XTR106

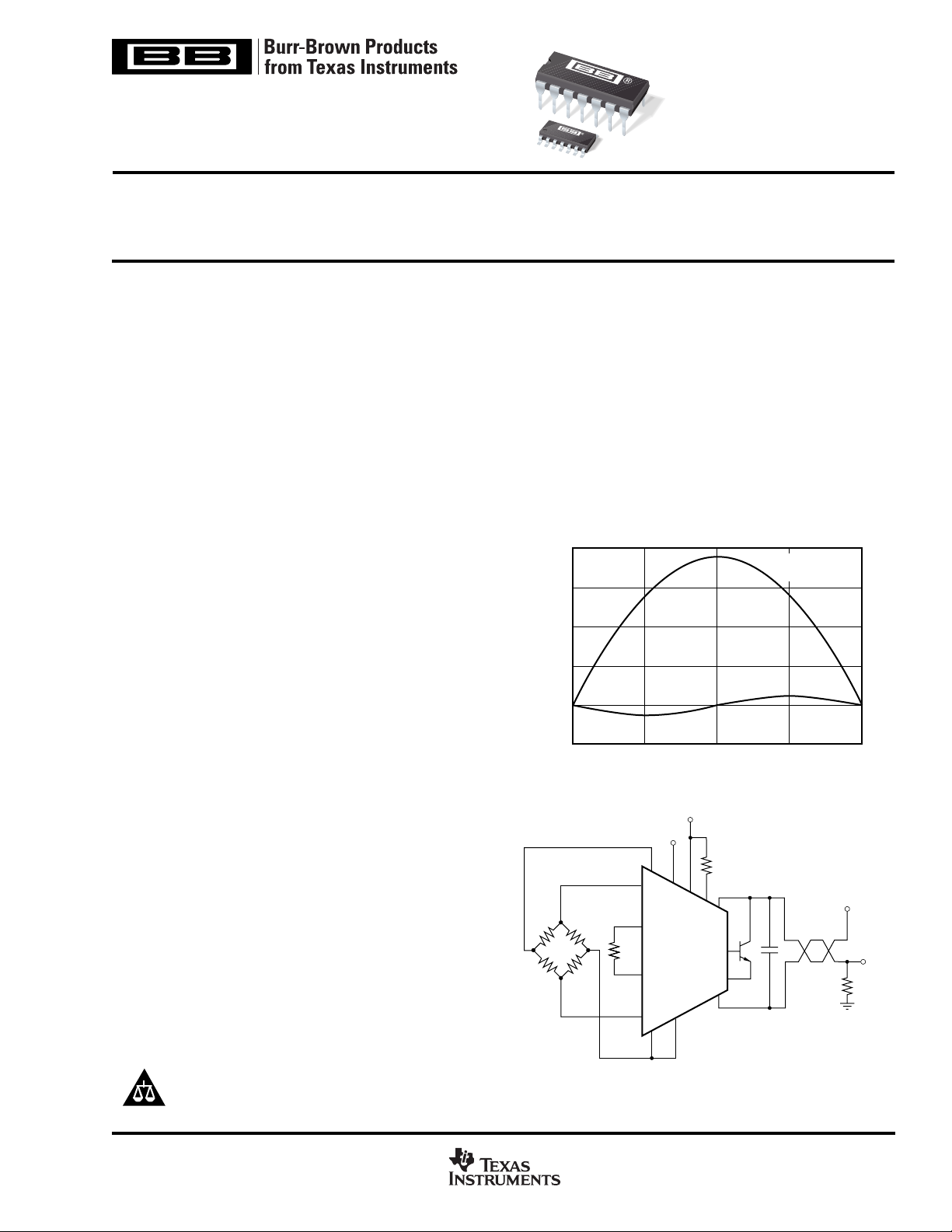

BRIDGE NONLINEARITY CORRECTION

USING XTR106

0

Bridge Output (mV)

10

2.0

1.5

1.0

0.5

0

–0.5

Uncorrected

Bridge Output

Corrected

5

Nonlinearity (%)

X

TR

1

06

SBOS092A – JUNE 1998 – REVISED NOVEMBER 2003

4-20mA CURRENT TRANSMITTER

with Bridge Excitation and Linearization

XTR106

FEATURES

● LOW TOTAL UNADJUSTED ERROR

● 2.5V, 5V BRIDGE EXCITATION REFERENCE

● 5.1V REGULATOR OUTPUT

● LOW SPAN DRIFT: ±25ppm/°C max

● LOW OFFSET DRIFT: 0.25µV/°C

● HIGH PSR: 110dB min

● HIGH CMR: 86dB min

● WIDE SUPPLY RANGE: 7.5V to 36V

● 14-PIN DIP AND SO-14 SURFACE-MOUNT

DESCRIPTION

The XTR106 is a low cost, monolithic 4-20mA, twowire current transmitter designed for bridge sensors. It

provides complete bridge excitation (2.5V or 5V reference), instrumentation amplifier, sensor linearization,

and current output circuitry. Current for powering additional external input circuitry is available from the

V

pin.

REG

The instrumentation amplifier can be used over a wide

range of gain, accommodating a variety of input signal

types and sensors. Total unadjusted error of the complete current transmitter, including the linearized bridge,

is low enough to permit use without adjustment in many

applications. The XTR106 operates on loop power supply voltages down to 7.5V.

Linearization circuitry provides second-order correction

to the transfer function by controlling bridge excitation

voltage. It provides up to a 20:1 improvement in

nonlinearity, even with low cost transducers.

The XTR106 is available in 14-pin plastic DIP and

SO-14 surface-mount packages and is specified for the

–40°C to +85°C temperature range. Operation is from

–55°C to +125°C.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

APPLICATIONS

● PRESSURE BRIDGE TRANSMITTERS

● STRAIN GAGE TRANSMITTERS

● TEMPERATURE BRIDGE TRANSMITTERS

● INDUSTRIAL PROCESS CONTROL

● SCADA REMOTE DATA ACQUISITION

● REMOTE TRANSDUCERS

● WEIGHING SYSTEMS

● ACCELEROMETERS

5V

www.ti.com

V

(5.1V)

REG

2.5V

V

V

REF

REF

5

R

Lin

Polarity

LIN

7.5V to 36V

I

OUT

4-20mA

+

I

G

RET

XTR106

–

R

Copyright © 1998-2003, Texas Instruments Incorporated

V

PS

V

O

R

L

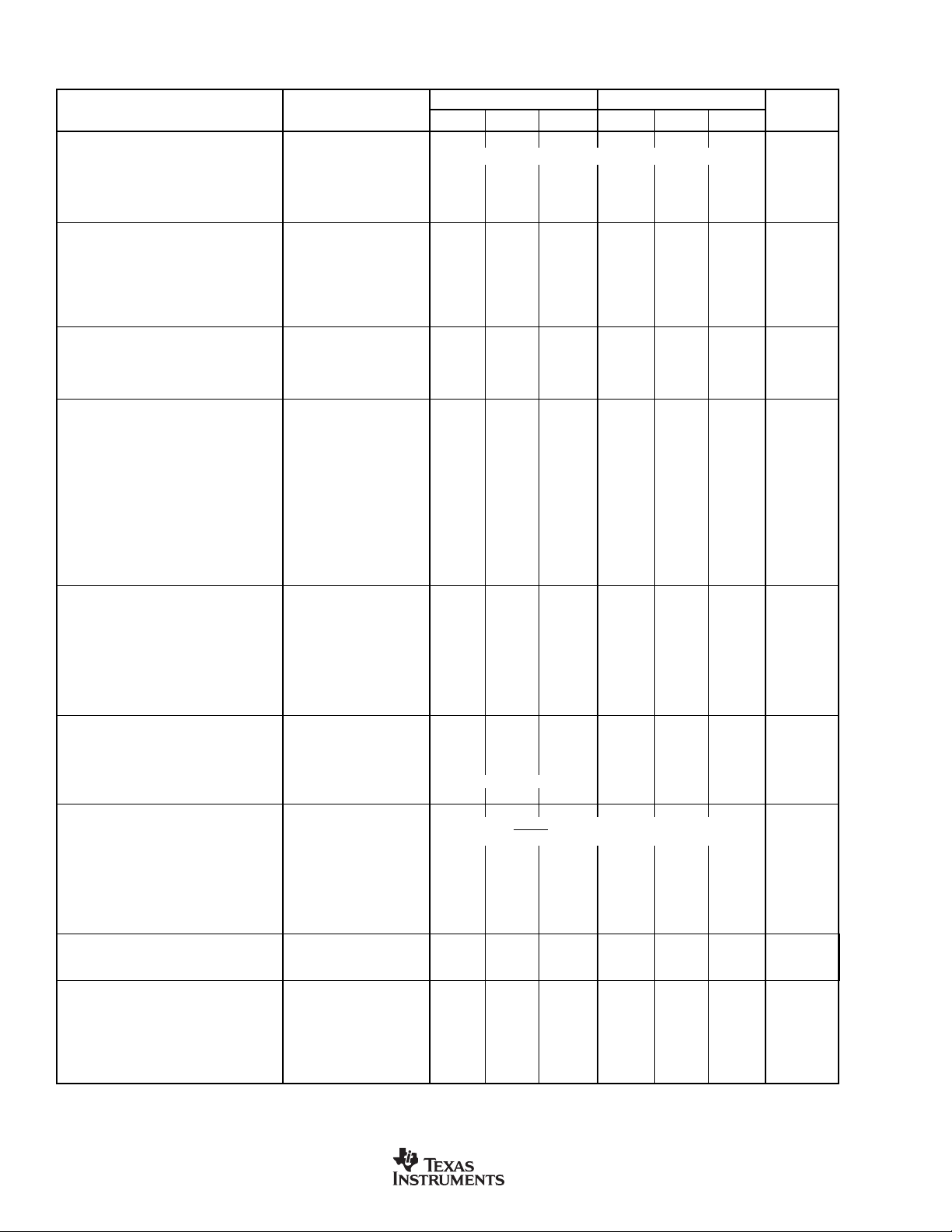

SPECIFICATIONS

At TA = +25°C, V+ = 24V, and TIP29C external transistor, unless otherwise noted.

XTR106P, U XTR106PA, UA

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

OUTPUT

Output Current Equation I

Output Current, Specified Range 4 20 ✻✻mA

Over-Scale Limit I

Under-Scale Limit I

ZERO OUTPUT

(1)

Initial Error ±5 ±25 ✻ ±50 µA

vs Temperature T

vs Supply Voltage, V+ V+ = 7.5V to 36V 0.04 0.2 ✻✻ µA/V

vs Common-Mode Voltage

vs V

(IO) 0.8 ✻ µA/mA

REG

Noise: 0.1Hz to 10Hz i

(CMRR)

OVER

UNDER

I

ZERO

O

I

= 0, I

REG

I

+ I

REF

= 0 1 1.6 2.2 ✻✻✻ mA

REF

= 2.5mA 2.9 3.4 4 ✻✻✻ mA

REG

VIN = 0V, RG = ∞ 4 ✻ mA

= –40°C to +85°C ±0.07 ±0.9 ✻✻ µA/°C

A

VCM = 1.1V to 3.5V

n

(5)

SPAN

Span Equation (Transconductance) S

Untrimmed Error Full Scale (V

vs Temperature

Nonlinearity: Ideal Input

INPUT

Offset Voltage V

vs Temperature T

vs Supply Voltage, V+ V+ = 7.5V to 36V ±0.1 ±3 ✻✻ µV/V

vs Common-Mode Voltage, RTI CMRR V

Common-Mode Range

Input Bias Current I

vs Temperature T

Input Offset Current I

vs Temperature T

Impedance: Differential Z

Noise: 0.1Hz to 10Hz V

VOLTAGE REFERENCES

(2)

(3)

(4)

(5)

Common-Mode 5 || 10 ✻ GΩ || pF

(5)

TA = –40°C to +85°C ±3 ±25 ✻✻ ppm/°C

Full Scale (VIN) = 50mV ±0.001 ±0.01 ✻✻ %

OS

V

CM

OS

IN

= –40°C to +85°C ±0.25 ±1.5 ✻ ±3 µV/°C

A

CM

B

= –40°C to +85°C20 ✻ pA/°C

A

= –40°C to +85°C5 ✻ pA/°C

A

n

Lin Polarity Connected

to V

Initial: 2.5V Reference V

5V Reference V

Accuracy V

vs Temperature T

vs Supply Voltage, V+ V+ = 7.5V to 36V ±5 ±20 ✻✻ ppm/V

vs Load I

Noise: 0.1Hz to 10Hz 10 ✻ µVp-p

(5)

V

REG

Accuracy ±0.02 ±0.1 ✻✻ V

vs Temperature T

vs Supply Voltage, V+ V+ = 7.5V to 36V 1 ✻ mV/V

Output Current I

Output Impedance I

LINEARIZATION

R

(external) Equation R

LIN

K

Linearization Factor K

LIN

(6)

2.5 2.5 ✻ V

REF

55✻ V

V

REF

REG

REG

LIN

LIN

REF

= –40°C to +85°C ±20 ±35 ✻ ±75 ppm/°C

A

REF

= –40°C to +85°C ±0.3 ✻ mV/°C

A

REG

Accuracy ±1 ±5 ✻✻ %

vs Temperature T

Max Correctable Sensor Nonlinearity B V

= –40°C to +85°C ±50 ±100 ✻✻ ppm/°C

A

) = 50mV ±0.05 ±0.2 ✻ ±0.4 %

IN

VCM = 2.5V ±50 ±100 ✻ ±250 µV

= 1.1V to 3.5V

, R

REG

(5)

= 0

LIN

= 2.5V or 5V ±0.05 ±0.25 ✻ ±0.5 %

= 0mA to 2.5mA 60 ✻ ppm/mA

= 0mA to 2.5mA 80 ✻ Ω

V

= 5V 6.645 ✻ kΩ

REF

V

= 2.5V 9.905 ✻ kΩ

REF

= 5V ±5 ✻ % of V

REF

V

= 2.5V –2.5, +5 ✻ % of V

REF

POWER SUPPLY V+

Specified +24 ✻ V

Voltage Range +7.5 +36 ✻✻V

TEMPERATURE RANGE

Specification –40 +85 ✻✻°C

Operating –55 +125 ✻✻°C

Storage –55 +125 ✻✻°C

Thermal Resistance

14-Pin DIP 80 ✻ °C/W

θ

JA

SO-14 Surface Mount 100 ✻ °C/W

✻ Specification same as XTR106P, XTR106U.

NOTES: (1) Describes accuracy of the 4mA low-scale offset current. Does not include input amplifier effects. Can be trimmed to zero. (2) Does not include initial

error or TCR of gain-setting resistor, R

measured with respect to I

pin. (6) See “Linearization” text for detailed explanation. VFS = full-scale VIN.

RET

. (3) Increasing the full-scale input range improves nonlinearity. (4) Does not include Zero Output initial error. (5) Voltage

G

IO = VIN • (40/RG) + 4mA, VIN in Volts, RG in Ω

24 28 30 ✻✻✻ mA

0.02 ✻ µA/V

0.035 ✻ µAp-p

S = 40/R

G

✻ A/V

±10 ±50 ✻ ±100 µV/V

1.1 3.5 ✻✻V

525 ✻ 50 nA

±0.2 ±3 ✻ ±10 nA

0.1 || 1 ✻ GΩ || pF

0.6 ✻ µVp-p

5.1 ✻ V

See Typical Curves ✻ mA

R

= K

LIN

4B

• , K

LIN

1 – 2B

in Ω, B is nonlinearity relative to V

LIN

FS

A

Ω

FS

FS

2

www.ti.com

XTR106

SBOS092A

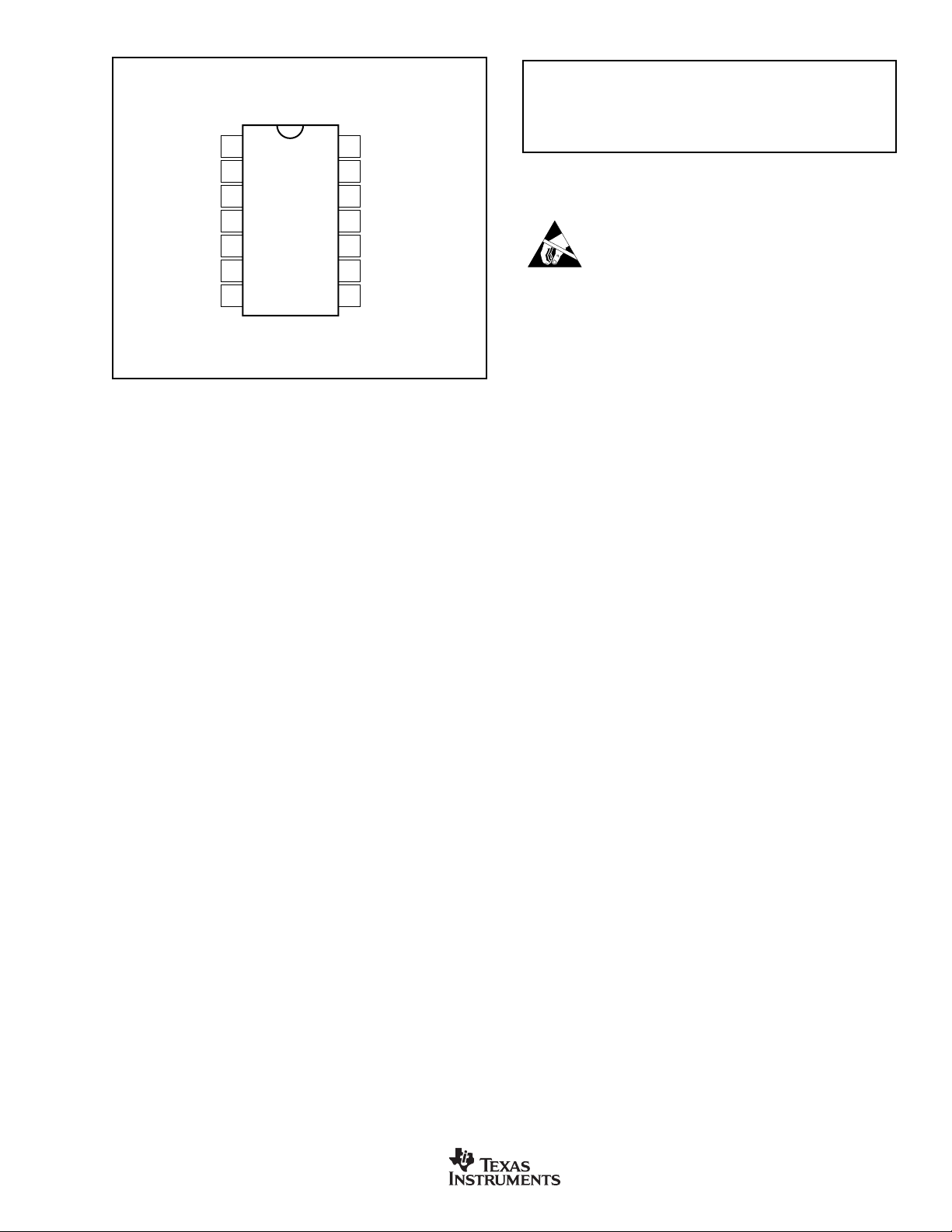

PIN CONFIGURATION

Top View DIP and SOIC

1

V

REG

–

2

V

IN

3

R

G

4

R

G

+

5

V

IN

6

I

RET

7

I

O

14

13

12

11

10

9

8

V

5

REF

V

2.5

REF

Lin Polarity

R

LIN

V+

B (Base)

E (Emitter)

PACKAGE/ORDERING INFORMATION

For the most current package and ordering information, see

the Package Option Addendum at the end of this data sheet.

ABSOLUTE MAXIMUM RATINGS

Power Supply, V+ (referenced to IO pin).......................................... 40V

Input Voltage, V

Storage Temperature Range ....................................... –55°C to +125°C

Lead Temperature (soldering, 10s) .............................................. +300°C

Output Current Limit ............................................................... Continuous

Junction Temperature ................................................................... +165°C

NOTE: (1) Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods may degrade

device reliability.

+

–

, VIN (referenced to I

IN

(1)

pin) ......................... 0V to V+

RET

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

XTR106

SBOS092A

www.ti.com

3

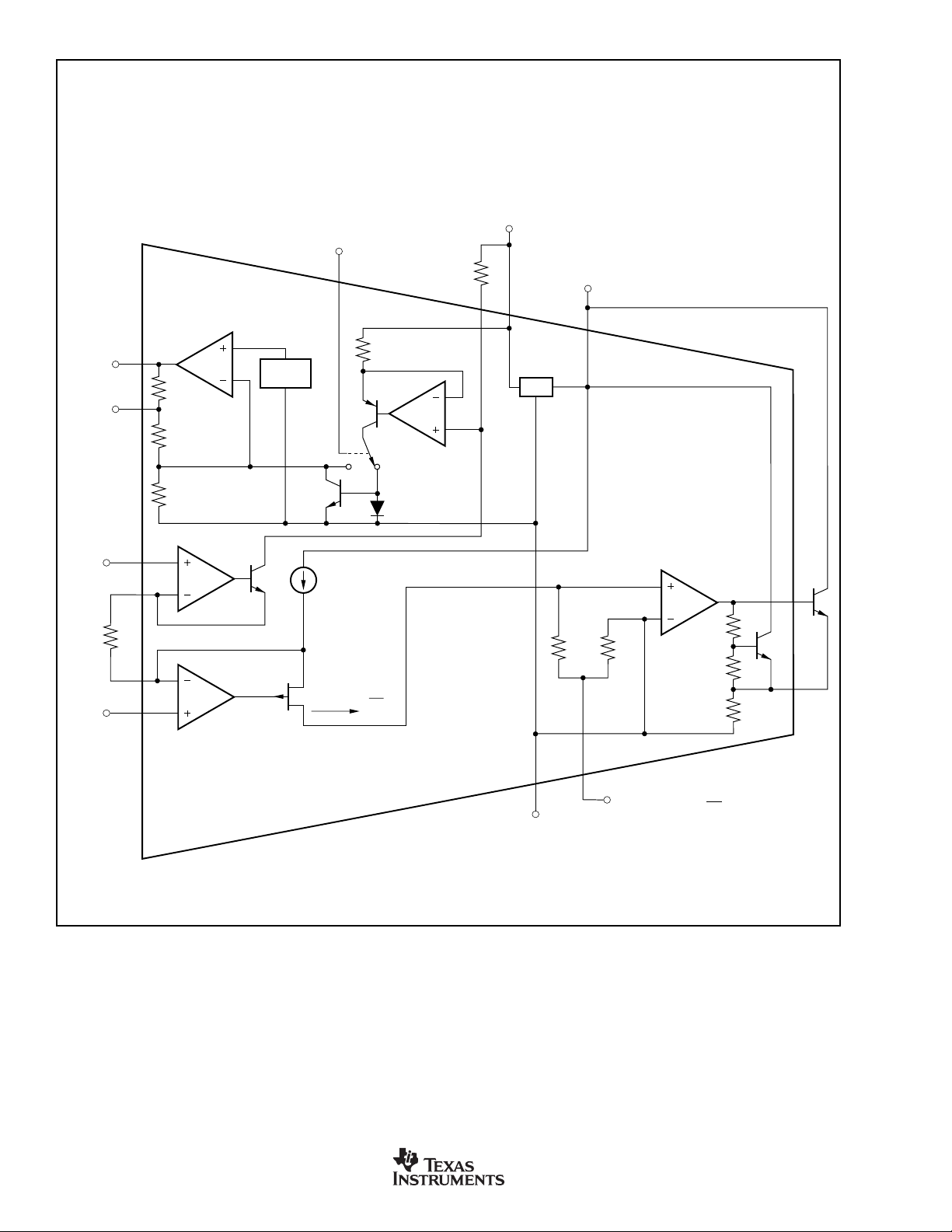

FUNCTIONAL DIAGRAM

Lin

Polarity

V

REG

12

R

LIN

11

1

V+

10

14

V

5

REF

REF

13

2.5

5

+

V

IN

V

4

REF

Amp

Bandgap

V

REF

100µA

Lin

Amp

Current

Direction

Switch

5.1V

B

9

R

G

975

3

V

2

–

V

IN

I = 100µA +

IN

R

G

25

Ω

Ω

E

8

6

I

RET

4

www.ti.com

7

= 4mA + V

I

O

• ( )

IN

40

R

G

XTR106

SBOS092A

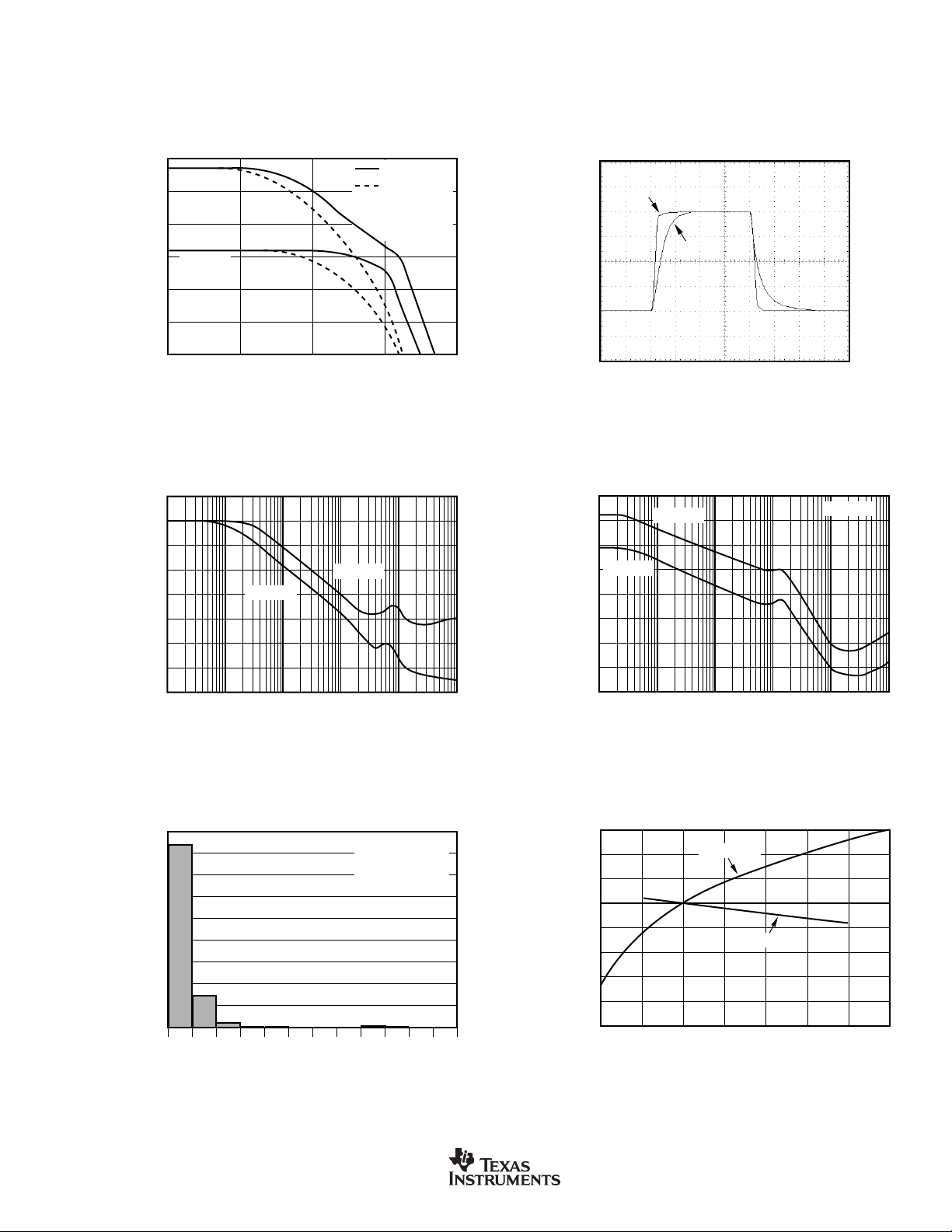

TYPICAL PERFORMANCE CURVES

At TA = +25°C, V+ = 24V, unless otherwise noted.

60

RG = 50Ω

50

40

30

RG = 1kΩ

C

C

OUT

C

OUT

connected

C

OUT

between V+ and I

20

TRANSCONDUCTANCE vs FREQUENCY

10

Transconductance (20 log mA/V)

= 250Ω

R

L

0

100 1k 10k 100k 1M

Frequency (Hz)

COMMON-MODE REJECTION vs FREQUENCY

110

100

90

80

70

RG = 1kΩ

RG = 50Ω

60

50

Common-Mode Rejection (dB)

40

30

10 1k100 10k 100k 1M

Frequency (Hz)

= 0.01µF

= 0.01µF

OUT

= 0.033µF

STEP RESPONSE

C

= 0.01µF

RG = 1kΩ

O

20mA

OUT

RG = 50Ω

4mA/div

4mA

50µs/div

POWER SUPPLY REJECTION vs FREQUENCY

160

140

RG = 50Ω

C

= 0

OUT

120

= 1kΩ

R

G

100

80

60

40

Power Supply Rejection (dB)

20

0

10 1k100 10k 100k 1M

Frequency (Hz)

90

80

70

60

50

40

30

Percent of Units (%)

20

10

0

XTR106

SBOS092A

INPUT OFFSET VOLTAGE DRIFT

PRODUCTION DISTRIBUTION

Typical production

distribution of

packaged units.

1.5

1.0

0.5

INPUT OFFSET VOLTAGE CHANGE

and V

vs V

REG

VOS vs I

CURRENTS

REF

REG

0

(µV)

–0.5

OS

∆ V

–1.0

VOS vs I

REF

–1.5

–2.0

–2.5

0

0.25

0.5

0.75

1.0

1.25

1.5

1.75

2.0

2.25

2.5

2.75

3.0

–1.0 –0.5 0 0.5 1.0 1.5 2.0 2.5

Current (mA)

Offset Voltage Drift (µV/°C)

www.ti.com

5

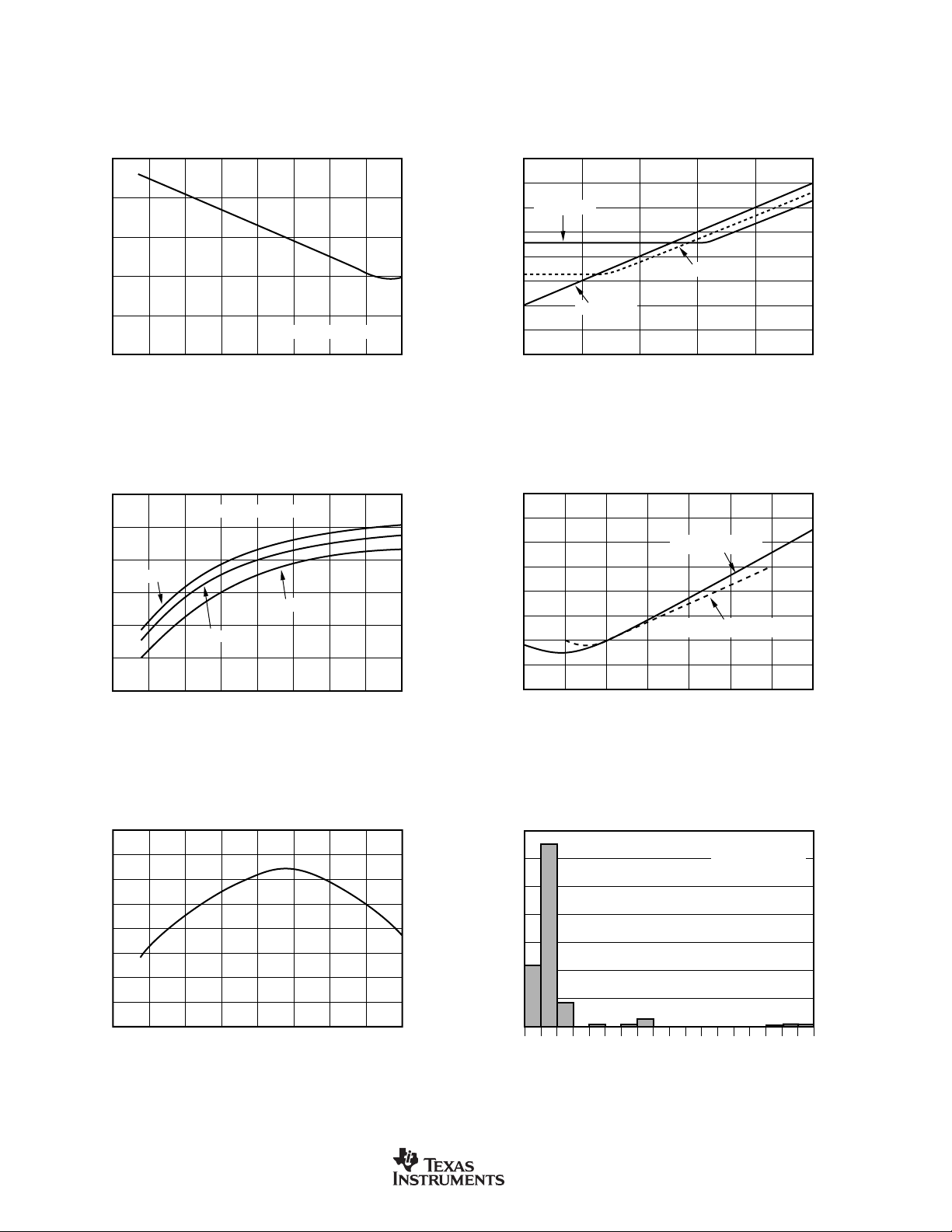

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, V+ = 24V, unless otherwise noted.

2.5

UNDER-SCALE CURRENT vs TEMPERATURE

2.0

1.5

1.0

Under-Scale Current (mA)

0.5

V+ = 7.5V to 36V

0

–75 –50 –25 0 25 50 75 100

Temperature (°C)

OVER-SCALE CURRENT vs TEMPERATURE

30

With External Transistor

29

28

V+ = 36V

27

26

Over-Scale Current (mA)

25

V+ = 24V

V+ = 7.5V

24

–75 –50 –25 0 25 50 75 100

Temperature (°C)

125

125

4.0

UNDER-SCALE CURRENT vs I

REF

3.5

T

3.0

= –55°C

A

2.5

2.0

TA = +25°C

1.5

1.0

Under-Scale Current (mA)

TA = +125°C

0.5

0

0 0.5 1.0 1.5 2.0 2.5

+ I

REG

(mA)

I

REF

ZERO OUTPUT ERROR

3.0

vs V

REF

and V

CURRENTS

REG

2.5

2.0

I

ZERO

Error vs I

1.5

1.0

0.5

0

Zero Output Error (µA)

I

ZERO

Error vs I

–0.5

–1.0

–1 –0.5 0 0.5 1.0 1.5 2.0

Current (mA)

+ I

REG

REG

REF

2.5

ZERO OUTPUT CURRENT ERROR

4

2

0

–2

–4

–6

–8

Zero Output Current Error (µA)

–10

–12

–75 –50 –25 0 25 50 75 100

6

vs TEMPERATURE

Temperature (°C)

125

www.ti.com

70

60

50

40

30

20

Percent of Units (%)

10

0

0

0.1

0.05

0.15

ZERO OUTPUT DRIFT

PRODUCTION DISTRIBUTION

Typical production

distribution of

packaged units.

0.2

0.3

0.4

0.5

0.25

0.35

0.45

0.55

0.6

Zero Output Drift (µA/°C)

0.65

0.7

0.8

0.85

0.9

0.75

XTR106

SBOS092A

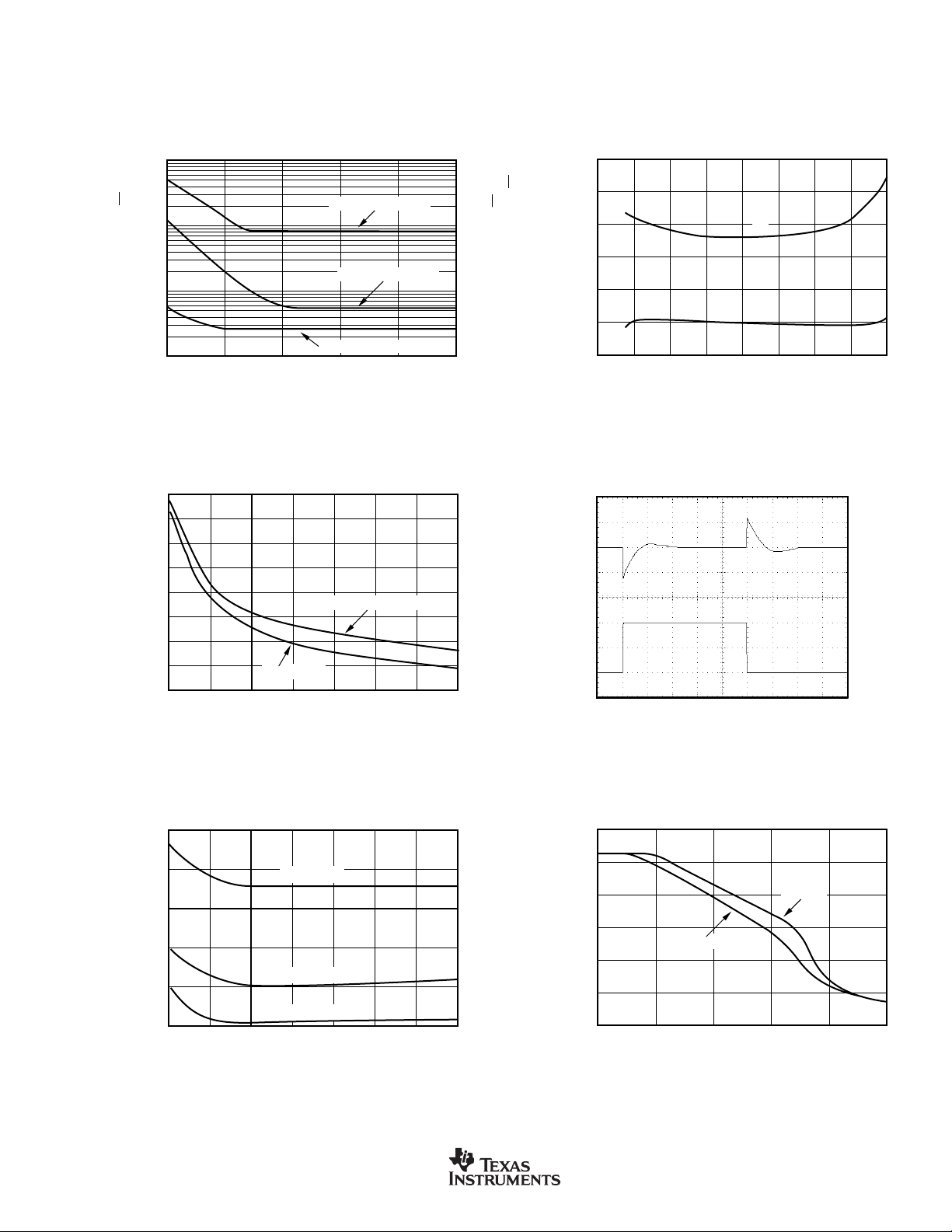

TYPICAL PERFORMANCE CURVES (CONT)

10 100 1k 10k 100k 1M

Frequency (Hz)

REFERENCE AC LINE REJECTION vs FREQUENCY

120

100

80

60

40

20

0

Line Rejection (dB)

V

REF

2.5

V

REF

5

At TA = +25°C, V+ = 24V, unless otherwise noted.

INPUT VOLTAGE, INPUT CURRENT, and ZERO

OUTPUT CURRENT NOISE DENSITY vs FREQUENCY

10k

Zero Output Noise

1k

Input Current Noise

100

Input Voltage Noise (nV/√Hz)

10

Input Voltage Noise

1 10 100 1k 10k

Frequency (Hz)

V

5.6

OUTPUT VOLTAGE vs V

REG

OUTPUT CURRENT

REG

5.5

5.4

5.3

5.2

5.1

Output Current (V)

REG

5.0

V

4.9

TA = +125°C

TA = +25°C, –55°C

4.8

–1.0 –0.5 0 0.5 1.0 1.5 2.0 2.5

Output Current (mA)

V

REG

100k

10k

1k

100

10

Input Current Noise (fA/√Hz)

Zero Output Current Noise (pA/√Hz)

INPUT BIAS and OFFSET CURRENT

vs TEMPERATURE

10

8

6

I

B

4

2

I

0

OS

Input Bias and Offset Current (nA)

–2

–75 –50 –25 0 25 50 75 100 125

Temperature (°C)

REFERENCE TRANSIENT RESPONSE

= 5V

V

REF

50mV/div

500µA/div

10µs/div

Output

Reference

1mA

0

5 vs V

V

REF

5.008

5.004

5.000

5 (V)

REF

V

4.996

4.992

4.988

–1.0 –0.5 0 0.5 1.0 1.5 2.0 2.5

V

REG

XTR106

SBOS092A

OUTPUT CURRENT

REG

T

= +25°C

A

T

= +125°C

A

T

= –55°C

A

Current (mA)

www.ti.com

7

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, V+ = 24V, unless otherwise noted.

40

35

30

25

20

15

Percent of Units (%)

10

5

0

02468

REFERENCE VOLTAGE DRIFT

PRODUCTION DISTRIBUTION

Typical production

distribution of

packaged units.

101214161820222426283032343638

Reference Voltage Drift (ppm/°C)

REFERENCE VOLTAGE DEVIATION

0.1

0

–0.1

–0.2

–0.3

–0.4

Reference Voltage Deviation (%)

–0.5

40

–75 –50 –25 0 25 50 75 100 125

vs TEMPERATURE

V

= 2.5V

REF

Temperature (°C)

V

= 5V

REF

8

www.ti.com

XTR106

SBOS092A

APPLICATIONS INFORMATION

Figure 1 shows the basic connection diagram for the XTR106.

The loop power supply, VPS, provides power for all circuitry.

Output loop current is measured as a voltage across the series

load resistor, RL. A 0.01µF to 0.03µF supply bypass capacitor

connected between V+ and IO is recommended. For applications where fault and/or overload conditions might saturate

the inputs, a 0.03µF capacitor is recommended.

A 2.5V or 5V reference is available to excite a bridge sensor.

For 5V excitation, pin 14 (V

bridge as shown in Figure 1. For 2.5V excitation, connect

pin 13 (V

2.5) to pin 14 as shown in Figure 3b. The output

REF

terminals of the bridge are connected to the instrumentation

amplifier inputs, VIN and VIN. A 0.01µF capacitor is shown

connected between the inputs and is recommended for high

+–

impedance bridges (> 10kΩ). The resistor RG sets the gain

of the instrumentation amplifier as required by the full-scale

bridge voltage, VFS.

Lin Polarity and R

provide second-order linearization

LIN

correction to the bridge, achieving up to a 20:1 improvement

in linearity. Connections to Lin Polarity (pin 12) determine

the polarity of nonlinearity correction and should be connected either to I

nected to V

R

is chosen according to the equation in Figure 1 and is

LIN

REG

dependent on K

or V

RET

even if linearity correction is not desired.

(linearization constant) and the bridge’s

LIN

nonlinearity relative to VFS (see “Linearization” section).

5) should be connected to the

REF

. Lin Polarity should be con-

REG

The transfer function for the complete current transmitter is:

IO = 4mA + VIN • (40/RG)(1)

VIN in Volts, RG in Ohms

where V

is the differential input voltage. As evident from

IN

the transfer function, if no RG is used (RG = ∞), the gain is

zero and the output is simply the XTR106’s zero current.

A negative input voltage, V

, will cause the output current

IN

to be less than 4mA. Increasingly negative VIN will cause the

output current to limit at approximately 1.6mA. If current is

being sourced from the reference and/or V

, the current

REG

limit value may increase. Refer to the Typical Performance

Curves, “Under-Scale Current vs I

REF

+ I

REG

” and “Under-

Scale Current vs Temperature.”

Increasingly positive input voltage (greater than the full-

scale input, VFS) will produce increasing output current

according to the transfer function, up to the output current

limit of approximately 28mA. Refer to the Typical Performance Curve, “Over-Scale Current vs Temperature.”

The I

references and V

is the reference point for V

references. The I

pin is the return path for all current from the

RET

. I

REG

RET

also serves as a local ground and

RET

and the on-board voltage

REG

pin allows any current used in external

circuitry to be sensed by the XTR106 and to be included in

the output current without causing error. The input voltage

range of the XTR106 is referred to this pin.

5V

(5)

R

(5)

R

2

1

Bridge

Sensor

NOTES:

(1) Connect Lin Polarity (pin 12) to I

bridge nonlinearity or connect to V

nonlinearity. The R

V

if linearity correction is not desired. Refer to “Linearization”

REG

section and Figure 3.

(2) Recommended for bridge impedances > 10kΩ

( 3)

= K

R

LIN

R

+ –

B

pin and Lin Polarity pin must be connected to

LIN

4B

•

LIN

1 – 2B

For 2.5V excitation, connect

pin 13 to pin 14

C

IN

(2)

0.01µF

(pin 6) to correct for positive

RET

(pin 1) for negative bridge

REG

in Ω)

(K

LIN

V

REG

V

5

REF

V

2.5

REF

14

13

XTR106

6

11

R

LIN

(1)

Lin

Polarity

12

or

V

5

+

V

IN

4

R

G

(4)

R

G

3

R

G

–

V

2

IN

I

RET

(3)

R

LIN

1

REG

V

REG

(4)

R

(5) R

accuracy of the bridge. See “Bridge Balance” text.

7.5V to 36V

10

V+

9

B

Q

1

E

8

I

O

7

I = 4mA + V

O

(1)

= (VFS/400µA) •

G

where K

and R2 form bridge trim circuit to compensate for the initial

1

IN

= 9.905kΩ for 2.5V reference

LIN

= 6.645kΩ for 5V reference

K

LIN

B is the bridge nonlinearity relative to V

VFS is the full-scale input voltage

Possible choices for Q

C

OUT

0.01µF

40

• ( )

R

G

1 + 2B

1 – 2B

TYPE

2N4922

TIP29C

TIP31C

(V

FS

in V)

PACKAGE

4-20 mA

R

L

(see text).

1

TO-225

TO-220

TO-220

I

O

FS

V

O

+

V

PS

–

FIGURE 1. Basic Bridge Measurement Circuit with Linearization.

XTR106

SBOS092A

www.ti.com

9

EXTERNAL TRANSISTOR

External pass transistor, Q

, conducts the majority of the

1

signal-dependent 4-20mA loop current. Using an external

transistor isolates the majority of the power dissipation from

the precision input and reference circuitry of the XTR106,

maintaining excellent accuracy.

Since the external transistor is inside a feedback loop its

characteristics are not critical. Requirements are: V

CEO

= 45V

min, β = 40 min and PD = 800mW. Power dissipation requirements may be lower if the loop power supply voltage is less

than 36V. Some possible choices for Q1 are listed in Figure 1.

The XTR106 can be operated without an external pass

transistor. Accuracy, however, will be somewhat degraded

due to the internal power dissipation. Operation without Q

is not recommended for extended temperature ranges. A

resistor (R = 3.3kΩ) connected between the I

pin and the

RET

E (emitter) pin may be needed for operation below 0°C

without Q1 to guarantee the full 20mA full-scale output,

especially with V+ near 7.5V.

10

V+

8

E

I

RET

XTR106

6

= 3.3kΩ

R

Q

I

O

7

0.01µF

For operation without external

transistor, connect a 3.3kΩ

resistor between pin 6 and

pin 8. See text for discussion

of performance.

FIGURE 2. Operation without External Transistor.

LOOP POWER SUPPLY

The voltage applied to the XTR106, V+, is measured with

respect to the IO connection, pin 7. V+ can range from 7.5V

to 36V. The loop supply voltage, VPS, will differ from the

voltage applied to the XTR106 according to the voltage drop

on the current sensing resistor, RL (plus any other voltage

drop in the line).

If a low loop supply voltage is used, RL (including the loop

wiring resistance) must be made a relatively low value to

assure that V+ remains 7.5V or greater for the maximum

loop current of 20mA:

RLmax =

(V+)–7.5V

20mA

–R

WIRING

(2)

It is recommended to design for V+ equal or greater than

7.5V with loop currents up to 30mA to allow for out-ofrange input conditions. V+ must be at least 8V if 5V sensor

excitation is used and if correcting for bridge nonlinearity

greater than +3%.

The low operating voltage (7.5V) of the XTR106 allows

operation directly from personal computer power supplies

(12V ±5%). When used with the RCV420 Current Loop

Receiver (Figure 8), load resistor voltage drop is limited to 3V.

BRIDGE BALANCE

Figure 1 shows a bridge trim circuit (R1, R2). This adjustment can be used to compensate for the initial accuracy of

the bridge and/or to trim the offset voltage of the XTR106.

The values of R1 and R2 depend on the impedance of the

bridge, and the trim range required. This trim circuit places

an additional load on the V

load on V

does not affect zero output. See the Typical

REF

output. Be sure the additional

REF

Performance Curve, “Under-Scale Current vs I

1

The effective load of the trim circuit is nearly equal to R2.

An approximate value for R1 can be calculated:

5V • R

R1≈

4 • V

B

TRIM

where, RB is the resistance of the bridge.

V

is the desired ±voltage trim range (in V).

TRIM

Make R2 equal or lower in value to R1.

LINEARIZATION

Many bridge sensors are inherently nonlinear. With the

addition of one external resistor, it is possible to compensate

for parabolic nonlinearity resulting in up to 20:1 improvement over an uncompensated bridge output.

Linearity correction is accomplished by varying the bridge

excitation voltage. Signal-dependent variation of the bridge

excitation voltage adds a second-order term to the overall

transfer function (including the bridge). This can be tailored

to correct for bridge sensor nonlinearity.

Either positive or negative bridge non-linearity errors can be

compensated by proper connection of the Lin Polarity pin.

To correct for positive bridge nonlinearity (upward bowing),

Lin Polarity (pin 12) should be connected to I

shown in Figure 3a. This causes V

to increase with bridge

REF

output which compensates for a positive bow in the bridge

response. To correct negative nonlinearity (downward bowing), connect Lin Polarity to V

3b. This causes V

to decrease with bridge output. The Lin

REF

(pin 1) as shown in Figure

REG

Polarity pin is a high impedance node.

If no linearity correction is desired, both the R

Polarity pins should be connected to V

(Figure 3c). This

REG

results in a constant reference voltage independent of input

signal. R

or Lin Polarity pins should not be left open

LIN

or connected to another potential.

R

is the external linearization resistor and is connected

LIN

between pin 11 and pin 1 (V

3b. To determine the value of R

) as shown in Figures 3a and

REG

, the nonlinearity of the

LIN

bridge sensor with constant excitation voltage must be

known. The XTR106’s linearity circuitry can only compensate for the parabolic-shaped portions of a sensor’s

nonlinearity. Optimum correction occurs when maximum

deviation from linear output occurs at mid-scale (see Figure

4). Sensors with nonlinearity curves similar to that shown in

+ I

REF

(pin 6) as

RET

and Lin

LIN

REG

.”

(3)

10

www.ti.com

XTR106

SBOS092A

Figure 4, but not peaking exactly at mid-scale can be

substantially improved. A sensor with a “S-shaped”

nonlinearity curve (equal positive and negative nonlinearity)

cannot be improved with the XTR106’s correction circuitry.

The value of R

in Figure 3. R

K

, which differs for the 2.5V reference and 5V reference.

LIN

is chosen according to Equation 4 shown

LIN

is dependent on a linearization factor,

LIN

The sensor’s nonlinearity term, B (relative to full scale), is

positive or negative depending on the direction of the bow.

V

REG

V

5

REF

5V

R

R

2

1

+ –

3a. Connection for Positive Bridge Nonlinearity, V

V

2.5

REF

2.5V

R

R

2

1

+ –

3b. Connection for Negative Bridge Nonlinearity, V

V

5

REF

5V

R

R

2

1

+ –

3c. Connection if no linearity correction is desired, V

V

2.5

REF

14

+

–

5

+

–

+

–

REF

6

14

6

REF

V

14

6

REF

13

XTR106

I

RET

= 5V

13

XTR106

= 2.5V

2.5

REF

13

XTR106

= 5V

5

4

R

G

3

2

V

REF

5

4

R

G

3

2

I

RET

5

4

R

G

3

2

I

RET

V

V

1

12

REG

12

REG

12

Lin

Polarity

1

Lin

Polarity

1

Lin

Polarity

R

LIN

11

R

LIN

11

R

LIN

11

A maximum ±5% non-linearity can be corrected when the

5V reference is used. Sensor nonlinearity of +5%/–2.5% can

be corrected with 2.5V excitation. The trim circuit shown in

Figure 3d can be used for bridges with unknown bridge

nonlinearity polarity.

Gain is affected by the varying excitation voltage used to

correct bridge nonlinearity. The corrected value of the gain

resistor is calculated from Equation 5 given in Figure 3.

XTR106

V

Lin

Polarity

I

RET

6

R

X

100kΩ

Open RX for negative bridge nonlinearity

Open R

for positive bridge nonlinearity

Y

3d. On-Board Resistor Circuit for Unknown Bridge Nonlinearity Polarity

EQUATIONS

Linearization Resistor:

R

= K

LIN

4B

•

LIN

1– 2B

Gain-Set Resistor:

V

1+ 2B

FS

RG=

400µA

•

1– 2B

Adjusted Excitation Voltage at Full-Scale Output:

V

where, K

REF(Adj)

= V

REF(Initial)

is the linearization factor (in Ω)

LIN

K

= 9905Ω for the 2.5V reference

LIN

K

= 6645Ω for the 5V reference

LIN

B is the sensor nonlinearity relative to V

(for –2.5% nonlinearity, B = –0.025)

V

is the full-scale bridge output without

FS

linearization (in V)

•

1+ 2B

1– 2B

Example:

Calculate R

2.5% downward bow nonlinearity relative to V

if the input common-mode range is valid.

V

REF

For a 2.5% downward bow, B = –0.025

(Lin Polarity pin connected to V

For V

R

LIN

RG=

VCM=

which falls within the 1.1V to 3.5V input common-mode range.

and the resulting RG for a bridge sensor with

LIN

= 2.5V and VFS = 50mV

= 2.5V, K

REF

(9905Ω)(4)(–0.025)

=

1– (2)(–0.025)

0.05V

400µA

V

REF(Adj)

2

= 9905Ω

LIN

1+ (2)( –0.025)

•

1– (2)(–0.025)

1

=

• 2. 5V •

2

REG

1

12

R

Y

15kΩ

(in Ω)

(in Ω)

(in V)

)

REG

= 943Ω

= 113Ω

1+ (2)( –0.025)

1– (2)(–0.025)

FS

and determine

FS

= 1.1 3V

(4)

(5)

(6)

FIGURE 3. Connections and Equations to Correct Positive and Negative Bridge Nonlinearity.

XTR106

SBOS092A

www.ti.com

11

When using linearity correction, care should be taken to

insure that the sensor’s output common-mode voltage remains within the XTR106’s allowable input range of 1.1V to

3.5V. Equation 6 in Figure 3 can be used to calculate the

XTR106’s new excitation voltage. The common-mode voltage of the bridge output is simply half this value if no

common-mode resistor is used (refer to the example in

Figure 3). Exceeding the common-mode range may yield

unpredicatable results.

For high precision applications (errors < 1%), a two-step

calibration process can be employed. First, the nonlinearity

of the sensor bridge is measured with the initial gain resistor

and R

the resulting sensor nonlinearity, B, values for RG and R

LIN

= 0 (R

pin connected directly to V

LIN

REG

). Using

LIN

are calculated using Equations 4 and 5 from Figure 3. A

second calibration measurement is then taken to adjust RG to

account for the offsets and mismatches in the linearization.

UNDER-SCALE CURRENT

The total current being drawn from the V

REF

and V

REG

voltage sources, as well as temperature, affect the XTR106’s

under-scale current value (see the Typical Performance

Curve, “Under-Scale Current vs I

REF

+ I

). This should be

REG

considered when choosing the bridge resistance and excitation voltage, especially for transducers operating over a

wide temperature range (see the Typical Performance Curve,

“Under-Scale Current vs Temperature”).

LOW IMPEDANCE BRIDGES

The XTR106’s two available excitation voltages (2.5V and

5V) allow the use of a wide variety of bridge values. Bridge

impedances as low as 1kΩ can be used without any additional circuitry. Lower impedance bridges can be used with

the XTR106 by adding a series resistance to limit excitation

current to ≤ 2.5mA (Figure 5). Resistance should be added

BRIDGE TRANSDUCER TRANSFER FUNCTION

10

9

8

7

6

5

4

3

Bridge Output (mV)

2

1

0

0

WITH PARABOLIC NONLINEARITY

Positive Nonlinearity

B = +0.025

B = –0.019

Negative Nonlinearity

Linear Response

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Normalized Stimulus

FIGURE 4. Parabolic Nonlinearity.

700µA at 5V

I

≈ 1.6mA

1/2

OPA2277

412Ω

1/2

OPA2277

amplifier

REG

10kΩ

10kΩ

3.4kΩ

5V

350Ω

3.4kΩ

Bridge excitation

voltage = 0.245V

Approx. x50

FIGURE 5. 350Ω Bridge with x50 Preamplifier.

1kΩ

V

R

125Ω

3

2

1

0

–1

–2

Nonlinearity (% of Full Scale)

–3

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

5

REF

V

2.5

V

REF

REG

14

13

5

+

V

IN

4

R

G

G

XTR106

3

R

G

–

V

IN

2

I

RET

1

Polarity

6

Lin

R

11

V+

I

12

NONLINEARITY vs STIMULUS

Positive Nonlinearity

B = +0.025

Negative Nonlinearity

Normalized Stimulus

I

= 0.7mA + 1.6mA ≤ 2.5mA

TOTAL

LIN

10

9

B

E

8

O

7

Shown connected to correct positive

bridge nonlinearity. For negative bridge

nonlinearity, see Figure 3b.

1N4148

0.01µF

IO = 4-20mA

B = –0.019

12

www.ti.com

XTR106

SBOS092A

to the upper and lower sides of the bridge to keep the bridge

output within the 1.1V to 3.5V common-mode input range.

Bridge output is reduced so a preamplifier as shown may be

needed to reduce offset voltage and drift.

OTHER SENSOR TYPES

The XTR106 can be used with a wide variety of inputs. Its

high input impedance instrumentation amplifier is versatile

and can be configured for differential input voltages from

millivolts to a maximum of 2.4V full scale. The linear range

of the inputs is from 1.1V to 3.5V, referenced to the I

RET

terminal, pin 6. The linearization feature of the XTR106 can

ERROR ANALYSIS

Table I shows how to calculate the effect various error

sources have on circuit accuracy. A sample error calculation

for a typical bridge sensor measurement circuit is shown

(5kΩ bridge, V

= 5V, VFS = 50mV) is provided. The

REF

results reveal the XTR106’s excellent accuracy, in this case

1.2% unadjusted. Adjusting gain and offset errors improves

circuit accuracy to 0.33%. Note that these are worst-case

errors; guaranteed maximum values were used in the calculations and all errors were assumed to be positive (additive).

The XTR106 achieves performance which is difficult to

obtain with discrete circuitry and requires less board space.

be used with any sensor whose output is ratiometric with an

excitation voltage.

SAMPLE ERROR CALCULATION

Bridge Impedance (RB)5kΩ Full Scale Input (VFS) 50mV

Ambient Temperature Range (∆T

Supply Voltage Change (∆V+) 5V Common-Mode Voltage Change (∆CM) 25mV (= V

ERROR SOURCE ERROR EQUATION ERROR CALCULATION UNADJ ADJUST

INPUT

Input Offset Voltage V

vs Common-Mode CMRR • ∆CM/VFS • 10

vs Power Supply (V

Input Bias Current CMRR • I

Input Offset Current IOS • RB/VFS • 10

EXCITATION

Voltage Reference Accuracy V

vs Supply (V

GAIN

Span Span Error (%)/100% • 10

Nonlinearity Nonlinearity (%)/100% • 10

OUTPUT

Zero Output | I

vs Supply (I

DRIFT (∆T

= 20°C)

A

Input Offset Voltage Drift • ∆T

Input Offset Current (typical) Drift • ∆TA• RB/(VFS) • 10

Voltage Refrence Accuracy 35ppm/°C • 20°C 700 700

Span 225ppm/°C • 20°C 500 500

Zero Output Drift • ∆T

NOISE (0.1Hz to 10Hz, typ)

Input Offset Voltage V

Zero Output I

Thermal R

Noise

B

Input Current Noise (i

NOTE (1): All errors are min/max and referred to input, unless otherwise stated.

)20°C Excitation Voltage (V

A

SAMPLE

6

• 10

OS/VFS

vs V+) • (∆V+)/VFS • 10

OS

• (RB/2)/VFS • 10

B

Accuracy (%)/100% • 10

REF

vs V+) • (∆V+) • (VFS/V

REF

– 4mA | /16000 µA • 10

ZERO

vs V+) • (∆V+)/16000µA • 10

ZERO

/(VFS) • 10

A

/16000µA • 10

A

(p-p)/VFS • 10

n

Noise/ 16000µA • 10

ZERO

6

6

6

6

6

) 20ppm/V • 5V (50mV/5V) 1 1

REF

6

6

6

6

6

6

6

6

6

[√2 • √ (RB/2)/1kΩ • 4nV / √Hz • √ 10Hz]/ VFS • 10

• 40.8 • √2 • RB/2)/VFS •

n

6

10

)5V

REF

200µV/50mV • 10

50µV/V • 0.025V/50mV • 10

3µV/V • 5V/50mV • 10

50µV/V • 25nA • 2.5kΩ/50mV • 10

3nA • 5kΩ/50mV • 10

0.25%/100% • 10

0.2%/100% • 10

0.01%/100% • 10

25µA/16000µA • 10

0.2µA/V • 5V/16000µA • 10

1.5µV/°C • 20°C / (50mV) • 10

5pA/ °C • 20°C • 5kΩ/ (50mV) • 10

0.9µA/°C • 20°C/16000µA • 10

0.6µV/ 50mV • 10

6

[√2 • √ 2.5kΩ/1kΩ • 4nV/ √Hz • √ 10Hz ] / 50mV • 10

0.035µA/16000µA • 10

(200fA/√Hz • 40.8 • √2 • 2.5kΩ)/50mV• 10

/2)

FS

6

6

6

6

6

Total Input Error 2625 325

6

Total Excitation Error 2501 1

6

6

Total Gain Error 2100 100

6

6

Total Output Error 1626 63

6

6

6

Total Drift Error 2936 2936

6

6

6

6

Total Noise Error 15 15

TOTAL ERROR: 11803 3340

1.18% 0.33%

ERROR

(ppm of Full Scale)

2000 0

25 25

300 300

0.1 0

300 0

2500 0

2000 0

100 100

1563 0

62.5 62.5

600 600

10 10

1125 1125

12 12

2.2 2.2

0.6 0.6

0.6 0.6

TABLE I. Error Calculation.

XTR106

SBOS092A

www.ti.com

13

REVERSE-VOLTAGE PROTECTION

The XTR106’s low compliance rating (7.5V) permits the

use of various voltage protection methods without compromising operating range. Figure 6 shows a diode bridge

circuit which allows normal operation even when the voltage connection lines are reversed. The bridge causes a two

diode drop (approximately 1.4V) loss in loop supply voltage. This results in a compliance voltage of approximately

9V—satisfactory for most applications. A diode can be

inserted in series with the loop supply voltage and the V+

pin as shown in Figure 8 to protect against reverse output

connection lines with only a 0.7V loss in loop supply

voltage.

OVER-VOLTAGE SURGE PROTECTION

Remote connections to current transmitters can sometimes be

subjected to voltage surges. It is prudent to limit the maximum

surge voltage applied to the XTR106 to as low as practical.

Various zener diode and surge clamping diodes are specially

designed for this purpose. Select a clamp diode with as low a

voltage rating as possible for best protection. For example, a

36V protection diode will assure proper transmitter operation

at normal loop voltages, yet will provide an appropriate level

of protection against voltage surges. Characterization tests on

three production lots showed no damage to the XTR106 with

loop supply voltages up to 65V.

Most surge protection zener diodes have a diode characteristic in the forward direction that will conduct excessive

current, possibly damaging receiving-side circuitry if the

loop connections are reversed. If a surge protection diode is

used, a series diode or diode bridge should be used for

protection against reversed connections.

RADIO FREQUENCY INTERFERENCE

The long wire lengths of current loops invite radio frequency interference. RF can be rectified by the sensitive

input circuitry of the XTR106 causing errors. This generally

appears as an unstable output current that varies with the

position of loop supply or input wiring.

If the bridge sensor is remotely located, the interference may

enter at the input terminals. For integrated transmitter assemblies with short connection to the sensor, the interference more likely comes from the current loop connections.

Bypass capacitors on the input reduce or eliminate this input

interference. Connect these bypass capacitors to the I

RET

terminal as shown in Figure 6. Although the dc voltage at

the I

terminal is not equal to 0V (at the loop supply, VPS)

RET

this circuit point can be considered the transmitter’s “ground.”

The 0.01µF capacitor connected between V+ and IO may

help minimize output interference.

V

5

+ –

Bridge

Sensor

5V

REF

R

B

R

G

0.01µF0.01µF

V

2.5

REF

14

5

4

3

2

13

+

V

IN

R

G

XTR106

R

G

–

V

IN

I

RET

6

10

V+

9

B

E

8

I

O

7

NOTE: (1) Zener Diode 36V: 1N4753A or Motorola

P6KE39A. Use lower voltage zener diodes with loop

power supply voltages less than 30V for increased

protection. See “Over-Voltage Surge Protection.”

0.01µF

Q

1

FIGURE 6. Reverse Voltage Operation and Over-Voltage Surge Protection.

(1)

D

1

1N4148

Diodes

The diode bridge causes

a 1.4V loss in loop supply

voltage.

Maximum V

less than minimum

voltage rating of zener

diode.

R

L

must be

PS

V

PS

14

www.ti.com

XTR106

SBOS092A

Type K

Isothermal

Block

1N4148

6kΩ

50Ω

4.8kΩ

5.2kΩ

100Ω

1MΩ

V

5

REF

0.01µF

See ISO124 data sheet

if isolation is needed.

1MΩ

20kΩ

OPA277

(1)

R

1kΩ

V

2.5

REF

14

13

I

RET

11

R

LIN

XTR106

Lin

Polarity

1

V

REG

12

5

+

V

IN

4

R

G

G

3

R

G

–

V

2

IN

6

V

REG

7.5V to 36V

10

V+

9

Q

B

1

E

8

I

O

7

IO = 4mA + VIN • ( )

(pin 1)

C

OUT

0.01µF

40

R

G

4-20 mA

R

L

I

O

V

O

+

V

PS

–

2kΩ

NOTE: (1) For burn-out indication.

0.01µF

FIGURE 7. Thermocouple Low Offset, Low Drift Loop Measurement with Diode Cold-Junction Compensation.

V

2.5

Bridge

Sensor

2.5V

– +

R

B

REF

5

V

REF

14

+

V

5

IN

4

R

G

R

G

3

R

G

–

2

V

IN

I

RET

6

13

XTR106

Lin

Polarity

V

REG

R

LIN

1

11

10

1N4148

See ISO124 data sheet

if isolation is needed.

+12V

1µF

V+

9

B

8

E

I

O

0.01µF

7

12

IO = 4-20mA

3

2

16

10

11

RCV420

4

1µF

12

15

V

14

O

13

5

= 0V to 5V

NOTE: Lin Polarity shown connected to correct positive bridge

nonlinearity. See Figure 3b to correct negative bridge nonlinearity.

FIGURE 8. ±12V-Powered Transmitter/Receiver Loop.

XTR106

SBOS092A

www.ti.com

–12V

15

PACKAGE OPTION ADDENDUM

www.ti.com

22-Oct-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

XTR106P ACTIVE PDIP N 14 25 Green (RoHS &

no Sb/Br)

XTR106PA ACTIVE PDIP N 14 25 Green (RoHS &

no Sb/Br)

XTR106PAG4 ACTIVE PDIP N 14 25 Green (RoHS &

no Sb/Br)

XTR106PG4 ACTIVE PDIP N 14 25 Green(RoHS &

no Sb/Br)

XTR106U ACTIVE SOIC D 14 58 Green (RoHS &

no Sb/Br)

XTR106U/2K5 ACTIVE SOIC D 14 2500 Green (RoHS &

no Sb/Br)

XTR106U/2K5E4 ACTIVE SOIC D 14 2500 Green (RoHS &

no Sb/Br)

XTR106UA ACTIVE SOIC D 14 58 Green (RoHS &

no Sb/Br)

XTR106UA/2K5 ACTIVE SOIC D 14 2500 Green (RoHS &

no Sb/Br)

XTR106UA/2K5E4 ACTIVE SOIC D 14 2500 Green (RoHS &

no Sb/Br)

XTR106UAG4 ACTIVE SOIC D 14 58 Green (RoHS &

no Sb/Br)

XTR106UE4 ACTIVE SOIC D 14 58 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU N / A for Pkg Type

CU NIPDAU N / A for Pkg Type

CU NIPDAU N / A for Pkg Type

CU NIPDAU N / A for Pkg Type

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

22-Oct-2007

Addendum-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com

TAPE AND REEL INFORMATION

11-Mar-2008

*All dimensions are nominal

Device Package

XTR106U/2K5 SOIC D 14 2500 330.0 16.4 6.5 9.0 2.1 8.0 16.0 Q1

XTR106UA/2K5 SOIC D 14 2500 330.0 16.4 6.5 9.0 2.1 8.0 16.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

11-Mar-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

XTR106U/2K5 SOIC D 14 2500 346.0 346.0 33.0

XTR106UA/2K5 SOIC D 14 2500 346.0 346.0 33.0

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...