Page 1

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

CC3200MOD

SWRS166 –DECEMBER 2014

CC3200MOD SimpleLink™ Wi-Fi®and Internet-of-Things Module Solution, a Single-Chip

Wireless MCU

1 Module Overview

1.1 Features

1

• The CC3200MOD is a Wi-Fi Module that Consists

of the CC3200R1M2RGC Single-Chip Wireless

MCU. This Fully Integrated Module Includes all

Required Clocks, SPI Flash, and Passives.

• Modular FCC, IC, and CE Certifications Save

Customer Effort, Time, and Money

• Wi-Fi CERTIFIED™ Modules, With Ability to

Request Certificate Transfer for Wi-Fi Alliance

Members

• 1.27-mm Pitch LGA Package for Easy Assembly

and Low-Cost PCB Design

• Applications Microcontroller Subsystem

– ARM Cortex-M4 Core at 80 MHz

– Embedded Memory Options

• Integrated Serial

• RAM (up to 256KB)

• Peripheral Drivers in ROM

– Hardware Crypto Engine for Advanced

Hardware Security Including

• AES, DES, and 3DES

• SHA and MD5

• CRC and Checksum

– 8-Bit, Fast, Parallel Camera Interface

– 1 Multichannel Audio Serial Port (McASP)

Interface With Support for I2S Format

– 1 SD (MMC) Interface

– 32-Channel Micro Direct Memory Access

(μDMA)

– 2 Universal Asynchronous

Receivers/Transmitters (UARTs)

– 2 Serial Peripheral Interfaces (SPIs)

– 1 Inter-integrated Circuit (I2C)

– 4 General-Purpose Timers (GPTs)

– 16-Bit Pulse-Width Modulation (PWM) Mode

– 1 Watchdog Timer Module

– 4-Channel 12-Bit Analog-to-Digital Converters

(ADCs)

– Up to 25 Individually Programmable GPIO Pins

• Wi-Fi Network Processor Subsystem

– 802.11b/g/n Radio, Baseband, and Medium

Access Control

– TCP/IP Stack

• 8 Simultaneous TCP, UDP, or RAW Sockets

• 2 Simultaneous TLS v1.2 or SSL 3.0

Sockets

– Powerful Crypto Engine for Fast, Secured

WLAN Connections With 256-Bit Encryption

– Station, Access Point, and Wi-Fi Direct™ Modes

– WPA2 Personal and Enterprise Security

– SimpleLink Connection Manager for Managing

Wi-Fi Security States

– TX Power

• 17 dBm at 1 DSSS

• 17.25 dBm at 11 CCK

• 13.5 dBm at 54 OFDM

– RX Sensitivity

• –94.7 dBm at 1 DSSS

• –87 dBm at 11 CCK

• –73 dBm at 54 OFDM

– Application Throughput

• UDP: 16 Mbps

• TCP: 13 Mbps

• Power-Management Subsystem

– Integrated DC-DC Converter With a Wide-

Supply Voltage:

• VBAT: 2.3 to 3.6 V

– Low-Power Consumption at 3.6 V

• Hibernate With Real-Time Clock (RTC):

7 μA

• Low-Power Deep Sleep: <275 μA

• RX Traffic: 59 mA at 54 OFDM

• TX Traffic: 229 mA at 54 OFDM

– Additional Integrated Components

• 40.0-MHz Crystal

• 32.768-kHz Crystal (RTC)

• 8-Mbit SPI Serial Flash RF Filter and

Passive Components

– Package and Operating Conditions

• 1.27-mm Pitch, 63-Pin, 20.5-mm ×

17.5 mm LGA Package for Easy Assembly

and Low-Cost PCB Design

• Operating Temperature Range: –20°C to

70°C

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

CC3200MOD

SWRS166 –DECEMBER 2014

1.2 Applications

• Internet of Things (IoT) • Internet Gateway

• Cloud Connectivity • Industrial Control

• Home Automation • Smart Plug and Metering

• Home Appliances • Wireless Audio

• Access Control • IP Network Sensor Nodes

• Security Systems • Wearables

• Smart Energy

1.3 Description

Start your design with the industry’s first programmable FCC, IC, CE, and Wi-Fi Certified Wireless

microcontroller (MCU) module with built-in Wi-Fi connectivity. Created for the Internet of Things (IoT), the

SimpleLink CC3200MOD is a wireless MCU module that integrates an ARM Cortex-M4 MCU, allowing

customers to develop an entire application with a single device. With on-chip Wi-Fi, Internet, and robust

security protocols, no prior Wi-Fi experience is required for faster development. The CC3200MOD

integrates all required system-level hardware components including clocks, SPI flash, RF switch, and

passives into an LGA package for easy assembly and low-cost PCB design. The CC3200MOD is provided

as a complete platform solution including software, sample applications, tools, user and programming

guides, reference designs, and the TI E2E™ support community

www.ti.com

The applications MCU subsystem contains an industry-standard ARM Cortex-M4 core running at 80 MHz.

The device includes a wide variety of peripherals, including a fast parallel camera interface, I2S, SD/MMC,

UART, SPI, I2C, and four-channel ADC. The CC3200 family includes flexible embedded RAM for code

and data; ROM with external serial flash bootloader and peripheral drivers; and SPI flash for Wi-Fi network

processor service packs, Wi-Fi certificates, and credentials.

The Wi-Fi network processor subsystem features a Wi-Fi Internet-on-a-chip™ and contains an additional

dedicated ARM MCU that completely off-loads the applications MCU. This subsystem includes an 802.11

b/g/n radio, baseband, and MAC with a powerful crypto engine for fast, secure Internet connections with

256-bit encryption. The CC3200MOD supports station, access point, and Wi-Fi Direct™ modes. The

device also supports WPA2 personal and enterprise security and WPS 2.0. The Wi-Fi Internet-on-a-chip

includes embedded TCP/IP and TLS/SSL stacks, HTTP server, and multiple Internet protocols. The

power-management subsystem includes integrated DC-DC converters supporting a wide range of supply

voltages. This subsystem enables low-power consumption modes, such as the hibernate with RTC mode

requiring less than 7 μA of current.

Table 1-1. Module Information

PART NUMBER PACKAGE BODY SIZE

CC3200MODR1M2AMOB MOB (63) 20.5 mm × 17.5 mm

(1) For more information, see Section 9, Mechanical Packaging and Orderable Information.

(1)

2 Module Overview Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

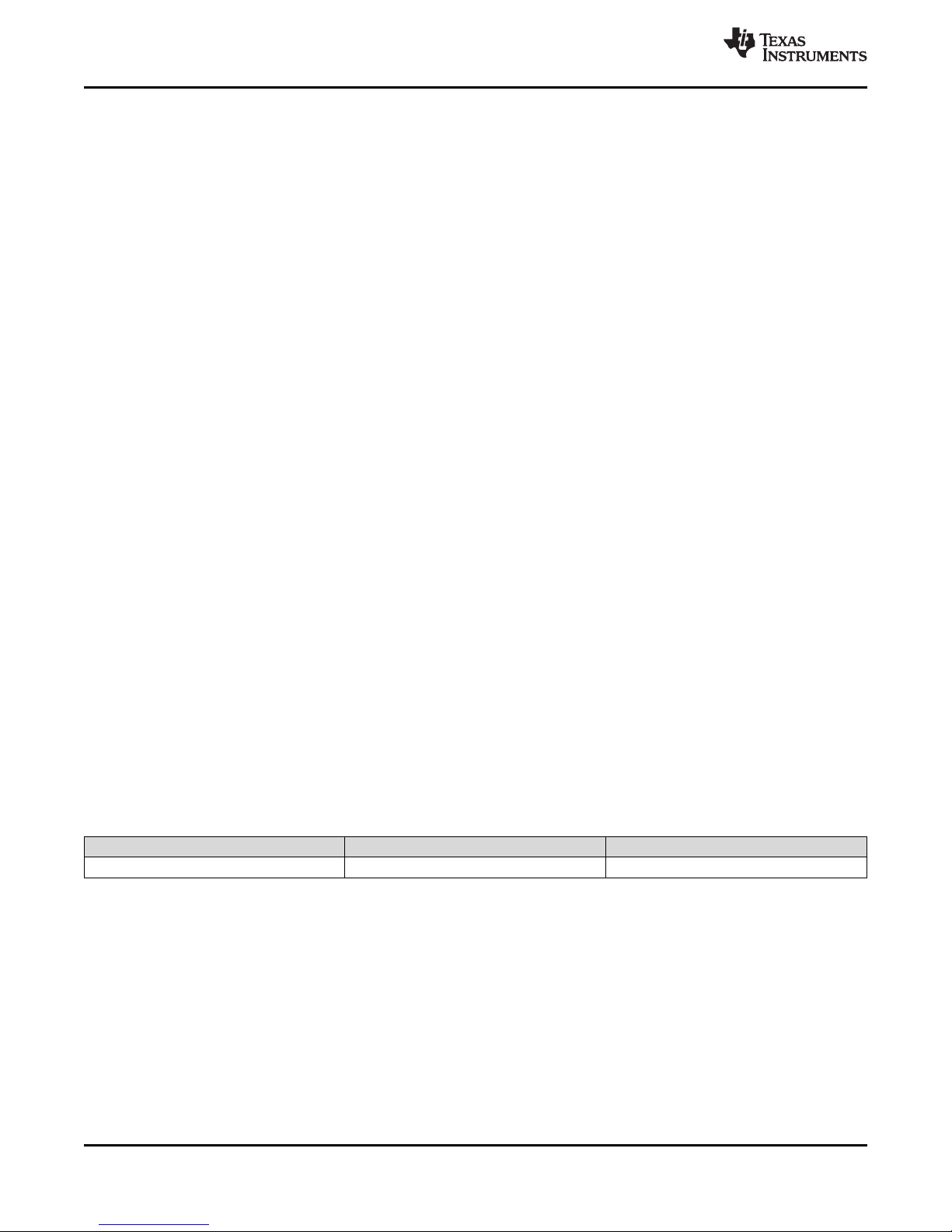

Page 3

CC3200MOD

V

CC

GPIO &

Peripheral

Interfaces

RF Filter

Serial

Flash

8Mbit

Pull-up

resistors

CC3200R1M2RGC

Power

Inductors

Caps

32-KHz

Crystal

40-MHz

Crystal

www.ti.com

1.4 Functional Block Diagram

Figure 1-1 shows the functional block diagram of the CC3200MOD module.

CC3200MOD

SWRS166 –DECEMBER 2014

(1) For 3200MOD module pin multiplexing details, refer to CC3200R device datasheet (literature number: SWAS032)

Figure 1-1. CC3200MOD Module Functional Block Diagram

Copyright © 2014, Texas Instruments Incorporated Module Overview 3

Submit Documentation Feedback

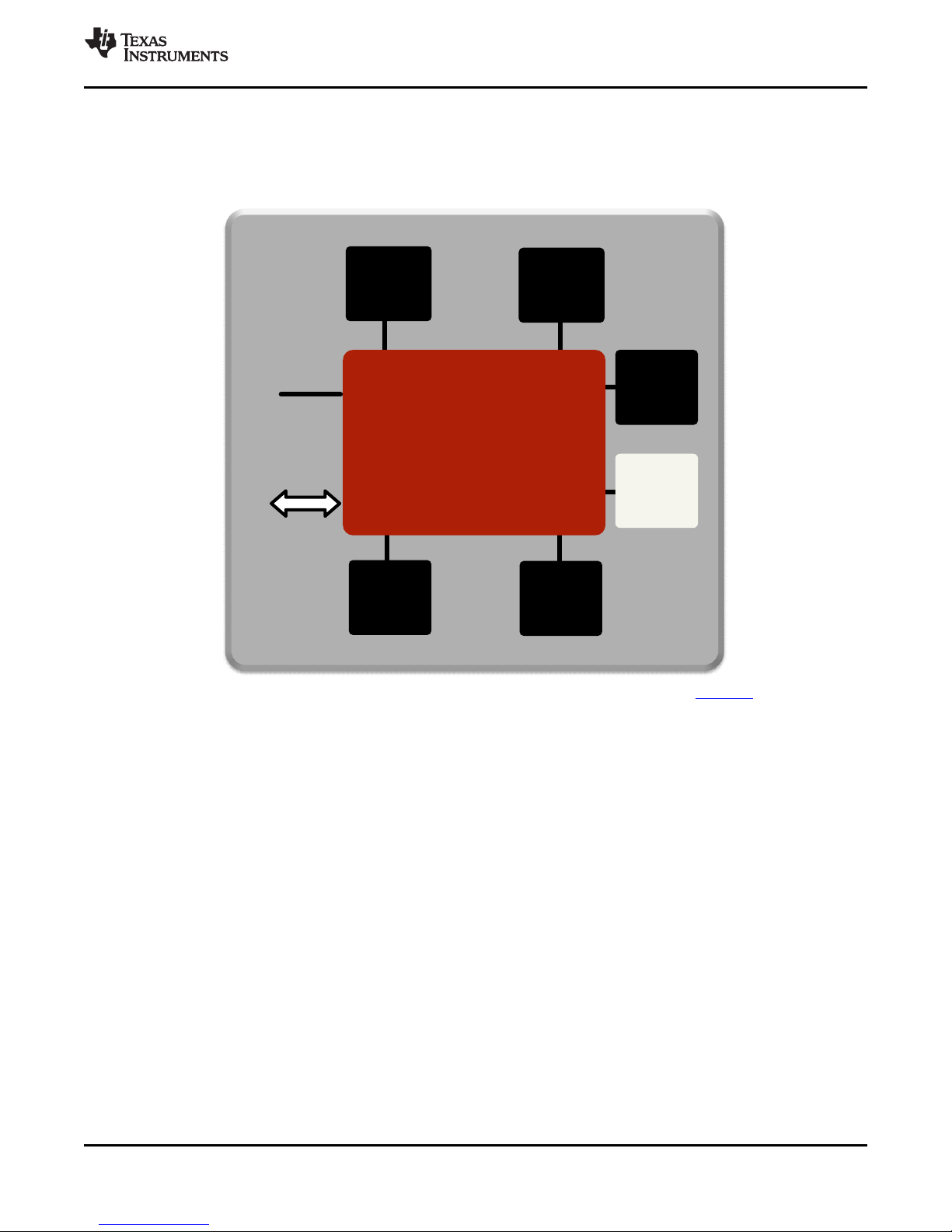

Page 4

ARM Cortex-M4 80 MHz Processor

ARM Processor (Wi-Fi Network Processor)

Wi-Fi Baseband

Wi-Fi MAC

Wi-Fi Radio

Wi-Fi Driver

Supplicant

TCP/IP

TLS/SSL

Internet Protocols

User Application

Embedded Wi-Fi

Embedded Internet

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Figure 1-2. CC3200 Hardware Overview

4 Module Overview Copyright © 2014, Texas Instruments Incorporated

Figure 1-3. CC3200 Software Overview

Submit Documentation Feedback

Page 5

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

Table of Contents

1 Module Overview ........................................ 1 5.3 ARM Cortex-M4 Processor Core Subsystem ....... 42

1.1 Features .............................................. 1 5.4 CC3200 Device Encryption ......................... 43

1.2 Applications........................................... 2 5.5 Wi-Fi Network Processor Subsystem ............... 44

1.3 Description............................................ 2 5.6 Power-Management Subsystem .................... 45

1.4 Functional Block Diagram ............................ 3 5.7 Low-Power Operating Mode ........................ 45

2 Revision History ......................................... 6 5.8 Memory.............................................. 46

3 Terminal Configuration and Functions.............. 7 5.9 Boot Modes.......................................... 48

3.1 CC3200MOD Pin Diagram ........................... 7 6 Applications, Implementation, and Layout ....... 51

3.2 Pin Attributes ......................................... 8 6.1 Reference Schematics.............................. 51

3.3 Pin Attributes and Pin Multiplexing.................. 10 6.2 Bill of Materials...................................... 52

3.4 Recommended Pin Multiplexing Configurations .... 19 6.3 Layout Recommendations .......................... 52

3.5 Drive Strength and Reset States for Analog-Digital

Multiplexed Pins..................................... 22

3.6 Pad State After Application of Power To Chip But

Prior To Reset Release ............................. 22

4 Specifications........................................... 23

4.1 Absolute Maximum Ratings......................... 23

4.2 Handling Ratings .................................... 23

4.3 Power-On Hours .................................... 23

4.4 Recommended Operating Conditions............... 23

4.5 Brown-Out and Black-Out........................... 24

4.6 Electrical Characteristics (3.3 V, 25°C) ............. 25

4.7 Thermal Resistance Characteristics for MOB

Package ............................................. 26

4.8 Reset Requirement ................................. 26

4.9 Current Consumption ............................... 27

4.10 WLAN RF Characteristics........................... 30

4.11 Timing Characteristics............................... 31

5 Detailed Description ................................... 42

5.1 Overview ............................................ 42

5.2 Functional Block Diagram........................... 42

7 Environmental Requirements and

Specifications........................................... 56

7.1 Temperature......................................... 56

7.2 Handling Environment .............................. 56

7.3 Storage Condition ................................... 56

7.4 Baking Conditions................................... 56

7.5 Soldering and Reflow Condition .................... 56

8 Product and Documentation Support.............. 58

8.1 Development Support ............................... 58

8.2 Device Nomenclature ............................... 58

8.3 Community Resources .............................. 59

8.4 Trademarks.......................................... 59

8.5 Electrostatic Discharge Caution..................... 59

8.6 Export Control Notice ............................... 59

8.7 Glossary............................................. 59

9 Mechanical Packaging and Orderable

Information .............................................. 60

9.1 Mechanical Drawing................................. 60

9.2 Package Option ..................................... 61

Copyright © 2014, Texas Instruments Incorporated Table of Contents 5

Submit Documentation Feedback

Page 6

CC3200MOD

SWRS166 –DECEMBER 2014

2 Revision History

DATE REVISION NOTES

November 2014 * Initial release.

www.ti.com

6 Revision History Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

44

45

46

47

48

49

50

51

52

53

54

27

26

25

24

23

22

21

20

19

18

17

28 29 30 31 3332 34 35 36 37 38 39 40 41 42 43

16 15 14 13 1112 10 9 8 7 6 5 4 3 2 1

63

59

55

62 61

60

57 56

58

GND

ANTSEL2

ANTSEL1

SOP1

SOP2

JTAG_TMS

JTAG_TCK

NC

GPIO28

JTAG_TDO

NC

GND

NC

NC

NC

GPIO22

GPIO13

GPIO12

GPIO17

GPIO16

GPIO15

GPIO14

GPIO11

GPIO10

GND

GND

GPIO0

NC

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

GPIO8

GPIO9

GND

NC

GND

RF

_

BG

GND

NC

SOP

0

nRESET

VBAT

_

DCDC

_

ANA

VBAT

_

DCDC

_

PA

GND

VDD

_

ANA

2

VBAT

_

DCDC

_

DIG

_

IO

NC

GPIO30

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC3200MOD

www.ti.com

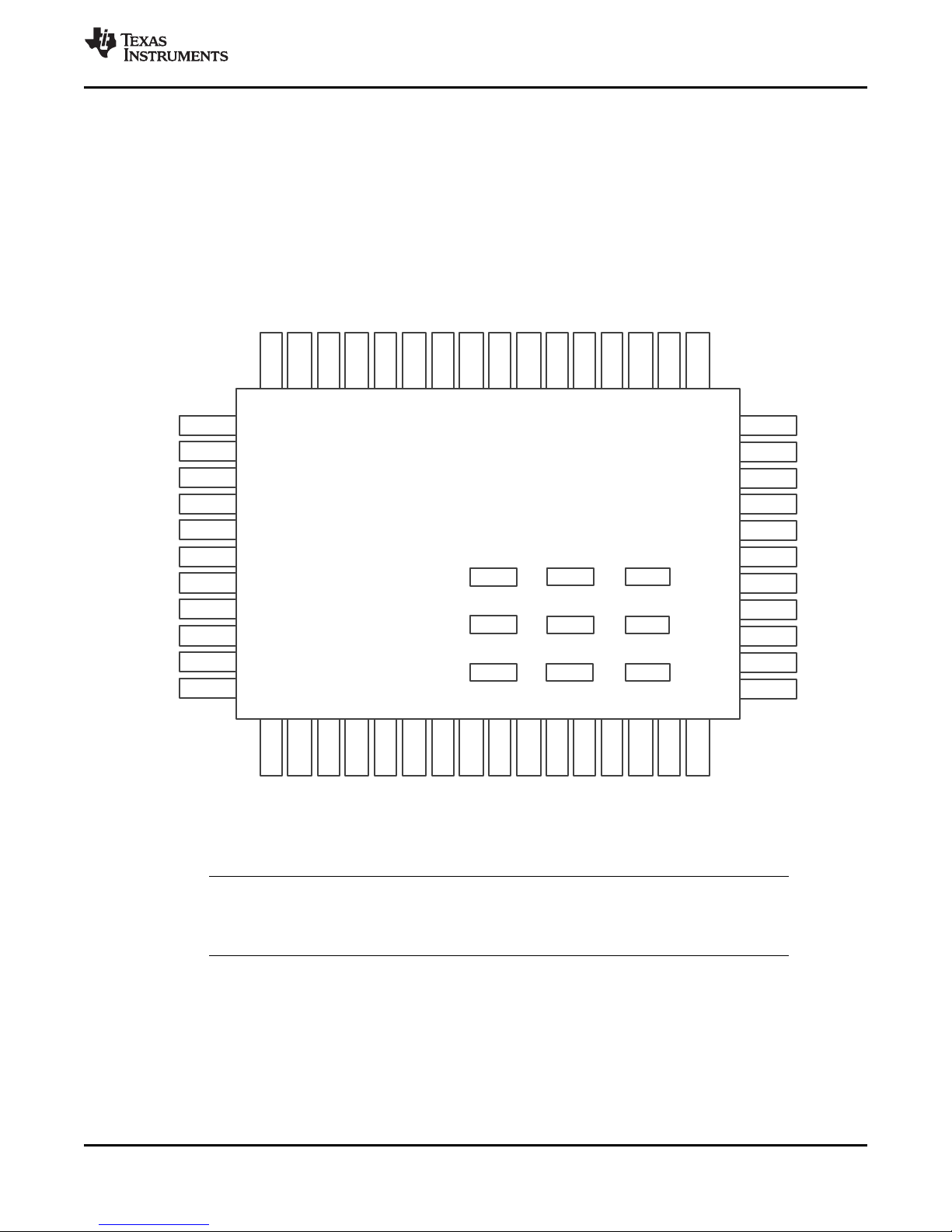

3 Terminal Configuration and Functions

3.1 CC3200MOD Pin Diagram

Figure 3-1 shows the pin diagram for the CC3200MOD.

CC3200MOD

SWRS166 –DECEMBER 2014

NOTE

Figure 3-1 shows the approximate location of pins on the module. For the actual mechanical

diagram refer to Section 9.

Figure 3-1. CC3200MOD Pin Diagram (Bottom View)

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 7

Submit Documentation Feedback

Page 8

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

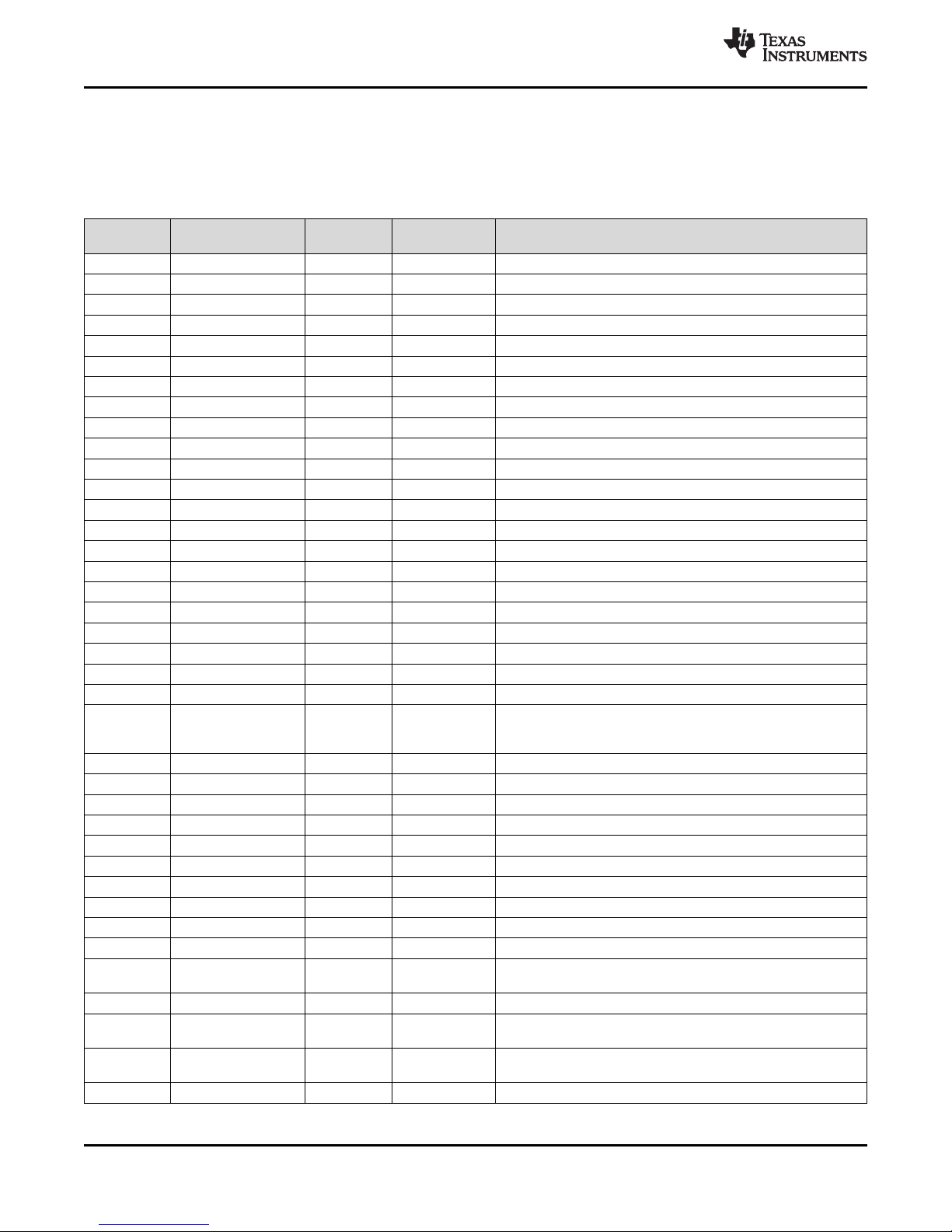

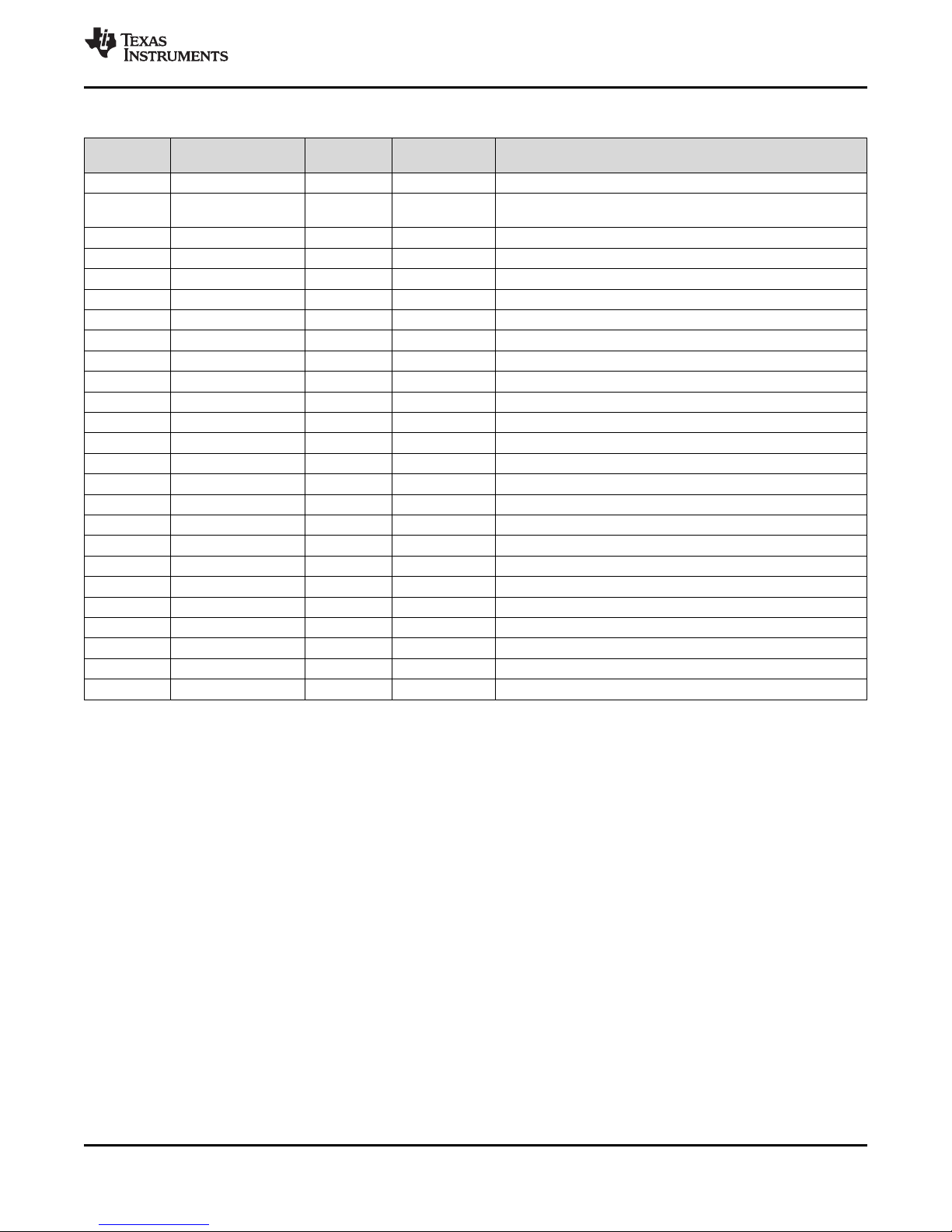

3.2 Pin Attributes

Table 3-1 lists the pin descriptions of the CC3200MOD module. "DEVICE PIN NO" refers to the pin

number of the QFN part CC3200. This is stated here because the QFN pin is referred to in the SDK.

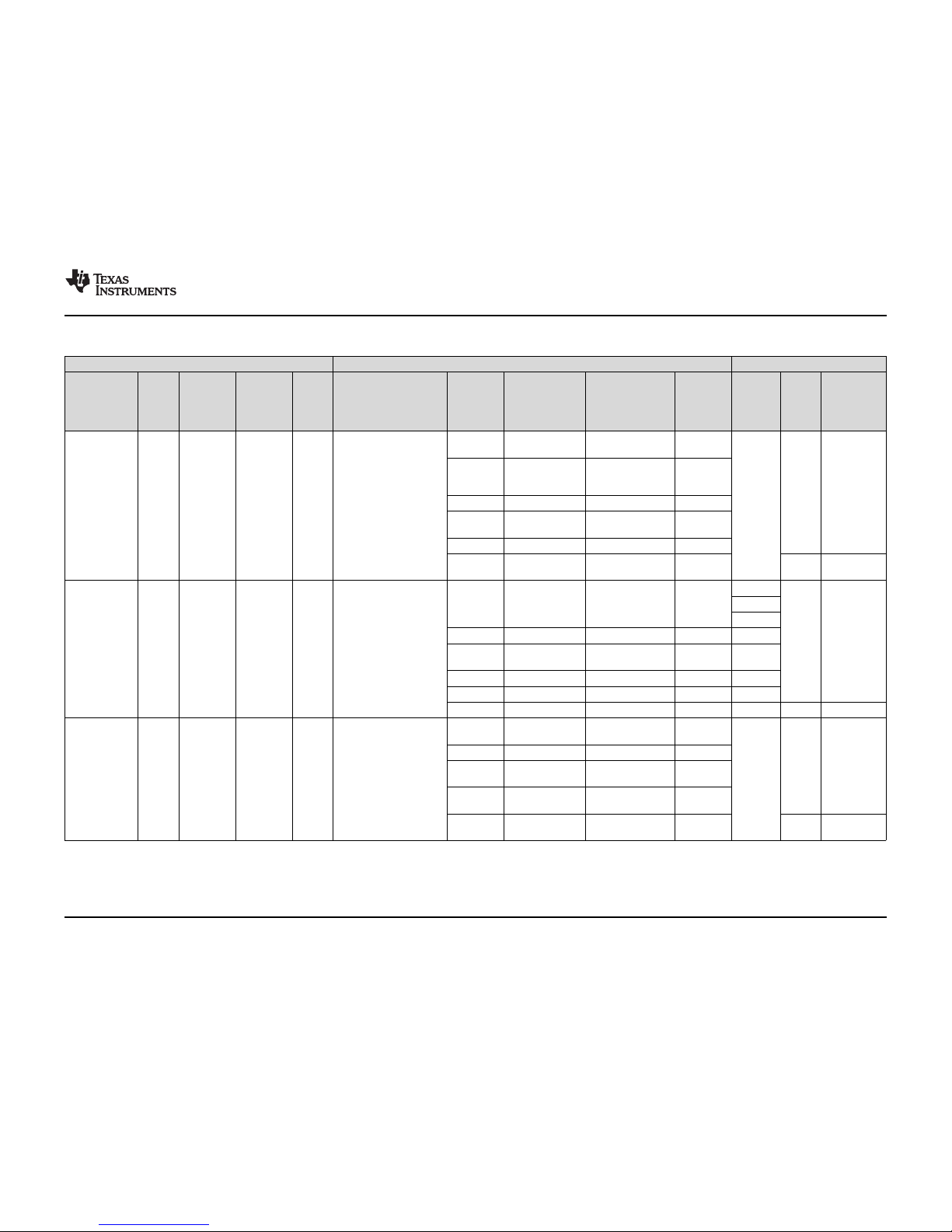

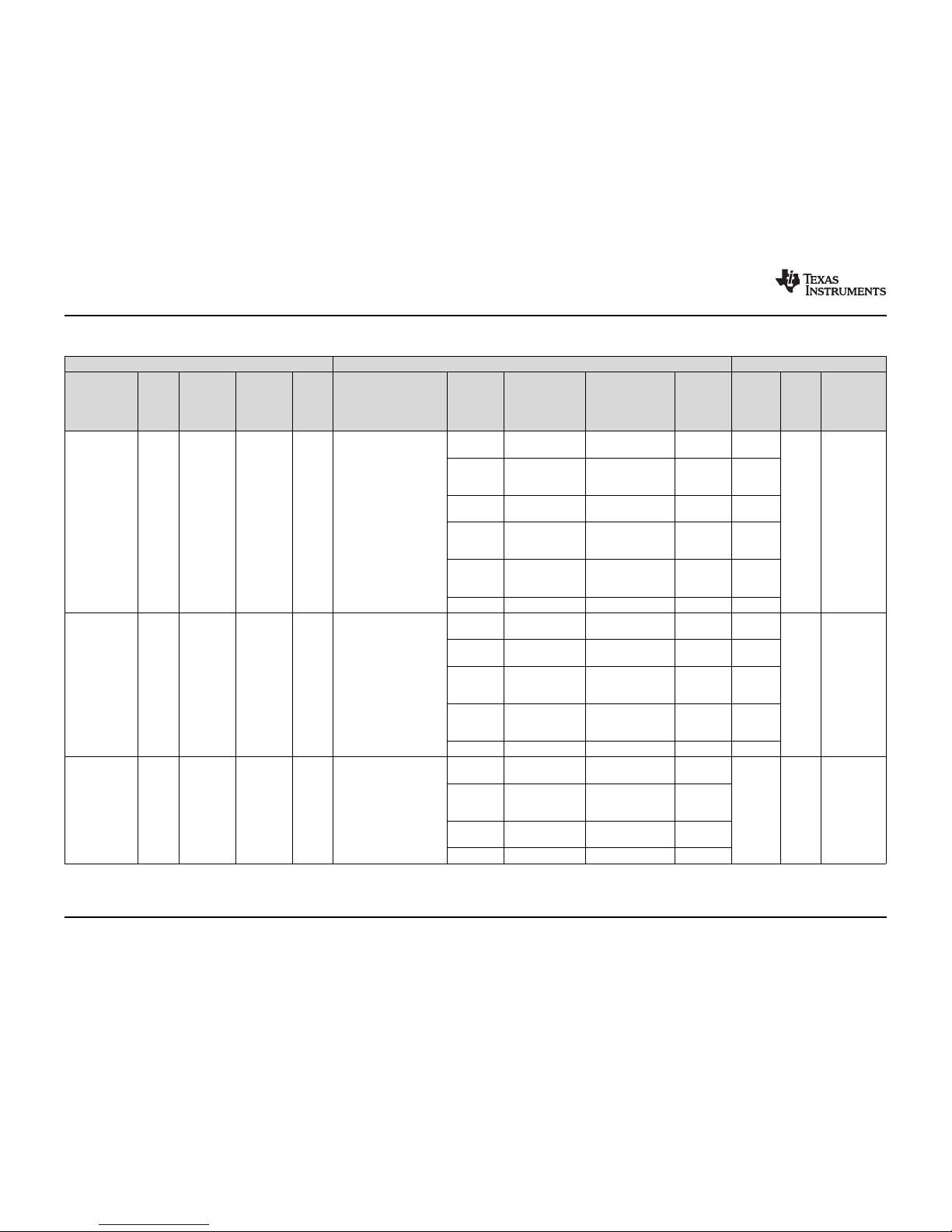

Table 3-1. Pin Attributes

MODULE MODULE PIN NAME TYPE DEVICE PIN NO MODULE PIN DESCRIPTION

PIN NO.

1 GND - Ground

2 GND - Ground

3 GPIO10 I/O 1 GPIO

4 GPIO11 I/O 2 GPIO

5 GPIO14 I/O 5 GPIO

6 GPIO15 I/O 6 GPIO

7 GPIO16 I/O 7 GPIO

8 GPIO17 I/O 8 GPIO

9 GPIO12 I/O 3 GPIO

10 GPIO13 I/O 4 GPIO

11 GPIO22 I/O 15 GPIO

12 JTAG_TDI I/O 16 GPIO

13 NC - 13 Reserved for TI

14 NC - 14 Reserved for TI

15 NC - 11 Reserved for TI

16 GND - Ground

17 NC - 12 Reserved for TI

18 JTAG_TDO I/O 17 GPIO

19 GPIO28 I/O 18 GPIO

20 NC - 23 Unused. Do not connect.

21 JTAG_TCK I/O 19 JTAG TCK input. Needs 100-kΩ pulldown resistor to ground.

22 JTAG_TMS I/O 20 JTAG TMS input. Leave unconnected if not used on product.

23 SOP2 - 21 Add 2.7-kΩ pulldown resistor to ground needed for functional

24 SOP1 - 34 Reserved. Do not connect.

25 ANTSEL1 I/O 29 Antenna selection control

26 ANTSEL2 I/O 30 Antenna selection control

27 GND - Ground

28 GND - Ground

29 NC - 27, 28 Reserved for TI

30 GND - Ground

31 RF_BG I/O 31 2.4-GHz RF input/output

32 GND - Ground

33 NC - 38 Reserved for TI

34 SOP0 - 35 Optional 10-kΩ pullup if user chooses to use SWD debug mode

35 nRESET I 32 Power on reset. Does not require external RC circuit

36 VBAT_DCDC_ANA - 37 Power supply for the device, can be connected to battery (2.3 V

37 VBAT_DCDC_PA - 39 Power supply for the device, can be connected to battery (2.3 V

38 GND - Ground

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

mode. Add option to pullup required for entering the UART load

mode for flashing.

(1)

(1)

instead of 4-wire JTAG

to 3.6 V)

to 3.6 V)

(1)

(1)

(1) For pin multiplexing details, refer to CC3200R device data sheet

8 Terminal Configuration and Functions Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

Table 3-1. Pin Attributes (continued)

MODULE MODULE PIN NAME TYPE DEVICE PIN NO MODULE PIN DESCRIPTION

PIN NO.

39 NC - 47 Leave unconnected

40 VBAT_DCDC_DIG_IO - 10, 44, 54 Power supply for the device, can be connected to battery (2.3 V

41 NC - 25, 36, 48 Reserved for TI

42 GPIO30 I/O 53 GPIO

43 GND - Ground

44 GPIO0 I/O 50 GPIO

45 NC - 51 Reserved for TI

46 GPIO1 I/O 55 GPIO

47 GPIO2 I/O 57 GPIO

48 GPIO3 I/O 58 GPIO

49 GPIO4 I/O 59 GPIO

50 GPIO5 I/O 60 GPIO

51 GPIO6 I/O 61 GPIO

52 GPIO7 I/O 62 GPIO

53 GPIO8 I/O 63 GPIO

54 GPIO9 I/O 64 GPIO

55 GND - Thermal Ground

56 GND - Thermal Ground

57 GND - Thermal Ground

58 GND - Thermal Ground

59 GND - Thermal Ground

60 GND - Thermal Ground

61 GND - Thermal Ground

62 GND - Thermal Ground

63 GND - Thermal Ground

to 3.6 V)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 9

Submit Documentation Feedback

Page 10

CC3200MOD

SWRS166 –DECEMBER 2014

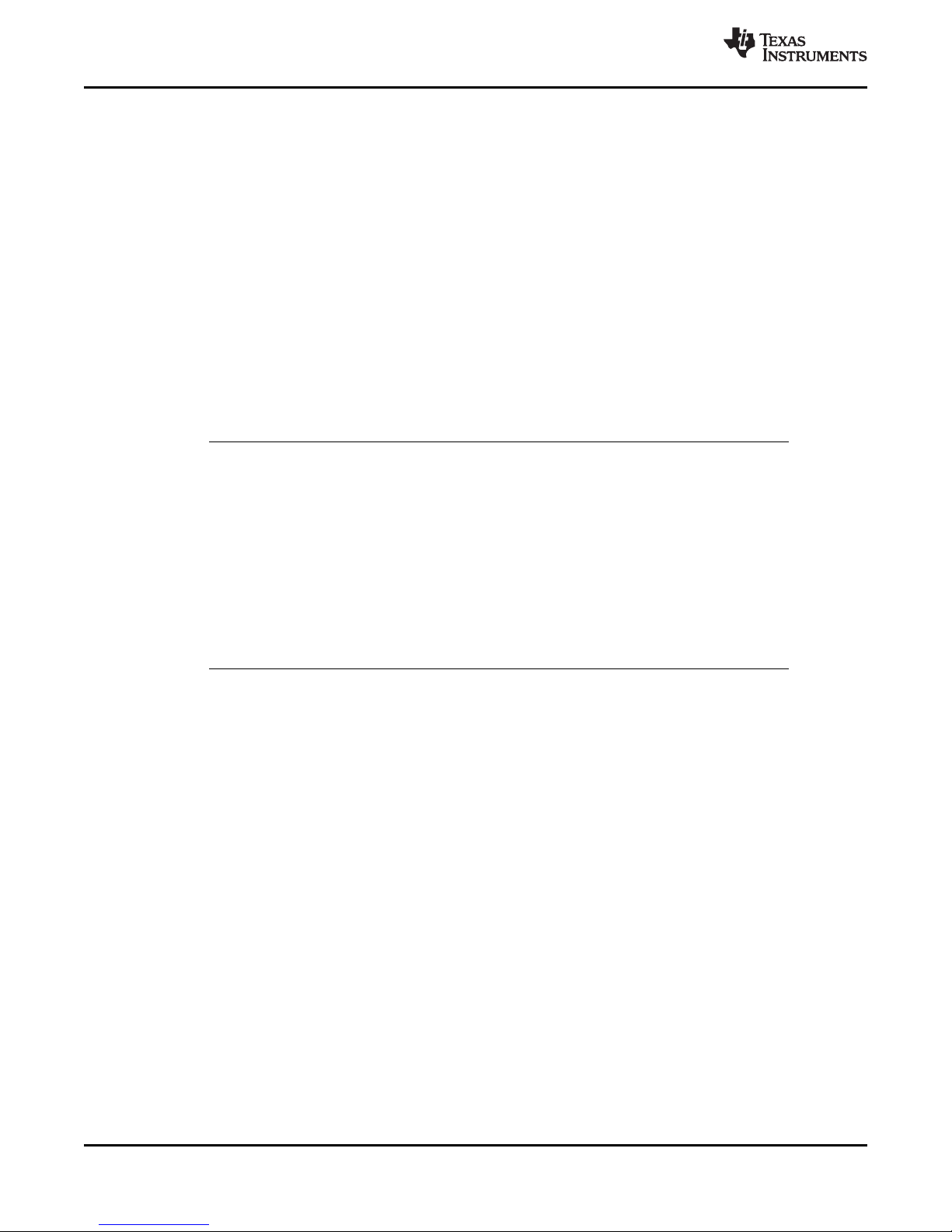

3.3 Pin Attributes and Pin Multiplexing

The module makes extensive use of pin multiplexing to accommodate the large number of peripheral

functions in the smallest possible package. To achieve this configuration, pin multiplexing is controlled

using a combination of hardware configuration (at module reset) and register control.

The board and software designers are responsible for the proper pin multiplexing configuration. Hardware

does not ensure that the proper pin multiplexing options are selected for the peripherals or interface mode

used. Table 3-2 describes the general pin attributes and presents an overview of pin multiplexing. All pin

multiplexing options are configurable using the pin mux registers. The following special considerations

apply:

• All I/Os support drive strengths of 2, 4, and 6 mA. Drive strength is configurable individually for each

pin.

• All I/Os support 10-μA pullups and pulldowns.

• These pulls are not active and all of the I/Os remain floating while the device is in Hibernate state.

• The VIO and VBAT supply must be tied together at all times.

• All digital I/Os are nonfail-safe.

If an external device drives a positive voltage to the signal pads and the CC3200MOD is not

powered, DC current is drawn from the other device. If the drive strength of the external

device is adequate, an unintentional wakeup and boot of the CC3200MOD can occur. To

prevent current draw, TI recommends any one of the following:

• All devices interfaced to the CC3200MOD must be powered from the same power rail as

the chip.

• Use level-shifters between the module and any external devices fed from other

independent rails.

• The nRESET pin of the CC3200MOD must be held low until the VBAT supply to the

module is driven and stable

www.ti.com

NOTE

10 Terminal Configuration and Functions Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

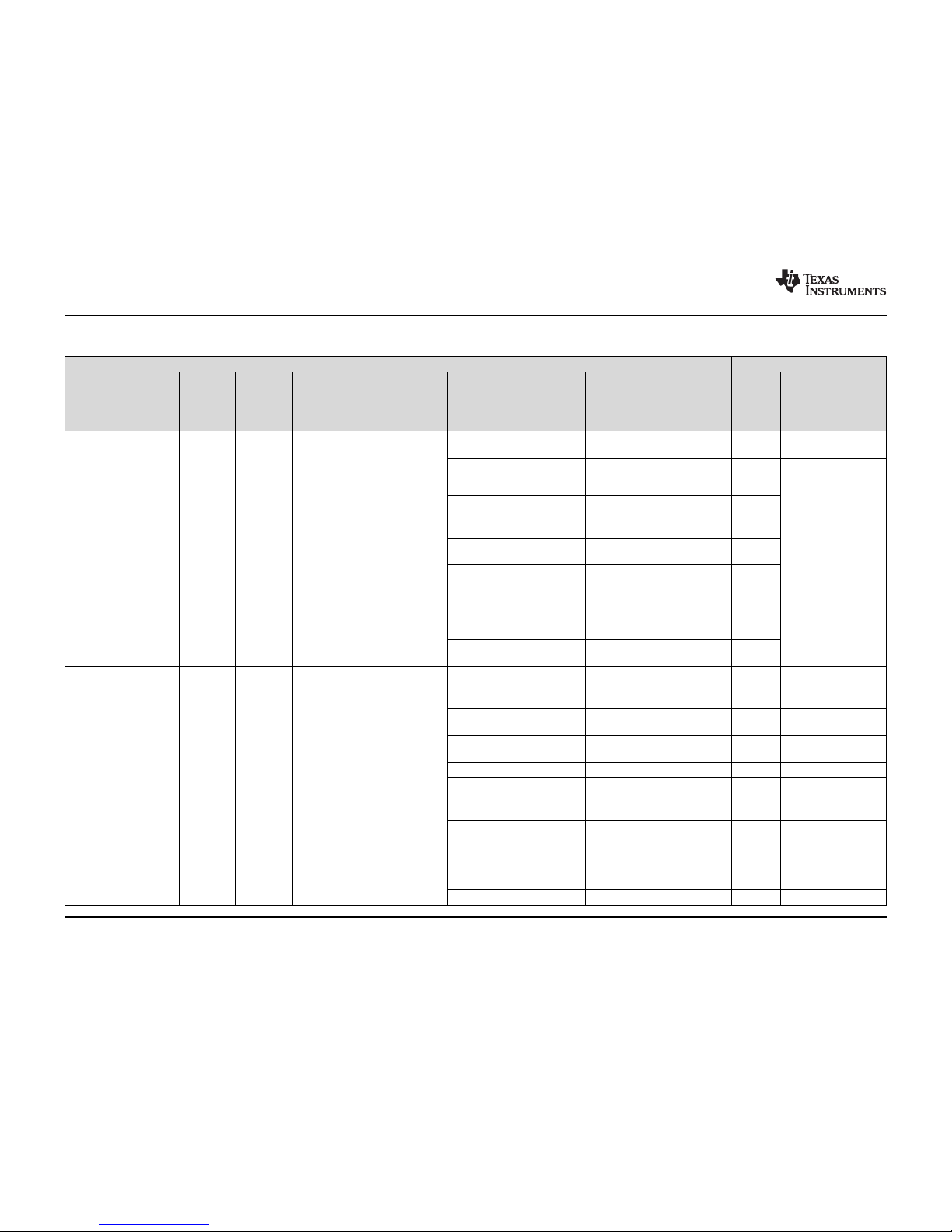

Table 3-2. Pin Multiplexing

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General-Purpose

0 GPIO10 I/O Hi-Z

I/O

1 I2C_SCL I2C Clock O Hi-Z

(Open

Drain)

GPIO_PAD_CONFIG_1

GPIO10 I/O No No No 0 Hi-Z Hi-Z

3 GT_PWM06 Pulse-Width O Hi-Z

(0x4402 E0C8)

Modulated O/P

7 UART1_TX UART TX Data O 1

6 SDCARD_CLK SD Card Clock O 0

12 GT_CCP01 Timer Capture Port I Hi-Z

General-Purpose

0 GPIO11 I/O Hi-Z

I/O

1 I2C_SDA I2C Data I/O Hi-Z

(Open

Drain)

3 GT_PWM07 Pulse-Width O Hi-Z

Modulated O/P

GPIO_PAD_CONFIG_1

4 pXCLK (XVCLK) Free Clock To O 0

GPIO11 I/O Yes No No 1 Hi-Z Hi-Z

Parallel Camera

(0x4402 E0CC)

6 SDCARD_CMD SD Card I/O Hi-Z

Command Line

7 UART1_RX UART RX Data I Hi-Z

12 GT_CCP02 Timer Capture Port I Hi-Z

13 McAFSX I2S Audio Port O Hi-Z

Frame Sync

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 11

Submit Documentation Feedback

Page 12

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General Purpose

0 GPIO12 I/O Hi-Z

I/O

3 McACLK I2S Audio Port O Hi-Z

Clock O

4 pVS (VSYNC) Parallel Camera I Hi-Z

GPIO_PAD_CONFIG_1

Vertical Sync

GPIO12 I/O No No No 2 Hi-Z Hi-Z

(0x4402 E0D0)

5 I2C_SCL I2C Clock I/O Hi-Z

(Open

Drain)

7 UART0_TX UART0 TX Data O 1

12 GT_CCP03 Timer Capture Port I Hi-Z

General-Purpose

0 GPIO13 I/O

I/O

5 I2C_SDA I2C Data I/O

(Open

GPIO_PAD_CONFIG_1

Drain)

GPIO13 I/O Yes No No 3 Hi-Z Hi-Z Hi-Z

(0x4402 E0D4) 4 pHS (HSYNC) Parallel Camera I

Horizontal Sync

7 UART0_RX UART0 RX Data I

12 GT_CCP04 Timer Capture Port I

General-Purpose

0 GPIO14 I/O

I/O

5 I2C_SCL I2C Clock I/O

(Open

GPIO_PAD_CONFIG_1

Drain)

GPIO14 I/O No No 4 Hi-Z Hi-Z Hi-Z

(0x4402 E0D8) 7 GSPI_CLK General SPI Clock I/O

4 pDATA8 Parallel Camera I

(CAM_D4) Data Bit 4

12 GT_CCP05 Timer Capture Port I

12 Terminal Configuration and Functions Copyright© 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General-Purpose

0 GPIO15 I/O

I/O

5 I2C_SDA I2C Data I/O

(Open

Drain)

Hi-Z Hi-Z

GPIO_PAD_CONFIG_1

7 GSPI_MISO General SPI MISO I/O

GPIO15 I/O No No 5 Hi-Z

(0x4402 E0DC)

4 pDATA9 Parallel Camera I

(CAM_D5) Data Bit 5

13 GT_CCP06 Timer Capture Port I

8 SDCARD_ SD Card Data I/O

DATA0

Hi-Z

General-Purpose

0 GPIO16 I/O Hi-Z

I/O

Hi-Z

7 GSPI_MOSI General SPI MOSI I/O Hi-Z

GPIO_PAD_CONFIG_1

Hi-Z Hi-Z

GPIO16 I/O No No 6

4 pDATA10 Parallel Camera I Hi-Z

(0x4402 E0E0)

(CAM_D6) Data Bit 6

5 UART1_TX UART1 TX Data O 1

13 GT_CCP07 Timer Capture Port I Hi-Z

8 SDCARD_CLK SD Card Clock O O

General-Purpose

0 GPIO17 I/O

I/O

5 UART1_RX UART1 RX Data I

Hi-Z Hi-Z

GPIO_PAD_CONFIG_1 7 GSPI_CS General SPI Chip I/O

Wake-Up

GPIO17 I/O No No 7 Select Hi-Z

Source

(0x4402 E0E4)

4 pDATA11 Parallel Camera I

(CAM_D7) Data Bit 7

8 SDCARD_ SD Card I/O

CMD Command Line

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 13

Submit Documentation Feedback

Page 14

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

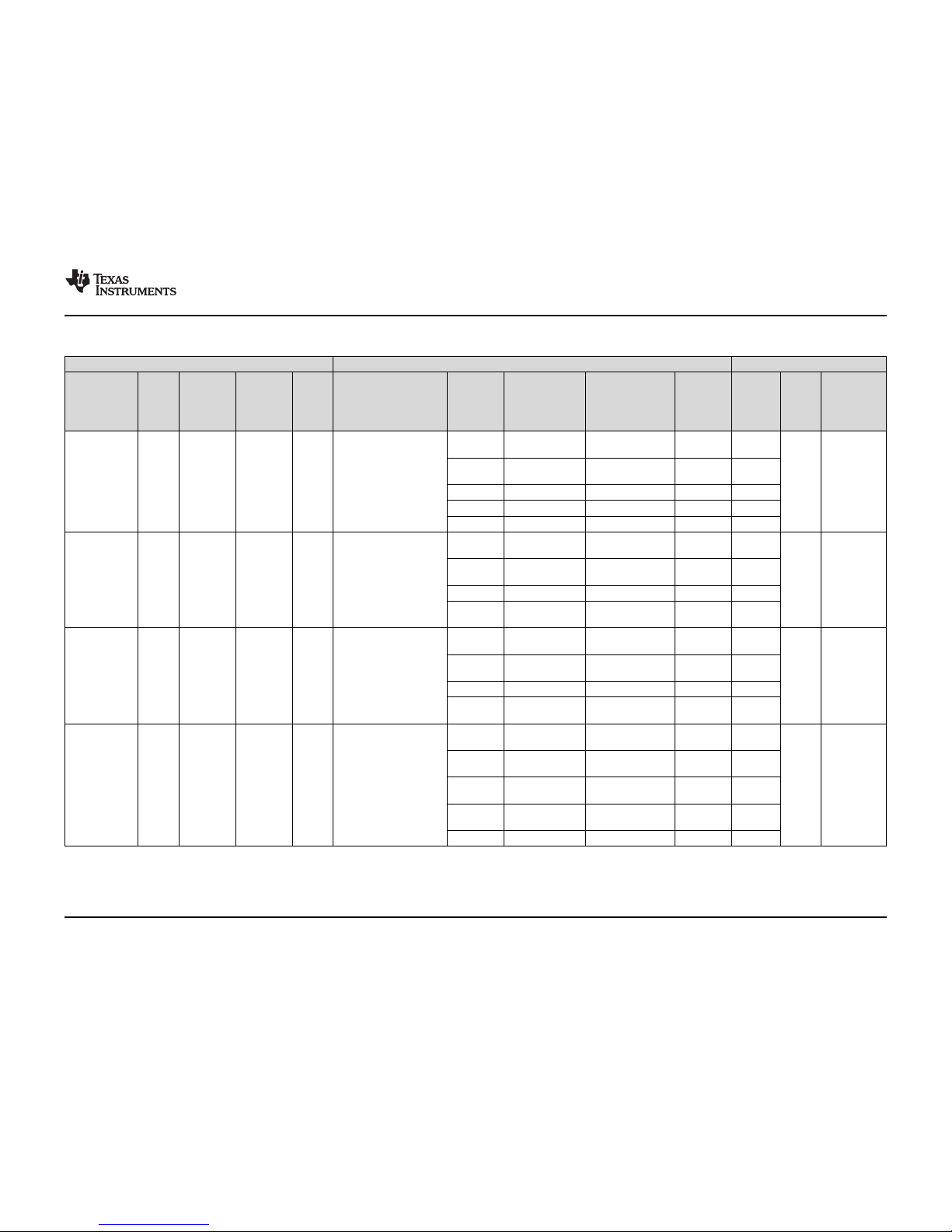

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General-Purpose

0 GPIO22 I/O Hi-Z

I/O

GPIO_PAD_CONFIG_2

GPIO22 I/O No No No 2 7 McAFSX I2S Audio Port O Hi-Z Hi-Z Hi-Z

(0x4402 E0F8) Frame Sync

5 GT_CCP04 Timer Capture Port I

JTAG TDI. Reset

1 TDI I

Default Pinout.

Hi-Z

General-Purpose

MUXed

0 GPIO23 I/O

GPIO_PAD_CONFIG_2

I/O

with

TDI I/O No No 3 Hi-Z Hi-Z

JTAG

2 UART1_TX UART1 TX Data O 1

(0x4402 E0FC)

TDI

9 I2C_SCL I2C Clock I/O Hi-Z

(Open

Drain)

JTAG TDO. Reset

1 TDO O

Default Pinout.

0 GPIO24 General-Purpose I/O

I/O

5 PWM0 Pulse Width O

MUXed

Modulated O/P

GPIO_PAD_CONFIG_

Wake-Up with

TDO I/O No 24 2 UART1_RX UART1 RX Data I Hi-Z Hi-Z Hi-Z

Source JTAG

(0x4402 E100)

9 I2C_SDA I2C Data I/O

TDO

(Open

Drain)

4 GT_CCP06 Timer Capture Port I

6 McAFSX I2S Audio Port O

Frame Sync

GPIO_PAD_CONFIG_

General-Purpose

GPIO28 I/O No 28 0 GPIO28 I/O Hi-Z Hi-Z Hi-Z

I/O

(0x4402 E110)

JTAG/SWD TCK

MUXed

1 TCK Reset Default I

with

Pinout

TCK I/O No No JTAG/ Hi-Z Hi-Z Hi-Z

SWD-

8 GT_PWM03 Pulse Width O

TCK

Modulated O/P

14 Terminal Configuration and Functions Copyright© 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

JATG/SWD TMS

MUXed

1 TMS Reset Default

with GPIO_PAD_CONFIG_

Pinout

TMS I/O No No JTAG/ 29 I/O Hi-Z Hi-Z Hi-Z

SWD- (0x4402 E114)

0 GPIO29 General-Purpose

TMSC

I/O

General-Purpose

0 GPIO25 O Hi-Z

I/O

9 GT_PWM02 Pulse Width O Hi-Z

Modulated O/P

GPIO_PAD_CONFIG_

2 McAFSX I2S Audio Port O Hi-Z Driven

SOP2 O Only No No No 25 Hi-Z

Frame Sync Low

(0x4402 E104)

See

(5)

TCXO_EN Enable to Optional O O

External 40-MHz

TCXO

See

(6)

SOP2 Sense-On-Power 2 I

User config

GPIO_PAD_CONFIG_2

not Antenna Selection

ANTSEL1 O Only No No 6 0 ANTSEL1

(3)

O Hi-Z Hi-Z Hi-Z

required Control

(0x4402 E108)

(8)

User config

GPIO_PAD_CONFIG_2

not Antenna Selection

ANTSEL2 O Only No No 7 0 ANTSEL2

(3)

O Hi-Z Hi-Z Hi-Z

required Control

(0x4402 E10C)

(8)

Config

SOP1 N/A N/A N/A N/A SOP1 Sense On Power 1

Sense

Config

SOP0 N/A N/A N/A N/A SOP0 Sense On Power 0

Sense

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 15

Submit Documentation Feedback

Page 16

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General-Purpose

0 GPIO0 I/O Hi-Z Hi-Z Hi-Z

I/O

12 UART0_CTS UART0 Clear To I Hi-Z Hi-Z Hi-Z

Send Input (Active

Low)

6 McAXR1 I2S Audio Port I/O Hi-Z

Data 1 (RX/TX)

7 GT_CCP00 Timer Capture Port I Hi-Z

User config

not GPIO_PAD_CONFIG_0

9 GSPI_CS General SPI Chip I/O Hi-Z

GPIO0 I/O No No

required (0x4402 E0A0)

Select

(8)

10 UART1_RTS UART1 Request O 1

To Send O (Active

Low)

3 UART0_RTS UART0 Request O 1

To Send O (Active

Low)

4 McAXR0 I2S Audio Port I/O Hi-Z

Data 0 (RX/TX)

General-Purpose

0 GPIO30 I/O Hi-Z Hi-Z Hi-Z

I/O

9 UART0_TX UART0 TX Data O 1

User config

2 McACLK I2S Audio Port O Hi-Z

GPIO_PAD_CONFIG_3

not

Clock O

GPIO30 I/O No No 0

required

(0x4402 E118)

3 McAFSX I2S Audio Port O Hi-Z

(8)

Frame Sync

4 GT_CCP05 Timer Capture Port I Hi-Z

7 GSPI_MISO General SPI MISO I/O Hi-Z

General-Purpose

0 GPIO1 I/O Hi-Z Hi-Z Hi-Z

I/O

3 UART0_TX UART0 TX Data O 1

GPIO_PAD_CONFIG_1 4 pCLK (PIXCLK) Pixel Clock From I Hi-Z

GPIO1 I/O No No No

(0x4402 E0A4) Parallel Camera

Sensor

6 UART1_TX UART1 TX Data O 1

7 GT_CCP01 Timer Capture Port I Hi-Z

16 Terminal Configuration and Functions Copyright© 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

ADC Channel 0

See

(5)

ADC_CH0 I

Input (1.5V max)

Analog

Input

0 GPIO2 General-Purpose I/O Hi-Z

(up to Wake-Up GPIO_PAD_CONFIG_2

I/O

GPIO2 See

(10)

No Hi-Z Hi-Z

1.8 V)/ Source (0x4402 E0A8)

3 UART0_RX UART0 RX Data I Hi-Z

Digital

6 UART1_RX UART1 RXt Data I Hi-Z

I/O

7 GT_CCP02 Timer Capture Port I Hi-Z

ADC Channel 1

See

(5)

ADC_CH1 I

Input (1.5V max)

Analog

Input

0 GPIO3 General-Purpose I/O Hi-Z

(up to GPIO_PAD_CONFIG_3

I/O

GPIO3 No See

(10)

No Hi-Z Hi-Z

1.8 V)/ (0x4402 E0AC)

6 UART1_TX UART1 TX Data O 1

Digital

I/O

4 pDATA7 Parallel Camera I Hi-Z

(CAM_D3) Data Bit 3

ADC Channel 2

See

(5)

ADC_CH2 I

Input (1.5V max)

Analog

Input

0 GPIO4 General-Purpose I/O Hi-Z

(up to Wake-up GPIO_PAD_CONFIG_4

I/O

GPIO4 See

(10)

No Hi-Z Hi-Z

1.8 V)/ Source (0x4402 E0B0)

6 UART1_RX UART1 RX Data I Hi-Z

Digital

I/O

4 pDATA6 Parallel Camera I Hi-Z

(CAM_D2) Data Bit 2

ADC Channel 3

See

(5)

ADC_CH3 I

Input (1.5V max)

Analog

0 GPIO5 General-Purpose I/O Hi-Z

Input

I/O

(up to GPIO_PAD_CONFIG_5

GPIO5 No See

(10)

No 4 pDATA5 Parallel Camera I Hi-Z Hi-Z Hi-Z

1.8 V)/ (0x4402 E0B4)

(CAM_D1) Data Bit 1

Digital

6 McAXR1 I2S Audio Port I/O Hi-Z

I/O

Data 1 (RX/TX)

7 GT_CCP05 Timer Capture Port I Hi-Z

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 17

Submit Documentation Feedback

Page 18

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General-Purpose

0 GPIO6 I/O Hi-Z

I/O

5 UART0_RTS UART0 Request O 1

To Send O (Active

Low)

4 pDATA4 Parallel Camera I Hi-Z

(CAM_D0) Data Bit 0

GPIO_PAD_CONFIG_6

GPIO6 No No No No Hi-Z Hi-Z

(0x4402 E0B8)

3 UART1_CTS UART1 Clear To I Hi-Z

Send Input (Active

Low)

6 UART0_CTS UART0 Clear To I Hi-Z

Send Input (Active

Low)

7 GT_CCP06 Timer Capture Port I Hi-Z

General-Purpose

0 GPIO7 I/O Hi-Z

I/O

13 McACLKX I2S Audio Port O Hi-Z

Clock O

3 UART1_RTS UART1 Request O 1

GPIO_PAD_CONFIG_7

GPIO7 I/O No No No To Send O (Active Hi-Z Hi-Z

(0x4402 E0BC)

Low)

10 UART0_RTS UART0 Request O 1

To Send O (Active

Low)

11 UART0_TX UART0 TX Data O 1

General-Purpose

0 GPIO8 I/O

I/O

6 SDCARD_IRQ Interrupt from SD I

Card (Future

GPIO_PAD_CONFIG_8

GPIO8 I/O No No No Hi-Z Hi-Z Hi-Z

support)

(0x4402 E0C0)

7 McAFSX I2S Audio Port O

Frame Sync

12 GT_CCP06 Timer Capture Port I

18 Terminal Configuration and Functions Copyright© 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

Table 3-2. Pin Multiplexing (continued)

General Pin Attributes Function Pad States

Pin Alias Use Select as Config Muxed Dig. Pin Mux Config Dig. Pin Signal Name Signal Signal LPDS

(1)

Hib

(2)

nRESET = 0

Wakeup Addl with Reg Mux Description Direction

Source Analog JTAG Config

Mux Mode

Value

General-Purpose

0 GPIO9 I/O

I/O

3 GT_PWM05 Pulse Width O

Modulated O/P

GPIO_PAD_CONFIG_9

GPIO9 I/O No No No 6 SDCARD_ SD Cad Data I/O Hi-Z Hi-Z Hi-Z

(0x4402 E0C4)

DATA0

7 McAXR0 I2S Audio Port I/O

Data (Rx/Tx)

12 GT_CCP00 Timer Capture Port I

(1) LPDS mode: The state of unused GPIOs in LPDS is input with 500-kΩ pulldown. For all used GPIOs , the user can enable internal pulls, which would hold them in a valid state.

(2) Hibernate mode: The CC3200 device leaves the digital pins in a Hi-Z state without any internal pulls when the device enters hibernate state. This can cause glitches on output lines unless

held at valid levels by external resistors.

(3) To minimize leakage in some serial flash vendors during LPDS, TI recommends the user application always enable internal weak pulldowns on FLASH_SPI_DATA and FLASH_SPI_CLK

pins.

(4) This pin has dual functions: as a SOP[2] (device operation mode), and as an external TCXO enable. As a TXCO enable, the pin is an output on power up and driven logic high. During

hibernate low-power mode, the pin is in a high impedance state but pulled down for SOP mode to disable TCXO. Because of SOP functionality, the pin must be used as output only.

(5) For details on proper use, see Drive Strength and Reset States for Analog-Digital Multiplexed Pins.

(6) This pin is one of three that must have a passive pullup or pulldown resistor on board to configure the chip hardware power-up mode. For this reason, the pin must be output only when

used for digital functions.

(7) This pin is reserved for WLAN antenna selection, controlling an external RF switch that multiplexes the RF pin of the CC3200 module between two antennas. These pins should not be

used for other functionalities in general.

(8) Device firmware automatically enables the digital path during ROM boot.

(9) This pin is shared by the ADC inputs and digital I/O pad cells. Important: The ADC inputs are tolerant up to 1.8 V. On the other hand, the digital pads can tolerate up to 3.6 V. Hence, care

must be taken to prevent accidental damage to the ADC inputs. TI recommends that the output buffer(s) of the digital I/Os corresponding to the desired ADC channel be disabled first (that

is, converted to high-impedance state), and thereafter the respective pass switches (S7, S8, S9, S10) should be enabled (see Drive Strength and Reset States for Analog-Digital

Multiplexed Pins).

(10) Requires user configuration to enable the ADC channel analog switch. (The switch is off by default.) The digital I/O is always connected and must be made Hi-Z before enabling the ADC

switch.

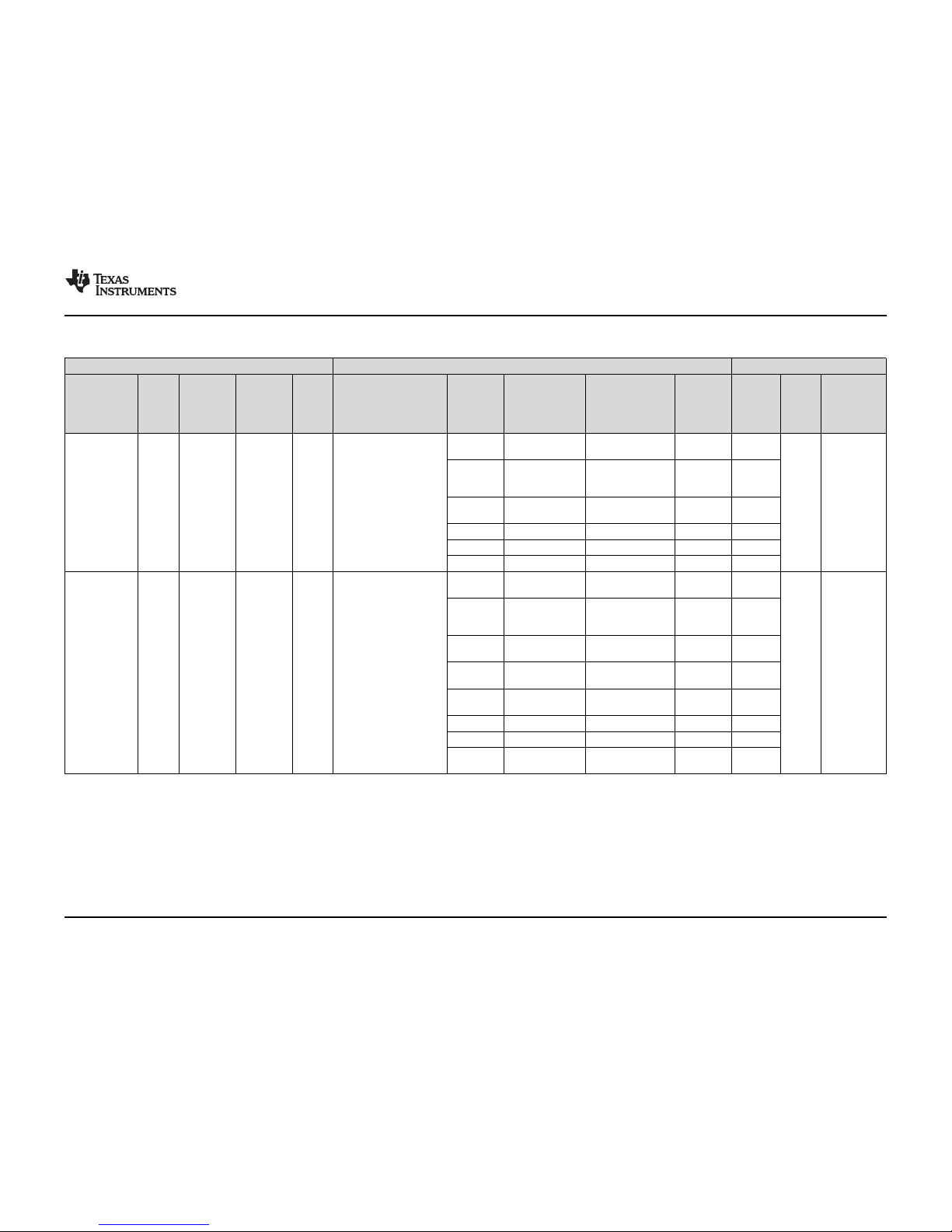

3.4 Recommended Pin Multiplexing Configurations

Table 3-3 lists the recommended pin multiplexing configurations.

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 19

Submit Documentation Feedback

Page 20

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

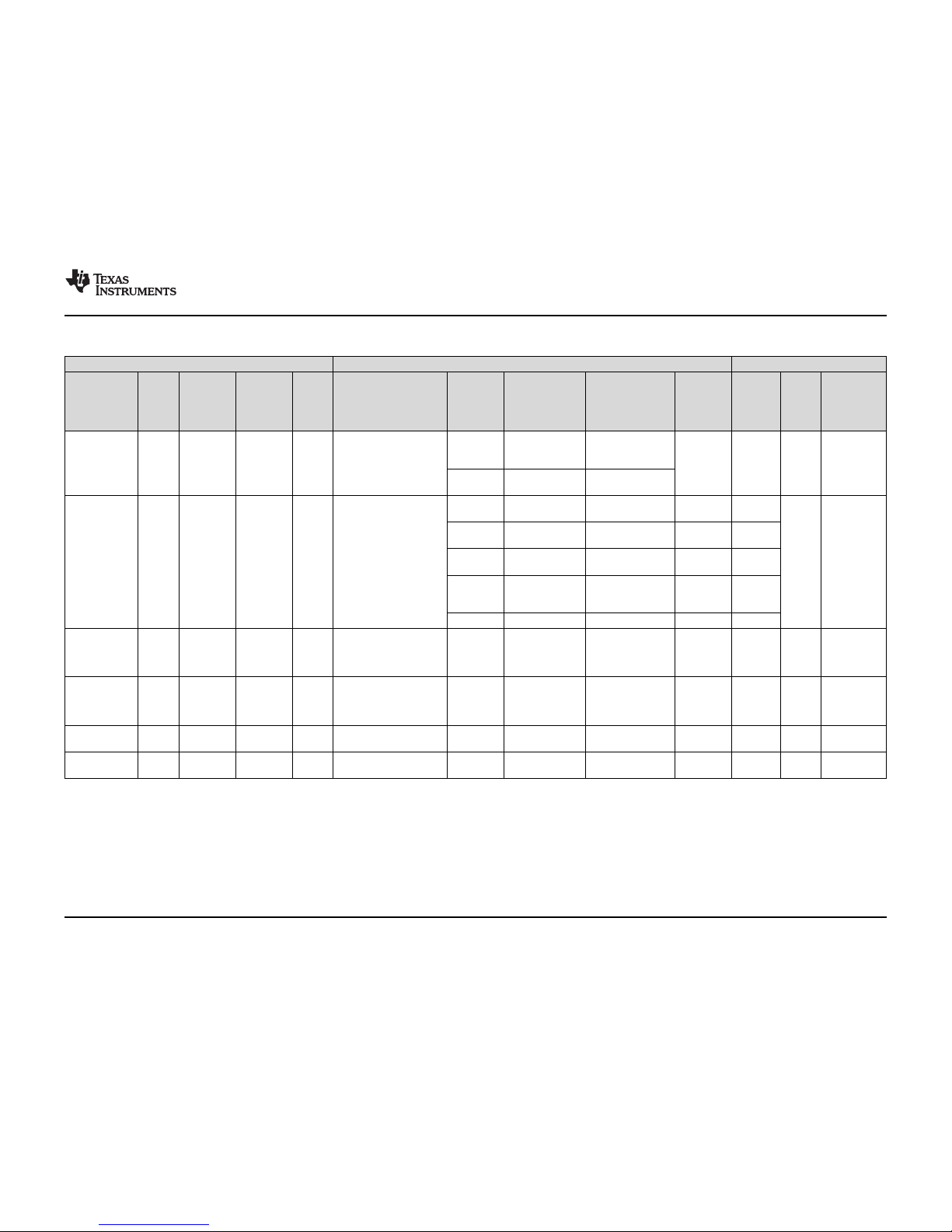

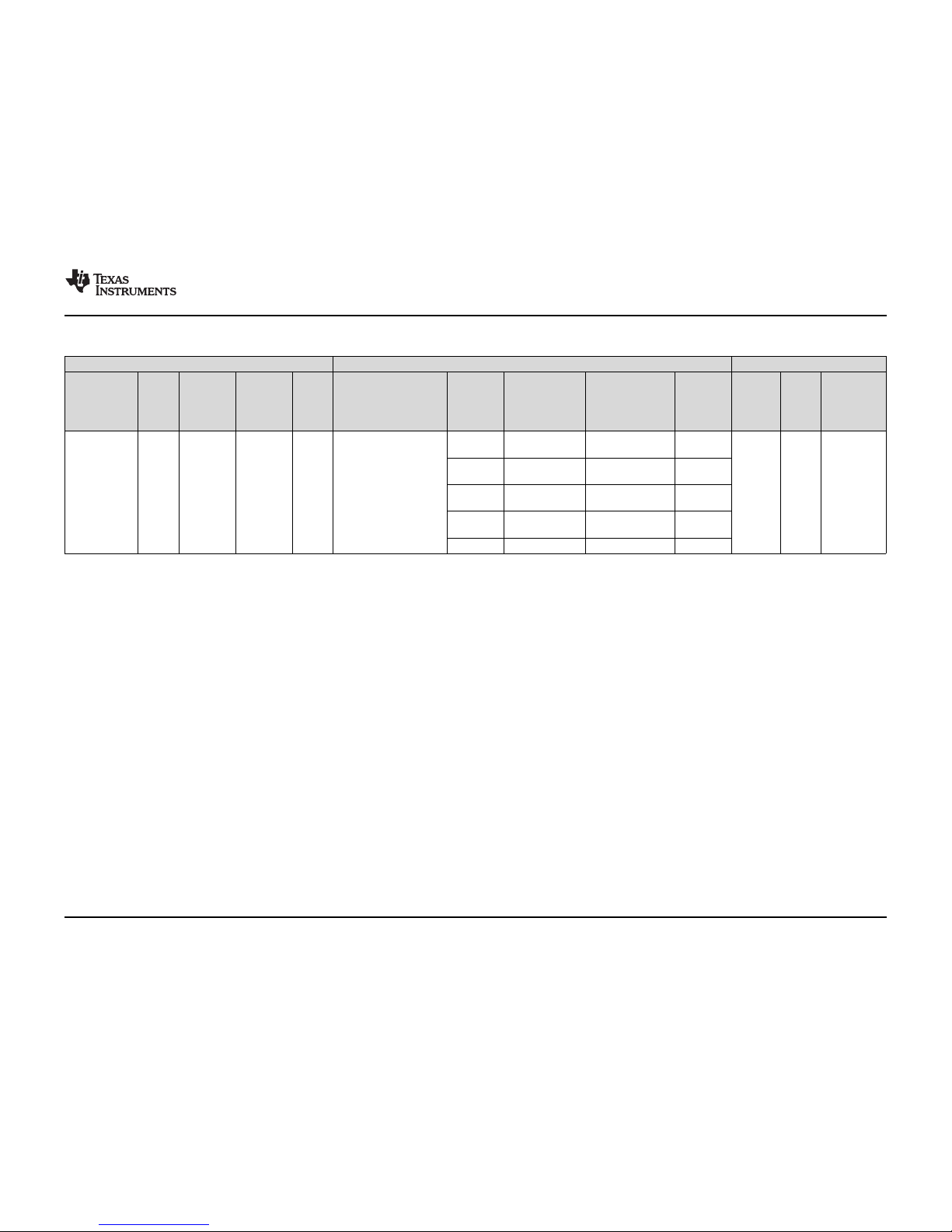

Table 3-3. Recommended Pin Multiplexing Configurations

CC3200 Recommended Pinout Grouping Use – Examples

(1)

Home Wifi Audio ++ Sensor-Tag Home Wifi Audio ++ WiFi Remote Sensor Door- Industrial Industrial Industrial GPIOs

Security High- Industrial Security Toys Industrial w/ 7x7 Lock Fire- Home Home Home

end Toys keypad and Alarm Toys Appliances Appliances Appliances"

audio w/o Cam Smart-Plug

External 32 External 32 External

kHz

(2)

kHz

(2)

TCXO 40

MHZ (-40 to

+85°C)

Cam + I2S I2S (Tx & Rx) I2S (Tx & Rx) Cam + I2S I2S (Tx & Rx) I2S (Tx & Rx) I2S (Tx or Rx) 4 Ch ADC + 3 Ch ADC + 2 Ch ADC +

(Tx or Rx) + + 1 Ch ADC + + 2 Ch ADC + (Tx or Rx) + + 1 Ch ADC + + 1 Ch ADC + + 2 Ch ADC + 1x 4wire 2wire UART + 2wire UART +

I2C + SPI + 1x 4wire 2wire UART + I2C + SWD + 2x2wire UART (Tx 2 wire UART UART + 1x SPI + I2C + I2C + SWD +

SWD + UART + 1x SPI + I2C + UART-Tx + UART + 1bit Only) I2C + + SPI + I2C + 2wire UART + SWD + 3 3 PWM + 11

UART-Tx + 2wire UART + SWD + 2 (App Logger) SD Card + SWD + 15 3 PMW + 3 SPI + I2C + PWM + 9 GPIO + 5

(App Logger) 1bit SD Card PMW + 6 4 GPIO + SPI + I2C + GPIO + 1 GPIO with SWD + 1 GPIO + 2 GPIO with

2 GPIO + + SPI + I2C + GPIO + 3 1PWM + *4 SWD + 4 PWM + 1 Wake-From- PWM + 6 GPIO with Wake-From1PWM + *4 SWD + 3 GPIO with overlaid GPIO + 1 GPIO with Hib + 5 GPIO GPIO + 1 Wake-From- Hib

overlaid GPIO + 1 Wake-From- wakeup from PWM + 1 Wake-From- SWD + GPIO with Hib

wakeup from PWM + 1 Hib HIB GPIO with Hib Wake-FromHib GPIO with Wake-From- Hib Enable

Wake-From- Hib for Ext 40

Hib MHz TCXO

Pin Pinout #11 Pinout #10 Pinout #9 Pinout #8 Pinout #7 Pinout #6 Pinout #5 Pinout #4 Pinout #3 Pinout #2 Pinout #1

GPIO_30 GSPI-MISO MCASP- MCASP- GPIO_30 GPIO_30 GPIO_30 GPIO_30 UART0-TX GPIO_30 UART0-TX GPIO_30

ACLKX ACLKX

GPIO_31 GSPI-CLK McASP-AFSX McASP-D0 GPIO_31 McASP-AFSX McASP-AFSX McASP-AFSX UART0-RX GPIO_31 UART0-RX GPIO_31

GPIO_0 GSPI-CS McASP-D1 McASP-D1 McASP-D1 McASP-D1 McASP-D1 McASP-D1 UART0-CTS GPIO_0 GPIO_0 GPIO_0

(Rx)

GPIO_1 pCLK UART0-TX UART0-TX PIXCLK UART0-TX UART0-TX UART0-TX GPIO-1 UART0-TX GPIO_1 GPIO_1

(PIXCLK)

GPIO_2 (wake) GPIO2 UART0-RX UART0-RX (wake) GPIO2 UART0-RX GPIO_2 UART0-RX ADC-0 UART0-RX (wake) (wake)

GPIO_2 GPIO_2

GPIO_3 pDATA7 (D3) UART1-TX ADC-CH1 pDATA7 (D3) UART1-TX GPIO_3 ADC-1 ADC-1 ADC-1 ADC-1 GPIO_3

GPIO_4 pDATA6 (D2) UART1-RX (wake) pDATA6 (D2) UART1-RX GPIO_4 (wake) ADC-2 ADC-2 (wake) (wake)

GPIO_4 GPIO_4 GPIO_4 GPIO_4

GPIO_5 pDATA5 (D1) ADC-3 ADC-3 pDATA5 (D1) ADC-3 ADC-3 ADC-3 ADC-3 ADC-3 ADC-3 GPIO_5

GPIO_6 pDATA4 (D0) UART1-CTS GPIO_6 pDATA4 (D0) GPIO_6 GPIO_6 GPIO_6 UART0-RTS GPIO_6 GPIO_6 GPIO_6

GPIO_7 McASP- UART1-RTS GPIO_7 McASP- McASP- McASP- McASP- GPIO_7 GPIO_7 GPIO_7 GPIO_7

ACLKX ACLKX ACLKX ACLKX ACLKX

(1) Pins marked "wake" can be configured to wake up the chip from HIBERNATE or LPDS state. In the current silicon revision, any wake pin can trigger wake up from HIBERNATE. The

wakeup monitor in the hibernate control module logically ORs these pins applying a selection mask. However, wakeup from LPDS state can be triggered only by one of the wakeup pins

that can be configured before entering LPDS. The core digital wakeup monitor use a mux to select one of these pins to monitor.

(2) The device supports the feeding of an external 32.768-kHz clock. This configuration frees one pin (32K_XTAL_N) to use in output-only mode with a 100K pullup.

20 Terminal Configuration and Functions Copyright© 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

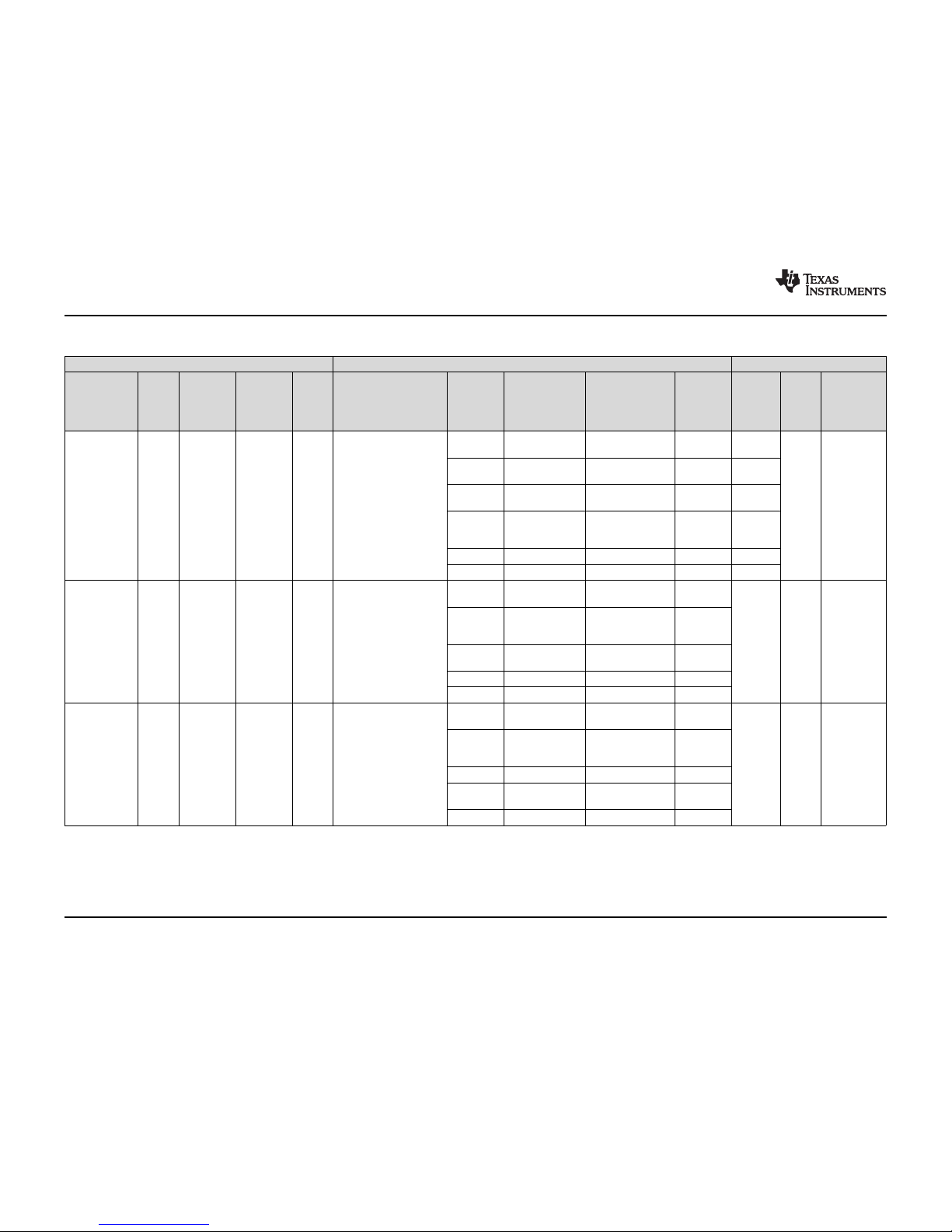

Table 3-3. Recommended Pin Multiplexing Configurations (continued)

CC3200 Recommended Pinout Grouping Use – Examples

(1)

GPIO_8 McASP-AFSX SDCARD-IRQ McASP-AFSX McASP-AFSX SDCARD-IRQ GPIO_8 GPIO_8 GPIO_8 GPIO_8 GPIO_8 GPIO_8

GPIO_9 McASP-D0 SDCARD- GT_PWM5 McASP-D0 SDCARD- GPIO_9 GT_PWM5 GT_PWM5 GT_PWM5 GT_PWM5 GPIO_9

DATA DATA

GPIO_10 UART1-TX SDCARD- GPIO_10 UART1-TX SDCARD- GPIO_10 GT_PWM6 UART1-TX GT_PWM6 GPIO_10 GPIO_10

CLK CLK

GPIO_11 (wake) SDCARD- (wake) (wake) SDCARD- GPIO_11 (wake) UART1-RX (wake) (wake) (wake)

pXCLK CMD GPIO_11 pXCLK CMD GPIO_11 GPIO_11 GPIO_11 GPIO_11

(XVCLK) (XVCLK)

GPIO_12 pVS (VSYNC) I2C-SCL I2C-SCL pVS (VSYNC) I2C-SCL GPIO_12 I2C-SCL I2C-SCL I2C-SCL GPIO_12 GPIO_12

GPIO_13 (wake) pHS I2C-SDA I2C-SDA (wake) pHS I2C-SDA GPIO_13 I2C-SDA I2C-SDA I2C-SDA (wake) (wake)

(HSYNC) (HSYNC) GPIO_13 GPIO_13

GPIO_14 pDATA8 (D4) GSPI-CLK GSPI-CLK pDATA8 (D4) GSPI-CLK I2C-SCL GSPI-CLK GSPI-CLK GSPI-CLK I2C-SCL GPIO_14

GPIO_15 pDATA9 (D5) GSPI-MISO GSPI-MISO pDATA9 (D5) GSPI-MISO I2C-SDA GSPI-MISO GSPI-MISO GSPI-MISO I2C-SDA GPIO_15

GPIO_16 pDATA10 GSPI-MOSI GSPI-MOSI pDATA10 GSPI-MOSI GPIO_16 GSPI-MOSI GSPI-MOSI GSPI-MOSI GPIO_16 GPIO_16

(D6) (D6)

GPIO_17 (wake) GSPI-CS GSPI-CS (wake) GSPI-CS GPIO_17 GSPI-CS GSPI-CS GSPI-CS (wake) (wake)

pDATA11 pDATA11 GPIO_17 GPIO_17

(D7) (D7)

GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22 GPIO_22

GPIO_23 I2C-SCL GPIO_23 GPIO_23 I2C-SCL GPIO_23 GPIO_23 GPIO_23 GPIO_23 GPIO_23 GPIO_23 GPIO_23

GPIO_24 I2C-SDA (wake) (wake) I2C-SDA (wake) (wake) (wake) (wake) (wake) GT-PWM0 (wake)

GPIO_24 GPIO_24 GPIO_24 GPIO_24 GPIO_24 GPIO_24 GPIO_24 GPIO_24

JTAG_TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK SWD-TCK

JTAG_TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS SWD-TMS

GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28 GPIO_28

GPIO_25 GT_PWM2 GT_PWM2 GT_PWM2 GT_PWM2 GT_PWM2 GT_PWM2 GT_PWM2 TCXO_EN GT_PWM2 GT_PWM2 GPIO_25 out

only

Copyright © 2014, Texas Instruments Incorporated Terminal Configuration and Functions 21

Submit Documentation Feedback

Page 22

CC3200MOD

SWRS166 –DECEMBER 2014

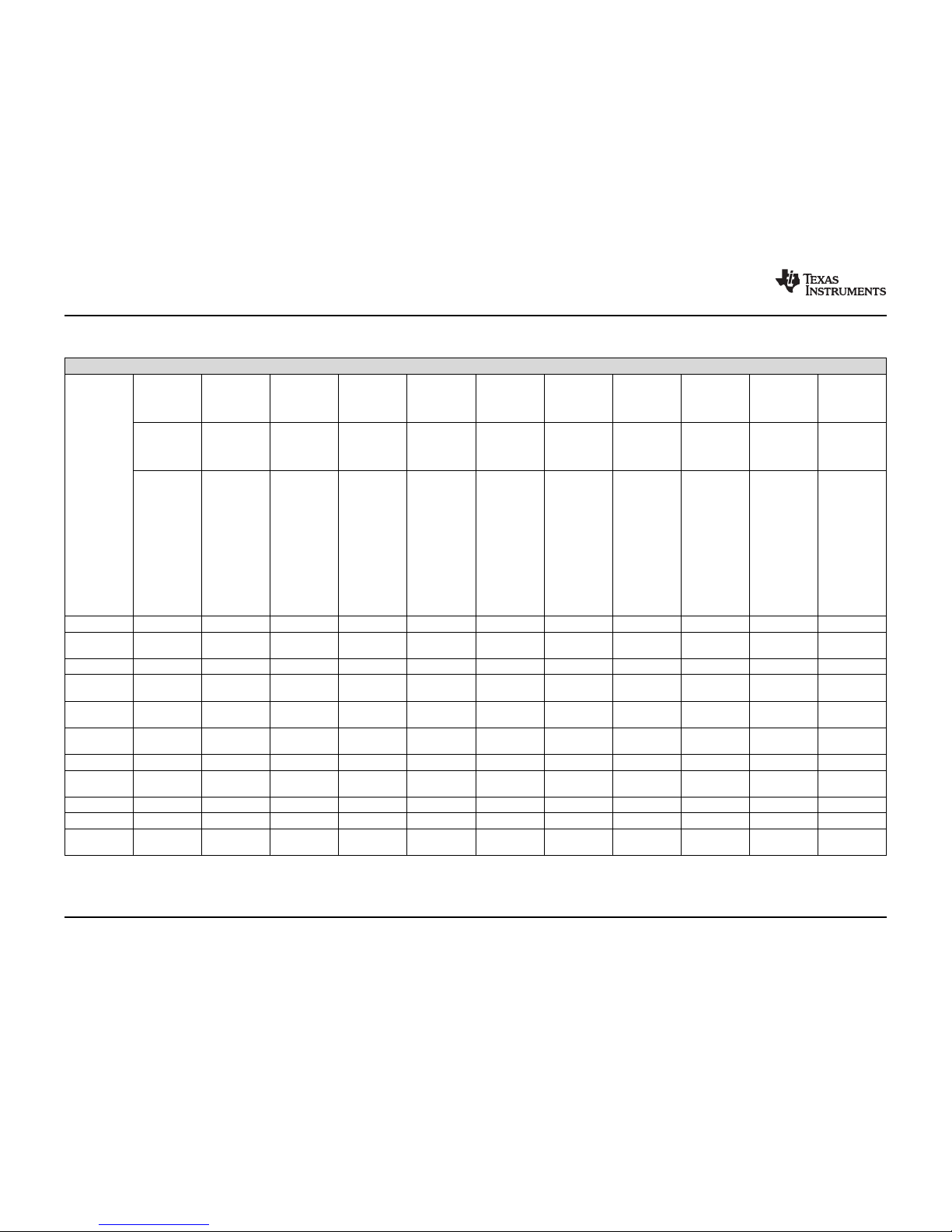

3.5 Drive Strength and Reset States for Analog-Digital Multiplexed Pins

Table 3-4 describes the use, drive strength, and default state of these pins at first-time power up and reset

(nRESET pulled low).

Table 3-4. Drive Strength and Reset States for Analog-Digital Multiplexed Pins

www.ti.com

Pin

25 of the RF switch (ANTSEL1). 4

26 of the RF switch (ANTSEL2). 4

44 Generic I/O 4

42 Generic I/O 4

47 4

48 4

49 4

50 4

Board Level Configuration Default State at First Power Analog Switches (ACTIVE, Maximum Effective Drive

Connected to the enable pin

Other use not recommended.

Connected to the enable pin

Other use not recommended.

Analog signal (1.8 V ADC is isolated. The digital Determined by the I/O state,

absolute, 1.46 V full scale) I/O cell is also isolated. as are other digital I/Os.

Analog signal (1.8 V ADC is isolated. The digital Determined by the I/O state,

absolute, 1.46 V full scale) I/O cell is also isolated. as are other digital I/Os.

Analog signal (1.8 V ADC is isolated. The digital Determined by the I/O state,

absolute, 1.46 V full scale) I/O cell is also isolated. as are other digital I/Os.

Analog signal (1.8 V ADC is isolated. The digital Determined by the I/O state,

absolute, 1.46 V full scale) I/O cell is also isolated. as are other digital I/Os.

and Use Up or Forced Reset LPDS, and HIB Power Strength (mA)

Analog is isolated. The digital Determined by the I/O state,

I/O cell is also isolated. as are other digital I/Os.

Analog is isolated. The digital Determined by the I/O state,

I/O cell is also isolated. as are other digital I/Os.

Analog is isolated. The digital Determined by the I/O state,

I/O cell is also isolated. as are other digital I/Os.

Analog is isolated. The digital Determined by the I/O state,

I/O cell is also isolated. as are other digital I/Os.

State after Configuration of

Modes)

3.6 Pad State After Application of Power To Chip But Prior To Reset Release

When a stable power is applied to the CC3200 chip for the first time or when supply voltage is restored to

the proper value following a prior period with supply voltage below 1.5 V, the level of the digital pads are

undefined in the period starting from the release of nRESET and until DIG_DCDC powers up. This period

is less than approximately 10 ms. During this period, pads can be internally pulled weakly in either

direction. If a certain set of pins are required to have a definite value during this pre-reset period, an

appropriate pullup or pulldown must be used at the board level. The recommended value of this external

pull is 2.7 KΩ.

22 Terminal Configuration and Functions Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

4 Specifications

4.1 Absolute Maximum Ratings

These specifications indicate levels where permanent damage to the module can occur. Functional operation is not ensured

under these conditions. Operation at absolute maximum conditions for extended periods can adversely affect long-term

reliability of the module.

SYMBOL CONDITION MIN TYP MAX UNIT

VBAT and VIO Respect to GND –0.5 3.3 3.8 V

Digital I/O Respect to GND –0.5 – VBAT + 0.5 V

RF pins –0.5 2.1 V

Analog pins –0.5 2.1 V

Temperature –40 +85 °C

4.2 Handling Ratings

MIN MAX UNIT

T

stg

V

ESD

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Storage temperature range –40 85 °C

Electrostatic discharge (ESD)

performance:

Human body model (HBM), per ANSI/ESDA/JEDEC

(1)

JS001

Charged device model (CDM),

per JESD22-C101

(2)

All pins –250 250 V

–1.0 1.0 kV

4.3 Power-On Hours

CONDITIONS POH

T

up to 85°C, assuming 20% active mode and 80% sleep mode 17,500

Ambient

4.4 Recommended Operating Conditions

Function operation is not ensured outside this limit, and operation outside this limit for extended periods can adversely affect

long-term reliability of the module.

SYMBOL CONDITION

VBAT and VIO Battery mode 2.3 3.3 3.6 V

Operating temperature – –20 25 70 °C

Ambient thermal slew –20 20 °C/minute

(1) Operating temperature is limited by crystal frequency variation.

(2) To ensure WLAN performance, the ripple on the power supply must be less than ±300 mV.

(1)

(2)

MIN TYP MAX UNIT

Copyright © 2014, Texas Instruments Incorporated Specifications 23

Submit Documentation Feedback

Page 24

CC3200MOD

SWRS166 –DECEMBER 2014

4.5 Brown-Out and Black-Out

www.ti.com

The module enters a brown-out condition whenever the input voltage dips below V

BROWN

(see Figure 4-1 and

Figure 4-2). This condition must be considered during design of the power supply routing, especially if operating

from a battery. High-current operations (such as a TX packet) cause a dip in the supply voltage, potentially

triggering a brown-out. The resistance includes the internal resistance of the battery, contact resistance of the

battery holder (4 contacts for a 2 x AA battery) and the wiring and PCB routing resistance.

Figure 4-1. Brown-Out and Black-Out Levels (1 of 2)

Figure 4-2. Brown-Out and Black-Out Levels (2 of 2)

In the brown-out condition, all sections of the CC3200MOD shut down within the module except for the Hibernate

block (including the 32-kHz RTC clock), which remains on. The current in this state can reach approximately 400

µA.

The black-out condition is equivalent to a hardware reset event in which all states within the module are lost.

24 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

4.6 Electrical Characteristics (3.3 V, 25°C)

GPIO Pins Except 29, 30, 45, 50, 52, and 53 (25°C)

PARAMETER TEST MIN NOM MAX UNIT

C

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

I

OH

Pin capacitance 4 pF

IN

High-level input voltage 0.65 × VDD VDD + 0.5 V V

Low-level input voltage –0.5 0.35 × VDD V

High-level input current 5 nA

Low-level input current 5 nA

High-level output voltage (VDD = 2.4 V

3.0 V)

Low-level output voltage (VDD = 0.4 V

3.0 V)

High-level 2-mA Drive 2 mA

source current,

VOH = 2.4

4-mA Drive 4 mA

6-mA Drive 6 mA

I

OL

Low-level sink 2-mA Drive 2 mA

current,

VOH = 0.4

4-mA Drive 4 mA

6-mA Drive 6 mA

(1) TI recommends using the lowest possible drive strength that is adequate for the applications. This recommendation minimizes the risk of

interference to the WLAN radio and mitigates any potential degradation of RF sensitivity and performance. The default drive strength

setting is 6 mA.

(1)

CONDITIONS

GPIO Pins 29, 30, 45, 50, 52, and 53 (25°C)

(1)

PARAMETER TEST MIN NOM MAX UNIT

CONDITIONS

C

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

I

OH

Pin capacitance 7 pF

IN

High-level input voltage 0.65 × VDD VDD + 0.5V V

Low-level input voltage –0.5 0.35 × VDD V

High-level input current 50 nA

Low-level input current 50 nA

High-level output voltage 2.4 V

(VDD= 3.0 V)

Low-level output voltage 0.4 V

(VDD= 3.0 V)

High-level 2-mA Drive 1.5 mA

source current,

VOH= 2.4

4-mA Drive 2.5 mA

6-mA Drive 3.5 mA

I

OL

Low-level sink 2-mA Drive 1.5 mA

current, VOH=

0.4

4-mA Drive 2.5 mA

6-mA Drive 3.5 mA

V

IL

nRESET

(2)

0.6 V

(1) TI recommends using the lowest possible drive strength that is adequate for the applications. This recommendation minimizes the risk of

interference to the WLAN radio and mitigates any potential degradation of RF sensitivity and performance. The default drive strength

setting is 6 mA.

(2) The nRESET pin must be held below 0.6 V to ensure the device is reset properly.

Copyright © 2014, Texas Instruments Incorporated Specifications 25

Submit Documentation Feedback

Page 26

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Pin Internal Pullup and Pulldown (25°C)

(1)

PARAMETER TEST CONDITIONS MIN NOM MAX UNIT

I

OH

I

OL

Pullup current, VOH= 2.4 5 10 µA

(VDD = 3.0 V)

Pulldown current, VOL= 0.4 5 µA

(VDD = 3.0 V)

(1) TI recommends using the lowest possible drive strength that is adequate for the applications. This recommendation minimizes the risk of

interference to WLAN radio and mitigates any potential degradation of RF sensitivity and performance. The default drive-strength setting

is 6 mA.

4.7 Thermal Resistance Characteristics for MOB Package

NAME DESCRIPTION °C/W

RΘ

RΘ

RΘ

RΘ

Psi

Psi

JC

JB

JA

JMA

JT

JB

Junction-to-case 9.08 0.00

Junction-to-board 10.34 0.00

Junction-to-free air 11.60 0.00

Junction-to-moving air 5.05 < 1.00

Junction-to-package top 9.08 0.00

Junction-to-board 10.19 0.00

(1) (2)

AIR FLOW (m/s)

(1) °C/W = degrees Celsius per watt.

(2) These values are based on a JEDEC-defined 2S2P system (with the exception of the Theta JC [RΘJC] value, which is based on a

JEDEC-defined 1S0P system) and will change based on environment as well as application. For more information, see these

EIA/JEDEC standards:

• JESD51-2, Integrated Circuits Thermal Test Method Environmental Conditions - Natural Convection (Still Air)

• JESD51-3, Low Effective Thermal Conductivity Test Board for Leaded Surface Mount Packages

• JESD51-7, High Effective Thermal Conductivity Test Board for Leaded Surface Mount Packages

• JESD51-9, Test Boards for Area Array Surface Mount Package Thermal Measurements

Power dissipation of 2 W and an ambient temperature of 70ºC is assumed.

(3) m/s = meters per second.

(3)

4.8 Reset Requirement

PARAMETER SYMBOL MIN TYP MAX UNIT

Operation mode level ViH 0.65 × VBAT V

Shutdown mode level

Minimum time for nReset low for resetting the 5 ms

module

Rise/fall times Tr/Tf 20 µs

(1) The nRESET pin must be held below 0.6 V for the module to register a reset.

(1)

ViL 0 0.6 V V

26 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

CC3200MOD

www.ti.com

SWRS166 –DECEMBER 2014

4.9 Current Consumption

TA= +25°C, V

MCU ACTIVE TX power level = 0 229 mA

MCU SLEEP TX power level = 0 226 mA

MCU LPDS 54 OFDM mA

MCU hibernate NWP hibernate 7 µA

Peak calibration current

(1) TX power level = 0 implies maximum power (see Figure 4-3 through Figure 4-5). TX power level = 4 implies output power backed off

approximately 4 dB.

(2) The CC3200 system is a constant power-source system. The active current numbers scale based on the V

(3) DTIM = 1

(4) The LPDS number reported is with retention of 64KB MCU SRAM. The CC3200 device can be configured to retain 0KB, 64KB, 128KB,

192KB or 256KB SRAM in LPDS. Each 64KB retained increases LPDS current by 4 µA.

(5) The complete calibration can take up to 17 mJ of energy from the battery over a time of 24 ms . Calibration is performed sparingly,

typically when coming out of Hibernate and only if temperature has changed by more than 20°C or the time elapsed from prior

calibration is greater than 24 hours.

= 3.6 V

BAT

PARAMETER TEST CONDITIONS

1 DSSS

TX 6 OFDM

NWP ACTIVE

54 OFDM

1 DSSS 59

54 OFDM 59

NWP idle connected

RX

(3)

1 DSSS

TX 6 OFDM

NWP ACTIVE

54 OFDM

1 DSSS 56

54 OFDM 56

NWP idle connected

RX

(3)

1 DSSS

TX 6 OFDM

NWP active

1 DSSS 53

54 OFDM 53

NWP LPDS

(4)

NWP idle connected

(5)

RX

(3)

V

= 3.3 V 450

BAT

V

= 2.3 V 620

BAT

(1) (2)

TX power level = 0 278

TX power level = 4 194

TX power level = 0 254

TX power level = 4 185

TX power level = 4 166

TX power level = 0 275

TX power level = 4 191

TX power level = 0 251

TX power level = 4 182

TX power level = 4 163

TX power level = 0 272

TX power level = 4 188

TX power level = 0 248

TX power level = 4 179

TX power level = 0 223

TX power level = 4 160

MIN TYP MAX UNIT

15.3

12.2

0.275

0.875

voltage supplied.

BAT

mA

Copyright © 2014, Texas Instruments Incorporated Specifications 27

Submit Documentation Feedback

Page 28

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Note: The area enclosed in the circle represents a significant reduction in current when transitioning from TX power

level 3 to 4. In the case of lower range requirements (13-dbm output power), TI recommends using TX power level 4

to reduce the current.

Figure 4-3. TX Power and IBAT vs TX Power Level Settings (1 DSSS)

Figure 4-4. TX Power and IBAT vs TX Power Level Settings (6 OFDM)

28 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

CC3200MOD

SWRS166 –DECEMBER 2014

Figure 4-5. TX Power and IBAT vs TX Power Level Settings (54 OFDM)

Copyright © 2014, Texas Instruments Incorporated Specifications 29

Submit Documentation Feedback

Page 30

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

4.10 WLAN RF Characteristics

WLAN Receiver Characteristics

TA= +25°C, V

Sensitivity

(8% PER for 11b rates, 10% PER for 9 OFDM –88.0

11g/11n rates)(10% PER)

Maximum input level

(10% PER)

(1) Sensitivity is 1-dB worse on channel 13 (2472 MHz).

= 2.3 to 3.6 V. Parameters measured at module pin on channel 7 (2442 MHz)

BAT

PARAMETER CONDITION (Mbps) MIN TYP MAX UNITS

1 DSSS –94.7

2 DSSS –92.6

11 CCK –87.0

6 OFDM –89.0

(1)

18 OFDM –85.0 dBm

36 OFDM –79.5

54 OFDM –73.0

MCS7 (Mixed Mode) –69.0

802.11b –3.0

802.11g –9.0

4.10.1 WLAN Transmitter Characteristics(1)

TA= +25°C, V

PARAMETERS CONDITIONS MIN TYP MAX UNIT

Max RMS Output Power measured at 1 dB

from IEEE spectral mask or EVM

Transmit center frequency accuracy –20 20 ppm

(1) Channel-to-channel variation is up to 2 dB. The edge channels (2412 and 2472 MHz) have reduced TX power to meet FCC emission

limits.

= 2.3 to 3.6 V. Parameters measured at module pin on channel 7 (2442 MHz)

BAT

1DSSS 17

2DSSS 17

11CCK 17.25

6OFDM 16.25

9OFDM 16.25 dBm

18OFDM 16

36OFDM 15

54OFDM 13.5

MCS7 (Mixed Mode) 12

30 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

4.11 Timing Characteristics

4.11.1 Reset Timing

4.11.1.1 nRESET (32K XTAL)

Figure 4-6 shows the reset timing diagram for the 32K XTAL first-time power-up and reset removal.

CC3200MOD

SWRS166 –DECEMBER 2014

Figure 4-6. First-Time Power-Up and Reset Removal Timing Diagram (32K XTAL)

Table 4-1 describes the timing requirements for the 32K XTAL first-time power-up and reset removal.

Table 4-1. First-Time Power-Up and Reset Removal Timing Requirements (32K XTAL)

ITEM NAME DESCRIPTION MIN TYP MAX

T1 Supply settling time 3 ms

T2 25 ms

T3 firmware to initialize Includes 32.768-kHz XOSC settling time 1.1 s

Hardware wakeup

time

Time taken by ROM

hardware

Depends on application board power supply, decap, and

so on

Copyright © 2014, Texas Instruments Incorporated Specifications 31

Submit Documentation Feedback

Page 32

CC3200MOD

SWRS166 –DECEMBER 2014

4.11.1.2 nRESET (External 32K)

Figure 4-7 shows the reset timing diagram for the external 32K first-time power-up and reset removal.

Figure 4-7. First-Time Power-Up and Reset Removal Timing Diagram (External 32K)

www.ti.com

Table 4-2 describes the timing requirements for the external 32K first-time power-up and reset removal.

Table 4-2. First-Time Power-Up and Reset Removal Timing Requirements (External 32K)

ITEM NAME DESCRIPTION MIN TYP MAX

T1 Supply settling time 3 ms

T2 25 ms

T3 firmware to initialize Time taken by ROM firmware 3 ms

Hardware wakeup

time

Time taken by ROM

hardware

Depends on application board power supply, decap, and

so on

32 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

www.ti.com

4.11.1.3 Wakeup from Hibernate

Figure 4-8 shows the timing diagram for wakeup from the hibernate state.

CC3200MOD

SWRS166 –DECEMBER 2014

Figure 4-8. nHIB Timing Diagram

NOTE

The 32.768-kHz XTAL is kept enabled by default when the chip goes to hibernate.

Table 4-3 describes the timing requirements for nHIB.

Table 4-3. Software Hibernate Timing Requirements

ITEM NAME DESCRIPTION MIN TYP MAX

T

hib_min

T

wake_from_

(1)

hib

(1) Twake_from_hib can be 200 ms on rare occasions when calibration is performed. Calibration is performed sparingly, typically when

(2) Wake-up time can extend to 75 ms if a patch is downloaded from the serial flash.

Minimum hibernate 10 ms

time

Hardware wakeup 50 ms

time plus firmware

initialization time

exiting Hibernate and only if temperature has changed by more than 20°C or more than 24 hours have elapsed since a prior calibration.

(2)

4.11.2 Peripherals

This section describes the peripherals that are supported by the CC3200 module:

• SPI

• McASP

• GPIO

• I2C

• IEEE 1149.1 JTAG

• ADC

Copyright © 2014, Texas Instruments Incorporated Specifications 33

Submit Documentation Feedback

Page 34

I3 I2 I4

I6 I7

I9

SWAS032-017

CLK

MISO

MOSI

I8

CC3200MOD

SWRS166 –DECEMBER 2014

• Camera parallel port

• UART

4.11.2.1 SPI

4.11.2.1.1 SPI Master

The CC3200 microcontroller includes one SPI module, which can be configured as a master or slave

device. The SPI includes a serial clock with programmable frequency, polarity, and phase, a

programmable timing control between chip select and external clock generation, and a programmable

delay before the first SPI word is transmitted. Slave mode does not include a dead cycle between two

successive words.

Figure 4-9 shows the timing diagram for the SPI master.

www.ti.com

Figure 4-9. SPI Master Timing Diagram

Table 4-4 lists the timing parameters for the SPI master.

Table 4-4. SPI Master Timing Parameters

LP

HT

IS

IH

OD

OH

(1)

clk

PARAMETER NAME MIN MAX UNIT

Clock period 50 ns

Clock low period 25 ns

Clock high period 25 ns

RX data setup time 1 ns

RX data hold time 2 ns

TX data output delay 8.5 ns

TX data hold time 8 ns

PARAMETER PARAMETER

NUMBER

I1 F Clock frequency 20 MHz

I2 T

I3 t

I4 t

I5 D Duty cycle 45% 55%

I6 t

I7 t

I8 t

I9 t

(1) Timing parameter assumes a maximum load of 20 pF.

34 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

I2 I1 I3

I4

McACLKX

McAFSX

McAXR0/1

SWAS032-015

I4

I3 I2 I4

I6 I7

I9

SWAS032-017

CLK

MISO

MOSI

I8

www.ti.com

4.11.2.1.2 SPI Slave

Figure 4-10 shows the timing diagram for the SPI slave.

Figure 4-10. SPI Slave Timing Diagram

Table 4-5 lists the timing parameters for the SPI slave.

Table 4-5. SPI Slave Timing Parameters

PARAMETER PARAMETER

NUMBER

I1 F Clock frequency @ VBAT = 3.3 V 20 MHz

I2 Tclk Clock period 50 ns

I3 tLP Clock low period 25 ns

I4 tHT Clock high period 25 ns

I5 D Duty cycle 45% 55%

I6 tIS RX data setup time 4 ns

I7 tIH RX data hold time 4 ns

I8 tOD TX data output delay 20

I9 tOH TX data hold time 24 ns

(1) Timing parameter assumes a maximum load of 20 pF at 3.3 V.

(1)

PARAMETER NAME MIN MAX UNIT

Clock frequency @ VBAT ≤ 2.1 V 12

CC3200MOD

SWRS166 –DECEMBER 2014

4.11.2.2 McASP

The McASP interface functions as a general-purpose audio serial port optimized for multichannel audio

applications and supports transfer of two stereo channels over two data pins. The McASP consists of

transmit and receive sections that operate synchronously and have programmable clock and frame-sync

polarity. A fractional divider is available for bit-clock generation.

4.11.2.2.1 I2S Transmit Mode

Figure 4-11 shows the timing diagram for the I2S transmit mode.

Copyright © 2014, Texas Instruments Incorporated Specifications 35

Figure 4-11. I2S Transmit Mode Timing Diagram

Submit Documentation Feedback

Page 36

I2 I1 I3

I4

McACLKX

McAFSX

McAXR0/1

SWAS032-016

I5

CC3200MOD

SWRS166 –DECEMBER 2014

Table 4-6 lists the timing parameters for the I2S transmit mode.

Table 4-6. I2S Transmit Mode Timing Parameters

PARAMETER PARAMETER

NUMBER

I1 fclk Clock frequency 9.216 MHz

I2 tLP Clock low period 1/2 fclk ns

I3 tHT Clock high period 1/2 fclk ns

I4 tOH TX data hold time 22 ns

(1) Timing parameter assumes a maximum load of 20 pF.

(1)

PARAMETER NAME MIN MAX UNIT

4.11.2.2.2 I2S Receive Mode

Figure 4-12 shows the timing diagram for the I2S receive mode.

www.ti.com

Figure 4-12. I2S Receive Mode Timing Diagram

Table 4-7 lists the timing parameters for the I2S receive mode.

Table 4-7. I2S Receive Mode Timing Parameters

PARAMETER PARAMETER

NUMBER

I1 fclk Clock frequency 9.216 MHz

I2 tLP Clock low period 1/2 fclk ns

I3 tHT Clock high period 1/2 fclk ns

I4 tOH RX data hold time 0 ns

I5 tOS RX data setup time 15 ns

(1) Timing parameter assumes a maximum load of 20 pF.

(1)

PARAMETER NAME MIN MAX UNIT

4.11.2.3 GPIO

All digital pins of the device can be used as general-purpose input/output (GPIO) pins.The GPIO module

consists of four GPIO blocks, each of which provides eight GPIOs. The GPIO module supports 24

programmable GPIO pins, depending on the peripheral used. Each GPIO has configurable pullup and

pulldown strength (weak 10 µA), configurable drive strength (2, 4, and 6 mA), and open-drain enable.

Figure 4-13 shows the GPIO timing diagram.

36 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

SWAS031-067

V

DD

80%

20%

t

GPIOF

t

GPIOR

www.ti.com

CC3200MOD

SWRS166 –DECEMBER 2014

Figure 4-13. GPIO Timing

4.11.2.3.1 GPIO Output Transition Time Parameters (V

Table 4-8 lists the GPIO output transition times for V

Table 4-8. GPIO Output Transition Times (V

DRIVE Tr(ns) Tf(ns)

STRENGTH

(mA)

DRIVE STRENGTH

CONTROL BITS

MIN NOM MAX MIN NOM MAX

supply

supply

= 3.3 V)

= 3.3 V.

supply

= 3.3 V)

(1)(2)

2MA_EN=1

2 4MA_EN=0 8.0 9.3 10.7 8.2 9.5 11.0

8MA_EN=0

2MA_EN=0

4 4MA_EN=1 6.6 7.1 7.6 4.7 5.2 5.8

8MA_EN=0

2MA_EN=0

8 4MA_EN=0 3.2 3.5 3.7 2.3 2.6 2.9

8MA_EN=1

2MA_EN=1

14 4MA_EN=1 1.7 1.9 2.0 1.3 1.5 1.6

8MA_EN=1

(1) V

(2) The transition data applies to the pins other than the multiplexed analog-digital pins 29, 30, 45, 50, 52, and 53.

= 3.3 V, T = 25°C, total pin load = 30 pF

supply

4.11.2.3.2 GPIO Output Transition Time Parameters (Vsupply = 1.8 V)

Table 4-9 lists the GPIO output transition times for V

Table 4-9. GPIO Output Transition Times (V

DRIVE Tr(ns) Tf(ns)

STRENGTH

(mA)

2 4MA_EN=0 11.7 13.9 16.3 11.5 13.9 16.7

4 4MA_EN=1 13.7 15.6 18.0 9.9 11.6 13.6

8 4MA_EN=0 5.5 6.4 7.4 3.8 4.7 5.8

(1) V

(2) The transition data applies to the pins other than the multiplexed analog-digital pins 29, 30, 45, 50, 52, and 53.

Copyright © 2014, Texas Instruments Incorporated Specifications 37

= 1.8 V, T = 25°C, total pin load = 30 pF

supply

DRIVE STRENGTH

CONTROL BITS

2MA_EN=1

8MA_EN=0

2MA_EN=0

8MA_EN=0

2MA_EN=0

8MA_EN=1

= 1.8 V.

supply

supply

= 1.8 V)

(1)(2)

MIN NOM MAX MIN NOM MAX

Submit Documentation Feedback

Page 38

I2 I6

I5

I9

I3I8

I7

I4

I1

I2CSCL

SWAS031-068

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Table 4-9. GPIO Output Transition Times (V

DRIVE Tr(ns) Tf(ns)

STRENGTH

(mA)

DRIVE STRENGTH

CONTROL BITS

MIN NOM MAX MIN NOM MAX

supply

= 1.8 V)

(1)(2)

(continued)

2MA_EN=1

14 4MA_EN=1 2.9 3.4 4.0 2.2 2.7 3.3

8MA_EN=1

4.11.2.3.3 GPIO Input Transition Time Parameters

Table 4-10 lists the input transition time parameters.

Table 4-10. GPIO Input Transition Time Parameters

PARAMETER CONDITION SYMBOL MIN MAX UNIT

Input transition time

(tr,tf), 10% to 90%

t

r

t

f

1 3

1 3

4.11.2.4 I2C

The CC3200 microcontroller includes one I2C module operating with standard (100 Kbps) or fast (400

Kbps) transmission speeds.

Figure 4-14 shows the I2C timing diagram.

ns

Figure 4-14. I2C Timing

Table 4-11 lists the I2C timing parameters.

Table 4-11. I2C Timing Parameters

PARAMETER PARAMETER PARAMETER NAME MIN MAX UNIT

NUMBER

I2 t

I3 t

I4 t

I5 t

I6 t

I7 t

I8 t

I9 t

LP

SRT

DH

SFT

HT

DS

SCSR

SCS

Clock low period See

SCL/SDA rise time – See

Data hold time NA –

SCL/SDA fall time – 3 ns

Clock high time See

Data setup time tLP/2 System clock

Start condition setup 36 – System clock

time

Stop condition setup 24 – System clock

time

(1) All timing is with 6-mA drive and 20-pF load.

(2) This value depends on the value programmed in the clock period register of I2C. Maximum output frequency is the result of the minimal

value programmed in this register.

(3) Because I2C is an open-drain interface, the controller can drive logic 0 only. Logic is the result of external pullup. Rise time depends on

the external signal capacitance and external pullup register value.

(2)

(2)

(1)

. - System clock

(3)

. ns

. – System clock

38 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 39

J2 J3 J4

J7 J8

J7

J8

J9 J10 J9 J10

J1

J11

TDI Input Valid

TDO Output Valid

TDO Output Valid

TMS Input Valid

TDI Input Valid

TCK

TDI

SWAS031-069

TMS Input Valid

www.ti.com

4.11.2.5 IEEE 1149.1 JTAG

The Joint Test Action Group (JTAG) port is an IEEE standard that defines a test access port (TAP) and

boundary scan architecture for digital integrated circuits and provides a standardized serial interface to

control the associated test logic. For detailed information on the operation of the JTAG port and TAP

controller, see the IEEE Standard 1149.1,Test Access Port and Boundary- Scan Architecture.

Figure 4-15 shows the JTAG timing diagram.

CC3200MOD

SWRS166 –DECEMBER 2014

Figure 4-15. JTAG Timing

Table 4-12 lists the JTAG timing parameters.

Table 4-12. JTAG Timing Parameters

PARAMETER PARAMETER PARAMETER NAME MIN MAX UNIT

NUMBER

J1 fTCK Clock frequency 15 MHz

J2 tTCK Clock period 1/fTCK ns

J3 tCL Clock low period tTCK/2 ns

J4 tCH Clock high period tTCK/2 ns

J7 tTMS_SU TMS setup time 1

J8 tTMS_HO TMS hold time 16

J9 tTDI_SU TDI setup time 1

J10 tTDI_HO TDI hold time 16

J11 tTDO_HO TDO hold time 15

4.11.2.6 ADC

Table 4-13 lists the ADC electrical specifications.

Table 4-13. ADC Electrical Specifications

PARAMETER DESCRIPTION CONDITION AND MIN TYP MAX UNIT

Nbits Number of bits 12 Bits

INL Integral nonlinearity Worst-case deviation from –2.5 2.5 LSB

DNL Differential nonlinearity Worst-case deviation of any step –1 4 LSB

Input range 0 1.4 V

ASSUMPTIONS

histogram method over full scale

(not including first and last three

LSB levels)

from ideal

Copyright © 2014, Texas Instruments Incorporated Specifications 39

Submit Documentation Feedback

Page 40

2 µs 2 µs 2 µs 2 µs 2 µs 2 µs 2 µs 2 µs 2 µs 2 µs

Repeats Every 16 µs

ADC CLOCK

= 10 MHz

Sampling

4 cycles

SAR Conversion

16 cycles

Sampling

4 cycles

SAR Conversion

16 cycles

Sampling

4 cycles

SAR Conversion

16 cycles

Sampling

4 cycles

SAR Conversion

16 cycles

EXT CHANNEL 0

INTERNAL CHANNEL

EXT CHANNEL 1

INTERNAL CHANNEL

Internal Ch

CC3200MOD

SWRS166 –DECEMBER 2014

www.ti.com

Table 4-13. ADC Electrical Specifications (continued)

PARAMETER DESCRIPTION CONDITION AND MIN TYP MAX UNIT

Driving source 100 Ω

impedance

FCLK Clock rate Successive approximation input 10 MHz

Input capacitance 3.2 pF

Number of channels 4

F

sample

Sampling rate of each ADC 62.5 KSPS

F_input_max Maximum input signal frequency 31 kHz

SINAD Signal-to-noise and distortion Input frequency dc to 300 Hz 55 60 dB

I_active Active supply current Average for analog-to-digital 1.5 mA

I_PD Power-down supply current for Total for analog-to-digital when 1 µA

core supply not active (this must be the SoC

Absolute offset error FCLK = 10 MHz ±2 mV

Gain error ±2%

ASSUMPTIONS

clock rate

and 1.4 Vppsine wave input

during conversion without

reference current

level test)

Figure 4-16 shows the ADC clock timing diagram.

4.11.2.7 Camera Parallel Port

The fast camera parallel port interfaces with a variety of external image sensors, stores the image data in

a FIFO, and generates DMA requests. The camera parallel port supports 8 bits.

Figure 4-17 shows the timing diagram for the camera parallel port.

Figure 4-16. ADC Clock Timing

Figure 4-17. Camera Parallel Port Timing Diagram

Table 4-14 lists the timing parameters for the camera parallel port.

40 Specifications Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 41

www.ti.com

SWRS166 –DECEMBER 2014

Table 4-14. Camera Parallel Port Timing Parameters

PARAMETER PARAMETER PARAMETER NAME MIN MAX UNIT

NUMBER

pCLK Clock frequency 2 MHz

I2 T

I3 t

I4 t

I7 D Duty cycle 45% to 55%

I8 t

I9 t

clk

LP

HT

IS

IH

Clock period 1/pCLK ns

Clock low period T

Clock high period T

RX data setup time 2 ns

RX data hold time 2 ns

/2 ns

clk

/2 ns

clk

4.11.2.8 UART

The CC3200 device includes two UARTs with the following features:

• Programmable baud-rate generator allowing speeds up to 3 Mbps

• Separate 16 x 8 TX and RX FIFOs to reduce CPU interrupt service loading

• Programmable FIFO length, including 1-byte deep operation providing conventional double-buffered

interface

• FIFO trigger levels of 1/8, 1/4, 1/2, 3/4, and 7/8

• Standard asynchronous communication bits for start, stop, and parity

• Line-break generation and detection

• Fully programmable serial interface characteristics

– 5, 6, 7, or 8 data bits

– Even, odd, stick, or no-parity bit generation and detection

– 1 or 2 stop-bit generation

• RTS and CTS hardware flow support

• Standard FIFO-level and End-of-Transmission interrupts

• Efficient transfers using μDMA

– Separate channels for transmit and receive

– Receive single request asserted when data is in the FIFO; burst request asserted at programmed

FIFO level

– Transmit single request asserted when there is space in the FIFO; burst request asserted at

programmed FIFO level

• System clock is used to generate the baud clock.

CC3200MOD

Copyright © 2014, Texas Instruments Incorporated Specifications 41

Submit Documentation Feedback

Page 42

CC3200MOD

SPI

Peripheral

I C

Peripheral

2

V

CC

Miscellaneous

Peripheral

Camera

Sensor

GSPI

I C

2

Audio

Codec

GPIO/PWM

Parallel

Camera Port

I2S

CC3200MOD