Page 1

Technical Reference Manual

SLLU312–July 2019

TCAN4550-Q1 Functional Safety-Manual

This document is the safety-manual for the Texas Instruments TCAN4550-Q1 device. The manual

provides information to help developers integrate the TCAN4550-Q1 device into safety-related systems.

Contents

1 Introduction ................................................................................................................... 2

2 Product Functional Safety-Capability...................................................................................... 2

3 Product Overview............................................................................................................ 2

4 Development Process for Management of Systematic Faults........................................................ 21

List of Figures

1 CAN Bus States.............................................................................................................. 3

2 TCAN4550-Q1 Mixed Signal Functional Block Diagram ............................................................... 4

3 Digital Core Block Diagram and Clock Tree ............................................................................. 5

4 General Purpose Application............................................................................................... 6

5 Potential Failure Points ..................................................................................................... 6

6 State Diagram................................................................................................................ 8

7 Fail-safe Feature State Diagram ......................................................................................... 10

8 SPI and M_CAN Test Modes............................................................................................. 12

9 CAN Transceiver Test Mode ............................................................................................. 13

10 Timing for RST Pin in Normal and Standby Modes ................................................................... 17

11 Timing for RST Pin in Sleep Mode....................................................................................... 18

12 TI New-Product Development Process.................................................................................. 21

1 Potential Failure Points and Section ..................................................................................... 7

2 Safety-Mechanisms.......................................................................................................... 7

3 Mode Overview .............................................................................................................. 9

4 Under Voltage Lockout ................................................................................................... 11

5 Driver Function Table...................................................................................................... 11

6 Receiver Function Table Normal and Standby Modes................................................................ 12

7 Watchdog Registers and Descriptions .................................................................................. 16

8 Terminal Bias ............................................................................................................... 16

9 Internal SPI Status Field Descriptions (Address h000C) ............................................................. 18

10 Interrupts Field Descriptions (Address h0820) ......................................................................... 19

11 MCAN Interrupts Field Descriptions (Address h0824)................................................................. 20

SLLU312–July 2019

Submit Documentation Feedback

List of Tables

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

1

Page 2

Introduction

Trademarks

All trademarks are the property of their respective owners.

1 Introduction

The system and equipment manufacturer or designer (as a user of this document) is responsible to ensure

that their systems (and any TI hardware or software components incorporated in the systems) meet all

applicable safety, regulatory and system-level performance requirements. All application and safetyrelated information in this document (including application descriptions, suggested safety-measures,

suggested TI products, and other materials) is provided for reference only. Users understand and agree

that their use of TI components in safety-critical applications is entirely at their risk, and that user (as a

buyer) agrees to defend, indemnify, and hold harmless TI from any and all damages, claims, suits, or

expense resulting from such use.

This document is a safety-manual for the Texas Instruments TCAN4550-Q1 aCAN FD controller with

integrated transceiver for safety-critical applications. The safety-manual provides information to help

system developers create safety-related systems using a supported TCAN4550-Q1. This document

contains:

• An overview of the product architecture

• An overview of the development process used to reduce systematic failures

• An overview of the safety architecture for management of random failures

• The details of architecture partitions, implemented safety mechanisms, and recommended usage

The Safety Analysis Report documents the following information, which is not covered in this document:

• Failure rates estimation

• Qualitative failure analysis (design FMEA and pin-FMEA)

• Quantitative failure analysis (quantitative FMEDA)

• Safety metrics calculated per targeted standards per system example implementation

TI expects that the user of this document has a general familiarity with the TCAN4550-Q1 device. This

document is intended to be used in conjunction with the pertinent data sheets and other documentation.

This partition of technical content is intended to simplify development, reduce duplication of content, and

avoid confusion as compared to the definition of safety-manual as seen in IEC 61508:2010.

www.ti.com

2 Product Functional Safety-Capability

The TCAN4550-Q1 safety-capability is QM, Quality Managed, per ISO 26262:2018. The TCAN4550-Q1

was developed with Quality Managed product development process and qualified according to AEC Q100

Grade 1.

3 Product Overview

The TCAN4550-Q1 is a CAN FD controller with an integrated CAN FD transceiver supporting data rates

up to 8 Mbps. The CAN FD controller meets the specifications of the ISO 11898-1:2015 high speed

Controller Area Network (CAN) data link layer and meets the physical layer requirements of the ISO

11898-2:2016 High Speed Controller Area Network (CAN) specification providing an interface between the

CAN bus and the host system supporting both classical CAN and CAN FD up to 8 megabits per second

(Mbps). The TCAN4550-Q1 provides CAN FD transceiver functionality: differential transmit capability to

the bus and differential receive capability from the bus. The device includes many protection features

providing device and CAN bus robustness. The device can also wake up via remote wake up using the

CAN bus implementing the ISO 11898-2:2016 Wake Up Pattern (WUP). Input/Output support for 3.3 V

and 5 V microprocessors using the VIOpin for a seamless interface. The TCAN4550-Q1 has a Serial

Peripheral Interface (SPI) that connects to a local microprocessor for the device configuration,

transmission and reception of CAN frames. The SPI interface supports clock rates up to 18 MHz.

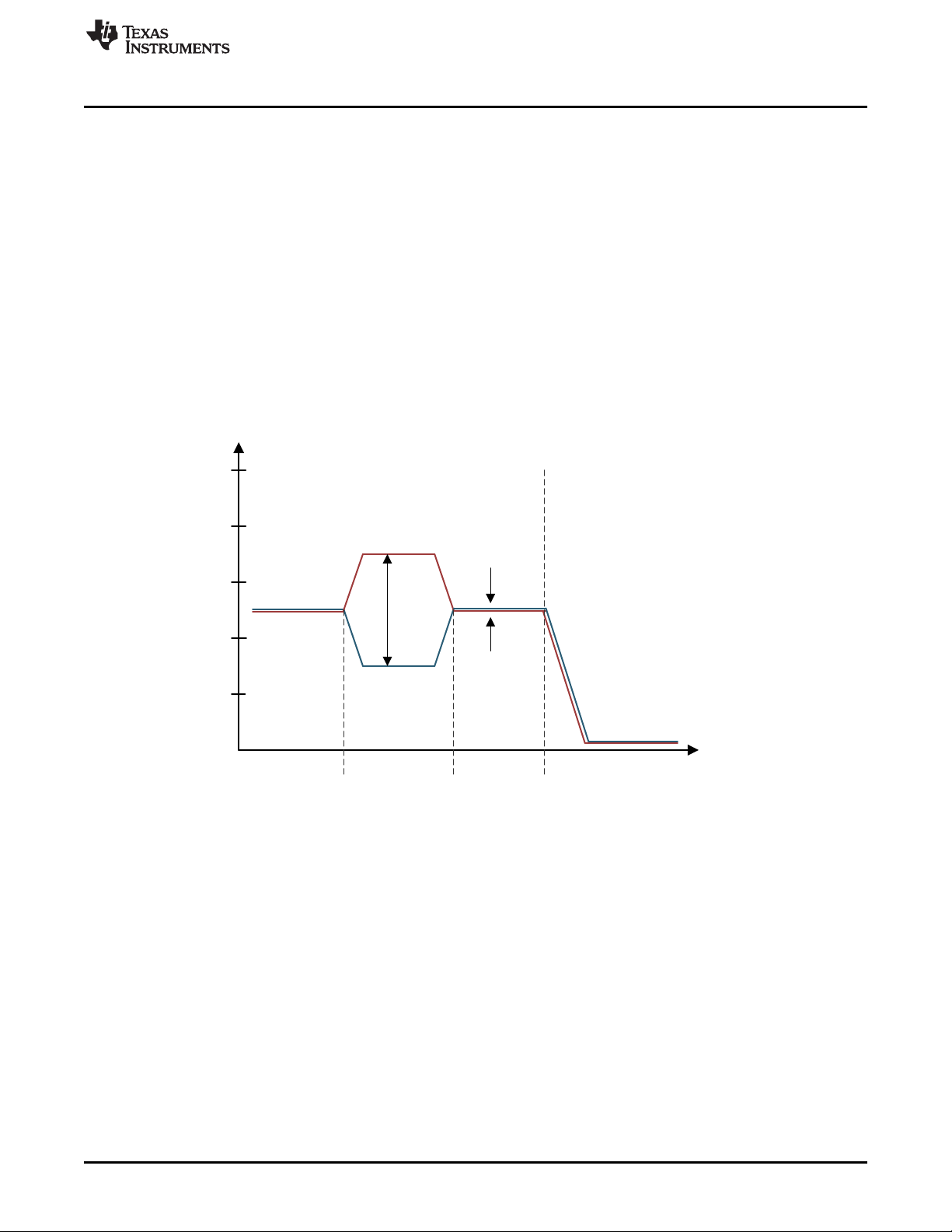

The CAN bus has two logical states during operation: recessive and dominant. See Figure 1

2

TCAN4550-Q1 Functional Safety-Manual

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 3

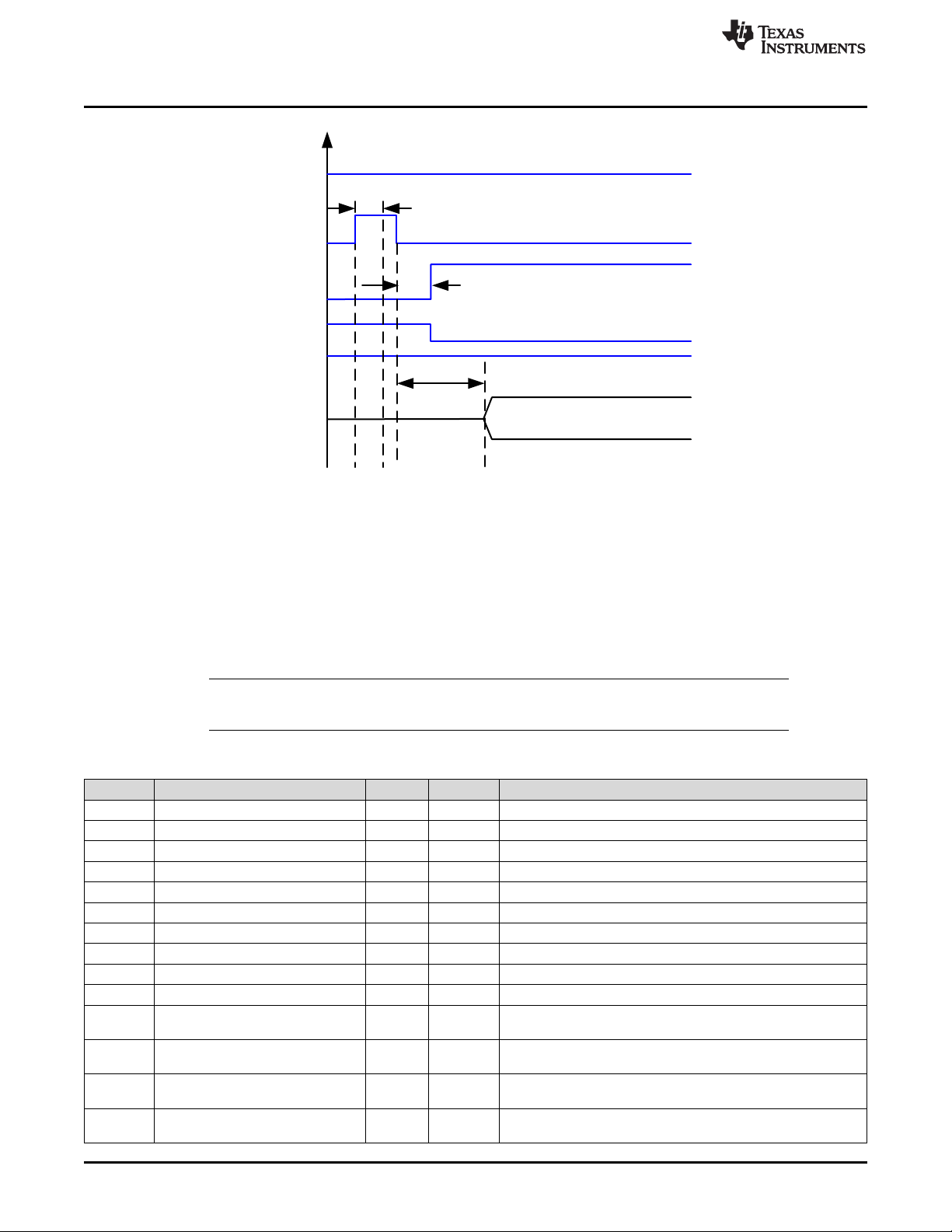

Recessive Dominant Recessive

Time, t

Typical Bus Voltage

Normal Mode

Standby Mode (Low

Power)

CANL

CANH

V

diff

V

diff

www.ti.com

In the recessive bus state, the bus is biased to a common mode of about 2.5 V via the high resistance

internal input resistors of the receiver of each node. Recessive is equivalent to logic high and is typically a

differential voltage on the bus of almost 0 V. The recessive state is also the idle state.

In the dominant bus state, the bus is driven differentially by one or more drivers. Current flows through the

termination resistors and generates a differential voltage on the bus. Dominant is equivalent to logic low

and is a differential voltage on the bus greater than the minimum threshold for a CAN dominant. A

dominant state overwrites the recessive state.

During arbitration, multiple CAN nodes may transmit a dominant bit at the same time. In this case the

differential voltage of the bus may be greater than the differential voltage of a single driver.

Transceivers with low power Standby Mode have a third bus state where the bus terminals are weakly

biased to ground via the high resistance internal resistors of the receiver. See Figure 1 and Figure 2.

Many of the pins can be configured for multiple purposes. Much of the parametric data is based on

internal links like the TXD/RXD_INT which represent the TXD and RXD of a standalone CAN transceiver.

The TCAN4550-Q1 has a test mode that maps these signals to an external pin in order to perform

compliance testing on the transceiver (TXD/RXD_INT_PHY) and CAN controller (TXD/RXD_INT_CAN)

independently.

Product Overview

Figure 1. CAN Bus States

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

3

Page 4

VSUP

VCCOUT

WAKEINH

RST

Crystal Osc

OSCIN

OSCOUT

INH

CTRL

CANH

CANL

RCVR

DRIVER

WUP RCVR

WUP/LUP

LOGIC

+ 32-Bit register

Comparator + analog

filter

WU

Clock from crystal osc/oscin

VCCOUT

Powerup

V3P6INT_SLEEP

V1P5INT_SLEEP

BG_1P25

ISRC_10U

V5INT

1.5V LDO

FLTR

WAKE

ISRC_10U

BG_1P25

V1P5INT

V1P5INT

V1P5INT_SLEEP

VCCOUT

VCCOUT

V3P6INT_SLEEP

VIO1

V1P5INT

WKRQ_nINT

CLKOUT/GPO1

SCLK

NCS

MOSI

MISO

NINT

Digital CORE

+

SRAM

GPO2

GND

VIO1

V5INT

Power and Control

CAN Transceiver and ControlSPI, M_CAN and Memory

Product Overview

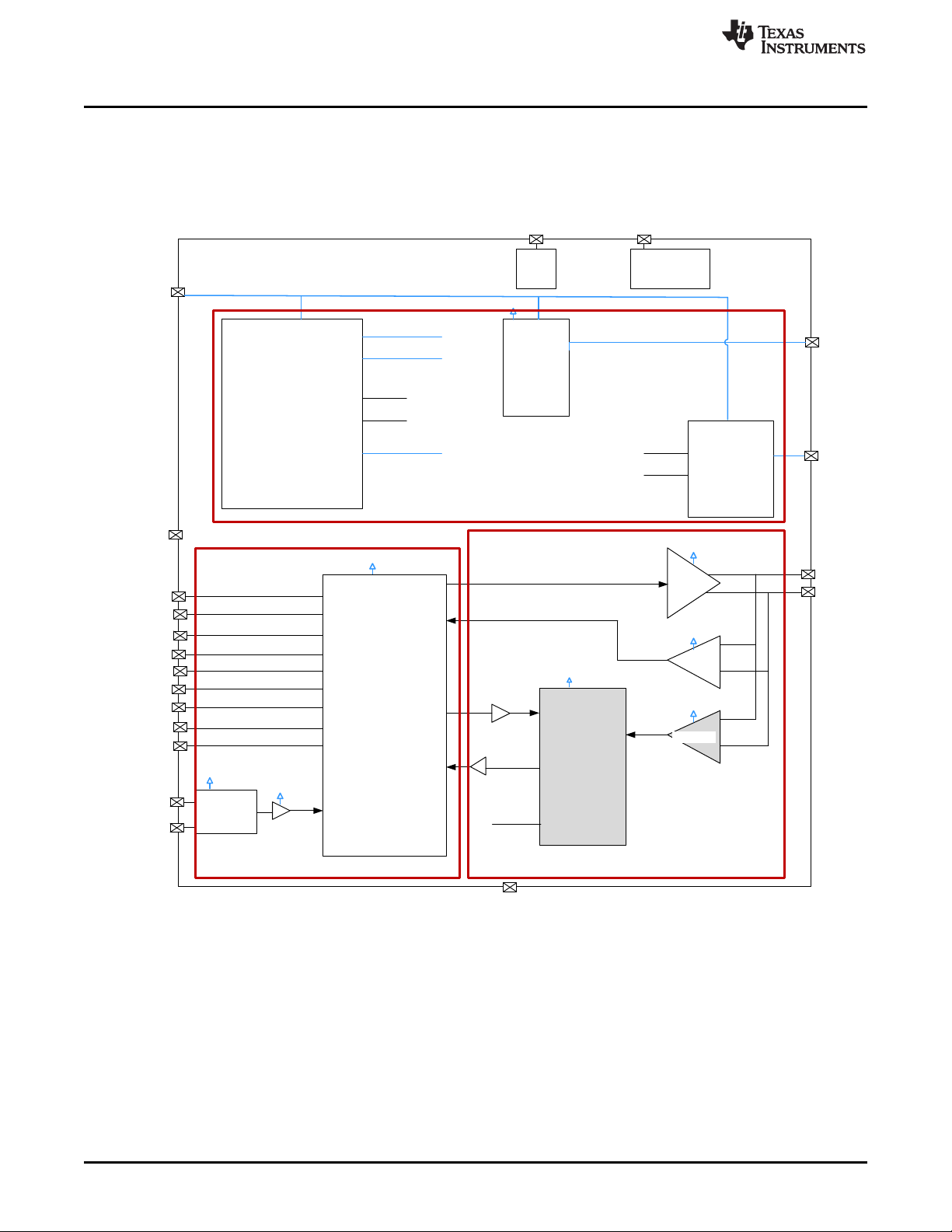

3.1 Block Diagram

The TCAN4550-Q1 is a mixed signal device containing both analog and digital cores. The device

integrates the Bosch M_CAN revision 3.2.1.1 controller which is not covered in this document. Figure 2

and Figure 3 are the high level mixed signal and digital core functional block diagrams. CCLK is internally

connected to the crystal/CLKIN.

www.ti.com

4

Figure 2. TCAN4550-Q1 Mixed Signal Functional Block Diagram

TCAN4550-Q1 Functional Safety-Manual

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 5

Main_core

mcan_core

supporting

blocks

(arbiter, time

stamp, driver

etc)

SPI

ECC

Controller

core

MCAN controller

Crystal

CCLK

Message

RAM

Watchdog

Register Map/

Interrupt

Logic

INH,

Device

Modes

FSM

Internal

Osc

SPI

High Power

(Standby/

Normal)

CAN

transceiver

logic, DTO

timer, bus

biasing

DFT

clock

WAKE

logic

Bus

biasing,

t

SILENT

timer

Sleep_core

DFT

www.ti.com

Product Overview

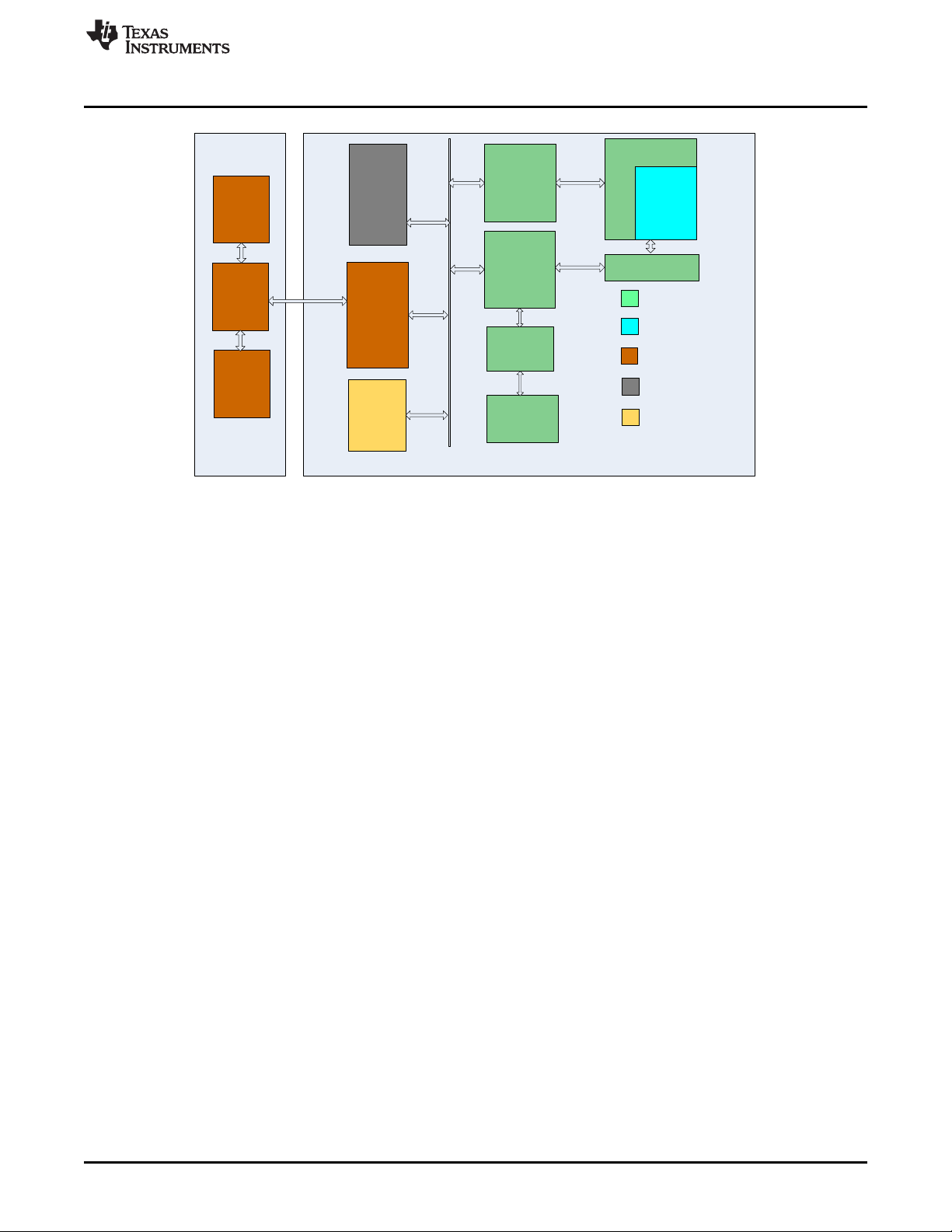

Figure 3. Digital Core Block Diagram and Clock Tree

3.2 Target Applications

The TCAN4550-Q1 is targeted at general-purpose automotive applications.

Examples of these types of applications include but are not limited to the applications that follow:

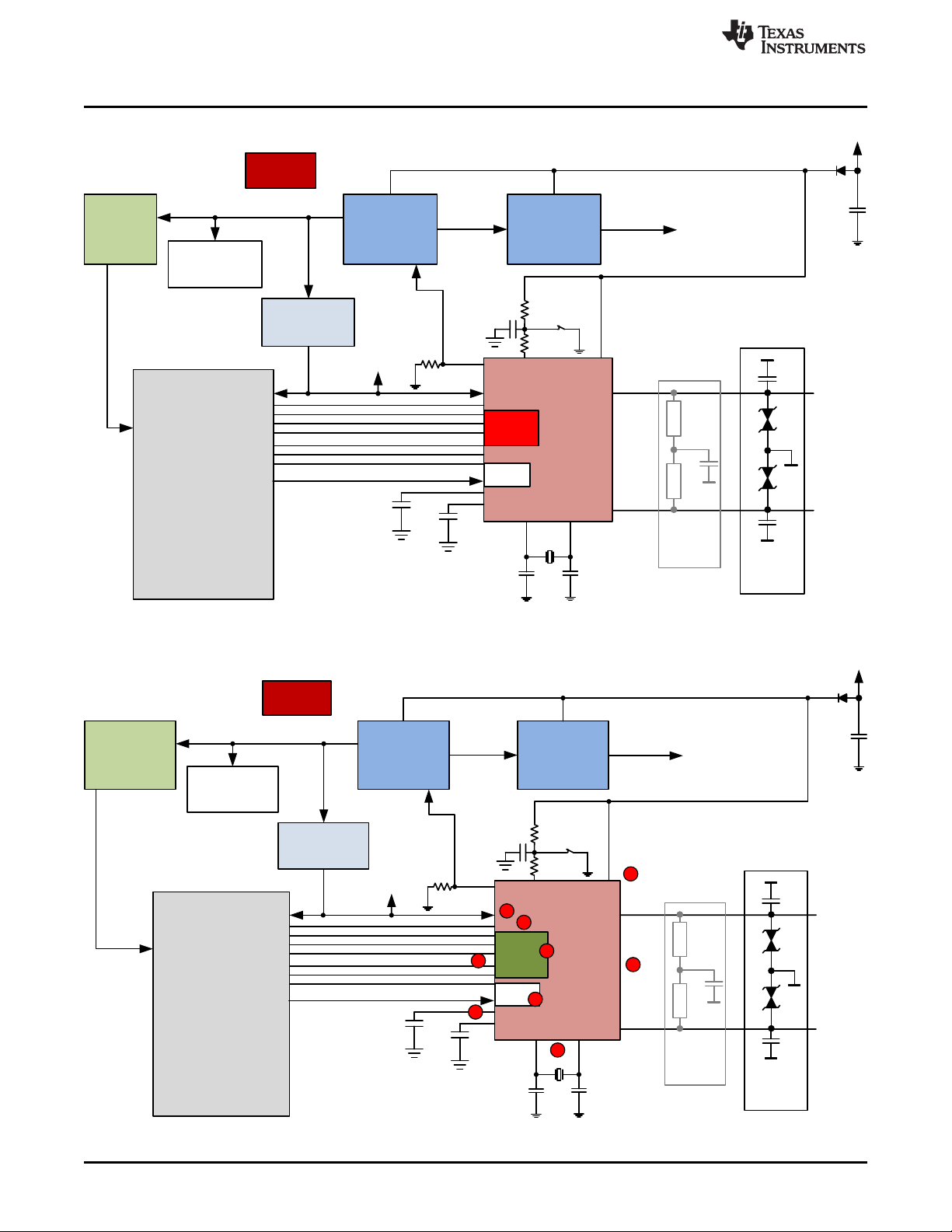

• General purpose applications where processor does not support CAN FD. See Figure 4

• CAN FD port expander

Figure 5 provides potential failure points that have diagnostic or test ability mechanisms. See Table 1 for

each potential failure point and subsection discussing this failure point.

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

5

Page 6

LM53635

Buck

3.3V, 3A

TPS57140

Buck

5V, 1.5A

TPS65917

PMIC

Processor

Without

CAN-FD Controller

Load SW

TPS22965

DDR3 Mem

TCAN4550

V

BAT

SPI

GPIO

3.3 V

12 V to 18 V

V

SUP

V

IO

INH

EN

EN

3.3 V

OSC1

WD

M_CAN

CAN-FD

Controller

Filters

100 NŸ

WAKE

33k

3.3 V

2-wire

CAN

bus

Optional:

Terminating

Node

Filtering,

Transient and

ESD

5 V

3k

CANH

CANL

10 µF

300 nF

GND

GND

22

nF

GND

V

CCOUT

FLTR

Add

Decoupling

Caps for All

Power

Connections

10

11

12

15

17

18

16

1

40 MHz

OSC2

20

1

4

3

2

5

6

RST

7

8

9

LM53635

Buck

3.3V, 3A

TPS57140

Buck

5V, 1.5A

TPS65917

PMIC

Processor

Without

CAN-FD Controller

Load SW

TPS22965

DDR3 Mem

TCAN4550RGY-Q1

V

BAT

SPI

GPIO

3.3 V

12 V to 18 V

V

SUP

V

IO

INH

EN

EN

3.3 V

Many V

OSC1

WD

CAN-FD

Controller

Filters

100 NŸ

WAKE

33k

3.3 V

2-wire

CAN

bus

Optional:

Terminating

Node

Filtering,

Transient and

ESD

5 V

3k

CANH

CANL

10 µF

300 nF

GND

GND

22

nF

GND

V

CCOUT

FLTR

Add

Decoupling

Caps for All

Power

Connections

10

11

12

15

17

18

16

1

40 MHz

OSC2

20

RST

Product Overview

www.ti.com

6

TCAN4550-Q1 Functional Safety-Manual

Figure 4. General Purpose Application

Figure 5. Potential Failure Points

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 7

www.ti.com

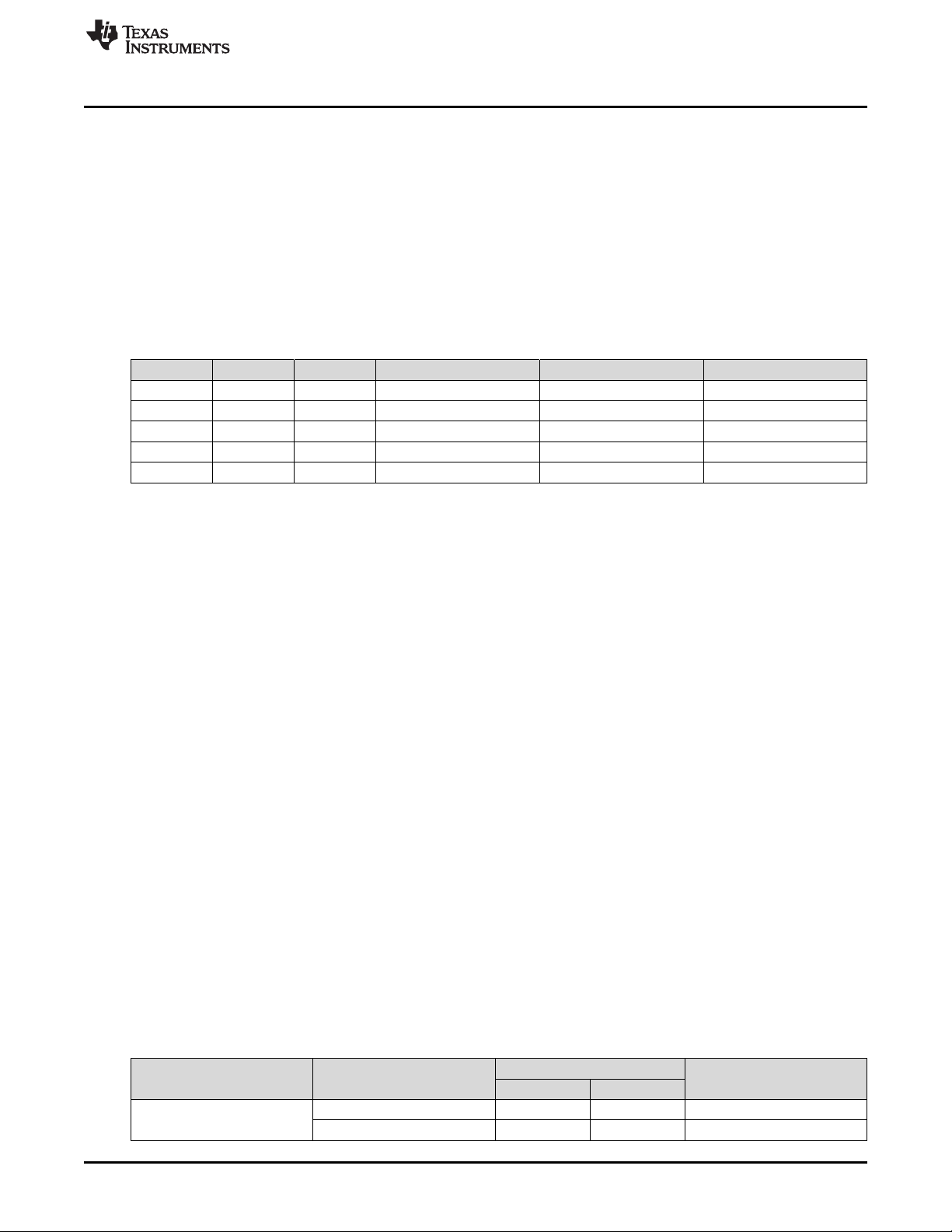

Table 1. Potential Failure Points and Section Figure 5

Potential

Failure

Point

from

Potential

Failure Point

Description

Section

Figure 5

Loss of clock

1

input

See Section 3.2.1.2 and Section 3.2.1.3

2 CAN bus See Section 3.2.1.3, Section 3.2.1.4, Section 3.2.1.5 and Section 3.2.1.6.5

3 Watchdog See Section 3.2.1.6.2

SPI/Processor

4

communication

5 Loss of V

6 Loss of V

See Section 3.2.1.6.1, Section 3.2.1.2, Section 3.2.1.3, Section 3.2.1.6.2, Section 3.2.1.6.3 and

Section 3.2.1.6.5

See Section 3.2.1.2, Section 3.2.1.3 and Section 3.2.1.6.5

SUP

See Section 3.2.1.2, Section 3.2.1.3 and Section 3.2.1.6.5

IO

7 RST pin failure See Section 3.2.1.6.3 and Section 3.2.1.6.4

M_CAN

8

Controller

9 Loss of V

See Section 3.2.1.5 and Section 3.2.1.6.5

See Section 3.2.1.3, Section 3.2.1.4 and Section 3.2.1.6.5

CCOUT

Table 2. Safety-Mechanisms

Product Overview

Safety-Mechanism

#

SM-01

SM-02 UV

SM-03 UV

SM-04 UV

Sleep Wake Error Timer

(SWE)t

Name Description Safety-Manual Section

Timer used for inactivity of expected functions.

INACTIVE

SUP

IO

CCOUT

Puts the device into Sleep mode

V

undervoltage detection and Interrupt

SUP

16'h0820[22]

VIOundervoltage detection and Interrupt

16'h820[21]

V

undervoltage detection and Interrupt

CCOUT

16'h0820[22]

SM-05 TSD Thermal Shutdown and Interrupt 16'h0820[19] 3.2.1.4

SM-06 IOS CAN bus short circuit current limiter 3.2.1.5

SM-07 SPI & M_CAN Test Mode Test Mode 3.2.1.5

SM-08

SM-09

SM-10

SPI & M_CAN Loop Back

Test Mode 1

SPI & M_CAN Loop Back

Test Mode 2

CAN Transceiver Test

Mode

Test Mode 3.2.1.5

Test Mode 3.2.1.5

Test Mode 3.2.1.5

Protocol Error in Data Phase; 16'h1050[28] points

SM-11 PED interrupt

to 16'h1044[10:8] DLEC[2:0]; Data Phase Last

Error Code

SM-12 PEA interrupt

SM-13 BEU interrupt

Protocol Error in Arbitration Phase; 16'h1050[27]

points to 16'h1044[2:0] LEC[2:0]; Last Error Code

Bit Error Uncorrected; 16'h1050[21] Message

RAM bit error detected, uncorrected

SM-14 Scratchpad write/read 3.2.1.6.1.1

SM-15 SPIERR flag SPI error detection and Interrupt 16'h0820[3] 3.2.1.6.1.2

SM-16

M_CAN forced dominant

and recessive

SM-17 SPI and FIFO TX and RX event FIFO 3.2.1.6.1.4

SM-18 ECC for Memory ECCERR detection and Interrupt 16'h0820[16] 3.2.1.6.1.5

SM-19 Timeout Watchdog WDTO detection and Interrupt 16'h0820[18] 3.2.1.6.2

SM-20 SCLK internal pull-up Floating pins 3.2.1.6.3

SM-21 SDI internal pull-up Floating pins 3.2.1.6.3

3.2.1.2

3.2.1.3

3.2.1.3

3.2.1.3

3.2.1.5 .1

3.2.1.5 .1

3.2.1.5 .1

3.2.1.6.1.3

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

7

Page 8

Normal Mode

RST: L

INH: H

Wake Pin: Active

All GPIO: Active

SPI: Active

OSC: Active

V

CCOUT

: Enabled

Power On

Start Up

Standby Mode

RST: L

Wake Sources: CAN, WAKE

INH: H

Wake Pin: Active

All GPIO: Active

SPI: Active

OSC: Active

V

CCOUT

: Enabled

Sleep Mode

RST: L

Wake Sources: CAN, WAKE

INH: floating

Wake Pin: Active

nINT Pin: Off

nWKRQ Pin: Active

Other GPIO: Off

SPI: Off

OSC: Off

V

CCOUT

: Off

SPI Write

MO = 00

SPI Write

MO = 01

SPI Write

MO = 10

NOTE: Upon a wake event the device will

transition into Standby mode and must be

reconfigured using SPI

Wake-up Event:

CAN bus

or

WAKE Pin

SPI Write

MO = 00

RST Pin: Set high to

reset device. Once

finished set back low

UVLO V

SUP

TSD Protected

RST: L

Wake Sources: WAKE

INH: H

Wake Pin: Active

All GPIO: Active

SPI: Active

OSC: Active

V

CCOUT

: Off

Timer Start

Normal Mode

TSD = 1

TSD State

TSD Timer

TSD = 0 &

Timer Expires

TSD = 1 &

Timer Expires

UVIO Protected

RST: L

Wake Sources: CAN, WAKE

INH: H

Wake Pin: Active

All GPIO: Off

SPI: Off

OSC: Off

V

CCOUT

: On

Timer Start

UVIO State

UVIO Timer

UVIO = 1

UVIO = 1

Normal Mode

UVIO = 0

UVIO = 1 &

Timer Expires

TSD = 1

Resets Sleep

Core

Note:

x UVIO Protected status will lose the CLKIN/Crystal. During this time the digital core will reset and the M_CAN will have to be

reprogrammed. If timer times out and UVIO = 1 the device goes to sleep at which time all are cleared.

x If a Thermal Shutdown and UVIO event take place at the same time the device will enter sleep mode until the faults are rectified

Continued decrease below UV

SUP

;

the device will reset and clear

everything and come back on as if

a power up sequence has taken

place entering standby mode

Power Off

SWE timer

times out

Product Overview

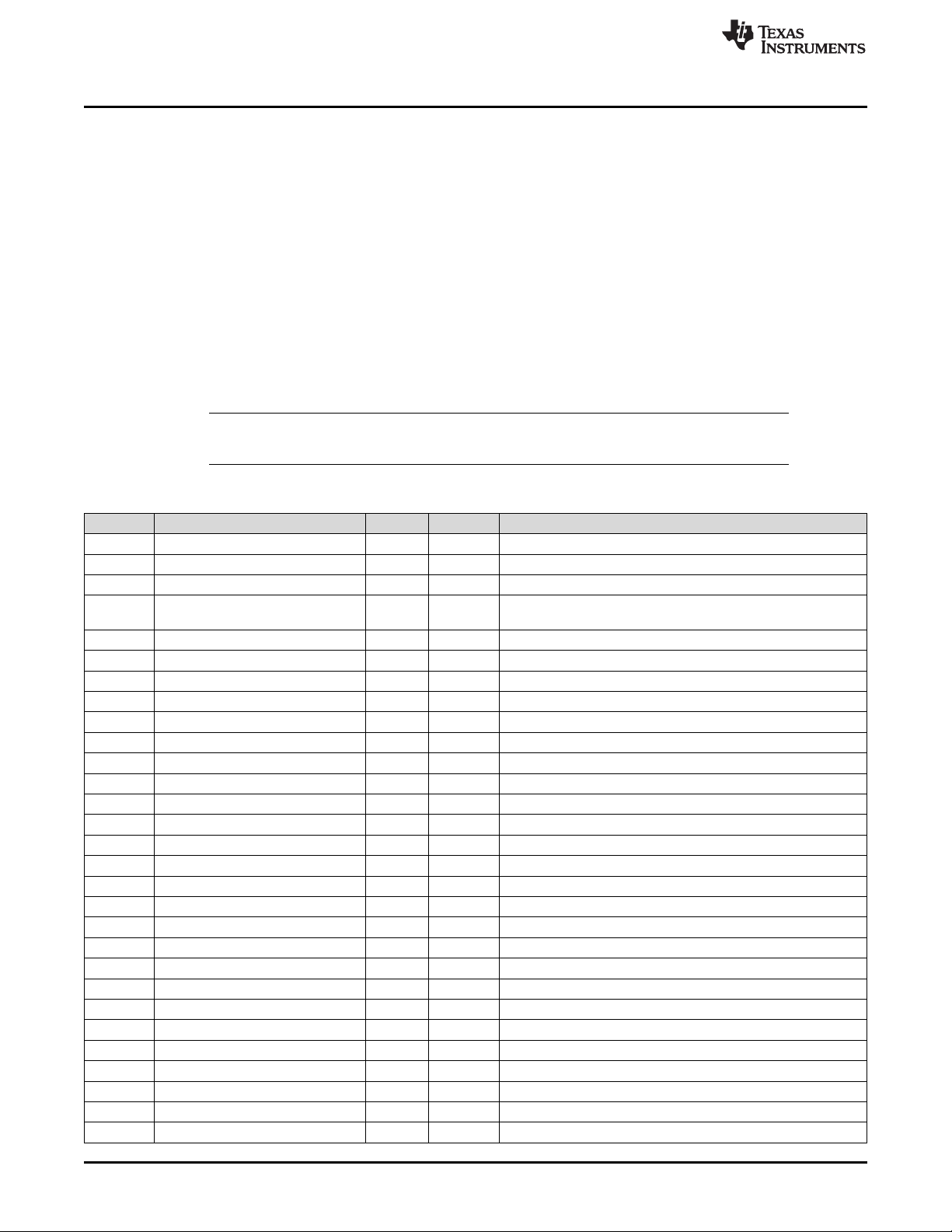

Safety-Mechanism

#

SM-22 nCS internal pull-up Floating pins 3.2.1.6.3

SM-23 nWKRQ internal pull-up Floating pins 3.2.1.6.3

SM-24 RST internal pull-down Floating pins 3.2.1.6.3

SM-25 RST Pin System POR reset 3.2.1.6.4

3.2.1 Diagnostic Features

The TCAN4550-Q1 device has several features that determines specific fault conditions in a system and

indicate this back to the processor or place the device into a protected state that may include Sleep mode.

Figure 5 is used to indicate these fault conditions. Figure 6 provides the devices state diagram and shows

two protected modes and Sleep mode.

www.ti.com

Table 2. Safety-Mechanisms (continued)

Name Description Safety-Manual Section

8

TCAN4550-Q1 Functional Safety-Manual

Figure 6. State Diagram

Copyright © 2019, Texas Instruments Incorporated

SLLU312–July 2019

Submit Documentation Feedback

Page 9

www.ti.com

3.2.1.1 Mode Overview

The TCAN4550-Q1 has several operating modes: Normal, Standby and Sleep modes, as well as two

protected modes. The first three mode selections are made by the writing to SPI register. The two

protected modes are modified Standby modes used to protect the device or bus and are entered from

a fault condition only. The TCAN4550-Q1 automatically goes from Sleep to Standby mode when

receiving a WUP or LWU event. See Table 3 for the various modes and what parts of the device are

active during the each mode.

The TCAN4550-Q1 state diagram figure, see Figure 6, shows the biasing of the CAN bus in each of

the modes of operation.

RST

Mode

Normal L On On On On Off Off On On On On On On Saved

Standby L On On On On On On On On On On Off On Saved

TSD

ProtectedL On On On On On On On On On On Off Off Saved

UV

IO

ProtectedL Off On Off Off On On Off Off Off Off

Sleep L Off On Off Off On On Off Off Off Off Off Off Partially Saved

nINT nWKRQ INH GPO2

Pin

Table 3. Mode Overview

Low

Power

WAK

CAN

RX

WD SPI GPIO1 OSC CAN TX/ RX V

E Pin

Mode

Dependent

Product Overview

CCOUT

On Saved

Memory &

Configuration

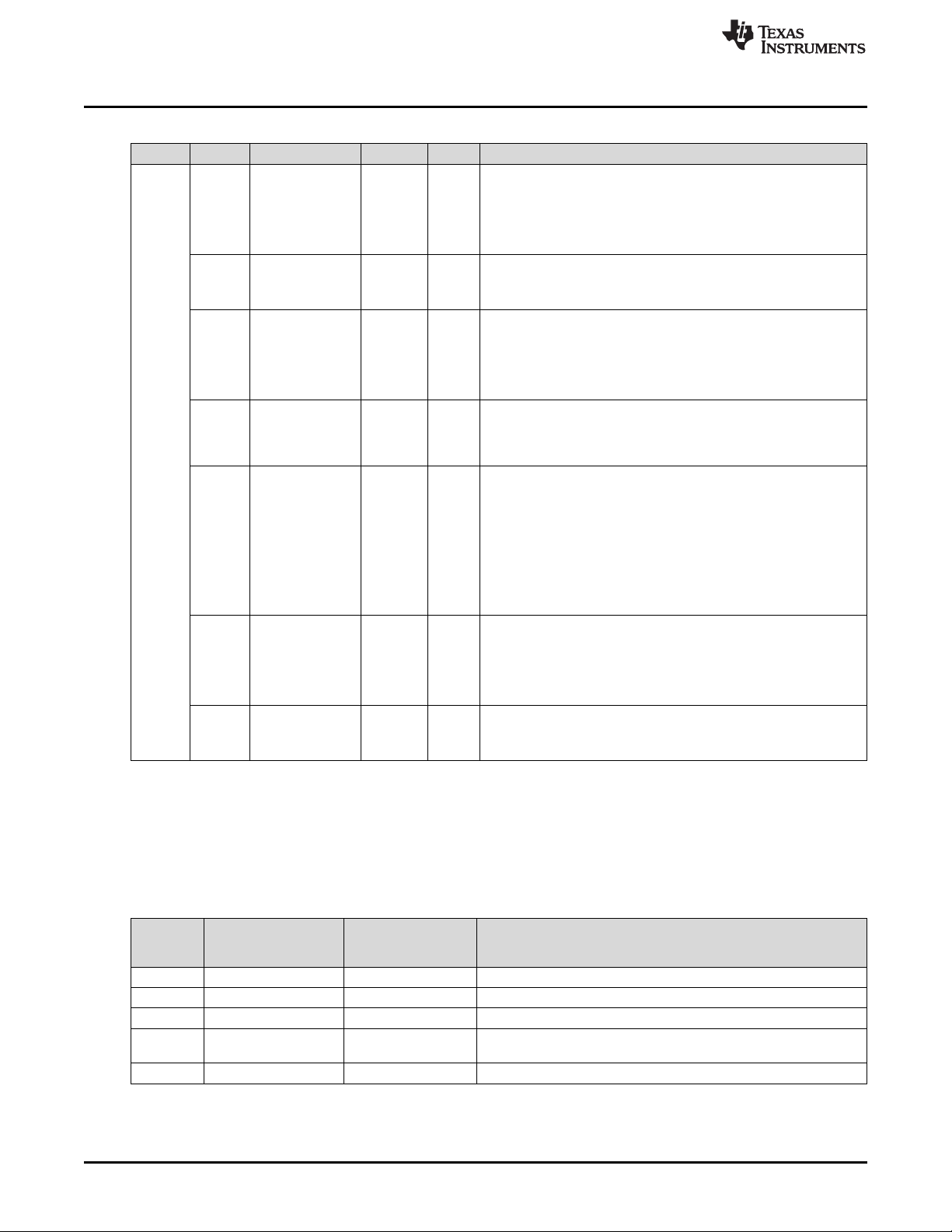

3.2.1.2 Sleep Wake Error Timer (SWE)

The sleep wake error (SWE) timer is a four minute timer that is used to place the device into Sleep mode

due to certain faults. The SWE timer is used to help mitigate certain faults shown by items 1, 4, 5 and 6 in

Figure 5 and is considered safety mechanism SM-01.

The TCAN4550-Q1 fail-safe feature is used in order to reduce node power consumption in case of a

system issue. Fail-safe is the method the device uses to enter Sleep mode from various other modes

when specific issues arise. This feature uses the SWE timer to determine if the node processor can

communicate to the TCAN4550-Q1. The SWE timer is default enabled through the SWE_DIS; 16'h0800[1]

= 0 but can be disabled by writing a one to this bit. Even when the timer is disabled, the timer

automatically works for power up and power on resets. Fail-safe feature is default disabled but can be

enabled by writing a one to 16'h0800[13], FAIL-SAFE_EN.

Upon power up the SWE timer, t

INACTIVE

the TCAN4550-Q1, clear the PWRON flag or configure the device for Normal mode; see Figure 7. This

feature cannot be disabled. If the device has not had the PWRON flag cleared or been placed into Normal

mode, it enters Sleep mode. The device wakes up if the CAN bus provides a WUP or a local wake event

takes place, thus entering Standby mode. Once in Standby mode, t

t

INACTIVE

expires, the device re-enters Sleep mode.

The second failure mechanism that causes the device to use the fail-safe feature, if enabled, is when the

device receives a CANINT, CAN bus wake (WUP) or WAKE pin (LWU), while in Sleep mode such that the

device leaves Sleep mode and enters Standby mode. The processor has four minutes to clear the flags

and place the device into Normal mode. If this does not happen the device enters Sleep mode.

The third failure mechanism that can trigger the failsafe feature is a silent CAN bus. If the CANSLNT flag

persists for t

. Examples of events that could create this are the CLKIN or crystal stops working, the

INACTIVE

processor is no longer working and not able to exercise the SPI bus, a go-to-sleep command comes in

and the processor is not able to receive it or is not able to respond. See Figure 7.

, starts and the processor has typically four minutes to configure

SILENCE

and t

INACTIVE

timers starts. If

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

9

Page 10

Standby Mode

SWE Timer

t

INACTIVE

Power On

Start Up

Sleep Mode

RST: L

Wake Sources: CAN, WAKE

INH: floating

Wake Pin: Active

nINT Pin: Off

nWKRQ Pin: Active

Other GPIO: Off

SPI: Off

OSC: Off

V

CCOUT

: Off

Stays in STBY mode

or switches to Normal

mode if programmed

No &

Cleared

Timed out

Does timer

Expire and PWRON

flag cleared?

SWE Timer

t

INACTIVE

Normal Mode

0800[13] = 1

Fail Safe Mode En

Bus Inactivity

t

SILENCE

timer

expires

setting CANSLNT

flag

Sleep Mode

RST: L

Wake Sources: CAN, WAKE

INH: floating

Wake Pin: Active

nINT Pin: Off

nWKRQ Pin: Active

Other GPIO: Off

SPI: Off

OSC: Off

V

CCOUT

: Off

Does timer

expire?

No &

Cleared

SWE Timer

t

INACTIVE

Monitoring CAN

Sleep Mode

RST: L

Wake Sources: CAN, WAKE

INH: floating

Wake Pin: Active

nINT Pin: Off

nWKRQ Pin: Active

Other GPIO: Off

SPI: Off

OSC: Off

V

CCOUT

: Off

Does timer

Expire and required

flags cleared?

Standby Mode

0800[13] = 1

Fail Safe Mode En

Bus Inactivity

Activity detected

leaving device in

current mode or

placing in selected

mode

Timed out

Power Up Failsafe Feature

Loss of Communication Failsafe Feature

Product Overview

www.ti.com

10

TCAN4550-Q1 Functional Safety-Manual

Figure 7. Fail-safe Feature State Diagram

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 11

www.ti.com

3.2.1.3 Undervoltage

The TCAN4550-Q1 has three undervoltage events that it monitors, UV

supply voltage to V

correct voltage levels. The V

this time. The device then disables the CAN transceiver and start putting the internal logic into a safe

state. If V

drops more, it eventually reaches the power on reset level. The device comes back up as if it

SUP

was the first time up once V

the device enters a UVIOprotected state. The digital I/O and the Crystal/CLKIN need VIOto perform

properly at the correct levels. These undervoltage levels help keep incorrect information off of the bus and

vice versa. These help mitigate faults shown as 1, 2, 4, 5, 6 and 9. The undervoltages are covered by

safety mechanism SM-02, SM-03 and SM-04.

drops below UV

SUP

CCOUT

SUP

, UVIOand UV

threshold the internal regulators may or may not provide the

SUP

SUP

CCOUT

LDO also provides 5 V for the CAN transceiver may enter UV

rises above the UV

threshold. When VIOdrops below the UVIOthreshold

SUP

Table 4. Under Voltage Lockout

Product Overview

. When the

at

CCOUT

V

> UV

> UV

< UV

> UV

< UV

SUP

SUP

SUP

SUP

SUP

SUP

V

> UV

> UV

> UV

< UV

< UV

IO

VIO

VIO

VIO

VIO

VIO

V

CCOUT

> UV

CCOUT

< UV

CCOUT

NA Protected High Impedance High (Recessive)

> UV

CCOUT

NA Protected High Impedance High Impedance

3.2.1.4 Thermal Shut Down

The TCAN4550-Q1 has a temperature monitor located by two components that can cause thermal issues;

V

LDO and CAN transceiver. This is a device protection mechanism. When TSD temperature is

CCOUT

reached, the device enters the TSD protected state as shown in Figure 6. In this state, the V

turned off and the CAN transceiver is disabled. This helps mitigate bus communication fault, shown as 2,

and V

issues, shown as 9, in Figure 5 and is considered safety mechanism SM-05. Undervoltage lock

CCOUT

out prevents operation of the device and communication with the MCU and the CAN FD Bus when there is

insufficient power on V

, VIOor V

SUP

3.2.1.5 CAN Bus Communication

CAN bus communication, shown as fault 2, is a main concern in a system. This can happen due to many

different mechanisms. Some have been covered in the previous sections of this document. The Bosch

M_CAN core has a CRC checker that validates the CAN data so corrupted data does not get transferred

to the node processor from the bus. The M_CAN core also provide two loop back test modes that allow

the implementer to determine if the data transmitted and received through the core are the same; see

Figure 8 loop back test mode 1 and 2. These three SPI↔M_CAN test modes are safety mechanism SM-

07, SM-08 and SM-09. If an error is detected there are two other test modes that can be utilized to

determine if the error is in the digital core or the transceiver; see Figure 8 and Figure 9. Driver and

receiver function test modes map the internal TXD_INT_PHY, RXD_INT_PHY and EN_INT signals to

GPIO to drive and receive data to CAN bus. Table 5 and Table 6 provide information on CAN bus state

when using transceiver test mode and is considered safety mechanism SM-10. Diagnostic tools like

dominant state timeout which makes sure the bus is not stuck dominant if the TXD_INT_PHY signal is

stuck low. The M_CAN signals TXD_INT_CAN and RXD_INT_CAN can be mapped to GPIO as an aid in

diagnostic to determine if the expected data is transmitted from SPI through M_CAN core and vise versa.

Table 5 and Table 6 provide information on CAN bus state when using transceiver test mode.

The TCAN4550-Q1 provides CAN bus short circuit current limiting and is considered safety mechanism

SM-06. These also mitigate potential faults 4 and 8.

DEVICE STATE BUS RXD_INT

Normal Per TXD_INT Mirrors Bus

Protected High Impedance High (Recessive)

Protected Recessive High Impedance

.

CCOUT

CCOUT

LDO is

DEVICE MODE TXD_INT INPUT

Normal

SLLU312–July 2019

Submit Documentation Feedback

Table 5. Driver Function Table

BUS OUTPUTS

CANH CANL

L H L Dominant

H or Open Z Z Biased Recessive

TCAN4550-Q1 Functional Safety-Manual

Copyright © 2019, Texas Instruments Incorporated

DRIVEN BUS STATE

11

Page 12

SCLK

CANH

V

CCINT2

CANL

SPI slave,

System

Controller

SDI

SDO

nCS

GPIO1

GPO2

M_CAN

Core

RX

TX

RXD_INT_CAN

TXD_INT_CAN

SCLK

CANH

V

CCINT2

CANL

SPI slave,

System

Controller

SDI

SDO

nCS

M_CAN

Core

RX

TX

= 1

SCLK

CANH

V

CCINT2

CANL

SPI slave,

System

Controller

SDI

SDO

nCS

M_CAN

Core

RX

TX

SPI & M_CAN Test Mode

SPI & M_CAN Loop Back Test Mode 1

SPI & M_CAN Loop Back Test Mode 2

Product Overview

DEVICE MODE TXD_INT INPUT

Table 5. Driver Function Table (continued)

BUS OUTPUTS

CANH CANL

Standby X Z Z Weak Pull to GND

Sleep X Z Z Weak Pull to GND

DRIVEN BUS STATE

Table 6. Receiver Function Table Normal and Standby Modes

www.ti.com

DEVICE MODE

CAN DIFFERENTIAL INPUTS

VID= V

CANH

– V

CANL

BUS STATE RXD_INT TERMINAL

VID≥ 0.9 V Dominant L

Normal

0.5 V < VID< 0.9 V Undefined Undefined

VID≤ 0.5 V Recessive H

VID≥ 1.15 V Dominant

Standby/Sleep

0.4 V < VID< 1.15 V Undefined

VID≤ 0.4 V Recessive

Any Open (VID≈ 0 V) Open H

See TCAN4550-Q1 data

sheet figure 24 for more

detial

12

TCAN4550-Q1 Functional Safety-Manual

Figure 8. SPI and M_CAN Test Modes

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 13

SCLK

CANH

V

CCINT2

CANL

SPI slave,

System

Controller

SDI

SDO

nCS

nINT

GPIO1

GPO2

M_CAN

Core

RX

TX

EN_INT

TXD_INT_PHY

RXD_INT_PHY

Transceiver Test Mode

www.ti.com

3.2.1.5.1 M_CAN

The M-CAN core which is an industry standard core supporting CAN FD and Classical CAN has three

interrupts that also lend themselves to confirmation the CAN bus information is accurate. These interrupts

are in register 16'h1050 and are as follows:

• 16'h1050[28] is an interrupt bit for Protocol Error in Data Phase (PED). If this bit shows up as a one

register 16'h1044[10:8] - DLEC (Data Phase Last Error Code) need to be reviewed to determine the

cause of the error. This is safety mechanism SM-11.

• 16'h1050[27] is an interrupt bit for Protocol Error in Arbitration Phase (PEA). If this bit shows up as a

one register 16'h1044[2:0] - LEC (Last Error Code) need to be reviewed to determine the cause of the

error. This is safety mechanism SM-12.

• 16'h1050[21] is an interrupt for Bit Error Uncorrected (BEU). This is an ECC between the M_CAN core

and message RAM. This is safety mechanism SM-13. This is not the same ECC error described in

processor communication section.

PED and PEA share the same code when the interrupt is set. These are three bit codes.

• 0 – No Error: No error occurred since LEC has been reset by successful reception or transmission

• 1 – Stuff Error: More than 5 equal bits in a sequence have occurred in a part of a received message

where this is not allowed

• 2 – Form Error: A fixed format part of a received frame has the wrong format

• 3 – AckError: The message transmitted by the M_CAN was not acknowledged by another node

• 4 – Bit1Error: During the transmission of a message (with the exception of the arbitration field), the

device wanted to send a recessive level (bit of logical value ‘1’), but the monitored bus value was

dominant

• 5 – Bit0Error: During the transmission of a message (or acknowledge bit, or active error flag, or

overload flag), the device wanted to send a dominant level (data or identifier bit logical value ‘0’), but

the monitored bus value was recessive. During Bus_Off recovery this status is set each time a

sequence of 11 recessive bits has been monitored. This enables the CPU to monitor the proceeding of

the Bus_Off recovery sequence (indicating the bus is not stuck at dominant or continuously disturbed)

• 6 – CRCError: The CRC check sum of a received message was incorrect. The CRC of an incoming

message does not match with the CRC calculated from the received data

• 7 – NoChange: Any read access to the Protocol Status Register re-initializes the LEC to ‘7’. When the

LEC shows the value ‘7’, no CAN bus event was detected since the last CPU read access to the

Protocol Status Register

Product Overview

Figure 9. CAN Transceiver Test Mode

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

13

Page 14

Product Overview

3.2.1.6 Processor Communication

Communication between the node processor and the TCAN4550-Q1 contain several features that can

help determine if there is an issue and have a method for recovery. Several of the previous features like

the SWE timer and UVIOhelp with determining if communication with the processor is possible. Other

diagnostic tools that are available are timeout watchdog, floating terminals, device reset and several fault

interrupts available through SPI. Signal fail-safe in case of open (floating terminals) allows default state of

pin signals incase of an open terminal, see Table 8

3.2.1.6.1 SPI Integrity

The TCAN4550-Q1 does not support CRC for SPI communication. There are several ways to periodically

determine the SPI bus integrity is valid. These cover potential fault 4.

For the most robust and mostly continuous method is double transmit and reads and double reads to

determine if the data is the same. This method though robust reduces the bandwidth capabilities of the

device so performing several periodic test can be beneficial.

The periodic test that can be performed are as follows:

• Scratchpad write/read, safety mechanism SM-14

• SPIERR flag, safety mechanism SM-15

• M_CAN forced dominate and recessive testing, safety mechanism SM-16

• SPI and FIFO, safety mechanism SM-17

• ECC for memory, safety mechanism SM-18

www.ti.com

3.2.1.6.1.1 SPI Scratchpad

Using the TCAN4550-Q1 scratchpad by the processor makes it possible to write and read back data for

verification of accuracy. This verifies SPI interface to register space. It can also be accomplished without

interfering with CAN bus.

3.2.1.6.1.2 SPIERR

The TCAN4550-Q1 SPI controller checks all SPI transactions for transaction end on a byte boundary and

the length of the transaction is what was specified. The SPIERR flag sets if anything is incorrect, see

Table 9 for the various issues that sets the SPIERR interrupt.

3.2.1.6.1.3 M_CAN Forced Dominant and Recessive

The TCAN4550-Q1 M_CAN controller is used to force a dominant and recessive output by the processor.

The way to accomplish this without impacting the CAN bus is to use two of the SPI & M_CAN test modes

at the same time. Figure 8 shows the three SPI & M_CAN test modes. The top two are the ones to utilize

for this test. When used together the output goes to the GPO2 pin. This allows the processor to verify the

output is what is expected without needing to understand the CAN FD protocol. This is accomplished by

using register 16'h0800[21]; TEST_MODE_EN and 16'h0800[0]; TEST_MODE_CONFIG followed by

setting test register 16'1010 for M_CAN core. This shows SPI through M_CAN working.

3.2.1.6.1.4 SPI and FIFO

Another method for processor communication is accomplished by it using the Event FIFO for transmitting

and receiving. This is initiated by the processor and the TCAN4550-Q1 provides interrupts as described

as follows.

For transmitting, enabling the Tx Event FIFO option in the M_CAN requires SPI writes to the Tx Event

FIFO acknowledge register to manage the fill level. If these updates are not made, the Tx Event FIFO

eventually gives a Tx Event FIFO full (interrupt) and then the Tx Event FIFO Element Lost (interrupt).

For receiving, if the Rx messages are stored in Rx FIFO, then SPI writes are required to the Rx FIFO

Acknowledge register to manage the fill level. If this SPI access is not working, the Rx FIFO fills and gives

a Rx FIFO 0/1 Full (interrupt) and then Rx FIFO 0/1 Message Lost (interrupt).

These are runtime checks that indirectly ensure the SPI interface is working properly.

14

TCAN4550-Q1 Functional Safety-Manual

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 15

www.ti.com

3.2.1.6.1.5 ECC for Memory

The TCAN4550-Q1 provides single bit error correct when writing to and reading from MRAM with the

integrated ECC function.

For transmitting; when a message is to be transmitted, the data is read from internal MRAM. If during this

read (39 bits at a time for 4-bytes of data), a single bit is flipped, then this bit error is automatically

detected and corrected. If 2 bits are flipped, M_CAN exits and does not transmit any data. The device

drops into Standby Mode. The M_CAN Bit Error Uncorrected (BEU) interrupt is set. This is an

uncorrectable error case. There is no provision for 3+ bits being flipped, but statistically this is considered

highly improbable. (3+ error bits could alias into pass, 1, or 2 errors)

For receiving; when a received message is being read through SPI, the data is first fetched from MRAM. If

during this read (39 bits at a time), a single bit is flipped, it is corrected. If 2 bits are flipped, an ECCERR

interrupt is issued to inform the micro the read is corrupt. The ECCERR should be cleared and the read

tried again. There is no provision for 3+ bits flipped. This is the SPI to message RAM ECC error and not

be confused with the BEU interrupt in bus communication section.

3.2.1.6.2 Timeout Watchdog

The TCAN4550-Q1 contains a watchdog (WD) timeout function. When using the WD timeout function the

WD runs continuously. The WD is default enabled and can be configured with four different timer values.

WD is active in Normal and Standby modes and off in Sleep mode. Once the device enters Standby or

Normal mode the timer does not start until the first input trigger event. This event can be either writing a

one to register 16'h0800[18] or if selected, by changing the voltage level on the GPIO1 pin either high or

low when configured for watchdog input. If the first trigger is not set the watchdog is disabled. The first

trigger can happen in Standby mode or Normal mode. This is system implementation specific. While the

timer is running, a SPI command writing a one to 16'h0800[18] resets the WD_TIMER timer, or if

configured for pin control the GPIO1 behaves as the watchdog input bit.

The TCAN4550-Q1 has two ways of setting the trigger bit: via a SPI command and, if selected, through a

GPI (GPIO1 configured as GPI). When a GPI pin is used any rising or falling edge resets the timer. A

watchdog event can be conveyed back to the microprocessor in two methods: interrupt on nINT pin, or if

selected, the GPO2 pin can be programmed to toggle upon a WD timeout. A timeout can initiate one of

three actions by the TCAN4550-Q1: interrupt, INH toggle plus putting the device into Standby mode or

toggle watchdog output reset pin if enabled. The input CLKIN or crystal values needs to be entered into

reg 16'h0800[27] and is either 20 MHz or 40 MHz. See Table 7 for the register settings for the watchdog

function. This can help mitigate potential faults shown as 3 and 4 and is safety mechanism SM-19.

Product Overview

NOTE:

• If the device enters UVIOprotected mode, the watchdog timer is held in reset.

When the device returns to Standby mode, the timer resumes counting.

• Once the command to enter Sleep mode takes place, the WD timer is turned off

and does not trigger a watchdog event.

• If the any of the watchdog registers needs to be changed, the watchdog must

be disabled and the change made and then re-enabled.

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

15

Page 16

Product Overview

Address BIT(S) Field Type Reset DESCRIPTION

16'h080

0

Table 7. Watchdog Registers and Descriptions

29:28 WD_TIMER R/W 2'b00

27 CLK_REF R/W 1'b1

23:22 GPO2_CONFIG R/W 2'b00

18 WD_BIT_SET W1C 1'b0

17:16 WD_ACTION R/W 2'b00

15:14 GPIO1_CONFIG RW 2'b01

3 WD_EN RXU 1'b1

www.ti.com

WD_TIMER: Watchdog timer

00 = 60 ms

01 = 600 ms

10 = 3 s

11 = 6 s

CLK_REF: CLKIN/Crystal frequency reference

0 = 20 MHz

1 = 40 MHz

GPO2_CONFIG: GPO2 configuration

00 = No action

01 = M_CAN_INT 0 interrupt (active low)

10 = Watchdog output

11 = Mirrors nINT pin

WD_BIT_SET: write a 1 to reset timer: if times out; this bit sets and

then the selected action from register 16'h0800[17:16] takes place.

Note: This is a self-clearing bit. Writing a 1 resets the timer and then

the bit clears.

WD_ACTION: Selected action when WD_TIMER times out

00 = Set interrupt flag and if a pin is configure to reflect WD output

as an interrupt the pin shows a low.

01 = Pulse INH pin and place device into Standby mode – high -

low - high ≈300 ms

10 = Pulse watchdog output pin if enabled – high - low - high ≈300

ms

11 = Reserved

Note: Interrupt flag is always set for a WD timeout event.

GPIO1_CONFIG: GPIO1 Pin Function Select

00 = GPO

01 = Reserved

10 = GPI – Automatically becomes a WD input trigger pin.

11 = Reserved

WD_EN - Watchdog Enable

0 = Disable

1 = Enabled

3.2.1.6.3 Floating Pins

In case of open (floating pins) default state of pin are provided by integrated pull-up or pull-down resistors

incase of an open pin. See Table 8 for details on pin bias conditions. These known states help keep

device pins at a defined level thus helping mitigate faults 4 and 7

Safety-

Mechanis

m #

SM-20 SCLK Pull up Weakly biases input

SM-21 SDI Pull up Weakly biases input

SM-22 nCS Pull up Weakly biases input so the device is not selected

SM-23 nWKRQ Pull up

SM-24 RST Pull down Weakly biases RST pin towards Normal operation mode

16

TCAN4550-Q1 Functional Safety-Manual

Table 8. Terminal Bias

Pin Pull-up or Pull-down COMMENT

Weakly biases output when using internal voltage rail. When using

open drain configuration an external pull up is needed.

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 17

V

SUP

14V

INH

V

IO

nWKRQ

14V

Device SPI

Access

Device ready to be

read and written to

Standby Mode

RST

Low

High

t

PULSE_WIDTH

•700 µs

Normal

or

Standby

Mode

www.ti.com

NOTE: The internal bias should not be relied upon as only termination, especially in noisy

environments but should be considered a fail-safe protection. Special care needs to be taken

when the device is used with MCUs utilizing open drain outputs.

3.2.1.6.4 RST Pin

The RST pin is a device reset pin. It has a weak internal pull down resistor for normal operation. If

communication has stopped with the TCAN4550-Q1 the RST pin can be pulsed high and then back low

for greater than t

settings and puts the device into Standby mode. If the device was in Normal or Standby mode, the INH

and nWKRQ pins remain active (on) and does not toggle; see Figure 10. If the device is in Sleep mode

and reset is toggled, the device enters Standby mode and at that time INH and nWKRQ turns on; see

Figure 11. This is considered SM-25.

After a RST has taken place a wait time of ≥ 700 µs should be used before reading or writing to the

TCAN4550-Q1

PULSE_WIDTH

Product Overview

to perform a power on reset to the device. This resets the device to the default

Figure 10. Timing for RST Pin in Normal and Standby Modes

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

17

Page 18

V

SUP

14V

INH

V

IO

nWKRQ

Device SPI

Access

Device ready to be

read and written to

Standby Mode

RST

Float

High

t

PULSE_WIDTH

•700 µs

Sleep Mode

Low

14V

Low

•250 µs

Product Overview

Figure 11. Timing for RST Pin in Sleep Mode

3.2.1.6.5 Interrupt and Internal Fault Detection

The TCAN4550-Q1 provides error detection and status notification register and interrupts to notify the host

MCU of errors on internal transactions and SPI transactions, see Table 9. It also contains internal RAM

(FIFO Buffer) ECC protection. The internal RAM is protected by ECC for single bit correction due to

transient faults impacting RAM content during the read operation. See Table 10 and Table 11 for device

interrupts and M_CAN specific interrupts. The Bosch M_CAN core has many other interrupt and fault tools

that are provided in the data sheet.

www.ti.com

NOTE: Though these interrupts show certain failures the ones associated to safety mechanism have

been included in the document above.

Table 9. Internal SPI Status Field Descriptions (Address h000C)

Bit Field Type Reset Description

31:30 RSVD RO 1’b0 Reserved

29 Internal_read_error W1C 1’b0 Internal read received an error response

28 Internal_write_error W1C 1’b0 Internal write received an error response

27 Internal_error_log_write W1C 1’b0 Entry written to the Internal error log

26 Read_fifo_underflow W1C 1’b0 Read FIFO underflow after 1 or more read data words returned

25 Read_fifo_empty W1C 1’b0 Read FIFO empty for first read data word to return

24 Write_fifo_overflow W1C 1’b0 Write/command FIFO overflow

23:22 RSVD RO 1’b0 Reserved

21 SPI_end_error W1C 1’b0 SPI transfer did not end on a byte boundary

20 Invalid_command W1C 1’b0 Invalid SPI command received

19 Write_overflow W1C 1’b0 SPI write sequence had continue requests after the data transfer

18 write_underflow W1C 1’b0 SPI write sequence ended with less data transferred then

17 Read_overflow W1C 1’b0 SPI read sequence had continue requests after the data transfer

16 read_underflow W1C 1’b0 SPI read sequence ended with less data transferred then

was completed

requested

was completed

requested

18

TCAN4550-Q1 Functional Safety-Manual

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 19

www.ti.com

Product Overview

Table 9. Internal SPI Status Field Descriptions (Address h000C) (continued)

Bit Field Type Reset Description

15:8 RSVD RO 8’h00 Reserved

7:6 RSVD RO 1’b0 Reserved

5 Write_fifo_available RO 1’b0 write fifo empty entries is greater than or equal to the

4 Read_fifo_available RO 1’b0 Read fifo entries is greater than or equal to the

3 Internal_access_active RO U Internal Multiple transfer mode access in progress

2 Internal_error_interrupt RO 1’b0 Unmasked Internal error set

1 SPI_error_interrupt RO 1’b0 Unmasked SPI error set

0 Interrupt RO U Value of interrupt input level (active high)

write_fifo_threshold

read_fifo_threshold

Table 10. Interrupts Field Descriptions (Address h0820)

Bit Field Type Reset Description

31 CANBUSNOM RU 1'b0

30:24 RSVD R 7b'0000

000

23 SMS R/WC 1'b0 Sleep Mode Status (Flag & Not an interrupt) Only sets when

22 UVSUP R/WC 1'b0 Under Voltage V

21 UVIO R/WC 1'b0 Under Voltage V

20 PWRON R/WC/U 1'b1 Power ON

19 TSD R/WC 1'b0 Thermal Shutdown

18 WDTO RU/WC 1'b0 Watchdog Time Out

17 RSVD R 1'b0 Reserved

16 ECCERR R/WC 1'b0 Uncorrectable ECC error detected

15 CANINT R/WC 1'b0 Can Bus Wake Up Interrupt

14 LWU R/WC 1'b0 Local Wake Up

13 WKERR R/WC 1'b0 Wake Error

12 RSVD R 1'b0 Reserved

11 RSVD R 1'b0 Reserved

10 CANSLNT R/WC 1'b0 CAN Silent

9 RSVD R 1'b0 Reserved

8 CANDOM R/WC 1'b0 CAN Stuck Dominant

7 GLOBALERR R 1'b0 Global Error (Any Fault)

6 WKRQ R 1'b0 Wake Request

5 CANERR R 1'b0 CAN Error

4 RSVD R 1'b0 RSVD

3 SPIERR R 1'b0 SPI Error

2 RSVD R 1'b0 Reserved

1 M_CAN_INT R 1'b0 M_CAN global INT

0 VTWD R 1'b0 Global Voltage, Temp or WDTO

CAN Bus normal (Flag and Not Interrupt)

Changes to 1 when in Normal mode after first Dom to Rec

transition

Reserved

Sleep mode is entered by a WKERR, UVIO timeout, or

UVIO+TSD fault

and UV

SUP

IO

CCOUT

GLOBALERR: Logical OR of all faults in registers 0x0820-0824.

WKRQ: Logical OR of CANINT, LWU and WKERR.

CANBUSNOM is not an interrupt but a flag. In Normal mode after the first dominant-recessive transition, it

is set. It resets to 0 when entering Standby or Sleep modes or when a bus fault condition takes place in

Normal mode.

SLLU312–July 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

19

Page 20

Product Overview

CANERR: Logical OR of CANSLNT and CANDOM faults.

SPIERR: is set if any of the SPI status register 16'h000C[30:16] is set.

• In the event of a SPI underflow, the error is not detected/alerted until the start of the next SPI

transaction.

• 16'h0010[30:16] are the mask for these errors

VTWD: Logical or of UV

, UVSUP, UVVIO, TSD, WDTO (Watchdog time out) and ECCERR.

CCOUT

CANINT: Indicates a WUP has occurred; Once a CANINT flag is set, LWU events are ignored. Flag can

be cleared by changing to Normal or Sleep modes.

LWU: Indicates a local wake event, from toggling the WAKE pin, has occurred. Once a LWU flag is set,

CANINT events is ignored. Flag can be cleared by changing to Normal or Sleep modes.

WKERR: If the device receives a wake up request WUP and does not transition to Normal mode or clear

the PWRON or Wake flag before t

, the device transitions to Sleep Mode. After the wake event, a

INACTIVE

Wake Error (WKERR) is reported and the SMS flag is set to 1.

NOTE: PWRON Flag is cleared by either writing a 1 or by going to Sleep mode or Normal mode

from Standby mode.

Table 11. MCAN Interrupts Field Descriptions (Address h0824)

Bit Field Type Reset Description

31:30 RSVD R 1'b0 Reserved

29 ARA R 1'b0 ARA: Access to Reserved Address

28 PED R 1'b0 PED: Protocol Error in Data Phase (Data Bit Time is used)

27 PEA R 1’b0 PEA: Protocol Error in Arbitration Phase (Nominal Bit Time is

26 WDI R 1'b0 WDI: Watchdog Interrupt

25 BO R 1'b0 BO: Bus_Off Status

24 EW R 1'b0 EW: Warning Status

23 EP R 1'b0 EP: Error Passive

22 ELO R 1'b0 ELO: Error Logging Overflow

21 BEU R 1'b0 BEU: Bit Error Uncorrected

20 BEC R 1'b0 BEC: Bit Error Corrected

19 DRX R 1’b0 DRX: Message stored to Dedicated Rx Buffer

18 TOO R 1'b0 TOO: Timeout Occurred

17 MRAF R 1'b0 MRAF: Message RAM Access Failure

16 TSW R 1'b0 TSW: Timestamp Wraparound

15 TEFL R 1'b0 TEFL: Tx Event FIFO Element Lost

14 TEFF R 1'b0 TEFF: Tx Event FIFO Full

13 TEFW R 1'b0 TEFW: Tx Event FIFO Watermark Reached

12 TEFN R 1'b0 TEFN: Tx Event FIFO New Entry

11 TFE R 1’b0 TFE: Tx FIFO Empty

10 TCF R 1'b0 TCF: Transmission Cancellation Finished

9 TC R 1'b0 TC: Transmission Completed

8 HPM R 1'b0 HPM: High Priority Message

7 RF1L R 1'b0 RF1L: Rx FIFO 1 Message Lost

6 RF1F R 1'b0 RF1F: Rx FIFO 1 Full

5 RF1W R 1'b0 RF1W: Rx FIFO 1 Watermark Reached

4 RF1N R 1'b0 RF1N: Rx FIFO 1 New Message

3 RF0L R 1’b0 RF0L: Rx FIFO 0 Message Lost

2 RF0F R 1'b0 RF0F: Rx FIFO 0 Full

used)

www.ti.com

20

TCAN4550-Q1 Functional Safety-Manual

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SLLU312–July 2019

Page 21

Assess

Review

Plan

Review

Create

Review

Validate

Review

and Release

to Market

Periodic

Post-Release

Reviews

Phase 1:

Assess

Phase 2:

Plan

Phase 3:

Create

Phase 4:

Validate

Sustain

Identify New

Product

Opportunities

Develop

Project Plan

IC Design and

Layout

Develop

Product

Specification

IC Design

Verification

Manage Project Execution and Risks

Develop Test and Validation

Hardware (HW) and Software (SW)

Develop Data Sheet and other

Documentation

Product

Support

Product

Monitoring

IC Valdiation

IC Qualification

www.ti.com

Development Process for Management of Systematic Faults

Table 11. MCAN Interrupts Field Descriptions (Address h0824) (continued)

Bit Field Type Reset Description

1 RF0W R 1'b0 RF0W: Rx FIFO 0 Watermark Reached

0 RF0N R 1'b0 RF0N: Rx FIFO 0 New Message

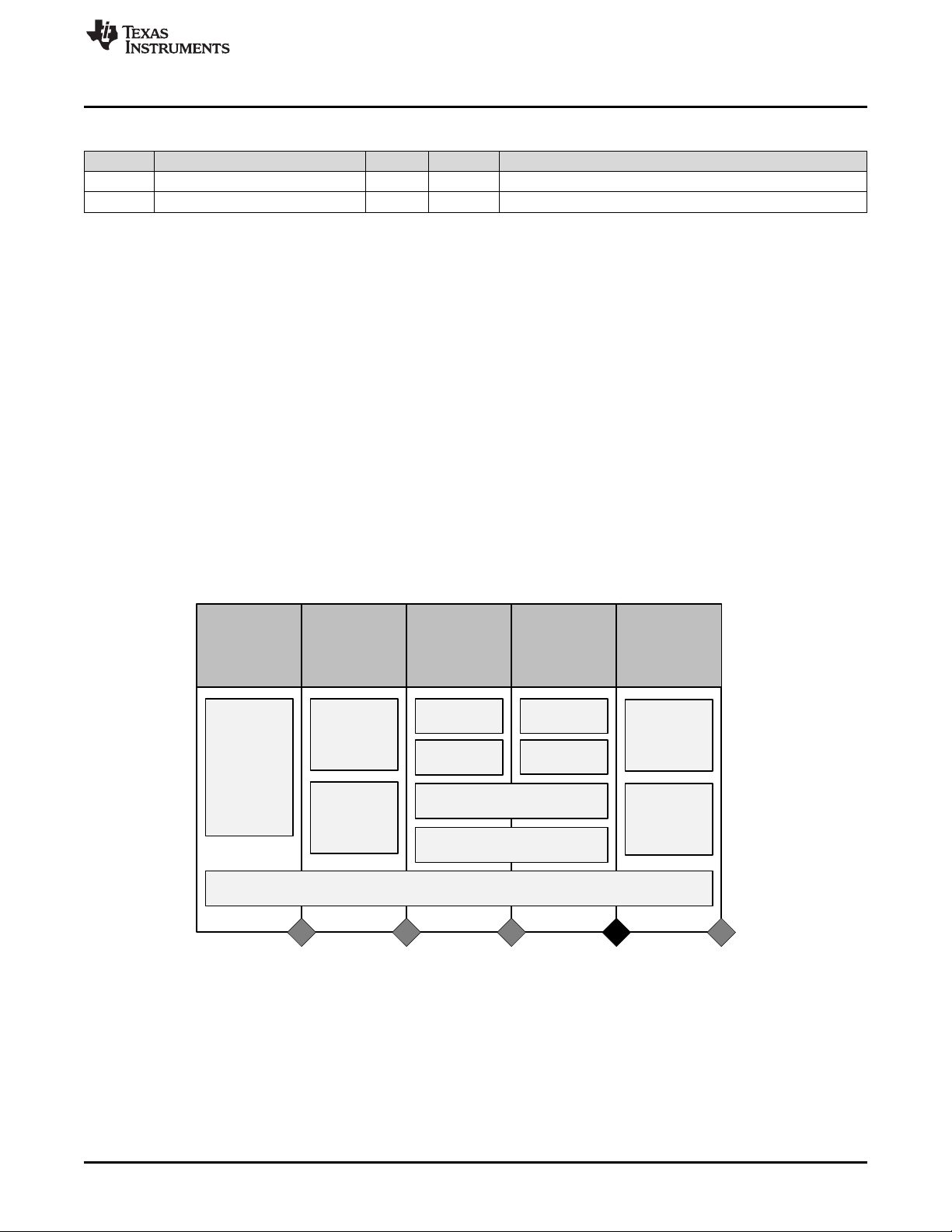

4 Development Process for Management of Systematic Faults

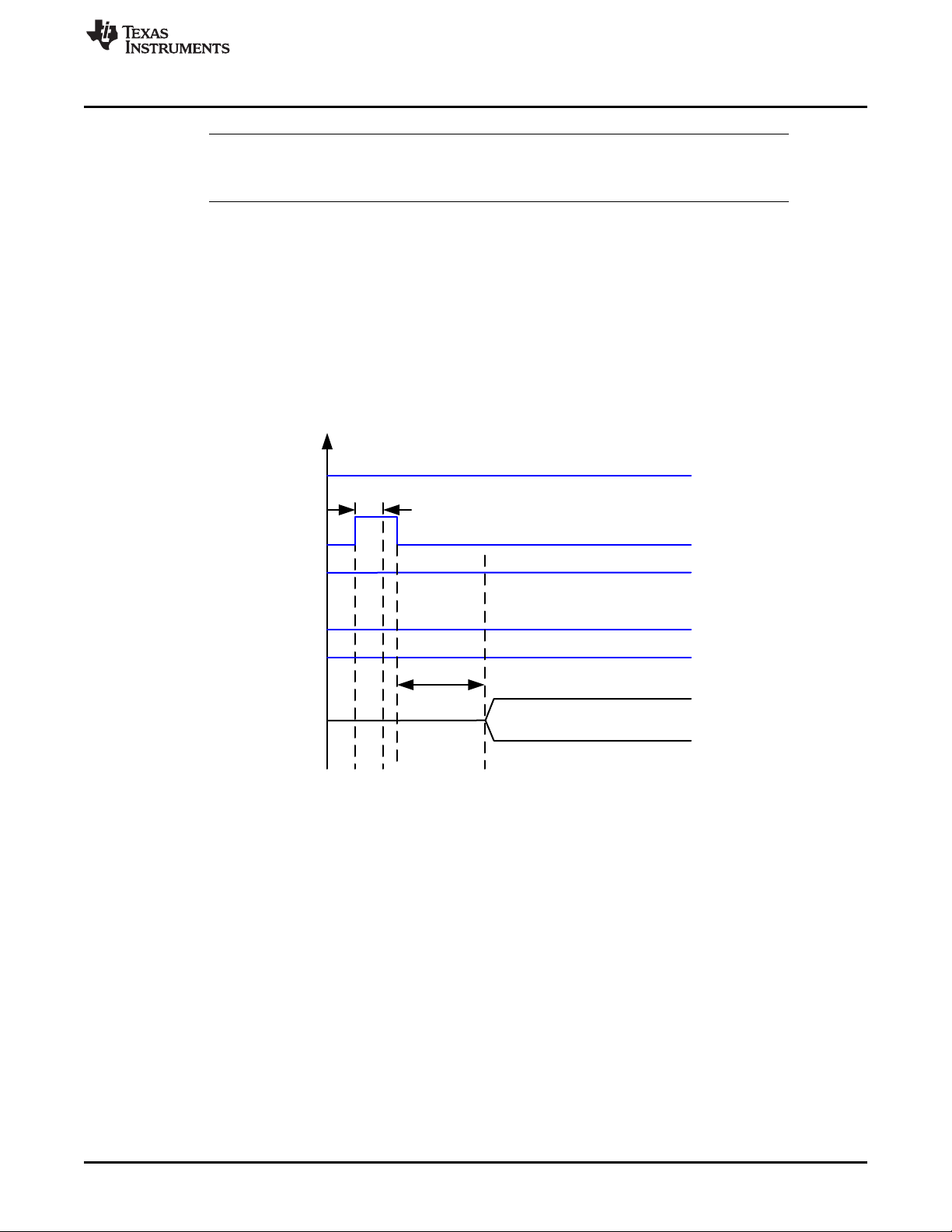

4.1 TI New-Product Development Process

Texas Instruments has been developing mixed-signal automotive ICs for functional safety-critical and

nonsafety critical automotive applications for over fifteen years. Automotive markets have strong

requirements regarding quality management and product reliability. Though not explicitly developed for

compliance to a functional safety standard, the TI new-product development process already featured

many elements necessary to manage systematic faults.

The device was developed using TI’s new product development process which has been certified as

compliant to ISO 9001 / IATF 16949 as assessed by Det Norske Veritas Certification, Inc.

The standard development process breaks development into phases:

• Assess

• Plan

• Create

• Validate

Figure 12 shows the standard process.

SLLU312–July 2019

Submit Documentation Feedback

Figure 12. TI New-Product Development Process

Copyright © 2019, Texas Instruments Incorporated

TCAN4550-Q1 Functional Safety-Manual

21

Page 22

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...