Page 1

TLK1501 Serdes EVM Kit

Setup and Usage

User’s Guide

June 2000 Mixed Signal Products

SLLU008

Page 2

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Page 3

About This Manual

This manual should be used to determine how to set up and use the TLK1501

evaluation module in order to evaluate the TLK1501 device.

How to Use This Manual

This document contains the following chapters:

Notational Conventions

Preface

Read This First

-

-

-

-

-

Notational Conventions

This document uses the following conventions.

-

Chapter 1 — Introduction

Chapter 2 — TLK1501 EVM Board Configuration

Chapter 3 — PCB Construction and Characteristics

Appendix A — Schematics, Board Layouts, and Suggested Optics and

Cable Assembly Specifications

Appendix B — NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s

SpeedBlaster Transceiver data sheet

Program listings, program examples, and interactive displays are shown

in a special typeface similar to a typewriter’s. Examples use a bold

version of the special typeface for emphasis; interactive displays use a

bold version of the special typeface to distinguish commands that you

enter from items that the system displays (such as prompts, command

output, error messages, etc.).

Here is a sample program listing:

0011 0005 0001 .field 1, 2

0012 0005 0003 .field 3, 4

0013 0005 0006 .field 6, 3

0014 0006 .even

Here is an example of a system prompt and a command that you might

enter:

C: csr –a /user/ti/simuboard/utilities

Read This First

iii

Page 4

Trademarks

-

In syntax descriptions, the instruction, command, or directive is in a bold

typeface font and parameters are in an

italic typeface

. Portions of a syntax

that are in bold should be entered as shown; portions of a syntax that are

italics

in

describe the type of information that should be entered. Here is

an example of a directive syntax:

.asect ”

section name

”,

address

.asect is the directive. This directive has two parameters, indicated by

tion name

and

address

. When you use .asect, the first parameter must be

an actual section name, enclosed in double quotes; the second parameter

must be an address.

-

Square brackets ( [ and ] ) identify an optional parameter. If you use an

optional parameter, you specify the information within the brackets; you

don’t enter the brackets themselves. Here’s an example of an instruction

that has an optional parameter:

LALK

The LALK instruction has two parameters. The first parameter,

stant

16–bit constant [, shift]

, is required. The second parameter,

16-bit con-

shift

, is optional. As this syntax

shows, if you use the optional second parameter, you must precede it with

a comma.

Square brackets are also used as part of the pathname specification for

VMS pathnames; in this case, the brackets are actually part of the pathname (they are not optional).

-

Braces ( { and } ) indicate a list. The symbol | (read as or) separates items

within the list. Here’s an example of a list:

sec-

Trademarks

{ * | *+ | *– }

This provides three choices: *, *+, or *–.

Unless the list is enclosed in square brackets, you must choose one item

from the list.

-

Some directives can have a varying number of parameters. For example,

the .byte directive can have up to 100 parameters. The syntax for this directive is:

.byte

value1 [, ... , valuen]

This syntax shows that .byte must have at least one value parameter, but

you have the option of supplying additional value parameters, separated

by commas.

TI is a trademark of Texas Instruments Incorporated.

NetLight and SpeedBlaster are trademarks of Lucent Technologies Inc.

iv

Page 5

Running Title—Attribute Reference

Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Introduction 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 TLK1501 EVM Kit Contents 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 TLK1501 EVM Board Configuration 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Typical Test and Setup Configurations 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Optical Interfacing and Configuration 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 PCB Construction and Characteristics 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Schematics, Board Layouts, and Suggested Optics and Cable

Assembly Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver B-1. . . . . . . . . .

Chapter Title—Attribute Reference

v

Page 6

Running Title—Attribute Reference

Figures

2–1 TLK1501 Serial Loop-Back Test Configuration 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 TLK1501 Serial Loop-Back Test Configuration 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 TLK1501 Serial PRBS BERT Test Configuration 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 TLK1501 Serial PRBS BERT Test Configuration 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 Optical Interface Configuration 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6 TLK1501EVM to Laser Module Configuration 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1 TLK1501 EVM Layer Construction 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1 TLK1501 EVM Transceiver Schematic A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–2 Optical Transceiver Schematic A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–3 Top Layer 1 A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–4 GND Layers 2 and 5 A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–5 Power Plane 1 A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–6 Bottom Layer 6 A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–7 Bottom Layer 7 A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–8 Top Layer 1 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–9 Detail of Top Layer 1 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–10 GND Layers 2 and 5 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–11 Detail of GND Layers 2 and 5 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–12 Power Plane 1 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–13 Detail of Power Plane 1 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–14 Bottom Layer 6 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–15 Detail of Bottom Layer 6 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–16 Bottom Layer 6 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–17 Detail of Bottom Layer 6 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ables

2–1 Default Transceiver Board Configuration as Shipped 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Configuration Changes Necessary for DC-Coupling of the High-Speed Signals 2-2. . . . . . . .

3–1 TLK1501 EVM TTL Bus PCB Transmission Line Characteristics 3-2. . . . . . . . . . . . . . . . . . . .

3–2 TLK1501 Differential Pair PCB Transmission Line Characteristics 3-2. . . . . . . . . . . . . . . . . . .

A–1 TLK1501 EVM Transceiver Bill of Materials A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 7

Chapter 1

Introduction

The Texas Instruments (TI) TLK1501 serdes evaluation module (EVM) board

is used to evaluate the TLK1501 device(VQFP) and associated optical interface (NetLight) for point-to-point data transmission applications.

The board enables the designer to connect 50 Ω parallel buses to both

transmitter and receiver connectors. The TLK1501, using high speed PLL

technology, serializes, encodes (8b/10b) and transmits data along one

differential pair. The receiver part of the device deserializes, decodes and

presents data on the parallel bus. The high speed (up to 1.6 Gbps) data lines

interface to four 50-Ω controlled-impedance SMA connectors. The designer

can either use this copper interface directly or loop back to the laser module

section for an optical interface(not provided).

Topic Page

1.1 Introduction 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

1-1

Page 8

Introduction

1.1 Introduction

The board can be used to evaluate device parameters while acting as a guide

for high-speed board layout. The evaluation board can be used as daughter

boards that are plugged into new or existing designs. Since the TLK1501

operates over a wide range of frequencies, the designers will need to optimize

their design for the frequency of interest. Additionally , the designers may wish

to use buried transmission lines and provide additional noise attenuation and

EMI suppression to optimize their end product.

As the frequency of operation increases, the board designer must take special

care to ensure that the highest signal integrity is maintained. To achieve this,

the board’s impedance is controlled to 50 Ω for both the high-speed differential

serial and parallel data connections. In addition, impedance mismatches are

reduced by designing the component pad size to be as close as possible to

the width of the connecting transmission lines. Vias are minimized and, when

necessary , placed as close as possible to the device drivers. Since the board

contains both serial and parallel transmission lines, care was taken to control

both impedance and trace length mismatch (board skew).

Overall, the board layout is designed and optimized to support high-speed

operation. Thus, understanding impedance control and transmission line

effects are crucial when designing high-speed boards.

Some of the advanced features offered by this board include:

-

PCB (printed-circuit board) is designed for high-speed signal integrity.

-

Flexibility–The PCB can be configured for copper or optical interfaces.

-

SMA and parallel fixtures are easily connected to test equipment.

-

All input/output signals are accessible for rapid prototyping.

-

Analog and digital power planes can be supplied through separate banana

jacks for isolation or can be combined using ferrite bridging networks.

-

Series termination resistors provide parallel RD outputs.

-

Onboard capacitors provide ac-coupling of high-speed signals.

1.2 TLK1501 EVM Kit Contents

-

TLK1501 EVM board

-

TLK1501 EVM kit documentation (This document)

1-2

Page 9

Chapter 2

TLK1501 EVM Board Configuration

The TLK1501 EVM board gives the developer various options for operation,

many of which are jumper selectable. Other options can be either soldered into

the EVM or connected through input connectors.

The TX and RX parallel connectors, J1–J4 of Figures 8 and 10 in Appendix A,

provide a connection for both transmitted and received data. The reference

clock is supplied through SMA connector J8 and jumper J5 must be installed

between pins 1 and 2. A direct clock connection can also be made to J5 pins

1 and 3. The high-speed serial data is transmitted through J13 and J14 SMA

connectors. The received recovered clock (RX_CLK) is output through J15

header. Received data connects through SMA connectors J17 and J23 on the

RX side of the board. Header J7 provides static signals (normally pulled high)

to configure the device for different modes of operation. The J20 header

indicates the optical transmitter has detected a signal and J21 allows the

operator to disable the optical transceiver.

The power planes are split three ways to provide power for different parts of

the board. This prevents coupling of switching noise between the analog and

digital sections of the TLK1501 and provides voltage isolation for the laser

section. The laser section of the board requires 3.3 volts and is energized

through the VCC connector. The VDD and VDDA connectors require 2.5 volts

and are joined together by a removable ferrite bead L3 that is installed in the

default configuration. Thus, only the VDD connection is necessary to energize

the TLK1501 device in the default configuration. In all sections of the board,

the ground planes are common and each ground plane is tied together at every

component ground connection. For a detailed schematic and layout see

TLK1501EVM Schematic, Optical Transceiver Schematic

Stack-up

in Appendix A.

and

Board Layer

Topic Page

2.1 Typical Test and Setup Configurations 2–3. . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Optical Interfacing and Configuration 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

TLK1501 EVM Board Configuration

2-1

Page 10

The board is normally delivered in a default configuration that requires external

clock and data inputs. The TLK1501 is shipped with jumpers for default

operation. Table 2–1 shows the default configuration for sending data.

Table 2–1.Default Transceiver Board Configuration as Shipped

Designator Function Condition

J5 GTX CLK SEL Jumper installed – Provides a method of supplying an input clock to

the board

J7 TESTEN Jumper installed (Logic 0)

Disables the TLK1501 test mode

J7 PRBSEN Jumper installed (Logic 0)

Disables the TLK1501 PRBS internal production test mode

J7 LCKREFN Jumper not installed (Logical 1)

Locks to received clock

J7 ENABLE Jumper not installed (Logical 1)

Enables the device for normal operation

J7 TXER Jumper installed (Logic 0)

Puts the TLK1501 in a state to transmit TX bus data

J7 LOOPEN Jumper installed (Logic 0)

Disables the TLK1501 internal loop back mode

J7 TXEN Jumper not installed (Logical 1)

Puts the TLK1501 in a state to transmit TX bus data

L3 VDD– bridge –VDDA Joins VDD and VDDA power planes

C24, C25 TX ac-coupling

capacitors

C22, C23 RX ac-coupling

capacitors

Note: For details, see TLK1501 data sheet

These capacitors (normally installed) are provided to ac-couple the

transmitted signal.

These capacitors (normally installed) are provided to ac-couple the

received signal

Table 2–2.Configuration Changes Necessary for DC Coupling of the High Speed Signals

Designator Function Condition or Changes Necessary for DC Coupling

C24, C25 TX ac-coupling

capacitors

C22, C23 TX ac-coupling

capacitors

R34 RX bias resistor Install zero ohm resistor.

R33 RX bias resistor Uninstall resistor (open circuit)

Install zero ohm resistors

Install zero ohm resistors.

R37, R38 TX termination

network

2-2

Uninstall resistors (open circuit) – Termination and pullup is achieved

at the receiver. Dif ferential swing is increased.

Page 11

2.1 Typical Test and Setup Configurations

The following configurations are used to evaluate and test the TLK1501

transceiver. The first configuration is a serial loopback of the high-speed

signals shown in Figure 2–1. The serial loopback allows the designer to

evaluate most of the functions of both transmitter and receiver sections of the

TLK1501 device. To test a system, a parallel bit error rate tester (BERT)

generates a predefined parallel bit pattern. The pattern is connected to the

transmitter through parallel connectors TD0–TD15. Additionally, two control

pins TX_ER and TX_EN are configured by the BERT for valid data

transmission (TX_ER low and TX_EN high). The TLK1501 device encodes,

serializes, and presents the data on the high-speed serial pair. The serial TX

data is then looped back to the receiver side and the device deserializes,

decodes, and presents the data on the receive side RD0–RD15. The data and

indication bits (RX_DV and RX_ER) are received by the BERT and compared

against the transmitted pattern and monitored for valid data and errors. If any

bit errors are received, a bit error rate is evaluated at the parallel receive BERT .

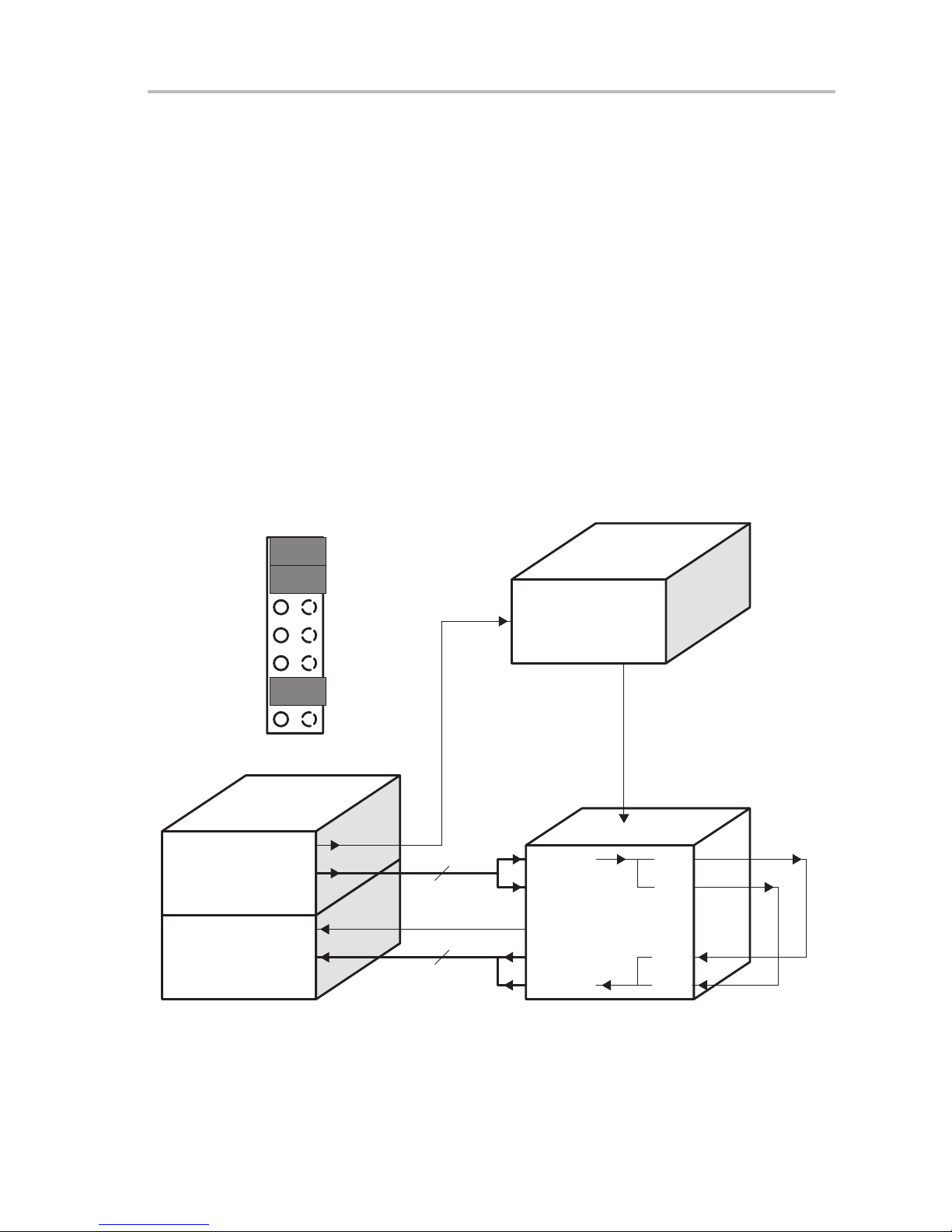

Figure 2–1.TLK1501 Serial Loop-Back Test Configuration

Jumper Selection

GND

TESTEN

PRBSEN

LCKREFN

J7

ENABLE

TX_ER

Pulse Generator

(Asynchronous to BERT)

EXT INPUT

T ypical Test and Setup Configurations

HP8133A

Channel 1

O/P

LOOPEN

TX_EN

GND

Parallel BERT

Frequency = 30-80 MHz

CLK OUT

TX Data Out 0-17

CLK IN

RX Data In 0-17

Receiver BERT

18 bits

18 bits

GTX_CLK

TD 0-15

TX_EN

TX_ER

RX CLK

RX_ER

RX_DV

RD 0-15

TLK1501EVM

Evaluation Board

TX+

TX–

RX+

RX–

TLK1501 EVM Board Configuration

2-3

Page 12

T ypical Test and Setup Configurations

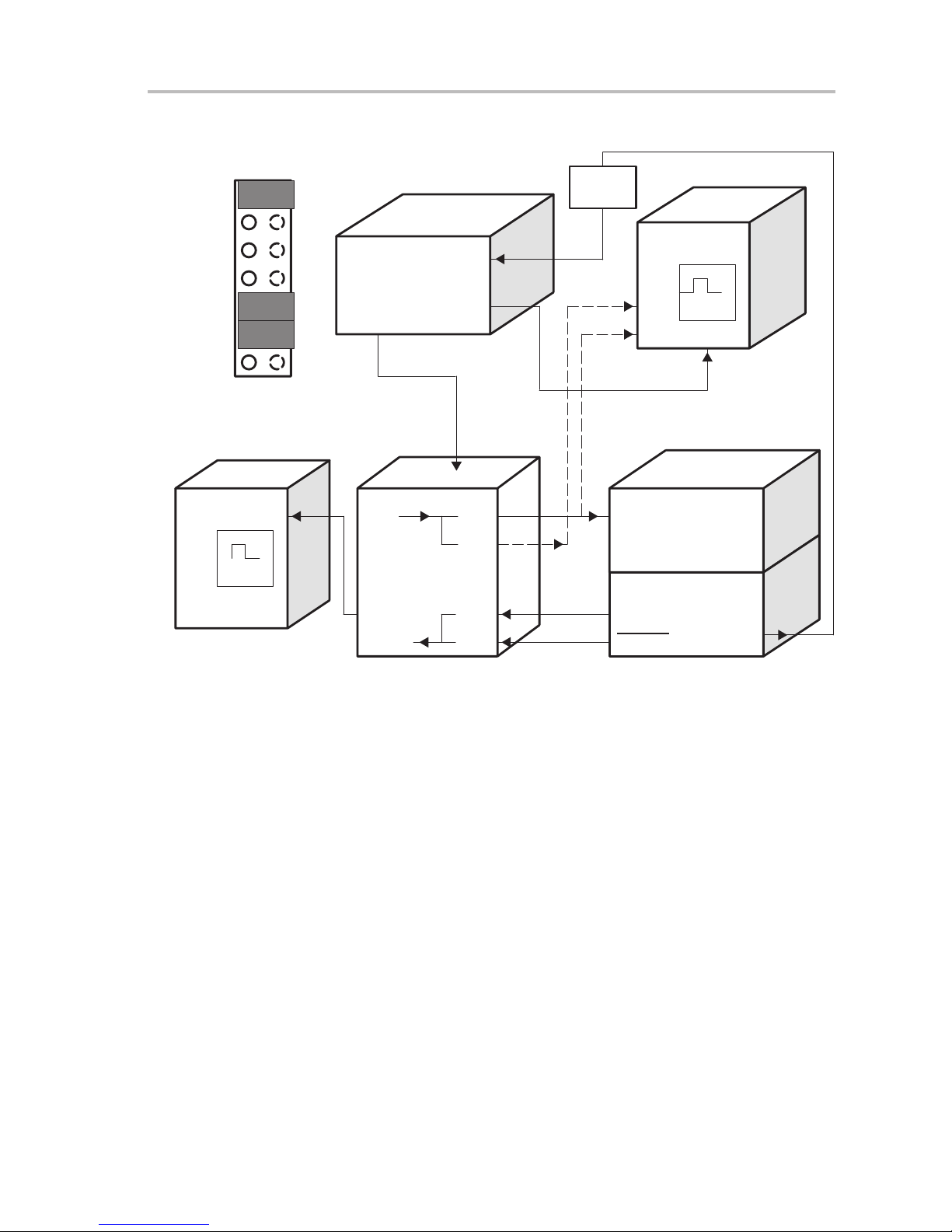

If a parallel BERT is not available, the designer can take advantage of the

built-in test mode of the device, see Figure 2–2. If the designer asserts the

PRBSEN pin high this results in a pseudorandom bit pattern to be transmitted.

This pin also puts the receiver in a mode to detect a valid PRBS pattern. A valid

pattern is indicated by the PRBSPASS pin indicating high. This test only

validates the high-speed serial portion of the device and system interconnects.

The PRBS pattern is compatible with most serial BERT test equipment. This

function allows the operator to isolate and test the transmitter and receiver

independently. A typical configuration is shown in Figure 2–3. The dashed

lines represent optional connections that can be made monitoring eye patterns

and measuring jitter.

Figure 2–2.TLK1501 Serial Loop-Back Test Configuration

Jumper Selection

GND

TESTEN

PRBSEN

LCKREFN

ENABLE

TX_ER

LOOPEN

TX_EN

J7

Channel 1

GND

HP8133A

Pulse Generator

TRIGGER

O/P

EXT

INPUT

OUT

HP83480 or

Tek 11801

Digital

Oscilloscope

CH1

CH2

Trigger

Channel 1

TDS820 Digital

Oscilloscope

GTX_CLK

PRBS

2^7-1

PRBS_PASS

RD 0-15

TLK1501EVM

Evaluation Board

TX–

TX+

RX+

RX–

PRBS 2^7-1

2-4

Page 13

Figure 2–3.TLK1501 Serial PRBS BERT Test Configuration

Jumper Selection

GND

TESTEN

PRBSEN

LCKREFN

ENABLE

TX_ER

LOOPEN

TX_EN

GND

Channel 1

J7

Pulse Generator

Channel 1

O/P

PRBS

2^7-1

HP8133A

EXT

INPUT

TRIGGER

OUT

GTX_CLK

TX–

TX+

CLK/20

T ypical Test and Setup Configurations

HP83480 or

Tek 11801

Digital

Oscilloscope

CH1

CH2

Trigger

Serial BERT

HP7004A 3 Gbps

Receiver BERT

Data In

TDS820 Digital

Oscilloscope

Transmitter BERT

PRBS_PASS

RD 0-15

TLK1501EVM

Evaluation Board

RX+

RX–

PRBS 2^7-1

Data Out

Data Out

CLK OUT

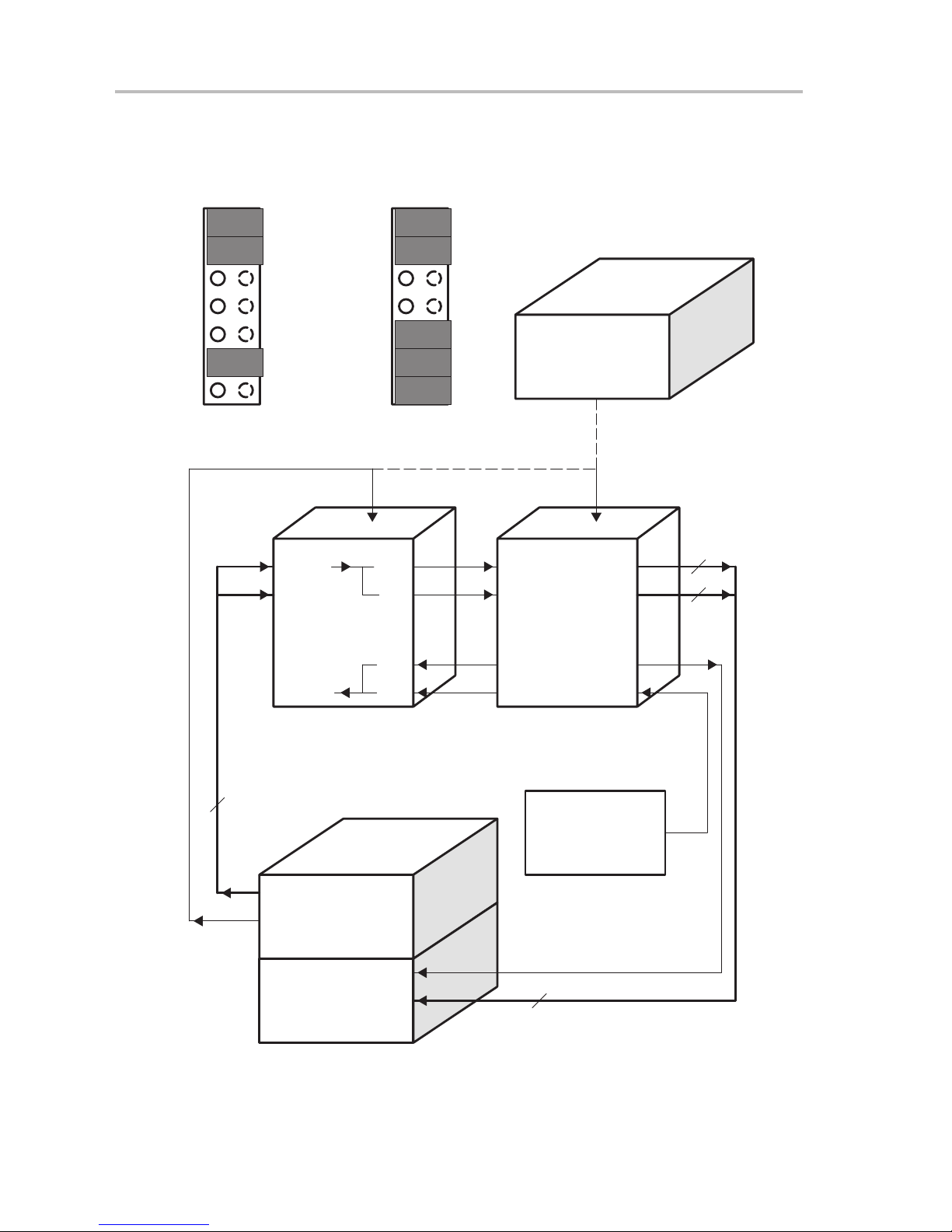

A board-to-board communication link is a practical method of evaluating the

TLK1501 in a system-like environment as shown in Figure 2–4. A Parallel

BERT or a logic analyzer can be used to provide and monitor signals to and

from the transceiver pairs. The BERT would need to configure the TX_ER and

TX_EN signals for data transmission before any data is sent. On the receive

side the RX_ER and RX_DV can monitor the device for errors. Both GTX_CLK

sources must have the same frequency within 200 PPM for asynchronous

operation. Synchronous operation can be achieved by using either the BERT

or a synchronized pulse generator to supply both boards with GTX_CLK

inputs.

TLK1501 EVM Board Configuration

2-5

Page 14

T ypical Test and Setup Configurations

Figure 2–4.TLK1501 Serial PRBS BERT Test Configuration

Jumper Selection

TESTEN

PRBSEN

LCKREFN

ENABLE

TX_ER

LOOPEN

TX_EN

EVM #1

GND

GND

J7

TD 0-15

TX_EN

TX_ER

TESTEN

PRBSEN

LCKREFN

ENABLE

TX_ER

LOOPEN

TX_EN

GTX_CLK

TX+

TX–

EVM #2

GND

GND

J7

Synchronous

RX+

RX–

HP8133A

Pulse Generator

(Asynchronous to BERT)

EXT INPUT

Channel 1

GTX_CLK

Trigger

O/P

Asynchronous

RD 0-15

RX_ER

Rx_DV

16 bits

2 bits

18 bits

TX Data Out 0-17

CLK Out

RX+

RD 0-15

TLK1501EVM #1

Evaluation Board EVM1

PRBS Disabled

Parallel BERT

Frequency = 30-80 MHz

Transmitter BERT

RX Data In 0-17

Receiver BERT

RX–

CLK IN

TX+

TX–

TLK1501EVM #2

Evaluation Board EVM2

Board configued to

send IDLE pattern:

TX_EN = 0

TX_ER = 0

18 bits

RX_CLK

TD 0-15

PRBS Disabled

Channel

1

2-6

Page 15

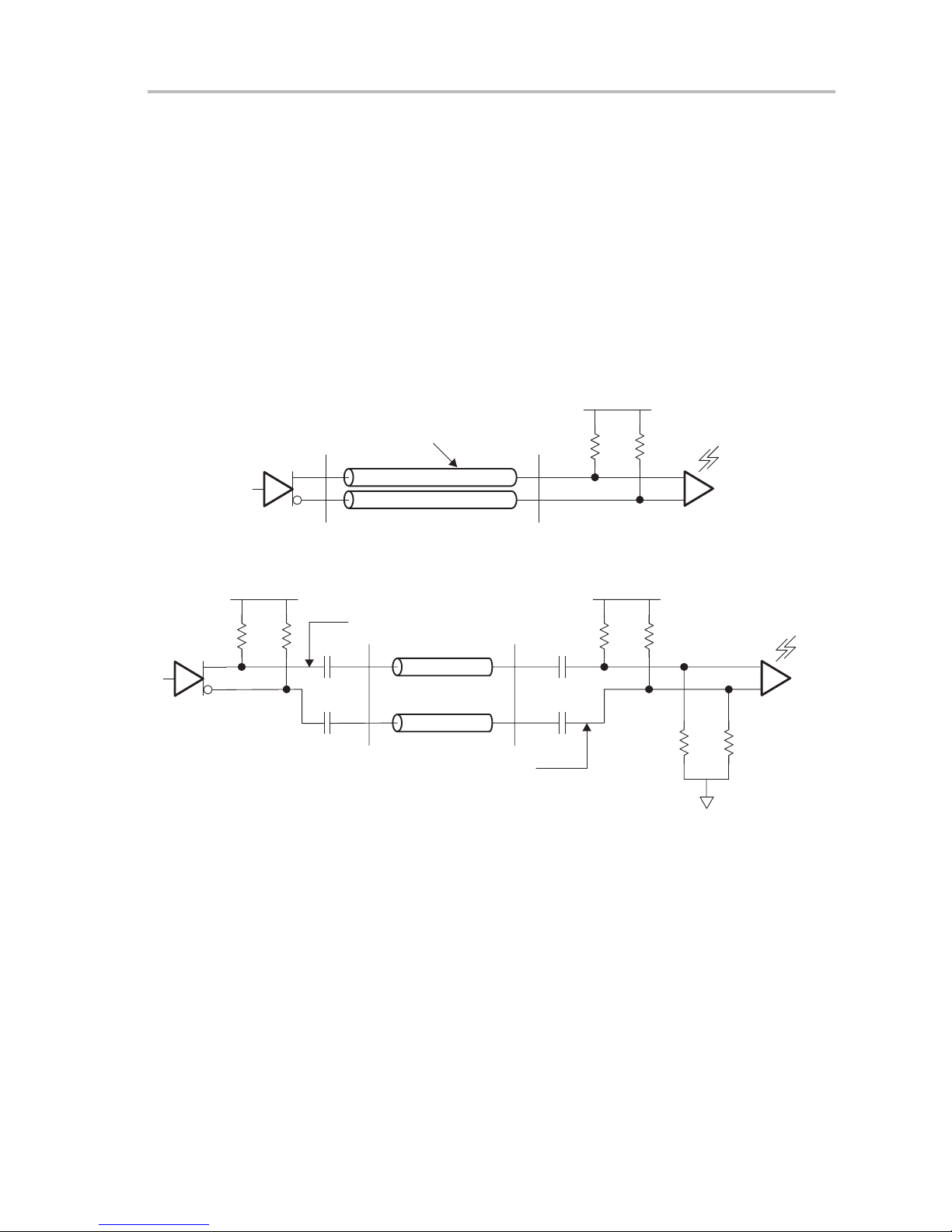

2.2 Optical Interfacing and Configuration

An interface between the TLK1501EVM and an optical transceiver can be

achieved in many ways, depending on the design of the optics module and its

associated interface circuitry . Direct connection is achieved only if the optical

interface supports the current mode logic levels of the TLK1501 device (VDD

– 1 V). If the optics module does not support or can not be biased to the CML

levels then ac-coupling must be used. Both ac- and dc-coupling schemes are

shown in Figure 2–5. The

an ac-coupled optics module. The board is shipped with an ac-coupled output

and all that is required is external loopback cabling.

Figure 2–5.Optical Interface Configuration

Laser Module Section

Optical Interfacing and Configuration

of the EVM is configured as

AC Coupling

TLK1501 TX

DC Coupling

TLK1501 TX

V

DD

50 Ω

CMLDC bias levels

voltage ≈ (VDD-1 V)

Biased to CML Levels

Biased to PECL Levels

50 Ω

50 Ω

V

DD

Optical Module

V

CC

Optical Module

50 Ω

The

external loopback as shown in Figure 2–6. This makes for a versatile system

where the laser can be connected independently to other EVM systems.

Laser Module Section

is isolated from the rest of the board and requires

TLK1501 EVM Board Configuration

2-7

Page 16

Optical Interfacing and Configuration

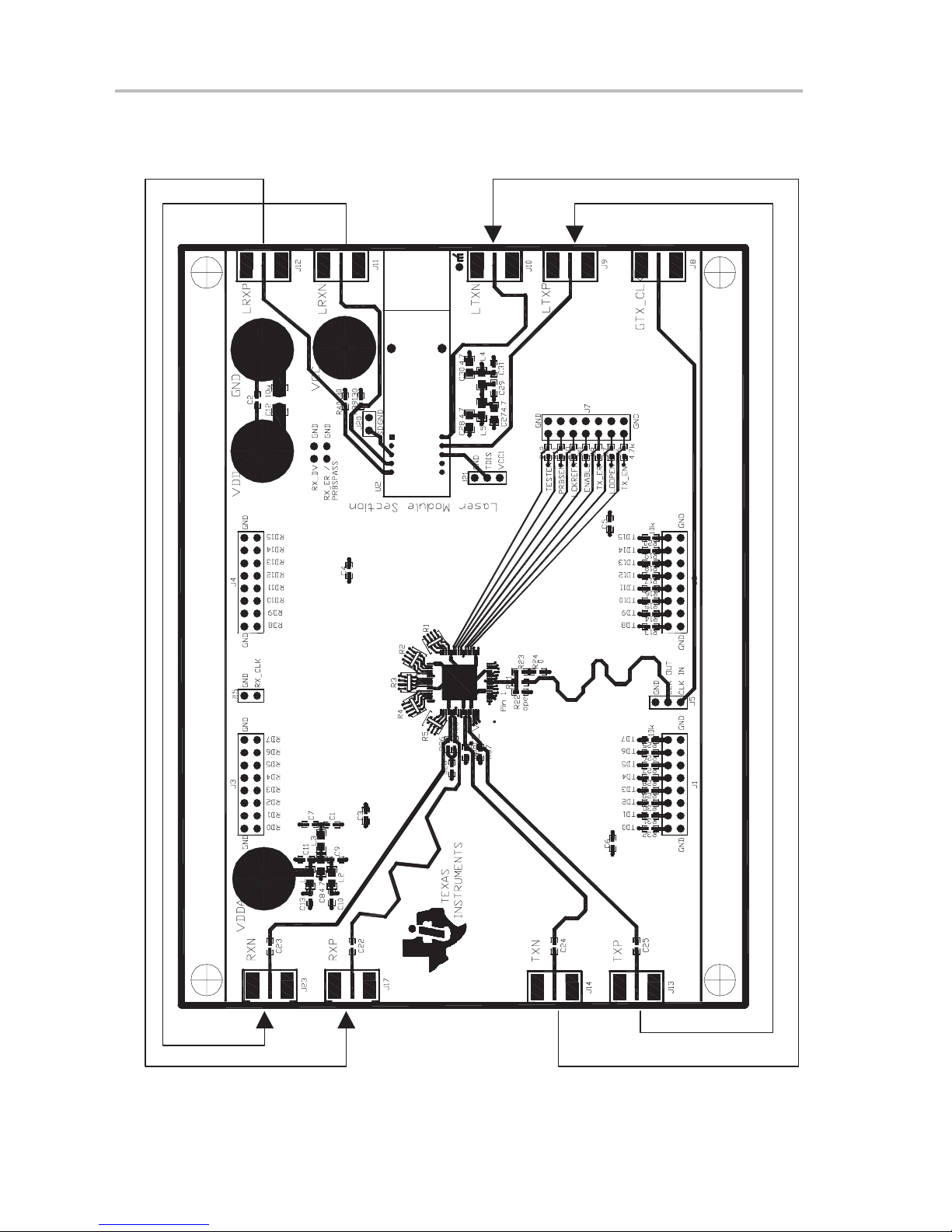

Figure 2–6.TLK1501 EVM to Laser Module Configuration

2-8

TLK2500 EVM Board Configuration

Page 17

Chapter 3

PCB Construction and Characteristics

The PCB characteristics are calculated and based on the layer construction

and trace width of the board. This should be useful in determining the proper

interface to the EVM and establishing system timing.

PCB Construction and Characteristics

3-1

Page 18

Table 3–1.TLK1501 EVM TTL Bus PCB Transmission Line Characteristics

Device

Pin No./Des.

62 – TXD0 TD0 0.0118 1.887 5.2 14.1 51.9 272.1

63 – TXD1 TD1 0.0118 1.884 5.2 14.1 51.9 271.7

64 – TXD2 TD2 0.0118 1.904 5.3 14.3 51.9 274.7

2 – TXD3 TD3 0.0118 1.898 5.3 14.2 51.9 273.7

3 – TXD4 TD4 0.0118 1.903 5.3 14.2 51.9 274.4

4 – TXD5 TD5 0.0118 1.899 5.3 14.2 51.9 273.8

6 – TXD6 TD6 0.0118 1.901 5.3 14.2 51.9 274.1

7 – TXD7 TD7 0.0118 1.906 5.3 14.3 51.9 274.8

10 – TXD8 TD8 0.0118 1.860 5.2 13.9 51.9 268.2

11 – TXD9 TD9 0.0118 1.908 5.3 14.3 51.9 275.1

12 – TXD10 TD10 0.0118 1.884 5.2 14.1 51.9 271.7

14 – TXD11 TD11 0.0118 1.912 5.3 14.3 51.9 275.7

15 – TXD12 TD12 0.0118 1.903 5.3 14.2 51.9 274.4

16 – TXD13 TD13 0.0118 1.910 5.3 14.3 51.9 275.4

17 – TXD14 TD14 0.0118 1.911 5.3 14.3 51.9 275.6

19 – TXD15 TD15 0.0118 1.901 5.3 14.2 51.9 274.1

51 – RXD0 RD0 0.0118 1.814 5.0 13.6 51.9 26.6

50 – RXD1 RD1 0.0118 1.804 5.0 13.5 51.9 260.3

49 – RXD2 RD2 0.0118 1.802 5.0 13.5 51.9 259.9

47 – RXD3 RD3 0.0118 1.862 5.2 13.9 51.9 268.5

46 – RXD4 RD4 0.0118 1.866 5.2 14.0 51.9 269.1

45 – RXD5 RD5 0.0118 1.876 5.2 14.0 51.9 270.5

44 – RXD6 RD6 0.0118 1.880 5.2 14.1 51.9 271.1

42 – RXD7 RD7 0.0118 1.865 5.2 14.0 51.9 268.9

40 – RXD8 RD8 0.0118 1.860 5.2 13.9 51.9 268.2

39 – RXD9 RD9 0.0118 1.860 5.2 13.9 51.9 268.2

37 – RXD10 RD10 0.0118 1.863 5.2 13.9 51.9 268.6

36 – RXD11 RD11 0.0118 1.872 5.2 14.0 51.9 269.9

35 – RXD12 RD12 0.0118 1.816 5.0 13.6 51.9 261.9

34 – RXD13 RD13 0.0118 1.855 5.2 13.9 51.9 267.5

32 – RXD14 RD14 0.0118 1.809 5.0 13.9 51.9 260.9

31 – RXD15 RD15 0.0118 1.821 5.1 13.6 51.9 262.9

Note: All values presented in this table are theoretical calculated values and may not reflect actual measured parameters.

Connector

Pin Label

Trace Width

(inches)

Length

(inches)

Capacitance

(pF)

Inductance

(nH)

Impedance

(Ω)

Line Delay

(ps)

Table 3–2.TLK1501 Differential Pair PCB Transmission Line Characteristics

Device

Pin No.

60 – DOUTTXP TXP 0.025 2.390 51.2 347.5

59 – DOUTTXN TXP 0.025 2.363 51.2 343.6

54 – DINRXP RXP 0.025 2.889 51.2 420.1

53 – DINRXN RXN 0.025 2.883 51.2 419.2

Note: All values presented in this table are theoretical calculated values and may not reflect actual measured parameters.

3-2

Connector

Pin No.

Trace Width

(inches)

Length

(inches)

Impedance

(Ω)

Line Delay

(ps)

Page 19

Figure 3–1.TLK1501 EVM Layer Construction

Layer 1 Top 50 Ω

Layer 2

Layer 3

Layer 4

Layer 5

Layer 6

Notes:

1) All cores consist of 1 oz. Cu.

2) Trace width

A) 25 mils (for 50 Ω Layer 1)

B) 11.8 mils (for 50 Ω Layer 6)

3) Overall board thickness is 62 mils ±5 mil

4) Copper and solder mask adds approximately 10 mils to the overall board thickness.

5) Impedance is 50 Ω ±5%

6) Material is G-Tek. Dielectric constant = 3.9

7) For overall thickness: add 1.2 to 1.4 mils for each metal layer in the stack-up.

14 Mil

5 Mil

21 Mil

05 Mil

07 Mil

GND1

V

DD1

V

DD2

GND2

Solder 50 Ω

PCB Construction and Characteristics

3-3

Page 20

3-4

Page 21

Appendix A

Schematics, Board Layouts, and Suggested

Optics and Cable Assembly Specifications

This appendix contains schematics and corresponding bill of materials for the

TLK1501EVM transceiver board along with board layouts. Specifications for

the NetLight 1417K4A 1300 nm laser assembly are also included.

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-1

Page 22

Figure A–1.TLK1501 EVM Transceiver Schematic

VDD

VDD

J19

0.01

0.01

0.01

0.01

0.01

100p

100p

100p

100p

100p

100p

J1

1

3

5

7

9

11

13

15

GND

10u

C32

C33

C34

C35

C36

C37

J22

C12

C6

C5

C4

C3

C2

VDD

10k 10k 10k 10k 10k 10k 10k

10k

R30 R31

R28 R29

R27R26R25

2

4

6

8

10

12

14

16

C14

VDD

TXP

J13

C25

R32

VDD

0.01

VDDA2

0.01

C38

J14

VDDA2

0.01

R37

49.9

C24

R38

49.9

0.01

C51

TXN

0.01

VDDA1

VDDA1

RXP

0.01

C39

J17

C22

C21

0.01

C19

0.01

C20

0.01

VDDA1

VDDA2

RXN

0.01

C40

J23

0.01

49.9

C23

R36

R35

49.9

C26

0.01

R33

825

R41

R5

VDDA1

0.01

C41

0.01

VDDA2

R34

200

100

51

VDD

C18 0.01

R4

J3

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

2 3

J8

GTX_CLK

VDD

open

R22

R21

0

1

J5

0.01

C42

1

3

5

7

9

11

13

15

49.9

R23

R24

0

J2

2

4

6

8

10

12

14

16

10k

10k 10k 10k 10k 10k 10k

R16 R17 R18 R19 R20R13

R14 R15

VDD

C15

0.01

VDD

R6

10k

VDD

4.7k

R7

4.7k

R8

4.7k

R9

4.7k

R10

4.7k

R11

4.7k

R12

4.7k

J7

VDD

C16

2

412141086

TLK1501

0.01

913 5 7 11 13

VDD

51

R1

2 4

J6

1

VDDA1

3

L1

J16

R3

R2

VDDA

51

J15

51

C17

0.01

51

J4

1

3

5

7

9

11

13

VDDA2

0.01

C13

0.01

C11

L3

VDD

15

0.01

C10

L2

0.01

C9

4.7

C8

0.01

C7

0.01

C1

2

4

6

8

10

12

14

16

A-2

Page 23

Figure A–2.Optical Transceiver Schematic

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-3

Page 24

Table A–1.TLK1501 EVM Transceiver Bill of Materials

Item Qty Mfg / Dist. Mfg Part No. Ref Des Description Value or Function

1 1 Digi-Key S2011–02–ND J6 2×2 HEADER 0.1 x 0.1 Centers

2 1 Digi-Key S2011–07–ND J7 2×7 HEADER 0.1 x 0.1 Centers

3 4 Digi-Key ECS–T1DX475R J1, J2, J3, J4 2×8 HEADER 0.1 x 0.1 Centers

4 1 Digi-Key S1111–03–ND J5 3 Pin jumper 0.1 Centers

5 4 Newark 39N867 J16,J18,J19,

J22

6 40 Digi-Key PCC1784CT–ND C1–C7,

C9–C11,

C13–C26, C29,

C31, C38–C51

7 4 Digi-Key PCC1842CT–ND C8,C27,

C28,C30

8 1 Digi-Key PCC1894CT–ND C12 Capacitor, SMT0805 25 V, 5%, 10 µF

9 3 Digi-Key 240–1018–1ND L1 – L3 Ferrite bead

10 2 Digi-Key S1111–02–ND J15, J20 Jumper Header, 1×2,

11 1 Lucent 1417K4A LAS U2 Laser Transceiver 2.5 Gbps

12 2 Digi-Key TSW–110–07–G–D R21, R24 Resistor, SMT, 0402 0 Ω

13 7 ANY P4.75KLTC–ND R6–R12 Resistor, SMT, 0402 4.7 kΩ

14 16 Digi-Key P10.0KLTC–ND R15–R20,

R25–R32

15 5 Digi-Key P49.9LCT–ND R23, R35, R36,

R37, R38

16 2 Digi-Key P130LTC–ND R39, R40 Resistor, SMT, 0402 130 Ω

17 2 Digi-Key P200LTC–ND R34, R41 Resistor, SMT, 0402 200 Ω

18 1 Digi-Key P825LTC–ND R33 Resistor, SMT, 0402 825 Ω

19 1 N/A N/A R22 Resistor, SMT, 0402 OPEN

20 5 MNR14 E0AB J 510 R1, R2, R3, R4,R5Resistor R–PAC(4) 51 Ω

Banana jack 100 V, 5%, 0.1 µF

Capacitor, SMT603 25 V, 5%, 0.01 µF

Capacitor, SMT0603 25 V, 5%, 4.7 µF

600 Ω

805 500ma

0.1 Center

Resistor, SMT, 0402 10 kΩ

Resistor, SMT, 0402 49.9 Ω

21 9 Newark 142–0711–821 SMA end-launch 422 Ω

22 4 Newark 92N4922 Standoff Standoff 0.5’ 4–40 thread

23 4 Newark 30F082 Machine Screw 4–40 × 3/8’

24 1 TI TLK1501 U1 TI TLK1501 DUT 64 PIN VQFP

25 6 Digi-Key PCC101ACVCT–ND C32–C37 Capacitor, SMT 0603 25 V, 20%, 100 pF

A-4

Page 25

Figure A–3.Top Layer 1

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-5

Page 26

Figure A–4.GND Layers 2 and 5

A-6

Page 27

Figure A–5.Power Plane 1

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-7

Page 28

Figure A–6.Bottom Layer 6

A-8

Page 29

Figure A–7.Bottom Layer 7

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-9

Page 30

Figure A–8.Top Layer 1

A-10

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

Page 31

R2

R1

R23

0

R24

R3

R4

R5

R21

Pin 1

R22

open

0

Figure A–9.Detail of Top Layer 1

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-11

Page 32

Figure A–10. GND Layers 2 and 5

A-12

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

Page 33

Figure A–11. Detail of GND Layers 2 and 5

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-13

Page 34

Figure A–12. Power Plane 1

A-14

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

Page 35

Figure A–13. Detail of Power Plane 1

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-15

Page 36

Figure A–14. Bottom Layer 6

A-16

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

Page 37

Figure A–15. Detail of Bottom Layer 6

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-17

Page 38

Figure A–16. Bottom Layer 6

A-18

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

Page 39

Figure A–17. Detail of Bottom Layer 6

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

A-19

Page 40

A-20

Schematics, Board Layouts, and Suggested Optics and Cable Assembly Specifications

Page 41

Appendix B

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s

SpeedBlaster Transceiver

The document shown in this appendix is an advanced information data sheet

from Lucent Technologies Inc.

Topic Page

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s Speedmaster

Transceiver Data Sheet B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lucent, NetLight, and Speedmaster are a trademarks of Lucent Technologies Inc.

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver

B-1

Page 42

B-2

Page 43

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver

B-3

Page 44

B-4

Page 45

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver

B-5

Page 46

B-6

Page 47

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver

B-7

Page 48

B-8

Page 49

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver

B-9

Page 50

B-10

Page 51

NetLight 1417K4A 1300 nm Laser 2.5 Gbits/s SpeedBlaster Transceiver

B-11

Page 52

B-12

Page 53

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

TLK1501EVM

Loading...

Loading...