Page 1

INSTALLATION MANUAL

THERMADOR PROFESSIONALTM Chimney Hoods

MANUEL D'INSTALLATION

Hottes avec conduit PROFESSIONALMC de THERMADOR

MANUAL D INSTALACIÓN

Campanas con conducto PROFESSIONALTM de

THERMADOR

Models/

Modèles/

Modelos:

HPCN36NS

HPCB36NS

HPCN48NS

HPCB48NS

Page 2

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Advance Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overall Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ductwork Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hood Transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hood Height Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Back Wall Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hanging the Chimney Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wire Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Integral Blower Motor Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chimney Extension Assembly & Installation (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Grease Trays and Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Service and Installer Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Before Calling Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installer Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Customer Support, Accessories & Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . back page

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 3

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: Please leave these instructions with this unit

for the owner. Show the owner the location of the circuit

breaker. Mark it for easy reference.

OWNER: Please retain these instructions for future

reference.

WARNING!

If the information in this manual is not followed exactly,

fire or shock may result causing property damage or

personal injury.

WARNING!

Turn off power circuit at service panel and lock out panel

before wiring this appliance. Requirement: 120 VAC, 60

Hz 15 A. Allow the appliance to cool after the power has

been turned off before servicing the appliance.

WARNING!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

• Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed on the back page.

• Before servicing or cleaning unit, switch power off at

service panel and lock the service panel to prevent

power from being switched on accidentally. When

the service panel cannot be locked, securely fasten

a prominent warning device, such as a tag, to the

service panel.

WARNING!

Do not repair or replace any part of the appliance unless

specifically recommended in the manuals. Improper

installation, service or maintenance can cause injury or

property damage. Refer to this manual for guidance. All

other servicing should be done by a qualified technician.

WARNING!

State of California Proposition 65 Warnings:

This product contains chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Electric Safety

WARNING!

IMPROPER GROUNDING CAN RESULT IN A

RISK OF ELECTRIC SHOCK

If the power cord is too short, have a qualified

electrician install an outlet near the appliance.

DO NOT USE AN EXTENSION CORD.

Consult a qualified electrician if the grounding

instructions are not completely understood, or

if doubt exists as to whether the appliance is

properly grounded.

WARNING!

ELECTRICAL SHOCK HAZARD

• DO NOT remove connections.

• DO NOT use an extension cord.

• Improper grounding can result in a risk of

electric shock.

• Failure to follow these instructions can

result in death, fire, or electrical shock.

GROUNDING INSTRUCTIONS

This appliance must be grounded. Grounding reduces the

risk of electric shock by providing a safe pathway for

electric current in the event of a short circuit.

English 1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Ensure appliance is properly installed and grounded by a

qualified technician. Installation, electrical connections and

grounding must comply with all applicable codes.

If required by the National Electrical Code (or Canadian

Electrical Code), this appliance must be installed on a

separate branch circuit.

WARNING!

To reduce the risk of fire or electric shock, do not use

this appliance with any solid-state speed control

devices.

Appliance Handling Safety

CAUTION!

Unit is heavy and requires at least two

people or proper equipment to move and

install.

Hidden surfaces may have sharp edges.

Use caution when handling the appliance.

Failure to do so may result in property

damage or personal injury.

Related Equipment Safety

Never modify or alter the construction of the appliance. For

example, do not remove panels, wire covers or brackets/

screws.

CAUTION!

FOR GENERAL VENTILATING USE ONLY. Do not use

to exhaust hazardous or explosive materials and vapors.

To reduce the risk of fire, use only metal ductwork.

When cutting or drilling into wall or ceiling, be careful not to

damage electrical wiring and other hidden utilities.

Use a quali¿ed and trained installer.

Safety Codes and Standards

This appliance complies with one or more of the following

Standards:

• UL 507, The Standard for the Safety of Electric Fans

• CSA C22.2 No. 113, Fans and Ventilators

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

Ventilation Safety

WARNING!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

• Installation work and electrical wiring must be done

by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated

construction.

• Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent back drafting.

Follow the heating equipment manufacturer's

guideline and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code

authorities.

• Use only metal ductwork.

• Ducted fans must always be vented to the outdoors.

Do not vent exhaust air into spaces within walls,

ceilings, attics, crawl spaces or garages.

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

English 2

Page 5

Advance Planning

Before You Begin

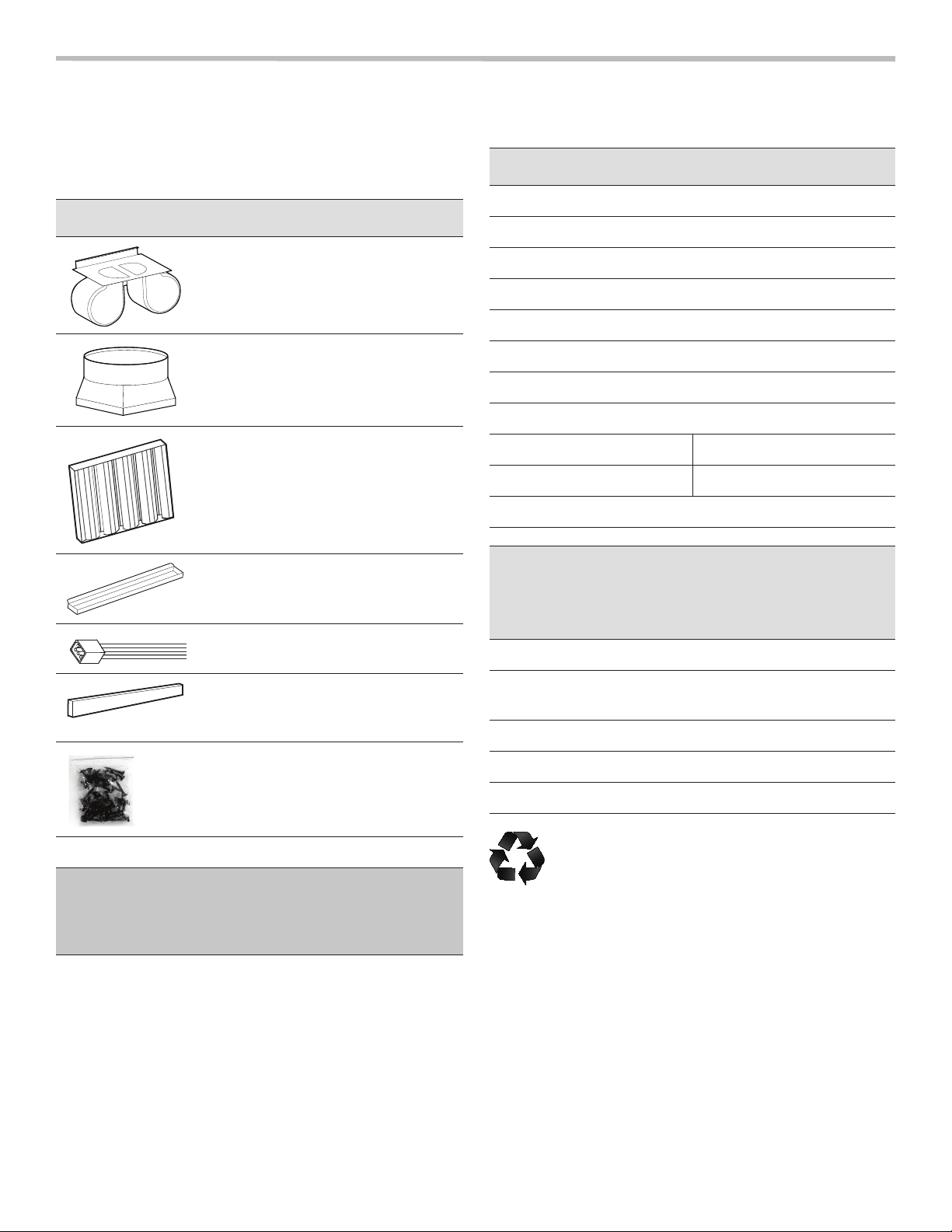

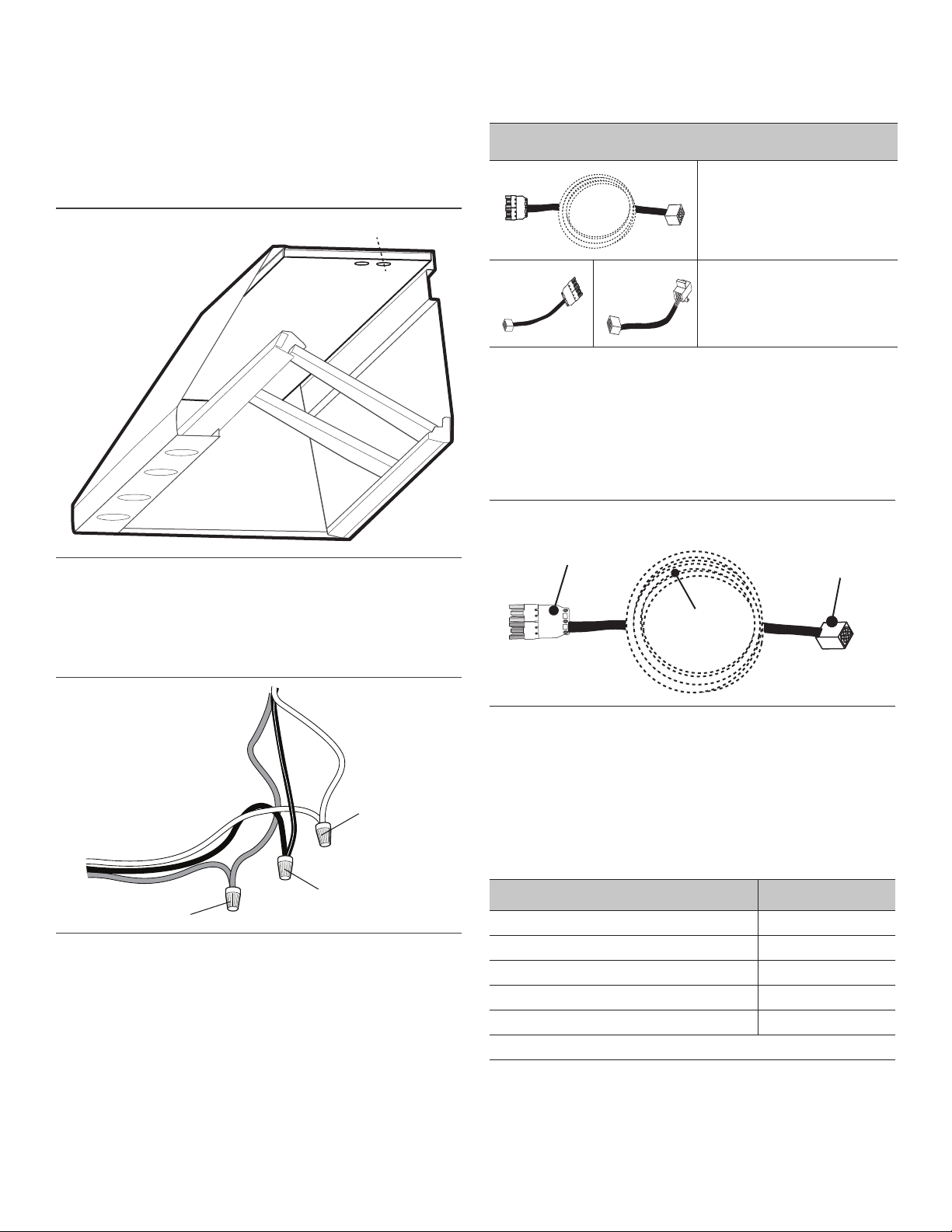

PARTS INCLUDED

1 – VTN1080 integral blower (HPCB

models only)

1 – Metal transition with backdraft

damper

2 or 3 – Stainless steel baffle filters

(depending on model size)

2 or 3 – Grease trays (depending on

model size)

1 – Remote blower adaptor

(HPCN models only)

TOOLS AND PARTS NEEDED

Aluminum tape, DO NOT use duct tape

1/2” (13 mm) Conduit if required, follow local codes

1” (25.4 mm) Strain relief

Ducting as needed

Blower (HPCN36NS and HPCN48NS models only)

Torx head and phillips screwdrivers

Drill with ¼”, 5/16”, and countersink drill bits

3/8” (9 mm) nut driver or socket and ratchet

Wire stripper Stud Finder

Step Ladder Level

Tape Measure

Optional accessories are available for separate

purchase. For available options and dealer

information, visit our website at

www.thermador.com.

Chimney Extensions (see page 16 for available options)

1 – Wood bracket used as Hood

Mounting Bracket. Part of install –

DO NOT THROW AWAY.

1 – Fastener assortment*

Literature Packet

* Hardware provided is for mounting through standard

thickness drywall or plaster into wood studs. Installers

are responsible to provide hardware for other types of

mounting situations.

25 ft. Blower Connector Cable for distances up to 25 ft.

(EXTNCB25)

Keep Hot Shelf

Backsplash

Remote Blower Roof Plate (RFPLT600 and RFPLT1000)

Remove all tape and packaging before using the

appliance. Please, recycle the packaging

material, as all THERMADOR appliance

packaging material is recyclable. Never allow

children to play with packaging material.

NOTE:

Do not throw away any packaging until appliance is fully

installed.

English 3

Page 6

General Information

C

This manual provides the proper installation instructions for two styles of THERMADOR PROFESSIONAL® Chimney

Hoods:

HPCNxxNS — This model series features brushed stainless-steel filters and halogen lights.

HPCBxxNS — This model series features brushed stainless-steel filters, an integral blower, and halogen lights.

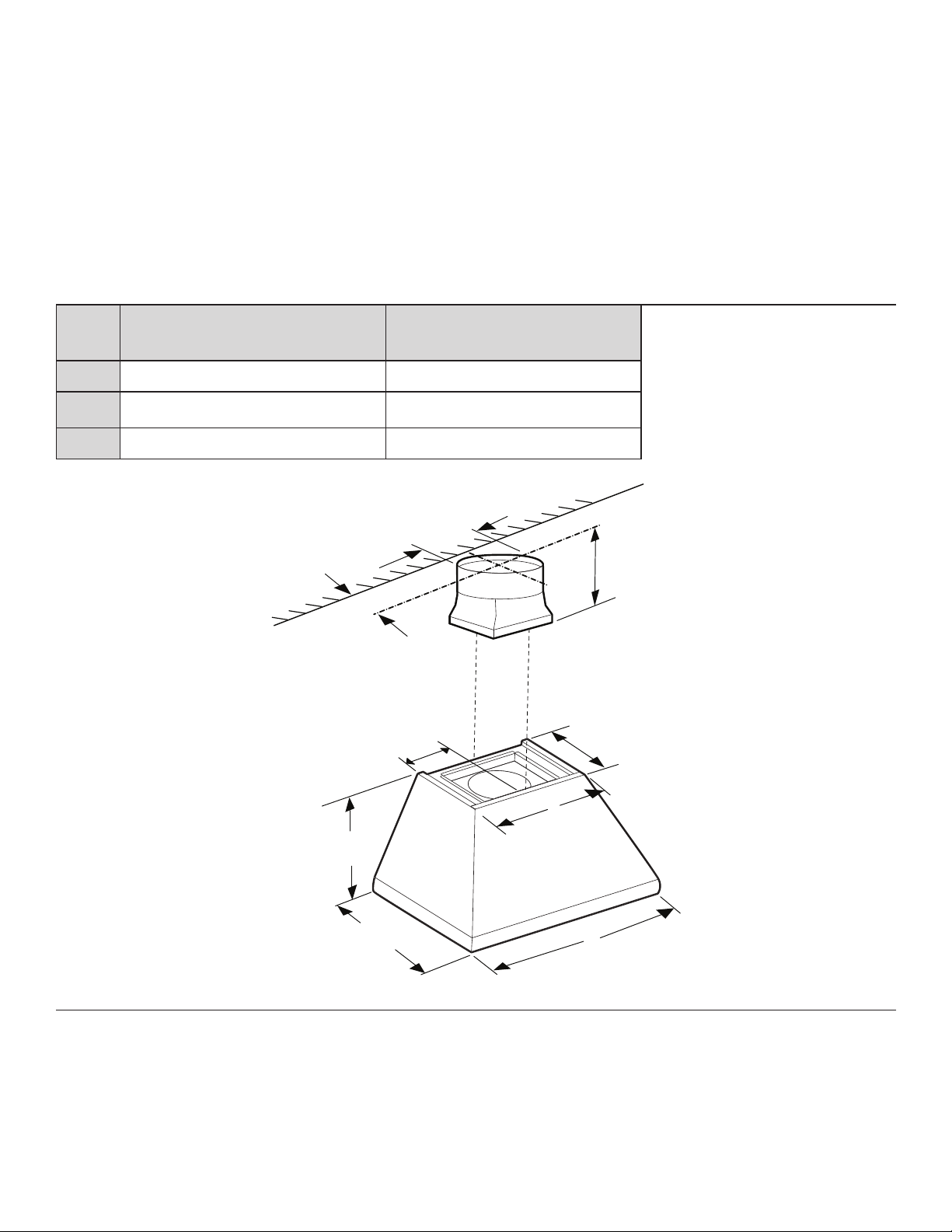

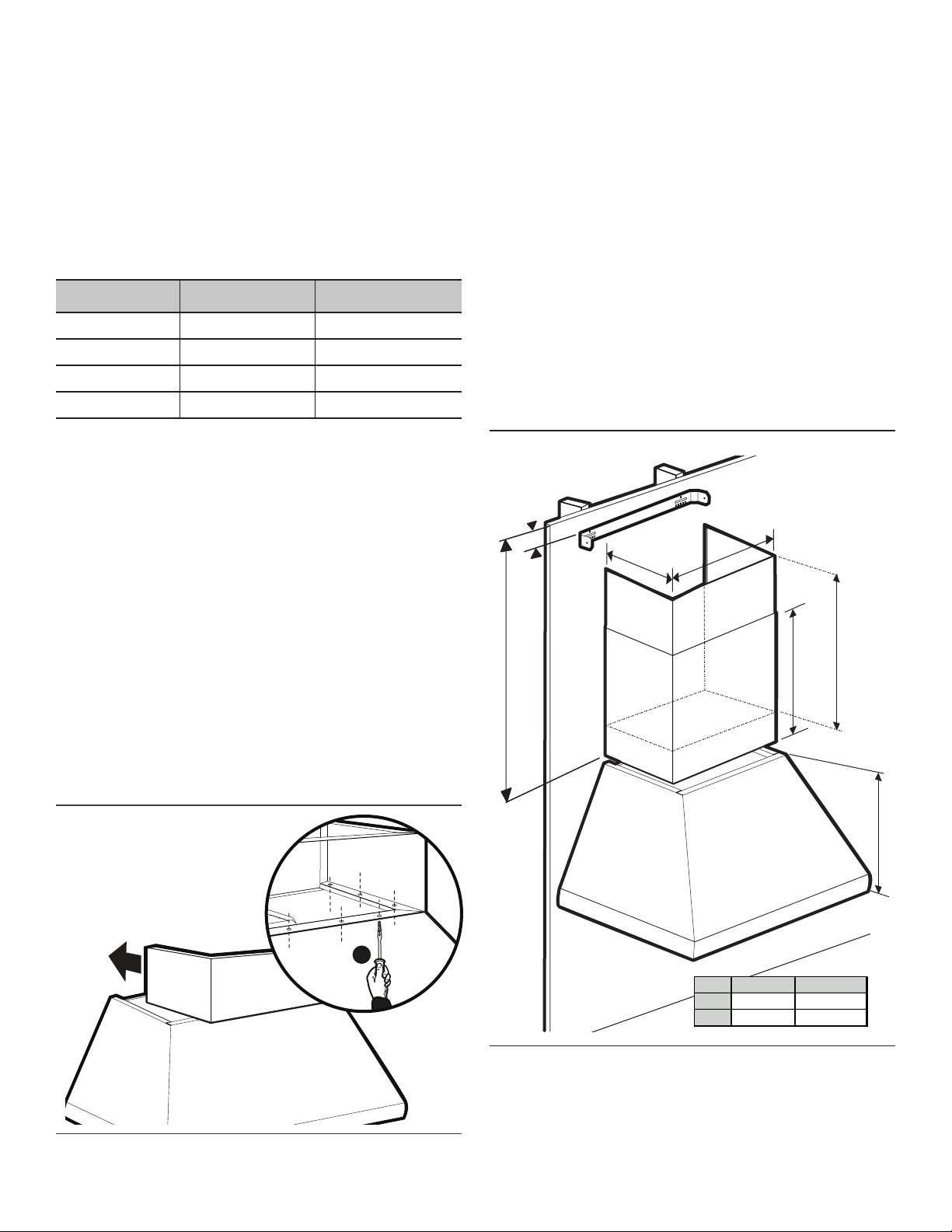

Overall Dimensions

36” (914)

inches (mm)

A 21” (533) 33” (838)

B

C 10½” (267) 16½” (419)

NOTE: Transition fits 10” (254) duct.

35 15/16” (838) 47 15/16” (1218)

48” (1,219)

inches (mm)

dia. 9½"

(dia. 243)

7¾”

(148)

C

3/

8

(212)

14

(356)

"

8

"

measurements in inches (mm)

NOTE:

Transition is centered.

English 4

18"

(457)

24"

(610)

A

B

Figure 1: Overall Hood Dimension

Page 7

Installation Preparation

18”

(457)

* 30" (762) min.

36” (914) max.

to Cooking Surface

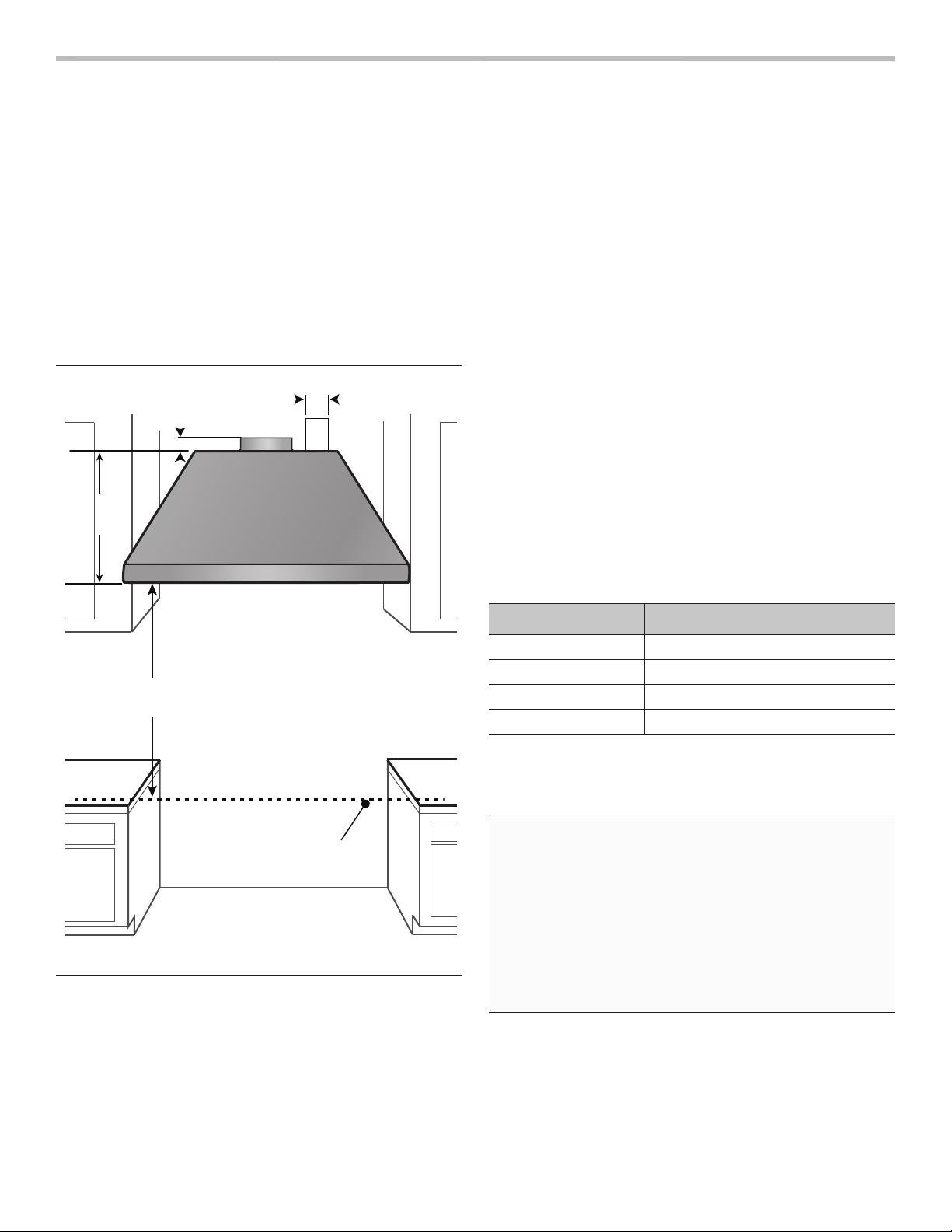

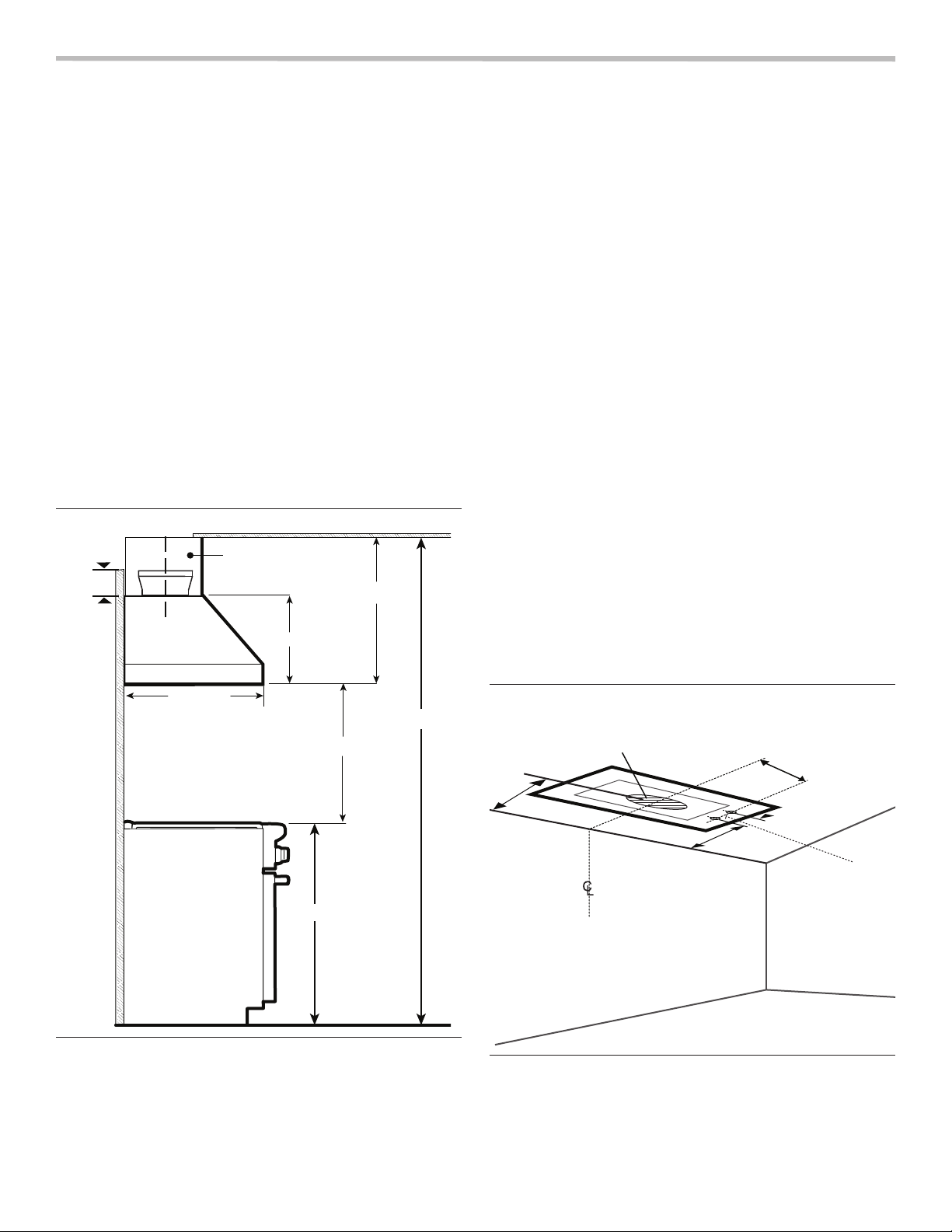

Installation Considerations

The chimney hood requires the ducting to be vented to the

outside. It cannot be used in conjunction with a

recirculation unit.

Hood installation height above a cooktop, rangetop or

range can vary. To obtain the necessary installation height

above a cooktop, rangetop or range, consult the

appliance's installation manual.

Electrical Location

3¼”

6½” (165)

18”

(457)

(457)

* Hood width should be no less

than the width of the cooking

surface.

* 30" (762) min.

* 30" (762) min.

36” (914) max.

36” (914) max.

to Cooking Surface

to Cooking Surface

* Follow cooking appliance

manufacturer’s recommendations

measurements in inches (mm)

NOTICE:

The hood could incur some damage from heat if a

THERMADOR PROFESSIONAL series range or rangetop

is operated with multiple burners at high settings under a

hood that is installed at minimum clearances while the

hood is turned off.

Figure 2: Typical Hood Installation

(83)

E

Cooking

Surface

Hood Width

The hood width should be no less than the width of the

cooking surface. For proper performance, the housing must

cover the entire cooking surface.

Where space is not restricted, a wider hood can be used to

increase coverage.

The hood needs to be centered over the cooking surface

for best performance.

Distance From Cooking Surface

The installation height has a minimum height of 30”

(762 mm) from the cooking surface; however, it is

necessary to follow the cooking appliance manufacturer’s

installation instructions for proper hood height.

Unit Weight

When calculating the load for the housing support system,

be sure to consider the weight of the ventilation unit.

MODEL WEIGHT

HPCN36NS 33 lbs. (15 kg)

HPCB36NS 49 lbs. (22 kg)

HPCN48NS 47 lbs. (21 kg)

HPCB48NS 63 lbs. (29 kg)

NOTE: “HPCN” models do not include the weight of an

integral blower. The integral blower weight is an

additional 16 lbs. (7 kg). “HPCB” models do include the

weight of an integral blower.

IMPORTANT:

The supplied weights address only the ventilation unit

and blower. Installer must account for weight of any

materials of construction when calculating the total dead

weight load of installation, including but not limited to:

wall, tile, mortar, plaster, brick, finishes, partitions, and

other similarly incorporated architectural and structural

items. It is the responsibility of the owner and the

installer to determine if additional requirements and/or

standards apply to specific installations.

English 5

Page 8

Wall Framing

Due to the weight of the hood, make sure the wood

mounting bracket is attached to all available wall studs.

Framing must be fastened together and to ceiling joists to

provide enough structural strength to support the weight of

the hood and internal blower, if applicable.

MAKE-UP AIR: Local building codes may require the use

of make-up air systems when using ducted ventilation

systems greater than specified CFM of air movement. The

specified CFM varies based on locale. It is the

responsibility of the owner and the installer to determine if

additional requirements and/or standards apply to specific

installations.

Wall framing should be, at minimum, made of 2" x 4"

lumber. Proper structural support is required to

accommodate the weight of the hood.

Ductwork Preparation

Discharge Direction

The exhaust air is discharged upwards through a duct or

directly through the outside wall into the open.

The hood can be mounted on the wall only with a vertical

discharge.

Ducting Recommendations

Proper performance is dependent upon proper ducting.

Local building codes may require the use of make-up air

systems when using ducted ventilation systems greater

than speci¿ed cubic feet per minute (CFM) of air

movement.

The speci¿ed CFM varies from locale to locale. It is the

responsibility of the owner and the installer to determine if

additional requirements and/or standards apply to specific

installations.

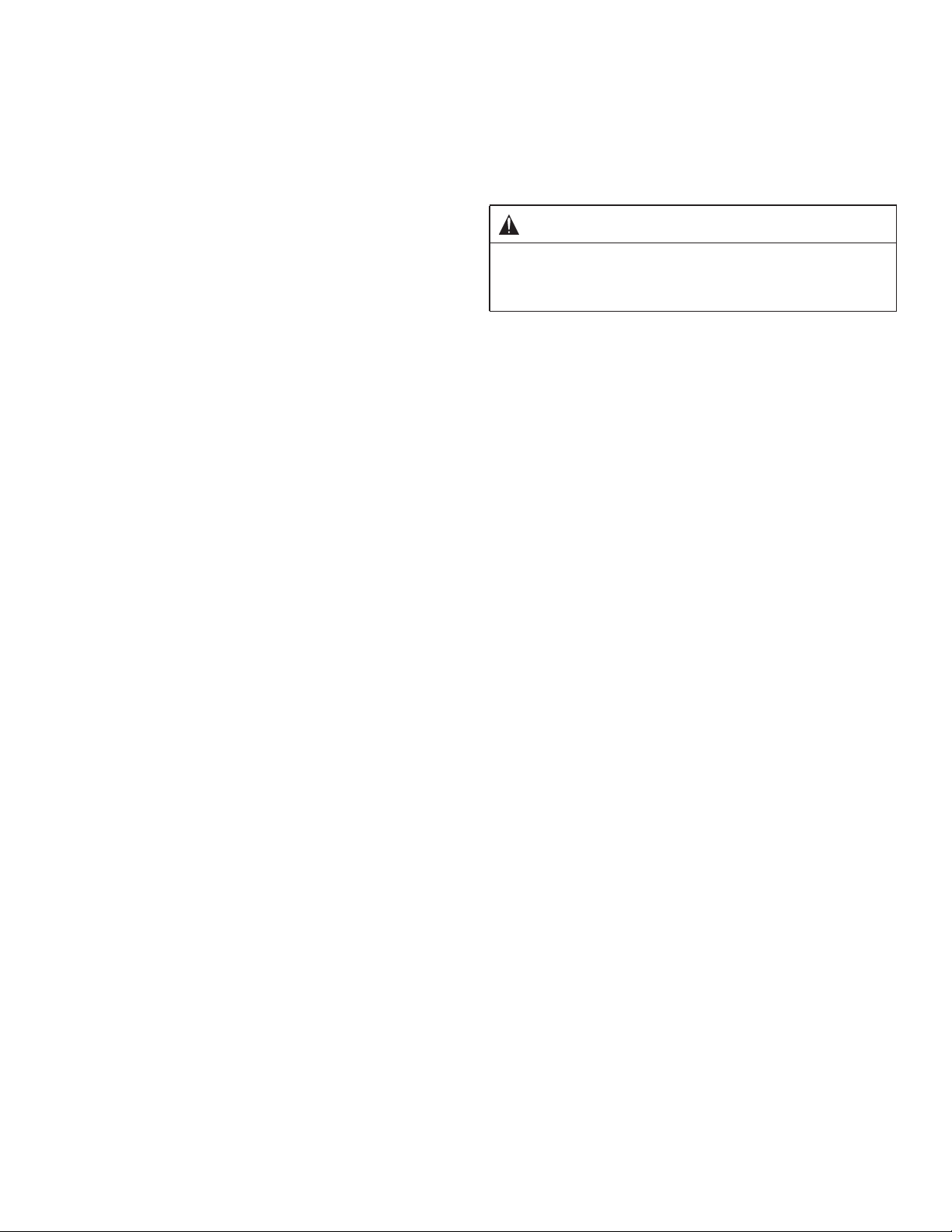

WARNING!

Vent ducting directly outdoors (not into an attic,

underneath the house, into the garage or into any

enclosed space).

The unit cannot be used in conjunction with a recirculation

unit.

THERMADOR recommends not exceeding 50 ft (15.24 m)

of duct.

Keep duct runs as short and straight as possible. Elbows

and transitions fittings reduce air flow efficiency. Back to

back elbows and “S” turns give very poor delivery and are

not recommended. A short straight length of duct at the

inlet of a remote blower gives the best delivery.

Hoods are supplied with a 10" (254 mm) round transition. A

locally supplied transition is required for other sizes.

Use “Equivalent Duct Lengths for Commonly Used

Transitions” on page 7 to compute permissible lengths for

duct runs to outdoors.

DO NOT USE FLEXIBLE DUCT; it creates back pressure/

air turbulence and reduces performance.

Always install a metal vent cover where the ductwork exits

the house.

COLD WEATHER installations should have an additional

backdraft damper installed to minimize reverse cold air flow

and a nonmetallic thermal break to minimize conduction of

outside temperatures as part of the ductwork. The damper

should be on the cold air side of the thermal break. The

break should be as close as possible to where the ducting

enters the heated portion of the house.

English 6

Page 9

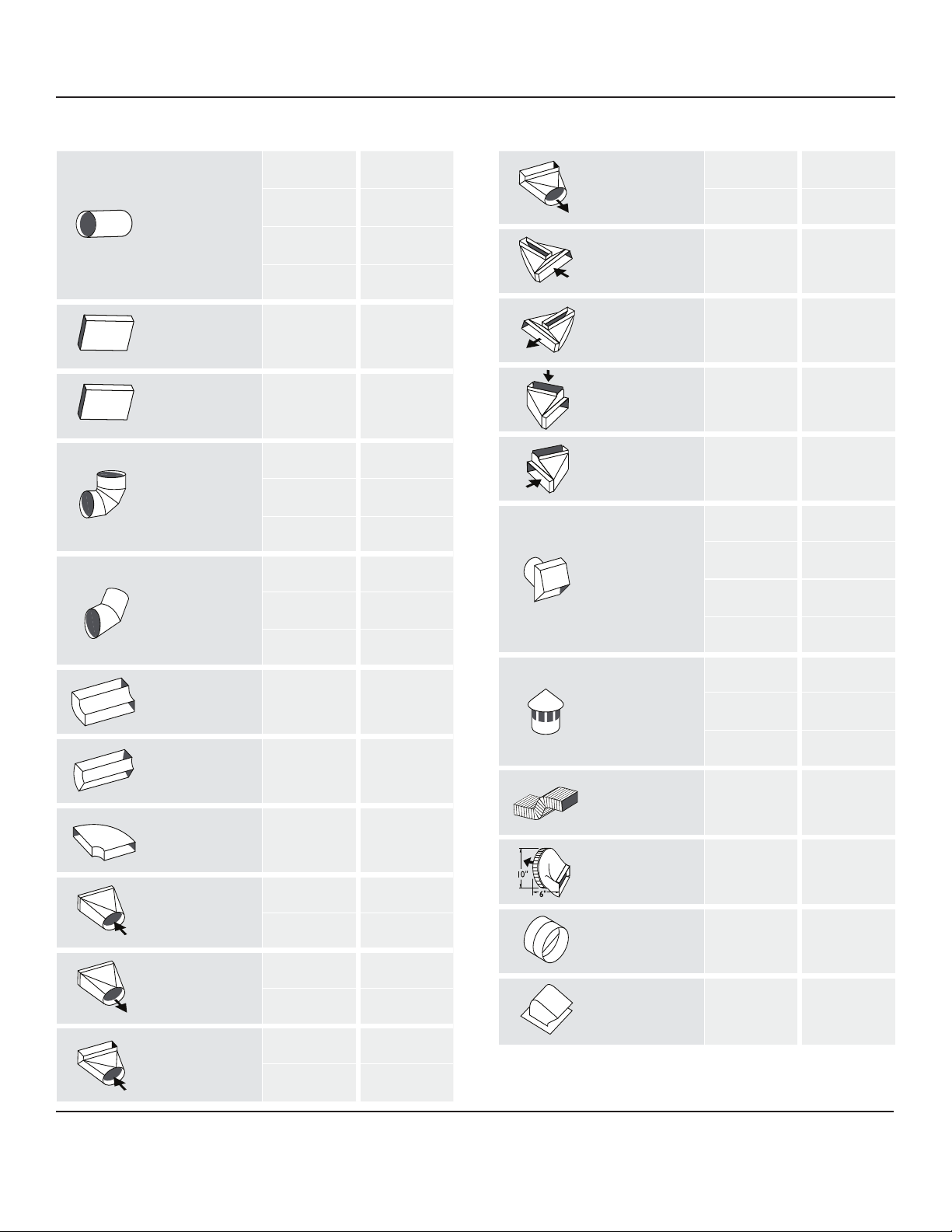

Equivalent Duct Lengths for Commonly Used Transitions

Duct Piece

Smooth

Straight

3¼" x 10"

Straight

3¼" x 14"

Straight

90° Elbow

Round

45° Elbow

Round

Size of Duct

Piece (in)

6 1.2

7 0.95

8 0.7

10 0.6

N/A 1

N/A 0.7

612

78

86

65

74

83

Equivalent

Length (ft)

Duct Piece

3¼" x 10"

to Round

90° Elbow

3¼" x 10"

Center Reverse

Elbow Left

3¼" x 10"

Center Reverse

Elbow Right

3¼" x 10" Left

Reverse Elbow

3¼" x 10"

Right Reverse

Elbow

Round

Wall Cap

Size of Duct

Piece (in)

610

75

N/A 15

N/A 25

N/A 15

N/A 25

62

72

82

10 2

Equivalent

Length (ft)

3¼" x 10"

90° Elbow

Round

3¼” x 10"

45° Elbow

Round

3¼" x 10"

Flat Elbow

Round to

3¼" x 10"

3¼" x 10"

to Round

Round to

3¼" x 10"

90° Elbow

N/A 5

N/A 15

N/A 20

61

71

65

73

610

78

62

Round

Roof Cap

2' Long

3¼" x 10"

Flex

3¼" x 10"

to Round

7" Inline

Backdraft

Damper

3¼" x 10"

Roof Jack

and Shutter

NOTE: These commonly used installation parts can be purchased

at a local hardware store. THERMADOR® does not manufacture all

these parts.

72

82

N/A 20

10 1

7

N/A

English 7

Page 10

Electrical Requirements

Hood Transition

CAUTION!

This range hood must be properly grounded. The unit

should be installed by a qualified electrician in

accordance with all applicable national and local

electrical codes.

The unit requires a 120V AC, 60Hz. 15A branch circuit.

The hood should only be connected to a dedicated circuit

(with ground) that has been installed according to relevant

regulations.

When connected to a GFCI-protected supply,

THERMADOR PROFESSIONAL hoods are suitable for

use in damp locations that are protected from outside

weather conditions and not subject to saturation with water

and other liquids, but can be subject to moderate degrees

of moisture (such as an outdoor covered patio or lanai

area). Refer to local codes, NEC/CEC, and or the Authority

Having Jurisdiction (AHJ) for additional information.

Check your local building codes for proper method of

installation. In the U.S., if there are no applicable local

codes, this unit should be installed in accordance with the

National Electric Code ANSI/NFPA No. 70, Current Issue.

In Canada, installation must be in accordance with the CAN

1- B149.1 and .2 - Installation Codes for Gas Burning

Appliances and/or local codes.

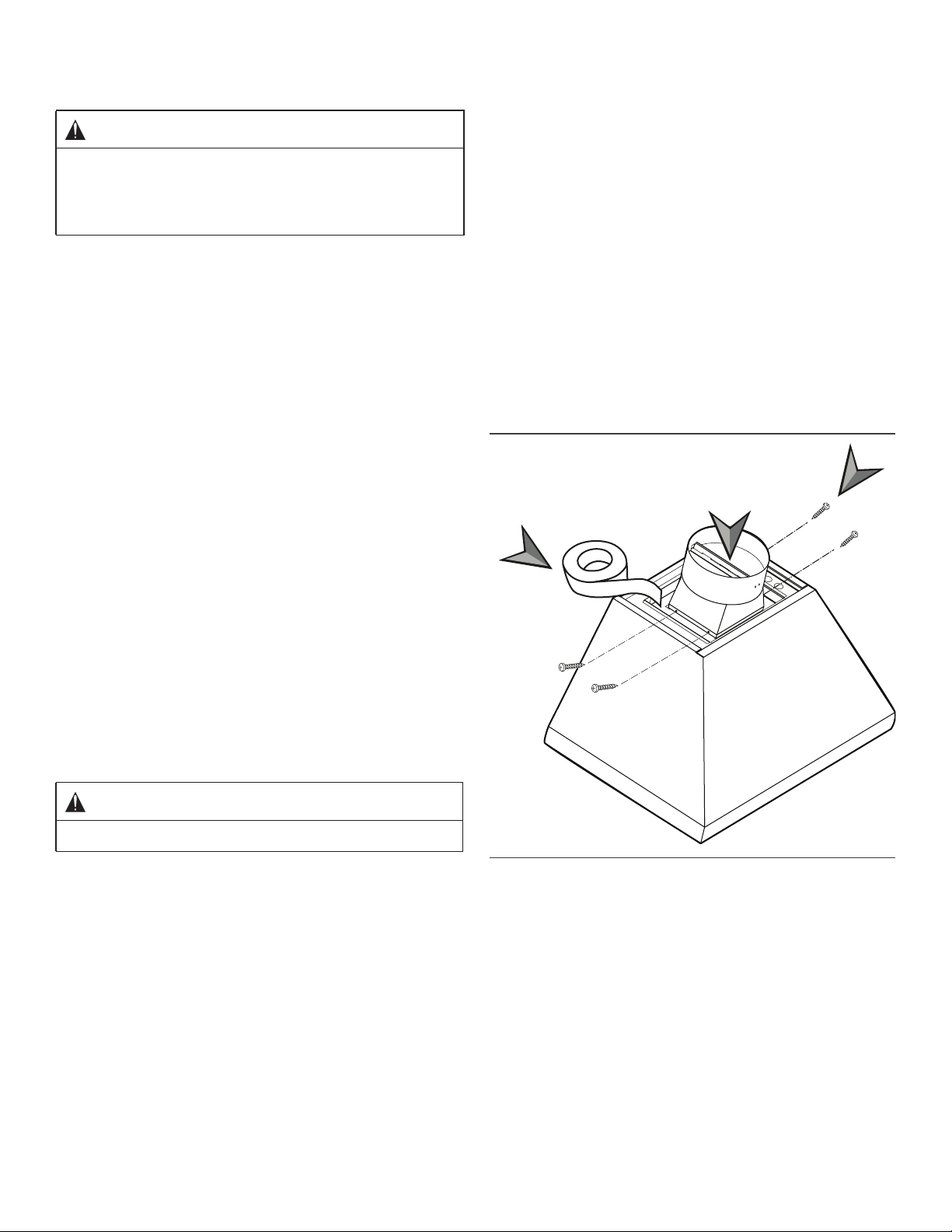

Assembly of the Transition:

The overall height of the transition is 8Ǫ" (212 mm). The

hood transition sits 6½” (165 mm) above the top of the

hood. 1Ǭ" will mount below the top edge of the hood. See

Figure 4 on page 9 for overall hood dimensions.

1. Align mounting holes at base of transition with the

mounting holes of the ½” (13 mm) flange located at the

top.

2. Fasten transition to hood using (4) 1” (25.4 mm) sheet

metal screws, included with hood.

3. Seal connection between transition and hood with

aluminum tape.

4. Remove tape holding damper closed.

2

1

3

The appliance must be grounded. In the event of an

electrical short circuit, grounding reduces the risk of electric

shock by providing a wire that allows the electric current to

escape.

WARNING!

The appliance must be grounded.

Electrical Data on the Data Rating Plate:

Data, including the model and serial number, is located on

the product data rating plate inside the appliance, visible

after removal of the filter frame (see Figure 29 on page 19).

Figure 3: Transition Connection

English 8

Page 11

Installation Instructions

*30” (762) min.

36” (914) max.

to cooking surface.

C

C

L

Hood Height Specifications

Figure 4 indicates a typical installation of the hood with an

optional chimney extension. Add or subtract chimney

extensions as appropriate to accommodate ceiling height

and recommended hood height.

The installation height is a minimum height of 30”

(762 mm) above the cooking surface; however, it is

necessary to follow the cooking appliance manufacturer’s

installation instructions for proper hood height.

Calculating Optional Duct Cover Height

Optional duct covers are available for purchase in 6”

(153 mm), 12” (305 mm), and 18” – 35” (457 – 889 mm)

sizes.

measurements in inches (mm)

Optional

Chimney

Extension

D

6½”

165)

C

C

L

L

3. Measure hood mounting height from the bottom of

hood to cooking surface (C, Figure 4). Dimension must

be a minimum 30" (762 mm).

4. Calculate optional duct cover height (D, Figure 4):

D = A – (B + C).

NOTICE:

The hood could incur some damage from heat if a

THERMADOR PROFESSIONAL series range or rangetop

is operated with multiple burners at high settings under a

hood that is installed at minimum clearances while the

hood is turned off.

Wiring Preparation

Ensure wiring does not interfere with optional chimney duct

covers (where the cover touches the wall).

Ceiling Cutout for Electrical Location

The junction box is located on the top right side of the hood

(see Figure 9). Wiring should enter the back wall at least

20" (508 mm) above the bottom of the installation height.

18” (457)

24” (610)

C

*30” (762) min.

*30” (762) min.

36” (914) max.

36” (914) max.

to cooking surface.

to cooking surface.

B

*Follow cooking

appliance manufacturer’s

recommendations

Figure 4: Hood Height Calculation

1. Measure height from floor to ceiling (A, Figure 4).

2. Measure height from floor to cooking surface (B,

Figure 4).

Prepare the wire hole cutout in the ceiling as indicated in

Figure 5 (only one hole cutout is necessary for the conduit).

measurements in inches (mm)

A

Hole to accomodate

10” (254) duct minimum

7¾”

(197)

13

”

/

6

(173)

16

1 ft –1 ft ¼” (336)

7

”

4

/

8

(48)

5/8” (16) dia. clearance

holes for ½” (12.7)

conduit to junction box

Hood Centerline

l

l

a

W

k

c

Ba

Figure 5: Electrical Location

English 9

Page 12

Back Wall Preparation

Distance to

cooking surface

plus 16” (406)

Wood

Bracket

(included)

Screws 2 ea

3” (76)

Drywall

NOTE:

Hardware provided is for mounting through standard

thickness drywall or plaster into wood studs. Installers are

responsible to provide hardware for other types of

mounting situations.

IMPORTANT:

The hood needs to be centered over the cooking surface

for best performance.

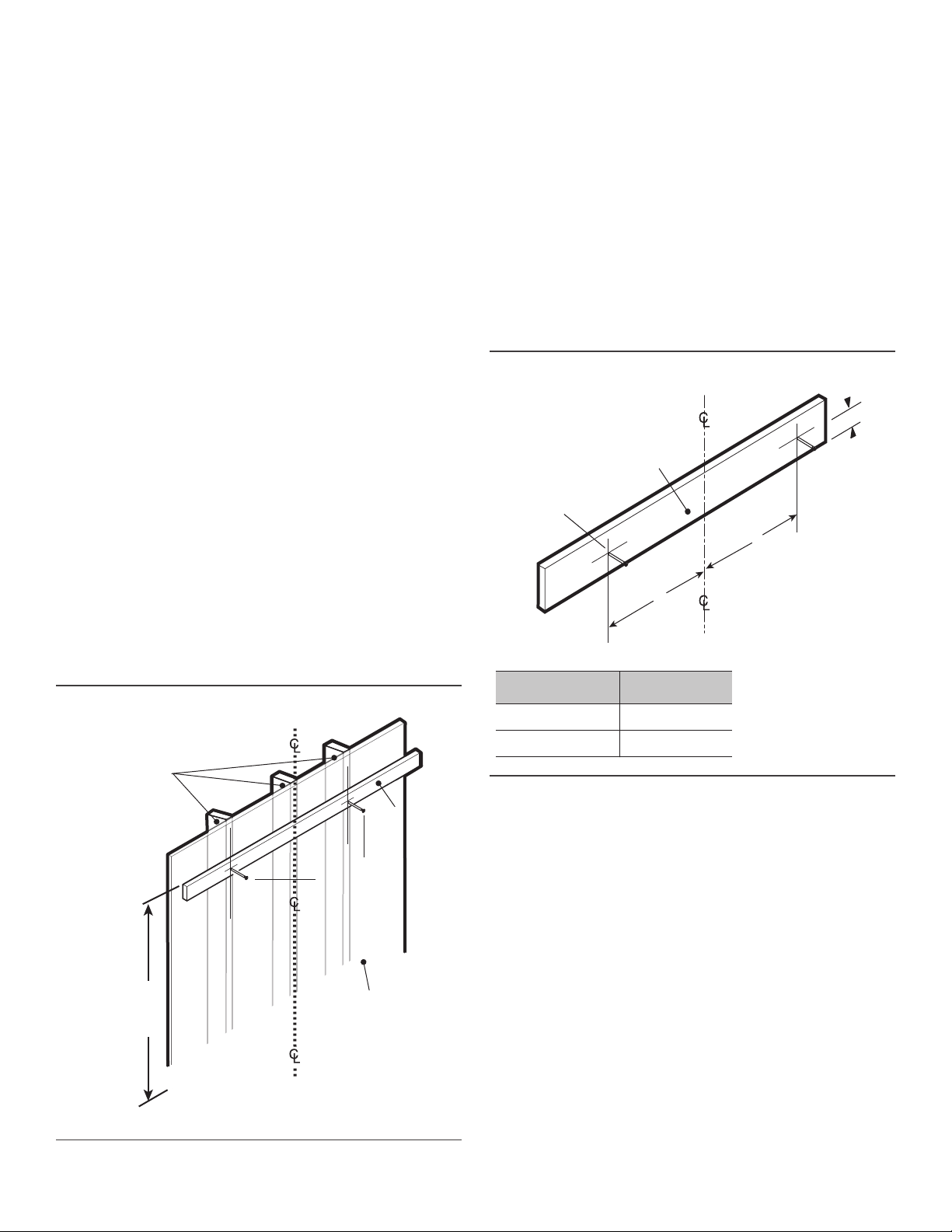

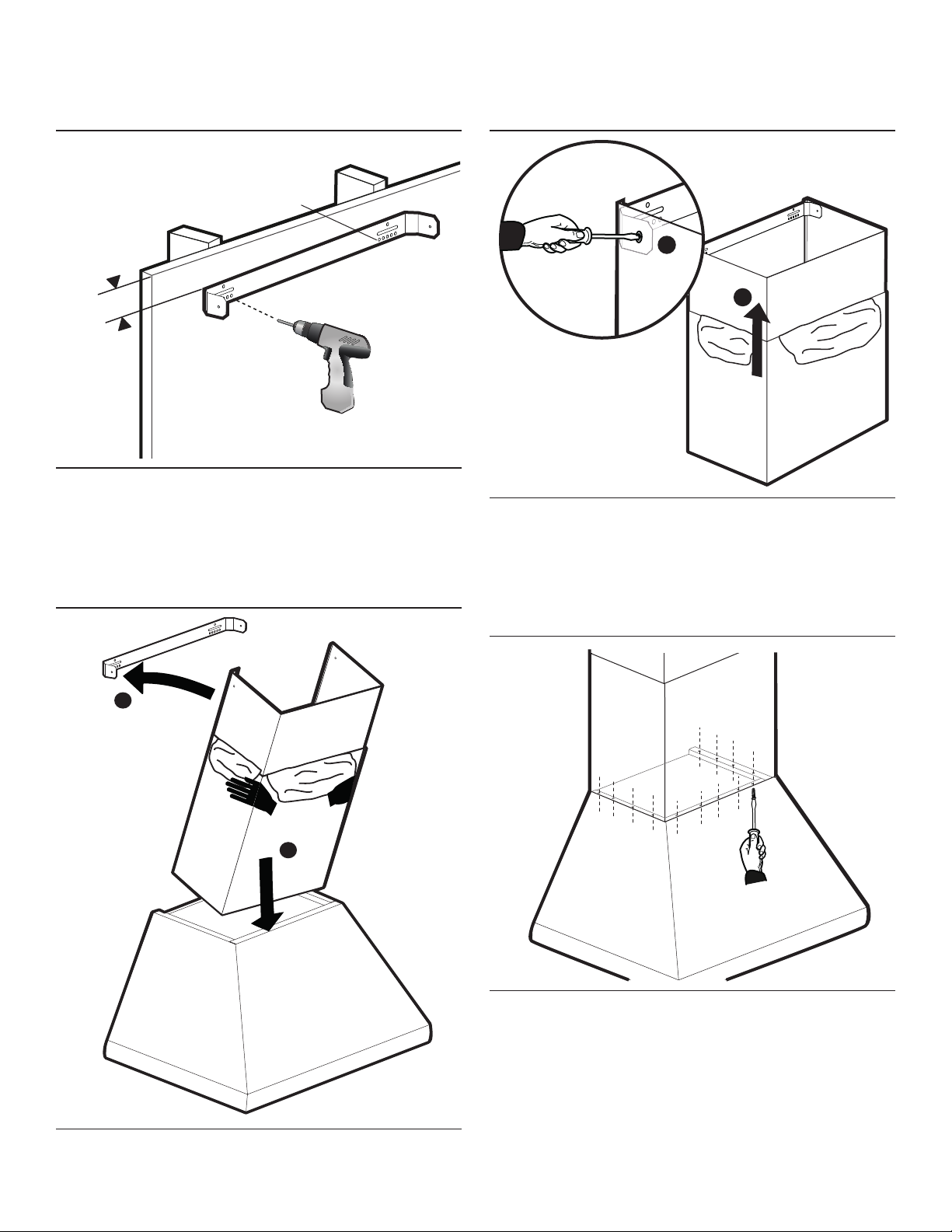

Wood Hanging Bracket

1. Calculate the hood installation height as described on

page 9.

2. Draw a horizontal line at a distance above the cooking

surface equal to the hood installation height plus 16”

(406 mm). This line is the mounting location of the

wood bracket shipped with the hood.

3. Find the centerline of the hood. Draw a vertical line

along this centerline up to the horizontal line drawn in

Step 2.

4. The hood is mounted to the wall using the wood

bracket shipped with the hood. Remove the wood

bracket located at the back side of the hood by

removing the two shipping screws (discard screws).

Mark the centerline of the wood bracket.

5. Locate a stud on both sides of the hood centerline to

use for mounting the wood bracket as shown in

Figure 6.

6. Align the top of the wood bracket along the horizontal

line drawn in Step 2. Align the centerlines of the

bracket and cooktop.

7. Drill a 3” (76 mm) deep ¼” (6 mm) tap hole through the

wood bracket, wall, and into the stud.

8. Remove the bracket and on a sturdy surface, make the

hole larger by drilling a 5/16” (8 mm) hole through the

wood bracket. Use a countersink bit to make a hole

large enough to countersink the screw heads to

prevent interference with the hood.

9. Use (2), 3” (76 mm) screws to attach the wood bracket

to the wall, as shown in Figure 6.

10. On the wood bracket, mark the locations used to hang

the hood according to Figure 7.

measurements in inches (mm)

2” (51)

Wood

Bracket

Screws 2 ea

1½” (38)

A

A

measurements in inches (mm)

Wall Studs

Distance to

Distance to

cooking surface

cooking surface

plus 16” (406)

plus 16” (406)

Cooking Surface

Cooktop Centerline

Wood

Wood

Bracket

Bracket

(included)

(included)

Screws 2 ea

Screws 2 ea

3” (76)

3” (76)

Drywall

Drywall

Figure 6: Mounting the Wooden Bracket

HOOD SIZE A

36” (914) 7¾” (197)

48” (1219) 13¾” (350)

Figure 7: Hanging the Hood

11. Drill a 3/16” (4.8 mm) tap hole through the wood

bracket and wall. These 5/8” (16 mm) screws do not

need to go into the studs.

12. Use (2) 1½” (38 mm) screws to secure the wood

bracket leaving ¼” (6 mm) of each screw exposed for

hanging the hood.

English 10

Page 13

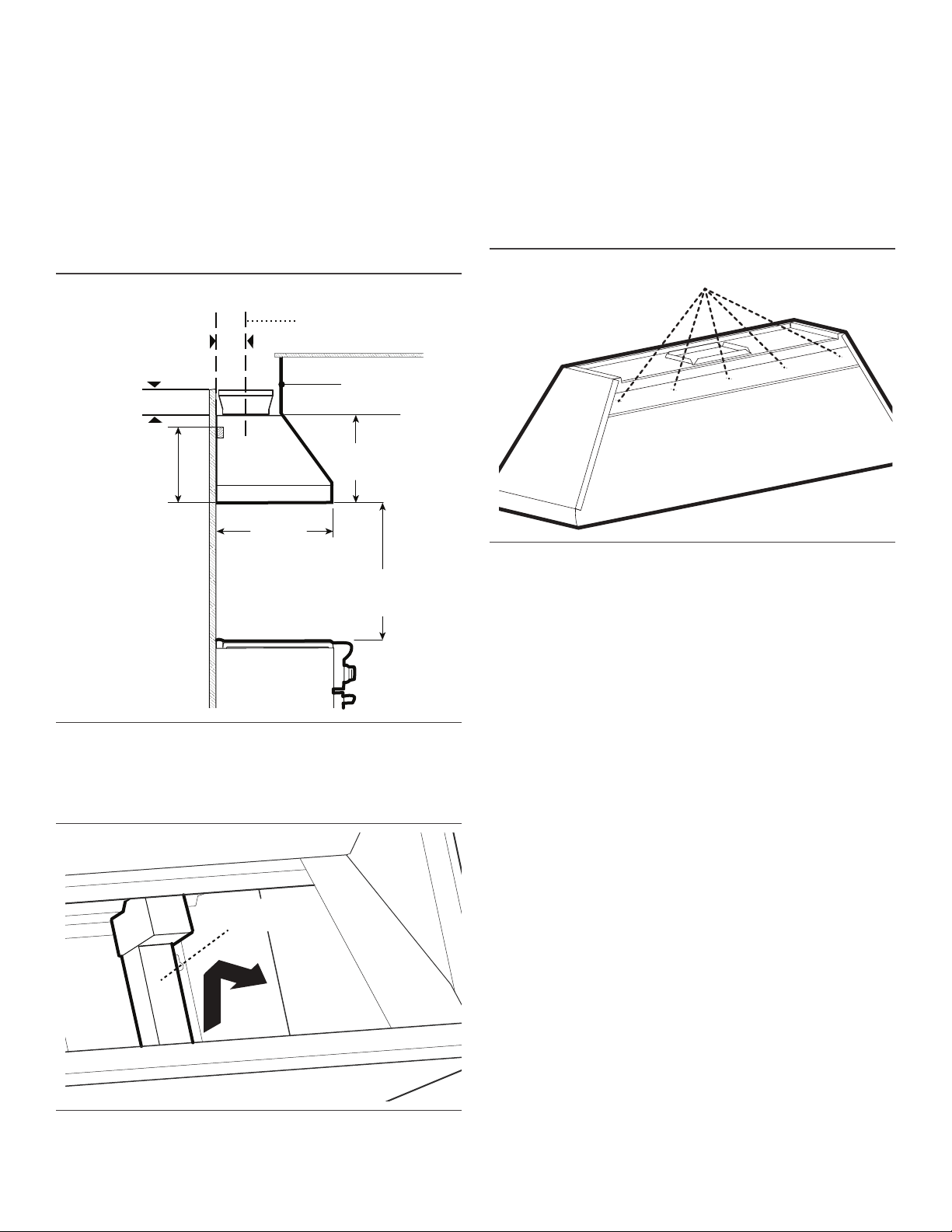

Hanging the Chimney Hood

C

L

*Hood height

min. 30” (762)

max. 36” (914) to

cooking surface

The transition supplied with the hood connects to standard

10-inch round duct. Installations require a cutout in the

ceiling to accommodate 10" (254 mm) duct and the ½”

(13 mm) conduit carrying power to the unit.

Chimney extensions, sold separately, are available to cover

the space between the top of the hood and ceiling (see

“Chimney Extension Installation (optional)” on page 16).

2. Remove one circular knockout behind junction box

channel.

3. Using two people to lift, rest the hood on the wood

bracket. Make sure the wood bracket fits into the

recess on the back of the hood.

4. From inside the hood, predrill the holes labeled “J” in

Figure 10 in hood into the wood bracket with a 5/8”

(16 mm) drill bit. Secure the hood to the wood bracket

with five (5) 1½” (38 mm) screws.

measurements in inches (mm)

7¾”

(197)

6½”

(165)

16" (406)

to top of wood

mounting strip

*Follow cooking

appliance

recommendations

Transition

Centerline

C

C

L

L

24” (610)

Hood Depth

Optional

Chimney

Extension

18”

(457)

*Hood height

*Hood height

min. 30” (762)

min. 30” (762)

max. 36” (914) to

max. 36” (914) to

cooking surface

cooking surface

J

Figure 10: Location of Screw Holes

5. Connect additional ducting.

Figure 8: Transition Centerline

1. Use a T-10 Torx head screwdriver to remove the screw

securing the junction box channel covering the wires.

Junction Box

Channel

Figure 9: Junction Box Channel

English 11

Page 14

Wire Connection

EXTNCB25 Blower Connection Cable

(optional)

Wire Routing

1. Run a 120V AC, 15 amp circuit power cable from the

service panel through one of the holes in the top plate.

Route Wire

Figure 11: Route Wire

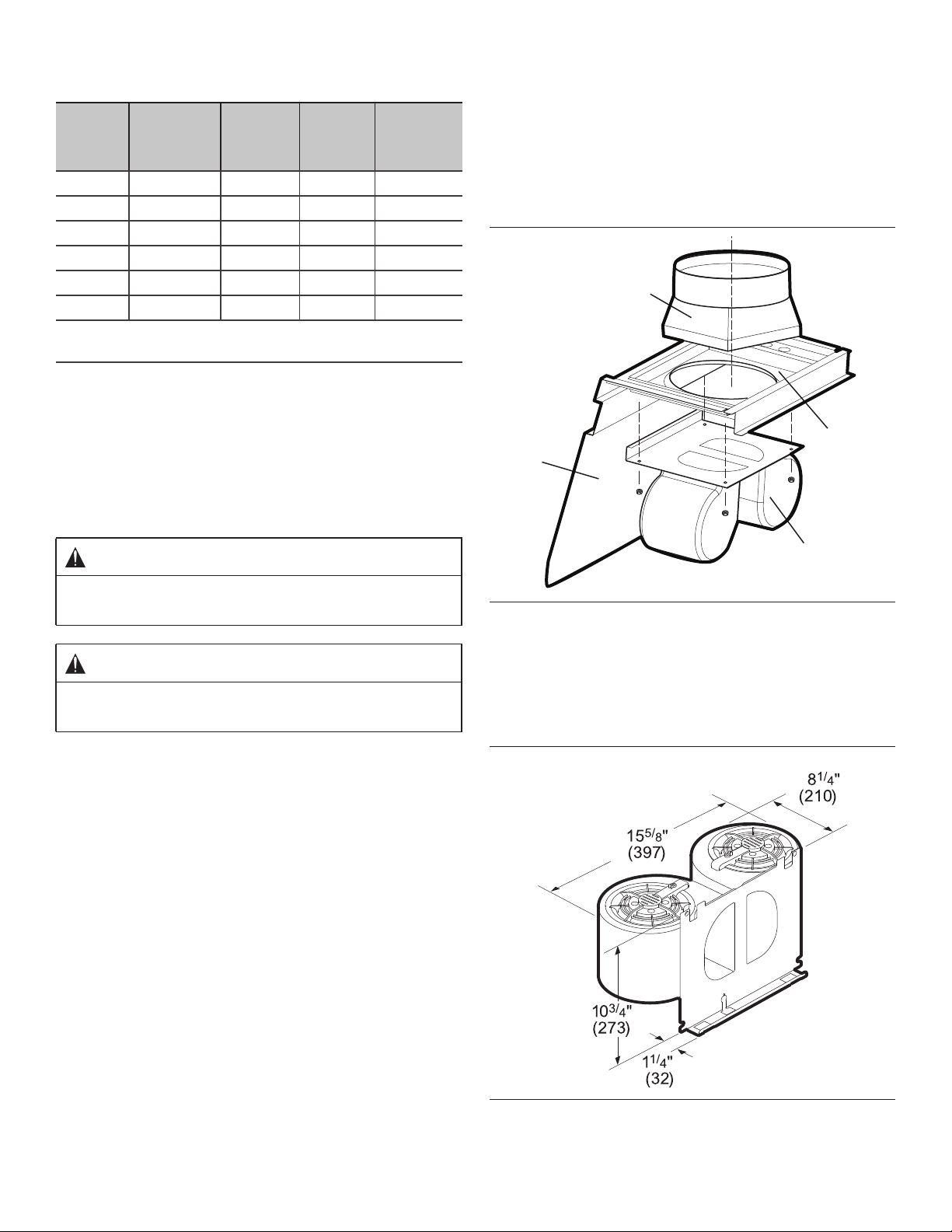

PARTS INCLUDED:

1 – 25ft cable

2 – Adapter Cables

(NOT NEEDED for

HPCN or HPCB

models)

Blower Extension Cable Connection

The internal blower harness should be routed through the

knockout and secured with a 1” (25.4 mm) strain relief. The

remote harness can then be connected to the blower

harness outside the unit (refer to Figure 11).

Connects to

Remote or

Inline blower

Connects

to Hood

2. Connect black wire to power supply black wire, white

wire to power supply white wire and green wire to

green wire or bare wire.

White to white

Green to green

or bare wire

Figure 12: Wire Connection

3. Place all wiring connections inside the junction box

channel. Reinstall on the top plate. Ensure that the

wires are secure and that no wires are pinched.

Black to black

25ft cable

Figure 13: Optional Blower Connection Cable

IMPORTANT:

Cutting of the connector will void the warranty of the

appliance.

The blower extension cable is compatible with the

following Inline & Remote blowers:

BLOWER SKU

Remote Blower VTR630*

Remote Blower VTR1030*

Remote Blower VTR1330*

Inline Blower VTI610*

Inline Blower VTI1010*

*Indicates a letter designating the release year.

English 12

Page 15

Blower Motor Installation

Blower SKU

Remote VTR630* 120 4.2 15

Remote VTR1030* 120 5.7 15

Remote VTR1330* 120 8.5 15

Inline VTI610* 120 4.2 15

Inline VTI1010* 120 5.7 15

Integral VTN1080* 120 5.4 15

* Indicates a letter designating the release year.

** With blower installed.

HPCB36NS and HPCB48NS models have a VTN1080

integral blower included. All other blower models are sold

separately. Use only THERMADOR blowers with these

ventilation hoods. See Table 1 Blower & Circuit Breaker

Ratings for recommended blowers. Contact Customer

Service for additional options.

Voltage

(AC)

Table 1: Blower & Circuit Breaker Ratings

Blower

Current

(Amps)

**Circuit

Breaker

(Amps)

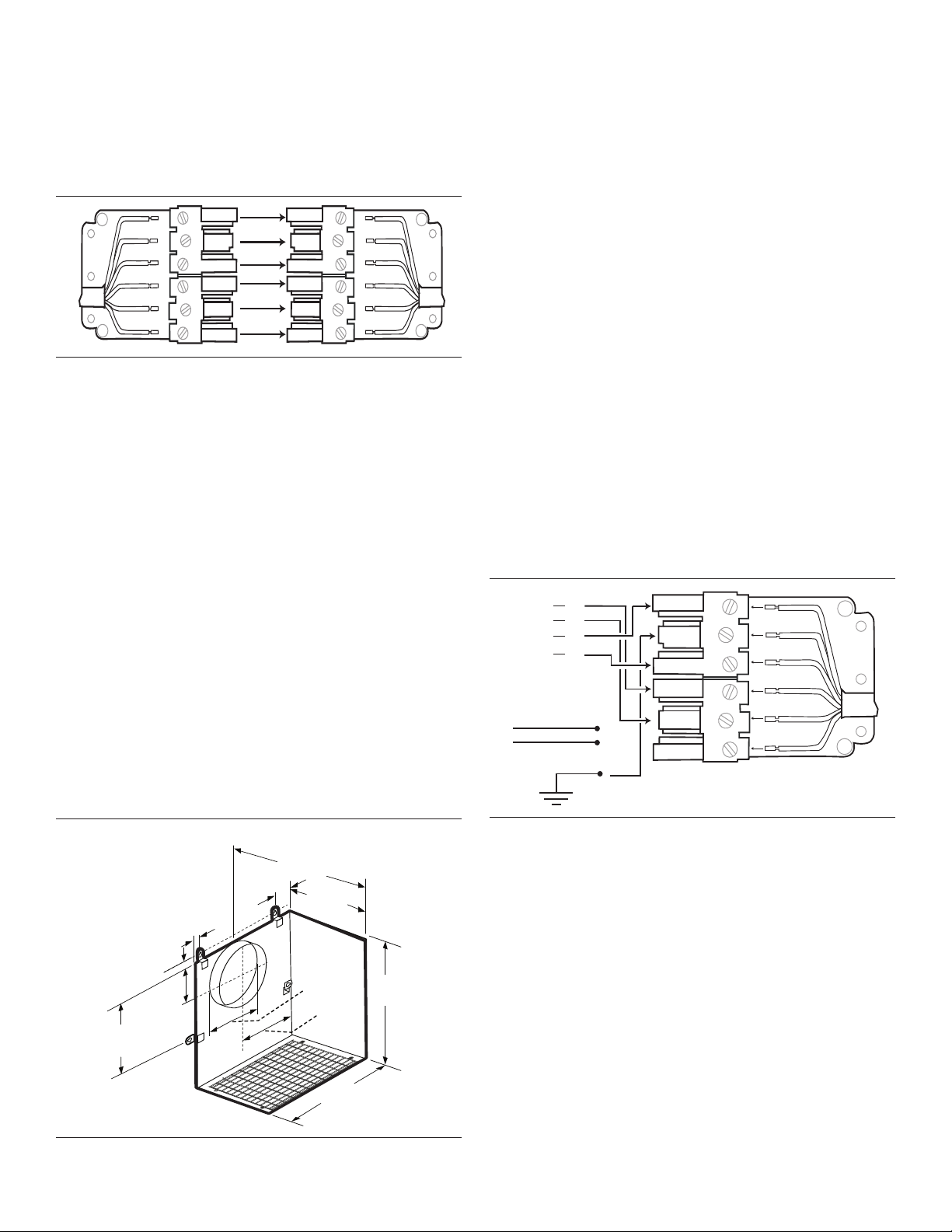

Integral Blower Installation Only

1. The blower is attached to the hood using weld studs

provided on the mounting plate (see Figure 14).

2. Guide the motor mounting plate over the studs.

3. Attach (4) nuts (included with hood) to the weld studs.

Tighten nuts with a 3/8” (9 mm) nut driver to secure the

blower to the hood.

Transition

Hood Back

Plate

Hood Top

Plate

CAUTION!

To reduce the risk of fire and electric shock, install this

range hood only with the blowers listed in Table 1.

WARNING!

Cutting the plug of the blower will void the warranty or

eligibility for return or exchange.

All hood models are rated for 120V AC installed with a

blower listed in Table 1, using a 15 amp dedicated circuit

breaker.

Blower selection will vary based on the volume of air that

needs moved and the length and location of the duct run.

For long duct runs with multiple turns and bends, consider

using a more powerful blower. For the most efficient airÀow exhaust, use a straight run or as few elbows as

possible (refer to “Ductwork Preparation” on page 6).

Blower Housing

Figure 14: Integral Blower Motor Install

Wiring the Hood with an Integral Blower

Integral Blower model VTN1080 should be installed after

hood is mounted to the wall.

measurements in inches (mm)

Figure 15: Integral Blower Model VTN1080

English 13

Page 16

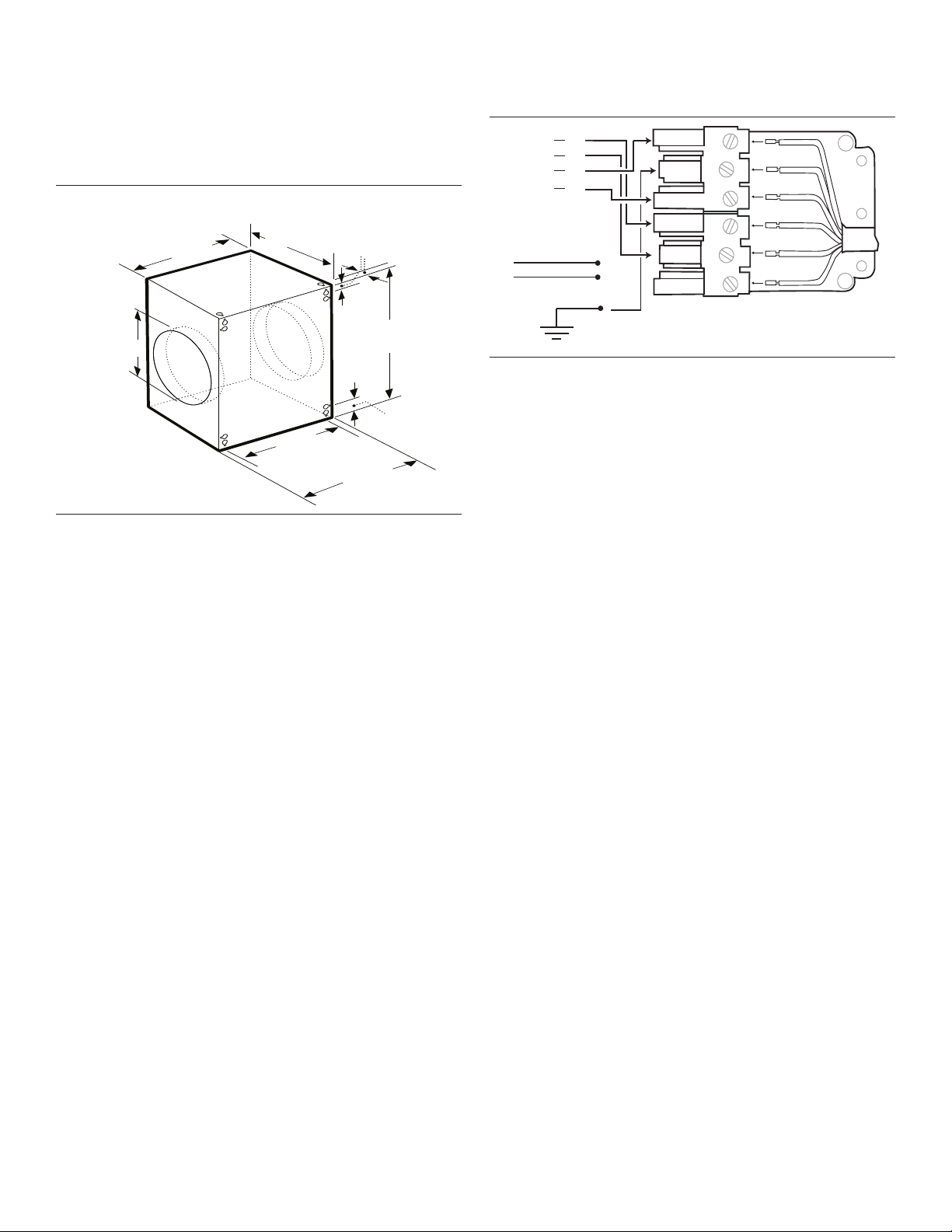

1. Remove junction box channel covering the wires (see

From Hood

From Blower

Brown

Green/Yellow

White

Red

Blue

Orange

Figure 9 on page 11).

2. Remove circular knockouts (Figure 9 on page 11).

3. Connect the blower’s Molex plug connector to the

connector present inside the hood, as shown in

Figure 16.

From Hood

From Hood From Blower

From Blower

Figure 16: Wiring the Hood with an Integral Blower

4. Install 1” (25.4 mm) conduit connector in junction box.

5. Run black, white, and green wires (#12 AWG) in 1”

(25.4 mm) conduit from the power supply to the

junction box.

6. Connect the power supply wires to the hood wires in

the following order: black to black, white to white, and

green wire to green ground screw on chassis. Use

spring type wire nuts.

• Wire nuts should be spring type wire nuts rated for

a minimum of two (2) #18 gauge wires and

maximum of four (4) #14 gauge wires, UL & CSA

rated to 600V and 302°F (150°C).

7. Reinstall the junction box channel.

Wiring the Hood with a Remote Blower

Depending on preference and ducting situation, these

blowers can be mounted on the roof or exterior wall of the

home. An exterior installation may be more appealing to

reduce noise in the kitchen.

1. Remove junction box channel covering the wires (see

Figure 9 on page 11).

2. Remove circular knockouts (Figure 9 on page 11).

3. Install 1” (25.4 mm) conduit connectors.

4. Run black, white, and green wires (#12 AWG) in 1”

(25.4 mm) conduit from the power supply to the

junction box.

5. Connect the power supply wires to the hood wires in

the following order: black to black, white to white, and

green wire to green ground screw on chassis. Use

spring type wire nuts.

• Wire nuts should be spring type wire nuts rated for

a minimum of two (2) #18 gauge wires and

maximum of four (4) #14 gauge wires, UL & CSA

rated to 600V and 302°F (150°C).

6. Connect the “pigtail” to the connector inside the

junction box.

7. Run five (5) #14 AWG wires in 1” (25.4 mm) conduit

from the remote blower to the second conduit

connector.

8. Connect the remote blower to the pigtail wires as per

Figure 18. Connect the remote blower green (ground)

wire to the ground screw in the junction box. Refer to

the blower installation instructions for further wiring

details.

SPEED 1

SPEED 2

SPEED 3

NEUTRAL

WH / BC / BL (16 AWG)

BK / N / NE (16 AWG)

RD

BU

BN

WH

120V, 60HZ, 20A

POWER SUPPLY

SP4

GROUND

N

SP1

SP2

SP3

L1NT1T2S3

Brown

Brown

Green/Yellow

Green/Yellow

White

White

Red

Red

Blue

Blue

Orange

Orange

measurements in inches (mm)

1/

2

"

8

(54)

7/

8

1

"

(48)

1/

2

6

"

(165)

7/

12

"

8

(327)

English 14

5/

8

13

"

(346)

1/

8

2

"

(54)

12

(308)

dia. 9

(251)

10 "

(254)

1/

8

7/

19

(505)

"

8

"

3/

20

"

4

(527)

7/

8

"

Figure 17: VTR1330 Remote Blower

Figure 18: Wiring the Hood with a Remote Blower

9. Reinstall the junction box channel.

Page 17

Wiring the Hood with an Inline Blower

Brown

Green/Yellow

White

Red

Blue

Orange

To minimize noise in the kitchen, these blowers are

mounted along the duct line anywhere between the kitchen

and the exterior wall. If there is easy access to duct line (in

an attic, for example), this may be an appealing option.

measurements in inches (mm)

"

12

(308)

1/

8

"

12

(305)

7/

8

" (22)

8. Connect the inline blower to the pigtail wires as per

Figure 20. Connect the inline blower green (ground)

wire to the ground screw in the junction box.

SPEED 1

SPEED 2

SPEED 3

NEUTRAL

WH / BC / BL (16 AWG)

BK / N / NE (16 AWG)

RD

BU

BN

WH

SP4

GROUND

N

SP1

SP2

SP3

L1NT1T2S3

Brown

Brown

Green/Yellow

Green/Yellow

White

White

Red

Red

Blue

Blue

Orange

Orange

ø9

(251)

7/

"

8

1/

19

(486)

1

"

8

3/

"

4

(44)

7/

12

"

8

(327)

14

3/

"

8

(365)

Figure 19: VTI1010 Inline Blower

1. Remove junction box channel covering the wires (see

Figure 9 on page 11).

2. Remove circular knockouts (Figure 9 on page 11).

3. Install 1” (25.4 mm) conduit connectors.

4. Run black, white, and green wires (#12 AWG) in 1”

(25.4 mm) conduit from power supply to junction box.

5. Connect the power supply wires to the hood wires in

the following order: black to black, white to white, and

green wire to green ground screw on chassis. Use

spring type wire nuts.

• Wire nuts should be spring type wire nuts rated for

a minimum of two (2) #18 gauge wires and

maximum of four (4) #14 gauge wires, UL & CSA

rated to 600V and 302°F (150°C).

6. Connect the “pigtail” to the connector inside the

junction box.

7. Run five (5) wires (#14 AWG) in 1” (25.4 mm) conduit

from the inline blower to the second conduit connector.

120V, 60HZ, 20A

POWER SUPPLY

Figure 20: Wiring the Hood with an Inline Blower

9. Reinstall the junction box channel.

English 15

Page 18

Chimney Extension

2

18” (457)

B

A

18” – 35”

( 457 – 889)

⅝” (16)

18”

(457)

17”

(432)

AB

36" 14" (356) 20¾" (527)

48" 14" (356) 32⅞" (835)

Installation (optional)

Telescoping Chimney Extension

Installation

Optional chimney extensions and telescoping extensions

are used to fill the space between the hood and ceiling

(available for separate purchase). Chimney extensions fill

the space between the hood and ceiling of 8' (2.4 m) and 9'

(2.7 m) ceilings. Telescoping extensions accommodate 10'

(3 m) ceilings. For dealer information, visit the Find a

Dealer section on our website at www.thermador.com.

MODEL 6” EXTENSION 12” EXTENSION

HPCN36NS CHMHP366N CHMHP3612N

HPCB36NS CHMHP366N CHMHP3612N

HPCN48NS CHMHP486N CHMHP4812N

HPCB48NS CHMHP486N CHMHP4812N

Chimney Extension Installation

IMPORTANT NOTE: Secure the Chimney Hood to the wall

before installing the Chimney Extension. See “Hanging the

Chimney Hood” on page 11 before securing the actual

Extension.

1. Installation of the chimney hood should maintain a

minimum height of 30" (762 mm) from the bottom of the

hood to the cooking surface. To determine placement

of the hood with a Chimney Extension, the height of the

chimney extension must be calculated (see

“Calculating Optional Duct Cover Height” on page 9).

2. From inside of hood, screw the supplied 5/8” (16 mm)

sheet metal screws through the holes on each side and

along the front into bottom of the extension, as shown

in Figure 21. (Screw quantity is dependent on hood

size.)

IMPORTANT NOTE:

Secure the Chimney Hood to the wall after installing the

Extension Mounting Bracket, but before installing the

Telescoping Chimney Extension. See “Hanging the

Chimney Hood” on page 11 before securing the actual

Extension.

Securing the Telescoping Chimney Extension Bracket

1. Ensure that the minimum height of 30" (762 mm) from

the bottom of the hood to the cooking surface will be

maintained (see “Calculating Optional Duct Cover

Height” on page 9).

2. Locate two studs at the mounting location, as shown in

Figure 22.

measurements in inches (mm)

B

B

⅝” (16)

18” – 35”

18” – 35”

( 457 – 889)

( 457 – 889)

A

17”

17”

(432)

(432)

18”

18”

(457)

(457)

1

Figure 21: Attachment of Chimney Extension to Hood

English 16

18” (457)

18” (457)

Figure 22: Hood Location

3. At the wall stud locations, measure ǫ” (16 mm) down

from the ceiling to the top of the bracket.

Page 19

4. Mount the bracket at the wall stud locations using (2)

3½” (89)

1½” (38 mm) screws (provided). Ensure that the

bracket is level.

measurements in inches (mm)

Adjustable

mount holes

7. Carefully pull the top part of the extension upwards.

Screw the left and right sides of the extension to the

mounting bracket with the supplied stainless screws.

2

3½” (89)

3½” (89)

Figure 23: Securing Bracket to the Wall

5. See “Hanging the Chimney Hood” on page 11 before

securing the Telescopic Chimney Extension.

6. Insert the complete duct cover at an angle and swivel

toward the wall.

2

1

Figure 25: Securing Completed Cover

8. From inside of hood, screw the supplied 5/8” (16 mm)

sheet metal screws through the holes on each side and

along the front into bottom of the extension. Screw

quantity is dependent on hood size.

1

Figure 26: Securing Telescopic Chimney Extension to Hood

Figure 24: Inserting Completed Cover

English 17

Page 20

Installing Grease Trays and

Grease

Tray

Grease

Tray Trough

Filters

NOTE:

Do not use cooktop while hood is disassembled.

To Install Filters and Grease Trays:

1. Turn the fan and lights off.

2. Install in the following order:

1) Grease Tray — Insert in rear tray. Grease trays

must be in place before installing the filters. Push

the grease tray in and down inside the grease tray

trough.

Grease

Grease

Tray

Tray

Grease

Grease

Tray Trough

Tray Trough

Figure 27: Grease Tray Install

2) Filters — Depending upon the size and model of

hood, there will be 2 or 3 filters per hood. Start with

an outside filter. Slide the filter up, toward the front

of the hood, then push down on top of the grease

tray.

Filters

Figure 28: Filter Install

Reverse the above directions to remove the filters and

grease trays. Ensure filters are cool and grease has

congealed before removal.

English 18

Page 21

User Servicing and Installer Checklist

Before Calling Service

See Use and Care Guide for troubleshooting information.

Refer to the Warranty in the Use and Care Guide. Please

be prepared with the information printed on your product

data rating plate when calling (see Figure 29).

To reach a service representative, see the contact

information at the back of the manual. Please be prepared

with the information printed on your product data rating

plate when calling (see Figure 29).

Keep your invoice or escrow papers for warranty validation

if service is needed.

Product Data Rating Plate

The data rating plate shows the model and serial number. It

is located under the filter.

Data Rating

Plate

Filters

Figure 29: Data Rating Plate Location

Installer Checklist

F Specified clearances maintained to cooking surface.

F Appliance is level.

F All packaging material removed.

F Receptacle with correct over-current protection is

provided for service cord connection.

F Proper ground connection.

F Owner is aware of location of the main circuit breaker.

F INSTALLER: Write the model number and serial

number found on the Data Rating Label Plate in the

USE AND CARE GUIDE. Leave the USE AND CARE

GUIDE

and the INSTALLATION MANUAL with the owner

of the appliance.

To Clean and Protect Exterior Surfaces

• Stainless steel may be cleaned by wiping with mild,

soapy water and a soft cloth. Always wipe and dry in

the direction of the stainless steel grain. Rinse with

clear water and dry with a soft cloth.

• For discolorations or deposits that persist, refer to the

Use and Care Guide.

• To polish and protect stainless steel, apply a stainless

steel conditioner with a soft cloth. The Thermador

Stainless Steel Conditioner is available for purchase in

the online eShop (www.thermador-eshop.com). Order

part number 00576697.

• DO NOT allow deposits to remain for long periods of

time.

• DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

• DO NOT allow salt solutions, abrasive sponges or

cleaners, disinfectants, bleaches or cleaning

compounds to remain in contact with stainless steel for

extended periods. Many of these compounds contain

chemicals which could prove harmful. Rinse with water

after exposure and wipe dry with a clean cloth.

English 19

Page 22

Table des Matières

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instructions de sécurité importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Planification préalable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Avant de commencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Renseignements généraux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions générales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Préparation de l’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Facteurs à prendre en compte pour l’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Préparation du conduit d’aération . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Exigences électriques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Raccord pour la hotte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Instructions d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Spécifications concernant la hauteur de la hotte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Préparation du câblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Préparation de la cloison arrière . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation de la hotte avec conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Branchement des câbles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation du ventilateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation des rallonges de conduit (optionnel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation des plateaux à graisse et des filtres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Service et liste de vérification de l’installateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Avant d’appeler le service à la clientèle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Liste de vérification à l’intention de l’installateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Entretien, Pièces et accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page verso

Cet appareil électroménager de THERMADORmc

est fait par BSH Home Appliances Ltd.

6696 Financial Drive, Unit 3

Mississauga, ON L5N 7J6

Des questions?

1-800-735-4328

www.thermador.ca

Nous attendons de vos nouvelles

Page 23

Sécurité

CONSIGNES DE SÉCURITÉ IMPORTANTES

LISEZ ET CONSERVEZ CES INSTRUCTIONS

INSTALLATEUR : Veuillez laisser ces instructions

d’installation au propriétaire de l’appareil. Montrez au

propriétaire l’emplacement du tableau de disjoncteurs.

Marquez-le pour qu’il soit facile à identifier.

PROPRIÉTAIRE : Veuillez conserver ces instructions pour

consultation ultérieure.

AVERTISSEMENT!

Si vous ne suivez pas rigoureusement les

renseignements fournis dans le présent manuel, un

incendie ou une décharge électrique pourrait causer des

dommages matériels ou des blessures corporelles.

AVERTISSEMENT!

Coupez l’alimentation du disjoncteur et verrouillez le

panneau avant de procéder au câblage de cet appareil.

Exigence : 120 VCA, 60 Hz, 15 A. Avant de procéder à

l’entretien de l’appareil, laissez-lui le temps de refroidir

une fois que vous avez coupé l’alimentation électrique.

AVERTISSEMENT!

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE

DÉCHARGE ÉLECTRIQUE OU DE BLESSURE,

RESPECTEZ LES CONSIGNES SUIVANTES :

• Utilisez cet appareil seulement de la manière prévue

par le fabricant. Si vous avez des questions,

communiquez avec le fabricant à l’adresse ou au

numéro de téléphone apparaissant sur la page verso

du présent manuel.

• Avant de procéder au nettoyage ou à l’entretien de

l’appareil, éteignez l’alimentation du panneau

électrique et bloquez le dispositif de déconnexion

pour éviter que l’alimentation ne soit accidentellement

rallumée. Si le dispositif de sectionnement

d’électricité ne peut être bloqué, attachez un

avertissement, comme une étiquette, bien en vue sur

le tableau électrique.

AVERTISSEMENT!

Disposition de la proposition 65 de l'État de la

Californie

Ce produit contient ou facilite l'émission d'un ou de

plusieurs produits chimiques qui, selon l'État de la

Californie, peuvent causer le cancer, des anomalies

congénitales ou d'autres problèmes congénitaux.

Consignes de sécurité en matière

d’électricité

AVERTISSEMENT!

LA MISE À LA TERRE INADÉQUATE DE

L’APPAREIL PEUT ENTRAÎNER UN RISQUE

DE DÉCHARGE ÉLECTRIQUE.

Si le cordon d’alimentation est trop court, faites

installer une prise murale près de l’appareil par

un électricien qualifié.

RALLONGE ÉLECTRIQUE.

Consultez un électricien qualifié si vous ne

comprenez pas totalement les consignes de

mise à la terre ou si vous avez des doutes quant

à la mise à la terre adéquate de l’appareil.

AVERTISSEMENT!

RISQUE DE DÉCHARGE ÉLECTRIQUE

• N’enlevez pas de connexion.

• N’utilisez pas une rallonge électrique.

• La mise à la terre inadéquate de l’appareil

peut entraîner un risque de décharge

électrique.

• Le non-respect des présentes instructions

peut entraîner la mort, causer un incendie

ou provoquer une décharge électrique.

N’UTILISEZ PAS UNE

AVERTISSEMENT!

Ne réparez et ne remplacez aucune pièce de l’appareil à

moins que cela ne soit expressément recommandé dans

le présent manuel. L’installation, la réparation ou

l’entretien inadéquat de cet appareil peut causer des

blessures corporelles ou des dommages matériels.

Consultez le présent manuel pour des conseils. Tous les

autres travaux d’entretien doivent être effectués par un

technicien qualifié.

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil doit être mis à la terre. La mise à la terre réduit

les risques de décharge électrique en fournissant au

courant électrique un fil d’échappement lors d’un courtcircuit.

Française 1

Page 24

CONSIGNES DE SÉCURITÉ IMPORTANTES

LISEZ ET CONSERVEZ CES INSTRUCTIONS

Assurez-vous que votre appareil est convenablement

installé et mis à la terre par un technicien qualifié.

L’installation, le branchement électrique et la mise à la terre

doivent être conformes à tous les codes en vigueur.

Si le Code national de l’électricité (ou le code canadien de

l’électricité) l’exige, cet appareil doit être installé sur un

circuit de dérivation séparé.

AVERTISSEMENT!

Pour réduire les risques d’incendie ou de décharge

électrique, n’utilisez pas cet appareil avec un tableau de

commande à semi-conducteurs.

Consignes de sécurité pour la

manipulation de l’appareil

ATTENTION!

L’appareil est lourd. Au moins deux personnes ou de

l’équipement adéquat sont requis pour le déplacer et

l’installer.

Les surfaces cachées de l’appareil peuvent comporter des

saillies coupantes. Faites preuve de prudence lors de la

manutention de l’appareil pour éviter de vous blesser ou

d’endommager votre propriété.

Consignes de sécurité relatives au

matériel

Ne modifiez jamais l’appareil. Par exemple, n’enlevez pas

de panneaux, couvre-fils ou supports/vis.

ATTENTION!

POUR VENTILATION GÉNÉRALE SEULEMENT.

N’utilisez pas cet appareil pour évacuer des vapeurs et

des matériaux explosifs ou dangereux. Pour réduire les

risques d’incendie, n’utilisez que des conduits

métalliques.

Lorsque vous coupez ou percez un mur ou un plafond,

assurez-vous de ne pas endommager le câblage électrique

ou toute autre installation technique dissimulée.

Normes et codes de sécurité

Cet appareil est conforme à une ou plusieurs des normes

suivantes :

UL 507 – norme visant la sécurité en matière de ventilateurs

•

électriques

• CAN/CSA-C22.2 No 113 – ventilateurs

Il est de la responsabilité du propriétaire et de l’installateur

de déterminer les exigences ou les normes

supplémentaires pouvant s’appliquer à des installations

particulières.

Sécurité en matière de ventilation

AVERTISSEMENT!

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE

DÉCHARGE ÉLECTRIQUE OU DE BLESSURE,

RESPECTEZ LES CONSIGNES SUIVANTES :

• Les travaux d’installation et de câblage électrique

doivent être faits par une personne qualifiée selon les

stipulations de toutes les normes et réglementations

en vigueur, dont les normes des constructions ayant

une cote de résistance au feu.

• Pour prévenir les contre-explosions, une certaine

quantité d’air est nécessaire pour la combustion et

l’évacuation des gaz par le carneau (cheminée) de

l’appareil de combustion. Respectez les directives du

fabricant d’outillage de chauffage et les normes de

sécurité, comme celles publiées par la NFPA

(Association nationale des services d’incendie), par la

Société américaine des ingénieurs en chauffage,

réfrigération et climatisation (ASHRAE) et par les

autorités locales.

• N’utilisez que des conduits métalliques.

• Les ventilateurs canalisés doivent toujours évacuer

l’air à l’extérieur. N’évacuez pas l’air dans les espaces

entre les murs, le plafond, le grenier, les vides

sanitaires ou le garage.

• Lorsque vous coupez ou percez un mur ou un

plafond, assurez-vous de ne pas endommager le

câblage électrique ou toute autre installation

technique dissimulée.

Ayez recours à un installateur qualifié.

Française 2

Page 25

Planification préalable

Avant de commencer

PIÈCES FOURNIES

1 – Ventilateur intégré VTN1080

(modèles HPCB seulement)

1 – Raccord métallique avec registre

antirefoulement

2 ou 3 – Filtres déflecteurs en acier

inoxydable (selon les dimensions du

modèle)

2 ou 3 – plateaux à graisse (selon les

dimensions du modèle)

PIÈCES ET OUTILS REQUIS

Ruban d’aluminium; n’utilisez PAS du ruban à conduit

Tube de 1/2 po (13 mm), s’il y a lieu; respectez les

codes locaux

Serre-câbles de 1 po (25,4 mm)

Conduit, selon les besoins

Ventilateur (modèles HPCN36NS et HPCN48NS

seulement)

Tournevis à tête étoilée et Torx

Perceuse avec mèches coniques de 1/4 po et 5/16 po

Monte-démonte écrou ou clé à rochet et douille de 3/8

po (9 mm)

Pince à dénuder Localisateur de montants

Escabeau Niveau

Ruban à mesurer

1 – Adaptateur de ventilateur à

distance (modèles HPCN seulement)

1 – Morceau de bois servant de

support de montage pour la hotte

Pour l’installation – NE PAS JETER.

1 – Trousse d’éléments de fixation*

Pochette de documents

* La quincaillerie fournie sert à fixer la hotte à

travers une cloison sèche ou du plâtre et des

montants de bois d’épaisseur standard. Les

installateurs sont responsables de fournir la

quincaillerie pour les autres types d’installation.

Les accessoires optionnels sont vendus

séparément. Pour connaître les différentes options

offertes et obtenir des renseignements sur votre

détaillant, visitez notre site Web au

www.thermador.ca.

Rallonges de conduit (consultez la page 16 pour

connaître les options disponibles)

Câble de connexion de ventilateur de 25 pieds pour

ventilateur à distance (EXTNCB25)

Étagère garde-chaud

Dosseret

Plaque d’ancrage de ventilateur à distance (RFPLT600

et RFPLT1000)

Enlevez tout le matériel d’emballage et le ruban

adhésif avant d’utiliser l’appareil. Veuillez

recycler le matériel d’emballage. Tout ce que

THERMADOR utilise pour emballer ses appareils

est recyclable. Ne laissez jamais des enfants

jouer avec le matériel d’emballage.

NOTE :

Ne jetez pas le matériel d’emballage avant d’avoir terminé

l’installation de l’appareil.

Française 3

Page 26

Renseignements généraux

C

Ce manuel fournit des instructions pour installer adéquatement deux types de hottes murales PROFESSIONALmc de

THERMADOR :

HPCNxxNS — Les modèles de cette série sont munis de filtres en acier inoxydable brossé et de lampes halogènes.

HPCBxxNS — Les modèles de cette série sont munis de filtres en acier inoxydable brossé, d’un ventilateur intégré et de

lampes halogènes.

Dimensions générales

36 po (914)

pounces (mm)

A 21 po (533) 33 po (838)

B

C 10½ po (267) 16½ po (419)

NOTE : Vous pouvez utiliser des raccords de 10 po (254 mm) avec le conduit.

15

35

/16 po (838) 47 15/16 po (1218)

48 po (1219)

pounces (mm)

dia. 9½"

(dia. 243)

8

3/

(212)

7¾”

(148)

14

C

(356)

"

8

"

Toutes les mesures sont en pouces (mm).

NOTE :

Le raccord est centré.

Française 4

18"

(457)

24"

(610)

A

B

Figure 1 : Dimensions générales de la hotte

Page 27

Préparation de l’installation

18 po

(457)

* 30 po (762) min.

36 po (914) max.

de la surface de cuisson

Facteurs à prendre en compte

pour l’installation

Le conduit de la hotte doit évacuer l’air à l’extérieur de la

maison. L’appareil ne peut être utilisé avec un ensemble de

reprise d’air.

La hauteur d’installation de la hotte au-dessus d’une

surface de cuisson ou d’une cuisinière peut varier. Pour

respecter la hauteur d’installation nécessaire au-dessus

d’une surface de cuisson ou d’une cuisinière, consultez le

manuel d’installation de l’appareil.

Emplacement des composantes électriques

3¼ po

6½ po (165)

18 po

(457)

* La largeur de la hotte ne doit

pas être inférieure à la largeur

de la surface de cuisson.

* 30 po (762) min.

* 30 po (762) min.

36 po (914) max.

36 po (914) max.

de la surface de cuisson

de la surface de cuisson

* Suivez les recommandations

du fabricant de l’appareil de

Toutes les mesures sont en pouces (mm)

AVIS :

La hotte pourrait être endommagée par de la chaleur si

plusieurs brûleurs d’une surface de cuisson ou d’une

cuisinière PROFESSIONAL de THERMADOR sont utilisés

simultanément à haute intensité et que la hotte est installée

à une distance inférieure aux espaces libres minimaux.

cuisson.

Figure 2 : Installation-type de la hotte

(83)

E

Surface

de cuisson

Largeur de la hotte

La largeur de la hotte ne doit pas être inférieure à la largeur

de la surface de cuisson. Pour un rendement adéquat, la

hotte doit couvrir la totalité de la surface de cuisson.

Lorsqu’il n’y a pas de contrainte d’espace, une hotte plus

large peut être utilisée pour augmenter la surface

d’aspiration.

Pour un rendement optimal, la hotte doit être centrée audessus de la surface de cuisson.

Distance entre la hotte et la surface de

cuisson

La hauteur minimale d’installation est de 30 po (762 mm)

au-dessus de la surface de cuisson. Toutefois, il est

impératif de respecter les instructions d’installation du

fabricant de l’appareil de cuisson en ce qui concerne la

hauteur adéquate d’installation de la hotte.

Poids de l’appareil

Lors du calcul de la charge du système de soutien du

boîtier, assurez-vous de tenir compte du poids de l’appareil

de ventilation.

MODÈLE POIDS

HPCN36NS 33 lb (15 kg)

HPCB36NS 49 lb (22 kg)

HPCN48NS 47 lb (21 kg)

HPCB48NS 63 lb (29 kg)

NOTE : Le poids des modèles HPCN ne tient pas compte

du poids du ventilateur intégré. Le poids du ventilateur

intégré est de 16 lb. (7 kg). Le poids des modèles HPCB

tient compte du poids du ventilateur intégré.

IMPORTANT :

Les poids mentionnés ne s’appliquent qu’à l’appareil de

ventilation et au ventilateur. L’installateur doit tenir

compte du poids des matériaux de construction lors du

calcul du poids mort total de l’installation, y compris, sans

s’y limiter, du mur, des tuiles, du mortier, du plâtre, des

briques, des éléments du fini, des cloisons et des autres

éléments architecturaux et structurels. Il est de la

responsabilité du propriétaire et de l’installateur de

déterminer les exigences ou les normes supplémentaires

pouvant s’appliquer à des installations particulières.

Française 5

Page 28

Charpente du mur

Compte tenu du poids de la hotte, assurez-vous que le

support de montage de la hotte est bien fixé à tous les

montants disponibles du mur.

La charpente du mur et les solives de plafond doivent être

suffisamment solides pour soutenir le poids de la hotte et

du ventilateur interne, s’il y a lieu.

Minimalement, la charpente du mur doit être faite de 2 x 4.

Un soutien structural adéquat est requis pour supporter le

poids de la hotte.

AIR D’APPOINT : Le code du bâtiment local peut exiger

l’utilisation d’un système d’air d’appoint lors de l’utilisation

d’un système de ventilation dont le nombre de pi

est supérieur à ce qui est indiqué. Le nombre de pi

indiqué varient d’un code à l’autre. Il est de la

responsabilité du propriétaire et de l’installateur de

déterminer les exigences ou les normes supplémentaires

pouvant s’appliquer à des installations particulières.

AVERTISSEMENT!

Le conduit doit directement évacuer l’air à l’extérieur (et

non dans le grenier, sous la maison, dans le garage ou

dans un espace clos).

3

/min d’air

3

/min

Préparation du conduit

d’aération

Orientation de la sortie d’air

L’air est évacué vers le haut, par le biais d’un conduit, ou

directement à l’extérieur à travers le mur arrière.

La hotte peut être fixée au mur avec une sortie d’air

verticale.

Recommandations pour le conduit

Le rendement adéquat de la hotte repose sur l’utilisation

d’un conduit d’aération adéquat. Le code du bâtiment local

peut exiger l’utilisation d’un système d’air d’appoint lors de

l’utilisation d’un système de ventilation avec des conduits

dont le nombre de pi

ce qui est indiqué.

Le nombre de pi

est de la responsabilité du propriétaire et de l’installateur

de déterminer les exigences ou les normes

supplémentaires pouvant s’appliquer à des installations

particulières.

3

/min d’air à évacuer est supérieur à

3

/min indiqué varient d’un code à l’autre. Il

L’appareil ne peut être utilisé avec un ensemble de reprise

d’air.

THERMADOR recommande de ne pas installer un conduit

de plus de 50 pi (15,24 m).

Installez le conduit le plus court et le plus droit possible.

Les coudes et les raccords réduisent l’efficacité de la

circulation de l’air. L’utilisation de deux coudes formant un

S donne de piètres résultats et elle n’est pas

recommandée. L’utilisation d’un conduit court et droit à

l’endroit où se trouve un ventilateur à distance donne de

meilleurs résultats.

Les hottes sont vendues avec un raccord circulaire de

10 po (254 mm). Vous devez vous procurer les raccords

d’autres dimensions chez un détaillant.

Utilisez le tableau « Longueur totale équivalente du conduit

avec les raccords les plus fréquemment utilisés » de la

page 7 pour calculer la longueur totale admissible du

conduit.

N’UTILISEZ PAS DE CONDUITS SOUPLES. Ces conduits

créent de la pression d’aspiration et de la turbulence en

plus d’offrir un rendement moins efficace.

Installez toujours un couvercle métallique à l’endroit où le

conduit sort de la maison.

TEMPÉRATURES FROIDES. Pour une installation où les

conditions météorologiques sont froides, un registre

antirefoulement supplémentaire doit être installé pour

minimiser l’entrée d’air froid de l’extérieur, avec un isolant

thermique non métallique pour minimiser la conduction de

la température extérieure dans le conduit. Le registre doit

se trouver du côté de l’air froid de l’isolant thermique.

L’isolant doit être installé le plus près possible de l’endroit

où le conduit entre dans la partie chauffée de la maison.

Française 6

Page 29

Longueur totale équivalente du conduit avec les raccords les plus fréquemment utilisés

Type de conduit

Circulaire droit

3¼ po x 10 po droit

3¼ po x 14 po droit

Coude circulaire

à 90°

Coude circulaire

à 45°

Coude de 3¼ po

x 10 po à 90°

Diamètre de la

pièce (po)

6 1.2

7 0.95

8 0.7

10 0.6

S.O. 1

S.O. 0.7

612

S.O. 5

78

86

65

74

83

Longueur

équivalente (pi)

Type de conduit

3¼ po x 10 po à

coude circulaire

à 90°

Coude inversé

gauche à centre de

3¼ po x 10 po

Coude inversé droit

à centre de 3¼ po

x 10 po

Coude inversé à

gauche de 3¼ po

x 10 po

Coude inversé à

droite de 3¼ po

x 10 po

Bouche d’aération

circulaire murale

Bouche d’aération

circulaire de toit

Diamètre de la

pièce (po)

610

75

S.O. 15

S.O. 25

S.O. 15

S.O. 25

62

72

82

10 2

62

72

Longueur

équivalente (pi)

Coude de 3¼ po

x 10 po à 45°

Coude plat de

3¼ po x 10 po

Circulaire à 3¼ po

x 10 po

3¼ po x 10 po

à circulaire

Circulaire à coude

de 3¼ po x 10 po

à 90°

S.O. 15

S.O. 20

61

71

65

73

610

78

82

Conduit souple de

3¼ po x 10 po de

2 pieds de long

3¼ po x 10 po

à circulaire

Registre

antirefoulement de

conduit de 7 po

Support de xation

et obturateur de toit

de 3¼ po x 10 po

NOTE : Ces pièces fréquemment utilisées sont en vente à votre

quincaillerie. THERMADOR ne fabrique pas toutes ces pièces.

S.O. 20

7

S.O.

10 1

Française 7

Page 30

Exigences électriques

Raccord pour la hotte

ATTENTION!

Cette hotte doit être convenablement mise à la terre. Un

technicien qualifié doit installer cet appareil en

conformité avec tous les codes de l’électricité locaux et

nationaux en vigueur.

Cet appareil doit être branché à un circuit de dérivation de

120 VCA, 60 Hz, 15 A.

La hotte doit être branchée à une prise de courant mise à

la terre et installée en conformité avec les réglementations

en vigueur.

Lorsqu’elles sont protégées par un disjoncteur de fuite à la

terre, les hottes encastrées sur mesure PROFESSIONAL

de THERMADOR peuvent être utilisées dans des endroits

humides à l’abri des conditions météorologiques

extérieures et de saturations par de l’eau et d’autres

liquides, quoiqu’elles puissent être soumises à un certain

degré d’humidité (par exemple, lors d’une installation sur

une terrasse couverte ou une véranda). Consultez les

codes locaux, le Code national de l’électricité/Code

Canadien de l’électricité, et l’autorité compétente pour

obtenir de plus amples renseignements.

Assemblage du raccord

La hauteur totale du raccord est de 8-3/8 po (212 mm). Le

raccord doit être installé à 6-1/2 po (165 mm) au-dessus de

la hotte. Une portion de 1-7/8 po doit se trouver sous le

rebord supérieur de la hotte. Consultez la Figure 4 à la

page 9 pour connaître les dimensions totales de la hotte.

1. Alignez les trous de montage de la base du raccord

avec les trous de montage de la bride de 1/2 po

(13 mm) du dessus de la hotte.

2. Fixez le raccord à la hotte à l’aide des quatre vis à tôle

de 1 po (25,4 mm) fournies avec la hotte.

3. Scellez les joints entre le raccord et la hotte avec du

ruban en aluminium.

4. Enlevez le morceau de ruban qui tient le registre en

position fermée.

2

1

3

Consultez le code de la construction de votre localité pour

connaître la méthode d’installation adéquate. Aux É.-U., si

aucun code local n’est en vigueur, cet appareil doit être

installé conformément à la plus récente édition de la norme

no 70 du Code national de l’électricité/NFPA (Association

nationale des services d’incendie). Au Canada,

l’installation doit respecter les normes d’installation CAN 1B149.1 et. 2 pour les appareils au gaz ou les codes locaux

en vigueur.

Cet appareil doit être mis à la terre. Dans les cas de courtcircuit, la mise à la terre réduit les risques de décharge

électrique en fournissant au courant électrique un fil par où

s’échapper.

ATTENTION!

Cet appareil doit être mis à la terre.

Données électriques apparaissant sur la

plaque signalétique :

Figure 3 : Installation du raccord

Les données électriques relatives à l’appareil, y compris le

numéro de modèle et le numéro de série, se trouvent sur la

plaque signalétique située à l’intérieur de l’appareil, visible

lors du retrait du cadre des filtres (consultez la Figure 29 à

la page 19).

Française 8

Page 31

Instructions d’installation

24 po (610)

*30 po (762) min.

36 po (914) max.

de la surface de cuisson

C

C

L

Trous de 5/8 po (16 mm)

de diamètre pour le

passage du tube pour

câbles de 1/2 po

(12,7 mm) vers la

boîte de connexion

Spécifications concernant la

hauteur de la hotte

La Figure 4 montre l’installation-type d’une hotte avec une

rallonge de conduit optionnelle. Ajoutez ou enlevez les

rallonges de conduit selon les besoins en tenant compte de

la hauteur du plafond et de la hauteur d’installation

recommandée de la hotte.

La hauteur minimale d’installation est de 30 po (762 mm)

au-dessus de la surface de cuisson. Toutefois, il est

impératif de respecter les instructions d’installation du

fabricant de l’appareil de cuisson en ce qui concerne la

hauteur adéquate d’installation de la hotte.

Calcul de la hauteur des pièces de

recouvrement de conduit optionnelles

Les pièces de recouvrement optionnelles sont en vente

dans des formats de 6 po (153 mm), 12 po (305 mm) et 18

– 35 po (457 – 889 mm).

1. Mesurez la distance entre le plancher et le plafond (A,

Figure 4).

2. Mesurez la distance entre le plancher et la surface de

cuisson (B, Figure 4).

3. Mesurez la hauteur de montage de la hotte entre le bas