TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

D

0 V to16 V, 50 mA Max PWM Gate Drive

Output

D

Dual Speed Command Input Capability

D

Effective Motor Voltage Adjustment

D

100% Duty Cycle Capability

D

Low Current (<200 µA) Sleep State

D

Built-in Soft Start

D

Over/Under V oltage Protection

D

Over Current Protection of External

FET/IGBT

D or N PACKAGE

V5P5

MAN

AUTO

SPEED

ROSC

COSC

INT

(TOP VIEW)

1

14

2

13

3

12

4

11

5

10

6

7

9

8

CCS

AREF

V

bat

GD

GND

ILS

ILR

description

The TPIC2101 is a monolithic integrated control circuit designed for direct current (dc) brush motor control that

generates a user-adjustable, fixed-frequency, variable duty cycle, pulse width modulated (PWM) signal

primarily to control rotor speed of a permanent magnet dc motor. The TPIC2101 can also be used to control

power to other loads such as solenoids and incandescent bulbs. This device drives the gate of an external, low

side NMOS power transistor to provide PWM controlled power to a motor or other loads. Inductive current from

motor or solenoid loads during PWM off-time is recirculated through an external diode.

The TPIC2101 accepts a 0% to 100% PWM signal (auto mode) or a 0 V to 2.2 V differential voltage (manual

mode), and internally engages the correct operating mode to accept the input type.

The device operates in a sleep state, a run state, or a fault state. In the sleep state the gate-drive (GD) terminal

is held low and the overall current draw is less than 200 µA. The normal operating mode of the device is in the

run state and is initiated by any speed command. When the device detects an overvoltage or current fault, it

enters the fault state.

The TPIC2101 is offered in a 14-terminal plastic DIP (N) package, and a SOIC (D) package, and is characterized

for operation over the operating free-air temperature range of –40°C to 105°C.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Copyright 1995, Texas Instruments Incorporated

1

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

functional block diagram

V5P5

Sleep

AUTO and MAN

Logic

Sleep AREF 20 kHz

Oscillator and

Voltage Ramp

Waveform Generator

MAN

AUTO

CCS

V5P5

2

AUTO and MAN

Input Config

3

I

CCS

CCS

14

Buffer

1

V

bat

Bandgap

Buffer

Sleep

AREF

V5P5

V

bat

+

_

MDET

V

bat

+

_

V5P5

V

bat

2×

Bandgap

and IBIAS

ADET

UVSD

20 kHz

20 kHz

Source

Select

Sleep

SPEED INT

47

V7

AREF

_

+

V

trip

V

ramp

V

bat/4

AREF

PWMout

V

bat

Switched

V

bat

AREF

20 kHz

ILimit

Logic

IDET GDDIS

Sleep OVSD

V

bat/8

V5P5

GD

Logic

AREF

OVSD

IFLT

UVSD

AREF

V5P5

V5P5

UVSD

Gate

Drive

8

ILR

9

ILS

12

V

bat

11

GD

10

GND

13 5 6

AREF ROSC COSC

NOTE A: For correct operation, no terminal may be taken below GND.

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

I/O

DESCRIPTION

DESCRIPTION

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

Terminal Functions

TERMINAL

NAME NO.

V5P5 1 O 5.5 V supply voltage. V5P5 is a regulated voltage supply from V

MAN 2 I Manual control input. MAN is an active high (greater than 5.5 V asserts the manual mode) input that serves

AUTO 3 I PWM control input. AUTO is an active low input that remains active if pulsed every 2048 counts of the

SPEED 4 O Integrator output. SPEED is an integrator output with a required minimum resistance between SPEED and

ROSC 5 O Oscillator resistor output. ROSC has an external resistor connected to ground which determines the

COSC 6 O Oscillator capacitor output. COSC has an external capacitor connected to ground which determines (with

INT 7 I Integrator input. INT is an input from an integrator that requires a 4.7 µF capacitor and a 20 k minimum

ILR 8 I Current limit reference. ILR is an input from a resistor divider off AREF.

ILS 9 I Current limit sense. ILS senses drain voltage of external FET. ILS trips within ±10 mV of ILR.

GND 10 Ground terminal

GD 11 O Gate drive output. GD, PWM output, 0-V

V

bat

AREF 13 O 5.5 V reference voltage. AREF is a 5.5 V reference voltage switched from V5P5 during the run state. AREF

CCS 14 Constant current sink. I

12 I Positive power input.

run state. This requires a 4.7 µF tantalum capacitor from V5P5 to GND for stability.

as a positive differential input (0-2.3 V full range) for the manual mode. In man mode, I

oscillator frequency. It also serves as a negative differential input for the manual mode. In auto mode, I

is approx. 13×Iccs pullup, I

INT terminals of 20 kΩ (typically 1 second RC time constant, or as required for soft start).

constant charging current of COSC. The IC forces a voltage of V

ROSC) switching frequency. f(osc) = 2/(ROSC×COSC)

resistance between the SPEED and INT terminals.

FET .

is used as a reference for ILR in current limit detection and is capable of sourcing 2 mA of current.

is approx. 20×I

auto

equals AREF/(2×R

CCS

pulldown in man mode.

ccs

voltage, provides a 0-V

bat

). Requires an external resistor.

ccs

, internally switched to AREF during the

bat

is approx. 20×I

man

/4 in run state.

bat

PWM output pre-drive for an external

bat

ccs

auto

.

recommended external components for auto and manual modes (see Figures 2 and 4)

TERMINAL

NAME NO.

V5P5 1 Capacitor – 4.7 µF tantalum

MAN 2 Capacitor – 0.1 µF

MAN 2 Resistor – 499 Ω, 1%, 100 ppm

AUTO 3 Capacitor – 0.47 µF

AUTO 3 Resistor – 499 Ω, 1%, 100 ppm

SPEED 4 Resistor – 100 kΩ, 1%, 100 ppm to INT terminal, (minimum 20 kΩ)

ROSC 5 Resistor – 45.3 kΩ

COSC 6 Capacitor – 2200 pF

INT 7 Capacitor – 4.7 µF

CCS 14 Resistor – 27.4 kΩ, 1%, 100 ppm

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

3

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

detailed description

The TPIC2101 is an integrated circuit that generates a fixed frequency , variable duty cycle PWM signal to control

the rotor speed of a permanent-magnet dc motor. This section provides a functional description of the device.

dual command speed input capability

The TPIC2101 is user configurable to either auto or manual mode, and can sense either configuration internal

to the IC. In automatic mode, the speed-command-signal is an open-collector PWM signal on the AUTO

terminal, and the MAN terminal is floating. In manual mode, the speed-command-signal is a variable resistance

across the AUTO and MAN terminals with the MAN terminal connected to V

sleep, run, and fault states

The TPIC2101 operates in a sleep state, a run state, or a fault state. In the auto mode, a zero-speed input

initiates the sleep state. In the manual mode, an open-circuit at the AUTO and MAN terminals initiates the sleep

state. The device will also be in the sleep state during fault conditions. In the sleep state, the gate drive terminal

(GD) is held low and the overall current draw is less than 200 µA. Any speed command initiates the run state,

which is the normal operating state of the device. The fault state is entered only when the device detects an

overvoltage or current fault. Fault state is exited either by removal of the overvoltage condition (exiting to run

state) or by resetting a current fault by entering the sleep state.

speed command adjustment

bat

.

The device adjusts the GD terminal PWM signal with changes in V

to keep the effective motor voltage

bat

constant. The effective motor voltage is defined to be the product of the GD terminal PWM rate and the voltage

of V

. Figure 1 shows motor voltage as a function of input speed command in the automatic mode for various

bat

battery voltages. PWM

is described as the duty cycle of the PWM signal at the AUTO terminal.

in

16

14

12

V

= 12

bat

10

8

6

Motor Voltage – V

4

2

0

V

= 8

bat

0204060

PWMin– Incoming Pulse Width Modulation – %

V

= 16

bat

80 100

Figure 1. Motor Voltage vs. Incoming PWM for Various Battery Voltages

over/under voltage protection

The IC enters the fault state if V

below the under-voltage shutdown (V

rises above over-voltage shutdown (V

bat

typically equals 7.5 volts) the IC enters sleep state. Hysteresis assures

UV

that the device will not toggle into and out of sleep state or fault condition.

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

typically equals 18.5 V). If V

OV

bat

falls

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

current limit protection

Current through the motor is limited by lowering the GD terminal PWM when a high current situation occurs.

If the condition persists, the device shuts off the gate drive (GD terminal) until the circuit is reset externally by

entering the sleep state.

theory of operation

This section explains the normal circuit operation for the automatic and manual states.

power supply and oscillator

TPIC2101

Positive voltage is supplied to the integrated circuit on the V

steps down the V

supply to the regulated 5.5 V supply at the V5P5 terminal. AREF is shorted to V5P5 in run

bat

terminal, ground is the GND terminal. The IC

bat

state and disconnected when the IC is in sleep state. Two terminal connections (COSC and ROSC) are provided

to control an internal oscillator. The oscillator freq, f

f

(osc)

+

ROSC COSC

2

, is defined by the following equation:

(osc)

Nominal oscillator frequency is 20-kHz based on the recommended components.

automatic mode signal decoding

In automatic state, a high-to-low signal transition on the AUTO terminal (open collector) will wake the device

from the sleep state into the run state. The speed command information is contained in the duty cycle of a 100 Hz

PWM signal on the same terminal. The speed information is inverted, i.e. a signal that is 10% high commands

a faster speed than a 20% high signal. In automatic mode the MAN terminal is floating. The device is capable

of rejecting ± 2 V of ground offset V

between the open-collector switching transistor and the GND terminal

IO

without affecting the output duty cycle. Two terminals are provided for an RC integrator (SPEED and INT) to

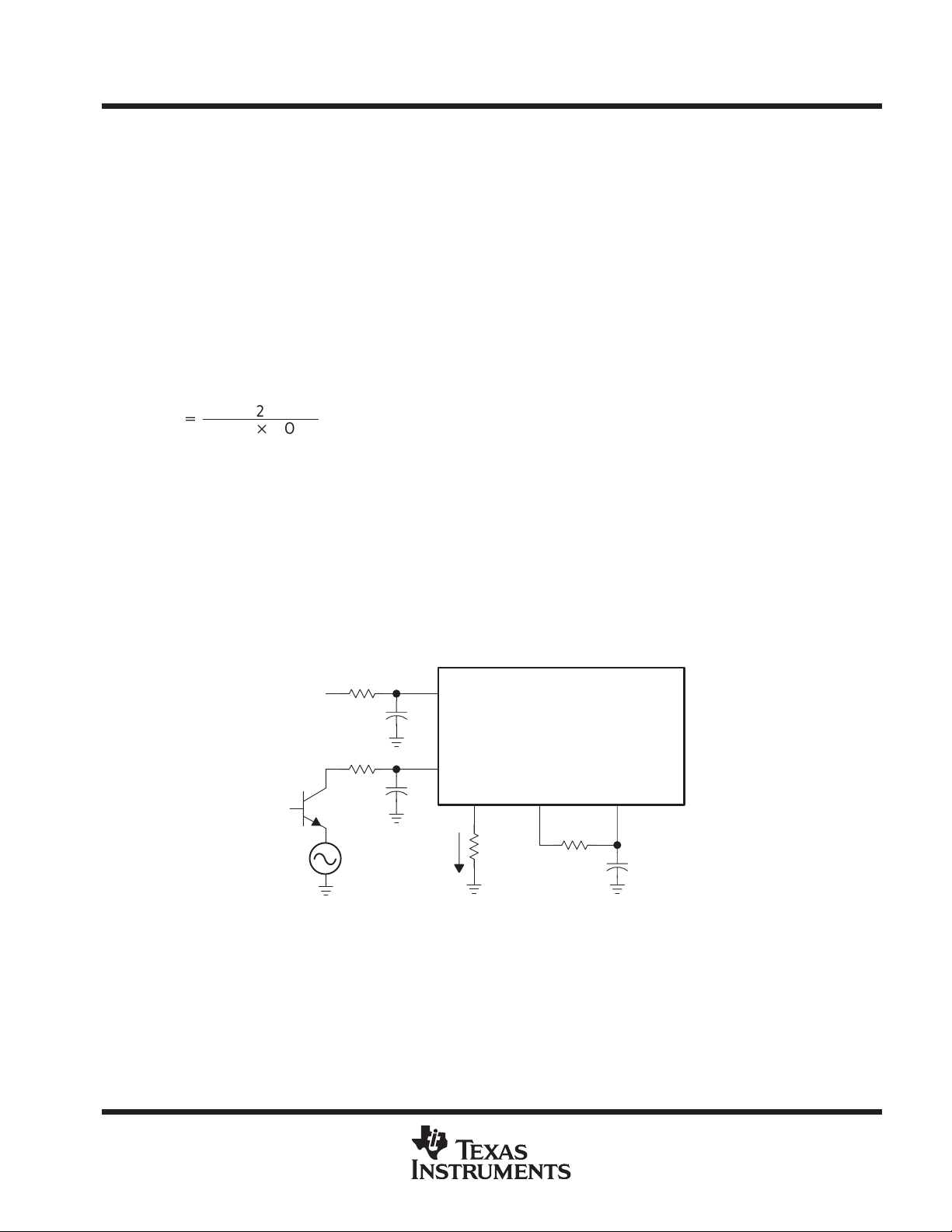

average the incoming PWM signal for use as a PWM comparator input. Figure 2 illustrates the automatic state

connections.

No Connection

V

IO

499 Ω

499 Ω

2

3

I = 100 µA

MAN

TPIC2101

AUTO

CCS SPEED INT

14 2.75 V 4 7

20 kΩ min

27.4 kΩ

4.7 µF

Figure 2. Automatic Mode Connections

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

5

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

automatic mode signal decoding (continued)

The device enters the sleep state if the PWM signal on the AUTO terminal is absent (the AUTO terminal remains

high or low) for 2048 clock cycles of the 20 KHz oscillator. An internal 1 mA pull-up resistor is provided for the

AUTO terminal when in the auto mode. This pull-up resistor is not present in the manual mode or during sleep

state.

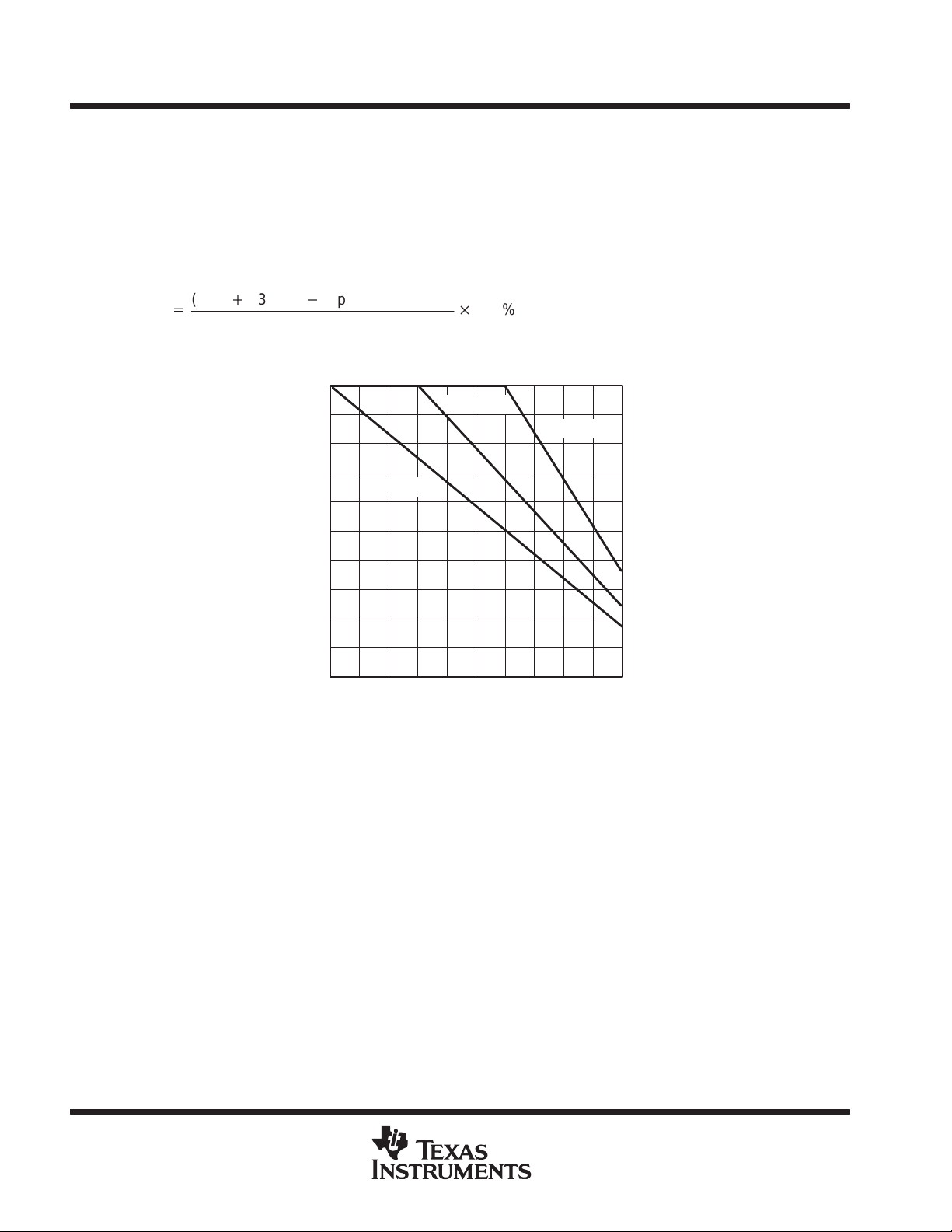

The device adjusts the output PWM duty cycle to keep the effective motor voltage constant with changing battery

voltages (V

) as per the equation:

bat

PWM

(2.88)13.12(1*Input Duty Cycle))

+

out

V

bat

100%

Figure 3 illustrates this transfer curve with various battery voltages.

100

V

= 12

90

80

70

60

50

– Output PWM – %

40

out

30

PWM

20

10

0

0 102030405060

V

= 16

bat

PWMin – Incoming Pulse Width Modulation – %

bat

V

bat

70 80 90 100

Figure 3. Output PWM vs. Incoming PWM for Various Battery Voltages

= 8

The allowable automatic mode PWM

variation is ± 7% over all operating conditions as indicated in the AC

out

characteristics Table.

manual mode speed signal decoding

In manual mode, a high input (>5.5V) on the MAN terminal changes the state of the device from sleep to run.

While in the run state the device senses the resistance between the MAN and AUTO terminals by turning on

a 2 mA current sink to each terminal. The MAN and AUTO current sinks are multiplied 20 X from the CCS current.

This 2 mA current sink creates a 1 V drop across each 0.5 kΩ resistor and a 0 to 2.2 V differential across the

0 to 1 kΩ potentiometer (and thus across the 2 terminals). The SPEED and INT terminals should be utilized as

in the proceeding section as a low-pass filter. When the connection to the MAN terminal is opened, the device

enters the sleep state. In addition, the device is capable of rejecting up to 2.2 V of source voltage offset (V

as indicated in Figure 4.

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

IO

),

manual mode speed signal decoding (continued)

47 Ω

V

IO

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

Battery

Enable

Switch

1 kΩ

pot

499 Ω

499 Ω

I = 100 µA

V

bat

2

MAN

TPIC2101

3

AUTO

CCS SPEED INT

14 2.75 V 4 7

20 kΩ min

27.4 kΩ

4.7 µF

Figure 4. Manual Mode Connections

As in the automatic mode, the device will adjust the GD terminal PWM duty cycle to keep the effective motor

voltage constant with changing battery voltages (V

PWM

out

+

(2.88)6.56(V

MAN

V

bat

*

V

AUTO

))

100%

). The transfer equation for the manual mode is:

bat

Figure 5 shows the output characteristic for various source voltages.

100

90

80

70

60

50

40

30

– Manual Mode Output PWM – %

out

20

PWM

10

0

0 0.2 0.4 0.6 0.8 1 1.2

Figure 5. Manual Mode Input Signal vs. Output PWM

The allowable manual mode PWM

characteristics table.

V

= 16

bat

V

= 12

bat

V

= 8

bat

1.4 1.6 1.8 2

V

- V

MAN

variation is ±7% over all operating conditions as indicated in the AC

out

– Differential Voltage – V

AUTO

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

7

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

over/under voltage operating

The TPIC2101 detects an over or under voltage condition (on the V

terminal) and turns off the gate drive

bat

circuit. The device remains in this condition until the supply voltage returns to normal operating voltage.

Hysteresis assures that the over/under voltage condition does not toggle off and on near the threshold. The INT

terminal pulls toward GND through an internal impedance of less than 500 Ω during the over-voltage condition

or during sleep state. This ensures a slow ramp up of the GD terminal PWM when the V

voltage returns to

bat

the operating range.

current limit operation

An over-current condition is detected if the ILS terminal is higher than the ILR terminal while the gate drive (GD

terminal) is high. This condition activates a closed-loop control, causing the INT terminal to be pulled low

(through an internal resistance less than 500 Ω) lowering the commanded duty cycle to close the loop.

current fault operation

During a window of 8192 clock cycles, a latch is set if at least once during the window, a current limit condition

is detected. If a current limit condition is set for eight consecutive 8192 clock cycle windows, the gate drive (GD

terminal) will be shut off for a disable period of 65536 clock cycles. During the disable period, the INT terminal

is pulled to GND through an internal resistance of less than 500 Ω. After the disable period is completed, an

internal restart is attempted. If the current limit is present again, as described above, for 8 consecutive windows,

the GD and INT terminals are again pulled to GND and the device remains in this current fault state until the

device is cycled through a sleep state to run state. However, if the current limit condition is not present during

any of the eight 8192 clock cycle windows, the latches for the 8 count window timer and the two cycle

shutdown/restart are reset. See timing diagrams, Figures 6, 7, and 8.

absolute maximum ratings over the operating free-air temperature range (unless otherwise

noted)

†

‡

†

‡

Supply voltage range, V

–0.3 V to 40 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

bat

Input voltage range, MAN, AUTO –0.3 V to 40 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, INT

Continuous gate drive output current, I

Continuous speed output current, I

Continuous output current, I

Continuous ROSC output Current, I

Continuous output current, I

Thermal Resistance, junction to ambient, R

CCS

ILR –0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

,

O(SPEED)

O(V5P5)

O(CCS)

±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GD

±1 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

, I

O(AREF)

O(ROSC)

20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

500 µA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

: D package 131°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ΘJA

N package 78°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air termperature range, T

Maximum junction temperature, T

Storage temperature range, T

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Under load dump conditions, the voltage on V

JM

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

bat

–40°C to 105°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

can reach 40 V within 1 ms.

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

AREF Input current I

Input voltage, V

Differential voltage, V

Input voltage, V

VI, ILR, ILS 0.5 2.75 V

Output resistance, input resistance, R

Output Resistance, ROSC, r

Output Capacitance, COSC, C

Gate drive frequency f = 2/(ROSC × COSC), f

Gate drive output capacitance, C

Operating free-air temperature, T

bat

(AREF)

I(MAN), VI(AUTO)

I(MAN)

(auto mode) 0 5.5 V

I(AUTO)

(manual mode) 6 16 V

– V

I(AUTO)

(CCS)

o

O

(GD)

O(GD)

A

8 12 16 V

0 2 mA

0 2.2 V

27.2 27.5 27.8 kΩ

20 100 kΩ

1 5 nF

20 kHz

3300 pF

–40 105 °C

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

9

TPIC2101

I

Quiescent current (sleep state), V

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

electrical characteristics, V

PARAMETER TEST CONDITION MIN TYP MAX UNIT

I

bat

bat(Q)

V

(AREF)

V

IO

I

IB

I

IO

I

OL(CLS)

V

IL(AUTO)

V

IH(AUTO)

I

I(AUTO)

I

I(AUTOQ)

V

IH(MAN)

V

IL(MAN)

V

ID(MAN)

†

Indicates electrical parameter not tested in production.

Supply current (average), V

Voltage supply regulation, AREF

Input offset voltage, current limit

comparator, ILS, ILR

Input bias current, current limit comparator,

†,

ILS, ILR

Input offset current, current limit comparator,

†

ILS, ILR

Pulldown current, ILS terminal

blanking, ILS

Automatic mode low level input

voltage, AUTO

Automatic mode high level input

voltage, AUTO

Input current, automatic mode, AUTO

Input current, auto sleep mode, AUTO

High level input voltage, manual mode, MAN

Low level input voltage, manual mode, MAN

Input voltage, manual mode high differential

(high speed command), MAN-AUTO

= 8 V to 16 V, T

bat

bat V

p

bat

= 25°C

A

V

= 16 V, GD open,

bat

f(osc) = 20 kHz,

MAN = AUTO =V

= 16 V, GD open,

bat

f(osc) = 20 kHz, MAN open,

Auto mode,

AUTO – 99% PWM

V

= 13 V,

bat

AUTO and MAN open

V

= 13 V,

bat

AUTO shorted to MAN, floating

I

= 0 – 2 mA,

(AREF)

MAN = AUTO = V

AUTO or MAN mode, ILS,

ILR common mode,

Voltage range 0.5 – 2.75 V,

V

= 4.5 V,

int

Detect I

(int)

ILS, ILR common mode,

Voltage range 0.5 – 2.75 V

ILS, ILR common mode,

Voltage range 0.5 – 2.75 V

ILS = 100 mV ,

GD commanded low

MAN open, AUTO mode,

Lower V

I(AUTO)

MAN open, AUTO mode,

Raise V

I(AUTO)

MAN open, Auto mode,

V

I(AUTO)

MAN open, Sleep state,

V

I(AUTO)

V

= 9 V to 16 V,

bat

V

IH(MAN)

Raise V

(MAN)

V

Lower V

V

V

=VI(

I(MAN)

I(MAN)

= 16 V,

bat

–3.5 V < MAN < V

bat

> 100 µA

= 0 V

= 0 V

= V

IH(AUTO)

until V

AUTO)

until V

bat

in

bat

until V

until V

I(SPEED)

I(SPEED)

,

I(AREF)

,

I(AREF)

bat

>2.4V

< 2.4 V

> 2.5 V

< 2.5 V

4 10 mA

2 10 mA

150 200 µA

165 200 µA

5.225 5.5 5.775 V

10 mV

250 nA

100 nA

250 360 µA

2.7 3 3.3 V

3.6 4 4.4 V

–1 –10 mA

–40 –80 µA

5 5.5 6 V

2.3 2.5 2.7 V

1.7 2.3 V

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

V

gg,g

V

g,g

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

electrical characteristics, V

PARAMETER TEST CONDITION MIN TYP MAX UNIT

Input voltage, manual mode

V

ID(low)

I

I(MAN)

I

I(AUTO)

I

I(MANRATIO)

I

I(MAN(a))

I

I(MANQ)

V

(CCS)

V

(OV)

V

hys(OV)

V

IT-(UVLO)

V

IT+(UVHI)

V

hys(UV)

OH(GD)

OL(GD)

V

GD(SL)

I

(GDP)

I

(INT)

low differential (low speed

command), MAN–AUTO

Input currents, auto and

manual mode, MAN, AUTO

Input current, manual mode

matching ratio, MAN, AUTO

Input current, man terminal

auto mode, MAN

Input current, man terminal

sleep mode, MAN

Constant current sink voltage

regulation, CCS

Over voltage shutdown, V

Hysteresis, over voltage, V

Under voltage shutdown

negative going threshold

voltage, V

Under voltage shutdown

positive going threshold

voltage, V

Hysteresis, under voltage, V

High level output voltage, gate

drive, GD

Low level output voltage, gate

drive, GD

Gate voltage, sleep-state, GD Sleep state, IGD = 2 mA 0.03 0.75 V

Pulldown current, gate drive

passive, GD

Pulldown current, INT

bat

bat

= 8 V to 16 V, T

bat

V

bat

where “∆” is the lesser of 2 V and 16 V –V

PWM

V

I(DIFF)

V

bat

where “∆” is the lesser of 2 V and 16 V –V

MAN – AUTO = 0 V to 2 V,

R

(css)

V

bat

where “∆” is the lesser of 2 V and 16 V –V

MAN – AUTO = 0 V to 2 V,

R

css

Auto mode, MAN = 2.2 V 5 10 15 µA

Sleep state, MAN = 2.2 V 5 10 15 µA

Auto or Man mode, I

V

bat

bat

bat

Detect I

V

bat

Detect I

MAN = V

Detect AREF < 2.5 V

MAN = V

Detect AREF > 2.5 V

batV(UVHI)

IGD = –50 mA, INT = 4.5 V,

Run state

IGD = –2 mA, INT = 4.5 V,

Run state

Run state, IGR = 50 mA,

V

I(INT)

Run state, IGD = 2 mA,

INT = 0 V, V

V

bat

Run state, V

V

I(INT)

= 25°C (continued)

A

–3.5 V < MAN < V

@ V

out

(diff)

= 0 V

–3.5 V < MAN < V

= 27.5 kΩ to GND

–3.5 V < MAN < V

= 27.5 kΩ to GND

rising from 16 V, INT = 1 V ,

> 100 µA

(INT)

rising from 20.1 V, INT = 1 V,

< 100 µA

(INT)

, V

bat

,V

bat

– V

(UVLO)

= 0 V, V

open, VGD = 0.75 V 7.5 20 µA

= 1 V

+∆V

bat

= 0.2 V ≥ PWM

+∆V

bat

+∆V

bat

(CCS)

falling from 9 V ,

bat

rising from 6.9 V,

bat

COSC

COSC

> V

ILS

,

bat

@

out

,

bat

,

bat

= –100 µA 2.58 2.78 2.92 V

= 1 V

= 1 V

,

ILR

1.70 2 2.30 mA

–7 7 %

17 18.5 20 V

0.5 0.8 0.99 V

7 7.5 8 V

8 8.5 9 V

0.5 1 V

V

–3 V

bat

V

–0.2 V

bat

2 3 mA

0.2 V

bat

bat

3.5 V

0.75 V

V

V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

11

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

switching characteristics, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

r

t

f

f

(osc)

Rise time

Fall time

Output PWM absolute

accuracy to spec equation

Oscillator frequency ROSC = 45.3 kΩ, COSC = 2200 pF 19 20 21 kHz

Minimum speed pedestal

PARAMETER MEASUREMENT INFORMATION

Time Block 1 Time Block 2 Time Block 3 Time Block 4 Time Block 5

Internal

Clock

ILS>ILR ?

1 = Yes, 0 = No

8192 Cycles 8192 Cycles 8192 Cycles 8192 Cycles 8192 Cycles

= 8 V to 16 V, T

bat

V

bat

ROSC = 45.3 kΩ, COSC = 2200 pF

V

bat

ROSC = 45.3 kΩ, COSC = 2200 pF

16 > V

GD open,

Measure at GD = 0.5 × V

MAN = AUTO=V

V

bat

AUTO @ 99% duty cycle

= 25°C

A

= 16 V, Load = 3300 pF,

= 16 V, Load = 3300 pF,

> 9 Manual and automatic modes

bat

@ 20 kHz

bat

= 16 15 21 %DC

bat

= 16, MAN floating,

1 µs

0.8 µs

–7% 7%

15 21 %DC

GD Terminal

INT Terminal

Through 500 Ω

Internal Latch

or Counter

Current Fault

Latch/Counter

Disable Latch

123 0

No Current Limit Condition Present in Time Block 4.

Internal Counter or Latch Set to zero. Current Limit

Condition Not Present For Eight Consecutive 8192 Cycles.

No Disable Period.

Figure 6. Current Fault Timing Diagram, Normal State

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

PARAMETER MEASUREMENT INFORMATION

Time

Block 1

Internal

Clock

ILS>ILR ?

1 = Yes, 0 = No

GD Terminal

INT Terminal

Through 500 Ω

Internal Latch

or Counter

Current Fault

Latch/Counter

Disable Latch

Time Block Repeated Six Times

Current Limit for Eight Consecutive Time Blocks.

Disable Output for 65536 Clock Cycles.

8192

Cycles

18012

Time

Block 8

8192

Cycles

65536 Cycles

Restart Attempted

No Current Limit Condition in Time Block 19.

Time

Block 17

8192

Cycles

Internal Latch or Counter Reset to Zero.

Time

Block 18

8192

Cycles

Restart Successful

Block 19

Cycles

Time

8192

0

Figure 7. Current Fault Timing Diagram, Over-Current Limit Condition

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

13

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

PARAMETER MEASUREMENT INFORMATION

Time

Block 1

Internal

Clock

ILS>CLR ?

1 = Yes, 0 = No

GD Terminal

INT Terminal

Through 500 Ω

Internal Latch

or Counter

Current Fault

Latch/Counter

Disable Latch

Time Block Repeated Six Times

Current Limit For Eight Consecutive Time Blocks.

Disable Output For 65536 Clock Cycles.

8192

Cycles

1801 8

Time

Block 8

8192

Cycles

65536 Cycles

Attempted

Block 17

Restart

Time

8192

Cycles

Time BlocK 17

Repeated Six Times

Restart Not Successful.

Enter Current Fault State.

Time

Block 21

8192

Cycles

Time

Block A

8192

Cycles

0

Current Fault State

(see Note A)

NOTE A: The integrated circuit remains in this state until cycled through the sleep state into the run state. Timing resumes as shown in time block

A at right.

Figure 8. Over-Current Fault State Timing Diagram 3

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

TYPICAL CHARACTERISTICS

MANUAL/AUTO CURRENT

vs

CCS CURRENT

5

V

= 12 V

bat

4.5

4

3.5

3

2.5

2

– Manual/Auto Current – mA

1.5

AUTO

I

1

MAN,

0.5

I

0

0 50 100 150 200 250

I

– CCS Current (Manual Mode) – µA

CCS

(MANUAL MODE)

Figure 9 Figure 10

INTEGRATOR PULLDOWN CURRENT

vs

INTEGRATOR INPUT VOLTAGE

18

V

= 12 V

bat

ILS>ILR

15

AUTO CURRENT

vs

CCS CURRENT (AUTO MODE)

–4

V

= 12 V

–3.6

–3.2

–2.8

–2.4

–2

–1.6

– Auto Current – mA

–1.2

AUTO

I

–0.8

–0.4

bat

0

0 –60 –120 –180 –240 –300

I

– CCS Current (Auto Mode) – µA

CCS

OSCILLATOR CAPACITOR CURRENT

vs

OSCILLATOR RESISTOR CURRENT

1000

Aµ

900

800

–40°C

105°C

25°C

12

–40°C

9

6

– Integrator Pulldown Current – mA

3

(INT)

I

0

012345

V

– Integrator Input Voltage – V

(INT)

105°C

25°C

Figure 11 Figure 12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

700

600

500

400

300

Oscillator Capacitor Current –

–

200

100

(COSC)

I

0

0 40 120 240

I

(ROSC)

• HOUSTON, TEXAS 77251–1443

80 160200 280 360 440480

– Oscillator Resistor Current – µA

320 400 520

15

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

TYPICAL CHARACTERISTICS

GATE DRIVE LOW SIDE

GATE DRIVE CURRENT

1

0.9

0.8

0.7

0.6

0.5

0.4

– Gate Drive Low Side – V

0.3

OL

V

0.2

0.1

0

0 5 10 15 20 25 30

IGD – Gate Drive Current – mA

EFFECTIVE MOTOR VOLTAGE

INCOMING PULSE WIDTH MODULATION

16

14

12

10

8

– Effective Motor Voltage – V

6

GATE DRIVE HIGH SIDE

vs

vs

GATE DRIVE CURRENT

16

105°C

25°C

–40°C

35 40 45 50

14.4

12.8

11.2

9.6

8

6.4

– Gate Drive High Side – V

4.8

OH

V

3.2

1.6

0

05045403530252015105

IGD – Gate Drive Current – mA

Figure 13 Figure 14

MOTOR RPM

V

bat

vs

= 14 V

V

bat

= 16 V

V

bat

V

bat

V

bat

= 10 V

= 8 V

INCOMING PULSE WIDTH MODULATION

2500

2000

= 12 V

1500

1000

Motor RPM – RPM

vs

V

= 14 V

bat

V

bat

V

bat

V

= 8 V

105°C

= 16 V

V

bat

25°C

–40°C

= 12 V

bat

= 10 V

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

V

–

GD

V

–

(bat)

V

16

motor

4

V

2

0 102030405060

PWMin – Incoming Pulse Width Modulation – % PWMin – Incoming Pulse Width Modulation – %

70 80 90 100

500

0

0 102030405060

Figure 15 Figure 16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

70 80 90 100

TPIC2101

DC BRUSH MOTOR CONTROLLER

SLIS060 – OCTOBER 1995

TYPICAL CHARACTERISTICS

6

5.4

4.8

4.2

3.6

3

2.4

– Output Voltage at V5P5 – V

1.8

1.2

O(V5P5)

V

0.6

0

024

OUTPUT VOLTAGE V5P5

OUTPUT VOLTAGE AT V5P5

vs

INPUT VOLTAGE AT V

6

8

V

– Input Voltage at V

I(Vbat)

bat

10 12 14 16

– V

bat

5.6

5.55

5.5

– Output Voltage at V5P5 – V

5.45

O(V5P5)

V

5.4

–40 –20 0 20 40 60 80 100

AMBIENT TEMPERATURE

TA – Ambient Temperature – °C

Figure 17 Figure 18

vs

V5P5

6

V

bat

5.9

5.8

5.7

5.6

5.5

5.4

– Output Voltage at V5P5 – V

5.3

5.2

O(V5P5)

V

5.1

5

05045403530252015105

OUTPUT VOLTAGE AT V5P5

vs

V5P5 OUTPUT CURRENT

= 7 V

105°C 25°C –40°C

I

O(V5P5)

– V5P5 Output Current – mA

Figure 19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

17

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...