Page 1

TMS320x2833x, 2823x Enhanced Pulse Width

Modulator (ePWM) Module

Reference Guide

Literature Number: SPRUG04A

October 2008–Revised July 2009

Page 2

2

SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, TexasInstruments Incorporated

Page 3

Preface ....................................................................................................................................... 8

1 Introduction ...................................................................................................................... 11

1.1 Submodule Overview .................................................................................................. 11

1.2 Register Mapping ...................................................................................................... 15

2 ePWM Submodules ............................................................................................................ 17

2.1 Overview ................................................................................................................ 17

2.2 Time-Base (TB) Submodule .......................................................................................... 20

2.3 Counter-Compare (CC) Submodule ................................................................................. 31

2.4 Action-Qualifier (AQ) Submodule .................................................................................... 37

2.5 Dead-Band Generator (DB) Submodule ............................................................................ 51

2.6 PWM-Chopper (PC) Submodule ..................................................................................... 55

2.7 Trip-Zone (TZ) Submodule ........................................................................................... 59

2.8 Event-Trigger (ET) Submodule ....................................................................................... 63

3 Applications to Power Topologies ....................................................................................... 68

3.1 Overview of Multiple Modules ........................................................................................ 68

3.2 Key Configuration Capabilities ....................................................................................... 68

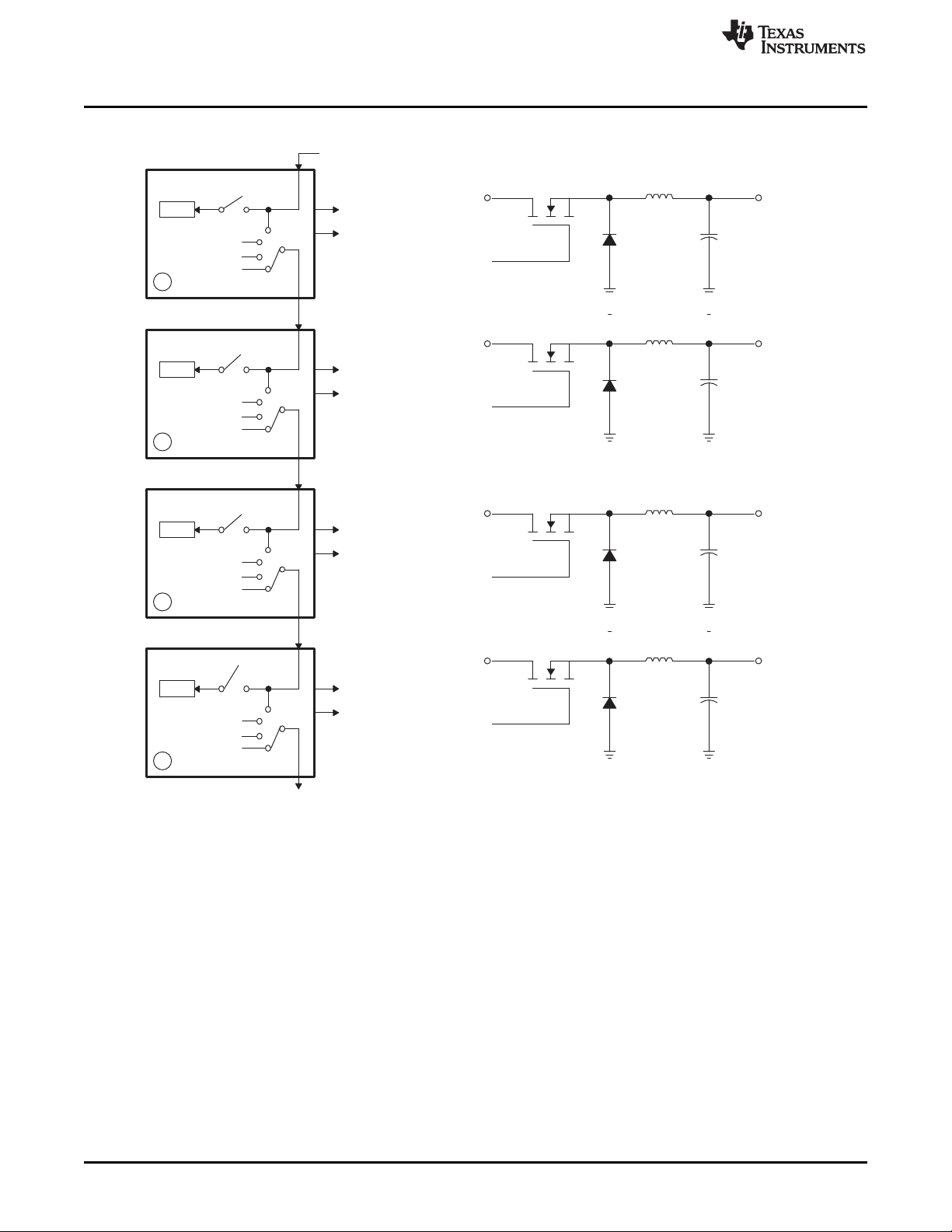

3.3 Controlling Multiple Buck Converters With Independent Frequencies .......................................... 69

3.4 Controlling Multiple Buck Converters With Same Frequencies .................................................. 73

3.5 Controlling Multiple Half H-Bridge (HHB) Converters ............................................................. 76

3.6 Controlling Dual 3-Phase Inverters for Motors (ACI and PMSM) ................................................ 78

3.7 Practical Applications Using Phase Control Between PWM Modules .......................................... 82

3.8 Controlling a 3-Phase Interleaved DC/DC Converter ............................................................. 83

3.9 Controlling Zero Voltage Switched Full Bridge (ZVSFB) Converter ............................................. 87

4 Registers .......................................................................................................................... 90

4.1 Time-Base Submodule Registers .................................................................................... 90

4.2 Counter-Compare Submodule Registers ........................................................................... 94

4.3 Action-Qualifier Submodule Registers .............................................................................. 97

4.4 Dead-Band Submodule Registers .................................................................................. 101

4.5 PWM-Chopper Submodule Control Register ..................................................................... 103

4.6 Trip-Zone Submodule Control and Status Registers ............................................................ 105

4.7 Event-Trigger Submodule Registers ............................................................................... 108

4.8 Proper Interrupt Initialization Procedure ........................................................................... 113

Appendix A Revision History ..................................................................................................... 114

SPRUG04A–October 2008–Revised July 2009 Table of Contents

Submit Documentation Feedback

© 2008–2009, TexasInstruments Incorporated

3

Page 4

www.ti.com

List of Figures

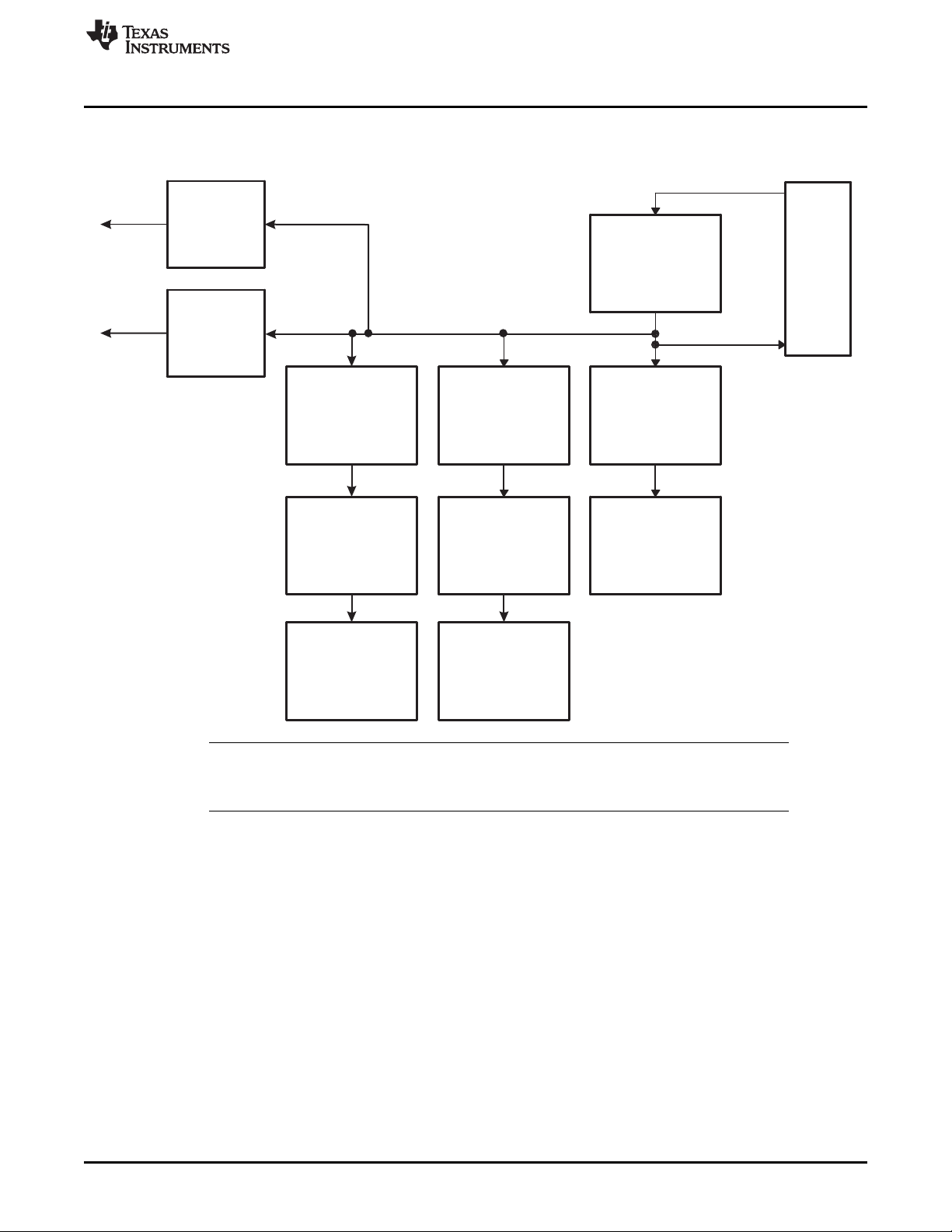

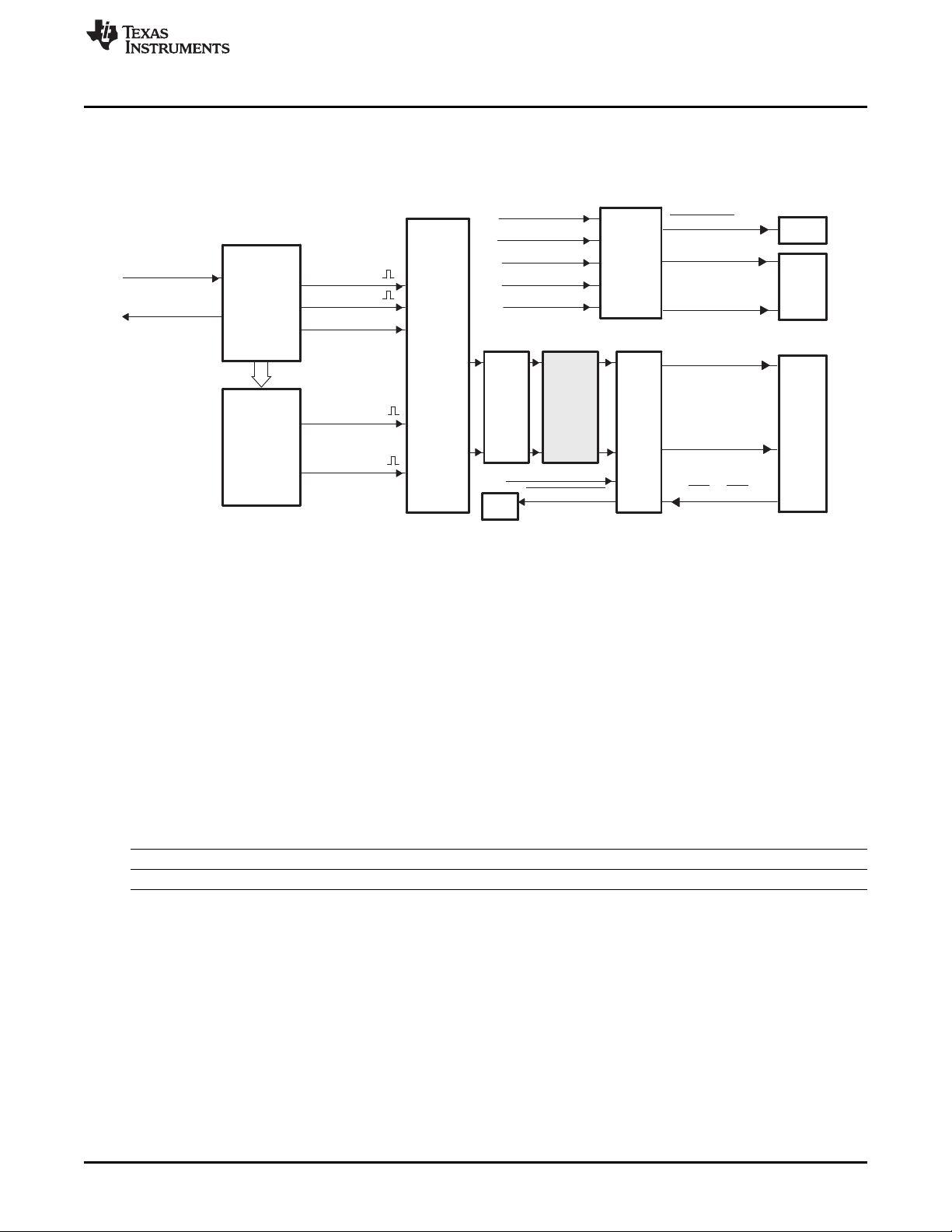

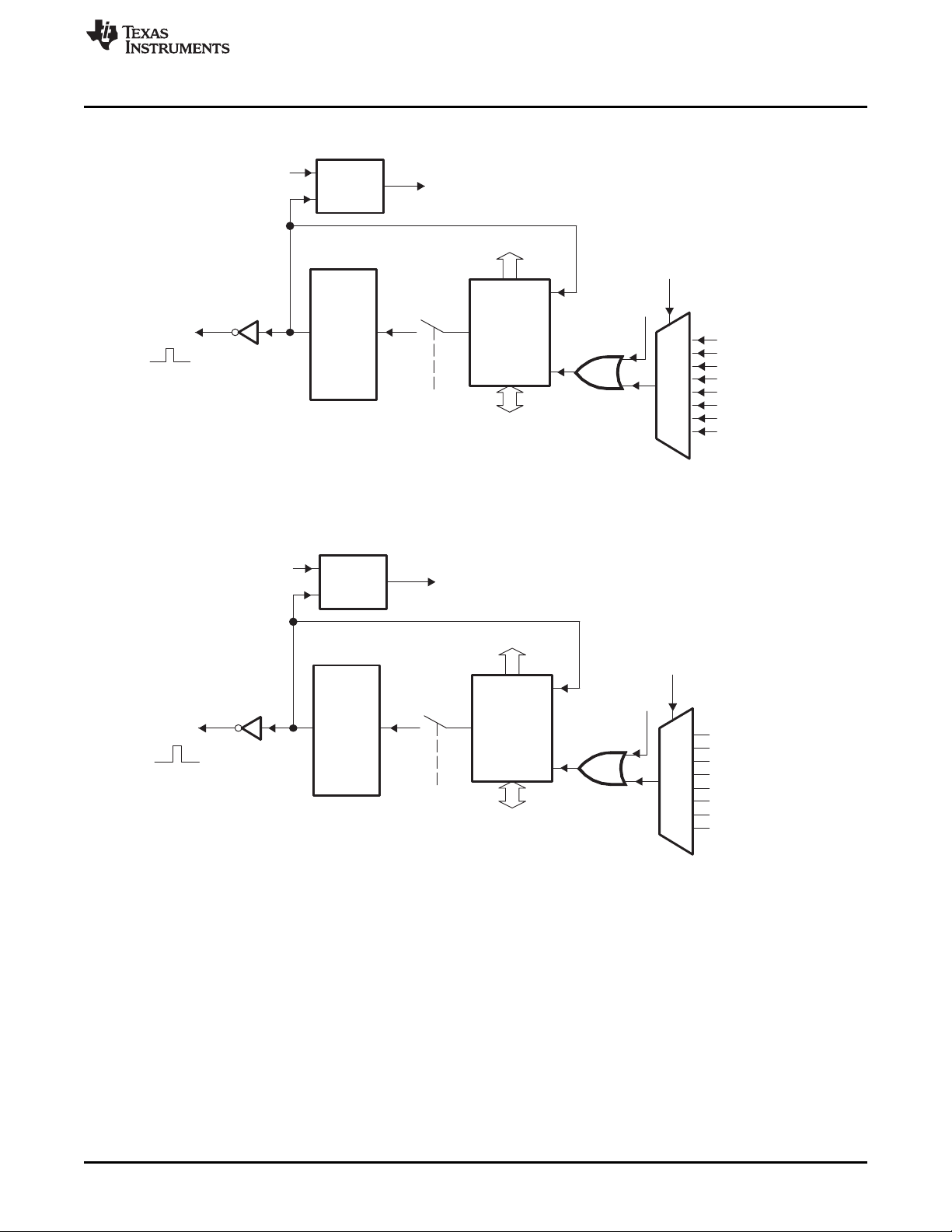

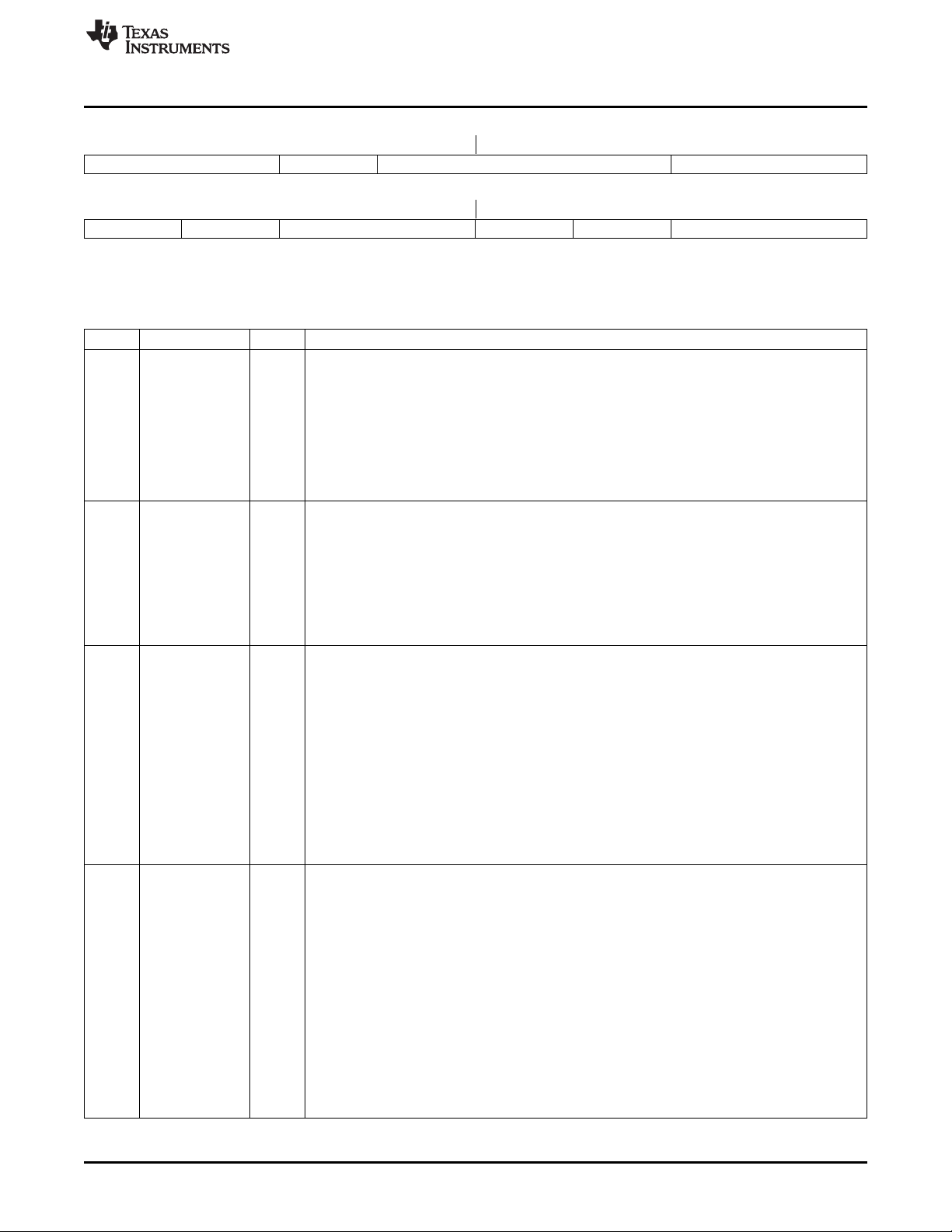

1 Multiple ePWM Modules.................................................................................................. 13

2 Submodules and Signal Connections for an ePWM Module ........................................................ 14

3 ePWM Submodules and Critical Internal Signal Interconnects...................................................... 15

4 Time-Base Submodule Block Diagram ................................................................................. 20

5 Time-Base Submodule Signals and Registers ........................................................................ 21

6 Time-Base Frequency and Period ...................................................................................... 23

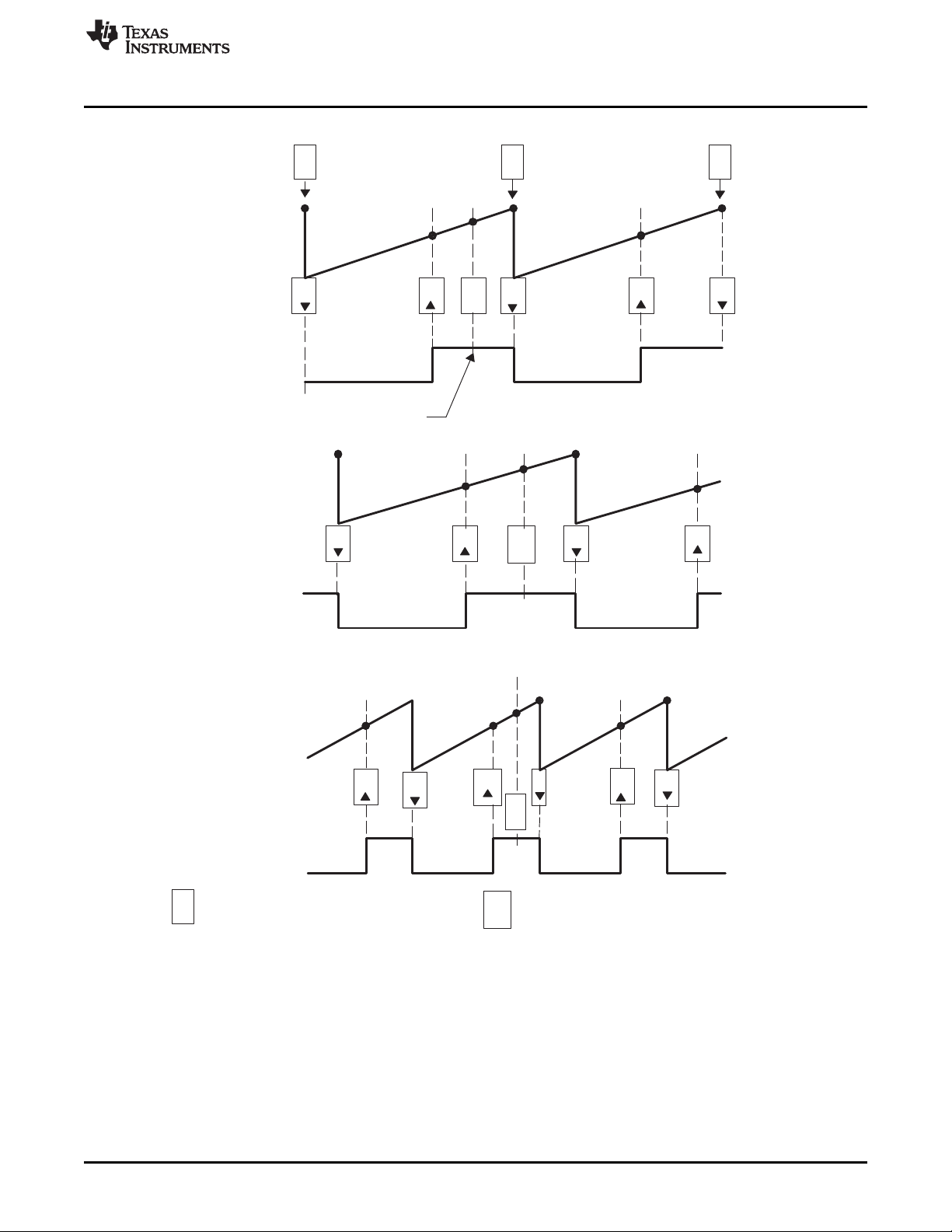

7 Time-Base Counter Synchronization Scheme 1 ...................................................................... 25

8 Time-Base Counter Synchronization Scheme 2 ...................................................................... 26

9 Time-Base Counter Synchronization Scheme 3 ...................................................................... 27

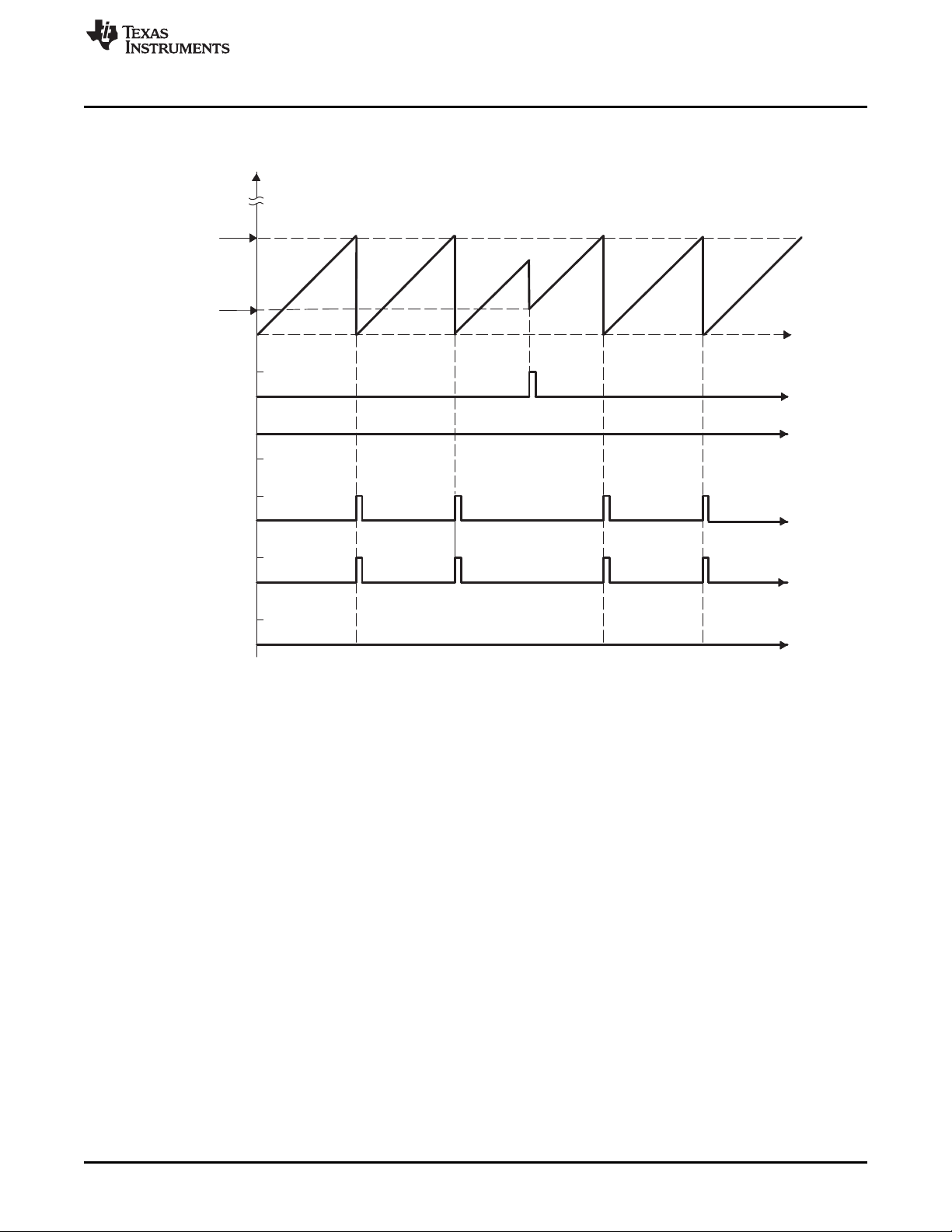

10 Time-Base Up-Count Mode Waveforms................................................................................ 29

11 Time-Base Down-Count Mode Waveforms............................................................................ 30

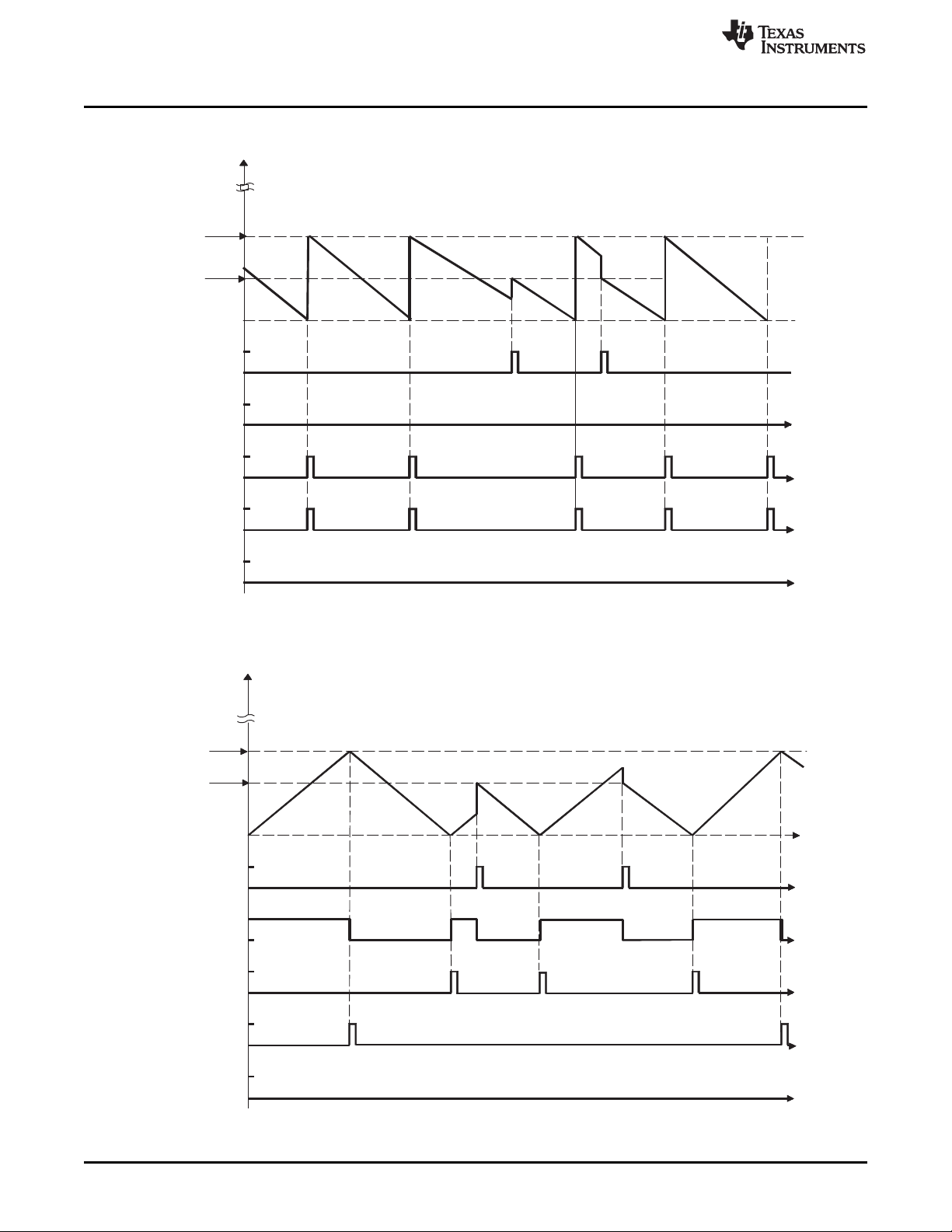

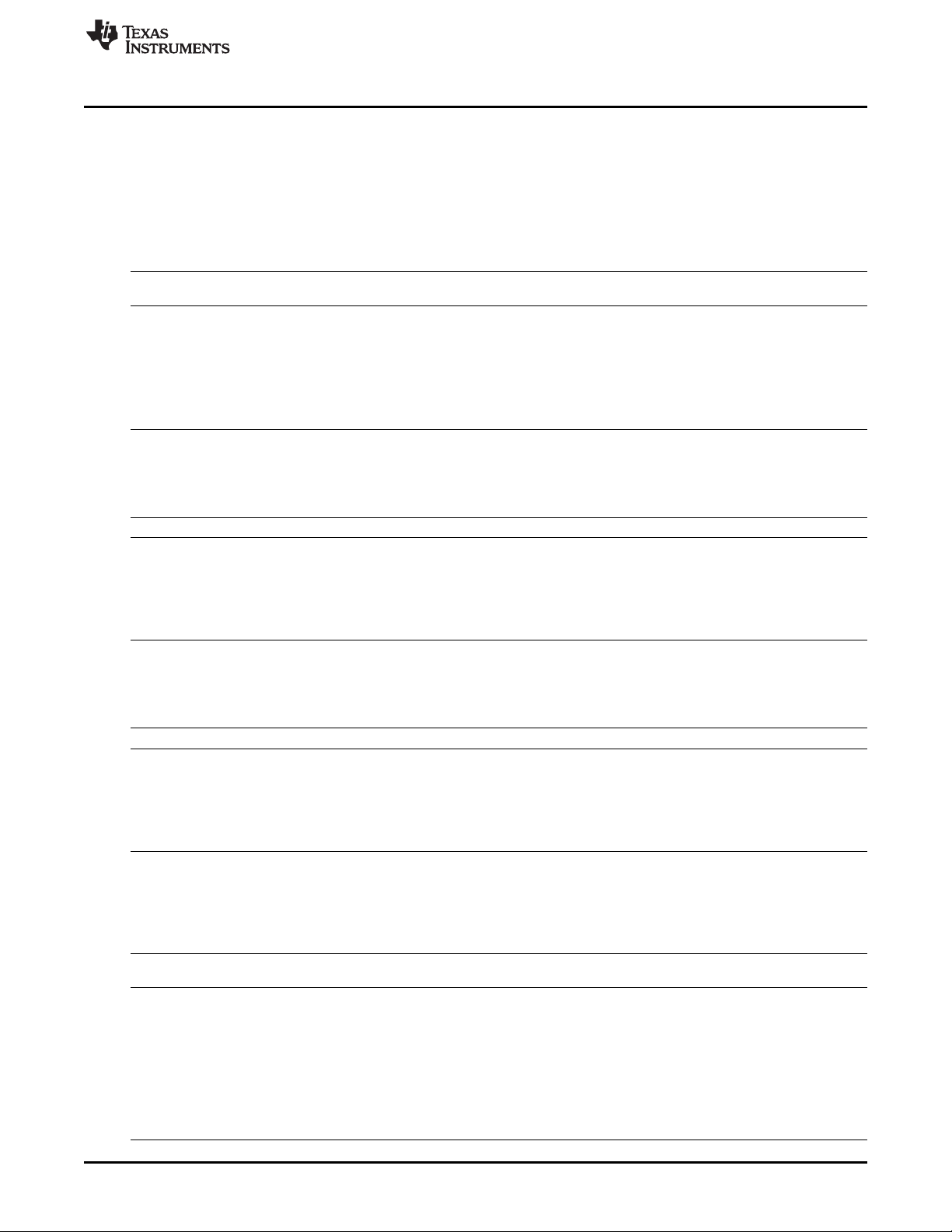

12 Time-Base Up-Down-Count Waveforms, TBCTL[PHSDIR = 0] Count Down On Synchronization Event..... 30

13 Time-Base Up-Down Count Waveforms, TBCTL[PHSDIR = 1] Count Up On Synchronization Event......... 31

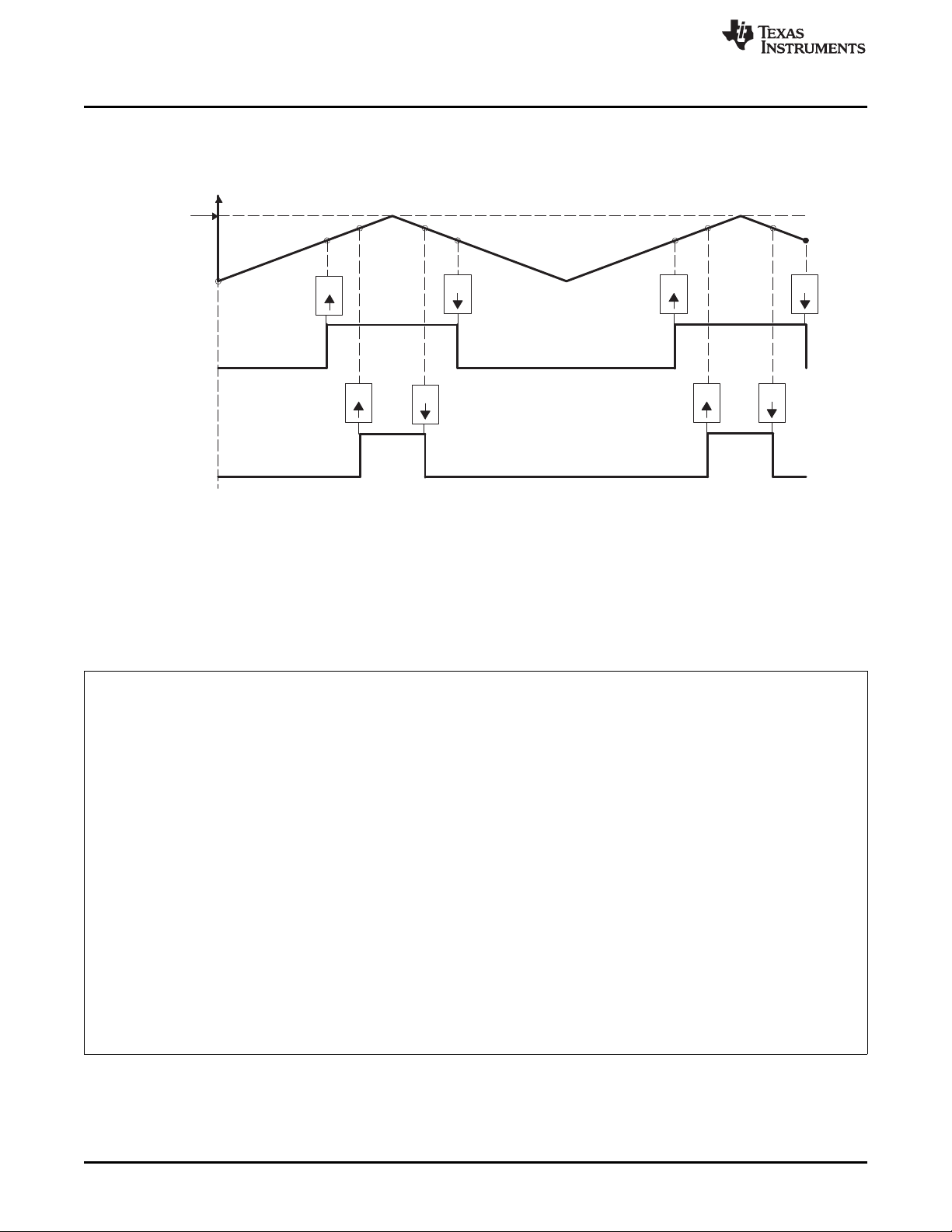

14 Counter-Compare Submodule........................................................................................... 31

15 Detailed View of the Counter-Compare Submodule.................................................................. 32

16 Counter-Compare Event Waveforms in Up-Count Mode ............................................................ 35

17 Counter-Compare Events in Down-Count Mode ...................................................................... 36

18 Counter-Compare Events In Up-Down-Count Mode, TBCTL[PHSDIR = 0] Count Down On

Synchronization Event ................................................................................................... 37

19 Counter-Compare Events In Up-Down-Count Mode, TBCTL[PHSDIR = 1] Count Up On Synchronization

Event ....................................................................................................................... 37

20 Action-Qualifier Submodule .............................................................................................. 38

21 Action-Qualifier Submodule Inputs and Outputs ...................................................................... 39

22 Possible Action-Qualifier Actions for EPWMxA and EPWMxB Outputs............................................ 40

23 Up-Down-Count Mode Symmetrical Waveform ....................................................................... 43

24 Up, Single Edge Asymmetric Waveform, With Independent Modulation on EPWMxA and

EPWMxB—Active High ................................................................................................... 44

25 Up, Single Edge Asymmetric Waveform With Independent Modulation on EPWMxA and

EPWMxB—Active Low.................................................................................................... 45

26 Up-Count, Pulse Placement Asymmetric Waveform With Independent Modulation on EPWMxA ............. 46

27 Up-Down-Count, Dual Edge Symmetric Waveform, With Independent Modulation on EPWMxA and

EPWMxB — Active Low.................................................................................................. 48

28 Up-Down-Count, Dual Edge Symmetric Waveform, With Independent Modulation on EPWMxA and

EPWMxB — Complementary ............................................................................................ 49

29 Up-Down-Count, Dual Edge Asymmetric Waveform, With Independent Modulation on EPWMxA—Active

Low.......................................................................................................................... 50

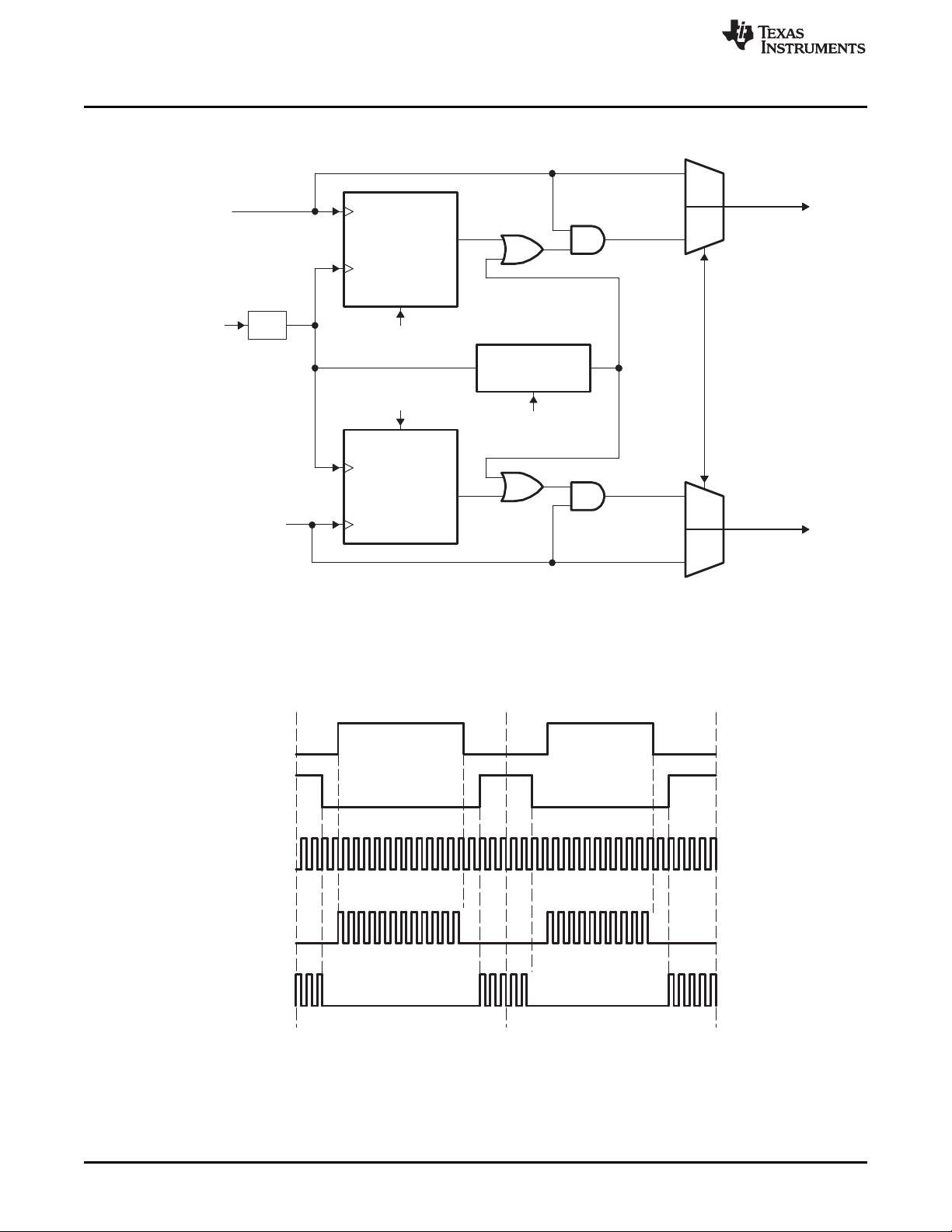

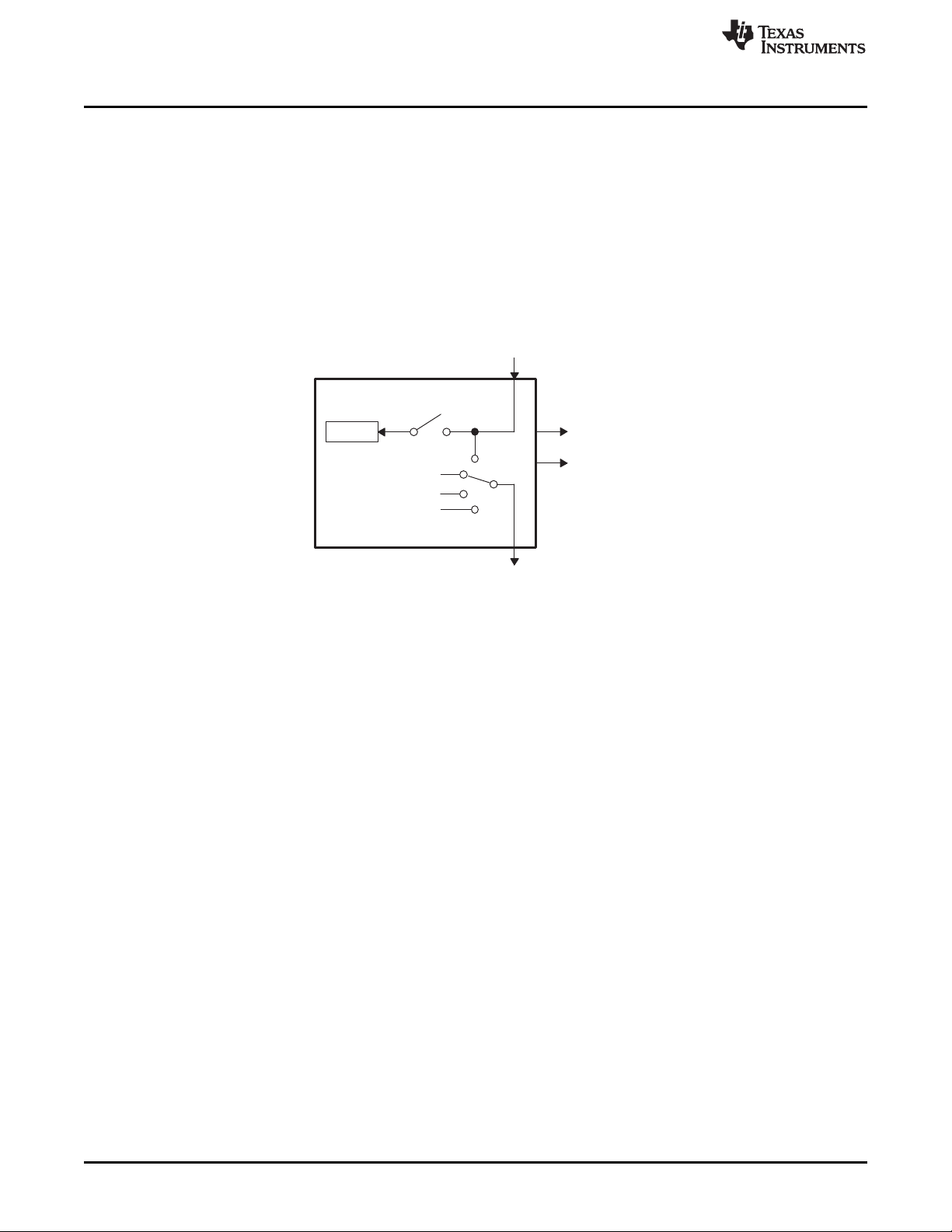

30 Dead_Band Submodule .................................................................................................. 51

31 Configuration Options for the Dead-Band Submodule ............................................................... 52

32 Dead-Band Waveforms for Typical Cases (0% < Duty < 100%).................................................... 53

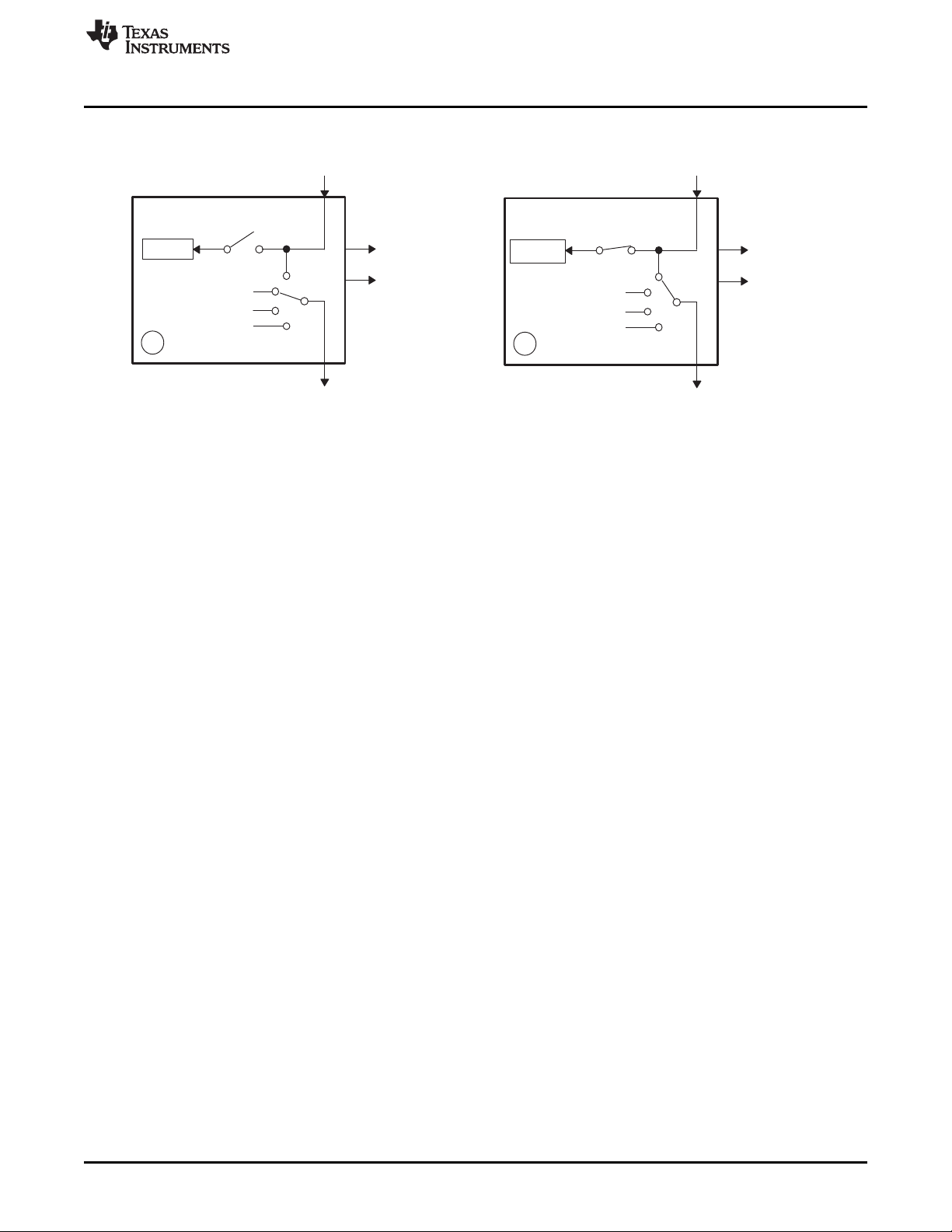

33 PWM-Chopper Submodule............................................................................................... 55

34 PWM-Chopper Submodule Operational Details....................................................................... 56

35 Simple PWM-Chopper Submodule Waveforms Showing Chopping Action Only................................. 56

36 PWM-Chopper Submodule Waveforms Showing the First Pulse and Subsequent Sustaining Pulses........ 57

37 PWM-Chopper Submodule Waveforms Showing the Pulse Width (Duty Cycle) Control of Sustaining

Pulses....................................................................................................................... 58

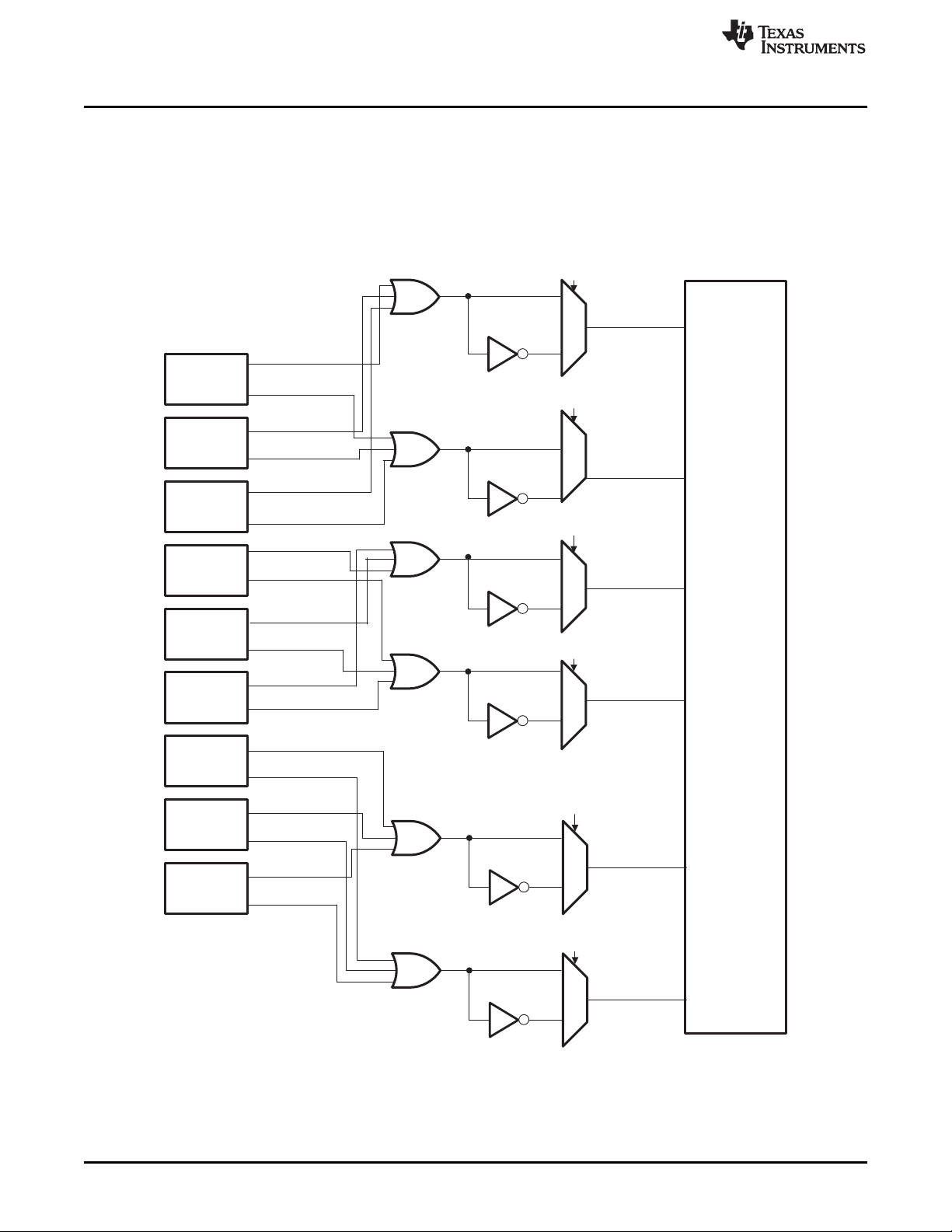

38 Trip-Zone Submodule..................................................................................................... 59

39 Trip-Zone Submodule Mode Control Logic ............................................................................ 62

40 Trip-Zone Submodule Interrupt Logic................................................................................... 63

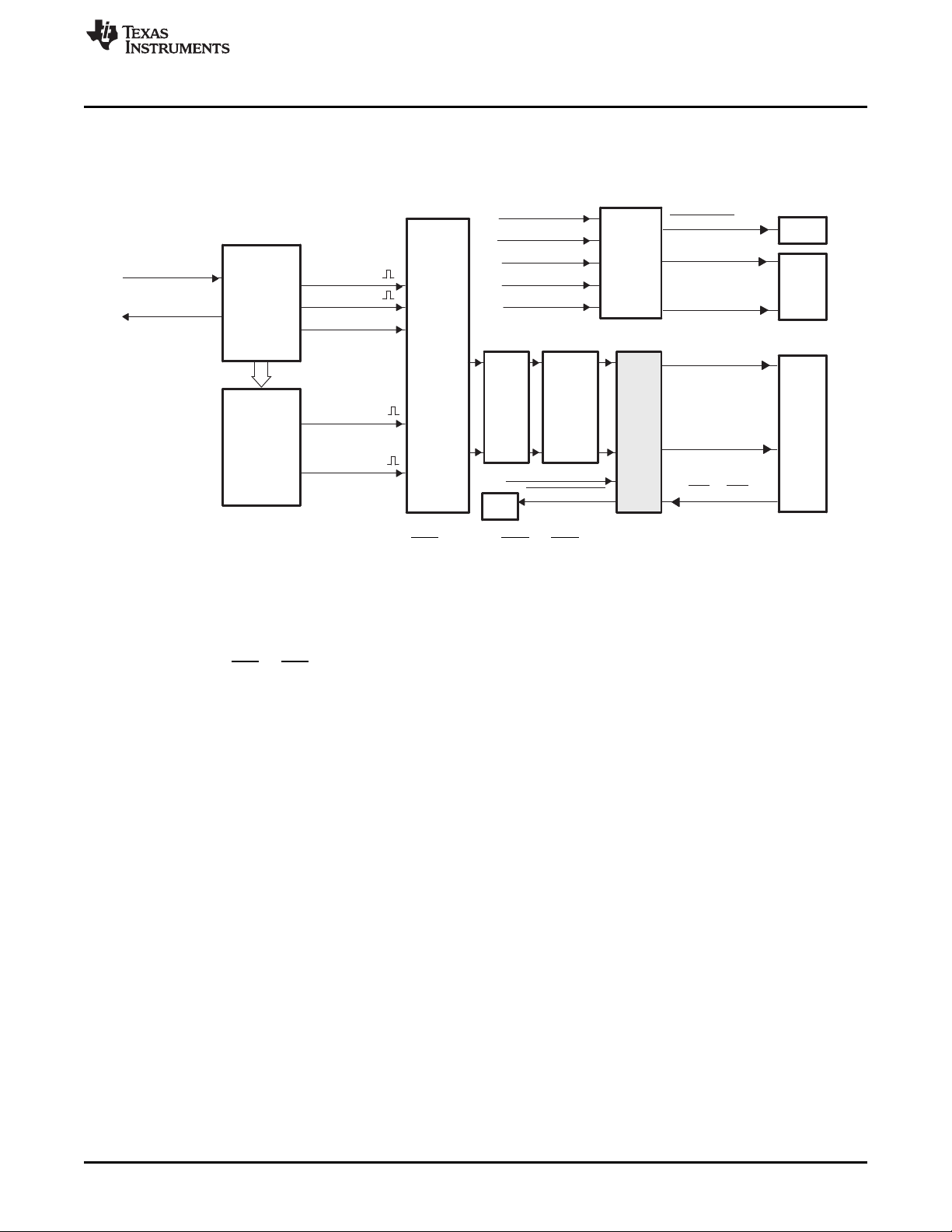

41 Event-Trigger Submodule ................................................................................................ 63

4

List of Figures SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

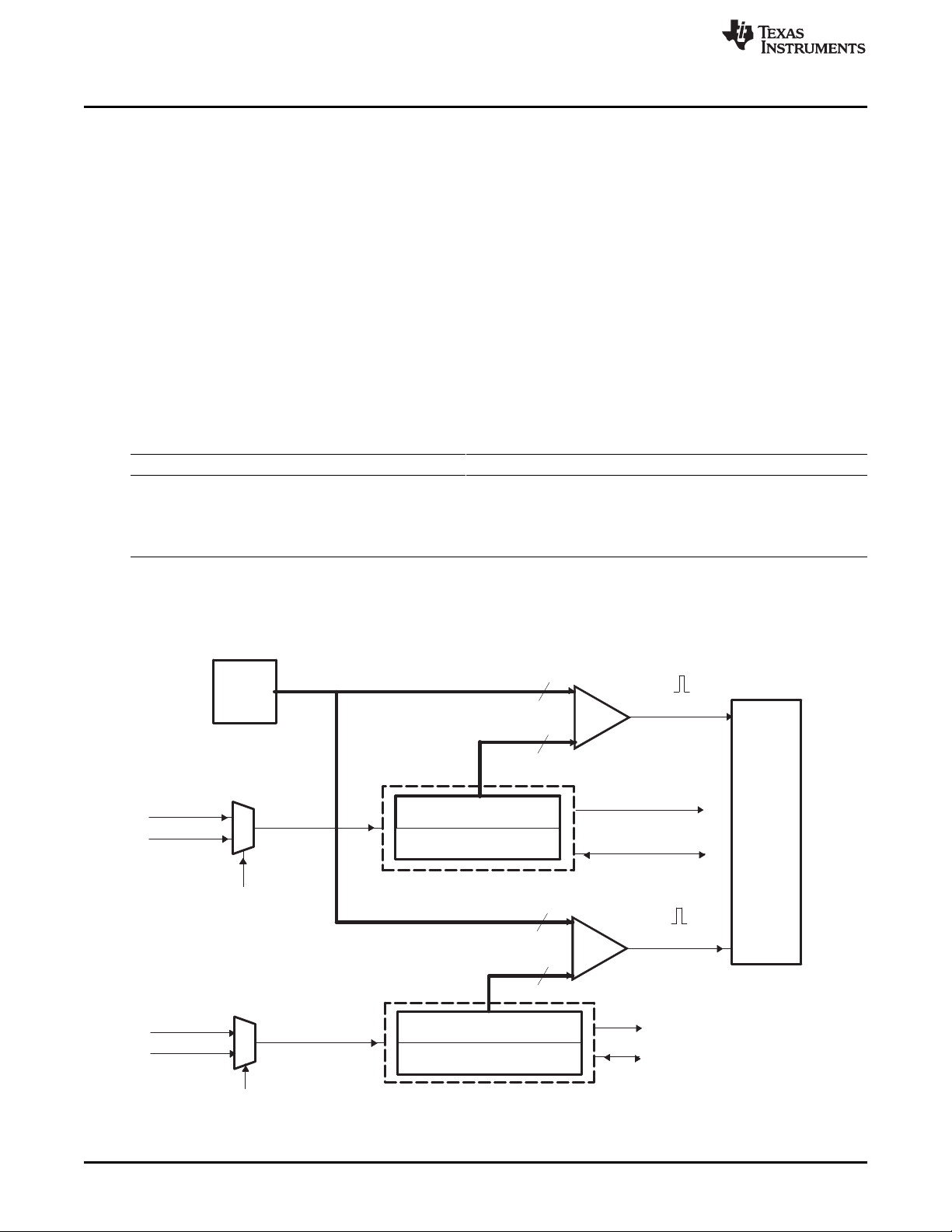

42 Event-Trigger Submodule Inter-Connectivity of ADC Start of Conversion......................................... 64

43 Event-Trigger Submodule Showing Event Inputs and Prescaled Outputs......................................... 65

44 Event-Trigger Interrupt Generator....................................................................................... 66

45 Event-Trigger SOCA Pulse Generator.................................................................................. 67

46 Event-Trigger SOCB Pulse Generator.................................................................................. 67

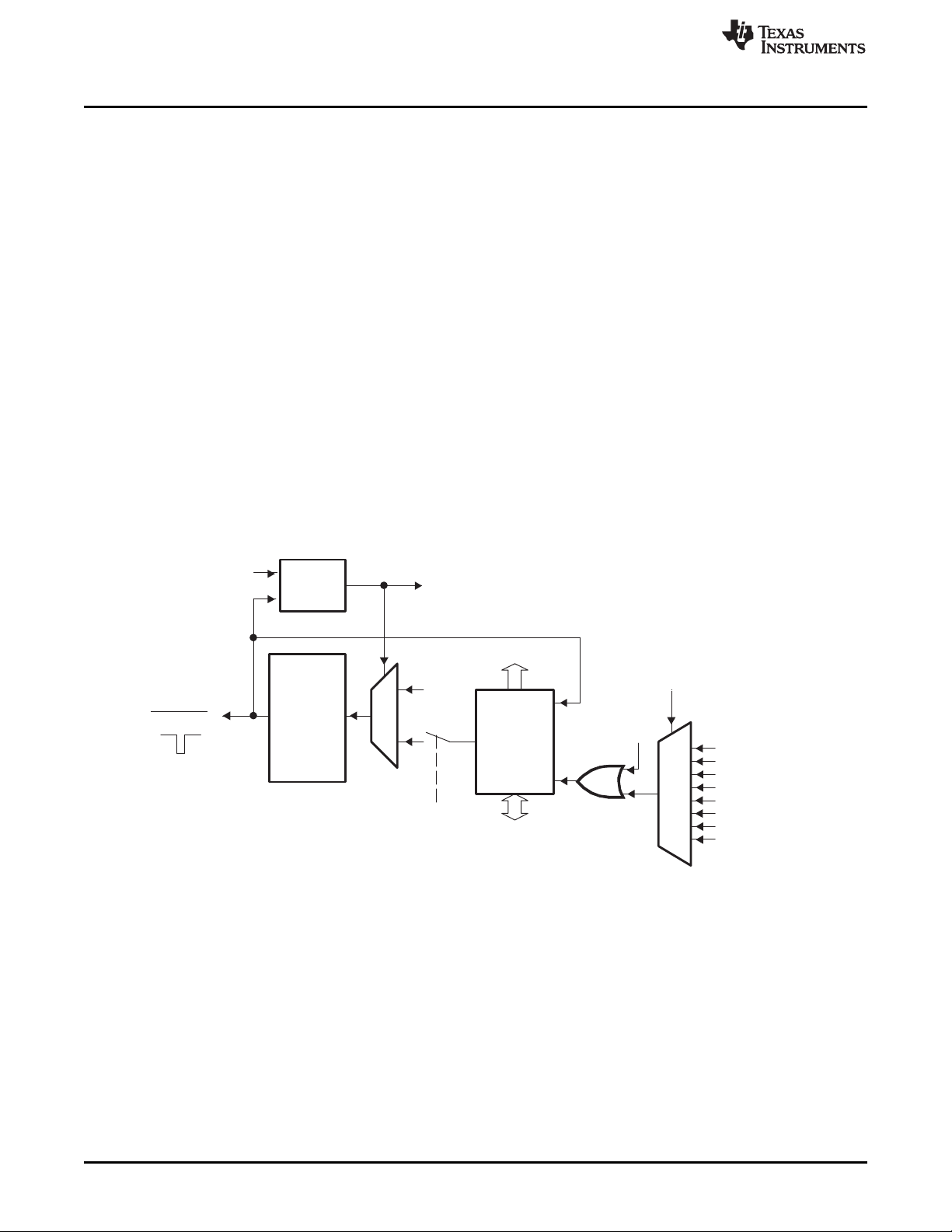

47 Simplified ePWM Module................................................................................................. 68

48 EPWM1 Configured as a Typical Master, EPWM2 Configured as a Slave ....................................... 69

49 Control of Four Buck Stages. Here F

50 Buck Waveforms for (Note: Only three bucks shown here).......................................................... 71

51 Control of Four Buck Stages. (Note: F

52 Buck Waveforms for (Note: F

53 Control of Two Half-H Bridge Stages (F

54 Half-H Bridge Waveforms for (Note: Here F

55 Control of Dual 3-Phase Inverter Stages as Is Commonly Used in Motor Control ............................... 79

56 3-Phase Inverter Waveforms for (Only One Inverter Shown) ....................................................... 80

57 Configuring Two PWM Modules for Phase Control................................................................... 82

58 Timing Waveforms Associated With Phase Control Between 2 Modules.......................................... 83

59 Control of a 3-Phase Interleaved DC/DC Converter.................................................................. 84

60 3-Phase Interleaved DC/DC Converter Waveforms for .............................................................. 85

61 Controlling a Full-H Bridge Stage (F

62 ZVS Full-H Bridge Waveforms........................................................................................... 88

63 Time-Base Period Register (TBPRD)................................................................................... 90

64 Time-Base Phase Register (TBPHS)................................................................................... 90

65 Time-Base Counter Register (TBCTR)................................................................................. 90

66 Time-Base Control Register (TBCTL) .................................................................................. 91

67 Time-Base Status Register (TBSTS) ................................................................................... 93

68 Counter-Compare A Register (CMPA) ................................................................................. 94

69 Counter-Compare B Register (CMPB).................................................................................. 94

70 Counter-Compare Control Register (CMPCTL) ....................................................................... 96

71 Compare A High Resolution Register (CMPAHR) ................................................................... 97

72 Action-Qualifier Output A Control Register (AQCTLA) ............................................................... 97

73 Action-Qualifier Output B Control Register (AQCTLB) ............................................................... 98

74 Action-Qualifier Software Force Register (AQSFRC)................................................................. 99

75 Action-Qualifier Continuous Software Force Register (AQCSFRC)............................................... 100

76 Dead-Band Generator Control Register (DBCTL) ................................................................... 101

77 Dead-Band Generator Rising Edge Delay Register (DBRED)..................................................... 103

78 Dead-Band Generator Falling Edge Delay Register (DBFED)..................................................... 103

79 PWM-Chopper Control Register (PCCTL)............................................................................ 103

80 Trip-Zone Select Register (TZSEL).................................................................................... 105

81 Trip-Zone Control Register (TZCTL) .................................................................................. 106

82 Trip-Zone Enable Interrupt Register (TZEINT)....................................................................... 106

83 Trip-Zone Flag Register (TZFLG)...................................................................................... 107

84 Trip-Zone Clear Register (TZCLR) .................................................................................... 107

85 Trip-Zone Force Register (TZFRC).................................................................................... 108

86 Event-Trigger Selection Register (ETSEL) ........................................................................... 108

87 Event-Trigger Prescale Register (ETPS) ............................................................................. 109

88 Event-Trigger Flag Register (ETFLG)................................................................................. 111

89 Event-Trigger Clear Register (ETCLR)................................................................................ 112

90 Event-Trigger Force Register (ETFRC)............................................................................... 112

PWM2

= F

≠ F

≠ F

PWM1

PWM2

= N x F

PWM2

)............................................................................. 74

PWM1)

= N x F

PWM2

PWM2

= F

PWM2

PWM1)

≠ F

PWM3

).............................................................. 73

PWM1

)............................................................ 76

PWM1

= F

)............................................................ 77

PWM1

..................................................................... 87

.................................................... 70

PWM4

SPRUG04A–October 2008–Revised July 2009 List of Figures

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

5

Page 6

www.ti.com

List of Tables

1 ePWM Module Control and Status Register Set Grouped by Submodule......................................... 16

2 Submodule Configuration Parameters.................................................................................. 17

3 Time-Base Submodule Registers ....................................................................................... 21

4 Key Time-Base Signals................................................................................................... 22

5 Counter-Compare Submodule Registers .............................................................................. 32

6 Counter-Compare Submodule Key Signals............................................................................ 33

7 Action-Qualifier Submodule Registers.................................................................................. 38

8 Action-Qualifier Submodule Possible Input Events ................................................................... 39

9 Action-Qualifier Event Priority for Up-Down-Count Mode............................................................ 41

10 Action-Qualifier Event Priority for Up-Count Mode.................................................................... 41

11 Action-Qualifier Event Priority for Down-Count Mode ................................................................ 41

12 Behavior if CMPA/CMPB is Greater than the Period................................................................. 41

13 Dead-Band Generator Submodule Registers.......................................................................... 51

14 Classical Dead-Band Operating Modes ............................................................................... 53

15 Dead-Band Delay Values in μS as a Function of DBFED and DBRED ........................................... 54

16 PWM-Chopper Submodule Registers .................................................................................. 55

17 Possible Pulse Width Values for SYSCLKOUT = 100 MHz ......................................................... 57

18 Trip-Zone Submodule Registers......................................................................................... 60

19 Possible Actions On a Trip Event ....................................................................................... 61

20 Event-Trigger Submodule Registers ................................................................................... 65

21 Time-Base Period Register (TBPRD) Field Descriptions ............................................................ 90

22 Time-Base Phase Register (TBPHS) Field Descriptions............................................................. 90

23 Time-Base Counter Register (TBCTR) Field Descriptions........................................................... 90

24 Time-Base Control Register (TBCTL) Field Descriptions ............................................................ 91

25 Time-Base Status Register (TBSTS) Field Descriptions ............................................................. 93

26 Counter-Compare A Register (CMPA) Field Descriptions ........................................................... 94

27 Counter-Compare B Register (CMPB) Field Descriptions ........................................................... 95

28 Counter-Compare Control Register (CMPCTL) Field Descriptions ................................................ 96

29 Compare A High Resolution Register (CMPAHR) Field Descriptions.............................................. 97

30 Action-Qualifier Output A Control Register (AQCTLA) Field Descriptions ........................................ 97

31 Action-Qualifier Output B Control Register (AQCTLB) Field Descriptions ........................................ 98

32 Action-Qualifier Software Force Register (AQSFRC) Field Descriptions .......................................... 99

33 Action-qualifier Continuous Software Force Register (AQCSFRC) Field Descriptions......................... 100

34 Dead-Band Generator Control Register (DBCTL) Field Descriptions............................................. 102

35 Dead-Band Generator Rising Edge Delay Register (DBRED) Field Descriptions............................... 103

36 Dead-Band Generator Falling Edge Delay Register (DBFED) Field Descriptions .............................. 103

37 PWM-Chopper Control Register (PCCTL) Bit Descriptions ....................................................... 104

38 Trip-Zone Submodule Select Register (TZSEL) Field Descriptions .............................................. 105

39 Trip-Zone Control Register (TZCTL) Field Descriptions ............................................................ 106

40 Trip-Zone Enable Interrupt Register (TZEINT) Field Descriptions ................................................ 106

41 Trip-Zone Flag Register (TZFLG) Field Descriptions ............................................................... 107

42 Trip-Zone Clear Register (TZCLR) Field Descriptions ............................................................. 108

43 Trip-Zone Force Register (TZFRC) Field Descriptions ............................................................. 108

44 Event-Trigger Selection Register (ETSEL) Field Descriptions .................................................... 109

45 Event-Trigger Prescale Register (ETPS) Field Descriptions ...................................................... 110

46 Event-Trigger Flag Register (ETFLG) Field Descriptions........................................................... 111

47 Event-Trigger Clear Register (ETCLR) Field Descriptions ......................................................... 112

6

List of Tables SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

48 Event-Trigger Force Register (ETFRC) Field Descriptions ........................................................ 112

49 Changes for this Revision............................................................................................... 114

SPRUG04A–October 2008–Revised July 2009 List of Tables

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

7

Page 8

The Enhanced Pulse Width Modulator (ePWM) module described in this reference guide is a Type 0

ePWM. See the TMS320x28xx, 28xxx DSP Peripheral Reference Guide (SPRU566) for a list of all

devices with a ePWM module of the same type, to determine the differences between the types, and for a

list of device-specific differences within a type. This reference guide includes an overview of the module

and information about each of its sub-modules:

• Time-Base Module

• Counter Compare Module

• Action Qualifier Module

• Dead-Band Generator Module

• PWM Chopper (PC) Module

• Trip Zone Module

• Event Trigger Module

Related Documentation From Texas Instruments

The following books describe the TMS320F2833x, 2823x module and related support tools that are

available on the TI website:

Data Manual and Errata—

SPRS439 — TMS320F28335, TMS320F28334, TMS320F28332, TMS320F28235, TMS320F28234,

TMS320F28232 Digital Signal Controllers (DSCs) Data Manual contains the pinout, signal

descriptions, as well as electrical and timing specifications for the F2833x/2823x devices.

Preface

SPRUG04A–October 2008–Revised July 2009

Read This First

SPRZ272 — TMS320F28335, TMS320F28334, TMS320F28332, TMS320F28235, TMS320F28234,

TMS320F28232 DSC Silicon Errata describes the advisories and usage notes for different

versions of silicon.

CPU User's Guides—

SPRU430 — TMS320C28x CPU and Instruction Set Reference Guide describes the central processing

unit (CPU) and the assembly language instructions of the TMS320C28x fixed-point digital signal

processors (DSPs). It also describes emulation features available on these DSPs.

SPRUEO2 — TMS320C28x Floating Point Unit and Instruction Set Reference Guide describes the

floating-point unit and includes the instructions for the FPU.

Peripheral Guides—

SPRU566 — TMS320x28xx, 28xxx DSP Peripheral Reference Guide describes the peripheral

reference guides of the 28x digital signal processors (DSPs).

SPRUFB0 — TMS320x2833x, 2823x System Control and Interrupts Reference Guide describes the

various interrupts and system control features of the 2833x and 2823x digital signal controllers

(DSCs).

SPRU812 — TMS320x2833x, 2823x Analog-to-Digital Converter (ADC) Reference Guide describes

how to configure and use the on-chip ADC module, which is a 12-bit pipelined ADC.

SPRU949 — TMS320x2833x, 2823x DSC External Interface (XINTF) Reference Guide describes the

XINTF, which is a nonmultiplexed asynchronous bus, as it is used on the 2833x and 2823x devices.

8

Preface SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

SPRU963 — TMS320x2833x, 2823x Boot ROM Reference Guide describes the purpose and features of

SPRUFB7 — TMS320x2833x, 2823x Multichannel Buffered Serial Port (McBSP) Reference Guide

SPRUFB8 — TMS320x2833x, 2823x Direct Memory Access (DMA) Module Reference Guide

SPRUG04 — TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module Reference

SPRUG02 — TMS320x2833x, 2823x High-Resolution Pulse Width Modulator (HRPWM) Reference

SPRUFG4 — TMS320x2833x, 2823x Enhanced Capture (eCAP) Module Reference Guide describes

SPRUG05 — TMS320x2833x, 2823x Enhanced Quadrature Encoder Pulse (eQEP) Module

Related Documentation From Texas Instruments

the bootloader (factory-programmed boot-loading software) and provides examples of code. It also

describes other contents of the device on-chip boot ROM and identifies where all of the information

is located within that memory.

describes the McBSP available on the 2833x and 2823x devices. The McBSPs allow direct

interface between a DSP and other devices in a system.

describes the DMA on the 2833x and 2823x devices.

Guide describes the main areas of the enhanced pulse width modulator that include digital motor

control, switch mode power supply control, UPS (uninterruptible power supplies), and other forms of

power conversion.

Guide describes the operation of the high-resolution extension to the pulse width modulator

(HRPWM).

the enhanced capture module. It includes the module description and registers.

Reference Guide describes the eQEP module, which is used for interfacing with a linear or rotary

incremental encoder to get position, direction, and speed information from a rotating machine in

high-performance motion and position control systems. It includes the module description and

registers.

SPRUEU1 — TMS320x2833x, 2823x Enhanced Controller Area Network (eCAN) Reference Guide

describes the eCAN that uses established protocol to communicate serially with other controllers in

electrically noisy environments.

SPRUFZ5 — TMS320x2833x, 2823x Serial Communications Interface (SCI) Reference Guide

describes the SCI, which is a two-wire asynchronous serial port, commonly known as a UART. The

SCI modules support digital communications between the CPU and other asynchronous peripherals

that use the standard non-return-to-zero (NRZ) format.

SPRUEU3 — TMS320x2833x, 2823x DSC Serial Peripheral Interface (SPI) Reference Guide

describes the SPI - a high-speed synchronous serial input/output (I/O) port - that allows a serial bit

stream of programmed length (one to sixteen bits) to be shifted into and out of the device at a

programmed bit-transfer rate.

SPRUG03 — TMS320x2833x, 2823x Inter-Integrated Circuit (I2C) Module Reference Guide describes

the features and operation of the inter-integrated circuit (I2C) module.

Tools Guides—

SPRU513 — TMS320C28x Assembly Language Tools v5.0.0 User's Guide describes the assembly

language tools (assembler and other tools used to develop assembly language code), assembler

directives, macros, common object file format, and symbolic debugging directives for the

TMS320C28x device.

SPRU514 — TMS320C28x Optimizing C/C++ Compiler v5.0.0 User's Guide describes the

TMS320C28x™ C/C++ compiler. This compiler accepts ANSI standard C/C++ source code and

produces TMS320 DSP assembly language source code for the TMS320C28x device.

SPRU608 — TMS320C28x Instruction Set Simulator Technical Overview describes the simulator,

available within the Code Composer Studio for TMS320C2000 IDE, that simulates the instruction

set of the C28x™ core.

SPRU625 — TMS320C28x DSP/BIOS 5.32 Application Programming Interface (API) Reference

Guide describes development using DSP/BIOS.

SPRUG04A–October 2008–Revised July 2009 Read This First

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

9

Page 10

Related Documentation From Texas Instruments

Application Reports—

SPRAAM0 — Getting Started With TMS320C28x Digital Signal Controllers is organized by

development flow and functional areas to make your design effort as seamless as possible. Tips on

getting started with C28x™ DSP software and hardware development are provided to aid in your

initial design and debug efforts. Each section includes pointers to valuable information including

technical documentation, software, and tools for use in each phase of design.

SPRAAD5 — Power Line Communication for Lighting Applications Using Binary Phase Shift

Keying (BPSK) with a Single DSP Controller presents a complete implementation of a power line

modem following CEA-709 protocol using a single DSP.

SPRAA85 — Programming TMS320x28xx and 28xxx Peripherals in C/C++ explores a hardware

abstraction layer implementation to make C/C++ coding easier on 28x DSPs. This method is

compared to traditional #define macros and topics of code efficiency and special case registers are

also addressed.

SPRA958 — Running an Application from Internal Flash Memory on the TMS320F28xxx DSP covers

the requirements needed to properly configure application software for execution from on-chip flash

memory. Requirements for both DSP/BIOS™ and non-DSP/BIOS projects are presented. Example

code projects are included.

SPRAA91 — TMS320F280x Digital Signal Controller USB Connectivity Using the TUSB3410

USB-to-UART Bridge Chip presents hardware connections as well as software preparation and

operation of the development system using a simple communication echo program.

www.ti.com

SPRAAD8 — TMS320x280x and TMS320F2801x ADC Calibration describes a method for improving

the absolute accuracy of the 12-bit ADC found on the TMS320x280x and TMS320F2801x devices.

Inherent gain and offset errors affect the absolute accuracy of the ADC. The methods described in

this report can improve the absolute accuracy of the ADC to levels better than 0.5%. This

application report has an option to download an example program that executes from RAM on the

F2808 EzDSP.

SPRAAI1 — Using the ePWM Module for 0% – 100% Duty Cycle Control provides a guide for the use

of the ePWM module to provide 0% to 100% duty cycle control and is applicable to the

TMS320x280x family of processors.

SPRAA88 — Using PWM Output as a Digital-to-Analog Converter on a TMS320F280x Digital Signal

Controller presents a method for utilizing the on-chip pulse width modulated (PWM) signal

generators on the TMS320F280x family of digital signal controllers as a digital-to-analog converter

(DAC).

SPRAAH1 — Using the Enhanced Quadrature Encoder Pulse (eQEP) Module in TMS320x280x,

28xxx as a Dedicated Capture provides a guide for the use of the eQEP module as a dedicated

capture unit and is applicable to the TMS320x280x, 28xxx family of processors.

SPRA820 — Online Stack Overflow Detection on the TMS320C28x DSP presents the methodology for

online stack overflow detection on the TMS320C28x DSP. C-source code is provided that contains

functions for implementing the overflow detection on both DSP/BIOS and non-DSP/BIOS

applications.

SPRA806 — An Easy Way of Creating a C-callable Assembly Function for the TMS320C28x DSP

provides instructions and suggestions to configure the C compiler to assist with C-callable

assembly routines.

TMS320C28x, C28x are trademarks of Texas Instruments.

10

Read This First SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

Reference Guide

SPRUG04A–October 2008–Revised July 2009

TMS320x2833x, 2823x Enhanced Pulse Width Modulator

(ePWM) Module

The enhanced pulse width modulator (ePWM) peripheral is a key element in controlling many of the power

electronic systems found in both commercial and industrial equipments. These systems include digital

motor control, switch mode power supply control, uninterruptible power supplies (UPS), and other forms of

power conversion. The ePWM peripheral performs a digital to analog (DAC) function, where the duty cycle

is equivalent to a DAC analog value; it is sometimes referred to as a Power DAC.

This reference guide is applicable for ePWM type 0 . See the TMS320x28xx, 28xxx DSP Peripheral

Reference Guide (SPRU566) for a list of all devices with an ePWM module of the same type, to determine

the differences between the types, and for a list of device-specific differences within a type.

1 Introduction

An effective PWM peripheral must be able to generate complex pulse width waveforms with minimal CPU

overhead or intervention. It needs to be highly programmable and very flexible while being easy to

understand and use. The ePWM unit described here addresses these requirements by allocating all

needed timing and control resources on a per PWM channel basis. Cross coupling or sharing of resources

has been avoided; instead, the ePWM is built up from smaller single channel modules with separate

resources that can operate together as required to form a system. This modular approach results in an

orthogonal architecture and provides a more transparent view of the peripheral structure, helping users to

understand its operation quickly.

In this document the letter x within a signal or module name is used to indicate a generic ePWM instance

on a device. For example output signals EPWMxA and EPWMxB refer to the output signals from the

ePWMx instance. Thus, EPWM1A and EPWM1B belong to ePWM1 and likewise EPWM4A and EPWM4B

belong to ePWM4.

1.1 Submodule Overview

The ePWM module represents one complete PWM channel composed of two PWM outputs: EPWMxA

and EPWMxB. Multiple ePWM modules are instanced within a device as shown in Figure 1. Each ePWM

instance is identical with one exception. Some instances include a hardware extension that allows more

precise control of the PWM outputs. This extension is the high-resolution pulse width modulator (HRPWM)

and is described in the TMS320x2833x, 2823x High-Resolution Pulse Width Modulator (HRPWM)

Reference Guide (SPRUG02) . See the device-specific data manual to determine which ePWM instances

include this feature. Each ePWM module is indicated by a numerical value starting with 1. For example

ePWM1 is the first instance and ePWM3 is the 3rd instance in the system and ePWMx indicates any

instance.

The ePWM modules are chained together via a clock synchronization scheme that allows them to operate

as a single system when required. Additionally, this synchronization scheme can be extended to the

capture peripheral modules (eCAP). The number of modules is device-dependent and based on target

application needs. Modules can also operate stand-alone.

Each ePWM module supports the following features:

• Dedicated 16-bit time-base counter with period and frequency control

• Two PWM outputs (EPWMxA and EPWMxB) that can be used in the following configurations:

– Two independent PWM outputs with single-edge operation

– Two independent PWM outputs with dual-edge symmetric operation

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

11

Page 12

Introduction

• Asynchronous override control of PWM signals through software.

• Programmable phase-control support for lag or lead operation relative to other ePWM modules.

• Hardware-locked (synchronized) phase relationship on a cycle-by-cycle basis.

• Dead-band generation with independent rising and falling edge delay control.

• Programmable trip zone allocation of both cycle-by-cycle trip and one-shot trip on fault conditions.

• A trip condition can force either high, low, or high-impedance state logic levels at PWM outputs.

• All events can trigger both CPU interrupts and ADC start of conversion (SOC)

• Programmable event prescaling minimizes CPU overhead on interrupts.

• PWM chopping by high-frequency carrier signal, useful for pulse transformer gate drives.

Each ePWM module is connected to the input/output signals shown in Figure 1. The signals are described

in detail in subsequent sections.

www.ti.com

– One independent PWM output with dual-edge asymmetric operation

12

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 13

PIE

TZ1

toTZ6

Peripheral

Frame1

ePWM1module

ePWM2module

ePWMxmodule

SYNCO

SYNCI

SYNCI

SYNCO

SYNCI

SYNCO

ADC

GPIO

MUX

xSYNCI

xSYNCO

xSOC

EPWMxA

EPWMxB

EPWM2A

EPWM2B

EPWM1A

EPWM1B

EPWM1INT

EPWM1SOC

EPWM2INT

EPWM2SOC

EPWMxINT

EPWMxSOC

ToeCAP1

www.ti.com

Introduction

Figure 1. Multiple ePWM Modules

The order in which the ePWM modules are connected may differ from what is shown in Figure 1. See

Section 2.2.3.3 for the synchronization scheme for a particular device. Each ePWM module consists of

seven submodules and is connected within a system via the signals shown in Figure 2.

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

13

Page 14

EPWMxINT

EPWMxTZINT

EPWMxSOCA

EPWMxSOCB

EPWMxSYNCI

EPWMxSYNCO

Time-base (TB) module

Counter-compare (CC) module

Action-qualifier (AQ) module

Dead-band (DB) module

PWM-chopper (PC) module

Event-trigger (ET) module

Trip-zone (TZ) module

Peripheral bus

ePWM module

TZ1

to TZ6

EPWMxA

EPWMxB

PIE

ADC

GPIO

MUX

Introduction

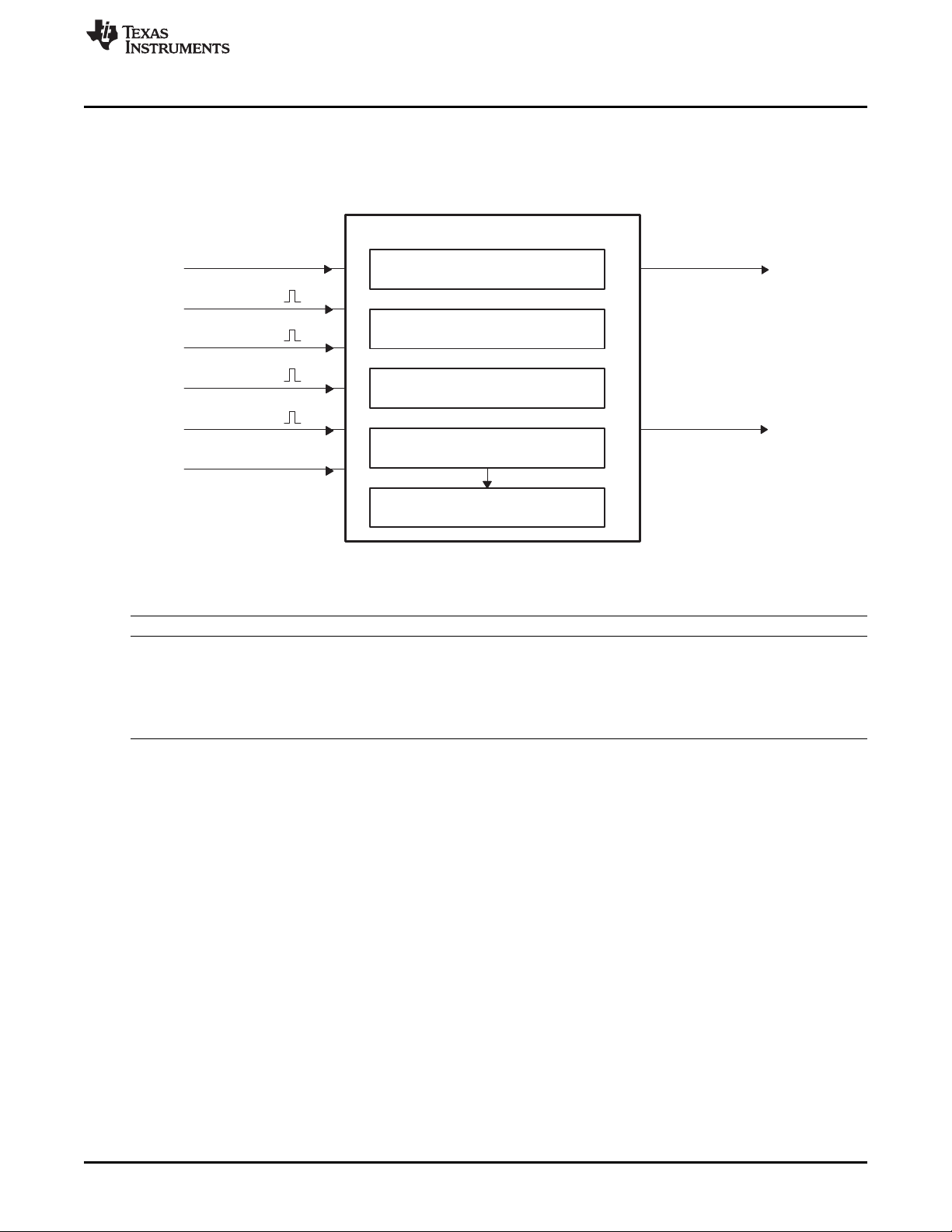

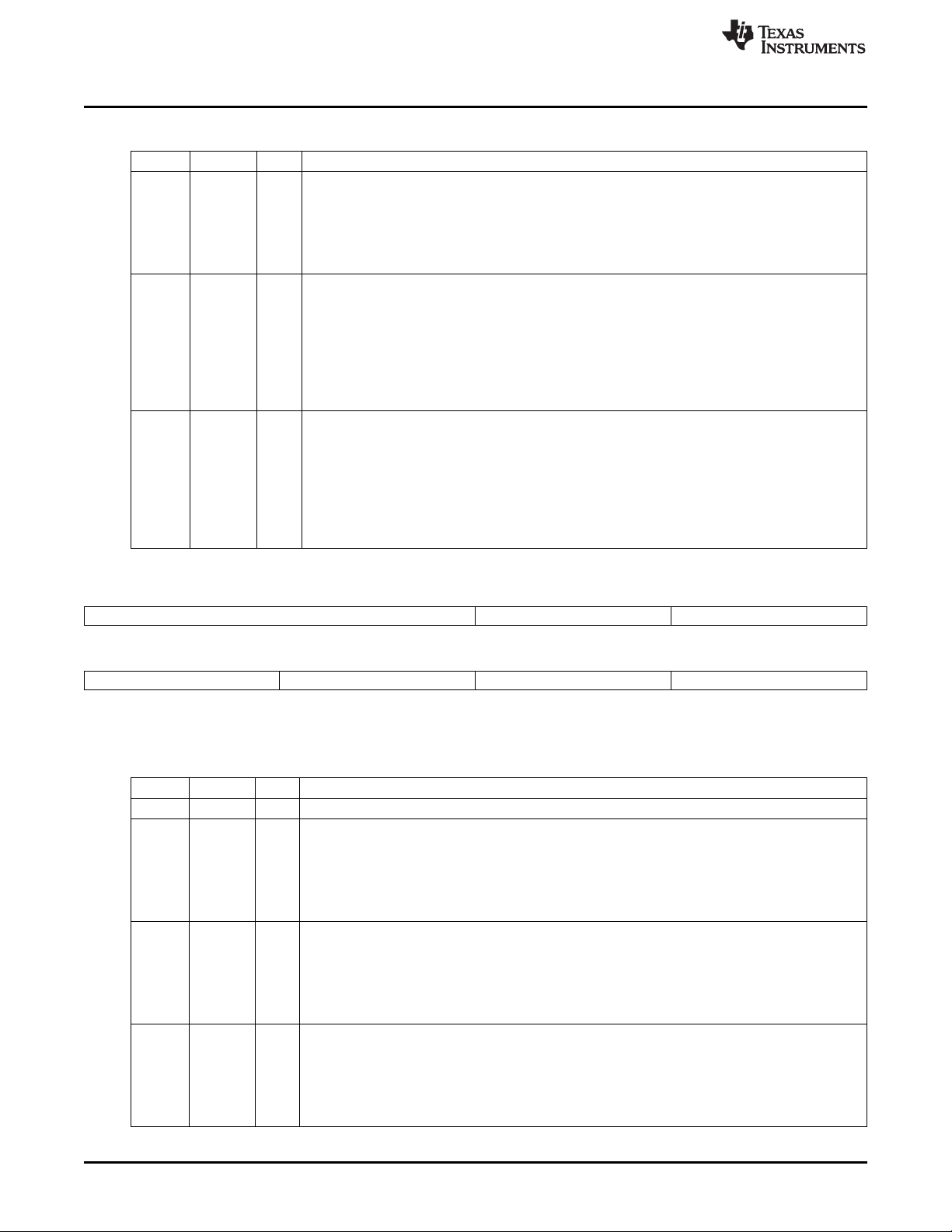

Figure 3 shows more internal details of a single ePWM module. The main signals used by the ePWM

module are:

• PWM output signals (EPWMxA and EPWMxB).

• Trip-zone signals (TZ1 to TZ6).

• Time-base synchronization input (EPWMxSYNCI) and output (EPWMxSYNCO) signals.

• ADC start-of-conversion signals (EPWMxSOCA and EPWMxSOCB).

• Peripheral Bus

www.ti.com

Figure 2. Submodules and Signal Connections for an ePWM Module

The PWM output signals are made available external to the device through the GPIO peripheral

described in the system control and interrupts guide for your device.

These input signals alert the ePWM module of fault conditions external to the ePWM module. Each

module on a device can be configured to either use or ignore any of the trip-zone signals. The TZ1 to

TZ6 trip-zone signals can be configured as asynchronous inputs through the GPIO peripheral.

The synchronization signals daisy chain the ePWM modules together. Each module can be configured

to either use or ignore its synchronization input. The clock synchronization input and output signal are

brought out to pins only for ePWM1 (ePWM module #1). The synchronization output for ePWM1

(EPWM1SYNCO) is also connected to the SYNCI of the first enhanced capture module (eCAP1).

Each ePWM module has two ADC start of conversion signals (one for each sequencer). Any ePWM

module can trigger a start of conversion for either sequencer. Which event triggers the start of

conversion is configured in the Event-Trigger submodule of the ePWM.

The peripheral bus is 32-bits wide and allows both 16-bit and 32-bit writes to the ePWM register file.

14

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

Action

qualifier

(AQ)

Time-base (TB)

Dead

band

(DB)

Counter compare (CC)

Trip

zone

(TZ)

Event

trigger and

interrupt

(ET)

PWM

chopper

(PC)

TZ1 to TZ6

TBPRD shadow (16)

TBPRD active (16)

CTR = PRD

CTR = ZERO

CTR = CMPA

CTR = CMPB

CTR_Dir

TBCTL[SWFSYNC] (software

forced sync)

TBPHS active (16)

Counter

UP/DWN

(16 bit)

TBCTR

active

(16)

Sync

in/out

select

MUX

S0

S1

CMPA active (16)

CMPA shadow (16)

CMPB active (16)

CMPB shadow (16)

EPWMxA

EPWMxB

EPWMxSOCB

EPWMxSOCA

EPWMxINT

EPWMxSYNCI

EPWMxSYNCO

TBCTL[SWFSYNC]

CTR_PRD

TBCTL[PHSEN]

CTR_Dir

CTR = ZERO

CTR = CMPA

CTR = CMPB

16

16

16

16

16

16

Phase

control

EPWMxTZINT

CTR=ZERO

www.ti.com

Introduction

Figure 3. ePWM Submodules and Critical Internal Signal Interconnects

1.2 Register Mapping

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

Figure 3 also shows the key internal submodule interconnect signals. Each submodule is described in

detail in its respective section.

The complete ePWM module control and status register set is grouped by submodule as shown in

Table 1. Each register set is duplicated for each instance of the ePWM module. The start address for each

ePWM register file instance on a device is specified in the appropriate data manual.

© 2008–2009, Texas Instruments Incorporated

15

Page 16

Introduction

TBCTL 0x0000 1 No Time-Base Control Register

TBSTS 0x0001 1 No Time-Base Status Register

TBPHSHR 0x0002 1 No Extension for HRPWM Phase Register

TBPHS 0x0003 1 No Time-Base Phase Register

TBCTR 0x0004 1 No Time-Base Counter Register

TBPRD 0x0005 1 Yes Time-Base Period Register

CMPCTL 0x0007 1 No Counter-Compare Control Register

CMPAHR 0x0008 1 Yes Extension for HRPWM Counter-Compare A Register

CMPA 0x0009 1 Yes Counter-Compare A Register

CMPB 0x000A 1 Yes Counter-Compare B Register

AQCTLA 0x000B 1 No Action-Qualifier Control Register for Output A (EPWMxA)

AQCTLB 0x000C 1 No Action-Qualifier Control Register for Output B (EPWMxB)

AQSFRC 0x000D 1 No Action-Qualifier Software Force Register

AQCSFRC 0x000E 1 Yes Action-Qualifier Continuous S/W Force Register Set

DBCTL 0x000F 1 No Dead-Band Generator Control Register

DBRED 0x0010 1 No Dead-Band Generator Rising Edge Delay Count Register

DBFED 0x0011 1 No Dead-Band Generator Falling Edge Delay Count Register

TZSEL 0x0012 1 Yes Trip-Zone Select Register

TZCTL 0x0014 1 Yes Trip-Zone Control Register

TZEINT 0x0015 1 Yes Trip-Zone Enable Interrupt Register

TZFLG 0x0016 1 Trip-Zone Flag Register

TZCLR 0x0017 1 Yes Trip-Zone Clear Register

TZFRC 0x0018 1 Yes Trip-Zone Force Register

ETSEL 0x0019 1 Event-Trigger Selection Register

ETPS 0x001A 1 Event-Trigger Pre-Scale Register

ETFLG 0x001B 1 Event-Trigger Flag Register

ETCLR 0x001C 1 Event-Trigger Clear Register

ETFRC 0x001D 1 Event-Trigger Force Register

PCCTL 0x001E 1 PWM-Chopper Control Register

HRCNFG 0x0020 1 Yes HRPWM Configuration Register

(1)

(2)

(3)

www.ti.com

Table 1. ePWM Module Control and Status Register Set Grouped by Submodule

Offset Size

Name

Locations not shown are reserved.

These registers are only available on ePWM instances that include the high-resolution PWM extension. Otherwise these

locations are reserved. These registers are described in the TMS320x2833x, 2823x High-Resolution Pulse Width Modulator

(HRPWM) Reference Guide (SPRUG02) . See the device specific data manual to determine which instances include the

HRPWM.

EALLOW protected registers as described in the specific device version of the System Control and Interrupts Reference Guide

listed in Related Documentation From Texas Instruments.

(1)

(x16) Shadow EALLOW Description

Time-Base Submodule Registers

(2)

Counter-Compare Submodule Registers

(2)

Action-Qualifier Submodule Registers

Dead-Band Generator Submodule Registers

Trip-Zone Submodule Registers

(3)

(3)

(3)

(3)

(3)

Event-Trigger Submodule Registers

PWM-Chopper Submodule Registers

High-Resolution Pulse Width Modulator (HRPWM) Extension

Registers

(2) (3)

16

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 17

www.ti.com

2 ePWM Submodules

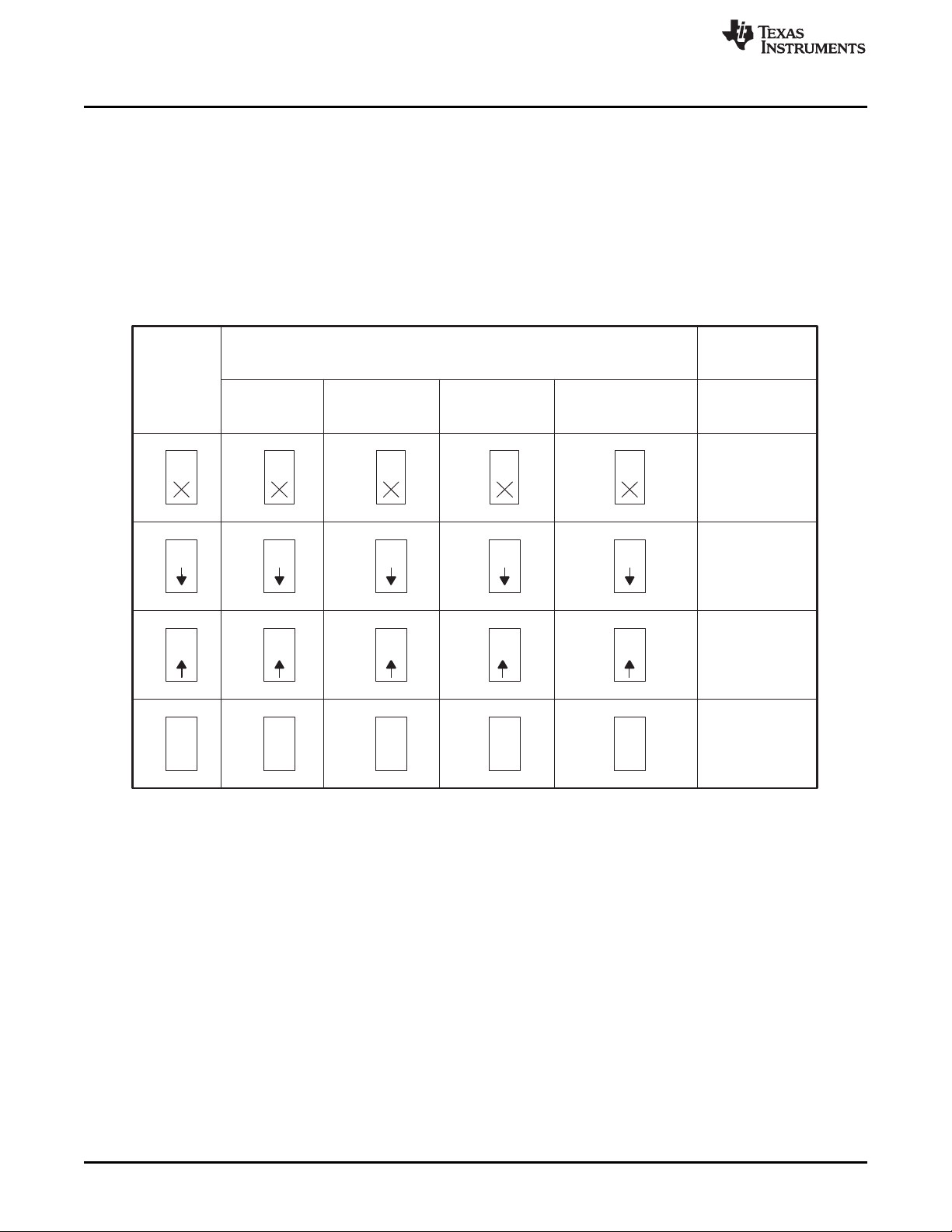

Seven submodules are included in every ePWM peripheral. Each of these submodules performs specific

tasks that can be configured by software.

2.1 Overview

Table 2 lists the seven key submodules together with a list of their main configuration parameters. For

example, if you need to adjust or control the duty cycle of a PWM waveform, then you should see the

counter-compare submodule in Section 2.3 for relevant details.

Submodule Configuration Parameter or Option

Time-base (TB)

Counter-compare (CC)

Action-qualifier (AQ)

Dead-band (DB)

PWM-chopper (PC)

ePWM Submodules

Table 2. Submodule Configuration Parameters

• Scale the time-base clock (TBCLK) relative to the system clock (SYSCLKOUT).

• Configure the PWM time-base counter (TBCTR) frequency or period.

• Set the mode for the time-base counter:

– count-up mode: used for asymmetric PWM

– count-down mode: used for asymmetric PWM

– count-up-and-down mode: used for symmetric PWM

• Configure the time-base phase relative to another ePWM module.

• Synchronize the time-base counter between modules through hardware or software.

• Configure the direction (up or down) of the time-base counter after a synchronization event.

• Configure how the time-base counter will behave when the device is halted by an emulator.

• Specify the source for the synchronization output of the ePWM module:

– Synchronization input signal

– Time-base counter equal to zero

– Time-base counter equal to counter-compare B (CMPB)

– No output synchronization signal generated.

• Specify the PWM duty cycle for output EPWMxA and/or output EPWMxB

• Specify the time at which switching events occur on the EPWMxA or EPWMxB output

• Specify the type of action taken when a time-base or counter-compare submodule event occurs:

– No action taken

– Output EPWMxA and/or EPWMxB switched high

– Output EPWMxA and/or EPWMxB switched low

– Output EPWMxA and/or EPWMxB toggled

• Force the PWM output state through software control

• Configure and control the PWM dead-band through software

• Control of traditional complementary dead-band relationship between upper and lower switches

• Specify the output rising-edge-delay value

• Specify the output falling-edge delay value

• Bypass the dead-band module entirely. In this case the PWM waveform is passed through

without modification.

• Create a chopping (carrier) frequency.

• Pulse width of the first pulse in the chopped pulse train.

• Duty cycle of the second and subsequent pulses.

• Bypass the PWM-chopper module entirely. In this case the PWM waveform is passed through

without modification.

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

17

Page 18

ePWM Submodules

Submodule Configuration Parameter or Option

Trip-zone (TZ)

Event-trigger (ET) • Enable the ePWM events that will trigger an interrupt.

Code examples are provided in the remainder of this document that show how to implement various

ePWM module configurations. These examples use the constant definitions shown in Example 1. These

definitions are also used in the C2833x/2823x C/C++ Header Files and Peripheral Examples (SPRC530) .

www.ti.com

Table 2. Submodule Configuration Parameters (continued)

• Configure the ePWM module to react to one, all, or none of the trip-zone pins .

• Specify the tripping action taken when a fault occurs:

– Force EPWMxA and/or EPWMxB high

– Force EPWMxA and/or EPWMxB low

– Force EPWMxA and/or EPWMxB to a high-impedance state

– Configure EPWMxA and/or EPWMxB to ignore any trip condition.

• Configure how often the ePWM will react to each trip-zone pins :

– One-shot

– Cycle-by-cycle

• Enable the trip-zone to initiate an interrupt.

• Bypass the trip-zone module entirely.

• Enable ePWM events that will trigger an ADC start-of-conversion event.

• Specify the rate at which events cause triggers (every occurrence or every second or third

occurrence)

• Poll, set, or clear event flags

Example 1. Constant Definitions Used in the Code Examples

// TBCTL (Time-Base Control)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// TBCTR MODE bits

#define TB_COUNT_UP 0x0

#define TB_COUNT_DOWN 0x1

#define TB_COUNT_UPDOWN 0x2

#define TB_FREEZE 0x3

// PHSEN bit

#define TB_DISABLE 0x0

#define TB_ENABLE 0x1

// PRDLD bit

#define TB_SHADOW 0x0

#define TB_IMMEDIATE 0x1

// SYNCOSEL bits

#define TB_SYNC_IN 0x0

#define TB_CTR_ZERO 0x1

#define TB_CTR_CMPB 0x2

#define TB_SYNC_DISABLE 0x3

// HSPCLKDIV and CLKDIV bits

#define TB_DIV1 0x0

#define TB_DIV2 0x1

#define TB_DIV4 0x2

// PHSDIR bit

#define TB_DOWN 0x0

#define TB_UP 0x1

// CMPCTL (Compare Control)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

//

LOADAMODE and LOADBMODE bits

#define CC_CTR_ZERO 0x0

#define CC_CTR_PRD 0x1

#define CC_CTR_ZERO_PRD 0x2 #

define CC_LD_DISABLE 0x3

// SHDWAMODE and SHDWBMODE bits

#define CC_SHADOW 0x0

#define CC_IMMEDIATE 0x1

// AQCTLA and AQCTLB (Action-qualifier Control)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// ZRO, PRD, CAU, CAD, CBU, CBD bits

18

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 19

www.ti.com

Example 1. Constant Definitions Used in the Code Examples (continued)

#define AQ_NO_ACTION 0x0

#define AQ_CLEAR 0x1

#define AQ_SET 0x2

#define AQ_TOGGLE 0x3

// DBCTL (Dead-Band Control)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// MODE bits

#define DB_DISABLE 0x0

#define DBA_ENABLE 0x1

#define DBB_ENABLE 0x2

#define DB_FULL_ENABLE 0x3

// POLSEL bits

#define DB_ACTV_HI 0x0

#define DB_ACTV_LOC 0x1

#define DB_ACTV_HIC 0x2

#define DB_ACTV_LO 0x3 // PCCTL (chopper control)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// CHPEN bit

#define CHP_ENABLE 0x0

#define CHP_DISABLE 0x1

// CHPFREQ bits

#define CHP_DIV1 0x0

#define CHP_DIV2 0x1

#define CHP_DIV3 0x2

#define CHP_DIV4 0x3

#define CHP_DIV5 0x4

#define CHP_DIV6 0x5

#define CHP_DIV7 0x6

#define CHP_DIV8 0x7

// CHPDUTY bits

#define CHP1_8TH 0x0

#define CHP2_8TH 0x1

#define CHP3_8TH 0x2

#define CHP4_8TH 0x3

#define CHP5_8TH 0x4

#define CHP6_8TH 0x5 #

define CHP7_8TH 0x6

// TZSEL (Trip-zone Select)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// CBCn and OSHTn bits

#define TZ_ENABLE 0x0

#define TZ_DISABLE 0x1

// TZCTL (Trip-zone Control)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// TZA and TZB bits

#define TZ_HIZ 0x0

#define TZ_FORCE_HI 0x1

#define TZ_FORCE_LO 0x2

#define TZ_DISABLE 0x3

// ETSEL (Event-trigger Select)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// INTSEL, SOCASEL, SOCBSEL bits

#define ET_CTR_ZERO 0x1

#define ET_CTR_PRD 0x2

#define ET_CTRU_CMPA 0x4

#define ET_CTRD_CMPA 0x5

#define ET_CTRU_CMPB 0x6

#define ET_CTRD_CMPB 0x7

// ETPS (Event-trigger Prescale)

// = = = = = = = = = = = = = = = = = = = = = = = = = =

// INTPRD, SOCAPRD, SOCBPRD bits

#define ET_DISABLE 0x0

#define ET_1ST 0x1

#define ET_2ND 0x2

#define ET_3RD 0x3

ePWM Submodules

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

19

Page 20

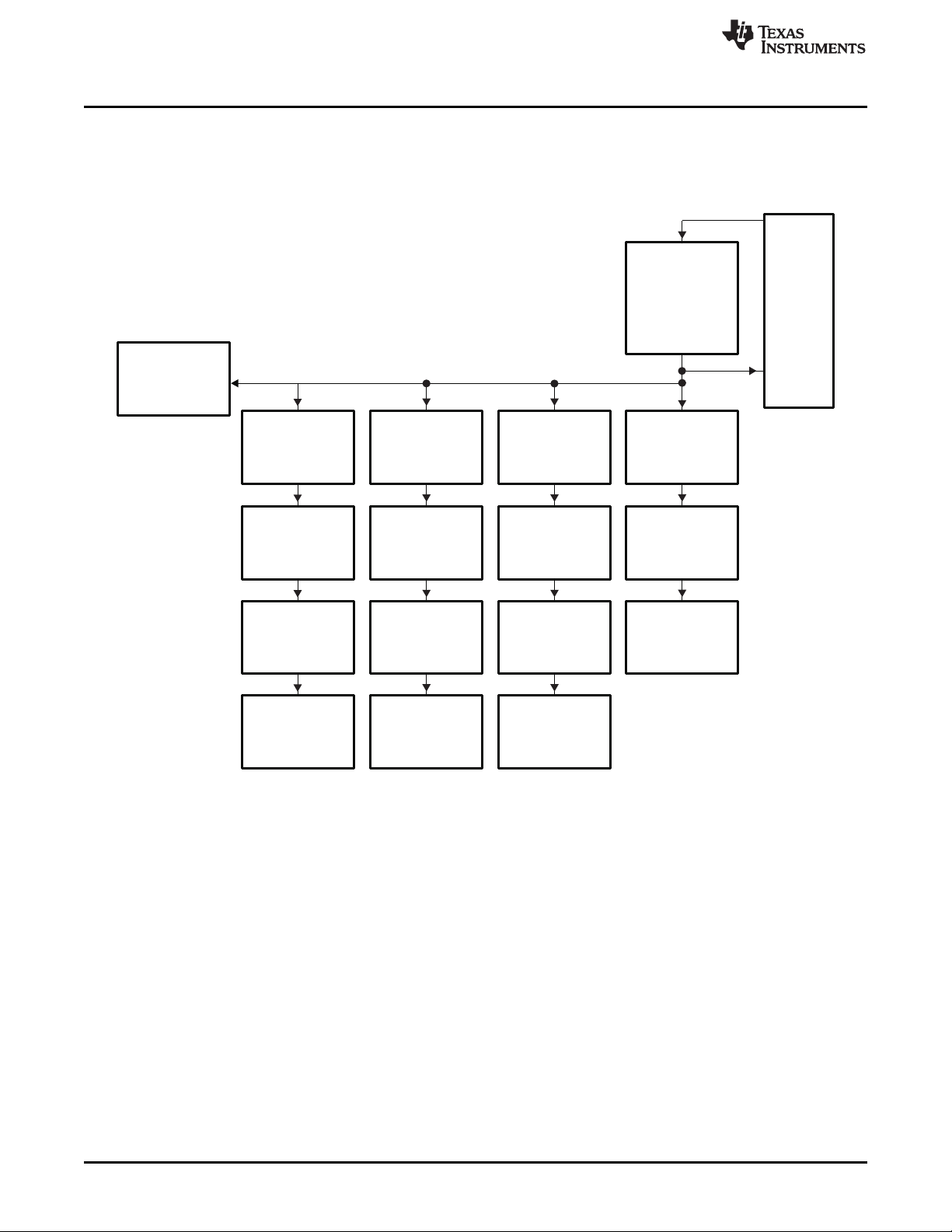

CTR = CMPB

CTR = CMPA

CTR_Dir

CTR = 0

CTR = PRD

Dead

Band

(DB)

Counter

Compare

(CC)

Action

Qualifier

(AQ)

EPWMxA

EPWMxB

CTR = CMPB

CTR = 0

EPWMxINT

EPWMxSOCA

EPWMxSOCB

EPWMxA

EPWMxB

TZ1 to TZ6

CTR = CMPA

Time-Base

(TB)

CTR = PRD

CTR = 0

CTR_Dir

EPWMxSYNCI

EPWMxSYNCO

EPWMxTZINT

PWM-

chopper

(PC)

Event

Trigger

and

Interrupt

(ET)

Trip

Zone

(TZ)

GPIO

MUX

ADC

PIE

PIE

ePWM Submodules

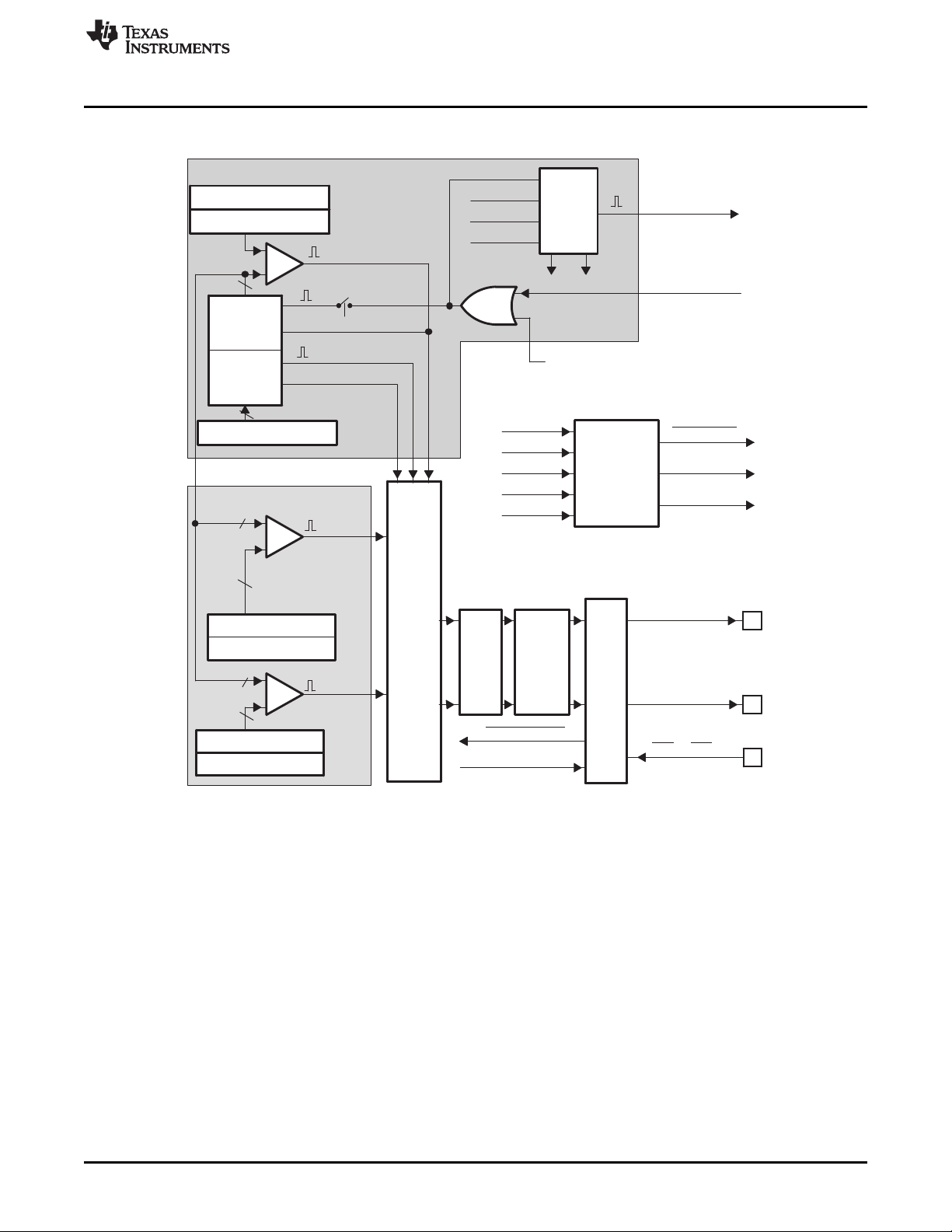

2.2 Time-Base (TB) Submodule

Each ePWM module has its own time-base submodule that determines all of the event timing for the

ePWM module. Built-in synchronization logic allows the time-base of multiple ePWM modules to work

together as a single system. Figure 4 illustrates the time-base module's place within the ePWM.

Figure 4. Time-Base Submodule Block Diagram

www.ti.com

2.2.1 Purpose of the Time-Base Submodule

You can configure the time-base submodule for the following:

• Specify the ePWM time-base counter (TBCTR) frequency or period to control how often events occur.

• Manage time-base synchronization with other ePWM modules.

• Maintain a phase relationship with other ePWM modules.

• Set the time-base counter to count-up, count-down, or count-up-and-down mode.

• Generate the following events:

– CTR = PRD: Time-base counter equal to the specified period (TBCTR = TBPRD) .

– CTR = Zero: Time-base counter equal to zero (TBCTR = 0x0000).

• Configure the rate of the time-base clock; a prescaled version of the CPU system clock

(SYSCLKOUT). This allows the time-base counter to increment/decrement at a slower rate.

20

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

TBCTL[SYNCOSEL]

TBPRD

PeriodActive

TBPRD

PeriodShadow

16

TBCTL[SWFSYNC]

CTR=PRD

TBPHS

PhaseActiveReg

Counter

UP/DOWN

16

Sync

Out

Select

EPWMxSYNCO

Reset

Load

16

TBCTL[PHSEN]

CTR=Zero

CTR=CMPB

Disable

X

EPWMxSYNCI

TBCTL[PRDLD]

TBCTR[15:0]

Mode

TBCTL[CTRMODE]

CTR=Zero

CTR_max

TBCLK

Clock

Prescale

SYSCLKOUT

TBCLK

TBCTL[HSPCLKDIV]

TBCTL[CLKDIV]

CTR_dir

TBCTR

CounterActiveReg

clk

Max

Dir

Zero

www.ti.com

2.2.2 Controlling and Monitoring the Time-base Submodule

Table 3 shows the registers used to control and monitor the time-base submodule.

Table 3. Time-Base Submodule Registers

Register Address offset Shadowed Description

TBCTL 0x0000 No Time-Base Control Register

TBSTS 0x0001 No Time-Base Status Register

TBPHSHR 0x0002 No HRPWM Extension Phase Register

TBPHS 0x0003 No Time-Base Phase Register

TBCTR 0x0004 No Time-Base Counter Register

TBPRD 0x0005 Yes Time-Base Period Register

(1)

This register is available only on ePWM instances that include the high-resolution extension (HRPWM). On ePWM modules that

do not include the HRPWM, this location is reserved. This register is described in the device-specific High-Resolution Pulse

Width Modulator (HRPWM) Reference Guide. See the device specific data manual to determine which ePWM instances include

this feature.

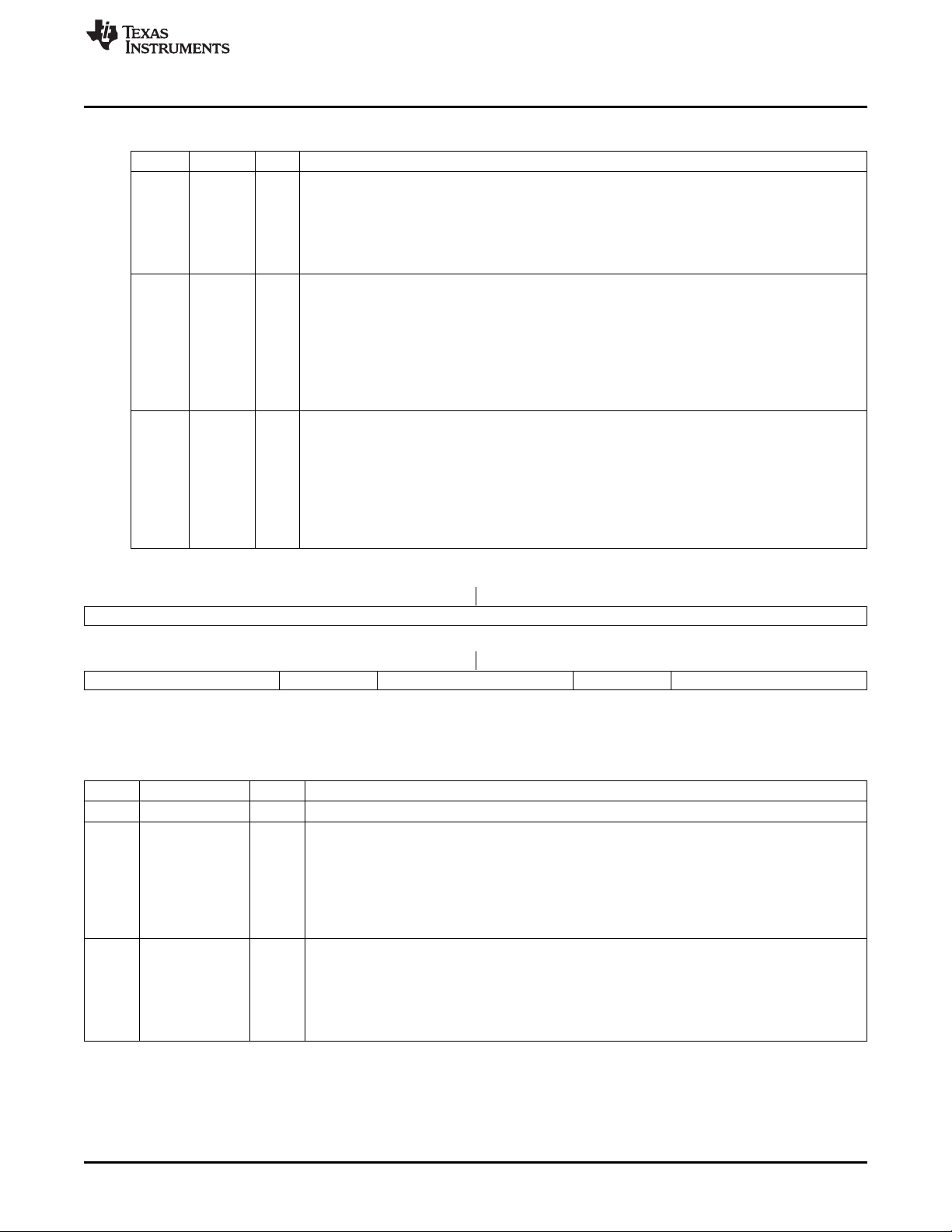

The block diagram in Figure 5 shows the critical signals and registers of the time-base submodule.

Table 4 provides descriptions of the key signals associated with the time-base submodule.

Figure 5. Time-Base Submodule Signals and Registers

ePWM Submodules

(1)

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

21

Page 22

ePWM Submodules

Signal Description

EPWMxSYNCI Time-base synchronization input.

EPWMxSYNCO Time-base synchronization output.

CTR = PRD Time-base counter equal to the specified period.

CTR = Zero Time-base counter equal to zero

CTR = CMPB Time-base counter equal to active counter-compare B register (TBCTR = CMPB).

CTR_dir Time-base counter direction.

CTR_max Time-base counter equal max value. (TBCTR = 0xFFFF)

TBCLK Time-base clock.

www.ti.com

Table 4. Key Time-Base Signals

Input pulse used to synchronize the time-base counter with the counter of ePWM module earlier in the

synchronization chain. An ePWM peripheral can be configured to use or ignore this signal. For the first ePWM

module (EPWM1) this signal comes from a device pin. For subsequent ePWM modules this signal is passed

from another ePWM peripheral. For example, EPWM2SYNCI is generated by the ePWM1 peripheral,

EPWM3SYNCI is generated by ePWM2 and so forth. See Section 2.2.3.3 for information on the

synchronization order of a particular device.

This output pulse is used to synchronize the counter of an ePWM module later in the synchronization chain.

The ePWM module generates this signal from one of three event sources:

1. EPWMxSYNCI (Synchronization input pulse)

2. CTR = Zero: The time-base counter equal to zero (TBCTR = 0x0000).

3. CTR = CMPB: The time-base counter equal to the counter-compare B (TBCTR = CMPB) register.

This signal is generated whenever the counter value is equal to the active period register value. That is when

TBCTR = TBPRD.

This signal is generated whenever the counter value is zero. That is when TBCTR equals 0x0000.

This event is generated by the counter-compare submodule and used by the synchronization out logic

Indicates the current direction of the ePWM's time-base counter. This signal is high when the counter is

increasing and low when it is decreasing.

Generated event when the TBCTR value reaches its maximum value. This signal is only used only as a status

bit

This is a prescaled version of the system clock (SYSCLKOUT) and is used by all submodules within the

ePWM. This clock determines the rate at which time-base counter increments or decrements.

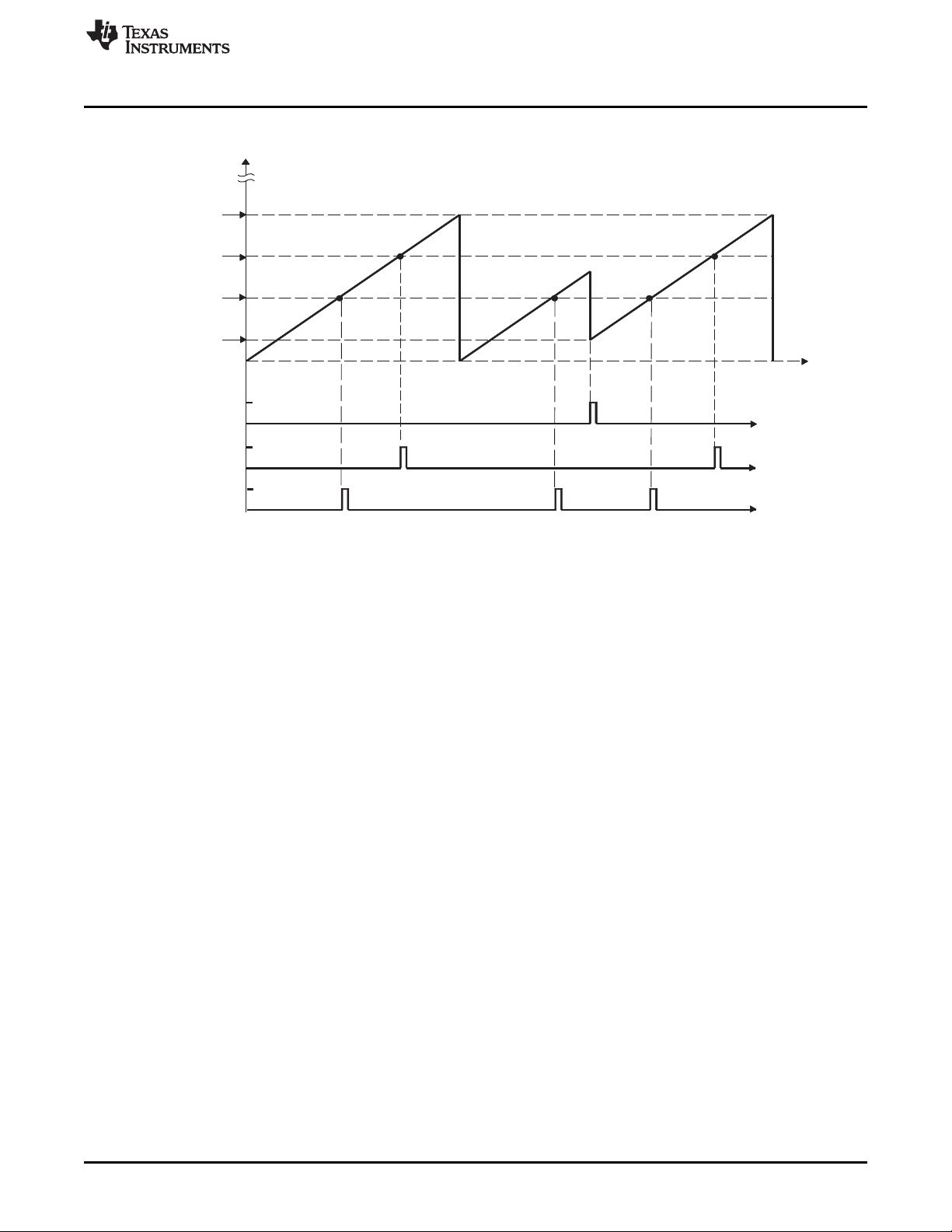

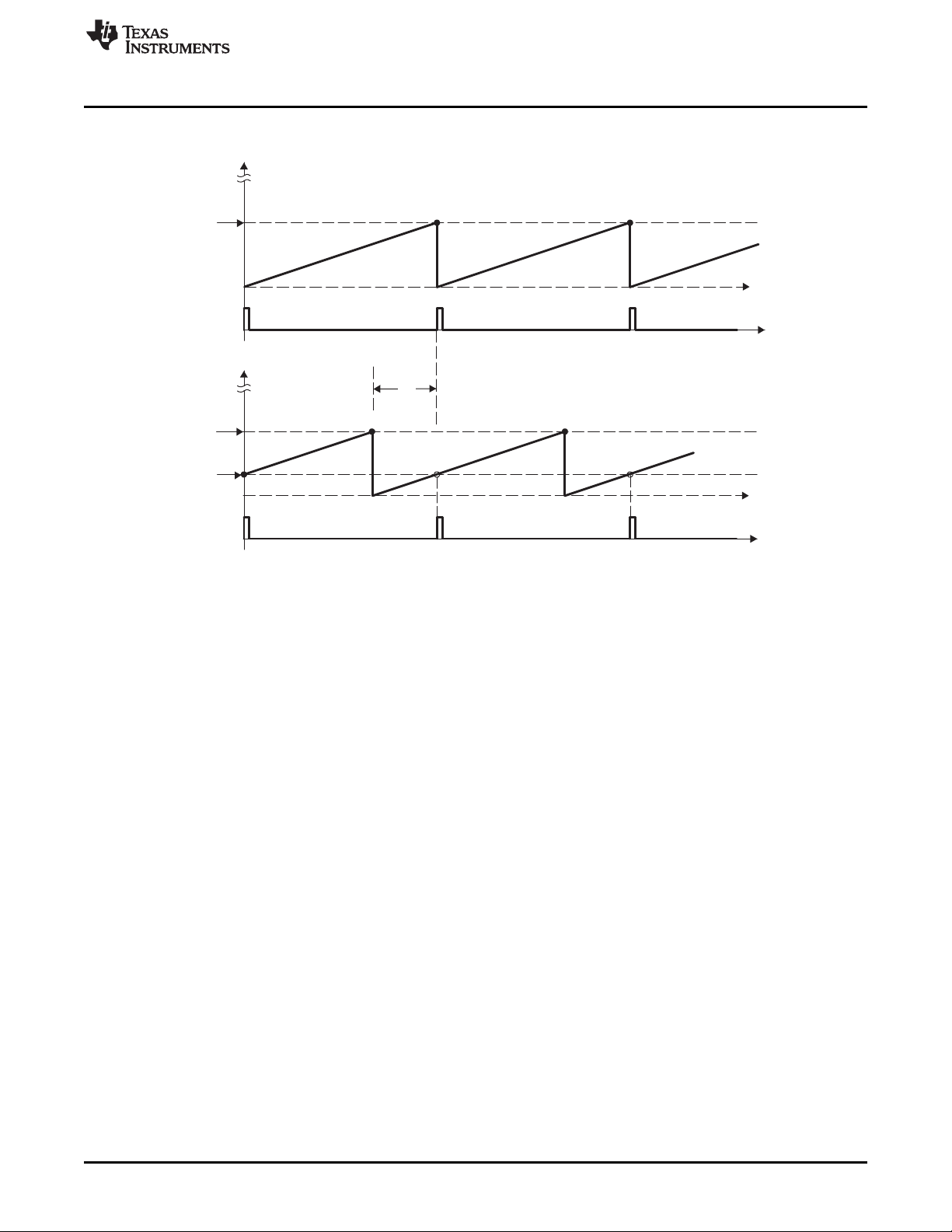

2.2.3 Calculating PWM Period and Frequency

The frequency of PWM events is controlled by the time-base period (TBPRD) register and the mode of the

time-base counter. Figure 6 shows the period (T

down-count, and up-down-count time-base counter modes when when the period is set to 4 (TBPRD = 4).

The time increment for each step is defined by the time-base clock (TBCLK) which is a prescaled version

of the system clock (SYSCLKOUT).

The time-base counter has three modes of operation selected by the time-base control register (TBCTL):

• Up-Down-Count Mode:

In up-down-count mode, the time-base counter starts from zero and increments until the period

(TBPRD) value is reached. When the period value is reached, the time-base counter then decrements

until it reaches zero. At this point the counter repeats the pattern and begins to increment.

• Up-Count Mode:

In this mode, the time-base counter starts from zero and increments until it reaches the value in the

period register (TBPRD). When the period value is reached, the time-base counter resets to zero and

begins to increment once again.

• Down-Count Mode:

In down-count mode, the time-base counter starts from the period (TBPRD) value and decrements until

it reaches zero. When it reaches zero, the time-base counter is reset to the period value and it begins

to decrement once again.

) and frequency (F

pwm

) relationships for the up-count,

pwm

22

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 23

PRD

4

4 4

PRD

4

1

2

3

0

1

2

3

0

1

2

3

0

Z

1

2

3

4

0

1

2

3

CTR_dir

1

2

3

4

0

1

2

3

0

Up Down Down

Up

T

PWM =

(TBPRD + 1) x T

TBCLK

For Up Count and Down Count

For Up and Down Count

F

PWM =

1/ (T

PWM)

T

PWM =

2 x TBPRD x T

TBCLK

F

PWM =

1 / (T

PWM)

1

2

3

4

0

1

2

3

4

0

1

2

3

0

T

PWM

Z

T

PWM

T

PWM

T

PWM

www.ti.com

ePWM Submodules

Figure 6. Time-Base Frequency and Period

2.2.3.1 Time-Base Period Shadow Register

The time-base period register (TBPRD) has a shadow register. Shadowing allows the register update to

be synchronized with the hardware. The following definitions are used to describe all shadow registers in

the ePWM module:

• Active Register

The active register controls the hardware and is responsible for actions that the hardware causes or

invokes.

• Shadow Register

direct effect on any control hardware. At a strategic point in time the shadow register's content is

transferred to the active register. This prevents corruption or spurious operation due to the register

being asynchronously modified by software.

The memory address of the shadow period register is the same as the active register. Which register is

written to or read from is determined by the TBCTL[PRDLD] bit. This bit enables and disables the TBPRD

shadow register as follows:

• Time-Base Period Shadow Mode:

The shadow register buffers or provides a temporary holding location for the active register. It has no

The TBPRD shadow register is enabled when TBCTL[PRDLD] = 0. Reads from and writes to the

TBPRD memory address go to the shadow register. The shadow register contents are transferred to

the active register (TBPRD (Active) ← TBPRD (shadow)) when the time-base counter equals zero

(TBCTR = 0x0000). By default the TBPRD shadow register is enabled.

• Time-Base Period Immediate Load Mode:

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

If immediate load mode is selected (TBCTL[PRDLD] = 1), then a read from or a write to the TBPRD

© 2008–2009, Texas Instruments Incorporated

23

Page 24

ePWM Submodules

memory address goes directly to the active register.

2.2.3.2 Time-Base Clock Synchronization

The TBCLKSYNC bit in the peripheral clock enable registers allows all users to globally synchronize all

enabled ePWM modules to the time-base clock (TBCLK). When set, all enabled ePWM module clocks are

started with the first rising edge of TBCLK aligned. For perfectly synchronized TBCLKs, the prescalers for

each ePWM module must be set identically.

The proper procedure for enabling ePWM clocks is as follows:

1. Enable ePWM module clocks in the PCLKCRx register

2. Set TBCLKSYNC= 0

3. Configure ePWM modules

4. Set TBCLKSYNC=1

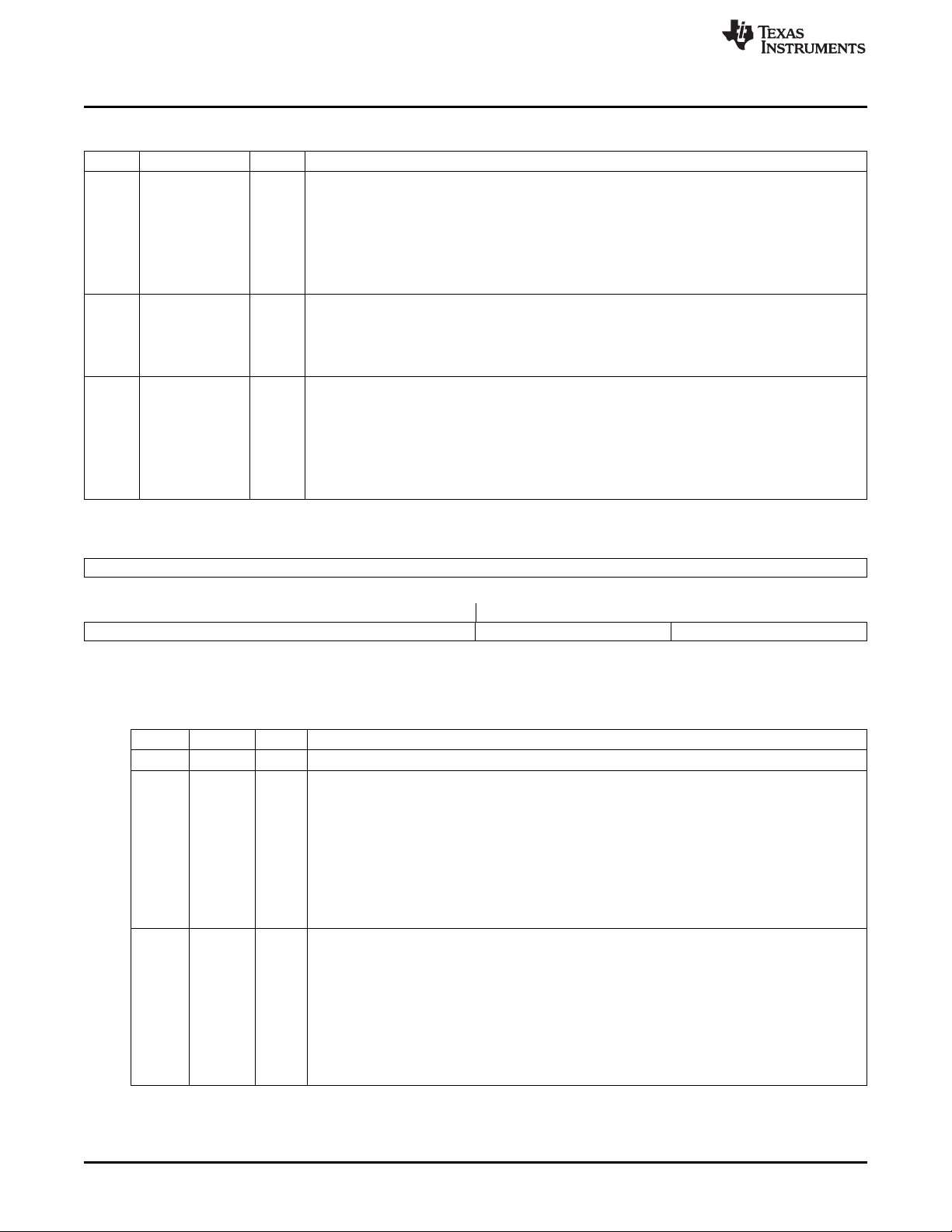

2.2.3.3 Time-Base Counter Synchronization

A time-base synchronization scheme connects all of the ePWM modules on a device. Each ePWM

module has a synchronization input (EPWMxSYNCI) and a synchronization output (EPWMxSYNCO). The

input synchronization for the first instance (ePWM1) comes from an external pin. The possible

synchronization connections for the remaining ePWM modules are shown in Figure 7, Figure 8, and

Figure 9.

Scheme 1 shown in Figure 7 applies to the 280x, 2801x, 2802x, and 2803x devices. Scheme 1 also

applies to the 2804x devices when the ePWM pinout is configured for 280x compatible mode

(GPAMCFG[EPWMMODE] = 0).

www.ti.com

24

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 25

EPWM2SYNCI

ePWM2

EPWM2SYNCO

EPWM1SYNCO

ePWM1

EPWM1SYNCI

GPIO

MUX

EPWM3SYNCO

ePWM3

EPWM3SYNCI

ePWMx

EPWMxSYNCI

SYNCI

eCAP1

EPWMxSYNCO

www.ti.com

ePWM Submodules

Figure 7. Time-Base Counter Synchronization Scheme 1

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

25

Page 26

EPWM1SYNCI

ePWM1

EPWM1SYNCO

GPIO

MUX

EPWM2SYNCI

ePWM2

EPWM2SYNCO

EPWM3SYNCI

ePWM3

EPWM3SYNCO

EPWM4SYNCI

ePWM4

EPWM4SYNCO

EPWM5SYNCI

ePWM5

EPWM5SYNCO

EPWM6SYNCI

ePWM6

EPWM36YNCO

EPWM7SYNCI

ePWM7

EPWM7SYNCO

EPWM9SYNCI

ePWM9

EPWM9SYNCO

EPWM10SYNCI

ePWM10

EPWM10SYNCO

EPWM11SYNCI

ePWM11

EPWM11SYNCO

EPWM13SYNCI

ePWM13

EPWM13SYnCO

EPWM14SYNCI

ePWM14

EPWM14SYNCO

EPWM15SYNCI

ePWM15

EPWM15SYNCO

EPWM8SYNCI

ePWM8

EPWM8SYNCO

EPWM12SYNCI

ePWM12

EPWM12SYNCO

EPWM16SYNCI

ePWM16

EPWM16SYNCO

SYNCI

eCAP1

ePWM Submodules

Scheme 2 shown in Figure 8 is used by the 2804x devices when the ePWM pinout is configured for

A-channel only mode (GPAMCFG[EPWMMODE] = 3). If the 2804x ePWM pinout is configured for 280x

compatible mode (GPAMCFG[EPWMMODE] = 0), then Scheme 1 is used.

www.ti.com

Figure 8. Time-Base Counter Synchronization Scheme 2

26

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

© 2008–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

EPWM1SYNCO

ePWM1

EPWM1SYNCI

GPIO

MUX

SYNCI

eCAP1

EPWM2SYNCI

ePWM2

EPWM2SYNCO

EPWM3SYNCO

ePWM3

EPWM3SYNCI

EPWM4SYNCI

ePWM4

EPWM4SYNCO

EPWM5SYNCO

ePWM5

EPWM5SYNCI

ePWM6

EPWM6SYNCI

eCAP4

EPWM7SYNCI

ePWM7

EPWM7SYNCO

EPWM8SYNCI

ePWM8

EPWM8SYNCO

EPWM9SYNCI

ePWM9

www.ti.com

Scheme 3, shown in Figure 9, is used by all other devices.

ePWM Submodules

Figure 9. Time-Base Counter Synchronization Scheme 3

NOTE: All modules shown in the synchronization schemes may not be available on all devices.

Please refer to the device specific data manual to determine which modules are available on

a particular device.

Each ePWM module can be configured to use or ignore the synchronization input. If the TBCTL[PHSEN]

bit is set, then the time-base counter (TBCTR) of the ePWM module will be automatically loaded with the

phase register (TBPHS) contents when one of the following conditions occur:

• EPWMxSYNCI: Synchronization Input Pulse:

The value of the phase register is loaded into the counter register when an input synchronization pulse

is detected (TBPHS → TBCTR). This operation occurs on the next valid time-base clock (TBCLK)

edge.

The delay from internal master module to slave modules is given by:

– if ( TBCLK = SYSCLKOUT): 2 x SYSCLKOUT

– if ( TBCLK != SYSCLKOUT):1 TBCLK

• Software Forced Synchronization Pulse:

Writing a 1 to the TBCTL[SWFSYNC] control bit invokes a software forced synchronization. This pulse

is ORed with the synchronization input signal, and therefore has the same effect as a pulse on

EPWMxSYNCI.

• This feature enables the ePWM module to be automatically synchronized to the time base of another

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

27

Page 28

ePWM Submodules

ePWM module. Lead or lag phase control can be added to the waveforms generated by different

ePWM modules to synchronize them. In up-down-count mode, the TBCTL[PSHDIR] bit configures the

direction of the time-base counter immediately after a synchronization event. The new direction is

independent of the direction prior to the synchronization event. The PHSDIR bit is ignored in count-up

or count-down modes. See Figure 10 through Figure 13 for examples.

Clearing the TBCTL[PHSEN] bit configures the ePWM to ignore the synchronization input pulse. The

synchronization pulse can still be allowed to flow-through to the EPWMxSYNCO and be used to

synchronize other ePWM modules. In this way, you can set up a master time-base (for example, ePWM1)

and downstream modules (ePWM2 - ePWMx) may elect to run in synchronization with the master. See

the Application to Power Topologies Section 3 for more details on synchronization strategies.

2.2.4 Phase Locking the Time-Base Clocks of Multiple ePWM Modules

The TBCLKSYNC bit can be used to globally synchronize the time-base clocks of all enabled ePWM

modules on a device. This bit is part of the device's clock enable registers and is described in the specific

device version of the System Control and Interrupts Reference Guide listed in Related Documentation

From Texas Instruments. When TBCLKSYNC = 0, the time-base clock of all ePWM modules is stopped

(default). When TBCLKSYNC = 1, all ePWM time-base clocks are started with the rising edge of TBCLK

aligned. For perfectly synchronized TBCLKs, the prescaler bits in the TBCTL register of each ePWM

module must be set identically. The proper procedure for enabling the ePWM clocks is as follows:

1. Enable the individual ePWM module clocks. This is described in the specific device version of the

System Control and Interrupts Reference Guide listed in Related Documentation From Texas

Instruments.

2. Set TBCLKSYNC = 0. This will stop the time-base clock within any enabled ePWM module.

3. Configure the prescaler values and desired ePWM modes.

4. Set TBCLKSYNC = 1.

www.ti.com

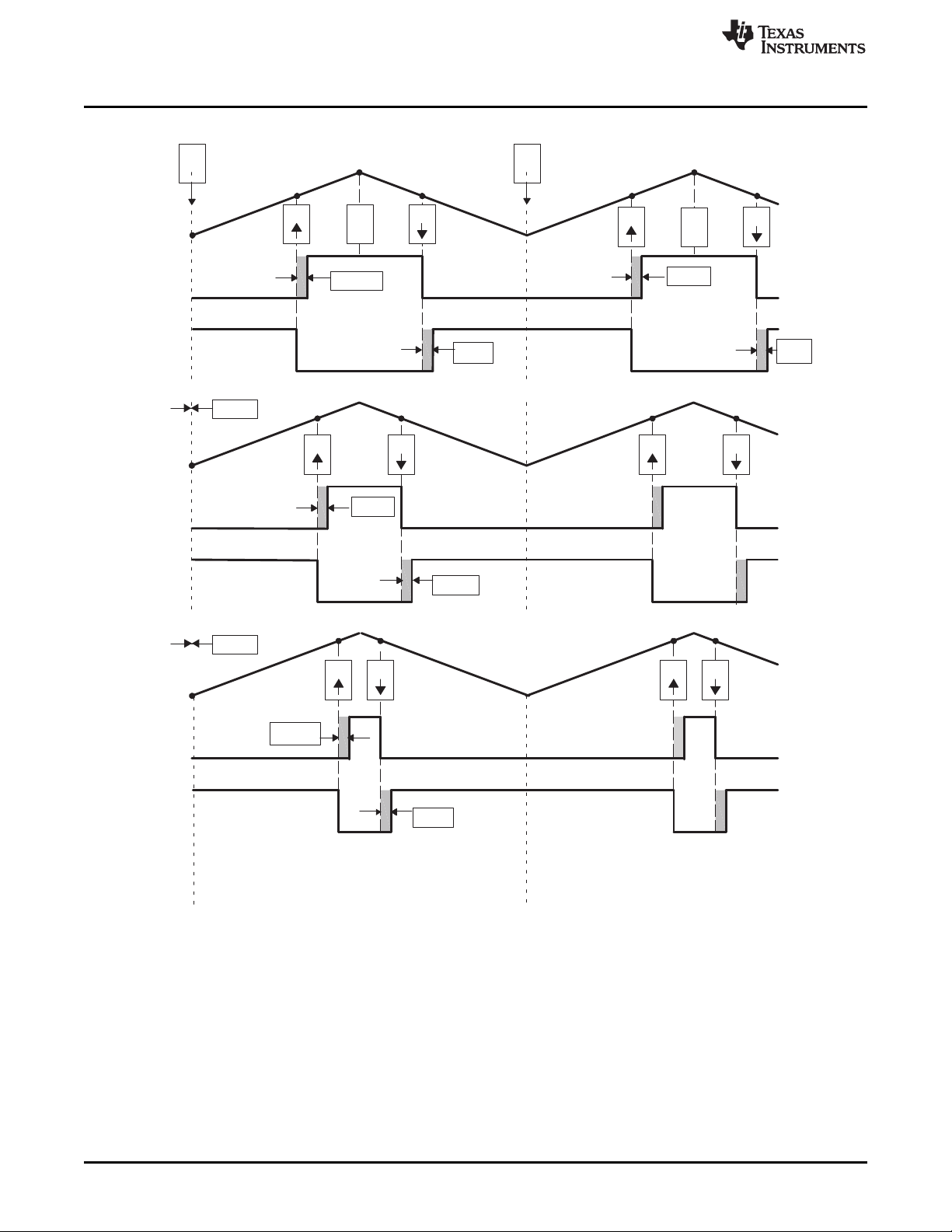

2.2.5 Time-base Counter Modes and Timing Waveforms

The time-base counter operates in one of four modes:

• Up-count mode which is asymmetrical.

• Down-count mode which is asymmetrical.

• Up-down-count which is symmetrical

• Frozen where the time-base counter is held constant at the current value

To illustrate the operation of the first three modes, the following timing diagrams show when events are

generated and how the time-base responds to an EPWMxSYNCI signal.

28

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 29

0000

TBCTR[15:0]

CTR_dir

CTR = zero

CNT_max

CTR = PRD

0xFFFF

TBPHS

(value)

TBPRD

(value)

www.ti.com

ePWM Submodules

Figure 10. Time-Base Up-Count Mode Waveforms

SPRUG04A–October 2008–Revised July 2009 TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

29

Page 30

0x000

0xFFFF

TBCTR[15:0]

TBPHS

(value)

TBPRD

(value)

CTR_dir

CTR = zero

CNT_max

CTR = PRD

0x0000

0xFFFF

TBCTR[15:0]

UP

DOWN

UP

DOWN

UP

DOWN

UP

TBPHS

(value)

TBPRD

(value)

CTR_dir

CTR=zero

CNT_max

CTR=PRD

ePWM Submodules

www.ti.com

Figure 11. Time-Base Down-Count Mode Waveforms

Figure 12. Time-Base Up-Down-Count Waveforms, TBCTL[PHSDIR = 0] Count Down On Synchronization

Event

30

TMS320x2833x, 2823x Enhanced Pulse Width Modulator (ePWM) Module SPRUG04A–October 2008–Revised July 2009

Submit Documentation Feedback

© 2008–2009, Texas Instruments Incorporated

Page 31

0x0000

0xFFFF

TBCTR[15:0]

UP

DOWN

UP

DOWN

UP

DOWN

TBPHS(value)

TBPRD(value)

EPWMxSYNCI

CTR_dir

CTR=zero

CNT_max

CTR=PRD

CTR = CMPB

CTR = CMPA

CTR_Dir

CTR = 0

CTR = PRD

Dead

Band

(DB)

Counter

Compare

(CC)

Action

Qualifier

(AQ)

EPWMxA

EPWMxB

CTR = CMPB

CTR = 0

EPWMxINT

EPWMxSOCA

EPWMxSOCB

EPWMxA

EPWMxB

TZ1 to TZ6

CTR = CMPA

Time-Base

(TB)

CTR = PRD

CTR = 0

CTR_Dir

EPWMxSYNCI

EPWMxSYNCO

EPWMxTZINT

PWM-

chopper

(PC)

Event

Trigger

and

Interrupt

(ET)

Trip

Zone

(TZ)

GPIO

MUX

ADC

PIE

PIE

www.ti.com

ePWM Submodules

Figure 13. Time-Base Up-Down Count Waveforms, TBCTL[PHSDIR = 1] Count Up On Synchronization

Event

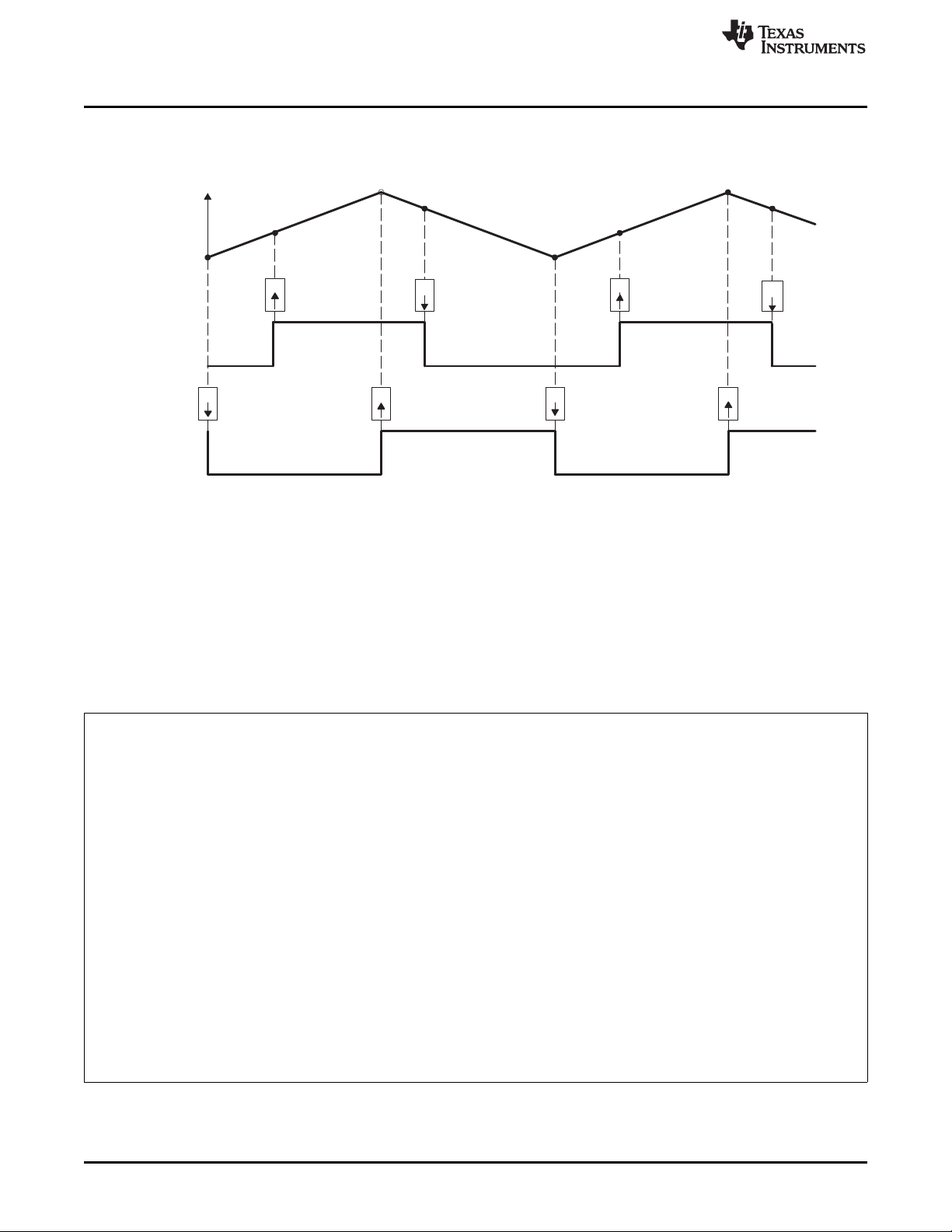

2.3 Counter-Compare (CC) Submodule

Figure 14 illustrates the counter-compare submodule within the ePWM.

Figure 14. Counter-Compare Submodule

Figure 15 shows the basic structure of the counter-compare submodule.