Page 1

l

! "

Data M anua

August 2007 MSDS Bus Solutions

SLLS442E

Page 2

TUSB2136

r

Data Manual

Universal Serial Bus Compound Hub

with General-Purpose 8052 MCU

Literature Number: SLLS442E

August 2007

Printed on Recycled Pape

Page 3

Contents

Section Title Page

1 Introduction 1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Features 1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Functional Block Diagram 1−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminal Assignments 1−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Ordering Information 1−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Terminal Functions 1−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Revision History 1−5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functional Description 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 MCU Memory Map 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Miscellaneous Registers 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 TUSB2136 Boot Operation 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 MCNFG: MCU Configuration Register 2−2. . . . . . . . . . . . . . . . .

2.2.3 PUR_n: GPIO Pullup Register for Port n (n = 0 to 3) 2−2. . . . .

2.2.4 INTCFG: Interrupt Configuration 2−3. . . . . . . . . . . . . . . . . . . . . .

2.2.5 WDCSR: Watchdog Timer, Control, and Status Register 2−3.

2.2.6 PCON: Power Control Register (at SFR 87h) 2−4. . . . . . . . . . .

2.3 Buffers + I/O RAM Map 2−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Endpoint Descriptor Block (EDB-1 to EDB-3) 2−5. . . . . . . . . . . . . . . . . . . .

2.4.1 OEPCNF_n: Output Endpoint Configuration 2−7. . . . . . . . . . . .

2.4.2 OEPBBAX_n: Output Endpoint X-Buffer Base-Address 2−7. .

2.4.3 OEPBCTX_n: Output Endpoint X Byte Count 2−8. . . . . . . . . . .

2.4.4 OEPBBAY_n: Output Endpoint Y-Buffer Base-Address 2−8. .

2.4.5 OEPBCTY_n: Output Endpoint Y Byte Count 2−8. . . . . . . . . . .

2.4.6 OEPSIZXY_n: Output Endpoint X/Y Byte Count 2−9. . . . . . . .

2.4.7 IEPCNF_n: Input Endpoint Configuration 2−9. . . . . . . . . . . . . .

2.4.8 IEPBBAX_n: Input Endpoint X-Buffer Base-Address 2−9. . . .

2.4.9 IEPBCTX_n: Input Endpoint X-Byte Base-Address 2−10. . . . . .

2.4.10 IEPBBAY_n: Input Endpoint Y-Buffer Base-Address 2−10. . . . .

2.4.11 IEPBCTY_n: Input Endpoint Y Byte Count 2−10. . . . . . . . . . . . .

2.4.12 IEPSIZXY_n: Input Endpoint X/Y-Buffer Size 2−11. . . . . . . . . . .

2.5 Endpoint-0 Descriptor Registers 2−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 IEPCNFG_0: Input Endpoint-0 Configuration Register 2−11. . .

2.5.2 IEPBCNT_0: Input Endpoint-0 Byte Count Register 2−12. . . . .

2.5.3 OEPCNFG_0: Output Endpoint-0 Configuration

Register 2−12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 OEPBCNT_0: Output Endpoint-0 Byte Count Register 2−13. . .

2.6 USB Registers 2−13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 4

2.6.1 FUNADR: Function Address Register 2−13. . . . . . . . . . . . . . . . .

2.6.2 USBSTA: USB Status Register 2−14. . . . . . . . . . . . . . . . . . . . . . .

2.6.3 USBMSK: USB Interrupt Mask Register 2−15. . . . . . . . . . . . . . .

2.6.4 USBCTL: USB Control Register 2−16. . . . . . . . . . . . . . . . . . . . . .

2.6.5 HUBCNFG: HUB-Configuration Register 2−17. . . . . . . . . . . . . . .

2.6.6 HUBPOTG: HUB Power-On to Power-Good

Descriptor Register 2−17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.7 HUBCURT: HUB Current Descriptor Register 2−17. . . . . . . . . . .

2.6.8 HUBPIDL: HUB-PID Register (Low-Byte) 2−18. . . . . . . . . . . . . .

2.6.9 HUBPIDH: HUB-PID Register (High-Byte) 2−18. . . . . . . . . . . . .

2.6.10 HUBVIDL: HUB-VID Register (Low-Byte) 2−18. . . . . . . . . . . . . .

2.6.11 HUBVIDH: HUB-VID Register (High-Byte) 2−18. . . . . . . . . . . . .

2.6.12 VIDSTA: VID/PID Status Register 2−18. . . . . . . . . . . . . . . . . . . . .

2.7 Function Reset and Power-Up Reset Interconnect 2−19. . . . . . . . . . . . . . .

2.8 Pullup Resistor Connect/Disconnect 2−19. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 8052 Interrupt and Status Registers 2−20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.1 8052 Standard Interrupt Enable Register 2−21. . . . . . . . . . . . . . .

2.9.2 Additional Interrupt Sources 2−21. . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.3 VECINT: Vector Interrupt Register 2−22. . . . . . . . . . . . . . . . . . . . .

) 2−23. . . . . . . . . . .

2.10 I

2.9.4 Logical Interrupt Connection Diagram (INT0

2.9.5 P2[7:0] Interrupt (INT1

2

C Registers 2−24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.1 I2CSTA: I

2.10.2 I2CADR: I

2.10.3 I2CDAI: I

2.10.4 I2CDAO: I

2

C Status and Control Register 2−24. . . . . . . . . . . . . .

2

C Address Register 2−25. . . . . . . . . . . . . . . . . . . . . . .

2

C Data-Input Register 2−25. . . . . . . . . . . . . . . . . . . . . .

2

C Data-Output Register 2−25. . . . . . . . . . . . . . . . . . .

) 2−23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 Read/Write Operations 2−25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.1 Read Operation (Serial EEPROM) 2−25. . . . . . . . . . . . . . . . . . . .

2.11.2 Current Address Read Operation 2−26. . . . . . . . . . . . . . . . . . . . .

2.11.3 Sequential Read Operation 2−26. . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.4 Write Operation (Serial EEPROM) 2−27. . . . . . . . . . . . . . . . . . . .

2.11.5 Page Write Operation 2−28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Electrical Specifications 3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Absolute Maximum Ratings Over Operating Free-Air

Temperature Range 3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Commercial Operating Condition 3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Electrical Characteristics, T

= 25°C, VCC = 3.3 V ± 0.3 V,

A

GND = 0 V 3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Application 4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Keyboard Section 4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Reset Timing 4−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical Data 5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Page 5

List of Illustrations

Figure Title Page

1−1 TUSB2136 Block Diagram 1−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−1 MCU Memory Map (TUSB2136B) 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 Reset Diagram 2−19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−3 Pullup Resistor Connect/Disconnect Circuit 2−20. . . . . . . . . . . . . . . . . . . . . . . . . .

2−4 Internal Vector Interrupt (INT0

2−5 P2[7:0] Input Port Interrupt Generation 2−23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−1 Keyboard LED Connection 4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−2 Keyboard Matrix Scan Connection 4−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−3 Partial Connection Bus Power Mode 4−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−4 Upstream Connection (a) Non-Switching Power Mode (b) Switching

Power Mode 4−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−5 Downstream Connection − Only One Port Shown 4−3. . . . . . . . . . . . . . . . . . . . .

4−6 Reset Timing 4−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

) 2−23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables

Table Title Page

2−1 XDATA Space 2−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 Memory Mapped Registers Summary (XDATA Range = FF80 → FFFF) 2−5. .

2−3 EDB and Buffer Allocations in XDATA 2−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−4 EDB Entries in RAM (n = 1 to 3) 2−7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−5 Input/Output EDB-0 Registers 2−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−6 External Pins Mapping to S[3:0] in VIDSTA Register 2−19. . . . . . . . . . . . . . . . . . .

2−7 8052 Interrupt Location Map 2−20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−8 Vector Interrupt Values 2−22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−1 GPIO Assignment for Matrix Scan and LED Drive 4−1. . . . . . . . . . . . . . . . . . . . .

v

Page 6

vi

Page 7

1 Introduction

The TUSB2136 is an integrated universal serial bus (USB) hub with a general-purpose 8052 microcontroller that can

be used for various USB controller applications. The TUSB2136 has 8K × 8 RAM space for application development.

Using a 12-MHz crystal, the onboard oscillator generates the internal system clocks. No additional programming is

required for any part of the hub functions. The device is programmed via an inter-IC (I

on from an EEPROM, or optionally, the application firmware can be downloaded from a host PC via USB. The

8052-based microprocessor allows several third-party standard tools to be used for application development. In

addition, the application code available in the general market can also be used (this may or may not require some

code modification due to hardware variations).

1.1 Features

• Multiproduct support with one code and one chip (up to 16 products with one chip)

• Fully compliant with the USB specification as a compound full-speed device: TID #30270119

• Supports 1.5- and 12-Mbits/s USB data rates

• Supports USB suspend/resume and remote wake-up operation

• Integrated two-port hub with individual power management per port

• Integrated 8052 microcontroller with:

− 256 × 8 RAM for internal data

− 8K × 8 RAM code space available for downloadable firmware from host or I

− 512 × 8 shared RAM used for data buffers and endpoint descriptor blocks (EDB) [1]

− Four 8052 GPIO ports (ports 0,1, 2 and 3)

− Master I

− Watchdog timer

2

C controller for external slave device access

2

C) serial interface at power

2

C port.

• Operates from a 12-MHz crystal

• On-chip PLL generates 48 MHz

• Supports a total of three input and three output (interrupt, bulk) endpoints

• Power-down mode

• 64-pin TQFP package

[1] This is the buffer space for USB packet transactions.

1−1

Page 8

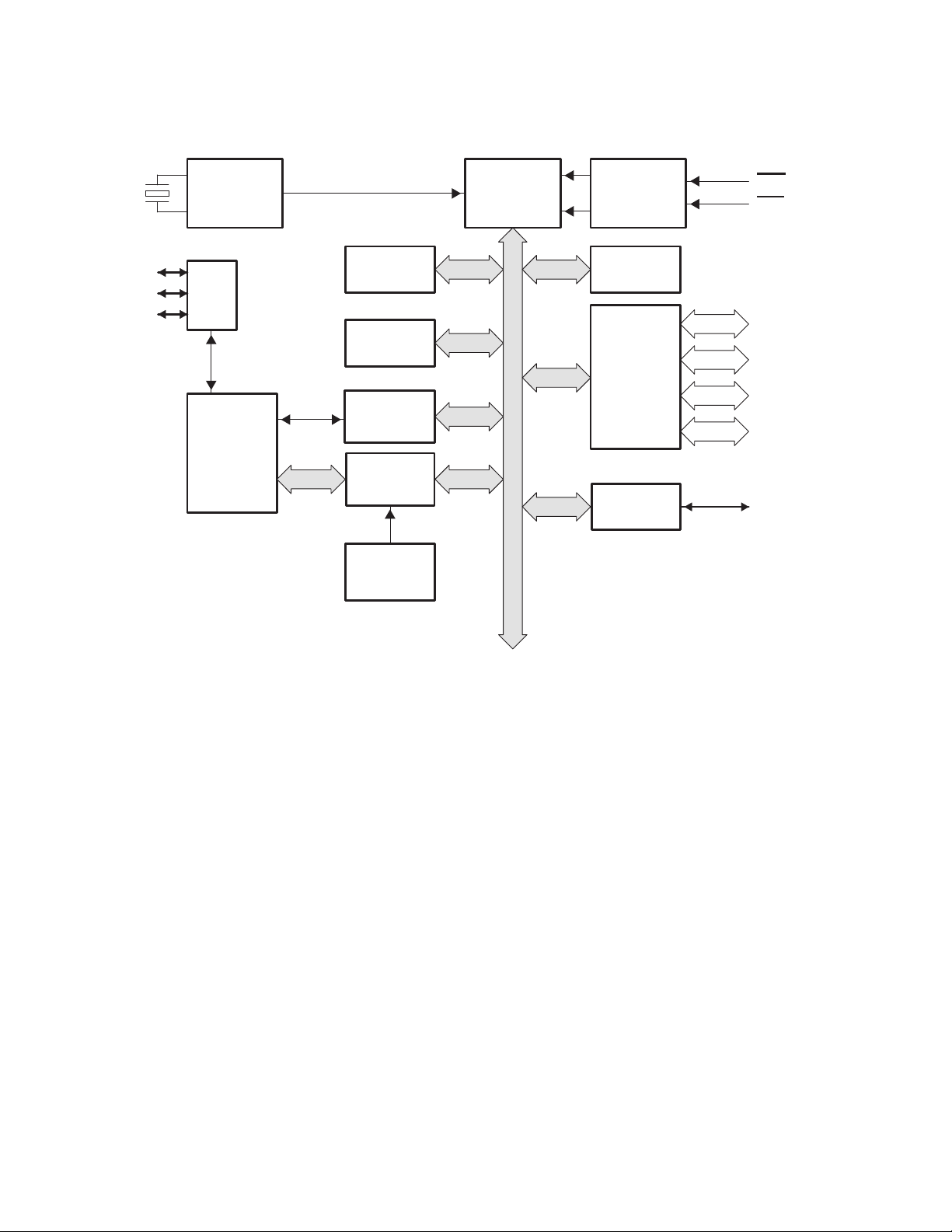

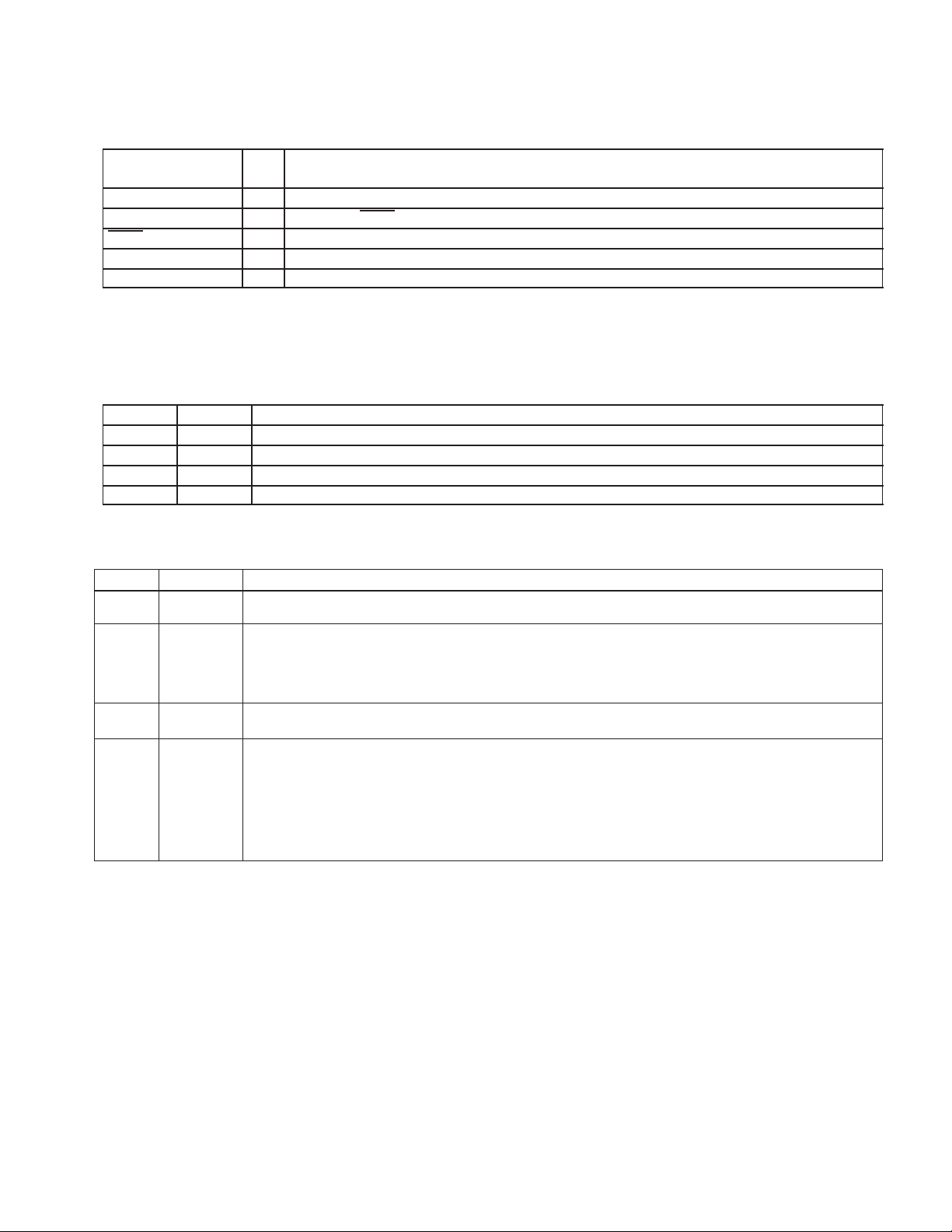

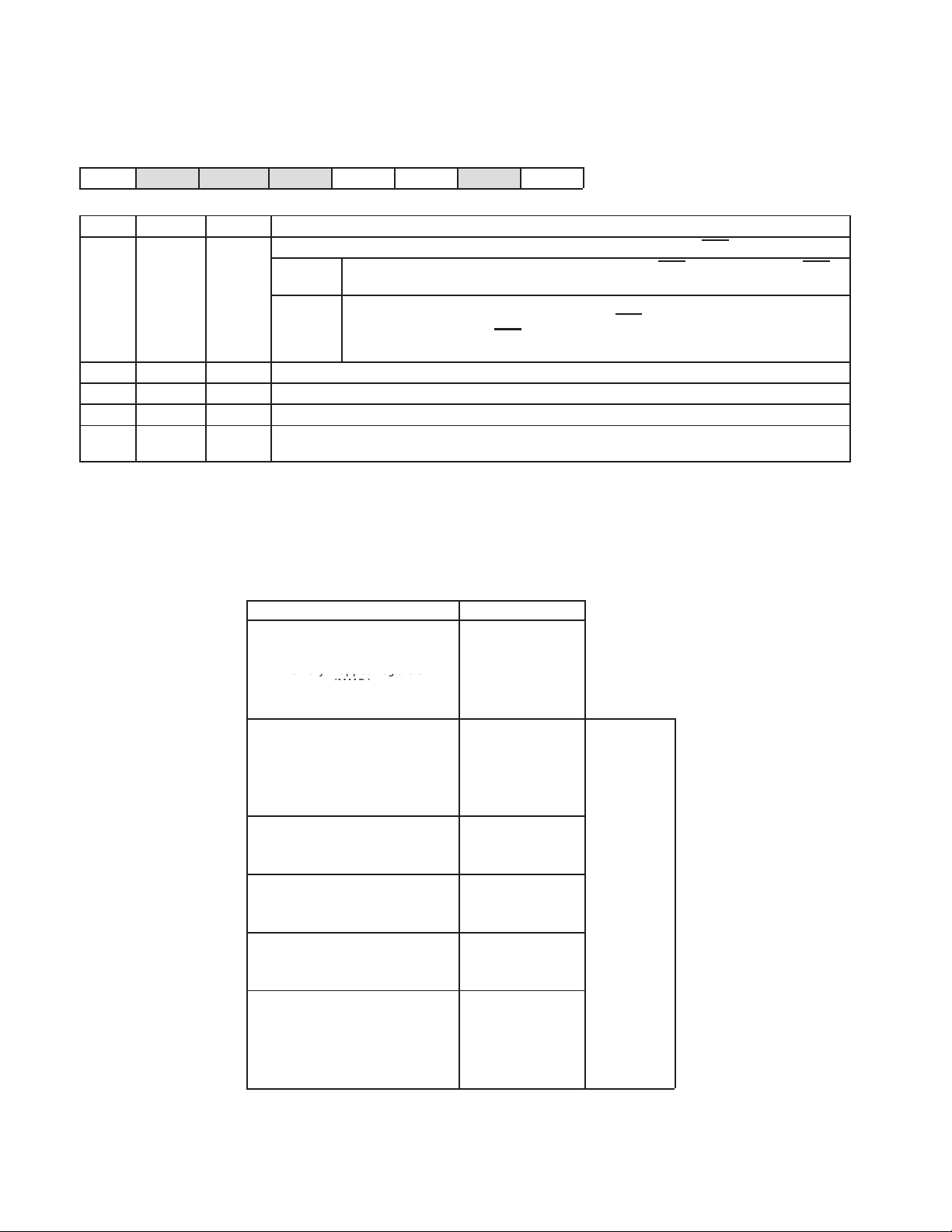

1.2 Functional Block Diagram

12 MHz

USB0

USB1

USB2

Clock,

PLL

and

Dividers

USB

HUB

USB

SIE

6K y 8

ROM

8K y 8

SRAM

CPU − I/F

Susp/Res

UBM

USB Buffer

Manager

TDM

Control

Logic

8052

Core

8

8

8

88

8

8

8

Reset and

Interrupt

Logic

2 y 16-Bit

Timers

Port-1

Port-2

Port-3

Port-4

I2C

Controller

8 P0[7:0]

8 P1[7:0]

8 P2[7:0]

8 P3[7:0]

RSTI

INT1

I2C Bus

Figure 1−1. TUSB2136 Block Diagram

1−2

Page 9

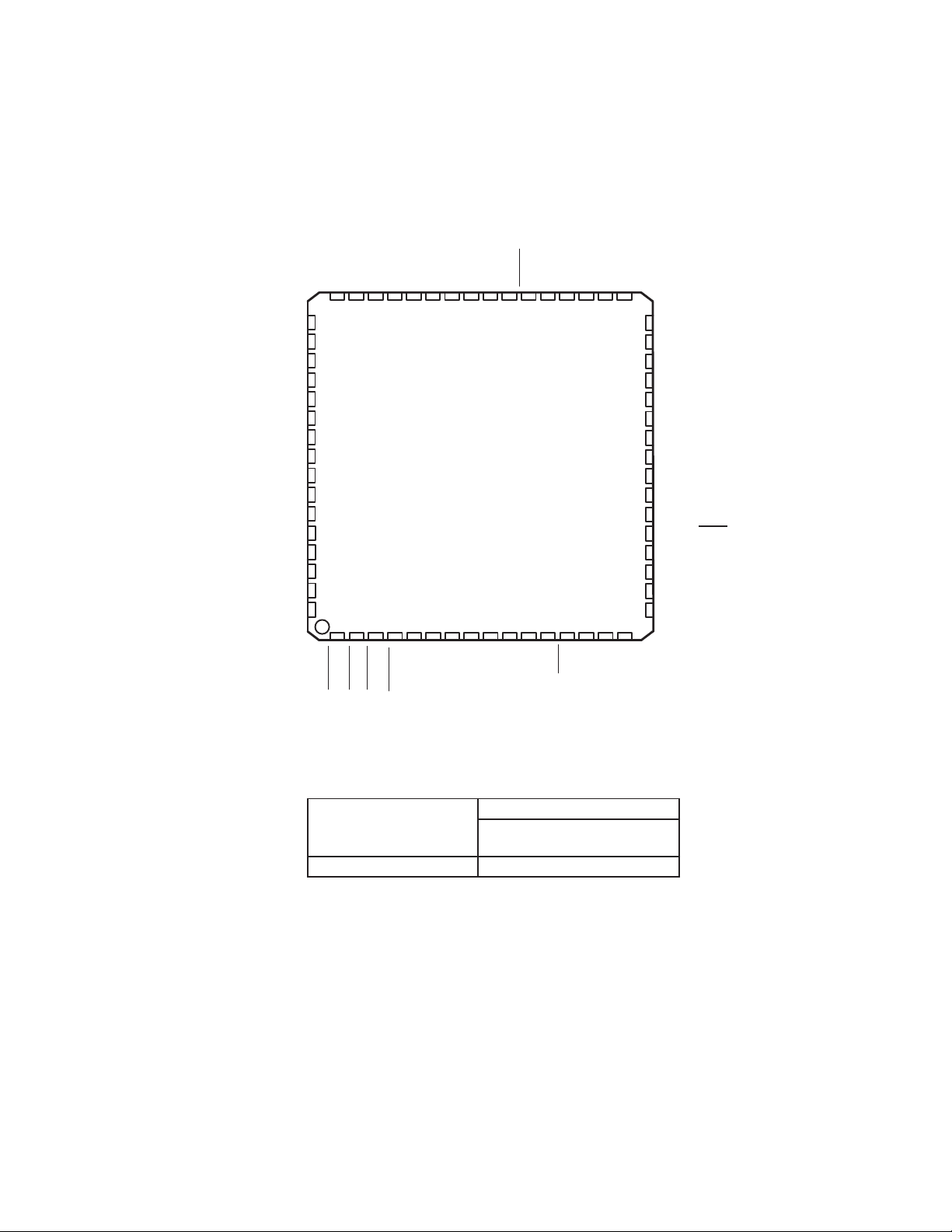

1.3 Terminal Assignments

P0.5

P0.4

P0.3

P0.2

P0.1

PM PACKAGE

(TOP VIEW)

P0.0

GND

P1.7

P1.6

V

CC

VDD18

VREN

P1.5

P1.4

P1.3

P1.2

P0.6

P0.7

P3.7

P3.6

P3.5

P3.4

P3.3

P3.2

P3.1/S1/TXD

P3.0/S0/RXD

GND

X2

X1

V

CC

DM2

DP2

1.4 Ordering Information

47 46 45 44 4348 42

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

12 3

PWR01

OVCR2

PWR02

5678

4

GND

OVCR1

DM1

40 39 3841

910111213

S2

S3

DP1

V

CC

37 36

SDA

SCL

35 34 33

14 15 16

RST

TEST0

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

SUSP

TEST1

P1.1

P1.0

P2.7

P2.6

P2.5

P2.4

P2.3

P2.2

GND

P2.1

P2.0

SELF/BUS

GND

DM0

DP0

PUR

PACKAGE

T

A

0°C to 70°C TUSB2136PM

PLASTIC QUAD FLATPACK

(PM)

1−3

Page 10

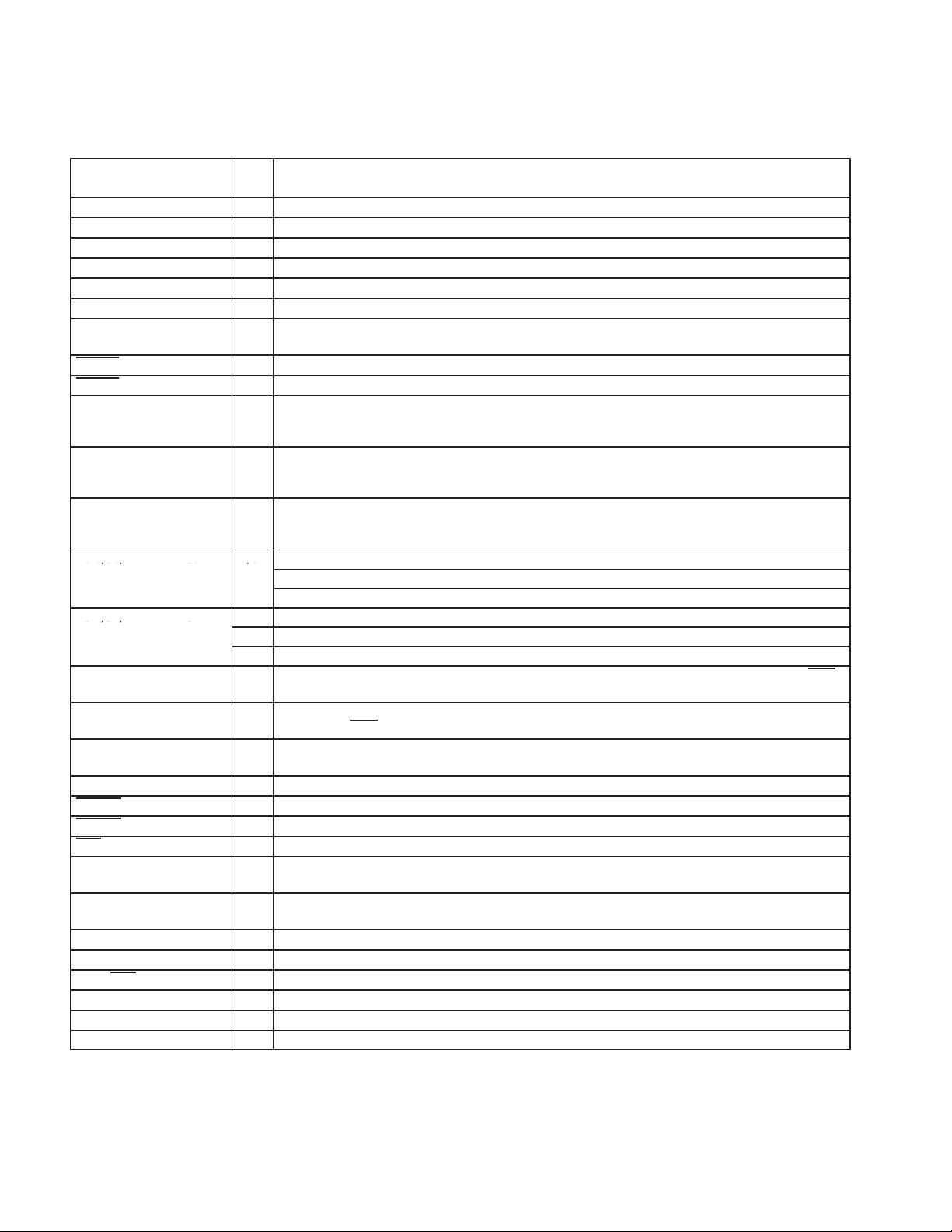

1.5 Terminal Functions

I/O

DESCRIPTION

P3.0/S0/RXD

58

I/O

P3.1/S1/TXD

57

TERMINAL

NAME NO.

DM0 19 I/O Differential data-minus USB port 0: upstream

DM1 6 I/O Differential data-minus port 1: downstream

DM2 63 I/O Differential data-minus port 2: downstream

DP0 18 I/O Differential data-plus USB port 0: upstream

DP1 7 I/O Differential data-plus port 1: downstream

DP2 64 I/O Differential data-plus port 2: downstream

GND 5, 20, 24,

42, 59

OVCR1 4 I Port 1: Overcorrect indicator; Schmitt-trigger input, 100-µA active pullup

OVCR2 1 I Port 2: Overcorrect indicator; Schmitt-trigger input, 100-µA active pullup

P0.[0:7] 43, 44, 45,

46, 47, 48,

49, 50

P1.[0:7] 31, 32, 33,

34, 35, 36,

40, 41

P2.[0:7] 22, 23, 25,

26, 27, 28,

29, 30

P3.0/S0/RXD 58 I/O

P3.1/S1/TXD 57

P3.2 56 I/O General-purpose I/O port 3 bit 2, Schmitt-trigger input, 100-µA active pullup, open-drain output†; INT0

P3.3 55 I/O General-purpose I/O port 3 bit 3, Schmitt-trigger input, 100-µA active pullup, open-drain output

P3.[4:7] 54, 53, 52,51I/O General-purpose I/O port 3 bit 4, Schmitt-trigger input, 100-µA active pullup, open-drain output

— Power supply ground

I/O General-purpose I/O port 0 bits 0−7, Schmitt-trigger input, 100-µA active pullup, open-drain output

I/O General-purpose I/O port 1 bits 0−7, Schmitt-trigger input, 100-µA active pullup, open-drain output

I/O General-purpose I/O port 2 bits 0−7, Schmitt-trigger input, 100-µA active pullup, open-drain output

P3.0: General-purpose I/O port 3 bit 0, Schmitt-trigger input, 100-µA active pullup, open-drain output

S0: See Section 2.6.12

RXD: Can be used as a UART interface

I/O P3.1: General-purpose I/O port 3 bit 1, Schmitt-trigger input, 100-µA active pullup, open-drain output

I/O S1: See Section 2.6.12

I/O TXD: Can be used as a UART interface

only used internally (see Section 2.9.4)

†;

may support INT1

input, depending on configuration (see Figure 2−5)

†

†

†

†

†

†

1−4

PUR 17 O Pullup resistor connection pin (3-state); push-pull CMOS output (±8 mA)

PWRO1 3 O Port 1: power on/off control signal; push-pull CMOS output (±8 mA)

PWRO2 2 O Port 2: power on/off control signal; push-pull CMOS output (±8 mA)

RST 13 I Controller master reset signal, Schmitt-trigger input, 100-µA active pullup

S2 8 I General-purpose input; can be used for VID/PID selection under firmware control. This input has no

S3 9 I General-purpose input. This input has no internal pullup, so it must be driven/pulled either low or high

SCL 12 O Serial clock I2C; push-pull output

SDA 11 I/O Serial data I2C; open-drain output

SELF/BUS 21 I USB power MODE select: self powered (HIGH), bus powered (LOW)

SUSP 16 O Suspend status signal: suspended (HIGH); unsuspended (LOW)

‡

TEST0

‡

TEST1

†

All open-drain output pins can sink up to 8 mA.

‡

The functions controlled by TEST0 and TEST1 are shown in the following table. Because these two pins have internal pullups, they can be left

unconnected for the default mode.

14 I Test input 0, Schmitt-trigger input, 100-µA active pullup

15 I Test input 1, Schmitt-trigger input, 100-µA active pullup

internal pullup, so it must be driven/pulled either low or high and connot be left unconnected.

and connot be left unconnected.

†

Page 11

1.5 Terminal Functions (Continued)

I/O

DESCRIPTION

TERMINAL

NAME NO.

V

CC

VDD18

VREN 38 I Voltage regulator enable: enable active LOW; disable active HIGH

X2 60 O 12-MHz crystal output

X1 61 I 12-MHz crystal input

†

During normal o p e r a t i o n , t h e i n t e r n a l 3 . 3 - t o 1 . 8 - V v o ltage regulator of the TUSB2136 is enabled and provides power to the core. To save power

during the suspend mode, the internal regulator is disabled. In this case, the pin becomes an input, and a simple external power source is required

to provide power to the core. This source needs to supply a very limited amount of power (10 µA maximum) within the voltage range of 1 V to

1.95 V.

NOTE 1: The MCU treats the outputs as open-drain types in that the output can be driven low continuously, but a high output is driven for two

10,39,62 — Power supply input, 3.3 V typical

†

37 1.8 V. When VREN is low, 1.8 V must be applied to provide current for the core during suspend.

clock cycles and then the output is placed in a high-impedance state.

TEST0

0 0 Selects 48-MHz clock input (from an oscillator or other onboard clock source)

0 1 Reserved for testing purposes

1 0 Reserved for testing purposes

1 1 Selects 12-MHz crystal as clock source (default)

TEST1 FUNCTION

1.6 Revision History

Version Date Changes

Dec−2000 Initial Release

A Feb−2001 1. Clarified pin descriptions for P3.2 (56), P3.3 (55), and VDDOUT (37).

B Jun−2002 1. Changed name of pin 37 from VDDOUT to VDD18 and enhanced pin description.

C Apr−2003 1. Simplified Terminal Function Table for GPIO Ports

2. Add red/write capability for each of the register bits.

3. Corrected Quiescent and Suspend current figures in Table 3.3.

4. Added Section 4.2 Reset Timing

5. Added NOTE to cover page.

2. Removed NOTE from cover page.

2. Clarified GPIO Port 3 pin descriptions in Terminal Function Table

3. Clarified functional description for Pins S2 and S3 (8 & 9)

4. Clarified TEST0 & TEST1 (14 & 15) pin functions in Terminal Functions Table

5. Added note on open-drain output pins for Terminal Functions Table

6. Added additional note for operation of VDD18 (pin 37) to Terminal Functions Table.

7. Removed most references to ROM version including Fig 2.2.

8. Added USB Logo to Cover page

1−5

Page 12

1−6

Page 13

2 Functional Description

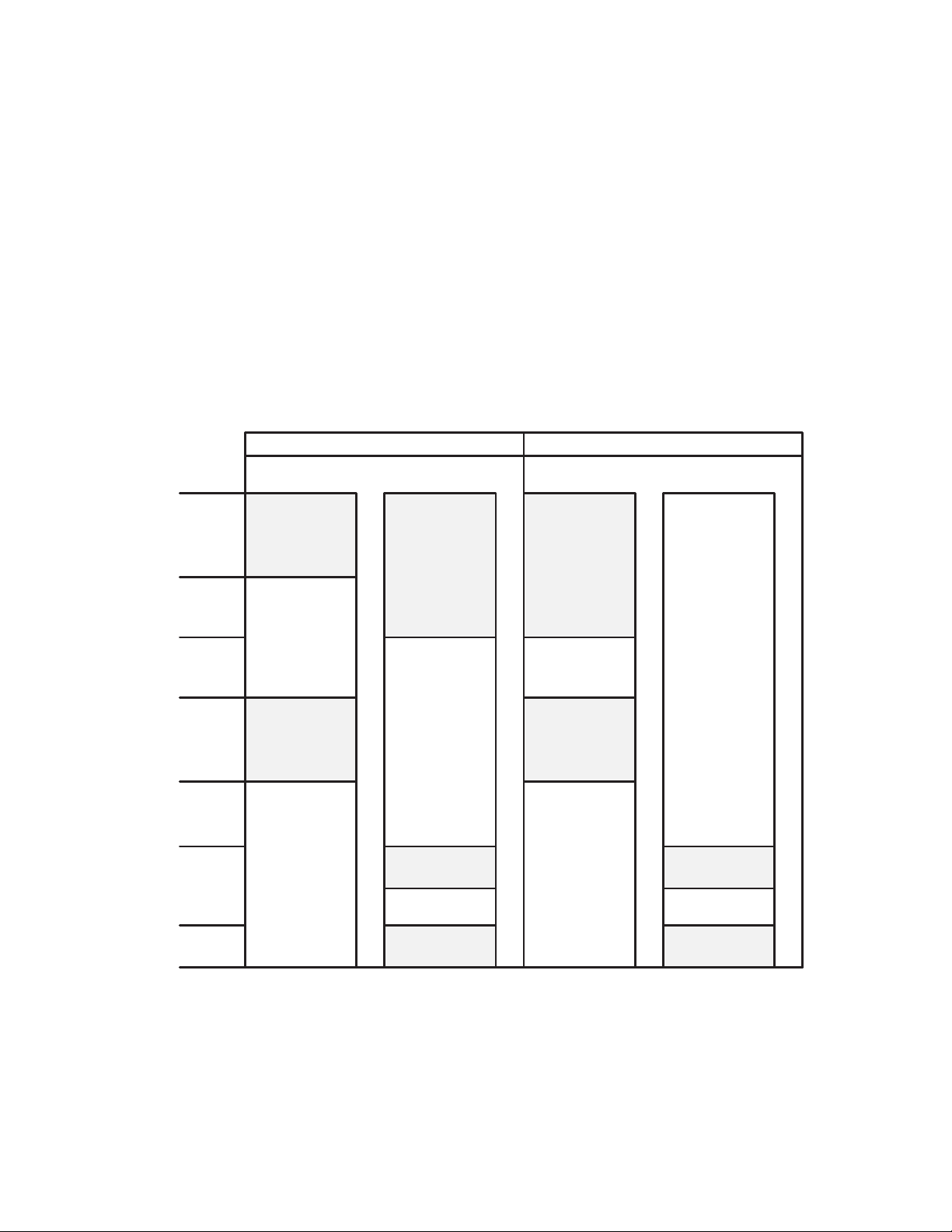

2.1 MCU Memory Map

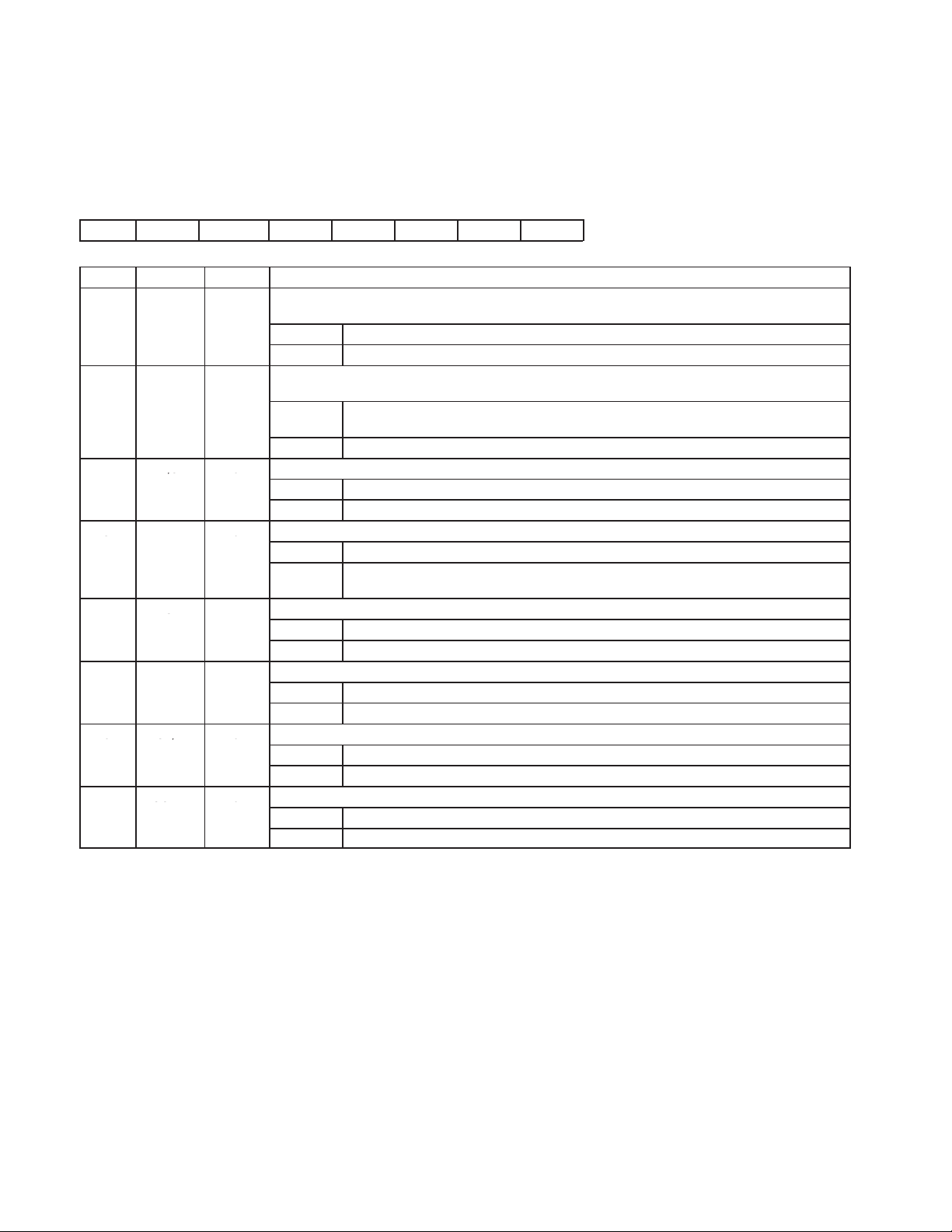

Figure 2−1 illustrates the MCU memory map under boot and normal operation. It must be noted that the internal 256

bytes of IDATA are not shown since it is assumed to be in the standard 8052 location (0000 to 00FF). The shaded

areas represent the internal ROM/RAM. For more information regarding the integrated 8052, see the TUSBxxxx

Microcontroller Reference Guide (SLLU044).

When the SDW bit = 0 (boot mode): The 6K ROM is mapped to address (0000−17FF) and is duplicated in location

(8000−97FF) in code space. The internal 8K RAM is mapped to address range (0000−1FFF) in data space. Buffers,

memory-mapped registers (MMRs), and I/O are mapped to address range (FD80−FFFF) in data space.

When the SDW bit = 1 (normal mode): The 6K ROM is mapped to (8000−97FF) in code space. The internal 8K RAM

is mapped to address range (0000−1FFF) code space. Buffers, MMR, and I/O are mapped to address range

(FD80−FFFF) in data space.

0000

17FF

1FFF

8000

97FF

FD80

Boot Mode (SDW = 0)

CODE

6K Boot ROM

6K Boot ROM

XDATA

8K

RAM

Read/Write

512 Bytes

RAM

Normal Mode (SDW = 1)

CODE

8K

Code RAM

Read Only

6K Boot ROM

XDATA

512 Bytes

RAM

FF80

FFFF

MMR

MMR

Figure 2−1. MCU Memory Map (TUSB2136B)

2.2 Miscellaneous Registers

2.2.1 TUSB2136 Boot Operation

Because the code space is in RAM (with the exception of the boot ROM), the TUSB2136 firmware must be loaded

from an external source. Two options for booting are available: an external serial EEPROM source connected to the

2−1

Page 14

I2C bus, or the host can be used via the USB. On device reset, the SDW bit (in the ROM register) and the CONT bit

0

SDW

0

5

OVCE

0

6

XINT

0

in the USB control register (USBCTL) are cleared. This configures the memory space to boot mode (see memory

map, Table 2−2) and keeps the device disconnected from the host.

The first instruction is fetched from location 0000 (which is in the 6K ROM). The 8K RAM is mapped to XDATA space

(location 0000h). The MCU executes a read from an external EEPROM and tests to see if it contains the code (test

for boot signature). If it contains the code, the MCU reads from EEPROM and writes to the 8K RAM in XDATA space.

If not, the MCU proceeds to boot from USB.

Once the code is loaded, the MCU sets SDW to 1. This switches the memory map to normal mode, i.e. the 8K RAM

is mapped to code space, and the MCU starts executing from location 0000h. Once the switch is done, the MCU sets

CONT to 1 (in the USBCTL register) This connects the device to the USB, resulting in the normal USB device

enumeration.

2.2.2 MCNFG: MCU Configuration Register

This register is used to control the MCU clock rate.

76 5 43210

RSV XINT OVCE R3 R2 R1 R0 SDW

R/W R/W R/W R/O R/O R/O R/O R/W

BIT NAME RESET FUNCTION

0 SDW 0

4−1 R[3:0] No effect These bits reflect the device revision number.

5 OVCE 0

6 XINT 0

7 RSV 0 Reserved

This bit enables/disables boot ROM.

SDW = 0 When clear, the MCU executes from the 6K boot ROM space. The boot ROM appears in two

locations: 0000 and 8000h. The 8K RAM is mapped to XDATA space; therefore, read/write

operation is possible. This bit is set by the MCU after the RAM load is completed. The MCU

cannot clear this bit. It is cleared on power-up reset or function reset.

SDW = 1 When set by MCU, the 6K boot ROM maps to location 8000h, and the 8K RAM is mapped to

code space, starting at location 0000h. At this point, the MCU executes from RAM, and write

operation is disabled (no write operation is possible in code space).

Hub overcorrect detection enable/disable bit.

OVCE = 0 Hub overcorrect detection is disabled.

OVCE = 1 Hub overcorrect detection is enabled.

INT1 source control bit

XINT = 0 INT1 is connected to the P3.3 pin and operates as a standard INT1 interrupt.

XINT = 1 INT1 is connected to the OR of port-2 inputs.

2.2.3 PUR_n: GPIO Pullup Register for Port n (n = 0 to 3)

PUR_0: GPIO pullup register for port 0

PUR_1: GPIO pullup register for port 1

PUR_2: GPIO pullup register for port 2

PUR_3: GPIO pullup register for port 3

76543210

PORT_n.7 PORT_n.6 PORT_n.5 PORT_n.4 PORT_n.3 PORT_n.2 PORT_n.1 PORT_n.0

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

0−7 PORT_n.N

(N = 0 to 7)

2−2

0 The MCU can write to this register. If the MCU sets this bit to 1, the pullup resistor is disconnected from

the pin. If the MCU clears this bit to 0, the pullup resistor is connected to the pin. The pullup resistor is

connected to the VCC power supply.

Page 15

2.2.4 INTCFG: Interrupt Configuration

7

WDE

0

76 5 43210

RSV RSV RSV RSV I3 I2 I1 I0

R/O R/O R/O R/O R/W R/W R/W R/W

BIT NAME RESET FUNCTION

0−3 I[3:0] 0010 The MCU can write to this register to set the interrupt delay time for port 2 on the MCU. The value of the

4−7 RSV 0 Reserved

lower nibble represents the delay in ms. Default after reset is 2 ms.

2.2.5 WDCSR: Watchdog Timer, Control, and Status Register

A watchdog timer (WDT) with 1-ms clock is provided. The watchdog timer only works when a USB start-of-frame has

been detected by the TUSB3210. If this register is not accessed for a period of 32 ms, the WDT counter resets the

MCU (see Figure 2−2, Reset Diagram). When the IDL bit in PCON is set, the WDT is suspended until an interrupt

is detected. At this point, the IDL bit is cleared and the WDT resumes operation. The WDE bit of this register is cleared

only on power-up or USB reset (if enabled). When the MCU writes a 1 to the WDE bit of this register the WDT starts

running.

76 5 43210

WDE WDR RSV RSV RSV RSV RSV WDT

R/W R/W R/O R/O R/O R/O R/O W/O

BIT NAME RESET FUNCTION

0 WDT 0 The MCU must write a 1 to this bit to prevent the WDT from resetting the MCU. If MCU does not write a 1 in a

5−1 RSV 0 Reserved

6 WDR 0

7 WDE 0

period of 31 ms, the WDT resets the device. Writing a 0 has no effect on the WDT. (The WDT is a 5-bit

counter using a 1-ms CLK). This bit is read as 0.

Watchdog reset indication bit. This bit indicates if the reset occurred due to power-on reset or watchdog

timer reset.

WDR = 0 A power-up or USB reset occurred.

WDR = 1 A watchdog time-out reset occurred. To clear this bit, the MCU must write a 1. Writing a 0 has

no effect.

Watchdog timer enable

WDE = 0 Disabled

WDE = 1 Enabled

2−3

Page 16

2.2.6 PCON: Power Control Register (at SFR 87h)

0

IDL

0

Internal

memory mapped registers

↑

memory mapped registers

(EDB)

Setup packet buffer

Input endpoint-0 buffer

RAM

Output endpoint-0 buffer

Data buffers

Data buffers

↑

(368 bytes)

76 5 43210

SMOD RSV RSV RSV GF1 GF0 RSV IDL

R/W R/O R/O R/O R/W R/W R/O R/W

BIT NAME RESET FUNCTION

0 IDL 0

1 RSV 0 Reserved

3−2 GF[1:0] 00 General-purpose bits. The MCU can write and read them.

6−4 RSV 0 Reserved

7 SMOD 0 Double baud-rate control bit. For more information see the UART serial interface in the M8052 core

MCU idle mode bit. This bit can be set by the MCU and is cleared only by the INT1 interrupt.

IDL = 0 The MCU is not in idle mode. This bit is cleared by the INT1 interrupt logic when INT1 is

IDL = 1 The MCU is in idle mode and RAM is in low-power mode. The oscillator/APLL is off and the

specification.

asserted for at least 400 µs.

WDT is suspended. When in suspend mode, only INT1

and generate an interrupt. INT1

recognized.

must be asserted for at least 400 µs for the interrupt to be

can be used to exit from the idle state

2.3 Buffers + I/O RAM Map

The address range from FD80 to FFFF is reserved for data buffers, setup packet, endpoint descriptor blocks (EDB),

and all I/O. RAM space of 512 bytes [FD80−FF7F] is used for EDB and buffers. The FF80−FFFF range is used for

memory-mapped registers (MMR). Table 2−1 represents the internal XDATA space allocation.

Table 2−1. XDATA Space

DESCRIPTION ADDRESS RANGE

(MMR)

Endpoint descriptor blocks

Setup packet buffer

Input endpoint-0 buffer

Output endpoint-0 buffer

FFFF

FF80

FF7F

↑

FF08

FF07

↑

FF00

FEFF

↑

FEF8

FEF7

↑

FEF0

FEEF

512 -Byte

2−4

FD80

Page 17

Table 2−2. Memory-Mapped Registers Summary (XDATA Range = FF80 → FFFF)

ADDRESS REGISTER DESCRIPTION

FFFF FUNADR FUNADR: Function address register

FFFE USBSTA USBSTA: USB status register

FFFD USBMSK USBMSK: USB interrupt mask register

FFFC USBCTL USBCTL: USB control register

FFFB HUBVIDH HUBVIDH: HUB-VID register (high-byte)

FFFA HUBVIDL HUBVIDL: HUB-VID register (low-byte)

FFF9 HUBPIDH HUBPIDH: HUB-PID register (high-byte)

FFF8 HUBPIDL HUBPIDL: HUB-PID register (low-byte)

FFF7 HUBCNFG HUBCNFG: HUB-configuration register

FFF6 VIDSTA VIDSTA: VID/PID status register

FFF5 HUBPOTG HUBPOTG: HUB power-on to power-good descriptor register

FFF4 HUBCURT HUBCURT: HUB current descriptor register

FFF3 I2CADR I2CADR: I2C address register

FFF2 I2CDAI I2CDAI: I2C data-input register

FFF1 I2CDAO I2CDAO: I2C data-output register

FFF0 I2CSTA I2CSTA: I2C status and control register

↑ RESERVED

FF97 PUR3 Port 3 pullup resistor register

FF96 PUR2 Port 2 pullup resistor register

FF95 PUR1 Port 1 pullup resistor register

FF94 PUR0 Port 0 pullup resistor register

FF93 WDCSR WDCSR: Watchdog timer, control and status register

FF92 VECINT VECINT: Vector interrupt register

FF91 RESERVED

FF90 MCNFG MCNFG: MCU configuration register

↑ RESERVED

FF84 INTCFG INTCFG: Interrupt delay configuration register

FF83 OEPBCNT_0 OEPBCNT_0: Output endpoint-0 byte count register

FF82 OEPCNFG_0 OEPCNFG_0: Output endpoint-0 configuration register

FF81 IEPBCNT_0 IEPBCNT_0: Input endpoint-0 byte count register

FF80 IEPCNFG_0 IEPCNFG_0: Input endpoint-0 configuration register

2.4 Endpoint Descriptor Block (EDB-1 to EDB-3)

Data transfers between USB, MCU and external devices are defined by an endpoint descriptor block (EDB). Four

input and four output EDBs are provided. With the exception of EDB-0 (I/O endpoint 0), all EDBs are located in SRAM

as shown in Table 2−3. Each EDB contains information describing the X and Y buffers. In addition, it provides general

status information.

2−5

Page 18

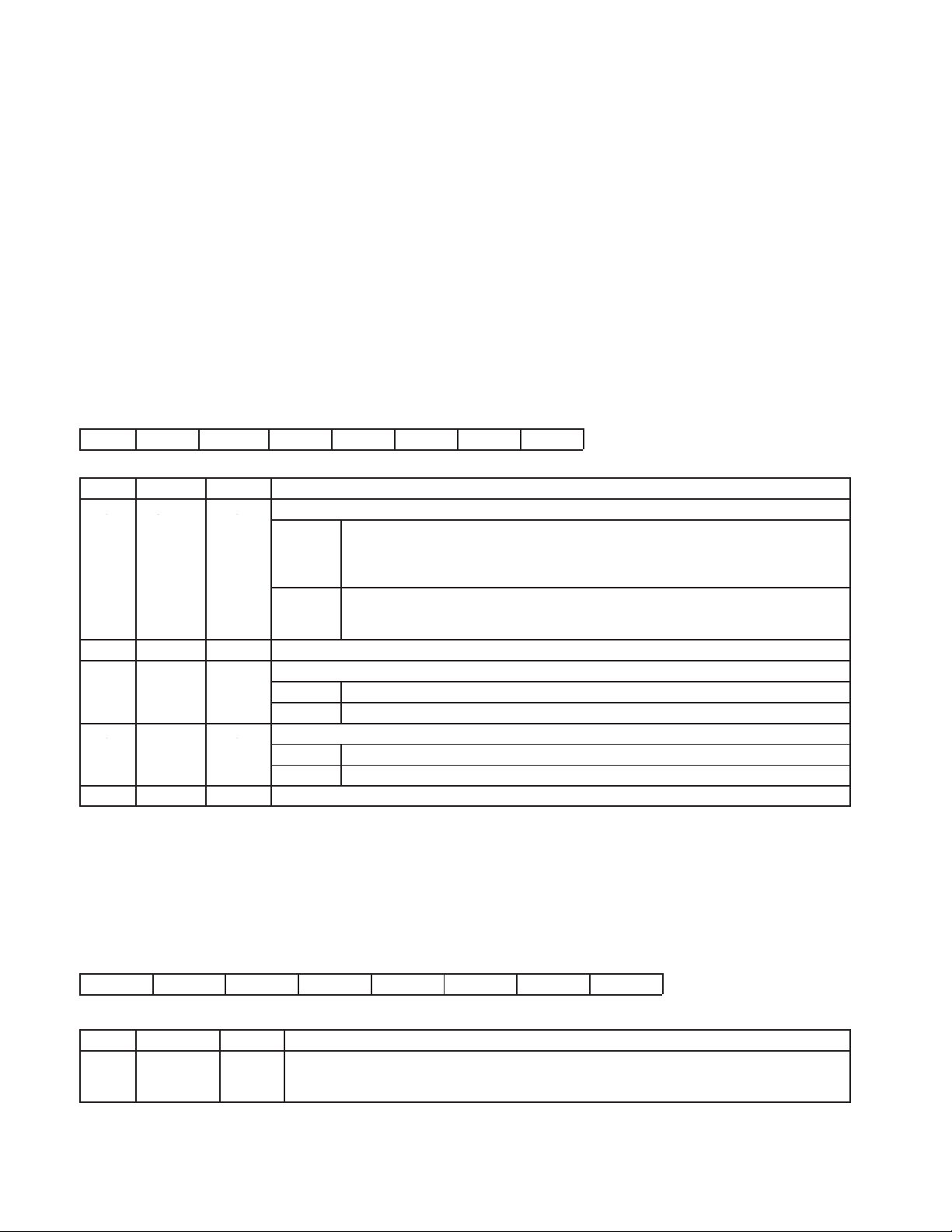

Table 2−3. EDB and Buffer Allocations in XDATA

32 bytes

RESERVED

8 bytes

Input endpoint 3: configuration

8 bytes

Input endpoint 2: configuration

8 bytes

Input endpoint 1: configuration

8 bytes

Output endpoint 3: configuration

8 bytes

Output endpoint 2: configuration

8 bytes

Output endpoint 1: configuration

8 bytes

Setup packet block

8 bytes

Input endpoint 0: buffer

8 bytes

Output endpoint 0: buffer

ADDRESS SIZE DESCRIPTION

FF7F

↑

FF60

FF5F

↑

FF58

FF57

↑

FF50

FF4F

↑

FF48

FF47

↑ 40 bytes RESERVED

FF20

FF1F

↑

FF18

FF17

↑

FF10

FF0F

↑

FF08

FF07

↑

FF00

FEFF

↑

FEF8

FEF7

↑

FEF0

FEEF Top of buffer space

↑

368 bytes Buffers space

FD80 Start of buffer space

32 bytes RESERVED

8 bytes Input endpoint 3: configuration

8 bytes Input endpoint 2: configuration

8 bytes Input endpoint 1: configuration

8 bytes Output endpoint 3: configuration

8 bytes Output endpoint 2: configuration

8 bytes Output endpoint 1: configuration

8 bytes Setup packet block

8 bytes Input endpoint 0: buffer

8 bytes Output endpoint 0: buffer

2−6

Page 19

Table 2−4 illustrates the EDB entries for EDB-1 to EDB-3. EDB-0 registers are described separately.

2

USBIE

x

3

STALL

0

4

DBUF

x

7

UBME

x

Table 2−4. EDB Entries in RAM (n = 1 to 3)

Offset ENTRY NAME DESCRIPTION

07 EPSIZXY_n I/O endpoint_n: X/Y buffer size

06 EPBCTY_n I/O endpoint_n: Y byte count

05 EPBBAY_n I/O endpoint_n: Y buffer base address

04 SPARE Not used

03 SPARE Not used

02 EPBCTX_n I/O endpoint_n: X byte count

01 EPBBAX_n I/O endpoint_n: X buffer base address

00 EPCNF_n I/O endpoint_n: configuration

2.4.1 OEPCNF_n: Output Endpoint Configuration (n = 1 to 3)

76 5 43210

UBME ISO TOGLE DBUF STALL USBIE RSV RSV

R/W R/W R/W R/W R/W R/W R/O R/O

BIT NAME RESET FUNCTION

1−0 RSV x Reserved = 0

2 USBIE x

3 STALL 0

4 DBUF x

5 TOGLE x USB toggle bit. This bit reflects the toggle sequence bit of DATA0, DATA1

6 ISO x ISO = 0 Non-isochronous transfer. This bit must be cleared by the MCU because only

7 UBME x

USB interrupt enable on transaction completion. Set/clear by MCU.

USBIE = 0 No interrupt

USBIE = 1 Interrupt on transaction completion

USB stall condition indication. Set/clear by MCU.

STALL = 0 No stall

STALL = 1 USB stall condition. If set by the MCU, a STALL handshake is initiated and the bit is cleared by

the MCU.

Double buffer enable. Set/clear by MCU.

DBUF = 0 Primary buffer only (X-buffer only)

DBUF = 1 Toggle bit selects buffer

non-isochronous transfer is supported.

USB buffer manager (UBM) enable/disable bit. Set/clear by MCU.

UBME = 0 UBM cannot use this endpoint.

UBME = 1 UBM can use this endpoint.

2.4.2 OEPBBAX_n: Output Endpoint X-Buffer Base-Address (n = 1 to 3)

76 5 43210

A

10

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 A[10:3] x A[10:3] of X-buffer base address (padded with 3 LSB of zeros for a total of 11-bits). This value is set by the

A

9

A

8

A

7

MCU. UBM or DMA uses this value as the start address of a given transaction. Furthermore, UBM or DMA

does not change this value at the end of a transaction.

A

6

A

5

A

4

A

3

2−7

Page 20

2.4.3 OEPBCTX_n: Output Endpoint X-Byte Count (n = 1 to 3)

76 5 43210

NAK C

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

6−0 C[6:0] x X-buffer byte count:

7 NAK x NAK= 0 No valid data in buffer. Ready for host out

6

C

5

C

4

000 0000b ³ Count = 0

000 0001b ³ Count = 1 byte

L

011 1111b ³ Count = 63 bytes

100 0000b ³ Count = 64 bytes

Any value ≥ 100 0001b produces unpredictable results.

NAK= 1 Buffer contains a valid packet from host (host-out request is NAK)

C

3

C

2

C

1

C

0

2.4.4 OEPBBAY_n: Output Endpoint Y-Buffer Base-Address (n = 1 to 3)

76 5 43210

A

10

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 A[10:3] x A[10:3] of Y-buffer base address (padded with 3 LSB of zeros for a total of 11 bits). This value is set by the

A

9

A

8

A

7

MCU. UBM or DMA uses this value as the start address of a given transaction. Furthermore, UBM or DMA

does not change this value at the end of a transaction.

A

6

A

5

A

4

A

3

2.4.5 OEPBCTY_n: Output Endpoint Y-Byte Count (n = 1 to 3)

76 5 43210

NAK C

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

6−0 C[6:0] x Y -buffer byte count:

7 NAK x NAK= 0 No valid data in buffer. Ready for host out

6

C

5

C

4

000 0000b ³ Count = 0

000 0001b ³ Count = 1 byte

L

011 1111b ³ Count = 63 bytes

100 0000b ³ Count = 64 bytes

Any value ≥ 100 0001b produces unpredictable results.

NAK= 1 Buffer contains a valid packet from host (host-out request is NAK)

C

3

C

2

C

1

C

0

2−8

Page 21

2.4.6 OEPSIZXY_n: Output Endpoint X-/Y-Byte Count (n = 1 to 3)

2

USBIE

x

3

STALL

0

4

DBUF

x

7

UBME

x

76 5 43210

RSV S

R/O R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

6−0 S[6:0] x X- and Y-buffer size:

7 RSV x Reserved = 0

6

S

5

S

4

000 0000b ³ Count = 0

000 0001b ³ Count = 1 byte

L

011 1111b ³ Count = 63 bytes

100 0000b ³ Count = 64 bytes

Any value ≥ 100 0001b produces unpredictable results.

S

3

S

2

S

1

S

0

2.4.7 IEPCNF_n: Input Endpoint Configuration (n = 1 to 3)

76 5 43210

UBME

R/W R/W R/W R/W R/W R/W R/O R/O

BIT NAME RESET FUNCTION

1−0 RSV x Reserved = 0

2 USBIE x

3 STALL 0

4 DBUF x

5 TOGLE x USB toggle bit. This bit reflects the toggle sequence bit of DATA0, DATA1

6 ISO x ISO = 0 Non-isochronous transfer. This bit must be cleared by the MCU because only

7 UBME x

ISO TOGLE DBUF STALL USBIE RSV RSV

USB interrupt enable on transaction completion

USBIE = 0 No interrupt

USBIE = 1 Interrupt on transaction completion

USB stall condition indication. Set by UBM, but can be set/cleared by the MCU.

STALL = 0 No stall

STALL = 1 USB stall condition. If set by the MCU, a ST ALL handshake is initiated and the bit is cleared

automatically.

Double buffer enable

DBUF = 0 Primary buffer only (X-buffer only)

DBUF = 1 Toggle bit selects buffer

non-isochronous transfer is supported.

UBM enable/disable bit. Set/clear by MCU.

UBME = 0 UBM cannot use this endpoint.

UBME = 1 UBM can use this endpoint.

2.4.8 IEPBBAX_n: Input Endpoint X-Buffer Base-Address (n = 1 to 3)

76 5 43210

A

10

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 A[10:3] x A[10:3] of X-buffer base address (padded with 3 LSB of zeros for a total of 11 bits). This value is set by the

A

9

A

8

A

7

MCU. UBM or DMA uses this value as the start-address of a given transaction. Furthermore, UBM or DMA

does not change this value at the end of a transaction.

A

6

A

5

A

4

A

3

2−9

Page 22

2.4.9 IEPBCTX_n: Input Endpoint X-Byte Count (n = 1 to 3)

76 5 43210

NAK C

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

6−0 C[6:0] x X-buffer byte count:

7 NAK x NAK = 0 Buffer contains a valid packet for host-in transaction

6

C

5

C

4

000 0000b ³ Count = 0

000 0001b ³ Count = 1 byte

L

011 1111b ³ Count = 63 bytes

100 0000b ³ Count = 64 bytes

Any value ≥ 100 0001b produces unpredictable results.

NAK = 1 Buffer is empty (host-in request is NAK)

C

3

C

2

C

1

C

0

2.4.10 IEPBBAY_n: Input Endpoint Y-Buffer Base-Address (n = 1 to 3)

76 5 43210

A

10

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 A[10:3] x A[10:3] of Y-buffer base address (padded with 3 LSB of zeros for a total of 11 bits). This value is set by the

A

9

A

8

A

7

MCU. UBM or DMA uses this value as the start-address of a given transaction. Furthermore, UBM or DMA

does not change this value at the end of a transaction.

A

6

A

5

A

4

A

3

2.4.11 IEPBCTY_n: Input Endpoint Y-Byte Count (n = 1 to 3)

76 5 43210

NAK C

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

6−0 C[6:0] x Y -buffer byte count:

7 NAK x NAK = 0 Buffer contains a valid packet for host-in transaction

6

C

5

C

4

000 0000b ³ Count = 0

000 0001b ³ Count = 1 byte

L

011 1111b ³ Count = 63 bytes

100 0000b ³ Count = 64 bytes

Any value ≥ 100 0001b produces unpredictable results.

NAK = 1 Buffer is empty (host-in request is NAK)

C

3

C

2

C

1

C

0

2−10

Page 23

2.4.12 IEPSIZXY_n: Input Endpoint X-/Y-Buffer Size (n = 1 to 3)

2

USBIE

0

3

STALL

0

7

UBME

0

76 5 43210

RSV S

R/O R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

6−0 S[6:0] x X- and Y-buffer size:

7 RSV x Reserved = 0

6

S

5

S

4

000 0000b ³ Count = 0

000 0001b ³ Count = 1 byte

L

011 1111b ³ Count = 63 bytes

100 0000b ³ Count = 64 bytes

Any value ≥ 100 0001b produces unpredictable results.

S

3

S

2

S

1

S

0

2.5 Endpoint-0 Descriptor Registers

Unlike EDB-1 to EDB-3, which are defined as memory entries in SRAM, endpoint-0 is described by a set of 4 registers

(two for output and two for input). Table 2−5 defines the registers and their respective addresses used for EDB-0

description. EDB-0 has no Base-Address Register, because these addresses are hardwired to FEF8 and FEF0. Note

that the bit positions have been preserved to provide consistency with EDB-n (n = 1 to 3).

Table 2−5. Input/Output EDB-0 Registers

ADDRESS REGISTER NAME DESCRIPTION BASE ADDRESS

FF83 OEPBCNT_0 Output endpoint-0: byte-count register

FF82 OEPCNFG_0 Output endpoint-0: configuration register FEF0

FF81 IEPBCNT_0 Input endpoint-0: byte-count register

FF80 IEPCNFG_0 Input endpoint-0: configuration register FEF8

2.5.1 IEPCNFG_0: Input Endpoint-0 Configuration Register

76 5 43210

UBME

R/W R/O R/O R/O R/W R/W R/O R/O

BIT NAME RESET FUNCTION

1−0 RSV 0 Reserved = 0

2 USBIE 0

3 STALL 0

4 RSV 0 Reserved = 0

5 TOGLE 0 USB toggle bit. This bit reflects the toggle sequence bit of DATA0, DATA1.

6 RSV 0 Reserved = 0

7 UBME 0

RSV TOGLE RSV STALL USBIE RSV RSV

USB interrupt enable on transaction completion. Set/clear by MCU.

USBIE = 0 No interrupt

USBIE = 1 Interrupt on transaction completion

USB stall condition indication. Set/clear by MCU.

STALL = 0 No stall

STALL = 1 USB stall condition. If set by the MCU, a ST ALL handshake is initiated and the bit is cleared

automatically by the next setup transaction.

UBM enable/disable bit. Set/clear by MCU.

UBME = 0 UBM cannot use this endpoint.

UBME = 1 UBM can use this endpoint.

2−11

Page 24

2.5.2 IEPBCNT_0: Input Endpoint-0 Byte Count Register

2

USBIE

0

3

STALL

0

7

UBME

0

76 5 43210

NAK RSV RSV RSV C

R/W R/O R/O R/O R/W R/W R/W R/W

BIT NAME RESET FUNCTION

3−0 C[3:0] 0000 Byte count:

0000b ³ Count = 0

L

0111b ³ Count = 7

1000b ³ Count = 8

1001b to 1111b are reserved. (If used, defaults to 8)

6−4 RSV 0 Reserved = 0

7 NAK 1 NAK= 0 Buffer contains a valid packet for host-in transaction.

NAK= 1 Buffer is empty (host-in request is NAK).

3

C

2

C

1

C

0

2.5.3 OEPCNFG_0: Output Endpoint-0 Configuration Register

76 5 43210

UBME

R/W R/O R/O R/O R/W R/W R/O R/O

BIT NAME RESET FUNCTION

1−0 RSV 0 Reserved = 0

2 USBIE 0

3 STALL 0

4 RSV 0 Reserved = 0

5 TOGLE 0 USB toggle bit. This bit reflects the toggle sequence bit of DATA0, DATA1.

6 RSV 0 Reserved = 0

7 UBME 0

RSV TOGLE RSV STALL USBIE RSV RSV

USB interrupt enable on transaction completion. Set/clear by MCU.

USBIE = 0 No interrupt

USBIE = 1 Interrupt on transaction completion

USB stall condition indication. Set/clear by MCU.

STALL = 0 No stall

STALL = 1 USB stall condition. If set by the MCU, a ST ALL handshake is initiated and the bit is cleared

automatically.

UBM enable/disable bit. Set/clear by MCU.

UBME = 0 UBM cannot use this endpoint.

UBME = 1 UBM can use this endpoint.

2−12

Page 25

2.5.4 OEPBCNT_0: Output Endpoint-0 Byte Count Register

76 5 43210

NAK RSV RSV RSV C

R/W R/O R/O R/O R/W R/W R/W R/W

BIT NAME RESET FUNCTION

3−0 C[3:0] 0000 Byte count:

0000b ³ Count = 0

L

0111b ³ Count = 7

1000b ³ Count = 8

1001b to 1111b are reserved. (If used, defaults to 8)

6−4 RSV 0 Reserved = 0

7 NAK 1 NAK= 0 No valid data in buffer. Ready for host out

NAK= 1 Buffer contains a valid packet from the host (NAK the host).

3

C

2

C

1

C

2.6 USB Registers

2.6.1 FUNADR: Function Address Register

This register contains the device function address.

76 5 43210

RSV FA6 FA5 FA4 FA3 FA2 FA1 FA0

R/O R/W R/W R/W R/W R/W R/W R/W

0

BIT NAME RESET FUNCTION

6−0 FA[6:0] 0000000 These bits define the current device address assigned to the function. The MCU writes a value to this

7 RSV 0 Reserved = 0

register as a result of the SET-ADDRESS host command.

2−13

Page 26

2.6.2 USBSTA: USB Status Register

5

RESR

0

6

SUSR

0

All bits in this register are set by the hardware and are cleared by the MCU when writing a 1 to the proper bit location

(writing a 0 has no effect). In addition, each bit can generate an interrupt if its corresponding mask bit is set (R/C

notation indicates read and clear only by the MCU).

76 5 43210

RSTR SUSR RESR PWOFF PWON SETUP RSV STPOW

R/C R/C R/C R/C R/C R/C R/O R/C

BIT NAME RESET FUNCTION

0 STPOW 0

1 RSV 0 Reserved = 0

2 SETUP 0

3 PWON 0

4 PWOFF 0

5 RESR 0

6 SUSR 0

7 RSTR 0

SETUP overwrite bit. Set by hardware when a setup packet is received while there is already a packet in the

setup buffer.

STPOW = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

STPOW = 1 SETUP overwrite

SETUP transaction received bit.

As long as SETUP is 1, IN and OUT on endpoint-0 are NAK regardless of the value of their real NAK bits.

SETUP = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

SETUP = 1 SETUP transaction received.

Power on request for port 3.

This bit indicates if power-on to port 3 has been received. This bit generates a PWON interrupt (if enabled).

PWON = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

PWON = 1 Power on to port 3 has been received.

Power off request for port 3. This bit indicates whether power-off to port 3 has been received. This bit

generates a PWOFF interrupt (if enabled).

PWOFF = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

PWOFF = 1 Power off to port 3 has been received.

Function resume request bit

RESR = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

RESR = 1 Function resume is detected.

Function suspended request bit. This bit is set in response to a global or selective suspend condition.

SUSR = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

SUSR = 1 Function suspend is detected.

Function reset request bit. This bit is set in response to the host initiating a port reset. This bit is not af fected

by a USB function reset.

RSTR = 0 The MCU can clear this bit by writing a 1. (Writing a 0 has no effect.)

RSTR = 1 Function reset is detected.

2−14

Page 27

2.6.3 USBMSK: USB Interrupt Mask Register

0

STPOW

0

2

SETUP

0

3

PWON

0

4

PWOFF

0

5

RESR

0

6

SUSR

0

7

RSTR

0

76 5 43210

RSTR SUSR RESR PWOFF PWON SETUP RSV STPOW

R/W R/W R/W R/W R/W R/W R/O R/W

BIT NAME RESET FUNCTION

0 STPOW 0

1 RSV 0 Reserved = 0

2 SETUP 0

3 PWON 0

4 PWOFF 0

5 RESR 0

6 SUSR 0

7 RSTR 0

SETUP overwrite interrupt enable bit

STPOW = 0 STPOW interrupt disabled

STPOW = 1 STPOW interrupt enabled

SETUP interrupt enable bit

SETUP = 0 SETUP interrupt disabled

SETUP = 1 SETUP interrupt enabled

Power-on interrupt enable bit

PWON = 0 PWON interrupt disabled

PWON = 1 PWON interrupt enabled

Power-off interrupt enable bit

PWOFF = 0 PWOFF interrupt disabled

PWON = 1 PWOFF interrupt enabled

Function resume interrupt enable

RESR = 0 Function resume interrupt disabled

RESR = 1 Function resume interrupt enabled

Function suspend interrupt enable

SUSR = 0 Function suspend interrupt disabled

SUSR = 1 Function suspend interrupt enabled

Function reset interrupt enable

RSTR = 0 Function reset interrupt disabled

RSTR = 1 Function reset interrupt enabled

2−15

Page 28

2.6.4 USBCTL: USB Control Register

2

B/S

0

3

RWE

0

4

FRSTE

1

5

RWUP

0

6

U1/2

0

7

CONT

0

Unlike the other registers, this register is cleared by the power-up-reset signal only . The USB reset cannot reset this

register (see the reset diagram in Figure 2−2).

76 5 43210

CONT

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

0 DIR 0

1 SIR 0

2 B/S 0

3 RWE 0

4 FRSTE 1

5 RWUP 0

6 U1/2 0

7 CONT 0

U1/2 RWUP FRSTE RWE B/S SIR DIR

As a response to a setup packet, the MCU decodes the request and sets or clears this bit to reflect the data

transfer direction.

DIR = 0 USB data OUT transaction (from host to TUSB2136)

DIR = 1 USB data IN transaction (from TUSB2136 to host)

SETUP interrupt status bit. This bit is controlled by the MCU to indicate to the hardware when SETUP

interrupt is being served.

SIR = 0 SETUP interrupt is not served. The MCU clears this bit before exiting the SETUP interrupt

routine.

SIR = 1 SETUP interrupt is in progress. The MCU sets this bit when servicing the SETUP interrupt.

Bus/self power control bit

B/S = 0 The device is bus powered.

B/S = 1 The device is self powered.

Remote wake-up enable bit

RWE = 0 The MCU clears this bit when the host sends a command to clear the feature.

RWE = 1 The MCU writes 1 to this bit when the host sends set device feature command to enable the

remote wake-up feature.

Function reset connection bit. This bit connects/disconnects the USB function reset from the MCU reset.

FRSTE = 0 Function reset is not connected to MCU reset.

FRSTE = 1 Function reset is connected to MCU reset.

Device remote wake-up request. This bit is set by the MCU and is cleared automatically.

RWUP = 0 Writing a 0 to this bit has no effect.

RWUP = 1 When the MCU writes a 1, a remote wake-up pulse is generated.

USB hub version

U1/2 = 0 This is a USB1.x hub.

U1/2 = 1 This is a USB2.x hub.

Connect/disconnect bit

CONT = 0 Upstream port is disconnected. Pullup disabled.

CONT = 1 Upstream port is connected. Pullup enabled.

2−16

Page 29

2.6.5 HUBCNFG: Hub Configuration Register

0

P1E

0

1

P1A

0

2

P2E

0

3

P2A

0

6

I/G

0

7

OCP

0

76 5 43210

OCP I/G P3.1 P3.0 P2A P2E P1A P1E

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

0 P1E 0

1 P1A 0

2 P2E 0

3 P2A 0

5−4 P3[1:0] 00 Hub port-3 embedded-function control field

6 I/G 0

7 OCP 0

Hub port-1 enable/disable control bit

P1E = 0 Port 1 is disabled.

P1E = 1 Port 1 is enabled.

Hub port−1; permanent attachment control bit.

P1A = 0 Port 1 is connected to a removable function.

P1A = 1 Port 1 is connected to a permanent attachment function.

Hub port-2 enable/disable control bit

P2E = 0 Port 2 is disabled.

P2E = 1 Port-2 is enabled.

Hub port-2 permanent-attachment control bit

P2A = 0 Port 2 is connected to a removable function.

P2A = 1 Port 2 is connected to a permanent-attachment function.

00b = Port 3 is disabled (doesn’t exist).

01b = Port 3 is permanently attached.

10b = Port 3 is connected to a removable function, but is not attached.

11b = Port 3 is connected to a removable function, and is attached.

Individual/gang power control bit

I/G = 0 Overcurrent and power control are controlled individually.

I/G = 1 Overcurrent and power control are gang controlled.

Overcurrent protection control bit

OCP = 0 Overcurrent protection is disabled.

OCP = 1 Overcurrent protection is enabled.

2.6.6 HUBPOTG: Hub Power-On to Power-Good Descriptor Register

76 5 43210

D7 D6 D5 D4 D3 D2 D1 D0

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[7:0] 00h Offset-5 in hub descriptor table

2.6.7 HUBCURT: Hub Current Descriptor Register

76 5 43210

D7 D6 D5 D4 D3 D2 D1 D0

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[7:0] 00h Offset-6 in hub descriptor table

2−17

Page 30

2.6.8 HUBPIDL: Hub PID Register (Low-Byte)

76 5 43210

D7 D6 D5 D4 D3 D2 D1 D0

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[7:0] 00h Hub PID low-byte value

2.6.9 HUBPIDH: Hub PID Register (High-Byte)

76 5 43210

D15 D14 D13 D12 D11 D10 D9 D8

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[15:8] 00h Hub PID high-byte value

2.6.10 HUBVIDL: Hub VID Register (Low-Byte)

76 5 43210

D7 D6 D5 D4 D3 D2 D1 D0

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[7:0] 00h Hub VID low-byte value

2.6.11 HUBVIDH: Hub VID Register (High-Byte)

76 5 43210

D15 D14 D13 D12 D11 D10 D9 D8

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[15:8] 00h Hub VID high-byte value

2.6.12 VIDSTA: VID/PID Status Register

This register is used to read the value on four external pins. The firmware can use this value to select one of the vendor

identification/product identifications (VID/PID) stored in memory. The TUSB2136 supports up to 16 unique VID/PIDs

with application code to support different products. This provides a unique opportunity for original equipment

manufacturers (OEMs) to have one device to support up to 16 dif ferent product lines by using S0−S3 to select VID/PID

and behavioral application code for the selected product.

76 5 43210

RSV RSV RSV RSV S3 S2 S1 S0

R/O R/O R/O R/O R/O R/O R/O R/O

BIT NAME RESET FUNCTION

3−0 S[3:0] x VID/PID selection bits. These bits reflect the status of the external pins as defined by Table 2−6. Note that a

7−4 RSV 0 Reserved = 0

pin tied low is reflected as a 0 and a pin tied high is reflected as a 1.

2−18

Page 31

Table 2−6. External Pins Mapping to S[3:0] in VIDSTA Register

COMMENTS

VIDSTA REGISTER PIN

S[3:0] NO. NAME

S0 58 P3.0 Dual function, P3.0 I/O or S0 input

S1 57 P3.1 Dual function, P3.1 I/O or S1 input

S2 8 S2 S2-pin is input

S3 9 S3 S3-pin is input

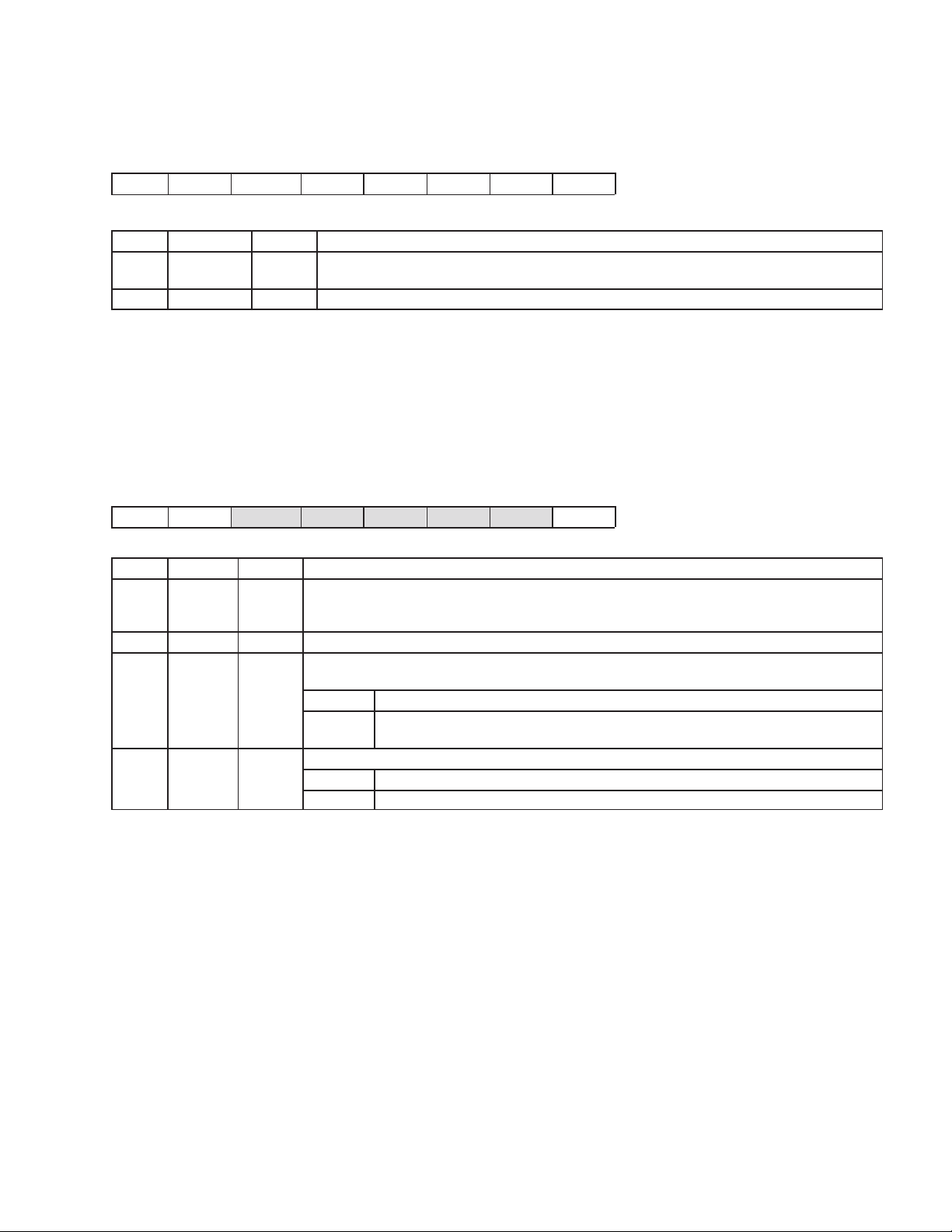

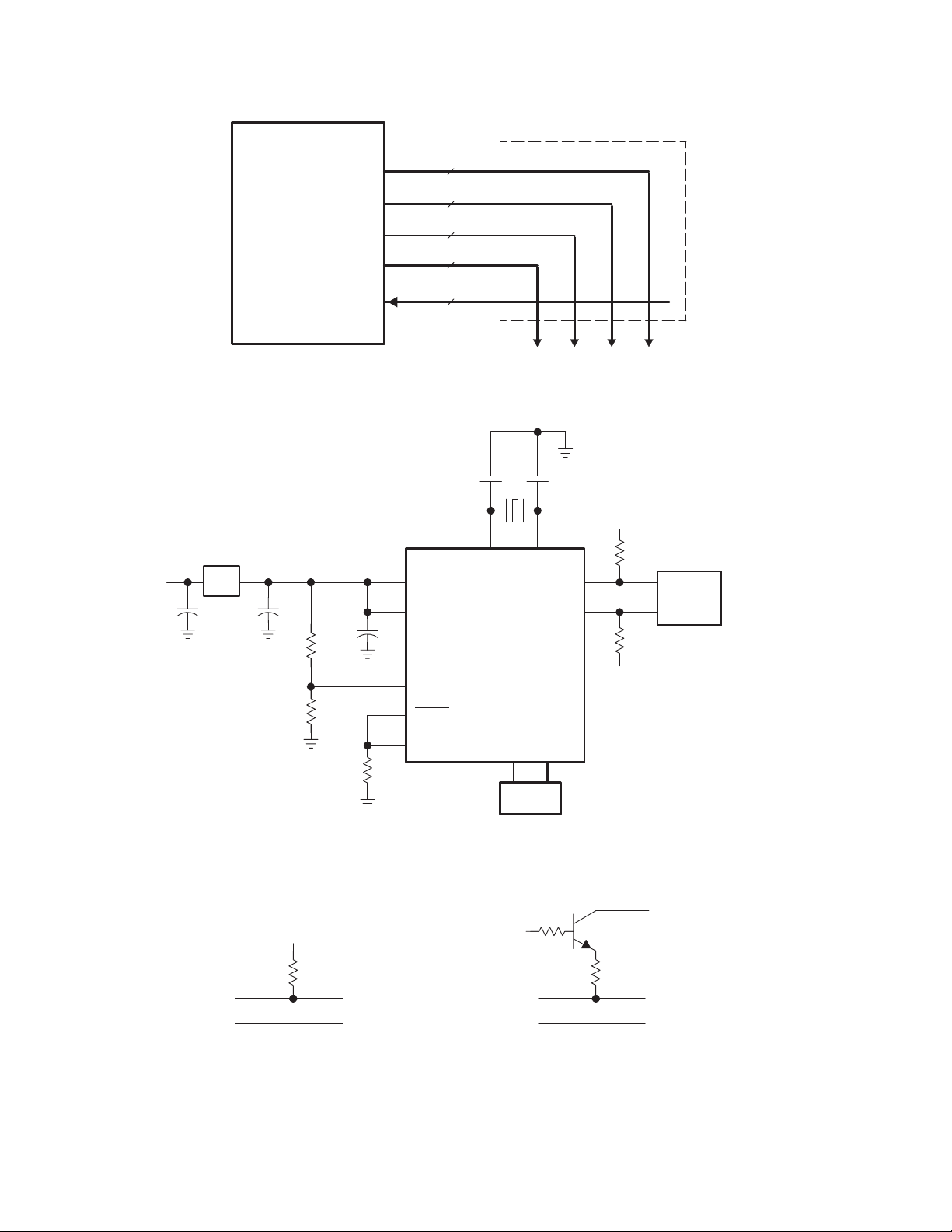

2.7 Function Reset and Power-Up Reset Interconnect

Figure 2−2 represents the logical connection of USB-function reset (USBR) and power-up reset (RST) pins. The

internal RESET

can be enabled or disabled by the FRSTE bit in the USBCTL register (on power up FRSTE = 0). The internal RESET

is used to reset all registers and logic, with the exception of the USBCTL and MISCTL registers. The USBCTL and

MCU configuration registers (MCNFG) are cleared by the PURS

signal is generated from the RST pin (PURS signal) or from the USB reset (USBR signal). The USBR

signal only.

USBCTL Register

MCNFG Register

All Internal MMR

RST

WDT Reset

WDE

PURS

USBR

RESET

USB Function Reset

FRSTE

MCU

Figure 2−2. Reset Diagram

2.8 Pullup Resistor Connect/Disconnect

After reading firmware into RAM, the TUSB2136 can reenumerate using the new firmware (no need to physically

disconnect and re-connect the cable). Figure 2−3 shows an equivalent circuit implementation for Connect and

Disconnect from a USB upstream port (also see Figure 4−4b). When the CONT bit in the USBCTL register is 1, the

CMOS driver sources V

(high speed). When the CONT bit is 0, the PUR pin is driven low . In this state, the 1.5-kΩ resistor is connected to GND,

resulting in device disconnection state. The PUR driver is a CMOS driver that can provide V

8-mA source current.

DD to the pullup resistor (PUR pin), presenting a normal connect condition to the USB hub

DD − 0.1 V minimum at

2−19

Page 32

CMOS

CONT-BitPUR

TUSB2046B

HUB

D+

D−

15 kΩ15 kΩ

1.5 kΩ

DP0

DM0

TUSB2136

Figure 2−3. Pullup Resistor Connect/Disconnect Circuit

2.9 8052 Interrupt and Status Registers

All seven 8052-standard interrupt sources are preserved. SIE is the standard interrupt enable register, which controls

the seven interrupt sources. All the additional interrupt sources are connected together as an OR to generate INT0

The INT0

signal is provided to interrupt the MCU (see interrupt connection diagram, Figure 2−4).

Table 2−7. 8052 Interrupt Location Map

INTERRUPT

SOURCE

ET2 Timer-2 interrupt 002BH

ES UART interrupt 0023H

DESCRIPTION START

ADDRESS

COMMENTS

.

ET1 Timer-1 interrupt 001BH

EX1 Internal INT1 or INT1 0013H Used for P2[7:0] interrupt

ET0 Timer-0 interrupt 000BH

EX0 Internal INT0 0003H Used for all internal peripherals

Reset 0000H

2−20

Page 33

2.9.1 8052 Standard Interrupt Enable Register

0

INT0

0

1

ET0

0

2

EX1

0

3

ET1

0

4ES0

5

ET2

0

7EA0

76 5 43210

EA RSV ET2 ES ET1 EX1 ET0 INT0

R/W R/O R/O R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

0 INT0 0

1 ET0 0

2 EX1 0

3 ET1 0

4 ES 0

5 ET2 0

6 RSV 0 Reserved

7 EA 0

Enable or disable external interrupt-0

EX0 = 0 External interrupt-0 is disabled.

EX0 = 1 External interrupt-0 is enabled.

Enable or disable timer-0 interrupt

ET0 = 0 Timer-0 interrupt is disabled.

ET0 = 1 Timer-0 interrupt is enabled.

Enable or disable external interrupt-1

EX1 = 0 External interrupt-1 is disabled.

EX1 = 1 External interrupt-1 is enabled.

Enable or disable timer-1 interrupt

ET1 = 0 Timer-1 interrupt is disabled.

ET1 = 1 Timer-1 interrupt is enabled.

Enable or disable serial port interrupts

ES = 0 Serial port interrupt is disabled.

ES = 1 Serial port interrupt is enabled.

Enable or disable timer-2 interrupt

ET2 = 0 Timer-2 interrupt is disabled.

ET2 = 1 Timer-2 interrupt is enabled.

Enable or disable all interrupts (global disable)

EA = 0 Disable all interrupts.

EA = 1 Each interrupt source is individually controlled.

2.9.2 Additional Interrupt Sources

All nonstandard 8052 interrupts (USB, I2C, etc.) are connected as an OR to generate an internal INT0. It must be

noted that the external INT0

interrupt (not edge-triggered). A vector interrupt register is provided to identify all interrupt sources (see vector

interrupt register definition, Section 2.9.3). Up to 64 interrupt vectors are provided. It is the responsibility of the MCU

to read the vector and dispatch the proper interrupt routine.

and INT1 are not used. Furthermore, INT0 must be programmed as an active-low level

2−21

Page 34

2.9.3 VECINT: Vector Interrupt Register

This register contains a vector value identifying the internal interrupt source that trapped to location 0003h. Writing

any value to this register removes the vector and updates the next vector value (if another interrupt is pending). Note

that the vector value is offset. Therefore, its value is in increments of two (bit 0 is set to 0). When no interrupt is pending,

the vector is set to 00h. Table 2−8 is a table of the vector interrupt values. As shown, the interrupt vector is divided

into two fields, I[2:0] and G[3:0]. The I-field defines the interrupt source within a group (on a first-come, first-served

basis) and the G-field defines the group number. Group G0 is the lowest and G15 is the highest priority.

76 5 43210

G3

R/W R/W R/W R/W R/W R/W R/W R/O

BIT NAME RESET FUNCTION

3−1 I[2:0] 000 This field defines the interrupt source in a given group. See Table 2−8, Vector Interrupt Values.

7−4 G[3:0] 0000 This field defines the interrupt group. I[2:0] and G[3:0] combine to produce the actual interrupt vector.

G2 G1 G0 I2 I1 I0 0

Bit 0 is always 0; therefore, vector values are offset by two.

Table 2−8. Vector Interrupt Values

G[3:0]

(Hex)

0 0 00 No interrupt

1 0 10 RESERVED

1 1 12 Output endpoint 1

1 2 14 Output endpoint 2

1 3 16 Output endpoint 3

1 4−7 18−1E RESERVED

2 0 20 RESERVED

2 1 22 Input endpoint 1

2 2 24 Input endpoint 2

2 3 26 Input endpoint 3

2 4−7 28−2E RESERVED

3 0 30 STPOW packet received

3 1 32 SETUP packet received

3 2 34 PWON interrupt

3 3 36 PWOFF interrupt

3 4 38 RESR interrupt

3 5 3A SUSR interrupt

3 6 3C RSTR interrupt

3 7 3E RESERVED

4 0 40 I2C TXE interrupt

4 1 42 I2C RXF interrupt

4 2 44 Input endpoint 0

4 3 46 Output endpoint 0

4 4−7 48 → 4E RESERVED

5−15 X 90 → FE RESERVED

I[2:0]

(Hex)

VECTOR

(Hex)

INTERRUPT SOURCE

2−22

Page 35

2.9.4 Logical Interrupt Connection Diagram (INT0)

Figure 2−4 represents the logical connection of the interrupt sources and the relation of the logical connection with

INT0

. The priority encoder generates an 8-bit vector, corresponding to 64 interrupt sources (not all are used). The

interrupt priorities are hard wired. V ector 46h is the highest and 12h is the lowest. Table 2−8 lists the interrupt source

for each valid interrupt vector.

Interrupts

Priority

Encoder

46h

Interrupt Sources

L

12h

Vector

INT0

Figure 2−4. Internal Vector Interrupt (INT0)

2.9.5 P2[7:0] Interrupt (INT1)

Figure 2−5 illustrates the conceptual port-2 interrupt. All port-2 input signals are connected in a logical OR to generate

the INT1

addition, INT1

the MCU configuration register (MCNFG) is used to select the EX1 interrupt source. When XINT = 0, P3.3 is the

source, and when XINT = 1, P2[7:0] is the source.

interrupt. Note that the inputs are active low and INT1 is programmed as a level-triggered interrupt. In

is connected to the suspend/resume logic for remote wake-up support. As illustrated, the XINT bit in

P2[7:0]

INT1

P3.3

Suspend/

Resume

Logic

XINT Bit

Figure 2−5. P2[7:0] Input Port Interrupt Generation

2−23

Page 36

2.10 I2C Registers

2

TIE

0

4

1/4

0

6

RIE

0

The TUSB2136 only supports a master-slave relationship; therefore, it does not support bus arbitration.

2.10.1 I2CSTA: I2C Status and Control Register

This register is used to control the stop condition for read and write operations. In addition, it provides transmitter and

receiver handshake signals with their respective interrupt enable bits.

76 5 43210

RXF

R/C R/W R/C R/W R/C R/W R/W R/W

BIT NAME RESET FUNCTION

0 SWR 0

1 SRD 0

2 TIE 0

3 TXE 1

4 1/4 0

5 ERR 0

6 RIE 0

7 RXF 0

RIE ERR 1/4 TXE TIE SRD SWR

Stop write condition. This bit defines whether the I2C controller generates a stop condition when data from

the I2CDAO register is transmitted to an external device.

SWR = 0 Stop condition is not generated when data from I2CDAO register is shifted out to an external

device.

SWR = 1 Stop condition is generated when data from I2CDAO register is shifted out to an external device.

Stop read condition. This bit defines whether the I2C controller generates a stop condition when data is

received and loaded into I2CDAI register.

SRD = 0 Stop condition is not generated when data from SDA line is shifted into the I2CDAI register.

SRD = 1 Stop condition is generated when data from SDA line is shifted into the I2CDAI register.

I2C transmitter empty interrupt enable

TIE = 0 Interrupt disabled

TIE = 1 Interrupt enabled

I2C transmitter empty. This bit indicates that data can be written to the transmitter. It can be used for polling or

it can generate an interrupt.

TXE = 0 Transmitter is full. This bit is cleared when the MCU writes a byte to I2CDAO register.

TXE = 1 Transmitter is empty. The I2C controller sets this bit when the content of the I2CDAO register is

copied to the SDA shift register.

Bus speed selection

1/4 = 0 100-kHz bus speed

1/4 = 1 400-kHz bus speed

Bus error condition. This bit is set by the hardware when the device does not respond. It is cleared by the

MCU.

ERR = 0 No bus error

ERR = 1 Bus error condition has been detected. Clears when MCU writes a 1. Writing a 0 has no effect.

I2C receiver ready interrupt enable

RIE = 0 Interrupt disabled

RIE = 1 Interrupt enabled

I2C receiver full. This bit indicates that the receiver contains new data. It can be used for polling or it can

generate an interrupt.

RXF = 0 Receiver is empty. This bit is cleared when MCU reads the I2CDAI register.

RXF = 1 Receiver contains n e w d a t a . T h i s bit is set by the I2C controller when the received serial data has

been loaded into I2CDAI register.

2−24

Page 37

2.10.2 I2CADR: I2C Address Register

0

R/W

0

This register holds the device address and the read/write command bit.

76 5 43210

A

6

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

0 R/W 0

7−1 A[6:0] 0000000 Seven address bits for device addressing

A

5

A

4

A

3

Read/write command bit.

R/W = 0 Write operation

R/W = 1 Read operation

A

2

A

1

A

0

R/W

2.10.3 I2CDAI: I2C Data-Input Register

This register holds the received data from an external device.

76 5 43210

D

7

R/O R/O R/O R/O R/O R/O R/O R/O

BIT NAME RESET FUNCTION

7−0 D[7:0] 0 8-bit input data from an I2C device

D

6

D

5

D

4

D

3

D

2

D

1

D

2.10.4 I2CDAO: I2C Data-Output Register

0

This register holds the data to be transmitted to an external device. Writing to this register starts the transfer on the

SDA line.

76 5 43210

D7

R/W R/W R/W R/W R/W R/W R/W R/W

BIT NAME RESET FUNCTION

7−0 D[7:0] 0 8-bit output data to an I2C device

D6 D5 D4 D3 D2 D1 D0

2.11 Read/Write Operations

2.11.1 Read Operation (Serial EEPROM)

A serial read requires a dummy byte write sequence to load in the 16-bit data word address. Once the device address

word and data word are clocked out and acknowledged by the device, the MCU starts a current address sequence.

The following describes the sequence of events to accomplish this transaction:

Device Address + EEPROM [high byte]

• The MCU sets I2CSTA[SRD] = 0. This prevents the I

content of the I2CDAI register is received.

• The MCU sets I2CSTA[SWR] = 0. This prevents the I

the content of the I2CDAO register is transmitted.

• The MCU writes the device address (R/W bit = 0) to the I2CADR register (write operation).

2

C controller from generating a stop condition after the

2

C controller from generating a stop condition after

• The MCU writes the high byte of the EEPROM address into the I2CDAO register, starting the transfer on

the SDA line.

2−25

Page 38

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CADR register is transmitted to the EEPROM (preceded by start condition on SDA).

• The content of the I2CDAO register is transmitted to the EEPROM (EEPROM address).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been

transmitted.

• No stop condition is generated.

EEPROM [low byte]

• The MCU writes the low byte of the EEPROM address into the I2CDAO register.

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CDAO register is transmitted to the device (EEPROM address).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been

transmitted.

• This completes the dummy write operation. At this point, the EEPROM address is set and the MCU can

perform a single or a sequential read operation.

2.11.2 Current Address Read Operation

Once the EEPROM address is set, the MCU can read a single byte by executing the following steps:

1. The MCU sets I2CSTA[SRD] = 1, forcing the I

register is received.

2

C controller to generate a stop condition after the I2CDAI

2. The MCU writes the device address (R/W bit = 1) to the I2CADR register (read operation).

3. The MCU writes a dummy byte to the I2CDAO register, starting the transfer on the SDA line.

4. The RXF bit in I2CSTA is cleared.

5. The content of the I2CADR register is transmitted to the device, preceded by a start condition on SDA.

6. Data from the EEPROM is latched into the I2CDAI register (stop condition is transmitted).

7. The RXF bit in I2CSTA is set, and interrupts the MCU, indicating that the data is available.

8. The MCU reads the I2CDAI register. This clears the RXF bit (I2CSTA[RXF] = 0).

2.11.3 Sequential Read Operation

Once the EEPROM address is set, the MCU can execute a sequential read operation by executing the following steps

(Note: this example illustrates a 32-byte sequential read):

1. Device Address

• The MCU sets I2CSTA[SRD] = 0. This prevents the I

the I2CDAI register is received.

• The MCU writes the device address (R/W bit = 1) to the I2CADR register (read operation).

• The MCU writes a dummy byte to the I2CDAO register, starting the transfer on the SDA line.

• The RXF bit in I2CSTA is cleared.

• The content of the I2CADR register is transmitted to the device (preceded by a start condition on SDA).

2

C controller from generating a stop condition after

2−26

2. N-Byte Read (31 bytes)

• Data from the device is latched into the I2CDAI register (stop condition is not transmitted).

Page 39

• The RXF bit in I2CSTA is set, and interrupts the MCU, indicating that data is available.

• The MCU reads the I2CDAI register, clearing the RXF bit (I2CSTA[RXF] = 0).

• This operation repeats 31 times.

3. Last-Byte Read (byte 32)

2

• The MCU sets I2CST A[SRD] = 1. This forces the I

C controller to generate a stop condition after the

I2CDAI register is received.

• Data from the device is latched into the I2CDAI register (stop condition is transmitted).

• The RXF bit in I2CSTA is set, and interrupts the MCU, indicating that data is available.

• The MCU reads the I2CDAI register, clearing the RXF bit (I2CSTA[RXF] = 0).

2.11.4 Write Operation (Serial EEPROM)

The byte write operation involves three phases: 1) device address + EEPROM [high byte] phase, 2) EEPROM [low

byte] phase, and 3) EEPROM [DATA]. The following describes the sequence of events to accomplish the byte write

transaction:

Device Address + EEPROM [high byte]

2

• The MCU sets I2CSTA[SWR] = 0. This prevents the I

the content of the I2CDAO register is transmitted.

• The MCU writes the device address (R/W bit = 0) to the I2CADR register (write operation).

C controller from generating a stop condition after

• The MCU writes the high byte of the EEPROM address into the I2CDAO register, starting the transfer on

the SDA line.

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CADR register is transmitted to the device (preceded by a start condition on SDA).

• The content of the I2CDAO register is transmitted to the device (EEPROM high-address).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been

transmitted.

EEPROM [low byte]

• The MCU writes the low byte of the EEPROM address into the I2CDAO register.

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CDAO register is transmitted to the device (EEPROM address).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been

transmitted.

2−27

Page 40

EEPROM [DATA]

2

• The MCU sets I2CST A[SWR] = 1. This forces the I

C controller to generate a stop condition after the content

of the I2CDAO register is transmitted.

• The MCU writes the DATA to be written to the EEPROM into the I2CDAO register.

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CDAO register is transmitted to the device (EEPROM data).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been

transmitted.

2

• The I

C controller generates a stop condition after the content of the I2CDAO register is transmitted.

2.11.5 Page Write Operation

The page write operation is initiated the same way as byte write, with the exception that a stop condition is not

generated after the first EEPROM [DATA] is transmitted. The following describes the sequence of writing 32 bytes

in page mode:

Device Address + EEPROM [high byte]

2

• The MCU sets I2CSTA[SWR] = 0. This prevents the I

the content of the I2CDAO register is transmitted.

• The MCU writes the device address (R/W bit = 0) to the I2CADR register (write operation).

• The MCU writes the high byte of the EEPROM address into the I2CDAO register.

C controller from generating a stop condition after

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CADR register is transmitted to the device (preceded by a start condition on SDA).

• The content of the I2CDAO register is transmitted to the device (EEPROM address).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been sent.

EEPROM [low byte]

• The MCU writes the low byte of the EEPROM address into the I2CDAO register.

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CDAO register is transmitted to the device (EEPROM address).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been sent.

31 Bytes EEPROM [DATA]

• The MCU writes the DATA to be written to the EEPROM into the I2CDAO register.

• The TXE bit in I2CSTA is cleared, indicating busy.

• The content of the I2CDAO register is transmitted to the device (EEPROM data).

• The TXE bit in I2CSTA is set, and interrupts the MCU, indicating that the I2CDAO register has been sent.

• This operation repeats 31 times.

2−28

Page 41

Last Byte EEPROM [DATA]