Page 1

Safety Manual for RM57x Hercules ARM Safety MCUs

User's Guide

Literature Number: SPNU575A

May 2014–Revised September 2016

Page 2

Contents

1 Introduction ........................................................................................................................ 8

2 Hercules RM57x Product Overview....................................................................................... 10

2.1 Targeted Applications .................................................................................................. 11

2.2 Product Safety Constraints ............................................................................................ 12

3 Hercules Development Process for Management of Systematic Faults ..................................... 13

3.1 TI Standard MCU Automotive Development Process ............................................................. 14

3.2 TI MCU Automotive Legacy IEC 61508 Development Process.................................................. 15

3.3 Yogitech fRMethodology Development Process ................................................................... 15

3.4 Hercules Enhanced Safety Development Process................................................................. 15

4 Hercules Product Architecture for Management of Random Faults........................................... 18

4.1 Safe Island Philosophy and Architecture Partition to Support Safety Analysis (FMEA/FMEDA) ............ 18

4.2 Identification of Parts/Elements....................................................................................... 19

4.3 Management of Family Variants...................................................................................... 20

4.4 Operating States........................................................................................................ 20

4.5 Management of Errors ................................................................................................. 22

5 System Integrator Recommendations ................................................................................... 23

5.1 System Integrator Activities ........................................................................................... 23

5.2 Hints for Performing Dependent/Common Cause Failure Analysis Including the Hercules MCU ........... 25

5.3 Hints for Improving Independence of Function/Co-Existence of Function When Using the Hercules MCU 25

5.4 Support for System Integrator Activities ............................................................................. 25

6 Brief Description of Elements .............................................................................................. 26

6.1 Power Supply ........................................................................................................... 26

6.2 Power Management Module (PMM) ................................................................................. 26

6.3 Clocks.................................................................................................................... 27

6.4 Reset ..................................................................................................................... 27

6.5 System Control Module................................................................................................ 28

6.6 Error Signaling Module (ESM) ....................................................................................... 29

6.7 CPU Subsystem ........................................................................................................ 29

6.8 Primary Embedded Flash ............................................................................................. 31

6.9 Flash EEPROM Emulation (FEE) .................................................................................... 32

6.10 Primary Embedded SRAM ............................................................................................ 33

6.11 CPU Interconnect Subsystem......................................................................................... 34

6.12 Peripheral Interconnect Subsystem .................................................................................. 35

6.13 Peripheral Central Resource 1 (PCR1).............................................................................. 35

6.14 Peripheral Central Resource 2 (PCR2).............................................................................. 36

6.15 Peripheral Central Resource 3 (PCR3).............................................................................. 36

6.16 EFuse Static Configuration ............................................................................................ 37

6.17 OTP Static Configuration.............................................................................................. 37

6.18 I/O Multiplexing Module (IOMM)...................................................................................... 38

6.19 Vectored Interrupt Module (VIM) ..................................................................................... 38

6.20 Real Time Interrupt (RTI).............................................................................................. 39

2

Table of Contents

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 3

www.ti.com

6.21 Direct Memory Access (DMA) ........................................................................................ 40

6.22 High-End Timer (N2HET), HET Transfer Unit (HTU) .............................................................. 40

6.23 Multi-Buffered Analog-to-Digital Converter (MibADC) ............................................................. 42

6.24 Enhanced Pulse Width Modulators (ePWM)........................................................................ 42

6.25 Enhanced Capture (eCAP)............................................................................................ 43

6.26 Enhanced Quadrature Encoder Pulse (eQEP) ..................................................................... 44

6.27 Multi Buffered Serial Peripheral Interface (MibSPI)................................................................ 45

6.28 Inter-Integrated Circuit (I2C) .......................................................................................... 46

6.29 Serial Communication Interface (SCI) ............................................................................... 46

6.30 Local Interconnect Network (LIN) .................................................................................... 47

6.31 Controller Area Network (DCAN)..................................................................................... 48

6.32 General-Purpose Input/Output (GIO) ................................................................................ 49

6.33 Ethernet.................................................................................................................. 49

6.34 External Memory Interface (EMIF) ................................................................................... 50

6.35 JTAG Debug, Trace, Calibration, and Test Access................................................................ 51

6.36 Cortex-R5F Central Processing Unit (CPU) Debug and Trace................................................... 51

6.37 Data Modification Module (DMM)..................................................................................... 51

6.38 RAM Trace Port Interface (RTP) ..................................................................................... 51

6.39 Parameter Overlay Module (POM)................................................................................... 52

6.40 Error Profiling Controller (EPC)....................................................................................... 52

6.41 Temperature Sensor ................................................................................................... 53

7 Brief Description of Diagnostics........................................................................................... 54

7.1 1oo2 Software Voting Using Secondary Free Running Counter ................................................. 54

7.2 Bit Error Detection ...................................................................................................... 54

7.3 Bit Multiplexing in FEE Memory Array ............................................................................... 54

7.4 Bit Multiplexing in Flash Memory Array.............................................................................. 54

7.5 Bit Multiplexing in Primary SRAM Memory Array................................................................... 54

7.6 Bit Multiplexing in Peripheral SRAM Memory Array................................................................ 54

7.7 CPU Illegal Operation and Instruction Trapping ................................................................... 55

7.8 Logic Built In Self-Test (LBIST) ...................................................................................... 55

7.9 Logic Built In Self-Test (LBIST) Auto-Coverage.................................................................... 56

7.10 CPU Lockstep Compare .............................................................................................. 56

7.11 VIM Lockstep Compare ............................................................................................... 56

7.12 Lockstep Comparator Self-Test....................................................................................... 56

7.13 CPU Online Profiling Using the Performance Monitoring Unit.................................................... 56

7.14 CPU Memory Protection Unit (MPU)................................................................................. 57

7.15 CRC Auto-coverage.................................................................................................... 57

7.16 CRC in Message........................................................................................................ 57

7.17 DCAN Acknowledge Error Detection................................................................................. 57

7.18 DCAN Form Error Detection .......................................................................................... 57

7.19 DCAN Stuff Error Detection........................................................................................... 57

7.20 DCAN Protocol CRC in Message..................................................................................... 57

7.21 Disable the DMM Pin Interface ....................................................................................... 58

7.22 Disable the RTP Pin Interface ........................................................................................ 58

7.23 Dual Clock Comparator (DCC)........................................................................................ 58

7.24 Autoload Self-Test...................................................................................................... 58

7.25 Efuse Autoload Self-Test Auto-Coverage ........................................................................... 58

7.26 EFuse ECC.............................................................................................................. 58

7.27 EFuse ECC Logic Self-Test........................................................................................... 58

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Contents

3

Page 4

www.ti.com

7.28 eQEP Quadrature Watchdog.......................................................................................... 58

7.29 eQEP Software Test of Quadrature Watchdog Functionality ..................................................... 59

7.30 Error Trapping - IOMM................................................................................................. 59

7.31 Error Trapping (including Peripheral Slave Error Trapping) - L2/L3 Interconnect.............................. 59

7.32 Ethernet Alignment Error Detection.................................................................................. 59

7.33 Ethernet Physical Layer Fault ........................................................................................ 59

7.34 External Monitoring of Warm Reset (nRST) ........................................................................ 59

7.35 External Monitoring via ECLK......................................................................................... 59

7.36 External Voltage Supervisor........................................................................................... 60

7.37 External Watchdog ..................................................................................................... 60

7.38 FEE Contents Check by Hardware CRC ............................................................................ 60

7.39 FEE Data ECC.......................................................................................................... 60

7.40 FEE Sector Protection ................................................................................................. 60

7.41 Flash Address and Control Bus Parity............................................................................... 61

7.42 Flash Contents Check by Hardware CRC........................................................................... 61

7.43 Flash ECC ............................................................................................................... 61

7.44 Flash Hard Error Cache and Livelock................................................................................ 61

7.45 Flash Sector Protection ................................................................................................ 62

7.46 Flash Wrapper Address ECC ......................................................................................... 62

7.47 Flash Wrapper Diag Mode 5 Test .................................................................................... 62

7.48 Flash Wrapper Diag Mode 7 Test .................................................................................... 62

7.49 Glitch Filtering on nRST and nPORRST ............................................................................ 62

7.50 Hardware CRC Check of External Memory ......................................................................... 62

7.51 Hardware CRC Check of OTP Contents ............................................................................ 62

7.52 Hardware Disable of JTAG Port ...................................................................................... 62

7.53 Information Redundancy Techniques ................................................................................ 63

7.54 Information Redundancy Techniques - CPU Specific ............................................................. 63

7.55 Information Redundancy Techniques - DCAN Specific............................................................ 63

7.56 Information Redundancy Techniques - DMA Specific ............................................................. 63

7.57 Information Redundancy Techniques - N2HET Specific .......................................................... 63

7.58 Internal Voltage Monitor (VMON) .................................................................................... 64

7.59 Internal Watchdog ...................................................................................................... 64

7.60 IOMM Master ID Filtering.............................................................................................. 64

7.61 LIN Checksum Error Detection ....................................................................................... 64

7.62 LIN No-Response Error Detection.................................................................................... 64

7.63 LIN Physical Bus Error Detection..................................................................................... 65

7.64 LIN / SCI Bit Error Detection .......................................................................................... 65

7.65 LIN / SCI Frame Error Detection ..................................................................................... 65

7.66 LIN / SCI Overrun Error Detection.................................................................................... 65

7.67 Locking Mechanism for Control Registers........................................................................... 65

7.68 Lockout of JTAG Access Using AJSM............................................................................... 65

7.69 Low Power Oscillator Clock Detector (LPOCLKDET).............................................................. 65

7.70 Memory Protection Unit (MPU) for Non-CPU Bus Masters ...................................................... 65

7.71 MibADC Calibration .................................................................................................... 66

7.72 MibADC Information Redundancy Techniques..................................................................... 66

7.73 MibADC Input Self-Test................................................................................................ 66

7.74 MibSPI/SPI Data Length Error Detection............................................................................ 66

7.75 MibSPI/SPI Data Overrun Detection................................................................................. 66

4

Contents

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 5

www.ti.com

7.76 MibSPI/SPI Slave Desync Detection................................................................................. 66

7.77 MibSPI/SPI Slave Timeout Detection................................................................................ 66

7.78 Monitoring by Second N2HET ........................................................................................ 67

7.79 Monitoring by eCAP or N2HET ....................................................................................... 67

7.80 Non-Privileged Bus Master Access .................................................................................. 67

7.81 OTP Autoload ECC..................................................................................................... 67

7.82 Parity in Message....................................................................................................... 67

7.83 Periodic Hardware CRC Check of OTP Contents.................................................................. 67

7.84 PCR Access Management: Protection Mode and MasterID Filtering............................................ 67

7.85 Periodic Hardware CRC Check of SRAM Contents................................................................ 68

7.86 Periodic Software Read Back of Static Configuration Registers ................................................ 68

7.87 Peripheral SRAM Parity................................................................................................ 68

7.88 Peripheral Memory ECC............................................................................................... 68

7.89 PLL Slip Detector ....................................................................................................... 68

7.90 Primary SRAM Address and Control Bus Parity.................................................................... 68

7.91 Primary SRAM Data and ECC Storage in Multiple Physical Banks per Logical Address..................... 69

7.92 Primary SRAM Correctable ECC Profiling .......................................................................... 69

7.93 ECC on Cache RAM ................................................................................................... 69

7.94 Primary SRAM Data ECC ............................................................................................. 69

7.95 Primary SRAM Wrapper Redundant Address Decode ............................................................ 69

7.96 Primary SRAM Hard Error Cache and Livelock .................................................................... 70

7.97 Privileged Mode Access and Multi-Bit Enable Keys for Control Registers...................................... 70

7.98 PBIST Check of Primary or Module SRAM ......................................................................... 70

7.99 PBIST Auto-coverage .................................................................................................. 71

7.100 Power Domain Inactivity Monitor..................................................................................... 71

7.101 PBIST Test of Parity Bit Memory..................................................................................... 71

7.102 PBIST Test of ECC Bit Memory...................................................................................... 71

7.103 Lockstep PSCON....................................................................................................... 71

7.104 Redundant Address Decode Self-Test .............................................................................. 71

7.105 Redundant Temperature Sensors.................................................................................... 71

7.106 Scrubbing of SRAM to Correct Detected Single Bit Errors ....................................................... 71

7.107 Shadow Registers...................................................................................................... 72

7.108 Software Check of Cause of Last Reset ........................................................................... 72

7.109 Software Read Back of CPU Registers ............................................................................. 72

7.110 Software Read Back of Written Configuration...................................................................... 72

7.111 Software Test of DCC Functionality ................................................................................. 72

7.112 Software Test of DWD Functionality................................................................................. 72

7.113 Software Test of DWWD Functionality .............................................................................. 72

7.114 Software Test of ECC Profiler (EPC) ................................................................................ 72

7.115 Software Test of Error Path Reporting .............................................................................. 72

7.116 Software Test of Flash Sector Protection Logic.................................................................... 72

7.117 Software Test of Function Including Error Tests ................................................................... 73

7.118 Software Test of Function Using I/O Loopback .................................................................... 73

7.119 Software Test of Function Using I/O Checking In GIO Mode .................................................... 73

7.120 Software Test of Function Using I/O Loopback in Transceiver/PHY ........................................... 73

7.121 Software Test of Function Using I/O Loopback Including Error Tests - IOMM Only .......................... 73

7.122 Software Test of Hardware CRC..................................................................................... 73

7.123 Software Test of MPU Functionality ................................................................................. 74

7.124 Software Test of Parity Logic ......................................................................................... 74

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Contents

5

Page 6

www.ti.com

7.125 Software Test of PBIST ............................................................................................... 74

7.126 Software Test of SRAM Wrapper Address Decode Diagnostic and ECC ...................................... 74

7.127 Software Test for Reset ............................................................................................... 74

7.128 Software Warm Reset Generation................................................................................... 74

7.129 Transmission Redundancy............................................................................................ 74

7.130 Use of CoreSight Debug Logic Key Enable Scheme.............................................................. 74

7.131 Use of DCC as Program Sequence Watchdog..................................................................... 74

7.132 Use of MPUs to Block Access to Memory Mapped Debug....................................................... 75

7.133 Execution of Interconnect Self-Test.................................................................................. 75

7.134 CPU Interconnect Hardware Checker............................................................................... 75

7.135 Timeout Monitoring on The Bus Transaction ....................................................................... 75

7.136 Transaction ECC (Data Lines) ....................................................................................... 75

7.137 Transaction Parity (Address and Control Lines) ................................................................... 76

7.138 Peripheral Interconnect New Memory Protection Unit (NMPU) .................................................. 76

7.139 Software Test of The New Memory Protection Unit (NMPU) Functionality..................................... 76

7.140 Software Test of ECC Logic .......................................................................................... 76

7.141 Multi-Bit Keyed Self-Correctable High-Integrity Bits ............................................................... 76

8 Next Steps in Your Safety Development ................................................................................ 77

Appendix A Summary of Safety Feature Usage.............................................................................. 78

Appendix B Development Interface Agreement ............................................................................ 125

B.1 Appointment of Safety Managers.................................................................................. 125

B.2 Tailoring of the Safety Lifecycle.................................................................................... 125

B.3 Activities Performed by TI .......................................................................................... 127

B.4 Information to be Exchanged....................................................................................... 128

B.5 Parties Responsible for Safety Activities ......................................................................... 128

B.6 Communication of Target Values.................................................................................. 129

B.7 Supporting Processes and Tools.................................................................................. 129

B.8 Supplier Hazard and Risk Assessment........................................................................... 129

B.9 Creation of Functional Safety Concept ........................................................................... 129

Appendix C Revision History ..................................................................................................... 130

6

Contents

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 7

www.ti.com

1 Device Revision Code Identification....................................................................................... 8

2 Hercules Product Architecture Overview................................................................................ 10

3 TI Standard MCU Automotive QM Development Process............................................................ 14

4 Hercules Enhanced Functional Safety Development Process....................................................... 17

5 Partition of Hercules MCU for Safety Analysis ......................................................................... 18

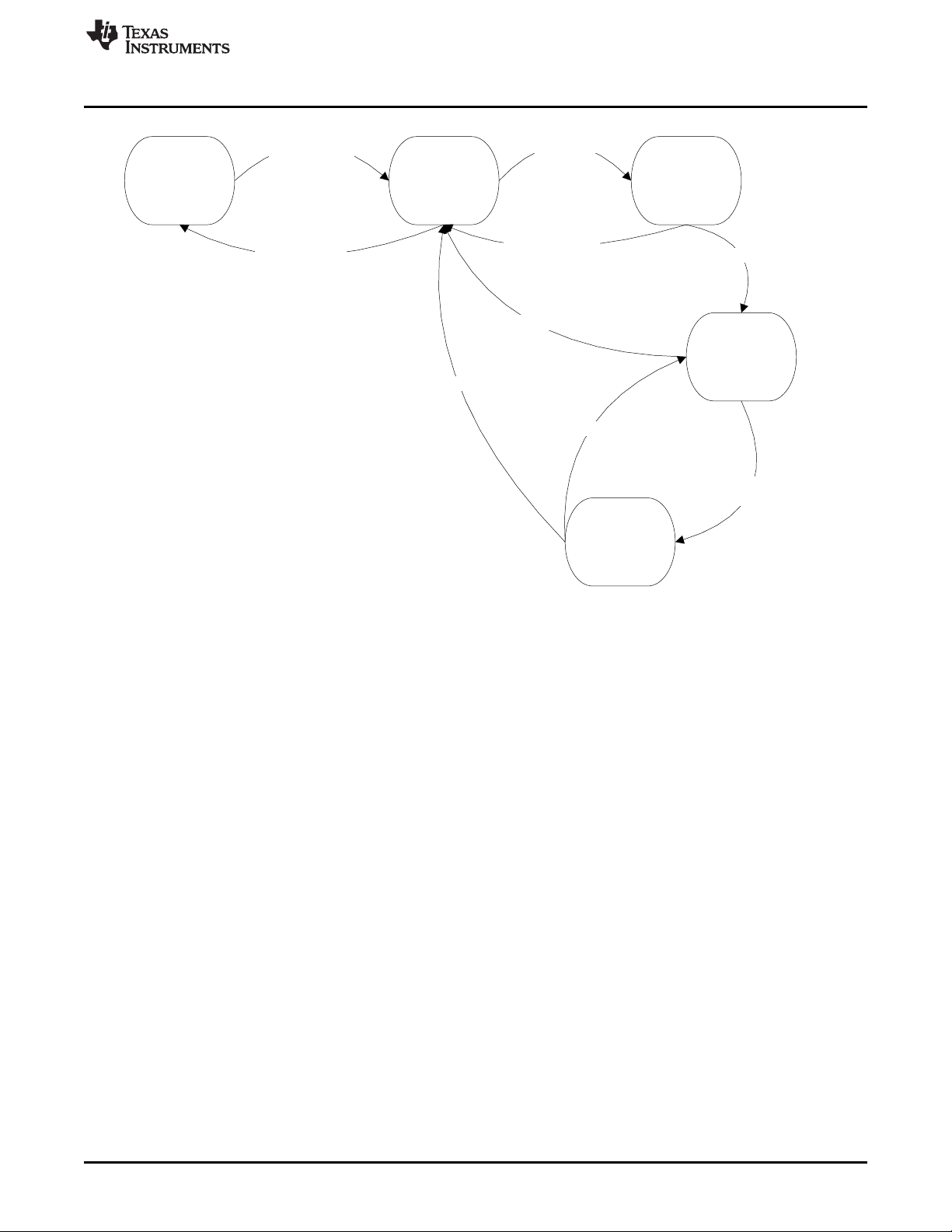

6 Operating States of the Hercules MCU ................................................................................. 21

7 Lockstep Temporal Diversity.............................................................................................. 30

8 Hercules Tailoring of Safety Lifecycle.................................................................................. 126

1 Identification of Parts/Elements .......................................................................................... 19

2 Summary of ESM Error Indication ....................................................................................... 22

3 Key to Summary of Safety Features and Diagnostics................................................................. 78

4 Summary of Safety Features and Diagnostics ........................................................................ 79

5 Activities Performed by TI vs. Performed by SEooC Customer .................................................... 127

6 Product Safety Documentation.......................................................................................... 128

7 Product Functional Documentation to be Considered in Safety-Related Design................................. 128

8 Product Safety Documentation Tools and Formats.................................................................. 129

9 SPNU575A Revisions.................................................................................................... 130

List of Figures

List of Tables

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

List of Figures

7

Page 8

843BZWTT

##B-#######

RM57L

G1

__

Device Revision Code

User's Guide

SPNU575A–May 2014–Revised September 2016

Safety Manual for RM57x Hercules ARM Safety MCUs

1 Introduction

You, a system and equipment manufacturer or designer, are responsible to ensure that your systems (and

any TI hardware or software components incorporated in your systems) meet all applicable safety,

regulatory, and system-level performance requirements. All application and safety related information in

this document (including application descriptions, suggested safety measures, suggested TI products, and

other materials) is provided for reference only. You understand and agree that your use of TI components

in safety critical applications is entirely at your risk, and that you (as buyer) agree to defend, indemnify,

and hold harmless TI from any and all damages, claims, suits, or expense resulting from such use.

This document is a safety manual for the Texas Instruments Hercules safety critical microcontroller

product family. The product family utilizes a common safety architecture that is implemented in multiple

application focused products. Product configurations supported by this safety manual include silicon

revisions A and B of the following products: (Note that the part numbers listed below are for revision B;

other revisions are slightly different. The device revision can be determined by the symbols marked on the

top of the device as seen in Figure 1 below this list).

• RM4xx Safety Critical Microcontrollers

– RM57L843-ZWT (Orderable Part #: RM57L843BZWTT)

– RM57L843-ZWT (Orderable Part #: RM57L843BZWTTR)

SafeTI is a trademark of Texas Instruments.

ARM, Cortex are registered trademarks of ARM Limited.

Adobe is a trademark of Adobe Systems Incorporated in the United States, and/or other countries.

IBM, DOORS are registered trademarks of International Business Machines Corporation, registered in many jurisdictions worldwide.

Microsoft, Excel are registered trademarks of Microsoft Corporation in the United States and/or other countries, or both.

All other trademarks are the property of their respective owners.

8

Figure 1. Device Revision Code Identification

This Safety Manual provides information needed by system developers to assist in the creation of a safety

critical system using a supported Hercules microcontroller. This document contains:

• An overview of the superset product architecture

• An overview of the development process utilized to reduce systematic failures

• An overview of the safety architecture for management of random failures

• The details of architecture partitions, implemented safety mechanisms

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 9

www.ti.com

The following information is documented in the Safety Analysis Report Summary for RM57x ARM®-Based

Safety Critical Microcontrollers (SPNU578) and is not repeated in this document:

• Summary of failure rates of the MCU estimated at the chip level

• Assumptions of use utilized in calculation of safety metrics

• Summary of targeted standard (IEC 61508, ISO 26262, and so forth) safety metrics at the chip level

The following information is documented in the Detailed Safety Analysis Report for RM57x ARM®-Based

Safety Critical Microcontrollers (SPNU579) and is not repeated in this document:

• Fault model used to estimate device failure rates suitable to enable calculation of customized failure

• Quantitative FMEA (also known as FMEDA, Failure Modes, Effects, and Diagnostics Analysis) with

The following information is documented in the Safety Report, and will not be repeated in this document:

• Results of assessments of compliance to targeted standards

The user of this document should have a general familiarity with the Hercules product families. For more

information, see http://www.ti.com/hercules. This document is intended to be used in conjunction with the

pertinent data sheets, technical reference manuals, and other documentation for the products under

development.

For information which is beyond the scope of the listed deliverables, please contact your TI sales

representative or http://www.ti.com.

Introduction

rates

detail to the sub-module level of the device, suitable to enable calculation based on customized

application of diagnostics

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

9

Page 10

Level Two Hierarchy

Level Three Hierarchy

Level One Hierarchy

Cortex R5F CPU

Cluster

Bus Master

Peripheral

Bus Master

Peripheral

Debug Bus

Master

General

DMA

Level Two

CPU Master

Level Two

CPU Slave

Peripheral Central Resource 1

Peripheral

Peripheral

Peripheral

Peripheral

Peripheral

Peripheral

Bus Master

Peripheral

Peripheral Central Resource n

Peripheral

Peripheral

Peripheral

Peripheral

Peripheral

Peripheral

Low Latency

Peripheral Port

Peripheral InterconnectCPU Interconnect

CRCCRC

Flash External

Memory

Interface

SRAM

Flash Emulated

EEPROM

Hercules RM57x Product Overview

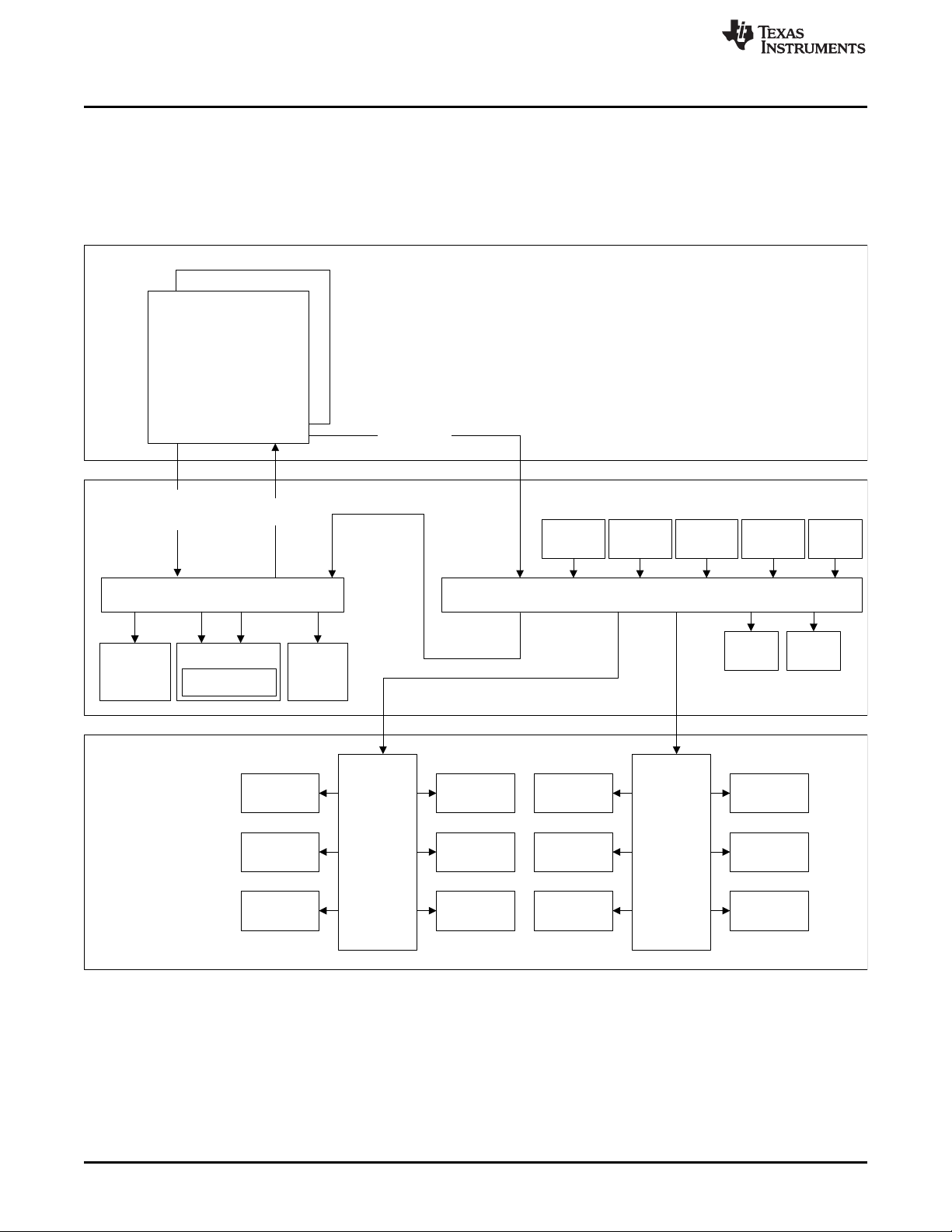

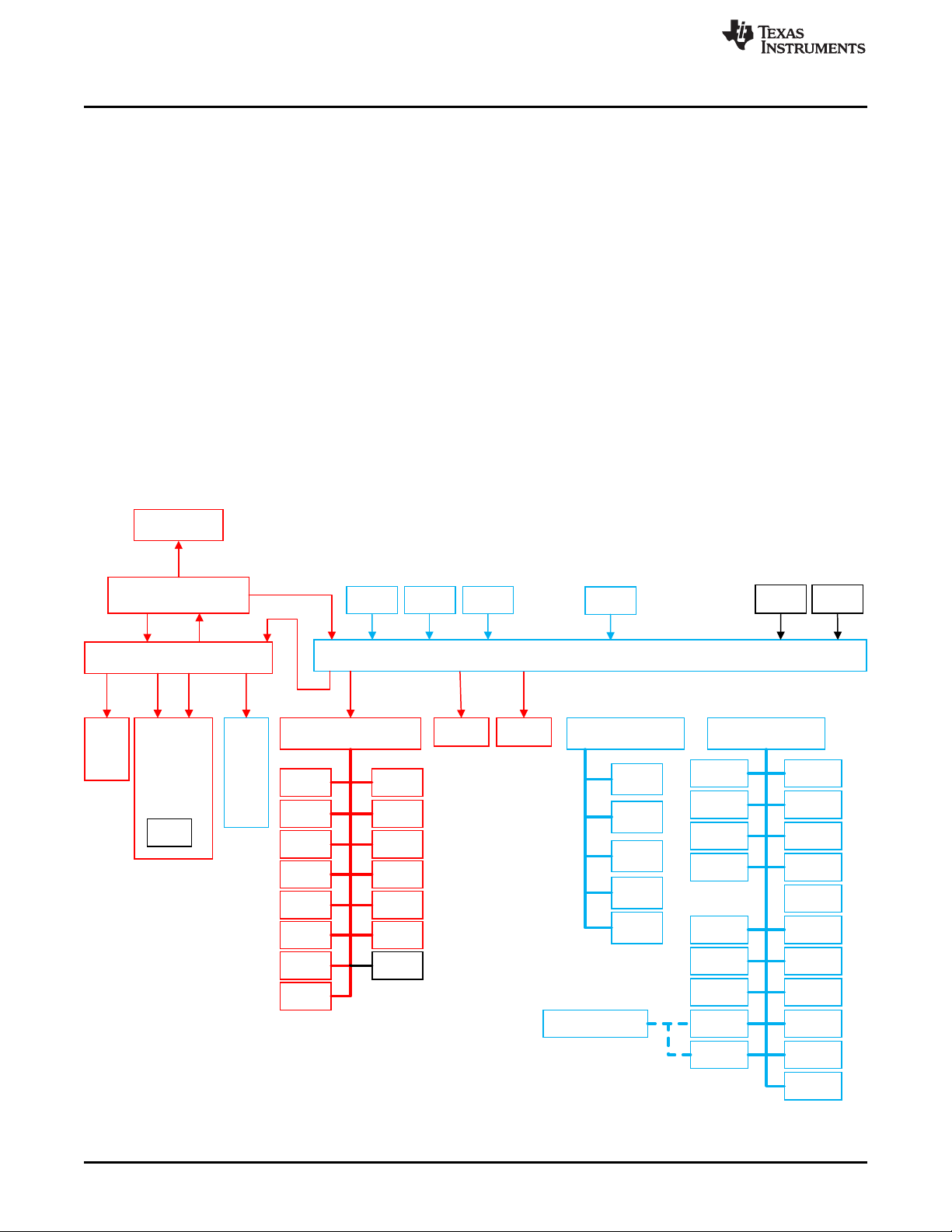

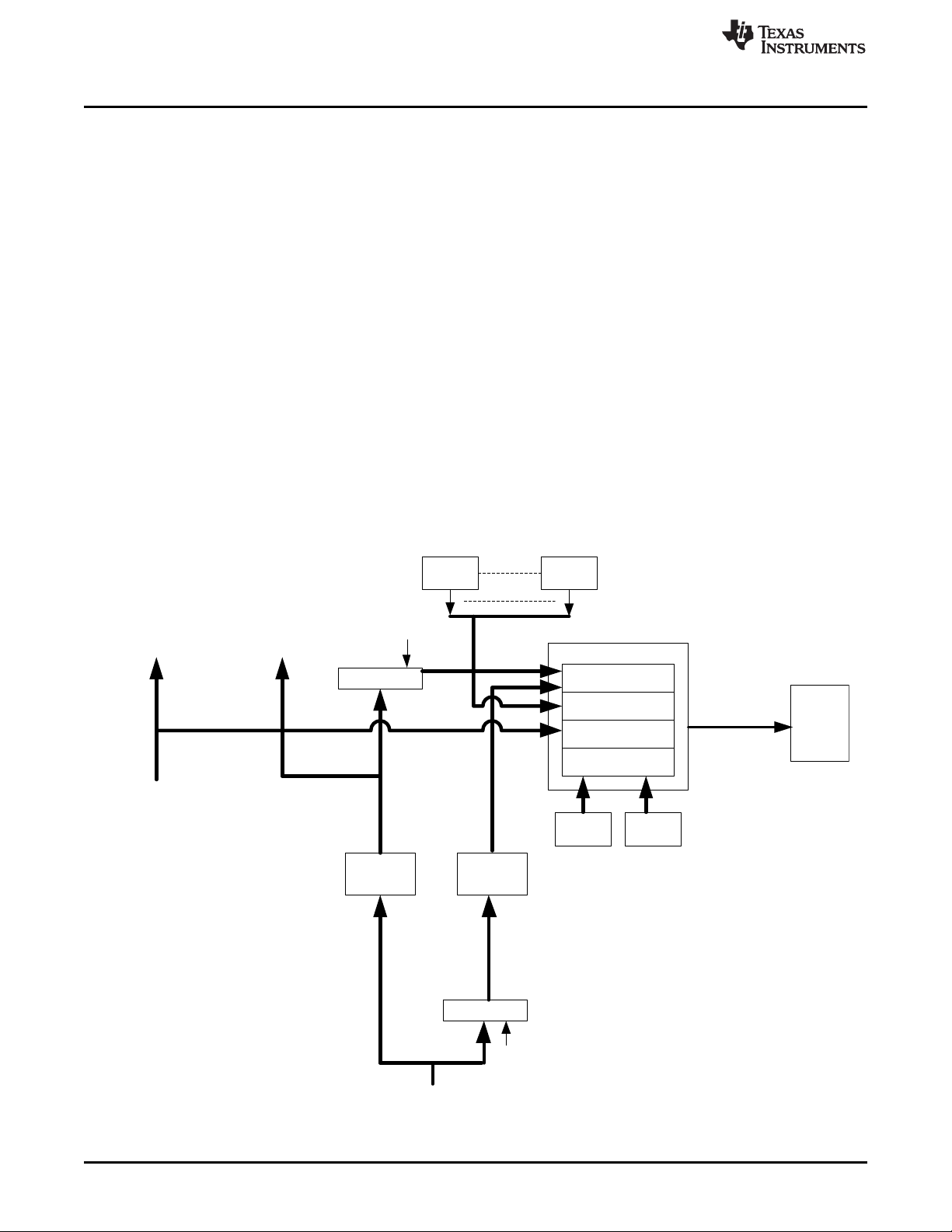

2 Hercules RM57x Product Overview

The RM57x 65 nm Hercules product family is an evolution of the proven TMS570LS Hercules products in

the 65 nm manufacturing process. A simplified graphical view of the product superset architecture can be

seen in Figure 2. This is a basic representation of the architecture and is not all inclusive. For example,

products in the family may scale based on the number of peripherals, number of bus master peripherals,

or amount of memory - but the programmer's model remains consistent.

www.ti.com

Figure 2. Hercules Product Architecture Overview

10

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 11

www.ti.com

The Hercules product architecture utilizes the ARM Cortex®-R5F CPU in a cached memory configuration

with both instruction and data caches. The Cortex-R5F CPU is implemented with a checker Cortex-R5F

CPU in a lockstep configuration. This provides cycle by cycle checking of correct CPU operation while

keeping a simple, easy to use, single core programmer's model. The Cortex R5F CPU has a multithreaded level two bus master interface, which provides access to the level two memory hierarchy,

supporting up to seven concurrent CPU accesses in flight. A level two slave interface allows bus masters

access to the level one cache memories for test, debug, and fault insertion purposes. A separate low

latency peripheral port provides access to peripherals. In addition, a Snoop Control Unit (SCU) module is

present to snoop non-CPU bus master accesses for the purpose of I/O cache coherency.

The level two device hierarchy is dominated by two switched central resource interconnect modules (also

known as bus matrices or crossbars): CPU Interconnect Subsystem and Peripheral Interconnect

Subsystem. These device level interconnect modules allow multiple bus masters to access multiple bus

slaves. Prioritization, routing, decode, and arbitration functions are provided. Access to the memory

subsystem (Flash, FEE, SRAM, and EMIF) is provided via the CPU Interconnect Subsystem. Peripherals

are accessed via the Peripheral Interconnect Subsystem and multiple level three peripheral interconnect

segments (PCR1, PCR2, and PCR3). Bus masters to the level two device hierarchy include CPUs, bus

master peripherals, debug bus masters, and general purpose direct memory access (DMA) controllers.

Bus slaves on the level two hierarchy include the primary Flash memory, primary SRAM, Flash EEPROM

emulation memory, and external memory interface (EMIF), one or more peripheral bus segments (PCRs),

and Cortex-R5F slave port access..

The level three hierarchy is primarily composed of peripherals. Peripherals are grouped into one or more

peripheral bus segments (PCRs), managed by a peripheral central resource. The peripheral central

resource provides address decode functionality for bus transactions targeting peripherals.

Hercules RM57x Product Overview

2.1 Targeted Applications

The Hercules MCU family is targeted at general purpose safety applications. Multiple safety applications

were analyzed during the concept phase. Example target applications include:

• Automotive braking systems, including anti-lock braking (ABS), anti-lock braking with traction control

(ABS+ TC), and electronic stability control (ESC)

• Motor control systems, particularly electronic power steering (EPS) systems and electric vehicle (EV)

power train

• General purpose safety computation, such as integrated sensor cluster processing and vehicle strategy

generation in an active safety system

• Industrial automation such as programmable logic controllers (PLCs) and programmable automation

controllers (PACs) for safety critical process control

In the case of overlapping requirements between target systems, TI has attempted to design the device

respecting the most stringent requirements. For example, the fault tolerant time intervals for timer logic in

an ESC application are typically on the order of 100 ms. In an EPS application, the fault tolerant time

interval is typically on the order of 10 ms. In such case, TI has performed timer subsystem analysis

respecting <10 ms fault tolerant time interval.

While TI considered certain applications during the development of these devices, this should not restrict a

customer who wishes to implement other systems. With all safety critical components, rationalization of

the component safety concept to the system safety concept should be executed by the system integrator.

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

11

Page 12

Hercules RM57x Product Overview

2.2 Product Safety Constraints

This device is a Type B device, as defined in IEC 61508:2010

This device claims no hardware fault tolerance (HFT = 0), as defined in IEC 61508:2010

For safety components developed according to many safety standards, it is expected that the component

safety manual will provide a list of product safety constraints. For a simple component, or more complex

components developed for a single application, this is a reasonable response. However, the Hercules

product family is both a complex design and is not developed targeting a single, specific application.

Therefore, a single set of product safety constraints cannot govern all viable uses of the product. The

Detailed Safety Analysis Report for RM57x ARM®-Based Safety Critical Microcontrollers (SPNU579)

provides a reference implementation of the Hercules product in a common system with relevant product

safety constraints.

www.ti.com

12

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 13

www.ti.com

Hercules Development Process for Management of Systematic Faults

3 Hercules Development Process for Management of Systematic Faults

For a safety critical development, it is necessary to manage both systematic and random faults. Texas

Instruments has created a unique development process for safety critical semiconductors that greatly

reduces probability of systematic failure. This process builds on a standard Quality Managed (QM)

development process as the foundation for safety critical development. This process is then augmented by

a second layer of development activities that are specific to safety critical developments targeting IEC

61508.

In 2007, TI first saw the need to augment this standard development process in order to develop products

according to IEC 61508. TI engaged with safety industry leader exida consulting to ensure the

development was compliant to the standard. During 2008, a process for safety critical development

according to IEC 61508 1st edition was implemented. This process has been executed on multiple

microcontroller developments that are currently shipping into safety critical systems. The Hercules family

product and safety architectures described in this document began development under the IEC 61508

development flow.

By mid 2009, it became clear that the emerging IEC 61508 2nd edition functional safety standards would

require enhanced process flow capabilities. Due to the lack of maturity of these draft standards, it was not

possible to implement a development process that ensured compliance before final drafts were available.

In mid 2010, TI started development of a process flow compliant to IEC 61508 2nd edition. TI worked in

detail with Yogitech and found that the companies have complementary capabilities. A partnership was

established for engineering services and safety consulting services to accelerate new safety-related

product development. Yogitech's existing fRMethodology development process and TI's IEC 61508

development process were merged and enhanced to create a new process addressing IEC 61508 2nd

edition.

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

13

Page 14

Business

Opportunity

Prescreen

Program

Planning

Create

Validate

Sample

Characterize

Qualify

Ramp Æ Sustain

Design In Team

Sustain

Team

Cross Functional Team

Identify new

product

opportunities

Develop

project plan

IC design and

layout

Characterize

Develop

manufacturing

test

Develop & build marketing collateral

Sample to

customers

Qualification

Build initial inventory

Optimize test

flow and yeilds

Manage project risks (market and execution)

Bench & ATE

verification

CP0

Commission

Review

CP1

Design

Kickoff

Review

CP2

PG Review

CP2.5

Qual Start

Review

CP3

TMS Review

CP4 Safe

Launch

Review

Hercules Development Process for Management of Systematic Faults

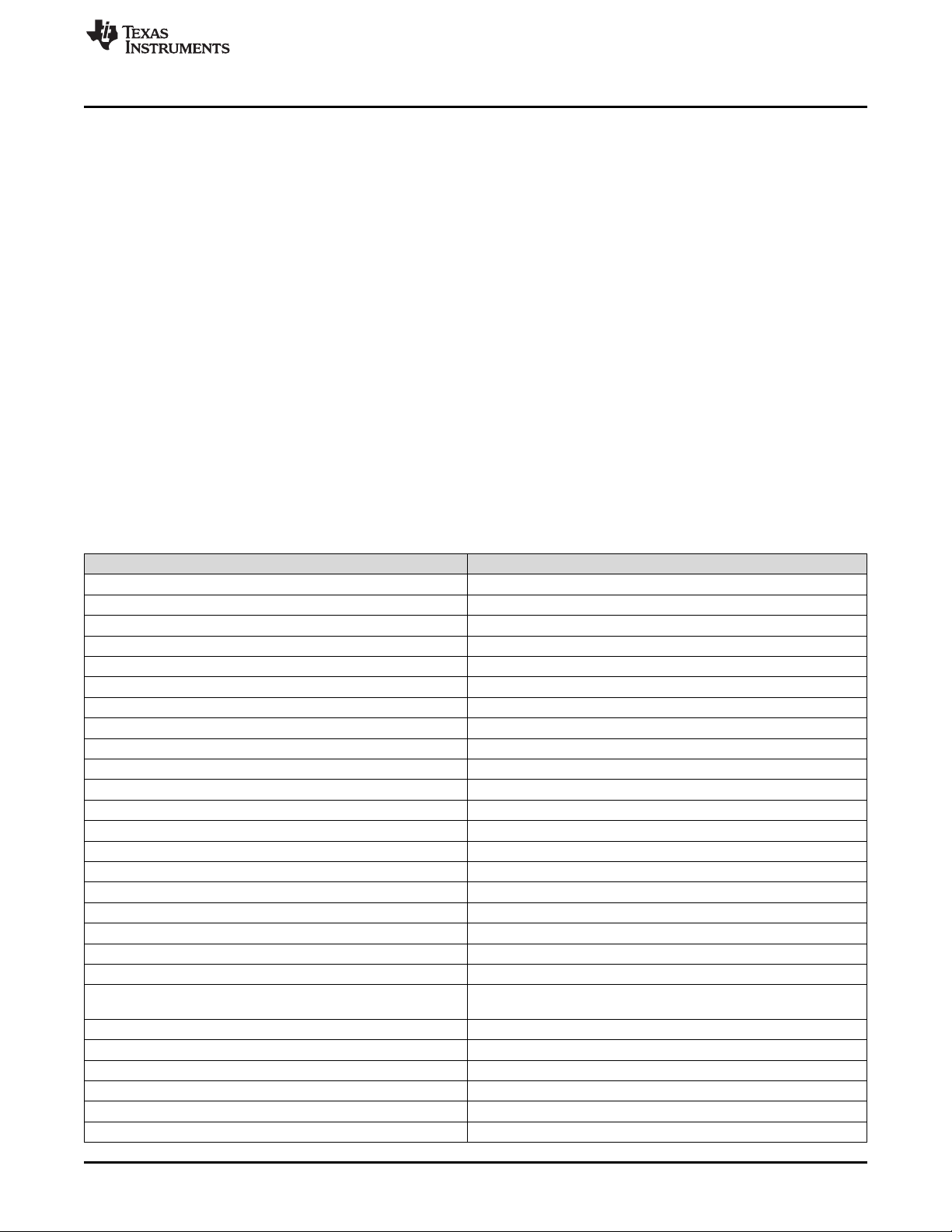

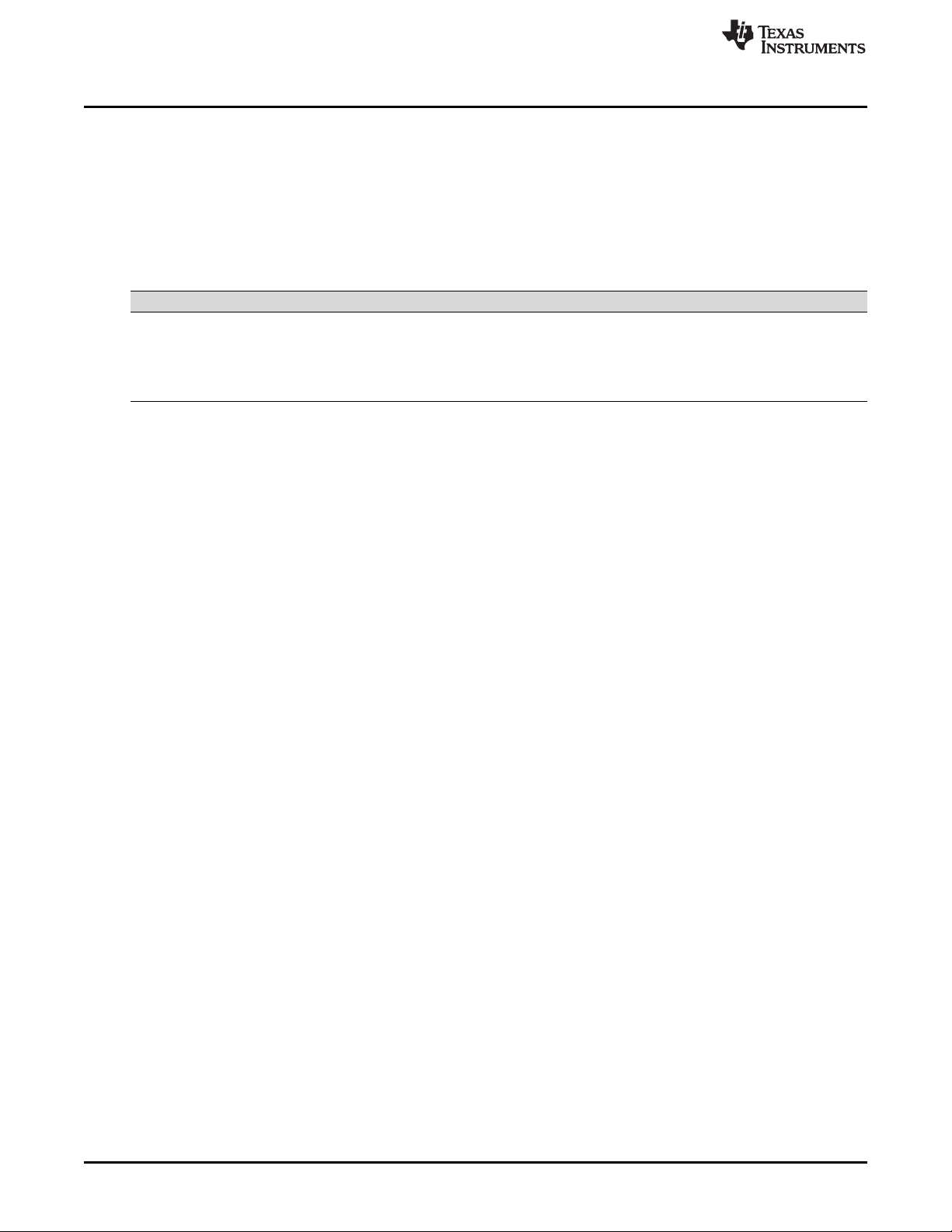

3.1 TI Standard MCU Automotive Development Process

Texas Instruments has been developing automotive microcontrollers for safety critical and non-safety

critical automotive applications for over twenty years. Automotive markets have strong requirements on

quality management and high reliability of product. Though not explicitly developed for compliance to a

functional safety standard, the TI standard MCU Automotive development process already features many

elements necessary to manage systematic faults. This development process can be considered to be

Quality Managed (QM), but does not achieve an IEC 61058 Safety Integrity Level (SIL). For up-to-date

information on TI quality process certifications, see http://www.ti.com/quality.

The standard process breaks development into phases:

• Business opportunity pre-screen

• Program planning

• Create

• Validate, sample, and characterize

• Qualify

• Ramp to production and sustaining production

The standard process is illustrated in Figure 3.

www.ti.com

Figure 3. TI Standard MCU Automotive QM Development Process

14

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 15

www.ti.com

Hercules Development Process for Management of Systematic Faults

3.2 TI MCU Automotive Legacy IEC 61508 Development Process

Texas Instruments developed an initial process for developing safety critical automotive microcontrollers in

2008. This process was developed targeting the IEC 61508 1st edition standard, as augmented with

available committee drafts of the 2nd edition. The process is developed as an additional layer of activities

that should be carried out in addition to the standard MCU Automotive QM development process. This

process as applied on the TMS570LS20216S product development has been assessed suitable for use in

IEC 61508 SIL 3 applications by exida Certification S.A. (certificate TI 071227 C001). In July 2012 the

development process and the TMS570LS20x/10x product family was assessed to the IEC 61508:2010

standard and certified suitable for use in IEC 61508 SIL 3 applications by exida Certification Services

(certificate TI 1204073 C001).

Key new activities in this process included:

• Nomination of a safety manager with ownership of all safety related activities

• Development of a safety plan to track safety related activities

• Generation, application, and validation of safety requirements

• Execution of qualitative (FMEA) and quantitative (FMEDA) safety analysis

• Authoring of safety manual and safety analysis report to support customer development

3.3 Yogitech fRMethodology Development Process

fRMethodology is the “white-box” approach for safety design exploration proprietary of YOGITECH,

including:

• fRFMEA, a methodology to perform the FMEA of an integrated circuit in accordance to IEC 61508

• fRFI, a tool to perform fault injection of an integrated circuit based on inputs derived from fRFMEA

YOGITECH’s fRMethodology mainly consists of:

• Splitting the component or system in elementary parts (“sensitive zones”)

• Computing their failure rates

• Using those failure rates to compute safety metrics

• Validating the results with fault injection

• Allowing sensitivity analyses of those metrics by changing architectural or technological parameters

• Delivering to the customer numbers to compare different architectures

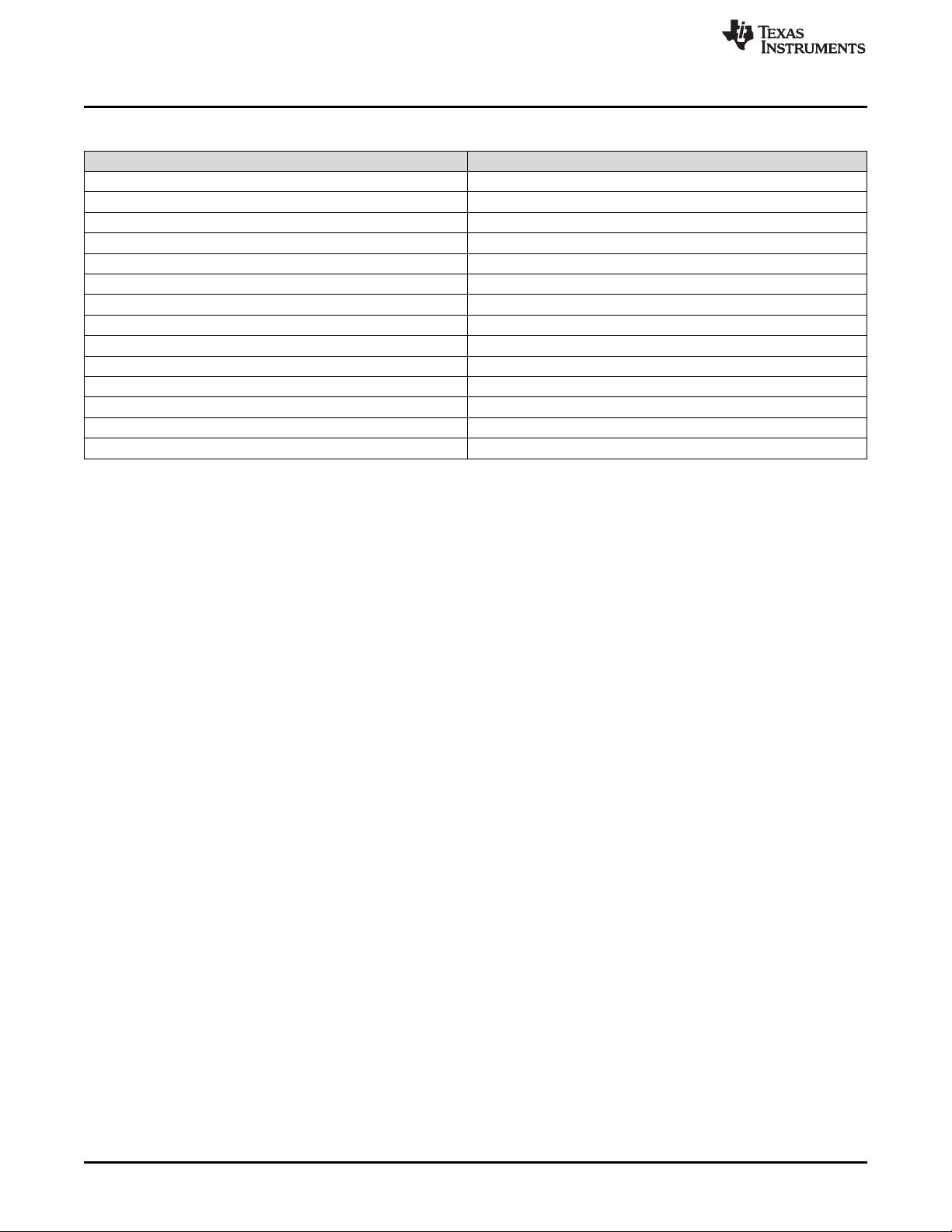

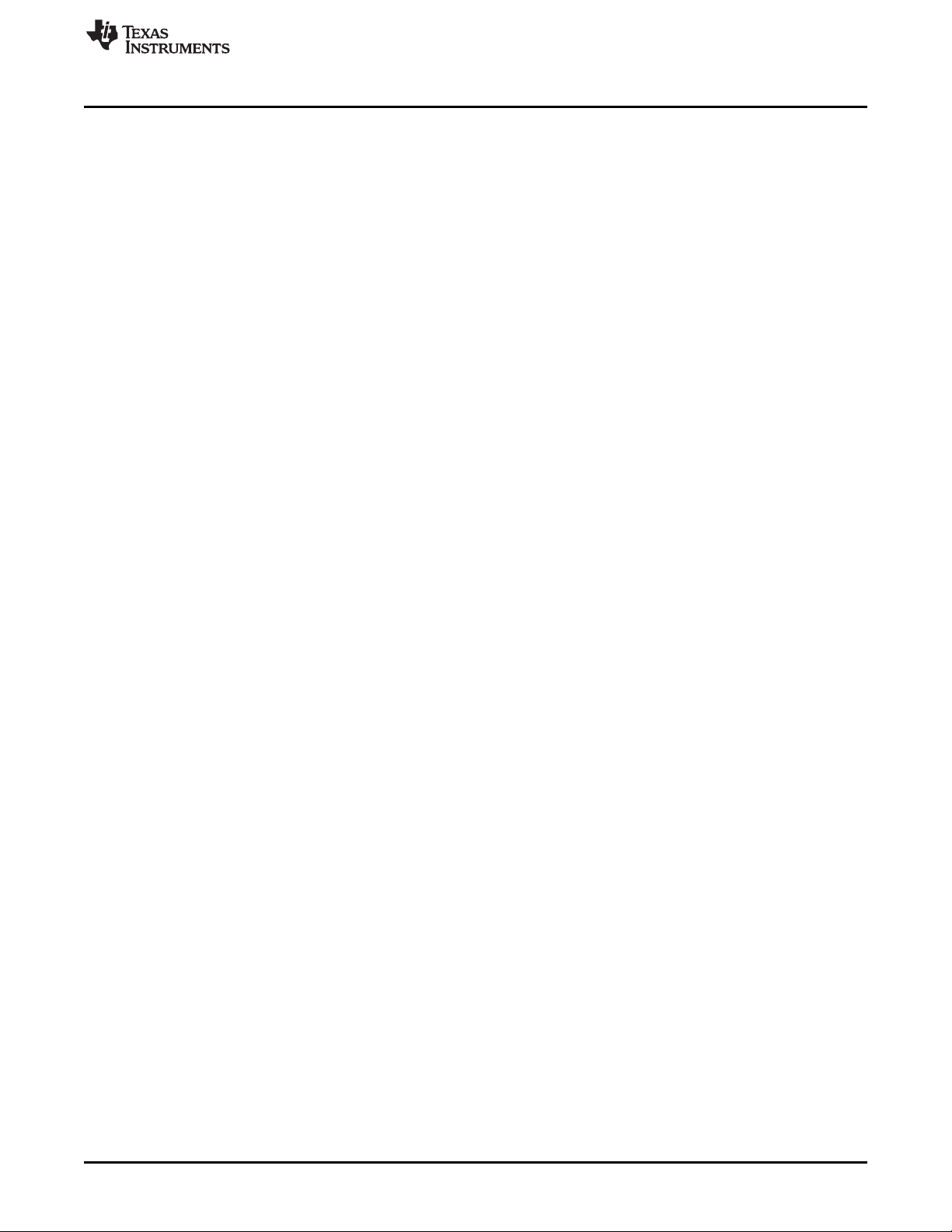

3.4 Hercules Enhanced Safety Development Process

The Hercules enhanced safety development process is a merger of the existing TI and Yogitech flows for

functional safety development. The goal of the process development is to take the best aspects of each

flow and collaborate, resulting in the best in class capabilities to reduce systematic faults.

The process flow is targeted for compliance to IEC 61508, and is under a process of continuous

improvement to incorporate new features of emerging functional safety standards. These functional safety

standards are targeted because TI and Yogitech believe they best represent the state of the art in

functional safety development for semiconductors. While not directly targeted at other functional safety

standards, it is expected that products developed to industry state-of-the-art can be readily utilized in other

functional safety systems.

The resulting flow was subsequently assessed by TUEV SUED for compliance to IEC 61508 and ISO

26262 and further enhanced based on technical findings. The development flow is certified by TUEV

SUED under certificate Q4B 13 03 84071 001.

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

15

Page 16

Hercules Development Process for Management of Systematic Faults

Key elements of the combined process flow are:

• Assumptions on system level design, safety concept, and requirements based on TI's expertise in

safety critical systems development

• Combined qualitative and quantitative or similar safety analysis techniques comprehending the sum of

silicon failure modes and diagnostic techniques known to both TI and Yogitech

• Fault estimation based on multiple industry standards as well as TI manufacturing data

• Application of Yogitech's state-of-the-art fault injection techniques for validation of claimed diagnostic

coverage

• Integration of lessons learned by both companies through multiple safety critical developments to IEC

61508

The Figure 4 is shown below in a simplified graphic.

www.ti.com

16

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 17

Phase 0

Business

Opportunity

Prescreen

Phase 1

Program Planning

Phase 2

Create

Phase 2.5

Validate, Sample,

and

Characterize

Phase 3

Qualify

Phase 4

Ramp/Sustain

Determine if safety

process execution is

necessary

Execute development

interface agreement

(DIA) with lead

customers and

suppliers

Define SIL/ASIL

capability

Generate safety plan

Initiate safety case

Analyze system to

generate system level

safety assumptions

and requirements

Develop component

level safety

requirements

Validate component

safety requirements

meet system safety

requirements

Implement safety

requirements in design

specification

Validate design

specification meets

component safety

requirements

Confirmation measure

review

Validate safety design

in silicon

Release safety

manual

Release safety

analysis report

Characterization of

safety design

Confirmation measure

review

Qualification of safety

design

Release safety case

report

Update safety manual

(if needed)

Update safety analysis

report (if needed)

Confirmation measure

review

Implement plans to

support operation and

production

Update safety case

report (if needed)

Periodic confirmation

measure reviews

Qualitative analysis of

design (FMEA and

FTA)

Develop safety

product preview

Validation of safety

design at RTL level

Quantitative analysis

of design (FMEDA)

Validation of safety

design at gate/layout

level

Confirmation measure

review

Execute safety design

Incorporate findings

into safety design

Incorporate findings

into safety design

www.ti.com

Hercules Development Process for Management of Systematic Faults

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Figure 4. Hercules Enhanced Functional Safety Development Process

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

17

Page 18

CPU Cache

with ECC

Dual Cortex-R5F CPUs in

Lockstep

CPU Interconnect Subsystem

Peripheral Central

Resource #1

SRAM

With

ECC

Flash

with ECC

&

Flash for

EEPROM

Emulation

with ECC

CRC2

ESM

CRC1

Lockstep

VIMs

RTI

DCC1

STC1

DCC2

STC2

EFUSE

IOMM

PMM

EPC

SCM

SYS

CCM-

R5F

EMIF

Slave

EMAC

Slaves

eQEP

1,2

eCAP

1..6

eTPWM

1..7

SCI3

SCI4

I2C1

I2C2

GIO

DCAN1

DCAN2

DCAN3

DCAN4

MibSPI1

MibSPI2

MibSPI3

MibSPI4

MibSPI5

LIN1/SCI1

LIN2/SCI2

N2HET1

N2HET2

MibADC1

MibADC2

Temp Sensor[1..3]

RTP

POM

Peripheral Central

Resource #2

Peripheral Central

Resource #3

DMA EMAC HTU1

HTU2

DAP DMM

Peripheral Interconnect Subsystem

EMIF

Hercules Product Architecture for Management of Random Faults

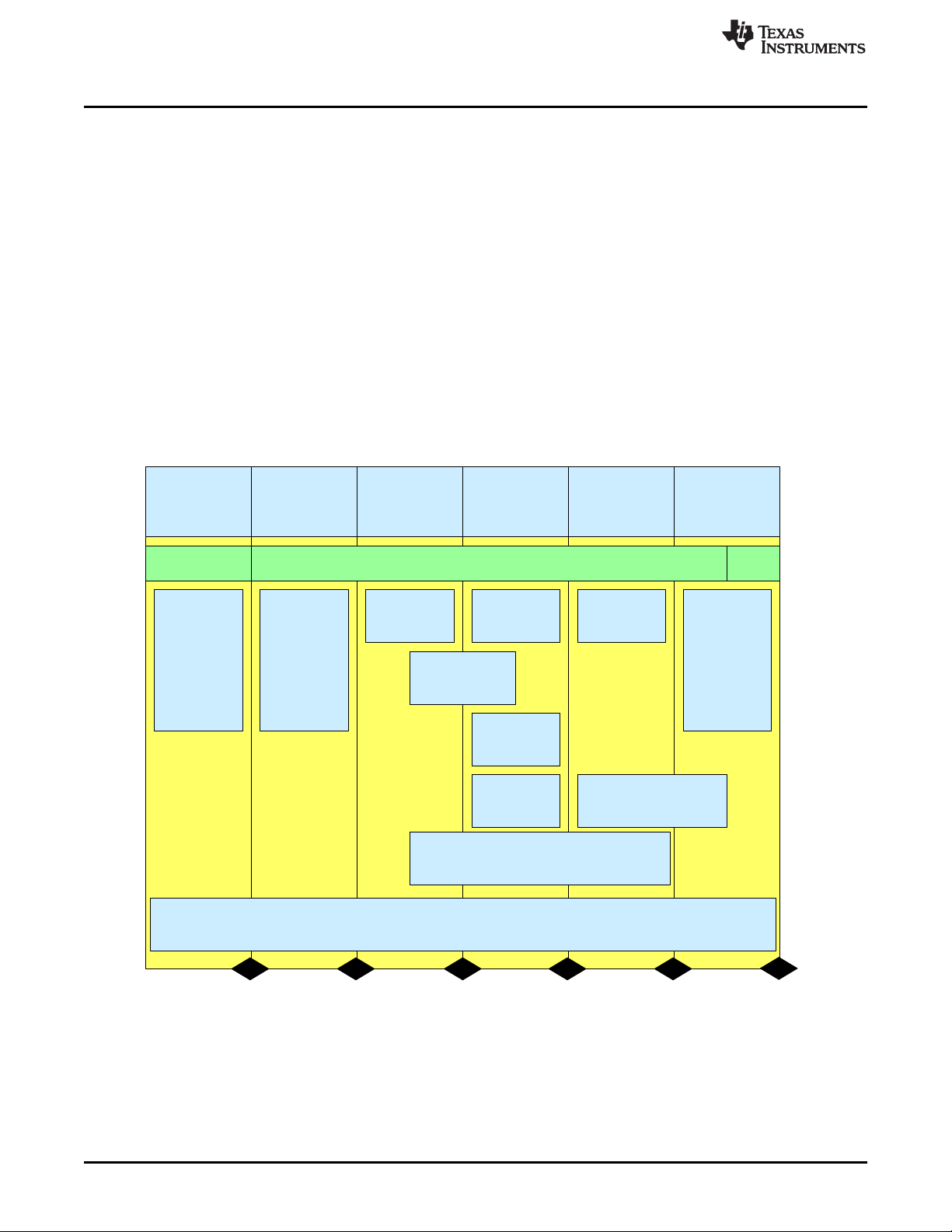

4 Hercules Product Architecture for Management of Random Faults

For a safety critical development it is necessary to manage both systematic and random faults. The

Hercules product architecture includes many safety mechanisms, which can detect and respond to

random faults when used correctly. This section of the document describes the architectural safety

concept for the MCU.

4.1 Safe Island Philosophy and Architecture Partition to Support Safety Analysis (FMEA/FMEDA)

The RM4x Hercules processors share a common safety architecture concept called a “safe island”

philosophy. The basic concept involves a balance between application of hardware diagnostics and

software diagnostics to manage functional safety, while balancing cost concerns. In the “safe island”

approach, a core set of elements are allocated continuously operating hardware safety mechanisms. This

core set of elements, including power and clock and reset, CPU, Flash memory, SRAM and associated

interconnect to Flash and SRAM, is needed to assure any functionally correct execution of software. Once

correct operation of these elements is confirmed, software can be executed on these elements in order to

provide software-based diagnostics on other device elements, such as peripherals. This concept has been

proven viable through multiple generations of safety-critical products in the automotive passenger vehicle

space.

Figure 5 illustrates the safe island approach overlaid to a superset configuration of the Hercules product

architecture.

www.ti.com

Figure 5. Partition of Hercules MCU for Safety Analysis

18

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 19

www.ti.com

Figure 5 illustrates three architectural partitions:

• “Safe Island Layer” (RED) – This is the region of logic that is needed for all processing operations. This

logic is protected heavily by on board hardware diagnostics and specific assumptions of use to assure

a high level of confidence in safe operation. Once this region is safed, it can be used to provide

comprehensive software diagnostics on other design elements.

• “Blended Layer” (BLUE) – This is the region of logic that includes most safety critical peripherals. This

region has less reliance on hardware diagnostics. Software diagnostics and application protocols are

overlaid to provide the remainder of needed diagnostic coverage.

• “Offline Layer” (BLACK) – This region of logic has minimal or no integrated hardware diagnostics.

Many features in this layer are used only for debug, test, and calibration functions; they are not active

during safety critical operation. Logic in this region could be utilized for safety critical operation

assuming appropriate software diagnostics or system level measures are added by the system

integrator.

4.2 Identification of Parts/Elements

For the purposes of a safety analysis, each module on this device can be considered to be a part or

element. Each part or element has been assigned a three letter unique identifier, which is used uniformly

in the Safety Manual, Safety Analysis Report, and FMEDA Documents to identify the element and it's

diagnostics. Table 1 lists each element present on this device and the unique identifier for this element.

The overall IEC 61508 systematic capability of the MCU is SC3. TI does not make claims of systematic

capability for specific IP modules on the device.

Table 1. Identification of Parts/Elements

Hercules Product Architecture for Management of Random Faults

Part / Element Name Unique Identifier

Clock CLK

Cortex-R5F Central Processing Unit (CPU) CPU

Controller Area Network (DCAN) CAN

Cortex-R5F Central Processing Unit (CPU) Debug and Trace DBG

CPU Interconnect Subsystem MEM

Data Modification Unit DMM

Direct Memory Access (DMA) DMA

Enhanced Capture (eCAP) CAP

EFuse Static Configuration EFU

External Memory Interface (EMIF) EMF

Enhanced Pulse Width Modulators (ePWM) PWM

Enhanced Quadrature Encoder Pulse (eQEP) QEP

Error Profiling Controller EPC

Error Signaling Module (ESM) ESM

Ethernet ETH

Flash EEPROM Emulation (FEE) FEE

Primary Flash FLA

General Purpose Input/Output (GIO) GIO

Inter-Integrated Circuit (I2C) IIC

Input/Output (I/O) Multiplexing Module (IOMM) IOM

Joint Technical Action Group (JTAG) Debug/Trace/Calibration

Access

Local Interconnect Network (LIN) LIN

Multi-Buffered Analog to Digital Converter (MibADC) ADC

Multi-Buffered Serial Peripheral Interface (MibSPI) MSP

High-End Timer (N2HET) Including HET Transfer Unit (HTU) HET

One Time Programmable (OTP) Flash Static Configuration OTP

Peripheral Interconnect Subsystem PER

JTG

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

19

Page 20

Hercules Product Architecture for Management of Random Faults

Table 1. Identification of Parts/Elements (continued)

Part / Element Name Unique Identifier

Peripheral Central Resource 1 P1T

Peripheral Central Resource 2 P2T

Peripheral Central Resource 3 P3T

Power Management Module (PMM) PMM

Parameter Overlay Module POM

Power Supply PWR

RAM Trace Port RTP

Reset RST

Real Time Interrupt (RTI) Operating System Timer RTI

Serial Communications Interface (SCI) SCI

SRAM RAM

System Control Module SYS

Temperature Sensors TSN

Vectored Interrupt Module (VIM) VIM

NOTE: The terms "element" and "part" may have specific meaning and imply specific requirements

dependent on the targeted functional safety standard. The terms are used here in a general sense.

TheHercules Architecture Brief Description of Elements section contains a brief description of the

elements listed above. For a full functional description of any of these modules, see the device-specific

technical reference manual.

www.ti.com

4.3 Management of Family Variants

The Hercules family architecture supports multiple product variants. These products could be implemented

as unique silicon designs or they can be shared silicon designs that have elements disabled or not

assured by specification, even if present in silicon. Only the elements of the superset architecture that are

specifically detailed in the device-specific data sheet and technical reference manual are assured to be

present and operate. When developing for the Hercules platform, it is recommended that the safety

concept be based on the superset product architecture to enable maximum scalability across family

variants. The superset architecture shown in the previous section is valid for all device part numbers noted

in the introduction of the safety manual.

4.4 Operating States

The Hercules MCU products have a common architectural definition of operating states. These operating

states should be observed by the system developer in their software and system level design concepts.

The operating states state machine is shown in Figure 6 and described below.

20

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 21

SafePowered Off

Power applied

nPORRST held

Cold Boot

nPORRST released

Warm Boot

SYS_nRST released internally

Operational

Proof tests completed

System init completed

nPORRST driven

Power Removed

SYS_nRST driven

nPORRST driven

nPORRST driven

www.ti.com

Hercules Product Architecture for Management of Random Faults

Figure 6. Operating States of the Hercules MCU

• "Powered Off" - This is the initial operating state of the Hercules MCU. No power is applied to either

core or I/O power supply and the device is non-functional. This state can only transition to the safe

state, and can only be reached from the safe state.

• "Safe" - In the safe state, the Hercules MCU is powered but non-operational. The nPORRST (power-on

reset, also known as cold reset) is asserted by the system but is not released until power supplies

have ramped to a stable state. The internal voltage monitor (VMON) safety mechanism also continues

to assert the nPORRST internal to the device if power supplies are not within a minimum operational

range. When the product is in the safe state, the CPU and peripherals are non-functional. Output

drivers are tri-stated and input/output pins are kept in an input only state.

• "Cold Boot" - In the cold boot state, key analog elements, digital control logic, and debug logic are

initialized for future use. The CPU remains powered but non-operational. When the cold boot process

is completed, the SYS_nRST signal is internally released, leading to the warm boot stage. The

SYS_nRST signal transition change can be monitored externally on the SYS_nRST I/O pin.

• "Warm Boot" - The warm boot mode resets digital logic and enables the CPU. The CPU begins

executing software from Flash memory and software initialization of the device can begin. There is no

hardware interlock to say that warm boot is completed; this is a software decision.

• "Operational" - During the operational mode, the device is capable of supporting safety critical

functionality.

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

21

Page 22

Hercules Product Architecture for Management of Random Faults

4.5 Management of Errors

When a diagnostic detects a fault, the error must be indicated. The Hercules product architecture provides

aggregation of fault indication from internal safety mechanisms using a peripheral logic known as the error

signaling module (ESM). The ESM provides mechanisms to classify errors by severity and to provide

programmable error response. The ESM does not, in and of itself, impact the overall function of the device

and serves the limited purpose of fault aggregation and classification. The error classifications in the ESM

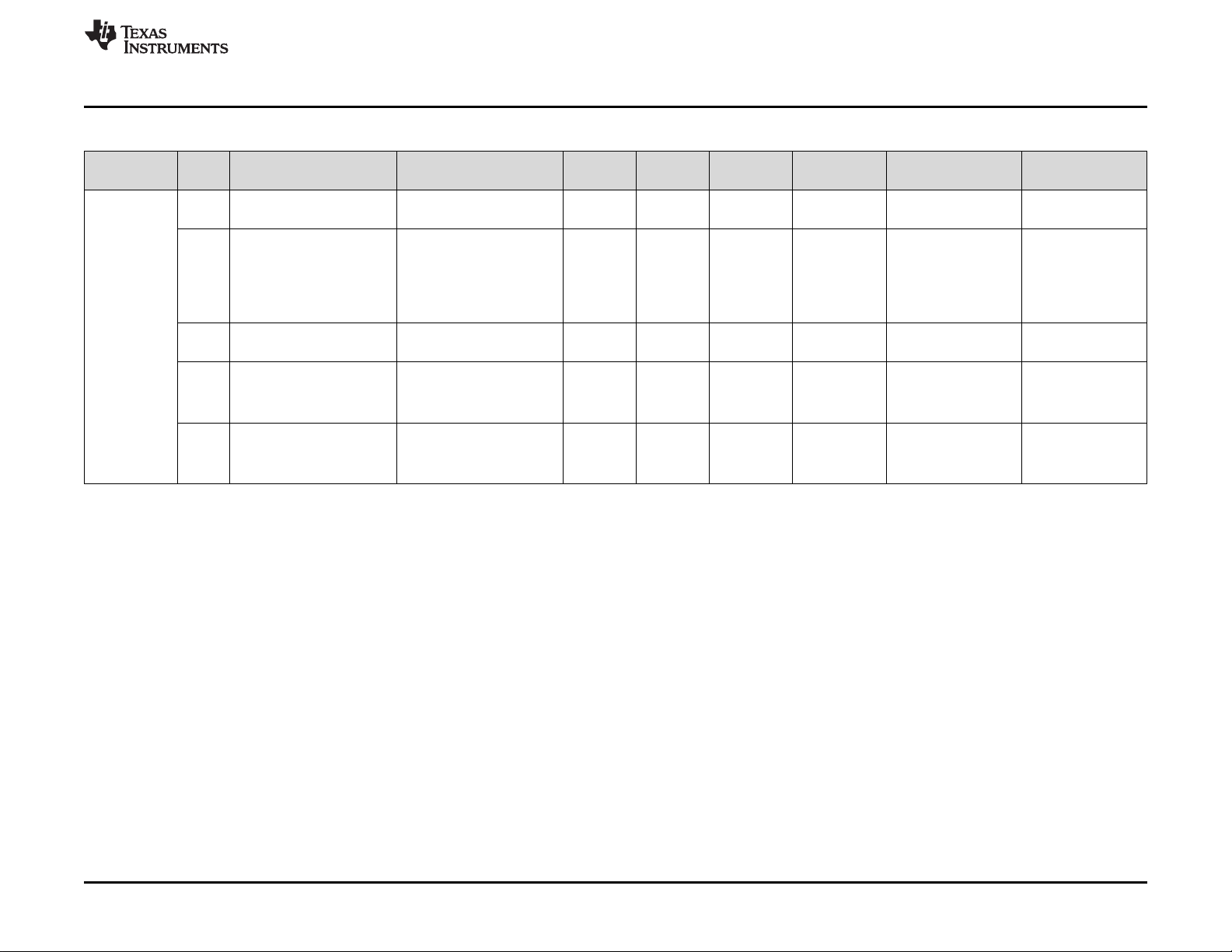

are summarized in Table 2.

Table 2. Summary of ESM Error Indication

Error Group Interrupt Response Error Pin Response Notes

1

2 Non maskable interrupt generated Error pin activated For errors that are generally of critical severity

3 No interrupt response Error pin activated

The error response is action that is taken by the MCU or system when an error is indicated. There are

multiple potential of error response possible for the Hercules product. The system integrator is responsible

to determine what error response should be taken and to ensure that this is consistent with the system

safety concept.

• CPU abort - This response is implemented directly in the CPU, for diagnostics implemented in the

CPU. During an abort, the program sequence transfers context to an abort handler and software has

an opportunity to manage the fault.

• CPU interrupt - This response can be implemented for diagnostics outside the CPU. An interrupt

allows events external to the CPU to generate a program sequence context transfer to an interrupt

handler where software has an opportunity to manage the fault.

• Generation of SYS_nRST - This response allows the device to change states to warm boot from

operational state. The SYS_nRST could be generated from an external monitor or internally by the

software reset or watchdog. Re-entry to the warm reset state allows possibility for software recovery

when recovery in the operational state was not possible.

• Generation of nPORRST - This response allows the device to change state to safe state from cold

boot, warm boot, or operational states. From this state, it is possible to re-enter cold boot to attempt

recovery when recovery via warm boot is not possible. It is also possible to move to the powered-down

state, if desired, to implement a system level safe state. This response can be generated from the

internal voltage monitor, but is primarily driven by monitors external to the MCU.

The ESM provides multiple registers that can be read by the CPU to determine the current status of

diagnostics and the state of the nERROR pin. For the severe group 2 errors, a shadow register is

provided that is not reset by SYS_nRST. This allows the possibility of warm reset reinitialization to identify

that a group 2 error initiated the external reset.

It is possible for the CPU to trigger the nERROR pin response manually to test system behavior or to

notify external logic of an internal fault not automatically indicated to ESM. The CPU is responsible to clear

indicated errors in the ESM, including clearing of the nERROR pin response.

The EPC is used as a complement to the ESM for error profiling . The primary goal of this module is to

provide a unified correctable ECC error (single bit ECC fault) profiling capability and error address cache

on ECC failures in system bus memory slaves like Flash, FEE, and SRAM. The secondary goal of this

module is to provide an ECC error reporting capability for bus masters, which do not natively have ECC

logic built in like the DMA and TUs. The ECC generation and evaluation logic for bus masters such as

DMA and the TUs are built into the CPU Interconnect Subsystem.

System level management of the external error response can be simplified through the use of a TI

TPS6538x power supply and safety companion device developed for use with the Hercules family.

Programmable interrupt and

programmable interrupt priority

Programmable response

www.ti.com

For errors that are generally not of critical

severity

For critical errors that are seen by diagnostic

implemented in CPU

22

Safety Manual for RM57x Hercules ARM Safety MCUs

Copyright © 2014–2016, Texas Instruments Incorporated

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Page 23

www.ti.com

5 System Integrator Recommendations

You, as a system and equipment manufacturer or designer, are responsible to ensure that your systems

(and any TI hardware or software components incorporated in your systems) meet all applicable safety,

regulatory, and system-level performance requirements. All application and safety related information in

this document (including application descriptions, suggested safety measures, suggested TI products, and

other materials) is provided for reference only. You understand and agree that your use of TI components

in safety critical applications is entirely at your risk, and that you (as buyer) agree to defend, indemnify,

and hold TI harmless from any and all damages, claims, suits, or expense resulting from such use.

A brief description of each element on this device and the general assumptions of use are provided in

Section 6.

A list of diagnostic mechanisms for this device and a brief description for each diagnostic are provided in

Section 7.

The effectiveness of the hardware safety mechanisms is noted in the Detailed Safety Analysis Report for

RM57x ARM®-Based Safety Critical Microcontrollers (SPNU579).

This information should be used to determine the strategy for utilizing safety mechanisms. The details of

each safety mechanism can be found in the device-specific technical reference manual.

Depending on the safety standard and end equipment targeted, it may be necessary to manage not only

single point faults, but also latent faults. Many of the safety mechanisms described in this section can be

used as primary diagnostics, diagnostics for latent fault, or both. When considering system design for

management of latent faults, take care to include failure of execution resources when considering latent

faults with software diagnostics, such as failure of CPU and memories.

System Integrator Recommendations

5.1 System Integrator Activities

The system integrator is responsible for carrying out a number of product development activities. These

activities carried out may include but are not limited to the following:

• Operational and Environmental Constraints

– Verify that the implementation of the TI component in the system design is compliant to

requirements in TI documentation. This includes but is not limited to the requirements found in

technical reference manuals, data sheets, errata documents, safety manuals, and safety analysis

reports

– Verify that the system operational lifetime (power-on hours) does not exceed lifetime specifications

for the TI component, as specified in the device data sheet. If the operational lifetime (power-on

hours) is not specified in the data sheet, the use case does not match published conditions, or

there are questions regarding device lifetime, please contact a TI quality/reliability engineering

representative or http://www.ti.com.

– Define system maintenance requirements. The Hercules MCU does not require maintenance.

– Define system repair requirements. The Hercules MCU is non-repairable with respect to permanent

faults. A power-on reset of the Hercules MCU may be considered a repair activity for transient

faults per some definitions of system repair requirements.

– Define system decommissioning requirements. The Hercules MCU has no specific decommisioning

requirements.

– Define system disposal requirements. The Hercules MCU has no specific disposal requirements.

• Avoidance of Systematic Errors

– Verify the application of appropriate best practices at all stages of hardware and system

development (including development of hardware and system diagnostics external to the MCU) to

avoid systematic failure and to control random failures. This may include but is not limited to

compliance to the requirements documented in IEC61508-2;Annex A Tables A.15 through A.18, as

well as Annex B Tables B.1 through B.6

– Verify that any software implemented (including software diagnostics) is developed with an

appropriate set of measures to avoid systematic errors

• Safety Concept Definition

– Define the supported safety functions and verify that the microcontroller behaves properly to

SPNU575A–May 2014–Revised September 2016

Submit Documentation Feedback

Copyright © 2014–2016, Texas Instruments Incorporated

Safety Manual for RM57x Hercules ARM Safety MCUs

23

Page 24

System Integrator Recommendations

support execution of the defined safety function. This microcontroller is a generic product, which is

capable of supporting a variety of safety functions but does not have fixed support for any specific

safety function.

– Define the system-level safe state concept considering safe-state entry, maintenance of safe state,

and safe-state exit as appropriate to the application and verify correct implementation

– Define the system-level error-handling concept and verify correct implementation.

– Define appropriate overall timing requirements for safety metrics to be calculated for the application

– Define appropriate safety metric targets for the application

• Safety Concept Implementation

– Select and implement an appropriate set of diagnostics and safety mechanisms from the MCU

safety manual as necessary to satisfy the requirements of the targeted standards and the high level

safety concept. Dependent on the results of the system level safety analysis, it may not be

necessary to implement all diagnostic measures which TI has identified.

– For the device diagnostics listed as "system" in Table 4, implement the diagnostic in a manner that

meets functional safety requirements of the system, particularly monitoring of the external clock,

monitoring of voltage, and MCU state monitoring via external watchdog logic. TI's recommendations

are based on analysis of what faults might be detected external to the MCU when considering fault

models/failure modes described in IEC 61508 -2 Annex A as to be considered for any claims of

high diagnostic coverage, including both permanent and transient failure modes.

– Implement appropriate mechanisms to detect shorts between pins on the device. Tests may include

I/O loopback tests, information redundancy, or system-level mechanisms designed to detect shorts.

– Any end-to-end communications diagnostics implemented should consider the failure modes and

potential mitigating safety measures described in IEC 61784-3:2010 and summarized in IEC 617843:2010 in Table 1.

– Ensure that any additional system level hardware or software diagnostics created or implemented

by the system integrator are developed with an appropriate process to avoid systematic errors.

– Define an appropriate diagnostic test interval per diagnostic to be implemented.

• Verification of Safety Concept including Safety Metric Calculation

– Verify the behavior of the MCU outputs in the system when the MCU is in a faulted condition.

– Evaluate the system design for specific failure modes of functional logic and diagnostic logic which

are detectable based on the specific application usage and the specific diagnostics applied. TI's

safety analysis for the MCU considers all fault models noted in IEC 61508-2 Annex A as to be