Page 1

TMS320C6000 DSP

Software-Programmable

Phase-Locked Loop (PLL) Controller

Reference Guide

Literature Number: SPRU233A

April 2003

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections,

modifications, enhancements, improvements, and other changes to its products and services at

any time and to discontinue any product or service without notice. Customers should obtain the

latest relevant information before placing orders and should verify that such information is current

and complete. All products are sold subject to TI’s terms and conditions of sale supplied at the

time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of

sale in accordance with TI’s standard warranty . Testing and other quality control techniques are

used to the extent TI deems necessary to support this warranty. Except where mandated by

government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are

responsible for their products and applications using TI components. To minimize the risks

associated with customer products and applications, customers should provide adequate design

and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any

TI patent right, copyright, mask work right, or other TI intellectual property right relating to any

combination, machine, or process in which TI products or services are used. Information

published by TI regarding third party products or services does not constitute a license from TI

to use such products or services or a warranty or endorsement thereof. Use of such information

may require a license from a third party under the patents or other intellectual property of that third

party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction

is without alteration and is accompanied by all associated warranties, conditions, limitations, and

notices. Reproduction of this information with alteration is an unfair and deceptive business

practice. TI is not responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated

by TI for that product or service voids all express and any implied warranties for the associated

TI product or service and is an unfair and deceptive business practice. TI is not responsible or

liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 3

About This Manual

This document describes the operation of the software-programmable phaselocked loop (PLL) controller in the digital signal processors (DSPs) of the

TMS320C6000 DSP family. This type of controller is used on the following

devices:

- TMS320C6711C

- TMS320C6712C

- TMS320C6713

Notational Conventions

This document uses the following conventions.

- Hexadecimal numbers are shown with the suffix h. For example, the

Preface

Read This First

following number is 40 hexadecimal (decimal 64): 40h.

Related Documentation From Texas Instruments

The following documents describe the C6000 devices and related support

tools. Copies of these documents are available on the Internet at www.ti.com.

Tip: Enter the literature number in the search box provided at www .ti.com.

TMS320C6000 CPU and Instruction Set Reference Guide (literature

number SPRU189) describes the TMS320C6000 CPU architecture,

instruction set, pipeline, and interrupts for these digital signal processors.

TMS320C6000 Peripherals Reference Guide (literature number SPRU190)

describes the peripherals available on the TMS320C6000 DSPs.

TMS320C6000 Technical Brief (literature number SPRU197) gives an

introduction to the TMS320C62x and TMS320C67x DSPs, develop-

ment tools, and third-party support.

TMS320C64x Technical Overview (SPRU395) gives an introduction to the

TMS320C64x DSP and discusses the application areas that are

enhanced by the TMS320C64x VelociTI.

3Title of DocSPRU233A

Page 4

Trademarks

Related Documentation From Texas Instruments / Trademarks

TMS320C6000 Programmer’s Guide (literature number SPRU198)

describes ways to optimize C and assembly code for the

TMS320C6000 DSPs and includes application program examples.

TMS320C6000 Code Composer Studio Tutorial (literature number

SPRU301) introduces the Code Composer Studio integrated development environment and software tools.

Code Composer Studio Application Programming Interface Reference

Guide (literature number SPRU321) describes the Code Composer

Studio application programming interface (API), which allows you to

program custom plug-ins for Code Composer.

TMS320C6x Peripheral Support Library Programmer’s Reference

(literature number SPRU273) describes the contents of the

TMS320C6000 peripheral support library of functions and macros. It

lists functions and macros both by header file and alphabetically,

provides a complete description of each, and gives code examples to

show how they are used.

TMS320C6000 Chip Support Library API Reference Guide (literature

number SPRU401) describes a set of application programming interfaces

(APIs) used to configure and control the on-chip peripherals.

Trademarks

Code Composer Studio, C6000, C62x, C64x, C67x, TMS320C6000,

TMS320C62x, TMS320C64x, TMS320C67x, and VelociTI are trademarks of

Texas Instruments.

4 Phase-Locked Loop (PLL) Controller SPRU233A

Page 5

Contents

1 Overview 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functional Description 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Multiplier and Dividers 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Reset Controller 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Configuration 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Initialization 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 PLL Mode (PLLEN = 1) 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Bypass Mode (PLLEN = 0) 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Power Down 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Power Wake Up 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Registers 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PLL Controller Peripheral Identification Register (PLLPID) 15. . . . . . . . . . . . . . . . . . . . . . . .

4.2 PLL Control/Status Register (PLLCSR) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PLL Multiplier Control Register (PLLM) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PLL Controller Divider Registers (PLLDIV0–3) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Oscillator Divider 1 Register (OSCDIV1) 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5Phase-Locked Loop (PLL) ControllerSPRU233A

Page 6

Figures

1 PLL Controller Block Diagram 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Reset Controller Lengthening the Internal Reset Signal 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 PLL Controller Peripheral Identification Register (PLLPID) 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLL Control/Status Register (PLLCSR) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 PLL Multiplier Control Register (PLLM) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 PLL Controller Divider Register (PLLDIV) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Oscillator Divider 1 Register (OSCDIV1) 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

1 PLL Controller Registers 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 PLL Controller Peripheral Identification Register (PLLPID) Field Descriptions 15. . . . . . . . . .

3 PLL Control/Status Register (PLLCSR) Field Descriptions 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLL Multiplier Control Register (PLLM) Field Descriptions 18. . . . . . . . . . . . . . . . . . . . . . . . . . .

5 PLL Controller Divider Register (PLLDIV) Field Descriptions 19. . . . . . . . . . . . . . . . . . . . . . . . .

6 Oscillator Divider 1 Register (OSCDIV1) Field Descriptions 20. . . . . . . . . . . . . . . . . . . . . . . . . .

6 Phase-Locked Loop (PLL) Controller SPRU233A

Page 7

1 Overview

Phase-Locked Loop (PLL) Controller

This document describes the operation of the software-programmable phaselocked loop (PLL) controller in the digital signal processors (DSPs) of the

TMS320C6000 DSP family. This type of controller is used on the following

devices:

- TMS320C6711C

- TMS320C6712C

- TMS320C6713

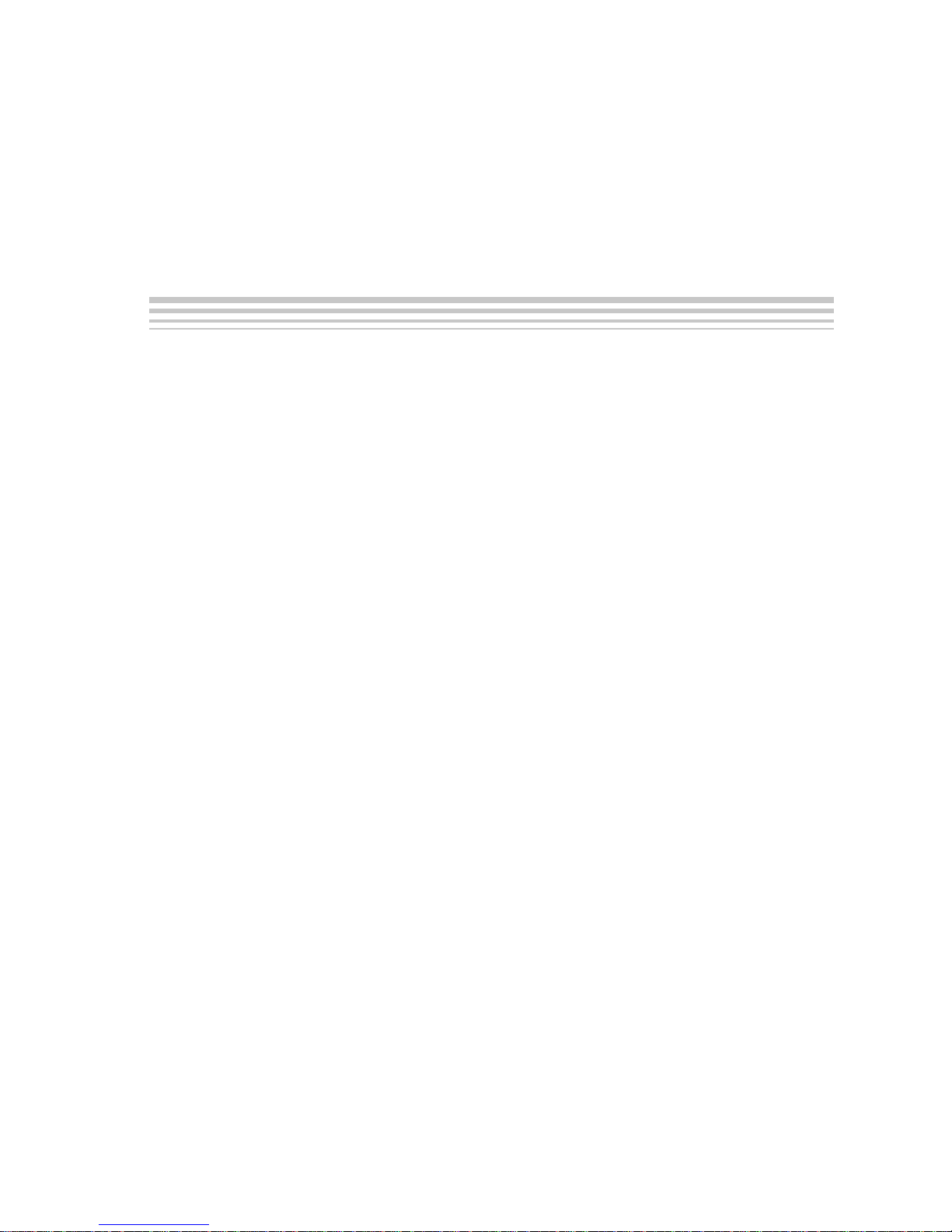

The PLL controller (Figure 1) features software-configurable PLL multiplier

controller, dividers (OSCDIV1, D0, D1, D2, and D3), and reset controller. The

PLL controller accepts an input clock, as determined by the logic state on the

CLKMODE0 pin, from the CLKIN pin or from the on-chip oscillator output

signal OSCIN. The PLL controller offers flexibility and convenience by way of

software-configurable multiplier and dividers to modify the input signal internally . The resulting clock outputs are passed to the DSP core, peripherals, and

other modules inside the C6000 DSP.

- The input reference clocks to the PLL controller:

J CLKIN: input signal from external oscillator (3.3V), CLKMODE0 = 1

J OSCIN: output signal from on-chip oscillator (1.2V), CLKMODE0 = 0

- The resulting output clocks from the PLL controller:

J AUXCLK: internal clock output signal directly from CLKIN or OSCIN.

J CLKOUT3: output of divider OSCDIV1.

J SYSCLK1: internal clock output of divider D1.

J SYSCLK2: internal clock output of divider D2.

J SYSCLK3: internal clock output of divider D3.

Refer to your device-specific datasheet on how these inputs and outputs of the

PLL controller are used.

7Phase-Locked Loop (PLL) ControllerSPRU233A

Page 8

Overview

Figure 1. PLL Controller Block Diagram

CLKMODE0

CLKIN

1

PLL controller

Divider D0

÷1, ÷2,...÷32

Reset

0

Divider D1 Divider D2

÷1, ÷2,...÷32

OSCIN

CLKOUT3

OSCDIV1

÷1, ÷2,...÷32

controller

AUXCLK SYSCLK1 SYSCLK2 SYSCLK3

†

See the device-specific datasheet for more details about the PLL.

PLL

PLLM

×1, ×2,...×32

÷1, ÷2,...÷32

†

Divider D3

÷1, ÷2,...÷32

PLLOUT

10

PLLEN

Phase-Locked Loop (PLL) Controller8 SPRU233A

Page 9

2 Functional Description

The following sections describe the multiplier, dividers, and reset controller in

the PLL controller.

2.1 Multiplier and Dividers

The PLL controller is capable of programming the PLL through the PLL multiplier

control register (PLLM) from a ×1 to ×32 multiplier rate (see the device-specific

datasheet for the PLL multiplier rates supported on your device). The clock

dividers (OSCDIV1, D0, D1, D2, and D3) are programmable from ÷1 to ÷32

divider ratio and may be disabled. The oscillator divider enable bit (OD1EN)

in the oscillator divider 1 register (OSCDIV1) determines the oscillator divider

output mode. When OD1EN = 0, the oscillator divider is disabled and no clock

is output; when OD1EN = 1, the oscillator divider is enabled and a clock is output. The divider enable bit (DnEN) in the PLL controller divider registers

(PLLDIVn) determines the divider output mode. When DnEN = 0, the divider

is disabled and no clock is output; when DnEN = 1, the divider is enabled and

a clock is output.

The input reference clock (either CLKIN or OSCIN) is directly output as the

auxiliary clock (AUXCLK) for use by some peripherals. For example, the multichannel audio serial port (McASP) uses AUXCLK to generate audio clocks. In

addition to AUXCLK, the input reference clock is directly input to the oscillator

divider (OSCDIV1). If OSCDIV1 is enabled, OD1EN = 1, the input reference

clock is divided down by the value in the oscillator divider ratio bits (RA TIO) in

OSCDIV1. The output from OSCDIV1 is the output clock CLKOUT3.

Functional Description

The divider D0 and the PLL may also be bypassed. The PLL enable bit

(PLLEN) in the PLL control/status register (PLLCSR) determines the PLL

controller mode. When PLLEN = 1, PLL mode, D0 and PLL are used; when

PLLEN = 0, bypass mode, D0 and PLL are bypassed and the input reference

clock is directly input to dividers D1, D2, and D3.

When in PLL mode (PLLEN = 1), the input reference clock is supplied to divider D0. If D0 is enabled, D0EN =1, the input reference clock is divided down by

the value in the PLL divider ratio bits (RATIO) in PLLDIV0. The output from

divider D0 is input to the PLL. The PLL multiplies the clock by the value in the

PLL multiplier bits (PLLM) in the PLL multiplier control register (PLLM). The

output from the PLL (PLLOUT) is input to dividers D1, D2, and D3.

When enabled (DnEN = 1), the dividers D1, D2, and D3 divide down by the

value in RA TIO in PLLDIVn the output clock of the PLL. The output clocks of

dividers D1, D2, and D3 have 50% duty cycle and are SYSCLK1, SYSCLK2,

and SYSCLK3, respectively .

9Phase-Locked Loop (PLL) ControllerSPRU233A

Page 10

Functional Description

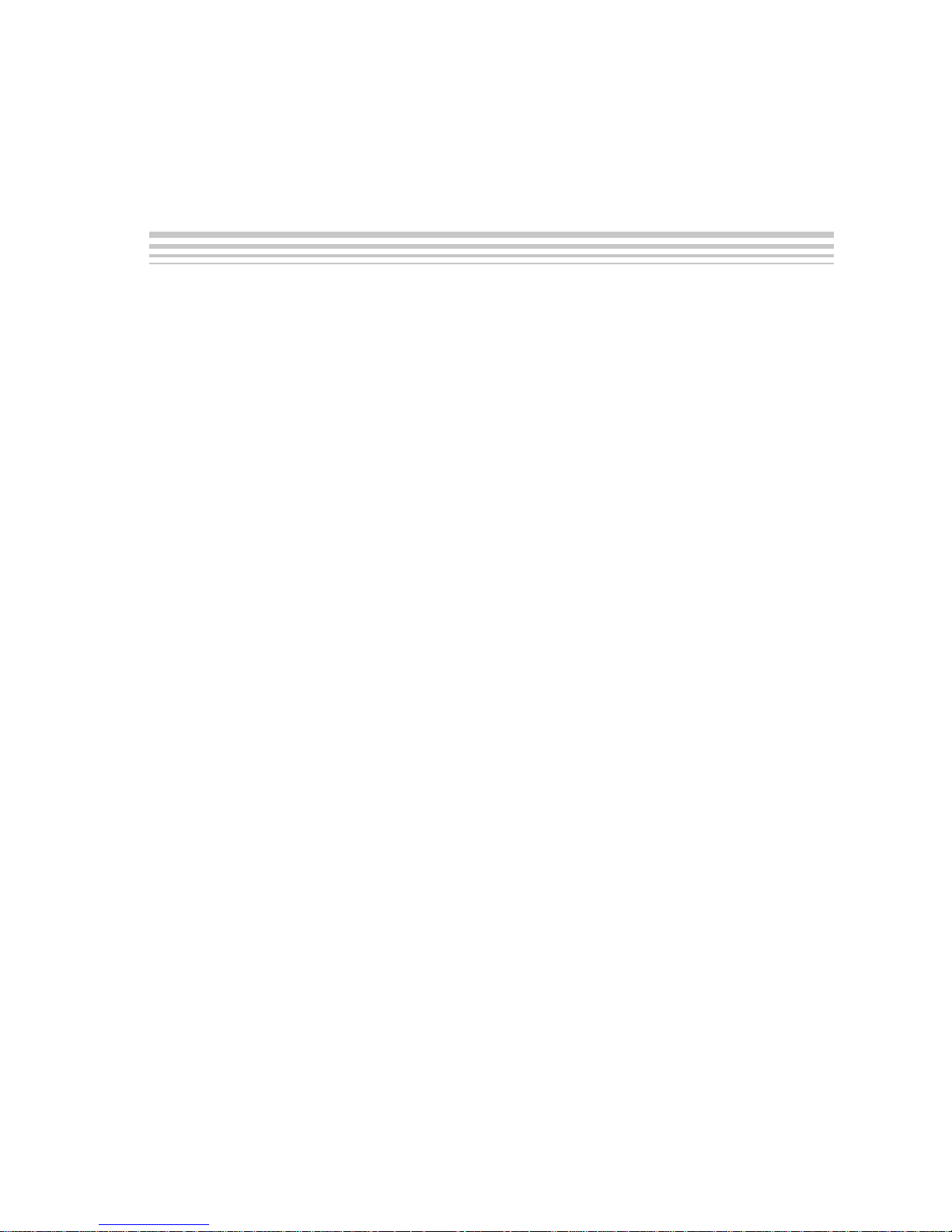

2.2 Reset Controller

At power up, the device RESET signal may not be asserted long enough to

wait for the on-chip or off-chip oscillator to stabilize. This means the input reference clock (either CLKIN or OSCIN) may be a bad clock when a device RESET

signal is deasserted high. After RESET is deasserted, the reset controller

lengthens the asynchronous internal reset signal to ensure that the input clock

source is stable.

The reset controller resides within the PLL controller and the main function is

to internally lengthen the reset signal from the RESET

clock source is stable (after 512 CLKIN cycles or 4096 OSCIN cycles). This

is to ensure that the rest of the device will see the internal reset deasserted only

after the input clock is stabilized. Figure 2 shows the lengthening of the internal

reset signal.

The PLL controller multiplier and dividers are bypassed when the internal reset

signal is low. The frequency of all clock outputs of the PLL controller (AUXCLK,

SYSCLK1, SYSCLK2, SYSCLK3, and CLKOUT3) are fixed to the input

reference clock (CLKIN or OSCIN) divided by 8. After 512 CLKIN cycles or

4096 OSCIN cycles, the reset controller brings the device out of reset and sets

the oscillator input stable bit (STABLE) in the PLL control/status register

(PLLCSR). The dividers are used after this point and are set to their default

divide ratio.

input pin until the input

Values are latched into the registers at the rising edge of RESET

Phase-Locked Loop (PLL) Controller10 SPRU233A

.

Page 11

Figure 2. Reset Controller Lengthening the Internal Reset Signal

Input clock not yet

stabilized. Internal

reset stays asserted.

Register values latched.

N input clock cycles

†

1.2 V CV

Asynchronous

internal reset

Input reference

RESET

Crystal

clock

DD

pin

123

Core power stabilized Device released from reset

Clock may not stabilize yet

†

Invalid

Functional Description

Clock now stable,

STABLE bit asserted

Output clocks are input reference clock/8

with dividers in bypass mode

Output clocks

†

N = 512 × CLKIN cycles when CLKMODE = 1 (input reference clock is CLKIN);

N = 4096 × OSCIN cycles when CLKMODE = 0 (input reference clock is OSCIN)

‡

Output clocks include AUXCLK, SYSCLK1, SYSCLK2, SYSCLK3, and CLKOUT3

‡

Invalid

†

Dividers now used with default

divide ratio. Output clocks are

divider output.

11Phase-Locked Loop (PLL) ControllerSPRU233A

Page 12

Configuration

3 Configuration

The following sections provide procedures for initialization, power down, and

wake up of the PLL controller.

3.1 Initialization

The PLL and PLL controller are to be initialized by software after reset. The

PLL controller registers should be modified only by the CPU or via emulation.

The HPI should not be used to directly access the PLL controller registers. The

initialization of the PLL controller should be performed as soon as possible at

the beginning of the program, before initializing any peripherals. Upon device

reset, one of the following two software initialization procedures must be done

to properly set up the PLL and PLL controller.

3.1.1 PLL Mode (PLLEN = 1)

If the system intends to use divider D0 and PLL, perform the following:

1) In PLLCSR, write PLLEN = 0 (bypass mode).

2) Wait 4 cycles of the slowest of PLLOUT, CLKIN (if CLKMODE = 1), and

OSCIN (if CLKMODE = 0).

3) In PLLCSR, write PLLRST = 1 (PLL is reset).

4) Program PLLDIV0, PLLM, and OSCDIV1.

5) Program PLLDIV1–3. Note that there must be wait states between

accesses to PLLDIV1–3. Each wait state is 8 cycles of the slowest of the

old and new SYSCLK1–3 clock rates. Some devices may also require

users to program the PLLDIV1–3 registers in a particular order, to ensure

no violation of system clock ratios. See PLL Controller section of the

device-specific datasheet for other restrictions.

6) Wait for PLL to properly reset. See device-specific datasheet for PLL reset

time.

7) In PLLCSR, write PLLRST = 0 to bring PLL out of reset.

8) Wait for PLL to lock. See device-specific datasheet for PLL lock time.

9) In PLLCSR, write PLLEN = 1 to enable PLL mode.

Steps 1, 2, and 3 are required when PLLEN and PLLRST bits are not already

0 and 1, respectively . These steps are not required when the device is coming

out of reset (they are performed by hardware).

Phase-Locked Loop (PLL) Controller12 SPRU233A

Page 13

3.1.2 Bypass Mode (PLLEN = 0)

If the system intends to bypass divider D0 and PLL, perform the following:

1) In PLLCSR, write PLLEN = 0 (bypass mode).

2) Wait 4 cycles of the slowest of PLLOUT, CLKIN (if CLKMODE = 1), and

OSCIN (if CLKMODE = 0).

3) In PLLCSR, write PLLRST = 1 (PLL is reset).

4) Program OSCDIV1.

5) Program PLLDIV1–3. Note that there must be wait states between

accesses to PLLDIV1–3. Each wait state is 8 cycles of the slowest of the

old and new SYSCLK1–3 clock rates. See PLL Controller section of the

device-specific datasheet for other restrictions.

Steps 1, 2, and 3 are required when PLLEN and PLLRST bits are not already

0 and 1, respectively . These steps are not required when the device is coming

out of reset (they are performed by hardware).

Configuration

3.2 Power Down

The PLL may be powered down, in which case the PLL controller is in bypass

mode and the DSP runs from a divided down version of the input reference clock.

The DSP is still able to respond to events because it is still being clocked by the

bypass clock (directly from CLKIN or OSCIN), although at a lower frequency.

Perform the following procedure to power down the PLL:

1) In PLLCSR, write PLLEN = 0 (bypass mode).

2) Wait 4 cycles of the slowest of PLLOUT, CLKIN (if CLKMODE = 1), and

3) In PLLCSR, write PLLPWRDN = 1 to power down the PLL.

OSCIN (if CLKMODE = 0).

13Phase-Locked Loop (PLL) ControllerSPRU233A

Page 14

Registers

Configuration / Registers

3.3 Power Wake Up

Perform the following procedure to wake up the PLL from its power-down mode:

1) In PLLCSR, write PLLEN = 0 (bypass mode).

2) Wait 4 cycles of the slowest of PLLOUT, CLKIN (if CLKMODE = 1), and

OSCIN (if CLKMODE = 0).

3) In PLLCSR, write PLLPWRDN = 0 to wake up the PLL.

4) Follow the reset sequence described in section 3.1.

4 Registers

The PLL controller registers configure the operation of the PLL controller. The

PLL controller registers are listed in T able 1. See the device- specifi c datashe et

for the memory address of these registers.

Table 1. PLL Controller Registers

Acronym Register Name Section

PLLPID PLL controller peripheral identification register 4.1

PLLCSR PLL control/status register 4.2

PLLM PLL multiplier control register 4.3

PLLDIV0–3 PLL controller divider registers 4.4

OSCDIV1

Oscillator divider 1 register 4.5

Phase-Locked Loop (PLL) Controller14 SPRU233A

Page 15

Registers

4.1 PLL Controller Peripheral Identification Register (PLLPID)

The PLL controller peripheral identification register (PLLPID) contains identification code for the PLL controller . PLLPID is shown in Figure 3 and described

in Table 2.

Figure 3. PLL Controller Peripheral Identification Register (PLLPID)

31 24 23 16

Reserved

R-0 R-0000 0001

15 8 7 0

CLASS REV

R-0000 1000 R-x

Legend: R = Read only; -x = value after reset

†

See the device-specific datasheet for the default value of this field.

TYPE

†

Table 2. PLL Controller Peripheral Identification Register (PLLPID) Field Descriptions

Bit field

31–24 Reserved – 0 These reserved bit locations are always read as 0. A value written

23–16 TYPE OF(value) Identifies type of peripheral.

15–8

7–0

†

For CSL implementation, use the notation PLL_PID_field_symval

†

CLASS OF(value) Identifies class of peripheral.

REV OF(value) Identifies revision of peripheral.

symval†Value Description

to this field has no effect.

10h PLL controller

1 Serial port

x See the device-specific datasheet for the value.

15Phase-Locked Loop (PLL) ControllerSPRU233A

Page 16

Registers

4.2 PLL Control/Status Register (PLLCSR)

The PLL control/status register (PLLCSR) is shown in Figure 4 and described

in Table 3.

Figure 4. PLL Control/Status Register (PLLCSR)

31 16

Reserved

R-0

15 7 6 5 4 3 2 1 0

Reserved

R-0 R-1 R/W-0 R/W-1 R/W-0 R/W-0 R/W-0

Legend: R = Read only; R/W = Read/write; -n = value after reset

STABLE Reserved PLLRST — PLLPWRDN PLLEN

Table 3. PLL Control/Status Register (PLLCSR) Field Descriptions

Bit field

31–7 Reserved – 0 Reserved. The reserved bit location is always read as 0. A

6 STABLE OF(value) Oscillator input stable bit indicates if the OSCIN/CLKIN input

5–4 Reserved – 0 Reserved. The reserved bit location is always read as 0.

3 PLLRST PLL reset bit.

2 Reserved – 0 Reserved. The reserved bit location is always read as 0.

†

For CSL implementation, use the notation PLL_PLLCSR_field_symval

†

†

symval

0 0 PLL reset is released.

1 1 PLL reset is asserted.

Value Description

value written to this field has no effect.

has stabilized. The ST ABLE bit is set to 1 after the reset

controller counts 4096 input clock cycles after the RESET

signal is asserted high.

0 OSCIN/CLKIN input is not yet stable. Oscillator counter is not

finished counting.

1 OSCIN/CLKIN input is stable.

Always write a 0 to this location.

Always write a 0 to this location.

Phase-Locked Loop (PLL) Controller16 SPRU233A

Page 17

Table 3. PLL Control/Status Register (PLLCSR) Field Descriptions (Continued)

Registers

Bit

field

†

†

DescriptionValuesymval

1 PLLPWRDN PLL power-down mode select bit.

NO 0 PLL is operational.

YES 1 PLL is placed in power-down state.

0 PLLEN PLL enable bit.

BYPASS 0 Bypass mode. Divider D0 and PLL are bypassed.

SYSCLK1/SYSCLK2/SYSCLK3 are divided down directly from

input reference clock.

ENABLE 1 PLL mode. PLL output path is enabled. Divider D0 and PLL are

not bypassed. SYSCLK1/SYSCLK2/SYSCLK3 are divided

down from PLL output.

†

For CSL implementation, use the notation PLL_PLLCSR_field_symval

17Phase-Locked Loop (PLL) ControllerSPRU233A

Page 18

Registers

4.3 PLL Multiplier Control Register (PLLM)

The P LL multiplier control register (PLLM) is shown in Figure 5 and described

in Table 4. The PLL M defines the input reference clock frequency multiplier in

conjunction with the PLL divider ratio bits (RA TIO) in the PLL controller divider 0 register (PLLDIV0).

Figure 5. PLL Multiplier Control Register (PLLM)

31 16

Reserved

R-0

15 5 4 0

Reserved

R-0 R/W-0 0111

Legend: R = Read only; R/W = Read/write; -n = value after reset

PLLM

Table 4. PLL Multiplier Control Register (PLLM) Field Descriptions

Bit Field symval

31–5 Reserved – 0 Reserved. The reserved bit location is always read as 0. A value

4–0 PLLM OF(value) 0–1Fh PLL multiplier bits. Defines the frequency multiplier of the input

†

For CSL implementation, use the notation PLL_PLLM_PLLM_symval

†

Value Description

written to this field has no effect.

reference clock in conjunction with the PLL divider ratio bits

(RATIO) in PLLDIV0. See the device-specific datasheet for the

PLL multiplier rates supported on your device.

Phase-Locked Loop (PLL) Controller18 SPRU233A

Page 19

Registers

4.4 PLL Controller Divider Registers (PLLDIV0–3)

The P LL c ont rol ler d iv ide r reg ist er (P LL DIV ) is shown in Figure 6 and described

in Table 5.

Figure 6. PLL Controller Divider Register (PLLDIV)

31 16

Reserved

R-0

15 14 5 4 0

DnEN

R/W-1 R-0 R/W-0

Legend: R = Read only; R/W = Read/write; -n = value after reset

†

For PLLDIV0 and PLLDIV1; for PLLDIV2 and PLLDIV3, reset value is 0 0001.

Reserved RATIO

†

Table 5. PLL Controller Divider Register (PLLDIV) Field Descriptions

Bit field

31–16 Reserved – 0 Reserved. The reserved bit location is always read as 0. A value

15 DnEN Divider Dn enable bit.

14–5 Reserved – 0 Reserved. The reserved bit location is always read as 0. A value

4–0 RA TIO OF(value) PLL divider ratio bits. For PLLDIV0, defines the input reference

†

For CSL implementation, use the notation PLL_PLLDIVn_field_symval

†

symval

DISABLE 0 Divider n is disabled. No clock output.

ENABLE 1 Divider n is enabled.

†

Value Description

written to this field has no effect.

written to this field has no effect.

clock frequency multiplier in conjunction with the PLL multiplier

bits (PLLM) in PLLM. For PLLDIV1–3, defines the PLL output

clock frequency divider ratio.

0 ÷1. Divide frequency by 1.

1h ÷2. Divide frequency by 2.

2h–1Fh ÷3 to ÷32. Divide frequency by 3 to divide frequency by 32.

19Phase-Locked Loop (PLL) ControllerSPRU233A

Page 20

Registers

4.5 Oscillator Divider 1 Register (OSCDIV1)

The oscillator divider 1 register (OSCDIV1) is shown in Figure 7 and described

in Table 6.

Figure 7. Oscillator Divider 1 Register (OSCDIV1)

31 16

Reserved

R-0

15 14 5 4 0

OD1EN Reserved RATIO

R/W-1 R-0 R/W-0 0111

Legend: R = Read only; R/W = Read/write; -n = value after reset

Table 6. Oscillator Divider 1 Register (OSCDIV1) Field Descriptions

Bit field

31–16 Reserved – 0 Reserved. The reserved bit location is always read as 0. A value

15 OD1EN Oscillator divider 1 enable bit.

14–5 Reserved – 0 Reserved. The reserved bit location is always read as 0. A value

4–0 RA TIO OF(value) Oscillator divider 1 ratio bits. Defines the input reference clock

†

For CSL implementation, use the notation PLL_OSCDIV1_field_symval

†

†

symval

DISABLE 0 Oscillator divider 1 is disabled. No clock output.

ENABLE 1 Oscillator divider 1 is enabled.

Value Description

written to this field has no effect.

written to this field has no effect.

frequency divider ratio for output clock CLKOUT3.

0 ÷1. Divide input reference clock frequency by 1.

1h ÷2. Divide input reference clock frequency by 2.

2h–1Fh ÷3 to ÷32. Divide input reference clock frequency by 3 to divide

input reference clock frequency by 32.

Phase-Locked Loop (PLL) Controller20 SPRU233A

Page 21

Index

Index

B

block diagram 8

C

CLASS bits 15

configuration 12

initialization 12

power down 13

wake up 14

D

DnEN bit 19

F

functional description 9

dividers 9

multiplier 9

reset controller 10

I

initialization 12

N

notational conventions 3

O

OD1EN bit 20

OSCDIV1 20

oscillator divider 1 register (OSCDIV1) 20

overview 7

P

PLL control/status register (PLLCSR) 16

PLL controller divider register (PLLDIV) 19

PLL controller peripheral identification register

(PLLPID) 15

PLL multiplier control register (PLLM) 18

PLLCSR 16

PLLDIV 19

PLLEN bit 16

PLLM 18

PLLM bits 18

PLLPID 15

PLLPWRDN bit 16

PLLRST bit 16

power down 13

R

RATIO bits

in OSCDIV1 20

in PLLDIV 19

registers 14

control/status register (PLLCSR) 16

controller divider register (PLLDIV) 19

multiplier control register (PLLM) 18

oscillator divider 1 register (OSCDIV1) 20

peripheral identification register (PLLPID) 15

related documentation from Texas Instruments 3

REV bits 15

21Phase-Locked Loop (PLL) ControllerSPRU233A

Page 22

Index

S

ST ABLE bit 16

T

trademarks 4

TYPE bits 15

W

wake up 14

22 Phase-Locked Loop (PLL) Controller SPRU233A

Loading...

Loading...