Page 1

Installation Instructions

for

Thermador Char Glo

Outdoor Barbecues

Models:

CGB30CZLP • CGB36FZLP

CGB48FZLP • CGB48FSZLP

®

!

▲

!

▲

Installer: Please leave these instructions with the unit for the owner.

Owner: Please retain these instructions for future reference.

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

AVERTISSEMENT: Si l’information dans ce manuel n’est pas suivie

exactement, une incendie ou une explosion peut résulter, entrainant des

dégats matériels, des blessures ou la mort.

Page 2

Contents

SECTION 1: Safety Information ................................................................. 1

SECTION 2: Gas Requirements............................................................ 2 – 3

Natural Gas Requirements .......................................................................... 2

Propane Gas Requirements ......................................................................... 2

Gas Consumption .......................................................................................... 2

Propane Hook-up .......................................................................................... 2

Important Gas Supply and Installation Information................................ 3

SECTION 3: Electrical Cautions .................................................................. 4

Electrical Requirements ................................................................................ 4

Grounding Instructions................................................................................. 4

SECTION 4: Unpacking, Moving and Placing the Unit ..................... 5 – 7

Locating your Char Glo® Barbecue ........................................................... 5

Liquid Propane to Natural Gas Conversion ............................................ 6

Gas and Electrical Hook-up ......................................................................... 7

SECTION 5: Test and Adjustment ................................................................ 8

Checking for Leaks ........................................................................................ 8

Burner Air Adjustment .................................................................................. 8

Installer Checklist........................................................................................... 8

Installation........................................................................................................ 8

Gas Supply ....................................................................................................... 8

Electrical ........................................................................................................... 8

Page 3

SECTION 1: SAFETY INFORMATION

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call your gas

supplier or your fire department.

FOR YOUR SAFETY

1. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall

not be stored in the vicinity of this or any

other appliance.

AVERTISSEMENT

S’il y a une odeur de gaz:

1. Coupez l’admission de gaz de l’appariel.

2. Ènteindre toute flamme nue.

3. Ouvrir le couvercle.

4. Si l’odeur peraiste, appeler immediatement

votre compagnie de gaz ou votre departement

des incendies.

AVERTISSEMENT

1. Ne pas entreposer ni utiliser de l‘essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de l’appareil, ni de tout autre

appareil.

2. Une bouteille de propane qui n’est pas

raccordée en vue de son utilisation, ne doit

pas etre entreposée dans le voisinage de cet

appareil ou de tout autre appareil.

Service must be performed by a qualified installer,

service agency or the gas supplier.

TESTED IN ACCORDANCE WITH ANSI Z21.58 – 1995, ANSI Z21.58a – 1998

STANDARD FOR OUTDOOR COOKING GAS APPLIANCES, AND CAN/CGA 1.6-M95,

CAN/CGA 1.6a-M98 STANDARD FOR OUTDOOR COOKING GAS APPLIANCES.

This unit is for outdoor use only in a well-ventilated area. Not to be

used in a building, garage or any other enclosed area.

Check your local building codes for the proper method of installation. In the absence of local codes this

unit should be installed in accordance with the National Fuel Gas Code No. Z223.1 Current Issue and

National Electrical Code ANSI/NFPA No. 70 Current Issue or the CAN/CGA – B149.1 Natural Gas

Installation Code or CAN/CGA - B149.2 Propane Installation Code and C22.1 Canadian Electrical Code

Part1.

Page 1

Page 4

SECTION 2: GAS REQUIREMENTS

NATURAL GAS REQUIREMENTS -

Inlet Connection: 1/2" NP with 3/8" NPT reducer adapter.

Supply Pressure: 6" to 14" W.C.

Manifold Pressure: 4" W.C.

IMPORTANT: A manual gas shut off valve must be installed external to the appliance, in

!

▲

!

▲

PROPANE GAS REQUIREMENTS -

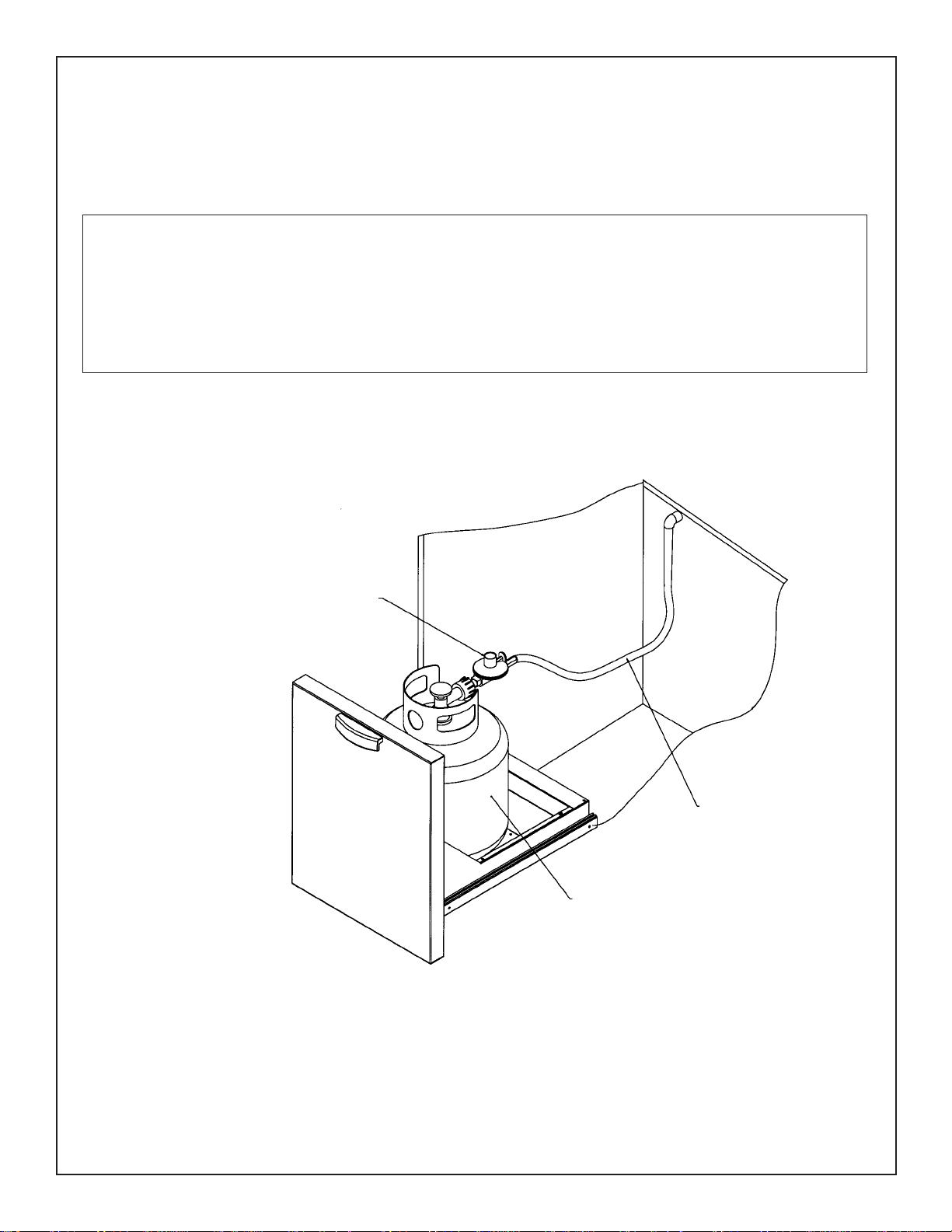

PROPANE HOOK-UP

a location accessible with the unit installed in the enclosure. Make sure the valve is turned

off prior to connecting the appliance.

IMPORTANT: Un robinet manuel d'isolement doit étre installé à l’extérieur de l’appareil, dans

un emplacement accessible avec l’unité installée dans la module. Assurez-vous que le robinet est

fermé avant de brancher l’appareil.

Inlet Connection: 1/2" NP with 3/8" NPT reducer adapter.

Supply Pressure: 11" to 14" W.C.

Manifold Pressure: 10" W.C.

Tank Gas Regulator

Gas Hose

Figure 1

GAS CONSUMPTION

The total gas consumption of the Thermador Char Glo® barbecues with all burners on "HI" is as

follows:

LP Gas Tank

CGB30RFZLP = 52,000 BTU/Hr

CGB36FZLP = 77,000 BTU/Hr

CGB48FZLP = 109,000 BTU/Hr

CGB48FSZLP = 107,000 BTU/Hr

Page 2

Page 5

SECTION 2: GAS REQUIREMENTS

For Massachusetts Installations:

1. Shut-off valve must be a “T” handle gas cock.

2. Flexible gas connector must not be longer than 36 inches.

3. Not approved for installation in a bedroom or a bathroom unless unit is direct vent.

CAUTION: The appliance and its individual shut-off valve must be disconnected from the

gas supply before any pressure testing of the system at test pressures in

excess of 1/2" psig (3.5kPa).

ATTENTION: L'appareil et son individu éteint soupape doit être débranché des avant

n'importe quelle pression essayere du système à examen dépassant 1/2" psig

(3.5kPa).

CAUTION: The appliance must be isolated from the gas supply system by closing its

individual manual shut-off valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2" psig (3.5kPa).

When checking the manifold gas pressure, the inlet pressure to the appliance

regulator should be at least 6.0" W.C. for natural gas, and 11.0" W.C. for

propane.

Do not attempt any adjustment of the pressure regulator.

ATTENTION: L’appareil doit étre isolé du circuit d’alimentation de gaz en fermant son

rob1net manuel d’isolement individuel pendant toutes essais sous pression

du circuit de tuyauterie d’alimentation de gaz aux pressions d’essai égales à

ou moins de 3.5kPa (1/2 psig).

En controlant la pression de gaz du tubulure, la pression de prise au

régulateur de l’appareil devrait étre au moins 11.2mm HG pour gaz naturel,

et 20.5mm HG pour gaz de propane.

N’essayez aucun réglage du régulateur de pression.

CAUTION: When connecting to propane gas supply, make certain that the propane gas

tank is equipped with its own high pressure regulator in addition to the

pressure regulator supplied with the appliance. The pressure of the gas at the

appliance regulator must not exceed 14" water column.

ATTENTION: En se reliant a l approvisionnement de gaz de propane, assurez-vous que le

réservoir de gaz de propane est équipé de son Propre régulateur à haute

pression en peus du régulateur de Pression fourni avec l’appareil. La pression

du gaz au régulateur de l’appareil ne doit pas exéceder 26.1 mm HG.

Page 3

Page 6

SECTION 3: ELECTRICAL REQUIREMENTS

AND GROUNDING INSTRUCTIONS

CAUTION

Installation of electrical supply circuit should be done by a qualified electrician in accordance with local

codes and ordinances. In the absence of local codes or ordinances, the supply should be installed in

accordance with the National Electric Code ANSI/NFPA No. 70, current issue, or Canadian Electric Code

C22.1 Part 1.

The Thermador Char Glo

60 Hz power supply. A properly grounded duplex outlet must be provided adjacent to the lower left rear

corner of the unit. See Figure 2.

A properly grounded duplex outlet made for outdoor applications should also be provided above the level

of the cooking surface on the left side of the unit. This outlet is required for connection of the rotisserie

motor. See Figure 2.

®

barbecues use an electronic ignition system that requires a 120 VAC, 15A,

WARNING

Electrical Grounding Instructions

This outdoor cooking gas appliance is equipped with a

three-prong (grounding) plug for your protection against

shock hazard and should be plugged directly into a

properly grounded three-prong receptacle. Do not cut

or remove the grounding prong from this plug.

AVERTISSEMENT

Instruction pour la mise a la terre electrique

Cet appareil est muni d’une fiche a trots broches (mise a la

terre) afin de vous proteger des chocs et doit etre branche

directement dans une prise de courant a trots broches

adequatement mise a la tem. II ne faut pas couper ou enlever

la broche de mise a la tem de cette fiche.

Figure 2

BARBECUE

Three-Prong Plug and Receptacle

Page 4

Page 7

SECTION 4: UNPACKING, MOVING AND PLACING THE UNIT

LOCATING YOUR CHAR GLO® BARBECUE

Leaving the unit on the pallet, move the unit close to the final installation site. Unpack and remove all accessory items, packing

materials and product literature from inside the unit. Verify the gas supply type. If the unit is not compatible with the gas supply,

it will be necessary to convert it for use with the supply. See conversion instructions below.

CONVERSION KIT BY MODEL

Model No. Orifice Description Part Number Quantity Remarks

CGB30CZLP 2.06mm (#46) Orifice Hood, Grill Burner 5040000445 2 To Convert LP To NG

1.40mm (#53) Orifice Hood, Infrared Burner 5040000443 1

Conversion Sticker 5040000623 1

CGB36FZLP 2.06mm (#46) Orifice Hood, Grill Burner 5040000445 3 To Convert LP To NG

1.40mm (#53) Orifice Hood, Infrared Burner 5040000443 1

0.93mm (#63) Orifice, Smoker Burner 5040000431 1

Conversion Sticker 5040000623 1

CGB48FSZLP 2.06mm (#46) Orifice Hood, Grill Burner 5040000445 3 To Convert LP To NG

1.40mm (#53) Orifice Hood, Infrared Burner 5040000443 1

0.93mm (#63) Orifice, Smoker Burner 5040000431 1

1.86mm (#49) Orifice, Side Burner 5040006713 2

Conversion Sticker 5040000623 1

CGB48FZLP 2.06mm (#46) Orifice Hood, Grill Burner 5040000445 4 To Convert LP To NG

1.40mm (#53) Orifice Hood, Infrared Burner 5040000443 2

0.93mm (#63) Orifice, Smoker Burner 5040000431 1

Conversion Sticker 5040000623 1

Tools/Parts Required

Socket Driver-1/4" Drive, 3" minimum extension

3/16" Or 7 mm Socket or Wrench

1/2" Deep Well Socket

1/2" Open Wrench

Liquid Propane Conversion to Natural Gas

All models are manufactured at the factory for use with LP

gas, and as such require conversion for use with an NG gas

supply. The conversion should be done by a qualified technician

or your gas supplier. All orifices required for conversion are

provided with the units. The following steps are necessary to

convert for NG operation:

1. Make sure that the unit is disconnected from the gas and

electrical supplies.

2. Remove the grill grates and radiants. Unbolt the main

burners from their attachment at the rear of the burner

box and remove.

3. Remove the knobs and control panel from the unit.

4. Locate the main burner orifices. From inside control

panel area, locate the brass elbows where the orifices

are attached. Use a wrench on the flats of these elbows

to keep them from turning during orifice removal and

installation. Remove the main burner orifices and replace

with the NG orifices supplied, marked 2.06 (46). Do not

over-tighten orifices. Orifice must extend a minimum of

1/8" into main burner air shutter with burner installed.

Make sure burner will not disengage from orifice..

Phillips Screwdriver

Slotted Screwdriver

Masking Tape

5. From behind the unit, remove the louvered cover on the

infrared rotisserie burner housing.

6. Locate the infrared burner orifice and remove. Replace

with the NG orifice supplied, marked 1.50 (53).

7. Locate the smoker burner. Slide the orifice out of the

burner and remove. Replace with the natural gas orifice

supplied, marked 0.93 (63). Reinstall the orifice into the

burner.

8. On Model CGB48FSZLP, convert the side burners for

NG operation as follows:

A. Remove the grate, burner caps, venturis and burner

bases. See Fig. 3, next page.

B. Remove the burner orifices. Use a 3/16" hex socket

on a 3" ratchet extension and apply a piece of tape

to the socket to hold the orifice in the socket while

removing. See Fig. 3A, next page.

C. Replace with the NG orifices supplied, number 1.86

(49). Tighten until snug. See Fig 3B, next page.

D. Reassemble the burner bases and venturis. Reinstall

burner caps and grate.

NOTE: Install the conversion sticker (supplied)

beside the rating label.

Page 5

Page 8

SECTION 4: UNPACKING, MOVING AND PLACING THE UNIT

2.06

(EXAMPLE)

9. On all models, the bypass jet must be turned counterclockwise with a small flat-bladed screwdriver

1 to 1-1/2 turns to set proper low flow rate. See Figures 4 and 5.

10. All Models are equipped with a Tank Gas

Pressure Regulator that is mounted on the LP

tank connector. The regulator is set for LP.

See Figure 6, below.

For use with NG, it must be changed. The regulator

is located in the left storage compartment. Remove

and replace with the accessory NATHOSE Kit.

See Figure 6A, below.

FIGURE 6

Tank Gas

Regulator

FIGURE 6A

Gas Hose

LP Gas Tank

Page 6

Page 9

SECTION 4: UNPACKING, MOVING AND PLACING THE UNIT

A regulator can also be purchased locally

provided it meets the following

specifications:

• The regulator must be rated for 4" W.C.

with capacity capable of supplying adequate

gas flow based on the input rating of the unit

(refer to Gas Consumption in Section 2).

• The regulator must be AGA certified for

use with natural gas in an outdoor application.

11. A flexible gas hose must be provided. This hose

can be purchased locally provided it is AGA

certified for use with natural gas in an outdoor

application. Connect the hose to the regulator.

12. Connect the unit to the gas supply.

13. Turn on the gas supply but do not attempt to

light any burners. Check the unit for leaks per

the instructions in Section 5, Page 8.

14. Reinstall main burners, making sure to install

and tighten the nuts that retain the burners at

the rear of the burner box. Reinstall the cover

on the infrared burner housing. Connect the

unit to the electrical supply. Light all burners

one by one and verify proper operation. See

Section 5, Page 8.

15. Reinstall radiants and grill grates.

16. The appliance shall not be located under

overhead unprotected combustible con–

struction.

GAS AND ELECTRICAL HOOK-UP

With the unit located by the gas stubout, connect

the gas supply hose to the manual shut-off valve and

open valve. Check the connection points at the

shut-off valve for any leaks and repair prior to

operating the unit. Connect the power supply cord

to the electrical supply outlet.

SITE PREPARATION

To combustible construction -

Below the cooking surface, combustible construction

can be placed adjacent to the unit. Clearance of 3" at the

lower left rear of the unit must be maintained to allow

adequate routing of the gas and electrical supply lines.

Minimum horizontal clearance from sides and back of

unit to adjacent vertical combustible construction extending above top of unit, 12" from sides and 20" from

back.

Degagement horizontal minimal a respecter entre les

cotes et l’arriere de l’appareil et une construction

combustible verticale adjacent depassant la partie

superieure de l’appareil, soit 12" (305mm) pounces des

cotes et 20" (508mm) ponces de l’arriere.

To non-combustible construction -

Above the cooking surface, a minimum 8" clearance

from the sides is required to allow use of the rotisserie

motor and skewer. A minimum of 3" clearance from the

rear is required to allow proper opening of the hood.

Below the cooking surface, non-combustible construction can be placed directly adjacent to the unit. Clearance of 3" at the lower left rear of the unit must be

maintained to allow adequate routing of the gas and

electrical supply lines.

In all installations, do not locate this outdoor cooking

gas appliance under unprotected combustible overhead

construction.

II est interdit d’installer le present appareil au-dessous

des surfaces combustibles non protegees.

Page 7

Page 10

SECTION 5: TEST AND ADJUSTMENT

CHECKING FOR LEAKS

All points of connection to the gas supply should be

checked for leaks anytime you smell gas. It is also

advisable to recheck them periodically. Follow the

steps outlined below:

A. Make a soap solution of one part liquid detergent

and one part water.

B. Make sure all controls are in the "OFF" position.

Turn on the gas supply to the unit. Use a spray

bottle, brush or rag to apply the solution to all

fittings and points of connection from the supply

stub out up to and including the inlet to the

BURNER AIR ADJUSTMENT

All burners are adjusted for proper flame

characteristics at time of assembly. If the unit has

been converted for use with alternate gas supply,

some adjustment of the air shutter on the main

burner may be necessary. Refer to Figure 7. If

adjustment is required, loosen the screw on the air

shutter and close or open shutter as required to

achieve proper flame characteristics. Tighten the

screw after adjustment.

(MUST BE DONE BY A QUALIFIED INSTALLER)

manifold. Bubbles will form where a leak exists.

C. If a leak is present, shut off the gas at the supply.

Tighten any leaking fittings, turn on the gas and

recheck.

D. If the unit has been converted for use with an

alternate gas, make sure the technician checks

for leaks at all points of connection in the

control panel area and at the infrared burner

prior to reassembly of the control panel and

cover (Refer to LP to NG Conversion

instructions in Section 4).

All burners should exhibit flames which are blue and

stable, with no yellow-tipping, lifting or excessive

noise when operating on either natural or LP gases.

See Figure 8 for pictorial representation of proper

flame characteristics.

The infrared rotisserie burner, smoker burner and

surface burners on model CGB48FSZLP are not

adjustable. If any of the flame characteristics noted

✓ INSTALLER CHECKLIST ✓

INSTALLATION

— Placement of unit.

— Specified clearances maintained to combustible

or noncombustible surfaces as applicable.

GAS SUPPLY

— Appliance is connected to the proper type of gas

supply.

— Manual gas shut off valve is installed in an accessible

location if using house stub out.

— Unit tested and free from gas leaks.

— Gas supply pressure does not exceed 14" W.C.

FIGURE 7

above are observed, check the burner for dirt or

residue in the ports, spider webs, etc., and clean or

repair as necessary.

ELECTRICAL

— Properly grounded receptacle is present for unit

and rotisserie motor as necessary.

— The burner box area is free of any packing materials

and that the burners, radiants and grates are

properly located and installed.

— Burner caps properly positioned and seated on

burner bases (Model CGB48FSZLP only).

Page 8

Page 11

NOTES

Page 12

Thermador reserves the right to change specifications or design without notice. Some models are certified for use in Canada.

Thermador is not responsible for products which are transported from the United States for use in Canada. Check with your

local Canadian distributor or dealer. Thermador, 5551 McFadden Avenue, Huntington Beach, CA 92649.

For the most up to date critical installation dimensions by fax, use your fax handset

CANADIAN GAS ASSOCIATION

APPROVED

®

and call 702/833-3600. Use code #8030.

5551 McFadden Avenue, Huntington Beach, CA 92649 • 800/735-4328

ECO 16305 • 5040004761 • © 2002 BSH Home Appliances Corp. • Litho U. S. A. 10/02

Loading...

Loading...