Page 1

查询DEM-VSP2262Y供应商

www.ti.com

CCD SIGNAL PROCESSOR for

VSP2262

VSP2262

DIGITAL CAMERAS

FEATURES

● CCD SIGNAL PROCESSING:

Correlated Double Sampling (CDS)

Programmable Black Level Clamping

● PROGRAMMABLE GAIN AMPLIFIER (PGA):

–6dB to +42dB Gain Ranging

● 12-BIT DIGITAL DATA OUTPUT:

Up to 20MHz Conversion Rate

No Missing Codes

● 79dB SIGNAL-TO-NOISE RATIO

● PORTABLE OPERATION:

Low Voltage: 2.7V to 3.6V

Low Power: 83mW (typ) at 3.0V

Stand-By Mode: 6mW

SHPCLPDM SHD SLOAD SCLK SDATA

Serial Interface

Input

Clamp

DESCRIPTION

The VSP2262 is a complete mixed-signal processing

IC for digital cameras, providing signal conditioning

and Analog-to-Digital (A/D) conversion for the output

of a CCD array. The primary CCD channel provides

Correlated Double Sampling (CDS) to extract video

information from the pixels, –6dB to +42dB gain

range with digital control for varying illumination

conditions, and black level clamping for an accurate

black level reference. Input signal clamping and offset

correction of the input CDS are also performed. The

stable gain control is linear in dB. Additionally, the

black level is quickly recovered after gain change. The

VSP2262Y is available in an LQFP-48 package and

operates from a single +3V/+3.3V supply.

RESET

Timing

Control

ADCCK

DRV

V

DD

CC

PBLK

Correlated

Double

Sampling

(CDS)

Optical Black (OB)

Level Clamping

COB

CCDIN

CCD

Output

Signal

Copyright © 2000, Texas Instruments Incorporated SBMS011 Printed in U.S.A. November, 2000

Preblanking

Programmable

Amplifier

CLPOB

Gain

(PGA)

–6dB

to

+42dB

Reference Voltage Generator

BYPP2 BYP BYPM REFN CM REFP DRVGND GNDA

Analog-

to-

Digital

Converter

Output

Latch

12-Bit

Digital

Output

B[11:0]

Page 2

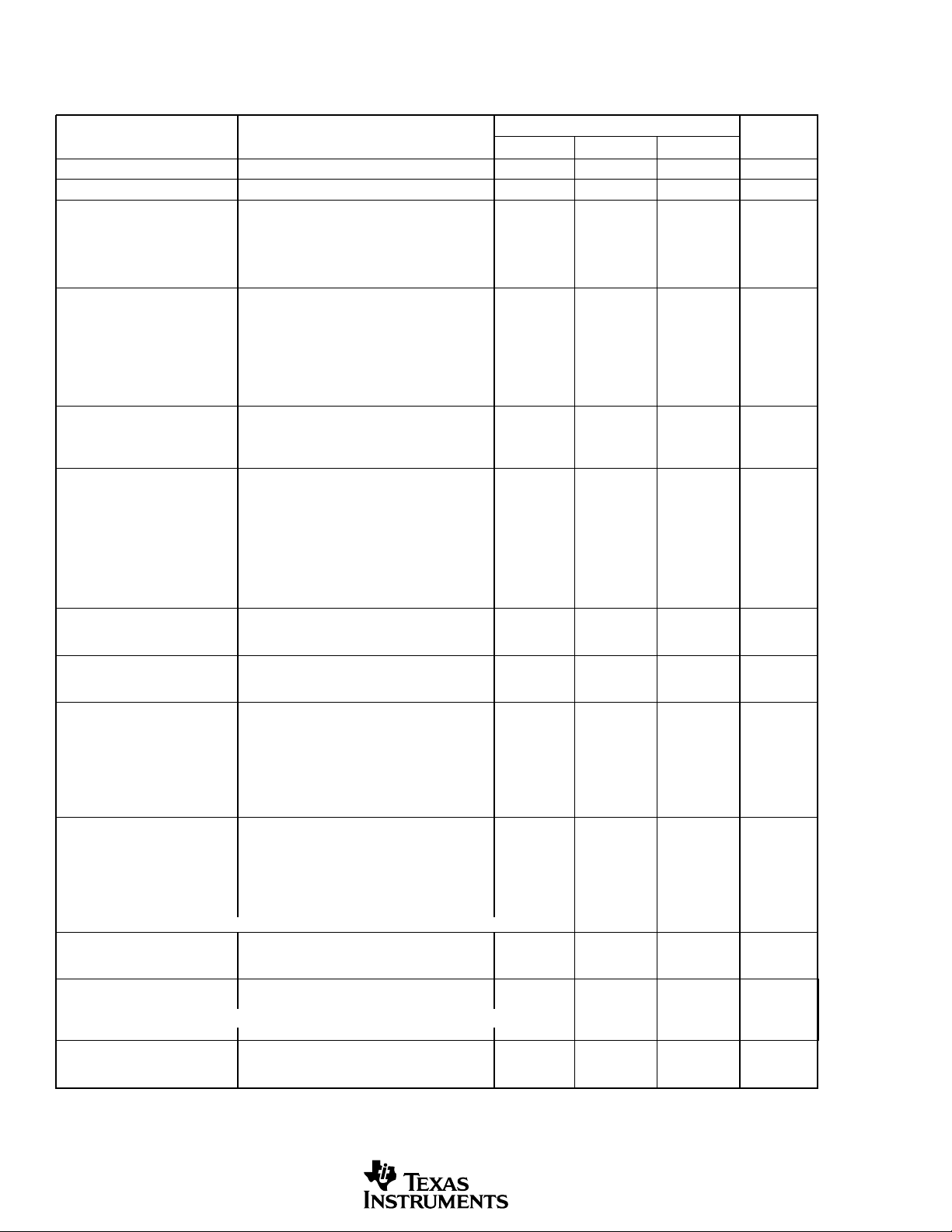

SPECIFICATIONS

At TA = +25°C, VCC = +3.0V, DRVDD = +3.0V, Conversion Rate (f

PARAMETER CONDITIONS MIN TYP MAX UNITS

RESOLUTION 12 Bits

CONVERSION RATE 20 MHz

DIGITAL INPUT

Logic Family TTL

Input Voltage LOW to HIGH Threshold Voltage (VT+) 1.7 V

HIGH to LOW Threshold Voltage (VT–) 1.0 V

Input Current Logic HIGH (I

Logic LOW (I

DIGITAL OUTPUT

Logic Family CMOS

Logic Coding Straight Binary

Output Voltage Logic HIGH (V

Logic LOW (V

ADCCK Clock Duty Cycle 50 %

Input Capacitance 5pF

Maximum Input Voltage –0.3 5.3 V

ANALOG INPUT (CCDIN)

Input Signal Level for Full-Scale Out

PGA Gain = 0dB 900 mV

Input Capitance 15 pF

Input Limit –0.3 3.3 V

TRANSFER CHARACTERISTICS

Differential Non-Linearity (DNL) PGA Gain = 0dB ±0.5 LSB

Integral Non-Linearity (INL) PGA Gain = 0dB ±1 LSB

No Missing Codes Guaranteed

Step Response Settling Time Full-Scale Step Input 1 Pixel

Overload Recovery Time Step Input from 1.8V to 0V 2 Pixels

Data Latency 9 (Fixed) Clock Cycles

Signal-to-Noise Ratio

(1)

Grounded Input Cap, PGA Gain = 0dB 79 dB

Grounded Input Cap, Gain = +24dB 55 dB

CCD Offset Correction Range –180 200 mV

CDS

Reference Sample Settling Time Within 1LSB, Driver Impedance = 50Ω 11 ns

Data Sample Settling Time Within 1LSB, Driver Impedance = 50Ω 11 ns

INPUT CLAMP

Clamp-On Resistance 400 Ω

Clamp Level 1.5 V

PROGRAMMABLE GAIN AMP (PGA)

Gain-Control Resolution 10 Bits

Maximum Gain Gain Code = 1111111111 42 dB

High Gain Gain Code = 1101001000 34 dB

Medium Gain Gain Code = 1000100000 20 dB

Low Gain Gain Code = 0010000000 0 dB

Minimum Gain Gain Code = 0000000000 –6dB

Gain Control Error ±0.5 dB

OPTICAL BLACK CLAMP LOOP

Control DAC Resolution 10 Bits

Optical Black Clamp Level Programmable Range of Clamp Level 2 60 LSB

OBCLP Level at CODE = 1000 130 LSB

Min Output Current for Control DAC

Max Output Current for Control DAC

Loop Time Constant C

Slew Rate C

= 0.1µF, Output Current from Control DAC is Saturated 1530 V/s

COB

COB Pin ±0.15 µA

COB Pin ±153 µA

COB

REFERENCE

Positive Reference Voltage 1.75 V

Negative Reference Voltage 1.25 V

POWER SUPPLY

Supply Voltage V

Power Dissipation Normal Operation Mode: No Load, DAC0 and DAC1 are Suspended 86 mW

CC

Stand-By Mode: f

TEMPERATURE RANGE

Operating Temperature –25 +85 °C

Thermal Resistance

θ

JA

LQFP-48 100 °C/W

NOTE: (1) SNR = 20 log(full-scale voltage/rms noise).

) = 20MHz, unless otherwise noted.

ADCCK

VSP2262Y

) VIN = +3V ±20 µA

IH

) VIN = 0V ±20 µA

IL

) IOH = –2mA 2.4 V

OH

) IOL = 2mA 0.4 V

OL

= 0.1µF µs

, DRV

DD

= Not Apply 6 mW

ADCCK

2.7 3.0 3.6 V

2

VSP2262

SBMS011

Page 3

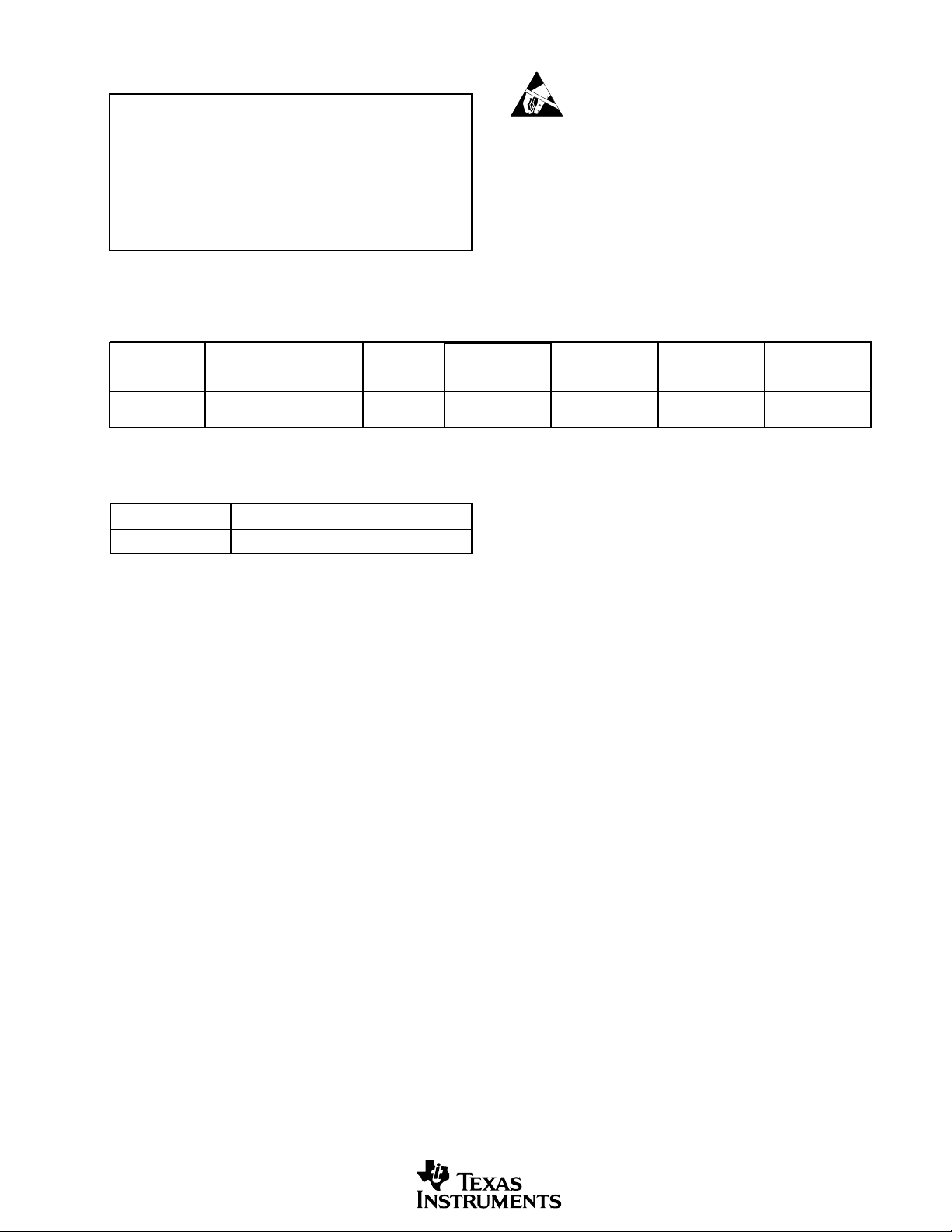

ABSOLUTE MAXIMUM RATINGS

Supply Voltage: VCC, DRVDD...........................................................+4.0V

Supply-Voltage Differences: Among V

Ground-Voltage Differences: Among GNDA .................................... ±0.1V

Digital Input Voltage ............................................................ –0.3 to +5.3V

Analog Input Voltage .................................................. –0.3 to V

Input Current (Any Pins Except Supplies) ..................................... ±10mA

Ambient Temperature Under Bias .....................................–40 to +125°C

Storage Temperature .........................................................–55 to +125°C

Junction Temperature .................................................................... +150°C

Lead Temperature (Soldering, 5s) ................................................ +260°C

Package Temperature (IR Reflow, Peak, 10s) ............................. +235°C

NOTE: (1) Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods may

degrade device reliability.

(1)

......................................... ±0.1V

CC

CC

+ 0.3V

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

PACKAGE/ORDERING INFORMATION

PACKAGE SPECIFIED

PRODUCT PACKAGE NUMBER RANGE MARKING NUMBER

DRAWING TEMPERATURE PACKAGE ORDERING TRANSPORT

VSP2262Y LQFP-48 340 0 to +85°C VSP2262Y VSP2262Y 250-Piece Tray

(1)

MEDIA

"""""VSP2262Y/2K Tape and Reel

NOTE: (1) Models with a slash (/) are available only in Tape and Reel in the quantities indicated (e.g., /2K indicates 2000 devices per reel). Ordering 2000 pieces

of “VSP2262Y/2K” will get a single 2000 piece Tape and Reel.

DEMO BOARD ORDERING INFORMATION

PRODUCT ORDERING NUMBER

VSP2262Y DEM-VSP2262Y

VSP2262

SBMS011

3

Page 4

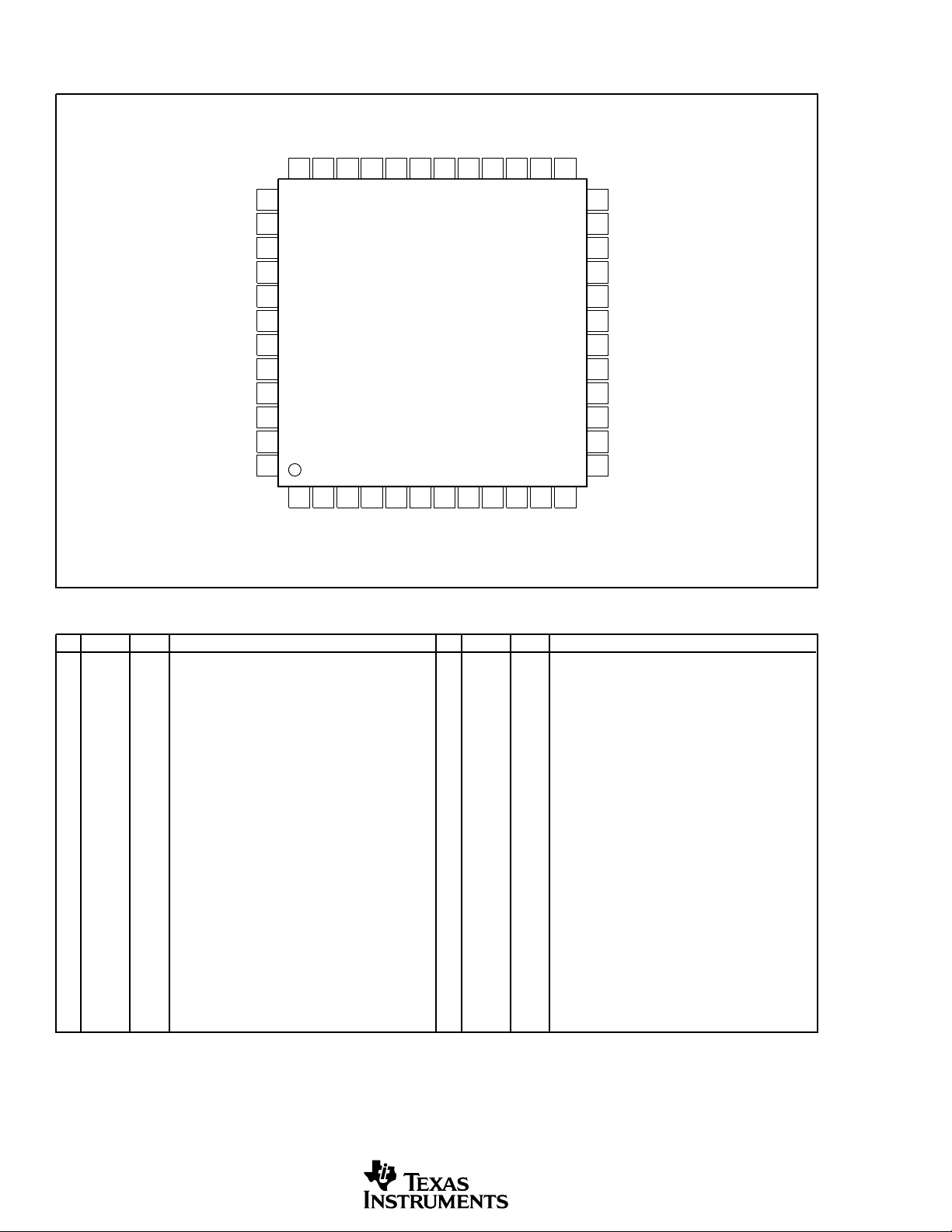

PIN CONFIGURATION

Top View LQFP

GNDA

GNDA

VCCVCCBYPM

36 35 34 33 32 31 30

BYP

CCDIN

BYPP2

COB

VCCGNDA

29 28 27 26

GNDA

CM

REFP

REFN

V

CC

GNDA

GNDA

NC

NC

RESET

SLOAD

SDATA

SCLK

37

38

39

40

41

42

43

VSP2262

44

45

46

47

48

24

23

22

21

20

19

18

17

16

15

14

13

V

CC

CLPDM

SHD

SHP

CLPOB

PBLK

V

CC

GNDA

ADCCK

GNDA

DRVGND

DRV

DD

12345678910112512

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B0 (LSB)

B11 (MSB)

PIN DESCRIPTIONS

(1)

PIN NAME TYPE

1 B0 (LSB) DO Bit 0 (LSB), A/D Converter Output

2 B1 DO Bit 1, A/D Converter Output

3 B2 DO Bit 2, A/D Converter Output

4 B3 DO Bit 3, A/D Converter Output

5 B4 DO Bit 4, A/D Converter Output

6 B5 DO Bit 5, A/D Converter Output

7 B6 DO Bit 6, A/D Converter Output

8 B7 DO Bit 7, A/D Converter Output

9 B8 DO Bit 8, A/D Converter Output

10 B9 DO Bit 9, A/D Converter Output

11 B10 DO Bit 10, A/D Converter Output

12

B11 (MSB)

13 DRV

14 DRVGND P Digital Ground, Exclusively for Digital Output

DD

15 GNDA P Analog Ground

16 ADCCK DI Clock for Digital Output Buffer

17 GNDA P Analog Ground

18 V

CC

19 PBLK DI Preblanking:

20 CLPOB DI Optical Black Clamp Pulse (Default = Active LOW)

21 SHP DI

22 SHD DI CDS Data Level Sampling Pulse (Default = Active LOW)

23 CLPDM DI Dummy Pixel Clamp Pulse (Default = Active LOW)

DESCRIPTION

DO Bit 11 (MSB), A/D Converter Output

P Power Supply, Exclusively for Digital Output

P Analog Power Supply

HIGH = Normal Operation Mode

LOW = Preblanking Mode: Digital Output “All Zero”

CDS Reference Level Sampling Pulse (Default = Active LOW)

PIN NAME

24 V

CC

25 GNDA P Analog Ground

26 GNDA P Analog Ground

27 V

CC

28 COB AO Optical Black Clamp Loop Reference

29 BYPP2 AO Internal Reference P

30 CCDIN AI CCD Signal Input

31 BYP AO Internal Reference C

32 BYPM AO Internal Reference N

33 V

CC

34 V

CC

35 GNDA P Analog Ground

36 GNDA P Analog Ground

37 CM AO A/D Converter Common-Mode Voltage

38 REFP AO A/D Converter Positive Reference

39 REFN AO A/D Converter Negative Reference

40 V

CC

41 GNDA P Analog Ground

42 GNDA P Analog Ground

43

NC

44

(5)

(5)

(5)

(5)

NC

45 RESET DI Asynchronous System Reset (Active LOW)

46 SLOAD DI Serial Data Latch Signal (Triggered at the Rising Edge)

47 SDATA DI Serial Data Input

48 SCLK DI Clock for Serial Data Shift (Triggered at the Rising Edge)

NOTES: (1) Type designators: P = Power Supply and Ground; DI = Digital Input; DO = Digital Output; AI = Analog Input; AO = Analog Output. (2) Should be

connected to ground with a bypass capacitor. We recommend the value of 0.1µF to 0.22 µF, however, it depends on the application environment. Refer to the “Optical

Black Level Clamp Loop” section for more detail. (3) Should be connected to ground with a bypass capacitor. We recommend the value of 400pF to 9000pF, however,

it depends on the application environment. Refer to the “Voltage Reference” section for more detail. (4) Should be connected to ground with a bypass capacitor

(0.1µF). Refer to the “Voltage Reference” section for more detail. (5) Refer to “Serial Interface” section for more detail.

(1)

TYPE

DESCRIPTION

P Analog Power Supply

P Analog Power Supply

P Analog Power Supply

P Analog Power Supply

P Analog Power Supply

– Should be Left OPEN

– Should be Left OPEN

(3)

(2)

(4)

(3)

(4)

(4)

(4)

4

VSP2262

SBMS011

Page 5

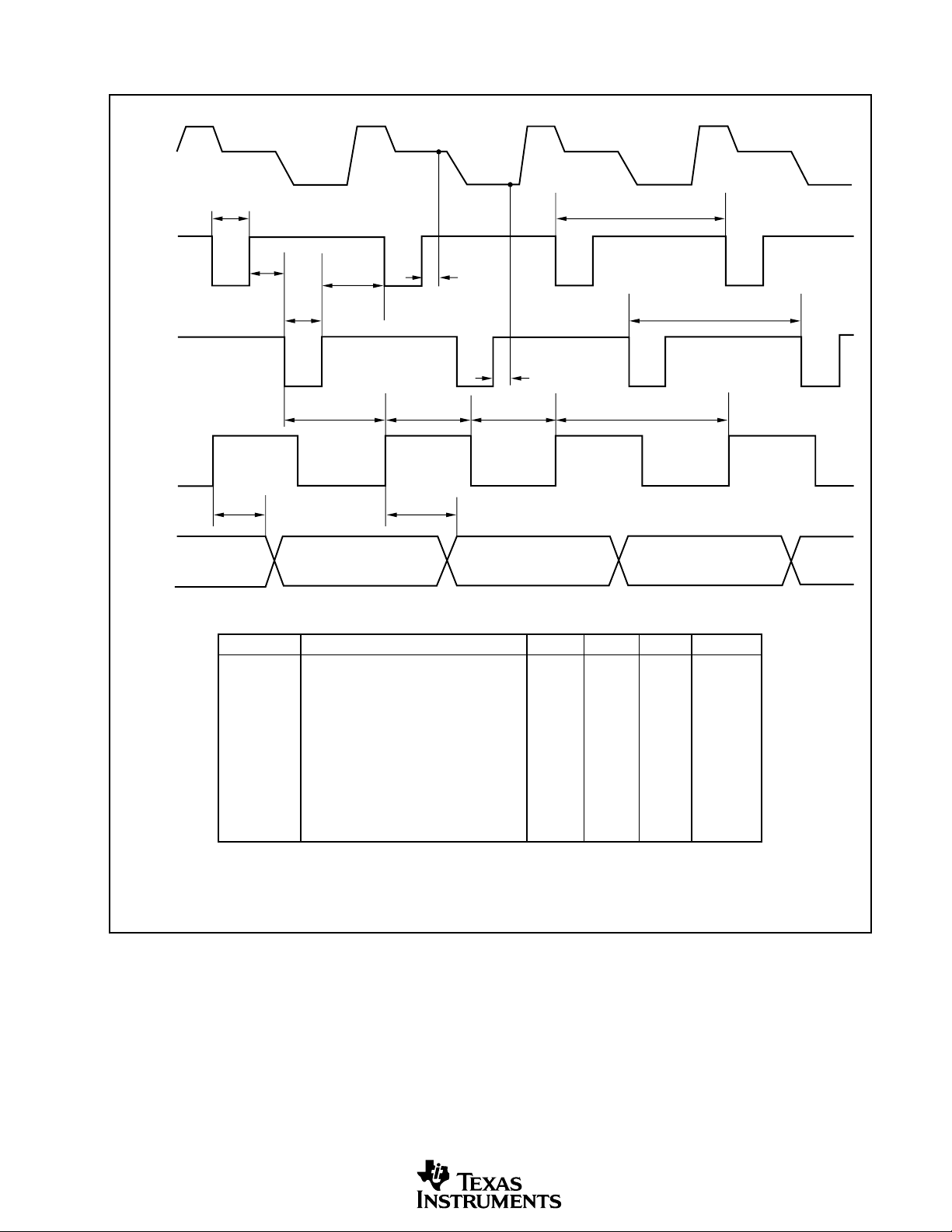

CDS TIMING SPECIFICATIONS

CCD

Output

Signal

N

N + 1 N + 2 N + 3

SHP

SHD

ADCCK

B[11:0]

t

WP

(1)

(1)

t

HOLD

t

PD

t

WD

t

INHIBIT

t

DP

t

t

S

t

S

t

ADC

OD

t

ADC

t

CKP

t

CKP

t

CKP

N – 9N – 8N – 7N – 11 N – 10

SYMBOL PARAMETER MIN TYP MAX UNITS

t

CKP

t

ADC

t

WP

t

WD

t

PD

t

DP

t

t

INHIBIT

t

HOLD

t

OD

ADCCK HIGH/LOW Pulse Width 20 ns

SHP Trailing Edge to SHD Leading Edge

SHD Trailing Edge to SHP Leading Edge

S

Clock Period 48 ns

SHP Pulse Width 14 ns

SHD Pulse Width 11 ns

(1)

8ns

(1)

12 ns

Sampling Delay 5 ns

Inhibited Clock Period 20 ns

Output Hold Time 7 ns

Output Delay 38 ns

DL Data Latency, Normal Operation Mode 9 (fixed) Clock Cycles

NOTE: (1) The description and timing diagrams in this data sheet are all based on the polarity of Active LOW

(default value). The user can select the active polarity (Active LOW or Active HIGH) through the serial interface.

Refer to the “Serial Interface” section for more detail.

VSP2262

SBMS011

5

Page 6

SERIAL INTERFACE TIMING SPECIFICATIONS

t

SLOAD

XS

t

XH

SCLK

SDATA

t

t

CKH

t

t

DS

DH

CKL

t

CKP

MSB

2 Bytes

SYMBOL PARAMETER MIN TYP MAX UNITS

t

t

t

CKP

CKH

CKL

t

DS

t

DH

t

XS

t

XH

Clock Period 100 ns

Clock HIGH Pulse Width 40 ns

Clcok LOW Pulse Width 40 ns

Data Setup Time 30 ns

Data Hold TIme 30 ns

SLOAD to SCLK Setup Time 30 ns

SCLK to SLOAD Hold Time 30 ns

NOTES: (1) Data shift operation should occur at the rising edge of SCLK while SLOAD is LOW. Two bytes of input

data are loaded to the parallel latch in the VSP2260 at the rising edge of SLOAD. (2) When the input serial data

is longer than two bytes (16 bits), the last two bytes become effective and the former bits are lost.

LSB

6

VSP2262

SBMS011

Page 7

THEORY OF OPERATION

INTRODUCTION

The VSP2262 is a complete mixed-signal IC that contains

all of the key features associated with the processing of the

CCD imager output signal in a video camera, a digital still

camera, security camera, or similar applications (see the

simplified block diagram on page 1 for details). The VSP2262

includes a Correlated Double Sampler (CDS), Programmable Gain Amplifier (PGA), Analog-to-Digital Converter

(ADC), input clamp, Optical Black (OB) level clamp loop,

serial interface, timing control, reference voltage generator,

and general-purpose 8-bit Digital-to-Analog Converters

(DAC). We recommend an off-chip emitter follower buffer

between the CCD output and the VSP2262 CCDIN input.

The PGA gain control, clock polarity setting, and operation

mode can be selected through the serial interface. All parameters are reset to the default value when the RESET pin goes

LOW asynchronously from the clocks.

capacitance can be seen at the input pin. The analog input

signal range at the CCDIN pin is 1Vp-p, and the appropriate

common-mode voltage for the CDS is around 0.5V to 1.5V.

The reference level is sampled during SHP active period,

and the voltage level is held on sampling capacitor C

at the

1

trailing edge of SHP. The data level is sampled during SHD

active period, and the voltage level is held on the sampling

capacitor C

at the trailing edge of SHD. The switched-

2

capacitor amplifier then performs the subtraction of these

two levels.

The user can select the active polarity of SHP/SHD (Active

HIGH or Active LOW) through the serial interface (refer to

the “Serial Interface” section for more detail). The default

value of SHP/SHD is “Active LOW”. However, immediately

after power ON, this value is Unknown. For this reason, the

appropriate value must be set by using the serial interface, or

reset to the default value by strobing the RESET pin. The

descriptions and the timing diagrams in this data sheet are all

based on the polarity of Active LOW (default value).

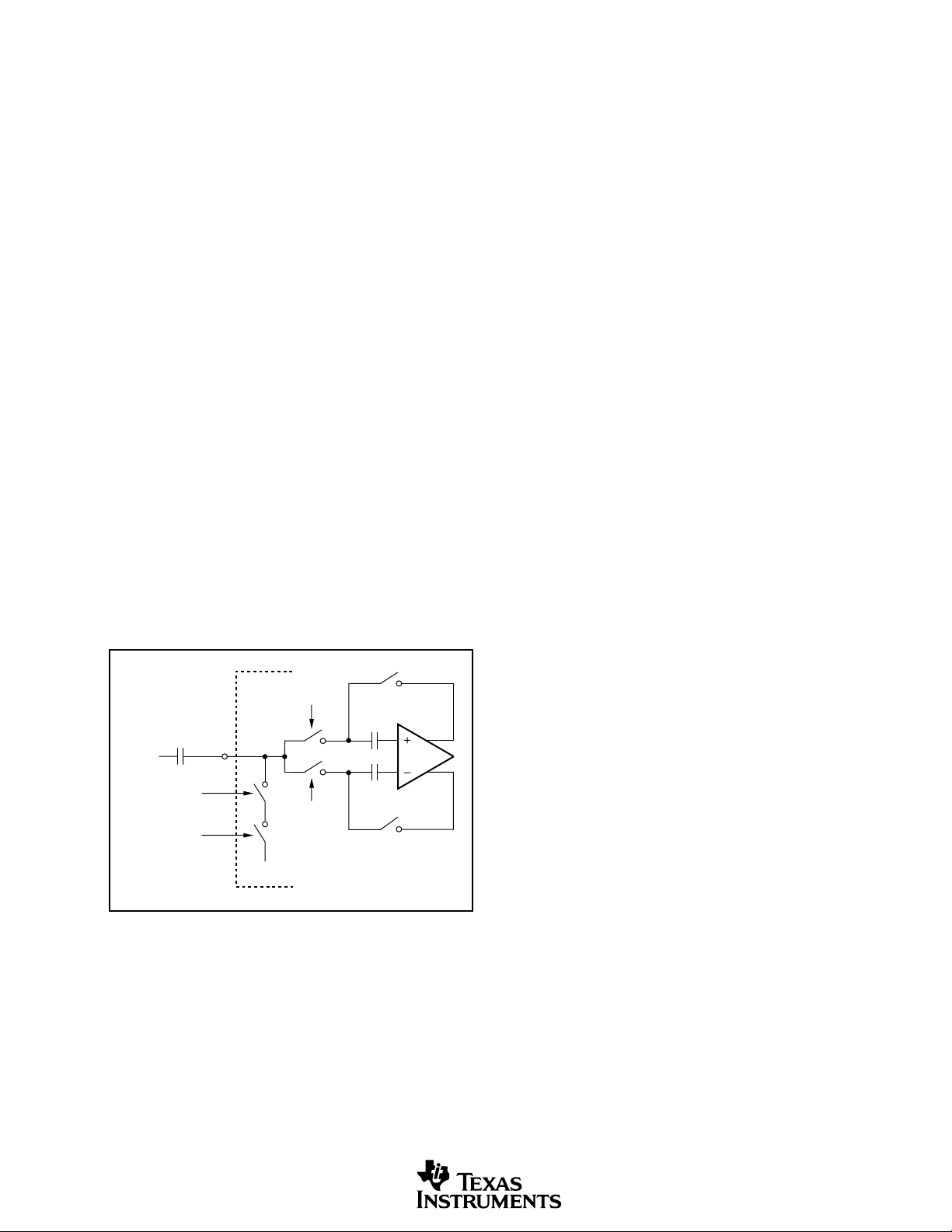

CORRELATED DOUBLE SAMPLER (CDS)

The output signal of a CCD imager is sampled twice during

one pixel period: once at the reference interval and the other

at the data interval. Subtracting these two samples from each

other extracts the video information of the pixel as well as

removes any noise that is common, or correlated, to both the

intervals. Thus, the CDS is very important in reducing the

reset noise and low-frequency noises that are present on the

CCD output signal. Figure 1 shows the simplified block

diagram of the CDS and input clamp.

CCD

Output

C

IN

CLPDM

SHP

VSP2262

CCDIN

CM (1.5V)

SHP

SHD

C

10pF

C

10pF

1

OPA

2

FIGURE 1. Simplified Block Diagram of CDS and Input

Clamp.

INPUT CLAMP OR DUMMY PIXEL CLAMP

The buffered CCD output is capacitively coupled to the

VSP2262. The purpose of the input clamp is to restore the

DC component of the input signal that was lost with the AC

coupling and establish the desired DC bias point for the

CDS. A simplified block diagram of the input clamp is

shown in Figure 1. The input level is clamped to the internal

reference voltage, CM (1.5V), during the dummy pixel

interval. More specifically, when both CLPDM and SHP are

active, the dummy clamp function becomes active. If the

dummy pixels and/or the CLPDM pulse are not available in

your system, the CLPOB pulse can be used in place of

CLPDM, as long as the clamping takes place during black

pixels. In this case, both the CPLDM pin (active at same

timing as CLPOB) and SHP become active during the

optical black pixel interval, and then the dummy clamp

function becomes active.

The active polarity of CLPDM and SHP (Active HIGH or

Active LOW) can be selected through the serial interface

(refer to the “Serial Interface” section for more detail).

The default value of CLPDM and SHP is “Active LOW”.

However, immediately after power ON, this value is Unknown. For this reason, the appropriate value must be set by

using the serial interface, or reset to the default value by

strobing the RESET pin. The descriptions and the timing

diagrams in this data sheet are all based on the polarity of

Active LOW (default value).

The CDS is driven through an off-chip coupling capacitor

(C

). AC coupling is strongly recommended because the

IN

DC level of the CCD output signal is usually several volts

too high for the CDS to work properly.

A 0.1µF capacitor is recommended for C

, depending on

IN

the application environment. Additionally, we recommend

an off-chip emitter follower buffer that can drive more than

10pF, because the 10pF capacitor and a few pF of stray

VSP2262

SBMS011

HIGH PERFORMANCE ANALOG-TO-DIGITAL

CONVERTER (ADC)

The ADC utilizes a fully differential and pipelined architecture. This ADC is well suited for low-voltage operations,

low power consumption requirements, and high-speed applications. It guarantees 12-bit resolution with no missing

codes. The VSP2262 includes a reference voltage generator

for the ADC. REFP (Positive Reference, pin 38), REFN

7

Page 8

(Negative Reference, pin 39), and CM (Common-Mode

Voltage, pin 37) should be bypassed to ground with a 0.1µF

ceramic capacitor and should not be used elsewhere in the

system, as they affect the stability of these reference levels,

which causes ADC performance degradation. Note that

these are analog output pins and, therefore, do not apply

external voltage.

PROGRAMMABLE GAIN AMPLIFIER (PGA)

Figure 2 shows the characteristics of the PGA gain. The PGA

provides a gain range of –6dB to +42dB, which is linear in dB.

The gain is controlled by a digital code with

10-bit resolution, and can be set through the serial interface

(refer to the “Serial Interface” section for more detail). The

default value of the gain control code is 128 (PGA Gain =

0dB)

.

However, immediately after power ON, this value is

Unknown. For this reason, the appropriate value must be set

by using the serial interface, or reset to the default value by

strobing the RESET pin.

50

40

30

20

Gain (dB)

10

0

–10

0

100

200

300

400

Input Code for Gain Control (0 to 1023)

500

600

700

800

900

1k

1023

FIGURE 2. The Characteristics of PGA Gain.

OPTICAL BLACK (OB) LEVEL CLAMP LOOP

To extract the video information correctly, the CCD signal

must be referenced to a well-established OB level. The

VSP2262 has an auto-calibration loop to establish the OB

level using the optical black pixels output from the CCD

imager. The input signal level of the OB pixels is identified

as the real “OB level”, and the loop should be closed while

CLPOB is active.

During the effective pixel interval, the reference level of the

CCD output signal is clamped to the OB level by the OB

level clamp loop. To determine the loop time constant, an

off-chip capacitor is required, and should be connected to

COB (pin 28). Time constant T is given in the following

equation:

T = C/(16384 • I

Where C is the capacitor value connected to COB, I

MIN

)

is the

MIN

minimum current (0.15µA) of the control Digital-to-Analog

Converter (DAC) in the OB level clamp loop, and 0.15µA is

equivalent to 1LSB of the DAC output current. When C is

0.1µF, time constant T is 40.7µs.

Additionally, the slew rate SR is given the following equa-

tion:

MAX

/C

MAX

is

SR = I

Where C is the capacitor value connected to COB, I

the maximum current (153µA) of the control DAC in the OB

level clamp loop, and 153µA is equivalent to 1023LSB of

the DAC output current.

Generally, OB level clamping at high speed causes “Clamp

Noise” (or “White Streak Noise”), however, the noise will

decrease by increasing C. On the other hand, an increased C

requires a much longer time to restore from Stand-by mode,

or right after power ON. Therefore, we consider 0.1µF to

0.22µF a reasonable value for C. However, it depends on the

application environment; we recommend making careful

adjustments using trial-and-error.

The “OB clamp level” (the pedestal level) is programmable

through the serial interface (refer to the “Serial Interface”

section for more detail). Table I shows the relationship

between input code and the OB clamp level.

INPUT CODE OB CLAMP LEVEL, LSBs OF 12 BITS

0000 2LSB

0001 18LSB

0010 34LSB

0011 50LSB

0100 66LSB

0101 82LSB

0110 98LSB

0111 114LSB

1000 (Default) 130LSB

1001 146LSB

1010 162LSB

1011 178LSB

1100 194LSB

1101 210LSB

1110 226LSB

1111 242LSB

TABLE I. Programmable OB Clamp Level.

The active polarity of CLPOB (Active HIGH or Active

LOW) can be selected through the serial interface (refer to

the “Serial Interface” section for more detail). The default

value of CLPOB is “Active LOW”. However, immediately

after power ON, this value is Unknown. For this reason, the

appropriate value must be set by using the serial interface, or

reset to the default value by strobing the RESET pin. The

descriptions and the timing diagrams in this data sheet are all

based on the polarity of Active LOW (default value).

PREBLANKING AND DATA LATENCY

The VSP2262 has an input blanking, or preblanking, function. When PBLK goes LOW, all digital outputs will go to

ZERO at the 11th rising edge of ADCCK. In this mode, the

digital output data comes out on the rising edge of ADCCK

with a delay of 11 clock cycles (data latency is 11). This is

8

VSP2262

SBMS011

Page 9

different from the preblanking mode in which the digital

output data comes out on the rising edge of ADCCK with a

delay of nine clock cycles (data latency is nine).

If the input voltage is higher than the supply rail by 0.3V or

lower than the ground rail by 0.3V, the protection diodes

will be turned on to prevent the input voltage from going any

further. Such a high swing signal may cause device damage

to the VSP2262 and should be avoided.

STAND-BY MODE

For the purpose of saving power, the VSP2262 can be set to

Stand-by mode (or Power-Down mode) through the serial

interface when the VSP2262 is not in use. Refer to the

“Serial Interface” section for more detail. In this mode, all

the function blocks are disabled and the digital outputs will

go to all ZEROs, causing the current consumption to drop to

1mA. Since all the bypass capacitors will discharge during

this mode, a substantial time (usually of the order of 200ms

to 300ms) is required to power up from Stand-by mode.

VOLTAGE REFERENCE

All the reference voltages and bias currents needed in the

VSP2262 are generated by its internal bandgap circuitry.

The CDS and the ADC use mainly three reference voltages:

REFP (Positive Reference, pin 38), REFN (Negative Reference, pin 39) and CM (Common-Mode Voltage, pin 37).

REFP, REFN and CM should be heavily decoupled with

appropriate capacitors (e.g., 0.1µF ceramic capacitor). Do

not use these voltages elsewhere in the system as they affect

the stability of the reference level, and cause ADC performance degradation. Note that these are analog output pins

and do not apply external voltage.

BYPP2 (pin 29), BYP (pin 31), and BYPM (pin 32) are also

reference voltages to be used in the analog circuit. BYP

should be connected to ground with a 0.1µF ceramic capacitor. Since the capacitor value for BYPP2 and BYPM affects

the step response, we consider 400pF to 9000pF to be a

reasonable value. However, as it depends on the application

environment, we recommend making careful adjustments

using trial-and-error.

BYPP2, BYP and BYPM should all be heavily decoupled

with appropriate capacitors, and not used elsewhere in the

system. They affect the stability of the reference levels, and

cause performance degradation. Note that these are analog

output pins and do not apply external voltage.

SERIAL INTERFACE

The serial interface has a 2-byte shift register and various

parallel registers to control all the digitally programmable

features of the VSP2262. Writing to these registers is controlled by four signals (SLOAD, SCLK, SDATA, and RESET). To enable the shift register, SLOAD must be pulled

LOW. SDATA is the serial data input and the SCLK is the

shift clock. The data at SDATA is taken into the shift

register at the rising edge of SCLK; the data length should

be two bytes. After the 2-byte shift operation, the data in the

shift register is transferred to the parallel latch at the rising

edge of SLOAD. In addition to the parallel latch, there are

several registers dedicated to the specific features of the

device and are synchronized with ADCCK. It takes five or

six clock cycles for the data in the parallel latch to be written

to those registers. Therefore, to complete the data updates, it

requires five or six clock cycles after parallel latching by the

rising edge of SLOAD.

See Table II for the serial interface data format. TEST is the

flag for the test mode (Texas Instruments proprietary only),

A0 to A2 is the address for the various registers, and D0 to

D11 is the data (or operand) field.

VSP2262

SBMS011

9

Page 10

MSB LSB

REGISTERS TEST A2 A1 A0 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Configuration 000000000000 00 0C0

PGA Gain 000100G9G8G7G6G5G4G3G2G1G0

OB Clamp Level 001000000000O3O2O1O0

Clock Polarity 001100000000 0P2P1P0

Reserved 0100xxxxxxxx xx x x

Reserved 0101xxxxxxxx xx x x

Reserved 0110xxxxxxxx xx x x

Reserved 0111xxxxxxxx xx x x

Reserved 1 xxxxxxxxxxxxx x x

x = Don’t Care.

TABLE II. Serial Interface Data Format.

REGISTER DEFINITIONS

C[0] Operation Mode, Normal/Stand-By

Serial Interface and Registers are always active, independently from the operation mode.

C0 = Operation Mode for the entire chip except the serial interface and registers.

(C0 = 0 “Active”; C0 = 1 “Stand-by”)

G[9:0] The Characteristics of PGA Gain (refer to Figure 2)

O[3:0] Programmable OB Clamp Level (refer to Table I)

P[2:0] Clock Polarity

P0 = Polarity for CLPDM (P0 = 0 “Active LOW”; P0 = 1 “Active HIGH”)

P1 = for CLPOB (P0 = 0 “Active LOW”; P0 = 1 “Active HIGH”)

P2 = for SHP/SHD (P0 = 0 “Active LOW”; P0 = 1 “Active HIGH”)

Immediately after power ON, these values are Unknown. The appropriate value must be set by using the serial interface, or reset

to the default value by strobing the RESET pin.

Default values are:

C[2:0] = 0 Normal Operation Mode

G[9:0] = 0010000000 PGA Gain = 0dB

O[3:0] = 1000 OB Clamp Level = 32LSB

P[2:0] = 000 CLPDM, CLPOB, SHP/SHD are all “Active LOW”

NOTE: (1) The descriptions and the timing diagrams in this data sheet are all based on the polarity of Active LOW (default value).

(1)

10

VSP2262

SBMS011

Page 11

TIMINGS

The CDS and the ADC are operated by SHP/SHD and their

derivative timing clocks generated by the on-chip timing

generator. The digital output data is synchronized with

ADCCK. See the VSP2262 “CDS Timing Specifications” for

the timing relationship among the CCD signal, SHP/SHD,

ADCCK and the output data. CLPOB is used to activate the

black level clamp loop during the OB pixel interval, and

CLPDM is used to activate the input clamping during the

dummy pixel interval. If the CLPDM pulse is not available in

your system, the CLPOB pulse can be used in place of

CLPDM as long as the clamping takes place during black

pixels (refer to the “Input Clamp and Dummy Pixel Clamp”

section for more detail). The clock polarities of SHP/SHD,

CLPOB and CLPDM can be independently set through the

serial interface (refer to the “Serial Interface” section for more

detail). The descriptions and the timing diagrams in this data

sheet are all based on the polarity of Active LOW (default

value). In order to keep a stable and accurate OB clamp level,

we recommend CLPOB should not be activated during PBLK

active period. Refer to the “Preblanking and Data Latency”

section for more detail. In Stand-by mode, ADCCK, SHP,

SHD, CLPOB and CLPDM are internally masked and pulled

HIGH.

POWER SUPPLY, GROUNDING AND DEVICE

DECOUPLING RECOMMENDATIONS

The VSP2262 incorporates analog circuitry and a very

high-precision, high-speed ADC that are vulnerable to any

extraneous noise from the rails or elsewhere. For this reason,

it should be treated as an analog component and all supply

pins except for DRV

should be powered by the only

DD

analog supply of the system. This will ensure the most

consistent results, since digital power lines often carry high

levels of wideband noise that would otherwise be coupled

into the device and degrade the achievable performance.

Proper grounding, short lead length, and the use of ground

planes are also very important for high-frequency designs.

Multi-layer PC boards are recommended for the best performance, since they offer distinct advantages like minimizing

ground impedance, separation of signal layers by ground

layers, etc. It is highly recommended that analog and digital

ground pins of the VSP2262 be joined together at the IC and

be connected only to the analog ground of the system. The

driver stage of the digital outputs (B[11:0]) is supplied

through a dedicated supply pin (DRV

) and it should be

DD

separated from the other supply pins completely, or at least

with a ferrite bead.

It is also recommended to keep the capacitive loading on the

output data lines as low as possible (typically less than

15pF). Larger capacitive loads demand higher charging

current surges that can feed back into the analog portion of

the VSP2262 and affect the performance. If possible, external buffers or latches should be used, providing the added

benefit of isolating the VSP2262 from any digital noise

activities on the data lines. In addition, resistors in series

with each data line may help minimize the surge current.

Values in the range of 100Ω to 200Ω will limit the instantaneous current the output stage has to provide for recharging the parasitic capacitances as the output levels change

from LOW to HIGH, or HIGH to LOW. Due to high

operation speed, the converter also generates high-frequency

current transients and noises that are fed back into the supply

and reference lines. This requires the supply and reference

pins to be sufficiently bypassed. In most cases, 0.1µF ceramic chip capacitors are adequate to decouple the reference

pins. Supply pins should be decoupled to the ground plane

with a parallel combination of tantalum (1µF to 22µF) and

ceramic (0.1µF) capacitors. The effectiveness of the decoupling largely depends on the proximity to the individual pin.

DRV

should be decoupled to the proximity of DRVGND.

DD

Special attention must be paid to the bypassing of COB,

BYPP2 and BYPM, since these capacitor values determine

important analog performances of the device.

VSP2262

SBMS011

11

Page 12

PACKAGE OPTION ADDENDUM

www.ti.com

30-Mar-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

VSP2262Y ACTIVE LQFP PT 48 250 TBD CU SNPB Level-1-235C-UNLIM

VSP2262Y/2K ACTIVE LQFP PT 48 2000 TBD CU SNPB Level-1-235C-UNLIM

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 13

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. T esting and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...