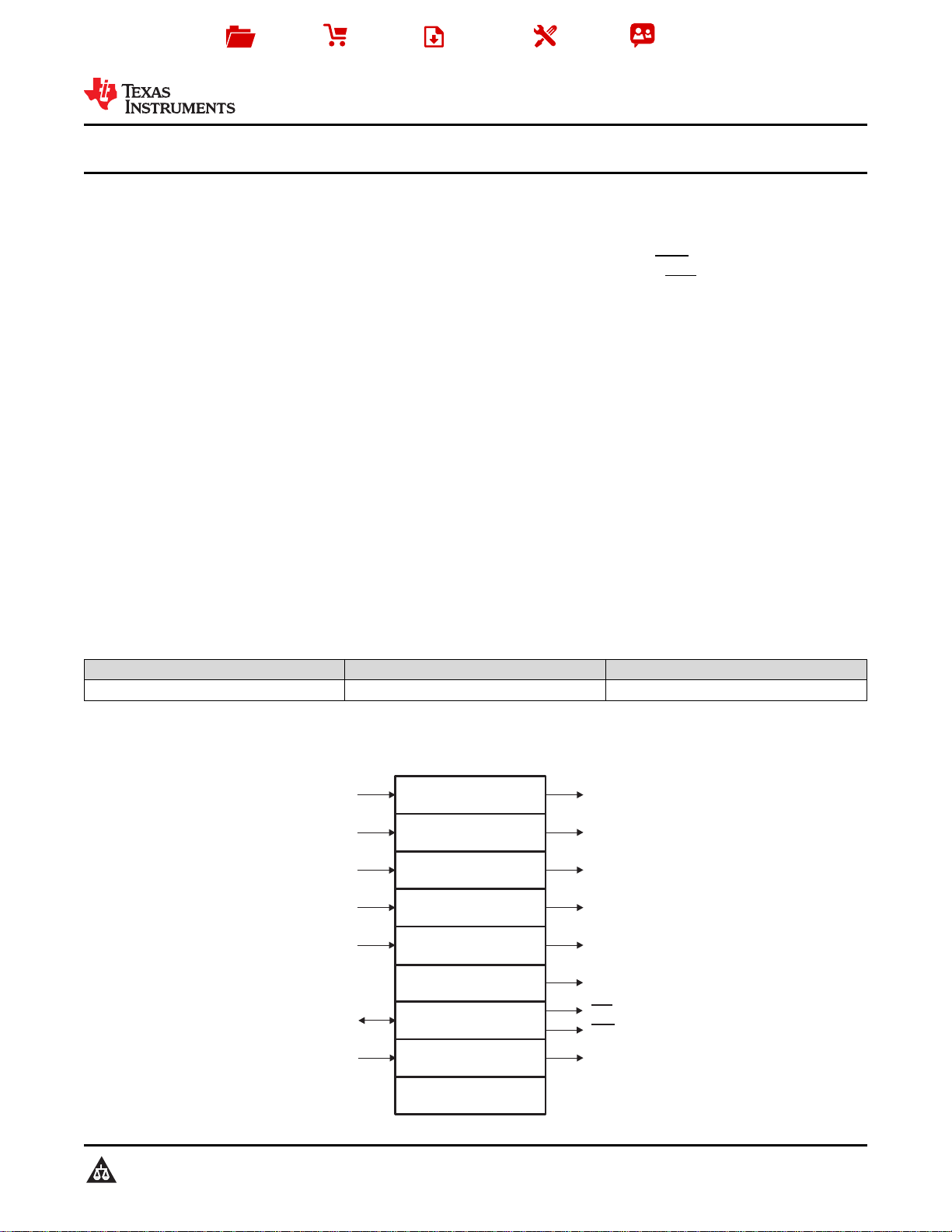

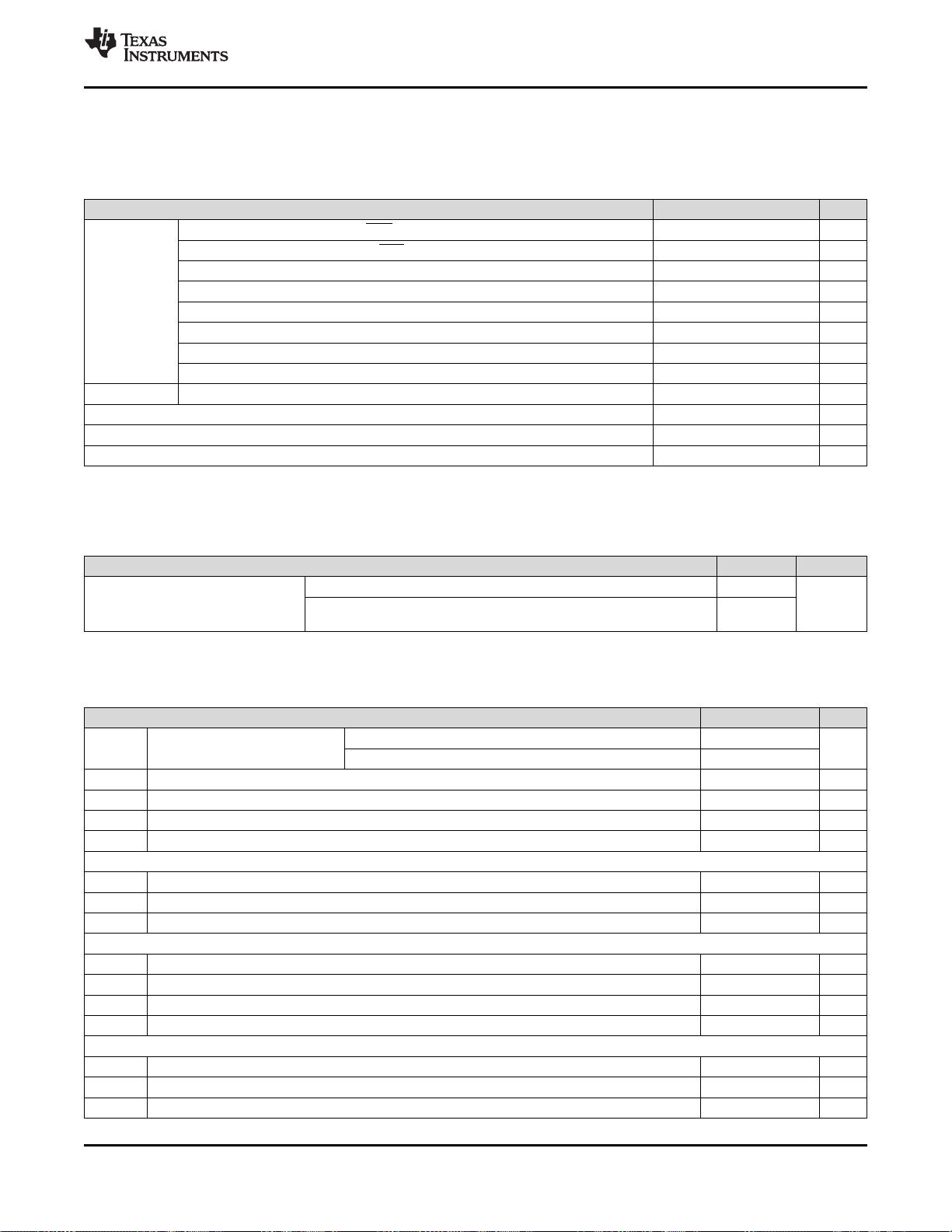

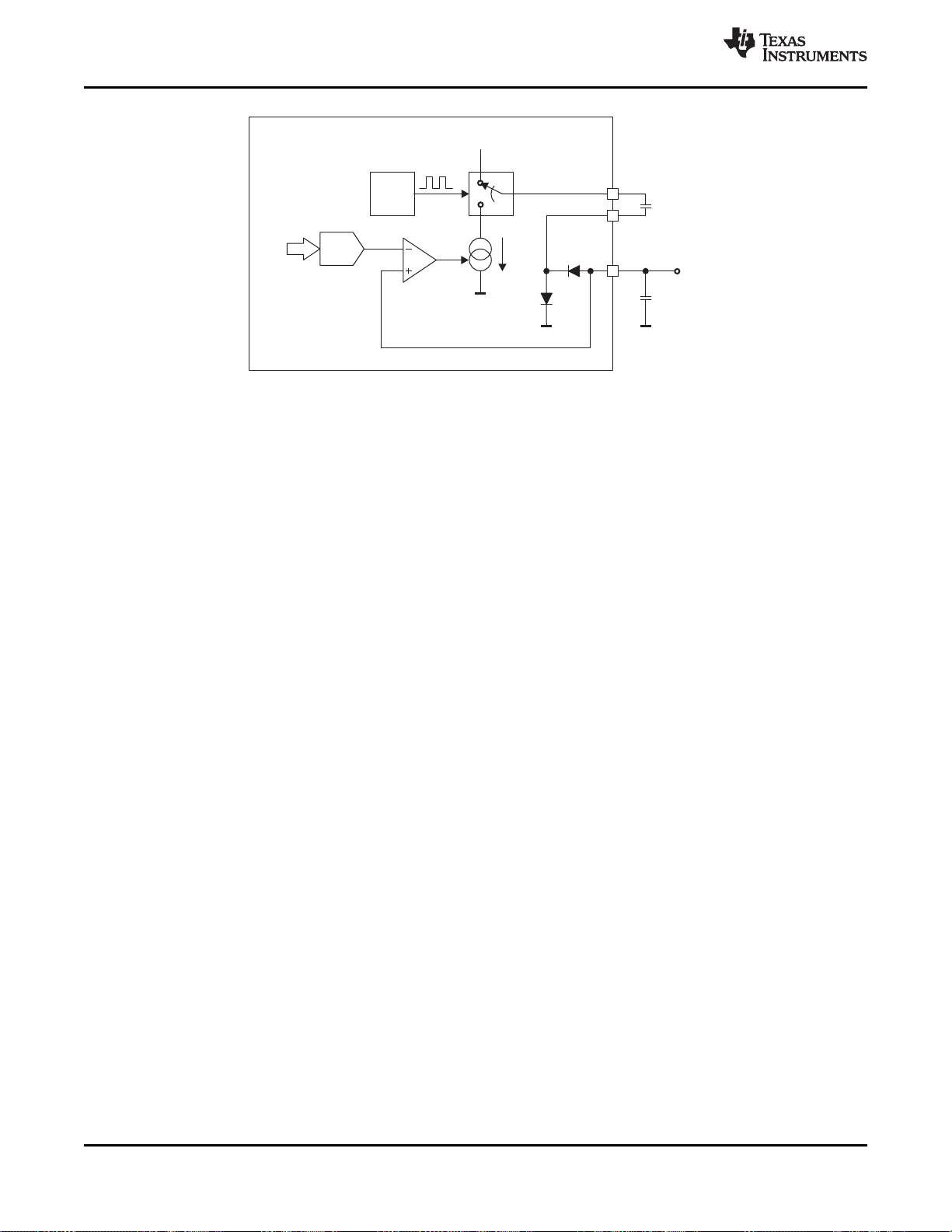

Boost Converter 1

Boost Converter 2

Linear Regulator

Programmable

VCOM Buffer

Miscellaneous

Negative Charge Pump

Boost Converter 3

WLED Driver

AV (6.5V to 9.6V)

DD

V (18V to 25.5V)

GH

V (1.0V to 2.5V)

CC

V (–5V to –8V)

GL

RST

<38 V

V (2.0V to 5.5V)

IN

AV

DD

V

IN

AV

DD

V (4.5V to 24V)

LED

V

COM

XAO

I C

2

Gate Voltage

Shaping

V

GHM

V

GH

Copyright © 2016, Texas Instruments Incorporated

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

TPS65154 LCD Bias IC with Integrated WLED Driver

1 Device Overview

1.1 Features

1

• 2.0 V to 5.5 V Input Voltage Range

• Synchronous Boost Converter (AVDD)

• Non-Synchronous Boost Converter (VGH)

• Low Dropout Linear Regulator (VCC)

• Programmable V

Calibrator with Integrated

COM

Buffer Amplifier

• 6-Channel WLED Driver with Direct Dimming and

Phase-Shift Dimming Modes

• Gate Voltage Shaping

1.2 Applications

• Notebook PCs • Tablet PCs

1.3 Description

The TPS65154 is a compact LCD bias solution primarily intended for use in Notebook and Tablet PCs.

The device comprises two boost converters to supply the LCD panel's source driver and gate driver; a

linear regulator to supply the system's logic voltage; a programmable V

a gate voltage shaping function; and a 6-channel WLED driver.

• Panel Reset Signal (XAO)

• T-CON Reset Signal (RST)

• On-Chip EEPROM with Write Protect

• I2C Interface

• Thermal Shutdown

• 48-Pin, 6 mm × 6 mm, 0.4 mm Pitch VQFN

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

with high-speed amplifier; and

COM

spacing

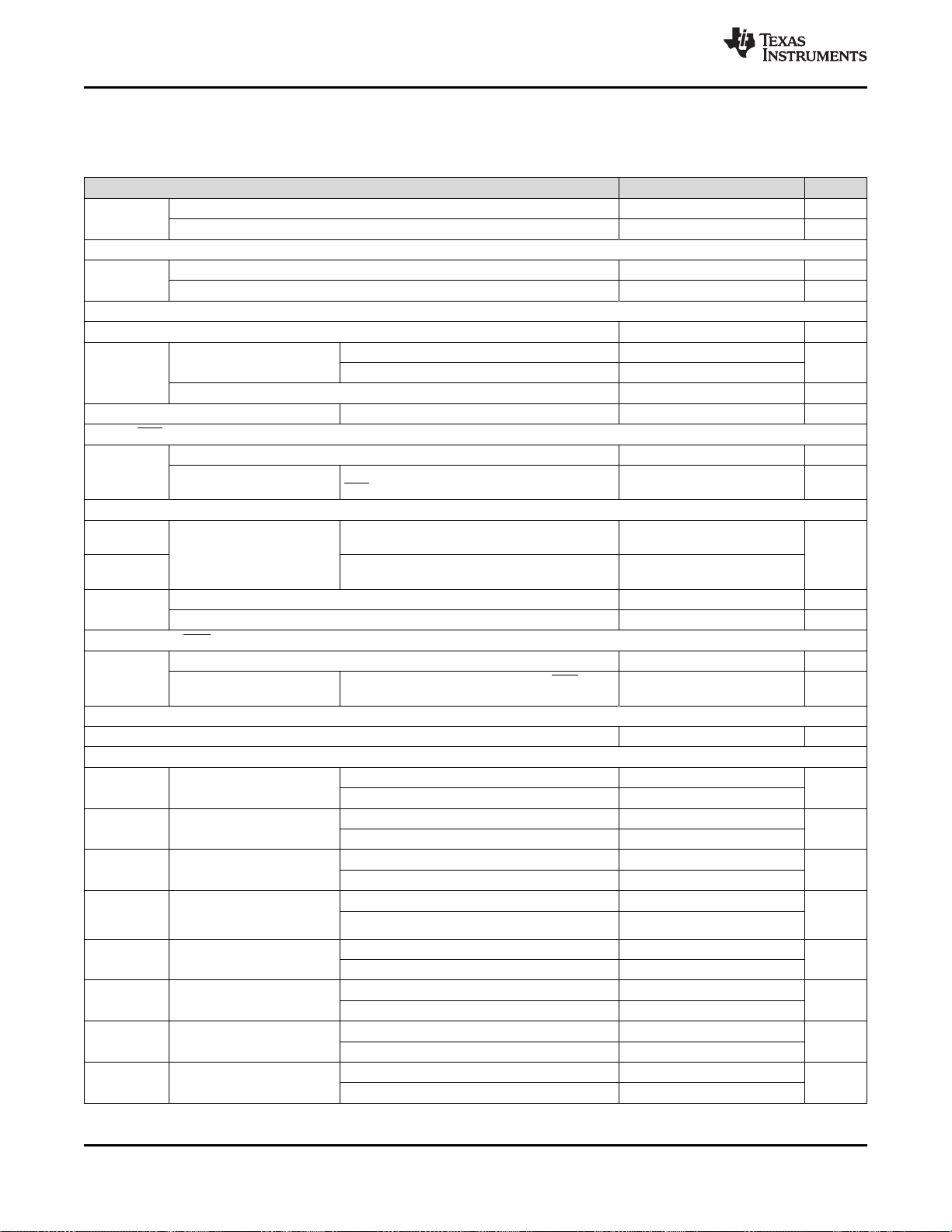

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

TPS65154 VQFN (48) 6.00 mm × 6.00 mm

(1) For all available packages, see the orderable addendum at the end of the data manual.

(1)

1.4 Simplified System Diagram

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

www.ti.com

Table of Contents

1 Device Overview ......................................... 1

1.1 Features .............................................. 1

1.2 Applications........................................... 1

1.3 Description............................................ 1

1.4 Simplified System Diagram........................... 1

2 Revision History ......................................... 2

3 Pin Configuration and Functions..................... 3

4 Specifications ............................................ 5

4.1 Absolute Maximum Ratings .......................... 5

4.2 ESD Ratings.......................................... 5

4.3 Recommended Operating Conditions ................ 5

4.4 Thermal Information .................................. 6

4.5 Electrical Characteristics ............................. 7

4.6 Timing Requirements................................. 9

5 Detailed Description ................................... 12

5.1 Overview ............................................ 12

5.2 Functional Block Diagram........................... 12

5.3 Feature Description ................................. 14

5.4 Device Functional Modes ........................... 22

5.5 Programming........................................ 26

5.6 Register Map ........................................ 38

6 Application and Implementation .................... 63

6.1 Application Information.............................. 63

6.2 Typical Application .................................. 63

7 Power Supply Recommendations .................. 75

8 Layout .................................................... 76

8.1 Layout Guidelines ................................... 76

8.2 Layout Example ..................................... 76

9 Device and Documentation Support ............... 78

9.1 Device Support ...................................... 78

9.2 Receiving Notification of Documentation Updates.. 78

9.3 Community Resources .............................. 78

9.4 Trademarks.......................................... 78

9.5 Electrostatic Discharge Caution..................... 78

9.6 Glossary............................................. 78

10 Mechanical, Packaging, and Orderable

Information .............................................. 79

10.1 Packaging Information .............................. 79

2 Revision History

Changes from Original (September 2013) to Revision A Page

• Changed from data sheet to data manual format ................................................................................ 1

• Added Device Information table, ESD Ratings table, Feature Description section, Device Functional Modes,

Application and Implementation section, Power Supply Recommendations section, Layout section, Device and

Documentation Support section, and Mechanical, Packaging, and Orderable Information section. ...................... 1

2

Revision History Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

1

2

3

4

5

6

13

14

15

16

17

18

36

35

34

33

32

31

Thermal Pad

48

47

46

45

44

43

NC

BSUP

AVDD

AVDD

SW1

PGND

NC

VGHM

RE

FLK

VGL

NC

OVP

SW3

PGND

IFB1

IFB2

NC

BGND

COMP1

VCOM

NEG

SCL

7

8

9

10

11

12

VIN

VCC

PGND

SW2

VGH

NC

30

29

28

27

26

25

IFB3

IFB4

IFB5

IFB6

AGND

NC

19

20

21

22

23

24

C1A

C1B

RST

XAO

ISET

NC

42

41

40

39

38

37

SDA

WP

COMP3ENPWM

NC

www.ti.com

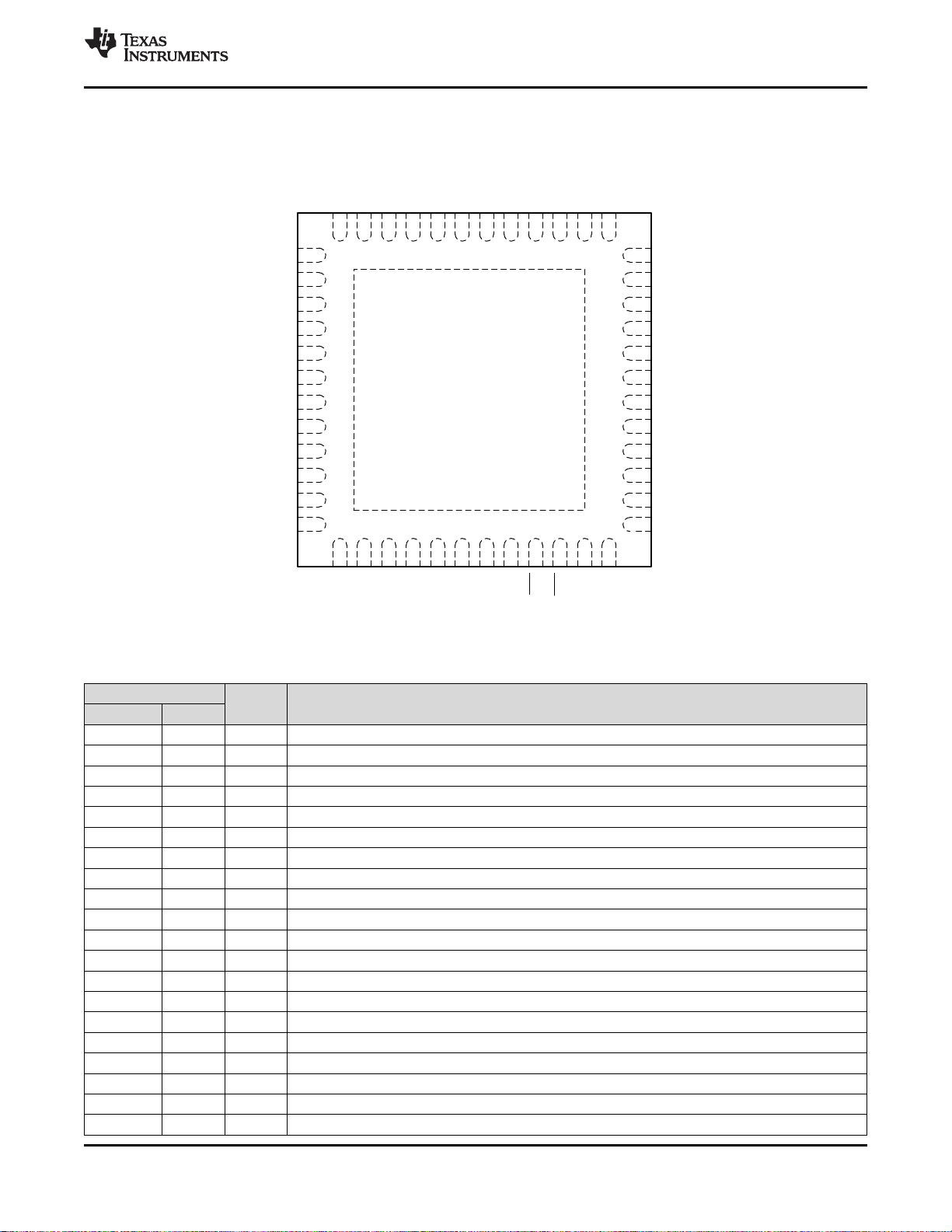

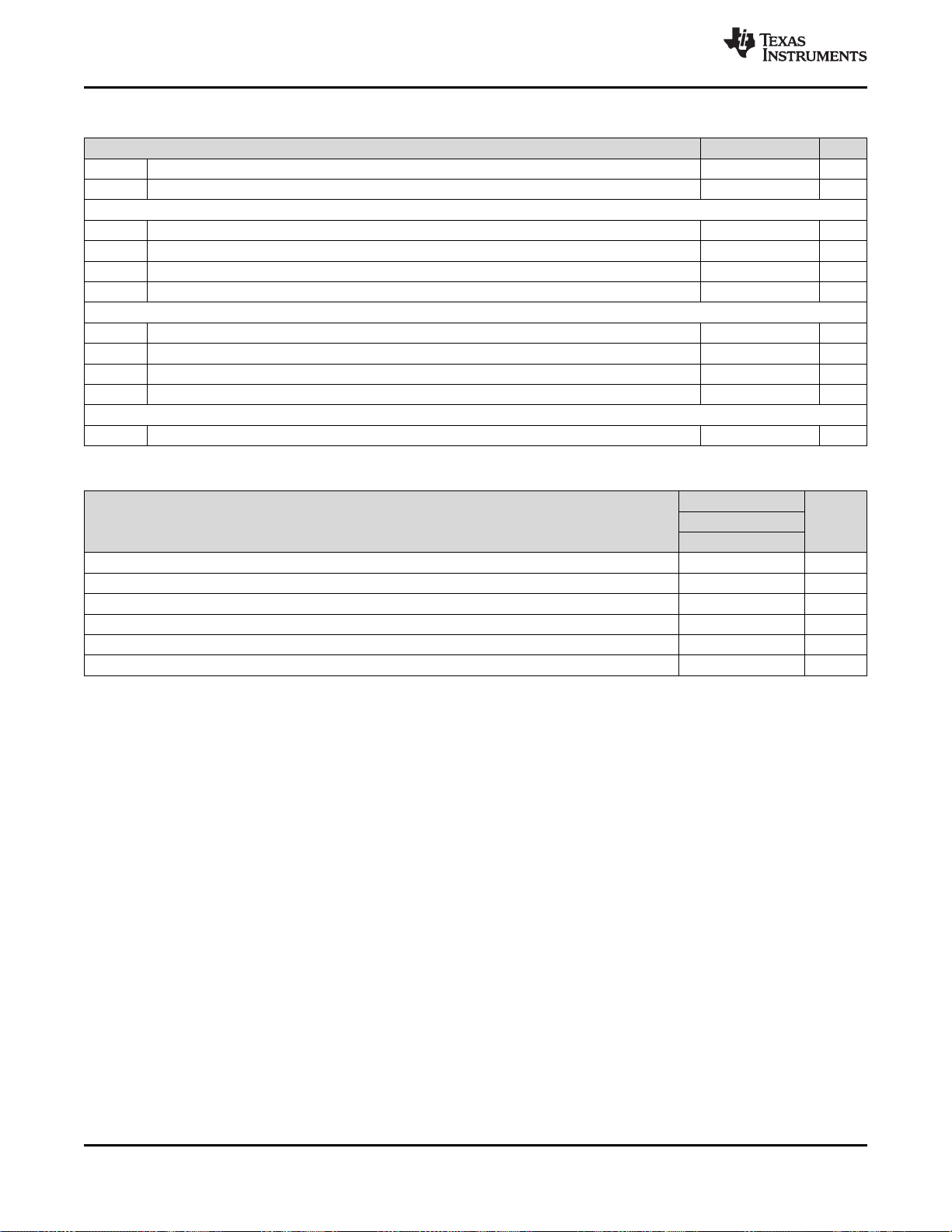

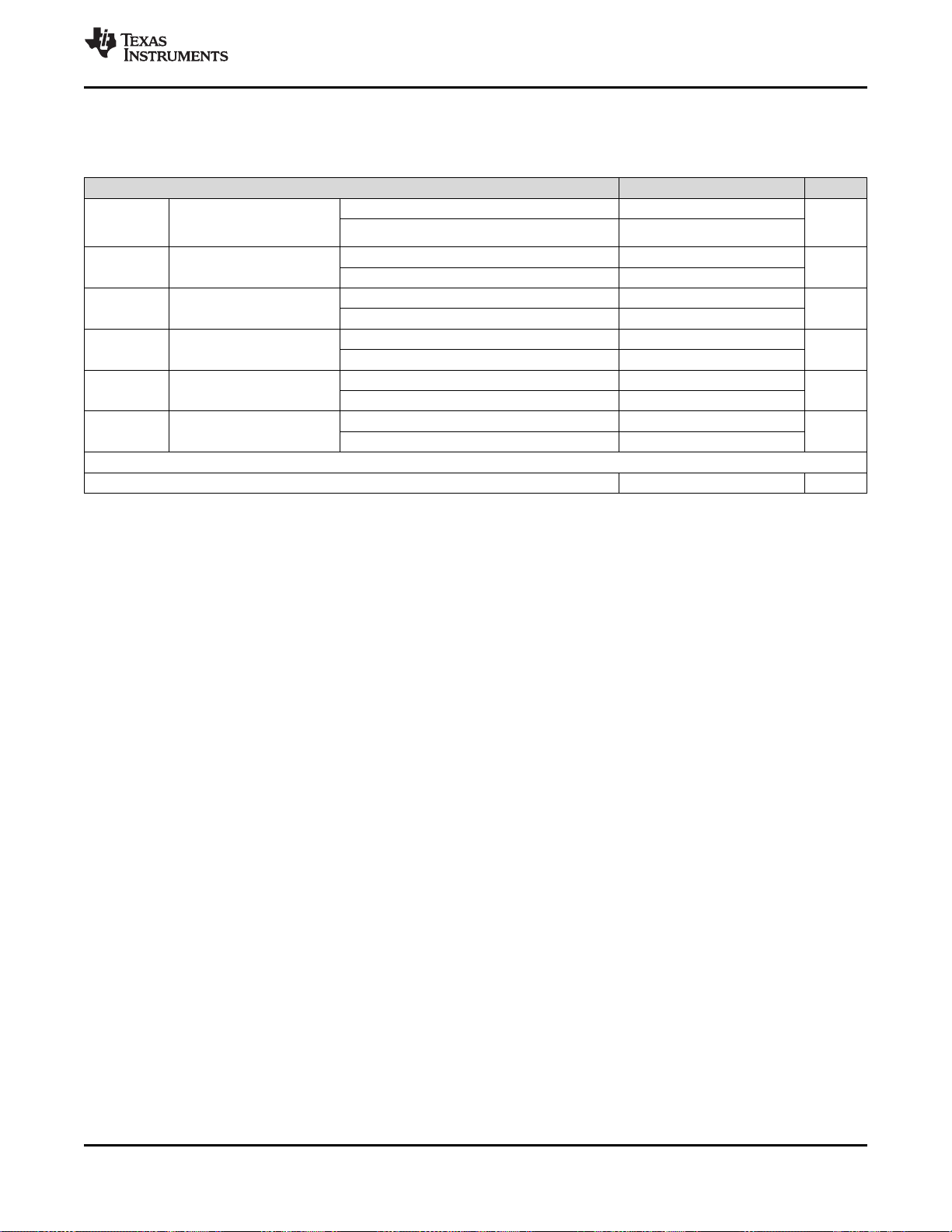

3 Pin Configuration and Functions

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 3-1. RSL Package, 48-Pin VQFN (Top View)

Pin Functions

PIN

NAME NO.

NC 1 N/A No internal connection.

BSUP 2 P Positive supply for the VCOM buffer.

AVDD 3 P Boost converter 1 output voltage sense.

AVDD 4 P Boost converter 1 rectifier output.

SW1 5 P Boost converter 1 switch pin.

PGND 6 P Ground.

VIN 7 P Positive supply.

VCC 8 P Linear regulator output.

PGND 9 P Ground.

SW2 10 P Boost converter 2 switch pin.

VGH 11 P VGHregulation point and positive supply for gate voltage shaping function.

NC 12 N/A No internal connection.

NC 13 N/A No internal connection.

VGHM 14 P Gate voltage shaping output.

RE 15 I/O Gate votlage shaping discharge resistor connection.

FLK 16 I/O Gate votlage shaping flicker clock input.

COMP2 17 I/O Internal linear regulator compensation network connection.

VGL 18 P Negative charge pump output and VGLregulation point.

C1A 19 P Negative charge pump flying capacitor connection.

C1B 20 P Negative charge pump flying ccapacitor connection.

TYPE DESCRIPTION

Submit Documentation Feedback

Product Folder Links: TPS65154

Pin Configuration and FunctionsCopyright © 2013–2016, Texas Instruments Incorporated

3

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

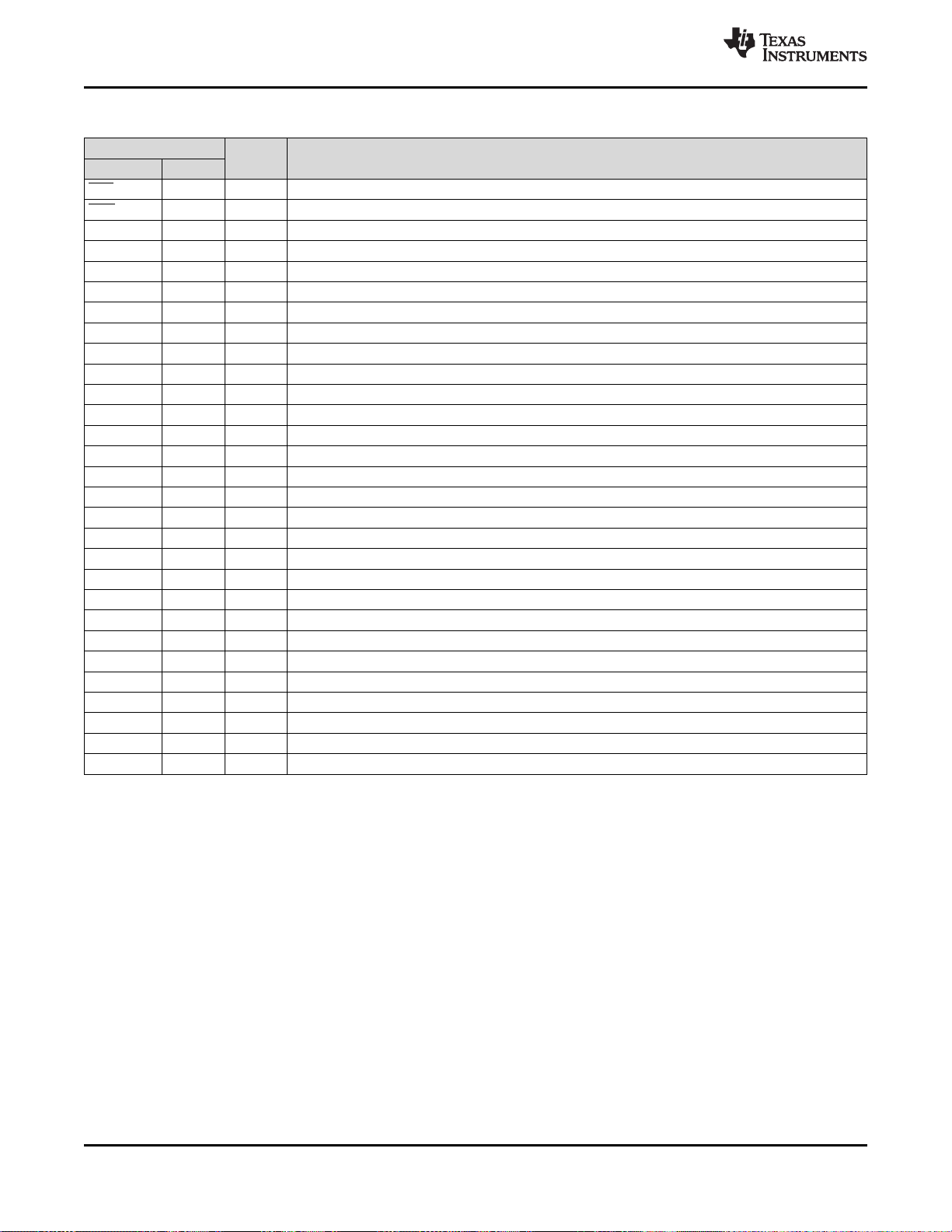

Pin Functions (continued)

PIN

NAME NO.

RST 21 I/O Reset generator output.

XAO 22 I/O Panel discharge generator output.

ISET 23 I/O WLED driver current-setting resistor connection.

NC 24 N/A No internal connection.

NC 25 N/A No internal connection.

AGND 26 P Ground.

IFB6 27 I/O WLED driver channel 6 output.

IFB5 28 I/O WLED driver channel 5 output.

IFB4 29 I/O WLED driver channel 4 output.

IFB3 30 I/O WLED driver channel 3 output.

IFB2 31 I/O WLED driver channel 2 output.

IFB1 32 I/O WLED driver channel 1 output.

PGND 33 P Ground.

SW3 34 P WLED driver boost converter switch pin.

OVP 35 I/O WLED driver boost converter output voltage sensing pin.

NC 36 N/A No internal connection.

NC 37 N/A No internal connection.

PWM 38 I/O WLED driver PWM input.

EN 39 I/O WLED driver enable input.

COMP3 40 I/O WLED driver boost converter compensation network connection.

WP 41 I/O EEPROM write protect input.

SDA 42 I/O I2C data.

SCL 43 I/O I2C clock.

NEG 44 I/O VCOM buffer inverting input.

VCOM 45 I/O VCOM buffer output.

COMP1 46 I/O Boost converter 1 compensation network connection.

BGND 47 P Ground.

NC 48 N/A No internal connection.

GND Pad P Ground.

TYPE DESCRIPTION

www.ti.com

4

Pin Configuration and Functions Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

www.ti.com

4 Specifications

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

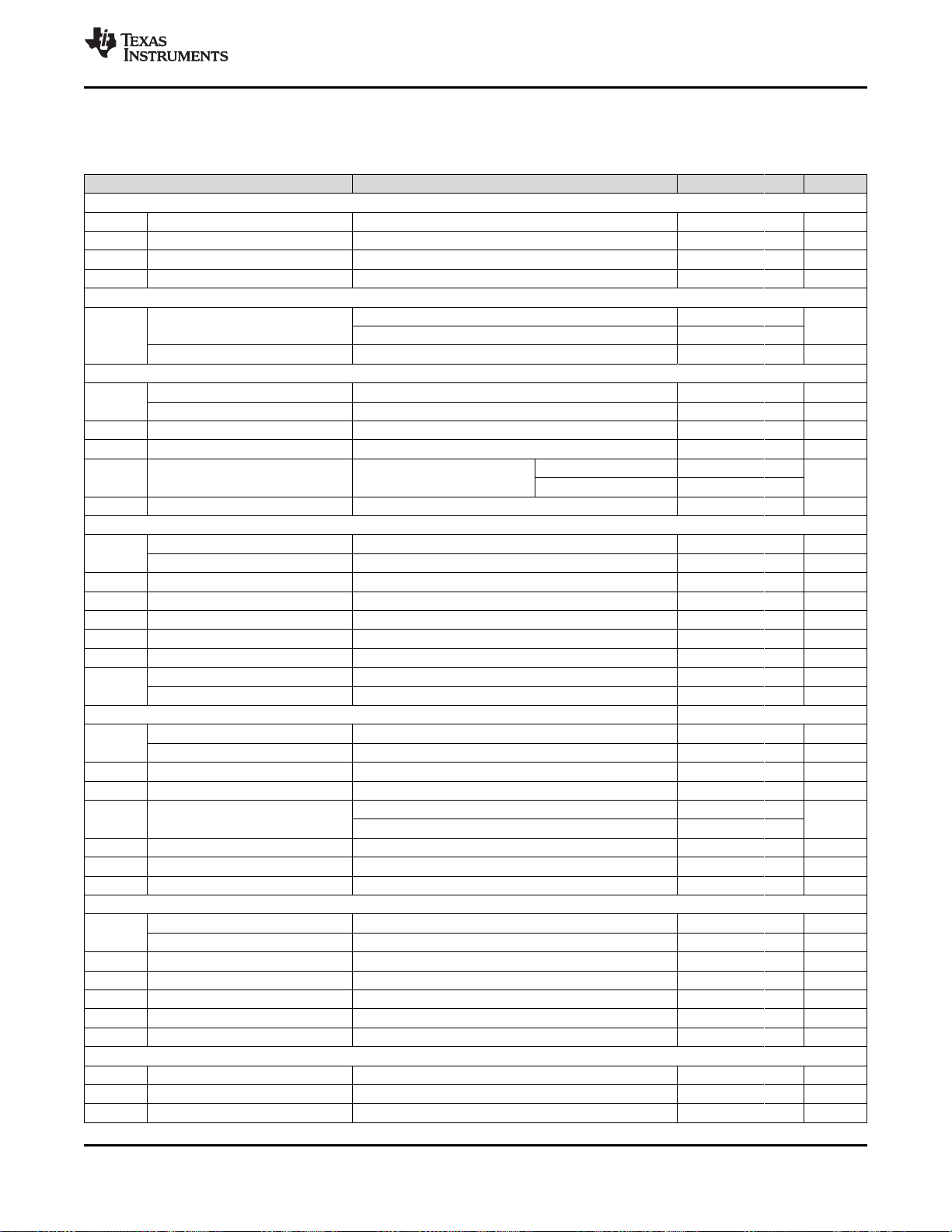

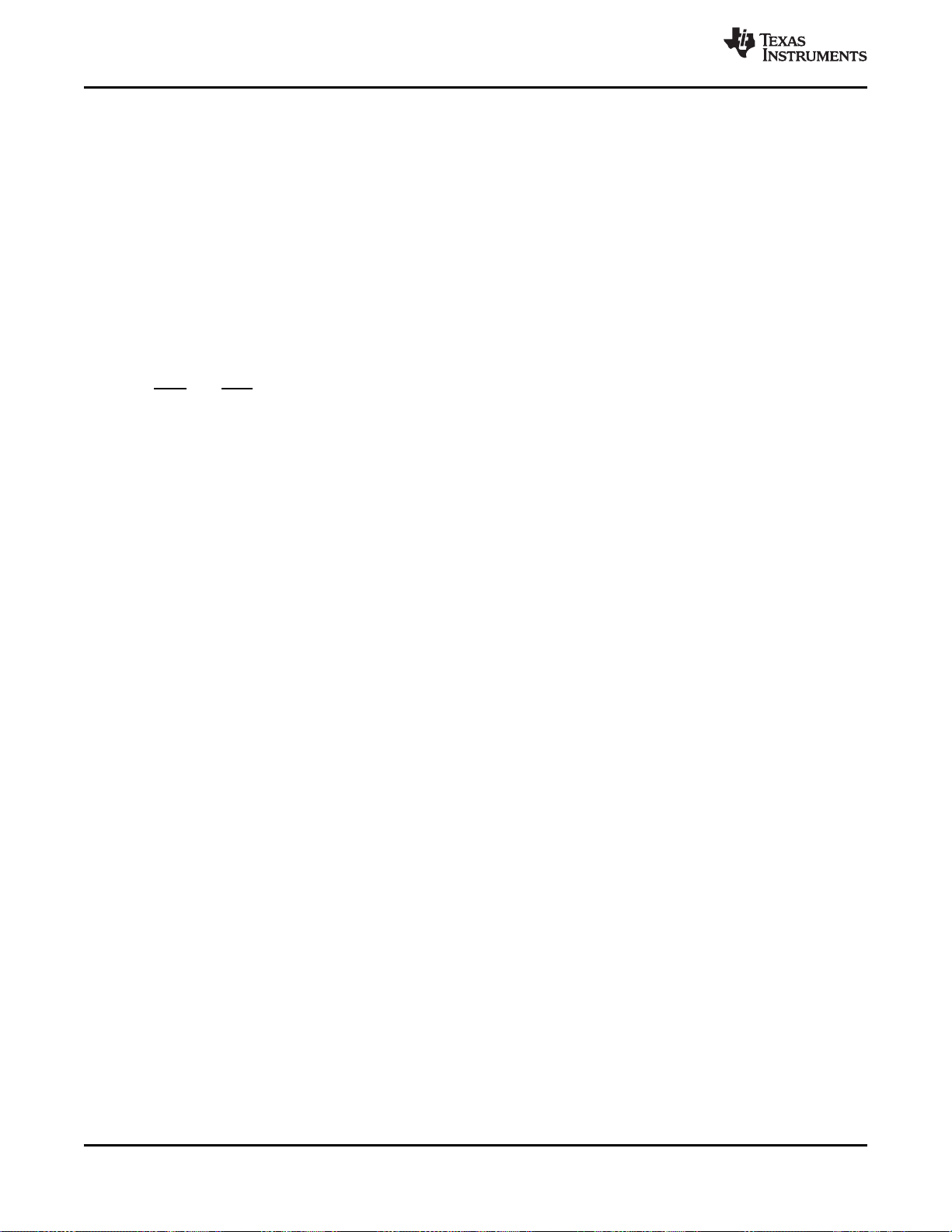

4.1 Absolute Maximum Ratings

(1)

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

VIN, VCC, SCL, SDA, FLK, WP, XAO, COMP1 –0.3 7 V

AVDD, SW1, VCOM, NEG, BSUP, RST –0.3 12 V

EN, PWM –0.3 20 V

Pin voltage

COMP2, COMP3, ISET –0.3 3.6 V

C1A, C1B –10 12 V

VGL –10 0.3 V

SW3, OVP –0.3 40 V

IFB1, IFB2, IFB3, IFB4, IFB5, IFB6, VGH, VGHM, RE, SW2 –0.3 30 V

Pin current SW2 TBD A

Ambient temperature, T

Junction temperature, T

Storage temperature, T

A

J

STG

–40 85 °C

–40 150 °C

–65 150 °C

(1) Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under “recommended operating

conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

4.2 ESD Ratings

VALUE UNIT

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

V

(ESD)

Electrostatic discharge

Charged-device model (CDM), per JEDEC specification JESD22-

(2)

C101

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

(1)

2000

700

V

4.3 Recommended Operating Conditions

MIN NOM MAX UNIT

V

IN

Input voltage range

dVIN/dt VINrise time 0.45 11 ms

V

V

dV

BSUP

BAT

BAT

Input voltage range 6.5 9.6 V

Input voltage range 4.5 24 V

/dt V

rise time 0.45 11 ms

BAT

LINEAR REGULATOR (VCC)

V

I

C

CC

ICC

OUT

Output voltage 1.0 2.5 V

Output current 300 mA

Output capacitance 4.7 10 22 µF

BOOST CONVERTER 1 (AVDD)

AV

IAV

DD

Boost converter 1 output voltage range 6.5 9.6 V

Boost converter 1 output current at VIN= 3.7 V 400 mA

DD

L Inductance 4.7 10 15 µH

C

OUT

Boost converter 1 output capacitance 4.7 10 22 µF

BOOST CONVERTER 2 (VGH)

AV

V

I

GH

DD

GH

Input voltage range 6.5 9.6 V

Output voltage range 18 25.5 V

Output current 25 mA

Normal operation 2.0 5.5

EEPROM programming 2.6 5.5

V

Submit Documentation Feedback

Product Folder Links: TPS65154

SpecificationsCopyright © 2013–2016, Texas Instruments Incorporated

5

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

www.ti.com

Recommended Operating Conditions (continued)

MIN NOM MAX UNIT

L Inductance 4.7 10 15 µH

C

OUT

Output capacitance 1 4.7 10 µF

NEGATIVE CHARGE PUMP (VGL)

V

GL

I

GL

C

FLY

C

OUT

Output voltage –5 –8 V

Output current 25 mA

Flying capacitance 0.5 µF

Output capacitance 0.5 5 µF

BOOST CONVERTER 3 (WLED)

V

I

OUT

OUT

Output voltage 38 V

Output current 250 mA

L Inductance 4.7 10 15 µH

C

OUT

Output capacitance 2.2 4.7 10 µF

INTERNAL REGULATOR

C

OUT

Capacitance connected to the TCOMP pin 1 µF

4.4 Thermal Information

TPS65154

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance 29.8 °C/W

Junction-to-case (top) thermal resistance 15.8 °C/W

Junction-to-board thermal resistance 5.2 °C/W

Junction-to-top characterization parameter 0.2 °C/W

Junction-to-board characterization parameter 5.1 °C/W

Junction-to-case (bottom) thermal resistance 0.8 °C/W

(1) For more information about traditional and new thermal metrics, see Semiconductor and IC Package Thermal Metrics application report.

(1)

UNITRSL (VQFN)

48 PIN

6

Specifications Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

www.ti.com

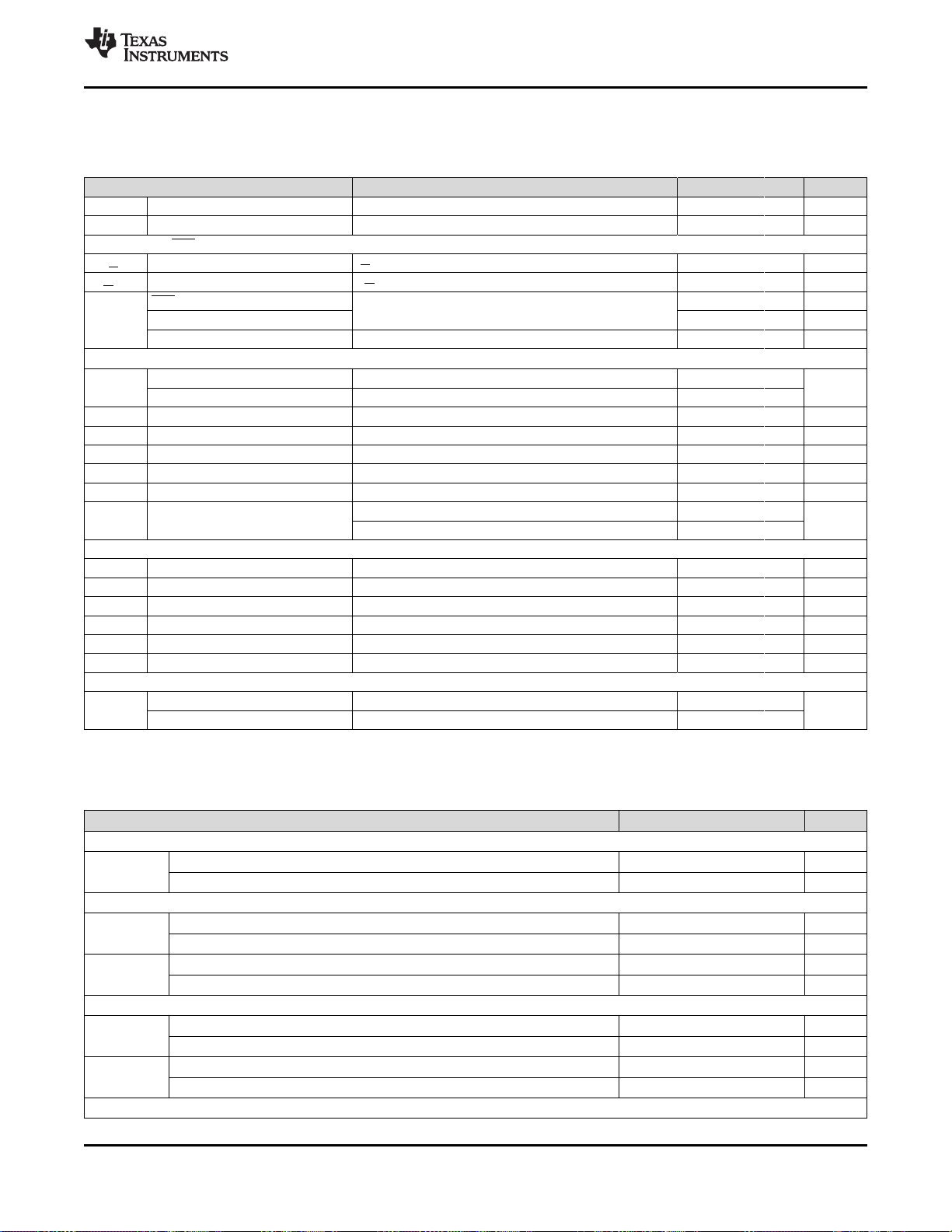

4.5 Electrical Characteristics

VIN= 3.3 V, V

(unless otherwise noted).

POWER SUPPLY

I

IN

I

AVDD

I

BSUP

I

GH

UNDERVOLTAGE LOCKOUT

V

UVLO

LINEAR REGULATOR (VCC)

V

CC

V

UVP

V

SCP

I

LIM

r

DS(ON)

BOOST CONVERTER 1 (AVDD)

AV

DD

V

UVP

V

SCP

r

DS(ON)

I

LIM

r

DS(ON)

f

SW

NEGATIVE CHARGE PUMP (VGL)

V

GL

V

UVP

V

SCP

I

DRVN

V

DO

f

SW

r

DS(ON)

BOOST CONVERTER 2 (VGH)

V

GH

V

UVP

V

SCP

r

DS(ON)

t

ON(MAX)

t

OFF

BOOST CONVERTER 3

V

OUT

I

LIM

r

DS(ON)

= 12 V, VCC= 2.5 V, AVDD= 8 V, VGL= –6.8 V, VGH= 20 V, TA= −40°C to 85°C. Typical values are at 25°C

LED

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Supply current into VIN pin Converters not switching 0.1 1 mA

Supply current into AVDD pins Pins 2 and 3 connected together 0.75 2.5 mA

Supply current into BSUP pin 2.5 5 mA

Supply current into VGH pin No load on VGHM 0.1 1 mA

Undervoltage lockout threshold

Hysteresis 90 mV

Linear regulator output voltage range 1.0 2.5 V

Tolerance ICC= 10 mA –3% +3%

Undervoltage protection threshold VCCfalling 60% 70% 75%

Short circuit protection threshold VCCfalling 25% 30% 40%

Current limit VCC= 5% below value at 10 mA.

Active pull-down resistance 10 21 35 Ω

Output voltage range 6.5 9.6 V

Tolerance –2% +2%

Undervoltage protection threshold 60% 70% 75%

Short-circuit protection threshold 25% 30% 35%

Switch ON resistance ISW= 1 A 0.1 0.25 Ω

Switch current limit 2.4 3.0 3.6 A

Rectifier ON resistance ISW= 1 A 0.25 0.4 Ω

Switching frequency 400 1000 kHz

Tolerance –20% +20%

Output voltage range –5 –8 V

Output voltage tolerance –3% 3.5%

Undervoltage protection threshold VGLrising 65% 70% 75%

Short-circuit protection threshold VGLrising 25% 30% 35%

Maximum drive current

Dropout voltage fSW= 500 kHz, C

Switching frequency 400 500 600 kHz

Discharge ON resistance I

Output voltage range 18 25.5 V

Tolerance –3% 3%

Undervoltage protection threshold VGHfalling 65% 70% 75%

Short-circuit protection threshold VGHfalling 25% 30% 35%

Switch ON resistance ISW= 1 A 0.3 1.0 Ω

Maximum tONtime 1 2 2.5 µs

t

time 2 2.7 4 µs

OFF

Output voltage range V

Switch current limit 2.0 2.7 3.7 A

Switch ON resistance ISW= 1 A 0.2 0.35 Ω

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

VINfalling 1.75

VINrising 2.2

TJ= 25°C to 125°C 300

TJ= –40°C 250

C1B sinking 50 150

C1B sourcing 60 160

= 0.5 µF, IGL= 10 mA 0.6 1.0 V

FLY

= 2 mA 2.1 3 3.9 kΩ

MEAS

+2 38 V

LED

TPS65154

V

mA

mA

Submit Documentation Feedback

Product Folder Links: TPS65154

SpecificationsCopyright © 2013–2016, Texas Instruments Incorporated

7

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

www.ti.com

Electrical Characteristics (continued)

VIN= 3.3 V, V

(unless otherwise noted).

V

OVP

V

IL

V

IH

VIH– VILEN input hysteresis 0.09 0.16 0.27 V

R

PULL-

DOWN

WLED DIMMING

I

FB

D

MIN

D

HYS

V

SET

K

SET

V

IL

V

IH

VIH– VILPWM input voltage hysteresis 0.09 0.16 0.27 V

R

PULL-

DOWN

RESET (RST)

V

OL

I

OH

PROGRAMMABLE VCOM

SET

ZSE

SET

FSE

DNL Differential nonlinearity

BW Small-signal bandwidth

I

OUT

SR Slew rate

I

IB–

V

DROP

GATE VOLTAGE SHAPING

r

DS(ON)H

r

DS(ON)L

V

IL

V

IH

VIH– VILFLK input hysteresis 0.09 0.15 0.27 V

= 12 V, VCC= 2.5 V, AVDD= 8 V, VGL= –6.8 V, VGH= 20 V, TA= −40°C to 85°C. Typical values are at 25°C

LED

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

OVP range 30 39 V

Tolerance -5% +5%

EN low input voltage ENfalling 0.6 V

EN high input voltage EN rising 1.5 V

EN pull-down resistance 450 750 1250 kΩ

Maximum current 40 mA

Channel-to-channel current matching –3% +3%

Output dimming resolution 10 bits

Minimum output duty cycle 1%

Input PWM jitter hysteresis

–0.048

%

0.048

%

ISET regulation voltage –3% 1.0 +3% V

ISET multiplication constant 1260 1296 1332

PWM low input voltage PWM falling 0.6 V

PWM high input voltage PWM rising 1.2 V

PWM pull-down resistance 450 750 1250 kΩ

Output voltage I

Leakage current V

VCOM DAC set zero-scale error V

= 1 mA (sinking) 0.2 0.5 V

RST

= 1.8 V 1 µA

RST

MIN

= 07h, V

= 07h −7 7

MAX

VMIN DAC set zero-scale error –1 1

VCOM set full-scale error V

MIN

= 07h, V

= 07h −7 7

MAX

VMIN set full-scale error −1 1

V

COM

MAX

V

MIN

Closed-loop; AV= –1; RF= 1 kΩ, RIN= 1 kΩ, VCM= 4 V; V

= 63 mVpp; RL= ∞

Peak output current

Open-loop; V

Open-loop; V

Open-loop; V

Open-loop; V

POS

POS

POS

POS

= 4 V, V

= 4 V, V

= 4 V, V

= 4 V, V

= 3 V 400

NEG

= –5 V 330

NEG

= 5 V 36

NEG

= 3 V 33

NEG

Input bias current (inverting input) Closed-loop; AV= +1; RF= 1 MΩ; V

Output voltage drop

Open-loop; V

10 mA

VGH to VGHM ON resistance VGH= 20 V, I

V

= 20 V, I

VGHM to RE ON resistance

FLK low input voltage threshold V

FLK high input voltage threshold V

GHM

V

= 6 V, I

GHM

falling 0.6 V

FLK

rising 1.2 V

FLK

= 4 V; I

POS

= 10 mA, V

GHM

GHM

= 10 mA, V

GHM

MEAS

= 10 mA, V

=

= 1.8 V 13 25 Ω

FLK

FLK

= 0 V 26 50

FLK

SIGNAL

= 4 V −1 1 μA

POS

V

= 3 V 0.06 0.1

NEG

V

= 5 V 0.03 0.1

NEG

= 0 V 26 50

1

1

1

21 MHz

LSBVMAX DAC set zero-scale error –1 1

LSBVMAX set full-scale error –1 1

LSBV

mA

V/µs

V

Ω

8

Specifications Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

TPS65154

www.ti.com

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Electrical Characteristics (continued)

VIN= 3.3 V, V

(unless otherwise noted).

I

IL

I

IH

PANEL RESET (XAO)

V

OL(XAO)

I

LK(XAO)

V

DET

I2C INTERFACE

ADDR

V

IL

V

IH

VIH– VILInput hysteresis 0.05 V

V

OL

C

I

C

B

EEPROM

V

IL

V

IH

VIH– VILWP input voltage hysteresis 0.03 0.05 0.1 V

R

PULL-UP

N

WRITE

THERMAL SHUTDOWN

T

SD

= 12 V, VCC= 2.5 V, AVDD= 8 V, VGL= –6.8 V, VGH= 20 V, TA= −40°C to 85°C. Typical values are at 25°C

LED

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

FLK low input current V

FLK high input current V

Output voltage I

Leakage current V

XAO Threshold voltage range

Tolerance –3% +3%

= 0 V –100 100 nA

FLK

= 1.8 V –100 100 nA

FLK

= 1 mA (sinking) 0.16 0.5 V

XAO

= 1.8 V 1 µA

XAO

VINfalling

V

UVLO

3.0 V

Hysteresis VINrising 0.05 0.3 V

Configuration parameters slave address 74h

Programmable VCOM slave address 28h

Low level input voltage SCL or SDA falling, standard and fast modes 0.6 V

High level input voltage SCL or SDA rising, standard and fast modes 1.0 V

Low level output voltage Sinking 3 mA 0.36 V

Input capacitance 10 pF

Capacitive load on SDA and SCL

Standard mode 400

Fast mode 400

WP low input voltage threshold VWPfalling 0.8 V

WP high input voltage threshold VWPrising 1.2 V

WP internal pull-up resistor 20 60 100 kΩ

Number of write cycles 1000

Data retention Storage temperature = 150 °C 100 1000 hrs

Thermal shutdown temperature 150

Thermal shutdown hysteresis 10

pF

°C

4.6 Timing Requirements

VIN= 3.3 V, V

(unless otherwise noted).

LINEAR REGULATOR (VCC)

t

DLY1

BOOST CONVERTER 1 (AVDD)

t

SS2

t

DLY2

NEGATIVE CHARGE PUMP (VGL)

t

SS3

t

DLY3

BOOST CONVERTER 2 (VGH)

= 12 V, VCC= 2.5 V, AVDD= 8 V, VGL= –6.8 V, VGH= 20 V, TA= −40°C to 85°C. Typical values are at 25°C

LED

Linear regulator start-up delay time 0 75 ms

Tolerance –20% 30%

Boost converter 1 soft-start duration range 0.5 75 ms

Tolerance –20% 30%

Boost converter 1 start-up delay range 0 75 ms

Tolerance –20% 30%

Negative charge pump soft-start duration 0 35 ms

Tolerance –20% 30%

Negative charge pump start-up delay 0 35 ms

Tolerance –20% 30%

Submit Documentation Feedback

Product Folder Links: TPS65154

MIN TYP MAX UNIT

SpecificationsCopyright © 2013–2016, Texas Instruments Incorporated

9

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Timing Requirements (continued)

VIN= 3.3 V, V

(unless otherwise noted).

t

SS4

BOOST CONVERTER 3

f

SW

WLED DIMMING

t

PWMIN

f

OUT

f

IN

RESET (RST)

t

RST

GATE VOLTAGE SHAPING

t

PLH

t

PHL

t

DLY4

PANEL RESET (XAO)

t

DLY6

TIMING

t

UVP

I2C INTERFACE

f

SCL

t

LOW

t

HIGH

t

BUF

t

hd:STA

t

su:STA

t

su:DAT

t

hd:DAT

= 12 V, VCC= 2.5 V, AVDD= 8 V, VGL= –6.8 V, VGH= 20 V, TA= −40°C to 85°C. Typical values are at 25°C

LED

Boost converter 2 soft-start duration range 0 35 ms

Tolerance –20% 30%

Switching frequency range 400 1000 kHz

Tolerance –20% 20%

Input pulse width 500 ns

Output frequency range

Direct dimming 0.1 15

DPWM dimming 15 22

Tolerance –20% 20%

Input frequency range PWM and direct dimming modes 0.1 15 kHz

Reset pulse duration range 0 15 ms

Tolerance

Measured from end of VCC's ramp to 50% of

RST's rising edge with a 10 kΩ pull-up resistor.

V

Propagation delay

C

V

C

Gate voltage shaping start-up delay range 0 35 ms

Tolerance –20% 30%

Panel reset duration range 0 35 ms

Tolerance

Measured from VIN= V

rising edge with a 10-kΩ pull-up resistor.

Undervoltage protection timeout 40 50 60 ms

Clock frequency

Clock low period

Clock high period

Bus free time between a

STOP and a START

condition

Hold time for a repeated

START condition

Set-up time for a repeated

START condition

Data set-up time

Data hold time

Standard mode 100

Fast mode 400

Standard mode 4.7

Fast mode 1.3

Standard mode 4.0

Fast mode 0.6

Standard mode 4.7

Fast mode 1.3

Standard mode 4.0

Fast mode 0.6

Standard mode 4.0

Fast mode 0.6

Standard mode 250

Fast mode 100

Standard mode 0.05 3.45

Fast mode 0.05 0.9

rising, V

GHM

= 150 pF, RE= 0 Ω

VGHM

falling, V

GHM

= 150 pF, RE= 0 Ω

VGHM

= 0 V/1.8 V, 50% thresholds,

FLK

=0 V/1.8 V, 50% thresholds,

FLK

to 50% of XAO's

DET

www.ti.com

MIN TYP MAX UNIT

–20% 20%

92 200

88 200

–20% 30%

kHz

ns

kHz

µs

µs

µs

µs

µs

ns

µs

10

Specifications Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

www.ti.com

Timing Requirements (continued)

VIN= 3.3 V, V

(unless otherwise noted).

t

RCL1

t

RCL

t

FCL

t

RDA

t

FDA

t

su:STO

EEPROM

t

WRITE

= 12 V, VCC= 2.5 V, AVDD= 8 V, VGL= –6.8 V, VGH= 20 V, TA= −40°C to 85°C. Typical values are at 25°C

LED

Rise time of SCL after a

repeated START condition

and after an ACK bit

Rise time of SCL

Fall time of SCL

Rise time of SDA

Fall time of SDA

Set-up time for STOP

condition

Standard mode 20+0.1C

Fast mode 20+0.1C

Standard mode 20+0.1C

Fast mode 20+0.1C

Standard mode 20+0.1C

Fast mode 20+0.1C

Standard mode 20+0.1C

Fast mode 20+0.1C

Standard mode 20+0.1C

Fast mode 20+0.1C

Standard mode 4.0

Fast mode 0.6

Write time 100 ms

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

MIN TYP MAX UNIT

B

B

B

B

B

B

B

B

B

B

1000

1000

1000

300

300

300

1000

300

300

300

ns

ns

ns

ns

ns

µs

Submit Documentation Feedback

Product Folder Links: TPS65154

SpecificationsCopyright © 2013–2016, Texas Instruments Incorporated

11

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

5 Detailed Description

5.1 Overview

The TPS65154 device integrates the bias and backlight functions needed by an active matrix liquid crystal

display.

The LCD bias functions comprise

• A synchronous boost converter to generate AV

• A non-synchronous boost converter to generate V

• An inverting charge pump to generate V

• An low dropout linear regulator to generate V

• A gate-voltage shaping function

• A programmable VCOM buffer

• XAO and RST signals

• An I2C programming interface

The backlight driver functions comprise

• A non-synchronous boost converter

• A six-channel WLED driver with PWM dimming

www.ti.com

DD

GH

GL

CC

The device configuration is stored in an on-chip nonvolatile memory, which can be programmed via an I2C

interface.

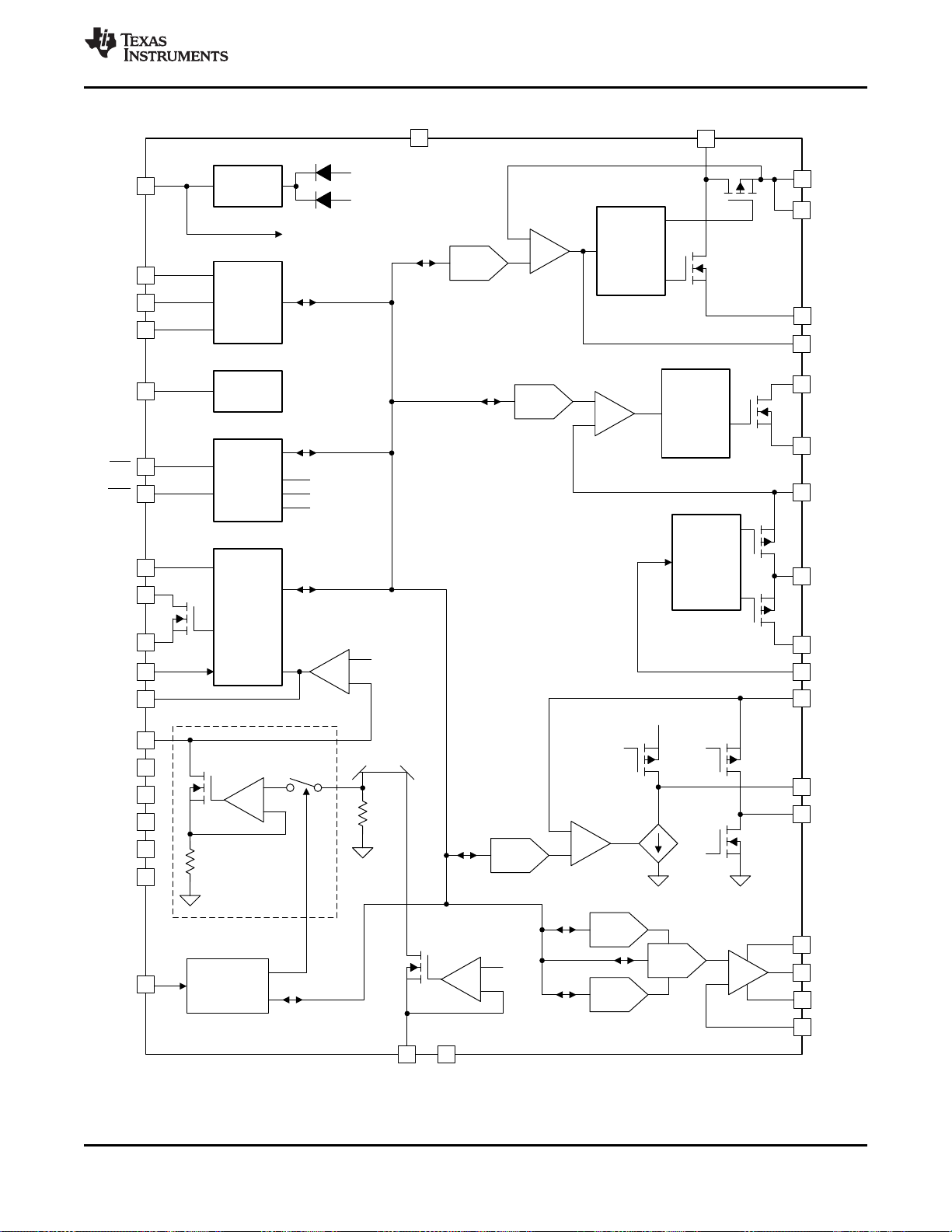

5.2 Functional Block Diagram

Figure 5-1 shows a top-level block diagram of the TPS65154.

12

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

PWM

Control

6

3

5

DAC

+

±

46

4

PWM

Control

9

10

DAC +

±

14

15

Gate

Voltage

Shaping

Control

16

11

I2C

Interface

41

42

43

WP

SDA

SCL

LDO

1920C1A

C1B

VGL

DAC +

±

18

VCOM

BSUP

BGND

NEG

2

47

44

45

+

±

DAC

DAC

DAC

AV

DD

8VCC

LDO17COMP2

To internal blocks

V

IN

AV

DD

Sequencing

21

22

RST

XAO

V

IN

V

UVLO

V

DET

32IFB1

31IFB2

30IFB3

29IFB4

28IFB5

27IFB6

PWM

Control

33

34

+

±

SW3

PGND

39EN

40COMP3

35OVP

V

ref

+±1 V

23

+

±

Only one channel

shown in detail

FLK

RE

VGHM

VGH

PGND

SW2

COMP1

PGND

AVDD

AVDD

SW1

ISET26AGND

7

VIN

Dimming

Control

37PWM

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 5-1. Top-Level Block Diagram

Submit Documentation Feedback

Product Folder Links: TPS65154

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

13

VIN

+

–

C

OUT

VCC

V

CC

DAC

VCC

Copyright © 2016, Texas Instruments Incorporated

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

5.3 Feature Description

The following sections describe the features of the TPS65154.

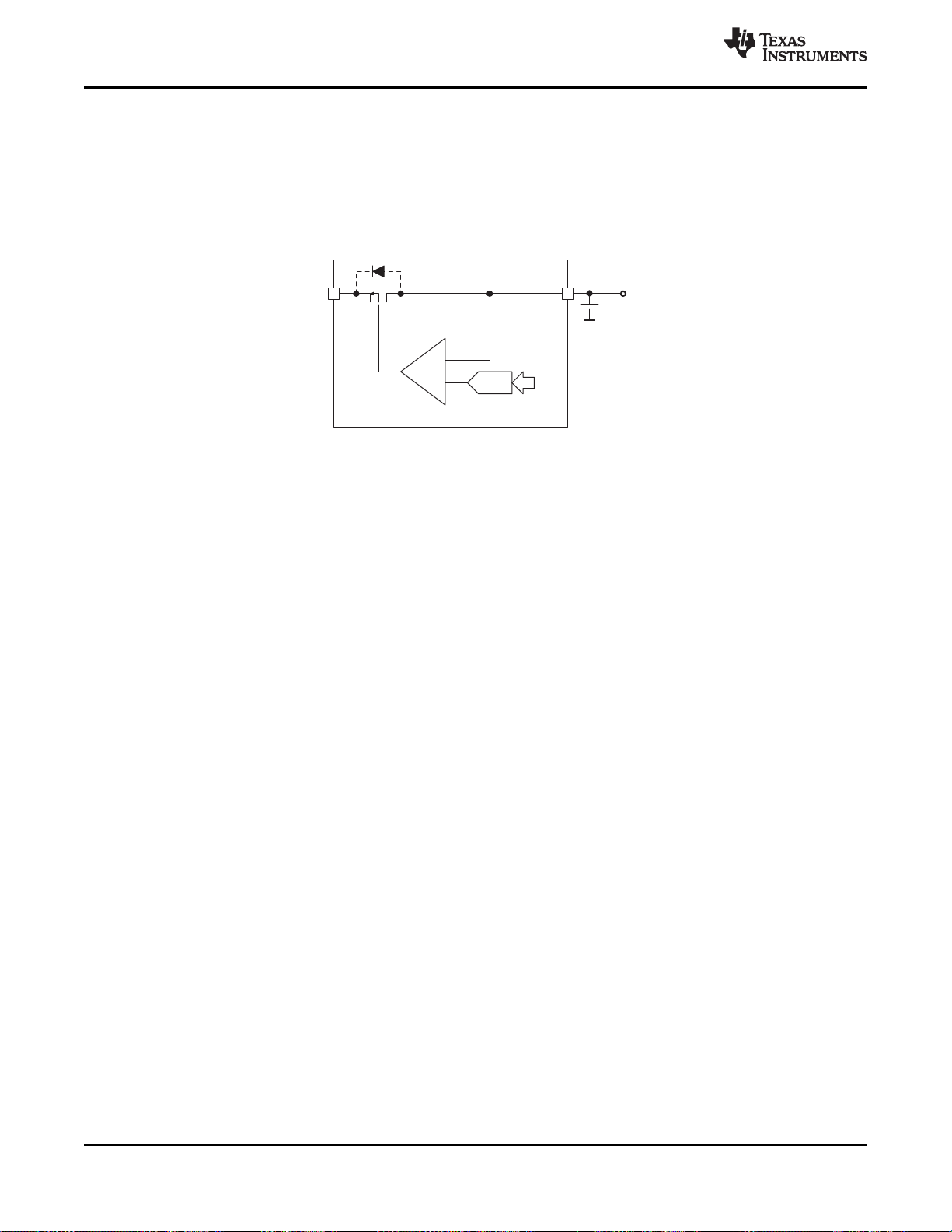

5.3.1 Linear Regulator (VCC)

The linear regulator is supplied directly from the VIN pin, and its output voltage can be programmed to

1.0 V, 1.2 V, 1.89 V, or 2.5 V using the VCC register.

Figure 5-2. Linear Regulator Block Diagram

www.ti.com

5.3.1.1 Power-Up (Linear Regulator)

The linear regulator starts t

threshold (VIN> V

). It does not have a soft-start function, and its output ramps up as fast as the

UVLO

milliseconds after the supply voltage exceeds the undervoltage lockout

DLY1

supply voltage slew rate and the linear regulator's output capacitance allow.

5.3.1.2 Power-Down (Linear Regulator)

The linear regulator is turned off as soon as the supply voltage falls below the undervoltage lockout

threshold (VIN< V

). VCCis actively discharged during power-down.

UVLO

5.3.1.3 Protection (Linear Regulator)

The linear regulator is protected against short-circuits and undervoltage conditions. An undervoltage

condition is detected if the linear regulator's output falls below 70% of its programmed voltage for longer

than 50 ms, in which case the IC is disabled. A short-circuit condition is detected if the linear regulator's

output falls below 30% of its programmed voltage, in which case the IC is disabled immediately (shortcircuit detection has no time delay associated with it). To recover normal operation following either an

undervoltage condition or short-circuit condition, the cause of the error must be removed and a POR

applied.

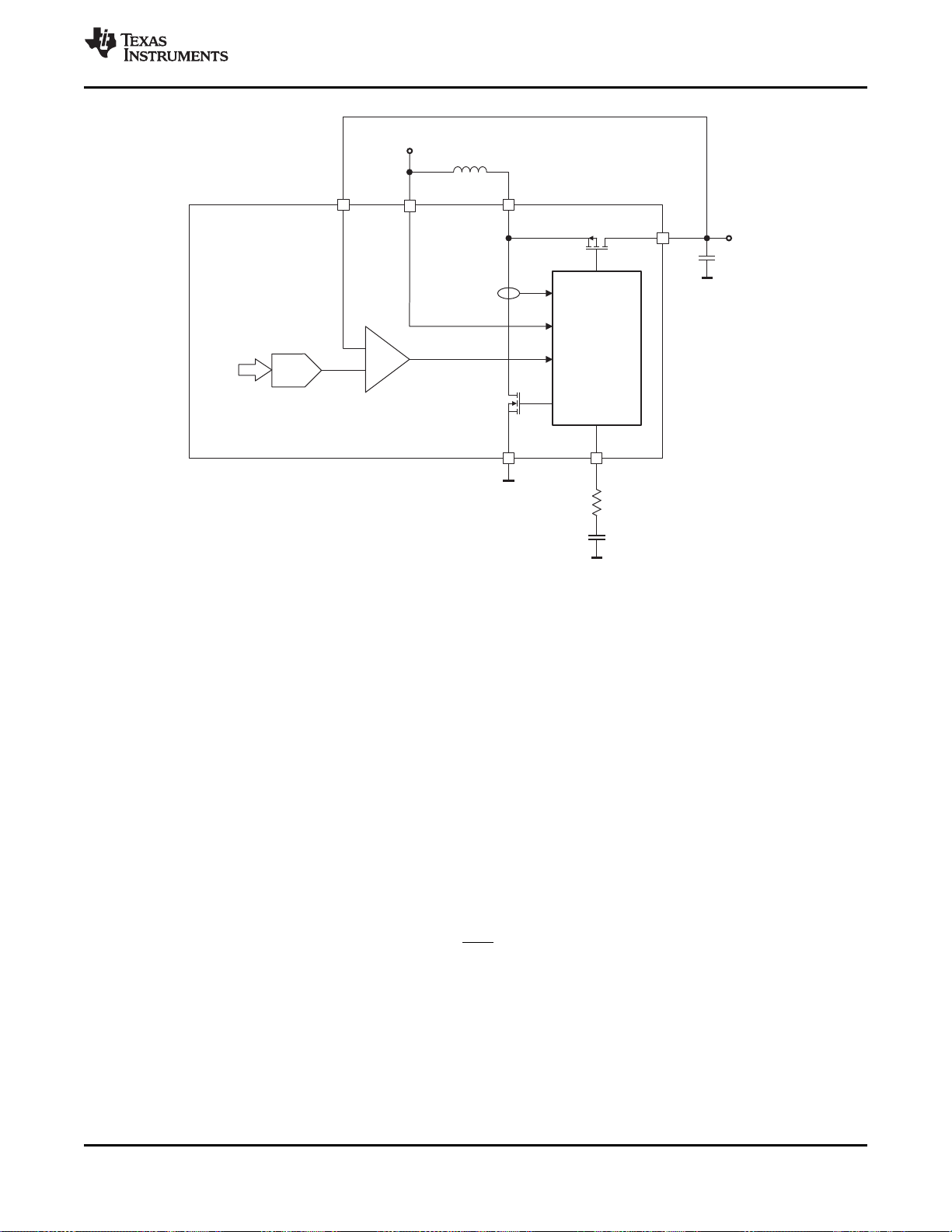

5.3.2 Boost Converter 1 (AVDD)

Boost converter 1 is synchronous and uses a virtual current mode topology that:

• achieves high efficiencies;

• allows the converter to work in continuous conduction mode under all operating conditions, simplifying

compensation; and

• provides true input-output isolation when the boost converter is disabled.

14

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

COMP1

SW1

V

IN

AV

DD

Q1B

Q1A

PWM

Control

GND

VIN

L

AVDD

+

–

C

OUT

R

COMP

C

COMP

DAC

AVDD

AVDD

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 5-3. Boost Converter 1 Internal Block Diagram

Boost converter 1's switching frequency can be programmed to 400 kHz, 600 kHz, 800 kHz, or 1 MHz

using the FSW1 register. Its output voltage can be programmed from 6.5 V to 9.6 V in 100 mV steps using

the AVDD register.

Boost converter 1 uses an external compensation network connected to the COMP1 pin to stabilize its

feedback loop. A simple series R-C network connected between the COMP1 pin and ground is sufficient

to achieve good performance, that is, stable and with good transient response. Good starting values,

which will work for most applications, are 25 kΩ and 3.9 nF.

In some applications (for example, those using electrolytic output capacitors), it may be necessary to

include a second compensation capacitor between the COMP1 pin and ground. This has the effect of

adding an additional pole in the feedback loop's frequency response, which cancels the zero introduced by

the output capacitor's ESR.

The synchronous topology of boost converter 1 ensures that AVDDis fully isolated from VINwhen the

converter is disabled.

5.3.2.1 Power-Up (Boost Converter 1)

Boost converter 1 starts t

milliseconds after RST goes high. Delay time t

DLY2

0 ms to 75 ms using the DLY2 register.

To minimize inrush current during start-up, boost converter 1 ramps its output voltage in t

Start-up time t

can be programmed from 0.5 ms to 75 ms using the SS2 register. Longer soft-start

SS2

times generate lower inrush currents.

5.3.2.2 Power-Down (Boost Converter 1)

can be programmed from

DLY2

milliseconds.

SS2

Boost converter 1 is disabled when VIN<V

AVDDby turning on Q2.

Submit Documentation Feedback

Product Folder Links: TPS65154

. When disabled, boost converter 2 actively discharges

UVLO

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

15

AV

DD

V

GH

SW2

GND

VGH

PWM

Control

+

–

VGH

AVDD

L

C

OUT

DAC

Copyright © 2016, Texas Instruments Incorporated

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

5.3.2.3 Protection (Boost Converter 1)

Boost converter 1 is protected against short-circuits and undervoltage conditions. An undervoltage

condition is detected if the boost converter's output falls below 70% of its programmed voltage for longer

than 50 ms, in which case the IC is disabled. A short-circuit condition is detected if the boost converter's

output falls below 30% of its programmed voltage, in which case the IC is disabled immediately (shortcircuit detection has no time delay associated with it). To recover normal operation following either an

undervoltage condition or short-circuit condition, the cause of the error must be removed and a POR

applied.

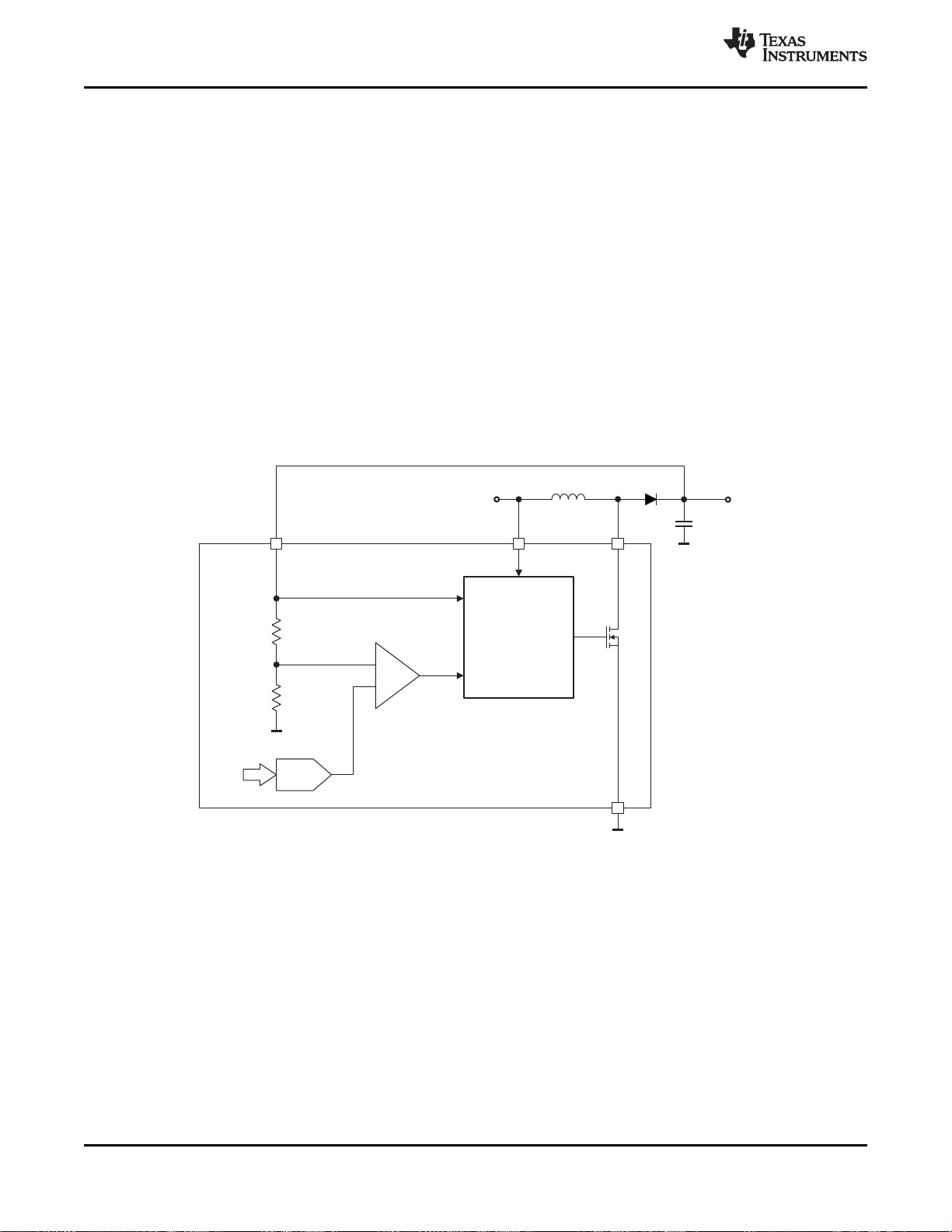

5.3.3 Boost Converter 2 (VGH)

Boost converter 2 is non-synchronous and uses a constant off-time topology. The converter's switching

frequency is not constant but adapts itself to VINand VGH. Boost converter 2 uses peak current control and

is designed to operate permanently in discontinuous conduction mode (DCM), thereby allowing the

internal compensation circuit to achieve stable operation over a wide range of output voltages and

currents. Boost converter 2's output voltage can be programmed from 18 V to 25.5 V using the VGH

register.

www.ti.com

Figure 5-4. Boost Converter 2 Block Diagram

5.3.3.1 Power-Up (Boost Converter 2)

Boost converter 2 is enabled as soon as VGLhas finished ramping down. To minimize inrush current

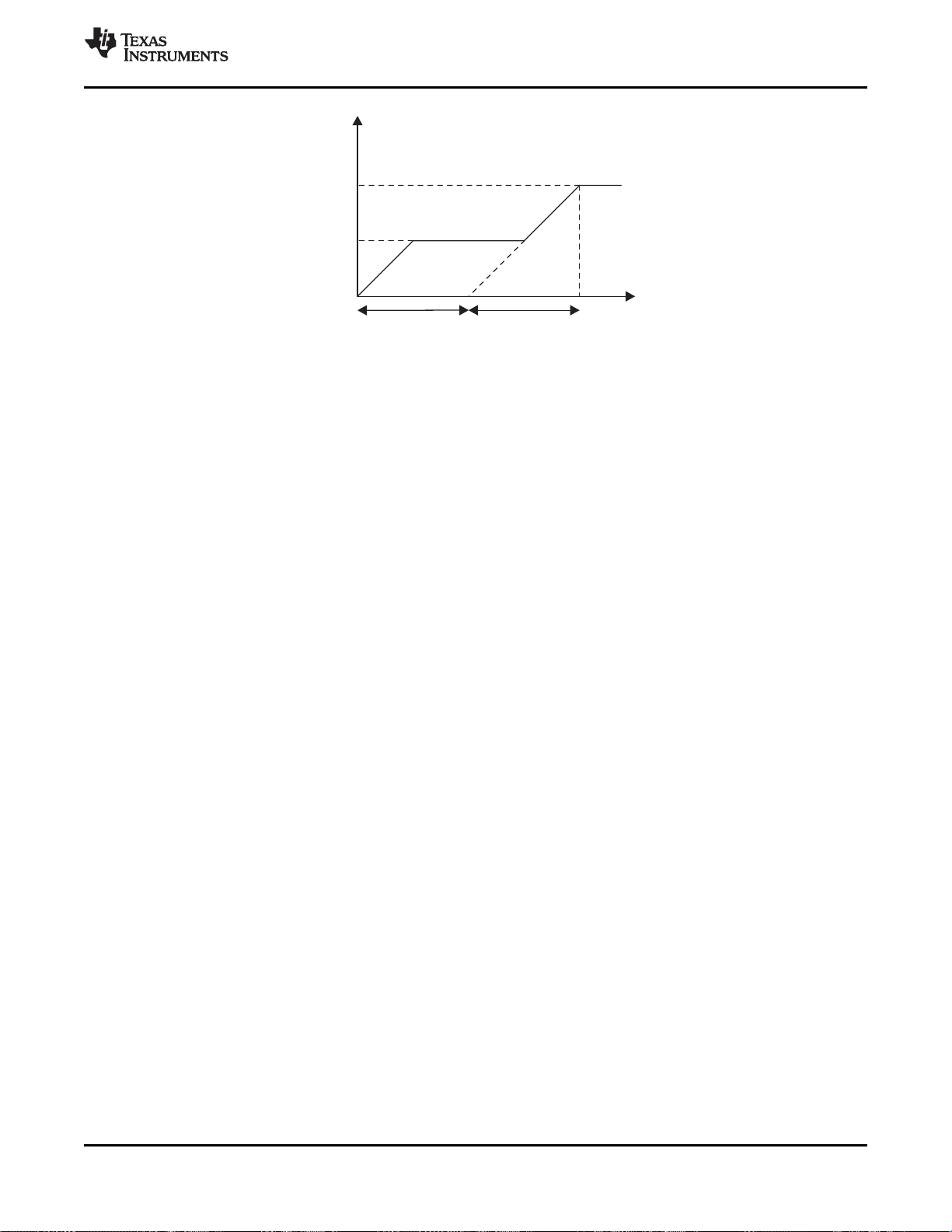

during start-up, boost converter 2 ramps VGHlinearly to its programmed value in t

16

time t

is non-synchronous, its output is already equal to AVDD(minus the voltage drop across its rectifier diode)

before it starts switching, which means that the time during which VGHis actually ramping during start-up

is less than the actual programmed soft-start time (see Figure 5-5).

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

can be programmed from 0.256 ms to 35 ms using the SS4 register. Because boost converter 2

SS4

Submit Documentation Feedback

Product Folder Links: TPS65154

seconds. Soft-start

SS4

t

SS4

t + t

DLY3 SS3

V

GH

AV

DD

www.ti.com

Figure 5-5. Boost Converter 2 Soft-Start

5.3.3.2 Power-Down (Boost Converter 2)

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Boost converter 2 is disabled when VIN<V

converter is disabled.

5.3.3.3 Protection (Boost Converter 2)

Boost converter 2 is protected against short-circuits and undervoltage conditions. An undervoltage

condition is detected if the boost converter's output falls below 70% of its programmed voltage for longer

than 50 ms, in which case the IC is disabled. A short-circuit condition is detected if the boost converter's

output falls below 30% of its programmed voltage, in which case the IC is disabled immediately (shortcircuit detection has no time delay associated with it). To recover normal operation following either an

undervoltage condition or short-circuit condition, the cause of the error must be removed and a POR

applied.

5.3.4 Negative Charge Pump (VGL)

The negative charge pump inverts AVDDand regulates its output to the voltage set by the VGL register.

VGLcan be programmed from –5 V to –8 V in 0.2 V steps using the VGL register, however, since the

negative charge pump inverts AVDDto generate its output, the most negative voltage that can be

generated is approximately –AVDD+1 V. Thus, if AVDD= 8.0 V, the usable range of VGLis approximately –5

V to –7 V. If VGLis programmed to a more negative voltage than this the charge pump may not be able to

regulate its output. This will not damage the IC, but performance may be impaired.

The negative charge pump in the TPS65154 is fully integrated and requires only two external capacitors to

operate (a flying capacitor connected between the C1A and C1B pins, and an output capacitor connected

between the VGL pin and ground).

. The converter's output is not actively discharged when the

UVLO

Submit Documentation Feedback

Product Folder Links: TPS65154

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

17

AV

DD

Osc.

V

GL

C

OUT

C

FLY

C1A

C1B

VGL

I

DRVN

VGL

DAC

Copyright © 2016, Texas Instruments Incorporated

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 5-6. Negative Charge Pump Block Diagram

5.3.4.1 Power-Up (Negative Charge Pump)

www.ti.com

The negative charge pump starts t

milliseconds after boost converter 1 (AVDD) starts ramping and

DLY3

ramps its output linearly from zero to its programmed output voltage in t

programmed from 0 ms to 35 ms using the DLY3 register. Soft-start time t

0 ms to 35 ms using the SS3 register.

5.3.4.2 Power-Down (Negative Charge Pump)

The negative charge pump is disabled when the supply voltage falls below the undervoltage lockout

threshold (VIN<V

). During power-down the charge pump's output is actively discharge to GND.

UVLO

5.3.4.3 Protection (Negative Charge Pump)

The negative charge pump is protected against short-circuits and undervoltage conditions. An

undervoltage condition is detected if the charge pump's output falls below 70% of its programmed voltage

for longer than 50 ms, in which case the IC is disabled. A short-circuit condition is detected if the charge

pump's output falls below 30% of its programmed voltage, in which case the IC is disabled immediately

(short-circuit detection has no time delay associated with it). To recover normal operation following either

an undervoltage condition or short-circuit condition, the cause of the error must be removed and a POR

applied.

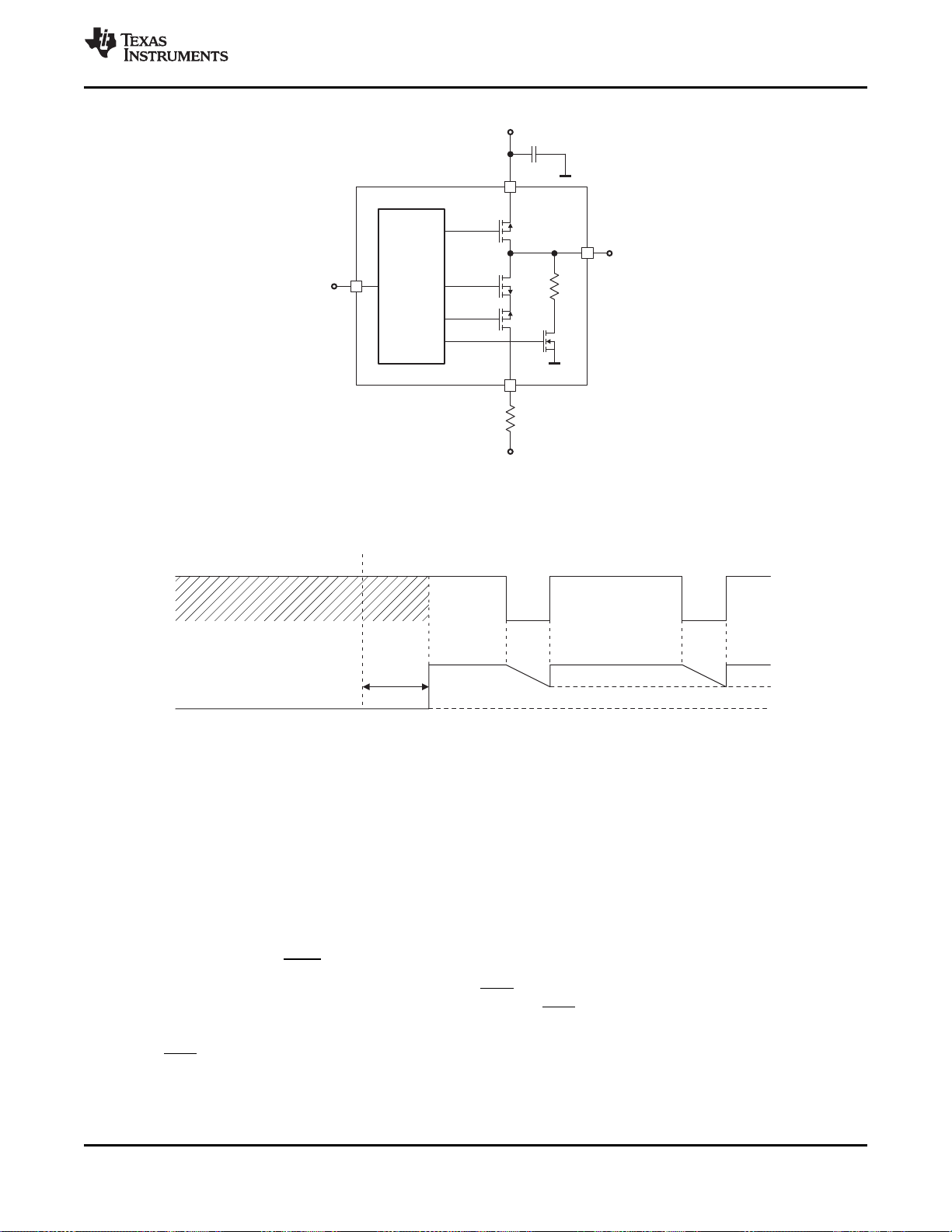

5.3.5 Gate Voltage Shaping

The gate voltage shaping function can be used to reduce image sticking in LCD panels by modulating the

LCD panel's gate ON voltage (VGH). Figure 5-7 shows a block diagram of the gate voltage shaping

function and Figure 5-8 shows the typical waveforms during operation.

ms. Delay time t

SS3

can be programmed from

SS3

DLY3

can be

18

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

Don’t Care

t

DLY4

V

PG4

V

GH

FLK

V

GHM

AV

DD

GND

V

GH

Control

Logic

FLK

V

GHM

R

E

Q1

Q3

AV

DD

Q2

Q4

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 5-7. Gate Voltage Shaping Block Diagram

Figure 5-8. Gate Voltage Shaping Waveforms

Gate voltage shaping is controlled by the FLK input. When FLK is high, Q1 is on, Q2, Q3 and Q4 are off,

and V

is equal to VGH. On the falling edge of FLK, Q1 is turned off, Q2 and Q3 are turned on, and the

GHM

LCD panel load connected to the VGHM pin discharges through the external resistor connected to the RE

pin.

During power-up, Q1, Q2 and Q3 are held off and Q4 is turned on, pulling the VGHM pin pulled to GND,

regardless of the state of the FLK signal, until t

ramping. The value of t

DLY4

During power-down Q1 is held permanently on and Q2, Q3 and Q4 permanently off, regardless of the

state of the FLK signal.

5.3.6 Panel Discharge (XAO)

The TPS65154 provides an output signal via its XAO pin that can be used to drive the outputs of the

display panel's gate driver IC high during power-down. The XAO pin is pulled low whenever VIN<V

V

DET

The XAO output is an open-drain type and requires an external pull-up, typically in the range 10 kΩ to

100 kΩ.

threshold voltage can be configured using the VDET register.

milliseconds after boost converter 2 (VGH) has finished

DLY4

can be programmed from 0 ms to 35 ms using the DLY4 register.

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

DET

. The

19

VCOM

VMAX

DAC

NEG

VCOM

BGND

BSUP

4/8×AV

DD

2/8×AV

DD

DAC

DACVMIN

2.5/8×AV

DD

3.5/8×AV

DD

V

COM

Feedback from

display panel

AV

DD

+

–

Copyright © 2016, Texas Instruments Incorporated

( )

127

VCOMVV

VV

MINMAX

MINCOM

×-

+=

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

5.3.7 Reset Generator (RST)

The RST pin generates an active-low reset signal for the rest of the system. During power-up, the reset

timer starts when VCChas finished ramping. The reset pulse duration t

to 15 ms using the RESET register. The RST signal is latched when it goes high and will not be taken low

again until the device is powered down (even if VCCtemporarily falls out of regulation). The active powerdown threshold (V

UVLO

or V

) can be selected using the RMODE bit in the CONFIG register.

DET

The RST output is an open-drain type that requires an external pull-up resistor. Pull-up resistor values in

the range 10 kΩ to 100 kΩ are recommended for most applications.

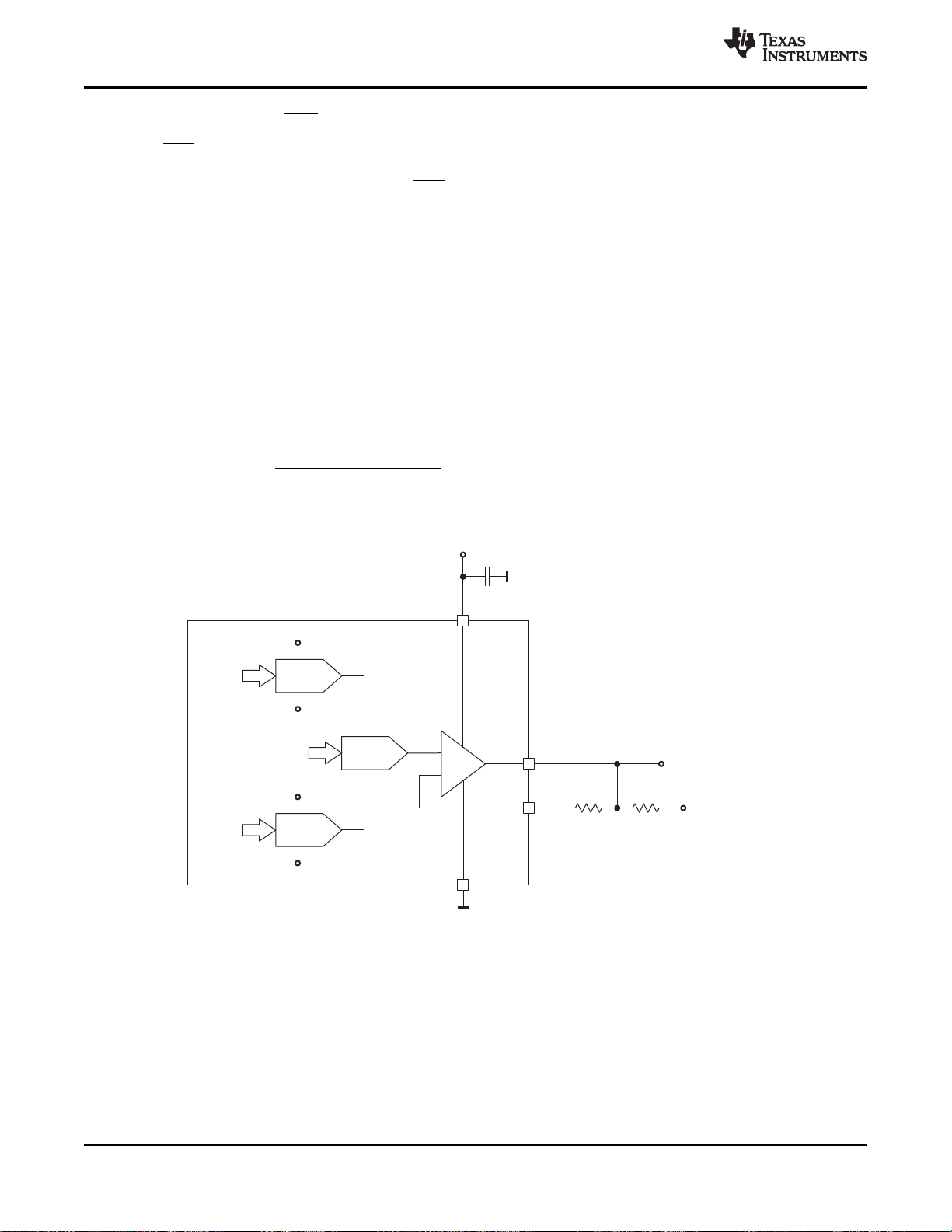

5.3.8 Programmable VCOM

can be programmed from 0 ms

RST

www.ti.com

The programmable VCOM uses three digital-to-analog converters (DACs) to generate a V

is subsequently buffered by a high-speed op-amp. The maximum value of V

is set by the 4-bit VMAX

COM

register, and can be programmed in the range 2.5/8×AVDDto 4/8×AVDD. The minimum value of V

voltage that

COM

COM

is

set by the 4-bit VMIN register, and can be programmed in the range 2/8 × AVDDto 3.5/8 × AVDD. Note, for

proper operation, V

can adjust the V

COM

must be greater than V

MAX

. By programming the 7-bit VCOM parameter, users

MIN

voltage appearing at the OUT pin between V

MIN

and V

as follows:

MAX

(1)

where VCOM is the value stored in the Wiper Register (see Figure 5-9).

20

Figure 5-9. Programmable VCOM Block Diagram

The programmable VCOM function has three registers. The volatile Wiper Register (WR) contains the

value currently output by the programmable VCOM DAC; this value is lost when power to the device is

removed. The non-volatile Initial Value Register (IVR) contains the value loaded into the DAC every time

the device is powered up. The Control Register (CR) determines whether data is written to or read from

the WR, the IVR, or both. If the CR contains 00h, during write operations data is stored in the WR and the

IVR, and during read operations data is read from the IVR. If the CR contains 80h, data is written to and

read from the WR register only. 00h and 80h are the only valid values for the CR. Table 5-1 shows the

programmable VCOM's register address map.

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

SET

SET

SET

MAX

K

R

V

www.ti.com

Table 5-1. Programmable VCOM Register Address Map

REGISTER ADDRESS NON-VOLATILE VOLATILE

00h Initial Value Register (IVR) Wiper Register (WR)

02h Not Used Control Register (CR)

5.3.8.1 Operational Amplifier Performance

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Like most op-amps, the V

op-amp in the TPS65154 is not designed to drive purely capacitive loads, so

COM

it is not recommended to connect a capacitor directly to its output in an attempt to increase performance;

however, the op-amp is capable of delivering high peak currents that make such capacitors unnecessary

in most applications.

High-speed op amps such as the one in the TPS65154 require care when using them. The most common

problem is when parasitic capacitance at the inverting input creates a pole with the feedback resistor,

reducing amplifier stability. Two things can be done to minimize the likelihood of this happening. Both of

these work by shifting the pole (which can never be completely eliminated) to a frequency outside the op

amp's bandwidth, where it has no effect.

• Reduce the value of the feedback resistor. In applications where no feedback from the panel is used,

the feedback resistor can be made zero. In applications where a non-zero feedback resistor has to be

used, a small capacitor (between 10 pF and 100 pF) across the feedback resistor will minimize ringing.

• Minimize the parasitic capacitance at the op amp's inverting input. This is achieved by using short PCB

traces between the feedback resistor and the inverting input, and by removing ground planes and other

copper areas above and below this PCB trace.

5.3.8.2 Power-Up (Programmable VCOM)

The programmable V

is enabled when AVDD> V

COM

5.3.8.3 Power-Down (Programmable VCOM)

During power-down, the programmable VCOM continues to operate until AVDD< V

5.3.9 WLED Driver

UVLO2

.

.

UVLO2

5.3.9.1 WLED Boost Converter

The WLED boost converter boosts a 4.5 V to 24 V supply V

strings connected to the WLED driver. It uses a fixed-frequency, current-mode topology. The converter's

output voltage is automatically adjusted to maintain the lowest feedback voltage (IFB1 to IFB6) between

450 mV and 750 mV, thus ensuring sufficient headroom for the output current sinks, but without

dissipating excessive power in the IC. This approach automatically compensates for changes in the LED

string voltage, for example, because of temperature effects. The WLED boost converter's switching

frequency can be programmed to 400 kHz, 600 kHz, 800 kHz, and 1 MHz using the FSW3 register.

The WLED boost converter features a soft-start circuit to limit inrush current when the converter starts.

The duration of the soft-start ramp depends on the value of the capacitor connected to the COMP3 pin.

Note, that because the converter is a non-synchronous type, its output voltage before it starts switching is

equal to V

(minus the voltage drop across its rectifier).

BAT

5.3.9.2 Current Sinks

The brightness of the LED strings is determined by the average current flowing through each string, which

is the product of the output duty cycle and the current sink's output current. The output current of all

current sinks is the same and is set by the external resistor connected between the ISET pin and ground:

Submit Documentation Feedback

Product Folder Links: TPS65154

to a higher voltage to supply the LED

BAT

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

(2)

21

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

where:

www.ti.com

• V

• R

• K

is the voltage on the ISET pin

SET

is the resistance between the ISET pin and GND

SET

is a constant

SET

When the TPS65154 measures zero current flowing in one of the IFB pins it determines that the string is

open and automatically disables that output. The WLED boost converter's output voltage is subsequently

regulated according to the remaining operational strings. If an application uses fewer than six LED strings,

it is recommended to connected the unused outputs to ground; this ensures the most rapid detection of

the unused strings. Once open strings have been detected, they remain disabled until a POR occurs or

EN is toggled.

5.3.9.3 Protection

The WLED boost converter and dimming circuits feature a variety of protection schemes to ensure reliable

operation when subjected to various failure modes. These protection schemes are listed in Table 5-2.

ERROR DETECTION ACTION RECOVERY

WLED boost converter output

voltage too high

WLED boost converter switch

current too high

All LED strings open-circuit I

Individual LED string(s) open-

Individual LED string(s) shorted-

circuit

circuited to ground

Table 5-2. WLED Driver Protection

V

exceeds programmed

OVP

threshold

(30 V, 33 V, 36 V or 39 V)

ISW> I

LIM

= 0 mA and V

IFB

I

= 0 mA and V

IFB

I

= 0 mA for longer than 4 ms

IFB

OUT

OUT

= V

= V

OVP

OVP

WLED boost converter output

regulated to programmed

threshold

Switch turned off

Disable all output channels and

boost converter

Disable affected output

channel(s)

Functional output channels

continue operating.

None required

Switch automatically re-enabled

at start of next switching cycle

Output channels re-enabled

following power cycle

Affected output channel(s) re-

enabled following power cycle

5.3.9.4 Enable and Start-Up

The WLED driver is enabled and disabled by EN, however, this signal has no effect until the LCD bias

functions have completed their start-up sequence. Following a POR, EN has no effect until t

complete; after that the WLED driver can be enabled and disabled at any time using EN (providing nothing

happens to cause the LCD bias functions to re-start) and applying a PWM signal. In applications that do

not generate an EN signal, the EN pin can be tied to VIN, in which case the WLED driver will start

automatically at the end of t

boost converter 3 from starting-up.

When the WLED driver is enabled it first checks the status of IFB1 to IFB6 and shuts down any channels

that it detects are disabled/unused. These channels will be subsequently ignored until a POR occurs or

EN is toggled.

5.3.10 Undervoltage Lockout

An undervoltage lockout function disables the IC when the supply voltage is too low for proper operation.

5.4 Device Functional Modes

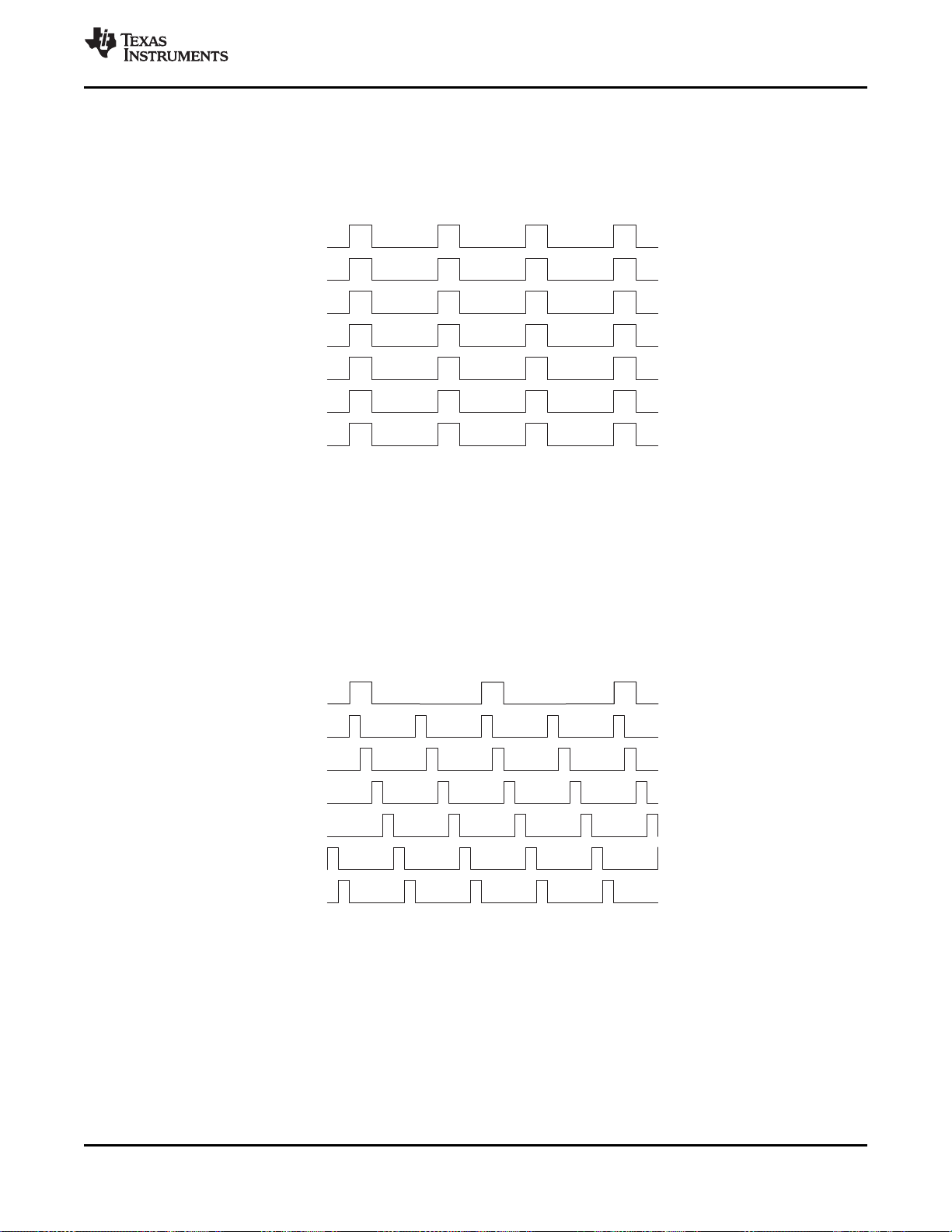

5.4.1 Dimming Modes

The TPS65154 support direct dimming and phase-shift dimming modes. The active dimming mode can be

selected using the DMODE bit in the CONFIG register.

. Note, that a permanently low PWM signal (0% duty cycle) will prevent

DLY4

DLY4

is

22

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

IFB1

IFB2

IFB3

IFB4

IFB5

IFB6

IFB1

IFB2

IFB3

IFB4

IFB5

IFB6

www.ti.com

5.4.1.1 Direct Dimming

When direct dimming is selected, the output current sinks are controlled directly by the PWM signal. In this

mode, they are turned on and off together, at the same frequency and duty cycle as the PWM signal (see

Figure 5-10).

5.4.1.2 Phase-Shift Dimming

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 5-10. Direct Dimming

When phase-shift dimming mode is selected, the output dimming frequency does not depend on the

frequency of the PWM signal but can be independently programmed from 15 kHz to 22 kHz using the

FDIM register. In this mode, the duty cycle information contained in the PWM signal is extracted and reused to generate up to six outputs, at the output frequency set by the FDIM register, and phase-shifted

with respect to each other by 360°/N, where N is the number of outputs in use (see Figure 5-11). Using

phase-shifted outputs, the maximum load current step is reduced by the same factor N, resulting in

reduced voltage ripple on the boost converter's output and consequently lower audible noise.

Figure 5-11. Phase-Shift Dimming

Submit Documentation Feedback

Product Folder Links: TPS65154

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

23

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

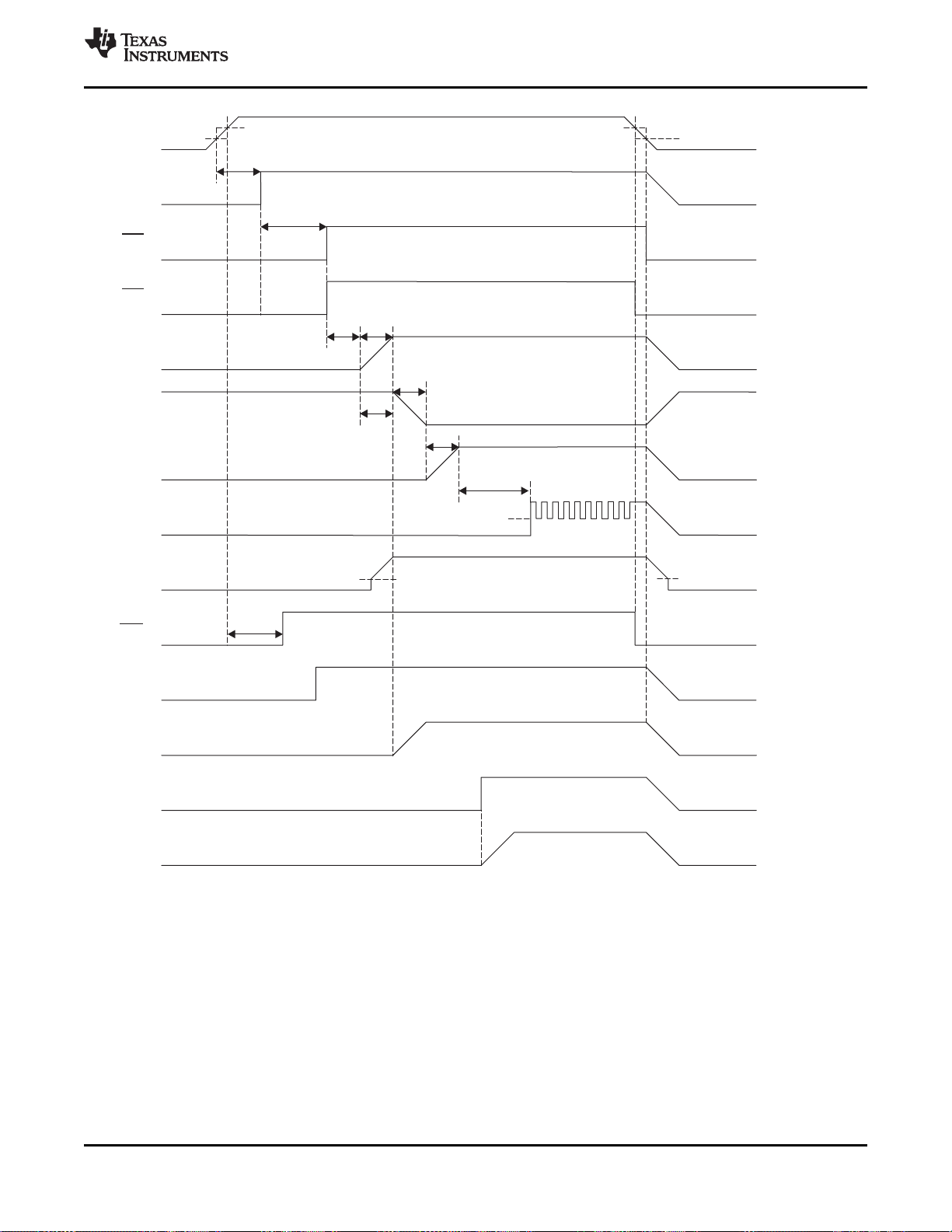

5.4.2 Power Sequencing

Figure 5-12 shows the typical power-up/down characteristic of the TPS65154.

5.4.2.1 Power-Up

www.ti.com

VCCstarts ramping t

RST is initially held low. t

AVDDstarts ramping t

VGLstarts ramping t

VGHstarts ramping as soon as VGLhas finished ramping.

V

is initially held low (connected to RE). t

GHM

shaping is enabled and V

XAO is initially held low. t

The WLED driver is enabled by the logical AND of AVDD(that is, AVDDhas finished ramping) and EN.

5.4.2.2 Power-Down

VCC, AVDD, VGHand VGLare disabled when VIN<V

XAO goes low when VINfalls below the threshold selected for it (V

RST goes low when VINfalls below the threshold selected for it (V

The WLED driver is turned off when EN = 0 or VIN< V

seconds after VIN> V

DLY1

seconds after VCChas finished ramping RST goes high.

RST

seconds after RST has gone high.

DLY2

seconds after AVDDstarts ramping.

DLY3

follows the state of FLK.

GHM

seconds after VIN>V

DLY6

UVLO

DLY4

.

seconds after VGHhas finished ramping, gate voltage

XAO goes high.

DET

.

UVLO

UVLO

or V

UVLO

or V

UVLO

.

DET

DET

).

).

24

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

V

IN

V

CC

t

DLY1

RST

t

DLY2

t

SS2

AV

DD

V

GL

V

GH

t

SS4

t

SS3

V

COM

t

DLY4

V >V

IN DET

AV >V

DD UVLO2

t

DLY3

V >V

IN DET

V >V

IN UVLO1

RST

RMODE=0

RMODE=1

t

RST

EN

V

LED

XAO

V >V

IN UVLO1

AV <V

DD UVLO2

V

GHM

t

DLY6

AV

DD

EN

V

LED

If EN goes high before AV , WLED

boost starts when AV finishes ramping

DD

DD

If EN goes high after AV , WLED

boost starts on rising edge of EN

DD

www.ti.com

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

Figure 5-12. Power Up/Down Sequencing

Detailed DescriptionCopyright © 2013–2016, Texas Instruments Incorporated

25

Submit Documentation Feedback

Product Folder Links: TPS65154

TPS65154

SLVSBG2A –SEPTEMBER 2013–REVISED JUNE 2016

5.5 Programming

5.5.1 Configuration

The TPS65154 divides the configuration parameters into two categories:

• Configuration parameters

• VCOM

In typical applications, all configuration parameters except VCOM are programmed by the subcontractor

during PCB assembly, and VCOM is programmed by the display manufacturer during display calibration.

5.5.1.1 General

Configuration parameters can be changed by writing the desired values to the appropriate RAM

register(s). The RAM registers are volatile and their contents are lost when power is removed from the

device. By writing to the Control Register, it is possible to store the active configuration in non-volatile

EEPROM; during power-up, the contents of the EEPROM are copied into the RAM registers and used to

configure the device.

5.5.1.1.1 I2C Interface

The TPS65154 features an industry-standard I2C interface that supports both Standard and Fast modes of

operation.

www.ti.com

5.5.1.1.2 Slave Addresses

The configuration parameters are all accessed using slave address 74h and the VCOM is accessed using

slave address 28h.

5.5.1.1.3 Write Protect

An active-high Write Protect pin (WP) prevents the configuration parameters from being changed by

accident. This pin is internally pulled high and must be actively pulled low to access to the EEPROM or

RAM registers. Note that the WP pin disables all I2C traffic to the TPS65154, and must also be pulled low

during read operations. This is to ensure that noise present on the I2C lines does not erroneously

overwrite the active configuration stored in RAM (which would not be protected by a simple EEPROM

write-protect scheme). The write protect function can be enabled and disabled using the WPEN bit in the

CONFIG register. Note that once the write protect function is enabled it is not possible to disable again it

without pulling the WP pin low. For this reason, it is strongly recommended that applications include some

way to pull the WP pin low (for example, a test pad), even if it is not normally used.

26

Detailed Description Copyright © 2013–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: TPS65154

Loading...

Loading...