Page 1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

SLUS489 − OCTOBER 2001

FEATURES

D High-Frequency (2-MHz) Voltage Mode PWM

Controller

D 1.8-V to 9.0-V Input Voltage Range

D 0.8-V to 8.0-V Output Voltage Range (Higher in

Non-Synchronous Boost Topology)

D High-Efficiency Buck, Boost, SEPIC or

Flyback (Buck-Boost) Topology

D Synchronous Rectification for High-Efficiency

D Drives External MOSFETs for High-Current

Applications

D Synchronizable Fixed-Frequency PWM or

Automatic Pulsed Frequency Modulation

(PFM) Mode

D Built-In Soft-Start

D User Programmable Discontinuous or

Continuous Conduction Mode

D Selectable Pulse-by-Pulse Current Limiting or

Hiccup Mode Protection

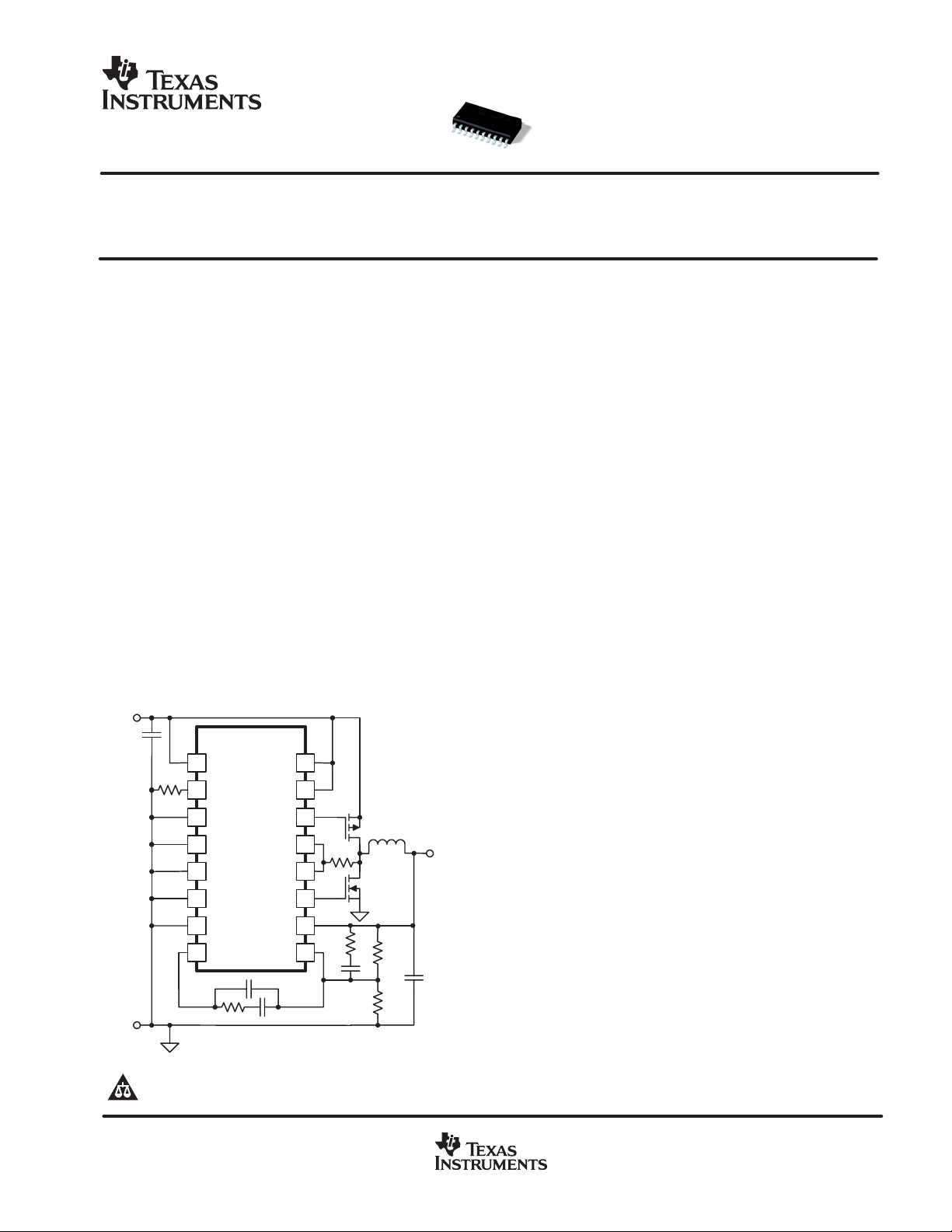

TYPICAL BUCK APPLICATION

VIN

TPS43000

RTN

5

BUCK

3

RT

SYNC/SD

1

CCM

4

2

CCS

PFM*

6

12

GND

7

COMP FB

VIN

VP

PDRV

SWP

SWN

NDRV

VOUT

9

14

13

15

16

11

10

8

VOUT

UDG−01036

APPLICATIONS

D Networking Equipment

D Servers

D Base Stations

D Cellular Telephones

D Satellite Telephones

D GPS Devices

D Digital Still and Handheld Cameras

D Personal Digital Assistants (PDAs)

DESCRIPTION

The TPS43000 is a high-frequency, voltage-mode,

synchronous PWM controller that can be used in buck,

boost, SEPIC, or flyback topologies. This highly flexible,

full-featured controller is designed to drive a pair of

external MOSFETs (one N-channel and one

P-channel), enabling it for use with a wide range of

output voltages and power levels. With an automatic

PFM mode, a shutdown current of less than 1 µA, a

sleep-mode current of less than 100 µA and a full

operating current of less than 2 mA at 1 MHz, it is ideal

for building highly efficient, dc-to-dc converters.

The TPS43000 operates over a wide input voltage

range of 1.8 V to 9.0 V. Typical power sources are

distributed power systems, two to four nickel or alkaline

batteries, or one to two lithium-ion cells. It can be used

to generate regulated output voltages from as low as

0.8 V to 8 V or higher. It operates either in a

fixed-frequency mode, where the user programs the

frequency (up to 2 MHz), or in an automatic PFM mode.

In the automatic mode, the controller goes to sleep

when the inductor current goes discontinuous, and

wakes up when the output voltage has fallen by 2%. In

this hysteretic mode of operation, very high efficiency

can be maintained over a very wide range of load

current. The device can also be synchronized to an

external clock source using the dual function SYNC/SD

input pin.

semiconductor products and disclaimers thereto appears at the end of this data sheet.

! " #$%! " &$'(#! )!%*

)$#!" # ! "&%##!" &% !+% !%" %," "!$%!"

"!)) -!.* )$#! &#%""/ )%" ! %#%""(. #($)%

!%"!/ (( &%!%"*

www.ti.com

Copyright 2001, Texas Instruments Incorporated

1

Page 2

SLUS489 − OCTOBER 2001

description (continued)

The TPS43000 features a selectable two-level current-limit circuit which senses the voltage drop across the

energizing MOSFET. The user can select either pulse-by-pulse current limiting or hiccup mode overcurrent

protection. The TPS43000 also features a low-power (LP) mode (which reduces gate charge losses in the

N-channel MOSFET at high input/output voltages), undervoltage lockout, and soft-start. The TPS43000 is

available in a 16-pin TSSOP (PW) package.

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†w

Input voltage (VIN, VP, VOUT) −0.3 V to 10 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(BUCK, CCM, CCS, PFM

, SYNC/SD) −0.3 V to VIN + 0.3 V. . . . . . . . . . . . . . . . . . . . . . .

(SWN) −0.3 V to 17 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(SWP) −0.3 V to VIN + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

Junction temperature range, T

stg

J

−65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

−55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only , a nd

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute- maximum-rated conditions for extended periods may affect device reliability. All voltages are with respect to

ground. Currents are positive into, negative out of the specified terminals.

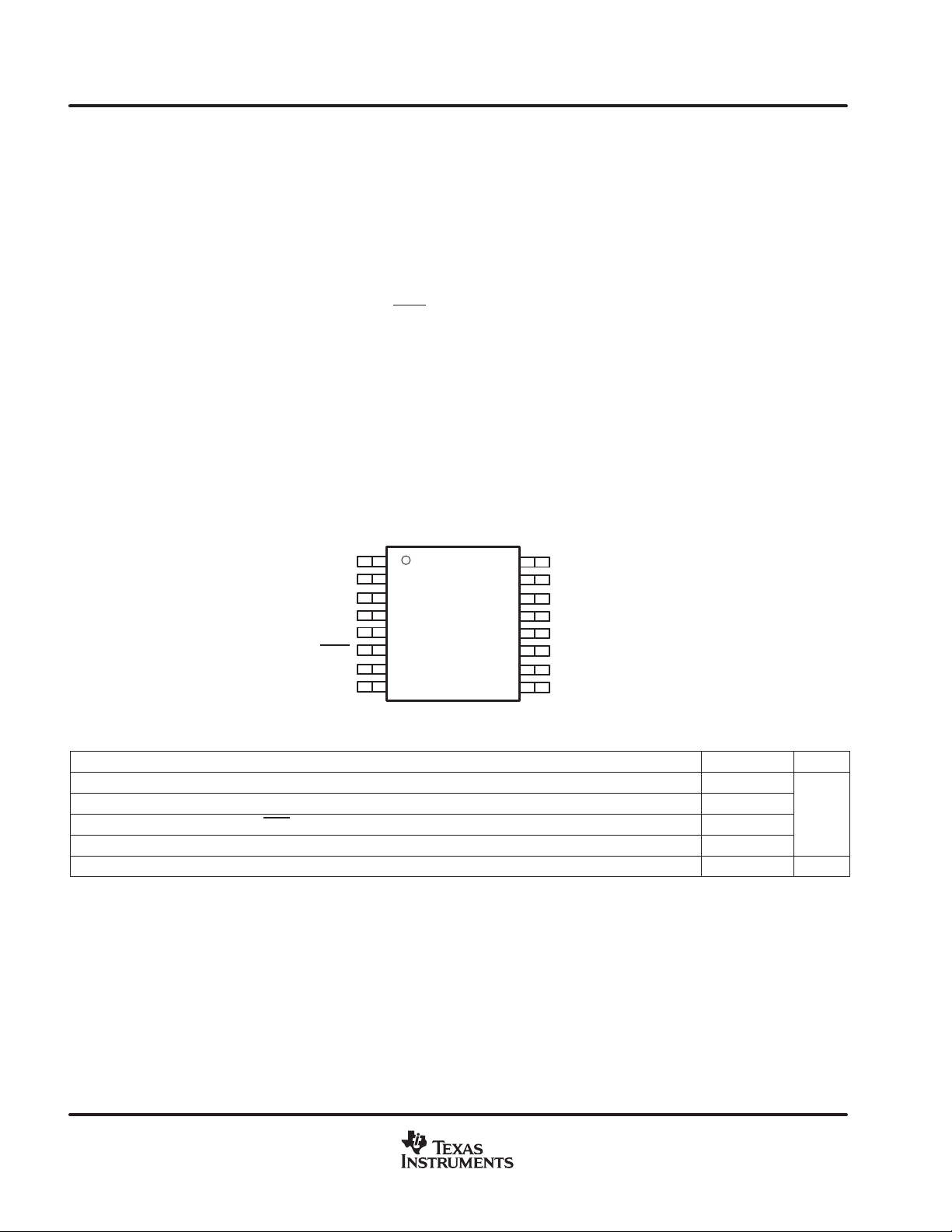

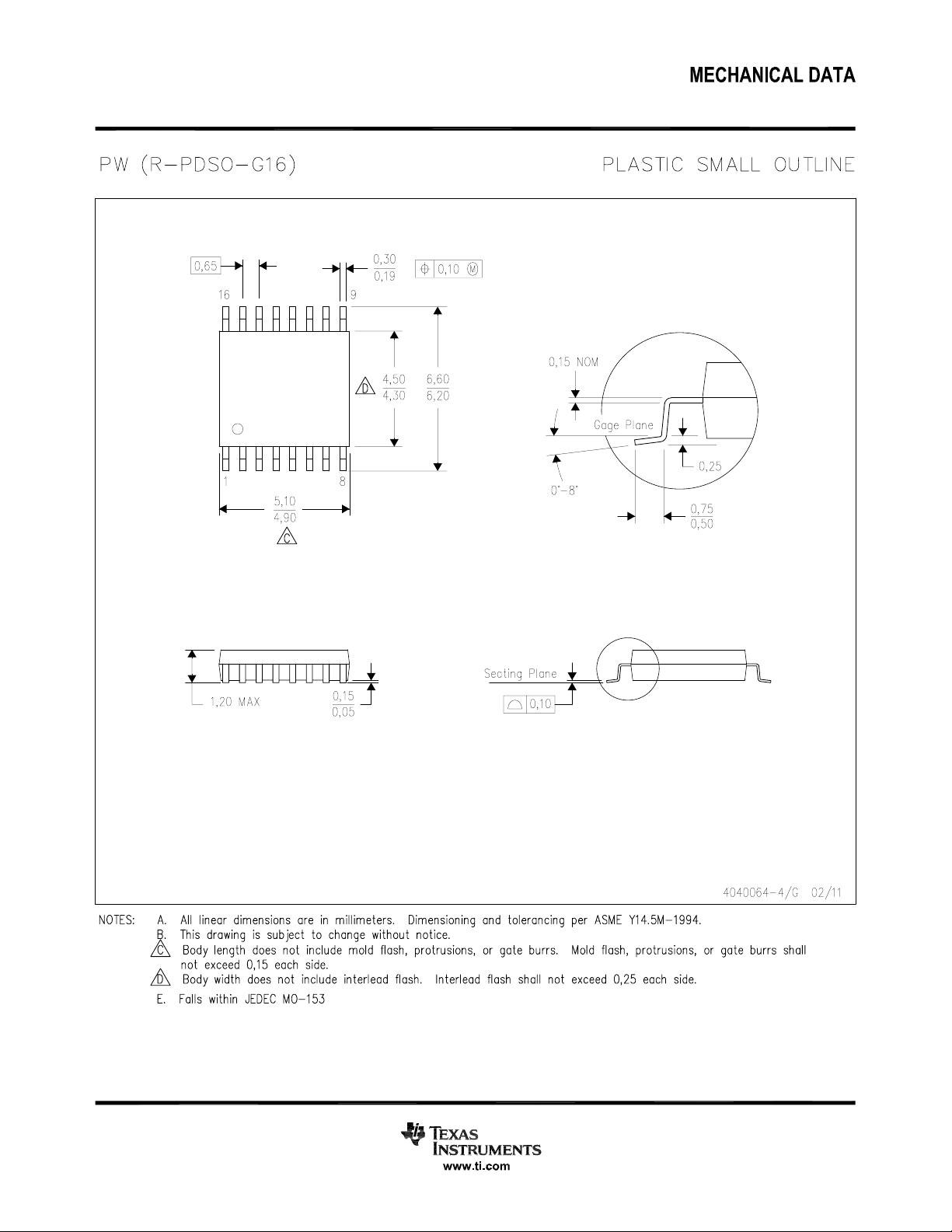

PW PACKAGE

(TOP VIEW)

SYNC/SD

CCS

RT

CCM

BUCK

PFM

COMP

FB

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

SWN

SWP

VP

PDRV

GND

NDRV

VOUT

9

VIN

recommended operating conditions

MIN MAX UNIT

Input voltage, VIN, VP 9

Input voltage, VOUT 8

Input voltage, BUCK, CCM, CCS, PFM, SYNC/SD, SWP 9

Input voltage, SWN 17

Operating junction temperature range, TJ

§

t is not recommended that the device operate for extended periods of time under conditions beyond those specified in this table.

2

§

www.ti.com

−40 85 °C

V

Page 3

VP = VOUT = 3.5 V, No load

VP = VOUT = 3.5 V, No load

µA

µA

SLUS489 − OCTOBER 2001

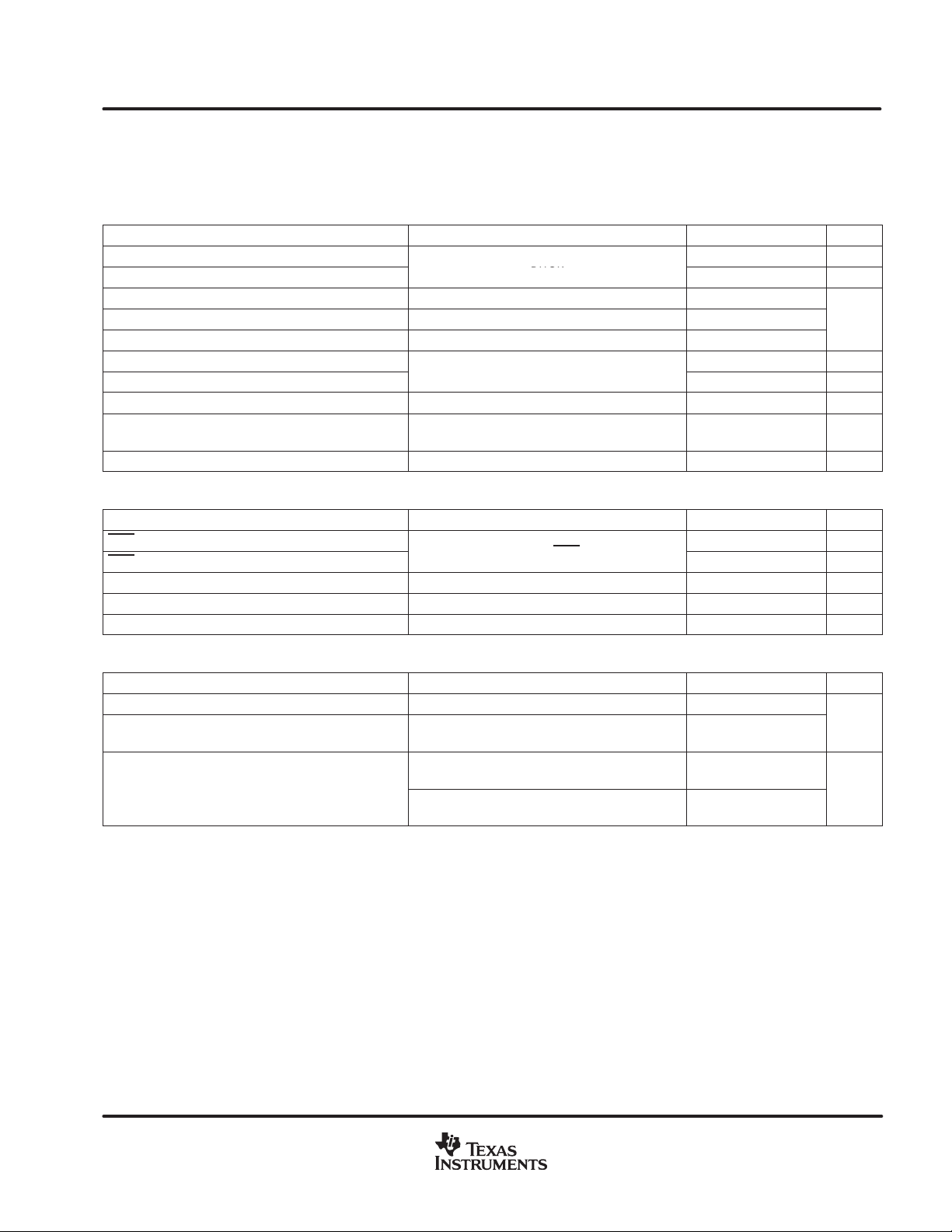

electrical characteristics over recommended operating junction temperature range,

= −40_C to 85_C for the TPS43000, RT = 75 kΩ (500 kHz), VIN = VP = 3.5 V, VOUT = 3.1 V, COMP/FB

T

A

pins shorted, BUCK-configured, T

VIN

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Start-up voltage

Undervoltage lockout (UVLO) hysteresis

Shutdown current

Operating current Not in PFM mode, no MOSFETs connected 1.0 1.4 mA

Sleep mode current PFM mode, COMP/FB=900 mV 75 140 µA

BOOST-configured VIN operating current

BOOST-configured VIN sleep mode current

VOUT

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Shutdown current SYNC/SD = VIN 0 2

Operating current Not in PFM mode, no MOSFETs connected 1 5

Sleep mode current PFM mode, COMP/FB=900 mV 0 2

BOOST-configured VOUT operating current

BOOST-configured VOUT sleep mode current

= T

(unless otherwise noted)

A

J

1.45 1.65 1.85 V

No MOSFETs connected

SYNC/SD = 1.6 V 1 10

SYNC/SD = VIN 0.5 2

Not in PFM mode, no MOSFETs connected,

BUCK pin grounded, VIN = 3.1 V,

VP = VOUT = 3.5 V

PFM mode, BUCK pin grounded,

VP = VOUT = 3.5 V, VIN = 3.1 V,

COMP/FB=900 mV

Not in PFM mode, no MOSFETs connected,

BUCK pin grounded, VIN = 3.1 V,

VP = VOUT = 3.5 V

PFM mode, BUCK pin grounded,

VP = VOUT = 3.5 V, VIN = 3.1 V,

COMP/FB=900 mV

60 150 300 mV

30 75 µA

25 60 µA

1.0 1.4 mA

50 120 µA

µA

µA

VP

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Shutdown current SYNC/SD = VIN 0.5 2

Operating current Not in PFM mode, no MOSFETs connected 500 800

Sleep mode current PFM mode, COMP/FB=900 mV 0 2

error amplifier

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VREG, regulation voltage (COMP/FB pin)

FB input current VFB = 800 mV −150 −10 150 nA

Sourcing current (out of COMP) VFB = (VREG − 100 mV), V

Sinking current (into COMP) VFB = (VREG + 100 mV), V

Maximum ouput voltage (COMP pin) VFB = 0 V, I

Minimum output voltage (COMP pin) VFB = 2 V, I

Unity gain bandwidth See Note 1 5 MHz

NOTE 1: Ensured by design. Not production tested.

1.8 V < VIN < 6 V 784 800 816

VIN = 3.5 V 788 800 812

= 0 V, −2.0 −0.5 mA

COMP

= 2 V 0.5 1.2 mA

COMP

= −100 µA 1.6 2.0 V

COMP

= +100 µA 70 120 mV

COMP

µA

mV

www.ti.com

3

Page 4

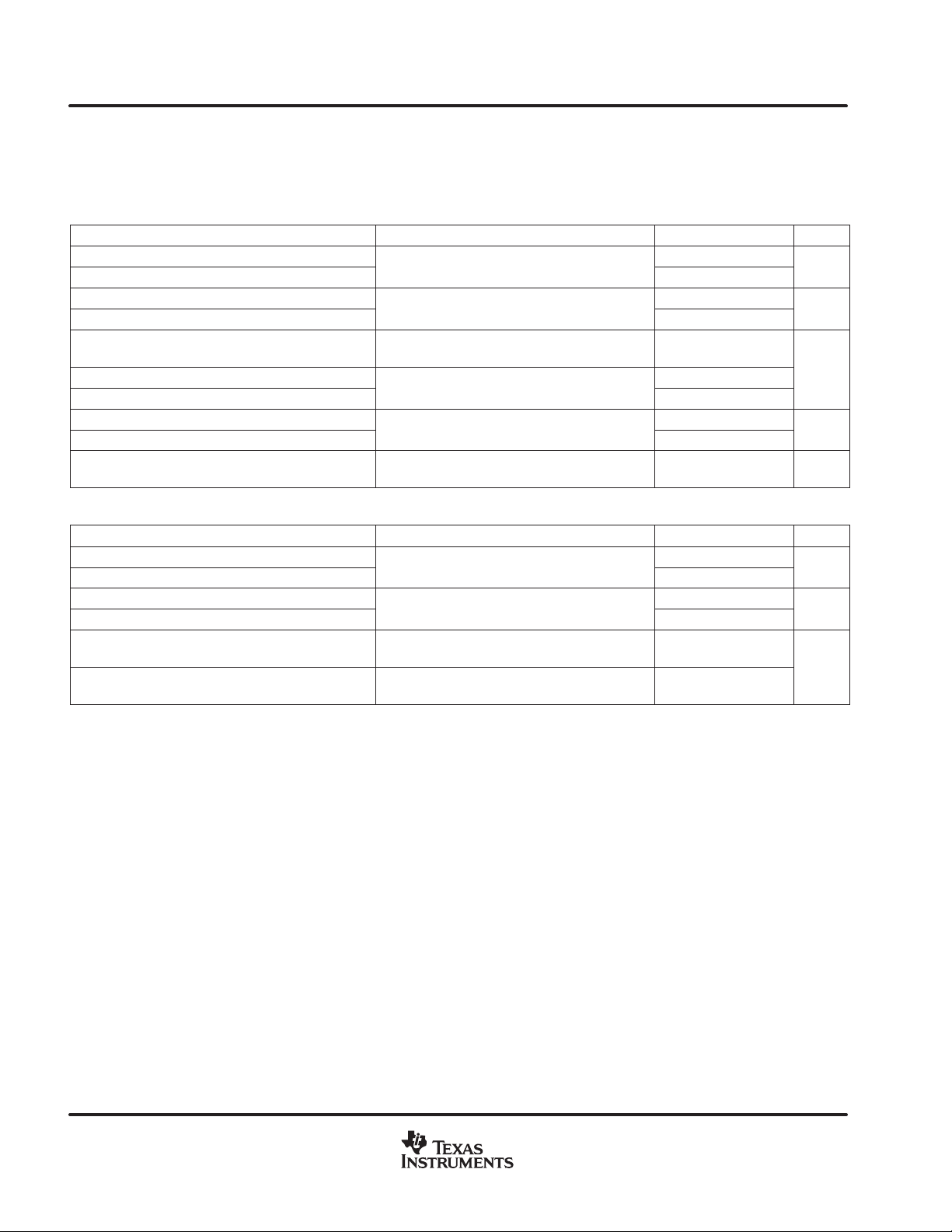

Soft-start time

Oscillator frequency

Constant current source configured if

Constant current source configured if

SLUS489 − OCTOBER 2001

electrical characteristics over recommended operating junction temperature range,

= −40_C to 85_C for the TPS43000, RT = 75 kΩ (500 kHz), VIN = VP = 3.5 V, VOUT = 3.1 V, COMP/FB

T

A

pins shorted, BUCK-configured, T

soft-start

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Soft-start time

oscillator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Oscillator frequency

SYNC/SD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Synchronization threshold voltage 0.8 1.25 1.6 V

SYNC pulse width SYNC/SD = 2 V, COMP/FB=600 mV 100 50 ns

SYNC input current SYNC/SD = 1.6 V 0.5 1 µA

SYNC high to shutdown delay time Float COMP, VFB = 0 V 10 22 35 µs

Synchronous range Force COMP/FB to 600 mV 1.1 f

= T

(unless otherwise noted)

A

J

RT = 37.5 kΩ (1 MHz) 1.0 3.0 6.0

RT = 75 kΩ (500 kHz) 2.0 5.5 12.0

RT = 150 kΩ (250 kHz) 4.0 10.5 24.0

RT = 37.5 kΩ (1 MHz), V

RT = 75 kΩ (500 kHz), V

RT = 150 kΩ (250 kHz), V

= 600 mV 0.90 1.00 1.10 MHz

COMP

= 600 mV 450 500 550 kHz

COMP

= 600 mV 225 250 280 kHz

COMP

o

1.5 f

o

ms

current limit

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Hiccup overcurrent threshold voltage Voltage measured from VIN to SWN 175 250 325 mV

Delay to termination of P-channel gate drive time Measured at PDRV 125 300 ns

BOOST configured hiccup overcurrent threshold

voltage

Delay to termination of N-channel gate drive time Measured at NDRV, BUCK grounded 150 300 ns

Consecutive overcurrent clock cycles before

shutdown

Clock cycles before restart 800 900 1000

CCS threshold voltage

CCS pull-down current

CCS current threshold voltage Measured from VIN to SWN 85 150 225

BOOST-configured CCS current threshold voltage

Voltage measured from SWN to GND,

BUCK grounded

V

> 1 V

CCS

Measured from SWN to GND,

BUCK grounded

175 250 325 mV

50 63 75

0.40 0.70 1.00 V

0.5 1.0 µA

85 150 225

mV

4

www.ti.com

Page 5

Continuous conduction allowed if

Continuous conduction allowed if

SLUS489 − OCTOBER 2001

electrical characteristics over recommended operating junction temperature range,

= −40_C to 85_C for the TPS43000, RT = 75 kΩ (500 kHz), VIN = VP = 3.5 V, VOUT = 3.1 V, COMP/FB

T

A

pins shorted, BUCK-configured, T

PWM

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

BUCK threshold voltage

BUCK pull-down current

BUCK maximum duty cycle VFB = 0 V 100%

BOOST maximum duty cycle BUCK grounded, VFB = 0 V 70% 90%

Minimum duty cycle VFB = 2 V 0%

CCM threshold voltage

CCM pull-down current

BUCK rectifier zero current threshold voltage Measured from SWP to GND −28 −12 0 mV

BOOST rectifier zero current threshold voltage

Delay to termination of P-channel gate drive time Measured at PDRV, BUCK grounded 200 300 ns

= T

(unless otherwise noted)

A

J

BUCK configured if V

V

> 1 V

CCM

Measured from SWP to VOUT,

BUCK grounded

BUCK

> 1 V

0.4 0.7 1.0 V

0.5 1.0 µA

0.4 0.7 1.0 V

0.5 1.0 µA

0 14 32 mV

pulsed frequency modulation

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

PFM threshold voltage

PFM pull-down current

FB voltage to awaken (exit sleep mode) 768 784 800 mV

Izero pulses required to enter sleep 5 7 9

Start-up delay time after sleep 2 5 µs

PFM mode not allowed if PFM > 1 V

0.4 0.7 1.0 V

0.5 1.0 µA

low power mode

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VOUT threshold voltage to enter low power mode VP = VIN = 5 V 3.45 3.60 3.80

VIN threshold voltage to enter low power mode

Hysteresis voltage to exit low power mode

VP = VOUT = 5 V,

BUCK grounded (boost configured)

VOUT < (V

VP = VIN = 5 V

VIN < (V

BUCK grounded, VP = VOUT = 5 V

THRESHOLD−VHYST

THRESHOLD−VHYST

),

),

3.45 3.60 3.80

225 312 415

225 312 415

V

mV

www.ti.com

5

Page 6

C

= 1 nF, VP = VIN = 5 V,

CO = 1 nF, VP = VIN = 5 V,

C

= 1 nF, VIN = 3.1 V,

CO = 1 nF, VIN = 3.1 V,

VP = VIN = 5 V, VOUT = 3.1 V

VP = VIN = 5 V, VOUT = 3.1 V

SLUS489 − OCTOBER 2001

electrical characteristics over recommended operating junction temperature range,

= −40_C to 85_C for the TPS43000, RT = 75 kΩ (500 kHz), VIN = VP = 3.5 V, VOUT = 3.1 V, COMP/FB

T

A

pins shorted, BUCK-configured, T

NDRV

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VIN driven rise time

VIN driven fall time

VIN driven pull-up resistance

VIN driven pull-down resistance

BUCK P-channel MOSFET off to N-channel

MOSFET on anti-x delay time

VOUT driven rise time

VOUT driven fall time

VOUT driven pull-up resistance

VOUT driven pull-down resistance

BOOST P-channel MOSFET off to N-channel MOS-

FET on anti-x delay time

= T

(unless otherwise noted)

A

J

VOUT = 3.1 V

VP = VIN = 5 V, VOUT = 3.1 V

VP = VIN = 5 V, VOUT = 3.1 V,

PDRV and NDRV transitioning HI delta

VP = VOUT = 5 V, BUCK grounded

VP = VOUT = VIN = 5 V, LP mode activated

VP = VOUT = 5 V, VIN = 3.1 V,

BUCK grounded

25 45

20 40

6.5 10.0

2.25 4.00

10 35 75

25 45

20 40

6.5 10.0

2.25 4.00

10 35 75 ns

ns

Ω

ns

Ω

PDRV

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VP driven rise time

VP driven fall time

VP driven pull-up resistance

VP driven pull-down resistance

BUCK N-channel MOSFET off to P-channel MOS-

FET on anti-x delay time

BOOST N-channel MOSFET off to P-channel MOS-

FET on anti-x delay time

CO = 1 nF

VP = VIN = 5 V, VOUT = 3.1 V

VP = VIN = 5 V, VOUT = 3.1 V,

NDRV and PDRV transitioning LO delta

VP = VOUT = 5 V, VIN = 3.1 V,

BUCK grounded

15 40

15 40

2.5 4.0

3.5 6.0

10 30 75

10 30 75

ns

Ω

ns

6

www.ti.com

Page 7

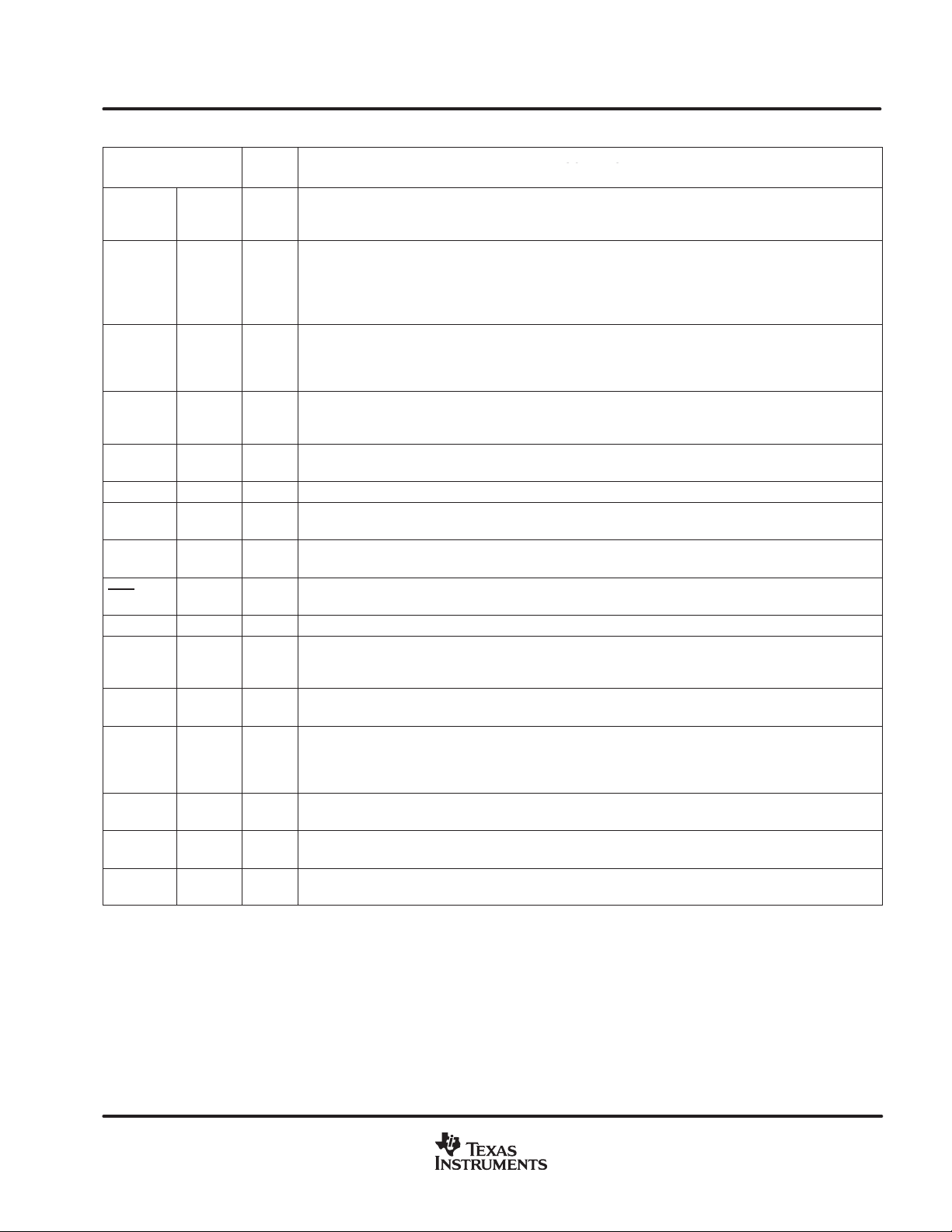

I/O

DESCRIPTION

SLUS489 − OCTOBER 2001

Terminal Functions

TERMINAL

NAME NO.

Input pin to select topology. Connect this pin to VIN for a buck converter, ground it for a boost or SEPIC.

BUCK 5 I

CCM 4 I

CCS 2 I

COMP 7 O

FB 8 I

GND 12 − Ground pin for the device.

NDRV 11 O

PDRV 13 O

PFM 6 I

RT 3 O A resistor from this pin to ground sets the PWM frequency.

SWP 15 I

SWN 16 I

SYNC/SD 1 I

VP 14 I

VIN 9 I

VOUT 10 O

This configures the logic to the two gate drive outputs, and controls D

pulldown.

Input pin determines whether or not the l

tion. Pulling this pin high ignores the Izero comparator’s output, forcing continuous conduction mode.

Connecting it to ground enables Izero, allowing discontinuous conduction mode (DCM) operation. Note

that even when pulled high, seven detected I

internal pull-down.

Current limit feature allowing selection of either pulse-by-pulse current limiting or hiccup mode overcurrent protection. Connect this pin to VIN to select pulse-by-pulse current limiting, the constant current

source mode. Connect this pin to ground to enable hiccup mode overcurrent protection. This pin has a

weak internal pulldown.

Output of the error amplifier. The compensation components are connected from this pin to the FB pin.

During sleep mode, this pin goes to high impedance, and is severed from the internal error amplifier’s

output so that it may hold its dc potential.

Inverting input to the error amplifier. It is connected to a resistor divider off of VOUT, and to the compensation network.

Gate drive output for the N-channel MOSFET (energizing MOSFET for the boost and SEPIC, rectifier

MOSFET for the buck).

Gate drive output for the P-channel MOSFET (energizing MOSFET for the buck, rectifier MOSFET for the

boost and SEPIC).

Input pin that disables/enables PFM operation. Connecting it to VIN disables PFM mode. Grounding this

pin enables PFM to occur automatically, based on lzero. This pin has a weak internal pulldown.

Connect this pin through a 1-kΩ resistor to the drain of the P-channel MOSFET for all topologies. It detects Izero pulses using the synchronous rectifier MOSFET. For the SEPIC topology, a Schottky clamp

tied to ground must be connected to this pin.

Connect this pin through a 1-kΩ resistor to the drain of the N-channel MOSFET for all topologies. It

senses overcurrent conditions using the inductor energizing MOSFET.

This dual-function pin is used to synchronize the oscillator or shutdown the controller, turning both

MOSFETs off. A pulse from 0 V to 2 V provides synchronization. Duty cycle is not critical, but it must be

at least 100 ns wide. Holding this pin to 2 V or greater for over 35 µs shuts down the device. This pin

has a weak internal pulldown.

Power rail input pin for the P-channel MOSFET gate driver. Connect this pin to VIN for a buck, and to

VOUT for a boost or SEPIC. Provide good local decoupling.

Input supply for the device. It provides power to the device, and may be used for the N−channel gate

drive. Provide good local decoupling

Connect this pin to the power supply output. It may be used for the gate drive to the N−channel MOSFET. Provide good local decoupling.

DESCRIPTION

comparator allows discontinuous conduction mode opera-

ZERO

pulses still initiate PFM mode. This pin has a weak

ZERO

. This pin has a weak internal

MAX

www.ti.com

7

Page 8

3

S

V

V

SLUS489 − OCTOBER 2001

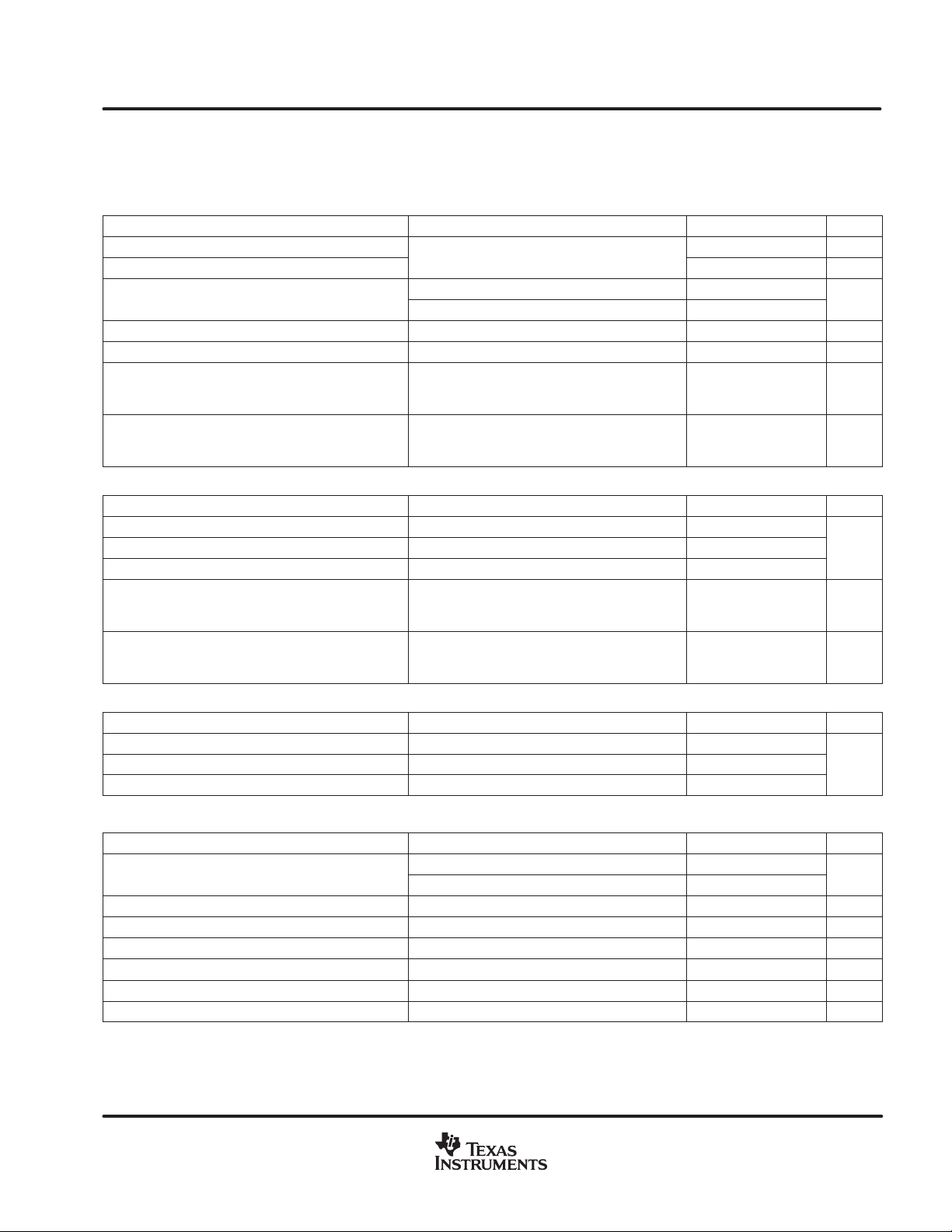

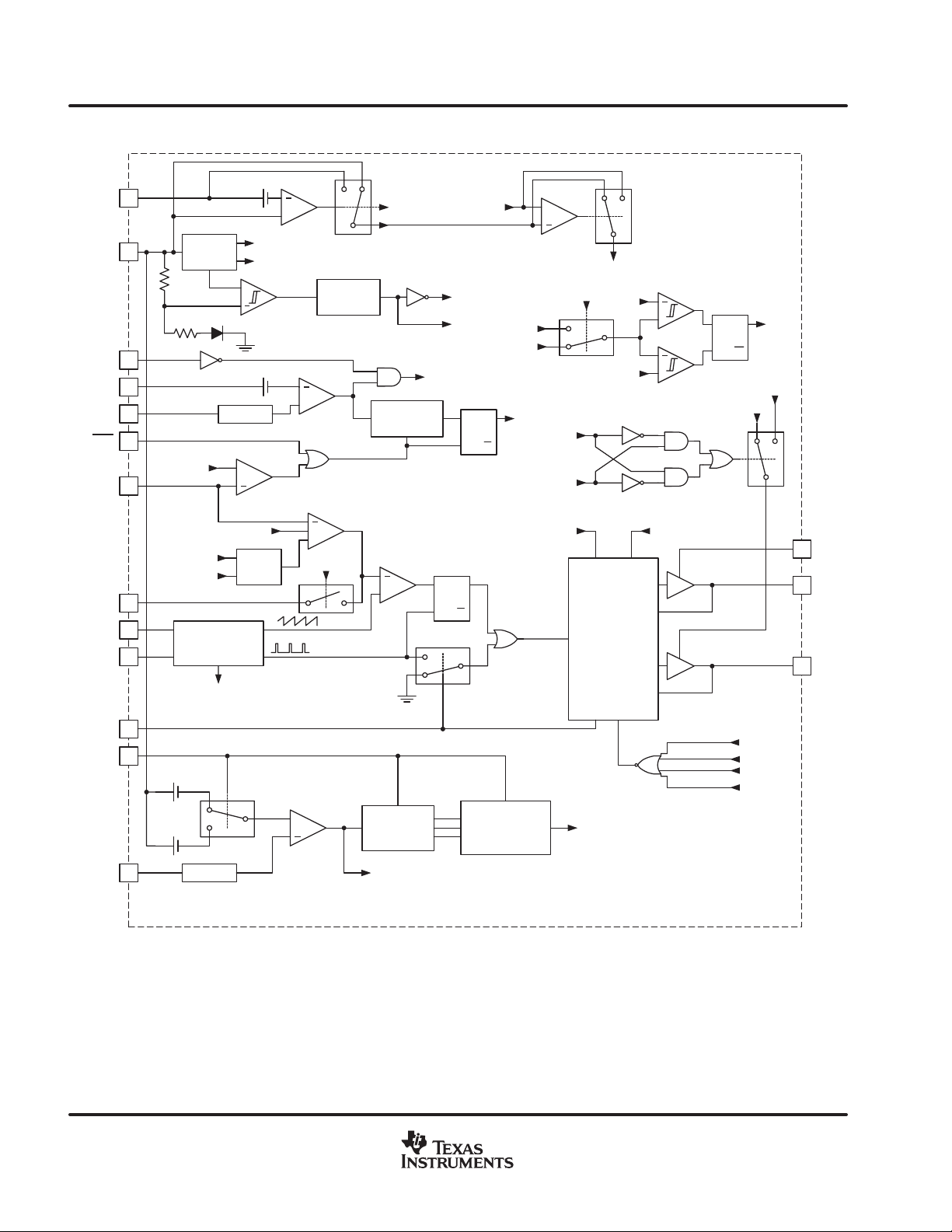

functional block diagram

300 mV

+

10 mV

LEB

+

800 mV

SOFT

START

++

800 mV

784 mV

200 mV

10

VOUT

9

VIN

R

1.6 R

CCM

4

GND

12

SWP

15

6

PFM

784 mV

8

FB

REFGOOD

HICCUP

7COMP

RT

3

YNC/SD

1

5

BUCK

2

CCS

150 mV

++

250 mV

SWN LEB

16

VREF

1.246 V

SHUTDOWN

TIMER AND

OSCILLATOR

SHUTDOWN

(SD)

+

UVLO

95% MAXIMUM DUTY

CYCLE NON−BUCK

+

+

DELAY

TO ZERO

IZERO

ERROR

AMPLIFIER

+

+

SLEEP

RESET

VINEST 2.75 V

VBEST

REFGOOD

REFBAD

RECTOFF

(STOP SWITCH

RECTIFICATION)

3−BIT UP

COUNTER

PWM

COMPARATOR

+

RESET

6−BIT

UP/DOWN

COUNTER

IMAX

(STOP ENERGIZING INDICATOR)

SQ

SQ

QR

VIN

VOUT

SLEEP

QR

RECTOFF IMAX

RECTIFY

RESET

SHUTDOWN

FOR 900

CYCLES THEN

SOFT−START

+

VINEST

LPM

VINEST

CONDUCTION

TOPOLOGY

PWM ENABLE

HICCUP

(STOP SWITCHING FOR 900

CYCLES THEN SOFT−START)

VDD

3.6 V

3.3 V

ANTI

CROSS

&

STEERING

LOGIC

+

+

SQ

QR

VIN

NDRV_RAIL

SD

REFBAD

SLEEP

HICCUP

LPM

VOUT

VP

14

PDR

13

NDR

11

TPS43000

8

www.ti.com

UDG−0104

Page 9

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

general information

The TPS43000 is a high-frequency, synchronous PWM controller optimized for distributed power, or

battery-powered applications where size and efficiency are of critical importance. It includes high-speed,

high-current MOSFET drivers for those applications requiring low R

block diagram).

optimizing efficiency

The TPS43000 optimizes efficiency and extends battery life with its low quiescent current and its synchronous

rectifier topology . The additional features of low-power (LP) mode and PFM mode maintain high efficiency over

a wide range of load current.

modes of operation

The TPS43000 has four distinct modes of operation:

D fixed PWM with discontinuous conduction mode (DCM) possible

external MOSFETs. (See functional

DS(on)

D fixed PWM with forced continuous conduction mode (CCM)

D automatic pulse frequency modulation (PFM) with DCM possible

D PFM with forced CCM

The device mode is controlled by the CCM and PFM

DCM by connecting the pin to ground or to force CCM by connecting the pin to VIN. The PFM

decide whether to allow automatic PFM by connecting the pin to ground or to force fixed PWM by connecting

the pin to VIN.

fixed PWM with DCM possible (PFM tied to VIN; CCM tied to ground)

In this mode, the device behaves like a standard switching regulator with the addition of a synchronous rectifier.

Shortly after the energizing MOSFET turns off, the synchronous rectifier turns on. The synchronous rectifier

turns off either when the inductor current goes discontinuous (DCM) or just prior to the start of the next clock

cycle (CCM) when the energizing MOSFET turns on. During the small time interval when neither the energizing

MOSFET nor the synchronous rectifier are turned on, the synchronous rectifier MOSFET body diode (or an

optional small external Schottky diode in parallel) carries the current to the output until it goes discontinuous.

The efficiency drops off at light loads as the losses become a larger percentage of the delivered load.

pins. The CCM pin lets the user decide whether to allow

pin lets the user

www.ti.com

9

Page 10

(1)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

fixed PWM with forced CCM (PFM and CCM tied to VIN)

CCM is forced under all operating conditions in this mode. The synchronous rectifier turns on shortly after the

energizing MOSFET turns off and remains on until just prior to the start of the next clock cycle when the

energizing MOSFET turns on. The user should design the converter to operate in CCM over its entire operating

range in order to prevent the inductor current from going negative. If the converter is allowed to run

discontinuous, the inductor current goes negative (i.e. the output discharges as the current reverses and goes

back through the rectifier to the input or ground.) With fixed PWM, the efficiency drops off at light loads as the

losses become a larger percentage of the delivered load.

PFM with DCM possible (PFM

In this mode, the device can operate in either fixed PWM or in PFM mode. When the device is initially powered,

it operates in fixed PWM mode until soft-start completion. It remains in this mode until it senses that the converter

is on the verge of breaking into discontinuous operation. When this condition is sensed, the converter enters

PFM mode, invoking a sleep state until the output voltage falls 2% below nominal (a 16-mV drop measured at

the FB pin). At this time, the controller starts up again and operates at its fixed PWM frequency for a short

duration (load dependent, typically 10 to 200 PWM cycles), increasing the output voltage. If the controller again

senses the converter is on the verge of going discontinuous, the cycle repeats. If discontinuous operation is not

sensed, the converter remains in fixed PWM mode. PFM mode results in a very low duty cycle of operation,

reducing all losses and greatly improving light load efficiency. During the sleep state, most of the circuitry internal

to the TPS43000 is powered down. This reduces quiescent current, which lowers the average dc operating

current, enhancing its efficiency.

PFM with forced CCM (PFM

This mode is similar to the PFM with DCM possible mode except that the controller forces the converter to

operate in CCM. The converter can be designed to run discontinuous at light loads. The controller senses

discontinuous operation and enters the PFM mode. With PFM, the converter can maintain a very high efficiency

over a very wide range of load current.

and CCM tied to ground)

tied to ground; CCM tied to VIN)

anticross−conduction and adaptive synchronous rectifier commutation logic

When operating in the continuous conduction mode (CCM), the energizing MOSFET and the synchronous

rectifier MOSFET are simply driven out of phase, so that when one is on the other is off. There is a built-in time

delay of about 40 ns to prevent any cross-conduction.

In the event that the converter is operating in the discontinuous conduction mode (DCM), the synchronous

rectifier needs to be turned off quickly, when the rectifier current drops to zero. Otherwise, the output begins to

discharge as the current reverses and goes back through the rectifier to the input or ground (this obviously

cannot happen when using a conventional diode rectifier). To prevent this, the TPS43000 incorporates a

high-speed comparator that senses the voltage on the synchronous rectifier using the SWP input, which is

connected to the synchronous rectifier MOSFET’s drain through a 1-kΩ resistor. This comparator is used to

determine when the inductor current is on the verge of going discontinuous and is referred to as the I

comparator. I n the boost and SEPIC (single-ended primary inductance converter) topologies, the synchronous

rectifier is turned off when the voltage on the SWP pin decreases to within 12 mV of VOUT. For this reason, it

is important to have the VOUT pin well decoupled. In the buck topology, the synchronous rectifier is turned off

when the voltage on the SWP pin increases to −12 mV with respect to ground. The I

as follows:

+

12 mV

R

DS(on)

www.ti.com

10

l

ZERO

threshold is defined

ZERO

ZERO

Page 11

(2)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

When the R

comparator is enabled, the MOSFET must be fully enhanced, and the drain-to-source voltage must be allowed

to settle. The TPS43000 has an internal circuit that enables the I

the rectifier MOSFET is enhanced.

NOTE: For the SEPIC topology, the voltage on the drain of the rectifier MOSFET swings to −VIN

when the energizing MOSFET is on. Therefore, in order to prevent the SWP input pin from being

damaged, it must connect to a Schottky diode clamp to ground.

PFM mode

For improved efficiency at light loads, the TPS43000 can be programmed to automatically enter PFM (Pulse

Frequency Modulation) mode by connecting the PFM

used for synchronous rectifier commutation. An internal digital counter is used to count the number of I

pulses at the output of the I

until the voltage at the FB pin falls to approximately 784 mV (output voltage drops 2% below nominal). At this

time, the controller turns back on and operates at its fixed-frequency for a short duration (load dependent,

typically 10 to 200 PWM cycles) increasing the output voltage. The cycle repeats when another seven I

pulses occur. This results in a very low duty cycle of operation, reducing all losses and improving light load

efficiency. During the sleep state, most of the circuitry internal to the TPS43000 is powered down. This reduces

quiescent current, which lowers the average dc operating current, enhancing its efficiency. The error amplifier

output is disconnected from the COMP pin during the sleep state. The COMP pin goes to high impedance and

maintains approximately the same voltage level it was at when it entered the sleep state. This minimizes error

amplifier overshoot/undershoot when coming out of the sleep state. The user can disable PFM by connecting

the PFM

low power mode

pin to VIN.

of the MOSFET is used as the sense element, several issues arise. Before the I

DS(on)

comparator approximately 40 ns after

ZERO

pin to ground. PFM is initiated by the I

comparator. When seven I

ZERO

pulses occur, the controller enters sleep state

ZERO

ZERO

ZERO

comparator

ZERO

ZERO

At relatively high gate drive voltages, gate drive losses can become excessive and begin to dominate under light

load conditions. The expression for gate drive power loss is given by equation (2). The power varies as a function

of the applied gate voltage squared.

2

ǒ

Ǔ

f

Q

P

GATELOSS

where Q

V

is the applied gate drive voltage, and f is the switching frequency.

G

When both VIN and VOUT are above 3.6 V, the TPS43000 automatically enters LP mode and selects the lower

voltage of VIN or VOUT to provide the gate drive voltage on the NDRV pin. This minimizes gate drive losses

at relatively high input and output voltages and helps maintain high efficiency at light loads. The PDRV pin

remains powered by either VIN (buck topology) or VOUT (boost, flyback, and SEPIC topologies) via the VP

power input pin.

To help provide a smooth transition in and out of LP mode, its circuitry has 300 mV of hysteresis. When either

VIN or VOUT drops below 3.3 V, the TPS43000 transitions back to normal mode and the NDR V pin is powered

by the higher potential of VIN or VOUT.

is the total gate charge, VS is the gate voltage specified in the MOSFET manufacturer’s data sheet,

G

+

V

G

G

V

S

,

www.ti.com

11

Page 12

(3)

(4)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

synchronization and shutdown

The TPS43000 incorporates a dual function synchronization and shutdown pin. It may be used to synchronize

the TPS43000’s switching frequency to an external clock, or to shutdown the device entirely.

To synchronize the internal clock to an external source, the SYNC/SD pin must be driven high, greater than

1.6 V. The circuitry synchronizes to the rising edge of the input. Duty cycle is not critical, but the pulse width must

be at least 100 ns wide but less than 10 µs to avoid shutdown. The external SYNC clock should be between

10% and 25% above the free-running switching frequency.

To ensure a shutdown of the converter, the SYNC/SD pin must be held high (above 1.6 V) for a minimum of

35 µs. In shutdown, both the energizing and rectifier MOSFETs are turned off. The quiescent current is reduced

to less than 10 µA with 1.6 V applied to SYNC/SD and less than 2 µA with VIN potential applied to SYNC/SD.

Bringing this pin low again allows the device to resume operation, starting with a full soft-start cycle.

overcurrent protection

The TPS43000 allows the user to select either pulse-by-pulse current limiting or hiccup mode overcurrent

protection using the CCS pin. To minimize external part count and minimize losses, the energizing MOSFET’s

R

to as the I

is connected to the energizing MOSFET’s drain through a 1-kΩ resistor. The I

SWN input to either ground (boost, flyback, and SEPIC topologies) or VIN (buck topology). Before the I

comparator is enabled, the energizing MOSFET must be fully enhanced, and the drain-to-source voltage must

be allowed to settle. The TPS43000 has an internal circuit that enables the I

60 ns after the energizing MOSFET is enhanced.

is used as the current sense element. The TPS43000 incorporates a high-speed comparator, referred

DS(on)

comparator, that senses the voltage across the energizing MOSFET using the SWN input ,which

MAX

comparator compares its

MAX

comparator approximately

MAX

MAX

pulse-by-pulse current limiting − constant current source mode (CCS tied to VIN)

In the pulse-by-pulse current limiting mode, the energizing MOSFET gate drive is terminated once the

overcurrent threshold is reached. An overcurrent, I

, is sensed when the voltage drop across the energizing

MAX

MOSFET reaches 150 mV. The pulse-by-pulse current limiting threshold is defined by the equation:

I

MAX(pp)

+

R

150 mV

DS(on)

In the boost, flyback, and SEPIC topologies, IMAX(pp) is reached when the voltage on the SWN pin is 150 mV

above ground. In the buck topology, IMAX(pp) is reached when the voltage on the SWN pin is 150 mV below

VIN. For this reason, it is important to have the VIN pin well decoupled. Pulse-by-pulse current limiting is enabled

by connecting the CCS input pin to VIN.

hiccup mode over current protection (CCS tied to ground)

In the hiccup mode overcurrent protection scheme, an internal digital counter is used to count the number of

I

pulses at the output of the I

MAX

comparator. An I

MAX

condition is sensed when the voltage drop across

MAX

the energizing MOSFET reaches 250 mV. The hiccup mode overcurrent threshold is defined by the equation:

I

MAX(hu)

In the boost, flyback, and SEPIC topologies, I

250 mV above ground. In the buck topology, I

is 250 mV below VIN. When 63 I

+

R

250 mV

DS(on)

MAX(hu)

MAX(hu)

MAX(hu)

condition is reached when the voltage on the SWN pin is

condition is reached when the voltage on the SWN pin

pulses are reached, both the energizing MOSFET and rectifier MOSFET

are turned off. The MOSFET switches are held off for 882 clock cycles before a soft-start is initiated. Hiccup

mode overcurrent protection is enabled by connecting the CCS input pin to ground.

12

www.ti.com

Page 13

(5)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

start-up and soft-start

The TPS43000 incorporates an UVLO circuit that disables the output drivers when the voltage at the VIN pin

is below 1.65 V. In order to prevent the converter from oscillating during low input voltage startup, the UVLO

circuit is designed with 200 mV of hysteresis and the converter remains on until VIN drops below 1.45 V.

The TPS43000 has a built-in soft-start that varies as a function of the switching frequency. The soft-start is a

closed-loop soft-start, meaning that the reference input to the error amplifier is ramped up over the soft-start

interval and the converter control loop is allowed to track the ramping reference signal. The soft-start interval

is set to approximately 2000 oscillator clock cycles. This method generally allows for faster soft-start times with

minimal output voltage overshoot at startup. During start-up, the synchronous rectifier is held off until the COMP

pin reaches 700 mV.

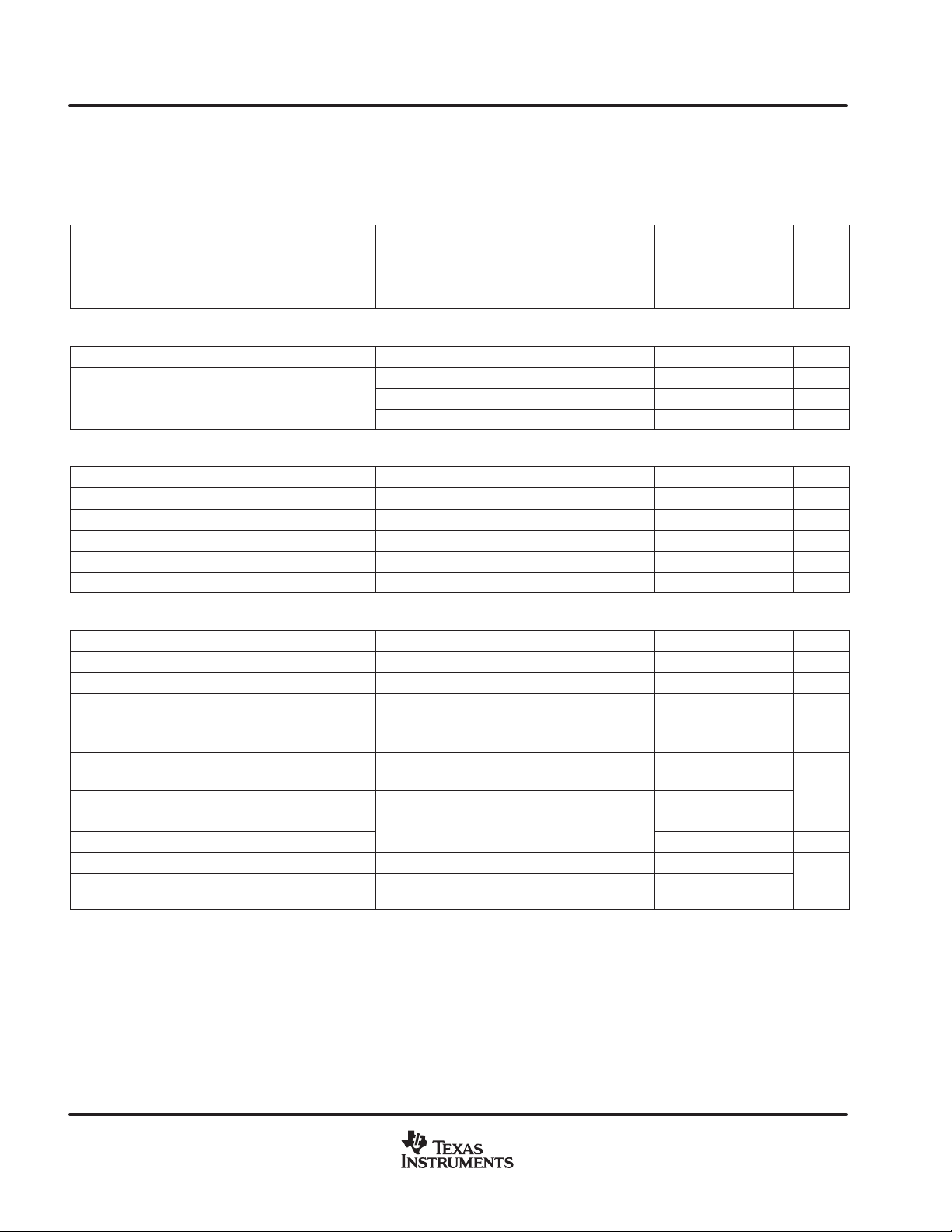

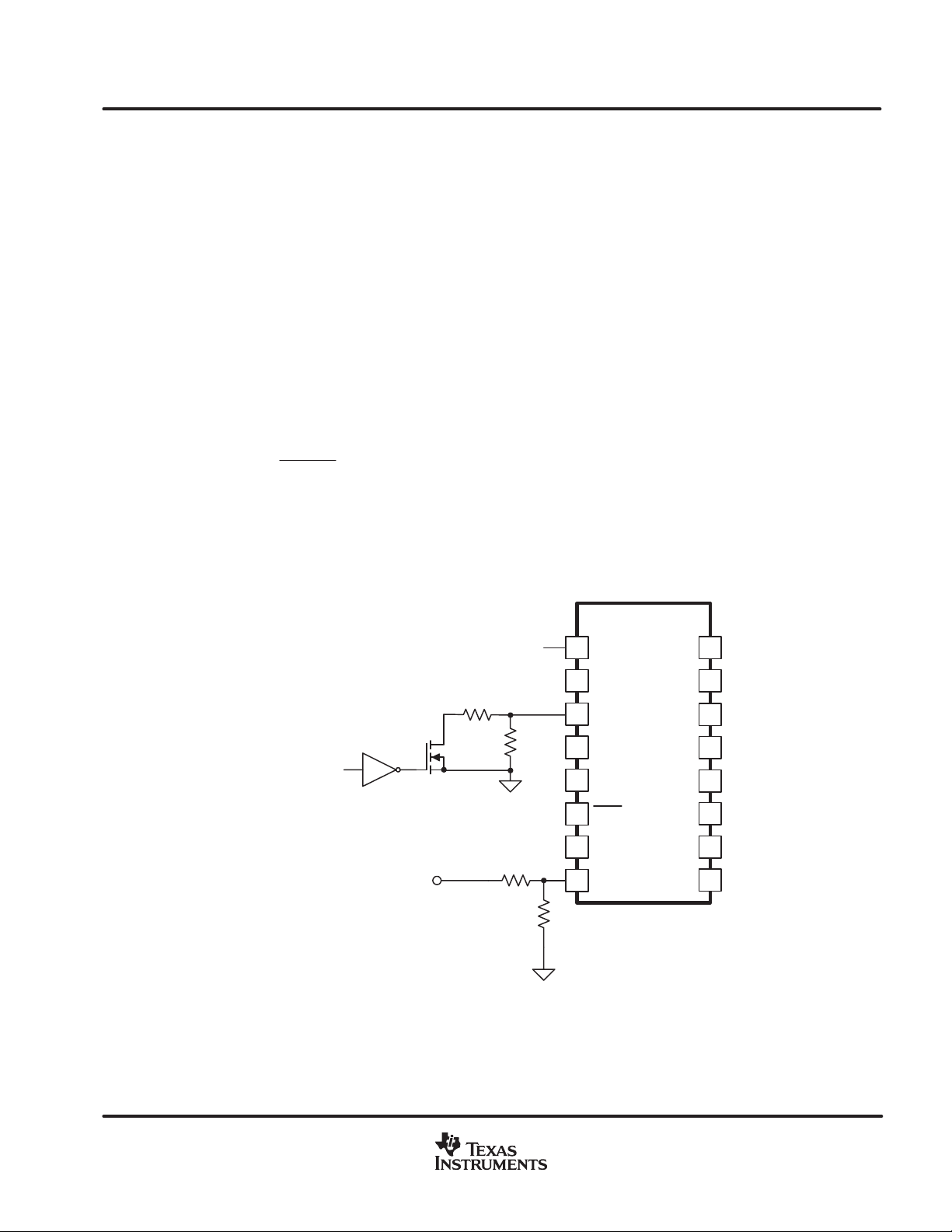

programming the PWM frequency

The oscillator frequency is programmed by a resistor from the RT pin to ground. The approximate operating

frequency is determined by the equation:

fSW(MHz) +

38

(kW)

R

T

The maximum operating frequency is 2 MHz. Some applications may want to remain in a fixed-frequency mode

of operation, even at light load, rather than going into PFM mode. This lowers efficiency at light load. One way

to improve the efficiency while maintaining fixed frequency operation is to lower the PWM frequency under

light-load conditions. This can be easily done, as shown in Figure 1. By adding a second timing resistor and a

small MOSFET switch, the host can switch between two discrete frequencies at any time.

TPS43000

SWN

SWP

VP

PDRV

GND

NDRV

VOUT

VIN

16

15

14

13

12

11

10

9

FREQUENCY

CONTROL

2N7002

V

OUT

RT2

R1

RT1

SYNC/SD

1

2

CCS

3

RT

4

CCM

5

BUCK

6

PFM

7

COMP

8

FB

R2

Figure 1. Changing the PWM Frequency

www.ti.com

UDG−01035

13

Page 14

C2

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

error amplifier

The TPS43000 uses voltage mode control for each of the topologies. The output voltage is sensed and fed back

to the FB pin (inverting input) and compared to an internal 800 mV reference connected to the non-inverting

input. The difference (i.e. error voltage), is amplified by the internal error amplifier. The output of the error

amplifier (COMP), is then compared to the oscillator sawtooth ramp to control the pulse width used to drive the

power switch (energizing MOSFET). The duty cycle is varied to regulate the output voltage. The higher the error

voltage, the longer the energizing MOSFET switch is on.

The transient response of a converter is a function of both small signal and large signal responses. The small

signal response is determined by the error amplifier’s loop compensation (feedback network), whereas the large

signal response is a function of the error amplifier’s gain bandwidth and slew rate (dv/dt) as well as the slew

rate of the inductor current (di/dt). The TPS43000 internal error amplifier has a 5-MHz unity gain bandwidth. This

almost assures that the loop bandwidth is limited by external circuit characteristics rather than error amplifier

limitations. The internal error amplifier is capable of sourcing and sinking an ensured 500 µA, which assures

that even during large signal transients, external components determine circuit behavior. Using low feedback

capacitance allows the error amplifier to rapidly slew from one level to another, insuring excellent transient

response.

loop compensation

The voltage loop needs to be compensated to provide control loop stability margin, and to minimize the output

voltage overshoot/undershoot response to line and load transients. A Type III error amplifier compensation

network can be used to optimize the loop response for any of the topologies and operating modes implemented

with the TPS43000. The T ype III amplifier circuit is shown in Figure 2. This configuration has a pole at the origin

and two zero-pole pairs. It can provide up to 180° of phase boost.

Av1

R3

VOUT

C3

R1

Figure 2. Type III Error Amplifier Compensation

Network

R

BIAS

R2

V

REF

C1

+

0 dB

Gain − dB

Av2

fz1 fz2 fp1 fp2

t − Time − ns

Figure 3. Type III Error Amplifier Compensation

Gain Response

14

www.ti.com

Page 15

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

APPLICATION INFORMATION

The frequency of the poles and zeros are defined by the following equations:

zeros

f

+

z1

(

2p R2 C1

1

)

SLUS489 − OCTOBER 2001

f

[

z2

(

2p R1 C3

poles

f

+

p1

(

f

[

p2

(

In voltage mode control, the buck, boost, flyback, and SEPIC toplogies all have a 2

characteristic when operated in CCM. In the buck topology, the frequency of the LC double pole is straight

forward.

f

+

LC

ǒ

In the boost, flyback, and SEPIC toplogies, the frequency of the LC double pole varies as a function of the duty

cycle.

f

+

LC

ǒ

In addition, each of the topologies have an ESR zero, which occurs when the output capacitor impedance

transitions from capacitive to resistive. The frequency at which this occurs is the ESR zero frequency, f

is defined by the equation:

1

1

2p R3 C3

1

2p R2 C2

1

1ń2

Ǔ

)

2p(LC

(

2p(LC

1 * D

)

)

1ń2

Ǔ

, assuming R1 ơ R3

)

)

, assuming C1 ơ C2

)

buck topology

boost, flyback, & SEPIC topologies

nd

order double-pole LC filter

ESR

, and

f

+

ESR

In the boost, flyback, and SEPIC topologies operated in CCM, there is also a right half-plane (RHP) zero. The

RHP zero has the same positive gain slope as the conventional zero, but has a 90° phase lag. This combination,

in conjunction with its dependence on line and load, make it nearly impossible to compensate within the control

loop. The frequency at which this RHP zero occurs, f

f

RHP

f

RHP

where RO is the equivalent output load resistance.

2p

R

+

R

+

ǒ

O

O

1

R

ESR

(

1 * D

(

2 p L

(

1 * D

(

2 p LD

Ǔ

)

)

C

2

)

boost topology

2

)

flyback topology

RHP

www.ti.com

, is defined by the equations:

15

Page 16

(15)

(16)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

With voltage-mode control, the closed-loop design goal for each of the topologies with the T ype III error amplifier

compensation is to set the crossover frequency above the resonant frequency of the LC filter (prevents filter

oscillations during a transient response), but below the lowest possible RHP zero frequency. This is

accomplished by setting the two zeros in the compensation network before the LC double pole frequency. This

provides a phase boost. The two poles should be placed a decade above the crossover frequency.

The following is a typical procedure for selecting the loop compensation values for a buck converter operated

in CCM:

Step 1. Select the desired crossover frequency a decade above the LC pole frequency.

Step 2. Set the resistor divider formed by R1 and R

R

sets the dc operating point of the loop, but has no effect on ac operation and does not factor into

BIAS

the loop compensation calculations.

Step 3. Set the zero formed by R1 and C3 to approximately one-half decade above the LC double pole to

compensate for the phase loss.

Step 4. Set the zero formed by R2 and C1 to approximately one-half decade below the LC double pole to avoid

a conditional instability.

Step 5. Set the pole formed by R3 and C3 to cancel the ESR zero of the output capacitor.

Step 6. Set the pole formed by R2 and C2 to approximately one-half decade above the crossover frequency.

to develop the desired regulation voltage. Note that

BIAS

If the converter is operated in DCM, the lead network (R3 and C3 in Figure 2) can be eliminated for all topologies.

This configuration is referred to as a Type II error amplifier compensation network and has a pole at the origin

and a single zero-pole pair. It can provide up to 90° of phase boost. The frequency of the pole and zero are

defined by the following equations:

zero

f

+

z1

(

2p R2 C1

pole

f

[

p1

(

2p R2 C2

The zero-pole pair is used to compensate for the power circuit’s ESR zero and the pole formed by the output

capacitor and the effective output resistance.

1

)

1

, Assuming C1 ơ C2

)

16

www.ti.com

Page 17

(17)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

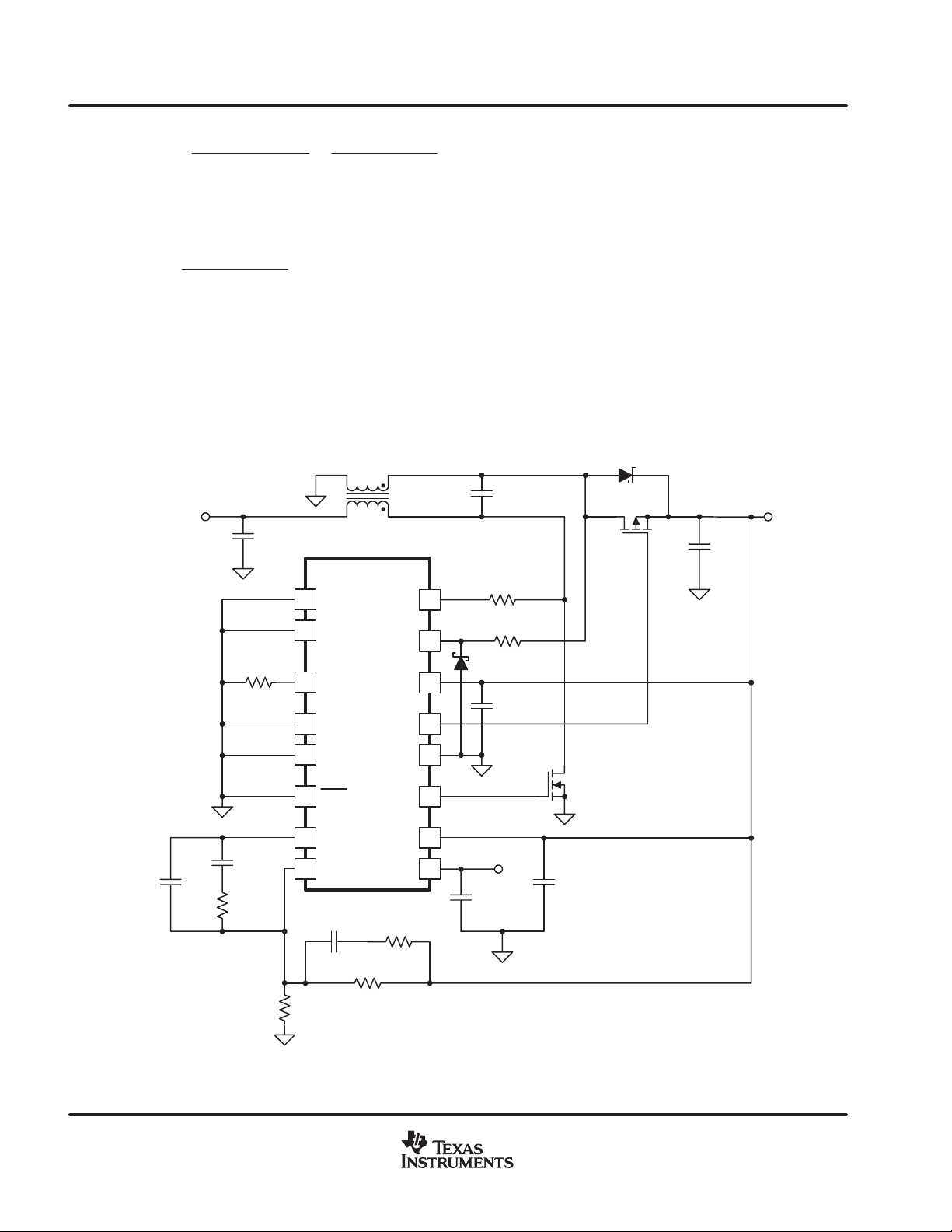

design examples: buck, boost, non-synchronous boost, flyback, and SEPIC

buck converter

The buck topology is simple and efficient, and should be used whenever the desired output voltage is less than

the minimum input voltage. Figure 4 shows the TPS43000 in a typical (750 kHz) buck converter with an input

voltage range of 3.0 V to 9.0 V, an output voltage of 2.7 V, and a load current from 0 A to 2 A.

Q2

16

15

14

13

12

11

10

9

Si9803DY

R5

1 kΩ

C5

0.47µF

C6

0.47µF

V

IN

0.47µF

V

IN

C2

10 pF

100µF

R4

49.9 kΩ

C1

560 pF

R2

75 kΩ

C7

1

SYNC/SD

2

CCS

RT

3

CCM

4

5

BUCK

6

PFM

7

COMP

8

FB

TPS43000

C3

100 pF

SWN

SWP

VP

PDRV

GND

NDRV

VOUT

VIN

R3

49.9 kΩ

3.3µH

Q1

Si9804DY

C4

L1

D1

ZHCS1000

(OPTIONAL)

C8

120 µF

V

OUT

V

IN

R1

127 kΩ

R

BIAS

53.6 kΩ

Figure 4. 2.7-V Output Buck Topology

For a buck converter, the average output current is related to the peak inductor current by:

Ipk+ I

OUT

ǒ

)

VIN* V

ǒ

2 fSW L

OUT

Ǔ

D

Ǔ

www.ti.com

UDG−01035

17

Page 18

(18)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

where fSW is the switching frequency , L is the inductor value, and D is the duty cycle. The duty cycle for a buck

converter is defined as:

V

OUT

D +

V

IN

Note that in these equations the voltage drop across the rectifier has been neglected.

boost converter

The boost topology is simple and efficient, and should be used whenever the desired output voltage is greater

than the maximum input voltage. Figure 5 shows the TPS43000 in a typical (750 kHz) boost converter with an

input voltage range of 2.5 V to 4.5 V, an output voltage of 5.0 V, and a load current from 0 A to 1 A.

D1

L1

3.3 µH

V

IN

C7

100 µF

R5

1 kΩ

1

SYNC/SD

TPS43000

SWN

16

ZHCS1000

(OPTIONAL)

Q2

Si9803DY

C8

120 µF

V

OUT

C2

330 pF

R4

49.9 kΩ

C1

3300 pF

R2

30.1 kΩ

2

CCS

3

RT

4

CCM

5

BUCK

6

PFM

7

COMP

8

FB

R

BIAS

53.6 kΩ

C3

680 pF

280 kΩ

R1

SWP

VP

PDRV

GND

NDRV

VOUT

VIN

24.9 kΩ

R3

15

14

13

12

11

10

C6

0.47 µF

Q2

Si9804DY

9

C5

0.47 µF

V

IN

C4

0.47 µF

UDG−01037

18

Figure 5. 5-V Output Boost Topology

www.ti.com

Page 19

(19)

(20)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

For a boost converter, the average output current is related to the peak inductor current by the following

equation:

ǒ

V

I

+

ǒ

V

OUT

ǒ

OUT

V

h V

* V

OUT

I

pk

where fSW is the switching frequency , L is the inductor value, and D is the duty cycle. The duty cycle for a boost

converter is defined as:

D +

Note that in these equations the voltage drop across the rectifier has been neglected.

non−synchronous boost converter

The TPS43000 can also be used in non-synchronous applications to provide output voltages greater than 8 V

from low voltage inputs. Figure 6 shows the TPS43000 in a non-synchronous boost converter (750 kHz)

application with an input voltage range of 2.5 V to 9.0 V, an output voltage of 12 V, and a load current from 0

A to 1 A. Since none of the device pins are exposed to the boosted voltage, the output voltage is limited only

by the ratings of the external MOSFET, rectifier, and filter capacitor. At these higher output voltages, good

efficiency is maintained since the rectifier drop is small compared to the output voltage. Note that the PFM mode

can still be used to maintain high efficiency at light load.

Since all the power supply pins (VIN, VOUT, VP) operate off the input voltage, it must be greater than 2.5 V and

high enough to assure proper gate drive to the charge MOSFET.

OUT

IN

IN

Ǔ

ǒ

VIN D

)

Ǔ

ǒ

2 fSW L

Ǔ

Ǔ

Ǔ

www.ti.com

19

Page 20

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

V

IN

C2

330 pF

100 µF

R4

49.9 kΩ

C1

3300 pF

R2

30.1 kΩ

C7

1

SYNC/SD

2

CCS

3

RT

4

CCM

5

BUCK

6

PFM

7

COMP

8

FB

3.3 µH

TPS43000

C3

680 pF

L1

SWN

SWP

VP

PDRV

GND

NDRV

VOUT

VIN

R3

24.9 kΩ

16

15

14

13

12

11

10

D1

ZHCS1000

V

OUT

C8

120 µF

R5

1 kΩ

V

IN

C6

0.47 µF

Q2

Si9804DY

V

IN

9

C5

0.47 µF

V

IN

C4

0.47 µF

R1

750 kΩ

R

BIAS

53.6 kΩ

Figure 6. 12-V Output Non-Synchronous Boost Topology

UDG−01038

20

www.ti.com

Page 21

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

flyback converter

A flyback converter (750 kHz) using the TPS43000 is shown in Figure 7. It uses a standard two-winding coupled

inductor with a 1:1 turns ratio. The advantage of this topology is that the output voltage can be greater or less

than the input voltage. For example, this is ideal for generating 3.3 V from a lithium-ion cell.

L1B

V

IN

C7

100 µF

1

2

R4

49.9 kΩ

3

4

L1A

3.3 µH

TPS43000

SYNC/SD

CCS

RT

CCM

SWN

SWP

VP

PDRV

R5 1 kΩ

16

R6 1 kΩ

15

14

C6

0.47 µF

13

D1

ZHCS1000

(OPTIONAL)

Q2

Si9803DY

C8

120 µF

V

OUT

R1

169 kΩ

GND

NDRV

VOUT

VIN

R3

6.81 kΩ

12

11

10

Q1

Si9804DY

C5

0.47 µF

V

IN

C4

0.47 µF

9

C2

82 pF

C1

3900 pF

R2

24.9 kΩ

5

BUCK

6

PFM

7

COMP

8

FB

1200 pF

R

BIAS

53.6 kΩ

C3

Figure 7. 3.3-V Output Flyback Topology

NOTE: Resistor-capacitor snubbers can be placed across the primary and secondary windings to

reduce ringing due to leakage inductance. These are optional, and may not be required in the

application.

UDG−01039

For a flyback converter, the average output current is related to the peak inductor current by:

www.ti.com

21

Page 22

(21)

(22)

SLUS489 − OCTOBER 2001

ǒ

V

I

+

pk

OUT

ǒ

h V

I

OUT

IN

Ǔ

ǒ

VIN D

Ǔ

)

Ǔ

ǒ

2 fSW L

Ǔ

where fSW is the switching frequency , L is the inductor value, and D is the duty cycle. The duty cycle for a flyback

converter is defined as:

V

ǒ

VIN) V

OUT

OUT

Ǔ

D +

Note that in these equations the voltage drop across the rectifier has been neglected.

SEPIC converter

The TPS43000 may also be used in the SEPIC topology. This topology, which is similar to the flyback, uses a

capacitor to aid in energy transfer from input to output. Figure 8 shows the TPS43000 in a SEPIC converter

(750 kHz) application with an input voltage range of 2.5 V to 6.0 V, an output voltage of 3.3 V, and a load current

from 0 A to 1 A.

L1B

C9

V

IN

C7

100 µF

1

2

R4

49.9 kΩ

3

4

L1A

4.9 µH

TPS43000

SYNC/SD

CCS

RT

CCM

SWN

SWP

VP

PDRV

16

15

14

13

10 µF

R5 1 kΩ

R6 1 kΩ

D1 BAT54

C6

0.47 µF

D1

ZHCS1000

(OPTIONAL)

Q2

Si9803DY

C8

120 µF

V

OUT

22

C2

82 pF

C1

3900 pF

R2

24.9 kΩ

R1

169 kΩ

GND

NDRV

VOUT

VIN

R3

6.81 kΩ

12

11

10

9

C5

0.47 µF

0.47 µF

5

BUCK

PFM

6

COMP

7

8

FB

C3

1200 pF

R

BIAS

53.6 kΩ

Figure 8. 3.3-V Output SEPIC Topology

www.ti.com

Q1

Si9804DY

C4

UDG−01040

Page 23

(23)

(24)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

The SEPIC topology offers the same advantage of the flyback in that it can generate an output voltage that is

greater or less than the input voltage. However, it also offers improved efficiency. Although it requires an

additional capacitor in the power stage, it greatly reduces ripple current in the input capacitor and improves

efficiency by transferring the energy in the leakage inductance of the coupled inductor to the output. This also

provides snubbing for the primary and secondary windings, eliminating the need for RC snubbers. Note that

the capacitor must have low ESR, with sufficient ripple current rating for the application. Another advantage of

the SEPIC is that the inductors do not have to be on the same core.

theory of operation

When the energizing MOSFET (Q1) is on, V

At the same time, the voltage across the SEPIC capacitor C9 (equal to V

end also negative. Since L1A = L1B and the voltages across the two inductors are equal (V

currents ramp up at the same rate (di/dt=V

currents. When the energizing MOSFET turns off, the inductor current wants to continue to flow causing the

inductor voltages to reverse until the output rectifer begins to conduct. The voltage across L1B is clamped to

V

(plus the rectifier drop) and with its dotted end positive. The voltage across the SEPIC capacitor (VIN)

OUT

cancels with V

and the voltage across the two inductors are equal (V

(di/dt=V

by L1B when the energizing MOSFET is on. Since the voltages across the inductors are identical at all times

throughout the switcing cycle, the inductors can be coupled on a single magnetic core with an equal number

of turns. This improves the SEPIC application’s dynamic performance and also allows reduction of the input

filtering requirements through ripple steering.

OUT

and the voltage across L1A is also V

IN

/L). The SEPIC capacitor is charged by L1A when the energizing MOSFET is off and is discharged

is applied across L1A with the dotted end negative (see Figure 8).

IN

/L). The energizing MOSFET current is the sum of the two inductor

IN

with its dotted end positive. Again, since L1A=L1B

OUT

), the inductor current ramps down at the same rate

OUT

) is applied across L1B with its dotted

IN

), the inductor

IN

selecting the inductor

The inductor must be chosen based on the desired operating frequency and the maximum load current. Higher

frequencies allow the use of lower inductor values, reducing component size. Higher load currents require larger

inductors with higher current ratings and less winding resistance to minimize losses. The inductor must be rated

for operation at the highest anticipated peak current. Refer to equations 17, 19, and 21 to calculate the peak

inductor current for a buck, boost, flyback, or SEPIC design, based on VIN, VOUT, duty cycle, maximum load,

frequency, and inductor value. Some manufacturers rate their parts for maximum energy storage in microjoules

(µJ). This is expressed by:

2

ǒ

E + 0.5 L

where E is the required energy rating in microjoules, L is the inductor value in microhenries (µH) (with current

applied), and Ipk is the peak current in amps that the inductor sees in the application. Another way in which

inductor ratings are sometimes specified is the maximum volt-seconds applied. This is given simply by:

ǒ

VIN D

ET +

where ET is the required rating in V-µs, D is the duty cycle for a given VIN and V

frequency in MHz. Refer to equations 18, 20, and 22 to calculate the duty cycle for a buck, boost, flyback, or

SEPIC converter.

In any case, the inductor must use a low loss core designed for high-frequency operation. High-frequency ferrite

cores are recommended. Some manufacturers of off-the-shelf surface-mount designs are listed in Table 1. For

flyback and SEPIC topologies, use a two-winding coupled inductor. SEPIC designs can also use two discrete

inductors.

f

SW

Ǔ

I

pk

Ǔ

, and fSW is the switching

OUT

www.ti.com

23

Page 24

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

Table 1. SMT Commercial Inductor Manufacturers

Coilcraft Inc. (800) 322−2645 1102 Silver Lake RD, Cary, IL 60013

Coiltronics Inc. (407) 241−7876 6000 Park of Commerce Blvd, Boca Raton, FL 33487

Dale Electronics, Inc. (605) 665−9301 East Highway 50, Yankton, SD 57078

Pulse Engineering Ltd. (204) 633−432 1300 Keewatin Street, Winnipeg, MB R2X 2R9

Sumida

BH Electronics (612) 894−9590 12219 Wood Lake Drive, Burnsville, MN 55337

Tokin America Inc. (408) 432−8020 155 Nicholson Lane, San Jose CA 95134

1−847−545−6700

Fax 1−847−545−6720

selecting the filter capacitor

The input and output filter capacitors must have low ESR and low ESL. Surface-mount tantalum, OSCONs or

multilayer ceramics (MLCs) are recommended. The capacitor selected must have the proper ripple current

rating for the application. Some recommended capacitor types are listed in Table 2.

1701 Golf Road, Tower 3, Suite 400,

Rolling Meadows, IL 60008

Table 2. Recommended SMT Filter Capacitors

Manufacturer Part Number Features

AVX TPS series Low ESR tantalum

Kemet T410 series Low ESR tantalum

Murata GRM series Low ESR ceramic

Sanyo OSCON series Low ESR organic

Sprague

Tokin Y5U, Y5V Type Low ESR ceramic

Taiyo Yuden X5R Type Low ESR ceramic

591D series Low ESR, low profile tantalum

594D series Low ESR tantalum

circuit layout and grounding

As with any high-frequency switching power supply, circuit layout, hookup, and grounding are critical for proper

operation. Although this may be a relatively low-power , low-voltage design, these issues are still very important.

The MOSFET turn-on and turn-off times necessary to maintain high efficiency at high switching frequencies of

1 MHz or more result in high dv/dt and di/dts. This makes stray circuit inductance especially critical. In addition,

the high impedances associated with low-power designs, such as in the feedback divider, make them especially

susceptible to noise pickup.

layout

The component layout should be as tight as possible to minimize stray inductance. This is especially true of the

high-current paths, such as in series with the MOSFETs and the input and output filter capacitors.

The components associated with the feedback, compensation and timing should be kept away from the power

components (MOSFETs, inductor). Keep all components as close to the device pins as possible. Nodes that

are especially noise sensitive are the FB, RT and COMP pins.

24

www.ti.com

Page 25

(25)

SLUS489 − OCTOBER 2001

APPLICATION INFORMATION

grounding

A ground plane is highly recommended. The GND pin of the TPS43000 should be close to the source of the

N-channel MOSFET, the input filter capacitor, and the output filter capacitor. The grounded end of the RT

resistor, the feedback divider resistor, and the SYNC/SD, CCS, CCM, PFM

based on the application) form the signal ground and should be connected to the quietest location of the ground

plane (away from switching elements).

MOSFET gate resistors

The TPS43000 includes low-impedance CMOS output drivers for the two external MOSFET switches. The

NDRV output has a nominal pull-up resistance of 6.5 Ω and a nominal pull-down resistance of 2.25 Ω. The PDRV

output has a nominal pull-down resistance of 3.5 Ω and a nominal pull-up resistance of 2.5 Ω. For

high-frequency operation using low gate charge MOSFETs, no gate resistors are required. To reduce

high-frequency ringing at the MOSFET gates, low-value series gate resistors may be added. These should be

non-inductive resistors, with a value of 2 Ω to 10 Ω , depending on the frequency of operation. Lower values

result in better switching times, improving efficiency.

minimizing output ripple and noise spikes

The amount of output ripple is determined primarily by the type of output filter capacitor and how it is connected

in the circuit. In most cases, the ripple is dominated by the ESR (equivalent series resistance) and ESL

(equivalent series inductance) of the capacitor, rather than the actual capacitance value. Low ESR and ESL

capacitors are mandatory in achieving low output ripple. Surface-mount packages greatly reduce the ESL of

the capacitor, minimizing noise spikes. To further minimize high frequency spikes, a surface-mount ceramic

capacitor should be placed in parallel with the main filter capacitor. For best results, a capacitor should be

chosen whose self-resonant frequency is near the frequency of the noise spike. For high switching frequencies,

ceramic capacitors alone may be used, reducing size and cost.

, and BUCK pins (when tied to ground

For applications where the output ripple must be extremely low, a small LC filter may be added to the output.

The resonant frequency should be below the selected switching frequency, but above that of any dynamic loads.

The filter’s resonant frequency is given by:

f

+

RES

where f is the frequency in Hz, L is the filter inductor value in Henries, and C is the filter capacitor value in Farads.

It is important to select an inductor rated for the maximum load current and with minimal resistance to reduce

losses. The capacitor should be a low-impedance type, such as a tantalum.

If an LC ripple filter is used, the feedback point can be taken before or after the filter, as long as the filter’s

resonant frequency is well above the loop crossover frequency . Otherwise, the additional phase lag makes the

loop unstable. The only advantage to connecting the feedback after the filter is that any small voltage drop

across the filter inductor is corrected for in the loop, providing the best possible voltage regulation. However,

the resistance of the inductor is usually low enough that the voltage drop is negligible.

ǒ

2 p (L C

1

1ń2

Ǔ

)

www.ti.com

25

Page 26

PACKAGE OPTION ADDENDUM

www.ti.com

11-Apr-2013

PACKAGING INFORMATION

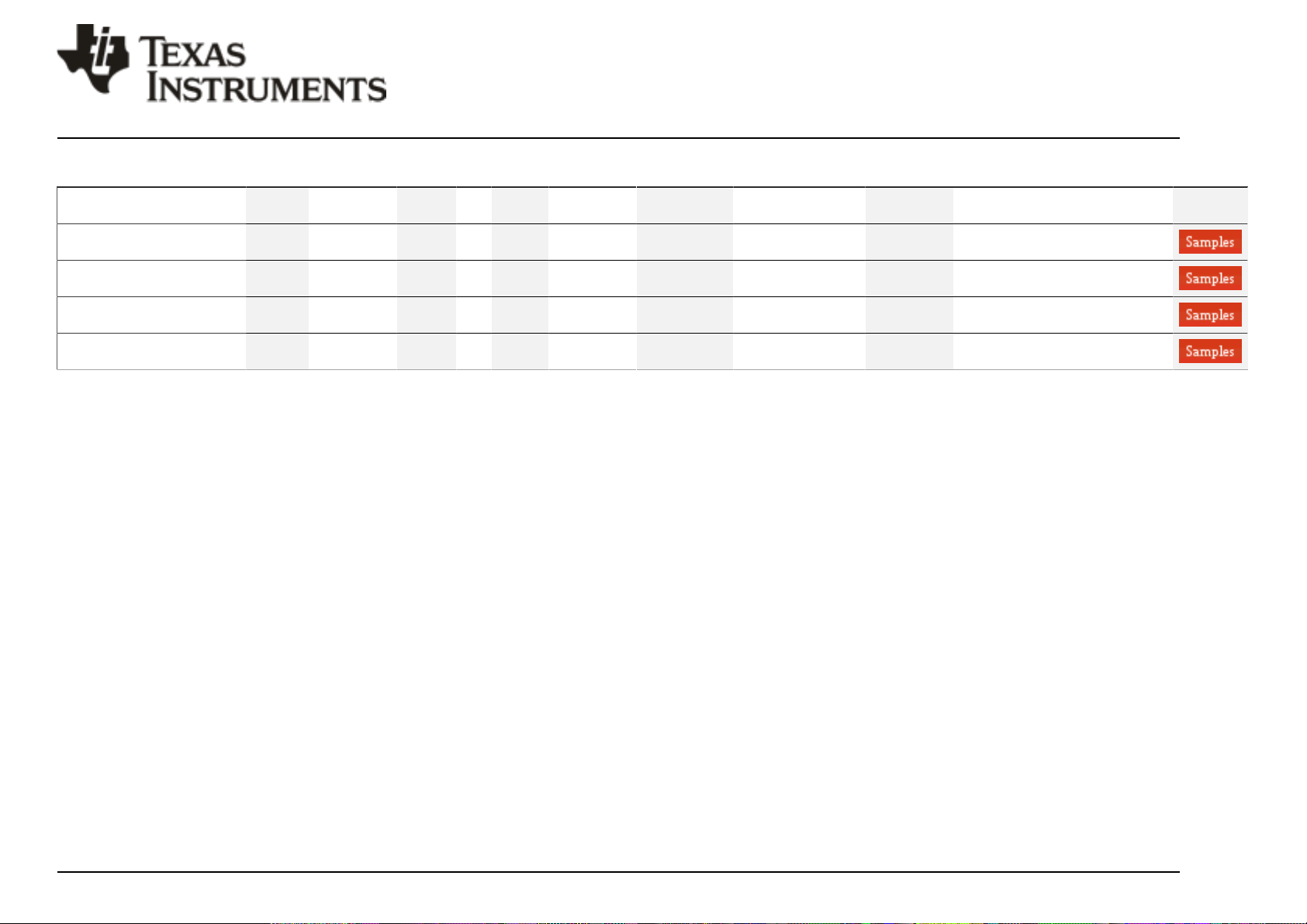

Orderable Device Status

TPS43000PW ACTIVE TSSOP PW 16 90 Green (RoHS

TPS43000PWG4 ACTIVE TSSOP PW 16 90 Green (RoHS

TPS43000PWR ACTIVE TSSOP PW 16 2000 Green (RoHS

TPS43000PWRG4 ACTIVE TSSOP PW 16 2000 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish MSL Peak Temp

(3)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 43000

CU NIPDAU Level-1-260C-UNLIM -40 to 85 43000

CU NIPDAU Level-1-260C-UNLIM -40 to 85 43000

CU NIPDAU Level-1-260C-UNLIM -40 to 85 43000

Op Temp (°C) Top-Side Markings

(4)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

Multiple Top-Side Markings will be inside parentheses. Only one Top-Side Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a

continuation of the previous line and the two combined represent the entire Top-Side Marking for that device.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Samples

Addendum-Page 1

Page 27

PACKAGE OPTION ADDENDUM

www.ti.com

11-Apr-2013

Addendum-Page 2

Page 28

PACKAGE MATERIALS INFORMATION

www.ti.com 14-Jul-2012

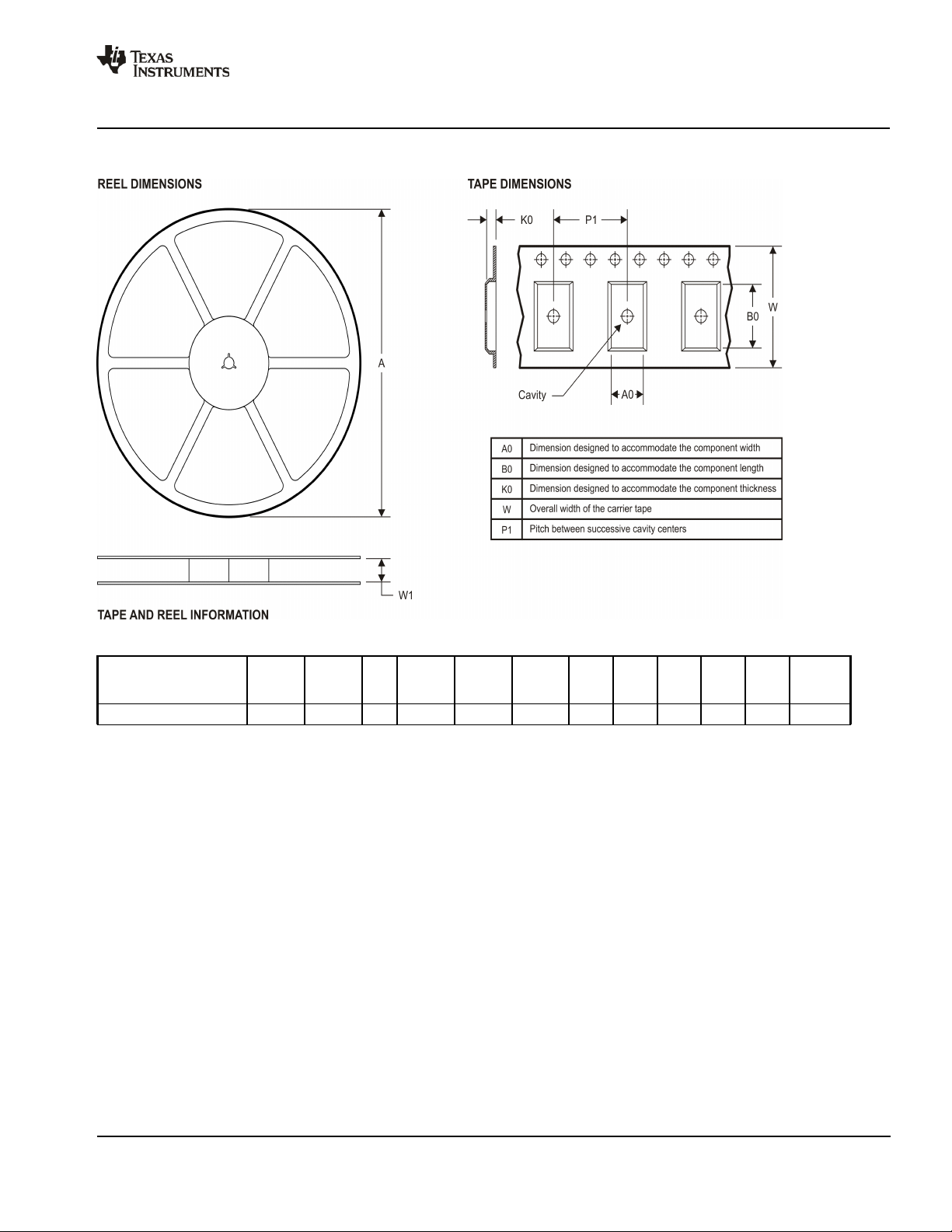

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

TPS43000PWR TSSOP PW 16 2000 330.0 12.4 6.9 5.6 1.6 8.0 12.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 29

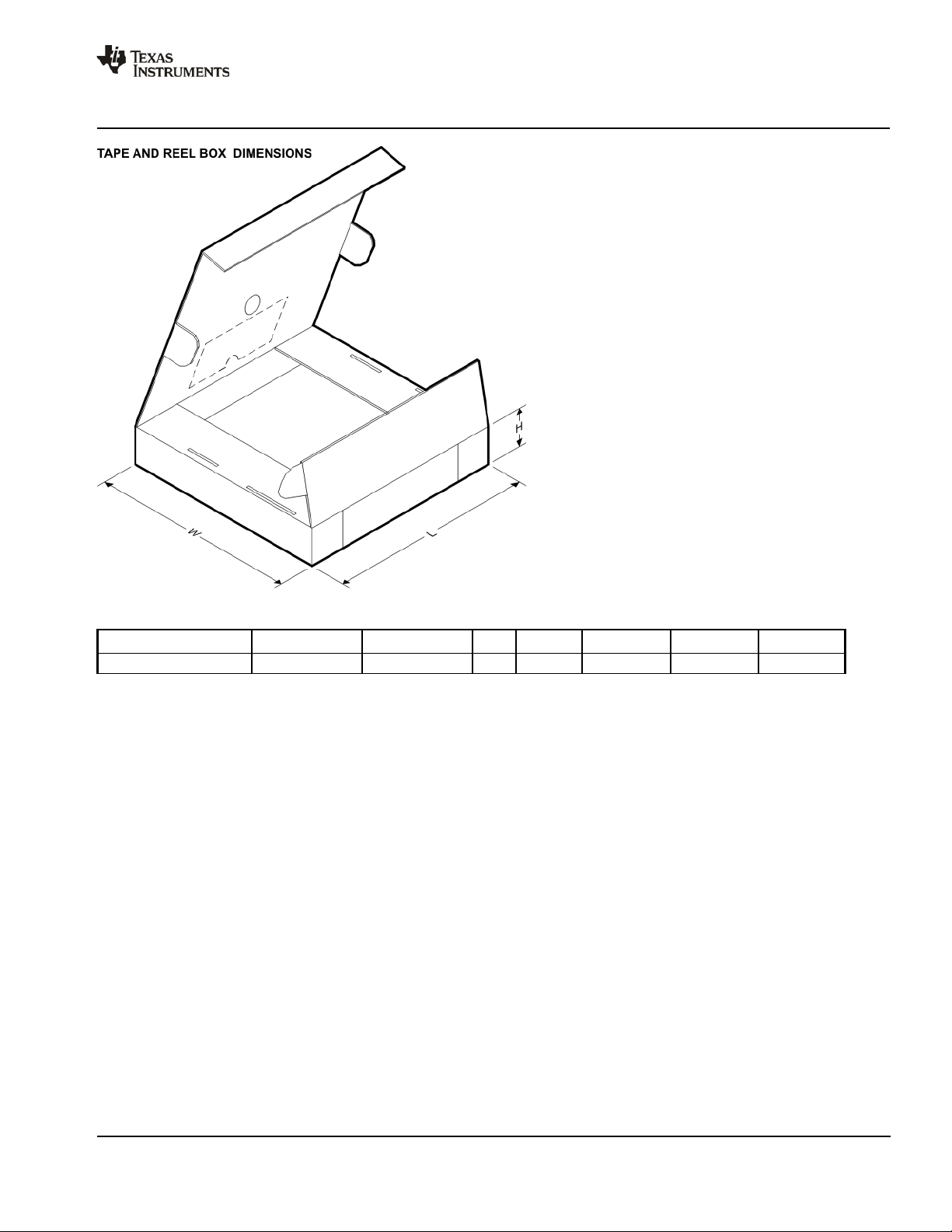

PACKAGE MATERIALS INFORMATION

www.ti.com 14-Jul-2012

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS43000PWR TSSOP PW 16 2000 367.0 367.0 35.0

Pack Materials-Page 2

Page 30

Page 31

Page 32

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Page 33

Loading...

Loading...