Page 1

April ’00 Preface

FCC ID: A92S251B

Series 2000 Reader System

Reader S251B RI-STU-251B

Reference Guide

11-06-21-054 April 2000

1

Page 2

S2510 Reader - Reference Guide April ’00

Edition One - April 2000

This is the first edition of this manual, it describes the following equipment:

TIRIS Reader S251B

Texas Instruments (TI) reserves the right to make changes to its products or services

or to discontinue any p roduc t o r se rvi ce at a ny ti me with out not ic e. T I prov id es cu stomer assistance i n various technic al areas, but do es not have full ac cess to data

concerning the use and applications of customer's products.

Therefore, TI assumes no liability and is not responsible for customer applications or

product or software design or performance relating to systems or applications incorporating TI produ cts. In addi tion, TI assu mes no liab ility and i s not respons ible for

infringement of patents and/or any other intell ectual or industrial proper ty rights of

third parties, which may result from assistance provided by TI.

TI products are not designed, intended, authorized or warranted to be suitable for life

support applications or a ny othe r li fe cr iti ca l appl ic ati on s wh ic h cou ld inv ol v e po tential risk of death, personal injury or severe property or environmental damage.

RI-STU-251B

The

Incorporated.

Copyright 2000 Texas Instruments Incorporated (TI)

This document may be downloaded onto a computer, stored and duplicated as nec-

essary to support the us e of the related TI products. Any othe r type of duplicatio n,

circulation or storage on data carriers in any manner not authorized by TI represents

a violation of the applicable copyright laws and shall be prosecuted.

logo and the word

TIRIS

TIRIS

2

are registered trademarks of Texas Instruments

Page 3

About This Guide

Conventions

PREFACE

Read This First

This manual describes t he TIRIS S251B Reader, its goal is to describe the reader ,

how it works, how to install it and how to use it.

Regulatory, safety and warranty notices that must be followed are given in

Chapter 5.

WARNING:

WARNING IS USED WHERE CARE MUST BE TAKEN, OR A CERTAIN

A

PROCEDURE

HARM TO YOUR HEALTH

OR

MUST BE FOLLOWED IN ORDER TO PREVENT INJURY

.

If You Need Assistance

Application Centers are located in Europe, North and S outh Amer ica, the Far E ast

and Australia to provide direct su pport. For more information, please contact your

nearest TIRIS Sales and Application Center. The contact addresses can be found on

our home page:

CAUTION:

This indicates information on conditions which must be

met, or a procedure which must be followed, which if not

heeded could cause permanent damage to the equipment

or software.

Note:

Indicates conditions which must be met, or procedures which must be

followed, to ensure proper functioning of the equipment or software.

Information:

Indicates information which makes usage of the equipment or software easier

http://www.tiris.com

3

Page 4

S2510 Reader - Reference Guide April ’00

Document Overview

Page

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General............................................................................................... 7

1.2 System Description ............................................................................ 7

1.3 Product Description....................................... ...... ....... ...... ....... ........... 7

Chapter 2: Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 General............................................................................................. 10

2.2 Product Description....................................... ...... ....... ...... ....... ......... 10

2.3 Mechanical Information.................................................................... 22

Chapter 3: Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Introduction....................................................................................... 24

3.2 Types of Synchronization................................................................. 24

Chapter 4: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Introduction....................................................................................... 30

4.2 General............................................................................................. 30

4.3 Mechanical Mounting ....................................................................... 30

4.4 Communication ................................................................................ 31

4.5 Synchronization................................................................................ 34

4.6 General Purpose Input/Outputs........................................................ 38

4.7 LED Outputs........... ....... ...... ...... ....... ...... ....... ...... ....... ...... ................ 39

4.8 Reset................................................................................................ 39

4.9 Antenna............................................................................................ 40

4.10 RF Power Output Adjustment........................................................... 40

Chapter 5: Warnings, Cautions and Notices . . . . . . . . . . . . . . . . . . . . . . . . . . 41

List of Figures

Figure 1: S251B Reader ................................................................................ 7

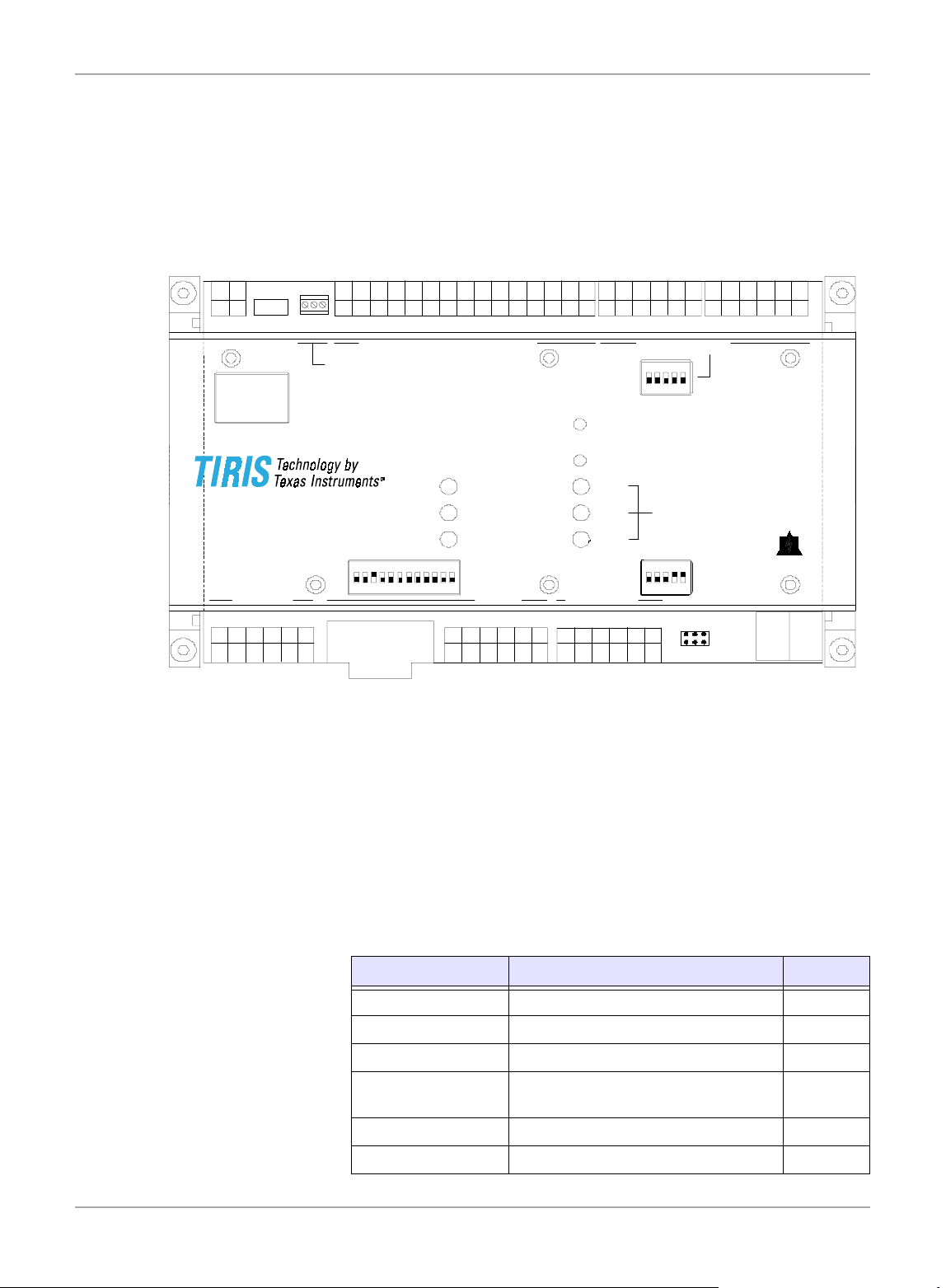

Figure 2: S251B Front Panel (with connector covers removed) .................. 10

Figure 3: S251B Connector Locations ......................................................... 11

Figure 4: CTL Setup Switches ..................................................................... 20

Figure 5: RS422/RS485/DAT Switches ....................................................... 21

Figure 6: Synchronization DIP Switches...................................................... 21

Figure 7: Distance between Antennas (top view)......................................... 28

Figure 8: Switch Settings for RS422 ............................................................ 33

Figure 9: Switch Settings for RS485 ............................................................ 33

Figure 10: Wired & Combined Wireless/Wired Sync. Interface Connection 34

Figure 11: Master/Slave Sync. Interface Connection (without Ack.)............ 35

Figure 12: Master/Slave Synchronization Interface Connection .................. 36

Figure 13: Carrier Phase Synchronisation Interface Connection................. 37

Figure 14: Connecting the LED Outputs ...................................................... 39

Figure 15: RESET Push-button Wiring ........................................................ 39

Page

4

Page 5

April ’00 Preface

List of Tables

Table 1: List of Connectors .......................................................................... 11

Table 2: Power Range Settings ................................................................... 12

Table 3: Supply Connector........................................................................... 12

Table 4: Supply Connector - Specifications ................................................. 13

Table 5: General Purpose Inputs/Outputs.................................................... 13

Table 6: General Purpose Inputs/Outputs - Specifications .......................... 14

Table 7: Synchronization Interface............................................................... 14

Table 8: Synchronization Interface - Specifications ..................................... 14

Table 9: Carrier Phase Synchronization Interface ....................................... 15

Table 10: CPS Interface - Specifications ..................................................... 15

Table 11: Open Collector & I/Os .................................................................. 16

Table 12: Open Collector & I/Os - Specifications......................................... 16

Table 13: RS232 SUB-D Connector ............................................................ 17

Table 14: RS232 WECO Connector ............................................................ 17

Table 15: RS422/RS485 Connector............................................................. 18

Table 16: RS422/RS485 Communications Interface - Specifications.......... 18

Table 17: Indicator Outputs.......................................................................... 19

Table 18: Indicator Outputs - Specifications ................................................ 19

Table 19: Antenna........................................................................................ 19

Table 20: Antenna - Specifications .............................................................. 19

Table 21: CTL Setup DIP Switches.............................................................. 20

Table 22: I/O Setting Switches (6 & 7)......................................................... 20

Table 23: RS422/RS485/DAT Settings DIP Switches.................................. 21

Table 24: Synchronization DIP Switches ..................................................... 21

Table 25: Indicators...................................................................................... 22

Table 26: Mechanical Information................................................................ 22

Table 27: Distances Between Antennas ...................................................... 28

Table 28: RS232 9-pin Connector................................................................ 31

Table 29: RS232 WECO Connector ............................................................ 32

Table 30: RS422/RS485 Connector............................................................. 33

Table 31: Wired and Combined Wireless/Wired Synchronization................ 34

Table 32: Master/Slave Synchronization Without Acknowledgement .......... 35

Table 33: Triggered Synchronization ........................................................... 35

Table 34: Master/Slave Synchronization With Acknowledgement............... 36

Table 35: General Purpose Inputs/Outputs.................................................. 38

Table 36: Antenna Specifications................................................................. 40

Page

5

Page 6

Chapter 1: Introduction

This introduces you to the S251B Reader, what it is and what it does.

Topic Page

1.1 General..........................................................................................................7

1.2 System Description............ ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... .........7

1.3 Product Description.....................................................................................7

1.3.1 Interfaces ...............................................................................................8

1.3.2 Communications Protocols ....................................................................8

CHAPTER 1

Introduction

6

Page 7

April ’00 Chapter 1. Introduction

1.1 General

This document provides information about the S251B Reader. It describes the reader

and how to install it.

1.2 System De scription

A TIRIS system co mprises a reader connected to a control device (us ually a host

computer) via an RS2 32, or an RS422/RS485 interface, an antenna and a transponder. It is used for wireless identification of TIRIS LF transponders.

The reader sends a 134.2 kHz power pulse to a transponder, the energy of the generated magnetic field is stored in the capacitor in the transponder and when the power pulse has finished the transponder immediately sends its data back to the reader.

1.3 Product Description

The Reader is an integral part of a TIRIS system, it provides all of the RF and control

functions required to communicate with TIRIS LF transponders.

The main task of the Reader is to send a power pulse via the antenna to initialize the

transponder, to demodulate the received identification signal and then send the data

to a control device. It is also used to send programming data to Read/Write and Multipage transponders.

The Reader is housed in an IP20 Polycarbonate box as shown Figure 1.

Figure 1: S251B Reader

If connected via an RS232 or an RS422 /RS485 inter face the comp uter send s commands to the reader using one of the two protocols used by the system (ASCII or TIRIS Bus Protocol), and the reader then communicates via its antenna with any

transponders within tha t antenna’s range . The antenna can be mou nted up to 5 m

(depending on the antenna) away from the reader.

7

Page 8

S2510 Reader - Reference Guide April ’00

1.3.1 Interfaces

The reader has the following connections/interfaces:

• Communications interface: RS232, RS422 or RS485 (F & G)

• 8 general purpose I/O lines (B)

• 2 Open Collector outputs (E)

• Synchronization bus (C)

• Carrier Phase Synchronization bus (D)

• Power connector (A)

• Indicator outputs connector (H)

• Antenna connector (I)

1.3.2 Communications Protocols

There are two protocols that can be used with the S251B Reader, they are:

ASCII Protocol.

TIRIS Bus Protocol.

If you are using on e r ea der p er c ontr ol ling dev i ce yo u m ay ch oose the protocol that

best suits your requirements. However, if you have more than one reader connected

to a bus running under a contr ol ling dev i ce then yo u mus t us e the T IRIS Bus Pr otocol.

For details regarding th ese communicatio ns protocols, please refer to the relevant

manual (11-06-21-037 for the ASCII Proto col, 11-06-21- 053 for the TBP) , available

at the TIRIS home page:

This is a simple protocol that you can use to send ASCII character commands to the reader. It is possible to use a standard terminal emulator program to send ASCII commands. The ASCII

protocol can only be used with RS232 or RS422.

This is a bina ry protocol suitable for c ommunication between a controllin g device (for example: a PC) a nd one or mor e

readers. For exampl e with a sing le reader u sing an RS23 2 interface or up to 31 readers using RS422/485. The TIRIS Bus protocol

can be used with RS232 or RS422/485.

http://www.tiris.com

8

Page 9

Chapter 2:Hardware

This chapter describes the hardware of the S251B Reader. It tells you which modules

together comprise the reader. It also describes the front panel (switches connections

etc.) and specifies the electrical inputs and outputs.

Topic Page

2.1 General........................................................................................................10

2.2 Product Description...................................................................................10

2.3 Mechanical Information.............................................................................22

CHAPTER 2

Hardware

2.2.1 Connectors...........................................................................................11

2.2.1.1 A - Supply Connector..................................................................12

2.2.1.2 B - General Purpose Inputs/Outputs...........................................13

2.2.1.3 C - Synchronization Interface .....................................................14

2.2.1.4 D - Carrier Phase Synchronization Interface ..............................15

2.2.1.5 E - Open Collector & I/Os...........................................................16

2.2.1.6 F1 & F2 - RS232 Communication Interface................................17

2.2.1.7 G - RS422/RS485 Communications Interface............................18

2.2.1.8 H - Indicator Outputs...................................................................19

2.2.1.9 I - Antenna Connector.................................................................19

2.2.2 Switches...............................................................................................20

2.2.3 Indicators..............................................................................................22

2.2.4 Potentiometers.....................................................................................22

2.2.4.1 RF Power Adjustment.................................................................22

2.2.4.2 EMI / Sync. Level Adjustment.....................................................22

9

Page 10

S2510 Reader - Reference Guide April ’00

2.1 General

This chapter describes the hardware comprising the S251B Reader and provides the

electrical specifications.

2.2 Product Description

The S251B Reader is contained in a IP20 polycarbonate box that enables easy integration into standard racks and cabinets.

The reader is shown in Figure 1 and the front panel is shown in Figure 2.

Figure 2: S251B Front Panel (with connector covers removed)

The reader comprises two mod ules assemb led toget her in a hou sing. The modules

are:

Control Module

Radio Frequency Module

which contains all th e cir cu itry requi r ed to co mmu ni cat e v ia th e

interface to the computer and external de vices, to provide synchronization, and to control the RFM. It includes a

Tuning

nance.

RIS reading unit that a re nee ded to initia lize a TIRIS transpon der

and to detect its return signal.

(DAT) function to autom aticall y tune th e antenn a to reso-

(RFM) which contains all the analog functions of a TI-

10

Dynamic Auto

Page 11

April ’00 Chapter 2. Hardware

2.2.1 Connectors

There are 10 connectors on the S251B, 7 WECO connectors, the antenna connector,

a 9-pin sub-D RS232 connector, a 6-pin connector for the indicator outputs and a 2pin connector for the anten na. The function of e ach pin on each con nector (except

the RS232 sub-D connector) is described in the following paragraphs. Their location

is shown in Figure 3.

Figure 3

A

12

+ -

Power Fuse

123

On

Reader S251B

O.C. - I/O

16

E F1 H

In order to gain access to the fuse and co nnec to r J you mu st fi rst re mov e the upper

two screws holding the front panel on, remove the plastic cover strip and then replace

the two screws. To gain access to the connectors H and I you must first remove the

lower two screws holding the front panel on, remove the plastic cover strip and then

replace the two screws.

:

S251B Connector Locations

J

1

General Purpose Inpu t / Ou tp u t

Power Range Setting

CTL Setup

On On

1 1

B

EMI

TX Active

Read O.K.

RS232

16

F2

15

16

Synchronization

On

1

RF Power Output Adj.

EMI / Sync. Level Adj.

L

!

O.K.

L

RS422 / 485

16

Antenna

Tuning

"

16

RS422

RS485

DAT

G

C

D

Antenna

1

I

2

The pins are not individually numbered on the connectors themselves (just on Figure

3 for your convenience).

The connectors are all marked on Figure 3 with a letter (from A to I) and are listed in

Table 1 which also shows the section that describes them

Table 1: List of Connectors

Identifying Letter Function Section

A Supply Connector 2.2.1.1

B General Purpose Inputs/Outputs 2.2.1.2

C Synchronization Interface 2.2.1.3

D

Carrier Phase Synchronization

Interface

2.2.1.4

E Open Collector Inputs/Output s 2.2.1.5

F1 RS232 Connector (9-pin SEB-D) 2.2.1.6

11

Page 12

S2510 Reader - Reference Guide April ’00

Table 1: List of Connectors

Identifying Letter Function Section

F2 RS232 Connector 2.2.1.6

G RS422/RS485 Connector 2.2.1.7

H Indicator Outputs 2.2.1.8

I Antenna Connector 2.2.1.9

2.2.1.1 A - Supply Connector

The Reader requires a single DC supply voltage (10 to 24 V) through a 2-pin connector marked with + for positive and – for negative

The Power Range Setting wired jumpers (marked J in Figure 3) and the actual power

supply have a dir ect consequence on the operating temperature of the reader as

shown in Table 2.

Table 2: Power Range Settings

Setting Input Power Operating Temperature Range

Pins 1 + 2 connected 10 - 15 V -20º to +70º C

“ 15 - 24 V

Pins 2 + 3 connected 18 - 24 V -20º to +70º C

(max. I_VSP = 0.9 A

-20º to +70º C

see caution 1).

peak

CAUTION:

1. In order to operate the reader over t he full temperature range

with pins 1 + 2 connected (15 to 24 V), the maximum current

consumption must not exceed 0.9 A

. Exceeding this

peak

value could result in unreliable functio ning of the dynamic

auto tuning, or sharp limitation of the transmitter output

power because of internal protection. If either of these should

occur, switch the device off and allow it time to recover; and

then when it is switched on again it will revert t o normal operation. Note that if either of these occur it is an indication that

the reader is not being operated within its specifications.

2. The reader itself generates heat, t herefore if it is incor porated

into a housing you must ensure (by proper design and/or

cooling) that the temperature immediately surrounding the

reader does not exceed the operating temperature range.

1..

Table 3: Supply Connector

Pin Signal Description Direction

1 + Positive supply input

2 - Ground input

12

Page 13

April ’00 Chapter 2. Hardware

Table 4: Supply Connector - Specifications

Parameter Minimum Maximum

Logic Supply Voltage VSL 10 V 24 V

Logic Supply current ISL - 2.5 A

2.2.1.2 B - General Purpose Inputs/Outputs

The Reader has ei ght general purpose TTL-Level Inputs/O utputs. By m eans of th e

configuration set-up, they can be set in groups of four to be Input or Output. Furthermore, there is a reset connection and a 5 V regulated output.

The pin assignment is given in Table 5 and their specifications are given in Table 6.

Table 5: General Purpose Inputs/Outputs

Pin Signal Description Direction

1 GP IO 7 General Purpose I/O 7 Input/Output

2 GP IO 6 General Purpose I/O 6 Input/Output

3 GP IO 5 General Purpose I/O 5 Input/Output

4 GP IO 4 General Purpose I/O 4 Input/Output

5 GP IO 3 General Purpose I/O 3 Input/Output

6 GP IO 2 General Purpose I/O 2 Input/Output

7 GP IO 1 General Purpose I/O 1 Input/Output

8 GP IO 0 General Purpose I/O 0 Input/Output

9 - not connected 10 IN1 Input 1 Input

11 IN0 Input 0 Input

12 RESET- Reset Input

13 VCC

14 GND Signal Ground 15 GND Signal Ground -

Regulated 5 Volt dc Supply

(see note)

Output

CAUTION:

Do not connect any power supply to pin 13 as it would

damage the reader .

The total consumption of the two VCC outputs (General

Purpose Inputs/Outputs pin 13 together with Open Collector & I/Os - pin 1) must not exceed 500 mA.

13

Page 14

S2510 Reader - Reference Guide April ’00

Table 6: General Purpose Inputs/Outputs - Specifications

Parameter Minimum Maximum

GP IO Output Voltage @ 6 mA

Low level

High level

-

3.15 V

0.9 V

5.25 V

2.2.1.3 C - Synchronization Interface

The synchronization in terface is used to establish h ard wired synchronization with

other readers through a single or double pair of wires. Its pin assignment is given in

Table 7 and its specifications are given in Table 8.

Table 7: Synchronization Interface

Pin Signal Description Direction

1 Sync Rx+ RS422/RS4 85 non-inverted synchronization data Input

2 Sync Rx- RS422/RS485 inverted synchronization data Input

3 GND Signal ground 4 Sync Tx+ RS422/RS485 non-inverted synchronization data Output

General Purpose IO Output Current

Low level

High level

GP IO 1 to 4 total Output Current 10 mA

GP IO 5 to 8 total Output Current 10 mA

Regulated 5 V Output Current 100 mA

-

-

25 mA

16 mA

5 Sync Tx- RS422/RS485 inverted synchronization data Output

6 GND Signal ground -

Table 8: Synchronization Interface - Specifications

Parameter Specification

Mode of Operation Differential

Number of Drivers On Line 32

Number of Receivers On Line 32

Maximum Cable Length 1200 m

Maximum Data Rate 10 Mbits/s

Maximum Common Mode Voltage +12 V / -7 V

Driver Voltage

Driver Load 60 mA

Driver Output Short Circuit Limit

High > +1.5 V

Low < -1.5 V

150mA to GND

250mA to VCC

14

Page 15

April ’00 Chapter 2. Hardware

Table 8: Synchronization Interface - Specifications

Parameter Specification

2.2.1.4 D - Carrier Phase Synchronization Interface

The carrier phase sy nchronization interfac e is used to establish hard wired carrier

phase synchronizati on with other readers throu gh a single pair of wires. Its pi n assignment is given in Table 9 and its specifications are given in Table 10.

Table 9: Carrier Phase Synchronization Interface

Pin Signal Description Direction

1 Sync Rx+ RS422/RS4 85 non-inverted synchronization data Input

2 S ync Rx- RS422/RS485 inverted synchronization data Input

3 GND Signal ground 4 Sync Tx+ RS422/RS485 non-inverted synchronization data Output

5 Sync Tx- RS422/RS485 inverted synchronization data Output

6 GND Signal ground -

Receiver Input 12 k

Receiver Sensitivity ±200 mV

Receiver Hysteresis 60 mV

Ω

Table 10: CPS Interface - Specifications

Parameter Specification

Mode of Operation Differential

Number of Drivers On Line 32

Number of Receivers On Line 32

Maximum Cable Length 1200 m

Maximum Data Rate 10 Mbits/s

Maximum Common Mode Voltage +12 V / -7 V

Driver Voltage

Driver Load 60 mA

Driver Output Short Circuit Limit

Receiver Input 12 k

Receiver Sensitivity ±200 mV

Receiver Hysteresis 60 mV

High > +1.5 V

Low < -1.5 V

150mA to GND

250mA to VCC

Ω

15

Page 16

S2510 Reader - Reference Guide April ’00

2.2.1.5 E - Open Collector & I/Os

This connector provid e two open collecto r connec tions to and from th e reader, plus

the RXSS output (used to set the local noise level), another 5 V regulated output and

an interrupt input. Its pin assignment i s given in Table 1 1 and its specifi cations are

given in Table 12.

Table 11: Open Collector & I/Os

Pin Signal Description Direction

1 VCC Regulated 5 Volt dc Supply (see note 1 below) Output

2 OC1 Open collector 1 Output

3 OC0 Open collector 0 Output

4 GND Signal ground 5 INT0 Interr upt 0 (see not e 2 below:) Inp ut

6 RXSS- RXSS Output

Notes:

1. The total consumption of the two VCC outputs (Open Collector & I/

Os - pin 1 together with General Purpose Inputs/Outputs pin 13)

must not exceed 500 mA.

2. This function is not used or supported by TIRIS standard firmware.

It can however be used, if required, by customers who are providing their own software.

Table 12: Open Collector & I/Os - Specifications

Parameter Minimum Maximum

Open Collector Voltage to GND 1.3 V 80 V

Open Collector Current 500 mA

Regulated 5 V Output 4.75 V 5.25 V

Interrupt Input 4.75 V 5.25 V

RXSS - 5.25 V

16

Page 17

April ’00 Chapter 2. Hardware

2.2.1.6 F1 & F2 - RS232 Communication Interface

Depending on the DIP-Switch configuration, the Reader will either communicate via

the RS232, RS422 or RS485 interface.

There are two interface connectors either of which can be used for an RS232C connection. They ar e: a sta nda rd RS 232 In ter fac e 9-pi n S UB -D ma le c onne ct or (F 1 o n

Figure 3) and a 6-pin WEC O connector (F2 on Figur e 3). Both of th ese conne ctors

allow communicatio n between th e reader and a cont rolling dev ice. The pin assignment for the SUB-D conn ector is given in T able 13 and the pin assignment for the

WECO connector is given in Table 14.

Both, the ASCII and TIRIS Bus protocol can be used with the RS232 interface.

Table 13: RS232 SUB-D Connector

Pin Signal Description Direction

1 - Not connected 2 TxD Transmit Data Output

3 RxD Receive Data Input

4 DTR Data Terminal Ready Input

5 GND Signal Ground 6 DSR Data Set Ready Output

7 - Not connected 8 - Not connected 9 - Not connected -

Table 14: RS232 WECO Connector

Pin Signal Description Direction

1 RxD Receive Data Input

2 DTR Data Terminal Ready Input

3 GND Signal Ground 4 TxD Transmit Data Output

5 DSR Data Set Ready Output

6 GND Signal Ground -

All interface parameter s are acc ordi ng to the RS2 32 s pec if ic ation and are not given

in detail in this manual . The DTR a nd DSR line s are curre ntly not us ed for any purpose.

17

Page 18

S2510 Reader - Reference Guide April ’00

2.2.1.7 G - RS422/RS485 Communications Interface

Depending on the DIP-Switch configuration, th e Reader will communicate via the

RS232, RS422 or RS485 interf ace. RS422/4 85 conne ct ions are mad e via the 6-pi n

WECO connector (G in Figure 3). Its pin assignment is given in Table 15 and its specifications are given in Table 16.

Both, the ASCII and TIRIS Bus Protocol can be used with the RS422 interface.

The ASCII protocol (or any other full-duplex protocol) cannot be used with the RS485

interface.

Table 15: RS422/RS485 Connector

Pin Signal Description

1Rx+/Tx+

2 Rx-/Tx-

3 GND Signal Ground - -

4Tx+

5 Tx- RS422 inverted data

6 GND Signal Ground - -

RS422/RS485 non-

inverted data

RS422/RS485

inverted data

RS422 non-inverted

data

Direction

RS422

Input Input/Output

Input Input/Output

Output/High

Impedance

Output/High

Impedance

Table 16: RS422/RS485 Communications Interface - Specifications

Parameter Specification

Mode of Operation Differential

Number of Drivers On Line 32

Number of Receivers On Line 32

Direction

RS485

-

-

Maximum Cable Length 1200 m

Maximum Data Rate 10 Mbits/s

Maximum Common Mode Voltage +12 V / -7 V

Driver Vo ltage

Driver Load 60 mA

Driver Output Short Circuit Limit

Receiver Input 12 k

Receiver Sensitivity ±200 mV

Receiver Hysteresis 60 mV

High > +1.5 V

Low < -1.5 V

150mA to GND

250mA to VCC

Ω

18

Page 19

April ’00 Chapter 2. Hardware

2.2.1.8 H - Indicator Outputs

This connector (H in Figure 3) is a 2 x 3-pin (double row) pin header connection which

provides the LED output signals. Its pin assignment is given in Table 17 and its specifications are given in Table 18.

Table 17: Indicator Outputs

Pin Signal Description Direction

1 ACTIVE Open collector output: RF Module transmitter signal Output

2

3 O.K. Open collector output: O.K. signal Output

4

5 RXSA

6 GND Signal ground -

Table 18: Indicator Outputs - Specifications

Maximum voltage at current limiti ng 270 Ω resistor - 5 V

2.2.1.9 I - Antenna Connector

The antenna must be connected to the reader via the antenna terminals. The pin assignment for the antenna connector is given in Table 19. If a custom designed antenna is used, it must be within the specifications defined in Table 20 in order to ensure

that the dynamic autotuning facility functions correctly.

V

R270

V

R270

Receiver signal strength output voltage (RXSA) 0.7 V 1.7 V

Current limited output: (270 Ω in series to VCC) Output

Current limited output (270 Ω in series to VCC) Output

Receiver signal strength adjust output to monitor the

receiver signal strength threshold level

Parameter Minimum Maximum

Open Collector (voltage ) - 10 V

Open Collector (current) - 80 mA

Output

Table 19: Antenna

Pin Signal Description

1 ANT Tx/Rx antenna

2 ANT Tx/Rx antenna

Table 20: Antenna - Specifications

Parameter Minimum Maximum

Antenna Resonance Voltage - 380 Vpeak

Antenna Inductance 26.0 µH 27.9 µH

Antenna Q-factor 40 350

19

Page 20

S2510 Reader - Reference Guide April ’00

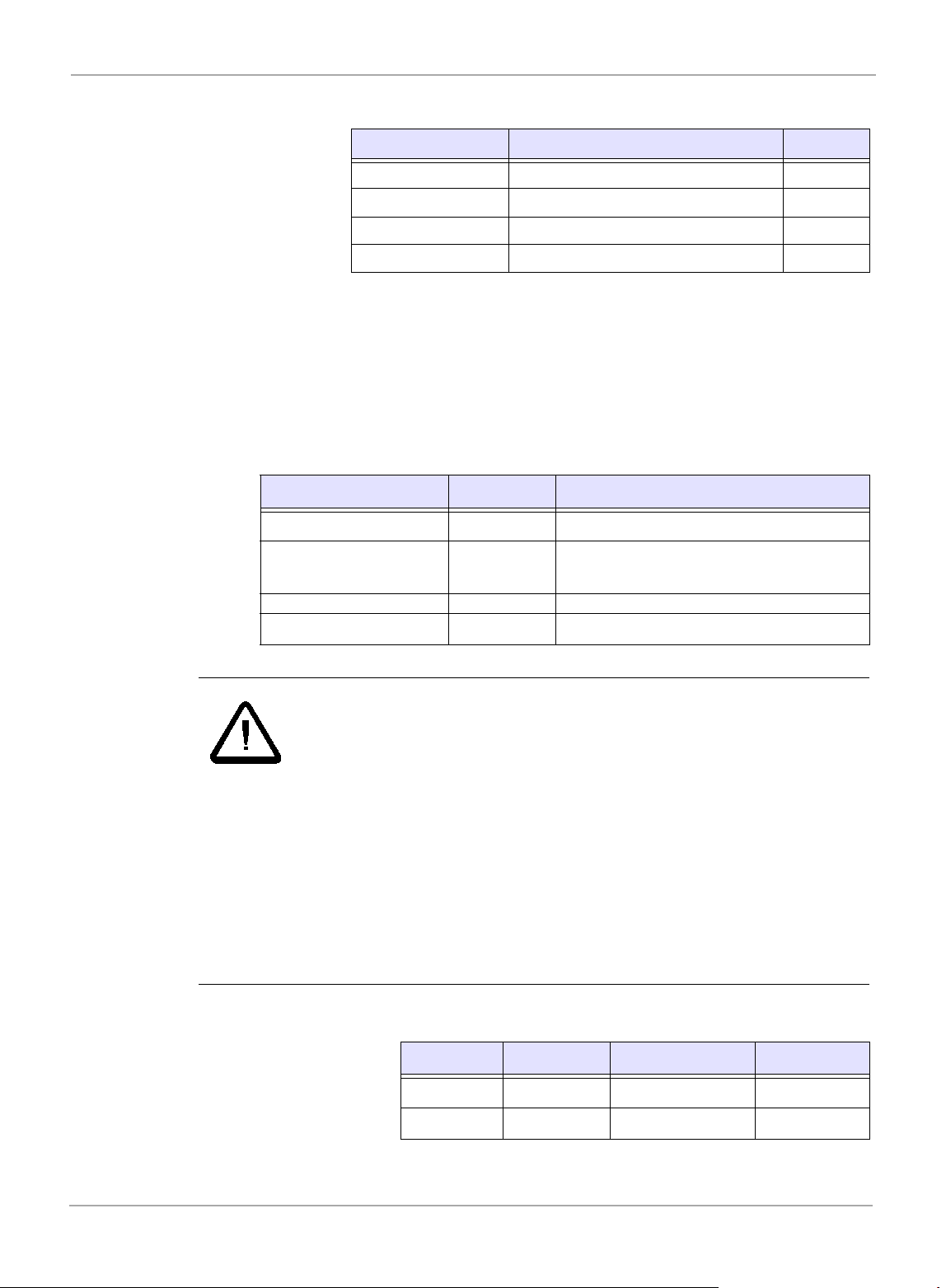

2.2.2 Switches

There are three banks of DIP swi tc hes on the S 251 B Rea der , on e is for the Control

Module set-up (12 switches), one is for the RS422/RS485/DAT settings (5 switches),

and the third one is for the synchronization settings (5 switches). The Control Module

set-up switches are l isted in Ta ble 21, the R S422/RS485 /DAT settin gs are lis ted in

Table 23, and the synchronization settings switches are listed in Table 24. The ON

position and switch 1 are always shown in the switch bank, the switch is on when the

switch is set to the up position.

Figure 4: CTL Setup Switches

ON

1

Table 21: CTL Setup DIP Switches

Switch OFF ON

1 RAM - VCC -

2

3 Reserved for Software Development

4

5 PSEN Reserved for Software Development

6 See Table 22

7 See Table 22

8 TIRIS Standard Configuration Customer Specific Configuration

9 Reserved

10 Reserved

11 TXCT-ON *

12 Not Connected

Chip Select ROM for TIRIS

Standard Firmware

Chip Select RAM for TIRIS Standard

Firmware

Reserved for Software Development

Chip Select RAM for TIRIS Standard

Firmware

Reserved for Software Development

* When this swi tch (1 1) is swi tched either f rom O N-to -OFF o r from OFF-to-

ON the reader’s transmitter is activated for 10 seconds.

Table 22: I/O Setting Switches (6 & 7)

SW6 SW7 Comment

OFF OFF No effect

ON ON/OFF Reset reader by switching RS232 DTR line

OFF ON Can be used by customer firmware for hardware handshake

20

Page 21

April ’00 Chapter 2. Hardware

Figure 5: RS422/RS485/DAT Switches

ON

1

Table 23: RS422/RS485/DAT Settings DIP Switches

Switch OFF ON

1 RS422 RS485

2 RS422 RS485

3-

4 DAT Disabled DAT Enabled

5 DAT LEDs Disabled DAT LEDs Enabled

RS422/RS485 Rx+/Rx-

line-to-line termination (120 Ω)

Notes:

SW1 and SW2 must always be in the same position as each other,

either both OFF or both ON.

Figure 6: Synchronization DIP Switches

ON

1

Table 24: Synchronization DIP Switches

Switch OFF ON

1 - Synchronization Rx+ line pull-up (180 Ω)

2 - Synchronization Rx- line pull-down (180 Ω)

3-

4 Set the RFM to Master Set the RFM to Slave in CPS Bus

5 - CPS line-to-line termination (120 Ω)

RS422/RS485 Rx+/Rx- line-to-line

termination (120 Ω)

21

Page 22

S2510 Reader - Reference Guide April ’00

2.2.3 Indicators

There are six LEDs on the front panel of the reader they are described in Table 25

Table 25: Indicators

Indicator Description

TX Active Indicates activation of the RF transmitter

Read O.K. Indicates a response from a valid transponder

Antenna

Tuning

The TX Active and Re ad O.K. L ED lines are a lso made avail able for external use if

required, details are given in section 4.7.

2.2.4 Potentiometers

There are two pote ntiometers that c an be adjusted t hrough the reader front panel,

they are: the RF Power Output ad justment potentiometer (2.2.4.1) and the EMI /

Sync. Level adjustment potentiometer (2.2.4.2).

2.2.4.1 RF Power Adjustment

EMI Indicates the presence of Electro Magnetic interference

L

O.K. The DAT has tuned the antenna to maximum resonance voltage

L

Antenna out of tune, inductance too high

↑

Antenna out of tune, inductance too low

↓

.

The potentiometer ca n be us ed to adj us t the int er nal os ci ll ato r puls e width and thus

the generated antenna voltage/field strength. Turning th e potentiometer clockwise

causes the field strength to be increased.

2.2.4.2 EMI / Sync. Level Adjustment

This potentiometer allows the receiver signal strength threshold level to be adjusted

for wireless synchronization. Turning the potentiometer clockwise results in maximum sensitivity.

There is one fuse on the S251B that is: 2A Slow-blow. If the fuse should blow, replace

it with the replacement fuse supplied with your reader.

2.3 Mechanical Information

The mechanical dimensions and weight are given in Table 26.

Table 26: Mechanical Information

Parameter Value

Height 120 mm

Width 120 mm

Length 200mm

22

Weight 900 g

Page 23

Chapter 3:Synchronization

If you are using more than one re ader in an ap plicat ion, it may mean th at you need

to synchronize their operation so that they do not interfere with each other. This

chapter describes the various synchronization options.

Topic Page

3.1 Introduction................................................................................................24

3.2 Types of Synchronization .........................................................................24

3.2.1 No Synchronization...................................... ....... ...... ....... ...... ....... ...... .24

3.2.2 Wireless Synchronization.....................................................................25

3.2.3 Wired Synchronization ..................................................... ...... ....... ...... .2 5

3.2.4 Combined Wireless/Wired Synchronization.........................................25

3.2.5 Master/Slave Synchronization..............................................................26

3.2.5.1 M/S Synchronization without Acknowledgement........................26

3.2.5.2 M/S Synchronization with Acknowledgement.............................26

3.2.5.3 Triggered Synchronization..........................................................27

3.2.6 Carrier Phase Synchronizati on ............................................................2 7

CHAPTER 3

Synchronization

23

Page 24

S2510 Reader - Reference Guide April ’00

3.1 Introduction

Where multiple readers are operating in the same area, it is necessary to coordinate

the activities of those readers to avoid mutual interference. This is known as synchronization. Synchroniz ation in this context m eans that the reade rs in your applic ation

are controlled in such a way that they do not interfere with each other.

There are several typ es of synchr onizati on that can be use d dependi ng on the situation in a particular application, for example: the type of transponder, the type of operation performe d on that transponder ( Charge-only read, General read, Program

page, Lock page), th e size of the an tennas and the s peed of the tr ansponder. The

different kinds of sy nchronizatio n are describe d in section 3.2 . How to actually setup your system to u se th e sy nc hr on iz at i on yo u’ ve chosen is describe d to ge th er wit h

the other installation procedures in Chapter 5.

The distance that readers’ antennas have to be separated before the need for some

method of synchr oni za tio n i s r equ ir ed, v arie s with l ocal c ond iti ons , for i n addi ti on to

purely airborne (radiated) interference, signals can travel from one reader to another

via metal structures (conducted). Metal structures can include the frames of metal

buildings, reinforcing bars in concrete floors and power or data cables.

3.2 Types of Synchronization

The S251B Reader can be configured to synchronize in a number of different ways:

No Synchronization (3.2.1)

Wireless Synchronizati on (3. 2.2)

Wired (3.2.3)

Combined Wireless/Wired (3.2.4)

Master/Slave Synchronization (3.2.5)

Carrier Phase Synchronization (3.2.6)

3.2.1 No Synchronization

This option is only us ed in conjunction w ith Software synchro nization, or if th ere is

only a single reader. No sync. and Master/Slave sync without acknowledgement are

the fastest methods of reading transponders.

If all readers are connected by the same RS485 data netwo rk, coordination of the

readers can be controlled directly by the Host Computer. For example, the Host

Computer may issue a Broadcast command for all readers to simultaneously perform

a read cycle and buffer the result. Another technique possible using the data network

is to issue individual commands to each reader in turn. This technique is used when

writing data to Multipag e Transponders (MPTs). Where a PLC has a num ber of

point-to-point connec tions to readers, it is also possible to coo rdinate the activities

via the ladder logic. With Software synchronization all readers will be simultaneously

transmitting or, each reader individually operating. In both cases the readers can be

configured to have No Synchroniz ation.

24

Page 25

April ’00 Chapter 3. Synchronization

3.2.2 Wireless Synchronization

Wireless synchroni zation can be used to control the coordination of readers, with

standard antennas, pr ovided the electrical noise in the env ironment is low for the

type of antenna in use and the noise levels are constant.

Wireless synchronization is only valid for charge-only reading of transponders.

During operation, when the reader detects noise above the adjusted background lev-

el it assumes that it is another re ader and “backs-off” for a set per iod before commencing its own cycle. Wireless synchronized readers can read together or

alternately.

Advantages:

1. There are no wires to run.

2. All readers are autonomous (no Master unit).

3. Enables Hand held readers to co-exist with fixed units (using wireless synchronization).

Disadvantages:

1. I n noisy environmen ts, there is too m uch sensitivity wi th larger antennas

(G04 and larger custo m antennas) to allow accurat e setting of the background levels.

2. It is not suitable for operations other than Charge-only read.

3. It cannot be used when other readers are writing information to transponders.

4. Whe re the environmenta l conditions change, for ex ample: a ground loop

antenna’s char acteristics are ch anged by a vehicle over it , the synch ronization adjustment could be wrong.

3.2.3 Wired Synchronization

Wired Synchroniz ation works in th e sam e way as wir eles s sync hroniz ation with th e

exception that the reader obtains its information about the presence of another reader through a hard wired connection and not via the antenna.

Advantages:

1. It is a Peer-to-Peer network and does not need a Master unit.

2. It use a single twisted pair cable.

Disadvantages:

1. It is only suitable for charge-only reading of transponders.

2. It cannot be used when other readers are writing information to transponders.

3. If the power fails at any of the readers the bus fails.

3.2.4 Combined Wireless/Wired Synchronization

When this option is selected, groups of reader connected by the wired synchronization cabling can sync hroniz e with other grou ps of wire d synchro nizati on re aders, or

with individual readers, by using wireless synchronization.

The advantages an d disadvantag es of both wire less and wired synchronizat ion as

given above still apply.

25

Page 26

S2510 Reader - Reference Guide April ’00

3.2.5 Master/Slave Synchronization

Master/Slave Synchronization is probably the most commonly used form of synchronization. One reader is configured to be the

the other readers, which are configured as

There are three variants:

Master/Slave Synchronization without Acknowledgement,

Master/Slave Synchronization with Acknowledgement

Triggered Synchronization.

3.2.5.1 M/S Synchronization without Acknowledgement.

This method of synchro nization is the fastest me thod of reading transpond ers and

was originally deve loped for readi ng tagged veh icles at speed . It assumes that all

readers are on the same synchroni zatio n bus and the read ers would no t, for example, recognise a handhel d reader th at is tryin g (probab ly uns uccess fully) to perform

a reading.

Advantages:

1. Uses a singl e twis ted pair ca ble .

2. Has the fastest read rate.

3. The Master can be used for Charge-only read or Write/Program.

Master

Slaves

and this reader then controls all

.

Disadvantages:

1. All readers must be on the same synchronization bus.

2. If the Master fails, all units stop.

3. Slave units cannot be individually tested without the Master running.

4. Slaves must perform exactl y the same RF-Task as the Master (read the

same page, write the same data to a transponder).

3.2.5.2 M/S Synchronization with Acknowledgement.

In Master/Slave Synchronization without acknowledgement, if a slave reads a transponder and the master doesn’t, the slave may miss the next pulse while it is processing the reading from that transponde r. In Master/Slave with Acknowledg ement the

Master has to wait until all slaves have completed their current cycle before initiating

the next cycle. This is achieved by using a 4 wire synchronization bus (twin twisted

pair) with the slave transmit lines coupled back to the Master receive lines.

This method has the following advantages over Master/Slave without Acknowledge

1. All units can Write/Program transponders (providing they do it together).

2. They wait for the slowest to complete.

Disadvantages:

1. The cable is a twin twisted pair.

2. The readers cannot be too close if writing is performed, because of the possibility of corr upted data. This re striction also in cludes the paged read of

multipage transpon ders .

26

Page 27

April ’00 Chapter 3. Synchronization

3.2.5.3 Triggered Synchronization

Triggered Synchron izatio n is a Master/Sl ave Sync hroni zation Bus where there i s just

a pulse signal. All readers are configured as masters, but it is only one unit or a trigger pulse source that issues the synchronization pulse at suitable intervals for the required operations on the transponder.

The more complex version of this is known as a Timing Bus, when different time windows are defined for different o perations to be carried out, for example: If m ultiple

readers are require d to read addressed pages of Mul tipage transponders, then to

write data back to the transponders, the timing bus would start a read window lasting

90 ms then initiate a time window of 320 ms for a write operation. In this way the differing times required for the two operations can be accommodated. At the same time

the readers would be instructed thru the communication interface, about which command to execute durin g each window. Therefore the slaves have to receive their

command before the master.

Advantages:

1. The master unit has total control over the coordination of the connected devices and can allow ‘windows’ for particular operations.

2. Reading and Writing can be accommodated, if there is sufficient separation

to prevent data corruption during the Write process.

Disadvantages:

1. C annot be used for address ing MP transponders if readers are close together as addressing conflicts can arise.

2. Carrier Phase synchronization cannot be used.

3.2.6 Carrier Phase Synchronization

In some applications it is necessary to use several charge-up antennas close to each

other. In these circumstanc e, the magnetic charge-up fie lds generated by different

antennas superimpo se on ea ch othe r a nd m ay ca use a beat effect on the magnetic

charge-up field, due to the slightl y different tra nsmission pha ses of differ ent Power

readers. This ef fect will not occur when t he tran smitt ers o f differen t read ers a re operated from the same oscillator signal.

This is Carrier Ph ase Synch ronization where al l of the re aders in a system use the

same oscillator. Carrier Phase synchronization must be used whenever Gate or Stick

antennas are facing each other and if they are inside the distances D1 or D2 as given

in Table 27 (Figur e 7 shows the places to measure D1 and D2). T his ensur es that

there will not be any “beat effect” between the antennas.

Note:

Remember that putting two antennas close together also changes

antenna inductance, so that the antennas may no longer be tuneable

to resonance.

27

Page 28

S2510 Reader - Reference Guide April ’00

Figure 7: Distance between Antennas (top view)

Table 27: Distances Between Antennas

Antenna type

RI_ANT_S02 <=> RI_ANT_S02 0.8 1.0

RI_ANT_G01 <=> RI_ANT_G01 1.7 1.5

RI_ANT_G02 <=> RI_ANT_G02 1.3 1.0

RI_ANT_G04 <=> RI_ANT_G04 2.0 1.7

Distance D1

[m]

Distance D2

[m]

28

Page 29

Chapter 4:Installation

This chapter provides you with the inform ation that you need to kno w in order to install the reader.

This chapter also describes how to incorporate the various synchronization options.

Topic Page

4.1 Introduction................................................................................................30

4.2 General........................................................................................................30

4.3 Mechanical Mounting.................................................................................30

4.3.1 Power Supply.......................................................................................30

CHAPTER 4

Installation

4.4 Communication..........................................................................................31

4.4.1 Configuration........................................................................................31

4.4.2 RS232 ..................................................................................................31

4.4.2.1 Activation ....................................................................................32

4.4.3 RS422 ..................................................................................................32

4.4.4 RS485 ..................................................................................................33

4.5 Synchronization .........................................................................................34

4.5.1 Software Controlled..............................................................................34

4.5.2 Wireless Synchronization.....................................................................34

4.5.3 Wired and Combined Wireless/Wired Synchronization........................34

4.5.4 Master/Slave (without acknowledgement) & Triggered Synch.............35

4.5.5 Master/Slave (with acknowledgement) ................................................36

4.5.6 Transmitter Carrier Phase Synchronisation (CPS) ..............................37

4.6 General Purpose Input/Outputs................................................................38

4.7 LED Outputs ...............................................................................................39

4.8 Reset ...........................................................................................................39

4.9 Antenna.......................................................................................................40

4.10 RF Power Output Adjustment...................................................................40

4.11 EMI / Sync. Level Adjustment...................................................................40

29

Page 30

S2510 Reader - Reference Guide April ’00

4.1 Introduction

Note:

Always ensure that the reader is switched off when making or breaking connections to it.

4.2 General

The S251B Reader has been des igned with easy in stalla tion in mind . The foll owing

information provides you with any details such as switch settings and so on that you

will need to know.

4.3 Mechanical Mounting

a. If you are mounting the reader on a DIN rail TS35, clip the reader into the bot-

tom of the rail and then snap it into the top.

or

b. If you are mounting the reader onto a wall where there is No vibration, snap in

the four mounting adapters and screw the reader to the wall using M4 screws.

or

c. If you are mounting it onto a wall where it may be subject to vibration, open the

reader, drill thru the marke d mounting ho les and screw the reader to the wal l

using M4 screws and the appropriate washers.

4.3.1 Power Supply

WARNING:

ARE MUST BE TAKEN WHEN HANDLING THE

C

VOLTAGE

HARMFUL TO YOUR HEALTH

DAMAGED THE ANTENNA SHOULD NOT BE CONNECTED TO THE

ACROSS THE ANTENNA TERMINALS COULD BE

THE ANTENNA INSULATION IS

. IF

S251B. HIGH

S251B.

Connect a Regulated dc power supply (betwee n 10 and 24 V pr oviding a min imum

of 2A) to the reader - the polarity of the connection is shown on the front panel of the

reader.

Set the Power Range Setting wire bridge to match your input voltage (see Table 2).

We recommend that you use a linear power s upply. If this is not possi ble and you

wish to use a switched m ode power supply , DO NOT use one that operates below

200 kHz. (switched mode power supplies that operate below 200 kHz. might interfere

with transponder signals and thus reduce the reading range).

30

Page 31

April ’00 Chapter 4. Installation

4.4 Communication

Follow the instruc tions given i n the sectio n that descr ibes the commun ications s etup that you have decided to use in your system: Section 4.4.2 for RS232, Section

4.4.3 for RS422 and Section 4.4.4 for RS485.

4.4.1 Configuration

CTL Setup switch 8 determines the mode of operation of the contr ol module when

power is applied to the con tr ol mod ule . W hen CT L Se tu p sw itch 8 is in the OFF position, standard TIRIS default parameters are used, these are:

- ASCII protocol

- 9600 baud, eight databits, no parity, one stop bit, X

- Normal Mode

- Wireless synchronization

- I/O 0 to 3 defined as input

- I/O 4 to 7 defined as output and logic high

- Hardware interface RS232C

If CTL Setup switch 8 is in the ON p osition, custo mer s pecifi c parame ters are use d

to operate the Control Modul e. These applic ation specific par ameters are stored in

the serial EEPROM on the Control Module.

on/Xoff

enabled

4.4.2 RS232

Note:

The setting of CTL Setup switch 8 is only checked after power on.

You can use the Sof tware Utility Progr am which is availabl e on the internet at our

site:

http://www.tiris.com

to configure your reader.

In order to confi gure the reader for cus tome r s pecifi c pa ra met ers yo u m us t c on nec t

the reader via the RS232 por t (c onn ect or F1 or F2) t o yo ur hos t and get c on nec tio n

using the TIRIS sta ndard paramet ers (with CT L Setup switch 8 is in the OFF position). Change the defau lt p ar ame ters to t he c ustom er s pecifi c param ete rs an d sav e

them. Set CTL Setup switch 8 to the ON position and re set the reader. The rea der

will then work with the customer specific parameters.

Either connect a 9-pin SUB-D female plug to the SUB-D connector, or connect up the

6-pin WECO connector mar ked “RS 23 2” on the rea der ’s front pa nel , the pi n s ignals

are given in Table 28 or Table 29.

Table 28: RS232 9-pin Connector

Pin Signal Description Direction

1 - Not connected 2 TxD Transmit Data Output

3 RxD Receive Data Input

4 DTR Data Terminal Ready Input

31

Page 32

S2510 Reader - Reference Guide April ’00

Table 28: RS232 9-pin Connector

Pin Signal Description Direction

5 GND Signal Ground 6 DSR Data Set Ready Output

7 - Not connected 8 - Not connected 9 - Not connected -

Table 29: RS232 WECO Connector

Pin Signal Description Direction

1 RxD Receive Data Input

2 DTR Data Terminal Ready Input

3 GND Signal Ground 4 TxD Transmit Data Output

4.4.2.1 Activation

4.4.3 RS422

5 DSR Data Set Ready Output

6 GND Signal Ground -

The Data Terminal Ready signal (DTR) is connected to the reset/watchdog circuit of

the S251B Reader. This ensures a PC controlled microcomputer initialization before

the default Read Mode is started.

When power is applied to the reader the Data Set Ready signal (DSR) of the RS232C interface is activated.

Connect the WECO (marked RS422 / 485) connector as shown in Table 30. Set the

switches as sho wn in Figure 8. If you are only using o ne reader the line terminal

switch 3 must be switched to ON, if you are using more than one reader only the last

reader in the line must be switched to ON (all other readers to OFF).

32

Page 33

April ’00 Chapter 4. Installation

Figure 8: Switch Settings for RS422

ON

1

Table 30: RS422/RS485 Connector

4.4.4 RS485

Pin Signal Description

1Rx+/Tx+

2 Rx-/Tx-

3 GND Signal Ground - -

4Tx+

5 Tx- RS422 inverted data

6 GND Signal Ground - -

RS422/RS485 non-

inverted data

RS422/RS485

inverted data

RS422 non-inverted

data

Direction

RS422

Input Input/Output

Input Input/Output

Output/High

Impedance

Output/High

Impedance

Direction

RS485

-

-

Connect the WECO (marked RS422 / 485) connector as shown in Table 30. Set the

switches as sho wn in Figure 9. If you are only using o ne reader the line terminal

switch 3 must be switched to ON, if you are using more than one reader only the last

reader in the line must be switched to ON (all other readers to OFF).

Figure 9: Switch Settings for RS485

ON

1

33

Page 34

S2510 Reader - Reference Guide April ’00

4.5 Synchronization

4.5.1 Software Controlled

There is no special wiring requ ired for this type of synch ronization. Make su re that

you set the software configuration to No Sync. when you are configuring the reader.

4.5.2 Wireless Synchronization

There are no switch or jumper settings for wireless synchronization. Make sure that

you set the software configuration to wir ele ss s yn ch roni za tio n whe n y ou are c onf iguring the reader.

4.5.3 Wired and Combined Wireless/Wired Synchronization

Figure 10 shows in which way the S251B Reader must be connected for a wired and

a combined wireless/wired synchronization. Make sure that you set the software configuration to match when yo u are c onfigu ring the read er. Ta ble 31 expl ains th e setting of the Synchronization DIP switches 1, 2 & 3.

Figure 10: Wired & Combined Wireless/Wired Sync. Interface Connection

Table 31: Wired and Combined Wireless/Wired Synchronization

Line

Termination

Dip Switch

SW1 ON OFF ON

SW2 ON OFF ON

SW3 ON OFF ON (see Note)

UNIT 1: UNIT 2...UNIT n-1: UNIT n:

Note:

If the distance between Unit 1 and Unit n is less than approximately

400 m, DIP switch SW3 can be left OFF.

34

Page 35

April ’00 Chapter 4. Installation

4.5.4 Master/Slave (without acknowledgement) & Triggered Synch.

Figure 11 shows the way that the Readers have to be connected for mast er/slave

synchroniz ati on wi tho ut a ckno wledg men t; a nd t rig gere d sy nchr oniz ati on. Ma ke sur e

that you set the software configuration to Master or Slave (according to Table 32 and

Table 33) acknowledgement) when you are configuring the reader.

Table 32 and Table 33 show the settings of the Line termination DIP switches.

Figure 11

: Master/Slave Sync. Interface Connection (without Ack.)

Table 32: Master/Slave Synchronization Without Acknowledgement

Line Termination

Dip Switch

SW1 ON OFF ON

SW2 ON OFF ON

SW3 OFF OFF ON (see Note)

Unit 1:

(Master)

Unit 2...Unit n-1:

(Slaves)

UNIT n: (Slave)

Note:

If the distance between Unit 1 and Unit n is less than approximately

400 m, DIP switch SW3 can be left OFF.

Table 33: Triggered Synchronization

Line

Termination

Dip Switch

SW1 Termination not required OFF ON

SW2 Termination not required OFF ON

SW3 Termination not required OFF ON (see Note)

UNIT 1:

Trigger Unit

UNIT 2...UNIT n-1:

(Master)

UNIT n: (Master)

35

Page 36

S2510 Reader - Reference Guide April ’00

4.5.5 Master/Slave (with acknowledgement)

Figure 12 shows the way that the Readers have to be connected for mast er/slave

synchronization with acknowledgement. Make sure that you set the software

configuration to Master or Sla ve (according to Table 34) when y ou are configur ing

the reader.

Table 34 shows the setting of DIP switch switches 1, 2 & 3.

Figure 12

:

Master/Slave Synchronization Interface Connection

Table 34: Master/Slave Synchronization With Acknowledgement

Line Termination

Dip Switch

SW1 ON OFF ON

SW2 ON OFF ON

Unit 1: (Master)

Unit 2...Unit n-1:

(Slaves)

UNIT n: (Slave)

SW3 ON OFF ON (see Note)

Note:

If the distance between Unit 1 and Unit n is less than approximately

400 m, DIP switch SW3 can be left OFF.

36

Page 37

April ’00 Chapter 4. Installation

4.5.6 Transmitter Carrier Phase Synchronisation (CPS)

To allow you to overcome the beat effect, the pulse width modulated oscillator signal

is accessible at the CPS connector D. All readers to be driven by one oscillator must

have their CPS connectors connected together as shown in Figure 13.

DIP switch Synchroniz ation-SW4 determines whether the internal oscillator or the

external oscillator signal is used. When the DIP switch Synchronization-SW4 is OFF,

the internal oscillator is used and the reader is referred to as an oscillator MASTER.

When the DIP Switch Syn chronization-SW4 is ON, the external oscillator sign al is

used and the reader is referred to as an oscillator SLAVE.

Note:

Only one oscillator MASTER is allowed per synchronized system.

Figure 13: Carrier Phase Synchronisation Interface Connection

to other

units

Master Slave

If you are using carrier phase synchroni zation you must confi gure your system to

Master/Slave in order to have one common master.

37

Page 38

S2510 Reader - Reference Guide April ’00

4.6 General Purpose Input/Outputs

The S251B Reader has 8 connections that can be defined as either inputs or outputs

(TTL level). These input/outputs must be configured in groups of 4 as shown in Table

35.

Table 35: General Purpose Inputs/Outputs

I/O I/O

0 1 2 3 4 5 6 7

I I I I I I I I

I I I I O O O O

O O O O I I I I

O O O O O O O O

I = Input; O = Output

38

Page 39

April ’00 Chapter 4. Installation

4.7 LED Outputs

The signals used for the indicator LEDs (Read O .K . an d T rans mi tti ng) ar e a va ilabl e

at Indicator Outputs connector (H), they can be used to drive external LEDs or buzzers, they must be connected as shown in Figure 14. Ensure that the values given Table 18 are not exceeded.

Figure 14: Connecting the LED Outputs

4.8 Reset

The S251B Reader provides a connection for an external reset on pin 12 of the General Purpose Input / O utput connector (B). Thi s pin can be used reset the S 251B

Reader externally. You can a pply an external reset to the reader by connecting a

push-button to the connectors as shown in Figure 15.

Figure 15: RESET Push-button Wiring

12

GND

15

RESET-

GENERAL I/O PORT

39

Page 40

S2510 Reader - Reference Guide April ’00

4.9 Antenna

The S251B Reader can be used together with the TIRIS antennas RI-ANT-G01E, RIANT-G02E, RI-ANT-G04E and RI-ANT-S02C. If you wish to use it with your own design antenna that antenna must conform to the specifications given in Table 36.

Note:

The Stick Antenna (RI-ANT-S02C) must only be used together with a

reader supply voltage up to 12 V. If you use this antenna with a higher

reader supply voltage the antenna becomes too warm which effects

the antenna’s Q.

Table 36: Antenna Specifications

Parameter Minimum Maximum

Antenna Resonance Voltage - 380 Vpeak

Antenna Inductance 26.0 µH 27.9 µH

Antenna Q-factor 40 350

The antenna must be connected to the terminals marked Antenna on the S251B.

4.10 RF Power Output Adjustment

Use the RF Power Output Adj. potentiometer to ad just the internal oscilla tor pulse

width and subsequently the anten na output voltag e to conf orm to your loca l regulations. Turning the potentiometer clockwise causes the field strength to increase.

4.1 1 EMI / Sync. Level Adjustment

EMI / Sync. Level Adj. potentiometer to adjust the receiver signal strength threshold

for the wireless synchr onization. Turning the potentiometer clockw ise results in a

maximum sensitivity.

If wireless synchronization is used, it is important that the EMI/Sync level Adj. potentiometer is correct ly adjus ted. This is one of the fin al adj ustmen ts to the reader an d

is done on site in the fin al lo catio n on ce the antenn a has been tu ned an d ALL THE

OTHER READER ARE SWITCHED OFF.

Turning the poten tiometer ad justs the receiver s ignal lev el threshol d and you must

set the reader’s ‘b ase level n oise’ in its final lo catio n, so that an y signal l arger tha n

the base level triggers the synchronization algorithm.

Send a single ‘X ’ ( ex ecu t e c omm and ) to the reader to stop any continuous rea din g,

and then turn the potentiom eter cl oc k wis e until th e yel lo w LED is fully li t. Slowly adjust the potentiometer back until the LED just goes out. Adjustment is then complete.

40

Page 41

Warnings, Cautions and Notices

Chapter 5: Warnings, Cautions and Notices

This chapter provides th e Warnings, Cautions and Notic es that are relevant to the

S251B reader.

Topic Page

5.1 FCC/PTT Regulations ................................................................................42

5.2 Important note to Purchasers/Users of the S251B Reader in the U.S.A.42

5.3 WARNING....................................................................................................42

CHAPTER 5

41

Page 42

S2510 Reader - Reference Guide April ’00

5.1 FCC/PTT Regulations

The TIRIS Reader RF produces emissions at 134.2 kHz. The radiation of the fundamental and the harmonic s will vary with the type of antenna and ot her devices or

functions connected to the Reader.

Prior to operating the S251B Reader together with antenna(s) and power supply, the

required FCC, PTT or relevant government agency approvals must be obtained.Sale, lease or operation in some countries may be subject to prior approval by

the government or other organizations.

5.2 Important note to Purchasers/Users of the S251B Reader in the U.S.A.

The TIRIS Reader is considered by the Federal Communications Commission (FCC)

to be a "subassembly". As such, no prior approval is required to import, sell or otherwise market the Reader in the United States. In order to form a functioning radio frequency (RF) device, the Reader must be connected to a suitable antenna and power

supply. A radio frequency device may not be operated unless authorized by the FCC

nor may a radio frequency device be marketed (i.e. sold, leased, imported, or advertised for sale or lease) without the prior grant of an FCC equipment authorization.

FCC authorization to operate an RF device may take one of two forms: first, the FCC

may grant the user an exper imental lic ense; se cond, the FCC may i ssue an equ ipment authorization pe rmitting use of th e RF device on an unli censed basis. TI ca n

assist the user in obtaining an experimental license that will cover a specific installation of the S251B Reader in a specific site or si tes. Exper imen tal authori zation s are

appropriate to cove r o perat ions during the developm ent o f an R F d ev ice. A grant of

equipment authorizati on (known as "certification") must be obtained from the FCC

before RF devices are marketed or operated on a non development basis.

5.3 WARNING

DEVICES CONSTRUCTED FOR EVALUATION INCORPORATING THIS Reader

SHOULD BE OPERATED ONLY UNDER AN EXPERIMENTAL LICENSE ISSUED

BY THE FCC AND MAY NOT BE MARKETED. BEFORE ANY DE VICE CONTAINING THIS Reader IS MARKETED, AN EQUIPMENT AUTHORIZATION FOR THE

DEVICE MUST BE OBTAINED FROM THE FCC.

Prospective marketer s of devi ce s co ntai ni ng thi s Reader are responsible for obtaining the necessary equipment authorization. Upon request TI can provide assistance

in obtaining FCC approval to market devices incorporating this Reader.

Care must be taken when handling the S251B. High voltage across the antenna terminals could be harmful to your health. If the antenna insulation is damaged the antenna should not be connected to the Reader.

42

Loading...

Loading...