TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

D

Optimized for Off-Line and dc-to-dc

Converters

D

Low Start-Up Current (<1 mA)

D

Automatic Feed-Forward Compensation

D

Pulse-by-Pulse Current Limiting

D

Enhanced Load-Response Characteristics

D

Undervoltage Lockout With Hysteresis

D

Double-Pulse Suppression

D

High-Current Totem-Pole Output

D

Internally Trimmed Bandgap Reference

D

500-kHz Operation

D

Error Amplifier With Low Output

COMP

ISENSE

NC – No internal connection

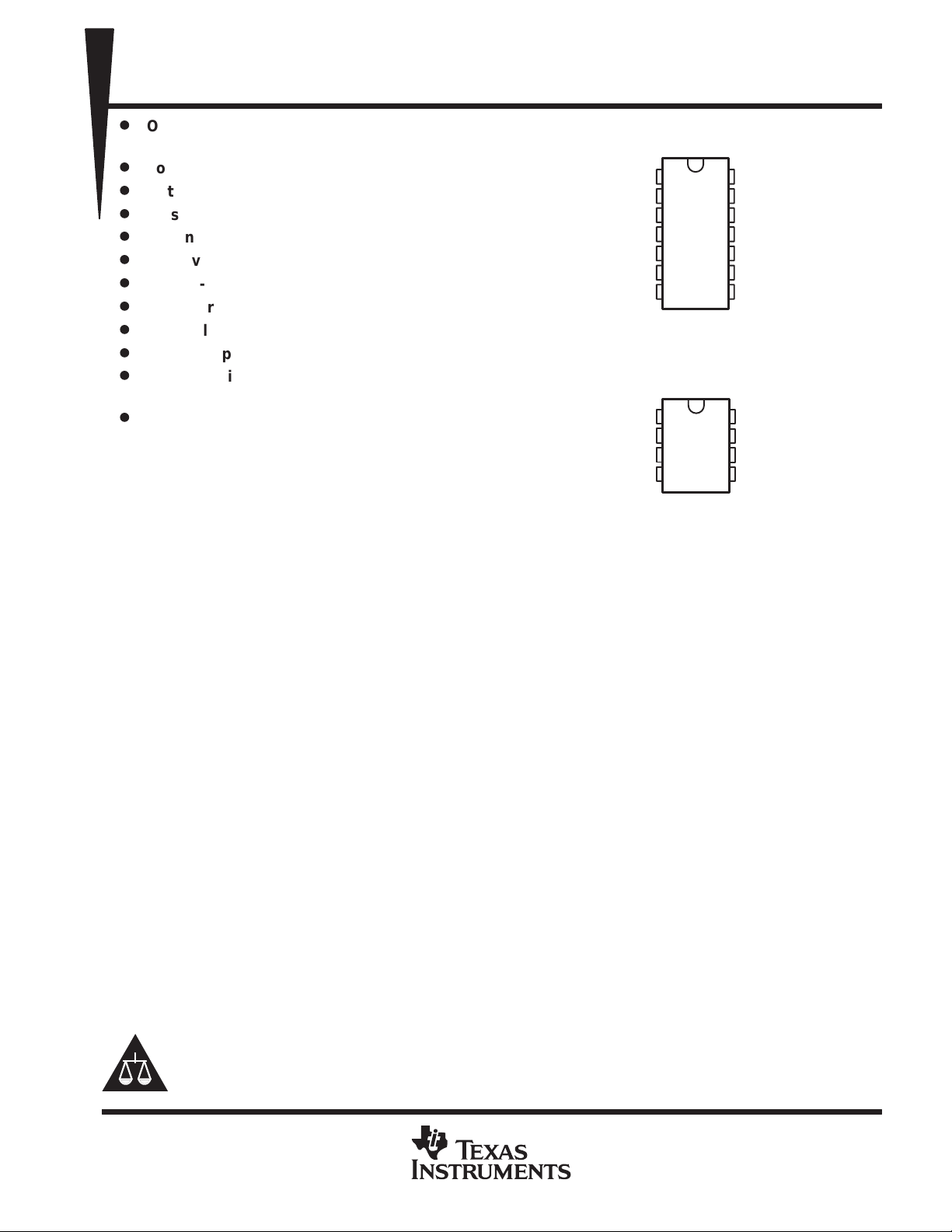

D PACKAGE

(TOP VIEW)

1

2

NC

3

VFB

4

NC

5

6

NC

RT/CT

7

D-8 OR P PACKAGE

(TOP VIEW)

REF

14

13

NC

12

V

CC

11

VC

10

OUTPUT

9

GND

8

POWER GROUND

Resistance

D

Designed to Be Interchangeable With

UC2842 and UC3842 Series

description

COMP

VFB

ISENSE

RT/CT

1

2

3

4

8

7

6

5

REF

V

CC

OUTPUT

GND

The TL284x and TL384x series of control

integrated circuits provide the features that are

necessary to implement off-line or dc-to-dc fixed-frequency current-mode control schemes with a minimum

number of external components. Some of the internally implemented circuits are an undervoltage lockout

(UVLO), featuring a start-up current of less than 1 mA, and a precision reference trimmed for accuracy at the

error amplifier input. Other internal circuits include logic to ensure latched operation, a pulse-width modulation

(PWM) comparator (which also provides current-limit control), and a totem-pole output stage designed to source

or sink high-peak current. The output stage, suitable for driving N-channel MOSFETs, is low when it is in the

off state.

Major differences between members of these series are the UVLO thresholds and maximum duty-cycle ranges.

Typical UVLO thresholds of 16 V (on) and 10 V (of f) on the TLx842 and TLx844 devices make them ideally suited

to off-line applications. The corresponding typical thresholds for the TLx843 and TLx845 devices are 8.4 V (on)

and 7.6 V (off). The TLx842 and TLx843 devices can operate to duty cycles approaching 100%. A duty-cycle

range of 0 to 50% is obtained by the TLx844 and TLx845 by the addition of an internal toggle flip-flop, which

blanks the output off every other clock cycle.

The TL284x-series devices are characterized for operation from –40°C to 85°C. The TL384x-series devices are

characterized for operation from 0°C to 70°C.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Copyright 1999, Texas Instruments Incorporated

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

TL284x, TL384x

CHIP FORM

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

T

A

0°C to 70°C

–40°C to 85°C

The D and D-8 packages are available taped and reeled. Add the suffix R to the device type (i.e.,

TL3842DR or TL3842DR-8).

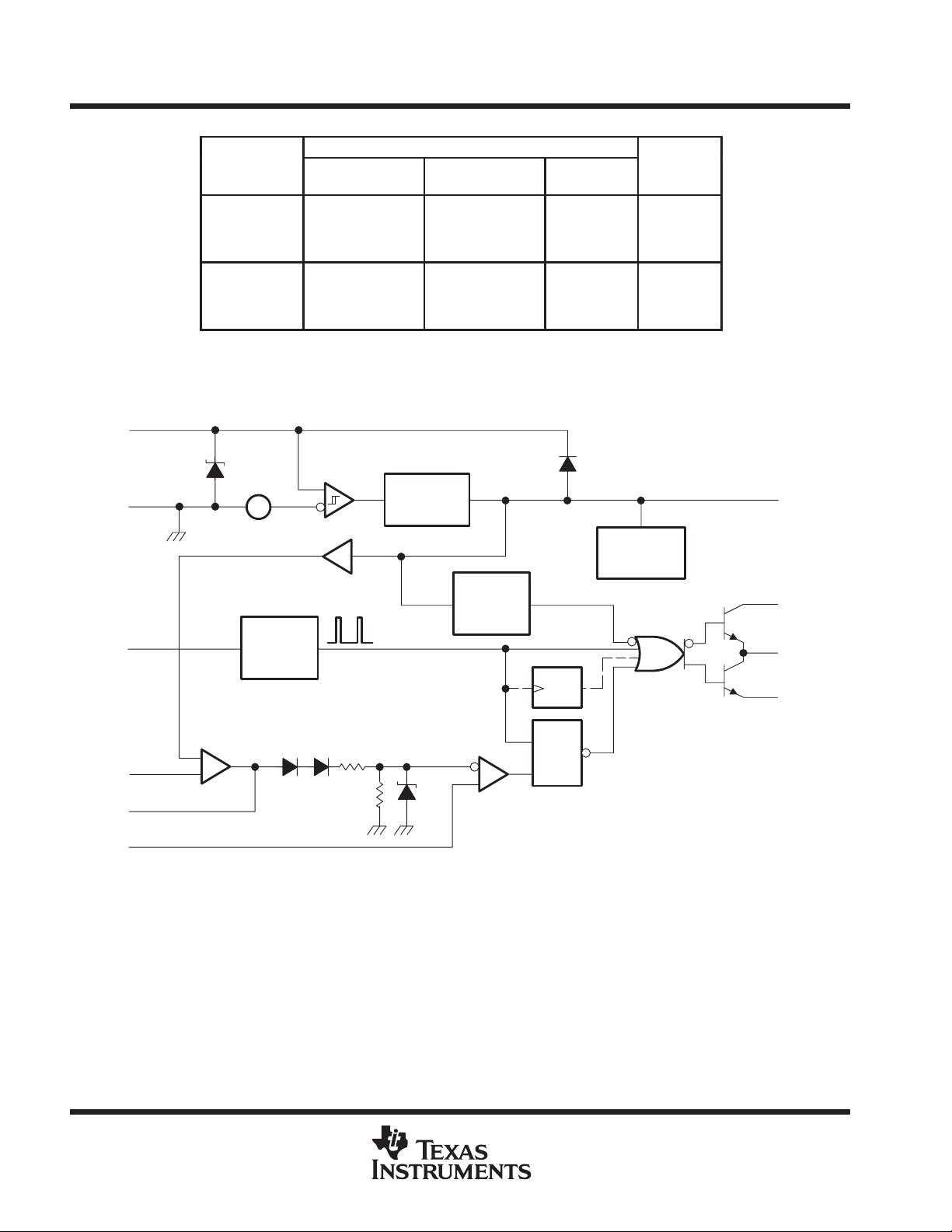

functional block diagram

12

V

CC

SMALL OUTLINE

(D)

TL3842D

TL3843D

TL3844D

TL3845D

TL2842D

TL2843D

TL2844D

TL2845D

Chip forms are tested at 25°C.

AVAILABLE OPTIONS

PACKAGED DEVICES

SMALL OUTLINE

(D-8)

TL3842D-8

TL3843D-8

TL3844D-8

TL3845D-8

TL2842D-8

TL2843D-8

TL2844D-8

TL2845D-8

PLASTIC DIP

(P)

TL3842P

TL3843P

TL3844P

TL3845P

TL2842P

TL2843P

TL2844P

TL2845P

(Y)

TL3842Y

TL3843Y

TL3844Y

TL3845Y

–

–

–

–

34 V NOM

9

GND

VFB

7

3

1

5

RT/CT

COMP

ISENSE

†

The toggle flip-flop is present only in TL2844, TL2845, TL3844, and TL3845.

Pin numbers shown are for the D Package.

–

OSC

Error

Amplifier

+

–

UVLO

+

2R

5-V REF

EN

R1 V

Current-

Comparator

V

ref

Good

Logic

Sense

14

REF

Internal

Bias

11

VC

10

OUTPUT

†

T

S

R

PWM

Latch

8

POWER

GROUND

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

O

T

TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

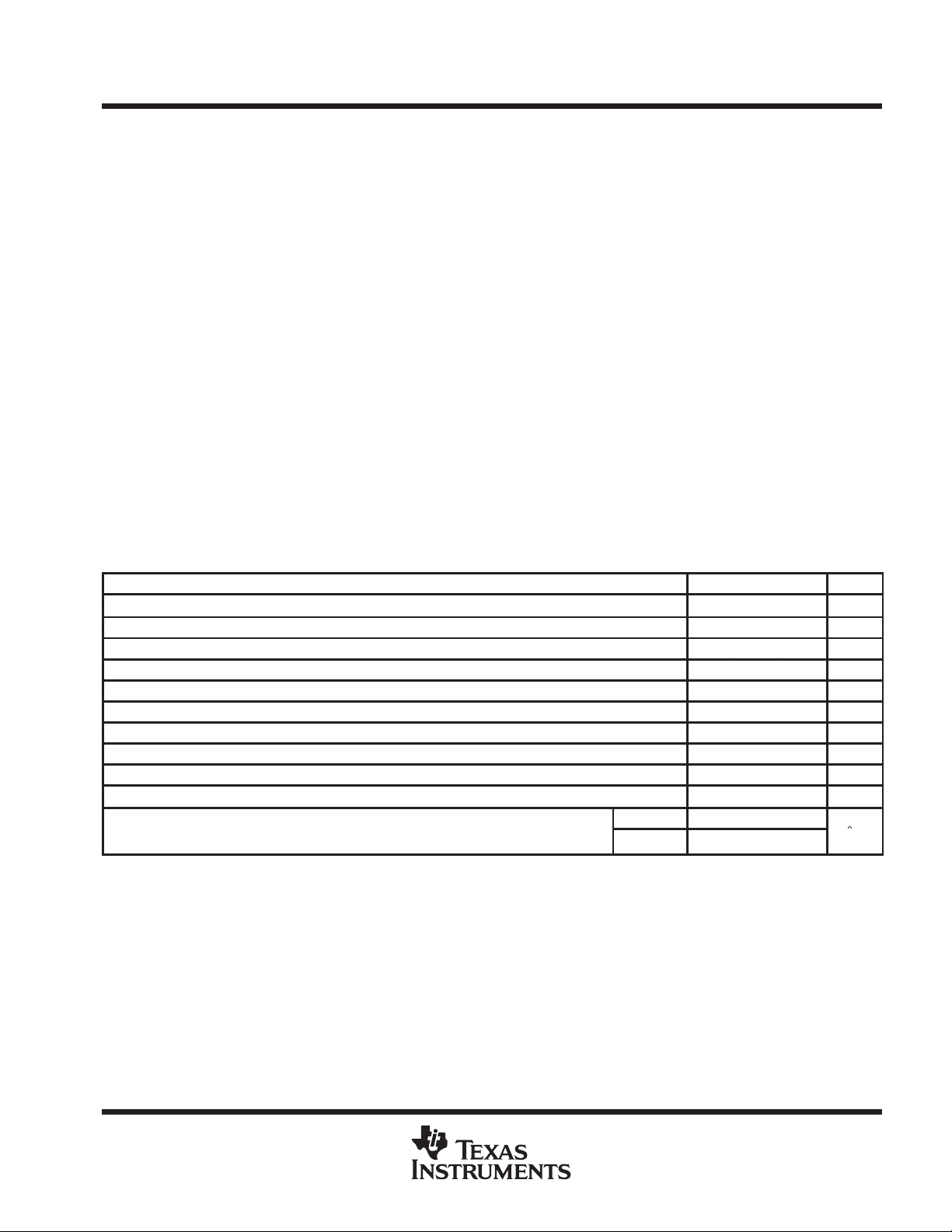

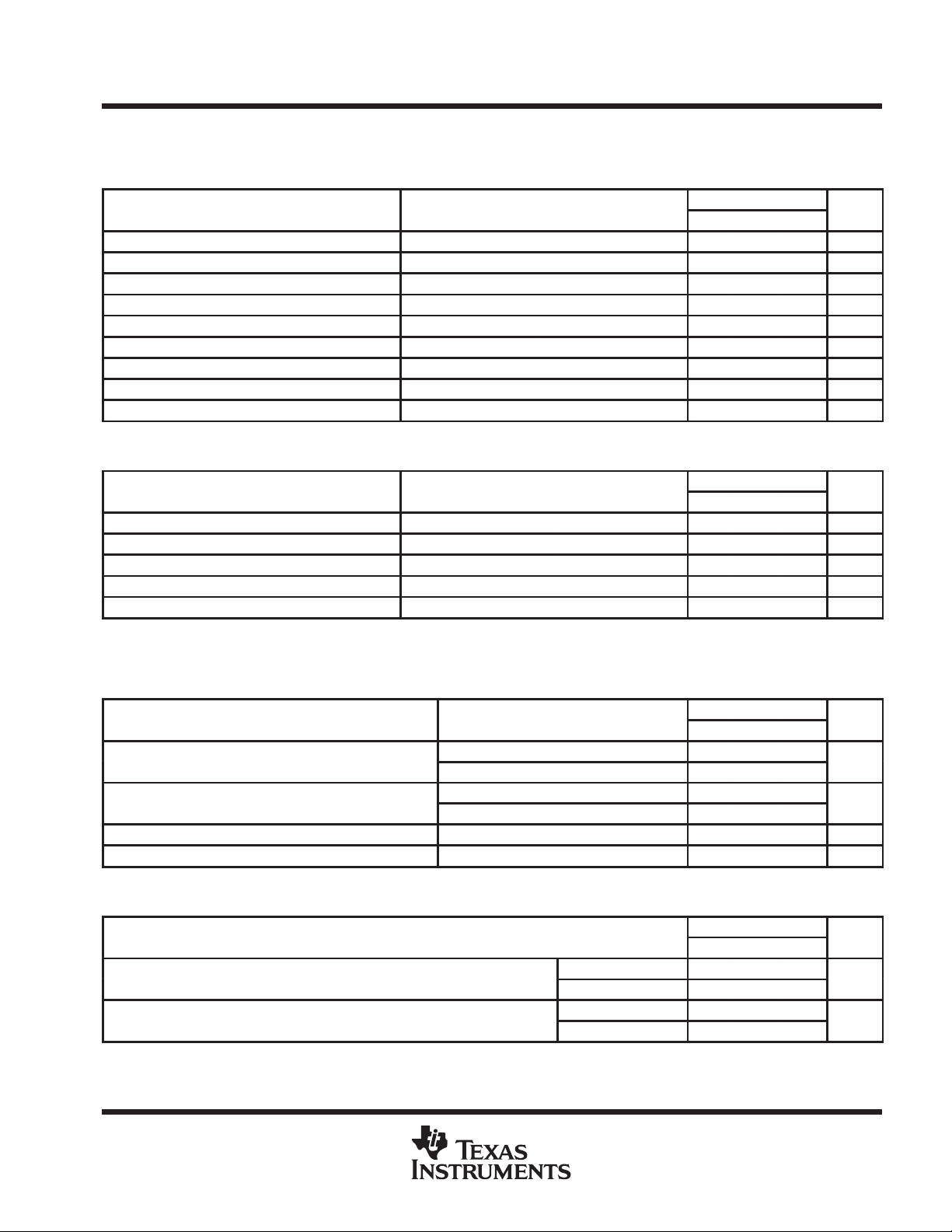

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage (see Note 1) (ICC < 30 mA) Self limiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog input voltage range, VI (VFB and ISENSE) –0.3 V to 6.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage, V

(OUTPUT) 35 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

Input voltage, VI, (VC, D package only) 35 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply current, ICC 30 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, IO ±1 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error amplifier output sink current 10 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Package thermal impedance, θ

(see Notes 2 and 3): D package 86°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . .

JA

D-8 package 97°C/W. . . . . . . . . . . . . . . . . . . . . . . . . .

P package 85°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Virtual junction temperature range, T

0°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

Output energy (capacitive load) 5 µJ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature, 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltages are with respect to the device GND terminal.

2. Maximum power dissipation is a function of TJ(max),

ambient temperature is PD = (TJ(max) – TA)/

3. The package thermal impedance is calculated in accordance with JESD 51.

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

θ

, and TA. The maximum allowable power dissipation at any allowable

θ

JA

JA

. Operating at the absolute maximum TJ of 150°C can impact reliability.

recommended operating conditions

MIN NOM MAX UNIT

osc

O

O(ref)

‡

‡

CC

J

A

TL284x –40 85

TL384x

–0.1 1 V

100 500 kHz

0 125

0 70

Supply voltage, VCC and VC

Input voltage, VI, RT/CT 0 5.5 V

Input voltage, VI, VFB and ISENSE 0 5.5 V

Output voltage, VO, OUTPUT 0 30 V

Output voltage, VO, POWER GROUND

Supply current, externally limited, I

Average output current, I

Reference output current, I

Oscillator frequency, f

Operating virtual junction temperature, T

perating free-air temperature,

‡

These recommended voltages for VC and POWER GROUND apply only to the D package.

30 V

25 mA

200 mA

–20 mA

°C

°C

†

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

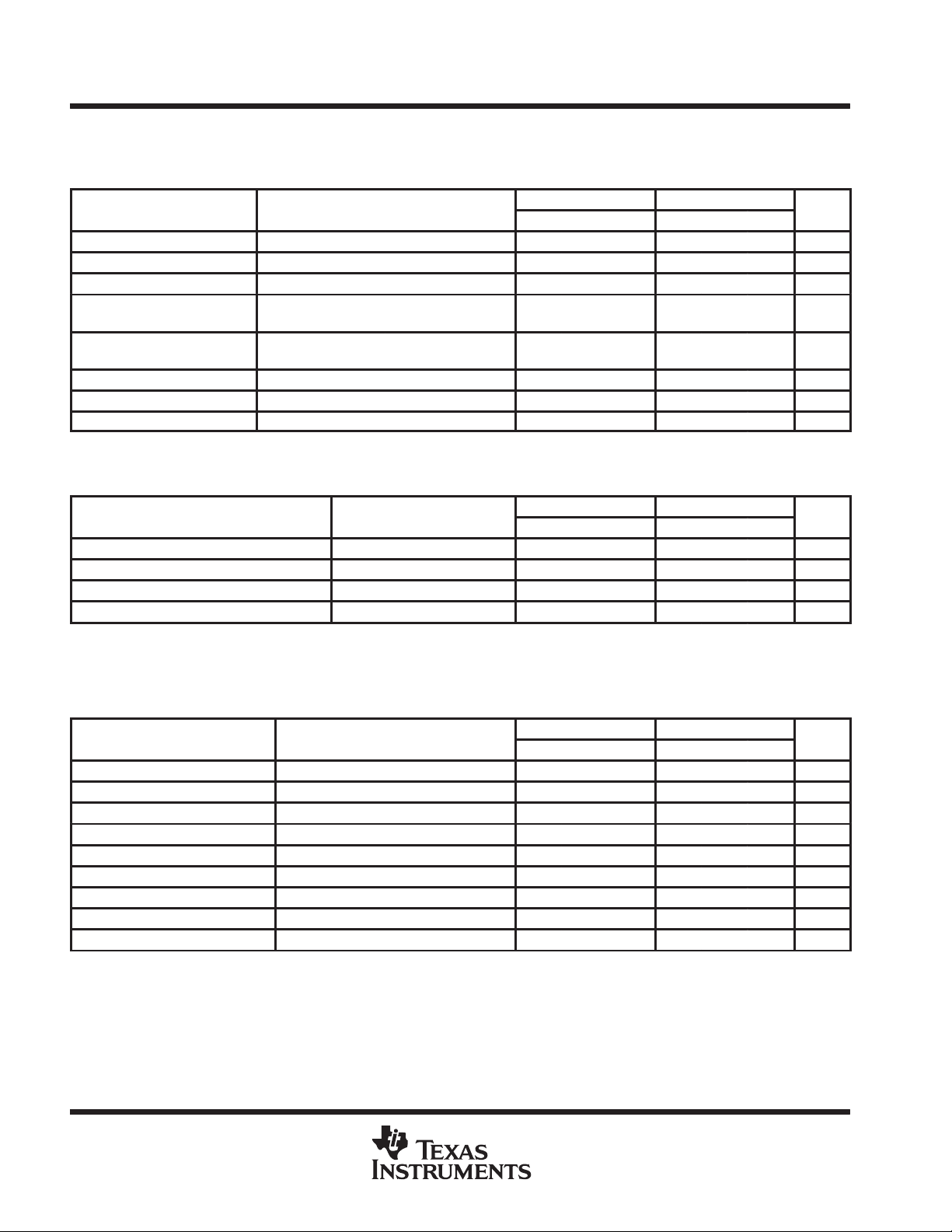

TL284x, TL384x

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

electrical characteristics over recommended operating free-air temperature range, V

Note 4), R

= 10 kΩ, C

T

= 3.3 nF (unless otherwise specified)

T

= 15 V (see

CC

reference section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

Output voltage IO = 1 mA, TA = 25°C 4.95 5 5.05 4.9 5 5.1 V

Line regulation VCC = 12 V to 25 V 6 20 6 20 mV

Load regulation IO = 1 mA to 20 mA 6 25 6 25 mV

Temperature coefficient

of output voltage

Output voltage

with worst-case variation

Output noise voltage f = 10 Hz to 10 kHz, TA = 25°C 50 50 µV

Output-voltage long-term drift After 1000 h at TA = 25°C 5 25 5 25 mV

Short-circuit output current –30 –100 –180 –30 –100 –180 mA

†

All typical values are at TA = 25°C.

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

VCC = 12 V to 25 V, IO = 1 mA to 20 mA 4.9 5.1 4.82 5.18 V

0.2 0.4 0.2 0.4 mV/°C

oscillator section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

Oscillator frequency (see Note 5) TA = 25°C 47 52 57 47 52 57 kHz

Frequency change with supply voltage VCC = 12 V to 25 V 2 10 2 10 Hz/kHz

Frequency change with temperature 50 50 Hz/kHz

Peak-to-peak amplitude at RT/CT 1.7 1.7 V

†

All typical values are at TA = 25°C.

NOTES: 4. Adjust VCC above the start threshold before setting it to 15 V .

5. Output frequency equals oscillator frequency for the TLx842 and TLx843. Output frequency is one-half oscillator frequency for the

TLx844 and TLx845.

error-amplifier section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

Feedback input voltage COMP at 2.5 V 2.45 2.50 2.55 2.42 2.50 2.58 V

Input bias current –0.3 –1 –0.3 –2 µA

Open-loop voltage amplification VO = 2 V to 4 V 65 90 65 90 dB

Gain-bandwidth product 0.7 1 0.7 1 MHz

Supply-voltage rejection ratio VCC = 12 V to 25 V 60 70 60 70 dB

Output sink current VFB at 2.7 V, COMP at 1.1 V 2 6 2 6 mA

Output source current VFB at 2.3 V, COMP at 5 V –0.5 –0.8 –0.5 –0.8 mA

High-level output voltage VFB at 2.3 V, RL = 15 kΩ to GND 5 6 5 6 V

Low-level output voltage VFB at 2.7 V, RL = 15 kΩ to GND 0.7 1.1 0.7 1.1 V

†

All typical values are at TA = 25°C.

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

High-level output voltage

V

Low-level output voltage

V

PARAMETER

UNIT

Start threshold voltage

V

Minimum operating voltage after startup

V

PARAMETER

UNIT

Maximum duty cycle

TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

electrical characteristics over recommended operating free-air temperature range, V

Note 4), R

= 10 kΩ, C

T

= 3.3 nF (unless otherwise specified) (continued)

T

= 15 V (see

CC

current-sense section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

Voltage amplification See Notes 6 and 7 2.85 3 3.13 2.85 3 3.15 V/V

Current-sense comparator threshold COMP at 5 V, See Note 6 0.9 1 1.1 0.9 1 1.1 V

Supply-voltage rejection ratio VCC = 12 V to 25 V, See Note 6 70 70 dB

Input bias current –2 –10 –2 –10 µA

Delay time to output 150 300 150 300 ns

†

All typical values are at TA = 25°C.

NOTES: 4. Adjust VCC above the start threshold before setting it to 15 V .

6. These parameters are measured at the trip point of the latch, with VFB at 0 V.

7. Voltage amplification is measured between ISENSE and COMP, with the input changing from 0 V to 0.8 V.

output section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

p

p

Rise time CL = 1 nF, TA = 25°C 50 150 50 150 ns

Fall time CL = 1 nF, TA = 25°C 50 150 50 150 ns

†

All typical values are at TA = 25°C.

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

IOH = –20 mA 13 13.5 13 13.5

IOH = –200 mA 12 13.5 12 13.5

IOL = 20 mA 0.1 0.4 0.1 0.4

IOL = 200 mA 1.5 2.2 1.5 2.2

undervoltage-lockout section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

TLx842, TLx844 15 16 17 14.5 16 17.5

TLx843, TLx845 7.8 8.4 9 7.8 8.4 9

p

†

All typical values are at TA = 25°C.

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

p

TLx842, TLx844 9 10 11 8.5 10 11.5

TLx843, TLx845 7 7.6 8.2 7 7.6 8.2

pulse-width-modulator section

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

TLx842, TLx843 95% 97% 100% 95% 97% 100%

TLx844, TLx845 46% 48% 50% 46% 48% 50%

Minimum duty cycle 0 0

†

All typical values are at TA = 25°C.

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

TL284x, TL384x

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

electrical characteristics over recommended operating free-air temperature range, V

Note 4), R

= 10 kΩ, C

T

= 3.3 nF (unless otherwise specified) (continued)

T

= 15 V (see

CC

supply voltage

TL284x TL384x

MIN TYP†MAX MIN TYP†MAX

Start-up current 0.5 1 0.5 1 mA

Operating supply current VFB and ISENSE at 0 V 11 17 11 17 mA

Limiting voltage ICC = 25 mA 34 34 V

†

All typical values are at TA = 25°C.

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

electrical characteristics, V

= 15 V (see Note 4), RT = 10 kΩ, C

CC

= 3.3 nF , TA = 25°C (unless otherwise

T

specified)

reference section

TL384xY

MIN TYP MAX

Output voltage IO = 1 mA 5 V

Line regulation VCC = 12 V to 25 V 6 mV

Load regulation IO = 1 mA to 20 mA 6 mV

Temperature coefficient of output voltage 0.2 mV/°C

Output noise voltage f = 10 Hz to 10 kHz 50 µV

Output-voltage long-term drift After 1000 h at TA = 25°C 5 mV

Short-circuit output current –100 mA

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

oscillator section

TL384xY

MIN TYP MAX

Oscillator frequency (see Note 5) 52 kHz

Frequency change with supply voltage VCC = 12 V to 25 V 2 Hz/kHz

Frequency change with temperature 5 Hz/kHz

Peak-to-peak amplitude at RT/CT 1.7 V

NOTES: 4. Adjust VCC above the start threshold before setting it to 15 V .

5. Output frequency equals oscillator frequency for the TLx842 and TLx843. Output frequency is one-half oscillator frequency for the

TLx844 and TLx845.

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

High-level output voltage

V

Low-level output voltage

V

PARAMETER

UNIT

Start threshold voltage

V

Minimum operating voltage after startup

V

TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

electrical characteristics, V

= 15 V (see Note 4), R

CC

= 10 kΩ, CT = 3.3 nF , TA= 25°C (unless otherwise

T

specified) (continued)

error-amplifier section

TL384xY

MIN TYP MAX

Feedback input voltage COMP at 2.5 V 2.50 V

Input bias current –0.3 µA

Open-loop voltage amplification VO = 2 V to 4 V 90 dB

Gain-bandwidth product 1 MHz

Supply-voltage rejection ratio VCC = 12 V to 25 V 70 dB

Output sink current VFB at 2.7 V, COMP at 1.1 V 6 mA

Output source current VFB at 2.3 V, COMP at 5 V –0.8 mA

High-level output voltage VFB at 2.3 V , RL = 15 kΩ to GND 6 V

Low-level output voltage VFB at 2.7 V, RL = 15 kΩ to GND 0.7 V

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

current-sense section

TL384xY

MIN TYP MAX

Voltage amplification See Notes 6 and 7 3 V/V

Current-sense comparator threshold COMP at 5 V, See Note 6 1 V

Supply-voltage rejection ratio VCC = 12 V to 25 V, See Note 6 70 dB

Input bias current –2 µA

Delay time to output 150 ns

NOTES: 4. Adjust VCC above the start threshold before setting it to 15 V .

6. These parameters are measured at the trip point of the latch, with VFB at 0 V.

7. Voltage amplification is measured between ISENSE and COMP, with the input changing from 0 V to 0.8 V.

output section

TL384xY

MIN TYP MAX

p

p

Rise time CL = 1 nF 50 ns

Fall time CL = 1 nF 50 ns

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

IOH = –20 mA 13.5

IOH = –200 mA 13.5

IOL = 20 mA 0.1

IOL = 200 mA 1.5

undervoltage-lockout section

TL384xY

MIN TYP MAX

TL3842Y, TL3844Y 16

TL3843Y, TL3845Y 8.4

p

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

p

TL3842Y, TL3844Y 10

TL3843Y, TL3845Y 7.6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TL284x, TL384x

PARAMETER

UNIT

Maximum duty cycle

PARAMETER

TEST CONDITIONS

UNIT

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

electrical characteristics, V

= 15 V (see Note 4), R

CC

= 10 kΩ, CT = 3.3 nF , TA = 25°C (unless otherwise

T

specified) (continued)

pulse-width-modulator section

TL384xY

MIN TYP MAX

TL3842Y, TL3843Y 97%

TL3844Y, TL3845Y 48%

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

supply voltage

TL384xY

MIN TYP MAX

Start-up current 0.5 1 mA

Operating supply current VFB and ISENSE at 0 V 11 17 mA

Limiting voltage ICC = 25 mA 34 V

NOTE 4: Adjust VCC above the start threshold before setting it to 15 V .

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

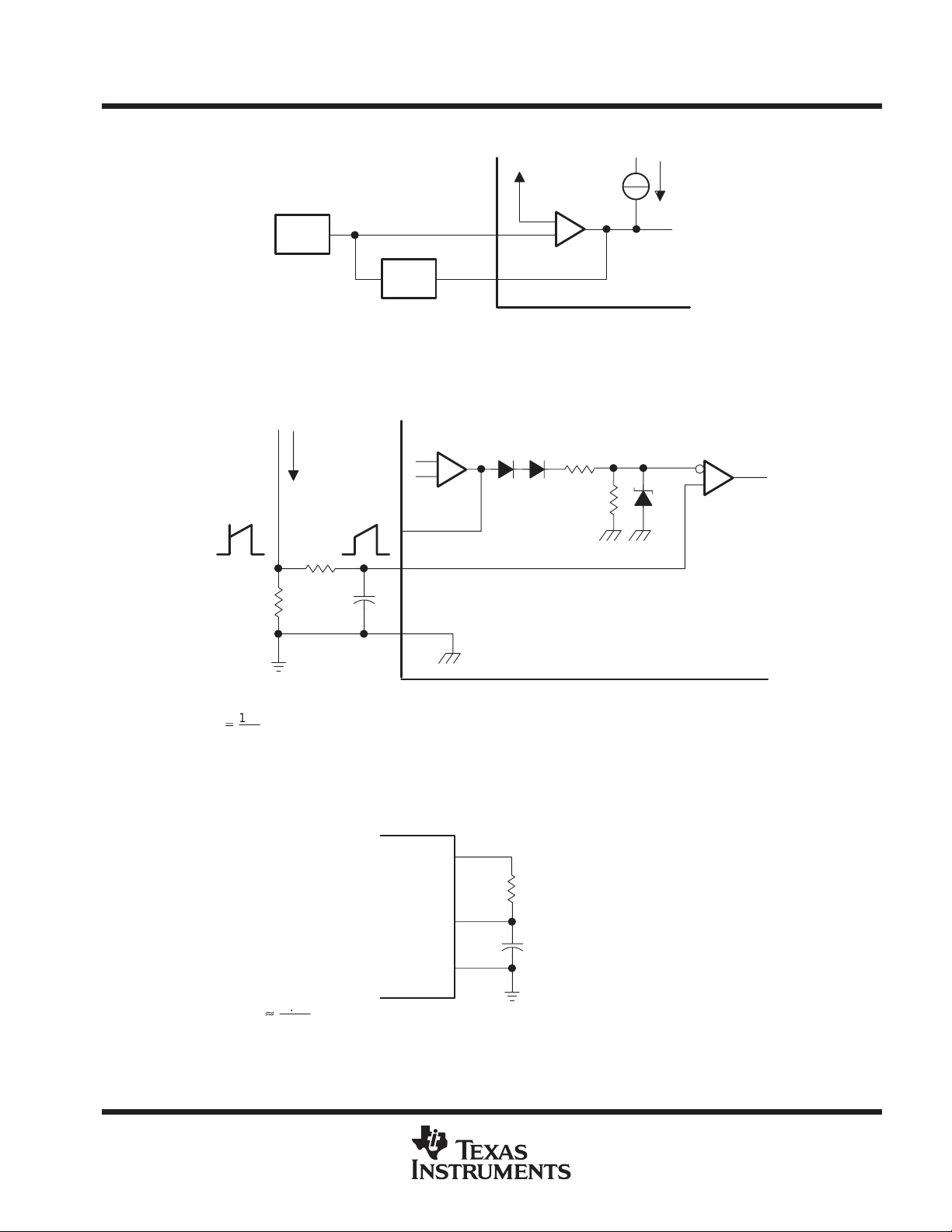

APPLICATION INFORMATION

Z

i

Z

f

NOTE A: Error amplifier can source or sink up to 0.5 mA.

Figure 1. Error-Amplifier Configuration

I

S

(see Note A)

COMP

R

f

R

S

C

ISENSE

f

GND

VFB

COMP

Error

Amplifier

+

–

2.5 V

Error

Amplifier

+

–

2R

0.5 mA

R1 V

Current-Sense

Comparator

NOTE A: Peak current (IS) is determined by the formula:

I

S(max

A small RC filter formed by resistor Rf and capacitor Cf may be required to suppress switch transients.

1V

+

)

R

S

Figure 2. Current-Sense Circuit

NOTE A: For RT > 5 kΩ:

1.72

f

[

RTC

T

Figure 3. Oscillator Section

REF

RT/CT

GND

R

T

(see Note A)

C

T

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

APPLICATION INFORMATION

100

40

sµ

10

Dead Time –

0.4

0.1

VCC = 15 V

RT ≥ 5 kΩ

TA = 25°C

4

1

DEAD TIME

vs

TIMING CAPACITANCE

CT – Timing Capacitance – nF

Figure 4

TIMING RESISTANCE

vs

FREQUENCY

100

40

Ω

CT = 22 nF

10

CT = 47 nF

– Timing Resistance – k

4

T

R

1

100401040

100 1 k 10 k 100 k 1 M

CT = 100 nF

VCC = 15 V

TA = 25°C

f - Frequency - Hz

CT = 10 nF

CT = 4.7 nF

CT = 22 nF

CT = 1 nF

Figure 5

open-loop laboratory test fixture

In the open-loop laboratory test fixture shown in Figure 6, high peak currents associated with loads necessitate

careful grounding techniques. Timing and bypass capacitors should be connected close to the GND terminal

in a single-point ground. The transistor and 5-kΩ potentiometer sample the oscillator waveform and apply an

adjustable ramp to the ISENSE terminal.

R

Error Amplifier

1 kΩ

Adjust

4.7 kΩ

4.7 kΩ

2N2222

100 kΩ

5 kΩ

ISENSE

Adjust

T

COMP

VFB

ISENSE

RT/CT

DUT

TL284x

TL384x

C

T

REF

V

CC

OUTPUT

GND

0.1 µF

Figure 6. Open-Loop Laboratory Test Fixture

A

0.1 µF

1 kΩ, 1 W

REF

V

CC

OUTPUT

GND

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TL284x, TL384x

CURRENT-MODE PWM CONTROLLERS

SLVS038E – JANUARY 1989 – REVISED DECEMBER 1999

APPLICATION INFORMATION

shutdown technique

The PWM controller (see Figure 7) can be shut down by two methods: either raise the voltage at ISENSE above

1 V or pull the COMP terminal below a voltage two diode drops above ground. Either method causes the output

of the PWM comparator to be high (refer to block diagram). The PWM latch is reset dominant so that the output

remains low until the next clock cycle after the shutdown condition at the COMP or ISENSE terminal is removed.

In one example, an externally latched shutdown can be accomplished by adding an SCR that resets by cycling

V

below the lower UVLO threshold. At this point, the reference turns off, allowing the SCR to reset.

CC

Shutdown

1 kΩ

330 Ω

500 Ω

REF

COMP

Shutdown

ISENSE

To Current-Sense

Resistor

Figure 7. Shutdown Techniques

A fraction of the oscillator ramp can be resistively summed with the current-sense signal to provide slope

compensation for converters requiring duty cycles over 50% (see Figure 8). Note that capacitor C forms a filter

with R2 to suppress the leading-edge switch spikes.

REF

0.1 µF

RT/CT

R

T

ISENSE

C

T

R1

R2

C

Figure 8. Slope Compensation

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

ISENSE

R

SENSE

11

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...