UC1907

UC2907

UC3907

DESCRIPTION

The UC3907 family of Load Share Controller ICs provides all the necessary

features to allow multiple independent power modules to be paralleled such

that each module supplies only its proportionate share to total load current.

This sharing is accomplished by controlling each module’s power stage

with a command generated from a voltage feedback amplifier whose reference can be independently adjusted in response to a common share bus

voltage.By monitoring the current from each module, the current share bus

circuitry determines which paralleled module would normally have the highest output current and, with the designation of this unit as the master, adjusts all the other modules to increase their output current to within 2.5% of

that of the master.

The current share bus signal interconnecting all the paralleled modules is a

low-impedance, noise-insensitive line which will not interfere with allowing

each module to act independently should the bus become open or shorted

to ground. The UC3907 controller will reside on the output side of each

power module and its overall function is to supply a voltage feedback loop.

The specific architecture of the power stage is unimportant. Either switching or linear designs may be utilized and the control signal may be either directly coupled or isolated though the use of an opto coupler or other

isolated medium.

Other features of the UC3907 include 1.25% accurate reference: a

low-loss, fixed gain current sense amplifier, a fully differential,

high-impedance voltage sensing capability, and a status indicator to designate which module is performing as master.

Load Share Controller

FEATURES

Fully Differential High Impedance

Voltage Sensing

Accurate Current Amplifier for Precise

Current Sharing

Opto Coupler Driving Capability

1.25% Trimmed Reference

Master Status Indication

4.5V TO 35V Operation

SLUS165 - MARCH 1999

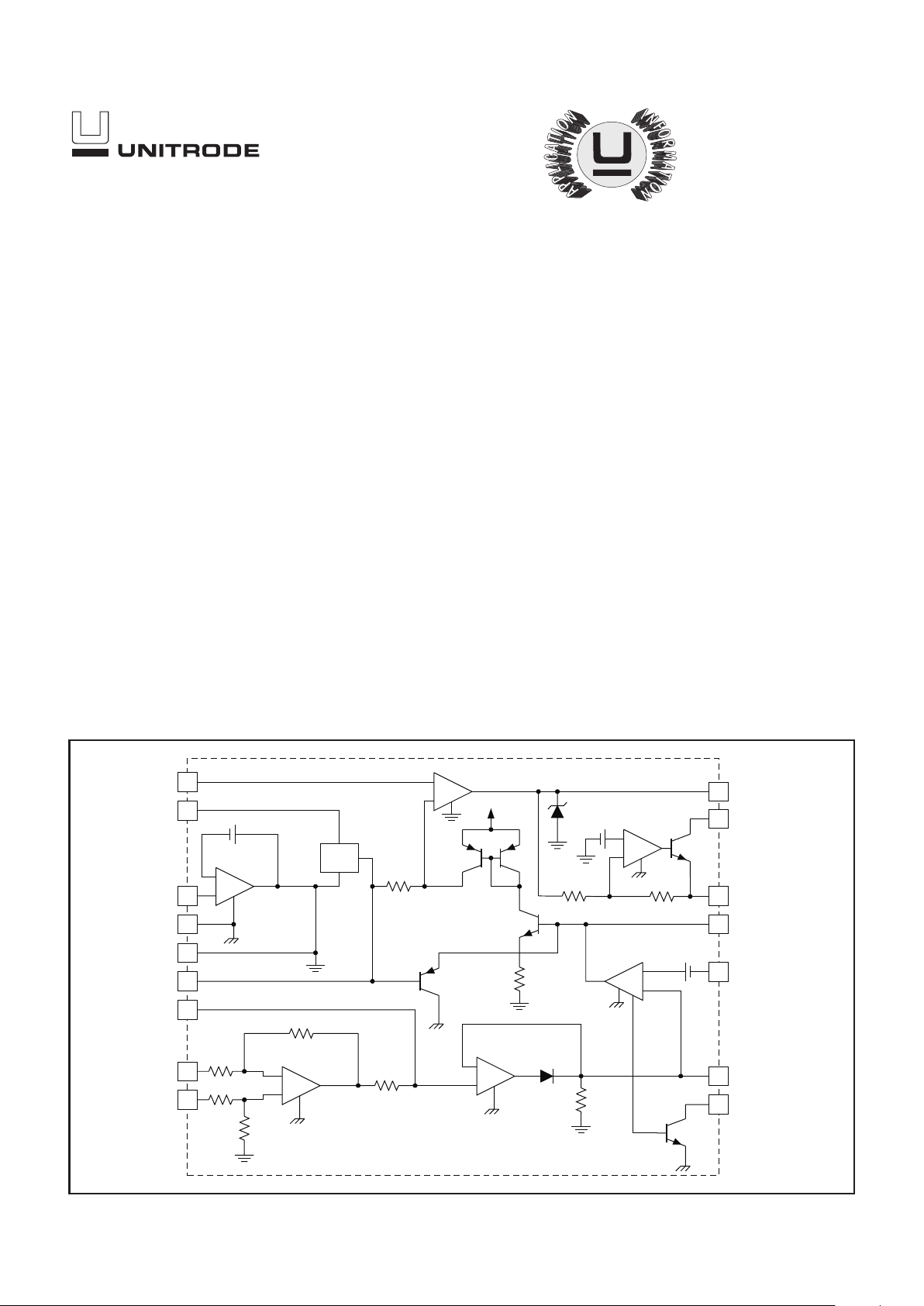

11

14

10

13

8

9

12

15

16

7

5

4

1

6

3

2

2k

2k

+

–

40k

40k

CURRENT SENSE

AMPLIFIER

100

+

–

BUFFER

AMPLIFIER

10k

+

–

+

50mV

ADJUST

AMPLIFIER

ADJ

17.5k

V

CC

1k

V

REF

1.750V

+

–

+

GROUND

AMPLIFIER

0.25V

GND

+

–

50k

20k

+

1.0V

1.75V

VOLTAGEERROR AMPLIFIER

ST ATUSINDICATE

CURRENT SHARE BUS

ADJ INPUT

ADJ OUT

ISET

OPTO DRIVE

COMP

(+) SENSE

VCC (4.5V TO35V)

(–) SENSE

POWER RTN

ARTIFICIAL GND

VREF

C/S OUT

C/S (–)

C/S (+)

DRIVE

AMPLIFIER

+

–

DRV

BLOCK DIAGRAM

UDG-99052

2

UC1907

UC2907

UC3907

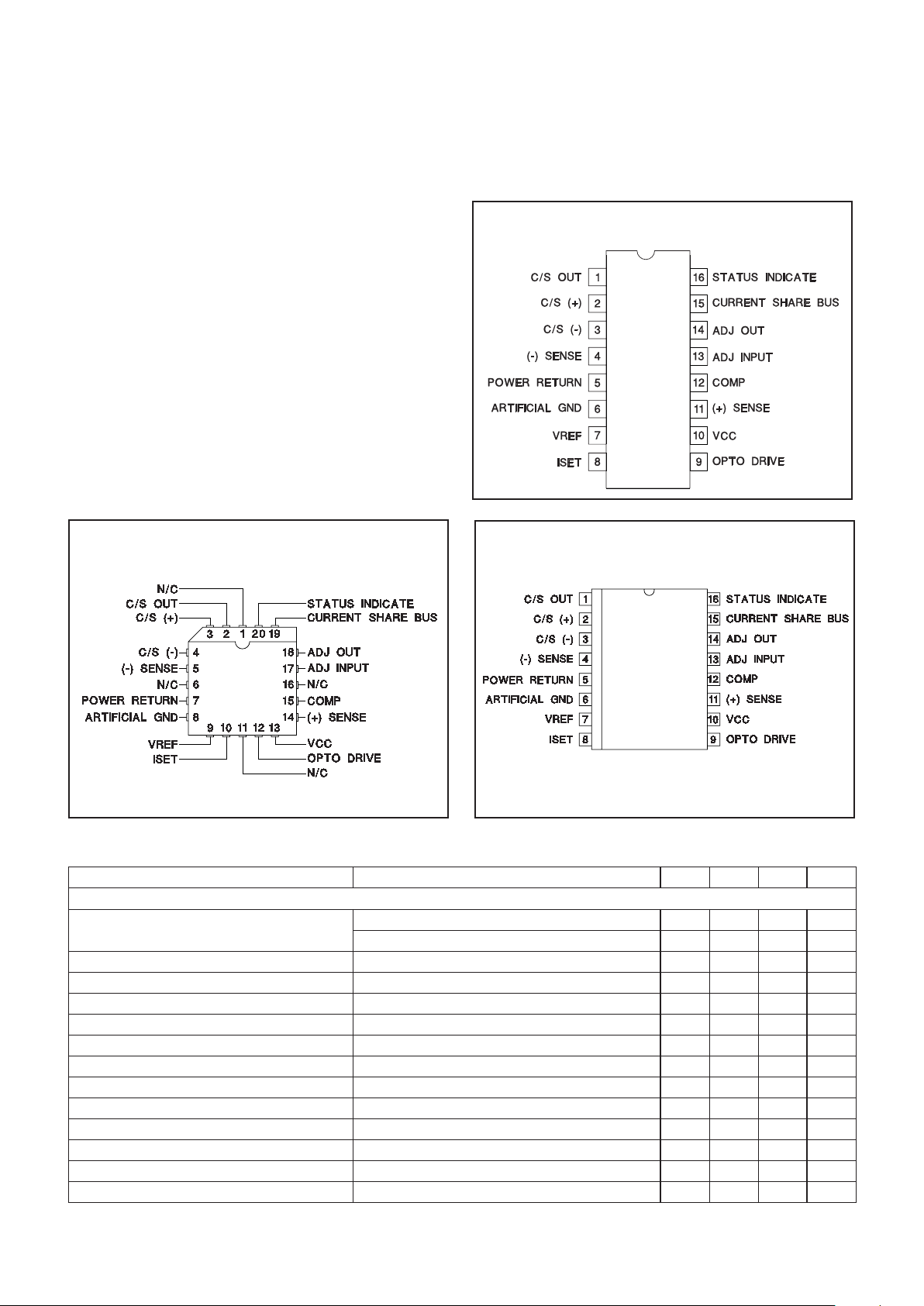

DIL-16 (Top View)

J or N Package

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +35V

Opto Out Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +35V

Opto Out Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +20mA

Status Indicate Sink Current. . . . . . . . . . . . . . . . . . . . . . +20mA

C/S Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +35V

Share Bus Voltage. . . . . . . . . . . . . . . . . . . . . . . – 0.3V to +35V

Other Analog Inputs and Outputs (Zener clamped)

Maximum Forced Voltage . . . . . . . . . . . . . . . – 0.3V to +10V

Maximum Forced Current. . . . . . . . . . . . . . . . . . . . . . ±10mA

Ground Amp Sink Current . . . . . . . . . . . . . . . . . . . . . . . +50mA

Pins 1, 9, 12, 15 Sink Current. . . . . . . . . . . . . . . . . . . . . +20mA

Storage Temperature Range. . . . . . . . . . . . . – 65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . – 55°C to +150°C

Lead Temperature (Solder 10 Seconds) . . . . . . . . . . . . +300°C

Pin Nos. refer to 16 Pin DIL Package

Currents are positive into, negative out of the specified

terminal. Consult packaging section of databook for thermal

limitations and considerations of package.

CONNECTION DIAGRAMS

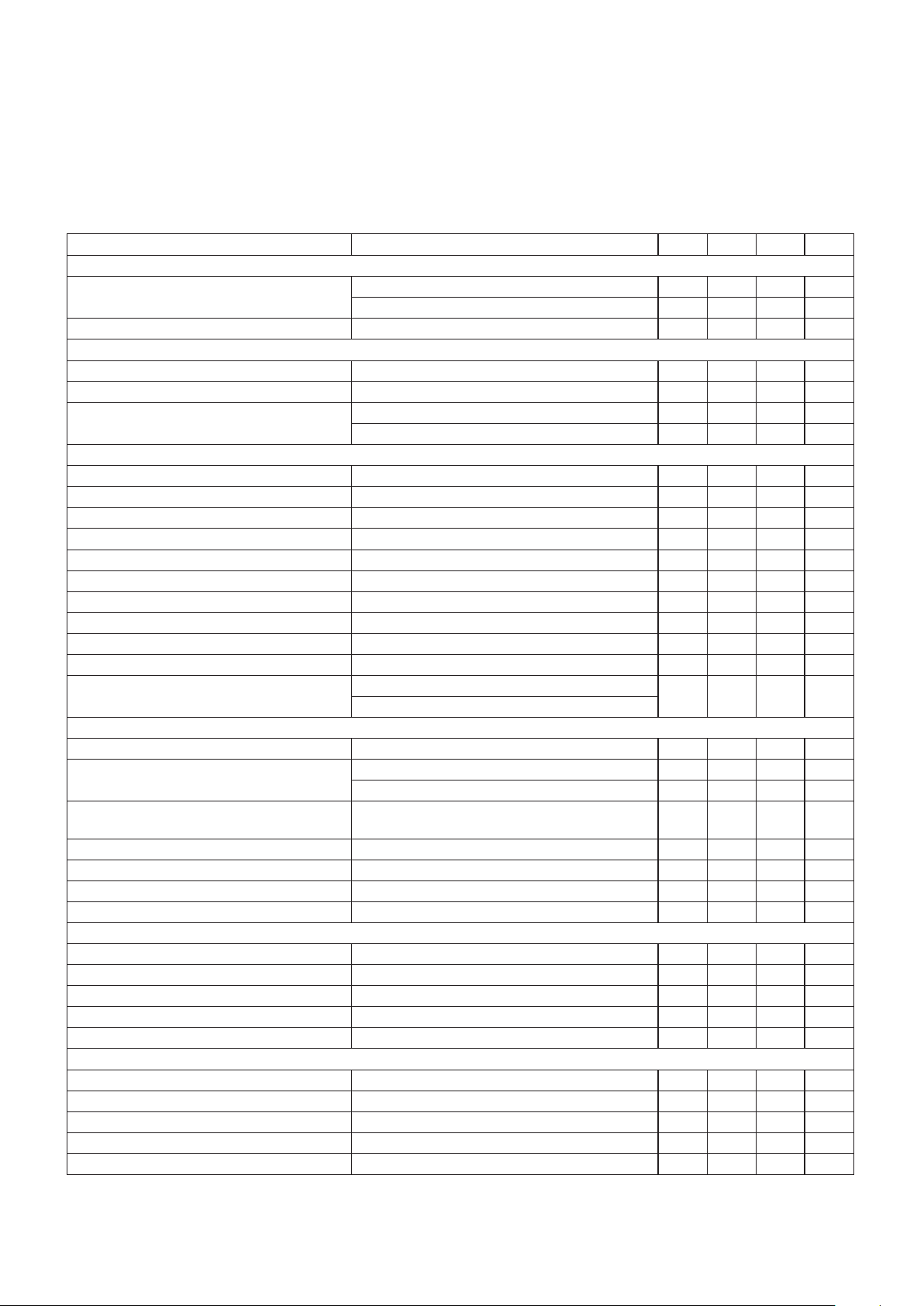

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated these specifications apply for TA= –55°C to +125°C for

UC1907; –40°C to +85°C for UC2907; and 0°C to +70°C for UC3907; VIN= 15V, TA=TJ.

PARAMETER TEST CONDITIONS

MIN TYP MAX UNITS

Voltage Amp Section

Input Voltage COMP = 1V, T

A

= 25°C 1.975 2.000 2.025 V

COMP = 1V, Over Temp 1.960 2.000 2.040 V

Line Regulation V

IN

= 4.5V to 35V 15 mV

Load Regulation I

L

Reference = 0.0mA to – 10mA 10 mV

Long Term Stability T

A

= 125°C, 1000hrs (Note 2) 5 25 mV

Total Output Variation Line, Load, Temp 1.960 2.040

Input Adjust Range ADJ OUT from max high to max low 85 100 115 mV

Input Bias Current –1 µA

Open Loop Gain COMP = 0.75V to 1.5V 65 dB

Unity Gain Bandwidth T

A

= 25°C (Note 2) 700 kHz

Output Sink Current (+) SENSE = 2.2V, COMP = 1V 6 15 mA

Output Source Current (+) SENSE = 1.8V, COMP = 1V 400 600 µA

V

OUT

High (+) SENSE = 1.8V, IL= – 400µa 1.85 2 V

V

OUT

Low (+) SENSE = 2.2V, IL= +1mA 0.15 0.40 V

PLCC–20, LCC–20 (Top View)

Q PACKAGE, L PACKAGE

SOIC-16 (Top View)

DW Package

3

UC1907

UC2907

UC3907

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated these specifications apply for TA= –55°C to +125°C for

UC1907; –40°C to +85°C for UC2907; and 0°C to +70°C for UC3907; VIN= 15V, TA=TJ.

PARAMETER TEST CONDITIONS

MIN TYP MAX UNITS

Reference Section

Output Voltage T

A

= 25°C 1.970 2.000 2.030 V

Over Operating Temp 1.955 2.000 2.045 V

Short Circuit Current VREF = 0.0V – 15 – 30 – 60 mA

Ground Amp Section

Output Voltage 200 250 300 mV

Common Mode Variation (–) SENSE from 0.0V to 2V 5 mV

Load Regulation I

L

= 0.0mA to 20mA, TA= 25°C 10 mV

I

L

= 0.0mA to 20mA, Over Temp 15 mV

Adjust Amp Section

Input Offset Voltage ADJ OUT = 1.5V, Vcm = 0.0V 40 50 60 mV

Input Bias Current – 2 µA

Open Loop Gain 1.5V≤ADJ OUT≤ 2.25V 65 dB

Unity Gain Bandwidth T

A

= 25°C, C

OUT

=1µF (Note 2) 500 Hz

Transconductance I

OUT

= – 10µA to +10µA, V

OUT

= 1.5V 1.7 3 4.5 ms

Output Sink Current Vid = 0.0V, ADJ OUT = 1.5V 55 135 225 µA

Output Source Current Vid = 250mV, ADJ OUT = 1.5V 110 200 350 µA

V

OUT

High Vid = 250mV, I

OUT

= – 50µA 2.20 2.70 2.90 V

V

OUT

Low Vid = 0.0V, I

OUT

= 50µA 0.75 1.15 V

Common Mode Rejection Ratio Vcm = 0.0 to 10V 70 dB

Output Gain to V/A V

OUT

ADJ OUT = 1.5V to 2V 50 57 64 mV/V

∆(+) SENSE/ ∆ADJ OUT

Current Amp Section

Gain Vcm = 0.0V, Vid = 50mV to 100mV 19.2 19.6 20.1 V/V

Output Voltage Vc/s (+) = Vc/s (–) = 0.0V, T

A

= 25°C 210 250 290 mV

Vc/s (+) = Vc/s (–) = 0.0V, Over Temp 180 250 330 mV

Input Offset Change with Common Mode

Input

Vcm = 0V to 13V 600 µV/V

V

OUT

High Vid = 1V 10 14.5 V

V

OUT

Low Vid = – 1V, IL= 1mA 350 450 mV

Power Supply Rejection Ratio V

IN

= 4.5V to 35V, Vcm = 0.0V 60 dB

Slew Rate 0.4 V/µs

Drive Amp Section Rset = 500Ω to Artificial Gnd, Opto Drive = 15V

Voltage Gain COMP = 0.5V to 1V 2.3 2.5 2.6 V/V

I

SETVOUT

High (+) SENSE = 2.2V 3.8 4.1 4.4 V

I

SETVOUT

Low (+) SENSE = 1.8V 270 300 mV

Opto out Voltage Range 435V

Zero Current Input Threshold 1.55 1.65 1.75 V

Buffer Amp Section

Input Offset Voltage Input = 1V 5 mV

Output Off Impedance Input = 1V, Output = 1.5V to 2V 5 10 20 kΩ

Output Source Current Input = 1V, Output = 0.5V 6 15 mA

Common Mode Rejection Ratio Vcm = 0.3V to 10V 70 dB

Power Supply Rejection Ratio V

IN

= 4.5V to 35V 70 dB

4

UC1907

UC2907

UC3907

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated these specifications apply for TA= –55°C to +125°C for

UC1907; –40°C to +85°C for UC2907; and 0°C to +70°C for UC3907; VIN= 15V, TA=TJ.

PARAMETER TEST CONDITIONS

MIN TYP MAX UNITS

Under Voltage Lockout Section

Startup Threshold 3.7 4.4 V

Threshold Hysteresis 20 mV

Status Indicate Section

V

OUT

Low ADJ OUT = Current Share Bus 0.2 0.5 V

Output Leakage ADJ OUT = 1V, V

OUT

= 35V 0.1 5 µA

Total Stand by Current Section

Startup Current VIN= UVLO – 0.2V 3 5 mA

Operating Current V

IN

= 35V 6 10 mA

Note 1: Unless otherwise specified all voltages are with respect to (–) SENSE. Currents are positive into, negative out of the

specified terminal.

Note 2: Guaranteed by design. Not 100% tested in production.

(–) SENSE (Pin 4) - This is a high-impedance pin intended to allow remote sensing of the system ground,

bypassing any voltage drops which might appear in the

power return line. This point should be considered as

the “true” ground. Unless otherwise stated, all voltages are with respect to this point.

ARTIFICIAL GROUND (Pin 6) - This is a low impedance

circuit ground which is exactly 250 millivolts above the (–)

SENSE terminal. This offset allows the Ground Buffer

Amplifier negative headroom to return all the control bias

and operating currents while maintaining a high impedance at the (–) SENSE input.

POWER RTN (Pin 5) - This should be the most negative

voltage available and can range from zero to 5V below

the (–) SENSE terminal. It should be connected as close

to the power source as possible so that voltage drops

across the return line and current sensing impedances

lie between this terminal and the (–) SENSE point.

VREF (Pin 7) - The internal Voltage Reference is a

band-gap circuit set at 2.0 Volts with respect to the (–)

SENSE input (1.75V above the ARTIFICIAL GROUND),

and an accuracy of ± 1.5%. This circuit, as well as all the

other chip functions, will work over a supply voltage

range of 4.5V to 35V allowing operation from unregulated

DC, an auxiliary voltage, or the same output voltage that

it is controlling. Under voltage lockout has been included

to insure proper startup by disabling internal bias currents until the reference rises into regulation.

VOLTAGE AMPLIFIER (Pins 11, 12) - This circuit is the

feedback control gain stage for the power module’s output voltage regulation, and overall loop compensation will

normally be applied around this amplifier. Its output will

swing from slightly above the ground return to an internal

clamp of 2.0 Volts. The reference trimming is performed

closed loop, and measured at pin 11, (+) SENSE. The

value is trimmed to 2V ±1.25%.

DRIVE AMPLIFIER (Pins 8, 9, 12) - This amplifier is

used as an inverting buffer between the Voltage Amplifier’s output and the medium used to couple the feedback

signal to the power controller. It has a fixed voltage gain

of 2.5 and is usually configured with a current-setting resistor to ground. This establishes a current - sinking output optimized to drive optical couplers biased at any

voltage from 4.5V to 35V, with current levels up to 20mA.

The polarity of this stage is such that an increasing voltage at the Voltage Amplifier’s sense input (as, for example, at turn on) will increase the opto’s current. In a

nonisolated application, a voltage signal ranging from

0.25V to 4.1V may be taken from the current-setting output but it should be noted that this voltage will also increase with increasing sense voltage and an external

inverter may be required to obtain the correct feedback

polarity.

CURRENT AMPLIFIER (Pins 1, 2, 3) - This amplifier has

differential sensing capability for use with an external

shunt in the power return line. The common-mode range

of its input will accommodate the full range between the

Power Return point and VCC–2V which will allow undefined line impedances on either side of the current shunt.

The gain is internally set at 20 giving the user the ability

to establish the maximum voltage drop across the current sense resistor at any value between 50 and 500 millivolts. While the bandwidth of this amplifier may be

reduced with the addition of an external output capacitor

to ground, in most cases this is not required as the compensation of the Adjust Amplifier will typically form the

dominant pole in the adjust loop.

PIN/BLOCK DESCRIPTIONS

5

UC1907

UC2907

UC3907

BUFFER AMPLIFIER (Pins 1, 15) - This amplifier is a

uni-directional buffer which drives the CURRENT SHARE

BUS - the line which will interconnect all power modules

paralleled for current sharing. Since the Buffer Amplifier

will only source current, it insures that the module with

the highest output current will be the master and drive

the bus with a low-impedance drive capability. All other

Buffer Amplifiers will be inactive with each exhibiting a

10kohm load impedance to ground. The Share Bus terminal is protected against both shorts to ground and accidental voltages in excess of 50 Volts.

ADJUST AMPLIFIER (Pins 13, 14, 15) - This amplifier

adjusts the individual module’s reference voltage to

maintain equal current sharing. It is a transconductance

type in order that its bandwidth may be limited, and noise

kept out of the reference adjust circuitry, with a simple

capacitor to ground. The function of this amplifier is to

compare its own module output current to the Share Bus

signal - which represents the highest output current - and

force an adjust command which is capable of increasing

the reference voltage as seen by the voltage amplifier by

as much as 100 millivolts. This number stems from the

17.5:1 internal resistor ratio between the Adjust Amplifier’s clamped output and the reference, and represents a

5% total range of adjustment-avalue which should be

adequate to compensate for unit-to-unit reference and

external resistor tolerances. The Adjust Amplifier has a

built-in 50mV offset on its inverting input which will force

the unit acting as the master to have a low output resulting in no change to the reference. While this 50mV offset

represents an error in current sharing, the gain of the

current amplifier reduces it to only 2.5mV across the current sense resistor. It should also be noted that when the

module is acting independently with no connection to the

Share Bus node, or when the Share Bus node is shorted

to ground, its reference voltage will be unchanged. Since

only the circuit acting as a master will have a low output

from the Adjust Amplifier, this signal is used to activate a

flag output to identify the master should some corrective

action be needed.

STATUS INDICATE (Pin 16) - This pin is an open collector output intended to indicate the unit which is acting as

the master. It achieves this by sensing when the adjust

amp is in its low state and pulling the status indicate pin

low.

ADDITIONAL INFORMATION

Please refer to additional application information.

[1] Application Note U-129,

UC3907 Load Share IC Simplifies

Parallel Power Supply Design

by Mark Jordan.

[2] Application Note U-163,

UC3902 Load Share Controller and

its Performance in Distributed Power Systems

by Laszlo

Balogh.

PIN/BLOCK DESCRIPTIONS (cont.)

Figure 1. Load system diagram.

UDG-94103

6

UC1907

UC2907

UC3907

12

5

11

15

16

8

9

13114

7

10

6

4

32

+

–

VOLT AGE ERROR

AMPLIFIER

+

–

50k20k

+

V

CC

0-20mA

ISOLATED

CONTROL

I

SET

0-4V

DIRECT

CONTROL

1.750V

REF

+

+

–

V

REF

RANGE 2.0V-2.1V

GND

AMPLIFIER

0.250V

+

–

CURRENT

SENSE

ADJ

COMP

+–

+

–

+

–

10k

CURRENT

SHARE

BUS

+

TO PWR

RETURN

ARTIFICIAL GND

FROM LOAD

(–) SENSE

(+) SENSE

C/S OUT ADJ IN

50mV

ADJUST AMPLIFIER

1.75V

1.0V

DRIVE

AMPLIFIER

PWR RET

V

CC

V

CC

REF

MODULE LOAD CURRENT

20X

MASTER

INDICATE

BUFFER

AMPLIFIER

UC3907

Figure 2. Load share connection diagram.

Figure 3. UC3907 In a load-sharing feedback loop for an off-line isolated supply.

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

UDG-94105

UDG-99053

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...