edge of the

socket driver used to replace the Star Burner or ifices,

as shown. The foam piece helps to retain the orifice in

the end of the socket, so it will not fall inside the

appliance during orifice removal or installation.

Star Burners

Appliance Model Numbers

Pro Cooktops:

PCG304G 4 each — 1.15mm PCG366G 6 each — 1.15mm PCG364GD* 4 each — 1.15mm PCG486GD* 6 each — 1.15mm

PRO-HARMONY™ Dual-Fuel Ranges:

PRD304GH 4 each — 1.15mm PRD366GH 6 each — 1.15mm PRD364GDH* 4 each — 1.15mm PRD486GDH* 6 each — 1.15mm

NOTE:

* Model numbers with letter "D" have an Electric

Griddle—which do not require conversion to gas.

High Altitude:

For safe LP conversion of an appliance for use at higher

elevations, consult the local gas company for their

recommendations for correct orifice sizes and any other

necessary adjustments that will provide proper gas

combustion at high altitudes.

Jet Orifice

(# 617163)

Foam Strip

English 3

Page 6

• Use a 7mm -or- 9/32” socket with 1/4” driver &

extension to reach down through the venturi and

remove the Natural Gas orifice from the burner’s jet

holder.

• Replace each star burner jet orifice with one of the

1.15mm, LP jets supplied in the kit. These are sized for

the Star Burners to produce 15,000 BTU/hr. [4.39 kW]

flow rate using Propane (LP) Gas.

Accessing the Gas Regulator

All dual-fuel range models and cooktop models have the

gas regulator located inside the cooktop/rangetop, under

the left side of the main top.

• The gas regulator is located inside the cooktop area,

typically near the left-rear corner.

Foam Strip

• Perform a brief gas leakage test of each orifice and

associated supply tube fittings, per the “Check for Gas

Leaks” section of these instructions. Proper access to

the burner’s jet holder can be accomplished after main

top removal — see following section “Accessing the

Gas Regulator” for instructions on how to remove the

main top and shields.

• Each orifice is stamped “115” (1.15mm orifice

diameter), as shown.

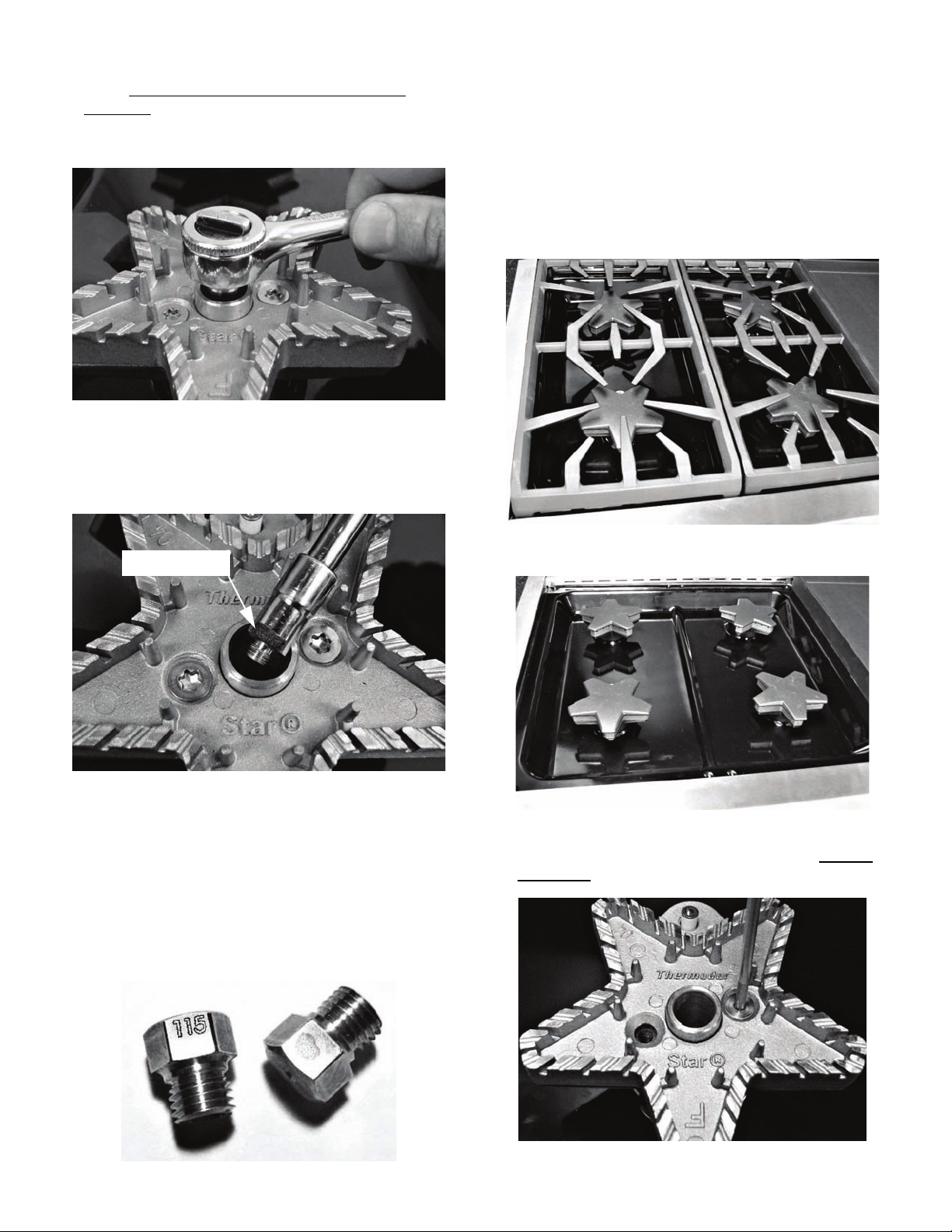

• Remove the cooking grates.

• Remove Star Burner caps, and then remove the two

Torx screws from each burner base using a T-27 or

T-30 driver.

English 4

Page 7

• Disconnect the female terminal on the spark wire from

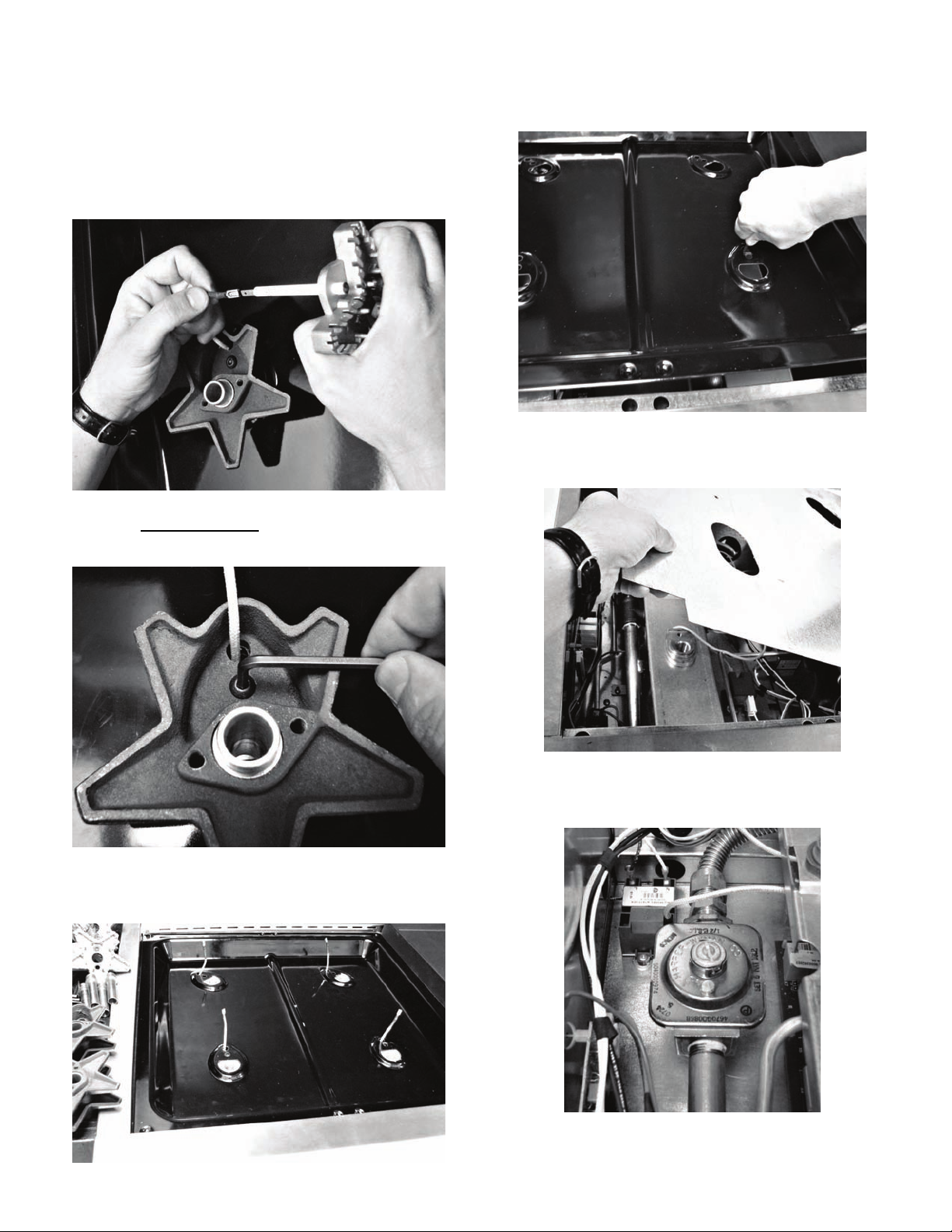

the male terminal on the electrode for each burner.

Important:

The locking tab on the female connector must be

depressed to release from the terminal on the electrode.

• An Allen Wrench or similar item can be used as a hook

to lift the main top up, sufficient for removal.

• Remove the shield under the main top, to access the

components underneath.

• Using a 4mm hex wrench

each of the burner pedestals.

• With the burner assemblies removed, the main top is

ready to be lifted off of the appliance.

, remove the screw attaching

• The gas regulator is located near the left rear corner,

inside the top area of the appliance.

English 5

Page 8

NOTE:

Fallen burner orifices left from the replacement process,

can be retrieved during this step.

Converting the Gas Regulator to LP Operation

WARNING:

If the Natural Gas orifices are left in place while

attempting to operate the appliance using

Propane (LP) Gas, at the higher pressure

setting for LP Gas, the burners will produce

large flames which may emit high levels of

carbon monoxide into the room, or a fire or

explosion may occur. Al l orifice replacements for

LP operation should be performed prior to

regulator conversion.

Harper-Wyman and Maxitrol are the two brands of gas

regulators that can be used on Thermador Professional

products.

®

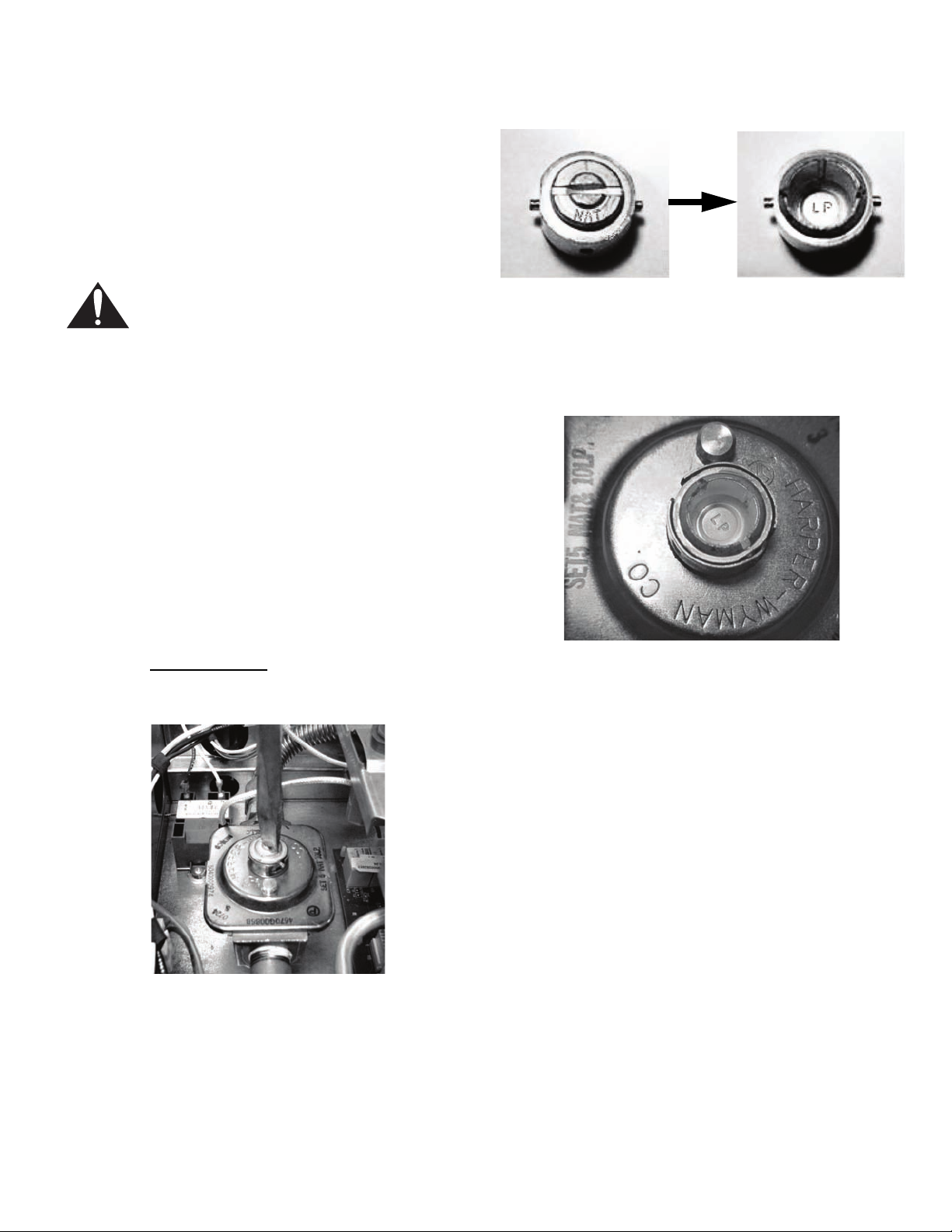

• Flip the conversion cap over to show the recessed

side. “LP” will show at the bottom of the recess.

• Use an extra large, slotted screwdriver, with .60” X

.060” blade, to re-install LP cap.

• Re-insert cap in top of the regulator with recess up ,

“LP” visible. Press down and rotate clockwise to lock

cap position.

Harper-Wyman regulator conversion:

• Use a large, slotted screwdriver, with .40” X .050”

blade, to remove conversion cap.

• Using a large screwdriver

cap and rotate counter-clockwise to release bayo net

mount.

, press down on conversion

English 6

Page 9

Maxitrol regulator conversion:

• Remove conversion cap with a 7/8” socket or wrench.

• Snap-out stem from bottom of the cap, flip stem over to

show “LP” end, and snap stem back into the cap, as

shown.

Flip Stem

Setting Manual Valve Screws for the Star® Burners

Screw driver for valve screw setting:

A precision screwdriver with high-strength blade, similar to

the *Wiha no. 26033

[0.50mm] thickness tip, shown below, should be used to

reposition the bypass screws for minimum flow settings on

manual valves.

*Used by permission from Wiha Quality Tools division of Willi

Hahn Corporation USA.

, with 1/8" [3.0mm] wide, .020"

• Re-install conversion cap —configured for LP gas—

back into top of the Maxitrol regulator.

Valve Screw

English 7

Page 10

Setting valve screws on

PRO-HARMONY™ Dual-Fuel Ranges

-and- Pro Cooktops:

• Remove knob from the valve stem by slowly pulling

knob straight out, away from control panel.

• To engage the valve screw, insert the precision

screwdriver with 1/8” blade into the hole in the bezel

created by removal of the mounting screw.

• Turn the valve screw clockwise just until "bottom out"

position is reached. DO NOT over-tighten the valve

screw.

NOTE:

• It is necessary that the two valves for XLO operation

(farthest left on control panel) are in the OFF position

for proper access to the valve screws through

clearance holes in the XLO potentiometers.

• Remove the bezel-mounting screw located to the right

of the valve stem, using a T-20 Torx driver

English 8

.

Page 11

Check for Gas Leaks

WARNING:

DO NOT use a flame of any kind to check for

gas leaks.

Burner Testing and Adjustment

Checking manifold pressure

(if necessary):

Gas leakage checking using a liquid

solution:

The replacement orifices in the PALPKITHC, LP

conversion kit, have straight threads (not pipe threads) and

do not require thread sealing compound.

Leak-checking should occur after the orifice conversio n is

complete, and before the burner is reassembled and

tested.

• Make sure that all of the LP orifices have been

tightened and that all valves and controls are in the

OFF position.

• Turn on electrical and gas supplies.

• Briefly evaluate the threaded connection of each

replaced orifice individually—that is, one orifice at a

time.

• Spray a g enero us a mou nt of so ap & water m i xture—or

other solution designed for checking gas leaks—on the

threaded junction at the base of the orifice. Avoid

spraying electrical devices. (A 25% dishwashing liquid

to water mixture is effective for this.)

• Briefly turn on the valve or control while blocking the

orifice hole with a soft pencil eraser, your finger, or

something similar.

Note:

It is normal to hear spark ignition noise during this process.

• Monitor the base of the orifice junction to see if bubbles

are forming anywhere around the threaded connection.

• Bubbles forming are indications of gas leaks. The

amount and sizes of the bubbles are indications of the

severity of the leakage.

• Repair all gas leaks immediately after their discovery;

this can often be accomplished by re-tightening the

orifice.

• Since considerable torque is sometimes used during

orifice replacement, leak-check other fitting junctions

leading up to the orifice as well.

• Turn off the gas and electrical supplies.

• Reassemble the appliance in preparation for testing

the newly-converted burner systems.

Checking the appliance manifold pressure is NOT

REQUIRED for the Propane Gas conversion; however, if

the outlet pressure of the gas regulator or the inlet pressure

to the appliance is suspect, the following procedure can be

used to check the manifold pressure.

• A manifold pressure measurement can be acquired at

one of the star burner orifices, as shown.

• Attach a portable or hand-held manometer, that reads

pressure in inches water column (“WC), using a piece

of PVC or vinyl tubing.

• Turn on the electrical and gas supplies to the cooktop

or range.

• Turn on one of the top burners to HI position. This is

important to acquire a true pressure reading u nder g as

flow conditions.

• Turn the manual valve for the burner being monitored

to HI position. (Spark ignition noise will be heard

coming from this burner.)

• The manifold pressure reading on the manometer

should be between 9.50 and 10.50“WC for an

appliance regulator converted to LP gas.

• If the manifold pressure reading is below this range,

verify that the regulator has been properly converted

for use with LP gas, and that the inlet pressure to the

appliance is between 11.0 and 14.0”WC.

English 9

Page 12

Checking LP flame characteristics & burner performance:

To observe the burner flames, remove th e minimum

number of components necessary for an un-obstructed

view. It may be ne ce ssary to tu rn off lights or close window

blinds to darken the room for easier viewing of the flame.

• Test Burner Ignition. Push in the burner control knob

and turn counter-clockwise (CCW) to “HI”. The ignitor

electrode & spark module will produce a clicking

sound. Once the air has been purged from the supply

lines, the burner should light within four (4) seconds.

• The LP flames should be stable, with no excessive

noise. The inner cones of the individual flames should

be well defined and distinctly separate from each other .

• Adjust the burner’s control valve to “LO” or “SIM” to

see that the flame continues to wrap around the burner .

Blow out the flame, or use a quick fan motion from a

writing tablet or piece of cardboard to extinguish the

flame, and then observe the burner’s ability to re-ignite

and wrap around (“carry-over”) the burner within

several seconds. The flame “carry-over” is essential for

proper burner ignition and re-ignition.

• Test re-ignition of the two Star

of the appliance by turning the control knobs to “XLO”

and observe the carry-over of the small simmer flames

as the XLO system cycles the two burners on and off.

• If the flame performance is not acceptable, verify that

the burner has the correct size LP orifice installed, and

that the regulator has been properly converted for LP

Gas.

• If the burner flame is uneven, flutters, makes ex cessive

noise, or lifts, some of the slots in the burne r base may

be blocked with food spillage or other debris. Clogged

slots can be cleared using a straightened paper clip,

needle, or similar object. Hard-to-remove, encrusted

food or debris can sometimes be removed using a

steel wool pad or fine-wire brush.

• A flame that is “lazy”, with excessively-long flames, can

be created by an in-correctly fitted burner cap. Many of

the outer mantles of the individual flames will tend to

“coalesce” or blend together. Verify that the b urner cap

is seated properly on its burner base. The cap should

fit reasonably flat when correctly-positioned in the ba se

and not rock significantly. (See illustration below.)

®

Burners on the left side

Dark Blue

Secondary

Cone

Light Blue

Primary

Cone

• Portions of the flame, along the burner, should not

exhibit excessive or continuous indications of “lifting” or

“lazy flame”.

• It is normal for slight yellow tipping of the flames to

appear after a few minutes of operation using Propane

(LP) Gas. Orange-colored streaks in the flame are

produced from burning airborne debris; this is normal

during initial start up and should dissipate within a few

minutes of operation.

Correct Burner

Cap Placement

Incorrect Burner

Cap Placement

English 10

Page 13

Final Step—Placement of LP Conversion Label

WARNING:

NEVER leave the gas conversion partially

completed. If the appliance is operated wh ile the

gas conversion is incomplete, high levels of

carbon monoxide may be emitted, or a fire or

explosion may occur .

IMPORTANT:

For proper identification and evidence of the appliance’s

conversion to Propane (LP) Gas, affix the provided

Conversion Label in a location next to the Rating Labels on

the appliance. This is particularly important if the converted

appliance is re-installed in a different home.

Location of Rating Labels on Thermador

®

Professional

Rating labels are found at various locations on the

appliances, depending upon the model series:

•Pro Cooktops

the underside, chassis bottom of the cooktop, and can

be accessed inside the cabinet area, underneath the

unit.

• Pro-Harmony Dual-Fuel Ranges

typically located either under the front edge o f rangetop

section -or- on a metal plate, attached with a lanyard to

the range's lower front-frame, behind the kick-panel.

(See illustration below.)

Rating labels on

Pro-Harmony DualFuel Ranges are

accessible under front

edge of rangetop,

with oven door open

or removed.

products:

— Rating labels are typically located on

— Rating labels are

Alternate Location —

Rating labels on label

plate, behind the

kick-panel, attached

with a lanyard to

range’s lower frontframe.

English 11

Page 14

Table des matières

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Importantes consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instructions de conversion . . . . . . . . . . . . . . . . . . . . . . . 2

Avant de commencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 1: Contenu des jeux de conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2: Table de conversion d'orifices à LP (par numéro de modèle) . . . . . . . . . . . . . . . . . 3

Remplacement des orifices des brûleurs de la cuisinière/surface de cuisson . 3

Accès au régulateur de pression du gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conversion du régulateur de pression du gaz pour un fonctionnement au LP . 7

®

Réglage des vis de la soupape manuelle des brûleurs Star

Inspection des fuites de gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Essai et ajustement des brûleurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . 8

Dernière étape — Placer l'étiquette de conversion au LP . . . . . . . . . . . . . . . . . . 12

Cet appareil électroménager de Thermador est fait par

This Thermador Appliance is made by

BSH Home Appliances Corporation

BSH Home Appliances Corporation

5551 McFadden Ave.

5551 McFadden Ave.

Huntington Beach, CA 92649

Huntington Beach, CA 92649

Questions?

Questions ?

1-800-735-4328

1-800-735-4328

www.thermador.com

www.thermador.com

We look forward to hearing from you!

Nous attendons de vos nouvelles !

Page 15

Sécurité

Importantes consignes de sécurité

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS AVANT D'UTILISER CET APPAREIL

Jeu de conversion de gaz naturel au gaz propane (LP)

pour les cuisinières mixtes et les surfaces de cuisson

Professional

POUR USAGE RÉSIDENTIEL SEULEMENT

IMPORTANT :

Seuls un technicien en entretien et en réparation ou un

installateur qualifié devraient procéder à la conversion de

cet appareil.

INSTALLATEUR :

Veuillez laisser les instructions de conversion de cet

appareil au propriétaire.

PROPRIÉTAIRE :

Veuillez conserver ces instructions pour consultation

ultérieure.

Contient des orifices de brûleurs Star

adéquate au gaz propane de tous les brûle urs des surfaces

de cuisson ou des cuisinières des modèles suivants.

®

de Thermador.

®

pour la conversion

AVERTISSEMENT :

Ce jeu de conversion doit être

installé par une entreprise

d'entretien et de réparation

qualifiée conformément aux

instructions du fabricant, ainsi

qu'aux codes et exigences en

vigueur des autorités compétentes.

Si les directives comprises dans

les présentes instructions ne sont

pas suivies avec exactitude, un

incendie, une explosion ou des

émanations de monoxyde de

carbone pourraient survenir, ce qui

pourrait causer des dommages

matériels, entraîner des blessures

ou causer la mort. L'entreprise

d'entretien et de réparation

qualifiée est responsable de

l'installation adéquate de ce jeu de

conversion. L'installation n'est pas

adéquate et complète avant que le

fonctionnement de l'appareil

converti n'ait été vérifié en

conformité avec les instructions

fournies par le fabricant du jeu de

conversion.

Conservez les pièces servant au gaz naturel pour une

future conversion de gaz LP au gaz naturel.

Ce jeu sert à la conversion du gaz naturel au gaz propane

(LP)des surfaces de cuisson Professional

cuisinières mixtes PRO-HARMONY™ de Thermador. Ce

jeu ne peut pas servir à convertir d'anciens modèles de

surfaces de cuisson et de cuisinières Professional de

Thermador (voir TABLEAU 2). Ce jeu ne peut pas être

utilisé pour convertir tous les brûleurs, toutes les

cuisinières à gaz Professional

autre type d'électroménager.

®

de Thermador, ou tout

®

et des

ATTENTION :

Débranchez l'alimentation électrique et

l'alimentation en gaz avant de procéder à la

conversion. Avant de mettre l'appareil sous

tension, assurez-vous que tous les boutons de

contrôle sont hors circuit.

Français 1

Page 16

Au technicien responsable de l'installation :

Il est important que vous preniez connaissance de ce qui

suit AVANT de procéder à la conversion de l'appareil.

Avis de la Loi sur la toxicité et la pot abilité de la Californie (proposition 65) :

• Assurez-vous que le système d'alimentation en gaz

propane (LP) est disponible et prêt à être utilisé. Cela

s'avère particulièrement important pour les nouvelles

constructions.

• Vous devez prévoir suffisamment de temps et de

ressources pour procéder convenablement et en

totalité à la conversion au LP avant de quitter l'endroit

où vous avez effectué le travail. Chaque étape décrite

dans les présentes instructions doit être suivie pour

convertir en toute sécurité l'appareil afin d'assurer un

fonctionnement adéquat au gaz propane. LA

CONVERSION INADÉQUATE OU INCOMPLÈTE DE

L'APPAREIL PEUT CAUSER UN RISQUE

D'ACCIDENT.

AVERTISSEMENT :

Ce produit contient ou facilite l’émission, lors

d’une utilisation ordinaire pour laquelle il est

prévu, d’un ou de plusieurs produits chimiques

qui, selon les connaissances de l’État de la

Californie, peuvent causer le cancer et/ou des

anomalies congénitales ou d’autres problèmes

congénitaux. Pour minimiser toute exposition à

ces produits chimiques :

1. Effectuez la conversion au LP

conformément aux instructions contenues

dans le présent manuel.

2. Pour assurer une combustion adéquate, la

conversion et l’ajustement des brûleurs

devraient être réalisés par une agence ou

un installateur accrédités.

3. Faites toujours fonctionner l’appareil

conformément aux instructions fournies

avec votre cuisinière ou votre surface de

cuisson.

4. Lorsque vous cuisinez au gaz, assurezvous de bien faire aérer la pièce en

ouvrant une fenêtre ou en utilisant un

ventilateur ou une hotte.

Instructions de conversion

Avant de commencer

ATTENTION :

Lorsque vous procédez à la conversion, coupez

l'alimentation en gaz de l'appareil avant de

débrancher l'alimentation électrique.

Outils requis :

• Ciseaux

• Douille de 7 mm (ou 9/32") avec clé de 1/4" et rallonge

• Clé Torx T-30 ou T-27

• Clé Allen de 4 mm

• Grand tournevis pour écrous à fente, lame de 0,40" x

0,050"

• Tournevis très grand pour écrous à fente, lame de

0,60" x 0,060"

• Clé à ouverture fixe de 7/8" ou clé à douille de 7/8"

• Clé Torx T-20 à poignée

• Tournevis d'hor loger avec lame de 1/8" x 0,020"

• Mélange d'eau savonneuse ou solution pour repérer

les fuites

Français 2

Page 17

Tableau 1: Contenu des jeux de conversion

monoxyde de carbone dans la pièce, ou un incendie ou

une explosion pourrait survenir.

Description

Instructions

PALPKITHC

Isolant adhésif,

morceau de 1"

Étiquette de

conversion au

propane

Sac de plastique 418148 1 Orifice de brûleur

®

Star

Ce jeu de conversion au propane contient les quantités

de pièces indiquées ci-dessus; toutefois, certains

orifices ne seront pas utilisés, selon les dimensions de

l'appareil converti au gaz propane. Consultez le

TABLEAU 2 pour les quantités appropriées d'orifices à

utiliser avec chaque modèle.

Numéro de

service

553122 1

418145 1

418146 1

617163 6

Quantité

ATTENTION :

Lorsque vous branchez l'appareil au gaz

propane, assurez-vous que le réservoir de gaz

propane est muni de son propre mécanisme

régulateur à haute pression. La pression de gaz

maximale de cet appareil ne devrait pas

excéder 14,0 pouces de colonne d'eau.

Lorsqu'ils sont convertis adéquatement en utilisant les

orifices LP prévus, les brûleurs fonctionnent au débit de

gaz propane (LP) suivant :

• Brûleurs Star

des orifices de 1,15 mm.

®

- 15 000 BTU/h. [4,39 kW] chacun, avec

Tableau 2: Table de conversion d'orifices à LP (par numéro de modèle)

Numéro de modèle de

l'appareil

Surface de cuisson Professional :

PCG304G 4 chaque - 1,15 mm PCG366G 6 chaque - 1,15 mm PCG364GD* 4 chaque - 1,15 mm PCG486GD* 6 chaque - 1,15 mm

Cuisinières mixtes PRO-HARMONY™ :

PRD304GH 4 chaque - 1,15 mm PRD366GH 6 chaque - 1,15 mm PRD364GDH* 4 chaque - 1,15 mm PRD486GDH* 6 chaque - 1,15 mm

NOTE :

* Les numéros de modèle portant la lettre D signifient

que l'appareil est muni d'une plaque chauffante qui ne

requiert pas de conversion au gaz.

Haute altitude :

Pour effectuer une conversion sécuritaire au gaz propane

pour une utilisation à haute altitude, consultez la société

gazière de votre localité afin d'obtenir ses

recommandations relativement aux dimensions correctes

des orifices et de tout autre ajustement nécessaire qui

assureront la combustion adéquate du gaz.

Orifices

de brûleurs Star

(nº 617163)

®

AVERTISSEMENT :

Ne laissez JAMAIS la conversion au gaz

partiellement terminée. Si l'appareil est utilisé

alors que la conversion n'est pas terminée, de

hauts volumes de monoxyde de carbone

pourraient être relâchés, ou un incendie ou une

explosion pourrait survenir.

AVERTISSEMENT :

Si les orifices à gaz naturel sont laissés en place

et que l'on tente de faire fonctionner l'appareil

avec du gaz propane (LP) au réglage de

pression élevée propre au gaz propane, les

brûleurs produiront de grandes flammes

pouvant émettre de hauts volumes de

Remplacement des orifices des brûleurs de la cuisinière/ surface de cuisson

NOTE :

Après le remplacement de chaque orifice, et avant de

réassembler le brûleur , ef fectuez un bref e ssai d'étan chéité

sur l'orifice et les raccords connexes, conformément à la

section " Inspection des fuites de gaz " des présentes

instructions.

Français 3

Page 18

Remplacement des orifices des brûleurs

®

Star

• Coupez un morceau de 3/8" de mousse adhésive

— Tous les modèles:

fournie avec le jeu de conversion et placez-le sur le

bord de la douille utilisée pour remplacer les orifices

des brûleurs Star

mousse aide à retenir l'orifice au bout de la douille et

l'empêche de tomber à l'intérieur de l'appareil lors du

retrait ou de l'installation de l'orifice.

®

, tel qu'illustré. Le morceau de

Bande de mousse

• Remplacez chaque orifice d'injecteur de brûleur Star

par l'un des injecteurs à LP de 1,15 mm fournis avec le

jeu de conversion. Ces injecteurs sont conçus pour

que les brûleurs Star

h [4,39 kW] avec du gaz propane (LP).

Bande de mousse

• Effectuez un bref essai d'étanchéité sur chaque orifice

et sur les raccords pour tubes connexes,

conformément à la section " Inspection des fuites de

gaz " des présentes instructions. Il est possible d'avoir

accès au porte-injecteur des brûleurs après le retrait de

la plaque principale du dessus de l'appareil. Consultez

la section " Accès au régulateur de pression du gaz "

pour savoir comment enlever la plaque principa le et les

pièces de protection.

• Chaque orifice porte l'inscription " 115 " (diamètre de

l'orifice de 1,15 mm), tel qu'illustré.

®

produisent un débit 15 000 BTU/

®

• Utilisez une douille de 7 mm (ou 9/32") avec une clé de

1/4" et une rallonge pour atteindre l'orifice à gaz naturel

à travers le venturi et pour l'enlever du porte-injecteur

du brûleur.

Français 4

Page 19

Accès au régulateur de pression du gaz

Le régulateur de pression du gaz de tous les modèles de

cuisinières mixtes et de surfaces de cuisson est situé à

l'intérieur de la surface de cuisson ou de la section des

ronds de la cuisinière, sous la plaque principale, du côté

gauche.

• Le régulateur de pression du gaz est situé à l'intérieur

de la plaque principale du dessus de l'appareil,

normalement près du coin arrière gauche.

• Enlevez les cuvettes des brûleurs, puis enlevez les

deux vis Torx à la base de chaque brûleur à l'aid e

d'une clé T-27 ou T-30.

• Débranchez le pôle femelle du pôle mâle du câble

d'allumage de l'électrode de chaque brûleur.

Important :

La languette de verrouillage du connecteur femelle doit

être enfoncée pour retirer le pôle de l'électrode.

• Enlevez les grilles de cuisson.

Français 5

Page 20

• Avec une clé Allen de 4 mm

chacune des bases des brûleurs en place.

, enlevez la vis fixant

• Enlevez les pièces de protection se situant sous la

plaque principale du dessus de l'appareil pour avoir

accès aux composantes.

• Lorsque les assemblages des brûleurs ont été enlevés,

la plaque principale du dessus de l'appareil peut être

retirée.

• Une clé Allen ou une clé semblable peut être utilisée

comme crochet pour soulever et enlever la plaque

principale du dessus de l'appareil.

• Le régulateur de pression du gaz est situé près du coin

arrière gauche, à l'intérieur de la partie supérieure de

l'appareil.

NOTE :

Les orifices des brûleurs qui sont tombés à l'intérieur de

l'appareil lors du processus de remplacement sont

récupérables à ce moment.

Français 6

Page 21

Conversion du régulateur de pression du gaz pour un fonctionnement au LP

AVERTISSEMENT :

Si les orifices à gaz naturel sont laissés en place

et que l'on tente de faire fonctionner l'appareil

avec du gaz propane (LP), au réglage de

pression élevée propre au gaz propane, les

brûleurs produiront de grandes flammes

pouvant émettre de hauts volumes de

monoxyde de carbone dans la pièce, ou un

incendie ou une explosion pourrait survenir. Le

remplacement des orifices pour un

fonctionnement au gaz propane devrait être

réalisé avant la conversion du régulateur.

Harper-Wyman et Maxitrol sont deux marques de

régulateurs de pression du gaz pouvant être utilisées avec

les produits Professional

®

de Thermador.

• Tournez la pièce de conversion pour que le côté

renfoncé soit visible. L'inscription " LP " se trouve au

fond du renfoncement.

• Utilisez un grand tournevis pour écrous à fente avec

une lame de 0,60" x 0,060" pour réinstaller la pièce

pour gaz propane.

• Réinsérez la pièce sur le dessus du régulateur avec la

partie enfoncé vers le haut (vous verrez l'inscription "

LP "). Appuyez et tournez dans le sens horaire pour

fixer la pièce en place.

Conversion avec un régulateur Harper-Wyman :

• Utilisez un grand tournevis pour écrous à fente avec

une lame de 0,40" x 0,050" pour enlever la pièce de

conversion.

• À l'aide d'un grand tournevis

conversion et tournez dans le sens antihoraire pour

dégager le support de baïonnette.

, appuyez sur la pièce de

Français 7

Page 22

Conversion avec un régulateur Maxitrol :

• Enlevez la pièce de conversion avec une clé fixe ou à

douille de 7/8".

• Faites ressortir la tige de la base de la pièce, inversez

la tige de manière à ce que l'extrémité LP soi t visible et

remettez la tige dans la pièce, tel qu'illustré.

Réglage des vis de la soupape

manuelle des brûleurs Star

Tournevis pour le réglage de la vis de la soupape :

Un tournevis d'horloger avec une lame à haute résistance,

semblable au *Wiha nº 26033

largeur de 1/8" [3,0 mm] et d'une épaisseur de 0,020" [0,50

mm], apparaissant sur la photo ci-dessous, devrait être

utilisé pour remettre en place les vis de dérivation et

obtenir les réglages minimaux des soupapes manuelles.

, avec une pointe d'une

®

Inversez la tige

• Réinstallez la pièce de conversion - configurée pour le

gaz propane - sur le régulateur Maxitrol.

*Utilisé avec la permission de la division Wiha Quality Tools de

Willi Hahn Corporation USA.

Vis de la soupape

Français 8

Page 23

Réglage des vis de la soupape pour les cuisinières mixtes PRO-HARMONY™ et les surfaces de cuisson Professional :

• Enlevez le bouton de la tige de la soupape en tirant

lentement le bouton vers l'extérieur, en vous éloignant

du tableau de commande.

• Pour enclencher la vis de la soupape, insérez le

tournevis d'horloger avec une lame de 1/8"

créé par le retrait de la vis.

• Tournez la vis de la soupape dans le sens horaire

jusqu'à ce que vous atteigniez la position de fond de la

vis. NE serrez PAS trop la vis.

NOTE :

• Pour un fonctionnement à XLO (bouton le plus à

gauche sur le tableau de commande), il faut que les

deux soupapes soient à la position hors circuit pour

accéder convenablement aux vis de la soupape à

travers les trous de passage des potentiomètres XLO.

dans le trou

• Enlevez la vis de montage avec collerette

d'encastrement située à la droite de la tige de la

soupape à l'aide d'une clé Torx T-20

.

Inspection des fuites de gaz

AVERTISSEMENT :

N'utilisez P AS un quelconque type de flamme

pour vérifier les fuites de gaz.

Inspection des fuites de gaz avec une solution liquide :

Les orifices de remplacement du jeu de conversion au LP

du PALPKITHC ont un filetage cylindrique (et non un

filetage au pas de gaz) et ne requièrent pas l'utilisation de

mastic pour joints filetés.

L'inspection des fuites devrait se faire une fois que la

conversion des orifices est terminée et avant que les

brûleurs ne soient réassemblés et testés.

• Assurez-vous que tous les orifices LP ont été serrés et

que toutes les soupapes et les commandes sont à la

position OFF.

Français 9

Page 24

• Branchez l'alimentation électrique et l'alimentation en

gaz.

• Testez brièvement et individuellement le raccord fileté

de chaque orifice remplacé - c'est-à-dire un orif ic e à la

fois.

• Vaporisez généreusement avec une solution d'eau

savonneuse - ou toute autre solution conçue pour

vérifier les fuites de gaz - la jonction filetée à la base de

l'orifice. Évitez de vaporiser les composantes

électriques. (Un mélange composé de 25 % de savon

à vaisselle dans de l'eau est efficace pour effectuer

cette vérification.)

• Allumez brièvement la soupape ou la commande en

bloquant le trou de l'orifice avec la gomme à effacer

d'un crayon, votre doigt ou quelque chose de

semblable.

Note :

Il est normal que vous entendiez des bruits d'allumage par

étincelle durant ce processus.

• Surveillez la base de la jonction de l'orifice pour voir si

des bulles se forment autour du raccord fileté.

• Les bulles indiquent qu'il y a une fuite de gaz. La

quantité et la taille des bulles sont des indicateurs de

l'ampleur de la fuite.

• Réparez toutes les fuites de gaz immédiatement lors

de leur découverte; pour ce faire, il suffit souvent de

resserrer l'orifice.

• Puisque les pièces sont parfois serrées fort lors du

remplacement des orifices, vérifiez également les

fuites aux autres jonctions de raccords connexes de

l'orifice.

• Débranchez l'alimentation électrique et fermez

l'alimentation en gaz.

• Réassemblez l'appareil en préparation pour tester le

système de brûleurs nouvellement installé.

Essai et ajustement des brûleurs

Vérification de la pression d'admission (si nécessaire) :

La vérification de la pression d'admission n'est PAS

REQUISE pour la conversion au gaz propane; toutefois, si

la pression de sortie du régulateur de pression du gaz ou la

pression d'entrée vers l'appareil semble suspecte, la

procédure suivante peut être utilisée pour vérifier la

pression d'admission.

• Il est possible d'obtenir une lecture de la pression

d'admission sur l'un des orifices des brûleurs Star

qu'illustré.

• Fixez un manomètre portable ou à main qui lit la

pression en pouces de colonne d'eau (po. CE) en

utilisant un morceau de PVC ou un tube en vinyle.

• Branchez l'alimentation électrique et l'alimentation en

gaz de la surface de cuisson ou de la cuisinière.

• Allumez l'un des brûleurs à la position HI. Il est

important d'obtenir une vraie lecture de pression dans

ces conditions de circulation du gaz.

• Tournez la soupape manuelle du brûleur testé à la

position HI. (Des bruits d'allumage par étincelle seront

émis par ce brûleur.)

• La lecture de la pression d'admission sur le manomètr e

devrait osciller entre 9,50 et 10,50 po. CE pour le

régulateur de tout appareil converti au gaz propane.

• o Si la lecture de la pression d'admission est en deçà

de cela, assurez-vous que la conversion du régulateur

a été bien effectuée pour une utilisation au gaz

propane et que la pression d'entrée vers l'appareil

oscille entre 11,0 et 14,0 po. CE.

®

, tel

Français 10

Page 25

Vérification des caractéristiques de la flamme de gaz propane et du rendement des brûleurs :

Lorsque vous observez les flammes des brûleurs, enlevez

aussi peu de composantes que nécessaire pour avoir une

vue non obstruée. Vous pourriez avoir à éteindre les

lumières ou fermer les stores des fenêtres pour assombrir

la pièce et ainsi mieux voir la flamme.

• Testez l'allumage des brûleurs. Appuyez sur le bouton

de commande du brûleur et tournez dans le sens

antihoraire jusqu'à la position HI. L'électrode de

l'allumeur et le module d'étincelle produiront un bruit de

déclic. Une fois que l'air est sorti de la conduite

d'alimentation, le brûleur devrait s'allumer en moins de

quatre (4) secondes.

• Les flammes de LP devraient être stables et ne pas

être trop bruyantes. Le cône intérieur de la flamme

devrait être bien défini et être distinctement séparé du

cône extérieur.

Dark Blue

Secondary

Cone

Light Blue

• La flamme, le long du brûleur , ne devrait p as comporter

des parties excessivement élevées ou de flammes "

paresseuses ".

• Il est normal que des pointes légèrement jaunes

apparaissent à l'extrémité des flamm es après quelques

minutes de fonctionnement au gaz propane (LP). Les

traits orangés dans la flamme sont produits par la

combustion de débris. Ce phénomène est normal

durant les moments suivant l'allumage et devrait se

dissiper après quelques minutes de fonctionnement.

• Ajustez la soupape de commande du brûleur à LO ou

SIM pour vérifier si la flamme continue de brûler tout

autour du brûleur. Éteignez la flamme en soufflant

dessus ou l'éventant à l'aide d'un bloc-note ou d'un

morceau de carton, puis observez la capacité du

brûleur à se rallumer et à propager la flamme sur tout

le brûleur en quelques secondes. La propag ation de la

flamme est essentielle pour l'allumage et le rallumage

adéquats du brûleur.

• Testez la capacité de rallumage des deux brûleurs

®

Star

sur le côté gauche de l'appareil en positionnant

les boutons de commande à XLO et observez la

propagation des petites flammes de mijotage pendant

que le système allume et éteint les deux brûleurs.

• Si le rendement de la flamme n'est pas convenable,

assurez-vous que des orifices de LP aux dimensions

adéquates sont installés et que le régulateur a été

convenablement converti pour une utilisation au LP.

• Si la flamme d'un brûleur est inégale, scintille, produit

des sons excessifs ou augmente, certaines des fentes

de la base du brûleur sont possiblement obstruées p ar

des débordements d'aliments ou par d'autres débris.

Les fentes bloquées peuvent être nettoyées à l'aide

d'un trombone, d'une épingle ou d'un objet semblable.

Les aliments ou les débris incrustés et difficiles à

enlever peuvent parfois être retirés en utilisant une

laine d'acier ou une brosse métallique.

• Une flamme " paresseuse ", avec de longues flammes,

peut se créer en raison d'une cuvette de brûleur mal

placée. Plusieurs des manteaux supérieurs des

flammes individuelles auront tendance à fusionner ou à

confluer. Assurez-vous que la cuvette du brûleur est

convenablement installée sur la base du brûleur.

Lorsque positionnée correctement, la cuvette devrait

Primary

Cone

Français 11

Page 26

être assez à plat sur la base et ne devrait pas trop se

balancer. (Voir illustration ci-dessous.)

Emplacement des étiquettes de

classification sur les produits

®

Professional

Les étiquettes de classification se trouvent à différents

endroits sur les appareils, selon les séries de mod èles :

de Thermador :

Positionnement

correct de la

cuvette du brûleur

Positionnement

incorrecte de la

cuvette du brûleur

Dernière étape — Placer l'étiquette de conversion au LP

AVERTISSEMENT :

Ne laissez JAMAIS la conversion au gaz

partiellement terminée. Si l'appareil est utilisé

alors que la conversion n'est pas terminée, de

hauts volumes de monoxyde de carbone

pourraient être relâchés, ou un incendie ou une

explosion pourrait survenir.

IMPORTANT :

Pour une identification et une preuve adéquates de la

conversion de l'appareil au gaz propane (LP), apposez

l'étiquette de conversion fournie près des étiquettes de

classification de l'appareil. Cela est particulièrement

important si l'appareil converti est réinstallé dans une

maison différente.

• Surfaces de cuisson Professional

classification se situent normalement sur la face

intérieure du bâti inférieur de la surface de cuisson. Il

est possible d'y avoir accès par l'intérieur du cabinet,

sous l'appareil.

• Cuisinières mixtes Pro-Harmony

classification se situent normalement sous la section

de la partie avant de la surface de la cuisinière ou sur

une plaque de métal fixée à la partie inférieure du bâti

de la cuisinière, derrière le panneau de seuil de

l'appareil. (Voir illustration ci-dessous.)

Vous pouvez accéder

aux étiquettes de

classification des

cuisinières mixtes ProHarmony sous la

section de la partie

avant de la surface de

la cuisinière, lorsque la

porte du four est

ouverte ou enlevée.

Autre emplacement Étiquettes de

classification fixées

sur la plaque se

trouvant derrière le

panneau de seuil sur

la partie avant

inférieure du bâti.

- Les étiquettes de

- Les étiquettes de

Français 12

Page 27

Contenidos

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones de seguridad importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones de conversión . . . . . . . . . . . . . . . . . . . . . 2

Antes de comenzar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table 1: Contenido de los juegos de conversión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2: Tabla de conversión de los orificios de LP (por numeró de modelo) . . . . . . . . . . . . 3

Reemplazo de los orificios de los quemadores de la estufa / parilla . . . . . . . . . . 3

Acceder al regulador de presión del gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conversión del regulador de presión del gas para un funcionamiento con LP . 7

®

Ajuste de los tornillo de la válvula manual de los quemadores Star

Inspección de los escapes de gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Prueba y ajuste de los quemadores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . 8

Última etapa — Colocar la etiqueta de conversión al LP . . . . . . . . . . . . . . . . . . 12

Este electrodomestico de Thermador es hecho por

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

¿Preguntas?

1-800-735-4328

www.thermador.com

¡Esparamos oir de usted!

Page 28

Seguridad

Instrucciones de seguridad importantes

LEA TODAS ESTAS INSTRUCCIONES ANTES DE UTILIZAR ESTE APARATO

Juego de conversión de gas natural a gas propano

(LP) para las estufas mixtas et las parillas

Professional

SÓLO PARA USO RESIDENCIAL

IMPORTANTE:

Sólo un técnico en servicios o un instalador cualificado

debería proceder a la conversión de este aparato.

INSTALADOR:

Deje las instrucciones de conversión de este aparato al

propietario.

PROPIETARIO:

Conserve estas instrucciones para futura consulta.

Contiene orificios de quemadores Star

de todos los quemadores de los modelos de parillas /

estufas siguientes.

Conserve las piezas de gas natural para una posible

conversión de gas LP a gas natural en el futuro.

®

de Thermador.

®

para la conversión

ADVERTENCIA:

Este juego de conversión debe ser

instalado por una agencia de

servicios cualificada conforme a la

instrucciones del fabricante y a los

códigos y exigencias vigentes de

las autoridades competentes. Si no

se sigue con exactitud la

información incluida en estas

instrucciones, un incendio, una

explosión o emanaciones de

monóxido de carbono podrían

suceder, lo que podría resultar en

daños materiales o en lesiones, o

causar la muerte. La agencia de

servicios cualificada es

responsable de la instalación

adecuada de este juego de

conversión. La instalación no se

puede considerar como adecuada

y completa antes de que el

funcionamiento del aparato haya

sido verificado, conforme a las

instrucciones proporcionadas por

el fabricante en el juego de

conversión.

Este juego se usa para convertir del gas natural al gas

propano (LP) las parillas Professional

PRO-HARMONY™ de Thermador . Este juego no se puede

utilizar para convertir antiguos modelos de parillas y

estufas Professional de Thermador (ver TABLA 2

juego no se puede utilizar

quemadores, todas las estufas de gas Professional

Thermador, o otros tipos de electrodomésticos.

Español 1

para convertir todos los

®

y las estufas mixtas

). Este

®

de

PRECAUCIÓN:

Desenchufe la alimentación eléctrica y de gas

antes de proceder a la conversión. Antes de

encender el aparato, asegúrese de que todas

las perillas estén apagadas.

Al técnico responsable de la instalación:

Es importante que Usted se entere de la siguiente

información ANTES de empezar la conversión del aparato.

• Asegúrese de que el sistema de alimentación en gas

propano (LP) está disponible et listo para ser utiliza do.

Esto es particularmente importante si se instal a en una

nueva construcción.

• Usted debe prever el tiempo y los recursos suficientes

par proceder adecuadamente y totalmente a la

conversión al LP antes de marcharse del sitio en que

hizo el trabajo. Cada etapa descrita en estas

Page 29

instrucciones debe ser realizada para convertir con

toda seguridad el aparato a fin de garantizar el

funcionamiento adecuado con gas propano. LA

CONVERSIÓN INADECUADA O INCOMPLETA DEL

APARATO PUEDE CAUSAR UN RIESGO DE

ACCIDENTE.

Aviso de la Ley del Est ado de California sobre la potabilidad y la toxicidad del agua (proposición 65):

ADVERTENCIA:

Este producto contiene o facilita, en el caso de

una utilización normal por la que está

concebido, uno o varios productos químicos

que, según el Estado de California, pueden

causar cáncer , defectos de nacimiento u otros

daños reproductivos. Para minimizar la

exposición a dichos productos químicos:

1. Proceda a la conversión al gas LP según

las instrucciones de este manual.

2. Para asegurar una combustión adecuada,

un instalador o una agencia acreditados

deberían proceder a la conversión y al

ajuste de los quemadores.

3. Siempre maneje el aparato según las

instrucciones proporcionadas con su

parrilla o estufa.

4. Cuando cocina con gas, asegúrese de que

la ventilación esté adecuada abriendo una

ventana o utilizando un ventilador o una

campana extractora.

Instrucciones de conversión

Antes de comenzar

PRECAUCIÓN:

Antes de proceder a la conversión, corte la

alimentación en gas del aparato antes de la

alimentación eléctrica.

Herramientas requeridas:

• Tijeras

• Boquilla de 7 mm (o 9/32") con llave de 1/4" y

extensión

• Llave Torx T-30 o T-27

• Llave Allen de 4 mm

• Gran destornillador de ranura, hoja de 0.40" x 0.050"

• Gran destornillador de ranura, hoja de 0.60" x 0.060"

• Llave fija de 7/8" o llave de boquilla de 7/8"

•Llave Torx T-20

• Destornillador de precisión con hoja de 1/8" x 0.020"

• Mezcla de agua jabonosa o solución para verificar los

escapes

Tabla 1: Contenido de los juegos de conversión

Descripción

Instrucciones

PALPJUEGOHC

Cinta de espuma,

pedazo de 1”

Etiqueta de

conversión al

propano

Bolsa de plástico 418148 1

Número de

servicio

553122 1

418145 1

418146 1

Cantidad

Español 2

Page 30

Tabla 1: Contenido de los juegos de conversión

Descripción

Orificio de quemador

®

Star

Este juego de conversión al propano contiene piezas en

las cantidades indicadas más abajo; sin embargo,

algunos orificios no se utilizarán según las dimensiones

del aparato convertido al gas propano. Consulte la

TABLA 2

usar con cada modelo.

para las cantidades apropiadas de orificios a

Número de

servicio

617163 6

Cantidad

PRECAUCIÓN:

Al conectar el aparato al gas propano,

asegúrese de que el depósito de gas propano

tiene su propio mecanismo regulador de

presión. La presión de gas máxima de este

aparato no debería exceder 14 pulgadas de

columna de agua.

Cuando los quemadores son convertidos adecuadamente

con los orificios de LP previstos, funcionan con el flujo de

gas propano (LP) siguiente:

Tabla 2: Tabla de conversión de los orificios de LP (por numeró de modelo)

Número de modelo del

aparato

Parilla Professional:

PCG304G 4 cada una — 1.15mm PCG366G 6 cada una — 1.15mm PCG364GD* 4 cada una — 1.15mm PCG486GD* 6 cada una — 1.15mm

PRO-HARMONY™ Dual-Fuel Ranges:

PRD304GH 4 cada una — 1.15mm PRD366GH 6 cada una — 1.15mm PRD364GDH* 4 cada una — 1.15mm PRD486GDH* 6 cada una — 1.15mm

NOTA:

* Los números de modelo que llevan la letra D

representan los aparatos equip ados de una plancha que

no necesita conversión al gas.

Orificios de

quemadores Star

(no. 617163)

®

• Quemadores Star

uno, con orificios de 1.15 mm.

®

- 15 000 BTU/h [4.39 kW] cada

ADVERTENCIA:

NUNCA deje la conversión al gas parcialmente

terminada. Si se utiliza el aparato cuando la

conversión no está terminada, grandes

volúmenes de monóxido de carbono podrían ser

producido, o un incendio o una explosión podría

ocurrir.

ADVERTENCIA:

Si se intenta hacer funcionar el aparato al gas

propano (LP) con el ajuste de presión propio d el

gas propano con los orificios de gas natural, los

quemadores producirán grandes llamas, las

cuales pueden emitir grandes volúmenes de

monóxido de carbono, o una explosión podría

ocurrir.

Gran altitud:

Para efectuar una conversión segura al gas propano para

un uso a gran altitud, consulte la empresa de gas de su

localidad a fin de obtener sus recomendaciones en

relación con las dimensiones correctas de los orificios y de

los otros ajustes necesarios para asegurar la combustión

adecuada del gas.

Reemplazo de los orificios de los quemadores de la estufa / parilla

NOTA:

Después de haber reemplazado cada orificio, y antes de

volver a ensamblar el quemador, haga una breve prueba

de escape en el orificio y los accesorios conexos, c onforme

a la sección "Inspección de los escapes de gas" de estas

instrucciones.

Español 3

Page 31

Reemplazo de los orificios de los

®

quemadores Star

• Corte un pedazo de 3/8" de cinta de espuma

(proporcionada con el juego de conversión) y

colóquelo sobre el borde de la boquilla para

reemplazar los orificios de los quemadores Star

como en la ilustración. El pedazo de espuma ayuda a

retener el orificio en la extremidad de la boquilla e

impide que se caiga en el interior del aparato en el

momento de quitar o de instalar el orificio.

— Todos los modelos:

Cinta de espuma

• Reemplace cada orificio del inyector del quemador

®

por uno de los inyectores de LP de 1.15 mm

Star

incluidos en el juego de conversión. Estos inyectores

están concebidos para que los quemadores Star

produzcan un flujo de 15 000 BTU/h [4.39 kW] con gas

®

,

propano (LP).

Cinta de espuma

• Haga una breve prueba de escape de gas en cada

orificio y en las conexiones de los tubos cercanos,

conforme a la sección "Inspección de los escapes de

gas" de estas instrucciones. Puede tener acceso a los

inyectores de los quemadores después de haber

quitado la placa superior principal del aparato. Ver la

sección siguiente " Acceder al regulador de presión del

gas" para saber como quitar la placa principal y las

piezas de protección.

• Cada orificio lleva la inscripción "115" (diámetro del

orificio de 115 mm), co mo en la ilustración.

®

• Utilice una boquilla de 7 mm (o 9/32") con una llave de

1/4" y una extensión para alcanzar el orificio de gas

natural a través del tubo de venturi y para quitarlo del

inyector del quemador.

Español 4

Page 32

Acceder al regulador de presión del gas

El regulador de presión del gas de todos los modelos de

estufas mixtas y parillas se ubica en el interior de la parilla

o en la sección de los fogones de la estufa, bajo la placa

superior principal, en el lado izquierdo.

• El regulador de presión del gas se ubica en el interior

de la placa superior principal, normalmente cerca del

rincón trasero izquierdo.

• Quite las tapas de los quemadores y los dos tornillos

en la base de cada quemador con una llave T-27 o T-

30.

• Desconecte el terminal hembra del terminal macho del

cable de chispas en el electrodo de cada quemador.

Importante:

Se debe pulsar sobre la lengüeta de cierre del conectador

hembra para quitar el terminal del electrodo.

• Quite las rejillas del aparato.

Español 5

Page 33

• Con una llave Allen de 4 mm

sujeta la base de cada quemador en su sitio.

• Cuando se han quitado los ensamblajes de los

quemadores, se puede quitar la placa superior

principal del aparato.

, quite el tornillo que

• Quite las piezas de protección ubicadas debajo de la

placa principal para tener acceso a los componentes.

• El regulador de presión del gas se ubica cerca del

rincón trasero izquierdo, en el interior de la placa

superior del aparato.

• Se puede utilizar una llave Allen o una llave semejante

como gancho para levantar la placa superior principal

del aparato.

NOTA:

Los orificios de los quemadores que se cayeron dentro del

aparato durante el proceso de reemplazo se pueden

recuperar en este momento.

Español 6

Page 34

Conversión del regulador de presión del gas para un funcionamiento con LP

ADVERTENCIA:

Si se intenta hacer funcionar el aparato al gas

propano (LP) con el ajuste de presión propio d el

gas propano con los orificios de gas natural, los

quemadores producirán grandes llamas, las

cuales pueden emitir grandes volúmenes de

monóxido de carbono, o una explosión podría

ocurrir. El reemplazo de los orificios para un

funcionamiento con gas propano se debería

hacer antes de la conversión del regulador.

Harper-Wyman y Maxitrol son dos marcas de reguladores

de presión del gas que se pueden utilizar con los productos

Professional

Conversión con un regulador HarperWyman:

®

de Thermador.

• Gire la pieza de conversión para que el lado hondo sea

visible. La inscripción "LP" se ubica en el fondo de esta

pieza.

• Utilice un gran destornillador de ranura con una hoja

de 0.60" x 0.060" para reinstalar la pieza de con versión

para gas propano.

• Vuelva a insertar la pieza en la parte superior del

regulador con el hondo hacia arriba (dejando ver la

inscripción "LP"). Empuje y gire en el sentido a las

agujas del reloj para fijar la pieza en su sitio.

• Utilice un gran destornillador de ranura con una hoja

de 0.40" x 0.050" para quitar la pieza de conversión.

• Con un gran destornillador

conversión y gire en el sentido contrario a las agujas

del reloj para soltar el soporte de bayoneta.

, empuje sobre la pieza de

Español 7

Page 35

Conversión con un regulador Maxitrol:

Invierta l

• Quite la pieza de conversión con una llave fija o una

llave con boquilla de 7/8"

• Saque la varilla de la base de la pieza, inviértala para

que la extremidad LP se vea et vuelva a poner la

varilla en la pieza, como en la ilustración.

.

a

varilla

Ajuste de los tornillo de la

válvula manual de los

quemadores Star

Destornillador para ajustar los tornillos de las válvulas:

Se debería utilizar un destornillador de precisión con una

hoja de alta resistencia, semejante al Wiha nº 26033*

una punta de una anchura de 1/8" [3,0 mm] y de un grosor

de 0,020" [0,50 mm], ilustrado en la foto aquí abajo, para

poner en su sitio los tornillos de derivación y obtener los

ajustes mínimos de las válvulas manuales.

*Utilizado con el permiso de la división Wiha Quality Tools de

Willi Hahn Corporation USA.

®

, con

• Reinstale la pieza de conversión - configurada para

gas propano - en el regulador Maxitrol.

Tornillo de

la válvula

Español 8

Page 36

Ajuste de los tornillos de las válvulas para las estufas mixtas PRO-HARMONY™ y las parillas Professional:

• Quite el botón de la varilla de la válvula tirando hacia el

exterior, alejándose del tablero.

• Para engranar el tornillo de la válvula, inserte el tornillo

de precisión con una hoja de 1/8" en el agujero que se

creó al quitar el tornillo de montaje.

• Gire el tornillo de la válvula en el sentido a las agujas

del reloj hasta el fondo. NO apriete demasiado el

tornillo de la válvula.

NOTA:

• Para un funcionamiento en la posición XLO (la perilla

en la extrema izquierda del tablero), las dos válvulas

deben estar en la posición apaga da para que se pueda

tener acceso adecuadamente a los tornillos de las

válvulas a través de los agujeros de los

potenciómetros XLO.

• Quite el tornillo de montaje con bisel ubicado a la

derecha de la varilla de la válvula con una llave Torx T-

20.

Inspección de los escapes de gas

ADVERTENCIA:

NO utilice ningún tipo de llama para detectar los

escapes de gas.

Inspección de los escapes de gas con una solución líquida:

Los orificios de reemplazo del juego de conversión al LP

del P ALPJUEGOHC tienen una r osca cilíndrica (no cónica)

y no necesitan la utilización de lacre para junta fileteada.

La inspección de los escapes se deberían hacer una vez

terminada la conversión de los orificios y antes de que se

reensamblen y testen los quemadores.

Español 9

Page 37

• Asegúrese de que todos los orificios LP hayan sido

apretados y que todas las válvulas y las perillas estén

apagadas.

• Conecte la alimentación eléctrica y la de gas.

• Testa brevemente y individualm ente los racores

roscados de cada orificio reemplazado - es decir un

orificio a la vez.

• Vaporice generosamente la parte roscada del orificio

con una solución de agua jabonosa - o con otra

solución concebida para detectar los escapes de gas.

Procure no vaporizar los componentes eléctricos. (Una

mezcla compuesta de 25% de jabón en agua es eficaz

para hacer esta inspección.)

• Encienda brevemente la válvula o la perilla

bloqueando el agujero del orificio con la goma de un

lápiz, su dedo o algo semejante.

Nota:

Es normal que oiga ruidos de encendido por chispas

durante este proceso.

• Fíjese en la base del cruce del orificio para ver si se

forman burbujas alrededor del racor roscado.

• Las burbujas indican que hay un escape de gas. La

cantidad y las dimensiones de las burbujas son

indicadores de la amplitud del escape.

• Repare todos los escapes inmediatamente cuando los

descubra. A menudo, sólo hace falta apretar de nuevo

el orificio para reparar el escape.

• Dado que sucede que las piezas están apretadas

fuertemente durante el reemplazo de los orificios,

inspeccione también los escapes en los otros cruces

de los racores adyacentes al orificio.

• Desconecte la alimentación eléctrica y la de gas.

• Reensamble el aparato en preparación para testar el

sistema de quemadores nuevamente instalado.

• Es posible tener una lectura de la presión de admisión

en uno de los orificios de los quemadores Sta r

en la ilustración.

• Ponga un manómetro portátil o de mano que lee la

presión en pulgadas de columna de agua ("W.C.)

utilizando un pedazo de PVC o un tubo de vinilo.

• Conecte las alimentaciones eléctrica y de gas de la

parilla / estufa.

• Encienda uno de los quemadores en la posición HI. Es

importante obtener una lectura real de la presión bajo

esas condiciones de circulación de gas.

• Gire la válvula manual del quemador que testa en la

posición HI. (El quemador producirá ruidos de

encendido por chispas.)

• La lectura de la presión de admisión del regulado r de

todo aparato convertido al gas propano en el

manómetro debería oscilar entre 9,50 et 10,50 "W.C.

• Si la lectura de la presión de admisión es inferi or a esa

cifra, asegúrese de que la conversión del regulador

haya sido bien efectuada para una utilización con gas

propano y que la presión de entrada hacia el aparato

oscila entre 11,0 et 14,0 "W.C.

®

, como

Prueba y ajuste de los quemadores

Verificación de la presión de admisión (si necesario):

La verificación de la presión de admisión NO ES

NECESARIA para la conversión al gas propano; sin

embargo, si la presión de salida del regulador de presión

del gas o la presión de entrada hacia el aparato parece

sospechosa, se puede recurrir al proceso siguiente para

verificar la presión de admisión.

Verificación de las características de la llama de gas propano y del rendimiento de los quemadores:

Cuando observa las llamas de los quemadores, quite el

mínimo de componentes para ver las llamas directamente .

Es posible que tenga que apagar las luces o cerrar las

persianas de las ventanas para oscurecer la habitación y

así ver mejor las llamas.

• Teste el encendido de los quemadores. Empuje la

perilla del quemador y gire en el sentido contrario a las

agujas del reloj hasta la posición HI. El electrodo del

encendedor y el módulo de chispas producirán un

chasquido. Una vez que haya salido el aire del

Español 10

Page 38

conducto de alimentación, el quemador debería

encenderse en menos de cuatro (4) segundos.

• Las llamas de LP deberían ser estables y hacer poco

ruido. El cono interior de la llama debería ser bien

definido y estar distintivamente separado del cono

exterior.

Dark Blue

Secondary

Cone

Light Blue

• Testa la capacidad de los dos quemadores Star

lado izquierdo del aparato para volver a encenderse

colocando los mandos à XLO y observe la prop agación

de la pequeñas llamas de fuego lento mientras el

sistema enciende y apaga los dos quemadores.

• Si el rendimiento de la llama no es adecuado,

asegúrese de que orificios de LP de dimensiones

adecuadas estén instalados y que el regulador haya

sido convenientemente convertido para una utilización

con LP.

• Si la llama de un quemador es irregular, centellea,

produce ruidos excesivos o cambia de tamaño,

algunos de los agujeros de la base del quemador

están posiblemente obstruidos por derrames de

alimentos o por otras partículas. Los agujeros

bloqueados se pueden limpiar con un clip, una ag uja o

con un objeto semejante. A veces, los alimentos y los

restos incrustados y difíciles de limpiar se pueden

quitar con un estropajo de acero o un cepillo metálico.

• Una llama " vaga", con largas llamas, se puede crear

porque la tapa del quemador está mal colocada. Varias

de las puntas de las llamas individuales tendrán

tendencia a fusionar o a confluir. Asegúrese de que la

tapa del quemador esté adecuadamente colo ca d a

sobre la base del quemador . Cuando e stá posicionada

convenientemente, la tapa debería estar de plano

sobre la base y no debería balancearse demasiado.

(Ver ilustración más abajo.)

®

del

Primary

Cone

• La llama, alrededor del quemador, no debería tener

partes excesivamente elevadas o llamas "vagas".

• Es normal que de las puntas de las llamas estén

levemente amarillas después de unos minutos de

funcionamiento con gas propano (LP). Los trazos

naranjas en las llamas son producidos por la

combustión de restos. Este fenómeno es normal

durante los momentos que siguen el encendido y

deberían disiparse después de unos minutos de

funcionamiento.

• Ponga la válvula de la perilla del quemador a LO o a

SIM para verificar si la llama sigue difundiéndose

alrededor del quemador. Apague la llama soplánd ola o

venteándola con hojas o con un trozo de cartón.

Luego, observe la capacidad del quemador a

encenderse de nuevo y a propagar la llama en todo el

quemador en pocos segundos. La propagación de la

llama es esencial para que se encienda y vuelva a

encender adecuadamente el quemador.

Posicionamiento

correcto de la tap a

del quemador

Posicionamiento

incorrecto de la

tapa del quemador

Español 11

Page 39

Última etapa — Colocar la etiqueta de conversión al LP

Ubicación de las etiquetas de clasificación

®

sobre los productos Professional

de

Thermador:

ADVERTENCIA:

NUNCA deje la conversión al gas parcialmente

terminada. Si se utiliza el aparato cuando la

conversión no está terminada, grandes

volúmenes de monóxido de carbono podrían ser

producido, o un incendio o una explosión podría

ocurrir.

IMPORTANTE:

Para una identificación y una prueba adecuadas de la

conversión del aparato al gas propano (LP), ponga la

etiqueta de conversión proporcionada cerca de las

etiquetas de clasificación del aparato. Esto es

particularmente importante si el aparato convertido se

reinstala en un hogar distinto.

Las etiquetas de clasificación se ubican en distinto s

lugares sobre los aparatos, según las series de los

modelos:

• Parillas Professional

se ubican normalmente en el lado interior del armazón

inferior de la parilla. Se puede tener acceso por el

interior del armario, debajo del aparato.

• Estufas mixtas Pro-Harmony

clasificación se ubican normalmente debajo de la

sección de la parte delantera de la estufa o sobre una

placa de metal colocada en la parte inferior del

armazón de la estufa, detrás del panel de pie del

aparato. (Ver ilustración más abajo.)

Se puede tener

acceso a las etiquetas

de clasificación de las

estufas mixtas ProHarmony debajo de la

sección de la parte

delantera de la

superficie de la estufa,

cuando se abre o quita