Page 1

1

2

3

4

8

7

6

5

VCC

DRV

GND

ZCD

VO_SNS

COMP

MULTIN

CS

UCC28051

C

BULK

1

2

3

4

8

7

6

5

STATUS

OVP

VDD

OUT

SS

FB

CS

GND

UCC28600

C

SS

C

BP

R

PL

R

SU

R

CS

C

VDD

Primary Secondary

TL431

Feedback

R

OVP2

R

OVP1

18 V

C

B

N

P

N

S

N

B

M

1

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

8-Pin Quasi-Resonant Flyback Green-Mode Controller

Check for Samples: UCC28600

1

FEATURES

2

• Green-Mode Controller With Advanced Energy

Saving Features PDP-TV, and Set Top Boxes

• Quasi-Resonant Mode Operation for Reduced • AC/DC Adapters and Offline Battery Chargers

EMI and Low Switching Losses (Low Voltage

Switching)

• Low Standby Current for System No-Load

Power Consumption

• Low Startup Current: 25 μA Maximum

• Programmable Overvoltage Protection, Line

and Load

• Internal Overtemperature Protection

• Current Limit Protection

– Cycle-by-Cycle Power Limit

– Primary-Side Overcurrent Hiccup Restart

Mode

• 1-A Sink TrueDrive™, -0.75-A Source Gate

Drive Output

• Programmable Soft-Start

• Green-Mode Status Pin (PFC Disable Function)

.

.

APPLICATIONS

• Bias Supplies for LCD-Monitors, LCD-TV,

• Energy Efficient Power Supplies up to 200 W

DESCRIPTION

The UCC28600 is a PWM controller with advanced

energy features to meet stringent world-wide energy

efficiency requirements.

UCC28600 integrates built-in advanced energy

saving features with high level protection features to

provide cost effective solutions for energy efficient

power supplies. UCC28600 incorporates frequency

fold back and green mode operation to reduce the

operation frequency at light load and no load

operations.

UCC28600 is offered in the 8-pin SOIC (D) package.

Operating junction temperature range is -40°C to

105°C.

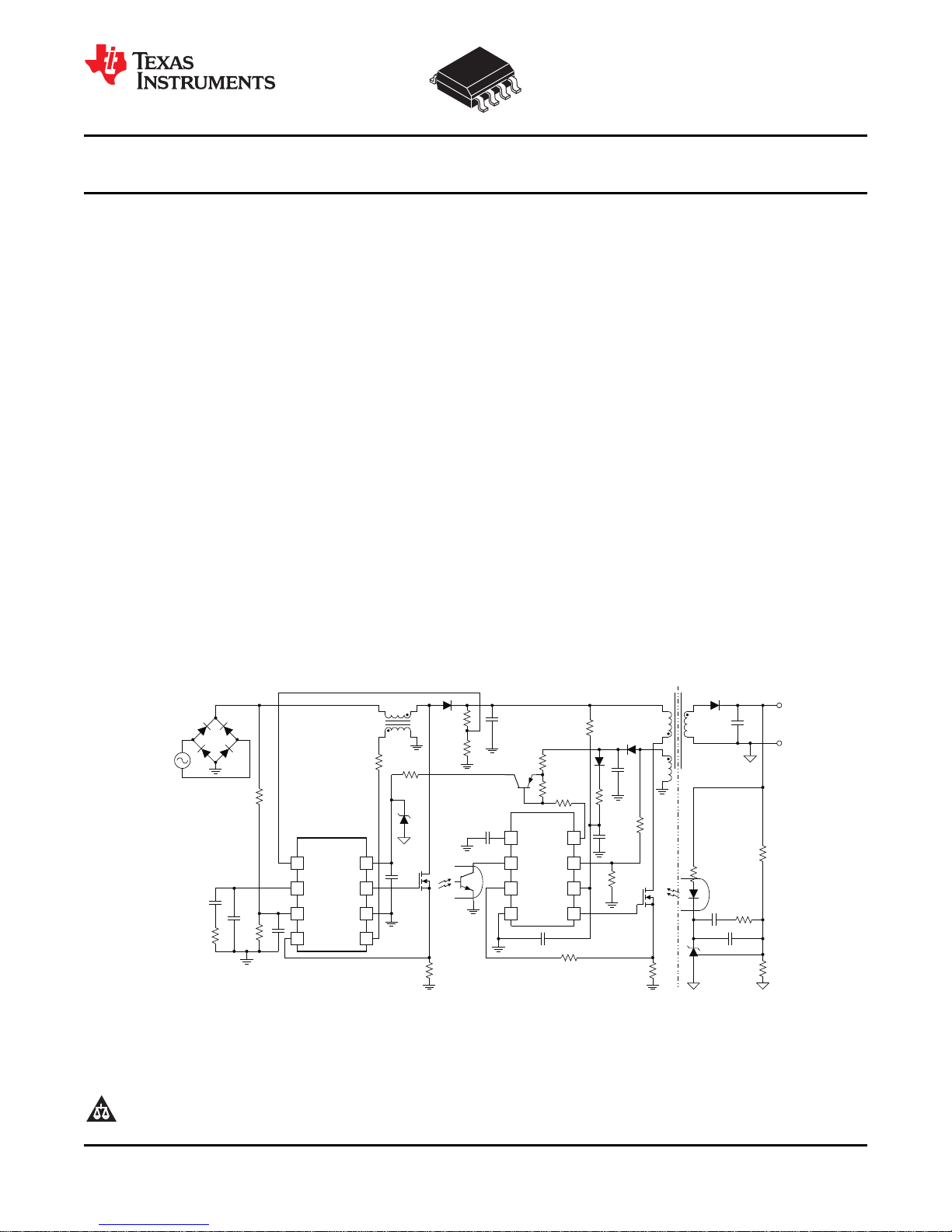

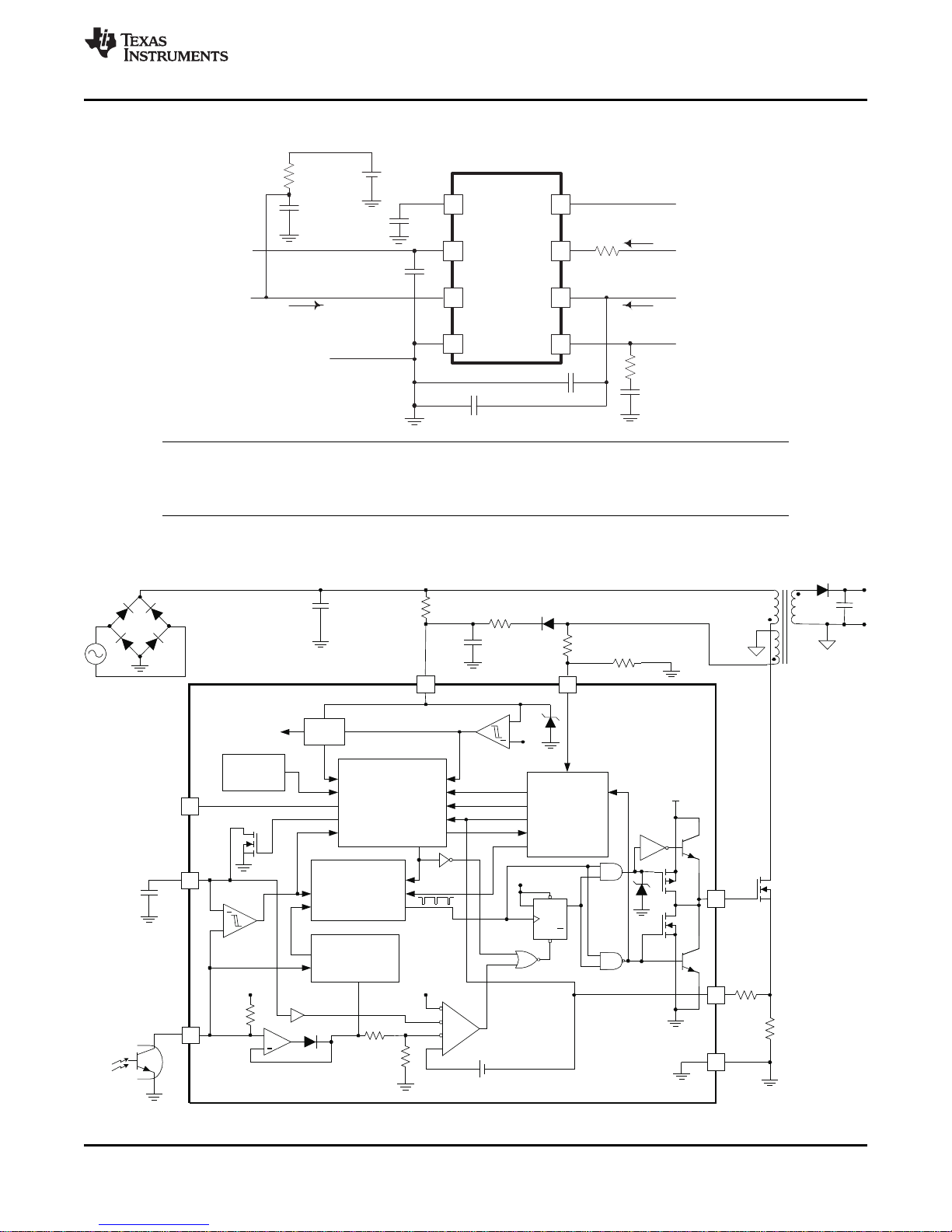

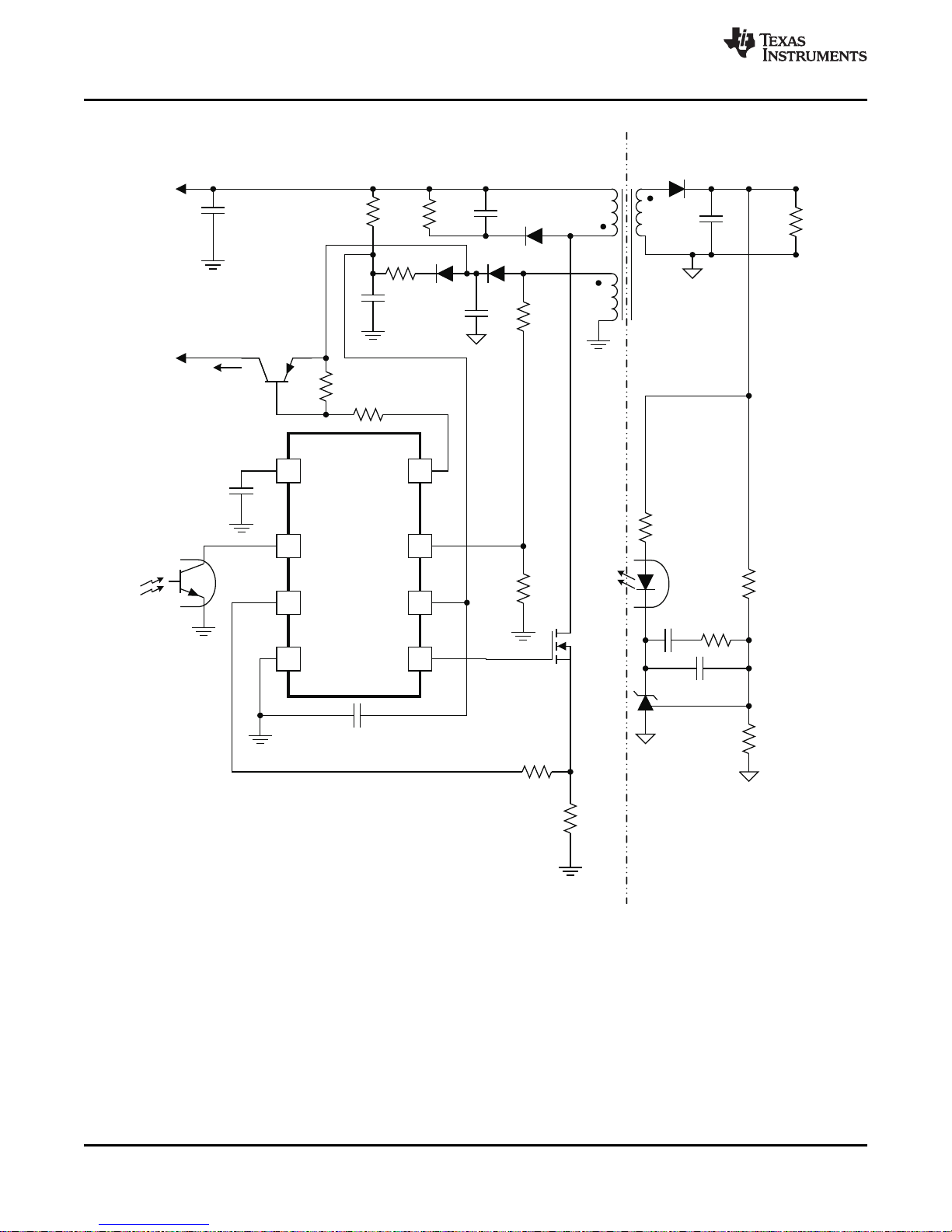

TYPICAL APPLICATION

1

2TrueDrive is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2005–2011, Texas Instruments Incorporated

Page 2

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

DESCRIPTION (CONT.)

The Design Calculator, (Texas Instruments Literature number SLVC104), located in the Tools and Software

section of the UCC28600 product folder, provides a user-interactive iterative process for selecting recommended

component values for an optimal design.

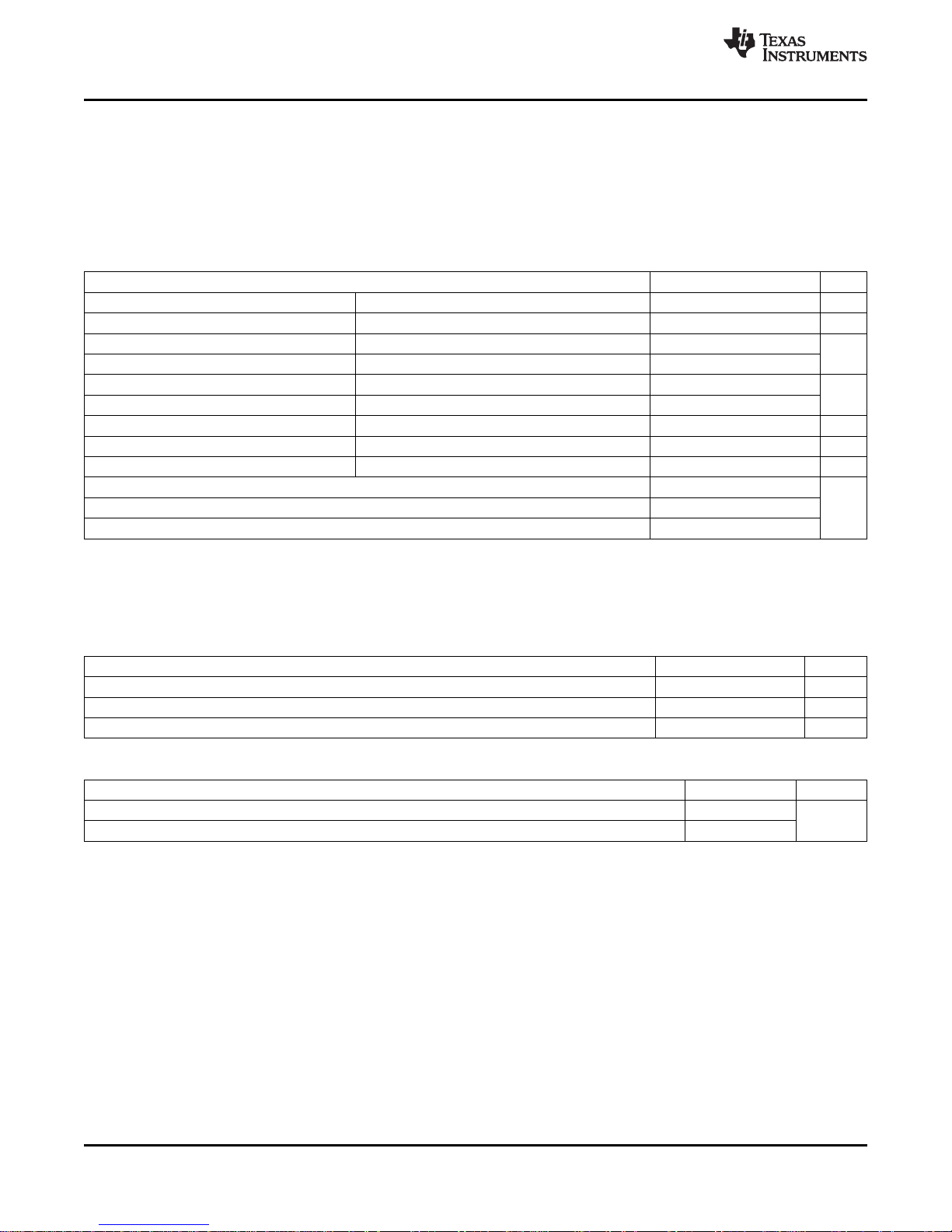

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

VDD Supply voltage range IDD< 20 mA 32 V

I

DD

I

OUT(sink)

I

OUT(source)

V

OVP

I

OVP(source)

V

STATUS

T

J

T

stg

T

LEAD

(1) Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under “recommended operating

conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability. All voltages

are with respect to GND. Currents are positive into, negative out of the specified terminal. Consult Packaging Section of the databook

for thermal limitations and considerations of packages.

Supply current 20 mA

Output sink current (peak) 1.2

Output source current (peak) -0.8

Analog inputs FB, CS, SS -0.3 to 6.0

VDD = 0 V to 30 V 30 V

Power dissipation SOIC-8 package, TA= 25°C 650 mW

Operating junction temperature range –55 to 150

Storage temperature –65 to 150 °C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300

(1)

UCC28600 UNIT

A

-1.0 to 6.0

-1.0 mA

V

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

VDD Input voltage 21 V

I

T

Output sink current 0 A

OUT

Operating junction temperature -40 105 °C

J

ELECTROSTATIC DISCHARGE (ESD) PROTECTION

MIN MAX UNIT

Human body model 2000

CDM 1500

V

2 Copyright © 2005–2011, Texas Instruments Incorporated

Page 3

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

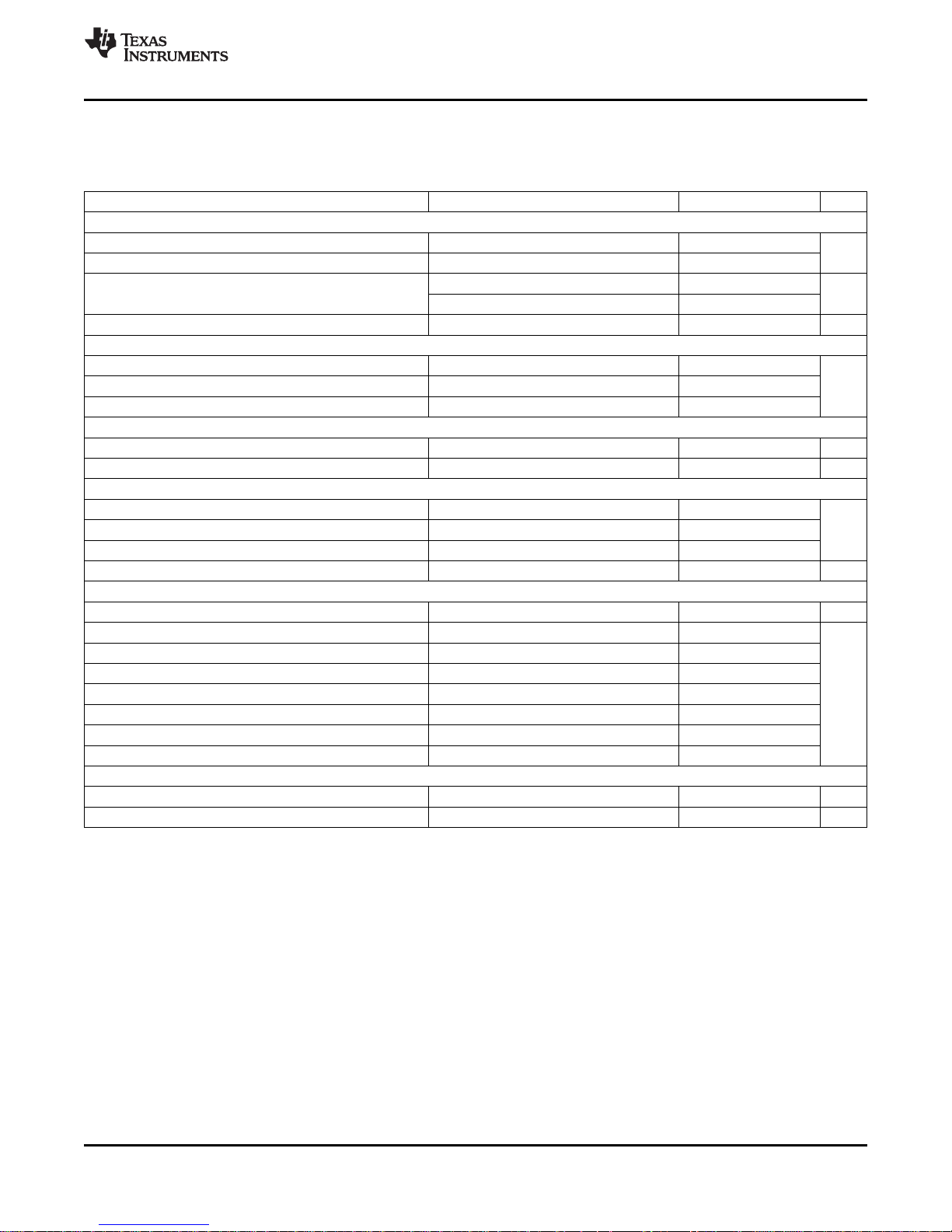

ELECTRICAL CHARACTERISTICS

VDD = 15 V, 0.1-μF capacitor from VDD to GND, 3.3-nF capacitor from SS to GND charged over 3.5 V, 500-Ω resistor from

OVP to -0.1 V, FB = 4.8 V, STATUS = not connected, 1-nF capacitor from OUT to GND, CS = GND, TA= -40°C to 105°C,

(unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Overall

I

STARTUP

I

STANDBY

I

DD

Undervoltage Lockout

VDD

(uvlo)

ΔVDD

(uvlo)

PWM (Ramp)

D

MIN

D

MAX

Oscillator (OSC)

f

QR(max)

f

QR(min)

f

SS

dTS/dFB VCO gain TSfor 1.6 V < VFB< 1.8 V -38 -30 -22 μs/V

Feedback (FB)

R

FB

V

FB

Status

R

DS(on)

I

STATUS(leakage)

(1) R

SCT

and C

Startup current VDD = V

-0.3 V 12 25

UVLO

Standby current VFB= 0 V 350 550

Operating current mA

Not switching 2.5 3.5

130 kHz, QR mode 5.0 7.0

VDD clamp FB = GND, IDD= 10 mA 21 26 32 V

Startup threshold 10.3 13.0 15.3

Stop threshold 6.3 8 9.3 V

Hysteresis 4.0 5.0 6.0

(1)

Minimum duty cycle VSS= GND, VFB= 2 V 0%

Maximum duty cycle QR mode, fS= max, (open loop) 99%

Maximum QR and DCM frequency 117 130 143

Minimum QR and FFM frequency VFB= 1.3 V 32 40 48 kHz

Soft start frequency VSS= 2.0 V 32 40 48

Feedback pullup resistor 12 20 28 kΩ

FB, no load QR mode 3.30 4.87 6.00

Green-mode ON threshold VFBthreshold 0.3 0.5 0.7

Green-mode OFF threshold VFBthreshold 1.2 1.4 1.6

Green-mode hysteresis VFBthreshold 0.7 0.9 1.1 V

FB threshold burst-ON VFBduring green mode 0.3 0.5 0.7

FB threshold burst-OFF VFBduring green mode 0.5 0.7 0.9

Burst Hysteresis VFBduring green mode 0.13 0.25 0.42

STATUS on resistance V

STATUS leakage/off current VFB= 0.44 V, V

are not connected in the circuit for maximum and minimum duty cycle tests, current sense tests and power limit tests.

CST

= 1 V 1.0 2.4 3.8 kΩ

STATUS

= 15 V -0.1 2.0 μA

STATUS

μA

Copyright © 2005–2011, Texas Instruments Incorporated 3

Page 4

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

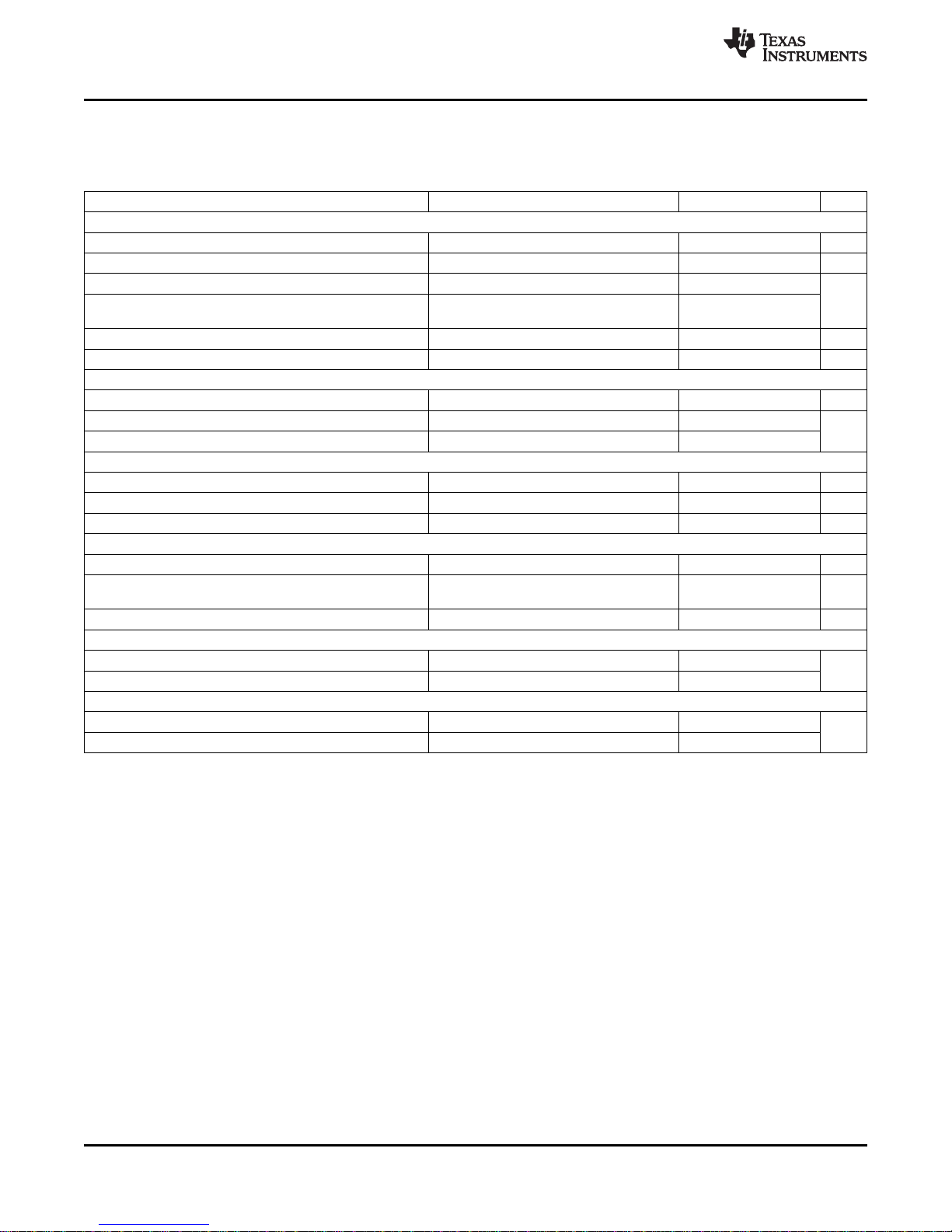

ELECTRICAL CHARACTERISTICS (continued)

VDD = 15 V, 0.1-μF capacitor from VDD to GND, 3.3-nF capacitor from SS to GND charged over 3.5 V, 500-Ω resistor from

OVP to -0.1 V, FB = 4.8 V, STATUS = not connected, 1-nF capacitor from OUT to GND, CS = GND, TA= -40°C to 105°C,

(unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Current Sense (CS)

A

CS(FB)

V

CS(os)

Power Limit (PL)

I

PL(cs)

V

PL

Soft Start (SS)

I

SS(chg)

I

SS(dis)

V

SS

Overvoltage Protection (OVP)

I

OVP(line)

V

OVP(on)

V

OVP(load)

Thermal Protection (TSP)

OUT

t

RISE

t

FALL

(2) R

(3) Ensured by design. Not production tested.

SCT

and C

(2)

Gain, FB = ΔVFB/ ΔV

CS

QR mode 2.5 V/V

Shutdown threshold VFB= 2.4 V, VSS= 0 V 1.13 1.25 1.38 V

CS to output delay time (power limit) CS = 1.0 V

CS to output delay time (over current

fault)

CS = 1.45 V

PULSE

PULSE

100 175 300

50 100 150

CS discharge impedance CS = 0.1 V, VSS= 0 V 25 115 250 Ω

CS offset SS mode, VSS≤ 2.0 V, via FB 0.35 0.40 0.45 V

(2)

CS current OVP = -300 μA -165 -150 -135 μA

CS working range QR mode, peak CS voltage 0.70 0.81 0.92

PL threshold Peak CS voltage + CS offset 1.05 1.20 1.37

Softstart charge current VSS= GND -8.3 -6.0 -4.5 μA

Softstart discharge current VSS= 0.5 V 2.0 5.0 10 mA

Switching ON threshold Output switching start 0.8 1.0 1.2 V

Line overvoltage protection I

OVP voltage at OUT = HIGH -125 -25 mV

Load overvoltage protection V

Thermal shutdown (TSP) temperature

(3)

threshold, OUT = HI -512 -450 -370 μA

OVP

VFB= 4.8 V, VSS= 5.0 V, I

μA

threshold, OUT = LO 3.37 3.75 4.13 V

OVP

OVP(on)

, = -300

130 140 150

Thermal shutdown hysteresis 15

Rise time 10% to 90% of 13 V typical out clamp 50 75

Fall time 10 20

are not connected in the circuit for maximum and minimum duty cycle tests, current sense tests and power limit tests.

CST

ns

V

°C

ns

4 Copyright © 2005–2011, Texas Instruments Incorporated

Page 5

STATUS

GND

V

FB

V

CS

V

OVP

V

OUT

V

DD

I

DD

I

OVP

R

OVP

500 Ω

C

OUT

1.0 nF

R

OUT

10 Ω

C

BIAS

1 µF

CDD 100 nF

I

CS

C

FB

47 pF

C

SS

3.3 nF

C

CST

560 pF

See Note

R

CST

37.4 kΩ

See Note

SS

VDD

GND

OUT

FB

CS

OVP

STATUS

UCC28600

+

1

2

3

4 5

6

7

8

5 V

2

1

6

5.0

VREF

SS

VDD

4

GND

5

OUT

FB

1.5R

8

3

CS

UVLO

+

C

BULK

Feedback

20kW

C

SS

7

OVP

On-Chip

Thermal

Shutdown

REF

26V

R

STATUS

13/8V

R

CS

R

OVP1

R

OVP2

C

VDD

+

400mV

REF

R

SU

+

Q

Q

SET

CLR

D

REF

GAIN=1/2.5

+

Modulation

Comparison

UCC28600

FaultLogic

LINE_OVP

LOAD_OVP

REF_OK

RUN

UVLO

CS

OVR_T

STATUS

SS_DIS

GREENMODE

FB_CLAMP

OSC_CL

FB

QRDETECT

LOAD_OVP

LINE_OVP

QR_DONE

____

OUT

CS

OSCILLATOR

QR_DONE

CLK

RUN

SS_OVR

OSC_CL

R

PL

PL

1.2V

SS_OVR BURST BURST

R

VDD

VDD

UCC28600

www.ti.com

OPEN LOOP TEST CIRCUIT

R

and C

CST

sense tests and power limit tests.

are not connected for maximum and minimum duty cycle tests, current

CST

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

NOTE

BLOCK DIAGRAM/TYPICAL APPLICATION

Copyright © 2005–2011, Texas Instruments Incorporated 5

Page 6

1

2

3

4

8

7

6

5

SS

FB

CS

GND

STATUS

OVP

VDD

OUT

UCC28600

D PACKAGE

(TOP VIEW)

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

ORDERING INFORMATION

T

A

-40°C to 105°C SOIC (D)

(1) SOIC (D) package is available taped and reeled by adding “R” to the above part numbers. Reeled quantities for UCC28600DR is 2,500

devices per reel.

PACKAGES PART NUMBER

(1)

UCC28600D

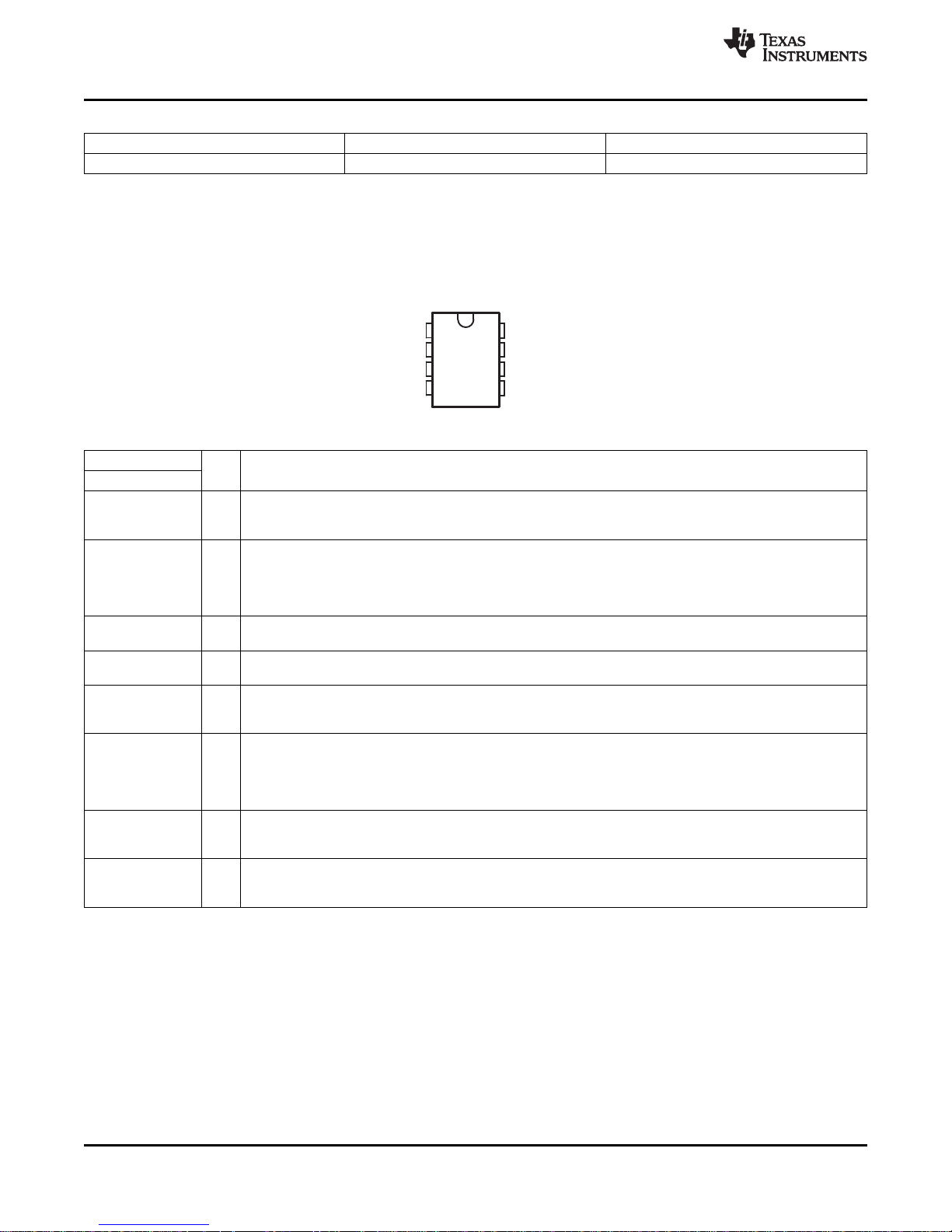

DEVICE INFORMATION

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

CS 3 I protection. The CS voltage input originates across a current sense resistor and ground. Power limit is

FB 2 I Connect the collector of the photo-transistor of the feedback optocoupler directly to this pin; connect the emitter

GND 4 -

OUT 5 O

OVP 7 I Detect line, load and resonant conditions using the primary bias winding of the transformer, adjust sensitivity

SS 1 I be placed as close as possible to the SS pin and GND, keeping trace length to a minimum. All faults discharge

STATUS 8 O disable the PFC control circuit (high impedance = green mode). STATUS pin is high during UVLO, (VDD <

VDD 6 I pin, as described in the GND pin description. Operating energy is usually delivered from auxiliary winding. To

I/O DESCRIPTION

Current sense input. Also programs power limit, and used to control modulation and activate overcurrent

programmed with an effective series resistance between this pin and the current sense resistor.

Feedback input or control input from the optocoupler to the PWM comparator used to control the peak current

in the power MOSFET. An internal 20-kΩ resistor is between this pin and the internal 5-V regulated voltage.

of the photo-transistor to GND. The voltage of this pin controls the mode of operation in one of the three

modes: quasi resonant (QR), frequency foldback mode (FFM) and green mode (GM).

Ground for internal circuitry. Connect a ceramic 0.1-μF bypass capacitor between VDD and GND, with the

capacitor as close to these two pins as possible.

1-A sink (TrueDrive™ ) and 0.75-A source gate drive output. This output drives the power MOSFET and

switches between GND and the lower of VDD or the 13-V internal output clamp.

Over voltage protection (OVP) input senses line-OVP, load-OVP and the resonant trough for QR turn-on.

with resistors connected to this pin.

Soft-start programming pin. Program the soft-start rate with a capacitor to ground; the rate is determined by the

capacitance and the internal soft-start charge current. Placement of the soft-start capacitor is critical and should

the SS pin to GND through an internal MOSFET with an R

comparator reacts to the lowest of the SS voltage, the internal FB voltage and the peak current limit.

ACTIVE HIGH open drain signal that indicates the device has entered standby mode. This pin can be used to

startup threshold), and softstart, (SS < FB).

Provides power to the device. Use a ceramic 0.1-μF by-pass capacitor for high-frequency filtering of the VDD

prevent hiccup operation during start-up, a larger energy storage cap is also needed between VDD and GND.

of approximately 100 Ω. The internal modulator

DS(on)

6 Copyright © 2005–2011, Texas Instruments Incorporated

Page 7

R

CS

+

ǒ

VPL* V

CS(os)

Ǔǒ

I

CS(2)

* I

CS(1)

Ǔ

I

CS(2)IP(1)

* I

CS(1)IP(2)

R

PL

+

ǒ

VPL* V

CS(os)

Ǔǒ

I

P(2)

* I

P(1)

Ǔ

I

CS(1)IP(2)

* I

CS(2)IP(1)

R

OVP1

+

1

I

OVP(line)

ǒ

N

B

N

P

V

BULK(ov)

Ǔ

R

OVP2

+ R

OVP1

ȧ

ȧ

ȡ

Ȣ

V

OVP(load)

N

B

N

S

ǒ

V

OUT(shutdown)

) V

F

Ǔ

* V

OVP(load)

ȧ

ȧ

ȣ

Ȥ

UCC28600

www.ti.com

TERMINAL COMPONENTS

TERMINAL

NAME NO.

CS 3 I

FB 2 I Opto-isolator collector

GND 4 - Bypass capacitor to VDD, CBP= 0.1 μF

OUT 5 O Power MOSFET gate

I/O DESCRIPTION

where:

• IP1is the peak primary current at low line, full load

• IP2is the peak primary current at high line, full load

• I

CS1

• I

CS2

• VPLis the Power Limit (PL) threshold

• V

CS(os)

(1) (2) (3)

is the power limit current that is sourced at the CS pin at low-line voltage

is the power limit current that is sourced at the CS pin at high-line voltage

is the CS offset voltage

(2)

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

(1)

(3)

(3)

(3)

(3)

(2)

OVP 7 I

(1) Refer to Figure 1 for all reference designators in the Terminal Components Table.

(2) Refer to the Electrical Characteristics Table for constant parameters.

(3) Refer to the UCC28600 Design Calculator (TI Literature Number SLVC104) or laboratory measurements for currents, voltages and times

in the operational circuit.

Copyright © 2005–2011, Texas Instruments Incorporated 7

where:

• I

OVP(line)

• V

BULK(ov)

• V

OVP(load)

• V

OUT(shutdown)

• VFis the forward voltage of the secondary rectifier

• NBis the number of turns on the bias winding

• NSis the number of turns on the secondary windings

• NPis the number of turns on the primary windings

is OVP

is the allowed input over- voltage level

is OVP

current threshold

line

(2)

load

is the allowed output over-voltage level

(2)

(3)

(3)

(3)

(3)

(3)

Page 8

CSSu I

SS

t

SS(min)

(

due power limit

)

A

CS(FB)

ǒ

VPL* V

CS(os)

Ǔ

t

SS(min)

+

ȧ

ȧ

ȱ

Ȳ

* R

LOAD(ss)COUT

2

ȏn

ȧ

ȡ

Ȣ

1 *

ǒ

V

OUT

* DV

OUT(step)

Ǔ

2

R

LOAD(ss)POUT(max)limit

ȧ

ȣ

Ȥ

ȧ

ȧ

ȳ

ȴ

t

SS(min)

+

ȧ

ȱ

Ȳ

C

OUTVOUT

2

2 P

LIM

ȧ

ȳ

ȴ

R

ST2

+

V

BE(off)

I

STATUS(leakage)

R

ST1

+

R

ST2

ƪ

VDD

(uvlo*on)

* V

BE(sat)

* R

DS(on)

ǒ

I

CC

b

sat

Ǔ

ƫ

* R

DS(on)VBE(sat)

ǒ

ǒ

I

CC

b

sat

Ǔ

R

ST2

Ǔ

) V

BE(sat)

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

TERMINAL COMPONENTS (continued)

TERMINAL

NAME NO.

SS 1 I

I/O DESCRIPTION

where t

or

• R

LOAD(ss)

• ΔV

• P

OUT(max limit)

• A

CS(FB)

• V

CS(os)

• ISSis the soft-start charging current

• VPLis the power limit threshold

(1) (2) (3)

is the greater of:

SS(min)

is the effective load impedance during soft-start

OUT(step)

is the allowed change in V

is the current sense gain

is the CS offset voltage

due to a load step

Programmed power limit level, in W

OUT

(5)

(5)

(5)

(5)

www.ti.com

(2)

(4)

(4)

(4)

STATUS 8 O

where:

• β

• V

• VDD

• ICCis the collector current of Q

• I

• V

• R

(4) Refer to the UCC28600 Design Calculator (TI Literature Number SLVC104) or laboratory measurements for currents, voltages and times

in the operational circuit.

(5) Refer to the Electrical Characteristics Table for constant parameters.

8 Copyright © 2005–2011, Texas Instruments Incorporated

is the gain of transistor QSTin saturation

SAT

BE(sat)

(uvlo-on)

STATUS(leakage)

is the maximum allowable voltage across the base emitter junction that will not turn QSTon

BE(off)

DS(on)

is the base-emitter voltage of transistor QSTin saturation

is the startup threshold

is the maximum leakage/off current of the STATUS pin

is the R

DS(on)

of STATUS

(5)

ST

(5)

(5)

Page 9

C

VDD

+

ƪ

ǒ

IDD) C

ISSVOUT(hi)fQR(max)

Ǔ

T

BURST

DV

DD(burst)

ƫ

C

VDD

+

ƪ

ǒ

IDD) C

ISSVOUT(hi)fQR(max)

Ǔ

t

SS

DVDD

(uvlo)

ƫ

R

VDD

+

ǒ

p

4

Ǔ

ǒ

N

B

NP

Ǔ

ȧ

ȡ

Ȣ

ǒ

V

DS1(os)fQR(max)LLEAKAGE

ǒ

CD) C

SNUB

Ǔ

Ǹ

IDD) C

ISSVOUT(hi)fQR(max)

ȧ

ȣ

Ȥ

R

SU

+

V

BULK(min)

I

STARTUP

UCC28600

www.ti.com

TERMINAL COMPONENTS (continued)

TERMINAL

NAME NO.

VDD 6 I

(6) Refer to the Electrical Characteristics Table for constant parameters.

(7) Refer to the UCC28600 Design Calculator (TI Literature Number SLVC104) or laboratory measurements for currents, voltages and times

in the operational circuit.

I/O DESCRIPTION

C

is the greater of:

VDD

or

where:

• IDDis the operating current of the UCC28600

• C

ISS

• V

OUT(hi)

• f

QR(max)

• T

BURST

• ΔVDD

• ΔVDD

• V

DS1(os)

• L

LEAKAGE

• CDis the total drain node capacitance of MOSFET M

• I

STARTUP

• C

SNUB

• tSSis the soft start charge time

(1) (2) (3)

(6)

is the input capacitance of MOSFET M

is VOH of the OUT pin, either 13 V (typ) V

is fSat high line, maximum load

is the measured burst mode period

is the allowed VDDripple during burst mode

(burst)

is the UVLO hysteresis

(uvlo)

is the amount of drain-source overshoot voltage

is the leakage inductance of the primary winding

is IDDstart-up current of the UCC28600

is the snubber capacitor value

(6)

(7)

1

(6)

OUT

(6)

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

(3)

clamp or less as measured

1

Copyright © 2005–2011, Texas Instruments Incorporated 9

Page 10

C

BULK

FEEDBACK

C

SS

R

CS

R

OVP1

R

OVP2

C

VDD

D1

R

SU

R

PL

TL431

2

1

6

SS

VDD

4 GND 5OUT

FB

8

3 CS

7OVP

STATUS

UCC28600

C

BP

100nF

R

ST2

R

ST1

C

OUT

PRIMARY SECONDARY

N

1

N

B

N

2

V

OUT

+

-

+

-

V

BULK

I

CC

R

VDD

Q

ST

R

OUT

R

SNUB

C

SNUB

M

1

PFC OUTPUT

or

BRIDGE RECTIFIER

PFC CONTROLLER BIAS

(if used)

C

BIAS

D2

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

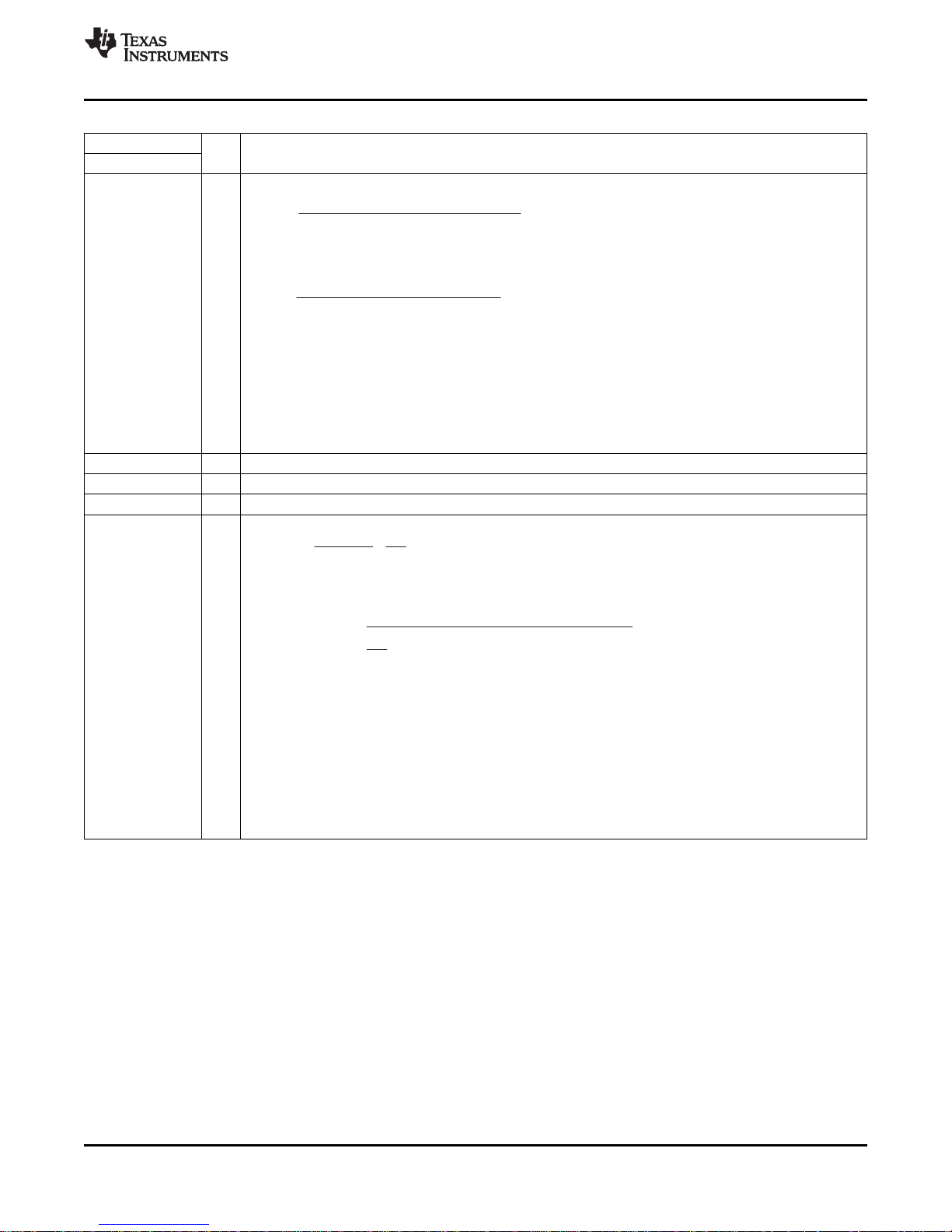

Figure 1. Pin Termination Schematic

10 Copyright © 2005–2011, Texas Instruments Incorporated

Page 11

V

FB

0.5V0.7V 1.4V 2.0V 4.0V 5.0V

GreenMode-ON,

Burst-OFF

GreenMode-OFF,

Burst-ON

Burst

Hysteresis

0V

GreenMode

Hysteresis

GreenMode

FFM

40kHz < f

S

< 130kHz

V

FB

Control Range Limit

InternalReference

QR Mode or DCMMode

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

APPLICATION INFORMATION

Functional Description

The UCC28600 is a multi-mode controller, as illustrated in Figure 3 and Figure 4. The mode of operation

depends upon line and load conditions. Under all modes of operation, the UCC28600 terminates the OUT = HI

signal based on the switch current. Thus, the UCC28600 always operates in current mode control so that the

power MOSFET current is always limited.

Under normal operating conditions, the FB pin commands the operating mode of the UCC28600 at the voltage

thresholds shown in Figure 2. Soft-start and fault responses are the exception. Soft-start mode hard-switch

controls the converter at 40 kHz. The soft-start mode is latched-OFF when VFBbecomes less than VSSfor the

first time after UVLOON. The soft-start state cannot be recovered until after passing UVLO

At normal rated operating loads (from 100% to approximately 30% full rated power) the UCC28600 controls the

converter in quasi-resonant mode (QRM) or discontinuous conduction mode (DCM), where DCM operation is at

the clamped maximum switching frequency (130 kHz). For loads that are between approximately 30% and 10%

full rated power, the converter operates in frequency foldback mode (FFM), where the peak switch current is

constant and the output voltage is regulated by modulating the switching frequency for a given and fixed VIN.

Effectively, operation in FFM results in the application of constant volt-seconds to the flyback transformer each

switching cycle. Voltage regulation in FFM is achieved by varying the switching frequency in the range from 130

kHz to 40 kHz. For extremely light loads (below approximately 10% full rated power), the converter is controlled

using bursts of 40-kHz pulses. Keep in mind that the aforementioned boundaries of steady-state operation are

approximate because they are subject to converter design parameters.

Refer to the typical applications block diagram for the electrical connections to implement the features.

, and then, UVLOON.

OFF

Copyright © 2005–2011, Texas Instruments Incorporated 11

Figure 2. Mode Control with FB Pin Voltage

Page 12

START

VDD > 13V?

Soft Start

Monitor V

FB

VFB> 2.0V1.4V < VFB< 2.0VVFB< 1.4V

Fixed V /s

Freq. Foldback

(Light Load)

Quasi-Resonant

Mode or DCM

(Normal Load)

VFB< 0.5V

VDD < 8V?

REF < 4V?

OVP = Logic High?

OT = Logic High?

OC = Logic High

RUN = Logic High

STATUS = Hi Z

Y

N

Y

Y

RUN = Logic Low

STATUS = Hi Z

Fixed V-sec

40kHz Burst

N

N

Fixed V /s

40kHz

Zero Pulses

STATUS = Hi Z

(In Green-Mode)

VFB> 1.2V?VFB> 1.5V?

STATUS = 0V

(In Run-Mode)

STATUS = 0V

(In Run-Mode)

STATUS = 0V

(In Run-Mode)

N

N

YY

RUN = Logic Low

Continuous Fault

Monitor

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

Figure 3. Control Flow Chart

12 Copyright © 2005–2011, Texas Instruments Incorporated

Page 13

fsw

QR Mode

Switching

Frequency

Feedback

Voltage

Power Supply

Output Voltage

t

t

t

(40 kHz)

This mode applies bursts of

40kHz soft−start pulses to the

power MOSFET gate. The

average fsw is shown in this

operating mode.

DCM

(maximum fs)

IC Off

Softstart

Regular Operation

Green Mode

Peak MOSFET

Current

t

Fixed Frequency

Status, pulled up

to VDD

t

Green Mode,

PFC bias OFF

Load Power

t

f

MAX

=

Oscillator Frequency

(130 kHz)

SS Mode

(Fixed fSW )

f

SS

V

FB

V

OUT

V

STATUS

Load shown is slightly

less than overcurrent

threshold

P

OUT, (max)

P

OUT

f

GRMODE_MX

(40 kHz)

f

QR_MIN

Internally Limit-

ed to 40 kHz

Hysteretic

Transition into

Green Mode

Frequency

Foldback

(Valley Switching, VS)

(VS)

FFM, (VS)

Green Mode

Burst Hysteresis

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

Copyright © 2005–2011, Texas Instruments Incorporated 13

Figure 4. Operation Mode Switching Frequencies

Page 14

OSC_CL

QR_DONE

4.0V

0.1V

SS_OVR

REF

S Q

QR

CLK

130 kHz OSC

Clamp

Comparator

OSC Valley

Comparator

OSC Peak

Comparator

RUN

+

+

+

Oscillator

+

+

+

FB_CL

OSC_CL

FB

1.4 V

2.0 V

450 kΩ

450 kΩ

100 kΩ

100 kΩ

Mode Clamps

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

Details of the functional boxes in the Block Diagram/Typical Application drawing are shown in Figure 5, Figure 6,

Figure 7 and Figure 8. These figures conceptualize how the UCC28600 executes the command of the FB voltage

to have the responses that are shown in Figure 2, Figure 3 and Figure 4. The details of the functional boxes also

conceptualize the various fault detections and responses that are included in the UCC28600. During all modes of

operation, this controller operates in current mode control. This allows the UCC28600 to monitor the FB voltage

to determine and respond to the varying load levels such as heavy, light or ultra-light.

Quasi-resonant mode and DCM occurs for feedback voltages VFBbetween 2.0 V and 4.0 V, respectively. In turn,

the CS voltage is commanded to be between 0.4 V and 0.8 V. A cycle-by-cycle power limit imposes a fixed 0.8-V

limit on the CS voltage. An overcurrent shutdown threshold in the fault logic gives added protection against

high-current, slew-rate shorted winding faults, shown in Figure 8. The power limit feature in the QR DETECT

circuit of Figure 7 adds an offset to the CS signal that is proportional to the line voltage. The power limit feature is

programmed with RPL, as shown in the typical applications diagram.

14 Copyright © 2005–2011, Texas Instruments Incorporated

Figure 5. Oscillator Details

Figure 6. Mode Clamp Details

Page 15

R

SU

R

OVP2

C

IN

C

VDD

R

OVP1

Auxiliary

Winding

+

+

+

+

7

Slope

+

0.1 V

0.1 V

-0.1 V

REF (5 V)

1 kW

3.75 V

0.45 V

QR_DONE

(Oscillator)

LOAD_OVP

(Fault Logic)

LINE_OVP

(Fault Logic)

REF (5 V)

3CS

OVP

VDD

OUT (From Driver)

UCC28600

R

PL1

CS

R

CS

Power Limit

Offset

I

LINE

Burst

(from FAULT logic)

01

+

QR Detect

I

LINE

I

LINE

2

C

OUT

R

PL2

N

S

N

P

N

B

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

Figure 7. QR Detect Details

Copyright © 2005–2011, Texas Instruments Incorporated 15

Page 16

S Q

QR

REF

D Q

Q

CLR

SET

Power−Up Reset

Thermal

Shutdown

+

+

1.25 V

+

SS/DIS

RUN

3 CS

OVR_T

LINE_OVP

(QR Detect)

LOAD_OVP

(QR Detect)

UVLO

REF_OK

Burst

REF

(5 V)

FB

7

FB

CS

SS_OVR

STATUS8

UCC28600

BURST

Over−Current

Shutdown

20 kΩ

Fault Logic

0.5 V/0.7 V

0.5 V/1.4 V

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

Figure 8. Fault Logic Details

Quasi-Resonant / DCM Control

Quasi-resonant (QR) and DCM operation occur for feedback voltages VFBbetween 2.0 V and 4.0 V. In turn, the

peak CS voltage is commanded to be between 0.4 V and 0.8 V. During this control mode, the rising edge of OUT

always occurs at the valley of the resonant ring after demagnetization. Resonant valley switching is an integral

part of QR operation. Resonant valley switching is also imposed if the system operates at the maximum

switching frequency clamp. In other words, the frequency varies in DCM operation in order to have the switching

event occur on the first resonant valley that occurs after a 7.7-μs (130-kHz) interval. Notice that the CS pin has

an internal dependent current source, 1/2 I

. This current source is part of the cycle-by-cycle power limit

LINE

function that is discussed in the Protection Features section.

Frequency Foldback Mode Control

Frequency foldback mode uses elements of the FAULT LOGIC, shown in Figure 8 and the mode clamp circuit,

shown in Figure 6. At the minimum operating frequency, the internal oscillator sawtooth waveform has a peak of

4.0 V and a valley of 0.1 V. When the FB voltage is between 2.0 V and 1.4 V, the FB_CL signal in Figure 6

commands the oscillator in a voltage controlled oscillator (VCO) mode by clamping the peak oscillator voltage.

The additional clamps in the OSCILLATOR restrict VCO operation between 40 kHz and 130 kHz. The FB_CL

voltage is reflected to the modulator comparator effectively clamping the reflected CS command to 0.4 V.

Green-Mode Control

Green mode uses element of the fault logic, shown in Figure 8 and the mode clamps circuit, shown in Figure 6.

The OSC_CL signal clamps the Green-mode operating frequency at 40 kHz. Thus, when the FB voltage is

between 1.4 V and 0.5 V, the controller is commanding an excess of energy to be transferred to the load which

in turn, drives the error higher and FB lower. When FB reaches 0.5 V, OUT pulses are terminated and do not

resume until FB reaches 0.7 V. In this mode, the converter operates in hysteretic control with the OUT pulse

terminated at a fixed CS voltage level of 0.4 V. The power limit offset is turned OFF during Green mode and it

returns to ON when FB is above 1.4 V, as depicted in Figure 8. Green mode reduces the average switching

frequency in order to minimize switching losses and increase the efficiency at light load conditions.

16 Copyright © 2005–2011, Texas Instruments Incorporated

Page 17

8

5

VCC

GND

UCC28051

C

VCC

0.1 mF

C

BULK

2

4

8

6

STATUS

VDD

FB

GND

UCC28600

R

ST1

R

ST2

R

CS

C

VDD

Primary Secondary

10 V

TL431

Feedback

M1

Q1

To Zero

Current

Detection

M2

R

VCC

C

BIAS

R

SU

N

B

N

P

N

S

D

Z1

D

BIAS

D

VDD

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

Fault Logic

Advanced logic control coordinates the fault detections to provide proper power supply recovery. This provides

the conditioning for the thermal protection. Line overvoltage protection (line OVP) and load OVP are

implemented in this block. It prevents operation when the internal reference is below 4.5 V. If a fault is detected

in the thermal shutdown, line OVP, load OVP, or REF, the UCC28600 undergoes a shutdown/retry cycle.

Refer to the fault logic diagram in Figure 8 and the QR detect diagram in Figure 7 to program line OVP and load

OVP. To program the load OVP, select the R

shut-down voltage. To program line OVP, select the impedance of the R

μA when the V

is 0.45 V during the ON-time of the power MOSFET at the highest allowable input voltage.

OVP

OVP1

– R

divider ratio to be 3.75 V at the desired output

OVP2

OVP1

– R

combination to draw 450

OVP2

Oscillator

The oscillator, shown in Figure 5, is internally set and trimmed so it is clamped by the circuit in Figure 5 to a

nominal 130-kHz maximum operating frequency. It also has a minimum frequency clamp of 40 kHz. If the FB

voltage tries to drive operation to less than 40 kHz, the converter operates in green mode.

Status

The STATUS pin is an open drain output, as shown in Figure 8. The status output goes into the OFF-state when

FB falls below 0.5 V and it returns to the ON-state (low impedance to GND) when FB rises above 1.4 V. This pin

is used to control bias power for a PFC stage, as shown in Figure 9. Key elements for implementing this function

include QST, R

ST1

and R

, as shown in the figure. Resistors R

ST2

ST1

and R

are selected to saturate QSTwhen it

ST2

is desirable for the PFC to be operational. During green mode, the STATUS pin becomes a high impedance and

R

causes QSTto turn-OFF, thus saving bias power. If necessary, use a zener diode and a resistor (DZ1and

ST1

RCC) to maintain VCCin the safe operating range of the PFC controller. Note the D

addition to the standard D

BIAS

- C

components. This added stage is required to isolate the STATUS circuitry

BIAS

VDD

- C

combination is in

VDD

from the startup resistor, RSU, to ensure there is no conduction through STATUS when VDD is below the UVLO

turn-on threshold.

Copyright © 2005–2011, Texas Instruments Incorporated 17

Figure 9. Using STATUS for PFC Shut-Down During Green Mode

Page 18

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

Operating Mode Programming

Boundaries of the operating modes are programmed by the flyback transformer and the four components RPL,

RCS, R

OVP1

and R

; shown in the Block Diagram/Application drawing.

OVP2

The transformer characteristics that predominantly affect the modes are the magnetizing inductance of the

primary and the magnitude of the output voltage, reflected to the primary. To a lesser degree (yet significant), the

boundaries are affected by the MOSFET output capacitance and transformer leakage inductance. The design

procedure here is to select a magnetizing inductance and a reflected output voltage that operates at the

DCM/CCM boundary at maximum load and maximum line. The actual inductance should be noticeably smaller to

account for the ring between the magnetizing inductance and the total stray capacitance measured at the drain

of the power MOSFET. This programs the QR/DCM boundary of operation. All other mode boundaries are preset

with the thresholds in the oscillator and green-mode blocks.

The four components RPL, RCS, R

OVP1

and R

must be programmed as a set due to the interactions of the

OVP2

functions. The use of the UCC28600 design calculator, TI Literature Number SLVC104, is highly recommended

in order to achieve the desired results with a careful balance between the transformer parameters and the

programming resistors.

Protection Features

The UCC28600 has many protection features that are found only on larger, full featured controllers. Refer to the

Block Diagram/Typical Application and Figures 1, 4, 5, 6 and 7 for detailed block descriptions that show how the

features are integrated into the normal control functions.

Overtemperature

Overtemperature lockout typically occurs when the substrate temperature reaches 140°C. Retry is allowed if the

substrate temperature reduces by the hysteresis value. Upon an overtemperature fault, CSSon softstart is

discharged and STATUS is forced to a high impedance.

18 Copyright © 2005–2011, Texas Instruments Incorporated

Page 19

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

Cycle-by-Cycle Power Limit

The cycle terminates when the CS voltage plus the power limit offset exceeds 1.2 V.

In order to have power limited over the full line voltage range of the QR Flyback converter, the CS pin voltage

must have a component that is proportional to the primary current plus a component that is proportional to the

line voltage due to predictable switching frequency variations due to line voltage. At power limit, the CS pin

voltage plus the internal CS offset is compared against a constant 1.2-V reference in the PWM comparator. Thus

during cycle-by-cycle power limit, the peak CS voltage is typically 0.8 V.

The current that is sourced from the OVP pin (I

) is reflected to a dependent current source of ½ I

LINE

LINE

, that is

connected to the CS pin. The power limit function can be programmed by a resistor, RPL, that is between the CS

pin and the current sense resistor. The current, I

NB/NPand resistor R

OVP1

. Current I

is programmed to set the line over voltage protection. Resistor RPLresults

LINE

, is proportional to line voltage by the transformer turns ratio

LINE

in the addition of a voltage to the current sense signal that is proportional to the line voltage. The proper amount

of additional voltage has the effect of limiting the power on a cycle-by-cycle basis. Note that RCS, RPL, R

R

must be adjusted as a set due to the functional interactions.

OVP2

OVP1

and

Current Limit

When the primary current exceeds maximum current level which is indicated by a voltage of 1.25 V at the CS

pin, the device initiates a shutdown. Retry occurs after a UVLO

/UVLOONcycle.

OFF

Over-Voltage Protection

Line and load over voltage protection is programmed with the transformer turn ratios, R

OVP1

and R

. The OVP

OVP2

pin has a 0-V voltage source that can only source current; OVP cannot sink current.

Line over voltage protection occurs when the OVP pin is clamped at 0 V. When the bias winding is negative,

during OUT = HI or portions of the resonant ring, the 0-V voltage source clamps OVP to 0 V and the current that

is sourced from the OVP pin is mirrored to the Line_OVP comparator and the QR detection circuit. The

Line_OVP comparator initiates a shutdown-retry sequence if OVP sources any more than 450 μA.

Load-over voltage protection occurs when the OVP pin voltage is positive. When the bias winding is positive,

during demagnetization or portions of the resonant ring, the OVP pin voltage is positive. If the OVP voltage is

greater than 3.75 V, the device initiates a shutdown. Retry occurs after a UVLO

/UVLOONcycle.

OFF

Undervoltage Lockout

Protection is provided to guard against operation during unfavorable bias conditions. Undervoltage lockout

(UVLO) always monitors VDD to prevent operation below the UVLO threshold.

Copyright © 2005–2011, Texas Instruments Incorporated 19

Page 20

–50 0 100 150

T – Temperature – °C

J

21

23

25

27

50

29

31

VDD – Clamp Voltage – V

–50 0 100 150

T – Temperature – °C

J

117

122

127

132

50

137

142

f – Switching Frequency – kHz

S

–50 0 100 150

T – Temperature – °C

J

0.70

0.75

0.80

0.85

50

0.90

0.95

PL Threshold, QR Mode, Peak CS Voltage – V

–50 0 100 150

T – Temperature – °C

J

–512

–492

–472

–452

50

–432

–412

–392

–372

I – Over Voltage Protection Threshold – µA

OVP

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

CLAMP VOLTAGE SWITCHING FREQUENCY

vs vs

TEMPERATURE TEMPERATURE

www.ti.com

TYPICAL CHARACTERISTICS

Figure 10. Figure 11.

PL THRESHOLD OVER VOLTAGE PROTECTION THRESHOLD

vs vs

TEMPERATURE TEMPERATURE

Figure 12. Figure 13.

20 Copyright © 2005–2011, Texas Instruments Incorporated

Page 21

R

PL1

+ R

PL

ǒ

R

CS

R

DCS

Ǔ

R

PL2

+

R

PL1

ǒ

R

CS

R

DCS

Ǔ

* 1

R

CS

R

PL1

R

PL2

From power

MOSFET

To CS

R

DCS

R

PL

From power

MOSFET

To CS

(a) (b)

UCC28600

www.ti.com

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

PRACTICAL DESIGN NOTES

Non-Ideal Current Sense Value

Resistors RCS, RPL, R

converter. Often, the ideal value for RCSis not available because the selection range of current sense resistors is

too coarse to meet the required power limit tolerances. This issue can be solved by using the next larger

available value of RCSand use a resistive divider with a Thevenin resistance that is equal to the ideal RPLvalue

in order to attenuate the CS signal to its ideal value, as shown in Figure 14. The equations for modifying the

circuit are:

• R

= ideal, but non-standard, value of current sense resistor.

DCS

• RPL= previously calculated value of the power limit resistor.

• RCS= available, standard value current sense resistor.

The board should be laid out to include R

readily available components.

OVP1

and R

must be programmed as a set due to functional interactions in the

OVP2

in order to fascillitate final optimization of the design based upon

PL2

(4)

(5)

Figure 14. Modifications to Fit a Standard Current Sense Resistor Value

Copyright © 2005–2011, Texas Instruments Incorporated 21

Page 22

PRIMARY SECONDARY

+

−

+

−

+

−

PRIMARY SECONDARY

+

−

+

−

+

−

(a)

(c)

0V

0V

(b)

0V

0V

(d)

V

D

V

D

V

D

V

D

V

G

V

G

V

G

V

G

L

M

L

M

L

LEAK

L

LEAK

V

BULK

V

BULK

C

BULK

C

BULK

V

IN

V

IN

V

R

V

R

∆V

SNUB

∆V

SNUB

C

SNUB

C

SNUB

R

SNUB2

R

SNUB1

R

SNUB1

C

D

C

D

R

CS

R

CS

M

1

M

1

D

S

D

S

Reduced L

LEAK CD

Resonance

L

LEAK CD

Resonance

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

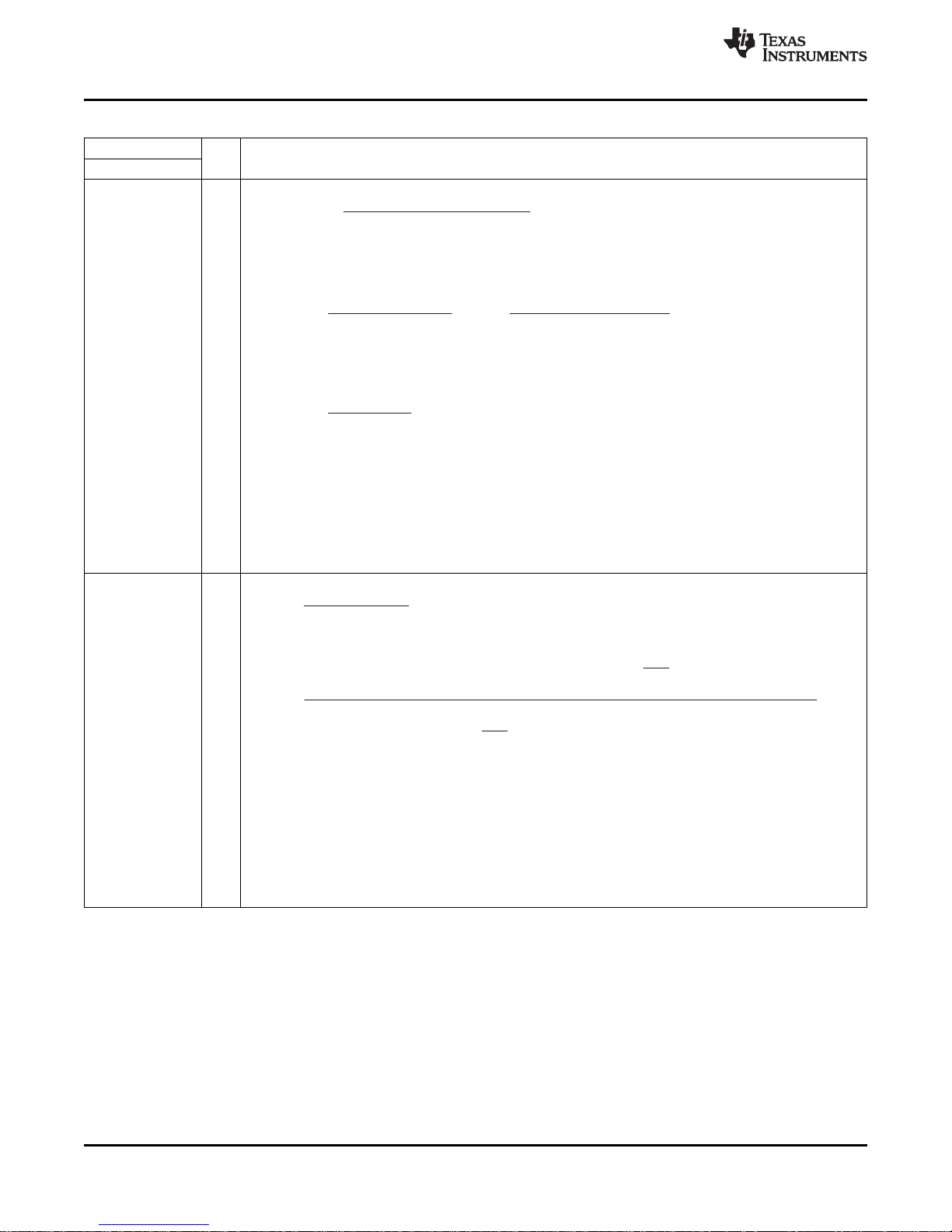

Snubber Damping

Resonance between the leakage inductance and the MOSFET drain capacitance can cause false load-OVP

faults, in spite of the typical 2-μs delay in load-OVP detection. The bias winding is sensitive to the overshoot and

ringing because it is well coupled to the primary winding. A technique to eliminate the problem is to use an R2CD

snubber instead of an RCD snubber, shown in Figure 15. A damping resistor added to the RCD snubber reduces

ringing between the drain capacitor and the inductance when the snubber diode commutates OFF.

Figure 15. (a) RCD Snubber, (b) RCD Snubber Waveform, (c) R2CD Snubber, (d) R2CD Snubber

Waveform

22 Copyright © 2005–2011, Texas Instruments Incorporated

Page 23

Pick

DV

SNUB

V

R

+ between 0.5 and 1

C

SNUB

+

I

cs(peak)

2

L

LEAK

ǒ

VR) DV

SNUB

Ǔ

2

* V

R

2

R

SNUB1

+ ǒ

1

2

)

V

R

DV

SNUB

Ǔ

1

C

SNUB

ǒ

1

f

S(max)

*

L

LEAKICS(peak)

DV

SNUB

Ǔ

( )

2

2

SNUB

R

R

SNUB

SNUB1

SNUB1

V

1 1

V 1

V

1

2 3

V 2

P R

R

é ù

é ù

ê ú

ê ú

D

æ ö

æ ö

ê ú

ê ú

+ ´ + ´

ç ÷

ç ÷

ê ú

è ø

ê ú

è ø

+

ê ú

ê ú

ë û

ë û

=

R

SNUB2

+

DV

SNUB

I

CS(peak)

PǒR

SNUB

Ǔ

+ I

CS(peak)

2

R

SNUB2

ȧ

ȧ

ȧ

ȧ

ȡ

Ȣ

1

3

L

LEAKfS(max)

ǒ

V

R

)

DV

SNUB

2

Ǔ

ȧ

ȧ

ȧ

ȧ

ȣ

Ȥ

Q +

2V

R

DV

SNUB

) 1

Ǹ

UCC28600

www.ti.com

Begin the design of the R2CD using the same procedure as designing an RCD snubber. Then, add the damping

resistor, R

Select a capacitor for ΔV

Pick R

SNUB

Pick R

SNUB2

. The procedure is as follows:

SNUB2

:

SNUB

to discharge C

to dampen the L

:

SNUB

LEAK-CSNUB

resonance with a Q that is between 1.7 and 2.2:

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

(6)

(7)

(8)

(9)

For the original selection of ΔV

SNUB

(10)

(11)

,

(12)

Copyright © 2005–2011, Texas Instruments Incorporated 23

Page 24

UCC28600

SLUS646J –NOVEMBER 2005– REVISED JULY 2011

www.ti.com

REFERENCES

1. Power Supply Seminar SEM-1400 Topic 2: Design And Application Guide For High Speed MOSFET Gate

Drive Circuits, by Laszlo Balogh, Texas Instruments Literature Number SLUP133

2. Datasheet, UCC3581 Micro Power PWM Controller, Texas Instruments Literature Number SLUS295

3. Datasheet, UCC28051 Transition Mode PFC Controller, Texas Instruments Literature Number SLUS515

4. UCC28600 Design Calculator, A QR Flyback Designer.xls, spreadsheet for Microsoft Excel 2003, Texas

Instruments Literature Number SLVC104

5. Design Considerations for the UCC28600, Texas Instruments Literature Number SLUA399

RELATED PRODUCTS

• UCC28051 Transition Mode PFC Controller (SLUS515)

• UCC3581 Micro Power PWM Controller (SLUS295)

REVISION HISTORY

Changes from Revision H (November 2005) to Revision I Page

• Changed Equation 9 ........................................................................................................................................................... 23

24 Copyright © 2005–2011, Texas Instruments Incorporated

Page 25

PACKAGE OPTION ADDENDUM

www.ti.com

11-Apr-2013

Addendum-Page 1

PACKAGING INFORMATION

Orderable Device Status

(1)

Package Type Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Op Temp (°C) Top-Side Markings

(4)

Samples

UCC28600D ACTIVE SOIC D 8 75 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 105 28600D

UCC28600DG4 ACTIVE SOIC D 8 75 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 105 28600D

UCC28600DR ACTIVE SOIC D 8 2500 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 105 28600D

UCC28600DRG4 ACTIVE SOIC D 8 2500 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 105 28600D

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

Multiple Top-Side Markings will be inside parentheses. Only one Top-Side Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a

continuation of the previous line and the two combined represent the entire Top-Side Marking for that device.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Page 26

PACKAGE OPTION ADDENDUM

www.ti.com

11-Apr-2013

Addendum-Page 2

OTHER QUALIFIED VERSIONS OF UCC28600 :

•

Automotive: UCC28600-Q1

NOTE: Qualified Version Definitions:

•

Automotive - Q100 devices qualified for high-reliability automotive applications targeting zero defects

Page 27

PACKAGE MATERIALS INFORMATION

www.ti.com 10-Apr-2015

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

UCC28600DR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 28

PACKAGE MATERIALS INFORMATION

www.ti.com 10-Apr-2015

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

UCC28600DR SOIC D 8 2500 340.5 338.1 20.6

Pack Materials-Page 2

Page 29

Page 30

Page 31

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Loading...

Loading...