1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

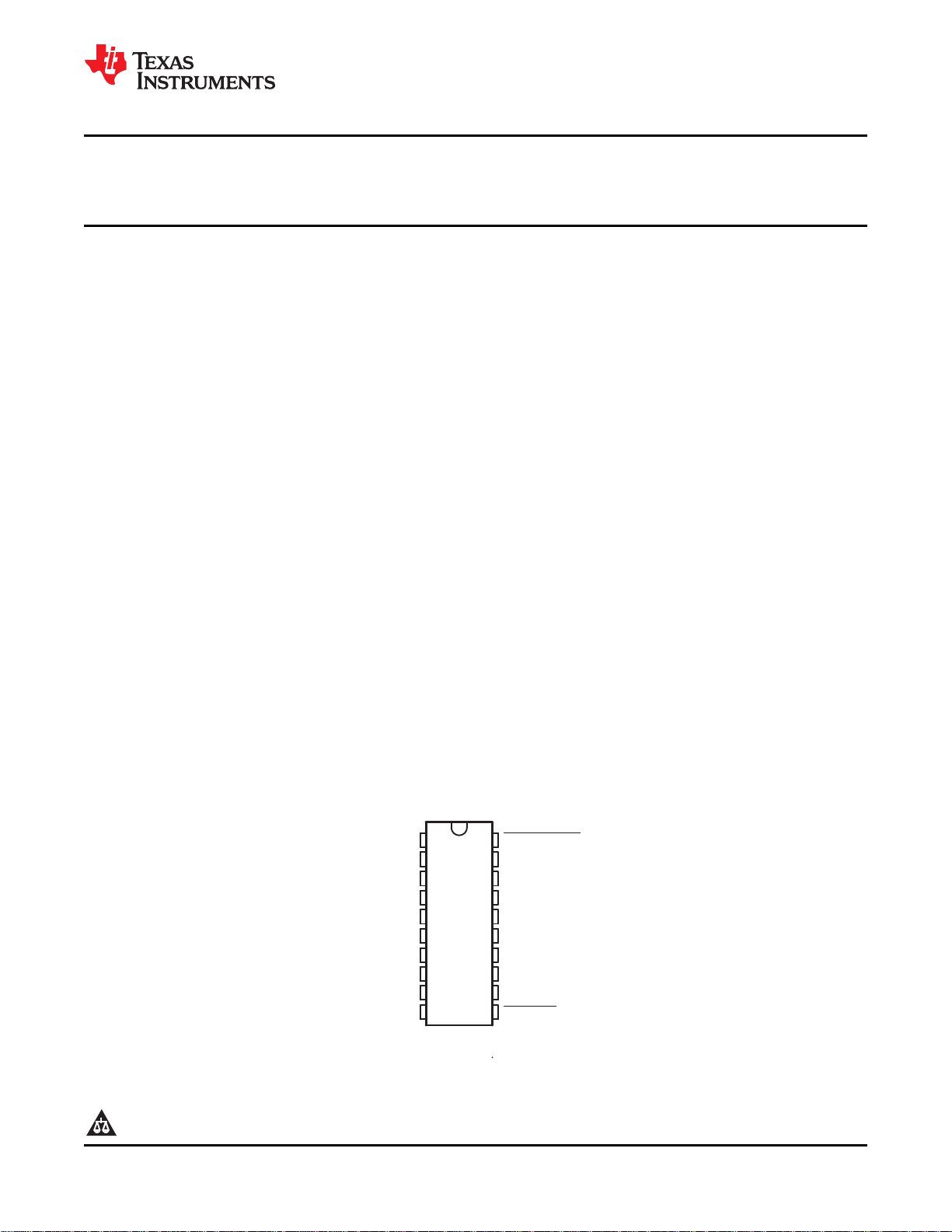

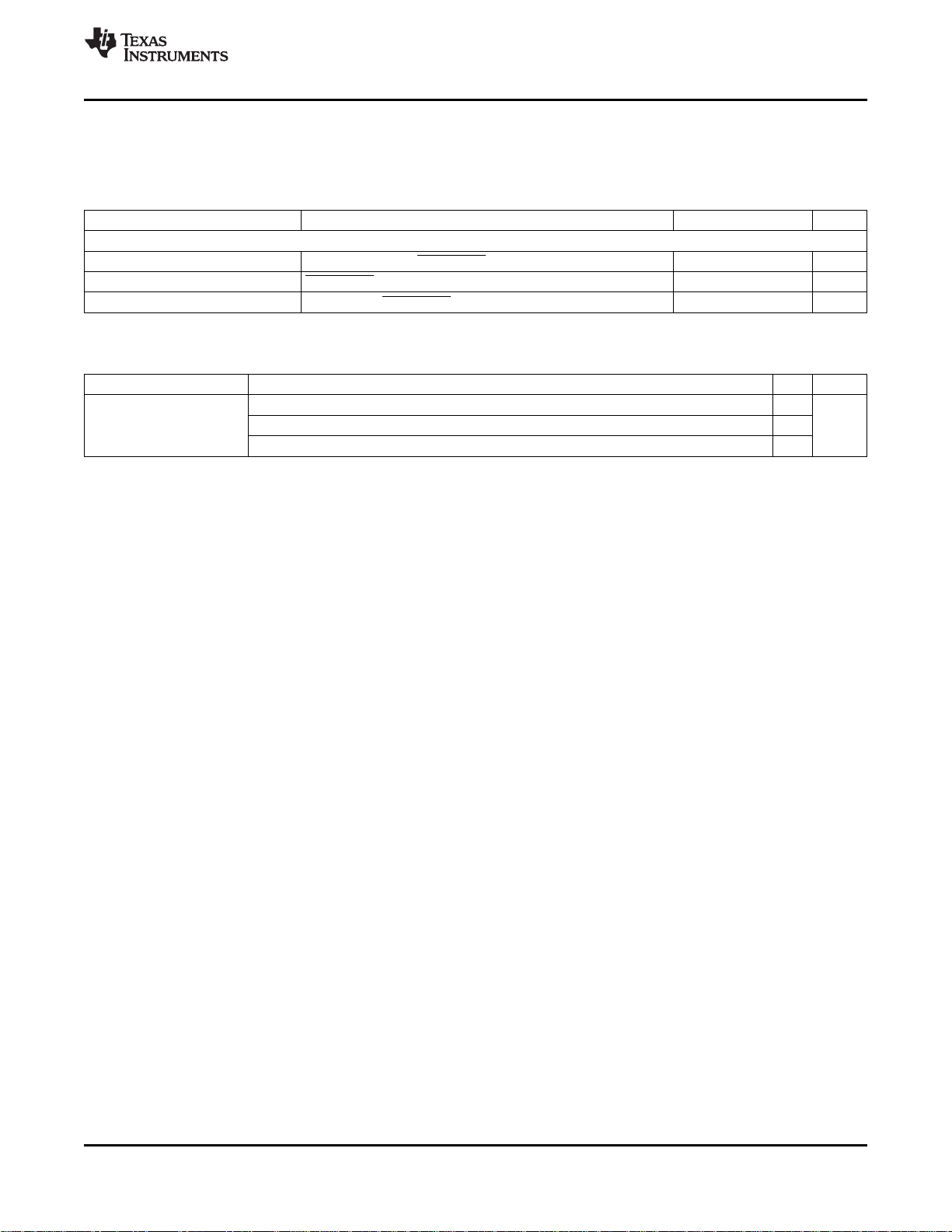

READY

C1+

V+

C1−

C2+

C2−

V−

DOUT2

RIN2

ROUT2

FORCEOFF

V

CC

GND

DOUT1

RIN1

ROUT1

FORCEON

DIN1

DIN2

INVALID

DB OR PW PACKAGE

(TOP VIEW)

TRS3318E

www.ti.com

2.5-V 460-kbps RS-232 TRANSCEIVER

WITH ±15-kV ESD PROTECTION

Check for Samples: TRS3318E

1

FEATURES

• ESD Protection for RS-232 I/O Pins

– ±15 kV (Human-Body Model)

– ±8 kV (IEC 61000-4-2, Contact Discharge)

– ±15 kV (IEC 61000-4-2, Air-Gap Discharge)

• 300-µA Operating Supply Current

• 1-µA Low-Power Standby Mode (With

Receivers Active)

• Designed to Transmit at a Data Rate of

460 kbps

• Auto-Powerdown Plus Option Features

Flexible Power-Saving Mode

• Operates From a Single 2.25-V to 3-V V

Supply

• Designed to be Interchangeable With Industry

Standard '3318 Devices

APPLICATIONS

• Battery-Powered Systems

• PDAs

• Cellular Phones

• Notebooks

• Hand-Held Equipment

• Pagers

CC

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

DESCRIPTION

The TRS3318E is a dual-driver, dual-receiver, RS232-compatible transceiver. The device features

auto-powerdown plus and enhanced electrostatic

discharge (ESD) protection integrated into the chip.

Driver output and receiver input are protected to ±15

kV using the IEC 61000-4-2 Air-Gap Discharge

method, ±8 kV using the IEC 61000-4-2 Contact

Discharge method, and ±15 kV using the HumanBody Model (HBM).

The device operates at a data rate of 460 kbps. The

transceiver has a proprietary low-dropout driver

output stage, enabling RS-232-compatible operation

from a 2.25-V to 3-V supply with a dual charge pump.

The charge pump requires only four 0.1-µF

capacitors and features a logic-level output (READY)

that asserts when the charge pump is regulating and

the device is ready to begin transmitting.

The TRS3318E achieves a 1-µA supply current using

the auto-powerdown feature. This device

automatically enters a low-power power-down mode

when the RS-232 cable is disconnected or the drivers

of the connected peripherals are inactive for more

than 30 s. The device turns on again when it senses

a valid transition at any driver or receiver input. Autopowerdown saves power without changes to the

existing BIOS or operating system.

This device is available in two space-saving

packages: 20-pin SSOP and 20-pin TSSOP.

1

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2007–2013, Texas Instruments Incorporated

TRS3318E

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

DETAILED DESCRIPTION

Flexible control options for power management are featured when the serial port and driver inputs are inactive.

The auto-powerdown plus feature functions when FORCEON is low and FORCEOFF is high. During this mode of

operation, if the device does not sense valid signal transitions on all receiver and driver inputs for approximately

30 s, the built-in charge pump and drivers are powered down, reducing the supply current to 1 µA. By

disconnecting the serial port or placing the peripheral drivers off, auto-powerdown plus can be disabled when

FORCEON and FORCEOFF are high. With auto-powerdown plus enabled, the device activates automatically

when a valid signal is applied to any receiver or driver input. INVALID is high (valid data) if any receiver input

voltage is greater than 2.7 V or less than –2.7 V, or has been between –0.3 V and 0.3 V for less than 30 µs

(typical number). INVALID is low (invalid data) if all receiver input voltage are between –0.3 V and 0.3 V for more

than 30 µs (typical number).

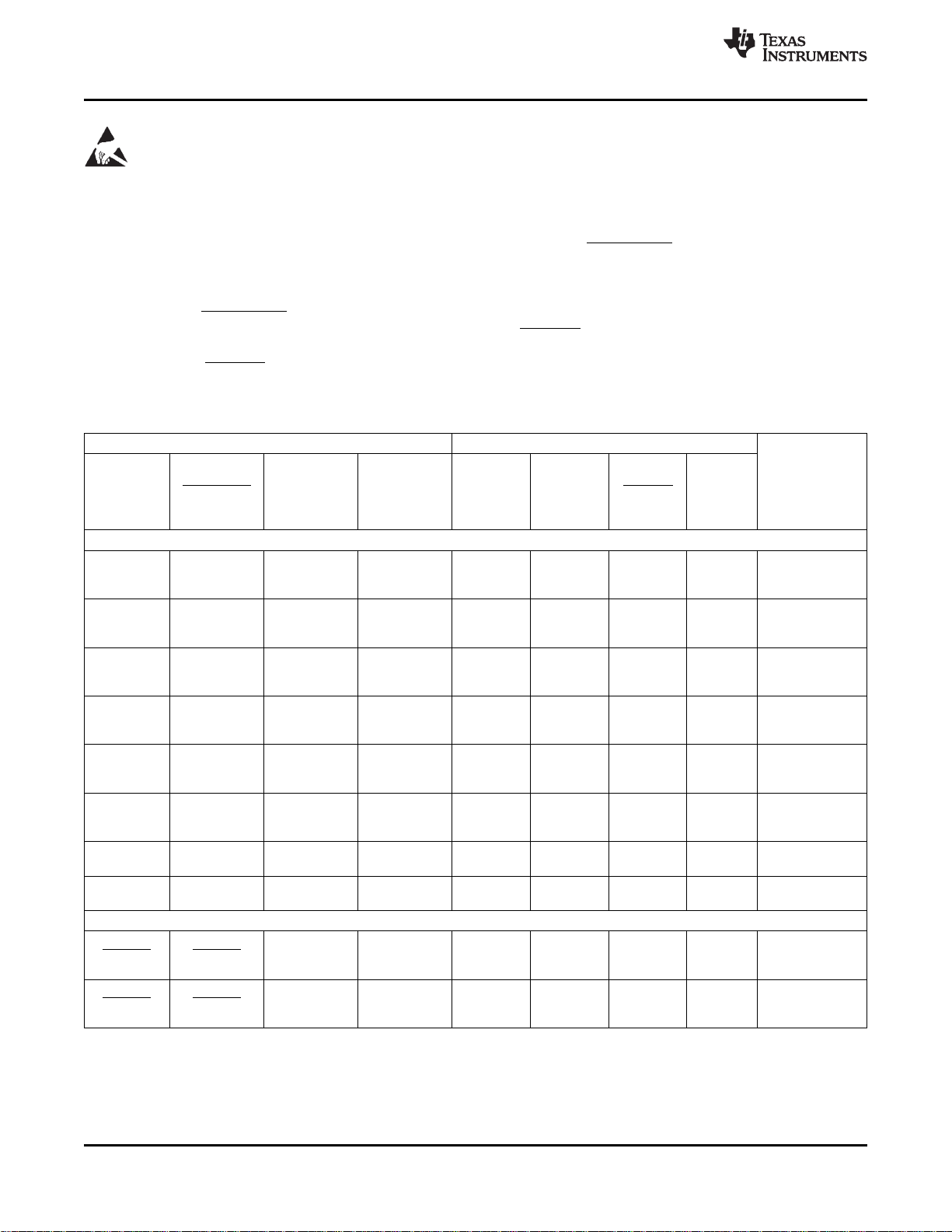

FUNCTION TABLE

INPUT CONDITIONS OUTPUT STATES

RECEIVER

FORCEON FORCEOFF LEVEL DRIVER RECEIVER INVALID READY

H H No No Active Active L H auto-powerdown

H H No Yes Active Active H H auto-powerdown

L H Yes No Active Active L H auto-powerdown

L H Yes Yes Active Active H H auto-powerdown

L H No No Z Active L L auto-powerdown

L H No Yes Z Active H L auto-powerdown

X L X No Z Active L L

X L X Yes Z Active H L

INVALID INVALID X No Z Active L L auto-powerdown

INVALID INVALID X Yes Active Active H H auto-powerdown

(1) H = high level, L = low level, X = irrelevant, Z = high impedance

OR DRIVER

EDGE

WITHIN 30 s

VALID

RS-232

PRESENT AT

RECEIVER

Auto-Powerdown Plus Conditions

Auto-Powerdown Conditions

(1)

OPERATING

MODE

Normal operation,

plus disabled

Normal operation,

plus disabled

Normal operation,

plus enabled

Normal operation,

plus enabled

Power down,

plus enabled

Power down,

plus enabled

Manual power

down

Manual power

down

Power down,

enabled

Normal operation,

enabled

2 Submit Documentation Feedback Copyright © 2007–2013, Texas Instruments Incorporated

Product Folder Links: TRS3318E

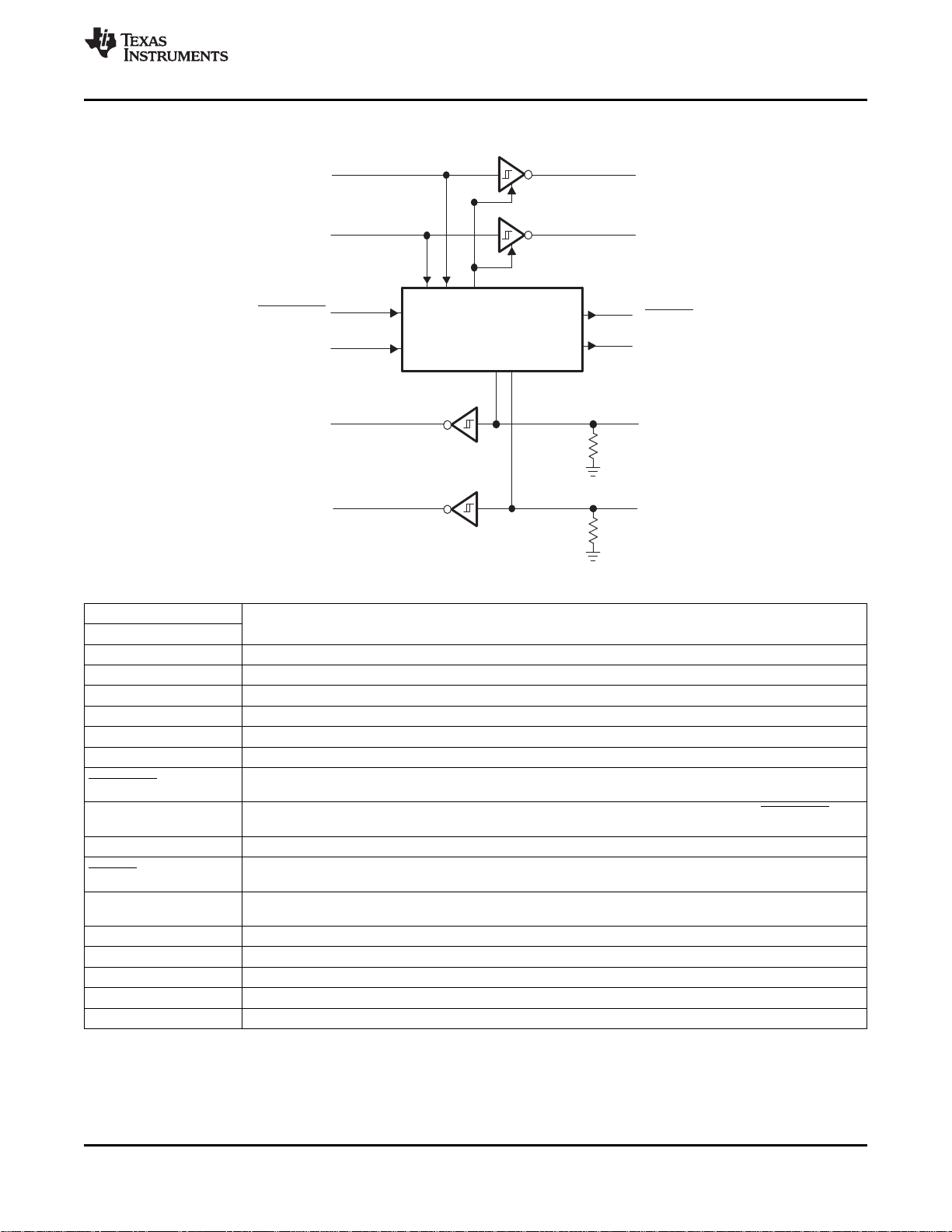

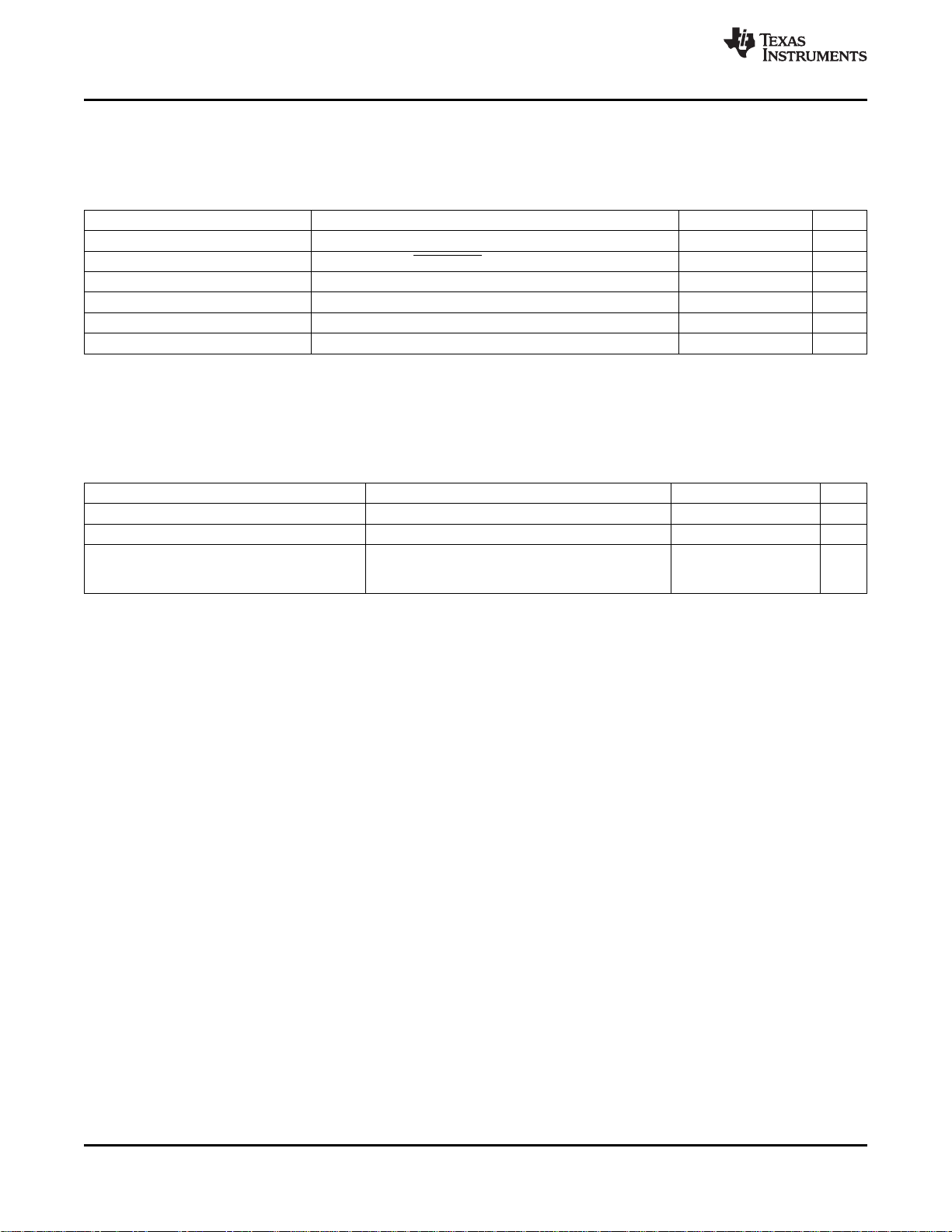

DIN2

DIN1

DOUT2

DOUT1

Auto-powerdown Plus

INVALID

RIN1

RIN2

FORCEOFF

FORCEON

ROUT1

ROUT2

13

12

20

14

15

10

17

8

11

16

9

5 k

5 k

Ω

Ω

READY

1

TRS3318E

www.ti.com

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

LOGIC DIAGRAM (POSITIVE LOGIC)

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

C1+ 2 Positive voltage-doubler charge-pump capacitor

C1– 4 Negative voltage-doubler charge-pump capacitor

C2+ 5 Positive inverting charge-pump capacitor

C2– 6 Negative inverting charge-pump capacitor

DIN 12, 13 CMOS driver inputs

DOUT 8, 17 RS-232 driver outputs

FORCEOFF 20

FORCEON 14

GND 18 Ground

INVALID 11

READY 1

RIN 9, 16 RS-232 receiver inputs

ROUT 10, 15 CMOS receiver outputs

V+ 3 2 × VCCgenerated by the charge pump

V– 7 –2 × VCCgenerated by the charge pump

V

CC

Force-off input, active low. Drive low to power down transmitters and charge pump. This overrides autopowerdown and FORCEON (see Function Table).

Force-on input, active high. Drive high to override auto-powerdown, keeping transmitters on (FORCEOFF must

be high) (see Function Table).

Valid signal detector output, active low. A logic high indicates that a valid RS-232 level is present on a receiver

input.

Ready to transmit output, active high. READY is enabled high when V– goes below –3.5 V and the device is

ready to transmit.

19 2.25-V to 3-V single-supply voltage

DESCRIPTION

Copyright © 2007–2013, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: TRS3318E

TRS3318E

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

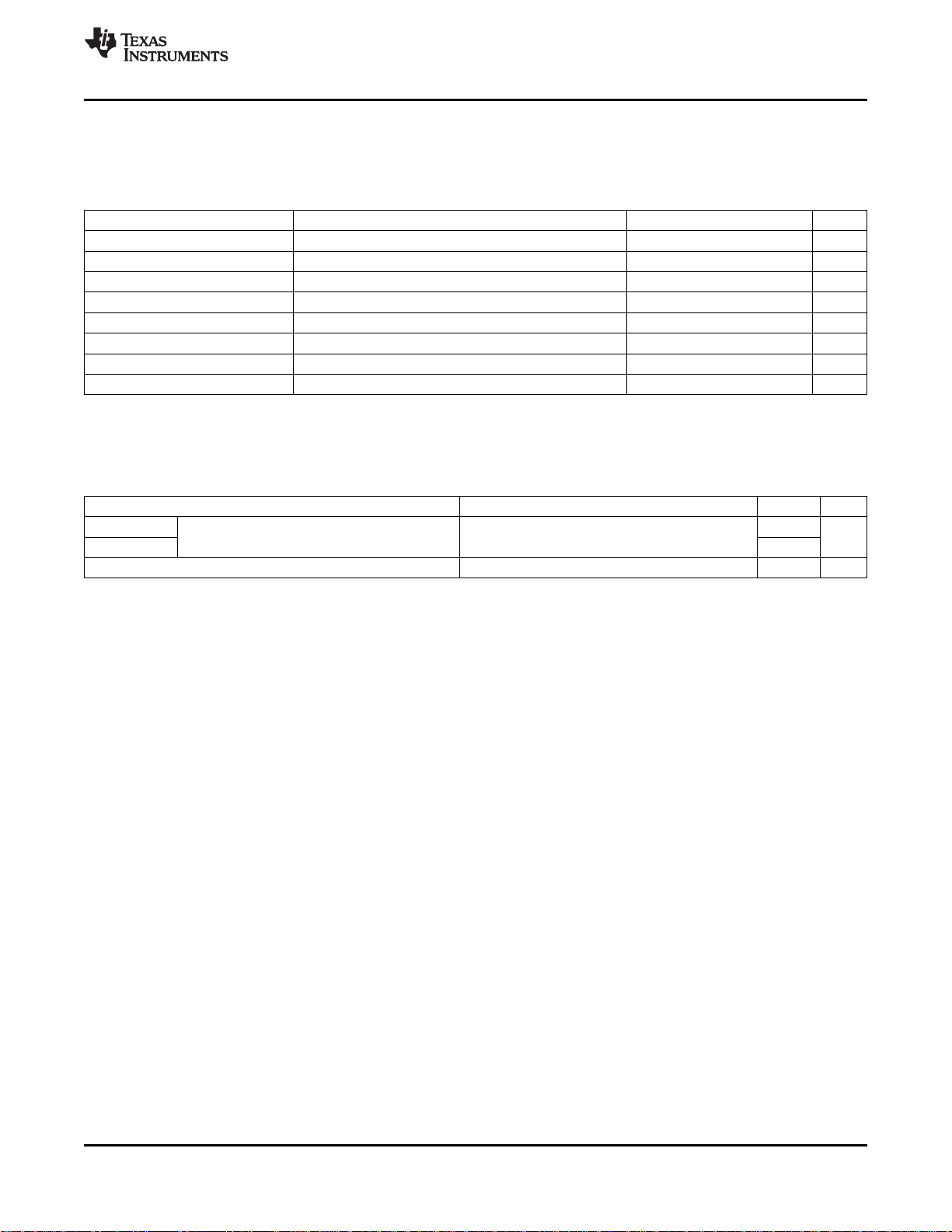

Absolute Maximum Ratings

(1)

www.ti.com

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

VCCto GND –0.3 6 V

V+ to GND

V– to GND

V+ + IV–I

Input voltage V

Output voltage V

Short-circuit duration DOUT to GND Continuous

Continuous power dissipation (TA= 70°C) mW

Storage temperature range –65 150 °C

Lead temperature (soldering, 10 s) 300 °C

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

(2) V+ and V– can have maximum magnitudes of 7 V, but their absolute difference cannot exceed 13 V.

(2)

(2)

(2)

DIN, FORCEON, FORCEOFF to GND –0.3 6

RIN to GND ±25

DOUT to GND ±13.2

ROUT, INVALID, READY to GND –0.3 VCC+ 0.3

20-pin SSOP (derate 8 mW/°C above 70°C) 640

20-pin TSSOP (derate 7 mW/°C above 70°C) 559

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

–0.3 7 V

–7 0.3 V

13 V

Recommended Operating Conditions

See Figure 4

MIN NOM MAX UNIT

Supply voltage 2.25 2.5 3 V

VIHDriver and control high-level input voltage VCC= 2.5 V to 3 V 0.7 × V

VILDriver and control low-level input voltage VCC= 2.5 V to 3 V 0 0.3 × V

VIReceiver input voltage –25 25 V

TAOperating free-air temperature °C

DIN, FORCEOFF,

FORCEON

DIN, FORCEOFF,

FORCEON

TRS3318EC 0 70

TRS3318EI –40 85

CC

5.5 V

CC

V

4 Submit Documentation Feedback Copyright © 2007–2013, Texas Instruments Incorporated

Product Folder Links: TRS3318E

TRS3318E

www.ti.com

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

Supply Current Section

Electrical Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF, TA= T

PARAMETER TEST CONDITIONS MIN TYP

DC Characteristics (VCC= 2.5 V, TA= 25°C)

Auto-powerdown plus supply current FORCEON = GND, FORCEOFF = VCC, All RIN and DIN idle 1 10 µA

Auto-powerdown supply current FORCEOFF = GND 1 10 µA

Supply current FORCEON = FORCEOFF = VCC, No load 0.3 2 mA

(1) Typical values are at VCC= 2.5 V, TA= 25°C.

MIN

to T

(unless otherwise noted)

MAX

(1)

MAX UNIT

ESD Protection

PARAMETER TEST CONDITIONS TYP UNIT

HBM ±15

RIN, DOUT IEC 61000-4-2 Air-Gap Discharge method ±15 kV

IEC 61000-4-2 Contact Discharge method ±8

Copyright © 2007–2013, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: TRS3318E

TRS3318E

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

www.ti.com

Driver Section

Electrical Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF, TA= T

PARAMETER TEST CONDITIONS MIN TYP

Driver input hysteresis 0.3 V

Input leakage current FORCEON, DIN, FORCEOFF ±0.01 ±1 µA

Output voltage swing All driver outputs loaded with 3 kΩ to ground ±3.7 ±4 V

Output resistance VCC= 0, Driver output = ±2 V 300 10M Ω

Output short-circuit current

Output leakage current VCC= 0 or 2.25 V to 3 V, V

(1) Typical values are at VCC= 2.5 V, TA= 25°C.

(2) Short-circuit durations should be controlled to prevent exceeding the device absolute power dissipation ratings, and not more than one

output should be shorted at a time.

(2)

MIN

to T

(unless otherwise noted) (see Figure 4)

MAX

= ±12 V, Drivers disabled ±25 µA

OUT

(1)

MAX UNIT

±25 ±60 mA

Switching Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF, TA= T

PARAMETER TEST CONDITIONS MIN TYP

Maximum data rate RL= 3 kΩ, CL= 1000 pF, One transmitter switching 460 kbps

|t

– t

PHL

| Driver skew

PLH

Transition-region slew rate Measured from 3 V to –3 V or –3 V to 3 V, 4 30 V/µs

(2)

MIN

to T

(unless otherwise noted) (see Figure 1)

MAX

VCC= 2.5 V, TA= 25°C, RL= 3 kΩ to 7 kΩ,

CL= 150 pF to 2500 pF

(1)

MAX UNIT

100 ns

(1) Typical values are at VCC= 2.5 V, TA= 25°C.

(2) Pulse skew is defined as |t

PLH

– t

| of each channel of the same device.

PHL

6 Submit Documentation Feedback Copyright © 2007–2013, Texas Instruments Incorporated

Product Folder Links: TRS3318E

TRS3318E

www.ti.com

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

Receiver Section

Electrical Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF, TA= T

PARAMETER TEST CONDITIONS MIN TYP

Input voltage range –25 25 V

Input threshold low TA= 25°C 0.3 × V

Input threshold high TA= 25°C 0.7 × V

Input hysteresis 0.3 V

Input resistance TA= 25°C 3 5 7 kΩ

Output leakage current ±0.05 ±10 µA

Output voltage low I

Output voltage high I

(1) Typical values are at VCC= 2.5 V, TA= 25°C.

= 0.5 mA 0.1 × V

OUT

= –0.5 mA 0.9 × V

OUT

MIN

to T

(unless otherwise noted) (see Figure 4)

MAX

CC

CC

(1)

MAX UNIT

CC

CC

Switching Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF (unless otherwise noted) (see Figure 4)

(1)

0.175

0.175

50 ns

t

t

|t

PHL

PLH

PHL

Receiver propagation delay RIN to ROUT, CL= 150 pF µs

– t

| Receiver skew

PLH

PARAMETER TEST CONDITIONS TYP

(2)

V

V

V

V

UNIT

(1) Typical values are at VCC= 2.5 V, TA= 25°C.

(2) Pulse skew is defined as |t

PLH

– t

| of each channel of the same device.

PHL

Copyright © 2007–2013, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: TRS3318E

TRS3318E

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

www.ti.com

Auto-Powerdown Plus Section

Electrical Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF, TA= T

PARAMETER TEST CONDITIONS MIN MAX UNIT

Receiver input threshold to INVALID high V

Receiver input threshold INVALID low –0.3 0.3 V

INVALID, READY voltage low I

INVALID, READY voltage high I

MIN

to T

(unless otherwise noted) (see Figure 4)

MAX

Positive threshold 2.7

Negative threshold –2.7

= 0.5 mA 0.1 × V

OUT

= –0.5 mA 0.8 × V

OUT

CC

CC

Switching Characteristics

over recommended ranges of supply voltage and operating free-air temperature,

VCC= 2.25 V to 3 V, C1–C4 = 0.1 µF, TA= T

PARAMETER TEST CONDITIONS MIN TYP

t

INVH

t

INVL

t

WU

t

AUTOPRDN

Receiver positive or negative threshold to INVALID high VCC= 2.5 V 1 µs

Receiver positive or negative threshold to INVALID low VCC= 2.5 V 30 µs

Receiver or driver edge to driver enabled VCC= 2.5 V 100 µs

Receiver or driver edge to driver shutdown VCC= 2.5 V 15 30 60 s

MIN

to T

(unless otherwise noted) (see Figure 4)

MAX

(1)

MAX UNIT

V

V

(1) Typical values are at VCC= 2.5 V, TA= 25°C.

8 Submit Documentation Feedback Copyright © 2007–2013, Texas Instruments Incorporated

Product Folder Links: TRS3318E

TEST CIRCUIT VOLTAGE WAVEFORMS

50 Ω

−3 V

3 V

Output

Input

V

OL

V

OH

t

PHL

Generator

(see Note B)

t

PLH

Output

C

L

(see Note A)

NOTES: A. CL includes probe and jig capacitance.

B. The pulse generator has the following characteristics: ZO = 50 Ω, 50% duty cycle, tr ≤ 10 ns, tf ≤ 10 ns.

0 V 0 V

50% 50%

50 Ω

TEST CIRCUIT VOLTAGE WAVEFORMS

0 V

2.25 V

Output

Input

V

OL

V

OH

t

PLH

Generator

(see Note B)

R

L

3 V

FORCEOFF

RS-232

Output

t

PHL

C

L

(see Note A)

NOTES: A. CL includes probe and jig capacitance.

B. The pulse generator has the following characteristics: PRR = 250 kbit/s, ZO = 50 Ω, 50% duty cycle, tr ≤ 10 ns, tf ≤ 10 ns.

50%

50%

1.125 V

1.125 V

50 Ω

TEST CIRCUIT VOLTAGE WAVEFORMS

−3 V

−3 V

3 V

3 V

0 V

3 V

Output

Input

V

OL

V

OH

t

TLH

Generator

(see Note B)

R

L

3 V

FORCEOFF

RS-232

Output

t

THL

C

L

(see Note A)

SR(tr) +

6 V

t

THL

or t

TLH

NOTES: A. CL includes probe and jig capacitance.

B. The pulse generator has the following characteristics: PRR = 250 kbit/s, ZO = 50 Ω, 50% duty cycle, tr ≤ 10 ns, tf ≤ 10 ns.

TRS3318E

www.ti.com

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

PARAMETER MEASUREMENT INFORMATION

Figure 1. Driver Slew Rate

Copyright © 2007–2013, Texas Instruments Incorporated Submit Documentation Feedback 9

Figure 2. Driver Pulse Skew

Figure 3. Receiver Propagation Delay Times

Product Folder Links: TRS3318E

t

WU

V

CC

0

0

V+

V−

V

CC

0

Driver

Inputs

Receiver

Inputs

}

INVALID

Output

Driver

Outputs

V

CC

Invalid

Region

Ready

Output

t

INVH

t

WU

t

INVL

VOLTAGE WAVEFORMS

TEST CIRCUIT

50 Ω

Generator

(see Note B)

ROUT

Auto-powerdown

Plus

INVALID

DOUTDIN

C

L

= 30 pF

(see Note A)

2.7 V

−2.7 V

0.3 V

−0.3 V

0 V

Valid RS-232 Level, INVALID

High

Indeterminate

Indeterminate

If Signal Remains Within This Region

For More Than 30 µs, INVALID

Is Low

†

Valid RS-232 Level, INVALID

High

†

Auto-powerdown disables drivers and reduces supply

current to 1 µA.

FORCEON

FORCEOFF

TRS3318E

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

PARAMETER MEASUREMENT INFORMATION (continued)

www.ti.com

10 Submit Documentation Feedback Copyright © 2007–2013, Texas Instruments Incorporated

Figure 4. INVALID Propagation Delay Times and Supply Enabling Time

Product Folder Links: TRS3318E

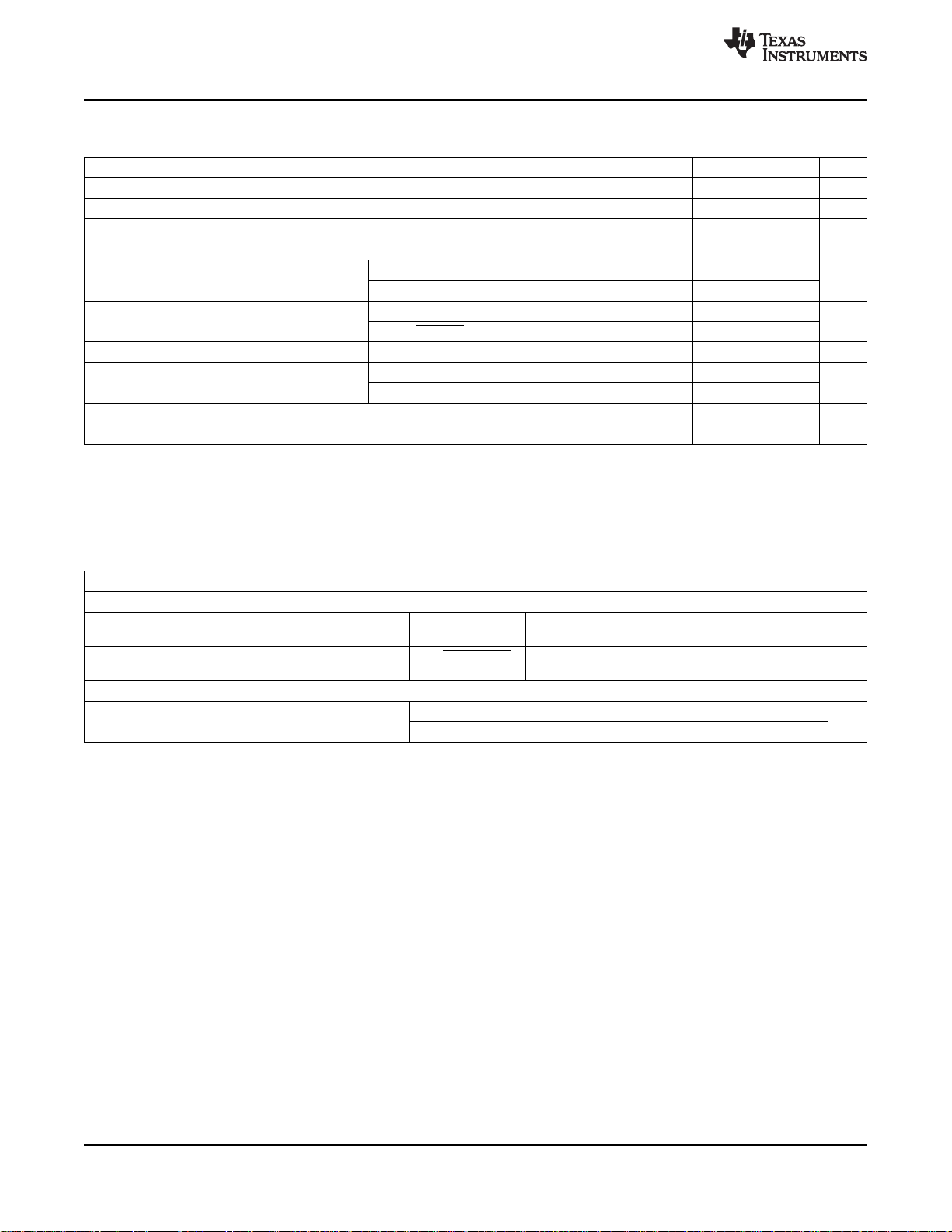

14

1

10

15

20

9

GND

18

13

6

5

4

2

RIN1

16

DOUT2

8

V−

7

V+

3

19

2.5 V

5k

5k

RS-232-Compatible

Outputs

RS-232-Compatible

Inputs

To Power-Management Unit

Auto-

powerdown

Plus

C1+

C1−

C2+

C2−

DIN1

DIN2

ROUT1

READY

FORCEON

17

RIN2

11

INVALID

FORCEOFF

0.1 mF

+

+

+

+

+

C3

0.1 mF

C4

0.1 mF

C1

0.1 mF

C2

0.1 mF

C

BYPASS

V

CC

12

ROUT2

DOUT1

RIN1

V

CC

TRS3318E

www.ti.com

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

APPLICATION INFORMATION

Figure 5. Typical Application Circuit

Copyright © 2007–2013, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: TRS3318E

TRS3318E

SLLS805B –APRIL 2007–REVISED OCTOBER 2013

www.ti.com

REVISION HISTORY

Changes from Revision A (April 2010) to Revision B Page

• Updated document to new TI datasheet format - no specification changes. ....................................................................... 1

• Removed Ordering Information table. ................................................................................................................................... 2

• Updated TERMINAL FUNCTIONS table to fix inconsistency. .............................................................................................. 3

12 Submit Documentation Feedback Copyright © 2007–2013, Texas Instruments Incorporated

Product Folder Links: TRS3318E

PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device Status

TRS3318ECDBR ACTIVE SSOP DB 20 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM 0 to 70 RV18EC

TRS3318ECPW ACTIVE TSSOP PW 20 70 RoHS & Green NIPDAU Level-1-260C-UNLIM 0 to 70 RV18EC

TRS3318ECPWR ACTIVE TSSOP PW 20 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM 0 to 70 RV18EC

TRS3318EIDB ACTIVE SSOP DB 20 70 RoHS & Green NIPDAU Level-1-260C-UNLIM 0 to 70 RV18EI

TRS3318EIDBR ACTIVE SSOP DB 20 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 RV18EI

TRS3318EIPW ACTIVE TSSOP PW 20 70 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 RV18EI

TRS3318EIPWR ACTIVE TSSOP PW 20 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 RV18EI

TRS3318EIPWRG4 ACTIVE TSSOP PW 20 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 RV18EI

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead finish/

Ball material

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

Samples

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

(6)

Lead finish/Ball material - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead finish/Ball material values may wrap to two

lines if the finish value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com 30-Dec-2020

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

TRS3318ECDBR SSOP DB 20 2000 330.0 16.4 8.2 7.5 2.5 12.0 16.0 Q1

TRS3318ECPWR TSSOP PW 20 2000 330.0 16.4 6.95 7.1 1.6 8.0 16.0 Q1

TRS3318EIDBR SSOP DB 20 2000 330.0 16.4 8.2 7.5 2.5 12.0 16.0 Q1

TRS3318EIPWR TSSOP PW 20 2000 330.0 16.4 6.95 7.0 1.4 8.0 16.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 30-Dec-2020

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TRS3318ECDBR SSOP DB 20 2000 853.0 449.0 35.0

TRS3318ECPWR TSSOP PW 20 2000 853.0 449.0 35.0

TRS3318EIDBR SSOP DB 20 2000 853.0 449.0 35.0

TRS3318EIPWR TSSOP PW 20 2000 853.0 449.0 35.0

Pack Materials-Page 2

PACKAGE OUTLINE

A

7.5

6.9

NOTE 3

10

SCALE 2.000

SSOP - 2 mm max heightDB0020A

SMALL OUTLINE PACKAGE

0.1 C

C

SEATING

PLANE

8.2

TYP

7.4

PIN 1 INDEX AREA

18X 0.65

11

20

2X

5.85

0.38

20X

0.22

0.1 C A B

1

B

5.6

5.0

NOTE 4

0 -8

0.25

0.95

0.55

A 15

DETAIL A

TYPICAL

4214851/B 08/2019

SEE DETAIL A

(0.15) TYP

GAGE PLANE

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not

exceed 0.15 mm per side.

4. This dimension does not include interlead flash. Interlead flash shall not exceed 0.25 mm per side.

5. Reference JEDEC registration MO-150.

www.ti.com

2 MAX

0.05 MIN

EXAMPLE BOARD LAYOUT

SSOP - 2 mm max heightDB0020A

SMALL OUTLINE PACKAGE

20X (0.45)

18X (0.65)

1

10

20X (1.85)

SYMM

(R0.05) TYP

20

SYMM

11

(7)

LAND PATTERN EXAMPLE

EXPOSED METAL SHOWN

SCALE: 10X

SOLDER MASK

OPENING

EXPOSED METAL

0.07 MAX

ALL AROUND

NON-SOLDER MASK

DEFINED

(PREFERRED)

METAL

15.000

SOLDER MASK DETAILS

METAL UNDER

SOLDER MASK

0.07 MIN

ALL AROUND

SOLDER MASK

DEFINED

NOTES: (continued)

6. Publication IPC-7351 may have alternate designs.

7. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

www.ti.com

SOLDER MASK

OPENING

EXPOSED METAL

4214851/B 08/2019

EXAMPLE STENCIL DESIGN

SSOP - 2 mm max heightDB0020A

SMALL OUTLINE PACKAGE

20X (0.45)

18X (0.65)

1

10

20X (1.85)

SYMM

(R0.05) TYP

20

SYMM

11

(7)

SOLDER PASTE EXAMPLE

BASED ON 0.125 mm THICK STENCIL

SCALE: 10X

4214851/B 08/2019

NOTES: (continued)

8. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

9. Board assembly site may have different recommendations for stencil design.

www.ti.com

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...