Page 1

TMS370 Microcontroller/Gang

Programmer

User’s Guide

2546239-9704 Microcontroller Products

Page 2

2546239-9704

Page 3

TMS370 Microcontroller/Gang

Programmer

User’s Guide

SPNU023

February, 1991

Page 4

IMPORTANT NOTICE

T exas Instruments (TI) reserves the right to make changes to its products or to discontinue any

semiconductor product or service without notice, and advises its customers to obtain the latest

version of relevant information to verify , before placing orders, that the information being relied

on is current.

TI warrants performance of its semiconductor products and related software to the specifications

applicable at the time of sale in accordance with TI’s standard warranty . T esting and other quality

control techniques are utilized to the extent TI deems necessary to support this warranty.

Specific testing of all parameters of each device is not necessarily performed, except those

mandated by government requirements.

Certain applications using semiconductor products may involve potential risks of death,

personal injury , or severe property or environmental damage (“Critical Applications”).

TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES

OR SYSTEMS OR OTHER CRITICAL APPLICATIONS.

Inclusion of TI products in such applications is understood to be fully at the risk of the customer.

Use of TI products in such applications requires the written approval of an appropriate TI officer .

Questions concerning potential risk applications should be directed to TI through a local SC

sales office.

In order to minimize risks associated with the customer’s applications, adequate design and

operating safeguards should be provided by the customer to minimize inherent or procedural

hazards.

TI assumes no liability for applications assistance, customer product design, software

performance, or infringement of patents or services described herein. Nor does TI warrant or

represent that any license, either express or implied, is granted under any patent right, copyright,

mask work right, or other intellectual property right of TI covering or relating to any combination,

machine, or process in which such semiconductor products or services might be or are used.

Copyright 1996, Texas Instruments Incorporated

Page 5

How to Use This Manual

This manual describes how to use and operate the TMS370 Microcontroller

Programmer and the TMS370 Gang Programmer. Chapter 1 gives an overview of each programmer and describes the correct way to install your specific

programmer. After your programmer is correctly installed, you can use the

configuration commands

3, respectively , to operate your programming system for your specific application.

This document contains the following chapters:

Chapter 1 Introduction and Installation

Presents a general description of how each programmer operates and the features available with each programmer. Also outlines the proper hardware and

software installation procedures.

and

display commands

Preface

Read This First

, described in Chapters 2 and

Chapter 2 Operating in the Configuration Window

Describes how the command menus and function keys operate and how to

input information at the system prompt. Describes the commands available

while operating in the configuration window.

Chapter 3 Operating in the Display Window

Describes how the command menus and function keys operate and how to

input information at the system prompt. Describes the commands available

while operating in the display window.

Appendix A Operating the Programmer in Batch Mode

Outlines how to create a configuration/batch file and how to invoke the file at

system start-up.

Appendix B Error Messages

Provides an alphabetical list of error messages and their meaning.

Appendix C Valid Configuration Parameters

Lists valid configuartion parameters for the devices supported by the programmers.

Appendix D Using Keystroke Capture Files

Describes how to use keystroke capture files to repeat a commonly used program and to verify routines.

Page 6

Related Documentation

Related Documentation

The following TMS370 documents are available through Texas Instruments

Incorporated:

TMS370 Family Data Manual

The

(literature number SPNS014) describes

the hardware aspects of the TMS370, such as pin functions, architecture, stack operation, and interface; the manual also includes the

TMS370 assembly language instruction set.

TMS370 Family Assembly Language Tools

The

(literature number

SPNU010) describes how to use of the TMS370 assembly language

tools (assembler, linker, archiver and code conversion utility) to create

and use objects that are in common object file format (COFF).

TMS370 Family C Compiler

The

(literature number (SPNU022) describes

the characteristics and operation of the TMS370 C Compiler.

TMS370 Family XDS/22 User’s Guide

The

(literature number SPNU008)

describes the hardware and software installation of the TMS370 Family

XDS22 consisting of the TMS370 debugger and emulator .

TMS370 PACT XDS/22 Addendum

The

(literature number SPNU019)

describes features and functions of the TMS370 P ACT XDS/22. Use this

addendum in conjunction with the

The

TMS370 Family XDS/11 User’s Guide

TMS370 Family XDS/22 User’s Guide.

(literature number SPNU015)

describes the hardware and software installation of the TMS370 Family

XDS11 consisting of the TMS370 debugger and emulator.

Style and Symbol Conventions

This document uses the following conventions.

Program listings, program examples, interactive displays, filenames, and

symbol names are shown in a special typeface similar to a typewriter’s. Examples use a bold version of the special typeface for emphasis; interactive displays use a bold version of the special typeface to

distinguish commands that you enter from items that the system displays

(such as prompts, command output, error messages, etc.).

Here is a sample program listing:

0011 0005 0001 .field 1, 2

0012 0005 0003 .field 3, 4

0013 0005 0006 .field 6, 3

0014 0006 .even

iv

Read This First

Page 7

Information About Cautions and Warnings

This book may contain cautions and warnings.

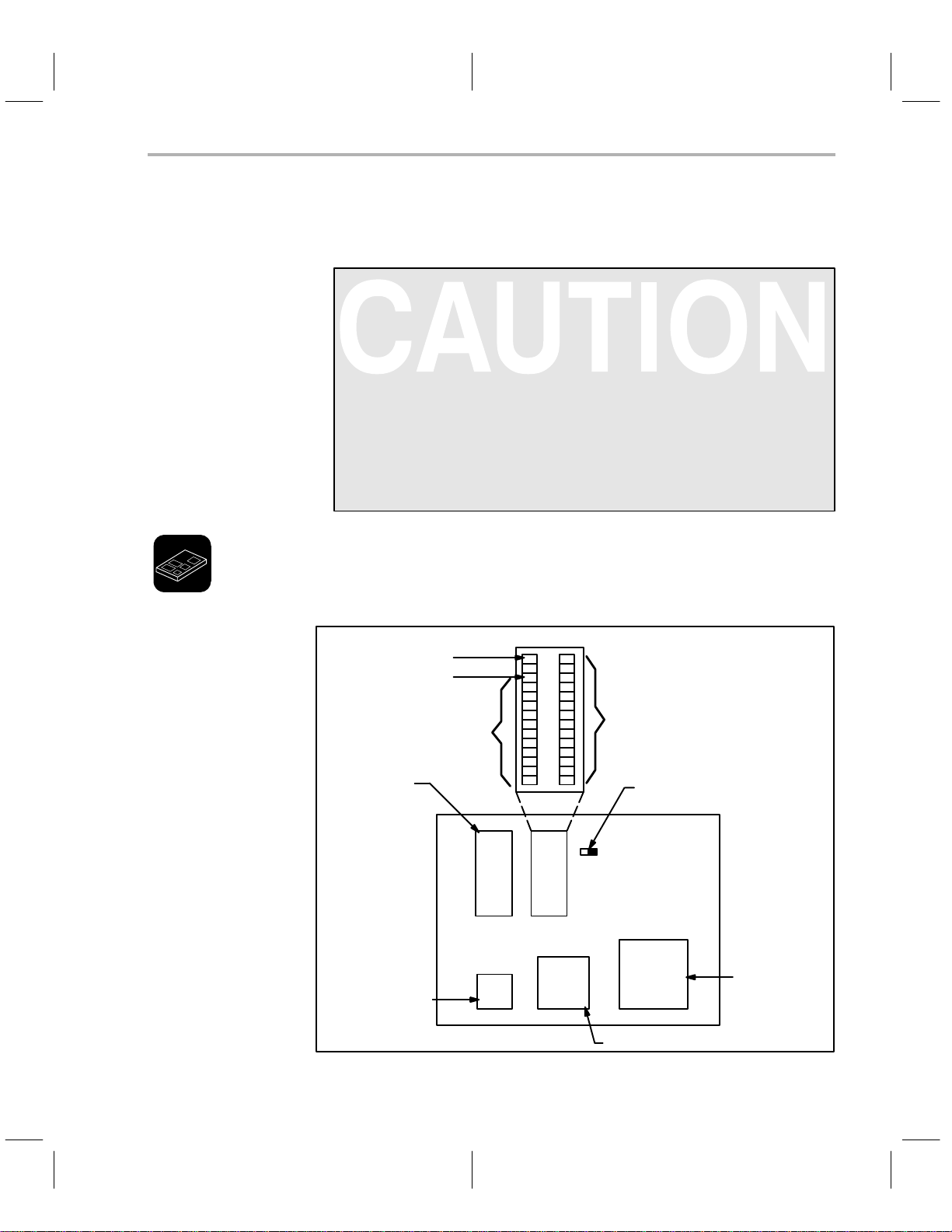

A caution describes a situation that could potentially damage your soft-

ware or equipment.

This is what a caution looks like.

A warning describes a situation that could potentially cause harm to you.

This is what a warning looks like.

Information About Cautions and Warnings

Trademarks

MS-DOS

XDS is a trademark of Texas Instruments Incorporated.

PC/AT is a trademark of International Business Machines Corporation.

The information in a caution or a warning is provided for your protection.

Please read each caution and warning carefully.

is a trademark of Microsoft Corp.

v

Page 8

vi

Read This First

Page 9

Contents

1 Introduction and Installation 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Microcontroller Programmer Overview and Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Gang Programmer Overview and Description 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Operating the Gang Programmer in PC Mode 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Operating the Gang Programmer in Standalone Mode 1-6. . . . . . . . . . . . . . . . . . . .

1.3 Properly Installing the Programmer Hardware 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Connecting a Programmer to the PDS Base Unit 1-8. . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Power Connection 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Connection to a PC 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Connection to an XDS 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5 Integrated Circuit (IC) Insertion 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Properly Installing the Programmer Software 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Installing the Software in a Single Directory 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Installing the Software in Multiple Directories 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Invoking the Programmer Software 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Getting Started—Example Sessions 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Interactive Programming Example 1 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Interactive Programming Example 2 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3 Batch Programming Example 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operating in the Configuration Window 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 How Command Menus Work 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Using the Special Function Keys 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 What Happens If I Make an Error? 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Understanding Your Input at the Cursor Prompt 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Configuration Window Overview and Description 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Secondary Configuration Window—the Show Ranges Window 2-7. . . . . . . . . . . . . . . . . . .

2.6.1 Selecting the Proper Program Algorithm 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Showing the Software Revision Information — the Show ID Command 2-9. . . . . . . . . . . .

2.8 Defining and Adding a Device to the Device Table—the Add Device Command 2-9. . . . .

2.9 Editing the Configuration Parameters and Device Table — the Edit Command 2-11. . . .

2.9.1 Editing the Configuration Parameters 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.2 Editing the Device Table 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 Loading the Device Table and Configuration Parameters From a

File — the Load Command 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 Selecting a Current Device — the Choose Device Command 2-15. . . . . . . . . . . . . . . . . . . .

vii

Page 10

Contents

2.12 Saving Configuration Parameters and the Device Table to a File — the

Save Command 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 Showing the Display Window — the Display Command 2-16. . . . . . . . . . . . . . . . . . . . . . . . .

2.14 Ending Your Current Session and Returning to DOS — the Quit Command 2-16. . . . . . .

3 Operating in the Display Window 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 How Command Menus Work 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Using the Special Function Keys 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 What Happens If I Make an Error 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Understanding Your Input at the Prompt 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Display Window Overview and Description 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Differences in Command Structures for Microcontroller

Programmer and Gang Programmer 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Filling a Block of PC Memory With a Value — the Fill Command 3-8. . . . . . . . . . . . . . . . . .

3.7 Loading a COFF File Into PC Memory— the Load Command 3-9. . . . . . . . . . . . . . . . . . . . .

3.8 Outputting a COFF File From PC Memory — the Output COFF Command 3-10. . . . . . . .

3.9 Moving Blocks of PC Memory—the Move Command 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 Programming a Device From PC Memory — the Program Command 3-13. . . . . . . . . . . . .

3.10.1 Programming Using the Microcontroller Programmer 3-13. . . . . . . . . . . . . . . . . . . .

3.10.2 Programming Using the Gang Programmer 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11 Showing and Operating Within a Text File—the Show Command 3-17. . . . . . . . . . . . . . . . .

3.11.1 Finding Character Strings Within a Text File — the Find Command 3-18. . . . . .

3.11.2 Finding the Next Occurence of Character String — the Next Command 3-18. . . .

3.11.3 Positioning the Cursor at a Specific Line Number — the Line Command 3-18. . .

3.11.4 Positioning the Cursor at Top of a File — the Top Command 3-18. . . . . . . . . . . . .

3.11.5 Positioning the Cursor at the Bottom of a File — the Bottom Command 3-18. . .

3.12 Uploading a Device’s Contents Into PC Memory—the Upload Command 3-19. . . . . . . . . .

3.12.1 Uploading Using the Microcontroller Programmer 3-19. . . . . . . . . . . . . . . . . . . . . . .

3.12.2 Uploading Using the Gang Programmer 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13 Verifying the Contents of a Device—the Verify Command 3-22. . . . . . . . . . . . . . . . . . . . . . .

3.13.1 Verifying Using the Microcontroller Programmer 3-22. . . . . . . . . . . . . . . . . . . . . . . .

3.13.2 Verifying Using the Gang Programmer 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.14 Editing the Contents of PC Memory—the Edit Command 3-26. . . . . . . . . . . . . . . . . . . . . . .

3.15 Using the Master Mode Menu—the Master Command 3-27. . . . . . . . . . . . . . . . . . . . . . . . . .

3.16 Suspending the Program and Entering DOS—the System Command 3-28. . . . . . . . . . . . .

3.17 Quitting the Program and Exiting to DOS—the Quit Command 3-28. . . . . . . . . . . . . . . . . . .

A Operating the Programmer in Batch Mode A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Understanding the Batch Mode File A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Batch File Command Rules and Descriptions A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1 Executable Batch Commands A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 Nonexecutable Batch Commands A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Batch Mode Status Messages A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Error Messages B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 Error Message Descriptions B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Configuration Parameters C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Using Keystroke Capture Files D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Table of Contents

Page 11

Running Title

Figures

1–1. Microcontroller Programmer Personality Module 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2. Gang Programmer Board 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3. Socket Identification 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1. Command Menu Structure 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. Configuration Window at System Startup 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3. The Show Ranges Window 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4. Valid Address Ranges Window 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1. Command Menu Structure 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2. PC Memory Display and Reverse Assembled Code Windows 3-5. . . . . . . . . . . . . . . . . . . . . . .

ix

Page 12

Running Title

Tables

1–1. XDS Memory Expansion/Communications Board Switch Settings 1-10. . . . . . . . . . . . . . . . . .

2–1. Edit Control Keys 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. Configuration Window Commands 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3. Show Ranges Parameter Summary 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4. Device T able Edit Commands 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1. Edit Control Keys 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2. Display Window Commands 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3. Reverse Assembled Code Window Commands 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4. Show Text File Commands 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5. Display Window Memory Edit Commands 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–1. Valid Configuration Parameters C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D–1. Valid Nonprintable Characters D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

Table of Contents

Page 13

Running Title

Examples

A–1. Example Configuration/Batch File A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D–1. Keystroke File Example.key D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 14

xii

Table of Contents

Page 15

Chapter 1

Introduction and Installation

This chapter describes how each programmer operates, how to install hardware, and how to install software. It also gives examples on getting started.

Chapter 1 comprises the following sections:

Section Page

1.1 Microcontroller Programmer Overview and Description 1-2. . . . . . . .

1.2 Gang Programmer Overview and Description 1-4. . . . . . . . . . . . . . . .

1.3 Properly Installing the Programmer Hardware 1-8. . . . . . . . . . . . . . . .

1.4 Properly Installing the Programmer Software 1-14. . . . . . . . . . . . . . . .

1.5 Invoking the Programmer Software 1-16. . . . . . . . . . . . . . . . . . . . . . . .

1.6 Getting Started—Example Sessions 1-17. . . . . . . . . . . . . . . . . . . . . . .

Because of obvious differences between the

the

gang programmer

tion specific to each type of programmer. When there are no icons present, you

should assume the information is common to all programmers.

This icon is used to distinguish descriptions and information

specific to the microcontroller programmer.

This icon is used to distinguish descriptions and information specific to the gang programmer.

When an icon is present, the information from the icon to the next icon,

the next section number (that is, 2.1, 2.2, 3.5, etc.)

mer symbolized by the icon.

Texas Instruments provides a hotline to assist you with technical questions

about the TMS370 family products and development tools. Phone (713)

274-2370 between the hours of 8:30 a.m. and 5:00 p.m. central time for technical assistance.

, icons are used to distinguish descriptions and informa-

microcontroller programmer

, is specific to the program-

and

or to

1-1

Page 16

Microcontroller Programmer Overview and Description

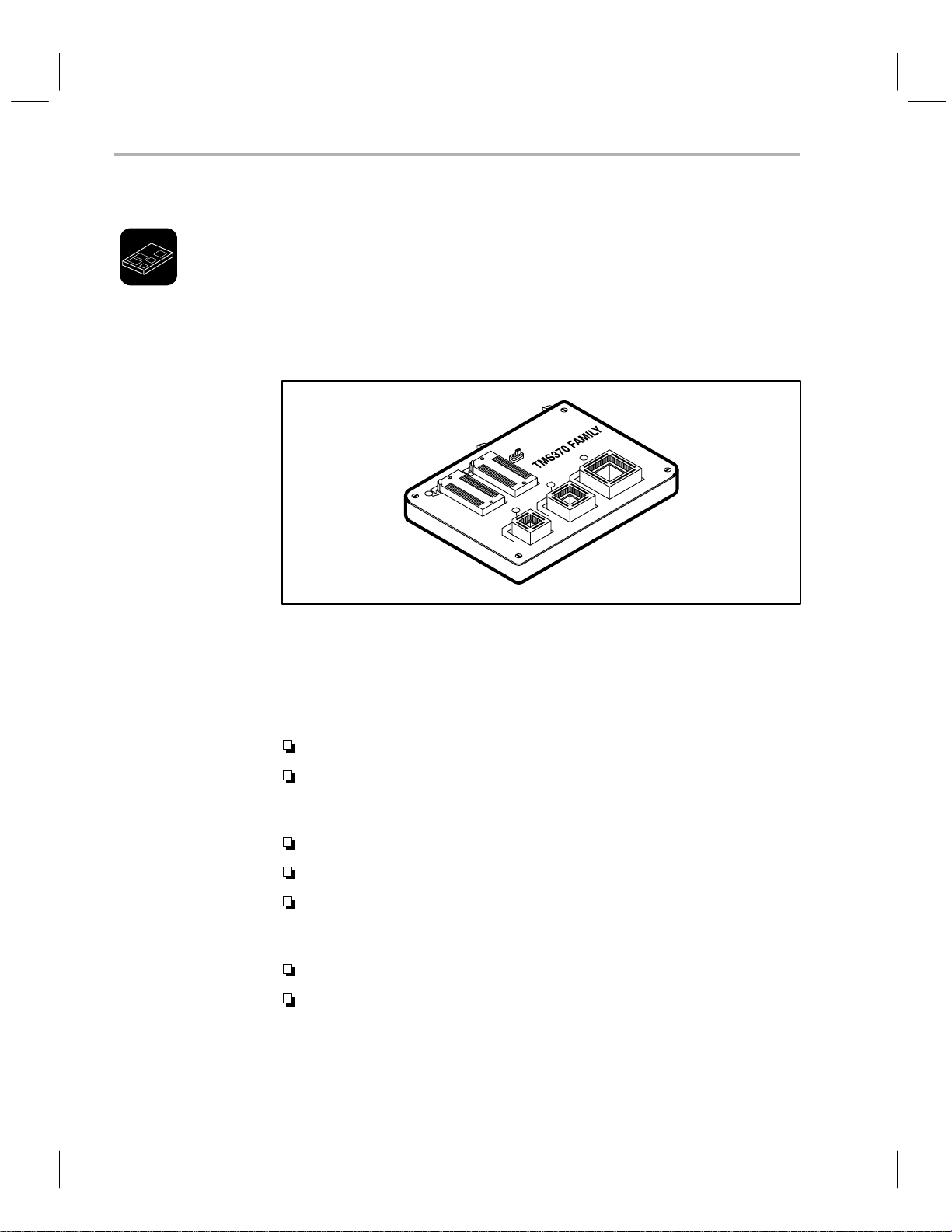

1.1 Microcontroller Programmer Overview and Description

The TMS370 Microcontroller Programmer is an interactive, menu-driven system that facilitates programming TMS370 family devices and EPROMs either

directly or through an XDS. The microcontroller programmer is currently

capable of programming the TMS370, TMS7742, TMS77C82, 2732, 2764,

27128, and 27256 device families. T o program the TMS7742 and TMS77C82

devices, you will need a 40-pin to 28-pin converter, which is sold separately.

Figure 1–1. Microcontroller Programmer Personality Module

T o operate the programmer , create a COFF file using the TMS370 Assembler

and Linker on a PC. The programmer loads the object code from the COFF

file into PC memory and programs a device from the data in PC memory . The

device is programmed and verified in units (packets) of 180 bytes at a time.

The programmer software has the following features:

Window-oriented screens with a menu-driven command structure.

Intermediate PC memory , which provides a storage area for downloading

a COFF file or uploading from the device. This allows you to inspect and

patch the loaded data.

Reversed assembly code display.

Ability to generate a COFF file from PC memory content.

Relocatable programming capability, which allows source data bytes

within a certain address range to be programmed at a specified location

in the device.

User-defined device types that allow new family members.

Ability to save or load the programmer configuration to or from a

configuration/batch file

In addition to these features, a limited batch mode is also supported.

.

1-2

Introduction and Installation

Page 17

Microcontroller Programmer Overview and Description

The base unit of the programmer contains two LEDs. The red LED is marked

program

sockets. The green LED is marked

or

device power

and is lit whenever power is applied to device

power

and indicates that the base is turned

on. This LED should turn on approximately three seconds after power is

supplied to the programmer.

Do not insert or remove devices from the programmer while the red

program (device power)

LED is lit!

On the front edge of the programmer base is a black banana plug receptacle.

This is attached to the safety ground of the power cord in order to assist you

in connecting to electrostatic protection equipment.

1-3

Page 18

Gang Programmer Overview and Description

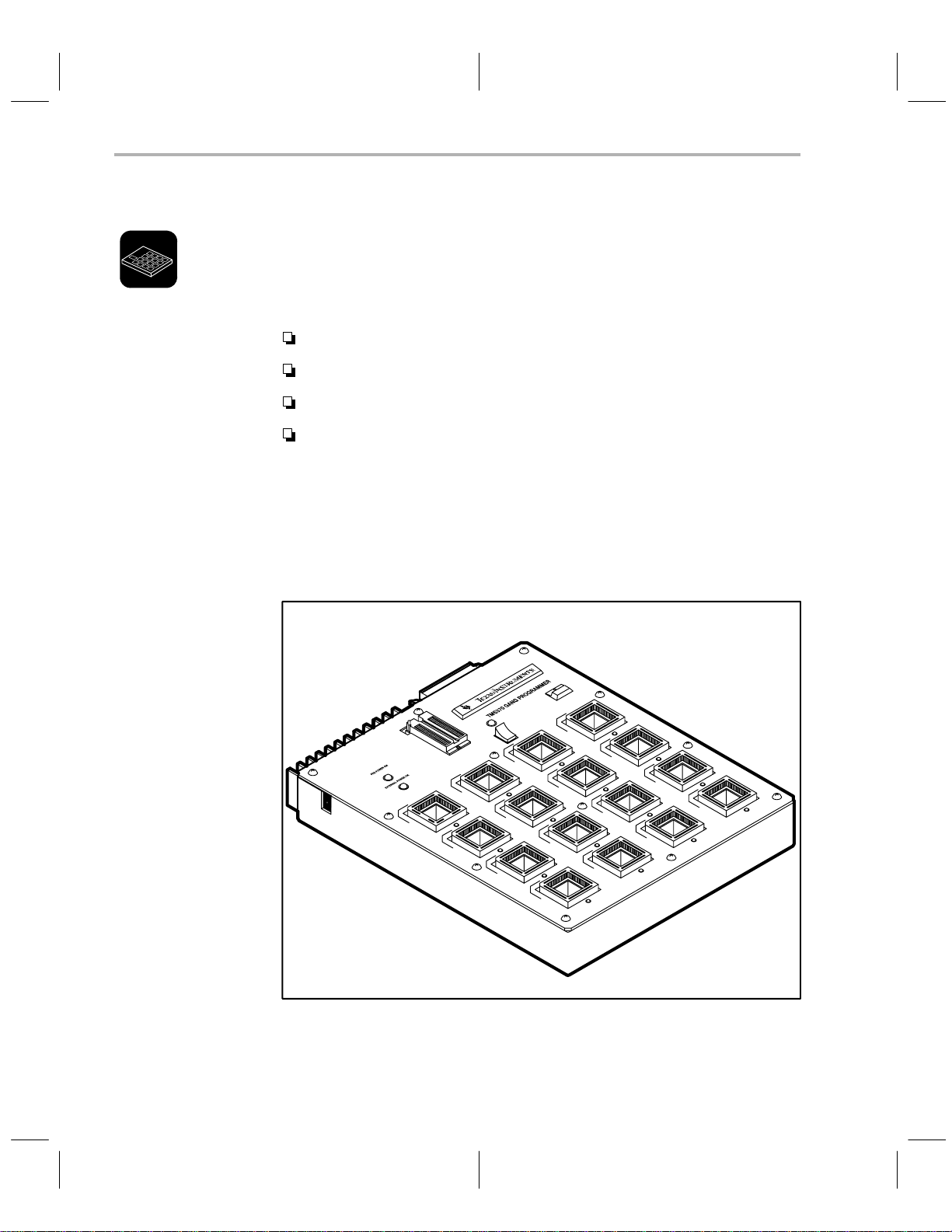

1.2 Gang Programmer Overview and Description

The TMS370 Gang Programmer is an interactive, menu-driven system that

provides programming support for on-chip EEPROM or EPROM of TMS370

microcontrollers in production environments.

The gang programmer has the following features:

Two modes of operation—PC mode and standalone mode.

Ability to program up to 16 devices.

LEDs that indicate programming or verification failure.

A buzzer that indicates programming completion.

The gang programmer consists of the standard programmer base, a gang programmer top, and the standard programmer software. If you already have a

standard TMS370 Microcontroller programmer, the gang programmer top can

be purchased separately . (There is a different programmer top for each package of TMS370 microcontrollers.)

Figure 1–2. Gang Programmer Board

1-4

The push-button switch in the upper right-hand corner is marked

used to start and stop programming or verification while operating in the stand-

Introduction and Installation

start

and is

Page 19

Gang Programmer Overview and Description

alone mode; it is ignored in PC mode. The red LED built into this switch is

marked

TMS370 power on

and indicates that power is being supplied to the

sockets on the gang programmer.

Do not insert or remove devices from the programmer while the red

TMS370 power on

LED is lit!

The main body of the gang programmer consists of 16 sockets whose type and

arrangement are dependent on the type of gang programmer top you have.

Below each socket is a red LED, which is used to indicate a failure of the device

in the socket immediately above the LED. These sockets are mounted on base

sockets to allow easy replacement if a socket is damaged.

The rocker switch on the top center of the gang programmer board is used to

select program or verify when used in standalone mode; it is ignored in PC

mode. The red LED just above this switch is lit when the switch is in the program position.

There are two green LEDs on the left top of the gang programmer. The top LED

is marked

PDS power on

er LED is marked

and indicates that the base unit is turned on. The low-

external power on

and is used to indicate that the external

+15V is properly connected to the programmer top. The external power jack

is located on the upper left side of the programmer top.

Typically , this programmer is used in PC mode to program initial units. However, you can use the 28-pin DIP socket at the top center of the programmer to

program a 27C512 EPROM as a master device. As the master device is programmed, a checksum is calculated and added to the configuration information stored in the master device. This allows the programmer to verify that the

master device has not become corrupted before it is used to program additional units. Once programmed, this master contains all of the configuration data

as well as the code to be programmed into the mocrcontrollers. Now, the gang

programmer with the master device can be moved to a production environment where you can easily program parts without the use of a personal computer; this is called standalone mode.

1-5

Page 20

Gang Programmer Overview and Description

1.2.1 Operating the Gang Programmer in PC Mode

In

PC mode

facilitates programming TMS370 family devices and EPROMs. The system allows you to perform any or all of the operations listed below.

Program any or all of the 16 devices from PC memory

Modify or add a new device to the device table

Verify any or all devices against either PC memory or the master device.

Upload any of the 16 devices.

Program the 512K master device.

Upload the master device with or without configuration data.

Enter standalone mode.

When you program in PC mode, all LEDs are turned on for a predetermined

time as part of an LED test. Then, the software checks whether a device exists

in each socket and whether it is properly installed by running a small read-write

test. If any device fails, the LED for that device blinks for a few seconds, there

are two short audible beeps, and the following error message is displayed:

Device test failed, continue? (y/n)

, the gang programmer is an interactive, menu-driven system that

If you have incorrectly inserted any device(s), you can fix them at this time. If

only empty sockets failed, you can continue the programming by pressing

The LED of the failed device(s) remains on during programming. At the end

of programming if there is a verification error on any other device, its LED turns

on also.

In the PC mode, the push button on the gang programmer is deactivated. The

interactive commands for this mode are discussed in Chapter 2 and 3.

The gang programmer’s ability to execute any or all of the programmer commands on a

master

device allows you to program a master device for use in

standalone mode or to verify programmed devices against the master device

or PC memory while in PC mode.

1.2.2 Operating the Gang Programmer in Standalone Mode

In

standalone mode,

access the stanalone mode from the PC mode by selecting the standalone

command; when the PC is not connected to the Gang Programmer during

power-up, standalone mode is automatically selected.

Standalone mode allows you to program and/or verify devices in a productiontype mode.

After you install the master 512K EPROM device and any devices you wish to

program or verify, the procedure for starting the programmer is quite simple.

the programmer works without the PC interface. Y ou can

.

1-6

Introduction and Installation

Page 21

Gang Programmer Overview and Description

1) Position the toggle switch to either the program position or the verification

position.

2) Press the push button on the programmer.

While you press the push button, all 16 LEDs turn on, and remain on to

verify LED operation, until you release the push button.

3) Release the push button to begin the programming or verification.

If any of the devices are bad or incorrectly inserted into a socket or if the

socket is empty, the programmer beeps twice, and the LED below the

socket begins blinking.

4) To resume programming/verification, press the push button (within a

2-second period).

5) If you want to correct the error, wait until the blinking LEDs stop blinking

but remain on. At this time, insert a new device (or reinsert the old device)

and try the programming/verification procedures again.

6) Once programming has begun, you can abort at any time by pressing the

push button.

If you try to program without a master or with an invalid master device, all 16

LEDs blink until you acknowledge the error by pressing the push button.

1-7

Page 22

Properly Installing the Programmer Hardware

1.3 Properly Installing the Programmer Hardware

Correctly installing the programmer hardware is essential to the proper operation of programmer system. The following subsections explain how to connect

the programming board to the PDS base unit and the required power connections for connecting your programmer to a PC or TMS370 XDS. Also included

in these subsections is a description of how to properly insert DIPs and PLCCs.

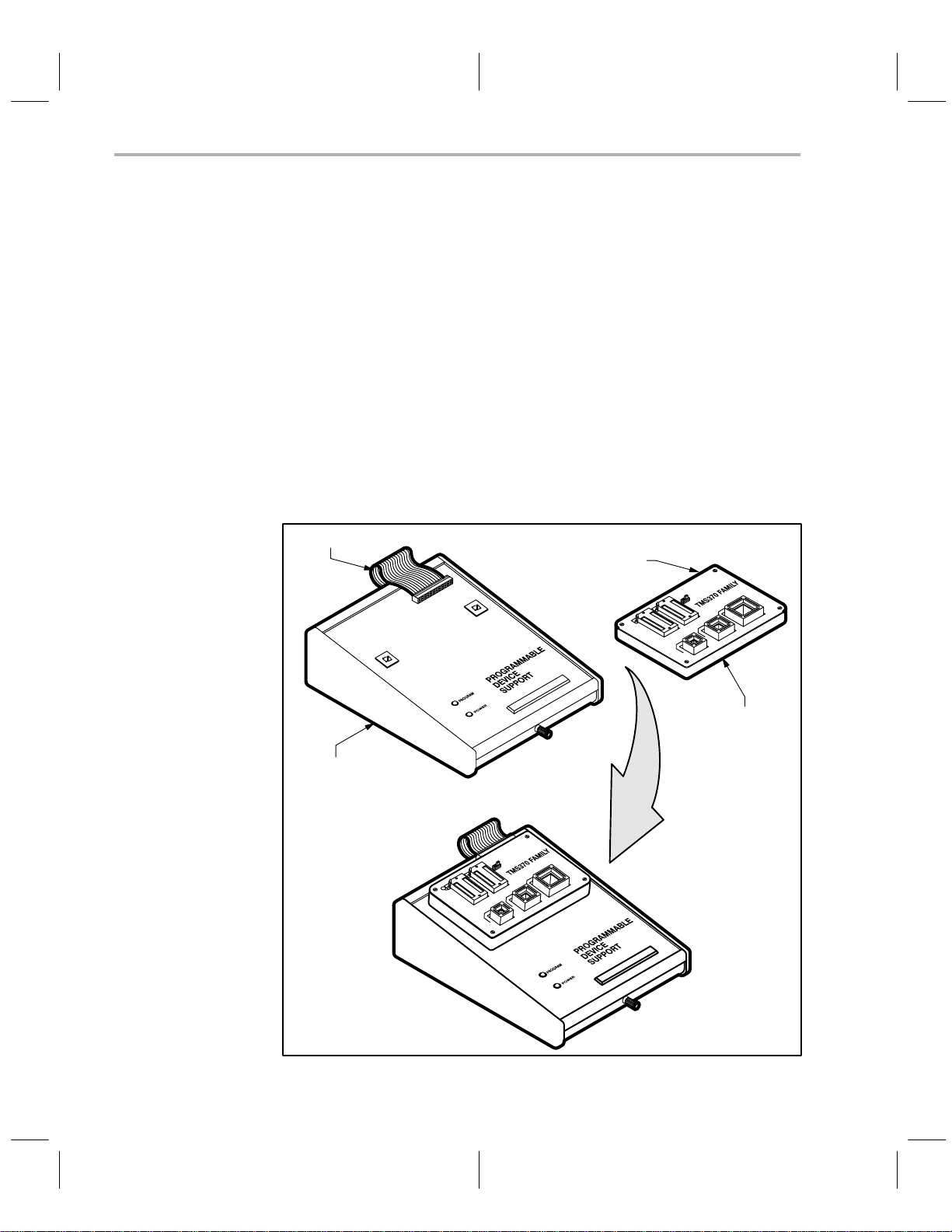

1.3.1 Connecting a Programmer to the PDS Base Unit

Connecting the programmer to the PDS is essentially the same for all programmers. The illustrations below show this process for the microcontroller programmer.

1) Line up the plastic tabs on the bottom of the programmer board with the

insertion hole in the top of the PDS base unit.

2) Press firmly until tabs are set.

3) Connect the ribbon cable from the PDS base unit to the connection on the

back of the programmer.

ribbon cable

ribbon

cable

connection

1-8

microcontroller

programmer

PDS base unit

connected PDS base

unit

and programmer board

Introduction and Installation

Page 23

1.3.2 Power Connection

The gang programmer also requires an external power supply of 15 volts/2

amps. The connection for this external power is marked EXTERNAL POWER

and is positioned near the top left corner of the programmer’s socket board.

Plug the the jack of the +15-volt wire into the external power socket. Connect

the white-striped wire to the +15-volt terminal of the power supply and the solid

black wire to the ground terminal of the power supply.

Properly Installing the Programmer Hardware

Connect the female end of the power cord to the PDS base unit.

The programmer can handle a power range of 105 to 265 volts AC at 47

to 440 hertz. All units are equipped with two power cords. If you are in the

U.S.A., use the power cord with a male connector that can be plugged

directly into a 120-V, 60-Hz power socket.

Outside the U.S.A., use the power cord with no male connector because

the type of receptacle to be used is unknown. Attach the appropriate connector for your power receptacle. The wires are color coded as follows:

Green and Yellow = Earth

Blue = Neutral

Brown = Live

1.3.3 Connection to a PC

1) Connect the end of the RS-232C cable consisting of a single 25-pin connector to the programmer.

2) Connect the end of the RS-232C cable consisting of two 25-pin

connectors to the serial communication port of the PC. (If an IBM PC/A T

is used, the 9-pin-to-25-pin converter cable provided must be used.)

1.3.4 Connection to an XDS

Connect the programmer through an XDS if you want to use both the XDS

Debugger and the microcontroller programmer, and if the PC has only one

communication port. Or, even if you have enough communication ports but do

not want to change the port number when you switch from one tool to the other,

you can use this method. The programmer works as if it is connected directly

to the PC.

Complete the following steps to connect the programmer through an XDS.

1) Connect port D of an XDS to the programmer by using the RS-232C cable

supplied with the programmer. The male connector on the double-headed

end of the cable connects to the XDS; the single-headed end connects to

the programmer.

1-9

Page 24

Properly Installing the Programmer Hardware

2) Connect port A of the XDS to the PC by using the cable supplied with the

XDS.

3) Ensure that the switches on the XDS Communications board are set as

in Table 1–1.

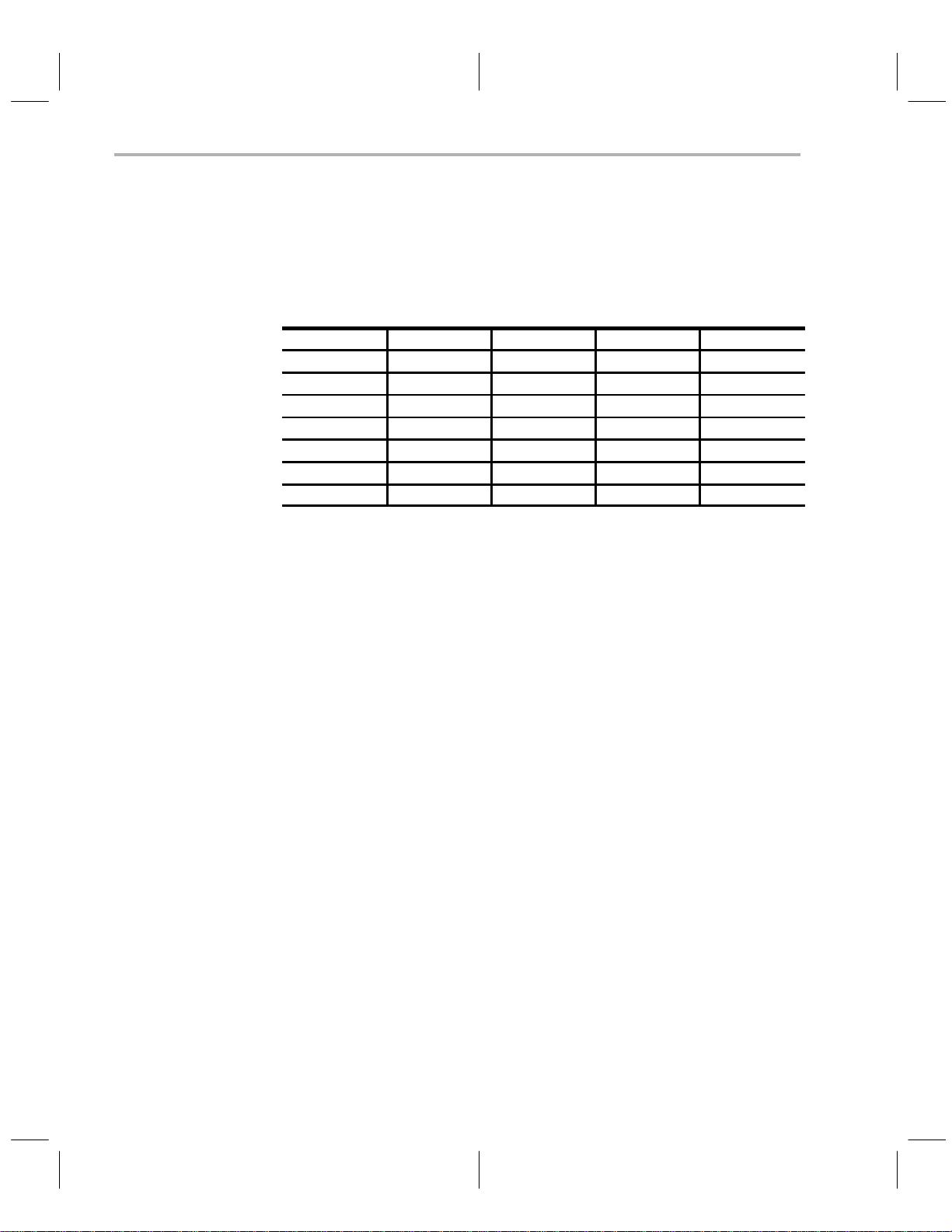

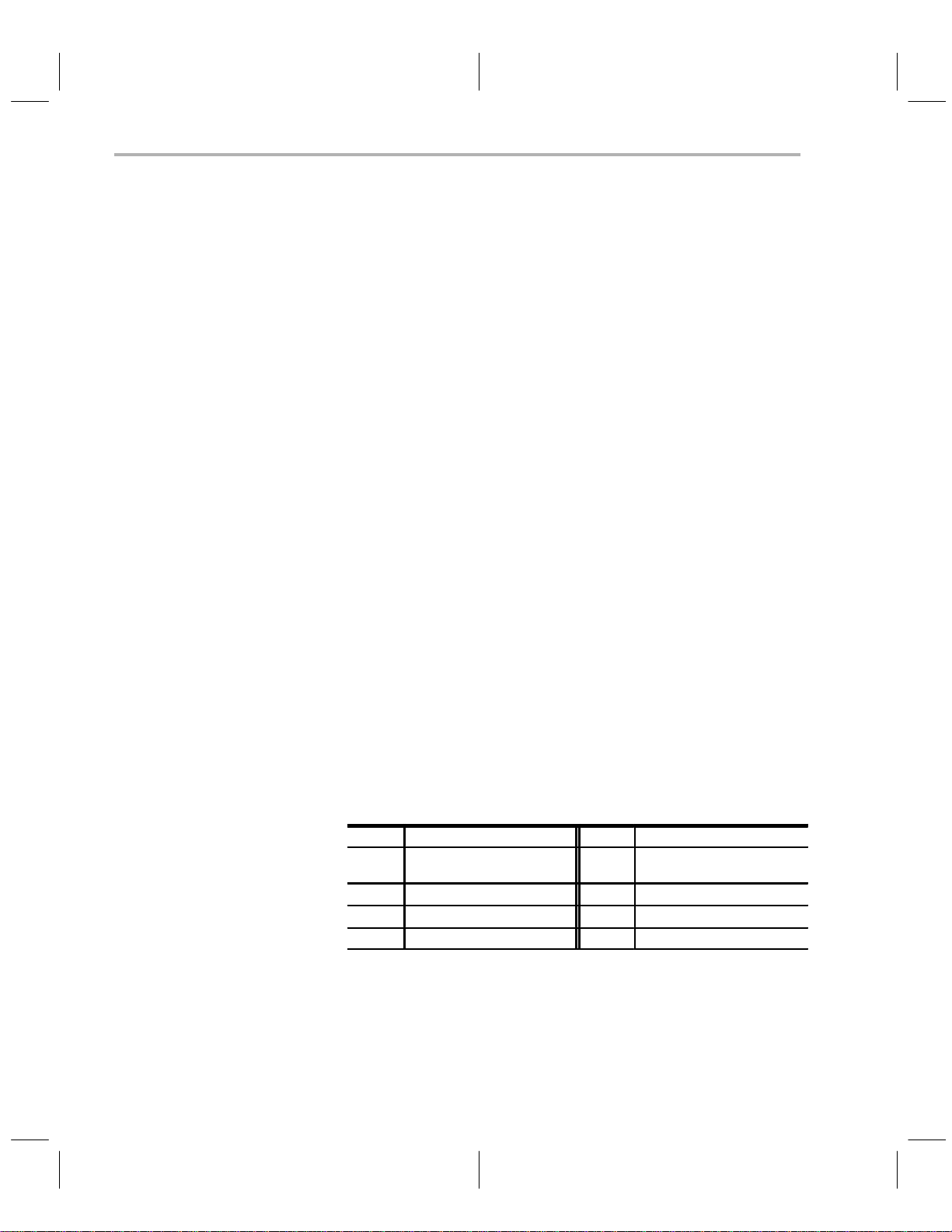

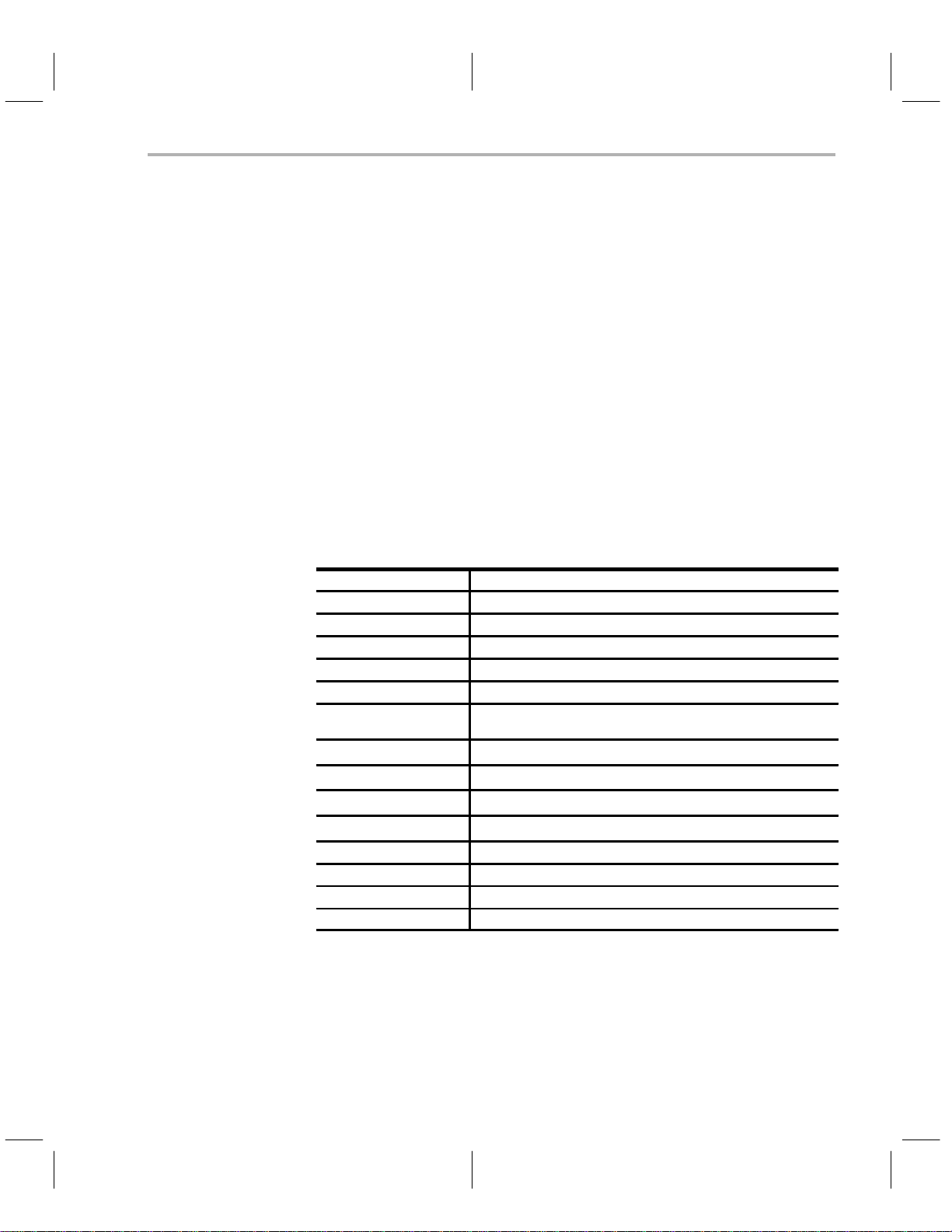

Table 1–1. XDS Memory Expansion/Communications Board Switch Settings

Switch No. S1 S2 S3 S4

1 Off Off Off Off

2 Off On Off Off

3 Off Off Off Off

4 Off On On Off

5 On Off On On

6 Off Off On On

7 On On On Off

1-10

Introduction and Installation

Page 25

1.3.5 Integrated Circuit (IC) Insertion

ICs may be inserted or removed while power is applied to the programmer;

however:

1) When using the microcontroller programmer, never use

more than one IC socket at a time. Damage to the IC or the

programmer could result.

2) Never insert or remove the IC while the red LED is on. Dam-

age to the IC or the programmer could result.

3) TMS devices contain circuits to protect their inputs and out-

puts against damage due to electrostatic discharges of up to

2 kV. However, you should employ the usual precautions

when handling MOS devices, such as storing the device in

conductive foam and grounding yourself when handling

them.

For the microcontroller programmer, decide which of the sockets (U1, U2, U3,

U4, or U5) to use for your device. Figure 1–3, shows the circuit board and IC

sockets.

Properly Installing the Programmer Hardware

Figure 1–3. Socket Identification

2764, 27128, and 27256

370Cx10 DIP

370Cx10 PLCC

2732 pin 1

pin 1

pin 1

2732

J2

U1 U2

U3 U4 U5

2764

27128

27256

Set to left for 2732

Set to right for 2764, 27128,

{

and 27256

370Cx32 PLCC

370Cx5x PLCC

1-1 1

Page 26

Properly Installing the Programmer Hardware

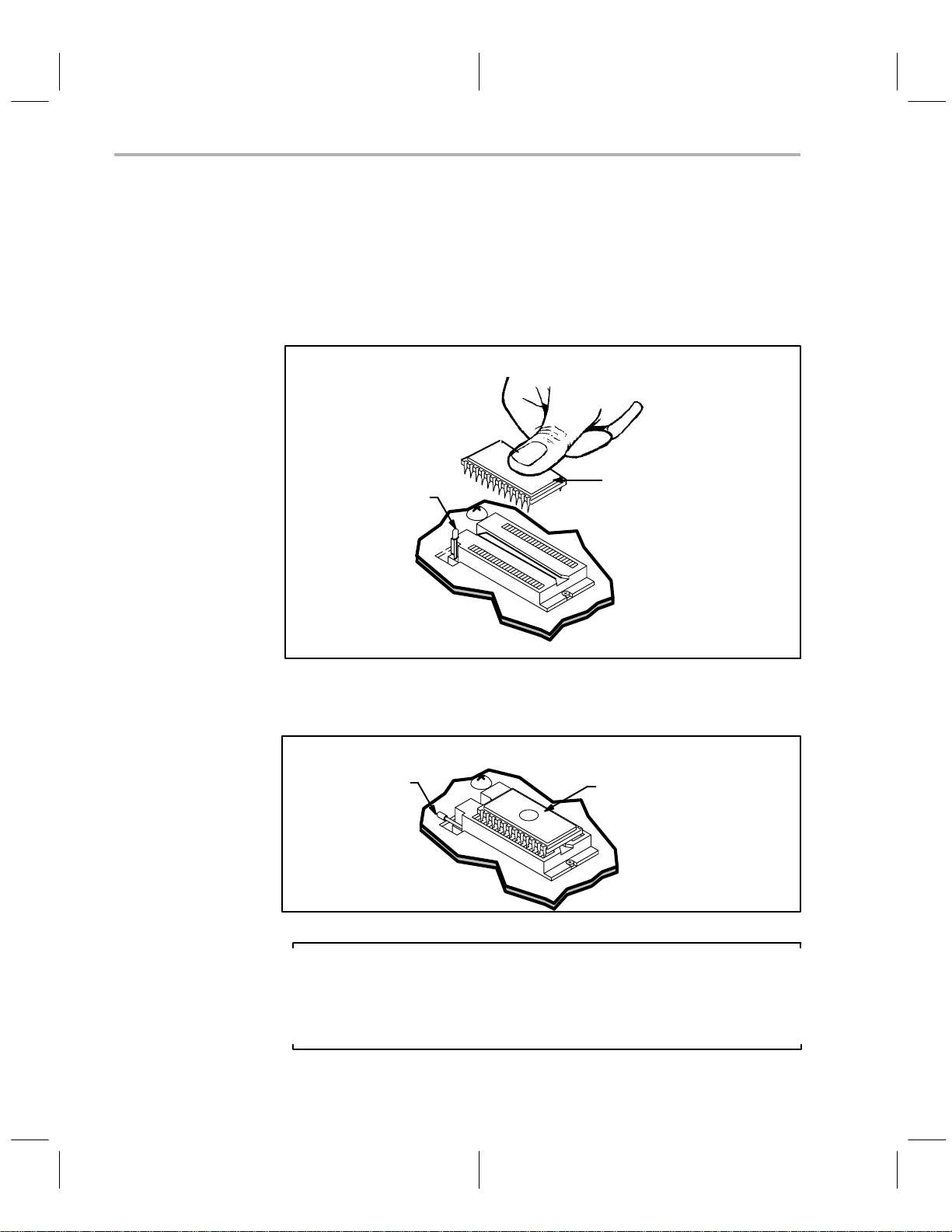

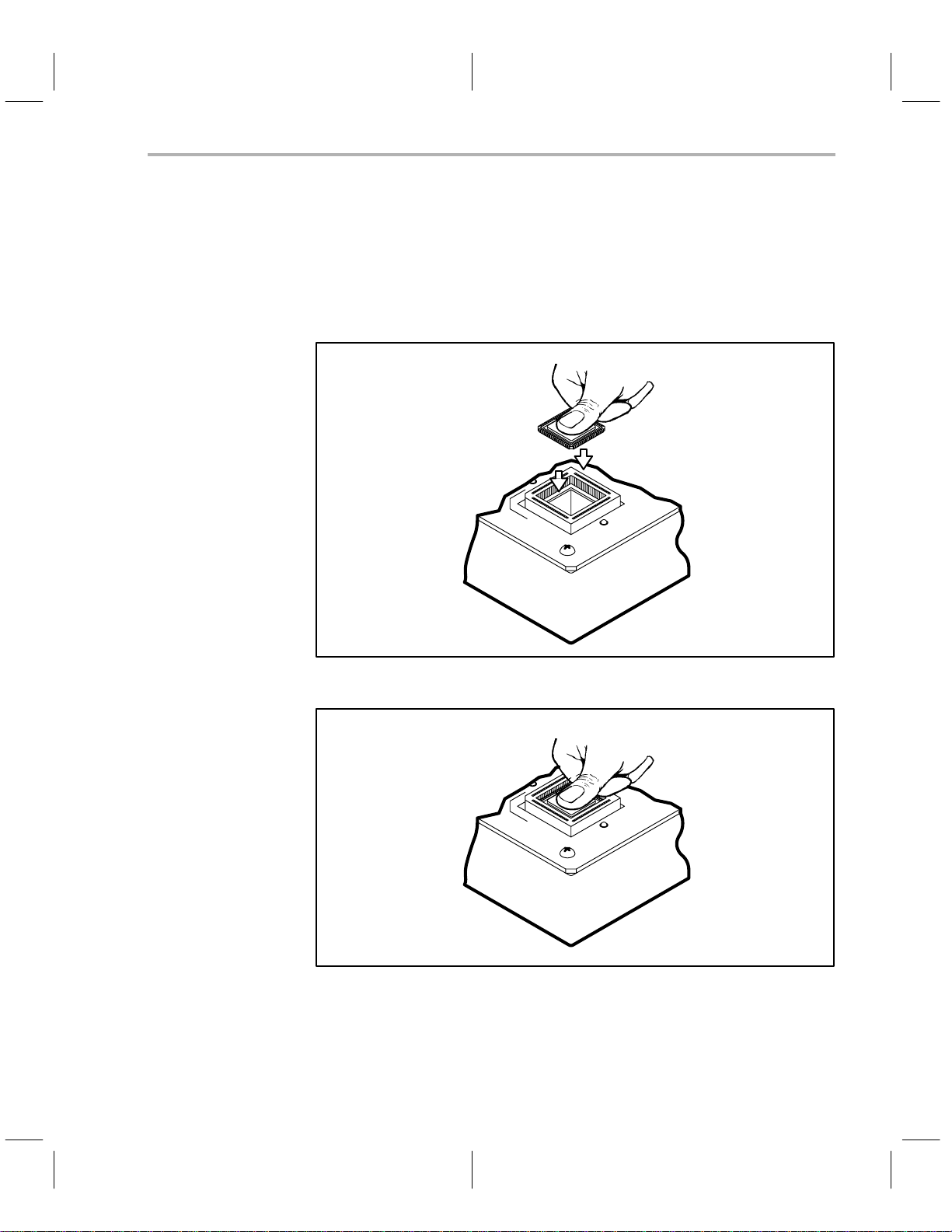

To install a DIP device:

1) Align the IC so that pin 1 is oriented in the upper-left corner, indicated on

the printed circuit board by a circled number 1:

2) Raise the locking arm, pulling it toward you to the upright position.

3) Insert the IC.

locking arm

DIP

4) Lower the locking arm by pushing it away from you and down, as far as

it will go.

locking arm

DIP

1-12

Note:

If you install a 2732 device in U2, be sure to use the bottom socket holes,

leaving the top four socket holes unused. The correct position for a 2732

is indicated by a bracket on the printed circuit board to the left of the socket.

Introduction and Installation

Page 27

Properly Installing the Programmer Hardware

To install a PLCC device:

With this release of the programmers, the PLCC sockets do not have a lid;

therefore, they are not sensitive to the device package height. These new

sockets also have the pin 1 orientation at the top of each socket, making it less

likely for you to insert a device backwards.

1) Place the PLCC in the empty socket.

2) Press firmly until it is properly seated.

The programmer hardware is now ready to use.

T o remove the device, press down firmly on the black plastic socket edges until

the device is pushed upward and released.

1-13

Page 28

Properly Installing the Programmer Software

1.4 Properly Installing the Programmer Software

Installing software is exactly the same whether you are using the Microcontroller Programmer or the Gang Programmer. Insert the diskette supplied with the

programmer into the PC disk drive and use one of the following methods to

copy the contents of the diskette to a directory in your hard disk.

1.4.1 Installing the Software in a Single Directory

This method is simple and suitable for a single user with only a few source files.

1) Make a directory to contain your programmer files.

MKDIR \370

2) Change your working directory to the directory you just created.

CD \370

3) Copy the files from the diskette.

COPY A:*.*

4) See Section1.5 for a description of how to invoke the programmer software.

1.4.2 Installing the Software in Multiple Directories

This method is useful if there are several different users or if one user is working on several different projects.

1) Create a directory for your programmer files.

MKDIR \370

2) Copy the programmer files into your programmer directory:

COPY A:*.* \370\*.*

3) Create project directories.

MKDIR \PROJ1

MKDIR \PROJ2

4) Add the programmer directory to the path command in the AUTOEXEC.BAT file.

PATH C:\DOS;C:\PROG;C:\REP;C:\370

where C:\370 is the added path to the programmer directory.

set

5) Include a

SET IPCDIR=C:\370

If the

device table

the programmer to search the programmer directory for the default device

command in the AUTOEXEC.BAT file as follows:

cannot be found elsewhere, the

set

command causes

1-14

Introduction and Installation

Page 29

Properly Installing the Programmer Software

table. The order in which the programmer looks for the device table is outlined below.

a) First, it looks for a device table file specified in the configuration/batch

file if the configuration/batch file was included in the command line to

invoke the programmer software.

PRGRM370 @PROJ1.CFG

where PROJ1.CFG is the configuration/batch file.

b) Next, it looks in the current directory for the default DEVICE.TBL.

c) Then, it looks in the directory specified by the ”SET IPCDIR” command

for the file DEVICE.TBL.

6) See Section 1.5 for a description of how to invoke the programmer software.

1-15

Page 30

Invoking the Programmer Software

1.5 Invoking the Programmer Software

Before activating the programmer, be sure that it is plugged in and correctly

connected as described in Section 1.3. Turn on the programmer’s power

switch (and the gang programmer’s external power) before invoking the programmer software.

The command to run the programmer software from the DOS prompt is:

prgrm370 [

COFF file

] [@

Config./Batchfile

] [–b] [–p=

port #

]

where

COFF file

Optional argument that specifies a file to be programmed or verified in the batch control mode or

loaded into PC memory in the interactive control

mode.

Config./Batch file

@

Optional argument that specifies a configuration/

batch file that contains the configuration parameters or the batch commands for the batch control

mode.

–b Optional argument that turns on the batch mode if

specified.

–p =

port #

The communication port number to be used. Default is 1.

After you invoke the programmer software, the PC screen briefly displays a

version number and copyright message.

If you specified a configuration/batch file but did not turn on the batch mode,

the configuration specified in the file is loaded as the current configuration. Any

other batch commands that would control the flow of the programming process

are ignored.

If you specified a configuration/batch file and turned on the batch mode with

the –b argument, the programmer software operates as directed by the batch

file.

1-16

If you specified a port number and the programmer is not physically connected

to that port, then the following error message is displayed.

Programmer not properly connected: Abort, Retry?

Aborting the invocation returns you to the DOS prompt. T o retry the invocation,

make sure the programmer is turned on and properly connected to the port

specified in the command. Then, press

followed by to restart the

programmer software.

Interactive mode commands are described in detail in Sections 2 and 3. Batch

commands are covered in Appendix 1.

Introduction and Installation

Page 31

1.6 Getting Started—Example Sessions

This section will help you get a quick start using your programmer. Once you

get started, the menu structure and prompts make the programmer easy to

learn and to use. The remainder of this manual provides a detailed reference

if you need further information on any of the commands, prompts, or error

messages. Use the T able of Contents at the front of the manual and the Index

at the end of the manual to direct you to the specific topic you need.

We assume that you are familiar with the TMS370 Assembler and Linker software and that a COFF file has been created that contains object code with

which a device can be programmed. These are prerequisites to using the

programmers and is beyond the scope of this manual.

1.6.1 Interactive Programming Example 1

This example assumes that the programmer software has been loaded onto

your PC, and that the DOS prompt is C:>.

In this example you will invoke the programmer, choose a device to program,

and use the

and portion of the object code to be programmed onto the device.

load

command to give the programmer the name of the object file

Getting Started—Example Sessions

1) From the DOS prompt, invoke the programmer to bring up the interactive

display in the configuration window.

C:\>prgrm370

The programmer title banner appears briefly; then the configuration

window appears with the top line containing the following command menu:

CONFIG:showID AddDevice Edit Load ChooseDevice Save Display Quit

2) Place a TMS370 device in the appropriate socket; press to select the

choose device command.

The cursor moves down the screen to the beginning of the Device Table.

Also, a function key command line containing the following commands

appears at the bottom of the screen:

F1NextPage F2PrevPage F4ShowRanges F5SelectDev F6DeleteDev

3) Move the cursor to the appropriate device using the cursor arrow keys.

Once you have found the correct device, press

4) Press

to return to the configuration command line, and then press

to select the device.

to move to the display window.

The display window command line contains the following commands:

Fill Load OutputCOFF Move Progm Show Upload Verify Edit Config sYs Quit

5) Press for the load command. The following prompt appears at the top

line of the screen:

1-17

Page 32

Getting Started—Example Sessions

Object file:

6) Enter the name of the COFF file containing the object code with which the

device is to be programmed. Press

Object base address: all

where

is to be used.

, and the following prompt appears:

all

is the default, meaning that the entire object code address range

7) Select the address range default of

all

by pressing .

The cursor returns to the display window command line.

8) Press

to start the programming process. A prompt appears, asking for

the name of a file in which programming errors are to be recorded.

Error file:

9) Enter a file name and press .

10) A prompt appears, asking for the starting address in PC memory of the

data to be used in programming.

PC memory base address: all

11) Accept the default all by pressing .

12) Programming begins, and the bottom line of the screen is replaced by a

status message informing you of the beginning address of the packet (180

bytes) currently being programmed. This line will be replaced by an error

message if an error should occur. Otherwise, when programming is complete, the bottom line of the screen shows a prompt asking if another device is to be programmed using the same parameters.

Programming Complete, Program another device? (y/n)

Press n and then to terminate programming and return to the display

window command line. The device is now programmed and verified, as-

suming no error messages appeared.

1-18

Introduction and Installation

Page 33

1.6.2 Interactive Programming Example 2

This sample session illustrates entering the interactive mode with the COFF

file automatically loaded into PC memory . If the programmer software is active,

that is, in the display or configuration windows, press

mer and verify your choice. This returns the DOS environment.

1) At the DOS prompt, type the following command:

C:\>prgrm370 xyz.out

where

xyz.out

which the device is to be programmed.

is the name of the COFF file containing the object code with

Getting Started—Example Sessions

to quit the program-

2) Press

. The programmer software will start and automatically load the

code in the xyz.out file into PC memory.

You can now operate the programmer in the interactive mode as usual.

This method saves a few steps in loading the COFF file if the default load

addresses are acceptable.

1.6.3 Batch Programming Example

This sample session illustrates batch mode programming. A configuration/

batch file (not to be confused with a DOS batch file) must exist in order to use

this method. If one does not, examine the detailed description in Appendix 1.

For this example, assume that your configuration/batch file is named abc.cfg.

If the programmer software is active, that is, in the display or configuration

windows, press

you to the DOS environment.

At the DOS prompt, type the following:

C:\>prgrm370 xyz.out @abc.cfg –b

where

xyz.out

@ symbol is a delimiter identifying abc.cfg as a configuration/batch file, and

–b

symbol turns on the batch mode. If the –b had been left off, the interac-

the

tive mode would have been entered, and the configuration specified in the

abc.cfg file would be used.

is the COFF file and

to quit the programmer and verify your choice. This returns

abc.cfg

is the configuration/batch file. The

For more information on the batch mode, see Appendix 1.

1-19

Page 34

1-20

Introduction and Installation

Page 35

Chapter 2

Operating in the Configuration Window

This chapter describes the commands offered in the configuration window of

the programmer’s display.

The first part of this chapter explains how the command menus and function

keys work; it also has a short section on entering information at the cursor

prompt.

have already read these sections in Chapter 3, there is no need to read them

in this chapter.

The remainder of this chapter describes the operation of the configuration window and explains each configuration command, walking you through the interactive display prompts where applicable.

Section Page

2.1 How the Command Menus Work 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Using the Special Function Keys 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 What Happens If I Make an Error? 2-3. . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Understanding Your Input at the Cursor Prompt 2-4. . . . . . . . . . . . . . .

2.5 Configuration Window Overview and Description 2-5. . . . . . . . . . . . .

2.6 Secondary Configuration Window—the Show

2.7 Showing the Software Revision Information 2-9. . . . . . . . . . . . . . . . . .

2.8 Defining and Adding a Device to the Device Table 2-9. . . . . . . . . . . .

2.9 Editing the Configuration Parameters and Device Table 2-11. . . . . . .

2.10 Loading the Device Table and Configuration Parameters

2.11 Selecting a Current Device 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 Saving Configuration Parameters and the Device Table

2.13 Showing the Display Window 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 Ending Your Current Session and Returning to DOS 2-16. . . . . . . . .

These sections are the same as the initial sections in Chapter 3; if you

Ranges Window 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

From a File 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to a File 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Page 36

How Command Menus Work

2.1 How Command Menus Work

The interactive mode of the programmer is driven by

displayed on the top line of the screen. A command menu is a list of command

names, each of which is displayed with one highlighted letter, usually the first

character in the name. The highlighted letter is the key you use to invoke the

command. You may type command letters in upper or lower case.

When you type a valid command letter, the programmer software clears the

command line, displays the name of the selected command, and executes the

command. Most commands require additional information, in which case the

programmer either prompts for parameters or displays a submenu of commands.

Figure 2–1 shows the command menu structure. This figure is provided as a

road map to the desired command(s).

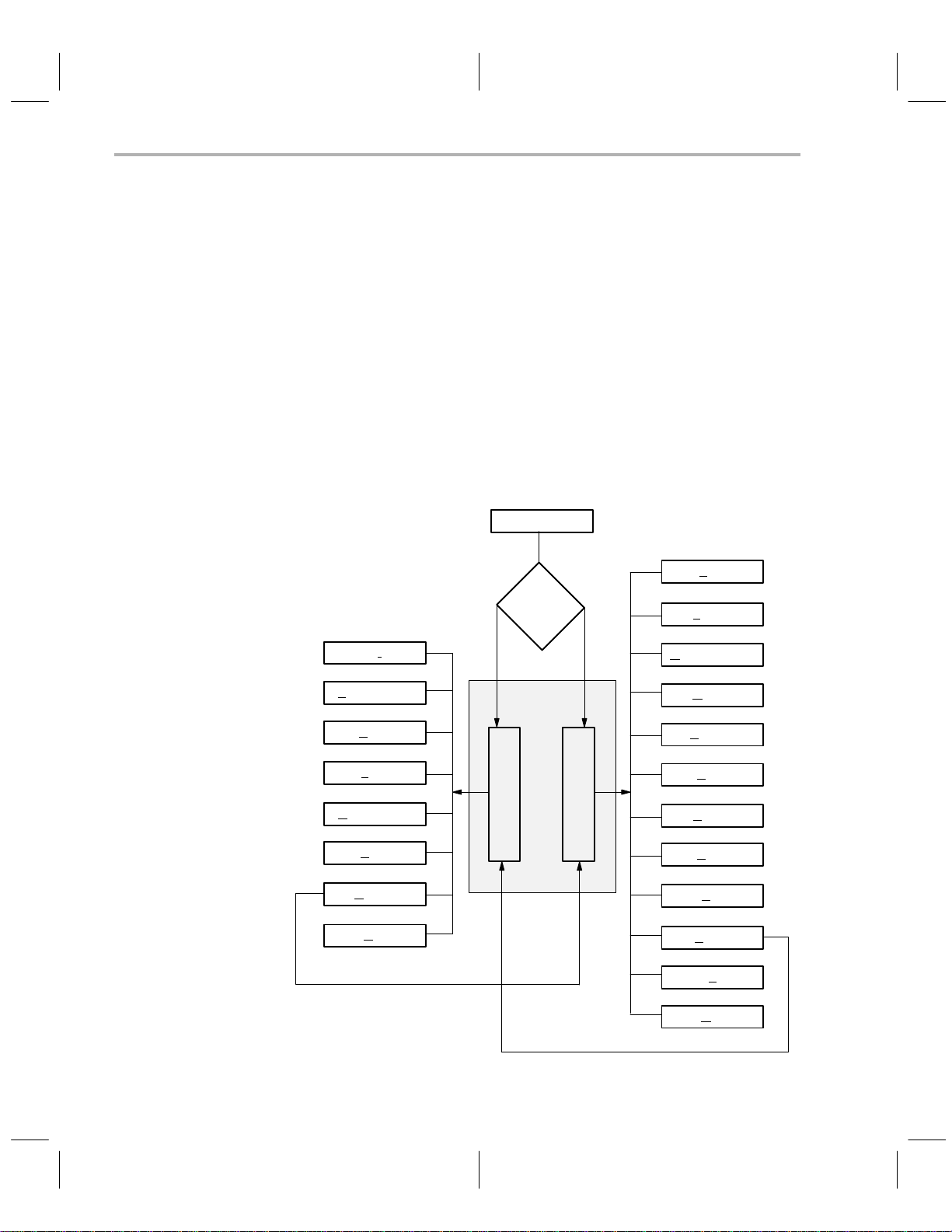

Figure 2–1. Command Menu Structure

D

showI

prgrm370

Config file

specified?

No Yes

command menus

Fill

Load

Output COFF

that are

2-2

dd Device

A

dit

E

Load

hoose Device

C

S

ave

D

isplay

Q

uit

Command

Windows

Config

Move

Prgrm

Display

Show

Upload

Verify

Edit

Config

sYs

Quit

Operating in the Configuration Window

Page 37

Using the Special Function Keys/What Happens If I Make an Error

2.2 Using the Special Function Keys

Function keys through invoke various actions in the programmer,

depending on your location in the command menu structure. The valid function

keys and their definitions for each mode are displayed on the bottom line of

the screen for reference. Press the highlighted key for the desired action.

Another special function key is

return to the next higher command menu level, press this function key . For ex-

ample, if you are in the

command menu.

fill memory

2.3 What Happens If I Make an Error?

If an error occurs, the programmer software displays an error message on the

bottom line of the screen and prompts you to

error state. You can type any key, including

sage is then cleared, and the function key line is redisplayed.

If the error was caused by an input to a prompt, the programmer software re-

turns to the prompt to let you re-enter a value. Otherwise, the software returns

to the next higher command menu.

To find an explanation of any error message, refer to Appendix 2.

. If you ever need to abort a command and

command, press to return to the display

hit any key

, on the keyboard. The mes-

to escape from the

2-3

Page 38

Understanding Your Input at the Cursor Prompt

2.4 Understanding Your Input at the Cursor Prompt

The programmer software often requires you to enter a response to a prompt

or to move the cursor to a value on the screen and modify it.

The previous or default value for the prompted parameter value is always displayed. Y ou can accept the displayed default or former value by pressing only

in response to the prompt.

If you type a new value, the characters are highlighted, and the cursor advances to the next field position.

by the programmer

020 (the underscored character indicates the cursor position). If you type 8

7

. For example, assume that the displayed default value is

over the default value, you would see 80

acter indicates the highlighted character on the screen). If you then pressed

the ENTER key, the value entered would be 0008,

All numeric input values are hexadecimal except for the VCC, VPP, and

program-pulse-duration-time values, which are decimal.

T able 2–1 lists special control keys. The effect of each key is given for both text

and numeric fields. Any control key not listed in the table has the same effect

.

as

Only the highlighted characters are accepted

20 on the screen (the boldface char-

not

8020.

Table 2–1. Edit Control Keys

Key Function

Terminates input and accepts current value.

Text: Inserts a space.

Numeric: Terminates input and accepts current value.

T ext: Erases character to the left of cursor and backs up one space.

Numeric: Erases character to the left of cursor and backs up one space.

T ext: Subsequently typed characters are inserted at the cursor posi-

tion; characters to the right of the cursor are moved right, even

out of the field. Remains in effect until the INSERT key or

another control key is typed.

Numeric: No effect.

Text: Deletes character at cursor.

Numeric: No effect.

Text: Moves cursor left one space without erasing.

Numeric: Moves cursor right one space without erasing.

Text: Moves cursor right to the next character and highlights it.

Numeric: Moves cursor right to the next character and highlights it.

2-4

Operating in the Configuration Window

Page 39

Configuration Window Overview and Description

2.5 Configuration Window Overview and Description

If you use the

configuration

command while in the display window, the config-

uration window illustrated in Figure 2–2 is displayed; it also displays when

the programmer software is first invoked.

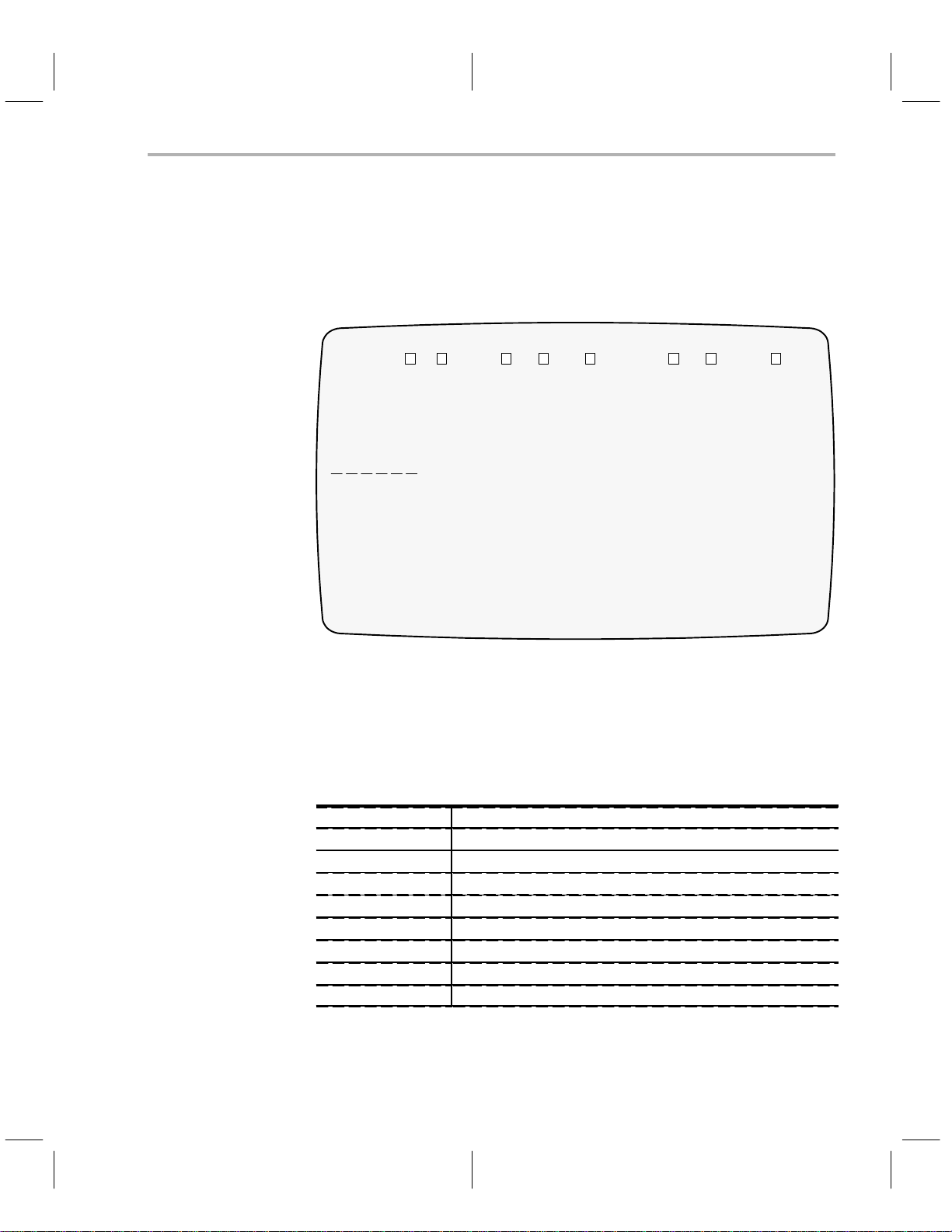

Figure 2–2. Configuration Window at System Startup

CONFIG:

Program Configuration

Port#: 1

Device Type

27128 TMS27C128

27256 TMS27C256

2732 TMS2732A

2764 TMS2764

7742 TMS7742

TMS370 16K_PE

Show D ddDevice dit oad hooseDevice ave isplay ui

t

TMS27C64

256_DEE

4K_PEE

512_DEE

C010

C050

The configuration window consists of three different areas—a command line,

a program configuration area, and the device table.

AEL DQC SI

command line

The

the data in the configuration window. These commands are listed in Table 2–2

and described in detail in Sections 2.7 through 2.14.

Table 2–2. Configuration Window Commands

Command Function

Show ID Display software title and revision level.

Add Device Add a new device to the device table.

Edit Edit the configuration parameters.

Load File Load current configuration or current device table from a file.

Choose Device Choose (set) the current device type.

Save File Save the current configuration or the current device table in a file.

Display Go to the display window.

Quit Quit (exit) and return to DOS.

The

program configuration area

tion port—port 1 or 2. To change this value, refer to Section 2.9.

lists the available commands you can use to manipulate

lists the current selection of the communica-

2-5

Page 40

Configuration Window Overview and Description

The

device table

lists devices that can be programmed through the programmer. The device table displays 12 device types at a time and is sorted first by

the device family names and then by the device first names. If there is more

than one device type under one device family, the family name is displayed

only once, on the first line of the device family . When a new device is specified

or a device table is loaded from an outside file, the device table is automatically

updated. If the actual device table contains more than 12 device types, you can

use the function keys to scroll through the table. When a current device is selected, it is highlighted within the table.

The device table supplied with your programmer software includes all of the

TMS370 devices available at the time the programmer was produced. As new

configurations are made available, TI updates the DEVICE.TBL file and

makes it available through our microcontroller bulletin board system. For information on how to use the bulletin board, contact the TMS370 hotline at the

number indicated on page 1-1.

2-6

Operating in the Configuration Window

Page 41

Secondary Configuration Window—the Show Ranges Window

2.6 Secondary Configuration Window—the Show Ranges Window

A small subwindow appears when you select the

, from the device area of the configuration window. Figure 2–3 illustrates

what the show ranges

Figure 2–3. The Show Ranges Window

CONFIG:

Program Configuration

Port#: 1

Device Type

27128 TMS27C128

27256 TMS27C256

2732 TMS2732A

2764 TMS2764

7742 TMS7742

TMS370 16K_PE

The show ranges window does not neccesarily default to show the ranges of

the chosen device. Instead, it shows the ranges of the device that the cursor

is next to in the device table. Y ou can scroll through the device table and notice

the parameters changing in accordance with each new device the cursor is

next to.

ChooseDevice

Valid address ranges for 2732/TMS2732A

START SIZE TYPE Vcc Vpp Pdt CtrlReg FmlyCode BlkErase Pbits

00000h 1000h EPROM 5 21 10 ooh 40h NO O’s only

TMS27C64

256_DEE

4K_PE

512_DEE

C010

C050

window looks like.

show ranges

function key,

Table 2–3. Show Ranges Parameter Summary

Parameter Description

Start Valid start address for programming.

Size Size of the valid program area.

Type The type of memory in this range (EEPROM or EPROM).

V

CC

V

PP

pdt Program pulse duration time.

ctrlReg The control register.

FmlyCode The hexadecimal family code of the device.

Blk-Erase The block erase toggle.

†

Pbits

†

The program algorithms are discussed in detail in subsection 2.6.1.

Valid Vcc values are 0, 5, or 6 volts.

Valid Vpp values are 0, 5, 12, 12.5 or 21 volts.

The program algorithm.

2-7

Page 42

Secondary Configuration Window—the Show Ranges Window

2.6.1 Selecting the Proper Program Algorithm

For EEPROM memory in devices, there are three programming modes:

writing 0s only, all 1s in the data bytes are ignored.

writing 1s only, all 0s in the data bytes are ignored.

writing 0s and 1s.

For all other types of memory,

writing 0s

is the only programming mode.

The three modes provided for the TMS370 allow the selection of the most

efficient programming.

When the 1s and 0s mode is used, the programmer makes two passes through

the address range, programming the 1s in one pass and the 0s in the other

pass. Assume that the binary value 1010 1010 is to be programmed into a given address. First, the 1s are programmed, giving a value of

1x1x1x1x

where

x is unknown (the previous contents of the location).

On the second pass, the 0s are programmed, resulting in

x0x0 x0x0

where x

is a don’t care state (in this case 1s from the first pass) so that the resulting

value after both passes is

1010 1010

, the desired value. This method is effec-

tive for modifying short segments of code.

If a large segment of code is to be modified, it will reduce programming time

by almost one half if you block erase to 1s and use the 0s-only mode.

When programming the EEPROM memory of TMS370 devices that also have

UV-erasable EPROMS, be sure to block erase the array before programming

the device. (Ultraviolet light causes the EEPROM bits to go to an intermediate

so that they must be block erased before programming.)

2-8

Operating in the Configuration Window

Page 43

Showing the Software Revision Information/Defining and Adding a Device to the Device Table

2.7 Showing the Software Revision Information — the Show ID Command

This command displays the software release/revision information on the top

line of the PC screen for reference. Press any key to return to the configuration

command line.

2.8 Defining and Adding a Device to the Device Table—the Add Device

Command

This command lets you define a new device type different from those in the

current device table, and then add it to the device table. When the

command is selected, the following programmer prompts appear.

Step 1: Identify the complete device name by answering the following two

prompts:

Device family name:

Device first name:

Legal device family names supported by the programmers are

TMS370, 2732, 2764, 27128, or 27256.

add device

Device first names are names that distinguish different versions of

the same device family.

The programmer software checks the device table to make sure the

new device is not a duplication. If the new device is a duplicate, the

following error message is displayed.

duplicate device name (hit any key)

Press any key to erase the error message and return to the first

prompt to re-enter different device names.

Step 2: Identify the programming address range by answering the following

two prompts:

Device Program Ranges – Start Address: 0000h

Device Program Ranges – Size: 0000h

Enter numerical values within the range (0000h–FFFFh) to the address prompts listed in Step 2.

Step 3: Identify the primary configuration parameters for the device by an-

swering the following four prompts:

Type of Memory:

Device VCC(in VDC – 0, 5 or 6) : 0

Device VPP (in VDC – 0, 5, 12, 12.5 or 21): 0

Program Pulse Duration time (in ms – [0–127]): 0

2-9

Page 44

Defining and Adding a Device to the Device Table

Valid types of memory are EPROM or EEPROM.

Legal V

values are listed following the prompt—0, 5, or 6. If you

CC

enter a value that is not one of the three valid choices, the following

error message appears:

invalid VCC value: 0, 5, or 6 (hit any key)

Press any key to erase the error message and return to the prompt

to enter the V

Legal V

PP

value again.

CC

values are listed following the prompt—0, 5, 12, 12.5, or

21. If you enter a value which is not one of the five choices, the following error message appears:

invalid VPP value: 0, 5, 12, 12.5 or 21 (hit any key)

Press any key to erase the error message and return to the prompt

to enter the V

Valid

pdt

values fall in the decimal range of 0–127 as shown at the

value again.

PP

end of the prompt. If you enter a value that is out of the range, an error

message is displayed as follows:

invalid Program Pulse Duration time: [0..127]

Press any key to erase the error message and return to the prompt

to enter the Program Pulse Duration time again.

Step 4: Identify the secondary configuration parameters by answering the

following four prompts:

2-10

Control Register:

This parameter is necessary only for programming TMS370 microcontrollers. The current valid values are 01Ah for the data EEPROM

range and 1Ch for the program memory range.

Family Code:

This parameter tells the programmer how to program the device. The

current valid values are:

Code Device Code Device

10h TMS370 EEPROM range 41h 2764, 27C64, SE77C42,

11h TMS370 EPROM range 42h 27C128

20h TMS7742 43h 27C256

40h 2732

Block Erase:

TMS77C82

Using the block erase parameter for devices with a family code of

10h (TMS370 EEPROM range) allows the array to be erased to 1s

or 0s. The block erase parameter is ignored for any other family code

none

and should be set to

for clarity.

Operating in the Configuration Window

Page 45

Editing the Configuration Parameters and Device Table

Program Algorithm:

If the family code is 10h (TMS370 EEPROM range), one of three programming algorithms can be chosen—

program 1s and 0s.

parameter, you can optimize for programming speed or can minimize the number of write erase cycles. This parameter is ignored for

any other family code and should be set to

After you have entered the program algorithm, the programmer repeats

the setup configuration starting at Step 2 to allow you to enter up to five

address blocks. Press

address blocks you need. You must enter at least one set of

parameters before exiting the command, or else the following warning

message is displayed.

Device parameters not complete, device not added.

Press any key to erase the warning message and return to the configuration command menu.

After you have entered all of the above parameters correctly , the newly defined device is added to the current device table and displayed in the device table window.

Using this parameter along with the

to exit the loop after you have entered all the

program 1s, program 0s,

block erase

program 0s only

for clarity .

add device

or

2.9 Editing the Configuration Parameters and Device Table — the Edit

Command

In the

edit

mode, you can edit the configuration

current device table.

2.9.1 Editing the Configuration Parameters

From the configuration window press for the edit command. Pressing

toggles you between the port # field and the device table, while pressing

in the port # field scrolls through the valid selections for the communication

port—port 1, or 2.

Press the key when you are finished editing the parameters to record your

changes and to return you to the configuration command menu.

Note:

In order to edit any of the current device table parameters, you must display

the parameters (show ranges) and then use the designated function key to

edit the ranges window. Refer to subsection 2.9.2 for a complete description.

port #

parameter field and the

2-1 1

Page 46

Editing the Configuration Parameters and Device Table

2.9.2 Editing the Device Table

The device table is a list of devices catagorized by

. The software diskette provides a device table file,

name

tains a list of devices and their configuration parameters. The devices and their

configurations are loaded automatically when the programmer software is invoked.

Pressing

from the

field. When this occurs, several function keys and their actions are displayed

at the bottom of the screen. (Choosing

place the cursor directly into the device table field if this field is the last one you

worked in. In other words, the

in before exiting back to the command line.)To edit the device table, use the

commands listed in Table 2–4.

Table 2–4. Device Table Edit Commands

Command Function

F1 (Page Down) Scroll forward through device table.

F2 (Page Up) Scroll backward through device table.

F3 (Next Window) Move to the communication port.

F4 (Show Ranges) Show the valid address ranges defined for the device highlighted

F5 (Select Device) Select the device next to the cursor.

F6 (Delete Device) Delete the device next to the cursor.

ESC (Escape) Return to the configuration command menu.

↑

↓

Return Key Accept the input value and move cursor to the next location on the

family name

port #

field causes the cursor to enter the device table

edit

from the command line will also

edit

command defaults to the last field you were

by the cursor.

Move up one line, scrolling if necessary.

Move down one line, scrolling if necessary.

same line.

and

device.tbl

device first

, that con-

If you press , a temporary window appears on the upper half of the screen

(as shown in Figure 2–4) that shows all the parameters of the current device.

Figure 2–4. Valid Address Ranges Window

Valid address ranges for 2732/TMS2732A

START SIZE TYPE Vcc Vpp Pdt CtrlReg FmlyCode BlkErase Pbits

00000h 1000h EPROM 5 21 10 ooh 40h NO O’s only

In order to edit these configuration parameters, press (this function key

changes from

called.) Use the editing protocol as described in Section 2.4 and the parameter

descriptions in Section 2.8 in order to customize these device parameters.

2-12

next window

to

edit ranges

when the show ranges window is

Operating in the Configuration Window

Page 47

Editing the Configuration Parameters and Device Table

Pressing causes this temporary window to disappear, and the previous

window is resumed.

Pressing

from the device table selects the device on the line where your

cursor is positioned. The device you have chosen is highlighted when selected.

Pressing

deletes the device on the line where your cursor is positioned.

If the deleted device is the current device, there is no current device type, and

you must select a new device from the device table.

2-13

Page 48

Loading the Device Table and Configuration Parameters From a File

2.10 Loading the Device Table and Configuration Parameters From a

File — the Load Command

When you select the L command, a submenu displays options for choosing a

file to load. The commands in this submenu are listed below; the letter that

invokes the command is printed in bold type.

Command Function

Device Table Load a device table file.

Configuration Load configuration parameters from a configuration/batch file.

Both load options prompt for only one parameter—the file to be loaded. If the

file specified does not exist, an error message is displayed as follows:

Can not open file: <file name> (hit any key)

Press any key to erase the error message and return to the prompt to enter

the correct file name.

If a file that is not a valid device table is specified, the following error message

is displayed:

Invalid/Wrong device table file: <file name> (hit any key)

Press any key to erase the error message and return to the configuration command menu.

Loading the Device Table

Select this option to load the current device table from a file that you

specify . The device table window is updated as the current device table is

reloaded.

Load the Configuration Parameters

This option loads the configuration parameters, listed below, from the

specified configuration file.

Communication port

Current device

Device table

If the device table file is specified, it will be loaded as the current device

table, and the device type specified in the configuration/batch file will be

searched for in the table.

2-14

Operating in the Configuration Window

Page 49

Selecting a Current Device/Saving the Configuration Parameters and Device Table to a File

2.11 Selecting a Current Device — the Choose Device Command

The

choose device

command moves the cursor directly to the device table.

Use the cursor control keys to move the cursor to the device you will be programming and press

ing

returns you to the configuration command line.

to select it. The selected device is highlighted. Press-

A device must be specified before the software allows you to enter the display

window.

2.12 Saving Configuration Parameters and the Device Table to a File — the

Save Command

The

save

command allows you to save the current configuration parameters

or device table to a specific file. The initial prompt after this command executes

gives you the following two choices; the letter used to invoke the command is

printed in bold type.

Command Function

Device Table Save the current device table in a file.

Configuration Save the current configuration in a Configuration/Batch file

Both save options prompt for only one parameter—the filename to save the

data into. The file you specify can be either an existing file or a new file. The

contents of an existing file are erased before the save takes place. The following paragraphs describe each option in detail.

Saving the Device Table

Use this option to save the current device table in a file that you specify.

The file can be loaded later through the

load device table

command or the

configuration/batch file. If the current device table is empty , no file will be

generated.

To prevent accidental overwriting of the default device table, the name

device.tbl

cannot be used for saving the current device table. If you wish to

update the default device table, save it under another name and then use

the DOS copy command to copy your new device table to

device.tbl.

Saving Configuration Parameters

Use this option to save the current configuration in a file that you specify .

The current configuration is the one defined in the load configuration section. If you have not selected a current device type, the following error

message is displayed:

No device is selected, can not build the file

Press any key to erase the error message and return to the configuration

command menu.

2-15

Page 50

Showing the Display Window/Ending Your Current Session and Returning to DOS

2.13 Showing the Display Window — the Display Command

When you choose the

to see if a current device type has been selected. If you have selected a current

device type, the programmer sets up the configuration and briefly displays the

following message before returning to the top level command.

Set programmer configuration.....

If you have

is displayed: