Page 1

Interfacing the TLV1562

Parallel ADĆConverter to the

TMS320C54x DSP

Application

Report

July 1999 Advanced Analog Products

SLAA040

Page 2

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Page 3

Contents

1 Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 The Board 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 TMS320C54x Starter Kit 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 TLV1562EVM 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 ADC TLV1562 Overview 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Suggestions for the ’C54x to TLV1562 Interface 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Recyclic Architecture 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Note on the Interface, Using an External ADC Clock Drive 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Onboard Components 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 TLC5618 – Serial DAC 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 TLV5651 – Parallel DAC 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Operational Overview 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Reference Voltage Inputs 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Input Data Bits 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Connections Between the DSP and the EVM 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Jumpers Used on the TLV1562EVM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 The Serial DAC/DSP System 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 The DSP Serial Port 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Other DSP/TLV1562 Signals 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 DSP Internal Serial Port Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Conversation Between the TLV1562 and the DSP 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Writing to the ADC 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Mono Interrupt Driven Mode Using RD

7.3 Mono Interrupt Driven Mode Using CSTART

7.4 Dual Interrupt Driven Mode 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Mono Continuous Mode 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Dual Continuous Mode 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Software Overview 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Software Development tools 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

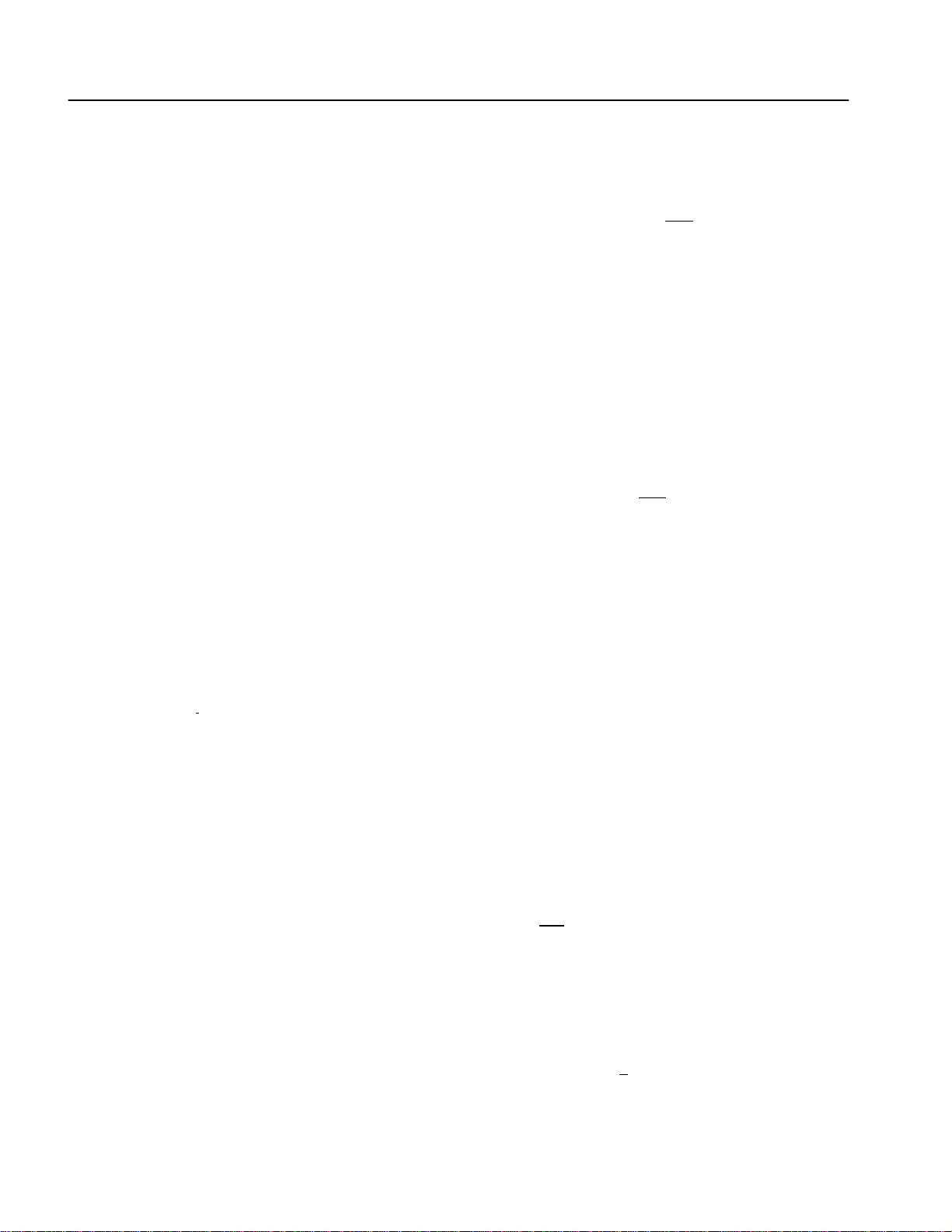

8.2 DSP Memory Map 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Programming Strategies for the ’C54x, Explanations 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Optimizing CPU Resources for Maximum Data Rates 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Address and Data Bus for I/O Tasks 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Timer Output 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Data Page Pointer 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.5 Generating the Chip Select Signal and the CSTART

8.3.6 Interfacing the Serial DAC 5618 to the DSP 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.7 Interrupt Latency 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.8 Branch Optimization (goto/dgoto, call/dcall, ...) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.9 Enabling Software Modules (.if/.elseif/.endif) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Software Code Explanation 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Software Principals of the Interface 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Flow Charts and Comments for All Software Modes 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 The Mono Interrupt Driven Mode Using RD

8.5.2 Mono Interrupt Driven Mode Using CSTART

8.5.3 Dual Interrupt Driven Mode 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.4 Mono Continuous Mode 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to Start Conversion 27. . . . . . . . . . . . . . . . . . . . . . . .

to Start Conversion 30. . . . . . . . . . . . . . . . . . . . . . .

Signal 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interfacing the TLV1562 Parallel AD-Converter to the TMS320C54x DSP

iii

Page 4

Contents

8.5.5 Dual Continuous Mode 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.6 C-Callable With Mono Interrupt Driven Mode Using CSTART

to Start Conversion 40. . . . . . . . .

8.6 Source Code 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 Common Software for all Modes (except C-Callable) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Mono Mode Interrupt Driven Software Using RD

to Start Conversion 46. . . . . . . . . . . . . . . . . . . .

8.6.3 Calibration of the ADC 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.4 Mono Mode Interrupt Driven Software Using CSTART

to Start Conversion 58. . . . . . . . . . . . . . .

8.6.5 Dual Interrupt Driven Mode 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.6 Mono Continuous Mode 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.7 Dual Continuous Mode 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.8 C-Callable 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Summary 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 References 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

SLAA040

Page 5

Figures

List of Figures

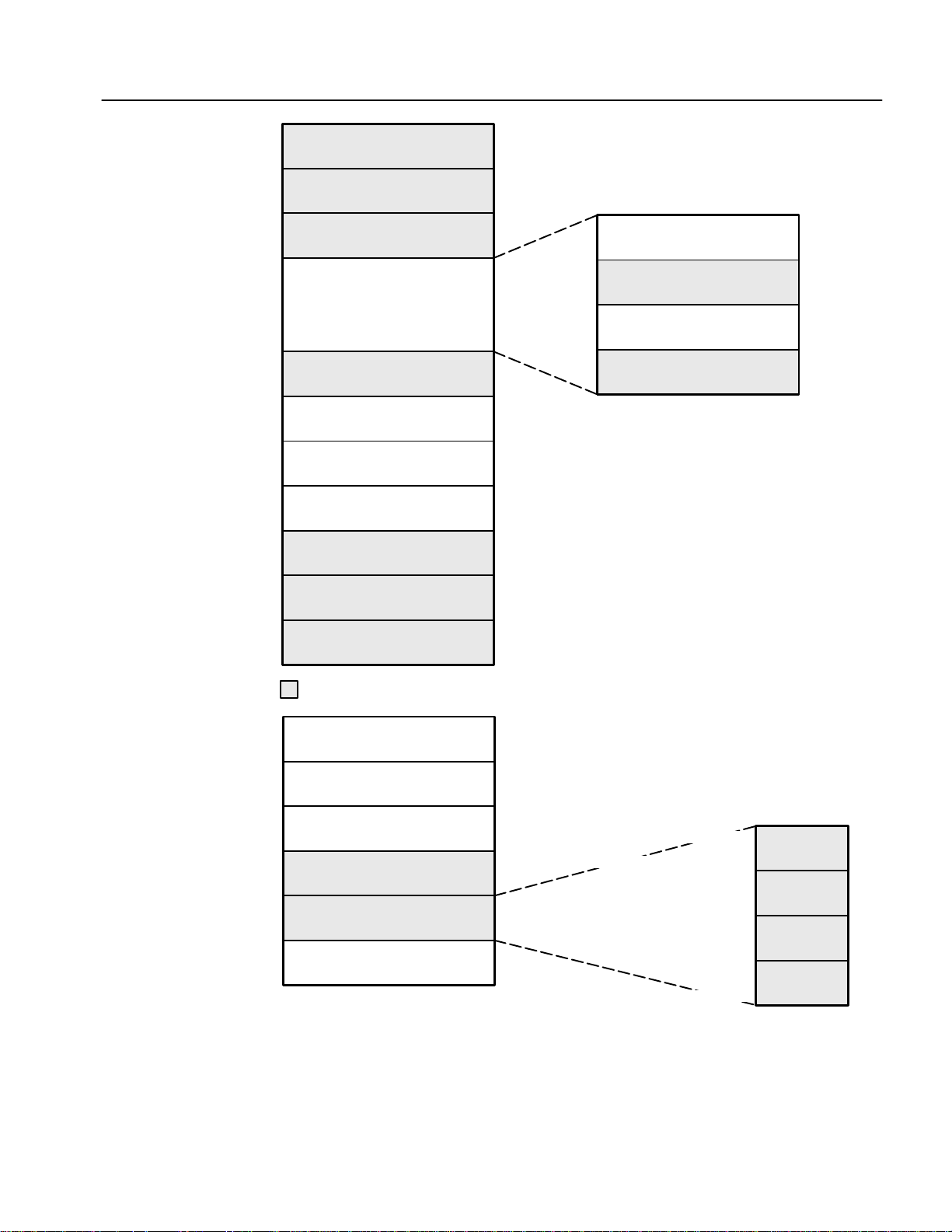

1 TLV1562 – DSP Interface of the EVM, Using RD or the CSTART Signal to Start Conversion 2. . . . . . . . . . . . . . .

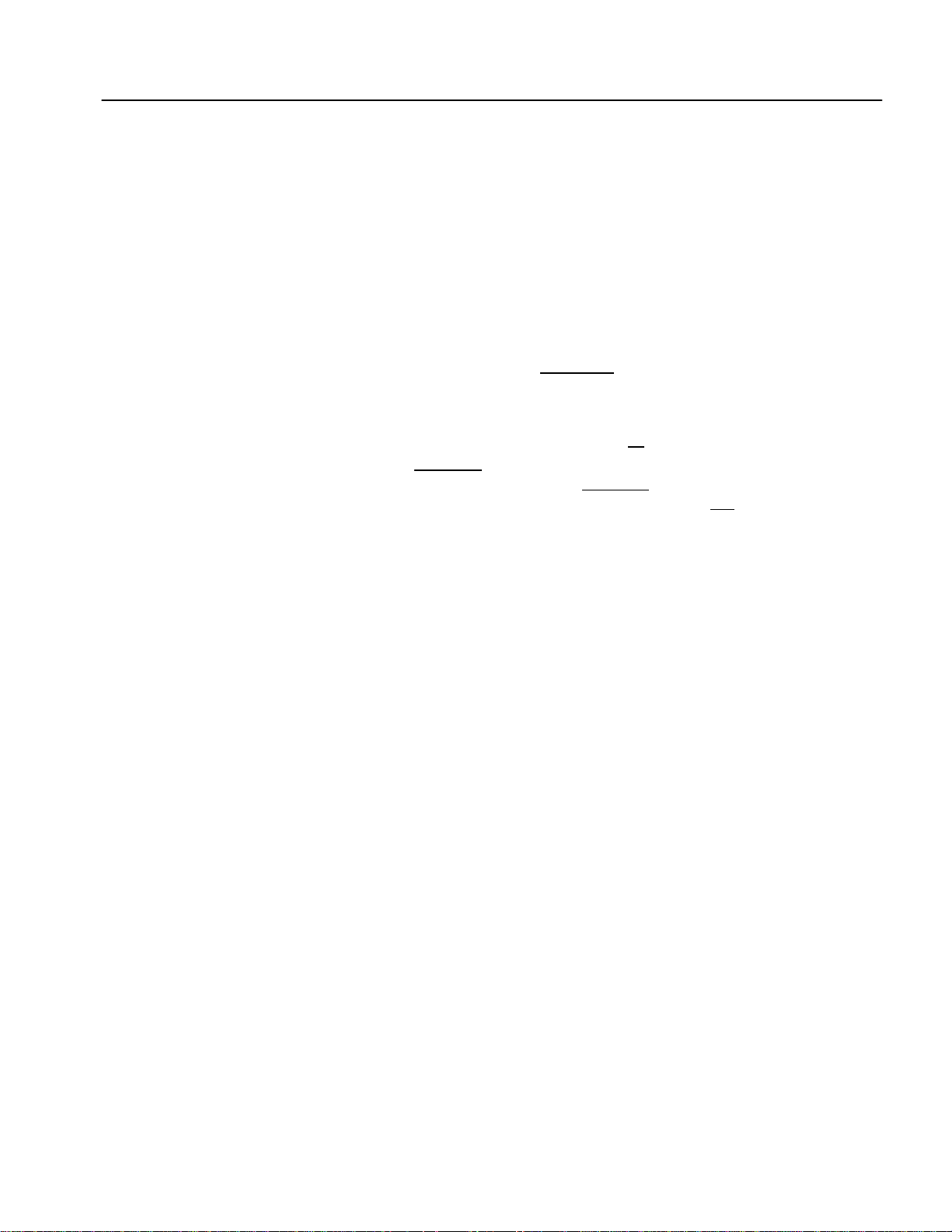

2 TLV1562 – DSP Interface of the EVM, Using RD

3 TLC5618 – DSP Interface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 TLC5651 – DSP Interface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Memory Map 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Software Flow of the Mono Interrupt Driven Solution 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Flow Chart Mono Interrupt Driven Mode Using CSTART

8 Time Optimization (monocst1) Maximum Performance at 12 MSPS with Internal Clock 33. . . . . . . . . . . . . . . . . . .

9 Flow Chart Dual Interrupt Driven Mode (Using CSTART

10 Flow Chart Mono Continuous Mode 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Flow Chart Dual Continuous Mode 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

or the CSTART Signal to Start Conversion 3. . . . . . . . . . . . . . .

to Start Conversion 31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

) to Start Conversion 35. . . . . . . . . . . . . . . . . . . . . . . . . . .

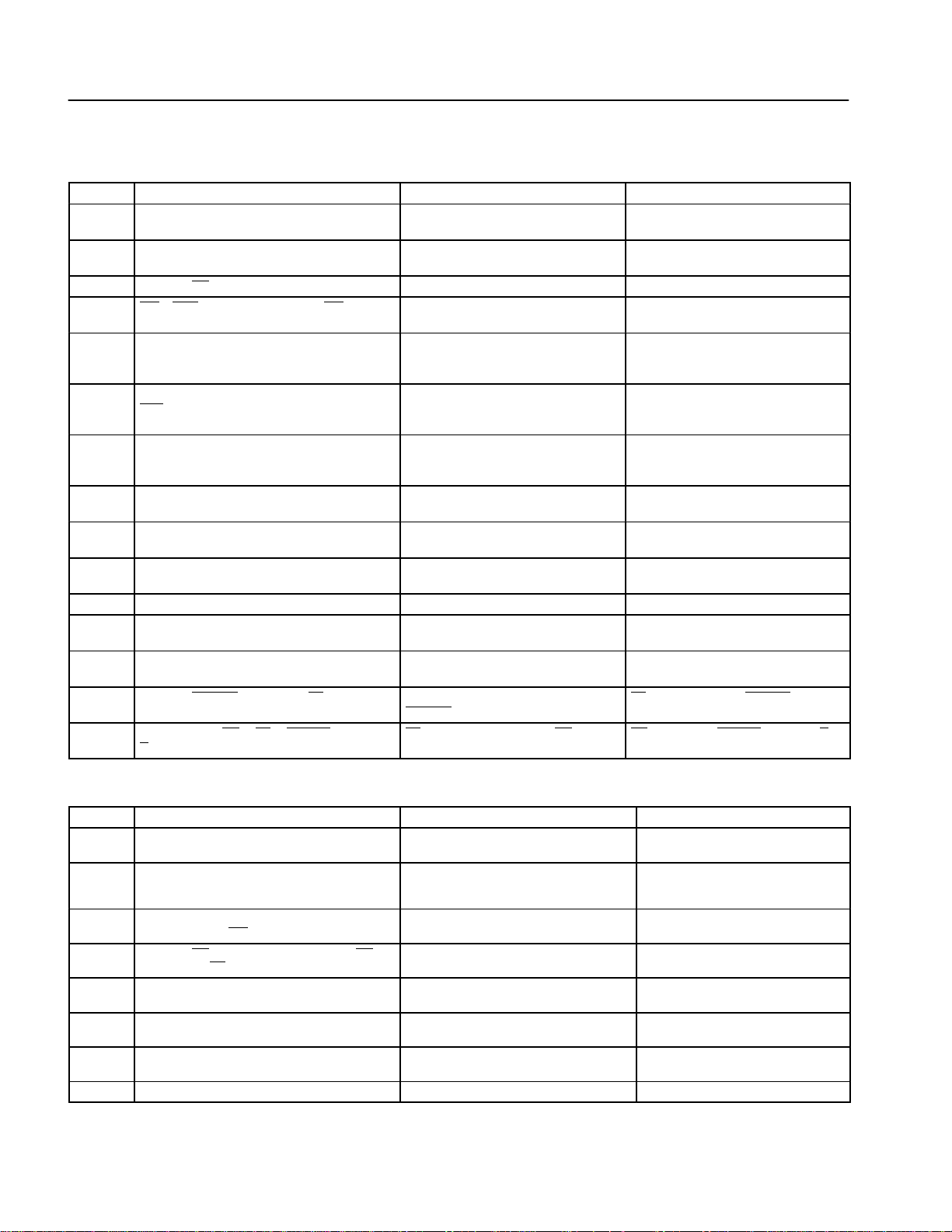

List of Tables

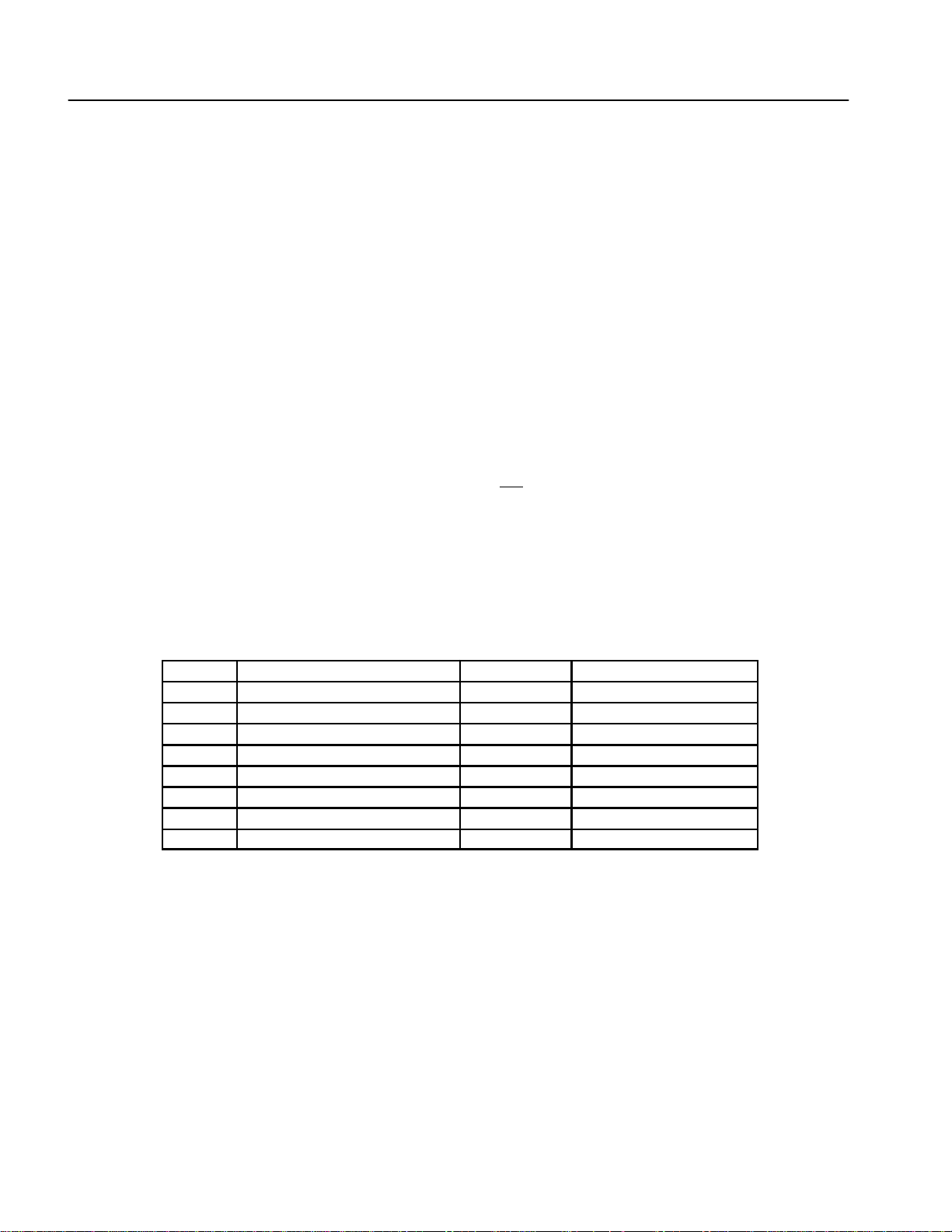

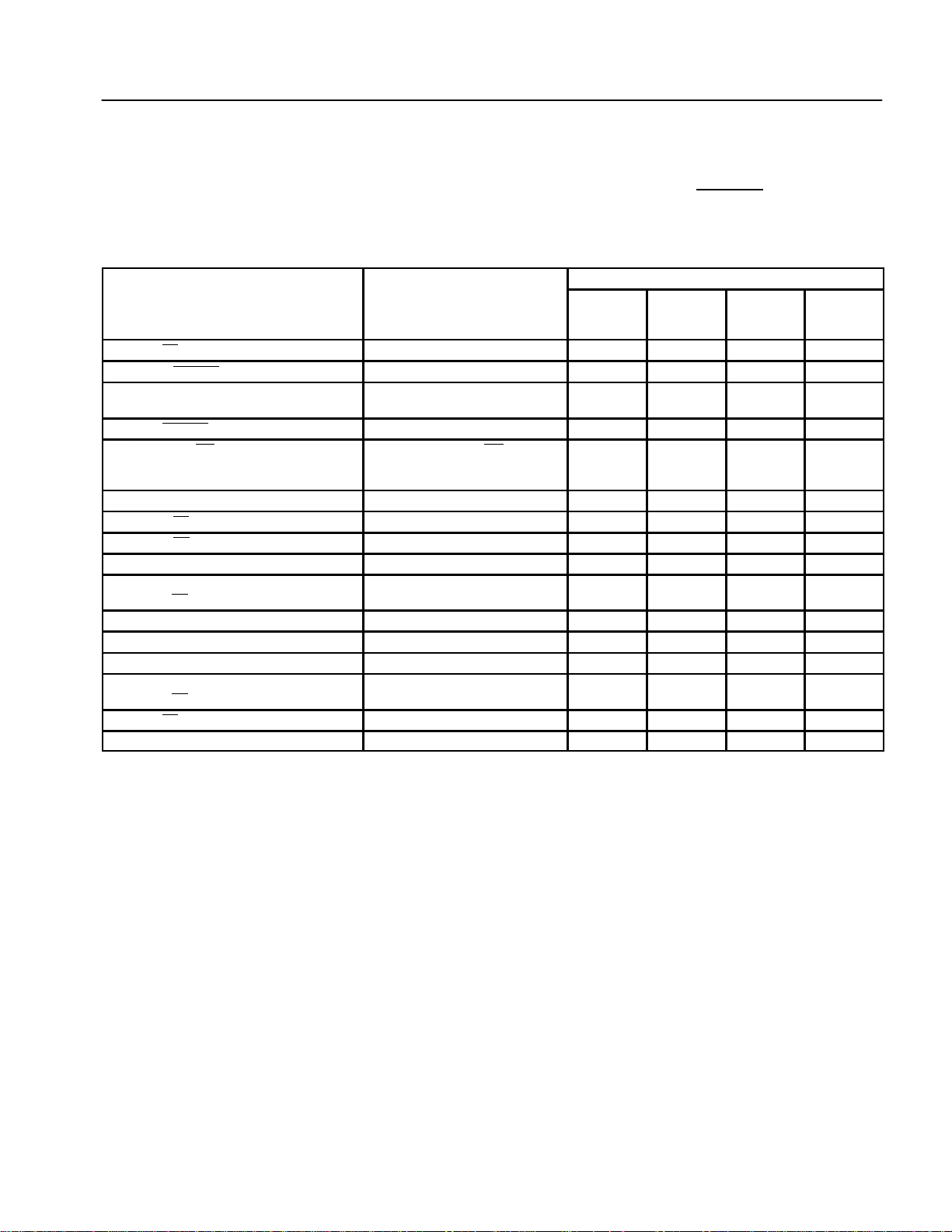

1 Signal Connections 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 3-Position Jumpers 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 2-Position Jumpers 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 DSP/DAC Interconnection 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 DSP Serial Port Signals and Registers 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 DSP Algorithm for Writing to the ADC 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 DSP Algorithm for Mono Interrupt Driven Mode Using RD

8 DSP Algorithm for Mono Interrupt Driven Mode Using CSTART

9 DSP Algorithm for Dual Interrupt Driven Mode 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 DSP Algorithm for Mono Continuous Mode 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 DSP Algorithm for Dual Continuous Mode 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Switch Settings 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Instruction in the Program Header (Step 1) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 Instruction in the Program Header (Step 1) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interfacing the TLV1562 Parallel AD-Converter to the TMS320C54x DSP

v

Page 6

vi

SLAA040

Page 7

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

Falk Alicke and Perry Miller

ABSTRACT

In this application report we discuss the hardware and software interface of the TL V1562,

10-bit parallel-output analog-to-digital converter (ADC) to the TMS320C54x digital signal

processor (DSP).

consists of the TLV1562 10-bit ADC, a THS5651 10-bit parallel output

communication digital-to-analog converter (CommsDAC) and a TLC5618A

serial-output digital-to-analog converter (DAC).

Following the discussion of the ADC we explain the need for both the THS5651

CommsDAC and the TLC5618A serial DAC.

The application report concludes with several software application examples and

recommendations for simplifying the software through modifications of the DSP

hardware interface circuit.

1 Introduction

The analog-to-digital (A/D) interface can present a significant design problem

because hardware and software must work together across the interface to

produce a usable, complete design. This application report provides a design

solution for the interface between the TLV1562 10-bit parallel-output

analog-to-digital converter (ADC) and the TMS320C54x digital signal processor

(DSP).

The report describes the hardware and software needed to interface the ’C54x

DSP to the TL V1562 ADC, which is intended for applications, such as industrial

control and signal intelligence in which large amounts of data must be processed

quickly. The first sections describe the basic operation of the TLV1562. For

additional information see the References section at the end of this report.

The hardware interface board, or evaluation module (EVM)

2 The Board

The TL V1562 evaluation module (EVM) is a four-layer printed circuit board (PCB)

constructed from FR4 material. The PCB dimensions are 180 mm × 112 mm ×

12 mm. Ribbon cables are used to interface the TLV1562EVM to the

TMS320C54x DSK plus starter kit.

2.1 TMS320C54x Starter Kit

The starter kit simplifies the task of interfacing to the ’C54x processor. It comes

with an ADC for voice bandwidth, and GoDSP code explorer as the software tool.

A 10-MHz oscillator provides the clock signal to allow 40-MHz internal DSP clock

cycles generated by the internal DSP PLL. Therefore, the board provides 40

MIPS of processing power.

Ribbon cables are used to connect the DSP with the EVM. Detailed descriptions

of all connections are given later in this report.

CommsDAC is a trademark of Texas Instruments.

1

Page 8

The Board

2.2 TLV1562EVM

The TLV1562EVM gives customers an easy start with employing many of the

features of this converter. A serial DAC (TLC5618A), a parallel DAC (THS5651),

and the ADC (TL V1562) make this EVM flexible enough to test the features of the

TLV1562. It also helps show how this ADC can be implemented.

2.3 ADC TLV1562 Overview

The TL V1562 is a CMOS 10-bit high-speed programmable resolution analog-todigital converter, using a low-power recyclic architecture.

The converter provides two differential or four single-ended inputs to interface the

analog input signals.

On the digital side, the device has a chip-select (CS

sample/conversion start signal (CSTART

input (WR

), and 10 parallel data I/O lines (D9:0).

The converter integrates the CSTART

), read signal input (RD), write signal

signal to coordinate sampling and

conversion timing without using the parallel bus. Since the TMS320C542 DSP

has no second general-purpose output, this signal is generated with the signal

(CSTART

) from the address decoder.

2.3.1 Suggestions for the ’C54x to TLV1562 Interface

The following paragraphs describe two suggested interfaces between the ’C54x

and the TLV1562.

2.3.1.1 The Universal Interface

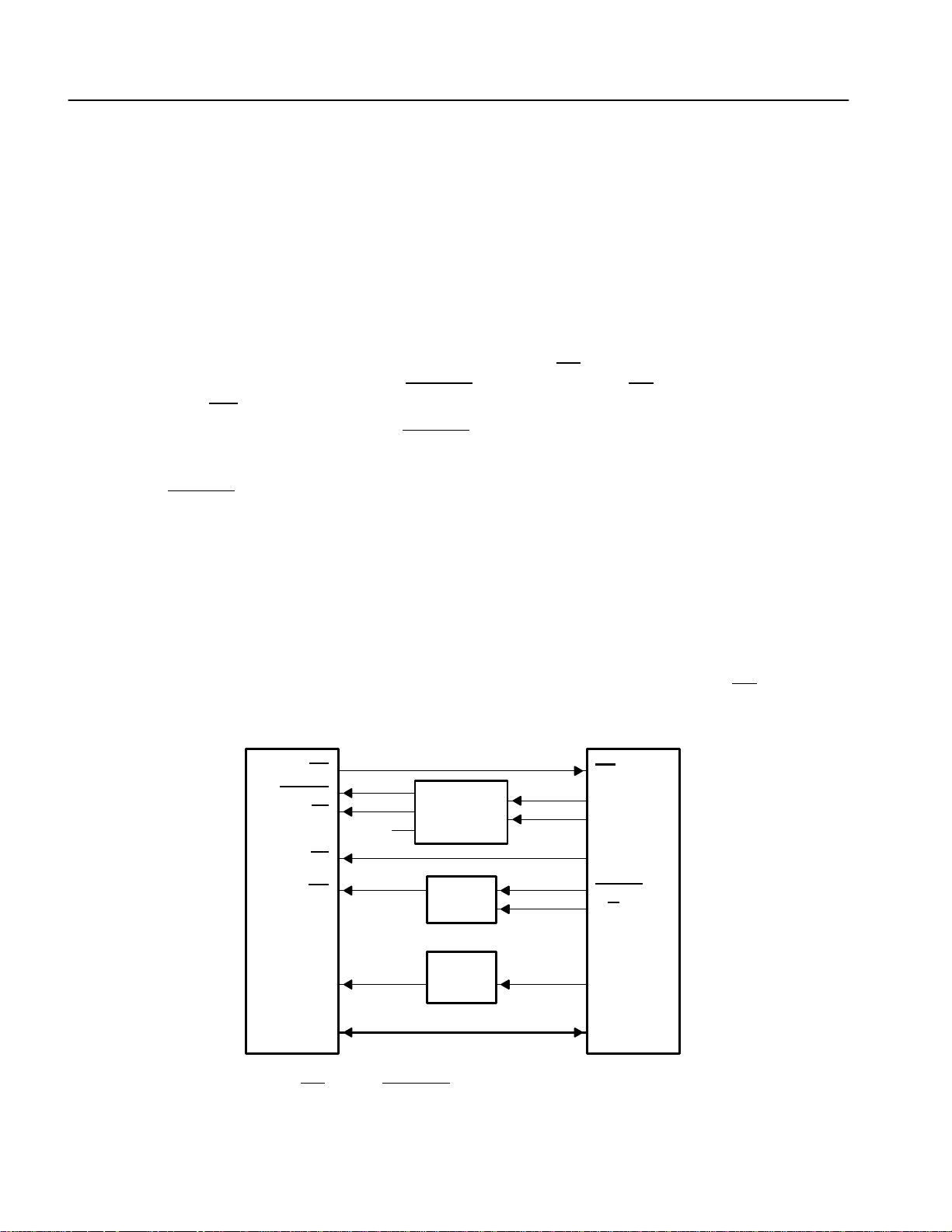

The schematic in Figure 1 shows the pin-to-pin connections between the

TL V1562 and ’C54x, realized on the EVM. This routing can test the converter in

each mode. One I/O-wait state is required for write operations to the ADC. The

read sequence from the ADC does not require any wait states because the RD

signal is generated with XF.

TLV1562 TMS320C54x

INT

CSTART

CS

01

10

11

Address

Decoder

), input clock (CLKIN),

INT

A0

A1

2 SLAA040

RD

WR

CLKIN

D(0–9) D(0–9)

≥ 1

1: x

Divider

XF

IOSTRB

R/W

CLOCKOUT

Figure 1. TLV1562 to ’C54x DSP Interface of the EVM,

Using RD or the CSTART Signal to Start Conversion

Page 9

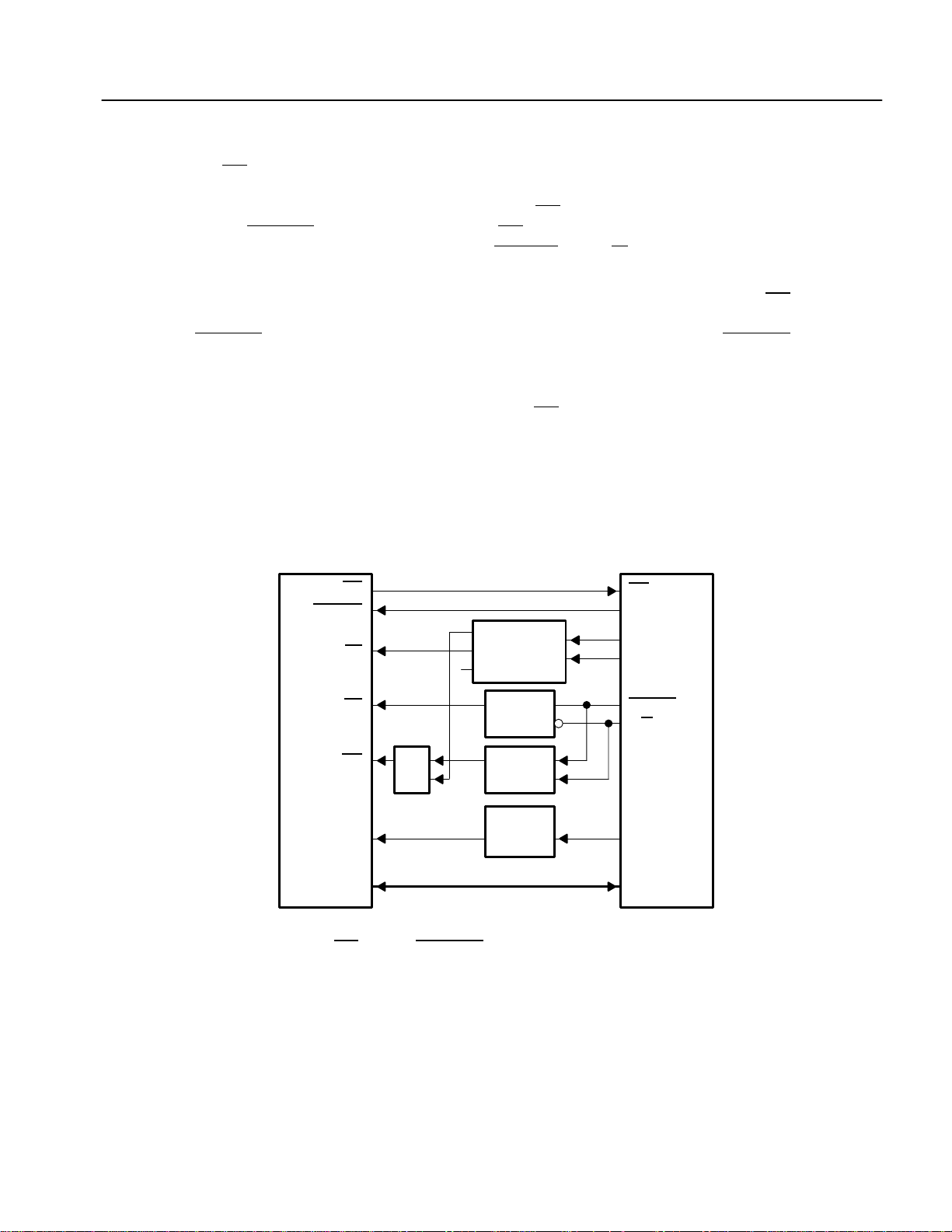

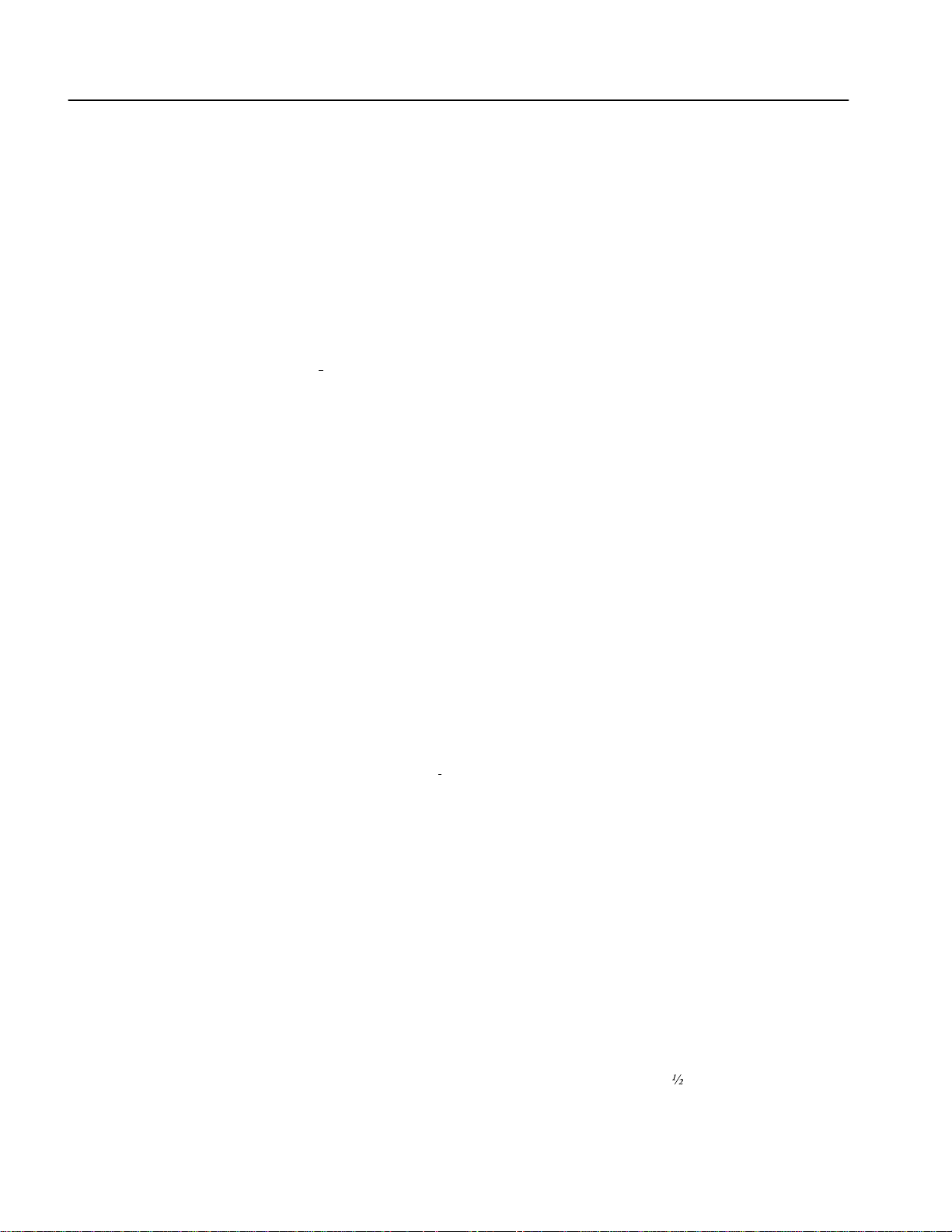

2.3.1.2 Simplification of Software Requirements Through Modified Interface

Of all the TL V1562 modes of operation, only the mono interrupt driven mode uses

the RD

signal to start the conversion. This requires a very flexible handling of the

read signal and therefore has to be performed by a general-purpose output

signal. If the application excludes using the RD

(using CSTART

instead). The TLV1562 RD input signal can be generated with

an OR gate, whose inputs are driven by IOSTRB

signal to start the conversion

and R/W signals from the DSP

(see Figure 2).

Using these connections saves the programming steps of setting/resetting RD

with the XF signal. Another advantage is having XF available to control the

CSTART

signal. This saves busy times on the address bus (in Figure 1, CST ART

was generated through A0/A1.) and simplifies the software code.

CAUTION:

The time t

EN(DATAOUT)

between the RD high-to-low transition

(generated by the DSP) and the arrival of valid ADC output

data on the data bus is related to the capacitive load of the

bus. In most cases, the ADC come out of the 3-state mode

and supplies the correct voltage levels onto the bus lines in

less than 50 ns. Thus, the minimum number of I/O-wait states

becomes two (for t

TLV1562 TMS320C54x

INT

CSTART

CS

EN(DATAOUT)

01

10

11

≤50 ns).

Address

Decoder

INT

XF

A0

A1

The Board

CLKIN

D(0–9) D(0–9)

Figure 2. TLV1562 to ’C54x DSP Interface of the EVM,

Using RD

2.3.2 Recyclic Architecture

One specialty of this ADC is its recyclic architecture. Instead of limiting the device

power by the highest possible resolution at the fastest speed, this converter is

able to work at three maximum speeds for three resolutions. The highest

resolution runs at 2MSPS maximum throughput rate; 8-bit resolution

corresponds to 3MSPS, and 4-bit resolution to 7MSPS.

RD

WR

≥ 1

&

≥ 1

1: x

Divider

IOSTRB

R/W

CLOCKOUT

or the CSTART Signal to Start Conversion

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

3

Page 10

The Board

This feature fits well into monitoring application. For example, the ADC may have

to trigger on one event out of some channels inside an extremely small time

window and then sample the correct channel with a higher resolution, but lower

throughput to analyze this process. This feature also fits well into home security

applications or applications that must monitor several inputs simultaneously.

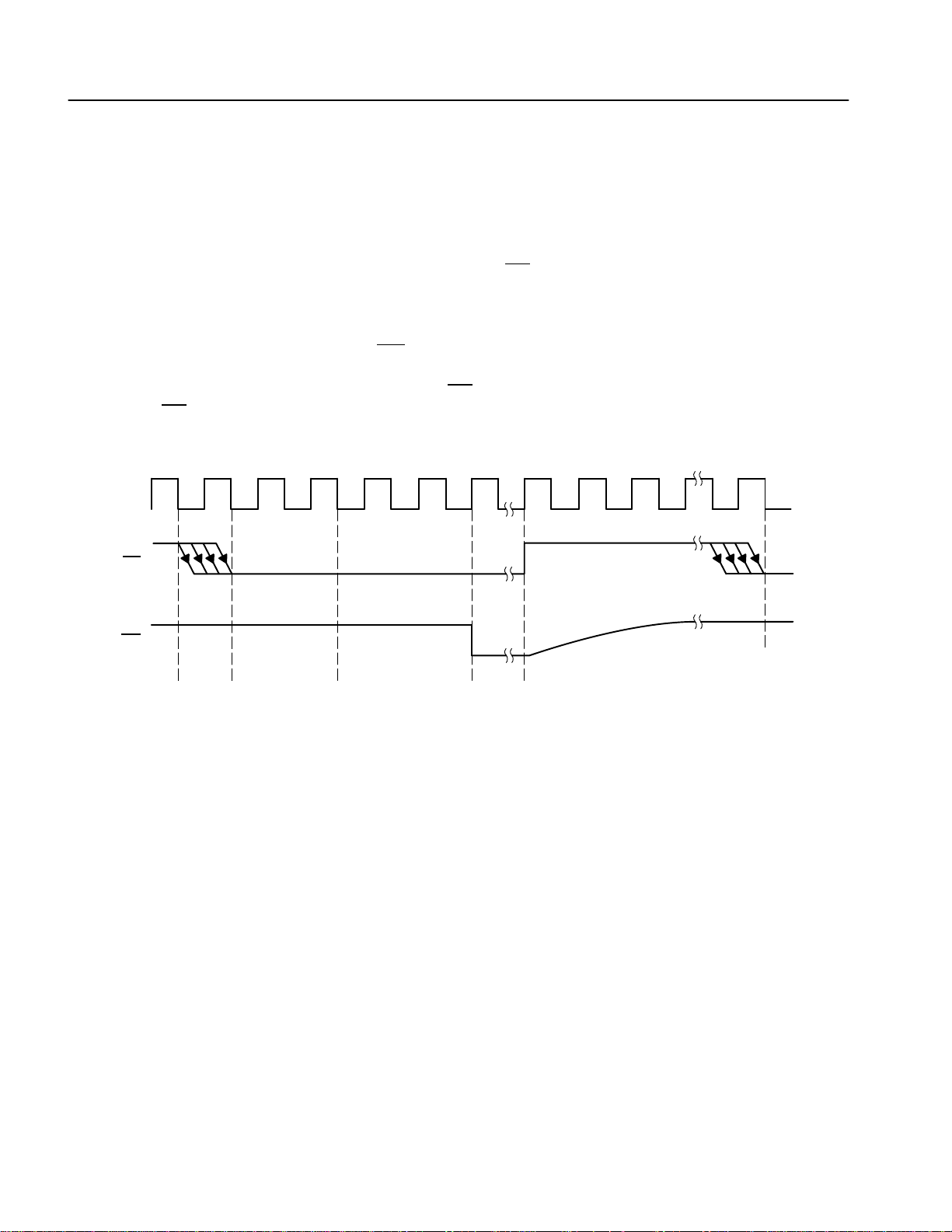

2.3.3 Note on the Interface, Using an External ADC Clock Drive

The TL V1562data sheet (Figure 9) shows that RD has to fall as close as possible

to the falling edge of the clock signal. The user must adhere to this timing,

otherwise the conversion result may be wrong. The user may not recognize the

erroneous result, since the ADC will signal that the conversion has finished during

the logic low transition of the INT

interface behavior of the ADC whether the timing is correct or not. The following

figure shows what happens when the RD

RD

falls nearly 1/2 of one cycle too late, the conversion result is valid on the 5

clock cycle.

signal. The following timing diagram shows the

falling edge is timed wrong. Although

th

12345678910

CLK

RD

INT

Conversion Starts

Next Sampling Starts

2.4 Onboard Components

These sections describe the EVM onboard components.

2.4.1 TLC5618A – Serial DAC

This 12-bit DAC has a serial interface that can run at 20-MHz clock; therefore, it

can update the output at 1.21 MSPS. Two outputs are available on the 8-pin

package. The buffered SPI of the DSP provides the DSP interface. Using the

auto-buffer mode, updating the data on the DAC requires only four CPU

instructions/samples.

1

Conversion Finished

4 SLAA040

Page 11

The Board

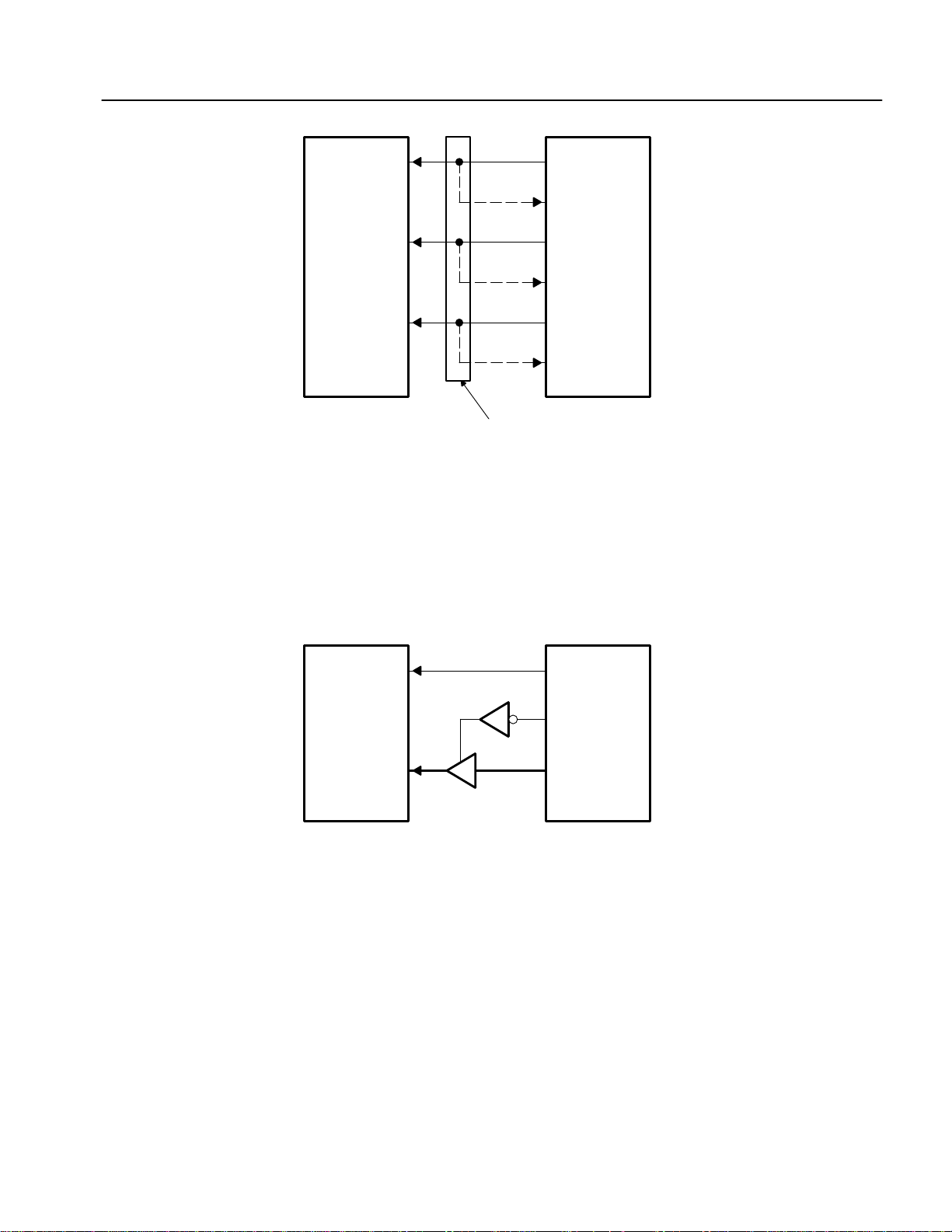

Serial DAC

SCLK

CS

TLC5618A

DIN

TLV1562 EVM Pin Connector

Figure 3. TLC5618A to ’C542 DSP Interface

2.4.2 THS5651 – Parallel Output CommsDAC

This 10-bit data converter has a parallel interface and is able to update its output

with 100 MSPS. The two outputs on the 28-pin package can each drive a current

between 2 mA and 20 mA with an output resistance >100 kΩ (ideal current

source: output impedance → ∞). The data bus and the address decoder provide

the interface to the DSP.

Parallel DAC

DSP

BCLKX

BCLKR

BFSX

TMS320C542

BFSR

BDX

BDR

DSP

CLK

THS5651

D(0–9)

Buffer

CLKOUT

TMS320C542

A(0–1) = 11

D(0–9)

b

Figure 4. THS5651 to C542 DSP Interface

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

5

Page 12

Operational Overview

3 Operational Overview

This chapter discusses the software and hardware interface for the TLV1562.

Plus the overall operational sequence of the A/D interface is described.

3.1 Reference Voltage Inputs

The voltage difference between the VREFP and VREFM terminals determines

the analog input range, i.e., the upper and lower limits of the analog inputs that

produce the full-scale (output data all 1s) and zero-scale (output data all 0s)

readings, respectively.

For design reasons, this high-speed sampling ADC does not have a groundreferenced input voltage range. Hence, level shifting is required unless the

application allows the signal to be ac coupled. Level shifting could be done with

single-supply op amps.

The absolute voltage values applied to VREFP, VREFM, and the analog input

should not be greater than the A V

input restrictions apply so consult the TL V1562 data sheet for further information.

The digital output is full scale when the analog input is equal to or greater than

the voltage on VREFP , and is zero scale when the input signal is equal to or lower

than VREFM.

supply minus 1 V , or lower than 0.8 V . Other

DD

3.2 Input Data Bits

The ADC contains the two user-accessible registers, CR0 and CR1. All user

defined features such as conversion mode, data output format or sample size are

programmed in CR0 and CR1. The data acquisition process must be started by

writing to these two registers. After this initialization, the converter processes

data in the same configuration until these registers are overwritten.

6 SLAA040

Page 13

3.3 Connections Between the DSP and the EVM

The following connections provide the interface between the DSP and the EVM:

Table 1. Signal Connections

Operational Overview

DSP Signal Connector/Pin on the DSKplus cir-

cuit board

General

GND Connector JP4: Pin 1, 10, 1 1, 12, 14,

15, 19, 20, 21, 27, 34, 35

Connector JP5: Pin 6, 10, 1 1, 12

VCC JP1/32 N/A VCC

Parallel Interface

CLKOUT JP3/2 J11/11 CLKIN

INT0

XF JP4/8 J11/3 RD

R/W JP4/30 J11/9 decoded to the WR line

IOSTRB JP4/36 J11/7 decoded to the WR line

A0 JP5/34 J11/2 addr. decoder for CS and CSTART

A1 JP5/35 J11/1 addr. decoder for CS and CSTART

D0 JP3/35 J10/13 D0

D1 JP3/34 J10/15 D1

D2 JP3/8 J10/17 D2

D3 JP3/12 J10/19 D3

D4 JP3/11 J10/21 D4

D5 JP3/15 J10/23 D5

D6 JP3/14 J10/25 D6

D7 JP3/18 J10/27 D7

D8 JP3/17 J10/29 D8

D9 JP3/21 J10/31 D9

Serial Interface to the DAC TLC5618A

BCLKR JP1/14 J11/25 SCLK

BCLKX JP1/17 J11/23 SCLK

BFSR JP1/20 J11/21 CS

BFSX JP1/23 J11/19 CS

BDR JP1/26 J11/17 DIN

BDX JP1/29 J11/15 DIN

JP5/1 J11/5 INT

Connector/Pin on

the TLV1562EVM

J10/2,J10/4,...,J10/34

J11/4,J11/6,...,J11/26

ADC Signal

GND

Signals D[9–0] of the TLV1562 and D[9–0] of the DSP are tied together in this

application to simplify hardware debugging during the development phase.

However, if the 2s complement feature of the DAC is to be used, it is easier to

connect D[15-6] of the DSP with D[9–0] of the ADC. A simple right shift of the

result then evaluates the result when sign extension mode (SXM) is enabled.

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

7

Page 14

Operational Overview

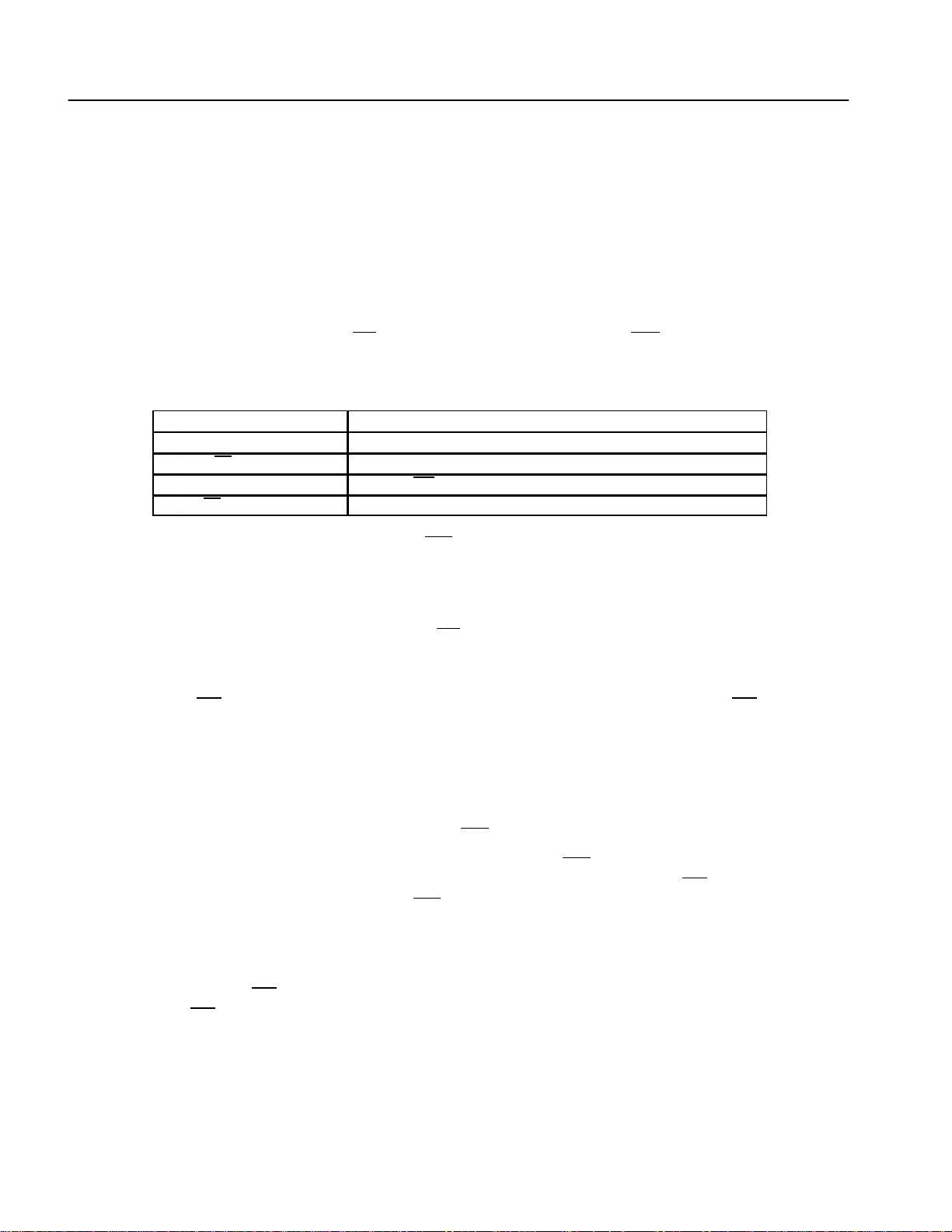

3.3.1 Jumpers Used on the TLV1562EVM

Table 2. 3-Position Jumpers

JUMPER GENERAL DESCRIPTION PIN 1-2 PIN 2-3

W1 Connects BP/CH3 (ADC) to R45 or GND; Input not in use, grounded to reduce noise Use as single input channel3 or

W2 Connects BM/CH4 (ADC) to R44 or GND; Input not in use, grounded to reduce noise Use as single input channel4 or

W3 Connects RD to XF or /RD1 Logic generator is connected to the ADC DSP is connected to the ADC

W4 WR + WR1 is connected with DSP_WR or

W5

W6

W7

W8 MCB_CLK is connected to BUFCLK (U14) or

W9 CLK input of the Counter (U2) is connected with

W10 ADC CLKIN is connected to CLK/2 or CLK/4 The ADC clock runs at a quarter of the

W11 Connects AP/CH1 (ADC) to R48 or GND; Input not in use, grounded to reduce

W12 Connects AM/CH2 (ADC) to R47 or GND; Input not in use, grounded to reduce

W13 Connects REFLO (TL V5651) to Vcc or GND Disable internal reference Enable internal reference

W14 Connects SCLK (TLC5618AA) to BCLKX or J8

W15 Connects CLK (TLV5651) to CLKOUT (DSP) or

W23 Connects CSTAR T to A0, A1, or XF A0 and A1 used to generate ADC

W24 Connects DSP_RD to XF or IOSTRB, ORed with

U12-J9/3

The three Jumpers define the prescaling of the

CLKOUT signal to the MCB_CLK Pin, if W8 is

set to Counter-Mode

(U11)

RD1

CLKOUT or CLKOUT/2

(BNC)

J7 (BNC)

/W from the DSP

R

Logic generator is connected to the ADC DSP is connected to the ADC

Counter-Mode (MCB_CLK signal is

divided by the counter, set-up with

Jumper W(5-7)

The counter is toggled by the DSP

system clock (signal BUFF_CLK)

DSP clock frequency (10 MHz)

noise

noise

Normal DSP mode An external clock source drives the

Normal DSP mode An external clock source drives the CLK

signal

CSTART

XF signal connected to ADC RD pin RD pin driven by IOSTRB ORed with R/W

differential input positive channel B

differential input negative channel B

Counter-Mode disabled (MCB_CLK is

synchronize with the CLKOUT signal)

The counter’s clock is prescaled by two

(toggled by half the DSP system clock

(CLKOUT2))

The ADC clock runs at half the DSP

clock frequency (20 MHz)

Use as single input channel 1 or

differential input positive channel A

Use as single input channel 2 or

differential input negative channel A

SCLK pin instead of the DSP

pin instead of the DSP

XF signal connects to CSTAR T pin

Table 3. 2-Position Jumpers

JUMPER GENERAL DESCRIPTION PINS SHORTED PINS OPEN

W16 Connects Mode input (TLV 5651) to GND MODE 0 is chosen (binary data input) MODE 1 is chosen (2s complement

W17 Connects REFIO (TLV5651) to VREF1 or leaves

the REFIO pin decoupled to GND via a 0.1 µF

capacitor

W18 Connects DIR (U19) to GND or leaves the DIR

pin connected to WR

W19 Connects OE (U19) to GND or leaves the OE pin

connected to CS

W20 Connects BDX to BDR or leaves BDR open DSP BDR pin gets a shortcuted feedback

W21 Connects BSFX to BSFR or leaves BCLKR open DSP BSFR pin gets a shortcuted feedback

W22 Connects BCLKX backwards with BCLKR or

leaves it open

W28 Connect Sleep input (TLV5651/5 GND Normal mode of operation Sleep mode seleted

Use as external reference voltage input Use as internal reference voltage

ADC can only write but not read to the data

bus

Output driver is isolated and disabled (no

signal can bus trough the data bus)

from the BDX (transmit) pin; normal mode

from the BSFX (transmit) pin; normal mode

DSP BCLKR pin gets a shortcuted feedback

from the BCLKX (transmit) pin; normal mode

8 SLAA040

data input)

output with this pin terminated into

GND in series with 0.1 pF

Normal operation mode

Normal operation mode

BDR remains open

BSFR remains open

BCLKR remains open

Page 15

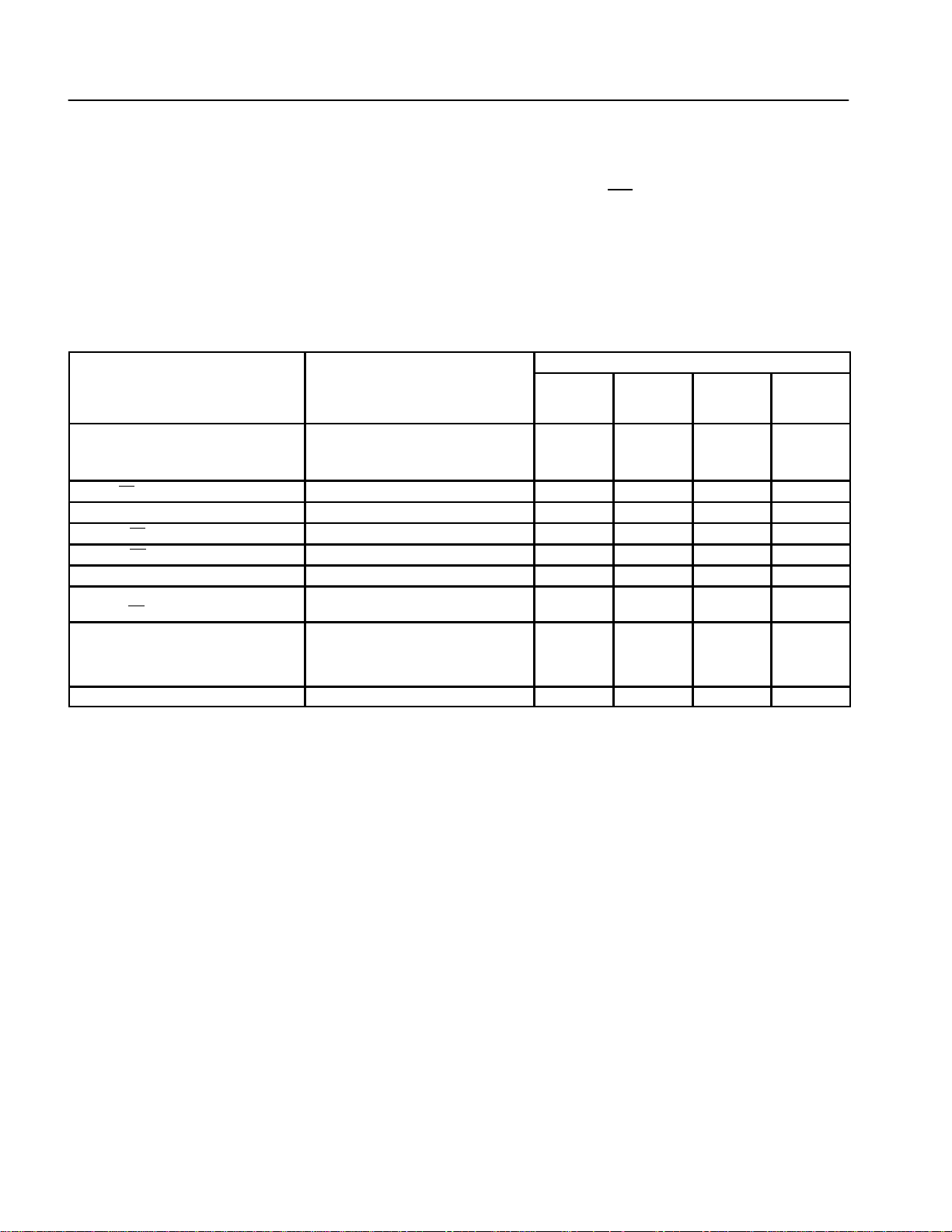

4 The Serial DAC/DSP System

The software configures the buffered DSP serial port to the 16-bit master mode

so that the DSP generates the frame sync signal at BFSX and the data clock at

BCLKX serial port terminals. Table 4 shows the connections between the DSP

and the DAC TLC5618A.

Table 4. DSP/DAC Interconnection

FROM DSP TO DSP TO DAC

BFSX BFSR CS

BCLKX CLKR I/O CLK

BDX BDR DATA IN

The following statements describe the generation and application of the

configuration and control signals.

• The DSP BCLKX output provides a 20-MHz data clock, which is a divide-by-2

of the DSP master clock.

• The DSP BDX output supplies the 16-bit control and data move to the

TLC5618A at DATA IN.

• The DSP BFSX frame synchronization signal, connected to CS, triggers the

start of a new frame of data.

The Serial DAC/DSP System

After the falling edge of FSX, the next 16 data clocks transfer data into the DSP

DR terminal and out of the DX terminal. Since this DSP/DAC interface is

synchronous, the FSX signal is sent to the FSR terminal, and the CLKX is sent

to the CLKR terminal.

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

9

Page 16

The DSP Serial Port

5 The DSP Serial Port

The buffered serial port provides direct communication with serial I/O devices and

consists of six basic signals and five registers. The DSP internal serial port

operation section discusses the registers.

The six signals are:

• BCLKX - The serial transmit clock. This signal clocks the transmitted data

from the BDX terminal to the DIN terminal of the TLC5618A.

• BCLKR - The serial receive clock. This signal clocks data into the DSP BDR

terminal. Since the DAC does not send any information back to the DSP, this

signal is not important.

• BDX - Data transmit. From this terminal the DSP transmits 16-bit data to the

DIN terminal of the TLC5618A.

• BDR - Data receive – not in use

• BFSX - Frame sync transmit. This signal frames the transmit data. The DSP

begins to transmit data from BDX on the falling edge of BFSX and continues

to transmit data for the next 16 clock cycles from the BCLKX terminal. The

BFSX signal is applied to the TLC5618A CS

• BFSR - Frame sync receive. This signal frames the receive data. The DSP

begins to receive data on the falling edge of BFSR and continues to recognize

valid data for the following 16 clocks from BCLKR. This signal is not important

for this application.

terminal.

Table 5 lists the serial port pins and registers.

Table 5. DSP Serial Port Signals and Registers

PINS DESCRIPTION REGISTERS DESCRIPTION

BCLKX Transmit clock signal BSPC Serial port control register

BCLKR Receive clock signal BSPCE extended BSPC

BDX Transmitted serial data signal BDXR Data transmit register

BDR Received serial data signal BDRR Data receive register

BFSX Transmit frame synchronization signal BXSR Transmit shift register

BFSR Receive frame synchronization signal BRSR Receive shift register

AXR Buffer start location

BKX Buffer size

For this application the DSP buffered serial port is programmed as the master,

so the BCLKX output is fed to the BCLKR terminal and the BFSX output is fed to

the BFSR terminal.

10 SLAA040

Page 17

6 Other DSP/TLV1562 Signals

These paragraphs describe other DSP and TLV1562 signals.

6.1 DSP Internal Serial Port Operation

Three signals are necessary to connect the transmit pins of the transmitting

device with the receive pins of the receiving device for data transmission. The

transmitted serial data signal (BDX) sends the actual data. BFSX initiates the

transfer (at the beginning of the packet), and BCLKX clocks the bit transfer. The

corresponding pins on the receive device are BDR, BFSR and BCLKR,

respectively.

The transmit is executed by the autobuffer mode. This means there is no need

to write to the serial port output buffer . Instead, the DSP continuously sends the

data, located in the memory beginning on AXR. When all data are sent (defined

by the buffer length in BXR), the first word (pointed to by AXR) is sent again.

Therefore, the program has only to store the samples into this memory location.

The rest of the task is handled in the background, using no CPU power.

Other DSP/TLV1562 Signals

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

11

Page 18

Conversation Between the TLV1562 and the DSP

7 Conversation Between the TLV1562 and the DSP

The complexity of the TLV1562 ADC may be confusing because of the number

of possible modes to drive the protocol between DSP and ADC. The following

paragraphs explain more about the data sheet descriptions for interfacing the

’C54x to the ADC.

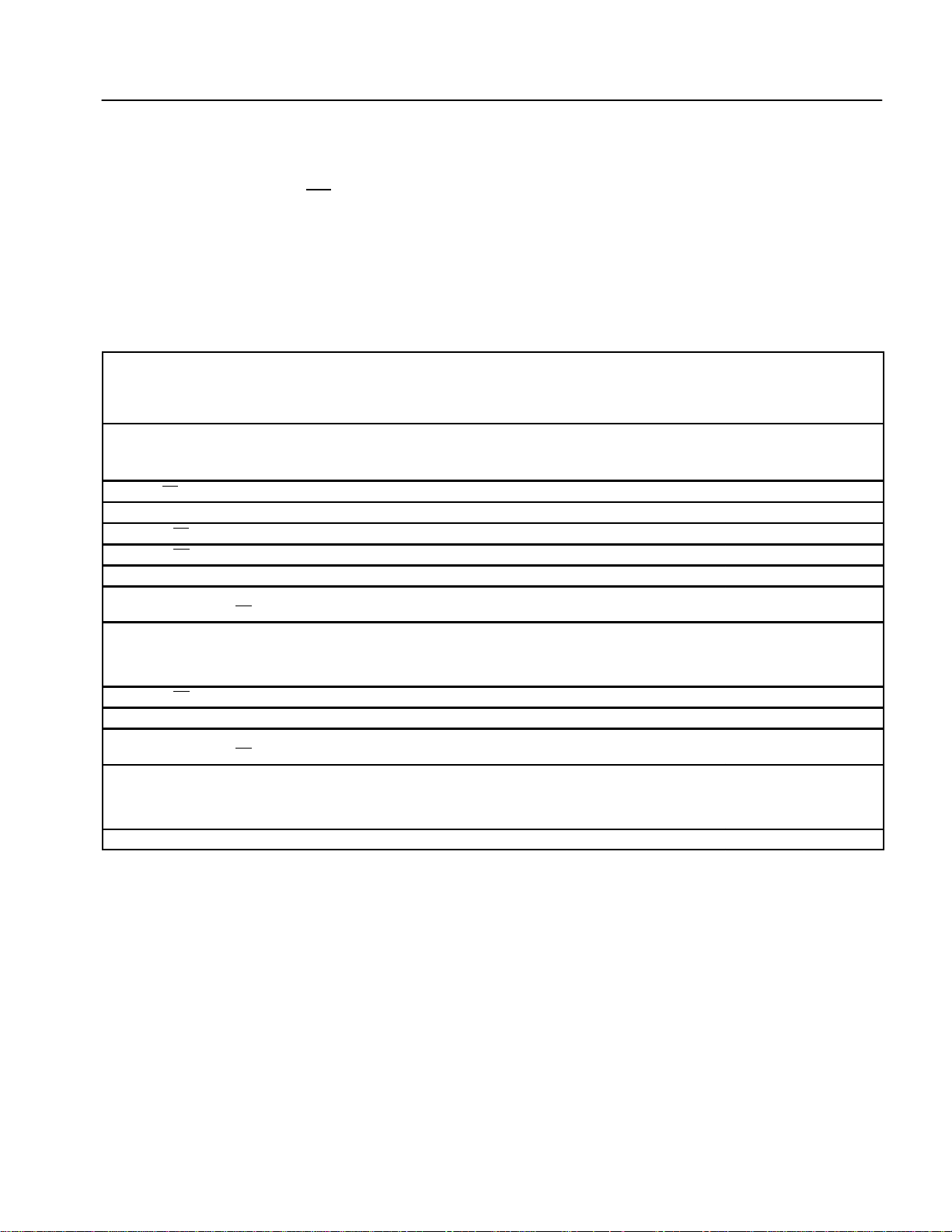

7.1 Writing to the ADC

Registers CR0 and CR1 must be set to choose any of the modes the TLV1562

offers. Therefore, a write sequence must be performed from the DSP to the ADC.

After selecting the ADC (CS

low), a high-low transition of the WR line tells the

converter that something is to be written to the data port.

Table 6. DSP Algorithm for Writing to the ADC

STEPS TIMING, NOTES

1. Set one DSP I/O waitstate Make timing between 40 MHz C54x CPU compatible with the TLV1562

2. Clear CS Select ADC

3. Send out data on the bus The signal WR is automatically handled by the DSP

4. Set CS Deselect ADC

7.2 Mono Interrupt Driven Mode Using RD

This mode is used when the application needs to sample one channel at a time

and performs the sampling, conversion, and serial transmission steps only once.

Although this mode produces continuous sampling data, the use of other modes

is recommended. One reason is the CS

sampling/conversion time. An interesting advantage of this mode is its ability to

control the start-sample time.

The RD

stops the sampling process (disconnects the capacitor from the input signal) and

starts the signal conversion. After two ADCSYSSCLKs, the sampling capacitor

gets connected back to the input signal to do the next sampling. The conversion

time needs five ADCSYSCLKs to finish the conversion before it gets written to the

data port.

signal controls the sampling and converting. Every falling edge of RD

signal has to stay low during the whole

During configuration, the rising edge of WR

Also, when conversion is finished, the ADC clears the INT signal purposes. Next

the ADC writes the conversion result to the data port. The rising edge of RD

this status; in other words, the INT

conversion result on the data port becomes invalid (the ADC data port gets

3-stated).

The configuration data needs to be written only once to the ADC. After this,

toggling the RD

the RD

12 SLAA040

starts the sampling.

resets

signal goes back to logic high and the

signal runs the ADC in a sampling/conversion/sending mode and

signal releases every new cycle.

Page 19

Table 7. DSP Algorithm for Mono Interrupt Driven Mode Using RD

STEPS TIMING, NOTES

0. Initialization

Write all configuration data to the

ADC

1. set CS deselect ADC (optional with APD=0)

2. clear CS Select ADC

3. Wait for

t

D(CSL-sample)

+1ADCSYSCLK

activate the mono interrupt-driven mode

in CR0(2;3)

(Note: if Hardware Auto power down is

enabled, Chip select has to be used,

otherwise CS can be left high)

t

D(CSL-sample)

t

D(CSL-sample)

= 5ns (APD=0)

= 500ns (APD=1)

Conversation Between the TLV1562 and the DSP

Wait cycles for the DSP internally (40 MHz DSPCLK):

APD=0

ADCSYCLK

= 7.5 MHz

≥6 ≥5 ≥26 ≥25

APD=0

ADCSYCLK

= 10 MHz

APD=1

ADCSYCLK

= 10 MHz

APD=1

ADCSYCLK

= 10 MHz

4. Clear RD ADC goes over from sampling into

conversion

5. Wait until INT goes low alternative: ignore the INT signal, wait 49

ns+5(6) ADCSYSCLK and goto step

number 7

6. Wait the time t

EN(DATAOUT)

t

EN(DATAOUT)

= 41 ns ≥2 ≥2 ≥2 ≥2

7. Read sample out from the data port;

Reset RD

signal

8. Goto step 1 or step 3 (if APD=0) for

more samples

≥34 ≥22 ≥34 ≥22

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

13

Page 20

Conversation Between the TLV1562 and the DSP

7.3 Mono Interrupt Driven Mode Using CSTART

Use the CSTART signal when two or more ADCs must sample/convert signals

at the same time. Instead of the RD

is started with the edges of the CST ART

get the data out of the ADC and onto the bus.

Table 8. DSP Algorithm for Mono Interrupt Driven Mode Using CSTART

STEPS TIMING, NOTES

1. Set CS Deselect ADC

2. Clear CSTART tTis starts sampling

3. Wait for t

4. Set CSTART This starts the conversion

5. Wait until INT goes low Alternative: ignore the INT signal,

6. Wait the time t

7. Clear CS Select the ADC

8. Clear RD Start communication

9. Wait the time t

10. Read sample out from the data port;

Reset RD

11. Set CS Deselect ADC

12. Go to step 2 for the next samples

W(CSTARTL)

D(INTL-CSI)

EN(DATAOUT)

signal

t

W(CSTARTL)

t

W(CSTARTL)

wait 14ns+5 ADCSYSCLK and goto

step number 7

t

D(INTL-CSI)

t

EN(DATAOUT)

signal, the timing for sampling and converting

signal. The RD signal is still required to

= 100 ns (APD=0)

= 600 ns (APD=1)

= 10 ns ≥1 ≥1 ≥1 ≥1

= 41 ns ≥2 ≥2 ≥2 ≥2

Wait cycles for the DSP internally (40MHz DSPCLK):

APD=0

ADCSYCLK

= 7.5 MHz

≥4 ≥4 ≥24 ≥24

≥33 ≥21 ≥33 ≥21

APD=0

ADCSYCLK

= 10 MHz

APD=1

ADCSYCLK

= 10 MHz

APD=1

ADCSYCLK

= 10 MHz

14 SLAA040

Page 21

7.4 Dual Interrupt Driven Mode

Using techniques similar to those described in the first two modes for

sampling/converting/sending tasks, the dual mode samples two channels at the

same time and sends out the results in series to the data port. The CST AR T

is used to start sampling and converting.

Table 9. DSP Algorithm for Dual Interrupt Driven Mode

STEPS TIMING, NOTES

1. Set CS Deselect ADC

2. Clear CSTART This starts sampling

3. Wait for t

4. Set CSTART This starts the conversion

5. Wait until INT goes low Alternative: ignore the INT signal,

6. Wait the time t

7. Clear CS Select the ADC

8. Clear RD Start communication

9. Wait the time t

10. Read sample out from the data port;

reset RD

11. Wait t

12. Clear RD- Start communication

13. Wait the time t

14. Read sample out from the data port;

reset RD

15. Set CS Deselect ADC

16. Goto step 2 for the next samples

W(CSTARTL)

D(INTL-CSL)

EN(DATAOUT)

signal

W(CSH)

EN(DATAOUT)

signal

t

W(CSTARTL)

t

W(CSTARTL)

wait 210ns+10 ADCSYSCLK and go

to step number 7

t

D(INTL-CSI)

t

EN(DATAOUT)

t

W(CSH)

t

EN(DATAOUT)

= 100ns (APD=0)

= 600ns (APD=1)

= 10 ns ≥1 ≥1 ≥1 ≥1

= 41 ns ≥2 ≥2 ≥2 ≥2

= 50 ns ≥2 ≥2 ≥2 ≥2

= 41 ns ≥2 ≥2 ≥2 ≥2

Conversation Between the TLV1562 and the DSP

pin

Wait cycles for the DSP internally (40MHz DSPCLK):

APD=0

ADCSYCLK

= 7.5MHz

≥4 ≥4 ≥24 ≥24

≥62 ≥48 ≥62 ≥48

APD=0

ADCSYCLK

= 10MHz

APD=1

ADCSYCLK

= 10MHz

APD=1

ADCSYCLK

= 10MHz

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

15

Page 22

Conversation Between the TLV1562 and the DSP

7.5 Mono Continuous Mode

This mode simplifies data acquisition, since there is no need to generate a signal

to sample or convert data. Instead, initializing this mode once, the ADC sends out

the data continuously and will be read by the DSP with the RD

CAUTION:

In this mode, the sampling result sent out by the ADC is the

value of the sample from the last cycle. Therefore, the first

sample after initialization is trash.

Table 10. DSP Algorithm for Mono Continuous Mode

Wait cycles for the DSP internally (40MHz DSPCLK):

STEPS TIMING, NOTES

0. Initialization N/A N/A

Write all configuration data to the

ADC

1. Set CS Deselect ADC N/A N/A

2. wait for t

3. Clear CS Select ADC N/A N/A

4. Clear RD Start conversion N/A N/A

5. Wait the time t

6. Read sample out from the data port;

reset RD

7. Wait for the time t

step 7 and 8 to ensure 5(6) ADCSYSCLk

8. Go to step 4 for more samples N/A N/A

(SAMPLE1)

EN(DATAOUT)

signal

(CONV1)

minus

Activate the mono continuous mode in

CR0(2;3)

t

(SAMPLE1)

t

EN(DATAOUT)

(Caution: the first result after initialization

is trash)

t

(CONV1)

7 and 8 take at least 4 DSPSYSCLK, the

calculation are 5(6) ADCSYSCLK minus

100 ns

= 100 ns ≥4 ≥4 N/A N/A

= 41 ns ≥2 ≥2 N/A N/A

= 5(6) ADCSYSCLK; since step

APD=0

ADCSYCLK

= 7.5 MHz

≥23 ≥16 N/A N/A

signal.

APD=0

ADCSYCLK

= 10 MHz

APD=1

ADCSYCLK

= 10 MHz

N/A N/A

N/A N/A

APD=1

ADCSYCLK

= 10 MHz

16 SLAA040

Page 23

Conversation Between the TLV1562 and the DSP

7.6 Dual Continuous Mode

The dual continuous mode provides a data stream of two input signals. The

characteristic of the data protocol is similar to the mono continuous mode but with

the use of two RD

In this mode, the sampling result sent out by the ADC is the

value of the sample from the last cycle. Therefore, the first

sample after initialization is trash.

Table 11. DSP Algorithm for Dual Continuous Mode

STEPS TIMING, NOTES

0. Initialization N/A N/A

Write all configuration data to the

ADC

1. Set CS deselect ADC N/A N/A

2. Wait for t

3. Clear CS Select ADC N/A N/A

4. Clear RD Start conversion

5. Wait the time t

6. Read first sample out from the

data port; reset RD

7. Wait for the time t

step 7 and 8 to ensure 5(6) ADCSYSCLk

8. Clear RD Start conversion

9. Wait the time t

10. Read second sample out from the

data port; reset RD

11. Wait for the time t

step 7 and 8 to ensure 5(6) ADCSYSCLk

12. Go to step 4 for more samples N/A N/A

(SAMPLE1)

EN(DATAOUT)

EN(DATAOUT)

signal

(CONV1)

signal

(CONV1)

minus

minus

cycles for one sample/hold cycle.

CAUTION:

Wait cycles for the DSP internally (40MHz DSPCLK):

ADCSYCLK

Activate the dual continuous mode in

CR0(2;3)

t

(SAMPLE1)

t

EN(DATAOUT)

(Caution: the first result after initialization

is trash)

t

(CONV1)

and 8 take at least 4 DSPSYSCLK, the

calculation are 5(6)ADCSYSCLK minus

100 ns

t

EN(DATAOUT)

(Caution: the first result after initialization

is trash)

t

(CONV1)

and 8 take at least 4 DSPSYSCLK, the

calculation are 5(6)ADCSYSCLK minus

100ns

= 100 ns ≥4 ≥4 N/A N/A

= 41 ns ≥2 ≥2 N/A N/A

= 5(6) ADCSysclk; since step 7

= 41 ns ≥2 ≥2 N/A N/A

= 5(6) ADCSysclk; since step 7

APD=0

= 7.5 MHz

≥23 ≥16 N/A N/A

≥23 ≥16 N/A N/A

APD=0

ADCSYCLK

= 10 MHz

APD=1

ADCSYCLK

= 10 MHz

N/A N/A

N/A N/A

N/A N/A

APD=1

ADCSYCLK

= 10 MHz

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

17

Page 24

Software Overview

8 Software Overview

The software in this report shows how to use all modes of the TL V1562 and useful

variations for each mode. It also includes a C program to start data acquisition

from a C level. To limit the number of programs, the report supplies five files for

running the ADC in five modes; a sixth program shows the C-callable function.

Each program can enable different software blocks to give the user a large choice

for generating the data acquisition. For more details, see paragraph 8.3.9.

Instead of using numbers for memory addresses or constants, very often

symbols replace the numbers. For that, the symbol (name) is assigned with the

real value (number) in the file header. The advantage of doing this is the higher

flexibility. Instead of changing a variable memory location in every related

instruction, the value for this location is changed only once in the program header.

This prevents software bugs from appearing through a forgotten correction of a

related instruction.

BSPC_BUFFER_START set 00800h ; memory location (800h) for the

@AXR = #(BSPC_BUFFER_START) ; assign the starting address of auto

8.1 Software Development tools

The DSKplus Starter Kit of the TMS320C54x comes with a free compiler to

generate an absolute object file from assembler code (DSKPLASM.EXE in the

TMS320C54x DSKplus development tools). The object code is then loaded into

the GoDSP software to run it on the kit.

An advanced version of this kit is the TMS320C54x Optimizing C Compiler/

Assembler/Linker (for example: TMDS324L855-02). These tools allow

generation of object code from C and assembler files. Furthermore, they also link

the code to an executable COFF file. The software in this report was created with

these tools.

For more information visit TI’s Internet page at:

http://www.ti.com/sc/docs/dsps/tools/c5000/c54x/index.htm

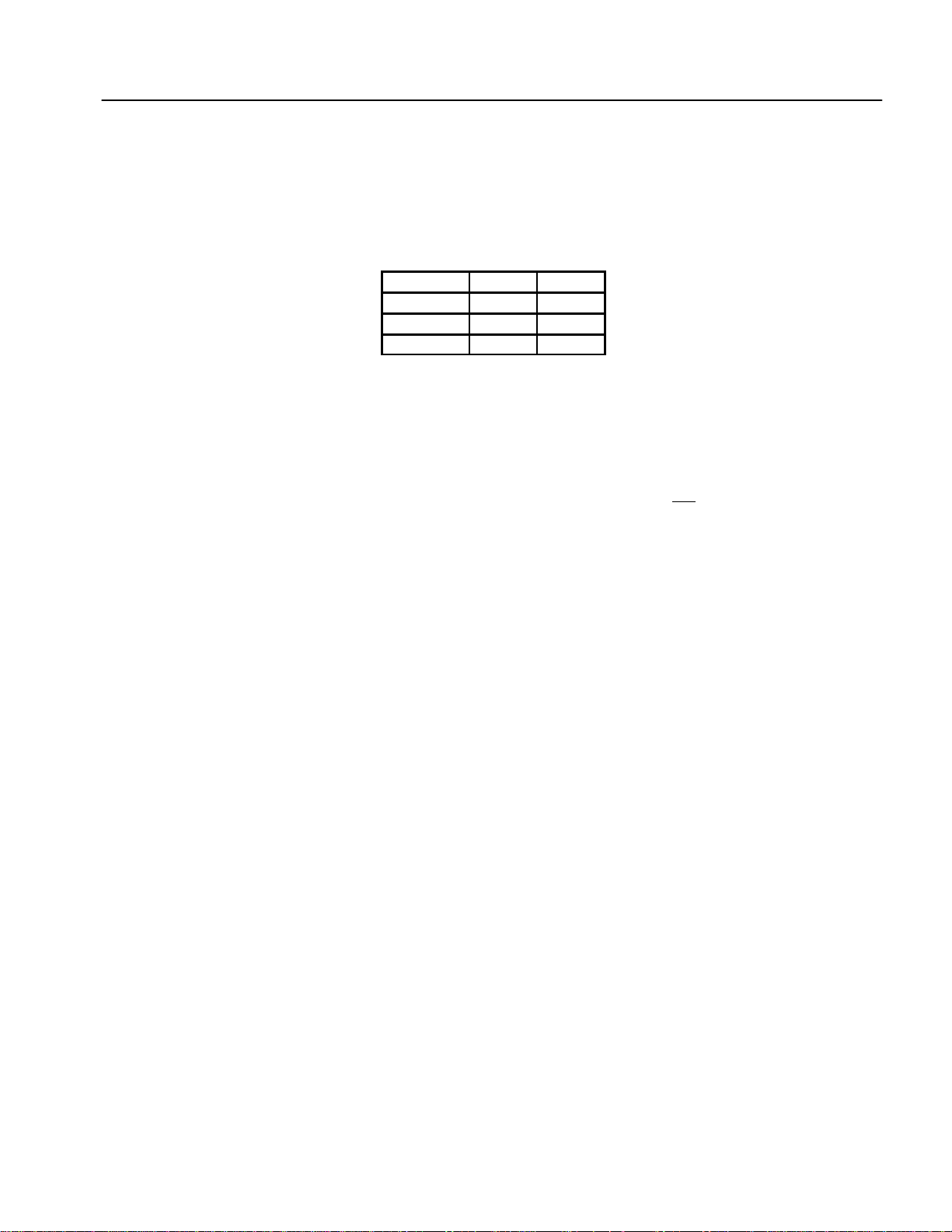

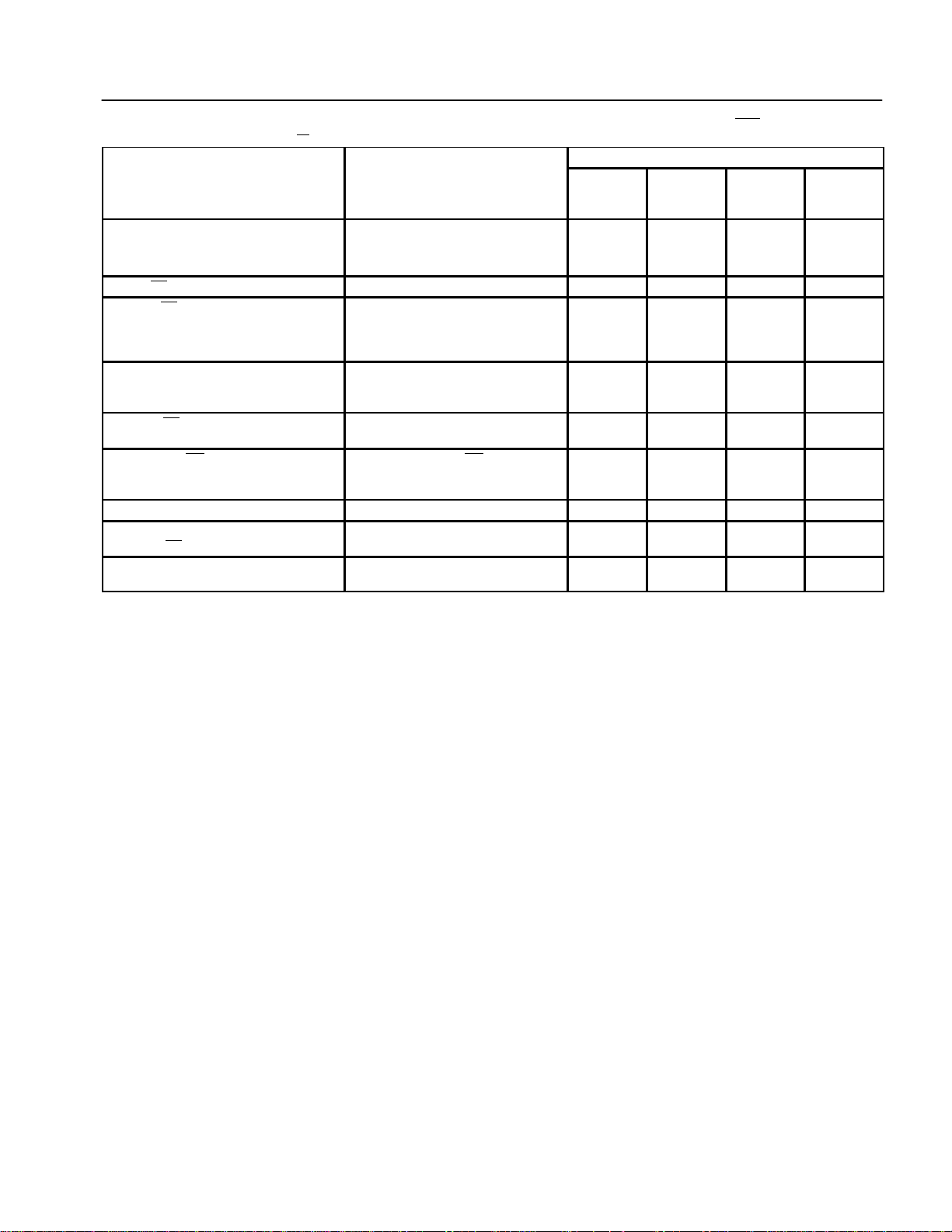

8.2 DSP Memory Map

Figure 6 shows the memory map assigned to the application.

PROGRAM MEMORY (on-chip DARAM 10k words (OVLY=1) from 0080h to 27FFh):

; start address of the SPC buffer

; buffer

.

18 SLAA040

Page 25

0000h

007Fh

0080h

00FFh

0100h

017Fh

0180h

07FFh

0800h

0FFFh

1000h

1009h

100Ah

17FFh

1800h

27FFh

2800h

EFFFh

F000h

F7FFh

F800h

FF7Fh

FF80h

FFFFh

(OVLY = 1)

Original Interrupts DSKplus

Starter Kit

Communication Kernel

Starter Kit

RAM

BSP RAM Block or Program RAM

Kernel Buffer (10 Words)

HPI RAM Block or Porgram RAM

Program

External

On-Chip ROM

ROM (Bootloader)

ROM Interrupts

01FFh

0200h

027Fh

0280h

02FFh

0300h

Software Overview

Unused

Software Interrupt Table

Unused

Linked Program Memory Code

0000h

005Fh

0060h

007Fh

0080h

27FFh

1800h

1FFFh

2000h

27FFh

2800h

FFFFh

Reserved Memory by The DSKplus Board

Memory-Mapped Register

Scratch-Pad RAM

DRAM See Program Memory

Software Data Memory

(All Variables)

Tables to Store Data Samples

External

Figure 5. Memory Map

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

data_log_A

data_loc_A + num_data_A

data_loc_B

data_loc_B + num_data_B

data_loc_C

data_loc_C + num_data_C

data_loc_D

data_loc_D + num_data_D

Table 1

Table 2

Table 3

Table 4

19

Page 26

Software Overview

8.3 Programming Strategies for the ’C54x, Explanations

Before listing the program code, this chapter introduces some basic instructions

(strategies) to provide the ’C54x user with some ideas for dealing with the DSP

architecture.

8.3.1 Optimizing CPU Resources for Maximum Data Rates

The ’C54x processor on the DSKplus starter kit runs at an internal clock

frequency of 40 MHz. Since the pipeline architecture allows most instructions to

be executed in one cycle, the DSP provides up to 40 MIPS. However, some

instructions, especially branch instructions, are not single cycle instructions;

therefore, they lower the available CPU power. Because of the high transfer rate

of the TLV1562 ADC,

performance. Since correct signal timing between DSP and ADC requires some

instructions per sample, the CPU power required between two samples is very

small.

The optimum case is to read a new sample, store it into memory, execute a

customized task as it could be data filtering (FFT, FIR, IIR), and send a digital

result to one of the DACs. Unfortunately, this task is impossible at the ADC’s

maximum throughput of 40 MIPS. Therefore, this software only stores the

samples and optionally moves them out to the DACs. Enabling all options at the

same time prevents the application from running at maximum throughput.

the software code must be optimized to test the full ADC

The following switches enable/disable these actions:

SAVE_INTO_MEMORY .set 00001h; set 1 to store the samples into memory

SEND_OUT_SERIAL .set 00001h; set 1 to send last sample to the serial DAC

SEND_OUT_PARALLEL .set 00001h; set 1 to send last sample out to the parallel DAC

8.3.2 Address and Data Bus for I/O Tasks

8.3.2.1 Writing

PORT(PA) = Smem

Writing something to the I/O bus uses the port instruction. PA sets the ADDRESS

bus permanently to that value. Smem is a value from memory , transferred for one

clock cycle to the DATA bus.

@send = #01234h ; set the content of memory address send to 1234h

port(0FFFFh) = @send ; set address bus to FFFFh and write 1234h for one cycle

; on the DATA bus

8.3.2.2 Reading

Smem = PORT(PA)

Reading from the I/O bus. P A sets the ADDRESS bus. Smem is a memory cell,

PA the address on the bus.

8.3.3 Timer Output

@TCR = #00010h ; deactivate timer

@PRD = #00000h ;

@TCR = #00C01h ; set timer output toggling frequency to ½ CLKOUT

; frequency ; and start toggling

20 SLAA040

Page 27

The timer output pin TOUT can be used to generate an output function with a

prescale from half the CLK frequency down to 1FFFF . The problem: the high-time

is always one clock cycle and only the low time of the TOUT signal changes with

the timer.

8.3.4 Data Page Pointer

DP = #0 ; load DP with 0

DP = #variable ; point with DP to the page, where variable is stored

DP ≠ #register ; error, this won’t work, the DP gets not loaded with

; register page, instead load DP with zero

If a register has to be written (example: IFR), the DP has to be loaded with zero

since DP=#register will not work.

8.3.5 Generating the Chip Select Signal and the CSTART Signal

port(CSTART) = @ZERO ; clear CSTART- (CSTARTlow)

port(ADC) = @CR0_SEND ; clear CS- (CSlow)

port(DEACTIVE) = @ZERO ; set CS or CSTART back (CS high or CSTARThigh)

The chip select signal and the CST ART signal can be accessed using the address

bus (decoder on A0/A1). The basic idea of having CSTART

triggering for sampling/conversion purposes without having to use CS

always blocks the address bus). Since the ’C542 DSP does not have enough

general purpose outputs, this application still uses the address bus to activate

CSTART.

was to allow ADC

Software Overview

(which

8.3.6 Interfacing the Serial DAC 5618A to the DSP

A buffered serial port on the ’C542 board interfaces the TLC5618A DAC. The

advantage of using a buffered serial port compared to the standard port is the

auto buffer mode. This allows the programmer to save CPU power . A background

process takes the data from a defined memory location (table) and moves it out

to the serial port. (An interrupt can be generated after sending out half or the full

table content. However, disabling this interrupt and writing the new ADC samples

into the same memory location where the SPI takes the send value from, allows

continuous transmission of the data stream to the DAC. When debugging the

EVM it is preferable to compare the analog output signal of the DAC with the

analog input signal applied to the ADC.

The TLC5618A is very easy to use. The sample size is limited to 10 bits and the

first six MSBs are set so that the converter outputs the value on the right pin in

the right mode.

The next lines of code show the initialization. The only requirement is to initialize

the buffered serial port, since the DAC does not need an initialization procedure.

@BSPC = #00000h ; reset SPI

@IFR = #00020h ; clear any pending SPI IRQ

@IMR = #00020h ; allow BXINT0

@BSPCE = #00521h ; set Auto buffer mode

@AXR = #(BSPC_BUFFER_START); set the starting address of the auto buffer

@BKX = #(BSPC_BUFFER_SIZE) ; buffer size

@BSPC = #0C07Ch ; start serial port, FSX in Burst (every word)

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

21

Page 28

Software Overview

8.3.7 Interrupt Latency

The time required to execute an interrupt depends on the handling of the IRQ at

the four-word vector address or jumping further with a GOTO instruction. Using

the fast return from IRQ instruction, and branching from the IRQ vector to a

separate routine memory location, produces an IRQ overhead of:

3 sysclk (goto IRQ vector) + 4sysclk (goto/dgoto) + 1 sysclk (fast return) = 8

instruction cycles

The time between when the IRQ occurs and the routine executes its first

instruction depends on the instruction in the CPU pipeline when the interrupt

occurs. Running a repeat command delays the IRQ until the full number of

repetitions is finished.

NOTE: Using a delayed branch instruction (dgoto) and putting

two useful words of instruction behind this instruction saves the

CPU calculation power.(See the explanations about delayed

branches Section 8.3.8).

8.3.8 Branch Optimization (goto/dgoto, call/dcall, ...)

The easiest solution for a branch is to use the goto instruction. Since the ’C54x

has a pipeline to allow execution of one instruction in one clock cycle, a simple

branch instruction will take four cycles for execution. Example:

GOTO MARK

...

MARK: DP = #1;

ARP = #5;

...

The program counter (PC) points after the last instruction (ARP=#5) past 6 sysclk

cycles. However, this can be optimized, using a delayed branch.

DGOTO MARK

DP = #1;

ARP = #5;

...

MARK: ...

The time to execute the same number of instructions is now only four CPU clock

cycles. (After four instructions, the PC points to the address MARK. The reason

for this is the processor’s pipeline finishes the instructions after dgoto and does

not just trash the already-processed fetch when the branch is in the pipeline’s

decoding state.

Conclusion: The goto and dgoto instructions both execute the branch in less

than four SYSCLCKs, but the dgoto instruction can execute the next two

instructions following dgoto in the same amount of time.

22 SLAA040

CAUTION:

Use the delayed branches carefully , since it looks confusing when

an instruction has been executed after a call instruction. A solution

is to first use the normal branches when writing the code, and when

all tasks have been finished, optimize the code with the delayed

algorithms.

Page 29

8.3.9 Enabling Software Modules (.if/.elseif/.endif)

To test different software solutions while keeping the number of files small

requires integrating all the modules in the same file. Furthermore, a switch is

needed to enable any of the software modules. Setting the constant SWITCH in

the program header to either one or zero enables/disables the instructions inside

an .IF-.ENDIF loop. Example:

SWITCH1 .set 00001h

SWITCH2 .set 00000h

...

.if SWITCH1

instruction_X ; the instructions on this line will be assembled

.elseif SWITCH2

instruction_Y ; the instructions on this line will be ignored

.endif

In this example, instruction_X is executed (linked into object code) while

instruction_Y is ignored. Setting SWITCH2 instead of SWITCH1 to 1 enables

instruction_Y and makes the compiler link it to object code. If both switches are

one, only instruction_X is compiled.

8.4 Software Code Explanation

Software Overview

The next capture describes the software solution to interface the TLV1562 and

the two DACs on the EVM board. Although the code looks very large and

complicated at first, it is a simple solution with only a little knowledge of the code

required to verify/customize the settings. The TLV1562 (ADC) offers a wide

choice of settings. First, choose the conversation mode. This application report

provides one file for each mode. Many settings (2s complement, channels, etc.)

must be selected. This software allows a variation of those parameters in the

program header. A simple switch enables or disables each component. After

recompiling the code with a special setting of all switches, the code becomes

much smaller and easier to understand. The .if/.elsif/.endif instruction allows the

program to use or ignore blocks of instruction between the statements.

If, for example, one does not want to use the serial DAC and disables the switch

SEND_OUT_SERIAL, all the source code for the serial conversation between

DSP and DAC is ignored. The compiler will not implement any code related to the

serial DAC.

8.4.1 Software Principals of the Interface

Controlling the status of signals can be done in different ways. One of the

challenges in this interface is controlling signal status when the ADC conversion

is finished and the digital result is ready to be transferred from the ADC to DSP.

A high/low transition on the INT

has completed the conversion. Optionally, the DSP can ignore the INT

initialize the conversion instead, wait for a defined time, and directly read the

result out of the ADC. This solution requires knowing the precise time for

conversion/data ready on the bus for each converter/mode.

line of the TL V1562 informs the DSP that the ADC

signal,

Three options are given for each mode to match different custom needs; they are

listed in the next three sections.

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

23

Page 30

Software Overview

8.4.1.1 Software Polling

The status of the input pin is tested in a loop until the valid transition occurs. After

this transition, the program branches to the next instruction (reads data sample).

Advantage:

• Relatively fast program response after high-to-low transition of INT

• The software compensates for variations of timing given in data sheets for

conversion and the real time until the flag goes high.

• Not critical for any software changes (e.g. adding new features)

• Even when the program reaches the polling loop later than the transition

occurred, it steps ahead properly.

Disadvantage:

• Time inside the polling loop is not usable for other software features (wasted

CPU power)

• A hang up (ADC does not respond) will not be recognized without a watchdog

algorithm

• The polling algorithm requires five instruction cycles. Depending on when the

conversion finishes during these five instructions (when the INT

low), the time response after the falling edge can vary up to the five instruction

cycles. As experiments confirmed, this can result in a variation in the length

of the sampling window. So, a filter algorithm (eg. FFT) on the samples might

result in slightly different results for a steady (stable) input function, related

to the sampling time variations. The only way to prevent this is to control the

conversion with the on-chip timer of the DSP. Unfortunately, the maximum

throughput falls off with increased requirements for CPU power.

signal goes

8.4.1.2 Timed Solution

How

long the ADC requires for conversion must be factored into the software flow.

In other words, the DSP has to wait a certain time between initializing the

conversion and reading the conversion result on the data bus from the ADC. This

timing is critical to the sampling device. If the conversion time of a data converter

changes (data sheet), the timing must be verified again.

Advantage:

• Fastest solution (with a fine tune, the maximum performance can be

extracted from the converter)

• Saves CPU power of the DSP (no time wasted for polling)

• Program can not hang up in an endless loop

• Less hardware required (input pin on the DSP and INT connection are left out)

Disadvantage:

• Every software variation changes timing and therefore, requires fine tuning

again. This can be avoided by using the DSP timer module, but since the

TLV1562 is an extremely fast device (2 MSPS at 10 bit), a timer module

solution becomes too slow.

• If the conversion time of the ADC varies for some reasons, this algorithm is

not able to respond; instead, the maximum conversion time is used.

24 SLAA040

Page 31

8.4.1.3 Interrupt Driven Solution

Usually, the most elegant solution is to use an interrupt procedure to control

external signals. The problem for this application is the high speed. First, if more

than a few words of code have to be executed between two samples, the software

has to ensure that the first interrupts will be completed before the second interrupt

is enabled. This can be done by globally disabling IRQs while

The second problem is the interrupt latency. According to the pipeline

architecture of the ’C54x, an interrupt routine is started at the earliest after three

clock cycles (the last instruction in the pipeline will be executed before branching

to the IRQ vector). Another processing overhead is the branch instruction from

the original IRQ vector to the IRQ handler memory location.

In summary , the large number of instructions used to organize the interrupt and

to branch from the actual code execution into the interrupt service routine will

significantly use up resources.

Advantages:

• Data acquisition runs fully automated in the background; the main program

(filtering, other controlling, etc.) does not need to control any data acquisition

software flow.

• Easy software debugging and implementing of new features (not critical for

any software changes)

• The software compensates for variations in timing given in data sheets for

conversion and the real time until the flag goes high.

Disadvantages:

• Program overhead uses a lot of resources, which is critical for maximum

throughput performance

• Watchdog algorithms needed to avoid a hang up of the ADC

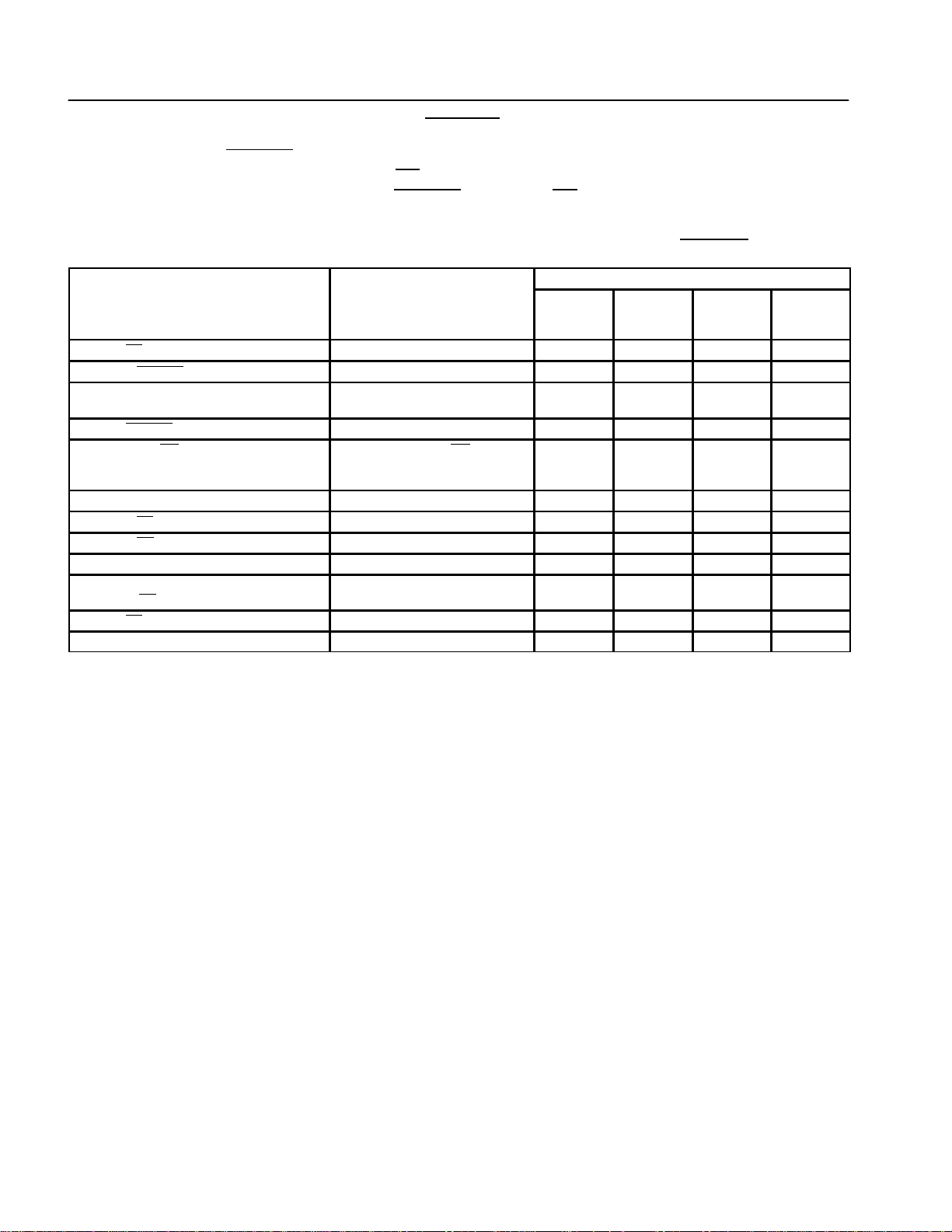

8.4.1.4 Enabling One Software Mode

Every main file (given later in this document), offers the following three switches

in the program header:

SWITCH DESCRIPTION

POLLING_DRV software polls the INT0 pin until conversion is finished

INT0_DRIVEN software uses Interrupt INT0 to organize conversion

NO_INT0_SIG INT0 signal not in use, interface is controlled with timing solution

Software Overview

executing one IRQ.

NOTE: Only one of the three switches is to be enabled.

Example: Run in interrupt driven mode:

POLLING_DRV .set 00000h

INT0_DRIVEN .set 00001h

NO_INT0_SIG .set 00000h

8.4.1.5 Setting the Right Switches

As the software offers the choice of three conversion-end recognition strategies,

it allows selection of other ADC-related features, such as the clock source, power

save mode, or the resolution. Depending on the custom requirements of data

throughput, the program header also defines whether the samples will be stored

into memory, sent serially out to the TLC5618A DAC, or sent in parallel to the

TLV5651 CommsDAC.

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

25

Page 32

Software Overview

SAVE_INTO_MEMORY Store the samples into DSP memory (location defined in constants.asm)

SEND_OUT_SERIAL Send the samples always to the serial DAC TLC5618A

SEND_OUT_PARALLEL Update always the parallel DAC with the last sample (DAC1) THS5651

R10BIT_RESOLUT Use maximum resolution of 10 bit

R8BIT_RESOLUT Use 8-Bit resolution

R4BIT_RESOLUT Use fastest mode (4-Bit resolution)

INTERNAL_CLOCK Use the internal clock of the ADC

EXTERNAL_CLOCK Use the external clock of the ADC

AUTO_PWDN_ENABLE ADC reduces power consumption after conversion

DIFF_INPUT_MODE Use differential mode instead of single ended inputs

IME_CALIBRATION Internal Midscale Error Calibration

SME_CALIBRATION System midscale error calibration

Table 12. Switch Settings

SWITCH DESCRIBTION

Note: the 3 switches are independent from each other

Note: enable only one of the 3 switches

Note: enable only one of the 2 switches

1 – enable power down mode

0 – no PWDN mode

1 – differential ADC input

0 – single ADC input

Note: the 2 switches are independent from each other; however, performing

more than one calibration does not make sense see data sheet)

Features not listed in Table 12 must be changed directly in the two data words,

CR0/1, that are sent to the ADC. In general, correct bit setting is described in the

data sheet. However, the file CONSTANT.ASM includes a look-up table to

simplify the task of setting the right bits in CR0 and CR1. Thus, all it requires is

to place the synonym for each feature into the correct bracket as shown in the

next example:

EXAMPLE

Task 1.1:

Sample channel 1 in mono interrupt driven mode with single ended inputs. Use

the internal 8-MHz clock of the ADC and do not run in any power save mode. The

result should have a binary format with 10-bit resolution. The conversion start is

controlled by the RD

signal.

Table 13. Instruction in the Program Header (Step 1)

R10BIT_RESOLUT .set 00001h ; enable 10-bit resolution

R8BIT_RESOLUT .set 00000h ;

R4BIT_RESOLUT .set 00000h ;

INTERNAL_CLOCK .set 00001h ; use internal clock

EXTERNAL_CLOCK .set 00000h ;

AUTO_PWDN_ENABLE .set 00000h ; disable auto power down

DIFF_INPUT_MODE .set 00000h ; single input mode

IME_CALIBRATION .set 00000h ; no internal calibration

SME_CALIBRATION .set 00000h ; no system calibration

26 SLAA040

Page 33

Task 1.2:

Use channel B in differential input mode and an external clock source. Following

changes have to be done with the set-up of Task 1.1:

Table 14. Instruction in the Program Header (Step 1)

R10BIT_RESOLUT .set 00001h ; enable 10-bit resolution

R8BIT_RESOLUT .set 00000h

R4BIT_RESOLUT .set 00000h

INTERNAL_CLOCK .set 00000h

EXTERNAL_CLOCK .set 00001h ; use external clock

AUTO_PWDN_ENABLE .set 00000h ; disable auto power down

DIFF_INPUT_MODE .set 00001h ; differential input mode

IME_CALIBRATION .set 00000h ; no internal calibration

SME_CALIBRATION .set 00000h ; no system calibration

Additional correction in the middle of the main program files (step 2):

@CR0_SEND = #(PAIR_B|MONO_INT|SINGLE_END|CLK_INTERNAL|NO_CALIB_OP);

@CR1_SEND = #(NO_SW_PWDN|NO_AUTO_PWDN|NO_2COMPLEMENT|NO_DEBUG|RES_10_BIT|RD_CONV_START);

CAUTION:

Changing statements in step 2 is not required, if they are

already defined in the header. For example, the statement

CLK_INTERNAL does not change to CLK_EXTERNAL in

step 2 because the clock source is defined in the program header

and therefore will be justified behind the step 2 instructions later

in the program. That is why in step 2 only the CH1-value is

replaced with PAIR_B, but nothing else has been specified.

Software Overview

8.4.1.6 Common Software for all Modes

The files CONST ANT .ASM and VECTORS.ASM include constant definitions and

the interrupt vector table. Those parameters are identical for all ADC modes.

Therefore, the two files will be used for each mode and are described next:

CONST ANT.ASM Definition of constant values as it is the bit code for different

ADC modes (CR0/1), the serial DAC send words and the

DSP memory saving locations

VECTORS.ASM Interrupt vector table of the TMS320C542

CALIBRAT.ASM ADC calibration procedure (except for mono interrupt driven

mode using RD

, this mode has not implemented any

calibration so far)

8.5 Flow Charts and Comments for All Software Modes

The following paragraphs show the flow charts and include comments for all

software modes.

8.5.1 The Mono Interrupt Driven Mode Using RD to Start Conversion

The following descriptions explain the software for the data acquisition in

monomode. The required interface connections are shown in Figure 1.

Interfacing the TLV1562 Parallel ADC to the TMS320C54x DSP

27

Page 34

Software Overview

Program Files:

MONOIDM1.ASM includes the complete software algorithm to control the monomode

CONSTANT.ASM common file of all modes (constants definition)

VECTORS.ASM common file of all modes (IRQ vector table)

Other Files:

linker.cmd organization of the DSP memory (data and program memory)

auto.bat batch file to start the compiler for the monomode software

asm500.exe C54x Code compiler

lnk500.exe C54x linker

The timing requirements to interface the ’C54x to the ADC are provided in

Tables 6 and 7. The STEP numbers given there can be found again as Marker

in the code. This helps to debug and verify the code.

Code verification:

T o verify the software, the user must change the code in the MONIDM1.ASM file

and save those changes. The next step is to recompile the three .ASM files by

executing the AUTO.BAT batch file. If compiler and linker finish without error

messages, the new output file is ready to load in the DSP program memory (e.g.

with the GoDSP development tools) and to execute.

The flow chart in Figure 7 gives a general overview of the software structure

(MONOIDM1.ASM).

28 SLAA040

Page 35

Start

Software Overview

1

No

H/L Transition on INTO ?

Yes

INTO (External Interrupt)

Save Modified Register of

The IRQ Routine, if Not

Automatically Saved by The

DSP

(Not Required)

1

INTO_DRINEN = 1

Main Program

Stay in Idle Mode

Wait States, AR Pointer , IRQ Table, Data Memory, Serial Port

Active Transmitter, Use Frame Sync,

Initialize (Id) The Two ADC Registers

CR0 = CR0_SEND

CR1 = CR1_SEND

Poll INTO Pin Until h/0 Transition Occurs

Initialize DSP

Initialize SPI

Generate External Clock

SAVE_INTO_MEMORY = 1

SAVE_INTO_MEMORY = 0

Start First Conversion

POLLING_DRIVEN = 1

Wait Until End of Conversion

Initialize DSP Memory For Sample Store

AR7 Points to The First Store Location

AR0 Points to The Table End

ADCOUNT = Table Size (Number of Samples)

NO_INTO_SIGNAL = 1

Wait Until End of Conversion

Wait For a Certain Time

1

INTO