www.ti.com

VIN

DRVN

FBN

REF

COMP

DLY1

DLY2

FDLY

SW SW

SUP

DRVP

GD

CPI

FBP

GND

PGND

PGND

VCOM

TPS65150

ADJ

CTRL

VGH

FB

IN

Vin

5 V

R8

500 k

C6

1 nF

R7

500 k

L1

3.9 H

D1

C1

22 F

C7

0.33 FD2

R3

620 k

D3

C3

0.33 F

R4

150 k

C8

220 nF

VGH

Control Signal

C9

2.2 nF

C10

22 pF

C11

10 nF

C12

10 nF

C13

100 nF

CPI

C16

0.33 F

D4

C5

1 F

C4

0.33 F

VGH

23 V/20 mA

V

COM

Output

C14

1 F

C15

22 pF

R1

820 k

R2

75 k

C2

22 F

R6

56 k

R5

1 M

CPI

V

S

13.5 V/450 mA

D5

VGL

−5 V/20 mA

V

IN

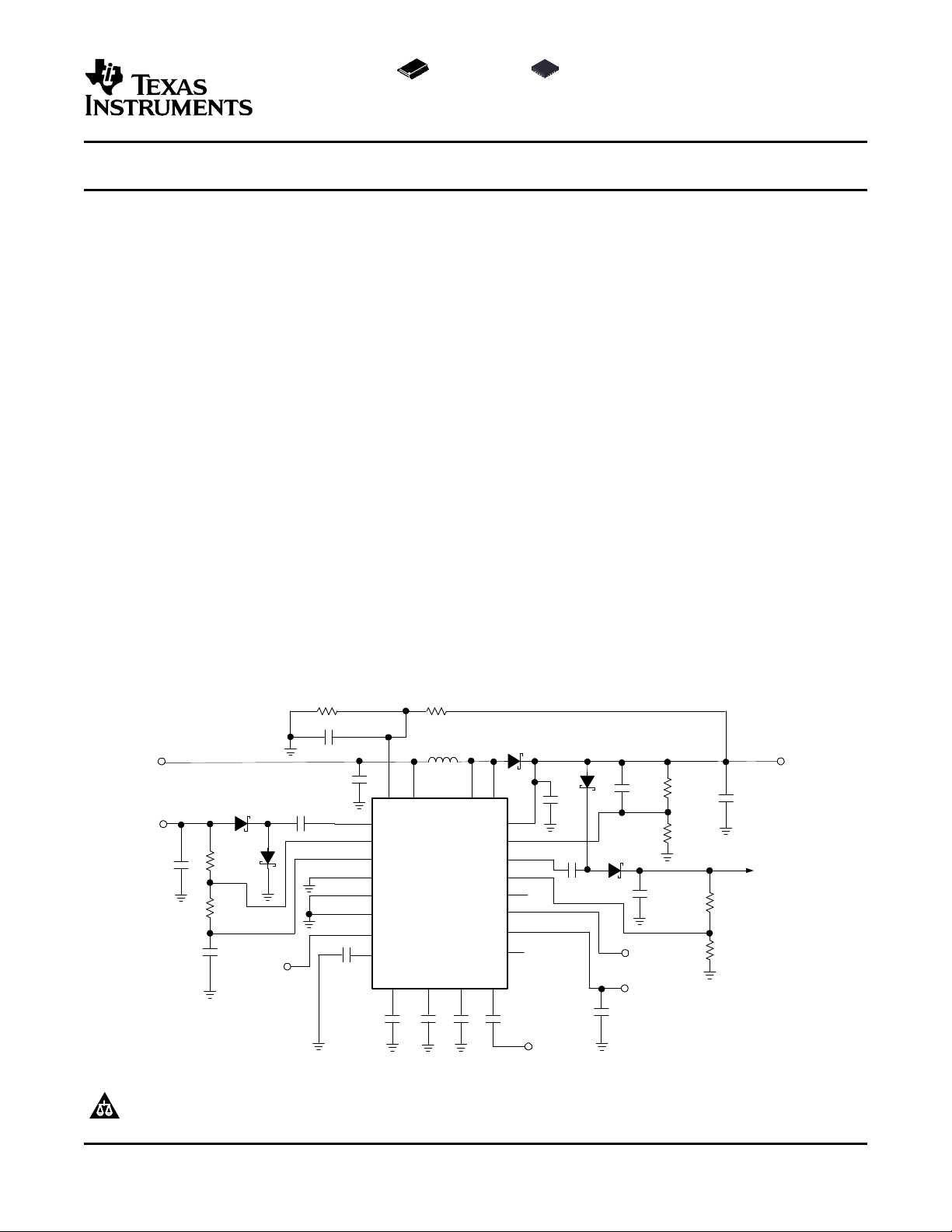

Low Input Voltage, Compact LCD Bias IC With VCOM Buffer

FEATURES APPLICATIONS

• 1.8-V to 6-V Input Voltage Range

• Integrated VCOM Buffer

• High Voltage Switch to Isolate VGH

• Gate Voltage Shaping of VGH

• 2-A Internal MOSFET Switch

• Main Output Vs up to 15 V With <1% Output

Voltage Accuracy

• Virtual Synchronous Converter Technology

• Negative Regulated Charge Pump Driver VGL

• Positive Regulated Charge Pump Driver VGH

• Adjustable Power On Sequencing

• Adjustable Fault Detection Timing

• Gate Drive Signal for external isolation

MOSFET

• Thermal Shutdown

• Available in TSSOP-24 Package

• Available in QFN-24 Package

TPS65150

SLVS576 – SEPTEMBER 2005

• TFT LCD Displays for Notebooks

• TFT LCD Display for Monitor

• Car Navigation Display

DESCRIPTION

The TPS65150 offers a very compact and small

power supply solution that provides all three voltages

required by thin film transistor (TFT) LCD displays.

With an input voltage range of 1.8 V to 6.0 V the

device is ideal for notebooks powered by a 2.5-V or

3.3-V input rail or monitor applications with a 5-V input voltage rail. Additionally the TPS65150 provides an integrated high current buffer to provide the VCOM voltage for the TFT backplane.

Two regulated adjustable charge pump driver provide

the positive VGH and negative VGL bias voltages for

the TFT. The device incorporates adjustable power

on sequencing for VGL as well as for VGH. This

avoids any additional external components to

implement application specific sequencing. The

device has an integrated high voltage switch to

isolate VGH.

TYPICAL APPLICATION

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPad is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2005, Texas Instruments Incorporated

www.ti.com

TPS65150

SLVS576 – SEPTEMBER 2005

These devices have limited built-in ESD protection. The leads should be shorted together or the device

placed in conductive foam during storage or handling to prevent electrostatic damage to the MOS gates.

DESCRIPTION (CONTINUED)

The same internal circuit can also be used to provide a gate shaping signal of VGH for the LCD panel controlled

by the signal applied to the CTRL input. For highest safety the TPS65150 has an integrated adjustable shutdown

latch feature to allow application specific flexibility. The device monitors the outputs (Vs, VGL, VGH); and, as

soon as one of the outputs falls below its power good threshold, the device enters shutdown latch, after its

adjustable delay time has passed by.

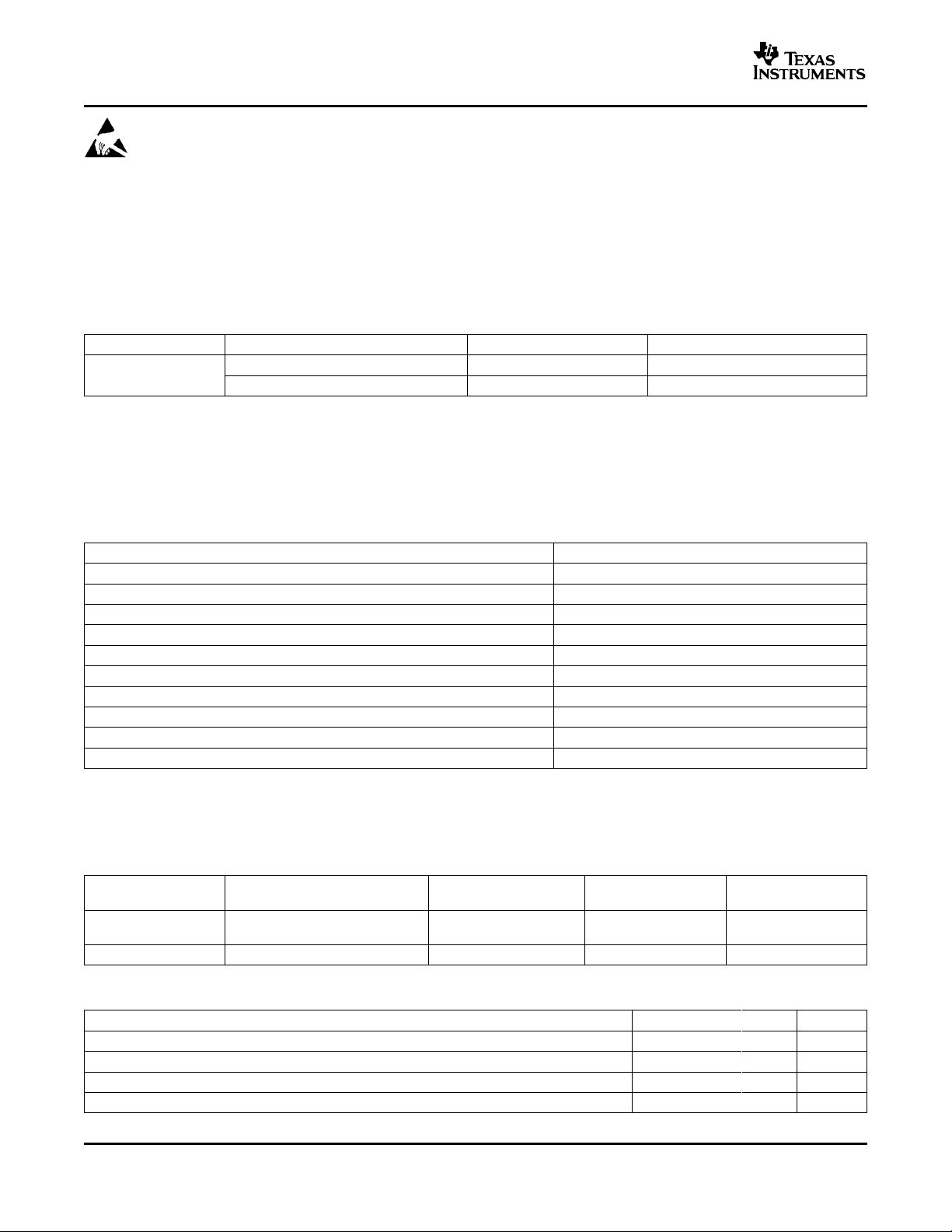

ORDERING INFORMATION

T

A

–40 ° C to 85 ° C

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com .

(2) The PWP package is available taped and reeled. Add R suffix to the device type (TPS65150PWPR) to order quantities of 2000 and

(TPS65150RGER) to order quantities of 3000 devices per reel. Without suffix the device is shipped in tubes.

ORDERING NUMBER PACKAGE

TPS65150PWP TSSOP24 (PWP) TPS65150

TPS65150RGE QFN-24 (RGE) TPS65150

(1)

(2)

PACKAGE MARKING

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

Voltages on pin VIN

Voltages on pin SUP –0.3 V to 15.5 V

Voltage on pin SW 20 V

Voltage on CTRL –0.3 V to 7 V

Voltage on GD 15.5 V

Voltage on CPI 32V

Continuous power dissipation See Dissipation Rating Table

Operating junction temperature range –40 ° C to 150 ° C

Storage temperature range –65 ° C to 150 ° C

Lead temperature (soldering, 10 sec) 260 ° C

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(2)

(1)

UNIT

–0.3 V to 7 V

DISSIPATION RATINGS

PACKAGE θ

24 pin TSSOP 30.13 C ° /W ( PowerPad™ 3.3 W 1.83 W 1.32 W

24 pin QFN 30 C ° /W (PowerPad

JA

soldered)

TM

soldered) 3.3 W 1.8 W 1.3 W

TA≤ 25 ° C TA= 70 ° C TA= 85 ° C

POWER RATING POWER RATING POWER RATING

RECOMMENDED OPERATING CONDITIONS

MIN TYP MAX UNIT

VIN Input voltage range 1.8 6.0 V

V

L Inductor

T

(1) Refer to application section for further information.

2

Output voltage range of the main boost converter V

S

A

(1)

Operating ambient temperature –40 85 ° C

S

15 V

4.7 µH

www.ti.com

TPS65150

SLVS576 – SEPTEMBER 2005

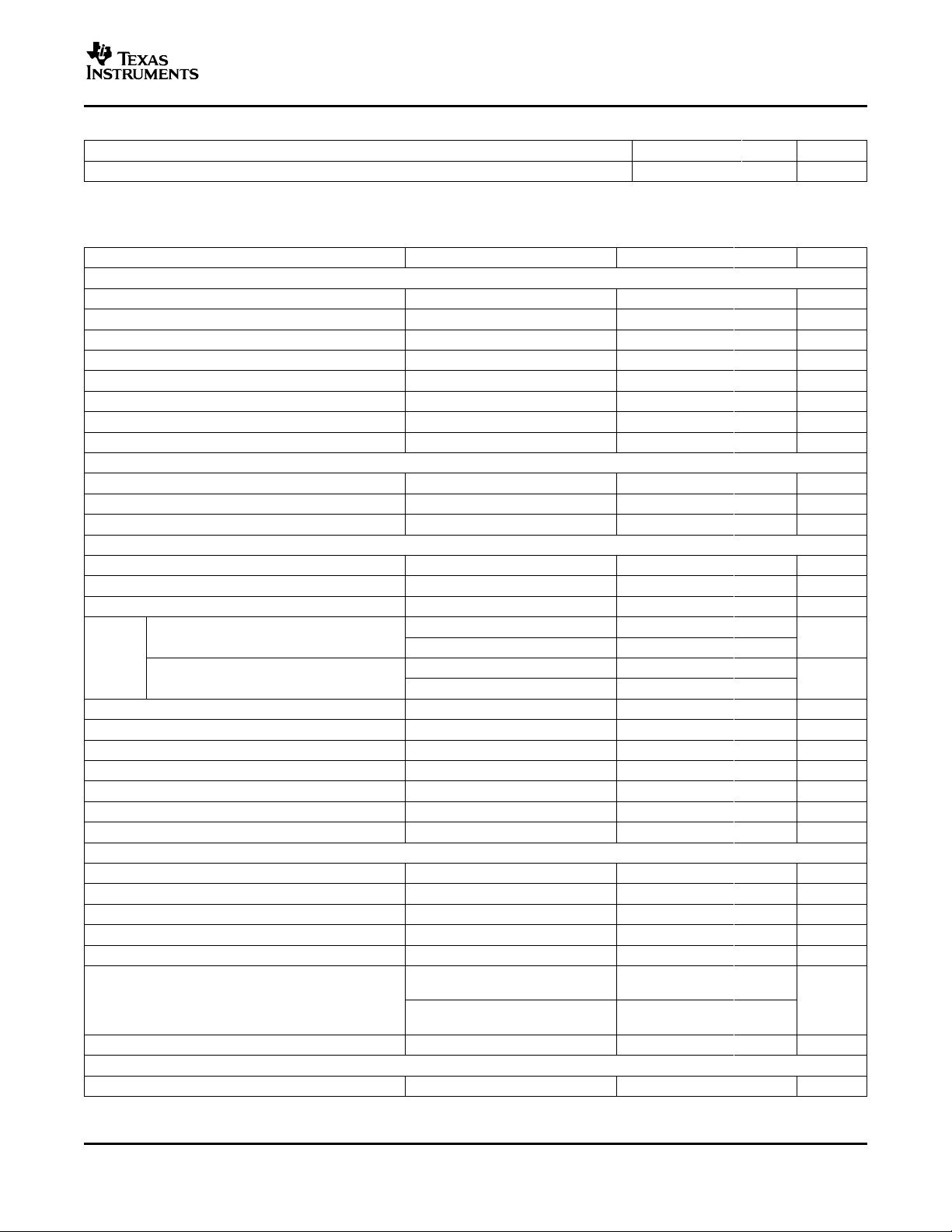

RECOMMENDED OPERATING CONDITIONS (continued)

MIN TYP MAX UNIT

T

ELECTRICAL CHARACTERISTICS

VIN = 3.3 V, Vs = 10 V, TA= –40 ° C to 85 ° C, typical values are at TA= 25 ° C (unless otherwise noted)

SUPPLY CURRENT

V

I

QVIN

I

QSUP

I

QVCOM

V

V

LOGIC SIGNALS CTRL

V

V

I

I

MAIN BOOST CONVERTER

V

V

I

FB

R

I

MAX

I

LIM

Ileak Switch leakage current V

Vovp Output overvoltage protection V

f

OSC

NEGATIVE CHARGE PUMP VGL

VGL Output voltage range –2 V

V

V

I

FB

R

V

POSITIVE CHARGE PUMP OUTPUT

V

Operating junction temperature –40 125 ° C

J

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

IN

Input voltage range 1.8 6.0 V

No load quiescent current into Vin Device is not switching 14 25 µA

No load quiescent current into SUP Device is not switching 1.9 3 mA

VCOM quiescent current into SUP 750 1500 µA

UVLO

hys

Undervoltage lockout threshold VINfalling 1.6 1.8 V

Undervoltage lockout threshold VINrising 1.7 1.9 V

Thermal shutdown Temperature rising 155 ° C

Thermal shutdown hysteresis 10 ° C

IH

IL

High level input voltage 1.6 V

Low level input voltage 0.4 V

Input leakage current CTRL=GND or VIN 0.01 0.2 µA

S

FB

Output voltage range 15 V

Feedback regulation voltage 1.136 1.146 1.154 V

Feedback input bias current 10 100 nA

N-MOSFET on-resistance (Q1) m Ω

DS(on)

P-MOSFET on-resistance (Q2) Ω

Vs = 10 V; Isw = 500 mA 200 300

Vs = 5 V; Isw = 500 mA 305 450

Vs = 10 V; Isw = 500 mA 8 15

Vs = 5 V; Isw = 500 mA 12 22

Maximum P-MOSFET peak switch current 1 A

N-MOSFET switch current limit (Q1) 2.0 2.5 3.4 A

= 15 V 1 10 µA

sw

rising 16 20 V

OUT

Oscilator frequency 1.02 1.2 1.38 MHz

Line regulation Vin=1.8V to 5.0V, Iload=1mA 0.007 %/V

Load regulation Vin=5V, Iload=0A to 400mA 0.16 %/A

REF

FB

Reference Voltage on pin REF 1.205 1.213 1.219 V

Feedback regulation voltage –36 0 36 mV

Feedback input bias current 10 100 nA

DS(on)

DropN

Q4 P-Channel switch RDSon I

Current sink voltage drop

(1)

= 20 mA 4.4 Ω

OUT

I

= 50 mA, 130 300

DRN

V

= V

FBN

FBNNominal

I

= 100 mA, 280 450

DRN

V

= V

FBN

FBNNominal

– 5%

– 5%

Load regulation VGL=-5V, Iload=0mA to 20mA 0.016 %/mA

CPO

Output voltage range CTRL = GND, VGH = open 30 V

mV

(1) The maximum charge pump output current is half the drive current of the internal current source or sink.

3

www.ti.com

TPS65150

SLVS576 – SEPTEMBER 2005

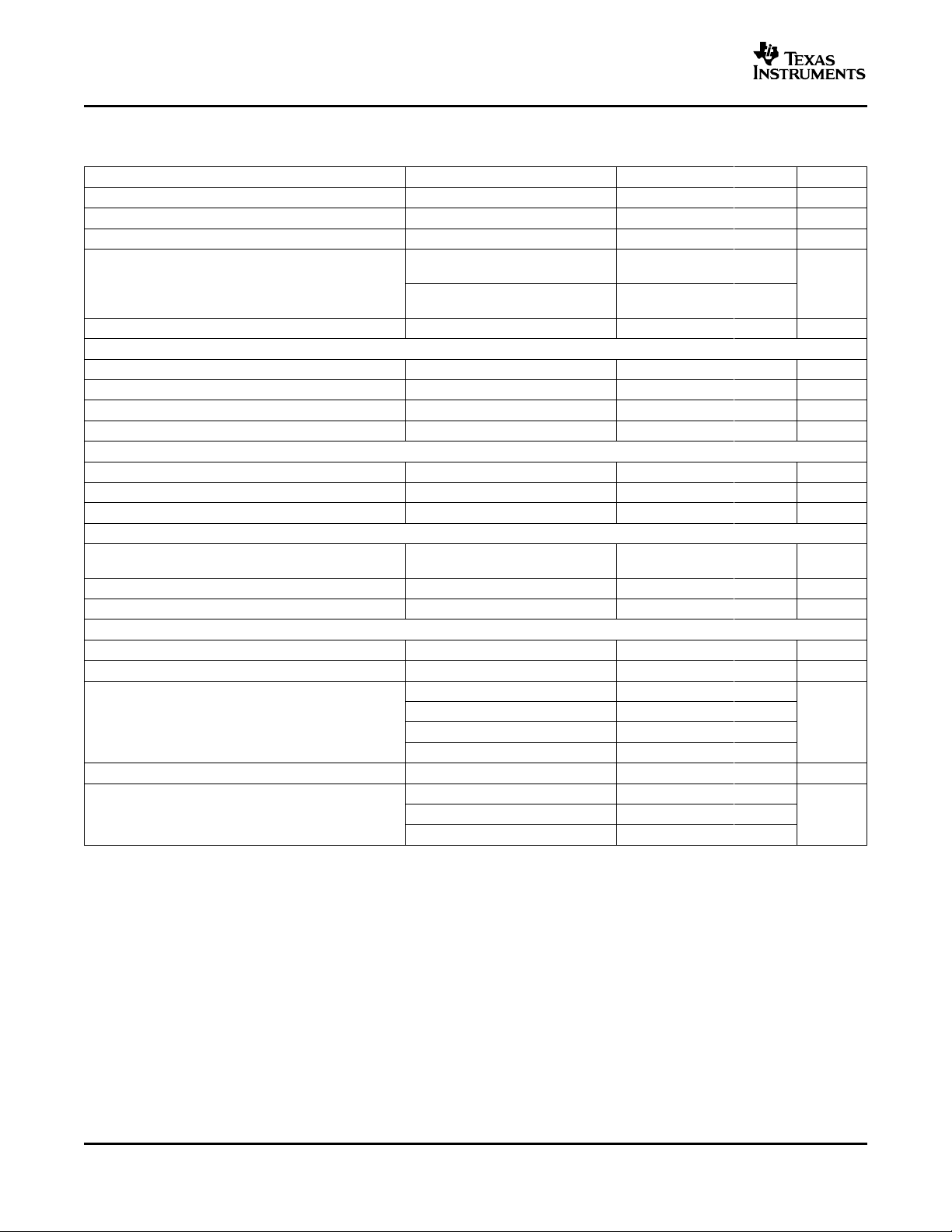

ELECTRICAL CHARACTERISTICS (continued)

VIN = 3.3 V, Vs = 10 V, TA= –40 ° C to 85 ° C, typical values are at TA= 25 ° C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

FB

I

FB

R

DS(on)

V

DropN

VGH ISOLATION SWITCH, GATE VOLTAGE FALL TIME CONTROL

R

DS(on)

Iadj Capacitor charge current Vadj = 20 V, CPI = 30 V 160 200 240 µA

I

VGH

TIMING CIRCUITS DLY1, DLY2, FDLY

I

DLY1

I

DLY2

R

FDLY

GATE DRIVE (GD)

V

(GD, Vs)

V

OL

I

LKG

Vcom Buffer

V

CM

V

os

I

B

I

peak

Feedback regulation voltage CTRL = GND, VGH = open 1.187 1.214 1.238 V

Feedback input bias current CTRL = GND, VGH = open 10 100 nA

Q3 P-Channel switch RDSon I

Current sink voltage drop

(1)

= 20 mA 1.1 Ω

OUT

I

= 50 mA, 420 650

DRP

V

= V

FBP

FBPNominal

I

= 100 mA, 900 1400

DRP

V

= V

FBP

FBPNominal

– 5%

– 5%

Load regulation VGH=24V, Iload=0mA to 20mA 0.07 %/mA

Q5 - Pass MOSFET R

DSon

Minimum output voltage Vadj = 0 V, I

I

= 20 mA 12 30 Ω

OUT

= 10 mA 2 V

VGH

Maximum output current 20 mA

Drive current into delay capacitor DLY1 V

Drive current into delay capacitor DLY1 V

Fault time delay resistror

Gate drive threshold

(2)

(3)

= 1.213 V 3 5 7 µA

DLY1

= 1.213 V 3 5 7 µA

DLY2

250 450 650 k Ω

Vs rising –12% of –4% of V

Vs Vs

Gate drive output low voltage I

Gate drive output leakage current V

= 500 µA 0.5 V

(sink)

= 15 V 0.001 1 µA

GD

Common mode input range 2.25 (Vs) –2V V

Input offset voltage I

= 0 mA –25 25 mV

OUT

Io = ± 25 mA –37 37

DC load regulation mV

Io = ± 50 mA –77 55

Io = ± 100 mA –85 85

Io = ± 150 mA –110 110

VCOMIN Input bias current –300 –30 300 nA

Peak output current Vs = 15 V 1.2

Vs = 10 V 0.65 A

Vs = 5 V 0.15

mV

(2) The fault time is calculated as: tF= C × R = C × 450 k Ω

(3) The GD signal is latched low when the main boost converter output Vs is within regulation. The GD signal is reset when the input

voltage or enable of the boost converter is cycled low.

4

www.ti.com

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

FB

DLY1

DLY2

VIN

SW

SW

PGND

PGND

SUP

VCOM

IN

FBP

FDLY

GD

COMP

FBN

REF

GND

DRVN

DRVP

CPI

VGH

ADJ

CTRL

Thermal PowerPAD*

1

2

3

4

5

6

18

17

16

15

14

13

7 8 9 10 11 12

19

20212223

24

Exposed

Thermal Die*

COMP

GD

FDLY

FB

DLY1

DLY2

VINSWSW

PGND

PGND

SUP

VGH

ADJ

CTRL

FBP

IN

VCOM

FBN

REF

GND

DRVN

DRVP

CPI

TPS65150

SLVS576 – SEPTEMBER 2005

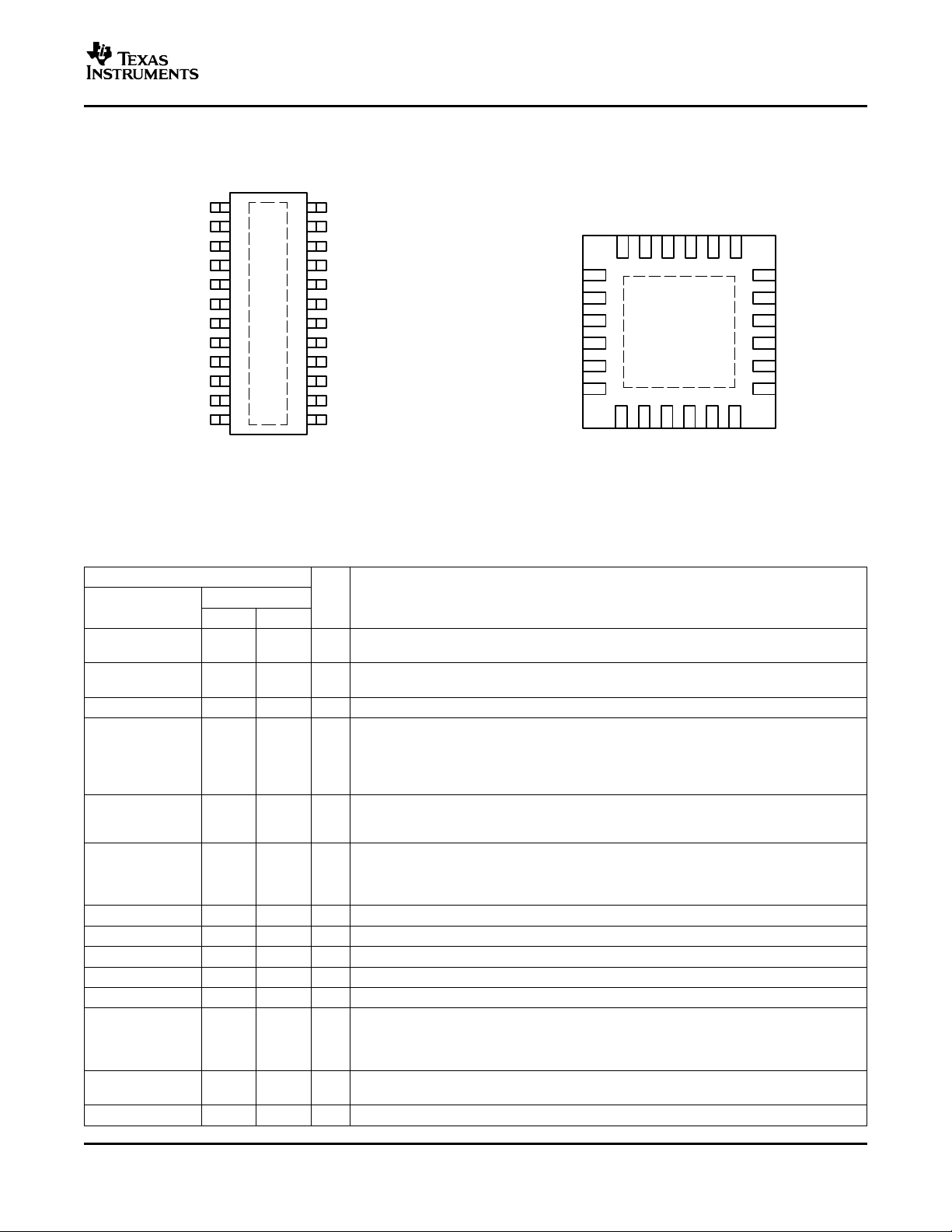

PIN ASSIGNMENT

* The thermal die (PowerPAD

TSSOP-24 Package

Top View

TM

) is connected to GND.

QFN-24 Package

Top View

TERMINAL FUNCTIONS

TERMINAL

NAME

ADJ 17 14 I/O

COMP 1 22 O

CPI 19 16 I Input of the VGH isolation switch and gate voltage shaping circuit.

CTRL 16 13 I function is not required, this pin needs to be connected to VIN. By doing this, the internal

DLY1 5 2 I/O delay time between the boost converter output Vs and the negative charge pump VGL

DLY2 6 3 I/O

DRVN 21 18 I/O Charge pump driver to generate the negative voltage VGL.

DRVP 20 17 I/O Charge pump driver to generate the positive output voltage VGH.

FB 4 1 I Feedback of the main boost converter generating Vsource (Vs).

FBN 24 21 I Feedback pin of the negative charge pump VGL.

FBP 15 12 I Feedback pin of the positive charge pump.

FDLY 3 24 I/O

GD 2 23 I

GND 22 19 Analog ground

NO. I/O DESCRIPTION

QFN TSSOP

Gate voltage shaping circuit. Connecting a capacitor to this pin sets the fall time of the

positive gate voltage (VGH).

This is the compensation pin for the main boost converter. A small capacitor and if required

a series resistor is connected to this pin.

Control signal for the gate voltage shaping signal. Apply the control signal for the gate

voltage control. Usually the timing controller of the LCD panel generates this signal. If this

switch between CPI and VGH provides isolation for the positive charge pump output VGH.

DLY2 sets the delay time for VGH to come up.

Power-on sequencing adjust. Connecting a capacitor from this pin to GND allows to set the

during startup.

Power-on sequencing adjust. Connecting a capacitor from this pin to GND allows to set the

delay time between the negative charge pump VGL and the positive charge pump during

startup. Note that Q5 in the Gate Voltage Shaping block only turns on when the positive

charge pump (FBP) is within regulation. (This provides input to output isolation of VGH).

Fault delay. Connecting a capacitor from this pin to Vin allows to set the delay time from

the point when one of the outputs (VS, VGH, VGL) drops below its power good threshold

until the devices enters the shutdown latch. To re-start the device the input voltage has to

be cycled to GND. This feature can be disabled by connecting the FDLY pin to Vin.

Active low open drain output. This output is latched low when the boost converter Vs is in

regulation. This signal can be used to drive an external MOSFET to provide isolation for Vs.

5

www.ti.com

TPS65150

SLVS576 – SEPTEMBER 2005

TERMINAL FUNCTIONS (continued)

TERMINAL

NAME

IN 14 11 I Input of the Vcom buffer. If this pin is connected to GND, the Vcom buffer is disabled.

PGND 10, 11 7, 8 Power ground

REF 23 20 O Internal reference output typically 1.213 V

SUP 12 9 I/O This pin needs to be connected to the output of the main boost converter and can’t be

SW 8, 9 5, 6 I Switch pin of the boost converter

VGH 18 15 O

VIN 7 4 I This is the input voltage pin of the device.

VCOM 13 10 O VCOM buffer output. Typically a 1-µF output capacitor is required on this pin.

PowerPAD

exposed thermal NA NA The PowerPAD

die

TM

,

NO. I/O DESCRIPTION

QFN TSSOP

Supply pin of the positive, negative charge pump and Boost Converter Gate Drive Circuit.

connected to any other voltage rail.

Positive output voltage to drive the TFT gates with an adjustable falltime. This pin is

internally connected with a MOSFET switch to the positive charge pump input CPI.

TM

needs to be soldered to GND

6

www.ti.com

0 0.1 0.2 0.3 0.4 0.5 0.6

100

90

80

70

60

50

40

VS = 13.5 V ,

VGH = VGL = No Load, Switching

VIN = 2.5 V

VIN = 3.3 V

VIN = 5 V

Efficiency − %

IO − Load Current − A

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

100

90

80

70

60

50

40

VS = 10 V ,

VGH = VGL = No Load, Switching

VIN = 2.5 V

VIN = 3.3 V

VIN = 5 V

Efficiency − %

IO − Load Current − A

TPS65150

SLVS576 – SEPTEMBER 2005

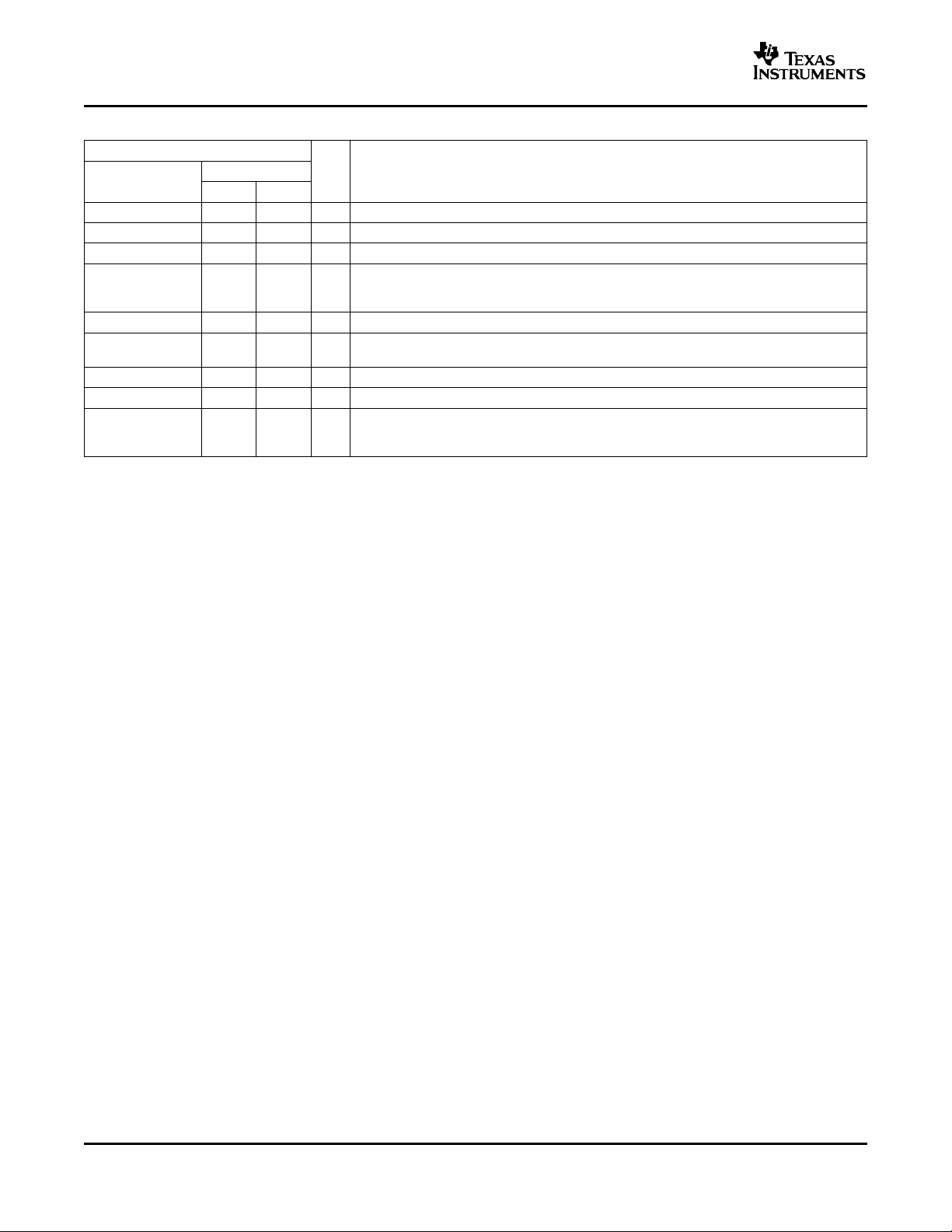

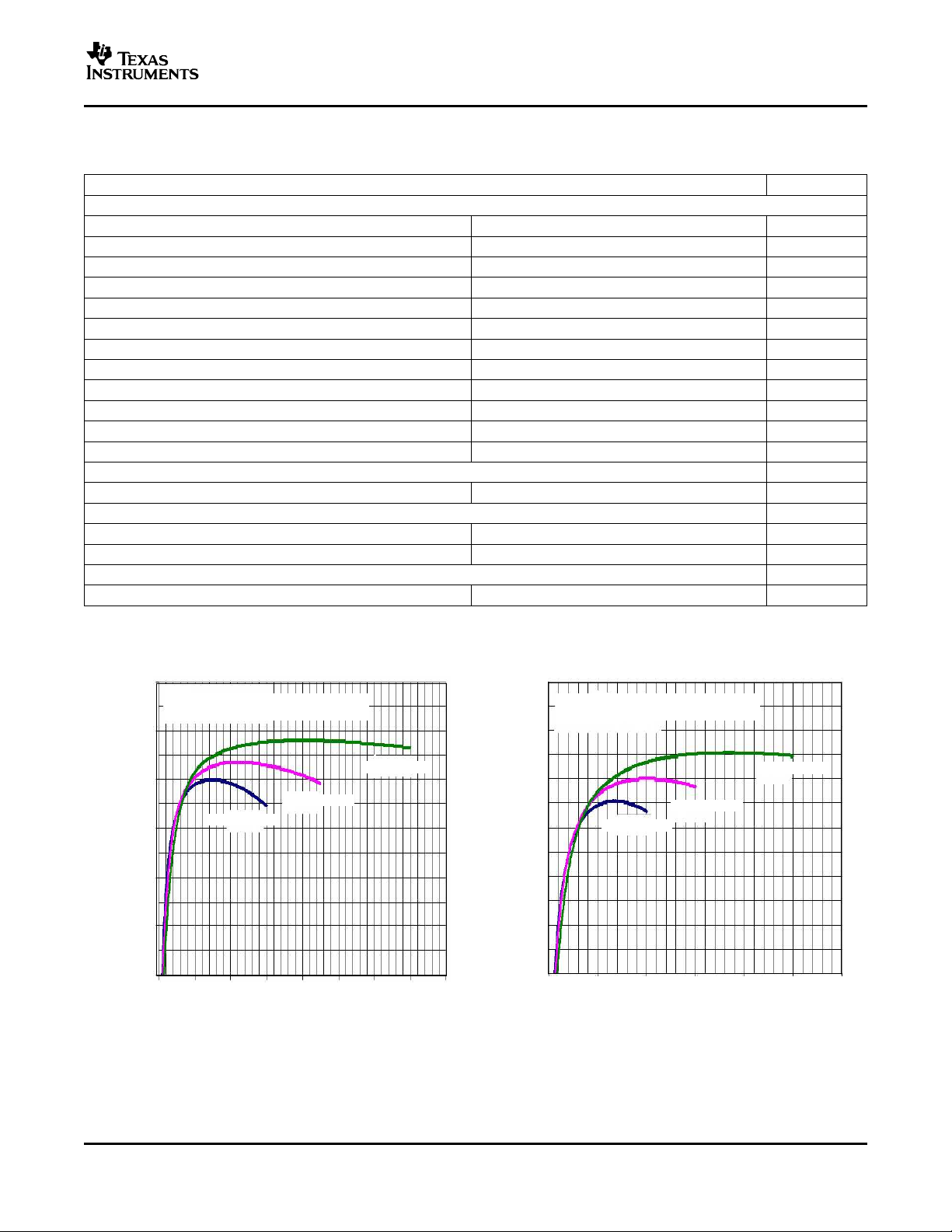

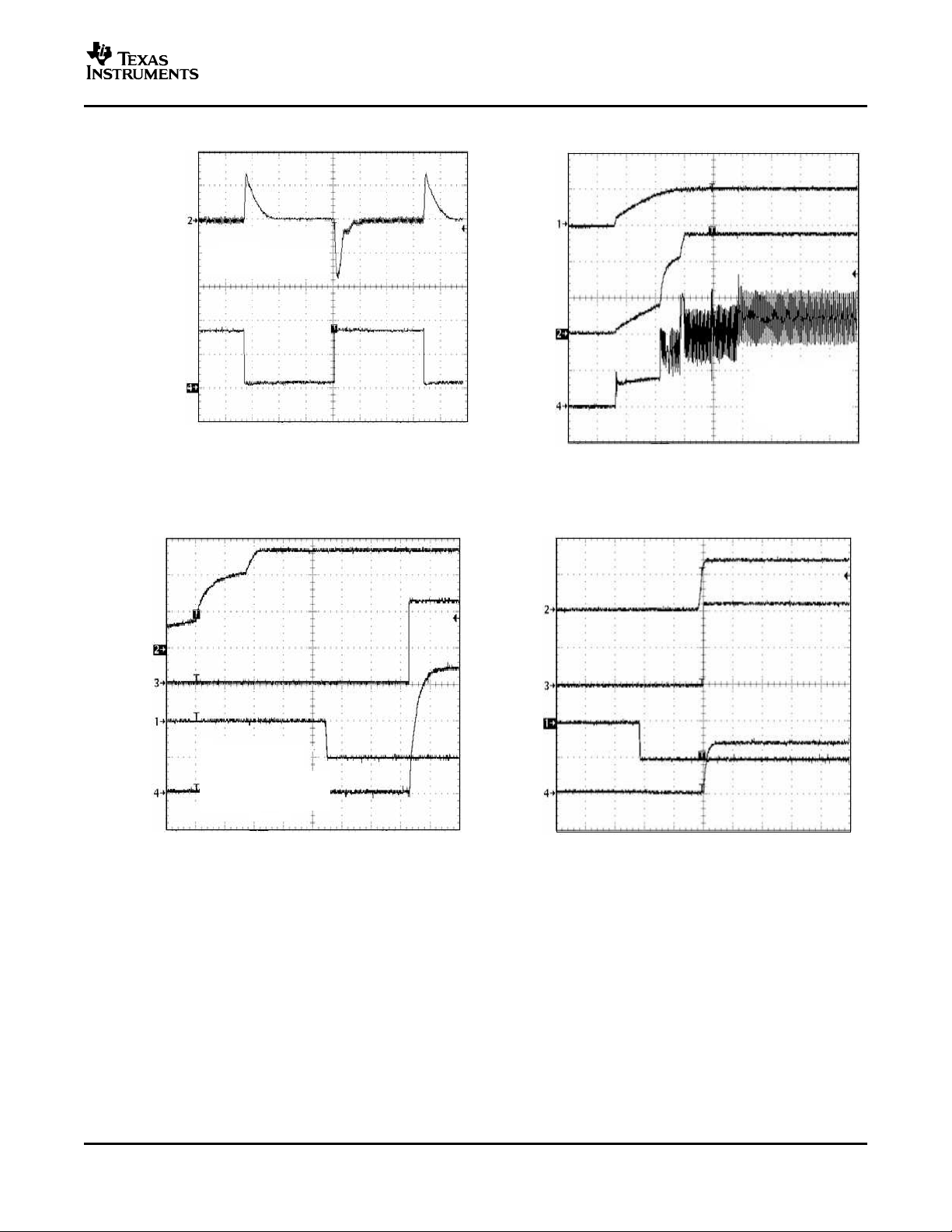

TYPICAL CHARACTERISTICS

TABLE OF GRAPHS

FIGURES

Main Boost Converter

η Efficiency vs Load current Vs=10 V 1

η Efficiency vs Load current Vs=13.5 V 2

η Efficiency vs Load current Vs=15 V 3

f

SW

Negative Charge Pump Driver

V

GL

Positive Charge Pump Driver

V

GH

V

GH

VCOM Buffer

Switching frequency vs Input voltage and temperature 4

PWM operation at nominal load current 5

PWM operation at light load current 6

Load transient response 7

Softstart boost converter 8

Power-on sequencing 9

Power-on sequencing External MOSFET in series to Vs 10

Gate voltage shaping of V

GH

Adjustable Fault detection 12

V

GL

V

GH

V

GH

vs load current 13

vs load current; Charge pump doubler stage 14

vs load current; Charge pump tripler stage 15

VCOM Buffer transconductance 16

11

EFFICIENCY EFFICIENCY

vs vs

LOAD CURRENT LOAD CURRENT

Figure 1. Figure 2.

7

www.ti.com

−40 −20 0 20 40 60 80 100 120

1.155

1.150

1.145

1.140

1.135

1.130

1.125

1.120

VS = 13.5 V

VIN = 7 V

VIN = 3.6 V

V

IN

= 1.8 V

f − Frequency − MHz

TA − Free-Air Temperature − C

0 0.05 0.1 0.15 0.2

100

90

80

70

60

50

40

Efficiency − %

IO − Load Current − A

0.25 0.3 0.35 0.4

VS = 15 V ,

VGH = VGL = No Load, Switching

VIN = 2.5 V

VIN = 3.3 V

VIN = 5 V

VIN = 5 V ,

VO = 13.5 V/300 mA

250 ns/div

V

SW

10 V/div

V

O

50 mV/div

I

L

1 A/div

V

SW

10 V/div

V

O

50 mV/div

I

L

1 A/div

VIN = 5 V

VO = 13.5 V/10 mA

250 ns/div

TPS65150

SLVS576 – SEPTEMBER 2005

EFFICIENCY SWITCHING FREQUENCY

vs vs

LOAD CURRENT TEMPERATURE

PWM OPERATION PWM OPERATION

NOMINAL LOAD CURRENT LIGHT LOAD CURRENT

Figure 3. Figure 4.

Figure 5. Figure 6.

8

www.ti.com

VO1

100 mV/div

I

O

30 mA to 330 mA

VIN = 3.3 V

VS = 10 V, CO = 22 F

100 s/div

V

IN

5 V/div

V

S

5 V/div

I

IN

500 mA/div

VIN = 5 V

VO = 13.5 V

I

out

= 200 mA

2.5 ms/div

V

S

5 V/div

VGH

10 V/div

VGL

5 V/div

VCOM

2 V/div

1 ms/div

VIN = 5 V

VO = 13.6 V/ 300 mA

VCOM CIN = 1 nF

V

S

5 V/div

VGH

10 V/div

VGL

5 V/div

VCOM

5 V/div

2.5 ms/div

LOAD TRANSIENT RESPONSE SOFT START BOOST CONVERTER

Figure 7. Figure 8.

TPS65150

SLVS576 – SEPTEMBER 2005

POWER-ON SEQUENCING POWER-ON SEQUENCING WITH

EXTERNAL ISOLATION MOSFET AT V

Figure 9. Figure 10.

S

9

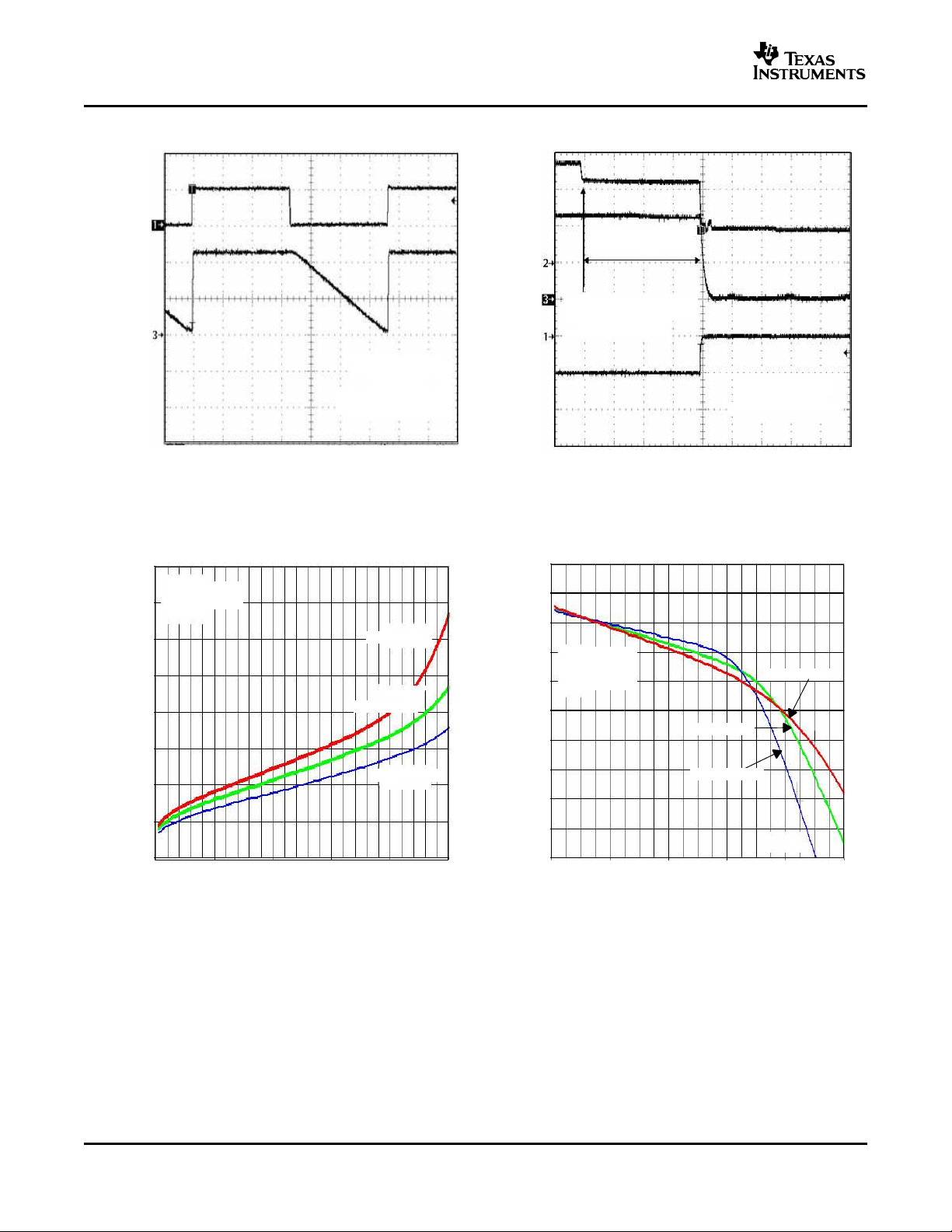

www.ti.com

V

S

5 V/div

VGH

10 V/div

VGL

5 V/div

Fault Delay Time

Fault

(Heavy Load at V

S

)

CFDLY = 100 nF

10 ms/div

CTRL

2 V/div

VGH

10 V/div

2.5 s/div

C

ADJ

= 68 pF

VGH = No Load

−4.86

−4.88

−4.90

−4.92

−4.94

−4.96

−4.98

−5.00

−5.02

0 0.02 0.04 0.06 0.08 0.1

VS = 10 V

VGL = –5 V

VGL − Gate Voltage Low − V

IO − Load Current − A

TA = 85C

TA = 25C

TA = −40C

25

24.50

24

23.50

23

22.50

22

21.50

21

20.50

20

0 0.02 0.04 0.06 0.08 0.1

VS = 15 V

VGH = 24 V

x2 Stage

TA = 85C

TA = 25C

TA = −40C

IO − Load Current − A

VGH − Gate Voltage High − V

TPS65150

SLVS576 – SEPTEMBER 2005

GATE VOLTAGE SHAPING V

GH

ADJUSTABLE FAULT DETECTION

Figure 11. Figure 12.

VGL– GATE VOLTAGE LOW V

vs vs

LOAD CURRENT LOAD CURRENT –X2 STAGE

– GATE VOLTAGE HIGH

GH

10

Figure 13. Figure 14.

www.ti.com

0 0.02 0.04 0.06 0.08 0.1

25

24.50

23.50

24

23

22.50

22

21.50

21

22.50

20

VS = 10 V

VGH = 24 V

x3 Stage

TA = 25C

TA = −40C

IO − Load Current − A

VGH − Gate Voltage High − V

TA = 85C

0.08

0.06

0.04

0.02

0

−0.02

−0.04

−0.06

−0.08

−150 −100 −50 0 50 100 150

VS = 10 V

V

VCOM

= 5 V

VCOM Buffer − V

IO − Load Current − A

TPS65150

SLVS576 – SEPTEMBER 2005

VGH– GATE VOLTAGE HIGH VCOM BUFFER dV

vs vs

LOAD CURRENT – X3 STAGE LOAD CURRENT

Figure 15. Figure 16.

OUT

11

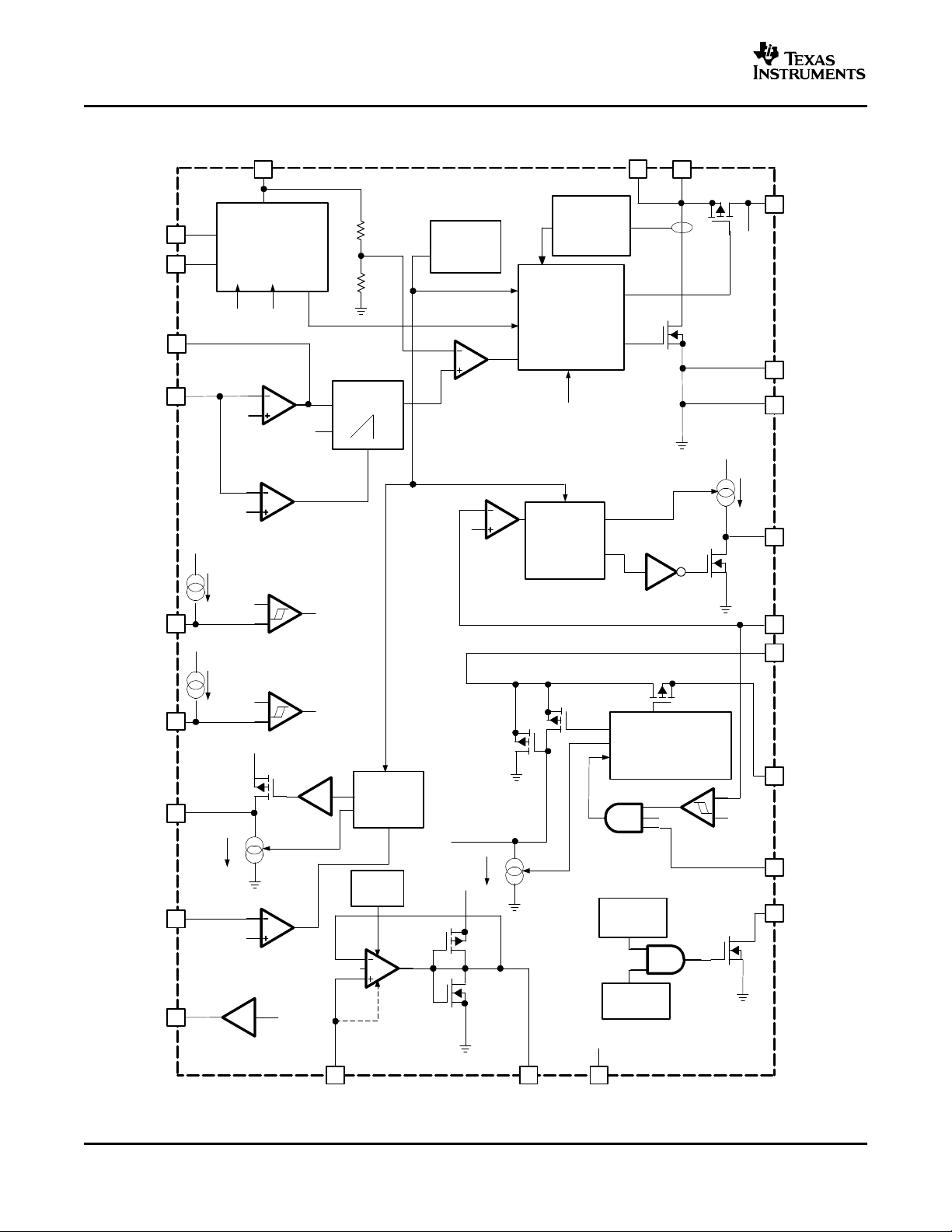

www.ti.com

Current

Control

Soft Start

1.2 MHz

Oscillator

VFB

1.154V

Comparator

GM Amplifier

Sawtooth

Generator

VFB

1.154

SUP

SUP

DRVP

FBP

Vref

1.213V

Vref

1.213V

Bias Vref=1.213V

Logic Control Block

Shutdown Latch Timer

Thermal Shutdown

DLY1

CTRL

ADJ

REF

FBN

DRVN

COMP

FB

VIN

SW SW

FDLY

VCOM

GND

Q1

Q3

Q4

SUP

Reference

Output

Negative

Charge Pump

Positive

Charge Pump

Main boost

converter

Vref

1.213V

Current

Control

Softstart

SUP

(Vout)

GM Amplifier

Low Gain

Current Limit

and

Soft Start

Control

Logic

Gate Drive circuit

Q2

SUP

I

DLY1

Vin

Vref

DL1

Delay Between

Vs and VGL

Gate Voltage

Control Circuit

IN

Q5

I

ADJ

Q6

Vref

1.213V

UVLO

CPI

Q7

Control

CTRL,EN,FBP=high

Q11=Q13=on, Q12=off

CTRL=low

Q11=Q13off, Q12=on

I

DRVP

I

DRVN

I

DLY2

Vin

Vref

Delay Between

VGL and VGH

DLY2

PGND

PGND

DL2

DL1 DL2

SUP

Soft Start

Q11

Q12

VCOM

Buffer

Disable

Main Boost

Soft Start

Completed

Main Boost

Power Good

GD

VGH

ADJ

Gate Drive

SUP

ADJ

TPS65150

SLVS576 – SEPTEMBER 2005

FUNCTIONAL BLOCK DIAGRAM

12

www.ti.com

TPS65150

SLVS576 – SEPTEMBER 2005

DETAILED DESCRIPTION

Main Boost Converter

The main boost converter operates with pulse width modulation (PWM) and a fixed switching frequency of 1.2

MHz. The converter uses an unique fast response, voltage mode controller scheme with input voltage

feedforward. This achieves excellent line and load regulation (0.16%/A load regulation typical) and allows the use

of small external components. To add higher flexibility to the selection of external component values the device

uses external loop compensation. Although the boost converter looks like a non-synchronous boost converter

topology operating in discontinuous conduction mode at light load current the TPS65150 maintains continuous

conduction even at light load currents. This is achieved by using the Virtual Synchronous Converter Technology

having an external Schottky diode with an integrated MOSFET in parallel connected between SW pin and the

SUP pin. See Functional Block Diagram. The intention of this MOSFET is to allow the current to go below ground

which is the case at light load conditions. For this purpose a small integrated P-Channel MOSFET, with typically

10- Ω R

voltage conducts the current. This causes the converter to operate with a fixed frequency in continuous

conduction mode over the entire load current range. This avoids the ringing on the switch pin as seen with

standard non-synchronous boost converter and allows a simpler compensation for the boost converter.

Soft Start

The main boost converter as well as the charge pump driver have an internal soft-start circuit. This avoids heavy

voltage drops at the input voltage rail or at the output of the main boost converter Vs during startup caused by

high inrush currents. As the main boost converter starts up the internal current limit threshold is increased in

three steps. The device starts with the first step where the current limit is set to 2/5 of the typical current limit (2/5

of 2.3 A) for 2048 clock cycles then increased to 3/5 of the current limit for 2048 clock cycles and the 3

the full current limit. This gives a typical start-up time around 5 ms.

, is sufficient. When the inductor current is positive the external Schottky diode with the lower forward

DS(on)

rd

step is

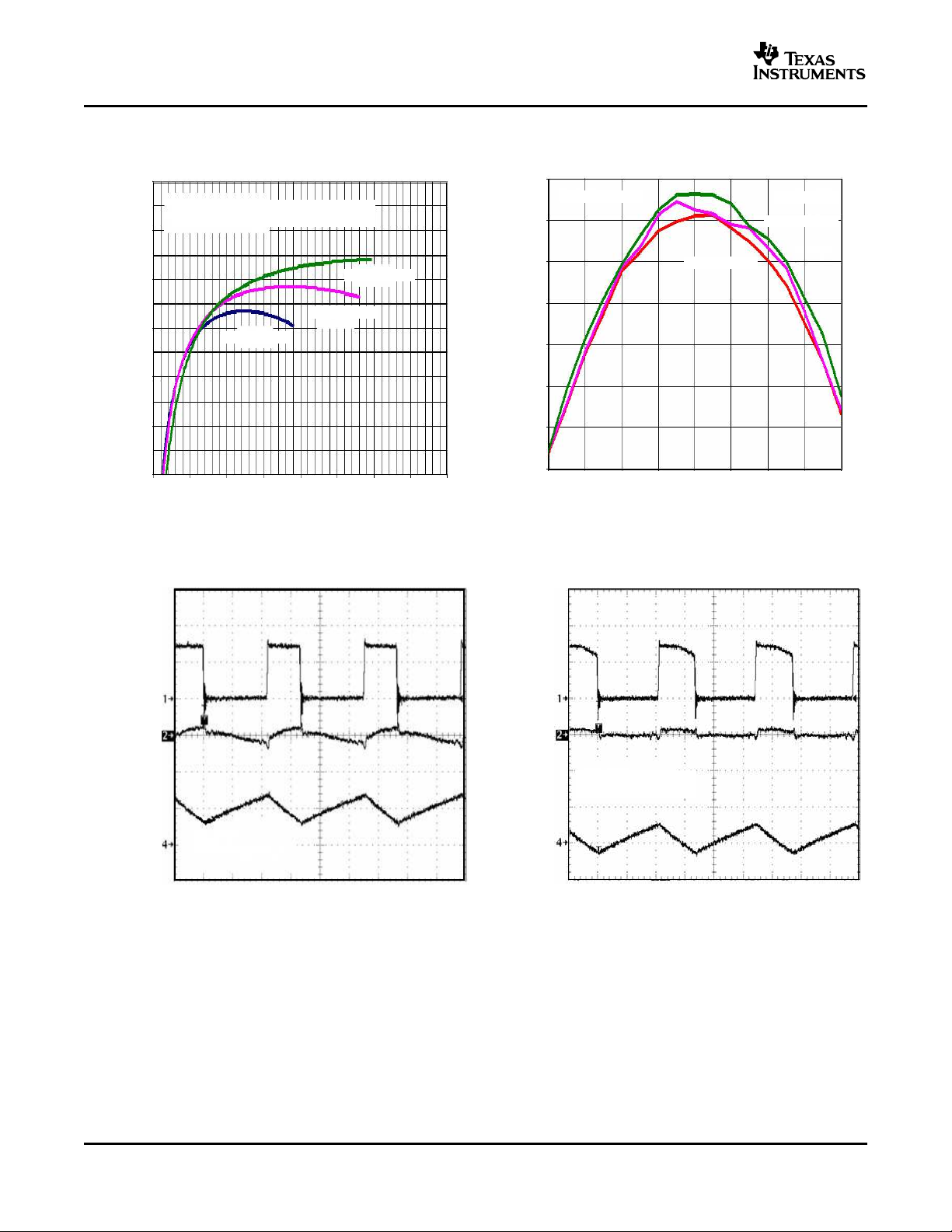

Adjustable Fault Delay

The TPS65150 has an adjustable delay timer integrated shutting down the entire device in case of a fault at the

outputs. The fault timer is also active during startup. Connecting a capacitor from the FDLY pin to Vin sets the

delay time, from the point where one of the outputs (VS, VGH, VGL) drops below its power good threshold, until

the device enters the shutdown latch. Since the fault delay timer is also active during startup, the device enters

shutdown when the output voltage of the main boost converter, Vs, does not reach its power-good threshold after

the fault delay time has passed. When an external isolation switch is used, shown in Figure 24, then the device

provides short circuit protection even during start-up. To restart the device, the input voltage has to be cycled to

GND. The shutdown function can be disabled by connecting FDLY to VIN. The fault delay time is calculated as:

tF= C × R = C × 450 k Ω = 100 nF × 450 k Ω ≈ 40 ms

Positive Charge Pump

The positive charge pump provides a regulated output voltage, set by the external resistor divider. Figure 17

shows an extract of the positive charge pump driver circuit out of the block diagram. The operation of the charge

pump driver can be understood best by looking at Figure 17 . During the first cycle Q3 is turned on and the flying

capacitor, Cfly, is charged to the source voltage, Vs. During the next clock cycle Q3 is turned off, and the current

source charges the drive pin, DRVP, up to the supply voltage, VSUP. Since the flying capacitor voltage sits on

top of the drive pin voltage the maximum output voltage is VGH=Vsup + Vs - Vdrop. Vdrop is the voltage drop

across the external diodes and internal charge pump MOSFETs.

13

www.ti.com

Q3

I

DRVP

DRVP

Current

Control

Soft Start

FBP

Cfly

Vs

R5

R6

C13

0.47 F

VGH

23 V/50 mA

SUP = VIN for V

S

> = 15 V

SUP = VS for V

S

< = 15 V

V

out

1.2131

R5

R6

R5 R6

V

out

V

FB

1 R6

V

out

1.213

1

V

out

V

REF

R3

R4

1.213 V

R3

R4

R3 R4

V

out

V

REF

R4

V

out

1.213

TPS65150

SLVS576 – SEPTEMBER 2005

DETAILED DESCRIPTION (continued)

Figure 17. Extract of the Positive Charge Pump Driver

If higher output voltages are required another charge pump stage can be added to the output, as shown in Figure

21 at the end of the data sheet. To minimize quiescent current a high impedance feedback divider should be

used. The top feedback resistor should not be selected larger than 1M Ω .

Setting the output voltage:

Negative Charge Pump

The negative charge pump provides a regulated output voltage set by the external resistor divider. The negative

charge pump operates very similar to the positive charge pump with the difference that the voltage on the supply

pin SUP is inverted. The maximum output voltage for a single stage charge pump inverter is VGL = (–VSUP) +

Vdrop. Vdrop is the voltage drop across the external diodes and internal charge pump MOSFETs.

Setting the output voltage:

The lower feedback resistor value, R4, should range between 40 k Ω to 120 k Ω ; or, the overall feedback

resistance should be within 500 k Ω to 1 M Ω . Smaller values load the reference too heavily; and larger values

may cause stability problems. The negative charge pump requires two external Schottky diodes. The peak

current rating of the Schottky diode has to be twice the load current of the output. For a 20-mA output current,

the BAT54 dual Schottky diode is a good choice.

(1)

(2)

14

www.ti.com

VGL

DLY1

VGH, with CTRL=high

DLY2

VIN

GD

Vs

Fall Time of VS, VGL and

VGH Depends on Load

Current and Feedback

Resistor Impedance

C

dly

5 A td

V

REF

5 A td

1.213 V

with td Desired delay time

TPS65150

SLVS576 – SEPTEMBER 2005

DETAILED DESCRIPTION (continued)

Power-on Sequencing, DLY1, DLY2

As soon as the input voltage is applied, and rises above the undervoltage lockout (UVLO), the device starts with

the main boost converter, Vs, coming up first. Then the negative voltage, VGL, comes up, set by the delay time

DLY1; and then the positive charge pump, VGH, set by the delay time DLY2. Finally, the VCOM buffer starts up.

The delay times, DLY1 and DLY2, are set by the capacitor value connected to these pins. An internal current

source charges the capacitor with a constant current of typically 5 µA until the voltage reaches the internal

comparator trip point of Vref = 1.213 V.

Figure 18. Power on Sequencing With CTRL = High

Setting the Delay Times DLY1, DLY2

Connecting an external capacitor to the DLY1 and DLY2 pins sets the delay time. If no delay time is required,

these pins can be left open. To set the delay time, the external capacitor connected to DLY1 and DLY2 is

charged with a constant current source of typically 5 µA . The delay time is terminated when the capacitor

voltage has reached the internal reference voltage of Vref = 1.213 V. The external delay capacitor is calculated:

Gate Drive, GD

The gate drive pin can be used to drive an external MOSFET, providing isolation for the main boost converter Vs.

The gate drive is an open drain output capable of sinking typically 500 µA. The gate drive is latched low as soon

as the main boost converter, Vs, reaches its power-good threshold. The gate drive signal goes high impedance

when the input voltage falls below the undervoltage lockout (UVLO) or the device enters shutdown latch triggered

by the fault delay.

VGH Switch / Gate Voltage Shaping, CPI – VGH

The gate voltage shaping circuit is used to reduce crosstalk between the LCD pixels by adjusting the fall time of

the positive gate voltage, VGH. The CTRL pin needs to be connected to Vin if the gate voltage shaping function

is not used. This function is implemented by adjusting the fall time of the gate voltage signal, VGH, generated by

the positive charge pump. The fall time can be adjusted with the external capacitor, Cadj connected to the ADJ

pin. The corresponding timing diagram is shown in Figure 20 .

(3)

15

www.ti.com

VGH

Q5

I

ADJ

Q6

Vref

1.213 V

CTRL

UVLO

ADJ

CPI

FBP

Cadj

47 pF

Q7

Control

CTRL, UVOL, FPB = High

Q5 = Q7 = ON, Q6 = OFF

CTRL = Low

Q5 = Q7 = OFF, Q6 = T urns ON

toff

VGH

VCPI

VL

ton

toffIadj x

Cadj

V

Control

Signal

(Pin CTRL)

V

Cadj

Iadj toff

V

with ladj 200 A

TPS65150

SLVS576 – SEPTEMBER 2005

DETAILED DESCRIPTION (continued)

Figure 19. Implementation of the Gate voltage shaping

Figure 20. Timing Diagram of the Gate voltage shaping

The control signal applied to CTRL sets the timing of VGH. When CTRL is high, Q5 is turned on and the positive

charge pump voltage applied on CPI is present on VGH. At the same time, the capacitor connected to ADJ is

charged up by Q7 to VGH, while Q6 is turned off. When CTRL is taken low, Q5 and Q7 turn off, and Q6 is slowly

turned on as the capacitor on ADJ is discharged by the discharge current I

value on C

desired voltage drop, ∆ V.

When the input voltage falls below the undervoltage threshold (UVLO) or the device enters shutdown latch

determines the fall time of VGH. For a given off time (toff), external capacitor Cadj determines the

ADJ

, typically 200 µA. The capacitor

ADJ

triggered by the fault delay timer, then VGH is disconnected from CPI by Q5 and is high impedance.

16

(4)

www.ti.com

1. Duty Cycle : D 1

Vin

Vout

2. Maximum output current : I

out

Isw

Vin D

2 ƒs L

(1 D)

3. Peak switch current : I

swpeak

Vin D

2 ƒs L

I

out

1 D

TPS65150

SLVS576 – SEPTEMBER 2005

DETAILED DESCRIPTION (continued)

Thermal Shutdown

A thermal shutdown is implemented to prevent damage because of excessive heat and power dissipation.

Typically, the thermal shutdown threshold is 155 ° C . When this threshold is reached, the device enters shutdown.

The device can be enabled again by cycling the input voltage to GND.

Vcom Buffer

The VCOM Buffer is a transconductance amplifier designed to drive capacitive loads. The IN pin is the input of

the VCOM buffer. If the VCOM buffer is not required for certain applications, it is possible to shut down the

VCOM buffer by connecting IN to ground, reducing the overall quiescent current. The VCOM buffer features a

soft start, avoiding a large voltage drop at Vs during startup. The VCOM buffer input, IN, cannot be pulled

dynamically to ground during operation.

Boost Converter Design Procedure

The first step in the design procedure is to verify whether the maximum possible output current of the boost

converter supports the specific application requirements. A simple approach is to estimate the converter

efficiency, by taking the efficiency numbers from the provided efficiency curves, or use a worst case assumption

for the expected efficiency, e.g. 75%.

(5)

With

Isw = Converter switch current (minimum switch current limit = 2.0 A)

fs = Converter switching frequency (typical 1.2 MHz)

L = Selected inductor value

η = Estimated converter efficiency (use the number from the efficiency plots, or 0.75 as an estimation)

The peak switch current is the steady-state peak switch current that the integrated switch, inductor, and external

Schottky diode has to be able to handle. The calculation must be done for the minimum input voltage where the

peak switch current is highest. For the calculation of the maximum current delivered by the boost converter it

needs to be considered that the positive and negative charge pumps as well as the VCOM buffer run from the

output of the boost converter as well.

Inductor Selection

Several inductors work with the TPS65150. Especially with external compensation, the performance can be

adjusted to the specific application requirements. The main parameter for the inductor selection is the inductor

saturation current, which should be higher than the peak switch current as calculated previously with additional

margin to cover for heavy load transients. The alternative, more conservative approach, is to choose the inductor

with a saturation current at least as high as the typical switch current limit of 2.5 A. The second important

parameter is the inductor DC resistance. Usually the lower the DC resistance the higher the efficiency. It is

important to note that the inductor DC resistance is not the only parameter determining the efficiency. For a

boost converter, where the inductor is the energy storage element, the type and material of the inductor

influences the efficiency as well. Especially at high switching frequencies of 1.2 MHz, inductor core losses,

proximity effects, and skin effects become more important. Usually an inductor with a larger form factor gives

higher efficiency. The efficiency difference between different inductors can vary between 2% to 10%. For the

TPS65150, inductor values between 3.3 µH and 6.8 µH are a good choice, but other values can be used as well.

Possible inductors are shown in Table 1 .

(6)

(7)

17

www.ti.com

D 1

Vin

Vout

I

avg

(1 D) Isw

Vin

Vout

2.0 A with lsw minimum switch current

of the TPS65150 (2.0 A)

TPS65150

SLVS576 – SEPTEMBER 2005

DETAILED DESCRIPTION (continued)

Table 1. Inductor Selection

INDUCTOR VALUE COMPONENT SUPPLIER DIMENSIONS IN mm Isat – DC Resistance

4.7 µH Coilcraft DO1813P-472HC 8,89 × 6,1 × 5,0 2.6 A – 54 m Ω

4.2 µH Sumida CDRH5D28 4R2 5,7 × 5,7 × 3 2.2 A – 23 m Ω

4.7 µH Sumida CDC5D23 4R7 6 × 6 × 2,5 1.6 A – 48 m Ω

4.2 µH Sumida CDRH6D12 4R2 6,5 × 6,5 × 1,5 1.8 A – 60 m Ω

3.9 µH Sumida CDRH6D28 3R9 7,0 × 7,0 × 3,0 2.6A – 20 m Ω

3.3 µH Sumida CDRH6D12 4R2 6,5 × 6,5 × 1,5 1.9 A – 50 m Ω

Output Capacitor Selection

For best output voltage filtering, a low ESR output capacitor is recommended. Ceramic capacitors have a low

ESR value, but tantalum capacitors can be used as well, depending on the application. A 22-µF ceramic output

capacitor works for most applications. Higher capacitor values can be used to improve the load transient

regulation. See Table 2 for the selection of the output capacitor.

Input Capacitor Selection

For good input voltage filtering, low ESR ceramic capacitors are recommended. A 22-µF ceramic input capacitor

is sufficient for most applications. For better input voltage filtering, this value can be increased. See Table 2 , and

Typical Applications for input capacitor recommendations.

Table 2. Input and Output Capacitor Selection

CAPACITOR VOLTAGE RATING COMPONENT SUPPLIER COMMENTS

22 µF/1206 16 V Taiyo Yuden EMK325BY226MM Cout

22 µF/1206 6.3 V Taiyo Yuden JMK316BJ226 Cin

Rectifier Diode Selection

To achieve high efficiency, a Schottky diode should be used. The reverse voltage rating should be higher than

the maximum output voltage of the converter. The required average rectified forward current rating of the

Schottky diode is calculated as the off time of the converter times the maximum switch current of the TPS65150:

Usually, a Schottky diode with 1-A maximum average rectified forward current rating is sufficient for most of the

applications. Secondly, the Schottky rectifier has to be able to dissipate the power. The dissipated power is the

average rectified forward current times the diode forward voltage.

PD = Iavg × VF = Isw × (1 – D) × VF with lsw = minimum switch current of the TPS65150 (2.0 A).

Typically, the diode should be able to dissipate 270 mW maximum depending on the load current and forward

voltage. In terms of efficiency, the main parameters of the diode are the forward voltage and the reverse leakage

current of the diode; both should be as low as possible.

Table 3. Rectifier Diode Selection

CURRENT RATING Vr V

Iavg

2 A 20 V 0.44 V at 2 A SL22, Vishay Semiconductor

2 A 20 V 0.5 V at 2 A SS22, Fairchild Semiconductor

1 A 30 V 0.44 V at 2 A MBRS130L, Fairchild Semiconductor

1 A 20 V 0.45 V at 1 A UPS120, Microsemi

1 A 20 V 0.45 V at 1 A MBRM120, ON Semiconductor

forward

COMPONENT SUPPLIER

(8)

(9)

18

www.ti.com

V

out

1.146 V1

R1

R2

C

FF

1

2 ƒz R1

1

2 8.8 kHz R1

TPS65150

SLVS576 – SEPTEMBER 2005

Setting the Output Voltage

The output voltage is set by the external resistor divider and is calculated as:

To minimize quiescent current high impedance feedback resistors should be used. The upper feedback resistor

R1 should not be larger than 1M Ω . Across the upper resistor, a bypass capacitor is required to speed up the

circuit during load transients. The capacitor value is selected according to Table 4 and the formula (12) as shown

in the next section.

Compensation (COMP) and feedforward capacitor

The regulator loop can be compensated by adjusting the external components connected to the COMP pin. The

COMP pin is the output of the internal transconductance error amplifier. The compensation capacitor adjusts the

low-frequency gain. Adding a resistor in series to it will increase the high frequency gain. Since the converter

gain changes with the input voltage different compensation capacitors are required. Lower input voltages require

a higher gain, and therefore a smaller compensation capacitor value.

(10)

Table 4. Compensation Components for different V

V

IN

2.5 V 470 pF 68 k Ω 8.8 kHz

3.3 V 470 pF 33 k Ω 7.8 kHz

5.0 V 2.2 nF 0 k Ω 11.2 kHz

C

COMP

R

COMP

Voltages

IN

f

Z

The feedforward capacitor across the feedback resistor devider of the boost converter sets an additional zero at

the frequency fz to compensate the loop. Typical values for fz are shown in Table 4 giving a feedforward

capacitor value as calculated below.

Please refer to the typical application circuits at the end of the datasheet for detailed circuit configurations and

values.

Layout Consideration

The PCB layout is an important step in the power supply design. An incorrect layout could cause converter

instability, load regulation problems, noise, and EMI issues. Especially with a switching dc-dc converter at

high load currents, too-thin PCB traces can cause significant voltage spikes. Good grounding becomes

important as well. If possible, a common ground plane to minimize ground shifts between analog (GND) and

power ground (PGND) is recommended. Additionally, the following PCB design layout guidelines are

recommended for the TPS65150:

1. Boost converter output capacitor, input capacitor and Power ground (PGND) should form a star ground or

should be directly connected together on a common power ground plane.

2. Place the input capacitor directly from the input pin (VIN) to ground.

3. Use a bold PCB trace to connect SUP to the output Vs.

4. Place a small baypass capacitor from the SUP pin to ground.

5. Use short traces for the charge-pump drive pins (DRVN, DRVP) of VGH and VGL because these traces

carry switching currents.

6. Place the charge pump flying capacitors as close as possible to the DRVP and DRVN pin, avoiding a high

voltage spikes at these pins.

7. Place the Schottky diodes as close as possible to the IC, respectively to the flying capacitors connected to

DRVP and DRVN.

8. Carfully route the chare pump traces to avoid interference with other circuits since they carry high voltage

switching currents .

9. Place the output capacitor of the VCOM buffer as close as possible to the output pin (VCOM).

(11)

19

www.ti.com

TPS65150

SLVS576 – SEPTEMBER 2005

10. The power pad of the TSSOP package needs to be soldered to the PCB for imroved thermal performance.

11. The thermal pad of the QFN package needs to be soldered to the PCB for reliability and thermal

performance reasons.

20

www.ti.com

VIN

DRVN

FBN

REF

COMP

DLY1

DLY2

FDLY

SW SW

SUP

DRVP

GD

CPI

FBP

GND

PGND

PGND

VCOM

TPS65150

D1

D2

D3

ADJ

CTRL

VGH

23 V/20 mA

VGH

VGH

Contol Signal

D4

D5

D6 D7

FB

SW

IN

CPI

CPI

VCOM

Output

R8

500 k

R7

500 k

C6 1 nF

L1

3.9 H

C1

22 F

C7

0.33 F

R3

620 k

R4

150 k

C3

0.33 F

C8

220 nF

R9

33 k

C9

470 pF

C10 C11 C12

22 pF

10 nF

10 nF

C5

1 F

0.33 F

C16

C17

0.33 F

C4

0.33 F

C18

0.33 F

R5

1 M

R6

56 k

C2

22 F

Vs

10 V/400 mA

R2

56 k

R2

430 k

C15

33 pF

C14

1 F

VGL

−5 V/20 mA

Vin

3.3 V

C13

100 nF

V

IN

VIN

DRVN

FBN

REF

COMP

DLY1

DLY2

FDLY

SW SW

SUP

DRVP

GD

CPI

FBP

GND

PGND

PGND

VCOM

TPS65150

D1

D2

D3

ADJ

CTRL

VGH

23 V/20 mA

VGH

VGH

Contol Signal

D4

D5

D6 D7

FB

SW

IN

CPI

CPI

VCOM

Output

R8

500 k

R7

500 k

C6 1 nF

L1

3.9 H

C1

22 F

C7

0.33 F

R3

620 k

R4

150 k

C3

0.33 F

C8

220 nF

R9

68 k

C9

470 pF

C10 C11 C12

22 pF

10 nF

10 nF

C5

1 F

0.33 F

C16

C17

0.33 F

C4

0.33 F

C18

0.33 F

R5

1 M

R6

56 k

C2

22 F

Vs

10 V/280 mA

R2

56 k

R2

430 k

C15

47 pF

C14

1 F

VGL

−5 V/20 mA

Vin

2.5 V

C13

100 nF

V

IN

TPS65150

SLVS576 – SEPTEMBER 2005

APPLICATION INFORMATION

Figure 21. Notebook LCD Supply powered from a 3.3V rail

Figure 22. Notebook LCD Supply powered from a 2.5V rail

21

www.ti.com

VIN

DRVN

FBN

REF

COMP

DLY1

DLY2

FDLY

SW SW

SUP

DRVP

GD

CPI

FBP

GND

PGND

PGND

VCOM

TPS65150

D3

ADJ

CTRL

VGH

VGH

Contol Signal

D5

FB

IN

CPI

CPI

D1

D2

D4

R8

500 k

R7

500 k

C6 1 nF

L1

3.9 H

C1

22 F

0.33 F

C2

22 F

Vs

13.5 V/450 mA

R2

75 k

C15

22 pF

C14

1 F

Vin

5 V

R1

820 k

C7

R3

620 k

R4

150 k

C3

0.33 F

C8

220 nF

C9

2.2 nF

0.33 F

C16

C4

0.33 F

R5

1 M

VGL

−5 V/20 mA

R6

56 k

C5

1 F

VGH

23 V/20 mA

C10 C11 C12

22 pF 10 nF 10 nF

VCOM

Output

C13

100 nF

V

IN

GD

C13

1 Fm

Q1

Vs

13.5 V/450 mA

VIN

DRVN

FBN

REF

COMP

DLY1 DLY2 F D LY

SW SW

SUP

DRVP

GD

CPI

FBP

GND

PGND

PGND

VCOM

TPS65150

D1

Vin

5 V

D2

D3

R5

1M

R6

56k

C2

22 Fm

C 15

22 pF

ADJ

CTRL

VGH

23 V/20 mA

VGH

VGH

Contol Signal

D4

D5

VGL

-5 V/20 mA

FB

C14

1 Fm

IN

C6

1 nF

R8

500 kW

R3

620 kW

R2

75 kW

R1

820 kW

R8

100 kW

R7

510 kW

R4

150 kW

R7

500 kW

L1

3.9 Hm

C1

22 Fm

C7

0.33 Fm

C16

0.33 Fm

C4

0.33 Fm

C3

0.33 Fm

C8

220 nF

C9

2.2 nF

C10

22 pF

C11

11 nF

C12

10 nF

C13

100 nF

CPI

CPI

V COM

Output

C5

1 Fm

VIN

C17

220 nF

SI2343

TPS65150

SLVS576 – SEPTEMBER 2005

APPLICATION INFORMATION (continued)

Figure 23. Monitor LCD Supply powered from a 5V rail

Figure 24. Typical Isolation and Short-Circuit Protection Switch for Vs using Q1 and Gate Drive Signal

22

(GD)

PACKAGE OPTION ADDENDUM

www.ti.com

18-Jul-2006

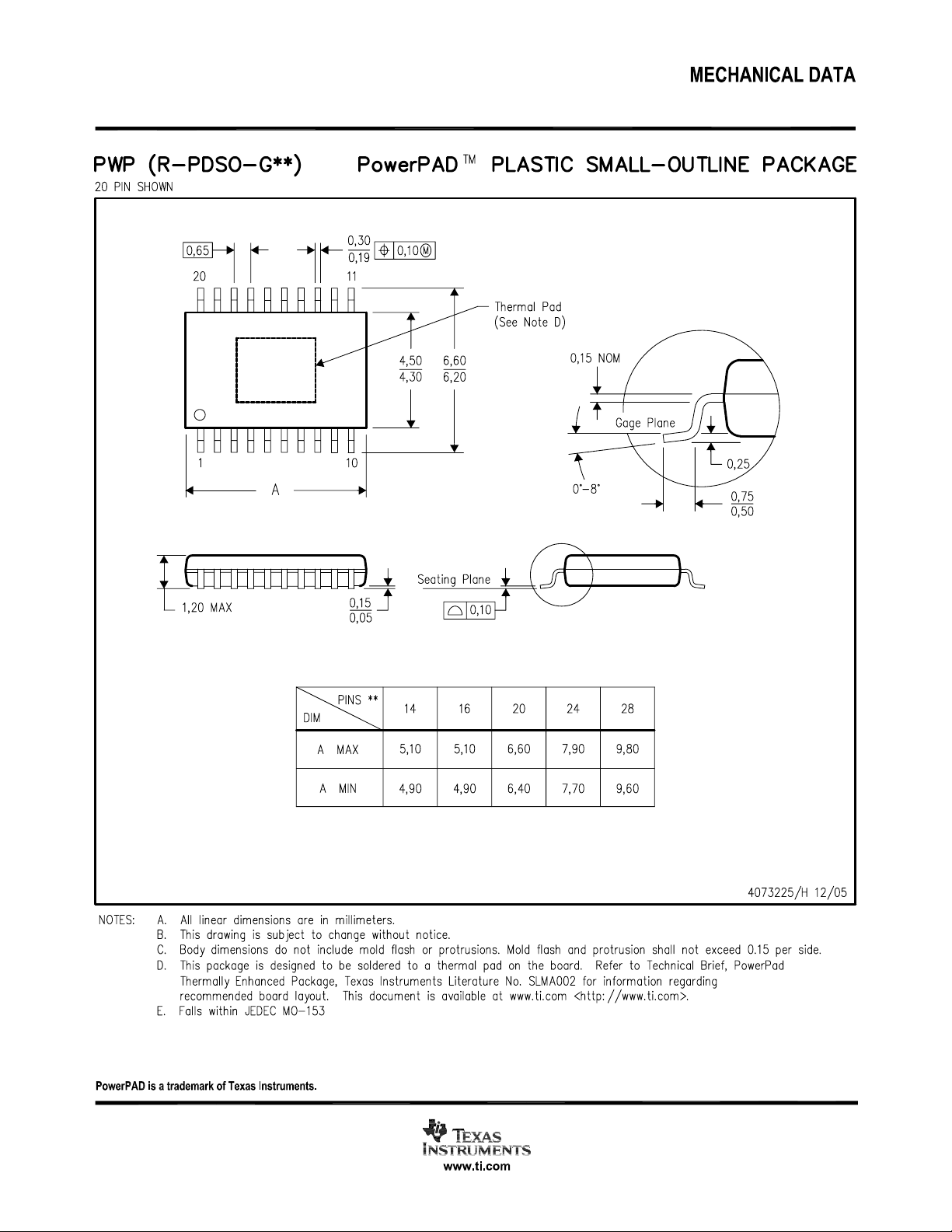

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS65150PWP ACTIVE HTSSOP PWP 24 60 Green (RoHS &

no Sb/Br)

TPS65150PWPG4 ACTIVE HTSSOP PWP 24 60 Green (RoHS &

no Sb/Br)

TPS65150PWPR ACTIVE HTSSOP PWP 24 2000 Green (RoHS &

no Sb/Br)

TPS65150PWPRG4 ACTIVE HTSSOP PWP 24 2000 Green (RoHS &

no Sb/Br)

TPS65150RGER ACTIVE QFN RGE 24 3000 Green (RoHS &

no Sb/Br)

TPS65150RGERG4 ACTIVE QFN RGE 24 3000 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2006, Texas Instruments Incorporated

Loading...

Loading...