Page 1

INSTALLATION

INSTRUCTIONS

For Thermador Professional

PRO-HARMONY™ Dual Fuel Ranges

®

INSTRUCTIONS

D’INSTALLATION

Pour toutes les cuisinières mixtes

Thermador Professional® PRO-HARMONY™

Models

DP30

DP36

Page 2

Please Read Entire Instructions

Before Proceeding

IMPORTANT: Save these instructions for the Local Electrical and Gas Inspectors' use.

INSTALLER: Please leave these Installation Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

W ARNING

Disconnect power before installing. Before

turning power ON, be sure that all controls

are in the OFF position.

IMPORT ANT

Local codes vary. Installation, gas

connections and grounding must

comply with all applicable codes.

W ARNING

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

— Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

:

For Massachusetts Installations:

1. Installation must be performed by a qualified

or licensed contractor, plumber or gas fitter

qualified or licensed by the state, province or

region where this appliance is being installed.

2. Shut-off valve must be a “T” handle gas

cock.

3. Flexible gas connector must not be longer

than 36 inches.

W ARNING

■ All Ranges can tip

■ Injury to Persons

could result

■ Install Anti-Tip Device

■ See Installation

Instructions

— WHAT TO DO IF YOU SMELL GAS

■ Do not try to light any appliance.

■ Do not touch any electrical switch.

■ Do not use any phone in your building.

■ Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

■ If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

TO REDUCE THE RISK OF TIPPING OF THE

APPLIANCE, IT MUST BE SECURED BY A

PROPERLY INSTALLED ANTI-TIP DEVICE.

VERIFY THAT THE ANTI-TIP DEVICE IS ENGAGED

PER INSTALLATION INSTRUCTIONS. (NOTE:

ANTI-TIP DEVICE IS REQUIRED ON ALL 30" AND

36" RANGES)

Note: This Range is NOT designed for installation

in manufactured (mobile) homes or for installation

in Recreational Park Trailers.

Do Not install this range outdoors.

Page 3

Contents

Important Installation Information .................1

Step 1: Ventilation Requirements................2

Step 2: Cabinet Preparation.................3 – 7

Step 3: Unpacking, Moving

and Placing the Range .........................8 – 9

Step 4: Installing Anti-Tip Device ......10 – 11

Step 5: Gas Requirements and Hookup....12

Step 6: Electrical Requirements,

Connection and Grounding ...............13 – 15

Step 7: Backguard Installation ..................16

Step 8: Door Removal and Reinstallation..17

Step 9: Burner Test and Adjustment...18 - 19

Installer Checklist......................................20

To Clean and Protect Exterior Surfaces....20

Page 4

Important Installation Information

GAS type verification

Verify the type of gas supplied to the location. Ensure that

the appliance is connected to the type of gas for which it is

certified. All models are certified for use with natural gas.

Field conversion of the appliance for use with propane gas

supply will require a conversion kit.

W ARNING

To avoid possible burn or fire hazard, a

backguard designed specifically for this range

must be installed whenever the range is used.

Refer to the Backguard Installation instructions on

page 16, for the correct backguard models that are

designed for this range. After selecting the correct

backguard, the range must be installed properly, using

the minimum clearances to combustible surfaces specified in the Cabinet Preparation instructions on pages 4

and 5.

Important

• A backguard must be utilized when there is less than a

12” horizontal clearance between combustible materials and the back edge of the range. A Thermador

backguard must be ordered separately and installed at

the rear of the range (A Low Back is supplied with 30"

model). For island installations and other installations

with more than 12” clearance, an optional stainless

steel Island Trim is available to cover the backguard

mounting flanges.

• Verify that the appliance is correct for the type of gas

being provided. Refer to Step 5 on Page 12 before

proceeding with the installation.

This appliance has been tested in accordance with ANSI

Z21.1, Standard for Household Cooking Appliances (USA)

and in accordance with CAN 1.1-M81 Domestic Gas Ranges

(Canadian).

It is strongly recommended that this appliance be installed

in conjunction with a suitable overhead vent hood. (See

Step 1 for Ventilation Requirements.) Due to the high heat

capability of this unit, particular attention should be paid to

the hood and duct work installation to assure it meets local

building codes.

Check local building codes for the proper method of appliance installation. Local codes vary. Installation, electrical

connections and grounding must comply with all applicable

codes. In the absence of local codes the appliance should

be installed in accordance with the National Fuel Gas Code

ANSI Z223.1/NFPA 54 current issue and National Electrical

Code ANSI/NFPA 70- current issue. In Canada, installation

must be in accordance with the CAN 1-B149.1 and .2 –

Installation Codes for Gas Burning Appliances and/or local

codes.

Gas Supply:

Natural Gas – 6 inch water column. (14.9 mb) min.,

14 inch (34.9 mb) maximum

Propane Gas – 11 inch water column. (27.4 mb) min.,

14 inch (34.9 mb) maximum

Electric Power Supply:

(See pages 12 and 13 for specifications.)

CAUTION

When connecting the unit to propane gas, make

certain the propane gas tank is equipped with its

own high-pressure regulator in addition to the

pressure regulator supplied with the range. The

maximum gas pressure to this appliance

must not exceed 14.0 inches water column

(34.9 mb) from the propane gas tank to the

pressure regulator.

CAUTION

This unit is designed as a cooking appliance.

Based on safety considerations, never use it for

warming or heating a room

This appliance complies with one or more of the following

standards:

• UL 858, Standard for the Safety of Household Electric

Ranges

• UL 923, Standard for the Safety of Microwave Cooking

Appliances

• UL 507, Standard for the Safety of Electric Fans

• ANSI Z21.1, American National Standard for Household

Cooking Gas Appliances

• CAN/CSA-C22.2 No. 113-M1984 Fans and Ventilators

• CAN/CSA-C22.2 No. 61-M89 Household Cooking Ranges

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards apply

to specific installations.

Due to the high heat of the cooktop burners, installing a

microwave oven with a ventilation system over the cooktop

is not recommended.

.

CAUTION

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units

should be avoided.

1

Page 5

Step 1: Ventilation Requirements

It is strongly recommended that a

suitable exhaust hood be installed

above the range. Downdraft

ventilation should not be used. The

table below indicates the

Thermador hoods, by model

number, that are recommended

for use with all ranges.

1. Select Hood and

Blower Models:

• For wall installations, the hood

width must, at a minimum,

equal the width of the range

cooking surface. Where

space permits, a hood larger

in width than the cooking surface may be desirable for improved ventilation performance.

• For island installations, the

hood width should, at a minimum, overhang the range

cooking surface by

side.

3" on each

IMPORTANT:

Ventilation hoods and blowers are

designed for use with single wall

ducting. However, some local

building codes or inspectors may

require double wall ducting. Consult local building codes and/or

local agencies, before starting, to

assure that hood and duct installation will meet local requirements.

Do not install a microwave oven/

ventilator combination above the

range, as these type of units do

not provide the proper ventilation

and are not suitable for use with

the range.

2. Hood Placement:

• For best smoke elimination,

the lower edge of the hood

should be installed 36" above

the range cooking surface.

(See Fig. 1).

• If the hood contains any combustible materials (i.e. a wood

covering), it must be a minimum of 40" above the cooking

surface.

3. Consider Make-Up

Air:

• Due to the high volume of ventilation air, a source of outside

replacement air is recommended. This is particularly

important for tightly sealed and

insulated homes.

• A qualified heating and ventilating contractor should be

consulted.

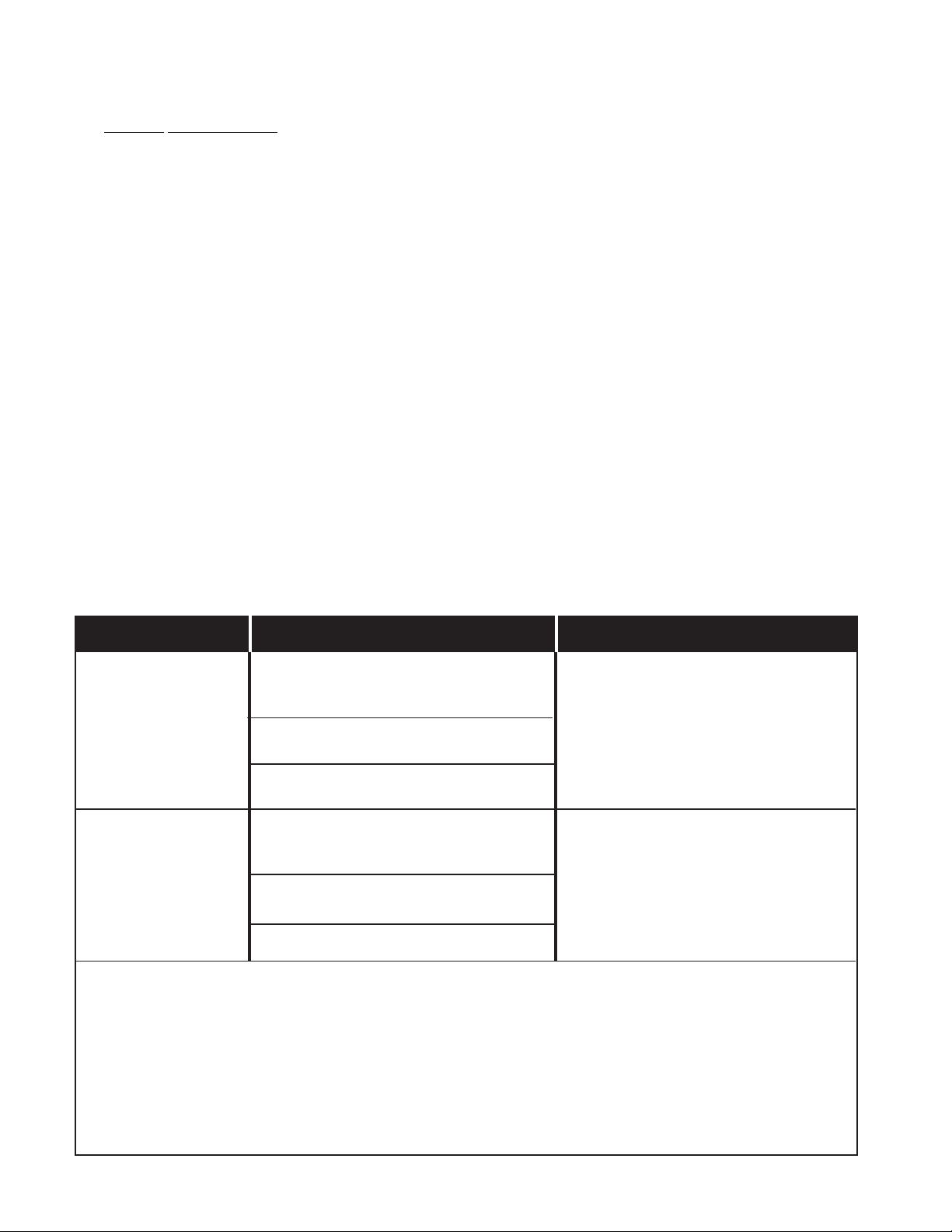

RANGE WIDTH

30" RANGE

36" RANGE

PH30CS

PHE30 / 36

HNW36YS

PHH30DS***

PH36CS / 42ZS

PHE36 / 42

HNW36YS / 42YS

PHH36DS***

WALL INST ALLATION ISLAND INST ALLATION

HOOD* BLOWER** HOOD BLOWER

VTR1030D,

VTR1530D,

or VTN1030C

VTR1030D

or VTR1530D

--- N/A ---

VTR1030D,

VTR1530D,

or VTN1030C

VTR1030D

or VTR1530D

--- N/A ---

HNI42YS

HTNI42YS

HNI42YS

HTNI42YS

VTR1030D

or VTR1530D

VTR1030D

or VTR1530D

Notes: * For wall installations where adequate space is available, the installer or user may elect to use a

hood that is wider than the rangetop cooking surface. This may be particularly beneficial for

installations having a long duct run or when heavy usage of the grill is anticipated, in which improved

capturing of the cooking exhaust is desired.

** Thermador offers a choice of remote (VTR1030D or VTR1530D) or internal (VTN1030C) blowers

for use in wall installations.

*** Hood models PHH30DS and PHH36DS include a 600-CFM built-in blower. For optimal

ventilation, a hood model with 1000-CFM blower or greater is recommended for ranges having a

griddle or grill.

2

Page 6

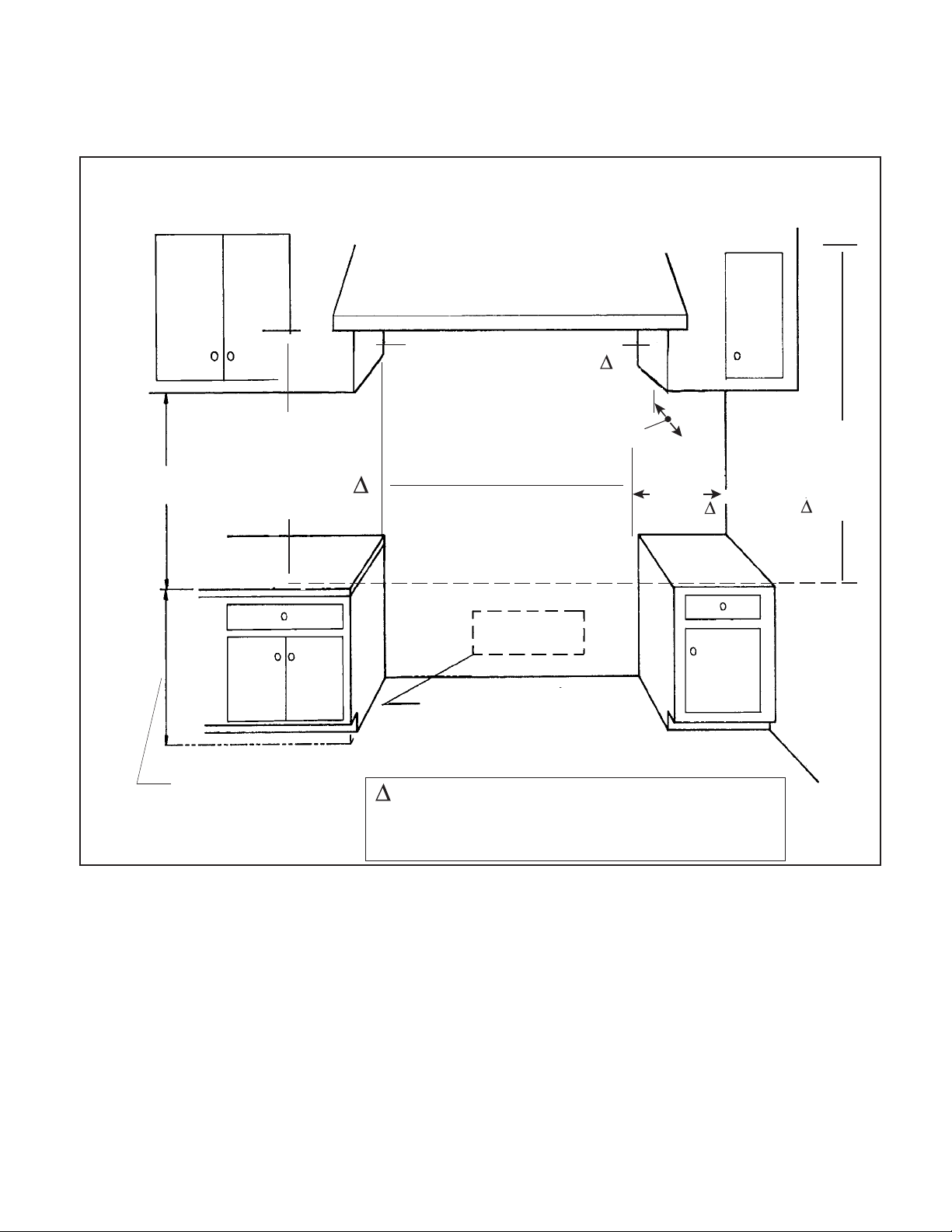

Step 2: Cabinet Preparation

1. The range is a free standing unit. If the unit is to

be placed adjacent to cabinets, the clearances

shown in Fig. 1 are required. The same clearances apply to island installations, except for the

overhead cabinets, which must have a space

wide enough to accept the flared island hood, as

indicated in Fig. 1.

2. These ranges may be recessed into the cabinets

beyond the edge of the front face of the oven (See

Figures 2A and 2B).

CAUTION

In these installations, the door and cabinet

can cause a pinching hazard.

3. The gas and electrical supply should be within the

zones shown in Fig. 3A.

Note: The maximum depth of over head cabinets

installed on either side of the hood is 13".

A 40-inch minimum clearance is required between

the top of the cooking surface and the bottom of an

unprotected cabinet. A 36-inch distance can be used

when the bottom of the wood or metal cabinet is

protected by not less than 1/4 inch of a flame retardant material covered with not less than No. 28 MSG

sheet steel, 0.015 inch (0.4 mm) thick stainless steel,

0.024 inch (0.6 mm) aluminum, or 0.020 inch (0.5

mm) thick copper. Flame retardant materials bear

the mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS

4. Any openings in the wall behind the range and in

the floor under the range must be sealed.

5. When there is less than a 12" horizontal clearance between combustible material and the

back edge of the range above the cooking surface, a Thermador Low Back or Pot and Pan

Shelf must be installed. (See Fig. 2A). When

clearance to combustible material is over 12",

a Thermador Island Trim may be used. (See Fig.

2B). Figures 2A and 2B indicate the space required for each type of backguard.

6. Always keep appliance area clear and free from

combustible materials, gasoline and other flammable vapors and liquids.

7. Do not obstruct the flow of combustion and ventilation air to the unit.

8. A (4) inch minimum clearance is needed when

the range is installed beside a combustible side

wall.

As defined in the “National Fuel Gas Code”

(ANSI Z223.1, Current Edition).

Followed by the flame spread and smoke ratings.

These designations are shown as “FHC (FIame

Spread/Smoke Developed).” Materials with “O” flame

spread ratings are flame retardant. Local codes may

allow other flame spread ratings.

3

Page 7

Step 2: Cabinet Preparation

FIG. 1 Cabinet Clearances

®

®

36" from bottom of overhead

Hood to cooking surface

18"

Min.

(40" min. if hood contains

combustible materials )

®

®

For 30" Ranges

For 36" Ranges

®

Min. Distance Between Overhead

Cabinets of Combustible Material Ð

®

30" or 36" Wide Hood

}

36" or 42" for Island

36" or 42" Wide Hood

}

42" or 48" for Island

30" Range – 30"

36" Range – 36"

Range width

30" or 36"

13" Max.

Cabinet

Depth

Cooking

Surface

®

®

}

4" Min. to

combustible

side wall

material ,

(both sides)

CAUTION: See

Figs. 2A, and 2B.

40" Min. to

combustible

material

from cooking

surface

Ð ,

®

®

®

•

®

*35-7/8" Min. Range Height

with Leveling Legs fully

retracted

*36-3/4" Max. Range Height

with Leveling Legs fully

extended.

For Electrical and Gas Supply Zone, see

Figure 3A.

as defined in the “National Fuel Gas Code” (ANSI Z223.1,

Current Edition). *The range height is adjustable. The level

of the range top must be at the same level or above the

countertop level.

4

Page 8

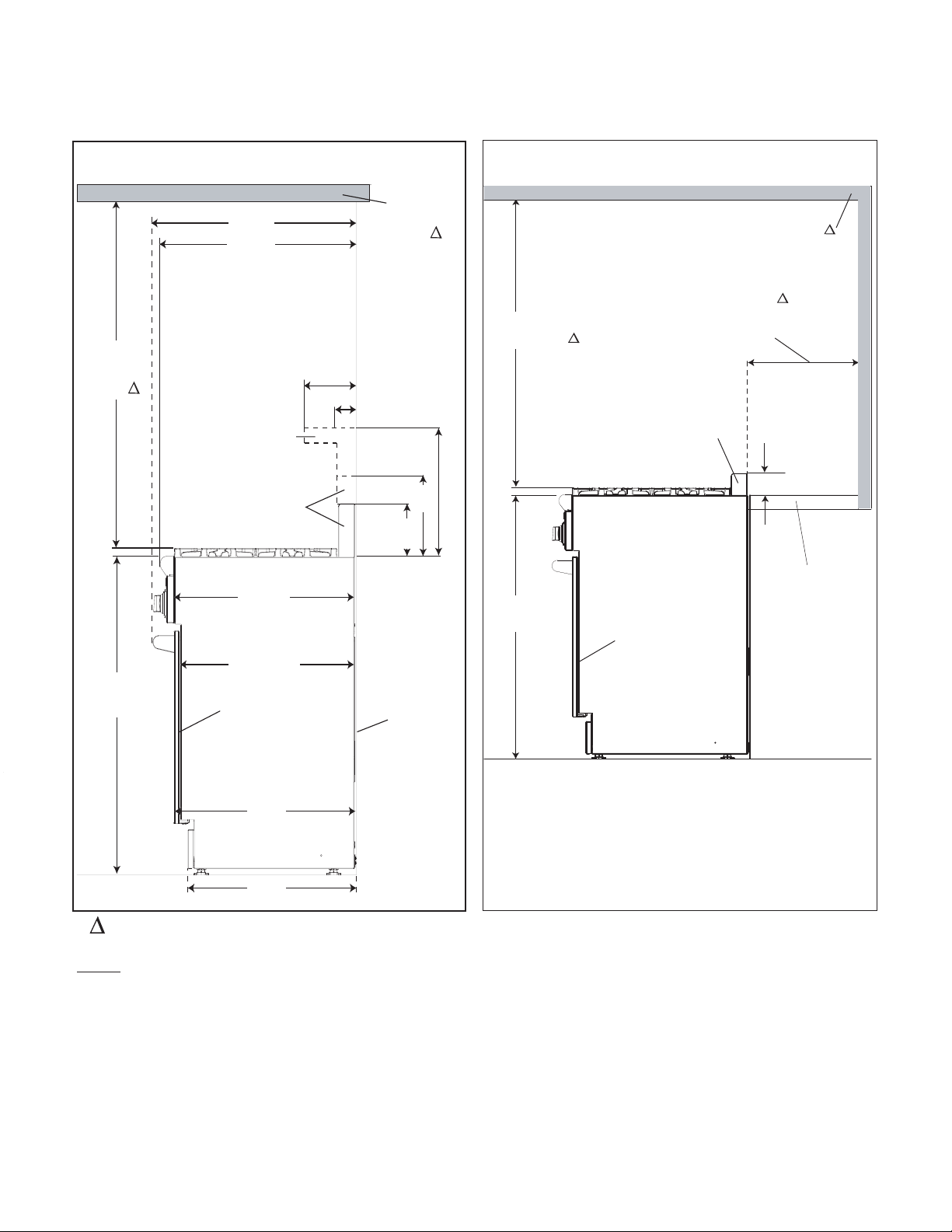

Step 2: Cabinet Preparation

FIG. 2A - Side View

40" min. to

combust-

ibles

Low Back Guard

27 5/8"

26 1/2"

Pot and

High Shelf

Pan Shelf

24 5/8"

10 3/4"

combustible

materials

2 1/4"

9"

(36")*

(DP36)

6"

(30")*

(DP304)

FIG. 2B - Side View

combustible

12" min. to

combustibles

40" min. to

combustibles

with island trim

island trim

materials

22"

3"

Countertop

36 3/4" max.

35 7/8" min.

front face

23 7/8" max

.

36 3/4" max.

35 7/8" min.

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition).

Front Face

24 3/4"

22 1/2"

Wall

Note:

With the oven door fully open, the top of the door extends to 44 5/8" from the back wall, behind the

range when installed. Installation must allow ample clearance for movement around the door when

fully open.

* Refers to 30" and 36" range models.

5

Page 9

Step 2: Cabinet Preparation

GAS AND ELECTRIC SUPPLY

FIG. 3A Gas & Electrical Supply Locations for All Dual Fuel Ranges

1 3/4" maximum protrusion

from wall for gas or

electrical supply

electrical

supply zone

8 1/2"

6"

NOTE:

If not already present, install gas shut-off valve in an easily accessible location. Make sure all users know where

and how to shut off the gas supply to the range.

NOTE: The installer should inform the consumer of the location of the gas shut-off valve.

NOTE: Any opening in the wall behind the appliance and any opening in the floor under the appliance must be sealed.

The dual fuel ranges may be connected to the power supply with a range supply cord kit or by hard-wiring to the power

supply. It is the responsibility of the installer to provide the proper wiring components (cord or conduit and wires) and

complete the electrical connection as dictated by local codes and ordinances, and/or the National Electric Code. The

units must be properly grounded. Refer to STEP 6 for details. Canadian models have power cord supplied.

6 "

30 1/4" (30" models)

36 1/4" (36" models)

gas

supply zone

6"

1 3/4"

6"

The range must be connected only to the type of gas for which it is certified. If the range is to be connected to

propane gas, ensure that the propane gas supply tank is equipped with its own high pressure regulator in addition to

the pressure regulator supplied with the range. (See STEP 5.)

NOTE: The range is designed for flush installation to the back wall. For a successful installation, it may be necessary to reposition the gas-supply line and electrical cords as the range is pushed back to its final installed position.

6

Page 10

Step 2: Cabinet Preparation

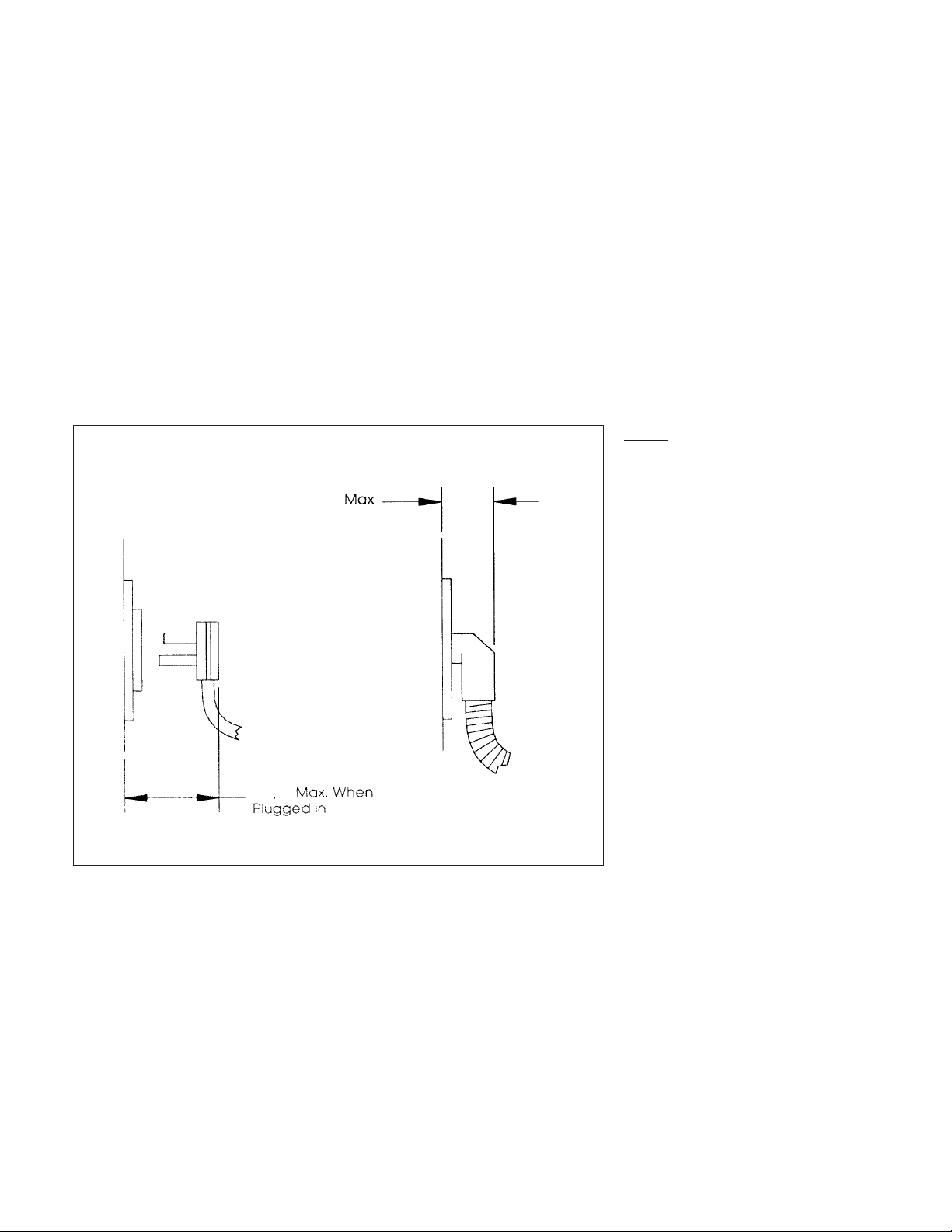

ELECTRICAL SUPPLY, DUAL FUEL RANGES

Installation of the range must be planned so that roughin of junction box for the receptacle or conduit connection will allow maximum clearance to the rear of the

unit.

When the power supply cord or conduit is connected

to the mating receptacle or junction box cover, the

combined plug/receptacle or junction box cover/conduit connector should protrude no more than 1 3/4"

from the rear wall. See Figure 3B.

FIG. 3B Wall Connection

1 3/4"

Refer to Figure 8 on page 14 for location of junction

box on unit. To minimize binding when the unit is

connected to the receptacle or junction box, orient the

receptacle or conduit connector, and slide back into

position.

Note: Canadian models (numbers ending in "CC")

have power cord supplied with range.

Note:

When using a 240VAC receptacle having its own housing, it

will be necessary to recess the

receptacle's housing into the rear

wall. Mount the receptacle securely to a wall stud, then seal

around the receptacle's housing.

Follow all local electrical codes.

1 3/4"

Power Cord & Receptacle

Junction Box & Conduit

7

Page 11

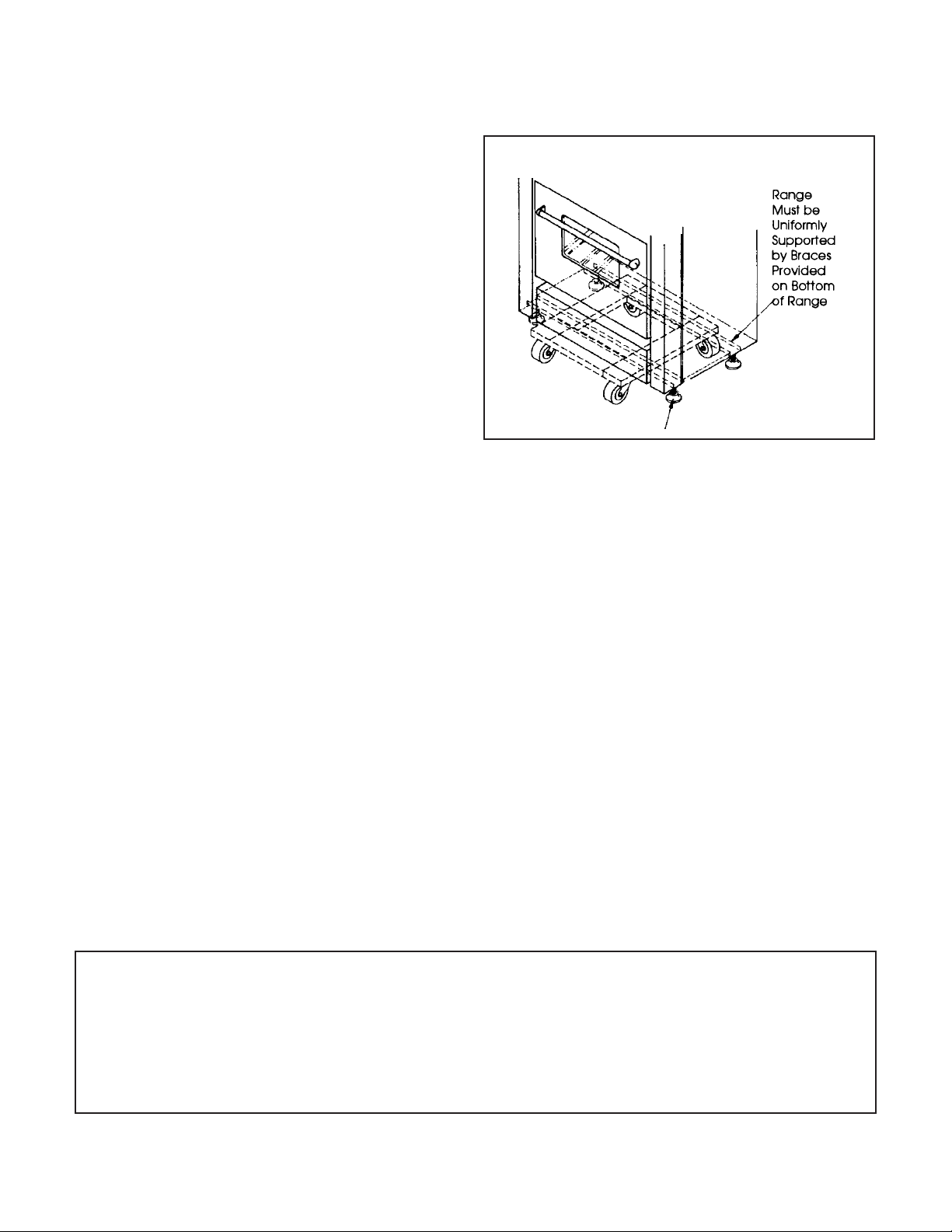

Step 3: Unpacking, Moving and Placing the Range

CAUTION

Proper equipment and adequate manpower must be

used in moving the range to

avoid injury, and to avoid

damage to the unit or the

floor. The unit is heavy

and should be handled

accordingly.

• The range has an approximate

shipping weight as shown in

Chart A. It is recommended that

the grates, griddle/grill plate and

frame, burner caps, front kick

panel and oven racks be removed to facilitate handling. This

will reduce the weight as shown

in Chart A and allow the range

to pass through 30" doorways.

See Figs. 2A and 2B on Page 5.

Do not remove the grill or

griddle assemblies.

Chart A 30" Range 36" Range

Shipping Weight 351 lbs. 371 lbs.

Weight without 228 lbs. 270 lbs.

packing materials

Without door, 185 lbs. 221 lbs.

burner caps, front kick

panel and oven racks

FIG. 4 – Removal of the Four (4) Shipping Bolts

• Remove the outer carton and

packing material from the shipping base. The

are held to the pallet by four (4)

bolts (see Fig. 4). After removing the bolts, the range must be

lifted and removed from the

pallet.

• Important: DO NOT lift the

range by the oven door's

handle, as this may damage

the door hinges and cause

the door to fit incorrectly to

the oven cavity.

dual fuel ranges

Pallet

NOTE: Leave adhesive-backed

foam layer over brushed-metal

surfaces, to protect finish from

scratches, until the range is installed in final position.

8

Page 12

Step 3: Unpacking, Moving and Placing the Range

• Due to the weight, a dolly with soft wheels

should be used to move this unit. The weight

must be supported uniformly across the bottom

(See Fig. 5).

• After transporting the range by dolly close to its

final location, the range can be tipped back and

supported on the rear legs while the dolly is

carefully removed. THE FLOOR UNDER THE

LEGS SHOULD BE PROTECTED (WOOD

STRIPS, CARPET, PANELING, ETC.) BEFORE PUSHING THE UNIT INTO POSITION.

The anti-tip device must be installed (STEP 4),

gas and electrical connections should be made

(STEPS 5 and 6), and the backguard installed

(STEP 7) before the range is placed in its final

position.

• For proper performance, the range must be

level. (It is very important for all products that

have the griddle or grill feature.) The range is

leveled by adjusting the legs with a wrench.

• Replace the kick panel. It is important that

the two (2) screws retaining the kick panel

are secure to prevent accidental access to

hot surfaces.

FIG. 5- Dolly Positioning

Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking the appliance. Never allow children to play with

packaging material.

IMPORT ANT: DO NOT lift the range by the

oven door's handle, as this may damage the

door hinges and cause the door to fit incorrectly to the oven cavity .

• Ensure that the burner caps are correctly

seated on the burner bases of the range's

cooktop.

Grill/Griddle Tilt Adjustment (Not All Models)

If the range is equipped with an electric griddle or gas grill, check the grill/griddle frame adjustment by

pouring two tablespoons of water on the back of the griddle or grill plate. The water should slowly roll

into the grease tray. If not, adjust the two screws under the back of the frame. Start with one half turn

counterclockwise (CCW) of the screws. Further adjustment should be made by one-quarter turn until

water slowly flows into the grease tray.

9

Page 13

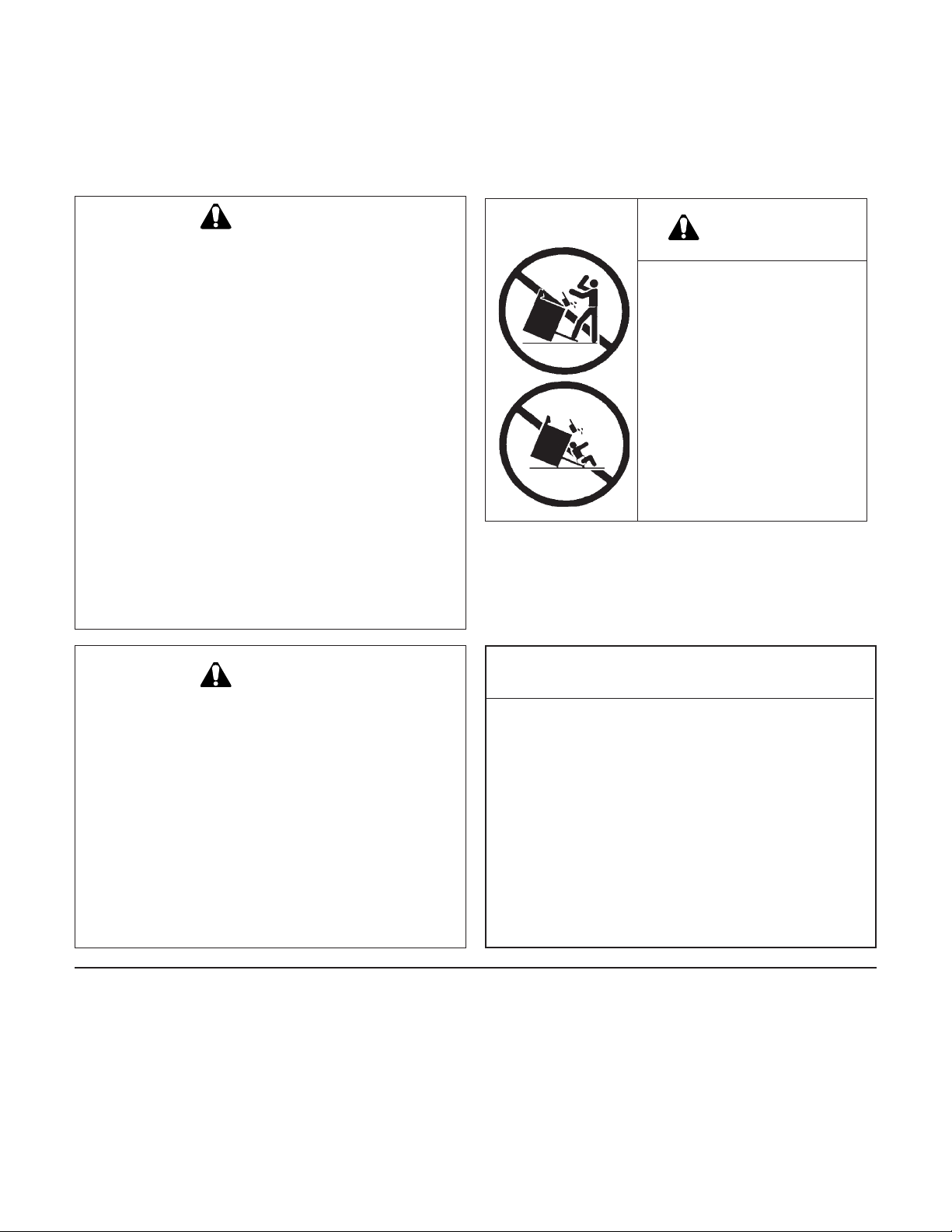

Step 4: Installing Anti-Tip Device

For all 30" and 36" ranges, an anti-tip device must be installed as per these

instructions.

W ARNING

RANGE TIPPING HAZARD

• All ranges can tip and injury can result.

To prevent accidental tipping of the range,

attach it to the floor, wall or cabinet by

installing the Anti-Tip Device supplied.

• A risk of tip-over may exist if the appliance is not installed in accordance with

these instructions.

• If the range is pulled away from the wall

for cleaning, service or any other reason,

ensure that the Anti-Tip Device is properly reengaged when the range is pushed

back against the wall. In the event of

abnormal usage (such as a person standing, sitting, or leaning on an open door),

failure to take this precaution can result

in tipping of the range. Personal injury

might result from spilled hot liquids or

from the range itself.

WARNING

• ALL RANGES CAN

TIP

• INJURY TO PERSONS COULD

RE-

SULT

• INSTALL

DEVICES

ANTI-TIP

PACKED

WITH RANGE

• SEE INSTALLATION

INSTRUCTIONS

W ARNING

ATTENTION

ELECTRICAL SHOCK HAZARD

• Use extreme caution when drilling holes

into the wall or floor. There may be concealed electrical wires located behind the

wall or under the floor.

• Identify the electrical circuits that could

be affected by the installation of the AntiTip Device, then turn off power to these

circuits.

• Failure to follow these instructions may

result in electrical shock or other personal injury.

PROPERTY DAMAGE

• Contact a qualified installer or contractor to determine the proper method for

drilling holes through the wall or floor

material (such as ceramic tile, hardwood,

etc.)

• Do not slide the range across an unprotected floor.

• Failure to follow these instructions may

result in damage to wall or floor coverings.

Tools Needed for Installation of Anti-Tip Device:

• Screwdriver, Phillips • Hammer

• Drill, electric or hand • Pencil or other marker

• Measuring tape or ruler

• 1/8" drill bit (wood or metal wall or floor)

• 3/16" carbide-tipped masonry drill bit (concrete or concrete block wall or floor)

• 3/16" anchors, drywall or concrete, 4 each (not required if mounting bracket is being attached to solid wood or metal)

10

Page 14

Step 4: Installing Anti-Tip Device

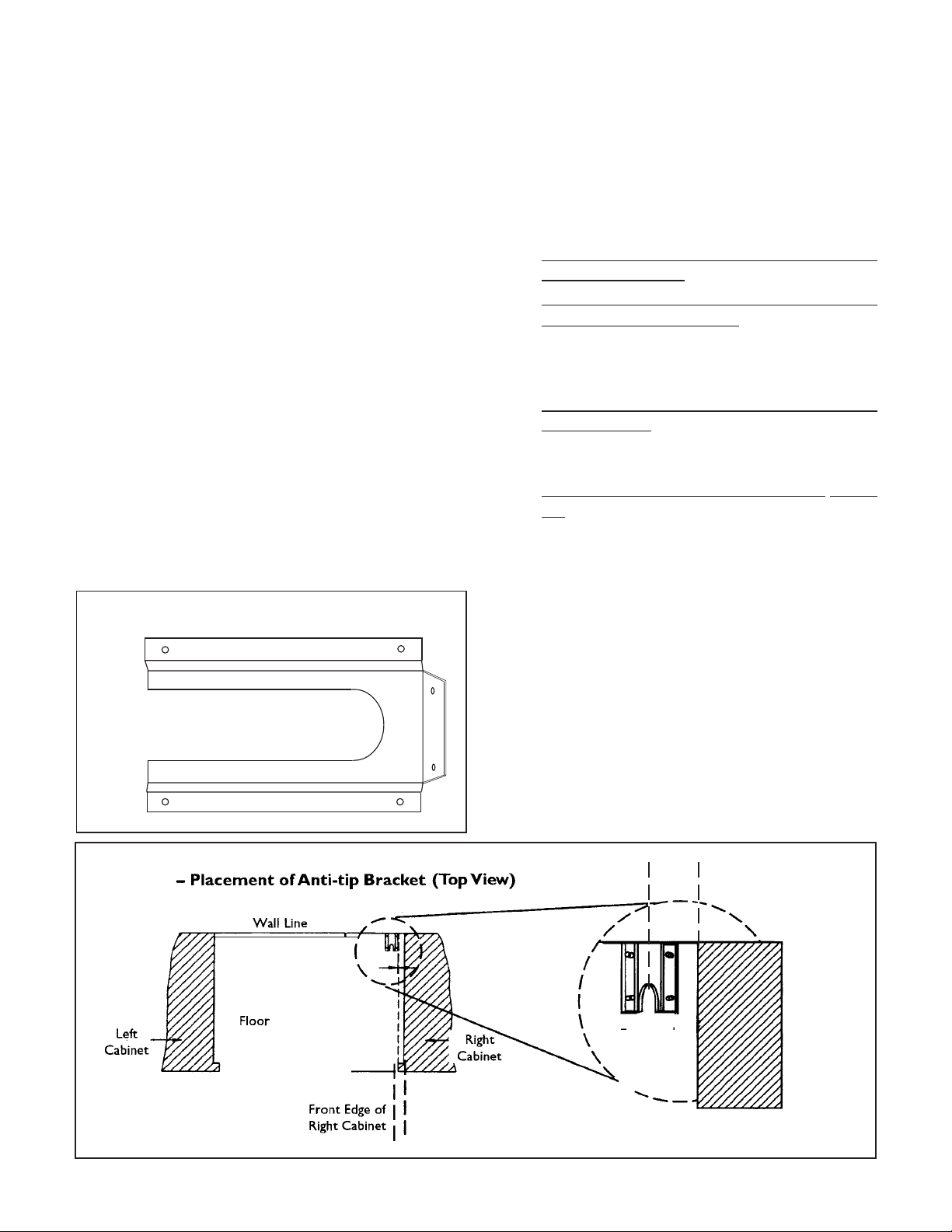

30" and 36" Dual Fuel Ranges (Figures 6 and 7)

Thermador Service Part No. Qty Description

415078 4 Screw, Phillips, #10 x 1-1/2"

600413 1 Anti-Tip Bracket, Floor-Mounted

IMPORTANT INSTALLATION INFORMATION:

• The anti-tip bracket may be attached to a solid

wood cabinet having a minimum wall thickness of

3/4".

• The thickness of the wall or floor may require use

of longer screws, available at your local hardware

store.

• In all cases, at least two (2) of the bracket mounting screws must be fastened to solid wood or

metal.

• Use appropriate anchors when fastening the

mounting bracket to any material other than hardwood or metal.

• Prepare holes at fastener locations as identified

below:

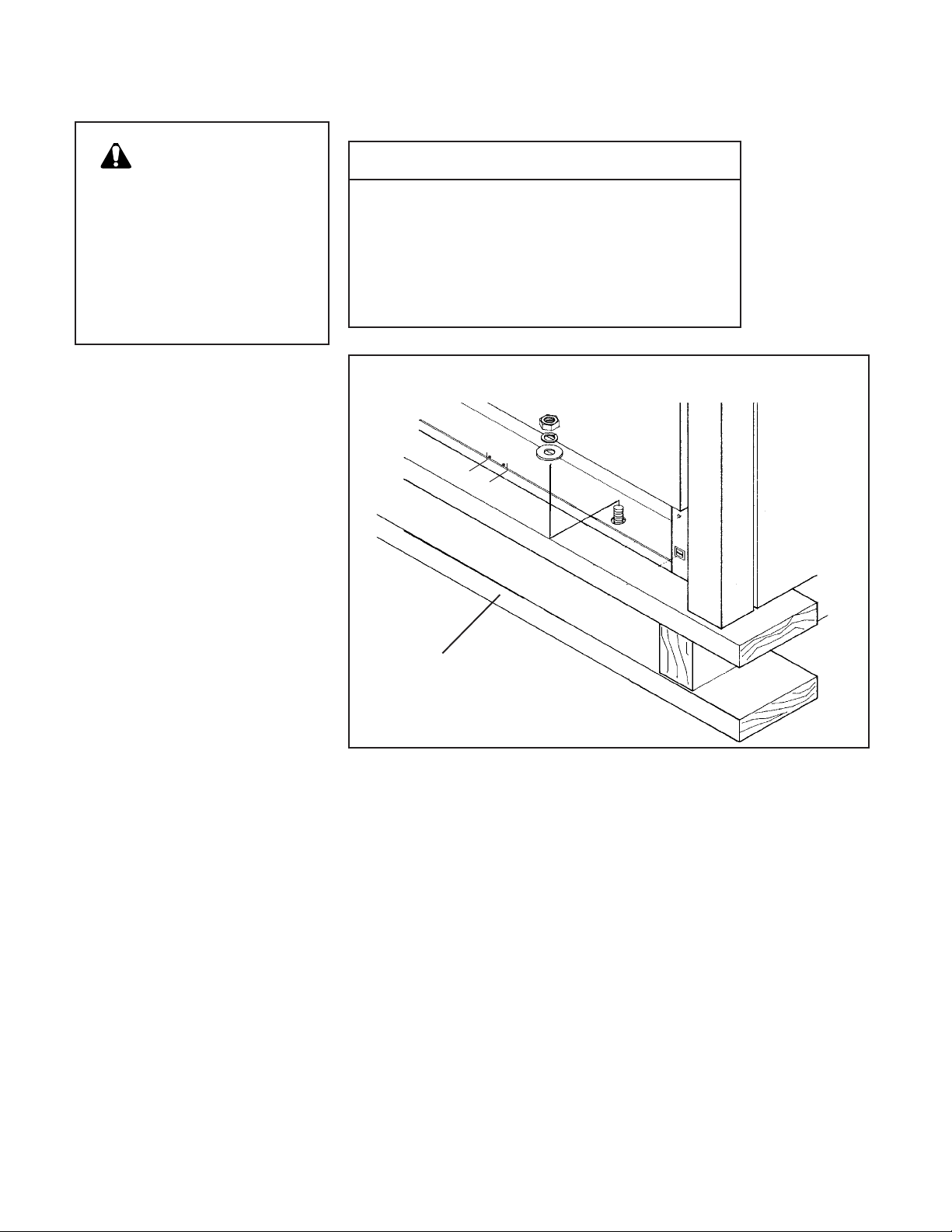

FIG. 6 - Mounting Anti-tip Bracket

- For walls, wall studs, or floors composed of

solid wood or metal, drill 1/8" pilot holes.

-

For walls or floors composed of drywall, sheetrock or other soft materials, drill 3/16" holes to

a minimum depth of 1-3/4", then tap plastic

anchors into each of the holes using a hammer.

For walls or floors composed of concrete or

concrete block, drill 3/16" holes to a minimum

depth of 1-3/4", then tap concrete anchors into

each of the holes using a hammer.

For walls or floors having ceramic tile cover-

ing, drill 3/16" holes through the tile only, then

drill into the material behind the tile as indicated immediately above.

• If the range is moved to a new location, the Anti-Tip

Device must be removed and reinstalled.

MOUNTING ANTI-TIP BRACKET

The alternative floor mounted bracket shall be installed

as follows:

FIG. 7

®

®

4-7/8"

typical either side)

a) Place bracket on floor in position shown in Figure

7 (Bracket may be used in either corner of the

installation area)

.

b) Secure to floor or wall stud.

c) Later, when the unit is installed, the adjustable leg

will slide under the bracket.

®

®

4-7/8"

from edge of range

11

Page 15

Step 5: Gas Requirements and Hookup

Verify the type of gas being used at the installation site.

The appliance is shipped from the factory for use

with natural gas. It must be converted for use with

propane. A qualified technician or installer must

do the conversion. Make certain the range matches

the type of gas available at this location.

For installation of the appliance at high altitude, please

consult your local gas company for their recommendation of the correct orifice sizes and any other

necessary adjustments that will provide proper gas

combustion at specified altitudes.

The field conversion kit for this series of Dual Fuel

Ranges is Thermador Model PLPKIT. Obey all instructions in PLPKIT for correct conversion of the gas

regulator and settings for the gas valves.

This appliance has been CSA certified for safe operation up to an elevation of 10,200 ft. without any modifications. Exception: For use with propane, the appliance must be converted per the LP conversion instructions.

CAUTION

When connecting unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator in addition to the

pressure regulator supplied with the appliance.

The pressure of the gas supplied to the appliance regulator must not exceed 14" (34.9 mb)

water column.

Natural Gas Requirements:

Inlet Connection: 1/2" NPT internal

(Minimum 3/4" dia. flex line.)

Supply Pressure: 6" min. to 14" max. water column.

(14.9 to 34.9 mb)

Manifold Pressure: 5" water column (12.5 mb)

HOOK UP

• A manual gas shut-off valve must be installed

external to the appliance, in a location accessible

from the front, for the purpose of shutting off the

gas supply. The supply line must not interfere with

the back of the unit. Make sure the gas supply is

turned off at the manual shut-off valve before

connecting the appliance.

• The range is supplied with its own pressure regu-

lator that has been permanently mounted within

the range body.

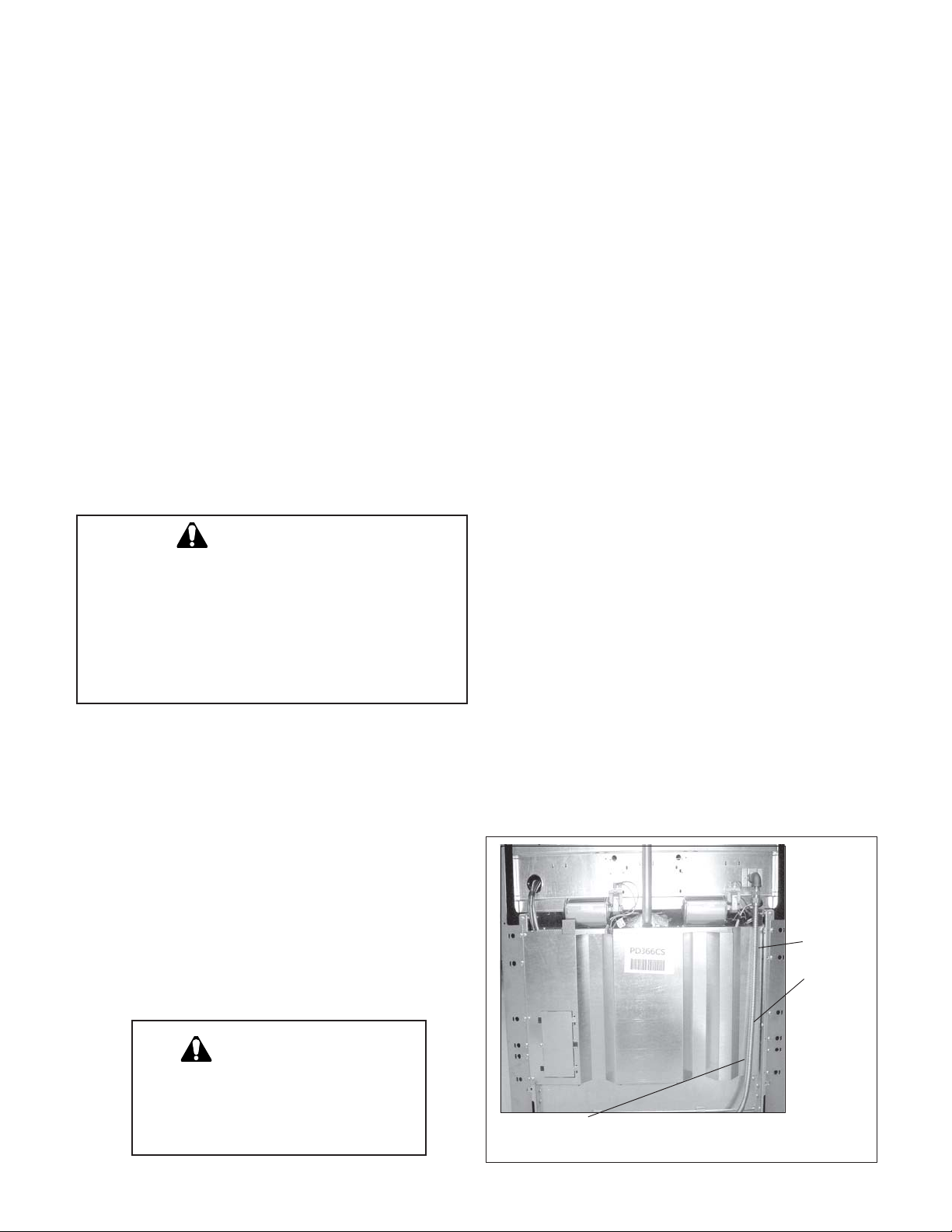

• Use 3/4" flex line to connect between the gas

supply and the appliance manifold pipe, which

exits the upper rear of the appliance. The appliance manifold pipe connection is 1/2" NPT. (See

Photo A.) Use caution to avoid crimping the 3/4"

flex line when making bends. Suggested length of

flex line is 48", however, please check local codes

for your area's requirements before installation.

• The gas supply connections shall be made by a

competent technician and in accordance with

local codes or ordinances. In the absence of local

codes, the installation must conform to the National

Fuel Gas Code ANSI Z223.1/NFPA54- current

issue.

• Always use pipe sealing compound or Teflon®

tape on the pipe threads, and be careful not to

apply excessive pressure when tightening the

fittings.

• Leak testing of the appliance shall be in accor-

dance with the following instructions.

• Turn on gas and check supply line connections

for leaks using a soap and water solution.

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

• Do not use a flame of any kind to check for

gas leaks.

Photo A

Propane Gas Requirements:

Inlet Connection: 1/2" NPT internal

(Minimum 3/4" dia. flex line.)

Supply Pressure: 11"min. to 14"max. water column.

(27.4 mb to 34.9 mb)

Manifold Pressure: 10" water column (24.9 mb)

W ARNING

Gas line must not come in contact

with any components inside back

cover of range. Run gas line in

channel in back of range.

Channel

for gas

line

®

Use 3/4" flex line to connect between the gas

supply and the appliance manifold pipe.

12

Page 16

Step 6: Electrical Requirements, Connection & Grounding

• Prior to servicing appliance, always disconnect

appliance electrical supply cord, if so equipped,

from wall receptacle. If appliance is hard-wired to

power supply, disconnect power to unit by turning

off the proper circuit breaker or disconnecting the

proper fuse. Lock service panel to prevent power

from being turned ON accidentally.

Chart B: Electrical Supply Circuit Requirements

MODELTYPE VOLTAGE CIRCUIT RATING FREQUENCY PHASE

30" 240/208 VAC 35 Amps x2 60 Hz. Single

(35 A each line)

36" 240/208 VAC 35 Amps x2 60 Hz. Single

(35 A each line)

36" with Grill 240/208 VAC 35 Amps x2 60 Hz. Single

(35 A each line)

36" with Griddle 240/208 VAC 35 Amps x2 60 Hz. Single

(35 A each line)

Dual Fuel range models can be connected or hardwired to the power supply as described on Page 15.

• A neutral supply wire must be provided from the

power source (breaker/fuse panel) because critical range components, including the surface

burner spark reignition module, require 120 VAC

to operate safely and properly. An improper 120/

240 VAC power supply will cause malfunction,

damage this appliance, and possibly create a

condition of shock hazard. If the correct power

supply circuit is not provided, it is the responsibility and obligation of the installer and user to have

proper power supply connected. This must be

accomplished in accordance with all applicable

local codes and ordinances by a qualified electrician. In the absence of local codes and ordi-

nances, the power supply connection shall be in

accordance with the National Electric Code.

• Observe all governing codes and ordinances

when grounding. In the absence of these codes

or ordinances observe National Electrical Code

ANSI/NFPA No. 70 current issue. See Pages 14

and 15 for grounding method.

• Electrical wiring diagrams and schematics have

been placed in the toe kick area of the range for

access by a qualified service technician.

• The DP Dual Fuel Ranges may be connected to

a 240/208 VAC power supply.

CAUTION

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.5 kPa.).

The appliance and its individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of the system at test pressures in excess of 1/2 psig (3.5 kPa.).

When checking the manifold gas pressure, the inlet pressure to the regulator should be at least 6" W.C.

(14.9 mb) for natural gas or 11" W.C. (27.4 mb) for propane.

Do not attempt any adjustment of the pressure regulator.

13

Page 17

Step 6: Electrical Requirements, Connection & Grounding

Range must be connected to the power supply utilizing one of the following methods. For all methods of

connection, the length of the cord or conduit/wiring must allow the unit to be slid completely out of the cabinet

without having to unplug or disconnect the unit from the power supply. Recommended minimum free length

of cord or conduit is four feet. Electrical installations and grounding must be in accordance with all local codes

and ordinances, and/or the National Electric Code, as applicable.

4-CONDUCTOR CORD -

•

NORMALLY, A UNIT MUST

BE CONNECTED TO THE

POWER SUPPLY WITH A 3POLE, 4-CONDUCTOR

CORD KIT RATED 125/250

VOLTS, 50 AMPERES, AND

MARKED FOR USE WITH

RANGES. The cord kit must

be attached to the range junction box with a strain relief

which will fit a 1" diameter hole.

If not already equipped, the

cord must have 1/4" faston

closed-loop lugs attached to

the free ends of the individual

conductors, preferably soldered in place.

FIG. 8 – Location of Junction

Box on dual fuel ranges.

PERMANENT CONNECTION

•

(HARD WIRING) - Units may

be hard wired to the power

supply. The installer must

provide approved flexible

aluminum conduit, 3/4" trade

size, maximum 6 feet long.

Locate the junction box on the

rear of the unit and remove

cover. Refer to Fig. 8. Remove

the ground strap retaining

screw and bend the ground

strap up. Refer to Fig. 9. The

conduit must be installed to

the junction box using an

approved conduit connector.

Wiring for the unit is to be

brought into the junction box

through the conduit. The ends

of the wiring must have

1/4" faston closed-loop lugs

attached, preferably soldered

in place. Make the connec-

tions to the terminal block provided. Secure the ground lead

to the junction box with the

screw previously used to secure the ground strap. Refer

to Fig. 10. The free end of the

conduit must be connected to

a junction box provided in the

gas and electrical supply zone,

as shown in Figure 3A on Page

6.

3-CONDUCTOR CORD –

•

WHERE LOCAL CODES

AND ORDINANCES PERMIT

GROUNDING THROUGH

NEUTRAL, AND CONVERSION OF SUPPLY TO 4

WIRE IS IMPRACTICAL,

UNIT MAY BE CONNECTED

TO THE POWER SUPPLY

WITH A 3-POLE,

3-CONDUCTOR CORD KIT

RATED 125/250 VOLTS, 50

AMPERES, AND MARKED

FOR USE WITH RANGES.

The cord kit must be attached

to the range junction box with a

strain relief which will fit a 1"

diameter hole. If not already

equipped, the cord must have

1/4" faston closed-loop lugs attached to the free ends of the

individual conductors, preferably soldered in place.

Installer - show the owner the

location of the circuit breaker or

fuse. Mark it for easy reference.

14

Page 18

Step 6: Electrical Requirements, Connection & Grounding

A 3- or 4-conductor supply may be connected to the

terminal block.

3-WIRE LEAD CONNECTION

1. Remove upper nuts only from the terminal block

studs. Do not remove nuts which secure range

internal wiring leads.

2. Secure the neutral, grounded wire of the supply

circuit, to the center stud of the terminal block with

nut. (See Fig. 10).

3. Secure the L1 (black) and L2 (red) power leads to

the outside terminal block studs (brass colored)

with nuts.

4. Tighten nuts securely.

4-WIRE CONNECTION

1. Remove upper nuts only from the terminal block

studs. Do not remove lower nuts which se-

cure range internal wiring leads.

2. Remove ground strap screw and bend the strap

up as shown in Fig. 11.

FIG. 9

FIG. 10

FIG. 11

Conductor Securement

®

3 Wire Connection

Neutral White

®

L1 Black

Ground Strap

®

Upper Nut

®

Cupped Washer

®

Supply Wire

Flat Washer

®

®

L2 Red

3. Secure the neutral wire to the center stud of the

terminal block with nut.

4. Secure the L1 (black) and L2 (red) power leads to

the outside terminal studs (brass colored) with

nuts.

5. Secure the bare copper ground lead to the range

chassis using the ground screw previously used

for the ground strap. Be sure that neutral and

ground terminals do not touch.

6. Tighten all connections securely.

15

Bend Ground Strap Up

FIG. 12

Secure Neutral Wire

L1 Black

®

®

L2 Red

®

Ground Wire

Page 19

Step 7: Backguard Installation

FIG. 13

Front of Range

Important: Rear panel of

Backguard must provide

holes to supply inlet air for

two (2) cooling fans.

®

®

®

®

®

Guard Strip

The back panel of backguard is positioned inside

these two guide channels on the back of the range.

W ARNING

• To avoid possible burn or fire hazard, a

backguard designed specifically for this range

must be installed whenever the range is used.

• DO NOT attempt to install a Thermador "GP"

Series Backguard, which has air holes in the

back panel to supply (only) one cooling fan.

[See above]

CAUTION

The Pot and Pan Shelf can get very hot!

DO NOT place the following items on top of

the Pot and Pan Shelf:

- plastics or containers that can melt

- flammable items

- a total load over 30 pounds (13.6kg)

6” or 9” LOW BACK:

6” Low Back – included with 30" models.

Model DFP36LB (9”) – for 36" models.

22” POT-and-PAN SHELF:

Model DFP30HS – for 30" models.

Model DFP36HS – for 36" models.

3” ISLAND TRIM:

Model DFP30IT – for 30" models.

Model DFP36IT – for 36" models.

· The backguard must be attached before sliding the

range into the final, installed position. A Low Back

or Pot-and-Pan Shelf must be installed when there

is less than 12” clearance from a combustible back

wall and the back of the range above the cooking

surface. SEE RANGE INSTALLATION MANUAL.

· An Island Trim is available for covering the

backguard area of the range for island installations;

however, the Island Trim can only be used where

there is a minimum of 12” horizontal clearance

between a combustible back wall and the back of

the range.

· The backguard is inserted inside the guide channels

on the back of the range, as shown in the illustration.

(Remove the griddle or grill assembly for sufficient

installation clearance on GE or GL model ranges.)

Using a T-20 size Torx driver, fasten the backguard

with four Torx-head (4) screws to the range side

panels.

· The Pot-and-Pan Shelf models require pre-assembly

of the top panel to the shell using nine (9) of the

enclosed Torx-head screws. For sufficient load

strength, YOU MUST attach two (2) screws through

the back corners of the top down into the shell.

· Use (3) Torx head screws to install the guard strip

on the back of the range, as shown in the illustration.

The center of the strip may be supported by a tab

from the back panel, and not require a screw.

· To secure the front of the back guard, install three

(3) of the Torx head screws through the lower front

panel of the backguard, into the flange at the back of

the range’s cooktop.

· The Pot-and-Pan Shelf models provide a shelf

above the cooktop to keep foods hot or store cooking

pans. OBSERVE CAUTIONS ON THE LEFT.

Chart C: Backguard Kit Model Numbers

Model 6" Std. Low Back 9" Low Back 22" Pot and Pan Shelf 3" Island Trim

30" Included with Range N/A DFP30HS DFP30IT

36" N/A DFP36LB DFP36HS DFP36IT

16

Page 20

Step 8: Door Removal and Reinstallation

CAUTION

USE CAUTION WHEN REMOVING THE

DOOR. THE DOOR IS VERY HEA VY.

• Make sure oven is cool and power to oven has

been turned off before removing the door.

Failure to do so could result in electrical shock

or burns.

• The oven door is heavy and fragile. Use both

hands to remove or replace the door.

• Grasp only the sides of the oven door when

removing or replacing it.

• Failure to grasp the oven door firmly and

properly could result in personal injury and

product damage.

• With the door off, never release the levers and

try to close the hinges. Without the weight of

the door, the powerful springs will snap the

hinges closed with great force.

Photo B.

Hinge bracket in closed position

To Remove the Oven Door:

1. Fully open the oven door.

2. Flip the hinge clip toward you (see illustration at

right).

3. Close the door until it stops (the open hinge clip

will hold the door about halfway open.

4. Grasp the door on the sides. The door is heavy

and fragile - always use both hands. Lift the door

up and out (there will be some spring resistance

to overcome). When the front of the door is high

enough, you will be able to pull the door straight

out.

5. Place the door in a safe and stable location.

To Reinstall the Oven Door:

1. Hold door on both sides. Insert hinges into hinge

slots. The door will be about halfway open.

It may be necessary to press firmly inward on the

lower portion of the door, using a rocking motion

to fully seat the door's hinges.

2. Open door all the way to expose hinge clips. Push

hinge clips away from you (toward the oven) until

they meet the hinge.

3. Close and open the door slowly to test the

installation. It should open and close smoothly and

be straight, not crooked

.

Photo C. Flip hinge clip toward you

Photo D. Hinge removed from oven

17

Page 21

Step 9: Burner Test and Adjustment

Install any loose components, such as burner caps

and grates, that may have been removed earlier. Be

certain that burner caps seat properly into the burner

bases. Before testing operation of the appliance,

verify that the unit and the gas supply have been

carefully checked for leaks and that the unit has been

connected to the electrical power supply. Turn the

manual gas shut-off valve to the open position.

Test Rangetop Burners

Test Burner Ignition. Select a rangetop burner

knob. Push down and turn counterclockwise to HI.

The ignitor/spark module will produce a clicking sound.

Once the air has been purged from the supply lines,

the burner should light within four (4) seconds.

Test Flame: High Setting. Turn burner on to HI. See

Figure 14 for appropriate flame characteristics.

If any of the rangetop burners continue to burn mostly

or completely yellow, verify that the burner cap is

positioned properly on the burner base, then retest. If

flame characteristics do not improve, call

Thermador®.

Test Flame: Low Setting. Turn burner on to LO.

Verify that the flame completely surrounds the burner.

There should be a flame at each burner port and there

should be no air gap between the flame and the

burner. If any burners do not carry over, call

Thermador®.

The two rangetop burners on the left side feature

XLO®, causing the flame to cycle on and off when the

knob is set to the XLO range. This is normal operation.

Repeat the Ignition and Flame Test procedures, described above for each rangetop burner and the grill

burner (if so equipped).

FIG. 14

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow, verify

that the regulator is set for the correct fuel. After

adjustment, retest.

Some orange-colored streaking is normal during

the initial start-up.

Allow unit to operate 4-5 minutes and re-evaluate

before making adjustments.

WHEN FLAME IS PROPERLY ADJUSTED:

There should be a flame at each burner port.

There should be no air gap between the flame

and burner port.

The gas grill uses a tube-style burner that has an air

shutter which allows adjustment to the amount of

primary air inside the burner tube.

Air shutters of tube-style burners are pre-adjusted at

the factory, and usually do not require readjustment

except under rare conditions such as installation at

high altitude.

If grill burner/flame adjustment is required, go to the

procedure: "Flame Adjustment (if necessary)".

Flame Characteristics

18

Page 22

Step 9: Burner Test and Adjustment

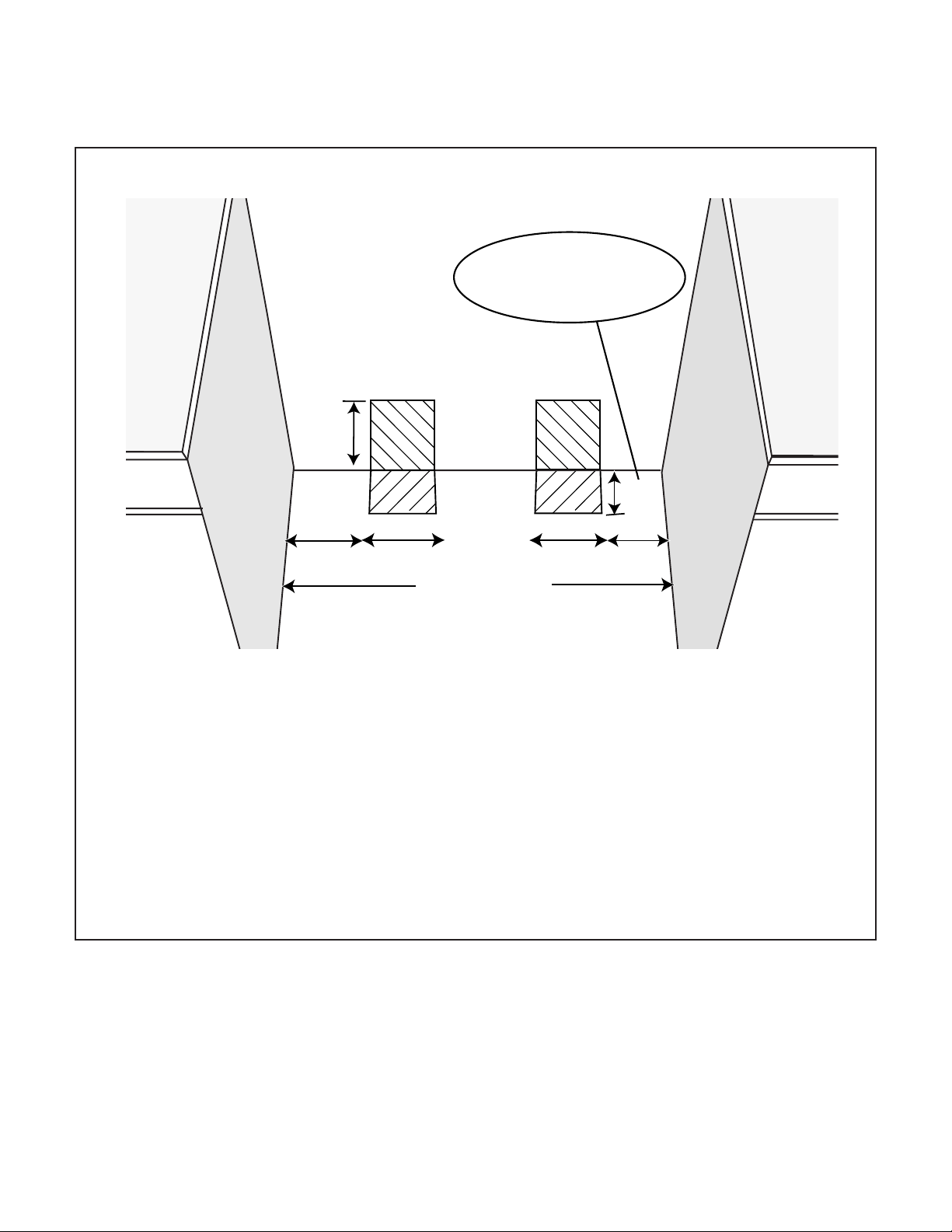

Flame Adjustment (if necessary):

Tube-style gas burners used in Thermador© appliances have air shutter systems which are similar to

the illustration in Figure 15, and can be adjusted

using the following method (unless adjustment is

not recommended). It is necessary to

burner from the appliance in order to perform airshutter adjustments.

• Loosen shutter screw(s) and turn shutter to

new position.

• Adjust the shutter to more-closed position if the

flame is lifting or blowing, or is not carrying over.

• Adjust the shutter to more-open position if the

flame is too yellow. (See Figure 15.)

• Retighten the shutter screw(s).

• After adjustment, reinstall the burner and perform flame evaluation. The air shutter must fit

over the orifice hood for proper operation of the

burner.

• Repeat procedure as needed until flame characteristics are acceptable. (See Figure 14).

remove the

W ARNING

Burner adjustments must be performed by a

qualified technician. Improper adjustments may

cause harmful by-products or void the

appliance's warranty.

Allow burners to cool before attempting to

remove them!

Call Thermador® if:

1. Any of the burners do not light.

2. Any of the burners continue to burn yellow.

FIG. 15

Air Shutter Adjustment (if necessary)

Screw

More Open:

Less Yellow Flame

More Closed:

Less Blue Flame

More Carryover

Less Lifting or Blowing

Air

Shutter

19

Page 23

INSTALLER CHECKLIST

FINAL CHECK LIST

❑ Specified clearances main-

tained to cabinet surfaces.

❑ Unit Level – front to back –

side to side.

❑ Burner caps positioned prop-

erly on burner bases.

❑ All packaging material removed.

❑ Island trim or backguard at-

tached according to instructions.

❑ Kick panel in place and two (2)

screws secure.

❑ The griddle or grill plate and

frame is correctly positioned,

tilted slightly forward. (See page

9 for adjustment procedure.)

GAS SUPPLY

❑ Manual gas shut off valve in-

stalled in an accessible location (without requiring removal

of range).

❑ Unit tested and free of gas

leaks.

❑ If used on propane gas, verify

that the propane gas supply is

equipped with its own high pressure regulator in addition to the

pressure regulator supplied

with the appliance.

ELECTRICAL

❑ Receptacle with correct over-

current protection is provided

for service cord connection.

❑ Proper ground connection.

OPERATION

❑ Bezels centered on burner

knobs, and knobs turn freely.

❑ Each burner lights satisfacto-

rily, both individually and with

other burners operating.

❑ Griddle or grill is tilted

forward and does not rock (not

all models).

❑ Oven door hinges seated and

hinge locks in proper position.

Door opens and closes properly.

❑ Burner grates correctly posi-

tioned, level, and do not rock.

❑ Start self-clean. When LOCK

light comes on, verify that door

is locked close. Cancel self

clean mode.

slightly

To Clean and Protect Exterior Surfaces

The stainless steel surfaces may be cleaned by

wiping with a damp soapy cloth, rinsing with clear

water and drying with a soft cloth to avoid water

marks. Any mild glass cleaner will remove fingerprints

and smears.

For discolorations or deposits that persist, refer to the

Care and Use Manual.

To polish and protect the stainless steel, use a cleaner/

polish such as Stainless Steel Magic

®

.

❑ INSTALLER: Leave the Care

and Use Manual and Installation Instructions with the owner

of the appliance.

DO NOT allow deposits to remain for long periods of

time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

DO NOT allow salt solutions, disinfectants, bleaches

or cleaning compounds to remain in contact with

stainless steel for extended periods. Many of these

compounds contain chemicals which could prove

harmful. Rinse with water after exposure and wipe dry

with a clean cloth.

20

Page 24

NOTES

Page 25

Veuillez lire toutes les instructions

avant de poursuivre

Important : Conserver ces instructions pour les inspecteurs en gaz et électricité locaux.

Installateur : Veuillez laisser ces instructions d’installation avec l’appareil pour le propriétaire.

Propriétaire : Veuillez conserver ces instructions pour consultation ultérieure.

AVERTISSEMENT

Coupez l’électricité avec d’installer l’appareil.

Avant de remettre l’électricité, assurez-vous

que toutes les commandes sont sur la position

OFF.

IMPORTANT

Les réglementations locales varient.

L’installation, les raccordements au gaz et les

mises à la terre doivent être conformes à toutes

les réglementations applicables.

AVERTISSEMENT :

L’information fournie dans le présent manuel

doit être très rigoureusement respectée, sous

peine d’incendie ou d’explosion entraînant des

dommages, des blessures ou la mort.

Ne stockez pas et n’utilisez pas d’essence ou

—

autres produits inflammables à proximité des

appareils.

— SI VOUS DÉTECTEZ UNE ODEUR DE GAZ

■ N’allumez aucun appareil.

■ Ne touchez pas aux interrupteurs électriques.

■ N’utilisez pas les téléphones du bâtiment.

■ Appelez immédiatement votre compagnie de gaz

de chez un voisin. Suivez les instructions de la

compagnie.

Pour les installations au

Massachusetts :

1.L’installation doit être réalisée par un

entrepreneur qualifié ou agréé, un plombier

ou un installateur de gaz qualifié ou autorisé

par l’État ou la région dans laquelle cet

appareil est installé.

2. Le robinet d’arrêt de gaz doit être pourvu

d’une poignée en « T ».

3. La longueur maximum autorisée du tuyau de

gaz est de 91,4 centimètres (36").

AVERTISSEMENT

■ Toutes les cuisinières

peuvent basculer

■ Des personnes peuvent

être blessées

■ Installez un dispositif

antibascule

■ Consultez les instructions

d’installation

AFIN DE DIMINUER LES RISQUES DE

BASCULEMENT , INST ALLEZ UN DISPOSITIF

ANTIBASCULE. ASSUREZ-VOUS QUE LE

DISPOSITIF ANTIBASCULE EST BIEN EN

PLACÉ, CONFORMÉMENT AUX INSTRUCTIONS D’INSTALLATION (REMARQUE : LE

DISPOSITIF ANTIBASCULE EST

OBLIGATOIRE POUR TOUTES LES

CUISINIÈRES DE 76,2 CM [30"] ET DE

91,4 CM [36 "]).

■ Si vous n’arrivez pas à contacter votre

compagnie de gaz, appelez les pompiers.

—L’installation et les réparations doivent être

réalisées par un installateur qualifié, un centre

de réparation agréé ou la compagnie de gaz.

Remarque : Cette cuisinière N’EST PAS conçue

pour les maisons mobiles ni pour les véhicules

récréatifs.

NE PAS installer cette gamme dehors.

Page 26

Table des matières

Information importante concernant l’installation ............... 1

Chapitre 1 : Exigences pour la ventilation ....................... 2

Chapitre 2 : Préparation de l’emplacement............... 3 – 7

Chapitre 3 : Déballage, manutention et mise

en place de la cuisinière ........................................... 8 – 9

Chapitre 4 : Installation du dispositif antibascule.. . 10 – 11

Chapitre 5 : Exigences pour l'alimentation de gaz et

raccordement ............................................................... 12

Chapitre 6 : Exigences pour l'alimentation électrique,

le branchement et la mise à la terre ...................... 13 – 15

Chapitre 7 : Installation de la plaque de protection ........ 16

Chapitre 8 : Installation et retrait de la porte .................. 17

Chapitre 9 : Test et réglage de brûler....................... 18-19

Liste de vérification de l’installateur .............................. 20

Nettoyage et protection des surfaces externes.............. 20

Page 27

Informations importantes à propos de l'installation

Vérification du type de GAZ

Vérifiez le type d'alimentation au gaz fourni du lieu

d’installation. L’appareil doit être raccordé au type de

gaz pour lequel il est certifié. Tous les modèles sont

certifiés pour une utilisation avec gaz naturel. Conversion sur place pour utilisation au gaz propane exigeant

le nécessaire de conversion.

AVERTISSEMENT

Pour éviter tout risque de brûlure ou d'incendie, un

dosseret conçu spécifiquement pour cette

cuisinière doit être installé lorsque l'appareil est

utilisé.

Voir les instructions d'installation du dosseret à

la page 16 pour les modèles de dosseret

approprié pour cet appareil. Une fois le dosseret

choisi, l'appareil doit être installé adéquatement

en utilisant les dégagements minimum pour surfaces combustibles spécifiées dans les instructions de préparation d'armoire, pages 4 et 5.

Important

• Utiliser un dosseret lorsque l'espace horizontal entre

les matériaux combustibles et le bord arrière de la

cuisinière est de moins de 30,5 cm (12 po). Commander

séparément le dosseret Thermador et l'installer à

l’arrière de la cuisinière (un dosseret bas est fourni

avec le modèle 30 po). Pour les installations en îlot et

autres installations avec un espace de plus de 30,5 cm

(12 po), une garniture en acier inoxydable est vendue

en option afin de recouvrir les brides de montage du

dosseret.

• S'assyrer que l’appareil convient au type de gaz fourni.

Consulter le Chapitre 5, page 12 avant de procéder à

l’installation.

Cet appareil a été testé conformément aux normes ANSI

Z21.1, pour les appareils de cuisson résidentiel (É.U.) et avec CAN 1.1-M81 pour les cuisinières à gaz

résidentielles (Canada).

On recommande fortement d’installer une hotte de

ventilation adaptée au-dessus de cet appareil (voir

Chapitre 1, Conditions de ventilation). Comme cet

appareil peut dégager une forte chaleur, on doit porter

une attention particulière aux travaux d’installations

des conduits et de la hotte, lesquels doivent être

conformes à la réglementation locale de construction.

Vérifiez la réglementation locale applicable pour

connaître la bonne méthode d’installation de l’appareil.

Les réglementations locales varient. L’installation, le

branchement électrique et la mise à la terre doivent

respecter toutes les réglementations applicables. À

défaut de réglementation, l’appareil doit être installé

conformément aux normes américaines en vigueur sur

le gaz combustible ANSI Z223.1/NFPA54 et l’électricité

ANSI/NFPA70. Au Canada, l'installation doit être

conforme aux normes canadiennes CAN 1-B149.1 et .2

1

du Code du bâtiment pour l'installation d'appareils

fonctionnant au gaz et/ou le code de construction

local.

Alimentation en gaz :

Gaz naturel : 14,9 mb min. (6 po, C.E.), à 34,9 mb max.

(14 po, C.E.

Gaz propane : 27,4 mb min. (11 po, C.E.), 34,9 mb

max. (14 po, C.E.)

Alimentation électrique :

(Voir pages 13 et 14 pour les données techniques)

MISE EN GARDE

Si l’appareil est alimenté au gaz propane,

assurez-vous que le réservoir de propane est

équipé de son propre détendeur en plus du

détendeur fourni avec la cuisinière. La pression

maximum d’arrivée du gaz de cet appareil

ne doit pas dépasser les 34,9 millibars (14

popo C.E.) entre le réservoir de propane et

le détendeur.

MISE EN GARDE

Cet appareil est conçu pour un usage culinaire.

Pour des raisons de sécurité, ne l’utilisez jamais

pour chauffer une pièce.

Cet appareil est conforme à une ou plusieurs normes

suivantes :

• UL 858, norme pour la sécurité des cuisinières

électriques domestiques

• UL 923, norme pour la sécurité des appareils à

cuisson aux micro-ondes

• UL 507, norme pour la sécurité des ventilateurs

électriques

• ANSI Z21.1, norme nationale américaine pour

appareils de cuisson à gaz domestiques

• CAN/CSA-C22.2 n° 113-M1984 ventilateurs et hottes

• CAN/CSA-C22.2 n° 61-M89 cuisinières domestiques

Il incombe au propriétaire et à l'installateur de déterminer

si des exigences et/ou normes additionnelles

s'appliquent pour une installation spécifique.

À cause de la chaleur intense des brûleurs de la

surface de cuisson, l'instalaltion d'un four à microondes avec un système de ventilation au-dessus de la

surface de cuisson n'est pas recommandée.

MISE EN GARDE

Afin d'éliminer les risques de brûlures ou

d’incendie provoqués par la chaleur, il est

conseillé d’éviter d’installer des armoires

au-dessus des tables de cuisson des

appareils.

Page 28

Chapitre 1 : Exigences pour la ventilation

Il est fortement recommandé d’installer

une hotte de ventilation appropriée audessus de la cuisinière. Une ventilation

par contre-tirage ne devrait pas être

utilisée. Le tableau ci-dessous

énumère, par numéro de modèle, les

hottes Thermador que l'on conseille

d’utiliser avec les cuisinières.

1. Choix du modèle de

hotte et de ventilateur

• Pour les installations murales, la

largeur de la hotte doit être au moins

égale à celle de la table de cuisson

de la cuisinière. Si l’espace le

permet, il est souhaitable d’installer

une hotte plus large que la table de

cuisson pour améliorer les

performances de ventilation.

• Pour les installations en îlot, la

largeur de la hotte devrait dépasser

d’au moins 7,62 cm (3") des deux

côtés de la table de cuisson de la

cuisinière.

IMPORTANT

Les hottes de ventilation et les

ventilateurs sont conçus pour une seule

conduite murale. Certaines

réglementations municipales du

bâtiment exigent toutefois une double

conduite. Consultez les normes

applicables et/ou la municipalité avant

de débuter les travaux pour vous assurer que l’installation des conduites

répond aux exigences locales.

Ne pas installer un combiné hotte/four à

micro-ondes au-dessus des surfaces

de cuisson. Ces appareils n’assurent

pas une ventilation appropriée et ne

conviennent pas aux surfaces de

cuisson.

2. Emplacement de la

hotte

• Pour une meilleure élimination des

fumées, le bord inférieur de la hotte

doit être placé à une distance de

91,4 cm (36") au-dessus de la table

de cuisson (voir Figure 1).

• Si la hotte contient des matériaux

combustibles (comme par exemple

un placage en bois), elle doit être

placée à au moins 101,6 cm (40")

au-dessus de la table de cuisson.

3. Apport d’air

• Un important volume d’air étant

nécessaire pour la ventilation, il est

recommandé de prévoir un apport

d’air de l’extérieur. Cet aspect revêt

une importance particulière dans les

logements bien isolés et très

étanches.

• Il est conseillé de consulter un

entrepreneur en chauffage et en

climatisation.

LARGEUR DE LA

CUISINIÈRE

PH30CS

PHE30 / 36

CUISINIÈRE

de 76,2 CM (30 po)

CUISINIÈRE

de 91,4 CM (36 po)

Remarques : * Pour les installations murales, si l’espace est suffisant, l’installateur ou l’utilisateur peut choisir

une hotte plus large que la table de cuisson de la cuisinière. Ceci peut être avantageux pour les

installations ayant un long conduit ou une utilisation accrue du gril ou du wok ; d'où l'importance de

capter l'échappement de cuisson.

**Thermador offre un choix de souffleries à distance (VTR1030D ou VTR1530D) ou interne (VTN1030C)

pour utilisation avec les installations murales.

***Les modèles de hotte PHH30DS et PHH36DS comprennent une soufflerie intégré de 600 PCM.

Pour une ventilation optimale, un modèle de hotte avec soufflerie de 100 PCM ou plus est recommandé

pour les surfaces de cuisson ayant une grille, un gril ou un wok.

HNW36YS

PHH30DS***

PH36CS / 42ZS

PHE36 / 42

HNW36YS / 42YS

PHH36DS***

INSTALLATION MURALE INSTALLATION EN ÎLOT

HOTTE* VENTILATEUR** HOTTE VENTILATEUR**

VTR1030D,

VTR1530D,

ou VTN1030C

VTR1030D

ou VTR1530D

--- N/A ---

VTR1030D,

VTR1530D,

ou VTN1030C

VTR1030D

ou VTR1530D

--- N/A ---

HNI42YS

HTNI42YS

HNI42YS

HTNI42YS

VTR1030D

ou VTR1530D

VTR1030D

ou VTR1530D

2

Page 29

Chapitre 2 : Préparation de l’emplacement

1. La cuisinière est un appareil monobloc. Si elle est

placée au milieu des armoires, les dégagements

requis sont indiqués à la Figure 1. Les mêmes

dégagements s’appliquent aux installations en îlot,

excepté pour les armoires suspendues qui doivent

laisser un espace suffisamment grand pour poser

la hotte d’îlot évasée, comme le montre la Figure

1.

2. Les cuisinières peuvent être encastrées entre les

armoires au-delà du bord de la partie frontale du

four (voir Figures 2A et 2B).

MISE EN GARDE

Dans ce type d’installation, la porte et l’armoire

peuvent comporter un risque de pincement.

3. Les arrivées d’électricité et de gaz doivent se

trouver dans les zones indiquées à la Figure 3A.

4. T oute ouverture dans le mur qui se trouve derrière

la cuisinière et dans le plancher sous la cuisinière

doit être refermée.

5. Si la distance entre un matériau combustible et

le bord arrière de la cuisinière au-dessus de la table

de cuisson est de moins de 30,5 cm (12 po), il est

obligatoire d’installer une plaque Thermador de

protection arrière, basse ou tablette à casserole

(voir Figure 2A). Si la distance du matériau

combustible est supérieure à 30,5 cm (12 po), il

est possible d’utiliser un enjoliveur Thermador pour

îlot (voir Figure 2B). Les Figures 2A et 2B indiquent

l’espace nécessaire pour chaque type de plaque

de protection.

6. L’appareil ne doit jamais se trouver à proximité de

matériaux combustibles, d’essence et d’autres

produits inflammables (vapeurs ou liquides).

7. L’air de combustion et de ventilation arrivant à

l’appareil doit pouvoir circuler librement dans les

conduites.

REMARQUE : La profondeur maximum des armoires

en hauteur installées d’un côté ou de l’autre de la hotte

est de 33 cm (13 po).

Un dégagement minimum de 40 po est nécessaire

entre le dessus de la surface de cuisson et le dessous

d’une armoire non protégée. Une distance de 36 po

doit être assurée lorsque le bas des armoires en bois

ou en métal est protégé par un matériau ignifuge

d’une épaisseur d'au moins 6,35 mm (1/4") recouvert

d’une feuille d’acier no 28 MSG de la même épaisseur,

de 0,4 mm (0,015") d’acier inoxydable, de 0,6 mm

(0,024") d’aluminium ou de 0,5 mm (0,02") de cuivre.

Les matériaux ignifuges portent la marque :

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS,

(panneaux de fibres et minéraux classés,

caractéristiques d’inflammation des surfaces),

suivie des taux de progression des flammes et des

fumées. Ces désignations sont indiquées par « FHC »

(Flame Spread/Smoke Developed – Progression des

flammes/Production de fumée). Les matériaux ayant

un taux « O » de progression de flammes sont

ignifuges. La réglementation municipale peut autoriser

un taux de progression des flammes différent.

8. Un dégagement minimum de 4 po est nécessaire

lorsque la cuisinière est installée à côté d'un mur

latéral combustible.

Tel que définit dans le code national de combustible à gaz (ANSI Z223.1, dernière édition).

3

Page 30

Chapitre 2 : Préparation de l’emplacement

FIG. 1 – Dégagement des armoires

Cuisinière de 76,2 cm (30 ")

Cuisinière de 91,4 cm (36 ")

®

Distance minimum entre les armoires

suspendues composées de matériaux

combustibles

Cuisinières de 30" - 76,2 cm

Cuisinières de 36" – 91,4 cm

®

®

Distance min.

de 45,8 cm

(18")

®

®

®

36" entre le dessous de la hotte et

la surface de cuisson (40 po min.

si la hotte contient des matériaux

combustibles ).

®

Hotte de 76,2 cm (30") ou de 91,4 cm (36")

}

91,4 cm (36") ou 106,7 cm (42") pour

Hotte de

}

106,7 cm (42") ou 121,9 cm (48")

36" ou 42"

Profondeur

max. de

l’armoire :

33 cm (13")

Largeur de la cuisinière

76,2 cm (30") ou 91,4 cm (36")

Table de

cuisson

®

}

®

installation en îlot

pour installation en îlot

®

®

Min. 10,16 cm

(4") à paroi

latérale com-

®

bustible en

matériau

(des deux

côtés).

MISE EN GARDE :

V

Distance min. de

®

101,6cm (40") entre la

table de cuisson

matériaux

combustibles .

®

oir Fig. 2A et 2B.

et les

®

•

®

Hauteur min. de la cuisinière avec

pieds élévateurs entièrement

rétractés : 91,1 cm (35-7/8")

Hauteur max. de la cuisinière

avec pieds élévateurs entièrement

déployés : 93,3 cm (36-3/4").

Zone d’arrivée d’électricité et de gaz (voir

Fig. 3A).

Tel que défini dans le « Code national du gaz combustible »

(ANSI Z223.1 – dernière édition). *La hauteur de la cuisinière

est réglable. Le dessus de la cuisinière doit être au même

niveau ou plus élevé que le plan de travail.

4

Page 31

Chapitre 2 : Préparation de l’emplacement

FIGURE 2A - Vue latérale

27 5/8 po

26 1/2 po

Min. 40 po

aux combustibles

Tablette à

Tablette haute

casserole

Dosseret bas

24 5/8po

Matériaux

combustibles

10 3/4po

2 1/4po

6po

(30")*

(DP304)

9po

(36")*

(DP36)

22po

FIGURE 2B - Vue latérale

Min. 40 po aux

combustibles

36 3/4 po max.

35 7/8 po min.

Devant

combustibles avec

garniture pour îlot

Garniture pour

Matériaux

combustibles

Min. 12 po aux

îlot

3 po

Plan de

travail

23 7/8po max.

36 3/4po max.

35 7/8po min.

Devant

Mur

24 3/4po

22 1/2po

Tel que définit dans le code national de combustible à gaz (ANSI Z223.1, dernière édition.

Remarque :

La porte du four ouverte, le haut de la porte à 44 5/8 po depuis la paroi arrière, derrière la cuisinière

installée. L'installation doit avoir un dégagement suffisant pour le mouvement autour de la porte

ouverte.

* Réfère à 30" et 36" modèles de la cuisinière.

5

Page 32

Chapitre 2 : Préparation de l’emplacement

ALIMENTATION DE GAZ ET ÉLECTRIQUE

FIGURE 3A - emplacement de l'alimentation électrique et en gaz pour les

cuisinières à combustion jumelée

Bordure minimale de

1 3/4 po depuis le mur

pour l'alimentation en gaz

ou électrique

Zone

d'alimentation

électrique

8 1/2 po

6 po

REMARQUE :

Une soupape d'arrêt de gaz manuelle (si elle n'est pas déjà en place) doit être facilement accessible. S'assurer

que toute personne sache où et comment fermer l'alimentation en gaz à la cuisinière.

REMARQUE : l'installateur doit indiquer au client l'emplacement de la soupape d'arrêt de gaz.

REMARQUE : toute ouverture dans le mur derrière l'appareil et/ou dans le plancher doit être scellée.

6 po

30 1/4 po (Modèle 30 po)

36 1/4 po (Modèle 36 po)

Zone

d'alimentation

en gaz

6 po

1 3/4 po

6 po

La cuisinière à combustion jumelée peut être branchée sur l'alimentation électrique avec un nécessaire de cordon

d'alimentation de cuisinière (fourni avec l'appareil) ou par un câblage fixe à l'alimentation. Il incombe à l'installation de

fournir les composants appropriés pour le câblage (cordon ou cuiduit et fils) et de compléter la connexion électrique selon

les règlements et codes locaux et/ou du Code national d'électricité. L'appareil doit être mis à la terre adéquatement.

Voir Chapitre 6 pour plus de détails. Les modèles pour le Canada ont un cordon d'alimentation.

La cuisinière doit être branchée seulement du le type de gaz pour laquelle elle est certifiée. Si la cuisinière

doit être branchée sur le gaz propane, s'assurer que le réservoir de gaz propane est doté de son régulateur de

haute pression en plus du régulateur fournie avec la cuisinière (voir Chapitre 5).

REMARQUE : la cuisinière est conçue pour être à égalité avec le mur arrière. Pour une installation adéquate, il peut

être nécessaire de repositionner la canalisation d'alimentation en gaz et le cordon électrique lorsque la cuisinière

est poussée en position d'installation finale.

6

Page 33

Chapitre 2 : Préparation de l’emplacement

ALIMENTATION ÉLECTRIQUE POUR LES CUISINIÈRES À COMBUSTION JUMELÉE

L'installation de la cuisinière doit être planifiée afin

que la boîte de jonction pour la prise ou la connexion

de conduit permette un dégagement maximum à

l'arrière de l'appareil.

Lorsque le cordon n'alimentation (non fourni) ou le

conduit est branché sur une prise correspondante ou

couvercle de boîte de jonction, la prise/fiche combinée

ou la boîte de jonction/connecteur de conduit ne

doivent pas dépasser de plus de 1 ¾ po du mur

arrière. Voir figure 3B.

FIG. 3B – RACCORDEMENT AU MUR

4,4 cm max.

(1-3/4")

Voir figure 8, page 14, pour l'emplacement de la boîte

de jonction sur l'appareil. Pour minimiser le pliage

lorsque l'appareil est branché sur la prise ou la boîte

de jonction, orienter la prise ou le connecteur de

conduit et faire glisser en position.

Remarque : les modèles canadiens (numéros se

terminant par «CC») sont dotés d'un cordon

d'alimentation.

Remarque :

Si l'on utilise une prise 240

VAC ayant son boîtier, il est

nécessaire d'encastrer le

boîtier de la prise dans le mur

arrière. Fixer de façon

sécuritaire la prise au

montant du mur, puis sceller

autour du boîtier.

les codes électriques locaux.

Observer

1 3/4 po max. une fois

branché

Cordon d’alimentation et prise

Boîte de dérivation et conduite

7

Page 34

Chapitre 3 : Déballage, manutention et mise en place

de la cuisinière

MISE EN GARDE

Un équipement adapté

manipulé par du personnel

expérimenté doit être utilisé

pour déplacer la cuisinière

afin de ne pas endommager

l’appareil ni le plancher. La

cuisinière est lourde et

repose sur des pieds

réglables en acier.

• Le poids approximatif de la

cuisinière à l’expédition est celui

qui est indiqué au Tableau A. Il

est recommandé d’ôter les

grilles, la grille/plaque gril, le

cadre, les chapeaux des

brûleurs, la plaque d’habillage et

les grilles du four pour faciliter

la manutention. Le poids de

l’appareil s’en trouvera diminué,

tel qu'indiqué au Tableau A et

permettra à la cuisinière de

passer par une porte de

76,2 cm (30"). Voir Figures 2A

et 2B à la Page 5. N’ôtez pas

le gril ni la plaque de cuisson.

Tableau A Cuisinière de Cuisinière de

76,2 cm (30 po) 91,4 cm (36 po)

Poids à l’expédition 351lb 371lb

Poids sans matériaux 228lb 270lb

d’emballage

Poids sansporte, 185lb 221lb

chapeaux de brûleurs, plaque

d’habillage et grilles de four

FIG. 4 – Retrait des quatre boulons avant installés pour

l’expédition

Pallette

• Retirez l’emballage externe et

les matériaux d’emballage de la

palette d’expédition. Toutes les

cuisinières à combustion

jumelée sont fixées sur une

palette à l’aide de quatre (4)

boulons (voir figure 4). Après

avoir enlevé les boulons,

soulevez la cuisinière et

enlevez-la de la palette.

• Important : NE PAS soulever

la cuisinière par la poignée

de porte. Cela peut

endommager les charnières

et ainsi la porte s'ajustera mal

dans l'ouverture.

REMARQUE : laisser la mousse

avec adhésir sur les surfaces en

métal brossé pour protéger le fini

des égratignures jusqu'à ce que

l'appareil soit installé à sa position

permanente.

8

Page 35