Page 1

@

I IA °

Page 2

ell

page

3-11

fr

es

page

pagina

12-20

21 -29

Page 3

Z_ SAFETY INSTRUCTIONS

Read All Instructions Before Using the Appliance.

READ AND SAVE THESE INSTRUCTIONS

Z_ WARNING

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE

FOLLOWING:

A. Installation work and electrical wiring

must be done by qualified person(s) in

accordance with allapplicable codes

and standards, including fire-related

construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent back-

drafting. Follow the heating equip-

ment manufacturer's guideline and

safety standards such as those

published by the National Fired

Protection Association (NFPA), and

the American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local

code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical

wiring and other hidden utilities.

D. Ducted fans must always be vented

to the outdoors.

E. Always unplug or disconnect the

appliance from the power supply

before servicing.

F. This unit is designed for indoor use

only. Use this unit only in the manner

intended by the manufacturer.

Z_ WARNING

For general ventilating use only. Do not

use to exhaust hazardous or explosive

materials and vapors.

To reduce risk of fire and to properly

exhaust air, be sure to duct air outside.

Do not vent exhaust air into spaces

within walls, ceilings, attics, crawl spaces

or garages.

TO REDUCE THE RISK OF FIRE, USE

ONLY METAL DUCT WORK.

To reduce the risk of fire or electric

shock, do not use the fan with any solid-

state speed control device.

This appliance has been found to be in

compliance with UL 507 Standard for

Electric Fans and CAN/CSA-22.2 No.

113 Canadian Standard for Fans and

Ventilators. It is the responsibility of the

owner and the installer to determine if

additional requirements or standard

apply in specific installation.

Parts Needed

[] Tape Measure

[] Phillips Head Screwdriver

[] Duct Tape

[] Ductwork (configuration varies

depending on location; see "Prior to

installation").

[] Additional Sheetmetal screws

(as necessary for ductwork installation)

Parts Supplied

[] Appliance assembly (1)

[] Sheetmetal Screws (6)

[] Wood Screws (4)

[] Counter Sink Screws (2)

[] Hardware for brackets on vent (2)

[] Plugs UX6 (6)

Page 4

IM PORTANT INFORMATION

Old appliances are not worthless rubbish.

Valuable raw materials can be reclaimed by

recycling old appliances. Before disposing

of your old appliance, render it unusable.

You received your new appliance in a

protective shipping carton. All packaging

materials are environmentally friendly and

recyclable. Please contribute to a better

environment by disposing of packaging

materials in an environmentally-friendly

manner.

The hood can only be used in exhaust air

mode.

Always mount the hood over the center of

the cooking surface.

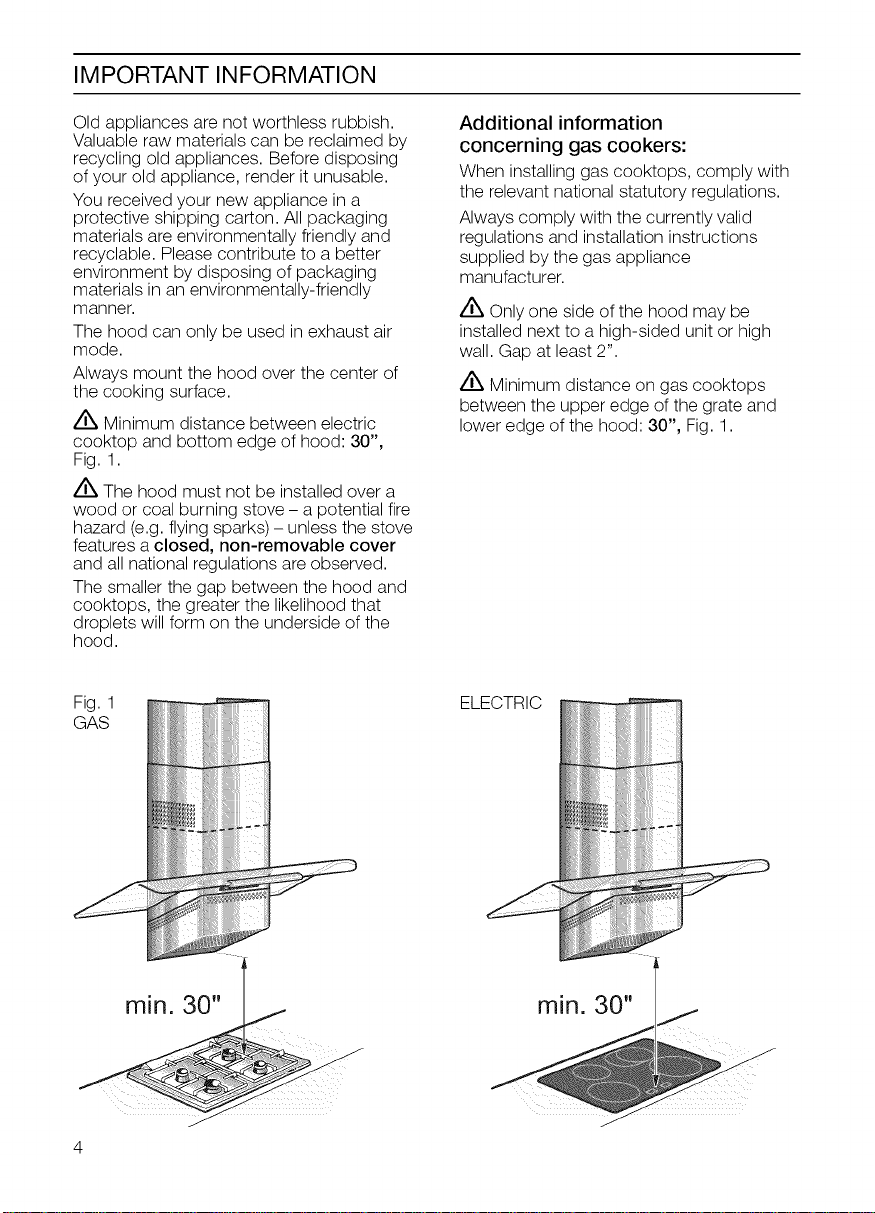

Z_ Minimum distance between electric

cooktop and bottom edge of hood: 30",

Fig. 1.

Z_ The hood must not be installed over a

wood or coal burning stove - a potential fire

hazard (e.g. flying sparks) - unless the stove

features a closed, non-removable cover

and all national regulations are observed.

The smaller the gap between the hood and

cooktops, the greater the likelihood that

droplets will form on the underside of the

hood.

Fig. 1

GAS

Additional information

concerning gas cookers:

When installing gas cooktops, comply with

the relevant national statutory regulations.

Always comply with the currently valid

regulations and installation instructions

supplied by the gas appliance

manufacturer.

Z_ Only one side of the hood may be

installed next to a high-sided unit or high

wall. Gap at least 2".

Z_ Minimum distance on gas cooktops

between the upper edge of the grate and

lower edge of the hood: 30", Fig. 1.

ELECTRIC

rain. 30"

J

J

min. 30"

Page 5

PRIOR TO INSTALLATION

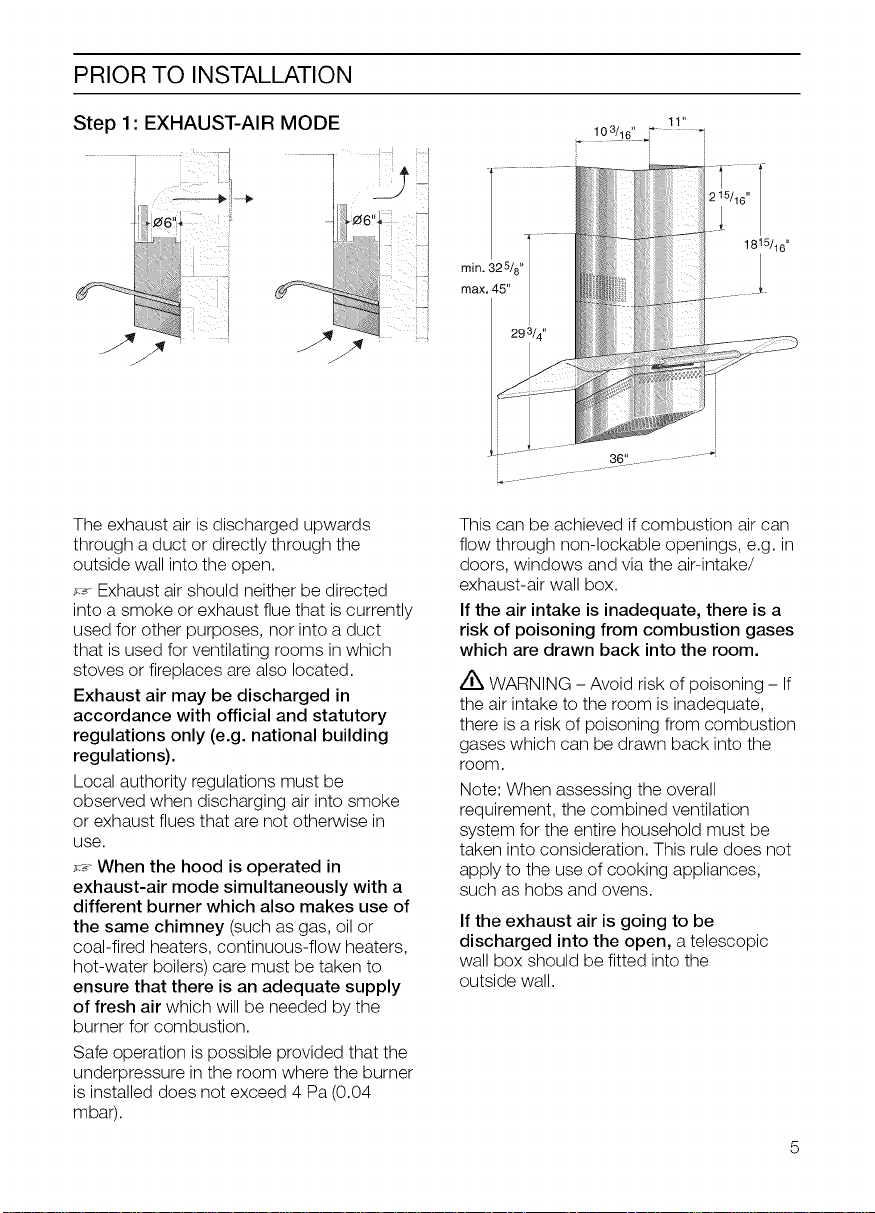

Step 1: EXHAUST-AIR MODE

f

¸¸¸

The exhaust air is discharged upwards

through a duct or directly through the

outside wall into the open.

_ Exhaust air should neither be directed

into a smoke or exhaust flue that is currently

used for other purposes, nor into a duct

that is used for ventilating rooms in which

stoves or fireplaces are also located.

Exhaust air may be discharged in

accordance with official and statutory

regulations only (e.g. national building

regulations).

Local authority regulations must be

observed when discharging air into smoke

or exhaust flues that are not otherwise in

use.

f_ When the hood is operated in

exhaust-air mode simultaneously with a

different burner which also makes use of

the same chimney (such as gas, oil or

coal-fired heaters, continuous-flow heaters,

hot-water boilers) care must be taken to

ensure that there is an adequate supply

of fresh air which will be needed by the

burner for combustion.

Safe operation is possible provided that the

underpressure in the room where the burner

is installed does not exceed 4 Pa (0.04

mbar).

]

min. 325/8" |

max. 45"

This can be achieved if combustion air can

flow through non-lockable openings, e.g. in

doors, windows and via the air-intake/

exhaust-air wall box.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

Z_ WARNING - Avoid risk of poisoning - If

the air intake to the room is inadequate,

there is a risk of poisoning from combustion

gases which can be drawn back into the

room.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

If the exhaust air is going to be

discharged into the open, a telescopic

wall box should be fitted into the

outside wall.

/

293/4"

36 _*

1815/16"

Page 6

PRIOR TO INSTALLATION

For optimum hood efficiency:

[] Short, smooth duct pipe.

[] As few bends in the ducting as possible.

[] Diameter of ducting to be as large as

possible and no tight bends in ducting.

If long, rough exhaust-air ducting,

many ducting bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

IMPORTANT: The manufacturer of the

hood accepts no liability for com-

plaints which can be attributed to the

design and layout of the ductwork.

[] Round pipes:

We recommend

Internal diameter: 6".

[] Flat ducts must have an internal cross-

section that equates to that of round

pipes.

There should be no sharp bends.

¢ 6" approx. 28.3 inches 2

[] If pipes have different diameters:

Insert sealing strip.

[] For exhaust-air mode, ensure that

there is an adequate supply of fresh air.

Step 2: PREPARING THE WALL

[] The wall must be flat and perpendicular.

[] Ensure that the wall is capable of provi-

ding a firm hold for mounting screws and

plugs.

Weight in kg: 23.5

CONNECTING A ¢ 6" EXHAUST-AIR

DUCT:

[] Mount the duct directlyonto the air out-

leton thehood.

Page 7

PRIOR TO INSTALLATION

Step 3: ELECTRICAL CONNECTION

Z_ WARNING: THIS APPLIANCE MUST

BE GROUNDED

The hood should only be connected to a

grounded socket that has been installed

according to relevant regulations.

Ifpossible, site the earthed socket directly

behind the chimney paneling.

[] The grounded socket should be

connected via its own circuit.

[] Ifthe grounded socket is no longer

accessible following installation of the

hood, ensure that there is a permanently

installed disconnector.

Step 4: INSTALL ELECTRICAL

SERVICE

Check your local building codes for proper

method of installation. In the U.S., if there

are no applicable local codes, this unit

should be installed in accordance with the

National Electric Code ANSI/NFPA No. 70,

Current Issue. (In Canada, installation must

be in accordance with the CAN 1- B149.1

and .2 - Installation Codes for Gas Burning

Appliances and/or local codes).

The appliance must be grounded. Inthe

event of an electrical short circuit, grounding

reduces the risk of electric shock by

providing an escape wire for the electric

current. This appliance is equipped with a

cord having a grounding wire with a

grounding plug. The plug must be plugged

into an outlet that is properly installed and

grounded.

Z_ WARNING - Improper grounding can

result in a risk of electric shock.

Consult a qualified electrician if the

grounding instructions are not completely

understood, or if doubt exists as to whether

the appliance is properly grounded.

Do not use an extension cord. If the power

supply cord is too short, have a qualified

electrician install an outlet near the

appliance.

If it is necessary to wire the hood directly

into the mains:

/X

WARNING - Avoid risk of electrical

shock - If the connecting cable for this

appliance is damaged, the cable must be

replaced by the manufacturer or his

customer service or a similarly qualified

person in order to prevent serious injury to

the user.

ELECTRICAL DATA:

Are to be found on the name plate inside

the appliance after removal of the filter

frame.

Z_ WARNING - Avoid risk of electrical

shock - Before undertaking any repairs,

always disconnect the hood from the

electricity supply.

Length of the connecting cable: 511/8".

This hood corresponds to EC regulations

concerning RF interference suppression.

Page 8

_u_or,ty e_fen_ersw_t_be_bEe for _m_gesA_En®ts ,n_d_n_n_hts_ _y _t_n_ g_n_ or reg_str_t,o_

@-

D

©-

K5o

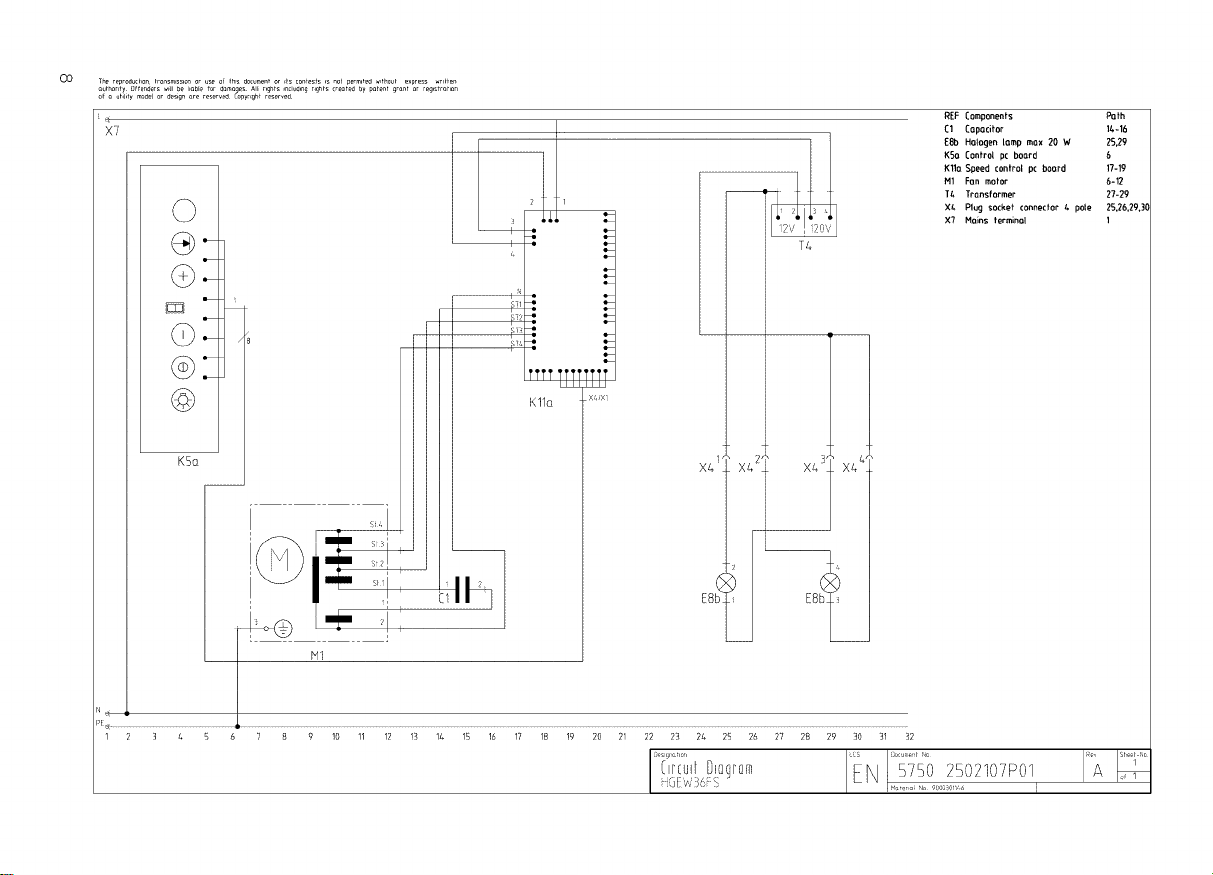

REF Components Path

EBb HQIogen Iomp rnQx 20 W 25,2g

Klla Speed _ontrol pc boord 17-1g

i_ll Fc_nmotor 6-12

T_ Trensformer 27-29

t K5O Control pc boc_rd 6

1 X_, Plug sexket Connector I* pole 2S,26,2g_3(

1 X? Mains terminal 1

K11c_

C1 CQpadtor 1_,-16

1 2 ] L 5 6 ? 8 9 10 11 12 13 % 15 16 17 18 19 20 21 22 2B 2l+ 25 28 27 28 29 30 B1 32

_,_e,,_ 4,, gocOC,l,_S I

Page 9

INSTALLATION

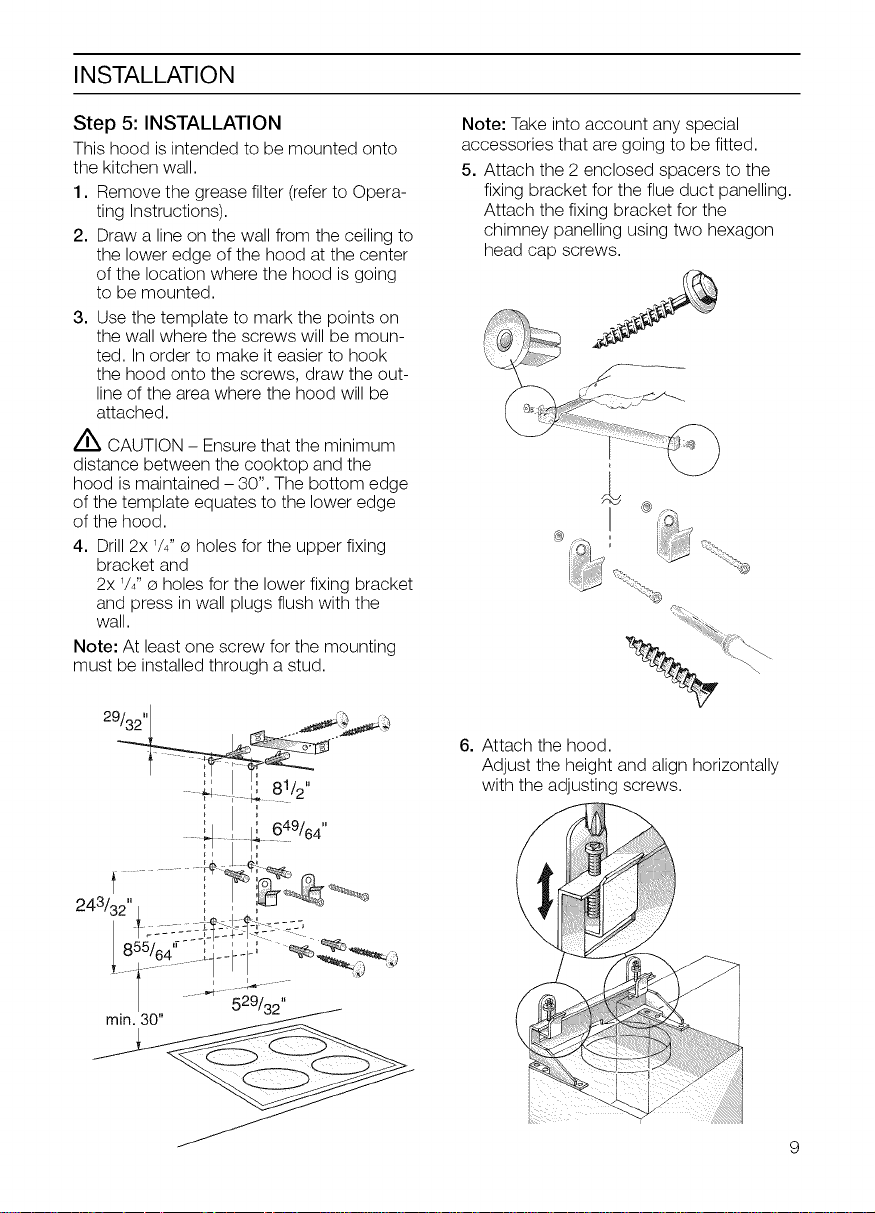

Step 5: INSTALLATION

This hood is intended to be mounted onto

the kitchen wall.

1. Remove the grease filter (refer to Opera-

ting Instructions).

2. Draw a line on the wall from the ceiling to

the lower edge of the hood at the center

of the location where the hood is going

to be mounted.

3. Use the template to mark the points on

the wall where the screws will be moun-

ted. In order to make it easier to hook

the hood onto the screws, draw the out-

line of the area where the hood will be

attached.

Z_ CAUTION - Ensure that the minimum

distance between the cooktop and the

hood is maintained - 30". The bottom edge

of the template equates to the lower edge

of the hood.

4. Drill 2x _/4"® holes for the upper fixing

bracket and

2x W' ® holes for the lower fixing bracket

and press in wall plugs flush with the

wall.

Note: At least one screw for the mounting

must be installed through a stud.

Note: Take into account any special

accessories that are going to be fitted.

5. Attach the 2 enclosed spacers to the

fixing bracket for the flue duct panelling.

Attach the fixing bracket for the

chimney panelling using two hexagon

head cap screws.

@

29/3 .... "_'%

i8'/"

, , _. ..... 2

': 1649/4'

............. ,'¢_',,-_ r_

243/32"/ , ,

I 855/_,'_- -,-,- ' I', -_%% ....

J t

..... 529/32.

/

6. Attach the hood.

Adjust the height and align horizontally

with the adjusting screws.

Page 10

INSTALLATION

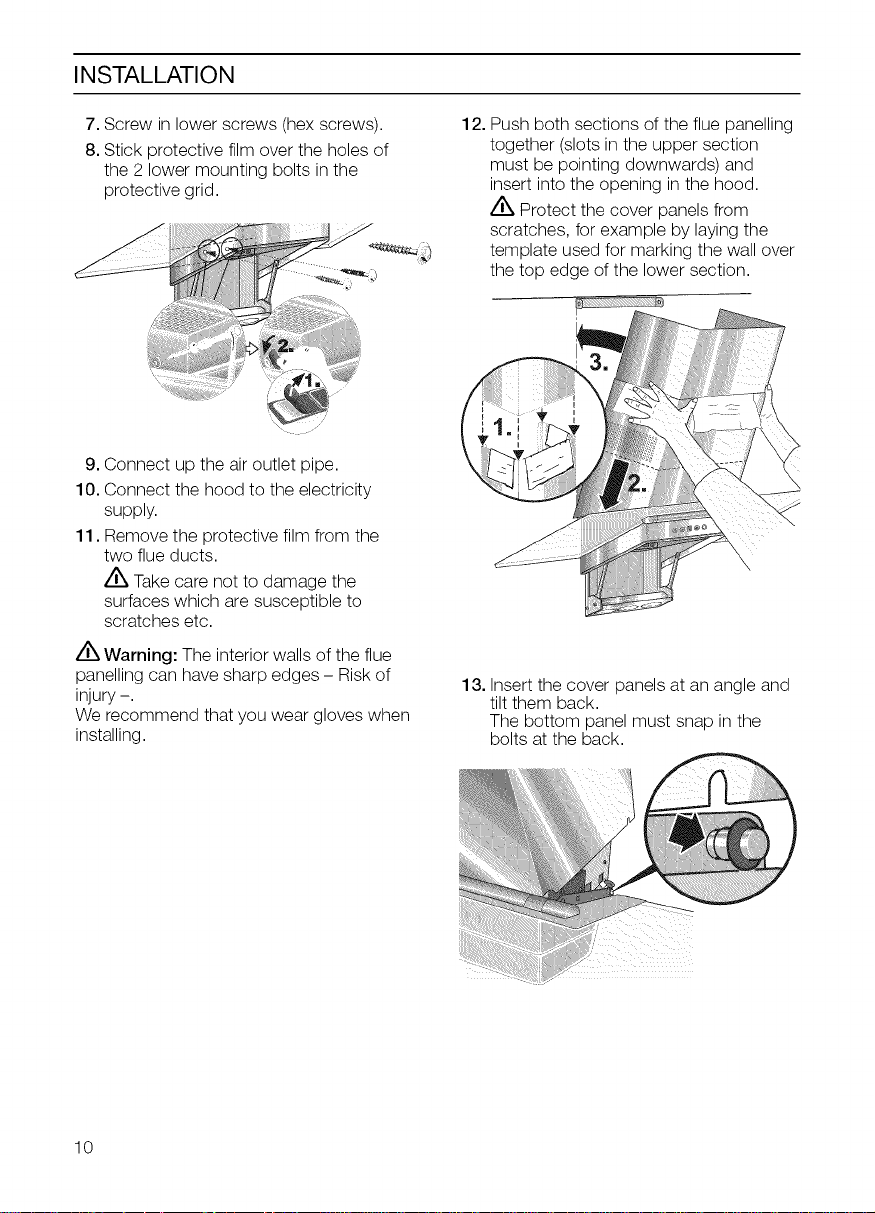

7. Screw in lower screws (hex screws).

8. Stick protective film over the holes of

the 2 lower mounting bolts in the

protective grid.

9. Connect up the air outlet pipe.

10. Connect the hood to the electricity

supply.

11. Remove the protective film from the

two flue ducts.

Z_ Take care not to damage the

surfaces which are susceptible to

scratches etc.

Z_ Warning: The interior walls of the flue

panelling can have sharp edges - Risk of

injury -.

We recommend that you wear gloves when

installing.

12. Push both sections of the flue panelling

together (slots in the upper section

must be pointing downwards) and

insert into the opening in the hood.

Z_ Protect the cover panels from

scratches, for example by laying the

template used for marking the wall over

the top edge of the lower section.

13. Insert the cover panels at an angle and

tilt them back.

The bottom panel must snap in the

bolts at the back.

10

Page 11

INSTALLATION

14. Slide out the upper section and attach

it to the mounting brackets at the sides

with two screws.

15. Unscrew the two transport braces.

The glass canopy will not pirot up and

down until' these brackets are

removed.

16. Insert the grease filter (refer to

Operating Instructions).

Ifthe vent system does not operate

satisfactorily during any of the above

procedures, review all steps in these

Installation Instructions to ensure that

nothing has been omitted or overlooked.

Also, refer to the Care & Use Manual for

additional information or call Thermador

Customer Support 1-800-735-4328.

11

Page 12

Z_ INSTRUCTIONS DE SECURITE

Life toutes les instructions avant d'utiliser I'appareil.

LIRE ET CONSERVER CES INSTRUCTIONS

Z_ AVERTISSEMENT

POUR REDUIRE LE RISQUE

D'INCENDIE, DE CHOC QECTRIQUE

OU DE BLESSURES, OBSERVER CE

QUI SUIT:

A. L'installation et le c&blage electrrique

doivent _tre effectues par des

personnes qualifiees conformement a,

toutes les normes et codes

applicables, incluant la construction

relative au feu.

B. Siffisamment d'air est necessaire pour

une combustion appropriee et

I'echappement des gaz par tirage

(cheminee) d'equipement a,

combustion pour evier le tirage

arriere. Suivre les directives du

fabricant d'equipement de chauffage

et les normes de securite telles celles

fournies par I'Association de

pretection des incendies nationale

(NFPA)et la Societe americaine

d'ingenierie de chauffage,

refrigeration et climatisation (ASHRAE)

ainsi que les codes Iocaux.

C. Au moment de couper ou percer un

mur ou plafond, ne pas endommager

le c&blage electriques et autres.

D. Les ventilateurs a,conduit doivent

toujours _tre ventiles vers I'exterieur.

E. Avant toute intervention, pensez b,

toujours debrancher I'appareil du

reseau d'alimentation electrique.

F. Cet appareil est con_u pour une

utilisation interieure seulement. Utiliser

cet appareil de la fa_on a,laquelle il

est destine par le fabricant.

Z_ AVERTISSEMENT

Pour ventilation generale seulement. Ne

pas ventiler des vapeurs ou materiaux

explosifs ou hasardeux.

Pour reduire le risque d'incendie et pour

un echappement d'air approprie,

s'assurer d'acheminer I'air vers

I'exterieur. Ne pas ventiler I'air

d'echappement dans les murs, plafonds,

greniers, espaces fermes ou garages.

POUR RC:DUIRELE RISQUE

D'INCENDIE, UTILISER DES CONDUITS

EN M€:TAL.

Pour reduire le risque d'incendie ou de

choc elecrique, ne pas utiliser le

ventilateur avec dispositif de contrOle de

vitesse a,semi-conducteur.

Cet appareil est conforme avec la norme

UL 507 pour ventilateurs electriques et la

norme canadienne CAN/CSA-22-2

n° 113 pour ventilateurs. II incombe au

proprietaire et a,I'installateur de

determiner si des normes ou exigences

additionnelles s'appliquent pour une

installation specifique.

Pieces necessaires

[] Metre a, ruban

[] Tournevis a,t_te Phillips

[] Ruban a,conduit

[] Systeme de gaines (la configuration

variant selon I'emplacement ; voir

>>Avant I'installation _).

[] Vis a,t61essuppl,ementaires (au besoin

pour I'installation de conduit)

12

Pieces incluses

[] Dispositif appareil (1)

[] Visa, metal (6)

[] Vis a, bois (4)

[] Vis a, t_te conique (2)

[] Quincaillerie pour fixations sur event (2)

[] Chevilles UX6 (6).

Page 13

INFORMATION IMPORTANTE

Les appareils usages ne sont pas de dechets

sans valeur. Leur elimination par recyclage

permet de recuperer de precieuses matieres

premieres. Avant de mettre au rebut un

appareil usage, rendez-le inutilisable.

Votre nouvel appareil vous a ete livre dans

une caisse d'expedition de protection. Tous

les materiaux d'emballage sont respectueux

de I'environnement et peuvent _tre recycles.

Veuillez contribuer o,un environnement plus

sain en mettant au rebut les materiaux d'em-

ballage dans le respect de I'environnement.

La hotte aspirante ne peut _tre utilisee qu'en

mode d'evacuation d'air.

Installez la hotte aspirante imperativement au-

dessus du centre de la plaque de cuisson.

Z_ Distance minimale entre la plaque

electrique et le bord inferieur de la hotte

aspirante : 30 po., Fig. 1.

Z_ N'installez pas la hotte aspirante au-

dessus d'un appareil de cuisson o,

combustible solide - generateur d'un risque

d'incendie (par projection d'etincelles p. ex.)

- o,moins que I'appareil ne soit muni d'un

couvercle ferm6 et inamovible, et que le

montage soit effectue dans le respect de la

reglementation nationale.

Plus I'ecart entre la hotte aspirante et les pla-

ques chauffantes est faible, plus des goutte-

lettes de condensation sont susceptibles de

s'accumuler sur la face interieure de la hotte.

Informations supplementaires

concernant les cuisinieres & gaz :

Lorsque vous installez des plaques

chauffantes _tgaz, veillez _t respecter la

reglementation legale nationale pertinente.

Veillez o,toujours respecter la

reglementation en vigueur et la notice

d'installation fournie par le fabricant de

I'appareil _tgaz.

Z_ Seul un cOte de la hotte aspirante peut

_tre installe pres d'une unite ou d'un mur

eleve. Prevoir un ecart d'au moins 2 po.

Z_ Distance minimale par rapport aux

plaques chauffantes o,gaz entre le bord de

la grille et le bord inferieur de la hotte

aspirante : 30 po., Fig. 1.

ELECTRIQUE

J

13

Page 14

AVANT L'INSTALLATION

I_tape 1: MODE D'I_VACUATION D'AIR

iii!ii ........ii.......

rain. 325/8"

max, 45"

L'air vicie est evacue vers le haut par un

conduit d'aeration ou directement D,I'air

libre en traversant lemur exterieur.

_ L'air vicie ne doit jamais _tre evacue vers

un conduit de cheminee ou d'evacuation en

service pour d'autres raisons, ni vers un

conduit servant D,I'aeration de pieces dans

lesquelles se trouvent egalement des

fourneaux ou des cheminees.

L'air vici_ doit 6tre 6vacu6

conform6ment &la r6glementation

officielle et 16gale seulement (p. ex. la

r6glementation nationale du b&timent).

Si I'air vicie doit _tre evacue par des

conduits de cheminee ou d'evacuation qui

ne sont pas en service, veuillez respecter la

reglementation des autorites locales.

f_ Lorsque la hotte aspirante est utilis6e

en mode d'6vacuation d'air simultan6-

ment avec un breleur diff6rent utilisant

6galement la m_me chemin6e, (tels des

appareils de chauffage au gaz, au fuel ou

au charbon, des chauffe-eau instantanes

ou des

chaudieres _teau chaude), veillez

imp6rativement & ce que I'apport d'air

frais soit suffisant pour assurer la

combustion adequate du brOleur.

Un fonctionnement sans risque est possible

si la sous-pression dans la piece oQ le

brOleur est installe ne depasse pas 4 Pa

(0,04 mbar).

14

On peut y parvenir en acheminant I'air

requis pour la combustion b,travers des

ouvertures non verrouillables amenagees

par exemple dans les portes ou les

fen_tres, et par le biais d'une ventouse

d'admission/d'evacuation d'air.

Si I'admission d'air est mauvaise, il

existe un risque d'intoxication par les

gaz d6gag6s Iors de la combustion qui

sont r6achemin6s dans la piece.

Z_ AVERTISSEMENT - €:vitezle risque

d'intoxication - Si I'admission d'air dans la

piece est mauvaise, ilexiste un risque

d'intoxication par les gaz degages Iors de la

combustion qui sont reachemines dans la

piece.

Remarque : Iors de I'evaluation de

I'exigence globale, toujours tenir compte de

I'ensemble des moyens d'aeration du

Iogement. Cette regle ne s'applique pas D,

I'utilisation d'appareils de cuisson, comme

les tables de cuisson et les cuisinieres.

Si I'air vici_ doit _tre 6vacu6 & I'ext6rieur,

une ventouse telescopique doit _tre

installee dans lemur exterieur.

Page 15

AVANT L'INSTALLATION

Pour un rendement optimal de la

hotte aspirante, veillez a. ce que :

[] Le conduit d'evacuation soit court et

lisse.

[] IIait le moins possible de coudes.

[] IIait le plus fort diametre et que les

coudes soient les plus arrondis

possibles.

Si I'on utilise des conduits

d'6vacuation d'air longs et rugueux,

de nombreux coudes ou des

diam_tres de tuyaux plus petits, le

taux d'6vacuation d'air sera inf6rieur

&son niveau optimal, ceci se

traduisant par une augmentation du

bruit.

IMPORTANT • Le fabricant de la hotte

aspirante d6cline toute responsabilit6

pour toute plainte pouvant 6tre

attribu6e au design et & I'agencement

du syst_me de conduits.

[] Conduits ronds •

nous recommandons des conduits au

diametre interieur de : 6 po.

[] Les conduits plats doivent avoir une

section interieure equivalente & celle des

conduits ronds.

II ne doit pas y avoir de coudes en

6querre.

¢ 6 po. env. 28,3 po. 2

[] Si les conduits ont des diam_tres

diff6rents :

Utiliser du ruban de scellement.

[] Dans le cas d'une utilisation en mode

d'6vacuation d'air veillez o,ce que

I'apport d'air frais soit suffisant.

I_tape 2 : PRI_PARATION DU MUR

[] Lemur doit _tre plat et perpendiculaire.

[] Veillez ace que lemur puisse supporter

solidement les vis et les pieces

d'ancrage necessaires a I'installation.

Poids en kg : 23.5

RACCORDEMENT D'UN CONDUIT

D'I_VACUATION D'AIR DE 6 PO. ¢ :

[] Montezle conduit directementsur la

sortie d'air de la hotte.

15

Page 16

AVANT L'INSTALLATION

E'tape 3 : BRANCHEMENT

ELECTRIQUE

Z_ AVERTISSEMENT:CET APPAREIL

DOlT #TRE MIS/_ LA TERRE

La hotte aspirante doit _tre raccordee

uniquement a, une prise electrique avec

mise a,la terre montee conformement a,la

reglementation pertinente.

Si possible, installez la prise de terre

directement derriere le panneau de

cheminee.

[] La prise de terre doit _tre raccordee a,

son propre circuit.

[] Si laprise de terre n'est plus accessible

apres avoir monte la hotte aspirante,

veillez a,ce qu'il y ait un sectionneur

permanent installe.

I_tape 4 : INSTALLATION DE LA

SERVITUDE I_LECTRIQUE

Consultez lescodes du b&timent Iocaux

pour choisir la methode d'installation qui

convient le mieux. Aux Etats-Unis, s'il

n'existe aucun code local applicable, cet

appareil doit _tre installe conformement a,

I'edition en cours du Code national de

I'electricite ANSI/NFPA N° 70. (Au Canada,

I'installation doit _tre conforme aux codes

d'installation CAN 1- B149.1 et .2 - codes

d'installation pour appareils a,gaz et/ou

codes Iocaux).

L'appareil doit _tre mis a,la terre. Dans

I'eventualite d'un court circuit electrique, la

mise a,la terre peut reduire le risque de

choc electrique en permettant au courant

de s'echapper. Cet appareil electromenager

est muni d'un cordon possedant un fil avec

une fiche de mise a,la terre. La fiche doit

_tre branchee dans une prise correctement

installee et mise a, la terre.

Z_ AVERTISSEMENT - Une mise a,la terre

defectueuse peut entraTner un risque de

choc electrique.

Si les consignes de mise _t la terre ne sont

pas parfaitement comprises, ou en cas de

doute sur la mise a, la terre correcte de

I'appareil, consulter un electricien qualifie.

Ne pas utiliser de rallonge. Si le cordon

d'alimentation est trop court, demander a,

un electricien quali% d'installer une prise a,

proximite de I'appareil.

16

S'il est n6cessaire de raccorder la hotte

aspirante directement sur le secteur :

Z_ AVERTISSEMENT - Ftvitez le risque de

choc electrique - Si le c&ble de branche-

ment de cet appareil a ete endommage, il

devra _tre remplace par le fabricant ou son

service apres-vente ou encore par une

ersonne possedant des qualifications

identiques afin d'eviter que I'utilisateur ne

subisse des blessures graves.

DONNC:ES €:LECTRIQUES :

visibles a,I'interieur de I'appareil sur la

plaque d'identification apres retrait du cadre

porte-filtre.

Z_ AVERTISSEMENT- Ftvitezle risque de

choc electrique - Avant toute intervention

sur I'appareil, veillez a,toujours debrancher

la hotte aspirante de I'alimentation

electrique.

Longueur du c&ble de raccordement :

51% po.

Cette hotte aspirante satisfait la

reglementation de I'UE en matiere de

suppression des interferences sur les

frequences radioelectriques.

Page 17

_u_or,ty e_fen_ersw_t_be_bEe for _m_gesA_En®ts ,n_d_n_n_h_s_ _y_n_ g_on_o, ,eg_str_t,o_

REF Composonts Circuit

EBb Ampoule _log_ne _x 20 W 25,29

Kllo Vorlateur de vitesse sur torte 17-19

MI Moteur d aspiration 6-12

T_, Trensformoteur 27-29

t K_ Corte de commonde 6

2 I X_, Jonctionenfich_et,pole 25,26,29,3(

C1 Condensofeur t_,-16

X7 Borne de raccordernent ou 1

@-

• _ secteur

D

©-

K11c_

K5o

1 2 ] L 5 6 ? 8 £ 10 11 12 13 % 15 16 17 18 19 20 21 22 2B 2l+ 25 28 27 28 29 30 B1 32

_,_e,,_ 4,, gocOC,l,_S I

Page 18

INSTALLATION

I_tape 5: INSTALLATION

Cette hotte aspirante est destinee s, _tre

montee sur un mur de cuisine.

1. Enlevez le filtre s,graisse (reportez-vous

s,la Notice technique d'utilisation).

2. Tirez un trait sur lemur depuis le plafond

jusqu'au bord inferieur de la hotte au

centre de I'emplacement oQ cette

derniere doit _tre montee.

3. Utilisez le gabarit pour tracer les reperes

de trou sur lemur oQ les vis doivent _tre

fixees. Pour suspendre facilement la

hotte sur les vis, dessinez le contour de

I'emplacement oQ elle doit _tre installee.

Z_ MISE EN GARDE - Veillez s,ce que la

distance minimale entre la plaque de

cuisson et la hotte aspirante soit conservee

- 30 po. Le bord inferieur du gabarit doit

correspondre au bord inferieur de la hotte

aspirante.

4. Percer 2 trous de 1/4po. ® pour la

corniere de fixation superieure et 2 trous

de _/4de po. ® pour la corniere de

fixation inferieure et enfoncez les

chevilles jusqu's, ce qu'elles soient de

niveau avec le mur.

Remarque • posez au moins une vis de

montage dans une solive.

Remarque: rappellez-vous que vous aurez

peut-_tre des accessoires speciaux _t

monter.

5. Faites encranter les 2 ecarteurs ci-joints

dans la corniere retenant le capotage de

cheminee.

Au moyen de 2 vis hexagonales, visser

les cornieres servant s, retenir le

capotage de cheminee.

29/3 .... "_'%

i8'/"

, , _,. ..... 2

': 1649/4'

............. ,'¢_',,-_ r_

2A3z ,,

_" z32 / ' ,

I 855/_,'_- -,-,- ' I', -_ ....

/ fo_ -_q--F-I- "_-_._

J t

..............s2;i32:,

18 _

6. Accrochez la hotte. A I'aide des vis de

reglage, ajustez sa hauteur et sa

verticalite.

Page 19

INSTALLATION

7. Vissez la vis inferieures

(boulon hexagonales).

8. Collez une par une les pellicules

plastique de protection sur les trous

des 2 vis de fixation inferieures situes

sur la grille protectrice.

9. Raccorder lahotte aux tuyaux.

10. Effectuer le branchement electrique de

la hotte.

11. Retirez la pellicule de plastique

protegeant les deux capots en inox.

Z_ Evitez d'endommager les surfaces

lisses en acier inox.

Z_ Prudence • les cotes interieurs des

capots de hotte peuvent presenter des

ar_tes vives. Risques de blessures.

Nous recommandons de porter des gants

de protection pendant lemontage.

12. Inserer I'un dans I'autre les deux

elements du capotage-cheminee (les

fentes de I'element telescopique

superieur doivent _tre tournees vers le

bas) puis les introduire dans la decoupe

menagee a,cet effet dans la hotte

aspirante.

Z_ Evitez de rayer les elements du

capotage-cheminee au moment de les

introduire I'un dans I'autre. Dans ce

but, placez par exemple le gabarit sur

les ar_tes de I'element inferieur.

13. Introduisez en biais I'ensemble du

capot de cheminee et faites-le basculer

en arriere. Ce faisant, le capot de

cheminee doit encranter en arriere dans

les goujons.

19

Page 20

INSTALLATION

14. Soulever I'element superieur puis le

visser au moyen de deux vis contre la

corniere de retenue.

15. Devissez les deux cales de transport.

16. Remettre le filtre _tgraisse en place (voir

la notice d'utilisation).

Si apres avoir termine les procedures

ci-dessus, le systeme de ventilation ne

fonctionne pas convenablement, passez en

revue les etapes de cette Notice

d'installation pour verifier que rien n'a ete

omis. Reportez-vous egalement au Manuel

d'utilisation et d'entretien pour obtenir des

informations supplementaires ou appelez le

Service a,la clientele de Thermador au

+1-800-735-4328.4328.

2O

Page 21

Z_ INSTRUCCIONES DE SEGURIDAD

Lea todas las instrucciones antes de usar el aparato.

LEA Y GUARDE ESTAS INSTRUCClONES

/'_ ADVERTENCIA

PARA REDUCIR EL RIESGO DE FUEGO,

DESCARGAS ELECTRICAS O SUFRIR

LESIONES, OBSERVE LO SIGUIENTE:

A. El trabajo de instalaci0n y la instalaci0n

electrica deben ser realizados por una

persona calificada de acuerdo con

todos los c0digos y normas aplicables,

incluyendo los c0digos de construcci0n

con respecto a incendios.

B. Se necesita suficiente aire para Iograr

una combustion apropiada y para sacar

los gases a traves de la chimenea del

quemador de gas combustible para

evitar el reflujo. Siga las pautas del

fabricante del calentador y las normas

de seguridad, tal como las que fueron

publicadas por la Asociaci0n Nacional

de Proteccion contra Fuegos (NFPA) y

la Sociedad Americana para Ingenierfa

de Calefacci0n, Refrigeraci0n y Aire

Acondicionado (ASHRAE) y de las

autoridades locales.

C. No dare el cableado electrico y otras

instalaciones ocultas cuando corte o

perfore la pared o el techo.

D. Ventiladores entubados deben ser ven-

tilados hacia el exterior.

E. Siempre desenchufe o desconecte el

electrodomestico de la fuente de

alimentaci0n electrica antes de realizar

el servicio tecnico.

Esta unidad fue dise_ada para uso

exclusivo en interiores. Use esta unidad

solamente para el uso intencionado por

el fabricante.

/'_ ADVERTENCIA

Solamente para uso de ventilaci0n

general. No se debe usar para extraer

materiales y vapores peligrosos o

explosivos.

Para reducir el riesgo de fuego y para

exraer el aire correctamente, asegOrese de

conducir el aire hacia el exterior. No

extraiga el aire de escape a espacios

dentro de paredes, techos, a,ticos,

espacios para arrastrarse o garajes.

PARA REDUCIR EL RIESGO DE FUEGO,

UTILICE SOLAMENTE DUCTOS DE

METAL.

Para reducir el riesgo de un fuego o de

una descarga electrica, no use el

ventilador con un regulador de velocidad

de esado s01ido.

Este aparato cumple con la norma UL 507

para ventiladores electricos y la norma

canadiense CAN/CSA-22.2 No. 113 para

ventiladores. Es la responsabilidad del

propietario y del instalador determinar si

aplican requerimientos o normas adiciona-

les en instalaciones especfficas.

Piezas necesarias

[] Cinta metrica

[] Destornillador con cabeza Phillips

[] Cinta para ductos

[] Conducto (la configuraci0n varfa segOn

el luga; para "Antes de la instalaci0n").

[] Tornillos autorroscantes adicionales (la

cantidad necesaria para la instalaci0n

del conducto)

Piezas incluidas

[] Conjunto del electrodomestico (1)

[] Tornillos autorroscantes (6)

[] Tornillos para madera (4)

[] Tornillos avellanados (2)

[] Elementos de sujeci0n para soportes en la

ventilaci0n (2)

[] Tacos UX6 (6)

21

Page 22

INFORMACION IMPORTANTE

Los electrodomesticos viejos no son basura

sin valor. Las valiosas materias primas

pueden recuperarse mediante el reciclado de

electrodomesticos viejos. Antes de desechar

su electrodomestico viejo, haga que sea

inutilizable.

Usted recibiO su electrodomestico nuevo en

una caja de envfo protectora. Todos los

materiales de embalaje son ecolOgicos y

reciclables. Ayude a Iograr un mejor

medioambiente desechando los materiales

de embalaje de manera ecolOgica.

La campana extractora s01opuede utilizarse

en el modo de aire de salida.

Siempre instale la campana extractora sobre

el centro de la parrilla.

Z_ Distancia mfnima entre la parrilla electrica

y el borde inferior de la campana extractora:

30", Fig. 1.

Z_ La campana extractora no debe instarse

sobre una estufa a combustible s01ido- se

puede producir un riesgo de incendio (p. ej.,

que se desprendan chispas), a menos que la

estufa tenga una tapa cerrada que no se

pueda retirar y que se cumplan todas las

reglamentaciones nacionales.

Cuanto ma,s peque_o es el espacio entre la

campana extractora y las placas calenta-

doras, mayor es la probabilidad de que se

formen gotas en la parte inferior de la cam-

pana extractora.

Fig. 1

GAS

InformaciOn adicional sobre estufas

a gas:

AI instalar placas calentadoras a gas,

cumpla con las reglamentaciones legales

nacionales pertinentes.

Siempre cumpla con las reglamentaciones

va,lidas vigentes y las instrucciones de

instalacion provistas por el fabricante del

electrodomestico de gas.

Z_ SOlo un lado de la campana extractora

puede instalarse junto a una unidad de

costado alto o a una pared alta.

La distancia debe ser de 2" como mfnimo.

Z_ Distancia mfnima en placas

calentadoras a gas entre el borde superior

de la rejilla y el borde inferior de la campana

extractora: 30", Fig. 1.

ELECTRICO

min. ....

22

min. 30"

J

Page 23

ANTES DELA INSTALACION

Paso 1: MODO DE AIRE DE SALIDA

iii!i; ........iii.......

El aire de salida debe ser liberado hacia

arriba a traves de un conducto o directa-

mente a traves de la pared externa a la

intemperie.

_ El aire de salida no debe ser dirigido a

un conducto de humo ni de salida que

actualmente se utilice para otros fines, ni a

un conducto que se utilice para ventilar

habitaciones en las cuales tambien se

encuentran estufas o chimeneas.

El aire de salida puede liberarse s61o

respetando las reglamentaciones

oficiales y legales (p. ej., reglamentacio-

nes nacionales sobre construcciOn).

Se deben cumplir las reglamentaciones de

autoridades locales al liberar el aire en con-

ductos de humo o de salida que no se utili-

cen para otros fines.

f_ Cuando se utiliza la campana

extractora en el modo de aire de salida

simultAneamente con una hornilla

diferente, que tambiOn utiliza la misma

chimenea (como calentadores a gas,

aceite o carbon, calentadores de flujo

continuo, calentadores de agua), se debe

asegurar que haya un suministro de aire

fresco suficiente, que serb, necesario para

la combustion en la hornilla.

La operaci6n segura es posible siempre

que la subpresi6n de la habitaci6n donde

esta,instalada la hornilla no supere los 4 Pa

(0,04 mbar).

min. 325/8" |

max, 45"

/

293/4"

36 _

Esto es posible si el aire de combustion

puede circular a traves de aberturas que no

puedan trabarse, como ser puertas y ven-

tanas, y a traves de cajas de entrada!salida

de aire en la pared.

Si la entrada de aire es insuficiente,

existe un riesgo de intoxicaciOn con los

gases de la combustion que vuelven a

ingresar a la habitaciOn.

Z_ ADVERTENCIA- Evite el riesgo de

intoxicaciOn. Si la entrada de aire a la

habitaciOn es insuficiente, existe un riesgo

de intoxicaciOn con los gases de la

combustion que vuelven a ingresar a la

habitaciOn.

Nota: AI evaluar el requisito total, se debe

tener en cuenta el sistema de ventilaciOn

combinado para todo el hogar. Esta norma

no se aplica al uso de electrodomesticos de

cocina, como parrillas y hornos.

Si el aire de salida ser& liberado a la

intemperie, se debe colocar una caja de

pared telescOpica en la pared externa.

23

Page 24

ANTES DE LA INSTALACION

Para obtener la m&xima eficiencia

de la campana extractora:

[] Tuberfa corta, lisa.

[] La menor cantidad posible de codos en

el conducto.

[] El diametro del conducto debe ser Io

mas grande posible y no debe tener

codos cerrados.

Si se utiliza un conducto de aire de

salida largo e irregular, hay muchos

codos en el conducto o el diAmetro

de la tuberia es mAs pequeffo, el

caudal de extracci6n de aire ya no

serA el mAximo, y el ruido aumentar&

IMPORTANTE: El fabricante de la

campana extractora no asume

responsabilidad alguna por las

reclamaciones que puedan atribuirse

al diseffo y a la distribuci6n del

conducto.

[] Tuberias circulares:

Recomendamos que el

diametro interno sea de 6".

[] Los conductos pianos deben tener una

secciOn transversal interna que sea igual

a la de las tuber[as circulares.

No debe haber codos cerrados.

¢ 6" aprox. 28,3 pulgadas 2

[] Si las tuberias tienen diAmetros dife-

rentes:

Coloque la tira selladora.

[] Para el modo de aire de salida, asegO-

rese de que haya un suministro de aire

fresco suficiente.

Paso 2: PREPARACION DE LA

PARED

[] La pared debe ser plana y perpendicular.

[] Verifique que la pared pueda sujetar

firmemente los tornillos y tacos de

montaje.

Peso en kg: 23.5

PARA CONECTAR UN CONDUCTO

DE AIRE DE SALIDA DE ¢ 6":

[] Instale el conducto directamente en la

salida de aire de la campana.

24

Page 25

ANTES DE LA INSTALACION

Paso 3: CONEXION ELI_CTRICA

Z_ ADVERTENCIA: ESTE ELECTRO-

DOMIeSTICO DEBE ESTAR CONECTADO

A TIERRA.

La campana extractora s01odebe

conectarse a una toma de corriente con

conexiOn a tierra que haya sido instalada

conforme alas reglamentaciones

pertinentes.

Si es posible, ubique la toma de corriente

con conexiOn a tierra directamente detra,s

de los paneles de la chimenea.

[] La toma de corriente con conexion a

tierra debe conectarse por medio de su

propio circuito.

[] Si latoma de corriente con conexion a

tierra no se encuentra accesible despues

de la instalaciOn de la campana

extractora, asegOrese de que haya un

desconectador instalado en forma

permanente.

Paso 4: INSTALE EL SERVICIO

EL_:CTRICO

Consulte el metodo de instalaciOn adecua-

do en sus cOdigos de construcciOn locales.

En los EE. UU., si no hubiera cOdigos loca-

les aplicables, esta unidad debe instalarse

conforme al Codigo Electrico Nacional

ANSI/NFPA N.° 70, ediciOn actual. (En

Canad_t, la instalaciOn debe realizarse de

conformidad con los CAN 1- B149.1 y .2 -

COdigos de InstalaciOn para Electrodome-

sticos de CombustiOn a Gas y/o los cOdi-

gos locales).

El electrodomestico debe estar conectado

a tierra. En caso de un cortocircuito electri-

co, la conexiOn a tierra reduce el riesgo de

descarga electrica proporcionando un

cable de escape para la corriente electrica.

Este electrodomestico viene equipado con

un cable con un hilo de conexiOn a tierra y

un enchufe para conexiOn a tierra.

El enchufe debe colocarse en una toma de

corriente que este correctamente instalada

y conectada a tierra.

Z_ ADVERTENCIA - La incorrecta

conexiOn a tierra puede causar una

descarga electrica.

Consulte a un electricista calificado si no

comprende la totalidad de las instrucciones

de conexiOn a tierra o si tiene alguna duda

respecto de si el electrodomestico esta,

correctamente conectado a tierra.

No use un cable de extension. Si el cable

de alimentaciOn electrica es demasiado

corto, solicite a un electricista calificado que

instale una toma de corriente cerca del

electrodomestico.

If it is necessary to wire the extractor

hood directly into the mains:

Z_ ADVERTENCIA- Evite el riesgo de

descarga electrica. Si el cable de conexiOn

de este electrodomestico esta,da_ado,

debe ser reemplazado por el fabricante o su

centro de servicio al cliente, o una persona

que este igualmente calificada, para

prevenir lesiones graves al usuario.

DATOS ELI_CTRICOS:

en la placa de nombre dentro del

electrodomestico despues de retirar el

marco del filtro.

Z_ ADVERTENCIA- Evite el riesgo de

descarga electrica. Antes de realizar una

reparaciOn, siempre desconecte la

campana extractora del suministro de

electricidad.

Longitud del cable de conexi6n: 51 1/8".

Esta campana extractora cumple con las

reglamentaciones de la CE con respecto a

la supresiOn de interferencia de RF.

25

Page 26

hO

of _ hliy mode o desr_n _re reserve_ [opy_,gh reserved

REF [omponentes Positi6n

Cl Condensodor lL_-16

EBb L6mpora hal6geno max 20 W 25,29

KSo Ploco electr6nicQ de mondo 6

Kllo Regulodor del n6m de revolu_ I%19

plo_a ele_tr_nico

M1 Motor del venfilodor 6_12

T_. Tronsformodor 27-29

X4 Conec_or 1. pole 25,26_29,30

X? Borne de conexi6n l

2 3 z, 5 6 7 8 9 I0 1 12 13 _ 15 16 17 18 19 20 21 22 23 2_ 25 26 27 2B 29 30 3 32

Page 27

INSTALACION

Step 5: INSTALACION

Esta campana extractora ha sido

dise_ada para ser montada en la pared de

la cocina.

1. Retire el filtro de grasa (consulte la

seccion Instrucciones de operaciOn).

2. Dibuje una Ifnea en la pared desde el

techo hasta el borde inferior de la

campana en el centro de la ubicaciOn

donde se montars, la campana.

3. Use la plantilla para marcar los puntos

en la pared donde se montars, n los

tornillos. Para poder enganchar mb,s

Dcilmente lacampana a los tornillos,

dibuje el contorno del &ea donde se

colocars, la campana.

/'_ PRECAUCION -AsegOrese de que la

distancia mfnima entre la parrilla y la

campana extractora se mantenga en 30". El

borde inferior de la plantilla es igual al borde

inferior de la campana extractora.

4. Perfore 2 agujeros de ® 1/4"para el

soporte de sujeciOn superior y 2

agujeros de ® 1/4"para el soporte de

sujeciOn inferior, y presione los tacos en

la pared de manera que queden a ras.

Nota" AI menos un tornillo debe instalarse a

traves de un pasador.

29/32"

Atenci6n" iTenganse en cuenta los

posibles accesorios opcionales que se

vayan a montar con la campana extractora!

5. Encajar los 2 distanciadores adjuntos en

la escuadra de soporte para el

revestimiento de la chimenea.

Montar y fijar la escuadra de soporte

del revestimiento con dos tornillos

hexagonales.

®

,_ _ 81/2"

....::....1:640/4,,

....o

l ........" _°-i_; _ N__

6. Enganchar la campana extractora.

Ajustar la altura y la posiciOn horizontal

de la misma con ayuda de los tornillos

de ajuste.

27

Page 28

INSTALACION

7. Enroscar el tornillos inferior

(tornillos hexagonal).

8. Pegar una Ib,mina protectora sobre los

agujeros de la rejilla protectora

correspondientes a los tornillos de

sujeciOn inferiores.

9. Empalmar el tubo de evacuaciOn del

aire en la campana extractora.

10. Conectar el aparato a la red electrica.

11. Retirar la la,mina protectora de los

revestimientos laterales de la chimenea.

Z_ iPrestar atenciOn a no da_ar la

superficie sensible de acero inoxidable

de los revestimientos!

Z_Atenci6n: La cara interior de los

elementos de revestimiento pueden tener

aristas vivas - ipeligro de lesiones!

Por esta razOn aconsejamos usar guantes

protectores durante el montaje.

12. Enganchar los dos elementos del

revestimiento de la chimenea

desplaza,ndolos uno respecto al otro -

las ranuras de la parte telescOpica

superior debera, estar hacia abajo.

Colocar el revestimiento en forma de

chimenea en la ranura de soporte de la

campana extractora.

Z_ iEvite los rasgu_os al montar los

elementos de revestimiento en forma

de chimenea, protegiendo con la

plantilla de montaje el borde del

elemento inferior del revestimiento.

13. Montar el revestimiento de chimenea

completo en posiciOn oblicua sobre el

cuerpo de la campana y desplazarlo

hacia atra,s, de modo que la parte

posterior del revestimiento encaje en

los pernos.

28

Page 29

INSTALACION

14. Levantar ligeramente el elemento

superior del revestimiento de la

chimenea y fijarlo lateralmente, con

ayuda de dos tornillos, a la escuadra

de soporte.

15. Desenroscar los dos seguros de

transporte.

16. Montar el filtro antigrasa (veanse al

respecto las instrucciones de uso de la

campana extractora).

Si el sistema de ventilaciOn no funciona

correctamente durante cualquiera de los

procedimientos mencionados, revise todos

los pasos de la secciOn Instrucciones de

instalaciOn para asegurarse de no haber

omitido ni pasado por alto ningOn paso.

Adema,s, consulte informaciOn adicional en

el Manual de Uso y Cuidado o Ilame a

Atencion al Cliente de Thermador al

1-800-735-4328.

29

Page 30

Notes

30

Page 31

Noticias

31

Page 32

Ther_ednr ° A. A=_.=_c..A.o=.

5551 McFadden Avenue, Huntington Beach, CA 92649 • 1-800-735-4328 ° wvvw.thermadoncom

9000326620 ° 10013 Rev B ° 02/08 © BSH Home Appliances Corporation ° Litho U.S.A.

9000 326 620

Printedin Germany 0208 Es.

Loading...

Loading...