Page 1

THS3001

High Speed Current

Feedback

Operational Amplifier

Evaluation Module

User’s Guide

March 1999 Mixed-Signal Products

SLOU021A

Page 2

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Page 3

Related Documentation From Texas Instruments

J

THS3001 HIGH-SPEED CURRENT-FEEDBACK OPERATIONAL

AMPLIFIER

for the THS3001 operational amplifier integrated circuit that is

used in the THS3001 evaluation module.

(literature number SLOS217) This is the data sheet

FCC Warning

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which

case the user at his own expense will be required to take whatever measures

may be required to correct this interference.

Preface

Trademarks

TI is a trademark of Texas Instruments Incorporated.

Chapter Title—Attribute Reference

iii

Page 4

iv

Page 5

Running Title—Attribute Reference

Contents

1 General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Features 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 THS3001 EVM Specifications 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Using The THS3001 EVM 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 THS3001 EVM Performance 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 General High-Speed Amplifier Design Considerations 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Reference 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 THS3001 High-Speed Operational Amplifier EVM Parts List 2-2. . . . . . . . . . . . . . . . . . . . . .

2.2 THS3001 EVM Board Layouts 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 THS3001 Rev. A High-Speed Operational Amplifier EVM Parts List 2-4. . . . . . . . . . . . . . .

2.4 THS3001 Rev. A. EVM Board Layouts 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figures

1–1 THS3001 Evaluation Module – Original Version 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 THS3001 Rev. A Evaluation Module 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 THS3001 EVM Schematic – Original Version 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 THS3001 Rev. A EVM Schematic 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5 THS3001 EVM Frequency Response with Gain = 2 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–6 THS3001 EVM Frequency Response with Inverting Gain = 1 1-7. . . . . . . . . . . . . . . . . . . . . . .

2–1 THS3001 EVM Component Placement Silkscreen and Solder Pads 2-2. . . . . . . . . . . . . . . . .

2–2 THS3001 EVM PC Board Layout – Component Side 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 THS3001 EVM PC Board Layout – Back Side 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 THS3001 Rev. A EVM Component Placement Silkscreen and Solder Pads 2-4. . . . . . . . . . .

2–5 THS3001 Rev. A EVM PC Board Layout – Component Side 2-5. . . . . . . . . . . . . . . . . . . . . . . .

2–6 THS3001 Rev. A EVM PC Board Layout – Back Side 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ables

2–1 THS3001 EVM Parts List 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 THS3001 Rev. A EVM Parts List 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

v

Page 6

vi

Page 7

Chapter 1

General Information

This chapter details the Texas Instruments (TI) THS3001 high-speed

operational amplifier evaluation module (EVM), SLOP130. It includes a list of

EVM features, a brief description of the module illustrated with a pictorial and

a schematic diagram, EVM specifications, details on connecting and using the

EVM, and a discussion on high-speed amplifier design considerations.

Topic Page

1.1 Features 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Description 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 THS3001 EVM Specifications 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Using The THS3001 EVM 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 THS3001 EVM Performance 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 General High-Speed Amplifier Design Considerations 1–8. . . . . . . . . . .

General Information

1-1

Page 8

Features

1.1 Features

1.2 Description

THS3001 operational amplifier EVM features include:

J

High Bandwidth — 340 MHz, –3 dB at ±15 VCC & Gain = 2

J

±5-V to ±15-V Operation

J

Inverting and Noninverting Single-Ended Inputs

J

Module Gain Set to +2 (Noninverting) and –1 (Inverting) — Adjustable

Through Component Change.

J

Nominal 50-Ω Impedance Inputs and Outputs

J

Standard SMA Miniature RF Connectors

J

Good Example of High-Speed Amplifier Design and Layout

The TI THS3001 high-speed current-feedback operational amplifier

evaluation module (EVM) is a complete high-speed amplifier circuit. It consists

of the TI THS3001 high-speed current-feedback operational amplifier IC,

along with a small number of passive parts, mounted on a small circuit board

measuring approximately 1.7 inch by 1.4 inch. The EVM uses standard SMA

miniature RF connectors for inputs and outputs and is completely assembled,

fully tested, and ready to use — just connect it to power, a signal source, and

a load (if desired).

Two versions of the THS3001 EVM are available. The original appears in

Figure 1–1 and the Rev. A version appears in Figure 1–2.

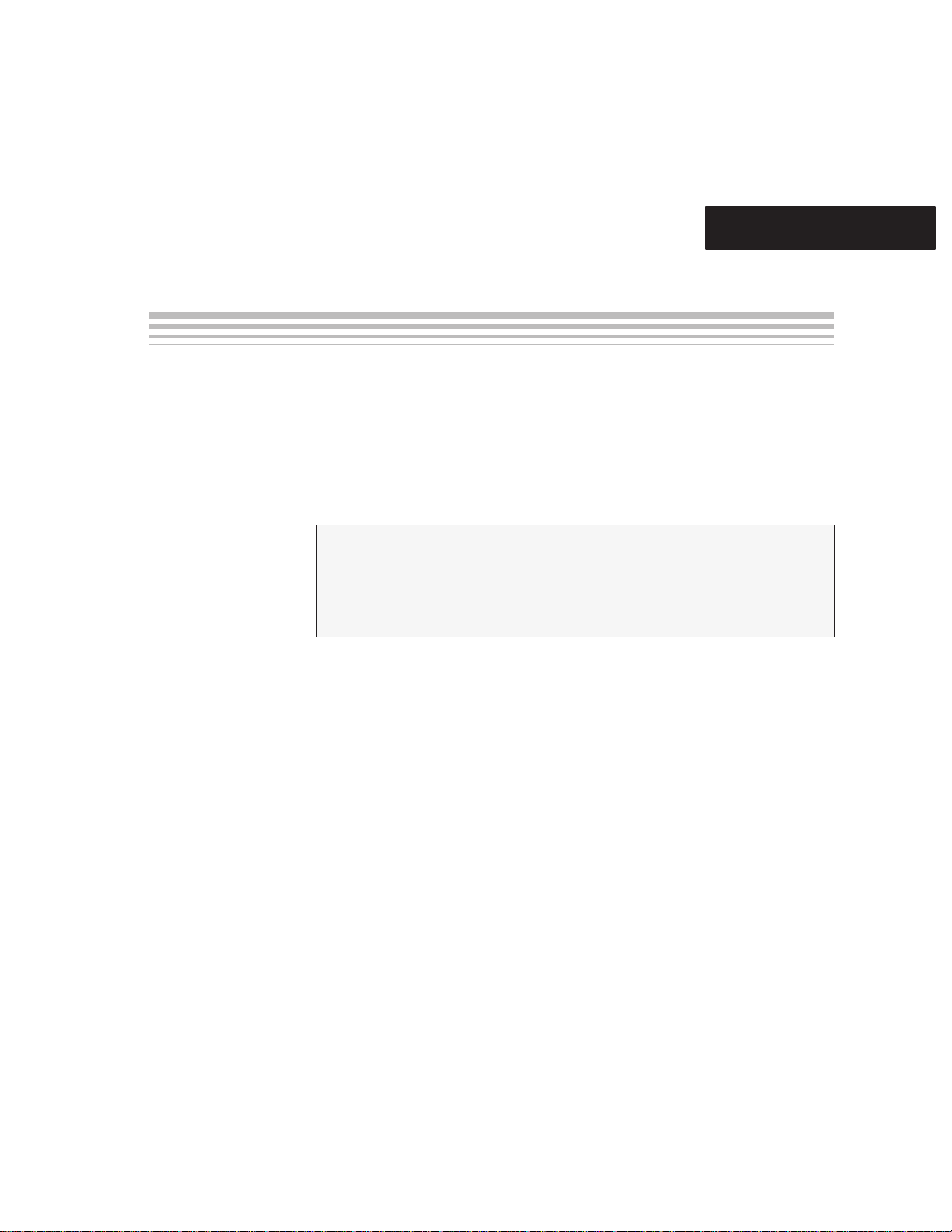

Figure 1–1.THS3001 Evaluation Module – Original Version

J3

–IN

GND

INVERTING

NONINVERTING

+IN

GND

009957

–VCC

J1

GND

C3

U1

R4

R3

LITERATURE NO

SLOP 130

THS3001 EVM

R5

+ +

+VCC

R1

C4

C1

C2

R2

J2

OUT

GND

1-2

General Information

Page 9

Figure 1–2.THS3001 Rev. A Evaluation Module

J1

–VCC

Rev. A

J2

–IN

GND

INVERTING

NONINVERTING

C1

R2

R1

GND

+

+VCC

C2

+

INSTRUMENTS

R4

C3

Description

TEXAS

J4

+IN

GND

J3

R3

U1

C4

SLOP130 Rev A

THS3001 EVM Board

The THS3001 EVM is equipped with both noninverting and inverting inputs.

The noninverting input is set for a gain of 2 and the inverting input is set for a

gain of 1. Each input is terminated with a 50-Ω resistor to provide correct line

impedance matching (Figure 1–3 for original version and Figure 1–4 for Rev .

A). The amplifier IC output is routed through a 50-Ω resistor both to provide

correct line impedance matching and to help isolate capacitive loading on the

output of the amplifier. Capacitive loading directly on the output of the IC

decreases the amplifier’s phase margin and can result in peaking or

oscillations.

Figure 1–3.THS3001 EVM Schematic – Original Version

V

R1

+

THS3001

–

C4

0.1 µF

CC

6.8 µF/35 V

7

U1

4

+

C1

+

Non-

Inverting

Input

Inverting

Input

J1

J3

C2

0.1 µF

1 kΩ

3

R3

49.9 Ω

2

R5

1 kΩ

R4

49.9 Ω

R5

R2

6

49.9 Ω

C3

6.8 µF/35 V

GND

OUT

J2

Output

–V

CC

General Information

1-3

Page 10

Description

Figure 1–4.THS3001 Rev. A EVM Schematic

J1

–V

CC

GND

V

CC

Rev. A

1

–V

2

3

CC

V

CC

Noninverting

–IN

Inverting

+IN

J2

R1

49.9 Ω

J3

R3

49.9 Ω

R2

1 kΩR41 kΩ

2

3

V

CC

7

–

U1

THS3001

+

4

–V

CC

6.8 µF

+

C3

0.1 µF

C4

0.1 µF

C1

6.8 µF

+

C2

R5

49.9 Ω

6

J4

Out

Even though the THS3001 is a current-feedback amplifier, the gain of the EVM

can easily be changed to support a particular application by simply changing

the ratio of resistors R1, R4, and R5 (R1, R2, and R4 for Rev . A) as described

in the following equations:

*

R

*

R1

*

Inverting Gain

+

Noninverting Gain+1

R

)

G

F

+

R

F

R

G

R5

+1)

R4

+

R2

R1

R4)R5

(Rev. A)

+1)

R4

R2)R1

(Rev. A)

In addition, some applications, such as those for video, may require the use

of 75-Ω cable and 75-Ω EVM input termination and output isolation resistors.

Any of the resistors on the EVM board can be replaced with a resistor of a

different value; however, care must be taken because the surface-mount

solder pads on the board are somewhat fragile and will not survive many

desoldering/soldering operations.

Because of the current feedback architecture, extra care must be taken to

ensure that a feedback resistor is always included in the design. In addition,

there must never be a capacitor directly in the feedback path between the

amplifier output and the noninverting input. Disregarding this guideline will

likely result in a part that oscillates.

1-4

General Information

Page 11

Note: External factors can significantly affect the overall gain of the EVM. For

example, connecting test equipment with 50-Ω input impedance to the EVM

output will divide the output signal level by a factor of 2 (assuming the output

isolation resistor on the EVM board remains 50 Ω). Similar effects can occur

at the input, depending upon how the input signal sources are configured. The

gain equations given above assume no signal loss in either the input or the

output.

The EVM circuit board is an excellent example of proper board layout for

high-speed amplifier designs and can be used as a guide for user application

board layouts.

1.3 THS3001 EVM Specifications

THS3001 EVM Specifications

Supply voltage range, ±V

Supply current, I

Input voltage, V

Output drive, I

CC

I

O

CC

Continuous power dissipation at T

For complete THS3001 amplifier IC specifications and parameter

measurement information, and additional application information, see the

THS3001 data sheet, TI Literature Number SLOS217.

±5 V to ±15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

= 25°C 740 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

6.5 mA Typ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±VCC, Max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

100 mA, Typ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information

1-5

Page 12

Using The THS3001 EVM

1.4 Using The THS3001 EVM

The THS3001 EVM operates from power-supply voltages ranging from ±5 V

to ±15 V. As shipped, the inverting input gain of the module is set to 1, the

noninverting input gain is set to 2, and signal inputs on the module are

terminated for 50-Ω nominal impedance cables. An oscilloscope is typically

used to view and analyze the EVM output signal.

1.4.1 Steps for THS3001 EVM

1) Ensure that all power supplies are set to

connections to the THS3001 EVM.

2) Select the operating voltage for the EVM and connect appropriate split

power supplies to the pads on the module marked

3) Connect the power supply ground to the module pad marked

4) Connect an oscilloscope to the module SMA output connector

through a 50-Ω nominal impedance cable (an oscilloscope having a 50-Ω

input termination is preferred for examining very high frequency signals).

5) Set the power supply to

6) Connect the signal input to either the noninverting input

2, or to the inverting input

1.4.2 Steps for THS3001 Rev. A EVM

1) Ensure that all power supplies are set to

connections to the THS3001 EVM.

2) Select the operating voltage for the EVM and connect appropriate split

power supplies to

3) Connect the power supply ground to

OFF

before making power supply

ON.

(J3)

for a gain of 1.

OFF

before making power supply

J1

terminals on the module marked

J1

terminal marked

–VCC

–VCC

and

+VCC.

GND.

(J1)

for a gain of

and

GND.

(J2)

+VCC.

1-6

4) Connect an oscilloscope to the module SMA output connector

through a 50-Ω nominal impedance cable (an oscilloscope having a 50-Ω

input termination is preferred for examining very high frequency signals).

5) Set the power supply to

6) Connect the signal input to either the noninverting input

2, or to the inverting input

Note that each input connector is terminated with a 50-Ω resistor to ground.

With a 50-Ω source impedance, the voltage seen by the THS3001 amplifier

IC on the module will be ½ the source signal voltage applied to the EVM.

7) Verify the output signal on the oscilloscope.

Note: The signal shown on an oscilloscope with a 50-Ω input impedance will

be ½ the actual THS3001 amplifier IC output voltage. This is due to the voltage

division between the output resistor (R2) and the oscilloscope input

impedance.

ON.

(J2)

for a gain of 1.

(J3)

for a gain of

(J4)

General Information

Page 13

1.5 THS3001 EVM Performance

Figure 1–5 shows the typical frequency response of the THS3001 EVM using

the noninverting input (G = 2). Typical values show a –3-dB bandwidth of

340 MHz with a ±15-V power supply and 260 MHz with a ±5-V power supply .

They also show a –0.1-dB frequency response of 17 MHz with a ±15-V power

supply and 20 MHz with a ±5-V power supply.

Figure 1–5.THS3001 EVM Frequency Response with Gain = 2

7

THS3001 EVM Performance

6

5

4

3

2

1

0

Output Amplitude – dB

–1

VI = 200 mV RMS

–2

R

= 150 Ω

load

–3

100K 1M 10M 100M

f – Frequency – Hz

VCC = ±5 V

VCC = ±15 V

1G

Figure 1–6 shows the typical frequency response of the THS3001 EVM using

the inverting input (G = 1). Typical –0.1 dB bandwidths are 15 MHz with a

± 15-V power supply and 17 MHz with a ±5-V power supply. Typical – 3-dB

bandwidths are 220 MHz at ±15-V and 210 MHz at ±5-V.

Figure 1–6.THS3001 EVM Frequency Response with Inverting Gain = 1

1

0

–1

–2

–3

–4

–5

–6

Output Amplitude – dB

–7

VI = 200 mV RMS

–8

R

= 150 Ω

load

–9

100K 1M 10M 100M

f – Frequency – Hz

VCC = ±5 V

VCC = ±15 V

1G

General Information

1-7

Page 14

General High-Speed Amplifier Design Considerations

1.6 General High-Speed Amplifier Design Considerations

The THS3001 EVM layout has been designed and optimized for use with

high-speed signals and can be used as an example when designing THS3001

applications. Careful attention has been given to component selection,

grounding, power supply bypassing, and signal path layout. Disregard of these

basic design considerations could result in less than optimum performance of

the THS3001 high-speed, current-feedback video operational amplifier.

Surface-mount components were selected because of the extremely low lead

inductance associated with this technology. Also, because surface-mount

components are physically small, the layout can be very compact. This helps

minimize both stray inductance and capacitance.

T antalum power supply bypass capacitors (C1 and C3 for original and C1 and

C2 for Rev. A) at the power input pads help supply currents for rapid, large

signal changes at the amplifier output. The 0.1 µF power supply bypass

capacitors (C2 and C4 for original version and C3 and C4 for Rev. A) were

placed as close as possible to the IC power input pins in order to keep the PCB

trace inductance to a minimum. This improves high-frequency bypassing and

reduces harmonic distortion.

A proper ground plane on both sides of the PCB should always be used with

high-speed circuit design. This provides low-inductive ground connections for

return current paths. In the area of the amplifier IC input pins, however, the

ground plane was removed to minimize stray capacitance and reduce ground

plane noise coupling into these pins. This is especially important for the

inverting pin while the amplifier is operating in the noninverting mode. Because

the voltage at this pin swings directly with the noninverting input voltage, any

stray capacitance would allow currents to flow into the ground plane, causing

possible gain error and/or oscillation. Capacitance variations at the amplifier

IC inverting input pin of less than 1 pF can significantly affect the response of

the amplifier.

In general, it is always best to keep signal lines as short and as straight as

possible. Sharp 90_ corners should be avoided — round corners or a series

of 45_ bends should be used, instead. Stripline techniques should also be

incorporated when signal lines are greater than three inches in length. These

traces should be designed with a characteristic impedance of either 50 Ω or

75 Ω, as required by the application. Such signal lines should also be properly

terminated with an appropriate resistor.

Finally , proper termination of all inputs and outputs should be incorporated into

the layout. Unterminated lines, such as coaxial cable, can appear to be a

reactive load to the amplifier IC. By terminating a transmission line with its

characteristic impedance, the amplifier’s load then appears to be purely

resistive and reflections are absorbed at each end of the line. Another

advantage of using an output termination resistor is that capacitive loads are

isolated from the amplifier output. This isolation helps minimize the reduction

in amplifier phase-margin and improves the amplifier stability for improved

performance such as reduced peaking and settling times.

1-8

General Information

Page 15

Chapter 2

Reference

This chapter includes a parts list and PCB layout illustrations for the THS3001

EVM and the THS3001 Rev. A EVM.

Topic Page

2.1 THS3001 High-Speed Operational Amplifier EVM Parts List 2–2. . . . . . .

2.2 THS3001 EVM Board Layouts 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 THS3001 Rev. A High-Speed Operational Amplifier EVM Parts List 2–4

2.4 THS3001 Rev. A EVM Board Layouts 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

2-1

Page 16

THS3001 High-Speed Current-Feedback Video Operational Amplifier EVM Parts List

2.1 THS3001 High-Speed Current-Feedback Video Operational Amplifier

EVM Parts List

Table 2–1.THS3001 EVM Parts List

Reference Description Size

C1, C3 Capacitor, 6.8 µF, 35 V, SM D Sprague 293D685X9035D2T

C2, C4 Capacitor, 0.1 µF, ceramic, 10%, SM 1206 Sprague 1 1C1201E104M5NT

J1, J2, J3 Connector, SMA 50-Ω vertical PC mount, through-

hole

R2, R3, R4 Resistor, 49.9 Ω, 1%, 1/10 W, SM 1206 Digi-Key P49.9CTR–ND

R1, R5 Resistor, 1 kΩ, 1%, 1/10 W, SM 1206 Digi-Key P1.0KCTR–ND

U1 IC, THS3001, operational amplifier SOIC-8 TI THS3001

PCB1 PCB, THS3001 EVM

Manufacturer/Digi-Key

Part Number

Amphenol ARF1205–ND

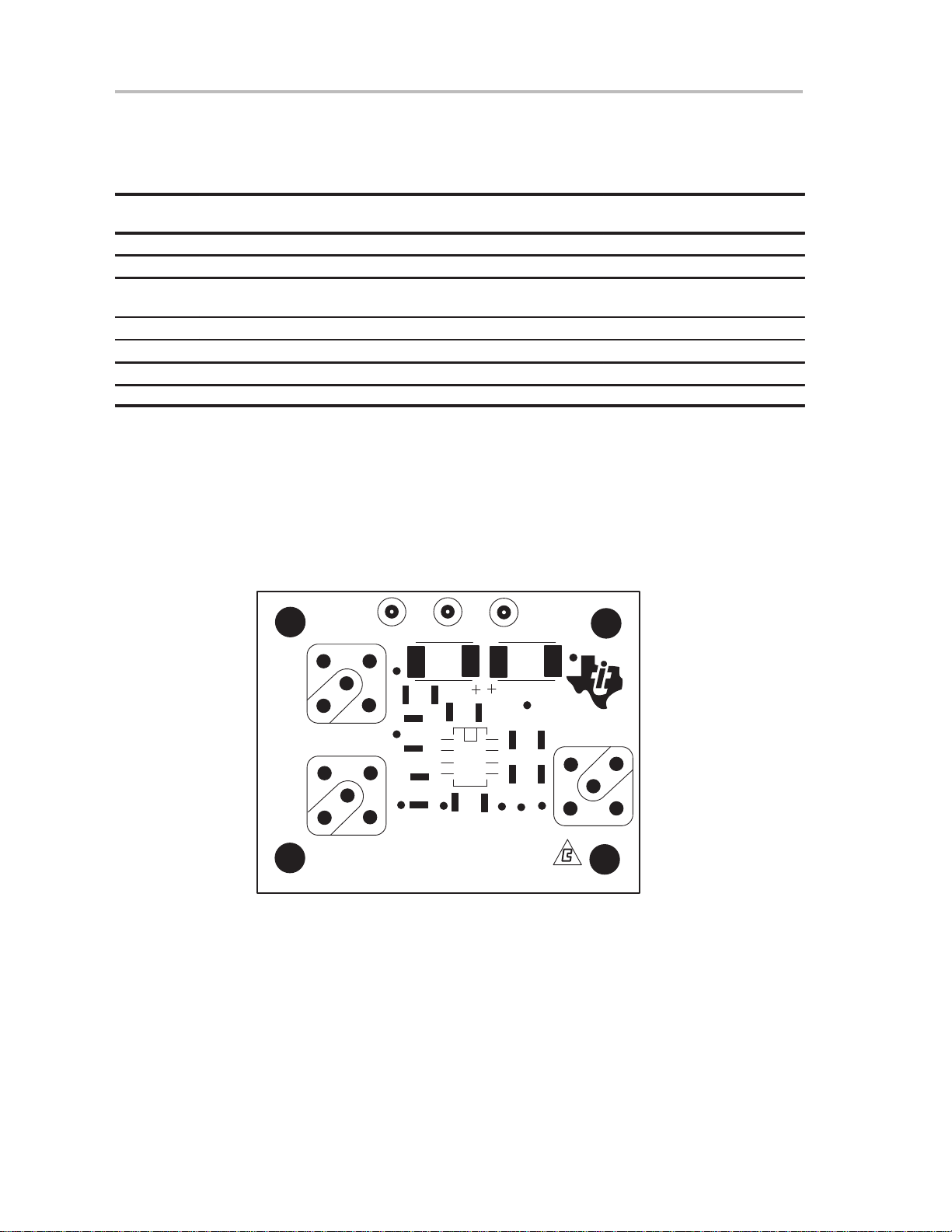

2.2 THS3001 EVM Board Layouts

Board layout examples of the THS3001 EVM PCB are shown in the following

illustrations. They are not to scale and appear here only as a reference.

Figure 2–1.THS3001 EVM Component Placement Silkscreen and Solder Pads

R1

C4

+VCC

C1

C2

R2

J2

009957

OUT

GND

–3

–VCC

J3

–IN

GND

INVERTING

NONINVERTING

+IN

GND

J1

GND

C3

R5

U1

R4

R3

LITERATURE NO.

SLOP 130

THS3001 EVM

2-2

Reference

Page 17

Figure 2–2.THS3001 EVM PC Board Layout – Component Side

Figure 2–3.THS3001 EVM PC Board Layout – Back Side

THS3001 EVM Board Layouts

Reference

2-3

Page 18

THS3001 Rev. A High-Speed Operational Amplifier EVM Parts List

2.3 THS3001 Rev. A High-Speed Operational Amplifier EVM Parts List

Table 2–2.THS3001 Rev. A EVM Parts List

Reference Description Size

C1, C2 Capacitor, 6.8 µF, 35 V, SM D Sprague 293D685X9035D2T

C3, C4 Capacitor, 0.1 µF, ceramic, 10%, SM 1206 Sprague 11C1201E104M5NT

J1 Terminal Block Digi-Key ED1515–ND

J2, J3, J4 Connector, SMA 50-Ω vertical PC

mount, through-hole

R1, R3, R5 Resistor, 49.9 Ω, 1%, 1/8 W, SM 1206 Digi-Key P49.9CTR–ND

R2, R4 Resistor, 1 kΩ, 1%, 1/8 W, SM 1206 Digi-Key P1.0KCTR–ND

U1 IC, THS3001, operational amplifier SOIC-8 TI THS3001

PCB1 PCB, THS3001 Rev. A EVM

Manufacturer/Digi-Key

Part Number

Amphenol ARF1205–ND

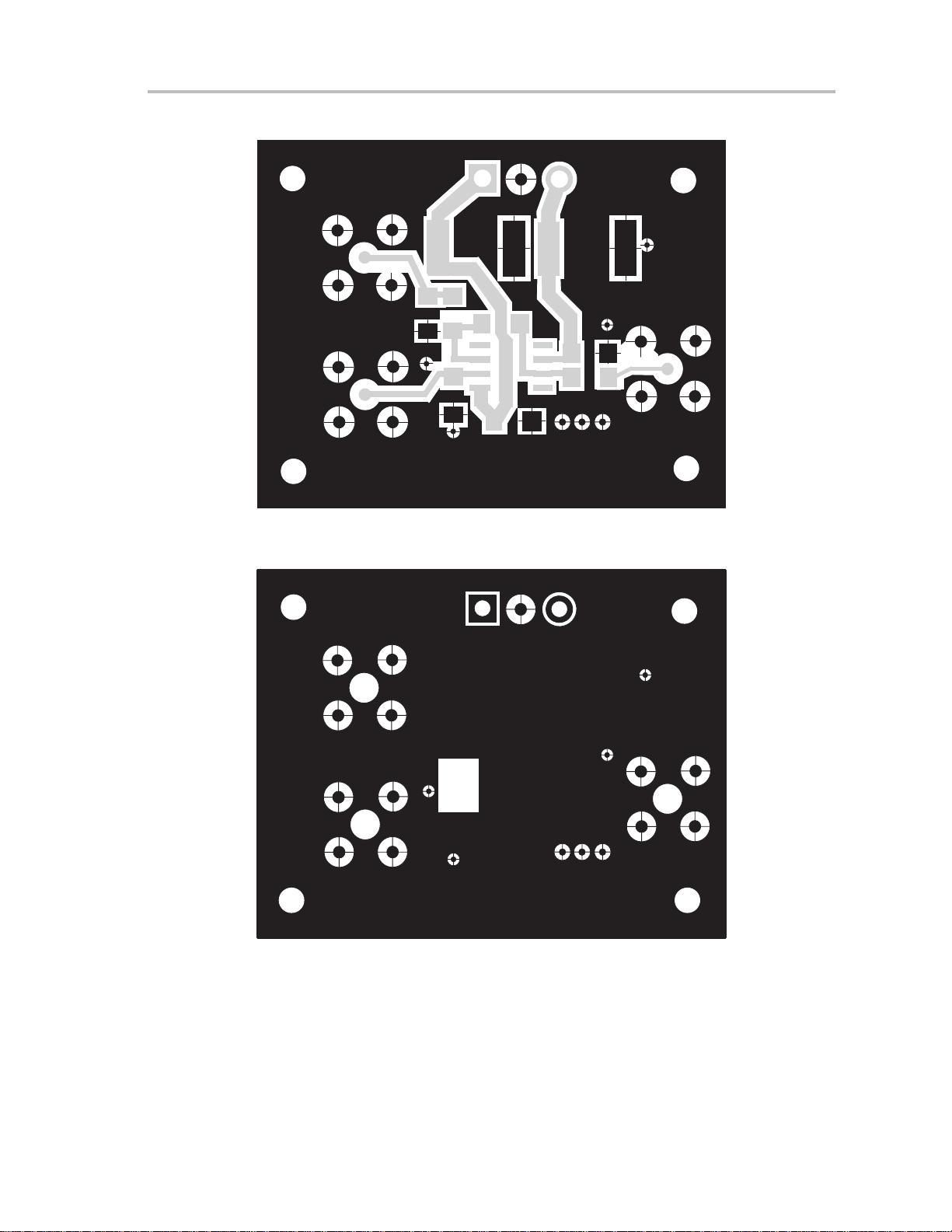

2.4 THS3001 Rev. A EVM Board Layouts

Board layout examples of the THS3001 Rev. A EVM PCB are shown in the

following illustrations. They are not to scale and appear here only as a

reference.

Figure 2–4.THS3001 Rev. A EVM Component Placement Silkscreen and Solder Pads

J1

Rev. A

–IN

GND

INVERTING

NONINVERTING

+IN

GND

J3

J2

–VCC

C1

R1

R3

R2

GND

U1

+

+

R4

C4

+VCC

C2

TEXAS

INSTRUMENTS

C3

R5

GND

J4

OUT

SLOP130 Rev A

THS3001 EVM Board

2-4

Reference

Page 19

THS3001 Rev. A EVM Board Layouts

Figure 2–5.THS3001 Rev. A EVM PC Board Layout – Component Side

Rev. A

Figure 2–6.THS3001 Rev. A EVM PC Board Layout – Back Side

Rev. A

Reference

2-5

Page 20

2-6

Reference

Loading...

Loading...