Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

RF430FRL15xH NFC ISO 15693 Sensor Transponder

1 Device Overview

1.1 Features

1

• ISO/IEC 15693, ISO/IEC 18000-3 (Mode 1)

Compliant RF Interface

• Power Supply System With Either Battery or

13.56-MHz H-Field Supply

• 14-Bit Sigma-Delta Analog-to-Digital Converter

(ADC)

• Internal Temperature Sensor

• Resistive Sensor Bias Interface

• CRC16 CCITT Generator

• MSP430™ Mixed-Signal Microcontroller

– 2KB of FRAM

– 4KB of SRAM

– 8KB of ROM

– Supply Voltage Range: 1.45 V to 1.65 V

– Low Power Consumption

• Active Mode (AM): 140 µA/MHz (1.5 V)

• Standby Mode (LPM3): 16 µA

– 16-Bit RISC Architecture

– Up to 2-MHz CPU System Clock

– Compact Clock System

• 4-MHz High-Frequency Clock

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

• 256-kHz Internal Low-Frequency Clock

Source

• External Clock Input

– 16-Bit Timer_A With Three Capture/Compare

Registers

– LV Port Logic

• VOLLower Than 0.15 V at 400 µA

• VOHHigher Than (V

– 0.15 V) at 400 µA

DDB

• Timer_A PWM Signal Available on All Ports

– eUSCI_B Module Supports 3-Wire and 4-Wire

SPI and I2C

– 32-Bit Watchdog Timer (WDT_A)

– ROM Development Mode (Map ROM Addresses

to SRAM to Enable Firmware Development)

– Full 4-Wire JTAG Debug Interface

• For Complete Module Descriptions, See the

RF430FRL15xH Family Technical Reference

Manual (SLAU506)

• For Application Operation and Programming, See

the RF430FRL15xH Firmware User's Guide

(SLAU603)

1.2 Applications

• Industrial Wireless Sensors • Medical Wireless Sensors

1.3 Description

The RF430FRL15xH device is a 13.56-MHz transponder chip with a programmable 16-bit MSP430™ lowpower microcontroller. The device features embedded universal FRAM nonvolatile memory for storage of

program code or user data such as calibration and measurement data. The RF430FRL15xH supports

communication, parameter setting, and configuration through the ISO/IEC 15693, ISO/IEC 18000-3

compliant RFID interface and the SPI or I2C interface. Sensor measurements are supported by the

internal temperature sensor and the onboard 14-bit sigma-delta analog-to-digital converter (ADC), and

digital sensors can be connected through SPI or I2C.

The RF430FRL15xH device is optimized for operation in fully passive (battery-less) or single-cell batterypowered (semi-active) mode to achieve extended battery life in portable and wireless sensing applications.

FRAM is a nonvolatile memory that combines the speed, flexibility, and endurance of SRAM with the

stability and reliability of flash, all at lower total power consumption.

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

eUSCI_B0

SPI

I C

2

8KB

ROM

CPU and

Working

Registers

4W-JTAG

Reset

Int-Logic

VDDB

TMS, TCK,

TDI, TDO

P1.0 to P1.7

RST/NMI

Debug

support

ANT

1

ANT

2

VSS

VDDH

CLKIN

VDDSW

VDD2X

CP1

CP2

VDDD

4KB

RAM

2KB

FRAM

CRC

16 bit

Timer_A

3 CC

Registers

IO Port

8 I/Os

with

interrupt

capability

14-Bit

Sigma-

Delta

ADC

ISO

15693

Decode

and

Encode

Watchdog

WDTA

32/16 Bit

ISO

15693

Analog

Front End

Power

Supply

System

MAB

LF-OSC

HF-OSC

ACLK

SMCLK

MCLK

Clock

System

C

RES

L

RES

ADC0/ADC1/ADC2

TEMP1/TEMP2

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

PART NUMBER PACKAGE BODY SIZE

RF430FRL152H VQFN (24) 4 mm x 4 mm

RF430FRL153H VQFN (24) 4 mm x 4 mm

RF430FRL154H VQFN (24) 4 mm x 4 mm

(1) For the most current part, package, and ordering information for all available devices, see the Package

Option Addendum in Section 9, or see the TI web site at www.ti.com.

(2) The sizes shown here are approximations. For the package dimensions with tolerances, see the

Mechanical Data in Section 9.

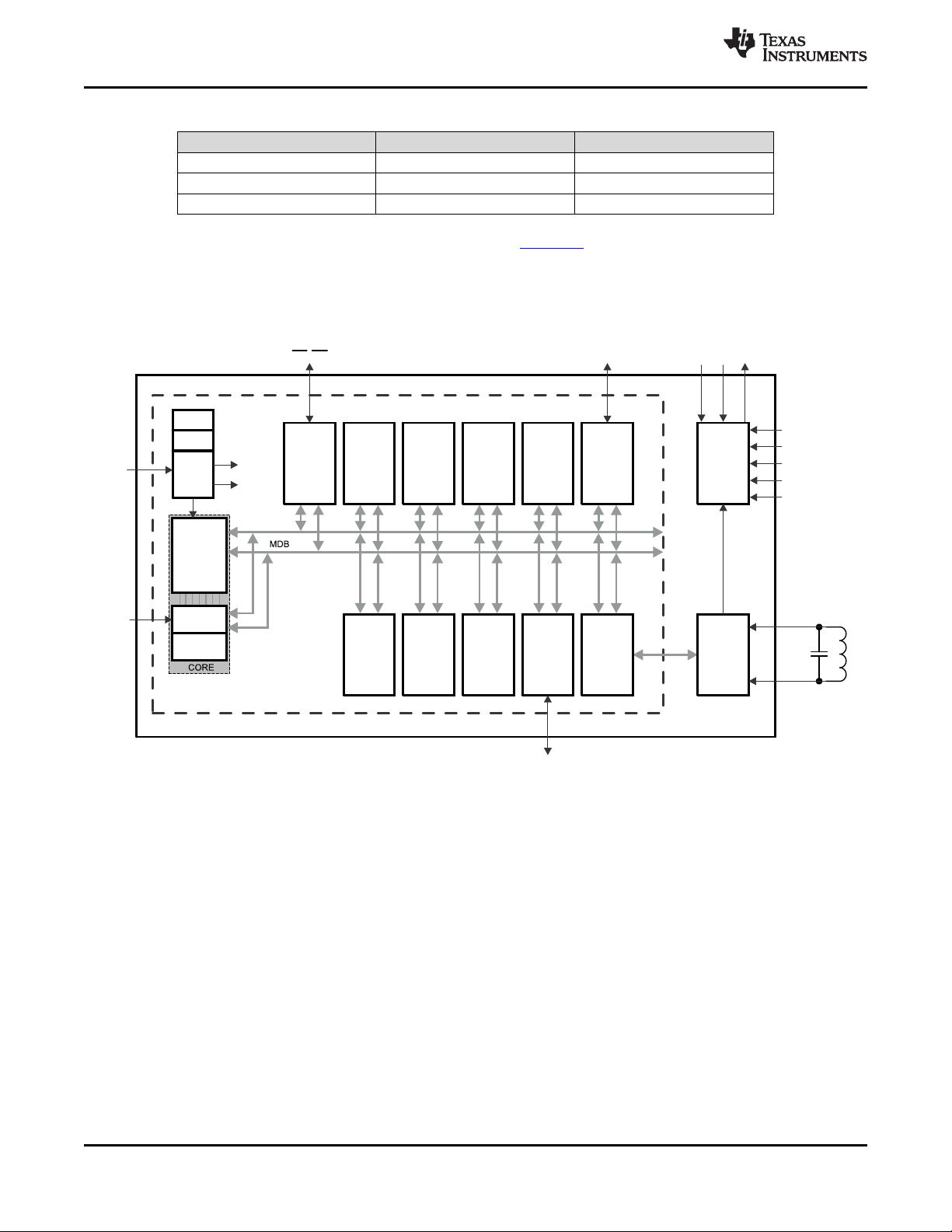

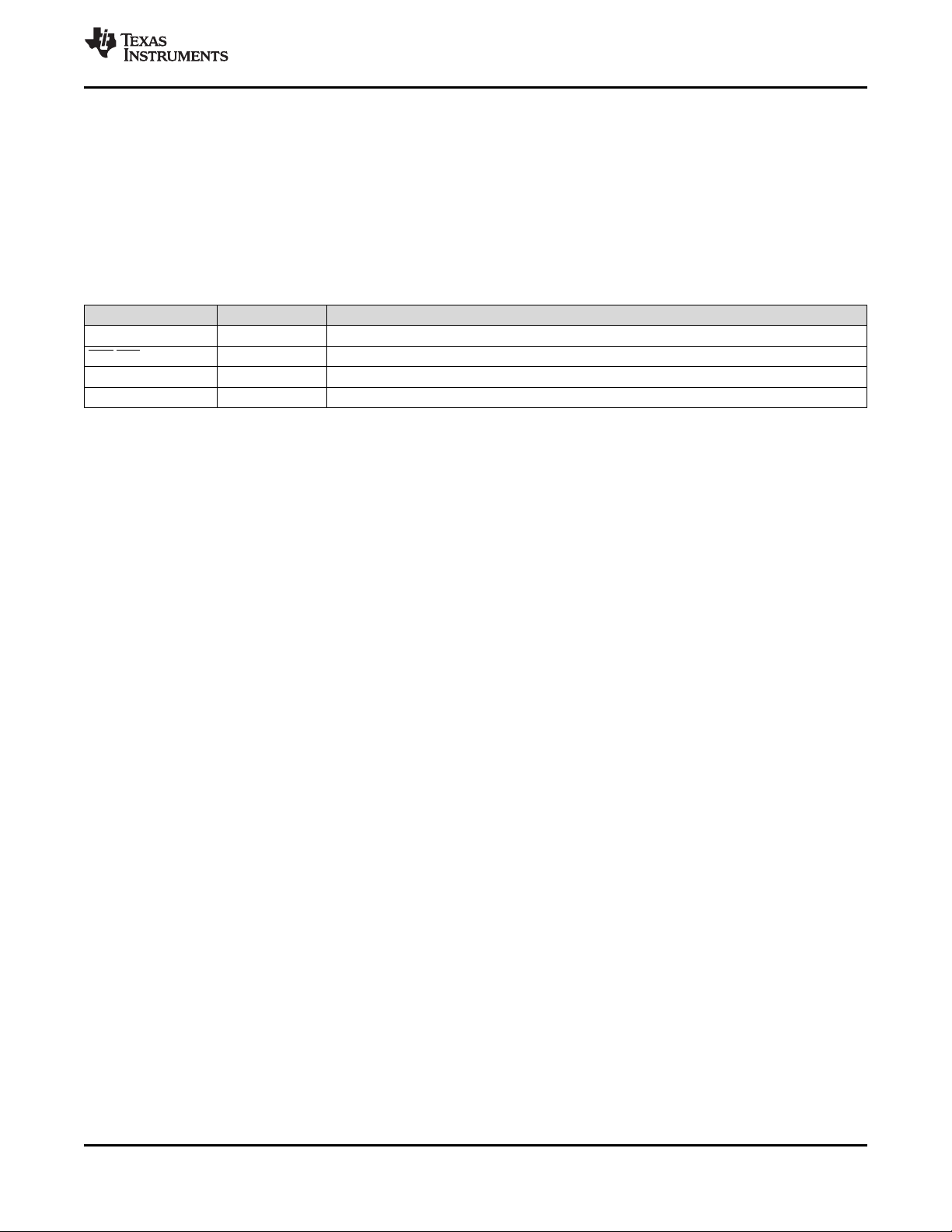

1.4 Functional Block Diagram

Figure 1-1 shows the block diagram of the RF430FRL15xH device.

Device Information

(1)

(2)

2 Device Overview Copyright © 2012–2014, Texas Instruments Incorporated

Figure 1-1. Functional Block Diagram

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

Table of Contents

1 Device Overview ......................................... 1 5.18 RFPMM, Power Supply Switch ..................... 19

1.1 Features .............................................. 1 5.19 RFPMM, Bandgap Reference....................... 19

1.2 Applications........................................... 1 5.20 RFPMM, Voltage Doubler........................... 19

1.3 Description............................................ 1 5.21 RFPMM, Voltage Supervision ...................... 19

1.4 Functional Block Diagram ............................ 2 5.22 SD14, Performance ................................. 20

2 Revision History ......................................... 4 5.23 SVSS Generator .................................... 20

3 Device Comparison ..................................... 5 5.24 Thermistor Bias Generator.......................... 21

4 Terminal Configuration and Functions.............. 6 5.25 Temperature Sensor ................................ 21

4.1 Pin Diagram .......................................... 6

4.2 Signal Descriptions ................................... 7

4.3 Pin Multiplexing....................................... 9

4.4 Connections for Unused Pins ........................ 9

5 Specifications........................................... 10

5.1 Absolute Maximum Ratings ........................ 10

5.2 ESD Ratings ........................................ 10

5.3 Recommended Operating Conditions............... 10

5.4 Recommended Operating Conditions, Resonant

Circuit................................................ 11 6.5 Memory.............................................. 26

5.5 Active Mode Supply Current Into V

External Current .................................... 11

5.6 Low-Power Mode Supply Current (Into V

Excluding External Current.......................... 11

5.7 Digital I/Os (P1, RST/NMI).......................... 12

5.8 High-Frequency Oscillator (4 MHz), HFOSC ....... 12

5.9 Low-Frequency Oscillator (256 kHz), LFOSC ...... 12

5.10 Wake-Up From Low-Power Modes ................. 13

5.11 Timer_A ............................................. 13

5.12 eUSCI (SPI Master Mode) Recommended

Operating Conditions................................ 14

5.13 eUSCI (SPI Master Mode) .......................... 14

5.14 eUSCI (SPI Slave Mode) ........................... 16

5.15 eUSCI (I

5.16 FRAM................................................ 18

5.17 JTAG ................................................ 18

2

C Mode)................................... 18

DDB

Excluding

)

DDB

5.26 RF13M, Power Supply and Recommended

Operating Conditions................................ 21

5.27 RF13M, ISO/IEC 15693 ASK Demodulator......... 21

5.28 RF13M, ISO/IEC 15693 Compliant Load Modulator 21

6 Detailed Description ................................... 22

6.1 CPU ................................................. 22

6.2 Instruction Set....................................... 22

6.3 Operating Modes.................................... 23

6.4 Interrupt Vector Addresses.......................... 24

6.6 Peripherals .......................................... 27

6.7 Port Schematics..................................... 33

6.8 Device Descriptors (TLV) ........................... 41

7 Applications, Implementation, and Layout ....... 42

8 Device and Documentation Support ............... 43

8.1 Device Support...................................... 43

8.2 Documentation Support ............................. 44

8.3 Related Links........................................ 44

8.4 Community Resources .............................. 45

8.5 Trademarks.......................................... 45

8.6 Electrostatic Discharge Caution..................... 45

8.7 Glossary............................................. 45

9 Mechanical Packaging and Orderable

Information .............................................. 45

9.1 Packaging Information .............................. 45

Copyright © 2012–2014, Texas Instruments Incorporated Table of Contents 3

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

2 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from November 13, 2014 to December 8, 2014 Page

• Corrected all instances of the title of the RF430FRL15xH Family Technical Reference Manual .......................... 1

• Corrected all instances of the title of the RF430FRL15xH Firmware User's Guide ......................................... 1

• Moved T

• Changed title of Section 5.2 to ESD Ratings.................................................................................... 10

to Absolute Maximum Ratings table ................................................................................ 10

stg

4 Revision History Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

www.ti.com

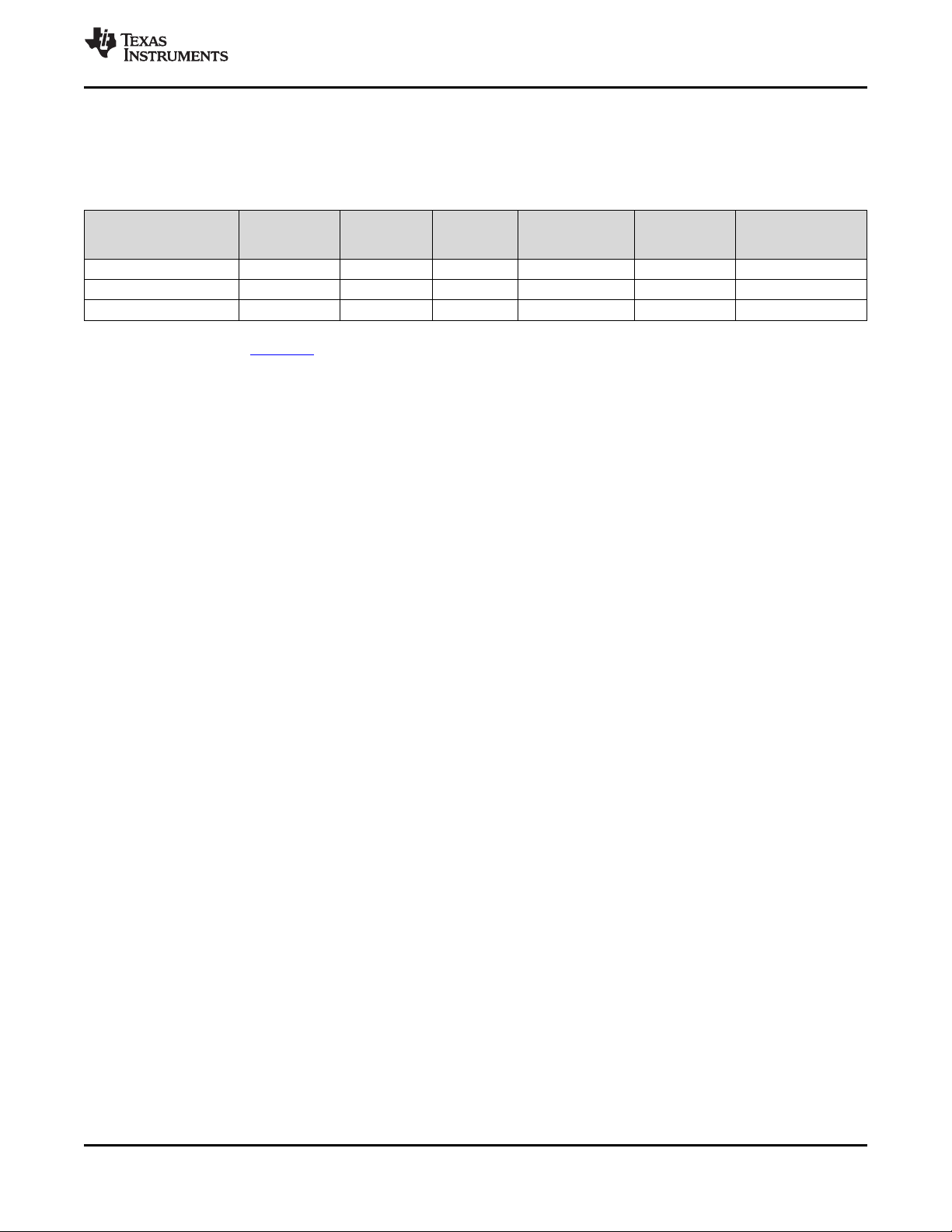

3 Device Comparison

Table 3-1 summarizes the available family members.

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

Table 3-1. Device Comparison

Device Timer ISO/IEC 15693 eUSCI_B SD14

RF430FRL152H 2 4 Yes Yes Yes Yes

RF430FRL153H 2 4 Yes Yes No Yes

RF430FRL154H 2 4 Yes Yes Yes No

(1) For the most current part, package, and ordering information for all available devices, see the Package Option Addendum in Section 9,

or see the TI web site at www.ti.com.

FRAM SRAM

(KB) (KB)

(1)

13.56-MHz

Front End

Copyright © 2012–2014, Texas Instruments Incorporated Device Comparison 5

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

VSS

Exposed die

attached pad

ADC2/TEMP2

SVSS

ADC1/TEMP1

TST1

TST2

ADC0

VDD2X

P1.3/SPI_STE/TA0.2/ACLK/TA0CLK

P1.2/SPI_CLK/MCLK/TA0.0

RST/NMI

P1.1/SPI_SOMI/SCL/ACLK/TA0.2/CCI0.0

VDDD

VDDH

TCK/P1.4/TA0.1/SMCLK/CCI0.1

TDI/P1.5/TA0.2/MCLK/CCI0.1

TDO/P1.6/TA0.0/TA0.2/CCI0.2

TMS/P1.7/TA0.1/TA0.0/CCI0.2

ANT1

VDDB

ANT2

VDDSW

CP1

CP2

1

2

3

4

5

6

18

17

16

15

14

13

7 8 9 10 11 12

24 23 22 21 20 19

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

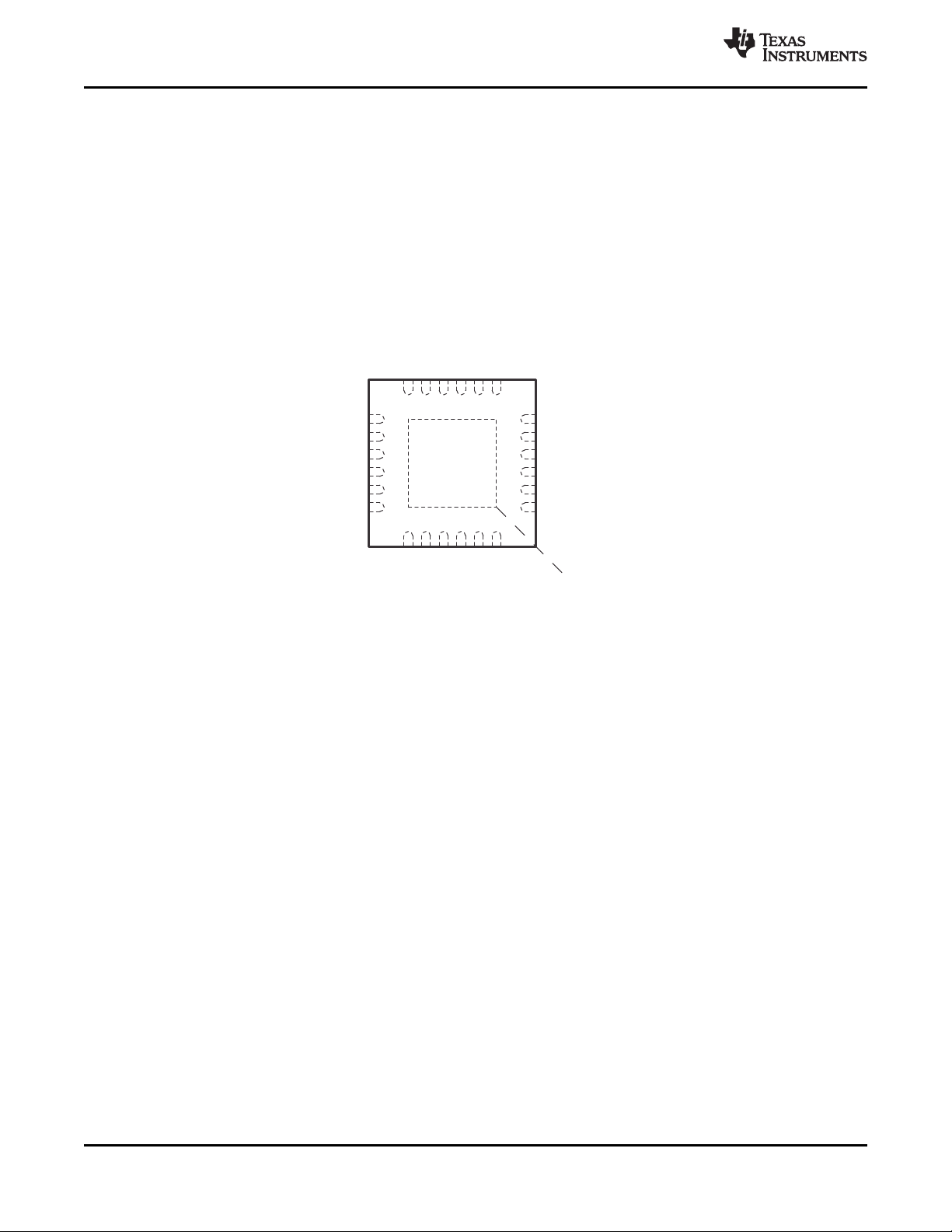

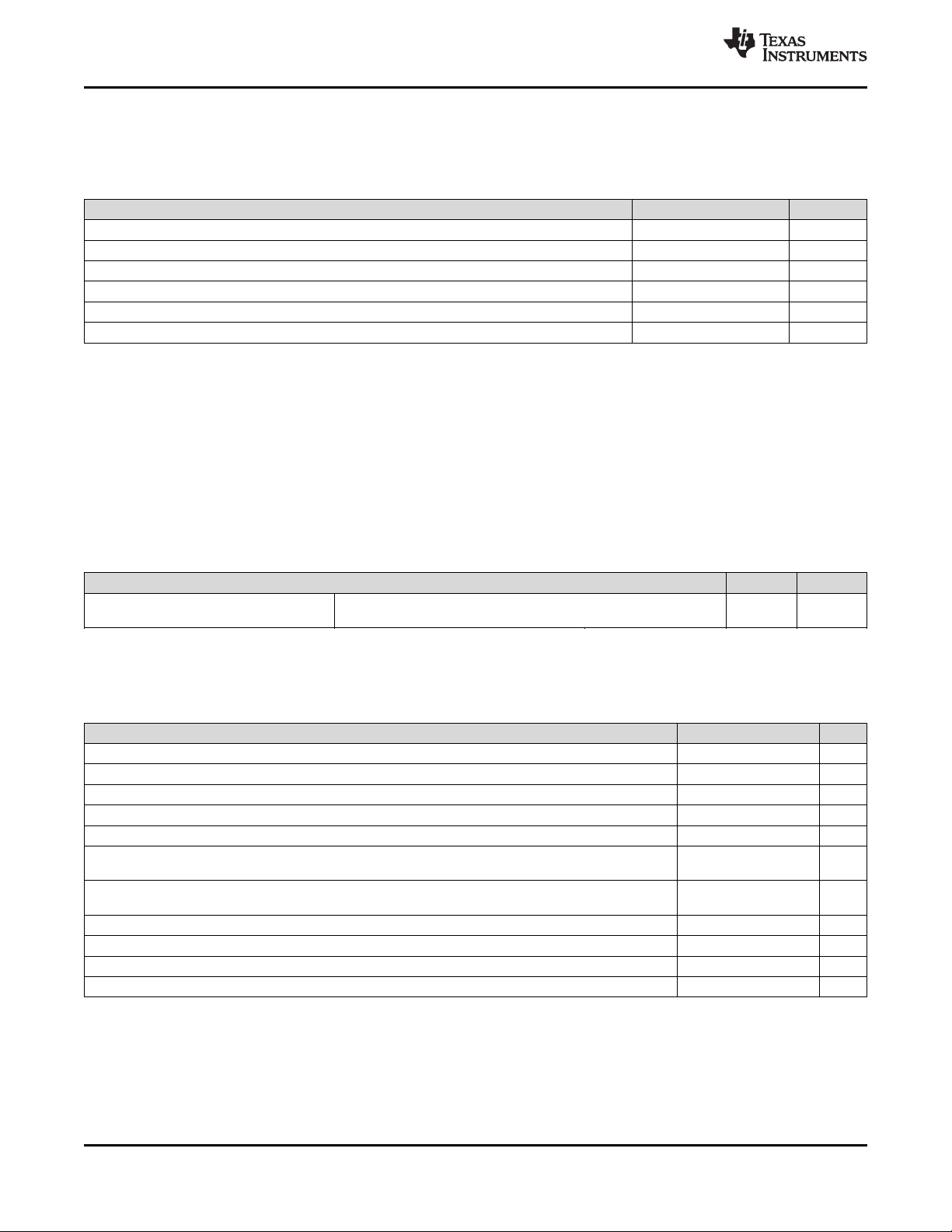

4 Terminal Configuration and Functions

4.1 Pin Diagram

Figure 4-1 shows the pin assignments on the 24-pin RGE package.

www.ti.com

Figure 4-1. 24-Pin RGE Package (Top View)

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

Submit Documentation Feedback

6 Terminal Configuration and Functions Copyright © 2012–2014, Texas Instruments Incorporated

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

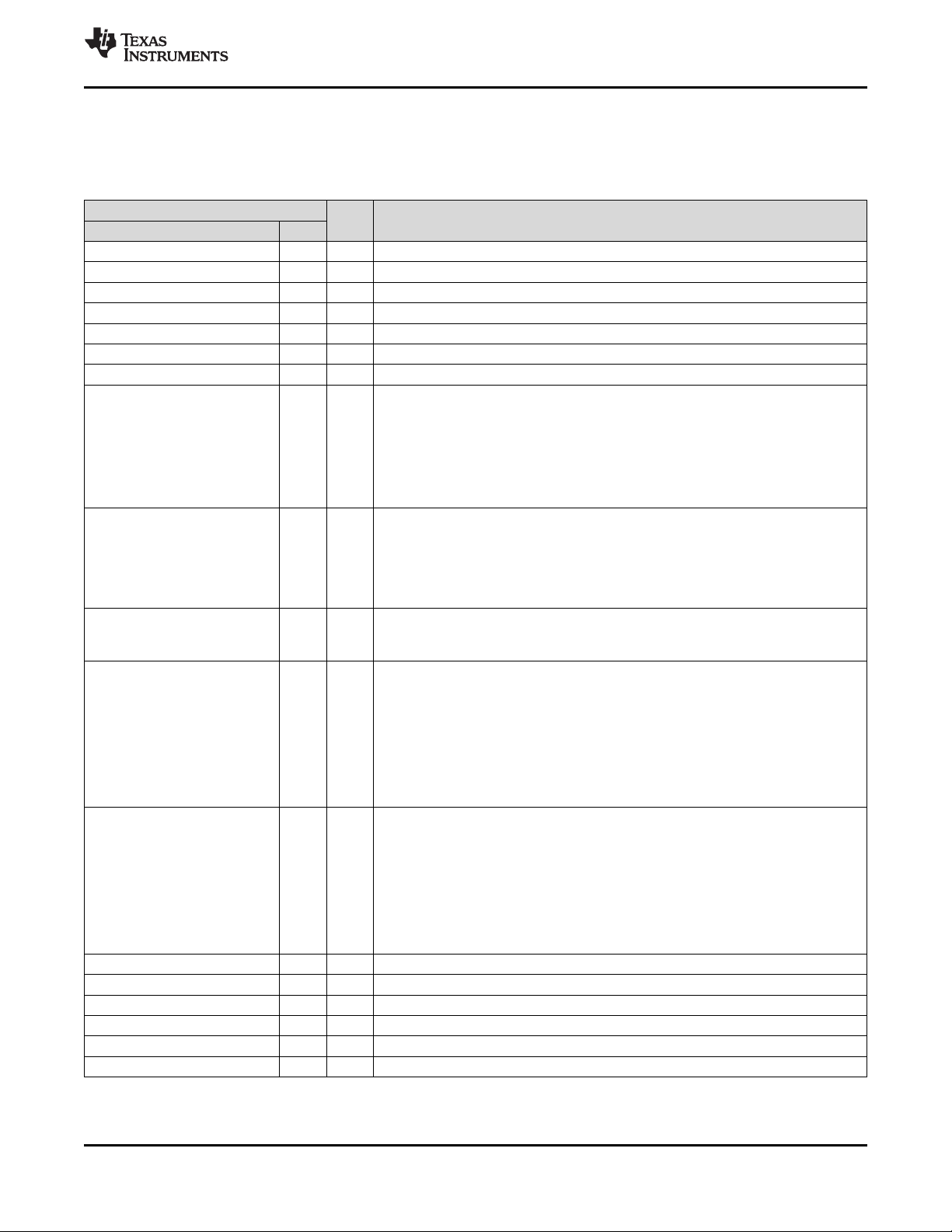

4.2 Signal Descriptions

Table 4-1 describes the signals.

Table 4-1. Signal Descriptions

TERMINAL

NAME NO.

ANT1 1 I Antenna input 1

ANT2 2 I Antenna input 2

V

V

DDSW

DDB

3 Switched supply voltage

4 Battery supply voltage

CP1 5 Charge pump flying cap terminal 1

CP2 6 Charge pump flying cap terminal 2

V

DD2X

7 Voltage doubler output

P1.3 General-purpose digital I/O

SPI_STE SPI slave transmit enable

TA0.2 Timer_A TA0 OUT2 output

8 I/O

ACLK ACLK output (divided by 1, 2, 4, 8, 16, or 32)

TA0CLK Timer_A TA0 clock signal TA0CLK input

I/O

(1)

DESCRIPTION

P1.2 General-purpose digital I/O

SPI_CLK SPI clock

9 I/O

MCLK MCLK output

TA0.0 Timer_A TA0 OUT0 output

RST/NMI 10 I

Reset input active low

Non-maskable interrupt input

P1.1 General-purpose digital I/O

SPI_SOMI SPI slave out master in

SCL I2C clock

11 I/O

ACLK ACLK output (divided by 1, 2, 4, or 8 )

TA0.2 Timer_A TA0 OUT2 output

CCI0.0 Timer_A TA0 CCR0 capture: CCI0B input, compare

P1.0 General-purpose digital I/O

SPI_SIMO SPI slave in master out

SDA I2C data

12 I/O

SMCLK SMCLK output

TA0.1 Timer0_A3 OUT1 output

CCI0.0 Timer_A TA0 CCR0 capture: CCI0A input, compare

ADC0 13 I ADC input pin 0

TST2 14 Internal; connect to GND

SVSS 15 Sensor reference potential

TST1 16 Internal; connect to GND

ADC1 / TEMP1 17 ADC input pin 1 / Resistive bias pin 1

ADC2 / TEMP2 18 ADC input pin 2 / Resistive bias pin 2

(1) I = input, O = output

Copyright © 2012–2014, Texas Instruments Incorporated Terminal Configuration and Functions 7

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

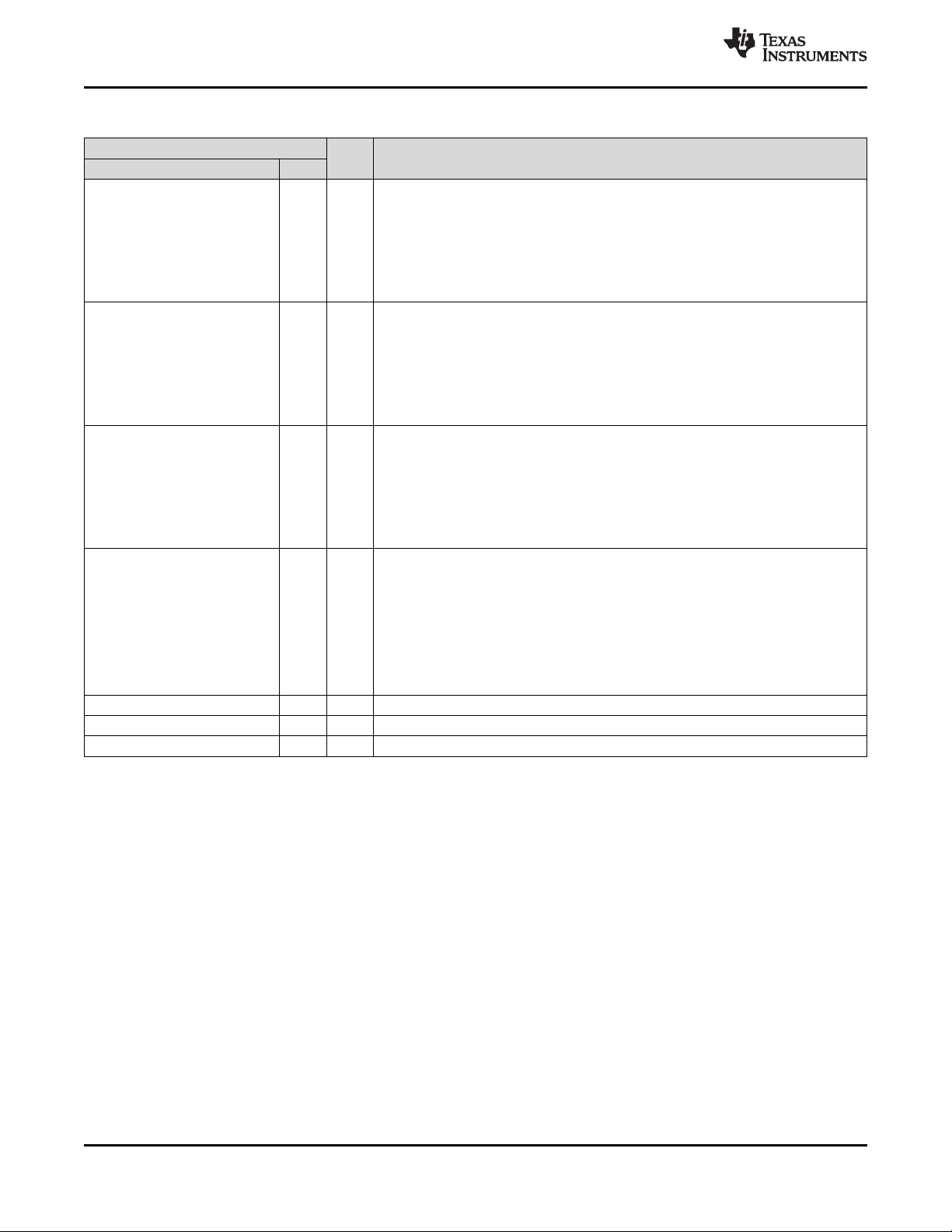

Table 4-1. Signal Descriptions (continued)

TERMINAL

NAME NO.

TMS JTAG test mode select

P1.7 General-purpose digital I/O

TA0.1 Timer_A TA0 OUT1 output

19 I/O

TA0.0 Timer_A TA0 OUT0 output

CCI0.2 Timer_A TA0 CCR2 capture: CCI2B input, compare

TDO JTAG test data output

P1.6 General-purpose digital I/O

TA0.0 Timer_A TA0 OUT0 output

20 I/O

TA0.2 Timer_A TA0 OUT2 output

CCI0.2 Timer_A TA0 CCR2 capture: CCI2A input, compare

TDI JTAG test data input

P1.5 General-purpose digital I/O

TA0.2 Timer_A TA0 OUT2 output

21 I/O

MCLK MCLK output

CCI0.1 Timer_A TA0 CCR1 capture: CCI1B input, compare

I/O

(1)

DESCRIPTION

www.ti.com

TCK JTAG test clock

P1.4 General-purpose digital I/O

TA0.1 Timer_A TA0 OUT1 output

22 I/O

SMCLK SMCLK output

CCI0.1 Timer_A TA0 CCR1 capture: CCI1A input, compare

CLKIN External clock input pin

V

DDH

V

DDD

V

SS

23 O Rectified voltage from RF-AFE

24 Digital supply voltage

Pad Ground reference, bonded to exposed pad

(2)

(2) VSS combines both digital ground (DVSS) and analog ground (AVSS)

8 Terminal Configuration and Functions Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

4.3 Pin Multiplexing

The GPIO port pins are multiplexed with other functions including analog peripherals and serial

communication modules. The pin functions are selected by a combination of register values and device

modes. For schematics of the port pins and details of the multiplexing for each, refer to Section 6.7.

4.4 Connections for Unused Pins

The correct termination of all unused pins is listed in Table 4-2.

Table 4-2. Connection of Unused Pins

Pin Potential Comment

TDI/TMS/TCK Open When used for JTAG function

RST/NMI VCCor V

Px.0 to Px.7 Open Set to port function, output direction

TDO Open Convention: leave TDO terminal as JTAG function

SS

10-nF capacitor to GND/V

SS

Copyright © 2012–2014, Texas Instruments Incorporated Terminal Configuration and Functions 9

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

5 Specifications

www.ti.com

5.1 Absolute Maximum Ratings

(1)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

MIN MAX UNIT

Voltage applied at V

Voltage applied at V

Voltage applied to any pin (references to VSS) -0.3 V

Diode current at any device pin

Current derating factor when I/O ports are switched in parallel electrically and logically

Storage temperature range, T

referenced to VSS(V

DDB

referenced to VSS(V

ANT

(2)

(4) (5) (6)

stg

) -0.3 1.65 V

AMR

) -0.3 3.6 V

AMR

+ 0.3 V

DDB

±2 mA

(3)

0.9

-40 125 °C

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are referenced to VSS.

(3) The diode current increases to ±4.5 mA when two pins are connected, it increases to ±6.75 mA when three pins are connected, and so

on.

(4) Soldering during board manufacturing must follow the current JEDEC J-STD-020 specification with peak reflow temperatures not higher

than classified on the device label on the shipping boxes or reels. If hand soldering is required for application prototyping, peak

temperature must not exceed 250°C for a total of 5 minutes for any single device.

(5) Data retention on FRAM memory cannot be ensured when exceeding the specified maximum storage temperature, T

(6) Programming of devices with user application code should only be performed after reflow or hand soldering. Factory programmed

.

stg

information, such as calibration values, are designed to withstand the temperatures reached in the current JEDEC J-STD-020

specification.

5.2 ESD Ratings

VALUE UNIT

V

ESD

Electrostatic discharge (ESD)

performance

Human body model (HBM), per ANSI/ESDA/JEDEC JS001

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) Low leakage pin: ADC0 has reduced ESD tolerance of ±500 V HBM.

(1)(2)

±2000 V

5.3 Recommended Operating Conditions

Typical data are based on V

V

DDB

V

SS

T

A

C

VDDB

C

VDDSW

C

FLY

C

VDD2X

C

VDDD

C

SVSS

f

SYSTEM

f

CLKIN

(1) Low equivalent series resistance (ESR) capacitor

(2) The MSP430 CPU is clocked directly with MCLK. Both the high and low phase of MCLK must not exceed the pulse duration of the

specified maximum frequency.

(3) Modules may have a different maximum input clock specification. See the specification of the respective module in this data sheet.

Supply voltage during program execution 1.45 1.65 V

Supply voltage (GND reference) 0 V

Operating free-air temperature 0 70 °C

Capacitor on V

Capacitor on V

Charge pump capacitor between CP1 and CP2.

Recommended ratio between C

Capacitor on V

Recommended ratio between C

Capacitor on V

Capacitor between SVSS and V

System frequency

External clock input frequency 32 kHz

= 1.5 V, TA= 25°C (unless otherwise noted)

DDB

(1)

DDB

(1)

DDSW

DD2x

DDD

.

(1)

(2) (3)

FLY

FLY

SS

and C

and C

(1)

VDD2X

VDD2X

is ≥ 1:10.

is ≥ 1:10.

MIN NOM MAX UNIT

100 nF

2.2 µF

(1)

(1)

10 nF

100 nF

1 µF

1 µF

2 MHz

10 Specifications Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

5.4 Recommended Operating Conditions, Resonant Circuit

MIN NOM MAX UNIT

f

c

V

ANT_peak

Z Impedance of LC circuit 6.5 15.5 kΩ

L

RES

C

RES

QT Tank quality factor 30

(1) See the RF13M parameter section.

Carrier frequency 13.56 MHz

Antenna input voltage 3.6 V

Coil inductance 2.66 µH

Resonance capacitance 51.8 – C

(1)

IN

pF

5.5 Active Mode Supply Current Into V

over recommended operating free-air temperature (unless otherwise noted)

PARAMETER V

EXECUTION

MEMORY

Excluding External Current

DDB

(1)

Frequency (f

DDB

1 MHz 2 MHz UNIT

MCLK

= f

SMCLK

TYP MAX TYP MAX

I

AM, FRAM

I

AM, RAM

I

AM, ROM

(2)

(2)

(2)

FRAM 1.5 V 330 420 480 580 µA

RAM 1.5 V 220 300 250 320 µA

ROM 1.5 V 220 300 230 300 µA

(1) All inputs are tied to 0 V or to VCC. Outputs do not source or sink any current.

(2) f

5.6 Low-Power Mode Supply Current (Into V

= 256 kHz, CPUOFF = 0, SCG0 = 0, SCG1 = 0, OSCOFF = 0

ACLK

) Excluding External Current

DDB

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

0ºC 20ºC 45ºC 70ºC

TYP MAX TYP MAX TYP MAX TYP MAX

I

LPM0

PARAMETER V

f

= off, f

MCLK

(2)

1 MHz, f

ACLK

CPUOFF = 1, SCG0 = 0,

SMCLK

= 32 kHz,

=

DDB

1.5 V 170 230 190 210 260 340 µA

SCG1 = 0, OSCOFF = 0

f

I

LPM3

= f

MCLK

f

(3)

= 16 kHz,

ACLK

CPUOFF = 1, SCG0 = 1,

SMCLK

= off,

1.5 V 12 20 13 16 25 65 µA

SCG1 = 1, OSCOFF = 0

f

I

LPM4

= f

MCLK

(4)

0 Hz

CPUOFF = 1, SCG0 = 1,

SMCLK

= f

ACLK

=

1.5 V 11 16 12 15 24 60 µA

SCG1 = 1, OSCOFF = 1

(1) Including current for WDT clocked by ACLK.

(2) CSS: SELM=SELS=HF_CLK, SELA=LF_CLK, DIVM=/2 (2MHz), DIVS=/4 (1MHz), DIVA=/8 (32kHz)

SD14: reset values

RFPMM: battery switch on (EN_BATSWITCH=1)

(3) CSS: SELM=HF_CLK, SELS=SELA=LF_CLK, DIVM=/2 (2MHz), DIVS=/32 (8kHz), DIVA=/16 (16kHz)

SD14: reset values

RFPMM: EN_BATSWITCH=1(battery switch enabled)

(4) CSS: SELM=HF_CLK, SELS=SELA=LF_CLK, DIVM=/2 (2MHz), DIVS=/32 (8kHz), DIVA=/16 (16kHz)

SD14: reset values

RFPMM: EN_BATSWITCH=1(battery switch enabled)

)

(1)

UNIT

Copyright © 2012–2014, Texas Instruments Incorporated Specifications 11

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

5.7 Digital I/Os (P1, RST/NMI)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

V

V

V

I

I

I

t

R

R

R

C

OH

OL

IH

IL

OH

OL

LKG

INT

PULL

RST

EXT

EXT

High-level output voltage V

Low-level output voltage V

High-level input voltage V

Low-level input voltage V

High-level output current V

Low-level output current V

High-impedance leakage current V

External interrupt timing

(3)

Pullup or pulldown resistor 30 35 40 kΩ

= 1.5 V, IOH= -400 µA

DDB

= 1.5 V, IOL= 400 µA

DDB

= 1.5 V V

DDB

= 1.5 V V

DDB

= 1.45 V to 1.65 V for port P1 -400 µA

DDB

= 1.45 V to 1.65 V for port P1 400 µA

DDB

= 1.45 V to 1.65 V -100 100 nA

DDB

P1.x, V

V

DDB

For pulldown: VIN= V

= 1.45 V to 1.65 V 200 ns

DDB

=1.5 V, For pullup: VIN= VSS,

Pullup on RST/NMI 30 35 40 kΩ

External pullup resistor on RST

terminal (optional)

External capacitor on RST terminal 10 nF

(1)

for port P1 V

(2)

for port P1 0.15 V

for port P1

DDB

(1) The maximum total current IOH, for all outputs combined should not exceed 500 µA to hold the maximum voltage drop specified, limited

by low leakage switches.

(2) The maximum total current IOL, for all outputs combined should not exceed 500 µA to hold the maximum voltage drop specified.

(3) An external signal sets the interrupt flag every time the minimum interrupt pulse duration t

INT

is met.

V

DDB

– 0.15

0.7 ×

V

DDB

0.3 ×

V

DDB

47 kΩ

5.8 High-Frequency Oscillator (4 MHz), HFOSC

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

HFOSC

Duty cycle 45% 50% 55%

t

START

±20% 3.04 3.8 4.56 MHz

1 µs

5.9 Low-Frequency Oscillator (256 kHz), LFOSC

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

LFO

Duty cycle 45% 50% 55%

t

START

trimmed ±5% 243 256 269 kHz

11 µs

12 Specifications Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

5.10 Wake-Up From Low-Power Modes

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

t

WAKE-UP LPM0

t

WAKE-UP LPM34

t

WAKE-UP RESET

PARAMETER TEST CONDITIONS V

Wake-up time from LPM0 to active

(1)

mode

Wake-up time from LPM3 or LPM4 to

active mode

Wake-up time from RST to active

mode.

(1)

V

(2)

stable 1.5 V 210 310 µs

DDB

DDB

1.5 V 3.2 6 µs

1.5 V 160 260 µs

(1) The wake-up time is measured from the edge of an external wake-up signal (for example, port interrupt or wake-up event) until the first

instruction of the user program is fetched. This time includes the activation of the FRAM during wake-up. f

(2) The wake-up time is measured from the rising edge of the RST signal until the first instruction of the user program is fetched. This time

includes the activation of the FRAM during wake-up. f

MCLK

= 2 MHz.

MIN TYP MAX UNIT

= 2 MHz.

MCLK

5.11 Timer_A

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

f

TA

t

TA,cap

PARAMETER TEST CONDITIONS V

DDB

Internal: SMCLK, ACLK

Timer_A input clock frequency External: TACLK 1.5 V 4 MHz

Duty cycle = 50% ± 10%

Timer_A capture timing 1.5 V 20 ns

All capture inputs, Minimum pulse

duration required for capture

MIN TYP MAX UNIT

Copyright © 2012–2014, Texas Instruments Incorporated Specifications 13

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

5.12 eUSCI (SPI Master Mode) Recommended Operating Conditions

f

eUSCI

PARAMETER CONDITIONS V

eUSCI input clock frequency 1.5 V f

Internal: SMCLK, ACLK

Duty cycle = 50% ± 10%

DDB

MIN TYP MAX UNIT

SYSTEM

MHz

5.13 eUSCI (SPI Master Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

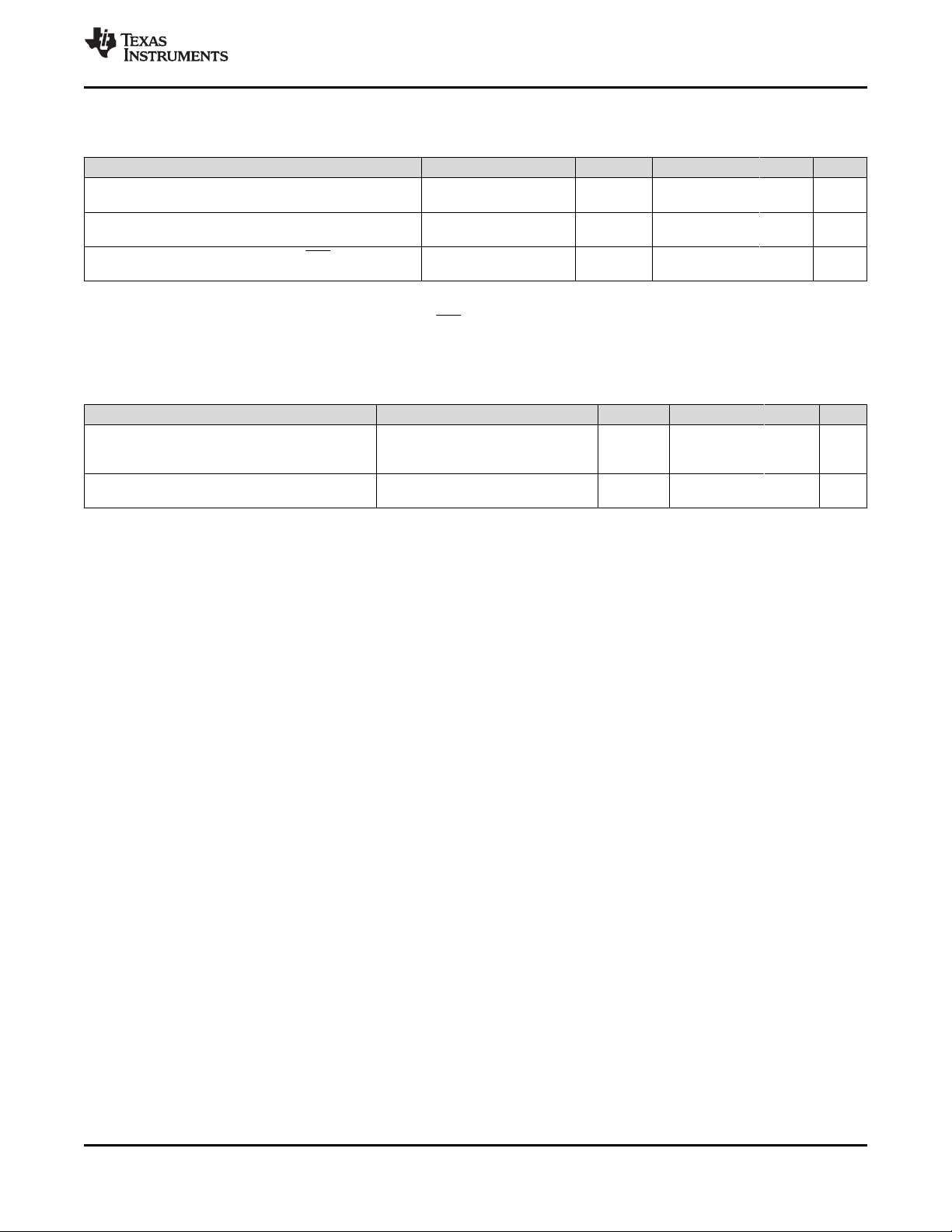

PARAMETER TEST CONDITIONS V

UCSTEM = 0,

t

STE,LEAD

STE lead time, STE active to clock

UCMODEx = 01 or 10

UCSTEM = 1,

UCMODEx = 01 or 10

UCSTEM = 0,

t

STE,LAG

STE lag time, Last clock to STE UCxCLK

inactive cycles

UCMODEx = 01 or 10

UCSTEM = 1,

UCMODEx = 01 or 10

UCSTEM = 0,

t

STE,ACC

STE access time, STE active to SIMO

data out

UCMODEx = 01 or 10

UCSTEM = 1,

UCMODEx = 01 or 10

UCSTEM = 0,

t

STE,DIS

STE disable time, STE inactive to

SIMO high impedance

UCMODEx = 01 or 10

UCSTEM = 1,

UCMODEx = 01 or 10

t

SU,MI

t

HD,MI

t

VALID,MO

t

HD,MO

(1) f

For the slave's parameters t

(2) Specifies the time to drive the next valid data to the SIMO output after the output changing UCLK clock edge. See the timing diagrams

SOMI input data setup time 1.5 V 35 ns

SOMI input data hold time 1.5 V 0 ns

SIMO output data valid time

SIMO output data hold time

UCxCLK

= 1/2t

LO/HI

with t

LO/HI

= max(t

SU,SI(Slave)

(2)

(3)

VALID,MO(eUSCI)

and t

UCLK edge to SIMO valid,

CL= 20 pF

CL= 20 pF 1.5 V 0 ns

+ t

VALID,SO(Slave)

SU,SI(Slave)

, t

SU,MI(eUSCI)

see the SPI parameters of the attached slave.

+ t

VALID,SO(Slave)

DDB

1.5 V 1

1.5 V 1

1.5 V 1

1.5 V 1

1.5 V 55

1.5 V 35

1.5 V 40

1.5 V 30

1.5 V 30 ns

).

in Figure 5-1 and Figure 5-2.

(3) Specifies how long data on the SIMO output is valid after the output changing UCLK clock edge. Negative values indicate that the data

on the SIMO output can become invalid before the output changing clock edge observed on UCLK. See the timing diagrams in Figure 5-

1 and Figure 5-2.

MIN TYP MAX UNIT

(1)

UCxCLK

cycles

ns

ns

14 Specifications Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

t

SU,MI

t

HD,MI

UCLK

SOMI

SIMO

t

VALID,MO

CKPL = 0

CKPL = 1

t

LOW/HIGHtLOW/HIGH

1/f

UCxCLK

t

STE,LEAD

t

STE,LAG

t

STE,ACC

t

STE,DIS

UCMODEx = 01

UCMODEx = 10

STE

t

SU,MI

t

HD,MI

UCLK

SOMI

SIMO

t

VALID,MO

CKPL = 0

CKPL = 1

t

LOW/HIGHtLOW/HIGH

1/f

UCxCLK

STE

t

STE,LEAD

t

STE,LAG

t

STE,ACC

t

STE,DIS

UCMODEx = 01

UCMODEx = 10

www.ti.com

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

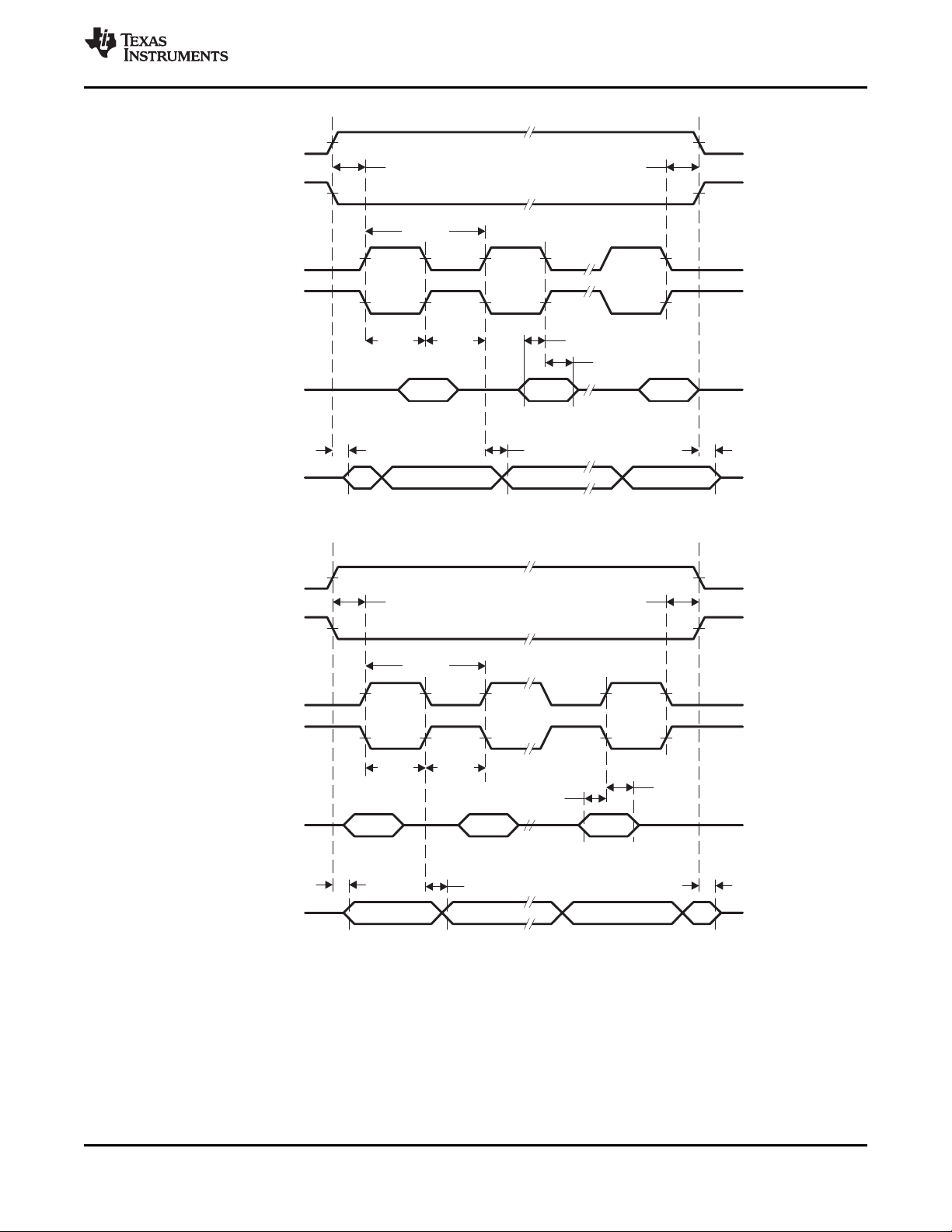

Figure 5-1. SPI Master Mode, CKPH = 0

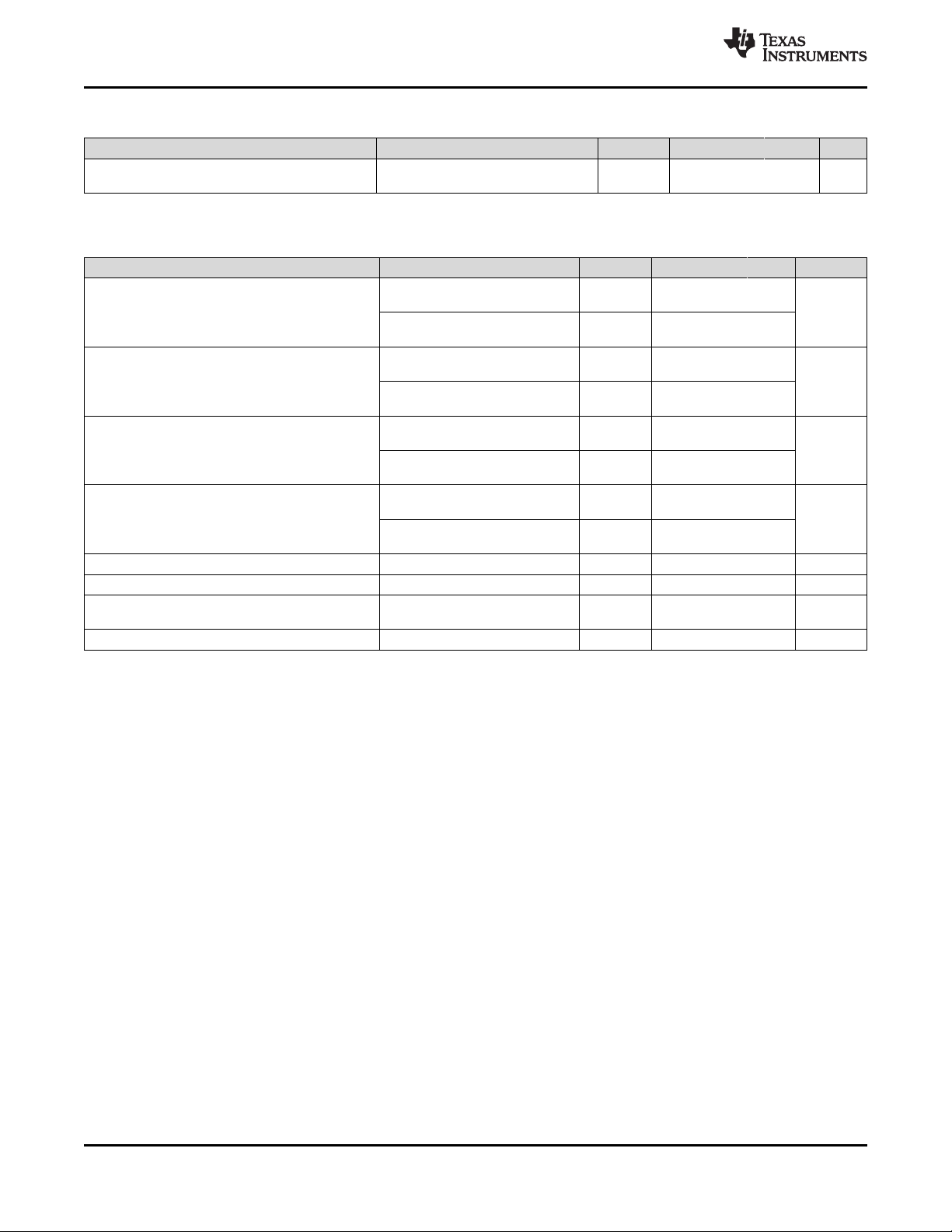

Figure 5-2. SPI Master Mode, CKPH = 1

Copyright © 2012–2014, Texas Instruments Incorporated Specifications 15

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

Submit Documentation Feedback

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

5.14 eUSCI (SPI Slave Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

t

STE,LEAD

t

STE,LAG

t

STE,ACC

t

STE,DIS

t

SU,SI

t

HD,SI

t

VALID,SO

t

HD,SO

(1) f

For the master's parameters t

(2) Specifies the time to drive the next valid data to the SOMI output after the output changing UCLK clock edge. See the timing diagrams

STE lead time, STE active to clock 1.5 V 7 ns

STE lag time, Last clock to STE inactive 1.5 V 0 ns

STE access time, STE active to SOMI data out 1.5 V 65 ns

STE disable time, STE inactive to SOMI high

impedance

SIMO input data setup time 1.5 V 2 ns

SIMO input data hold time 1.5 V 5 ns

SOMI output data valid time

SOMI output data hold time

UCxCLK

= 1/2t

LO/HI

with t

LO/HI

(2)

(3)

≥ max(t

VALID,MO(Master)

SU,MI(Master)

and t

VALID,MO(Master)

UCLK edge to SOMI valid,

CL= 20 pF

CL= 20 pF 1.5 V 4 ns

+ t

SU,SI(eUSCI)

, t

SU,MI(Master)

see the SPI parameters of the attached slave.

+ t

VALID,SO(eUSCI)

in Figure 5-3 and Figure 5-4.

(3) Specifies how long data on the SOMI output is valid after the output changing UCLK clock edge. See the timing diagrams in Figure 5-3

and Figure 5-4.

DDB

1.5 V 40 ns

1.5 V 30 ns

).

(1)

MIN TYP MAX UNIT

16 Specifications Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

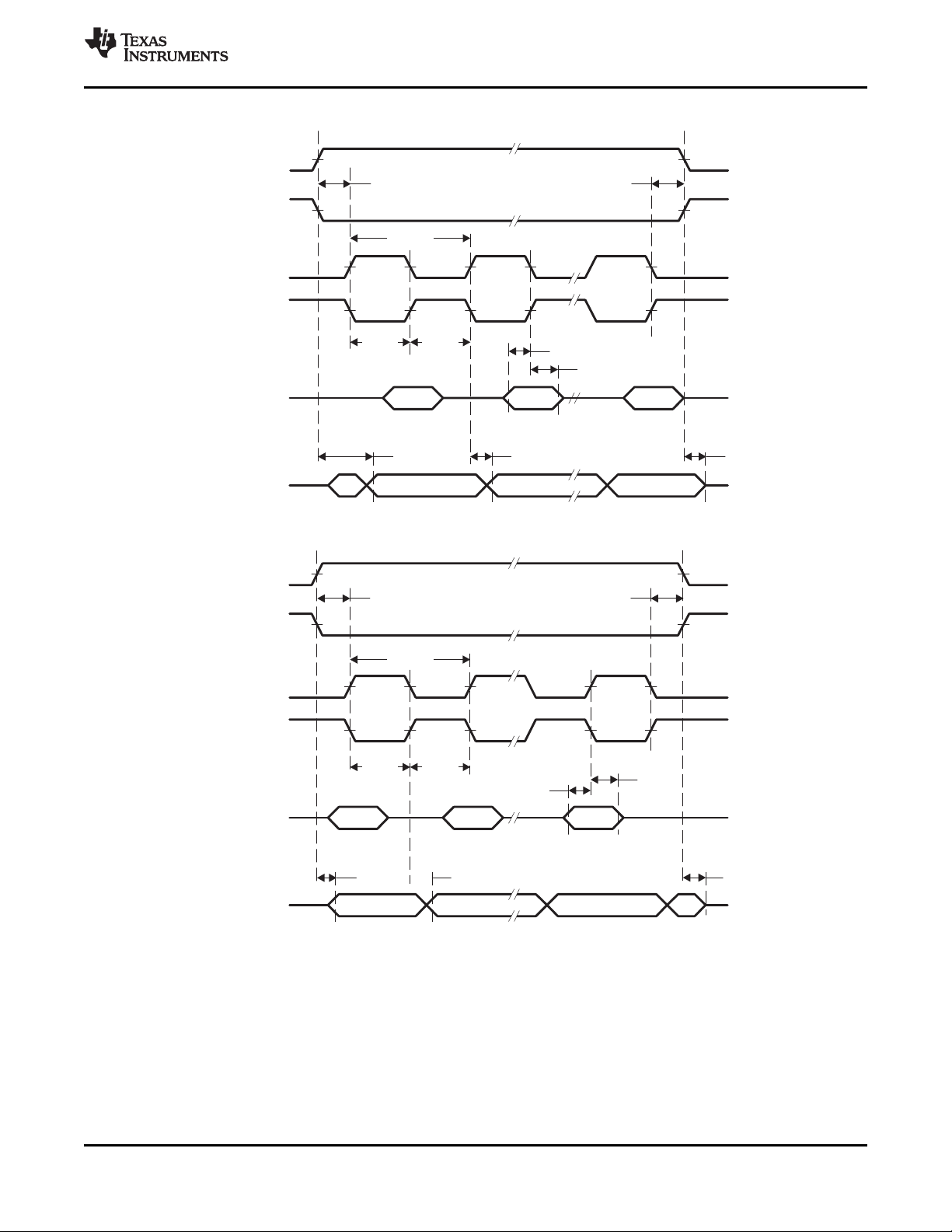

UCLK

CKPL = 0

CKPL = 1

SOMI

SIMO

t

SU,SI

t

HD,SI

t

VALID,SO

t

LOW/HIGH

1/f

UCxCLK

t

LOW/HIGH

t

DIS

t

ACC

STE

t

STE,LEAD

t

STE,LAG

UCMODEx = 01

UCMODEx = 10

UCLK

CKPL = 0

CKPL = 1

SOMI

SIMO

t

SU,SIMO

t

HD,SIMO

t

VALID,SOMI

t

LOW/HIGH

1/f

UCxCLK

t

LOW/HIGH

t

DIS

t

ACC

STE

t

STE,LEAD

t

STE,LAG

UCMODEx = 01

UCMODEx = 10

www.ti.com

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

Figure 5-3. SPI Slave Mode, CKPH = 0

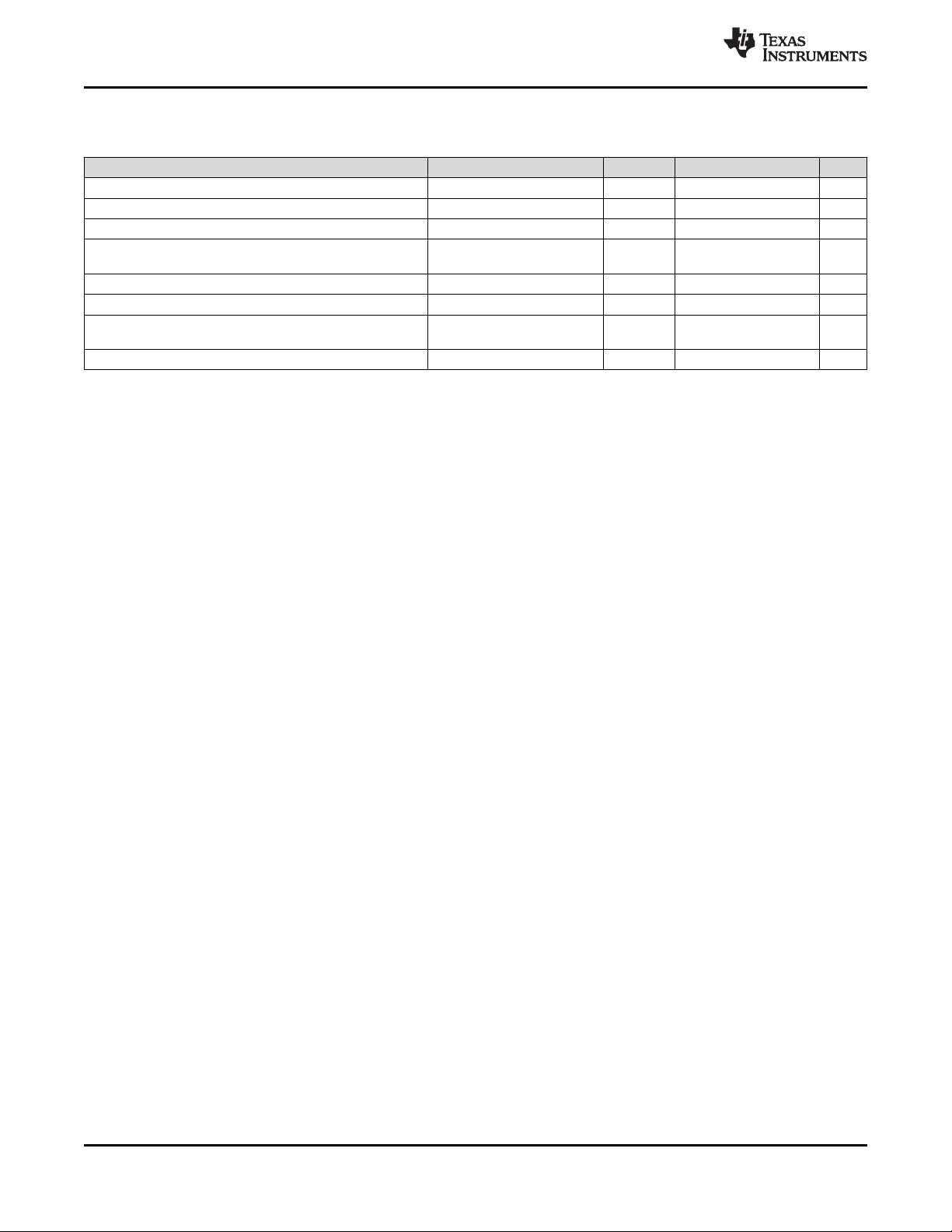

Figure 5-4. SPI Slave Mode, CKPH = 1

Copyright © 2012–2014, Texas Instruments Incorporated Specifications 17

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

Submit Documentation Feedback

SDA

SCL

t

HD,DAT

t

SU,DAT

t

HD,STA

t

HIGH

t

LOW

t

BUF

t

HD,STA

t

SU,STA

t

SP

t

SU,STO

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

5.15 eUSCI (I2C Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted) (see Figure 5-5)

f

eUSCI

f

SCL

t

HD,STA

t

SU,STA

t

HD,DAT

t

SU,DAT

t

SU,STO

t

SP

t

TIMEOUT

PARAMETER TEST CONDITIONS V

DDB

Internal: SMCLK, ACLK

eUSCI input clock frequency External: UCLK f

Duty cycle = 50% ± 10%

SCL clock frequency 1.5 V 0 400 kHz

f

= 100 kHz 4.0

Hold time (repeated) START 1.5 V µs

Setup time for a repeated START 1.5 V µs

SCL

f

> 100 kHz 0.6

SCL

f

= 100 kHz 4.7

SCL

f

> 100 kHz 0.6

SCL

Data hold time 1.5 V 0 ns

Data setup time 1.5 V 250 ns

f

= 100 kHz 4.0

Setup time for STOP 1.5 V µs

SCL

f

> 100 kHz 0.6

SCL

UCGLITx = 0 50 600 ns

Pulse duration of spikes suppressed by input

filter

UCGLITx = 1 25 300 ns

UCGLITx = 2 12.5 150 ns

1.5 V

UCGLITx = 3 6.25 75 ns

UCCLTOx = 1 27 ms

Clock low time-out UCCLTOx = 2 1.5 V 30 ms

UCCLTOx = 3 33 ms

MIN TYP MAX UNIT

SYSTEM

MHz

Figure 5-5. I2C Mode Timing

5.16 FRAM

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

WRITE

t

Retention

Word or byte write time 125 ns

Read/write endurance 10

15

cycles

Data retention duration TJ= 25°C 10 years

5.17 JTAG

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

f

TCK

(1) f

PARAMETER V

(1)

TCK input frequency, 4-wire JTAG

may be restricted to meet the timing requirements of the module selected.

TCK

DDB

1.5 V 0 4 MHz

18 Specifications Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

MIN TYP MAX UNIT

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

5.18 RFPMM, Power Supply Switch

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

TH+

V

TH-

V

HYST

I

BASVBAT

V

DROP

(1) Battery switch closed. Current = 400 µA

Positive going switching threshold

V

= V

TH+

DDB-VDDR

Negative going switching threshold

V

= V

TH-

DDB-VDDR

Switching voltage hysteresis

V

= V

V

V

HYST

DDB

DROP

TH+-VTH-

input leakage current V

= V

DDB

- V

DDSW

(1)

-60 -35 mV

30 70 110 mV

= 1.65 V, Battery switch open 20 nA

DDB

5.19 RFPMM, Bandgap Reference

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

REF

Output voltage V

= 1.4 V to 1.65 V 892 908 mV

DDSW

5.20 RFPMM, Voltage Doubler

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

V

DD2X

DD2X

Output voltage V

Output voltage V

DDSW

DDSW

= 1.4 V, I

= 1.4 V, I

= 1 µA, cont = 0 V

DD2X

= 100 µA, cont = 1 V

DD2X

2 ×

– mV

DDSW

74mV

2 ×

– mV

DDSW

104mV

35 60 mV

50 mV

5.21 RFPMM, Voltage Supervision

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER V

V

DDBTH+

V

DDBTH-

V

DDSWTH+

V

DDSWTH-

V

DDDTH+

V

DDDTH-

V

DD2XTH+

V

DD2XTH-

Positive threshold 1.5 V 1.45 V

Negative threshold 1.5 V 1.40 V

Positive threshold 1.40 V

Negative threshold 1.35 V

Positive threshold 1.5 V 1.00 V

Negative threshold 1.5 V 0.90 V

Positive threshold 1.5 V 2.70 V

Negative threshold 1.5 V 2.475 V

DDSW

MIN TYP MAX UNIT

Copyright © 2012–2014, Texas Instruments Incorporated Specifications 19

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

5.22 SD14, Performance

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN NOM MAX UNIT

f

M

Modulator clock frequency 2 kHz

RES Resolution 8 14 Bit

OSR Oversampling ratio 40 2048

B Bandwidth of input signal 1 Hz

V

I

V

offset

V

GErr

∆EG/∆T Gain error temperature coefficient.

E

Unadjusted

t

Start

Input voltage range VI= V

Offset error Complete signal chain -0.75 0.75

Gain error

(2)

(3)

Total unadjusted error -2 2

Startup time 20

(1) FSR = Full Scale Range (SD14 pre-amplifier Gain PGA gain - SD14 gain =1) .

(2) The gain error EGspecifies the deviation of the actual gain G

temperature and supply voltage variations.

(3) Not production tested.

Internal LF oscillator as clock source for

SD14 module

ADCx

- V

SVSS

0 V

REF

FSR

complete signal chain -2% 2%

complete signal chain 100 ppm/K

FSR

cycles

from the nominal gain G

act

: EG= (G

nom

– G

)/G

act

nom

. It covers process,

nom

mV

% of

% of

CLK

(1)

(1)

5.23 SVSS Generator

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

SVSS

t

Settling

Output voltage I

Settling time after switching SVSS on

(95% of final voltage)

= -5uA .. 0uA 80 125 165 mV

SVSS

Switch from VIRTGND = 1 to VIRTGND = 0 400 1000 ms

20 Specifications Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

5.24 Thermistor Bias Generator

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

OUT,TH

Output current V

= 0 to 0.7 V 2.0 2.4 3.0 µA

OUT

5.25 Temperature Sensor

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

Temperature coefficient 35.7 LSB/K

c

5.26 RF13M, Power Supply and Recommended Operating Conditions

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

DDH

C

IN

Antenna rectified voltage I

= 100 µA 1.8 2 3.6 V

DDH

Input capacitance 2 V RMS 31.5 35 38.5 pF

5.27 RF13M, ISO/IEC 15693 ASK Demodulator

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

DR

100

m100 Modulation depth 100%, test as defined in ISO10373 90% 100%

m10 Modulation depth 10%, test as defined in ISO10373 7% 30%

|t

PLH

t

, t

PLH

t

pd100

t

D100

Input signal data rate 100% downlink modulation, 100% ASK, ISO/IEC 15693 6 26 kbps

– t

| Delta propagation delay of RXD_10 to V

PHL

Propagation delay of RXD_10 to V

PHL

IN

IN

0 2.35 µs

0 7.07 µs

Propagation delay of RXD_100 7.07 µs

Minimum pulse duration of RxD_100 5 µs

5.28 RF13M, ISO/IEC 15693 Compliant Load Modulator

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

f

PICC

V

A_MOD

V

SUB15

Uplink subcarrier modulation frequency 0.2 1 MHz

Modulated antenna voltage, V

= 2,3V 0.5 V

A_unmod

Uplink modulation subcarrier level, ISO/IEC 15693 10 mV

Copyright © 2012–2014, Texas Instruments Incorporated Specifications 21

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6 Detailed Description

6.1 CPU

The MSP430 CPU has a 16-Bit RISC architecture that is highly transparent to the application. All

operations, other than program-flow instructions, are performed as register operations in conjunction with

seven addressing modes for source operand and four addressing modes for destination operand.

The CPU is integrated with 16 registers that provide reduced instruction execution time. The register-toregister operation execution time is one cycle of the CPU clock.

Four of the registers, R0 to R3, are dedicated as program counter, stack pointer, status register, and

constant generator respectively. The remaining registers are general-purpose registers.

Peripherals are connected to the CPU using data, address, and control buses, and can be handled with all

instructions.

6.2 Instruction Set

The instruction set consists of the original 51 instructions with three formats and seven address modes.

Each instruction can operate on word and byte data.

www.ti.com

22 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

www.ti.com

6.3 Operating Modes

The device has one active mode and three software selectable low-power modes of operation. An

interrupt event can wake up the device from any of the three low-power modes, service the request, and

restore back to the low-power mode on return from the interrupt program.

The software-selected low-power mode might not be reached if at least one module still

requests a clock on MCLK, SMCLK, or ACLK. The CPU, however, remains off until an

interrupt occurs.

The following operating modes can be configured by software:

• Active mode AM

– CPU is enabled

– All clocks are active.

• Low-power mode 0 (LPM0)

– CPU is disabled

– MCLK is disabled

– SMCLK is active

– ACLK is active

– HFOSC is off, if not selected for SMCLK or ACLK

• Low-power mode 3 (LPM3)

– CPU is disabled

– MCLK is disabled

– SMCLK is disabled

– ACLK is active

– HFOSC is off, if not selected for ACLK

• Low-power mode 4 (LPM4)

– CPU is disabled

– MCLK is disabled

– SMCLK is disabled

– ACLK is disabled

– HFOSC is off, LFOSC is on

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

NOTE

LPM1 is identical to LPM0, and LPM2 is identical to LPM3, because the SCG0 bit has no influence on

HFOSC.

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 23

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6.4 Interrupt Vector Addresses

The interrupt vectors and the power-up start address are located in the address range 0FFFFh to 0FFE0h.

Address Range 0FFDFh to 0FFD0h is reserved for bootcode signatures. The vector contains the 16-bit

address of the appropriate interrupt-handler instruction sequence.

Table 6-1. Interrupt Sources, Flags, and Vectors

www.ti.com

INTERRUPT SOURCE INTERRUPT FLAG PRIORITY

SYSTEM WORD

INTERRUPT ADDRESS

System Reset

Power-Up

WDTIFG

(1)

Reset FFFEh 15, highest

External Reset

Watchdog

System NMI

SVMIFG, VMAIFG

(1)

(Non)maskable 0FFFCh 14

Vacant memory access

User NMI

NMIIFG

(1)(2)

(Non)maskable 0FFFAh 13

NMI

TimerA0_A3 TA0CCR0 CCIFG0

(3)

Maskable 0FFF8h 12

TA0CCR1 CCIFG1

TimerA0_A3 TA0CCR2 CCIFG2 Maskable 0FFF6h 11

TA0CTL TAIFGTA0IV

Watchdog,

Interval Timer Mode

WDTIFG Maskable 0FFF4h 10

(1)(3)

RF13MRXIFG, RF13MTXIFG, RF13MRXWMIFG,

RF13M Module Maskable 0FFF2h 9

RF13MTXWMIFG, RF13MSLIFG,

RF13MOUFLIFG, RF13MRXEIFG,

RF13MIVx

(1)(3)

(SPI mode)

UCB0RXIFG, UCB0TXIFG

(I2C mode)

UCB0ALIFG, UCB0NACKIFG, UCB0STTIFG,

eUSCIB UCB0STPIFG, UCB0RXIFG3, UCB0TXIFG3, Maskable 0FFF0h 8

UCB0RXIFG2, UCB0TXIFG2, UCB0RXIFG1,

UCB0TXIFG1, UCB0RXIFG0, UCB0TXIFG0,

UCB0CNTIFG, UCB0CLTOIFG, UCB0BIT9IFG

(SD14IV)

Sigma Delta ADC SD14OVIFG, SD14IFG

I/O Port P1 Maskable 0FFECh 6

RFPMM Maskable 0FFEAh 5

RFPMMIFGV2X, RFPMMIFGVH, RFPMMIFGVR,

(1)(3)

(1)(3)

P1IFG.0 to P1IFG.7

(P1IV)

(1)(3)

RFPMMIFGVB, RFPMMIFGVF, RFPMMIV

Maskable 0FFEEh 7

0FFE8h 4

Reserved Reserved

(4)

⋮ ⋮

0FFDCh 0

(1) Multiple source flags

(2) A reset is generated if the CPU tries to fetch instructions from within peripheral space or vacant memory space.

(Non)maskable: the individual interrupt-enable bit can disable an interrupt event, but the general-interrupt enable cannot disable it.

(3) Interrupt flags are located in the module.

(4) Reserved interrupt vectors at these addresses are not used in this device and can be used for regular program code if necessary. To

maintain compatibility with other devices, it is recommended to reserve these locations.

24 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

Table 6-1. Interrupt Sources, Flags, and Vectors (continued)

INTERRUPT SOURCE INTERRUPT FLAG PRIORITY

CRC Value 0FFDAh

CRC Length 0FFD8h

Signatures

Loader Signature 1 0FFD6h

Loader Signature 0 0FFD4h

JTAG Signature 1 0FFD2h

JTAG Signature 0 0FFD0h

SYSTEM WORD

INTERRUPT ADDRESS

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 25

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

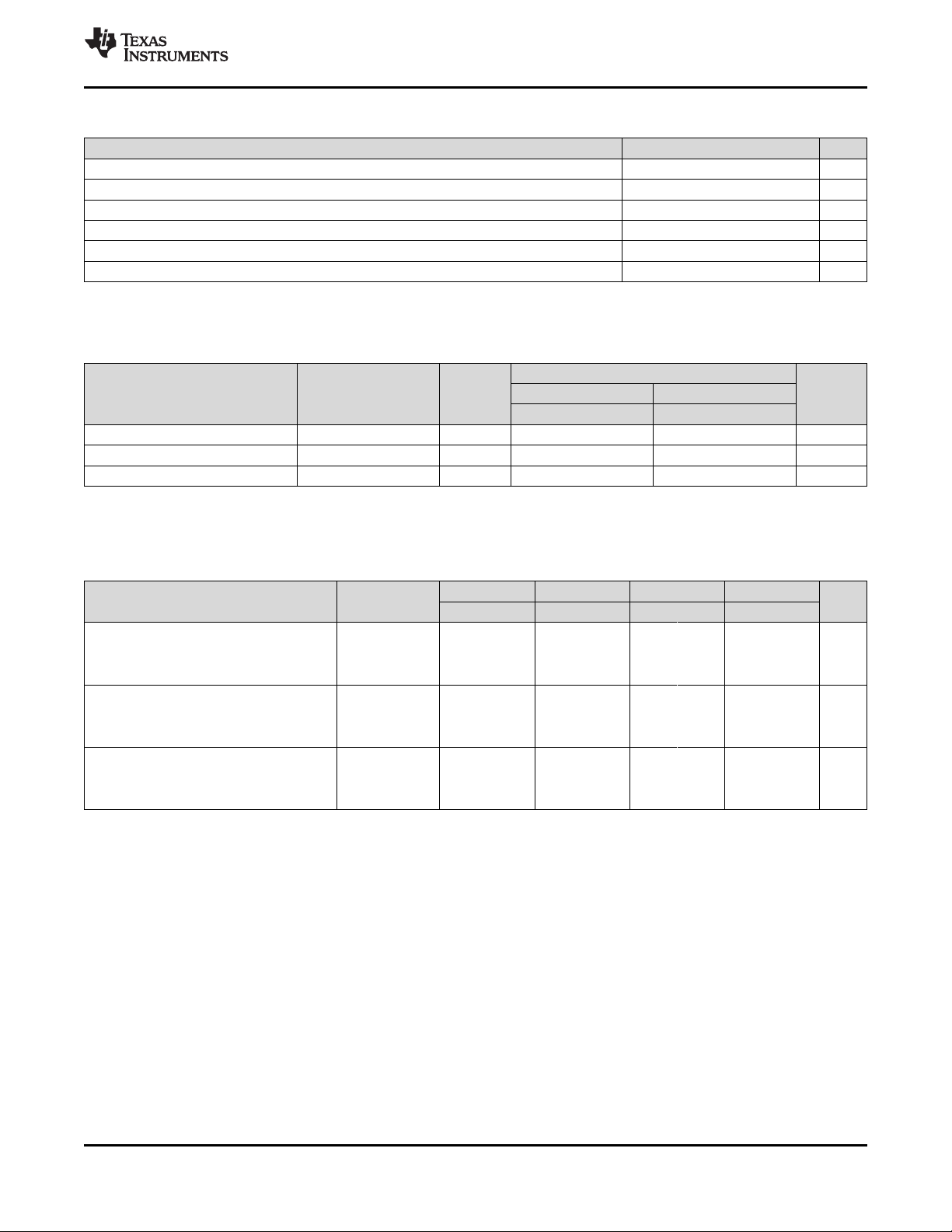

6.5 Memory

Table 6-2 shows the memory organization of the devices.

Table 6-2. Memory Map RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

TYPE RF430FRL152H RF430FRL152H

Memory (FRAM) Total Size 2048 B = 2 KB

Main: interrupt vector FRAM 0FFFFh-0FFE0h

Main: Code Memory Bank A

Boot Data (TLV) Size 64 B 64 B

Application ROM Size 7168 B = 7 KB 3584 B = 3.5 KB

ROM Development Memory Size - 3584 B = 3.5 KB

SRAM Memory Size 4096 B = 4 KB 512 B = 0.5 KB

Peripherals Size 4096 B = 4 KB 4096 B = 4 KB

(1) Write protectable. See also Table 6-3

(2) Address range includes interrupt vector.

(1)(2)

(1)

Bank B

(1)

Bank C

Bank D 448 B

FRAM 01A3Fh-01A00h 01A3Fh-01A00h

ROM 05FFFh-04400h 051FFh-04400h

SRAM - 02BFFh-01E00h

SRAM 02BFFh-01C00h 01DFFh-01C00h

RF430FRL153H RF430FRL153H

RF430FRL154H RF430FRL154H

Normal Mode ROM Development Mode

512 B

0FFFFh-0FE00h

512 B

0FDFFh-0FC00h

512 B

0FBFFh-0FA00h

0F9FFh-0F840h

00FFFh-00000h 00FFFh-00000h

6.5.1 FRAM

The FRAM can be programmed through the JTAG port or in-system by the CPU, data are received

through RF, SPI or I2C Sensor Interface.

Features of the FRAM include:

• Low-power ultra-fast-write non-volatile memory

• Byte and word access capability

• Automated wait state generation

The following address ranges can be write protected by setting the corresponding bit in the SYSCNF

register, see the RF430FRL15xH Family Technical Reference Manual (SLAU506).

Table 6-3. Write Protectable FRAM Address Ranges

BIT Address Range

FRAMLCK2

FRAMLCK1

FRAMLCK0

512 B

0FFFFh-0FE00h

512 B

0FDFFh-0FC00h

512 B

0FBFFh-0FA00h

26 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

www.ti.com

6.5.2 SRAM

The SRAM memory is made up of 8 sectors. Each sector can be completely powered down to save

leakage; however, all data is lost. Features of the SRAM memory include:

• SRAM memory has 8 sectors of 512 B each.

• Each sector 0 to 8 can be complete disabled; however, data retention is lost.

• Each sector 0 to 8 automatically enters low-power retention mode when possible.

6.5.3 Application ROM

The Application ROM consists of four parts. The RF Library provides ISO/IEC 15693 functions necessary

for operating the 13.65 MHz front end. The Function library holds the device and memory function used by

the boot code and RF library. These functions are user accessible. The ROM contains the predefined

application FW. The boot code checks the password and releases control to the application or enables

JTAG on password match, enters LPM4 and waits for debug session, see the RF430FRL15xH Firmware

User's Guide (SLAU603).

6.6 Peripherals

Peripherals are connected to the CPU through data, address, and control buses. All peripherals can be

managed using all instructions. For complete module descriptions, see the RF430FRL15xH Family

Technical Reference Manual (SLAU506).

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6.6.1 Digital I/O, (P1.x)

There is one I/O port implemented, P1, with eight I/O lines RF430FRL15xH.

• All individual I/O bits are independently programmable.

• Any combination of input, output, and interrupt conditions is possible.

• Programmable pullup or pulldown resistor on all ports.

• Edge-selectable interrupt input capability for all ports on P1.

• Read and write access to port-control registers is supported by all instructions.

6.6.2 Versatile I/O Port P1

The versatile I/O ports P1 feature device dependent reset values. The reset values for the

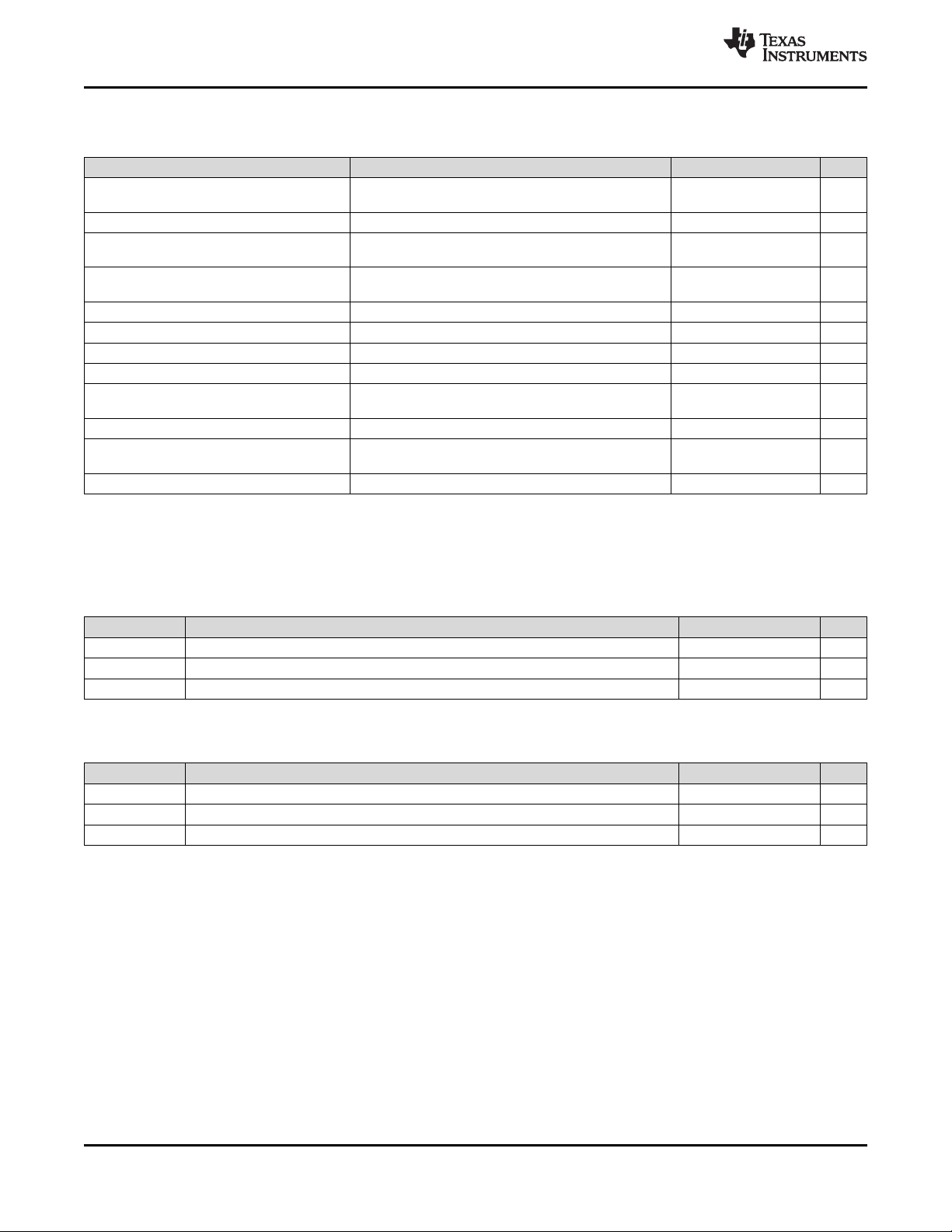

RF430FRL15xH devices are shown in Table 6-4.

Table 6-4. Versatile Port Reset Values

PORT

NUMBER

P1.0 0 0 0 0 0 PUC yes P1.0, input

P1.1 0 0 0 0 0 PUC yes P1.1, input

P1.2 0 0 0 0 0 PUC yes P1.2, input

P1.3 0 0 0 0 0 PUC yes P1.3, input

P1.4 1 0 1 1 1 PUC yes JTAG TCK, P1.4, input

P1.5 1 0 1 1 1 PUC yes JTAG TDI, P1.5, input

P1.6 0 0 0 1 1 PUC yes JTAG TDO, P1.6, output

P1.7 1 0 1 1 1 PUC yes JTAG TMS, P1.7, input

PxOUT PxDIR PxREN PxSEL0 PxSEL1 RESET PORTS ON COMMENT

6.6.3 Oscillator and System Clock

The clock system in the RF430FRL15xH devices is supported by the Compact Clock System (CCS)

module that includes support for an internal trimmable 256-kHz current-controlled low-frequency oscillator

(LFOSC) and an internal 4-MHz current-controlled high-frequency oscillator (HFOSC).

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 27

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

The CCS module is designed to meet the requirements of both low system cost and low power

consumption. The CCS provides a fast turn-on of the oscillators in less than 1 ms. The CCS module

provides the following clock signals:

• Auxiliary clock (ACLK), sourced from the 256-kHz internal LFOSC.

• Main clock (MCLK), the system clock used by the CPU. MCLK can be sourced by same sources made

available to ACLK.

• Sub-Main clock (SMCLK), the subsystem clock used by the peripheral modules. SMCLK can be

sourced by same sources made available to ACLK.

6.6.4 Compact System Module (C-SYS_A)

The Compact SYS module handles many of the system functions within the device. These include poweron reset and power-up clear handling, NMI source selection and management, reset interrupt vector

generators, as well as, configuration management. It also includes a data exchange mechanism through

JTAG called a JTAG mailbox that can be used in the application.

Table 6-5. System Module Interrupt Vector Registers

www.ti.com

INTERRUPT VECTOR

REGISTER

SYSRSTIV, System Reset No interrupt pending 019Eh 00h

SYSSNIV, System NMI No interrupt pending 019Ch 00h

SYSUNIV, User NMI No interrupt pending 019Ah 00h

SYSBERRIV, Bus Error No interrupt pending 0198h 00h

INTERRUPT VECTOR WORD ADDRESS OFFSET PRIORITY

Brownout (BOR) 02h Highest

SVMBOR (BOR) 04h

RST/NMI (BOR) 06h

DoBOR (BOR) 08h

Security violation (BOR) 0Ah

DoPOR (POR) 0Ch

WDT time-out (PUC) 0Eh

WDT key violation (PUC) 10h

CCS key violation 12h

PMM key violation 14h

Peripheral area fetch (PUC) 16h

Reserved 18h-3Eh Lowest

SVMIFG 02h Highest

VMAIFG 04h

JMBINIFG 06h

JMBOUTIFG 08h

Reserved 0Ah-3Eh Lowest

NMIFG 02h Highest

OFIFG 04h

BERR 06h

Reserved 08h-3Eh Lowest

Reserved 02h-3Eh Lowest

6.6.5 Watchdog Timer (WDT_A)

The primary function of the watchdog timer (WDT_A) module is to perform a controlled system restart

after a software problem occurs. If the selected time interval expires, a system reset is generated. If the

watchdog function is not needed in an application, the module can be configured as an interval timer and

can generate interrupts at selected time intervals.

28 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

www.ti.com

6.6.6 Reset, NMI, SVMOUT System

The reset system of the RF430FRL15xH devices features the function reset input, reset output, and NMI

input.

6.6.7 Timer_A (Timer0_A3)

Timer_A is a 16-bit timer/counter with three capture/compare registers. Timer_A can support multiple

capture/compares, PWM outputs, and interval timing. Timer_A also has extensive interrupt capabilities.

Interrupts may be generated from the counter on overflow conditions and from each of the

capture/compare registers.

Table 6-6. Timer0_A3 Signal Connections

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

INPUT PIN DEVICE INPUT MODUL INPUT MODULE DEVICE OUTPUT OUTPUT PIN

NUMBER SIGNAL SIGNAL OUTPUT SIGNAL SIGNAL NUMBER

8 – P1.3 TA0CLK TACLK

ACLK (internal) ACLK

SMCLK (internal) SMCLK

TA0CLK TACLK

12 – P1.0 TA0.0 CCI0A 9 – P1.2

11 – P1.1 TA0.0 CCI0B 20 – P1.6

V

SS

V

DDB

22 – P1.4 TA0.1 CCI1A 12 – P1.0

21 – P1.5 TA0.1 CCI1B 22 – P1.4

V

SS

V

DDB

20 – P1.6 TA0.2 CCI2A 11 – P1.1

19 – P1.7 TA0.2 CCI2B 8 – P1.3

V

SS

V

DDB

GND 19 – P1.7

Vcc

GND 19 – P1.7

Vcc

GND 21 – P1.5

Vcc 20 – P1.6

MODULE BLOCK

Timer NA NA

CCR0 TA0 TA0.0

CCR1 TA1 TA0.1

CCR2 TA2 TA0.2

6.6.8 Enhanced Universal Serial Communication Interface (eUSCI_B0)

The eUSCI_B0 module is used for serial data communication. The eUSCI module supports synchronous

communication protocols such as SPI (3 pin or 4 pin) and I2C.

The eUSCI_B0 module provides support for SPI (3 pin or 4 pin) or I2C.

6.6.9 ISO/IEC 15693 Analog Front End (RF13M)

The ISO/IEC 15693 module supports contact-less communication over the analog front end according to

ISO/IEC 15693 with data rates up to 26.48 kbps for receive and 26.48 kbps for transmit. It includes

decode of receive data and encode of transmit data, both synchronous with the AFE carrier clock.

6.6.10 ISO/IEC 15693 Decoder/Encoder (RF13M)

The module interfaces directly to the analog front end to ensure correct timing for transmit and receive of

data derived from the 13.56-MHz carrier frequency.

6.6.11 CRC16 Module (CRC16)

The CRC16 module produces a signature based on a sequence of entered data values and can be used

for data

checking purposes. The CRC16 module is compliant with ISO/IEC 13239, it is 16 bits long, polynominal is:

x16+ x12+ x5+ 1, direction is backward, and preset is 0xFFFF. For more information see ISO/IEC 13239.

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 29

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6.6.12 14-Bit Sigma-Delta ADC (SD14)

A sigma-delta modulator is provided for high resolution analog-to-digital conversion of quasi-dc voltages:

• First-order integrator, 1-bit comparator, 1-bit DAC

• Sampling frequency of up to 2 kHz

• Fully differential

6.6.13 Programmable Gain Amplifier (SD14)

The PGA features a very high-impedance input and a programmable gain combined with full offset

compensation, very low offset drift, and low noise.

6.6.14 Peripheral Register Map

Table 6-7. Peripheral Register Map

www.ti.com

MODULE NAME REGISTER DESCRIPTION REGISTER OFFSET

RF13M RF13M RX/TX High/Low Watermark Configuration Register RF13MWMCFG 0800h 0Eh

RF13M RX/TX FIFO Fill Level register RF13MFIFOFL 0Ch

RF13M CRC accumulator Register RF13MCRC 0Ah

RF13M Transmit Data FIFO Register RF13MTXF 08h

RF13M Receive Data FIFO Register RF13MRXF 06h

RF13M Interrupt Vector Register RF13MIV 04h

RF13M Interrupt Register RF13MINT 02h

RF13M Control Register RF13MCTL 00h

SD14 SD14 Interrupt Vector Register SD14IV 0700h 0Ch

SD14 Intermediate Conversion Result Register SD14MEM3 0Ah

SD14 Intermediate Conversion Result Register SD14MEM2 08h

SD14 Intermediate Conversion Result Register SD14MEM1 06h

SD14 Conversion Result SD14MEM0 04h

SD14 Control Register 1 SD14CTL1 02h

SD14 Control Register 0 SD14CTL0 00h

eUSCI_B0 Interrupt Vector Word Register UCB0IV 0640h 2Eh

Interrupt Flags Register UCB0IFG 2Ch

Interrupt Enable Register UCB0IE 2Ah

I2C Slave Address Register UCB0I2CSA 20h

Address Mask Register UCB0ADDMASK 1Eh

Received Address Register UCB0ADDRX 1Ch

I2C Own Address 3 Register UCB0I2COA3 1Ah

I2C Own Address 2 Register UCB0I2COA2 18h

I2C Own Address 1 Register UCB0I2COA1 16h

I2C Own Address 0 Register UCB0I2COA0 14h

Transmit Buffer Register UCB0TXBUF 0Eh

Receive Buffer Register UCB0RXBUF 0Ch

Byte Counter Threshold Register UCB0TBCNT 0Ah

Status Word Register UCB0STATW 08h

Bit Rate 1 Register UCB0BR1 07h

Bit Rate 0 Register UCB0BR0 06h

Control Word 1 Register UCB0CTLW1 02h

Control Word 0 Register UCB0CTLW0 00h

BASE

ADDRESS

30 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

www.ti.com

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

Table 6-7. Peripheral Register Map (continued)

MODULE NAME REGISTER DESCRIPTION REGISTER OFFSET

Timer0_A3 Timer0_A Interrupt Vector Register TA0IV 0340h 2Eh

Capture/Compare Register 2 TA0CCR2 16h

Capture/Compare Register 1 TA0CCR1 14h

Capture/Compare Register 0 TA0CCR0 12h

Timer0_A Counter Register TA0R 10h

Capture/Compare Control 2 Register TA0CCTL2 06h

Capture/Compare Control 1 Register TA0CCTL1 04h

Capture/Compare Control 0 Register TA0CCTL0 02h

Timer0_A Control Register TA0CTL 00h

Port P1 Port P1 Interrupt Flag Register P1IFG 0200h 1Ch

Port P1 Interrupt Enable Register P1IE 1Ah

Port P1 Interrupt Edge Select Register P1IES 18h

Port P1 Interrupt Vector Word Register P1IV 0Eh

Port P1 Selection 1 Register P1SEL1 0Ch

Port P1 Selection 0 Register P1SEL0 0Ah

Port P1 Pullup/Pulldown Enable Register P1REN 06h

Port P1 Direction Register P1DIR 04h

Port P1 Outout Register P1OUT 02h

Port P1 Input Register P1IN 00h

CSYS_A Reset Vector Generator Register SYSRSTIV 0180h 1Eh

System NMI Vector Generator Register SYSSNIV 1Ch

User NMI Vector Generator Register SYSUNIV 1Ah

Bus Error Vector Generator Register SYSBERRIV 18h

System Configuration Actuator 0 Register SYSCA0 14h

System Configuration Register SYSCNF 10h

JTAG Mailbox Output Register 1 SYSJMBO1 0Eh

JTAG Mailbox Output Register 0 SYSJMBO0 0Ch

JTAG Mailbox Input Register 1 SYSJMBI1 0Ah

JTAG Mailbox Input Register 0 SYSJMBI0 08h

JTAG Mailbox Control Register SYSJMBC 06h

System Control Register SYSCTL 00h

CCS CCS Control 8 Register CCSCTL8 0160h 10h

CCS Control 7 Register CCSCTL7 0Eh

CCS Control 6Register CCSCTL6 0Ch

CCS Control 5 Register CCSCTL5 0Ah

CCS Control 4 Register CCSCTL4 08h

CCS Control 1 Register CCSCTL1 02h

CCS Control 0 Register CCSCTL0 00h

WDT_A, CRC Watchdog Timer Control Register WDTCTL 0150h 0Ch

CRC Result Reverse Register CRCRESR 06h

CRC Initialization and Result Register CRCINIRES 04h

CRC Data In Reverse Byte Register CRCDIRB 02h

CRC Data In Register CRCDI 00h

FRAM Control General Control 1 Register GCCTL1 0140h 06h

General Control 0 Register GCCTL0 04h

FRAM Control 0 Register FRCTL0 00h

BASE

ADDRESS

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 31

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

www.ti.com

Table 6-7. Peripheral Register Map (continued)

MODULE NAME REGISTER DESCRIPTION REGISTER OFFSET

RFPMM RFPMM Interrupt Vector Register RFPMMIV 0120h 08h

RFPMM Interrupt Flag Register RFPMMIFG 06h

RFPMM Interrupt Enable Register RFPMMIE 04h

RFPMM Control Register 1 RFPMMCTL1 02h

RFPMM Control Register 0 RFPMMCTL0 00h

Special Functions SFR Reset Pin Control Register SFRRPCR 0100h 04h

SFR Interrupt Flag Register SFRIFG1 02h

SFR Interrupt Enable Register SFRIE1 00h

BASE

ADDRESS

32 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

TA0.1

SPI_SIMO/SDA

SMCLK

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModul x IN

#

Pad Logic

P1.0/SPI_SIMO/SDA/SMCLK /TA0 .1/CCI 0.0

PortsOn

P1IRQ.x

P1IE.x

P1IES.x Set

Q

P1IFG.x

eUSCI_B0

Bus

Keeper

www.ti.com

6.7 Port Schematics

6.7.1 Port P1.0 Input/Output

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

(1) X = Don't care

(2) Module controls direction of port, depending on whether RF430 device is master or slave.

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 33

Table 6-8. Port P1.0 Pin Functions

CONTROL BITS OR SIGNALS

PIN NAME (P1.x) x FUNCTION

P1.0/SPI_SIMO/SDA/SMCLK/TA0.1/CCI0.0 0 SMCLK 1 1 0 0

P1.0 (I/O) I:0; O:1 0 0 0

SPI_SIMO/SDA

TA0.1 1 1 1 0

Timer A0, CCI0A 0 ≠0 ≠0 X

(2)

P1DIR.x P1SEL1.x P1SEL0.x

1 0 1 0

(1)

RSELx/

ASELx

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

TA0.2

SPI_SOMI/SCL

ACLK

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModul x IN

#

Pad Logic

P1.1/SPI_SOMI/SCL/ACLK/TA0.2/CCI0.0

PortsOn

P1IRQ.x

P1IE.x

P1IES.x Set

Q

P1IFG.x

eUSCI_B0

Bus

Keeper

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6.7.2 Port P1.1 Input/Output

www.ti.com

(1) X = Don't care

(2) Module controls direction of port, depending on whether RF430 device is master or slave.

34 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Table 6-9. Port P1.1 Pin Functions

CONTROL BITS OR SIGNALS

1 0 1 0

P1DIR.x P1SEL1.x P1SEL0.x

P1.1 (I/O) I:0; O:1 0 0 0

SPI_SOMI/SCL

TA0.2 1 1 1 0

Timer A1, CCI0B 0 ≠0 ≠0 X

(2)

PIN NAME (P1.x) x FUNCTION

P1.1/SPI_SOMI/SCL/ACLK/TA0.2/CCI0.0 1 ACLK 1 1 0 0

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

(1)

RSELx/ASE

Lx

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

TA0.0

SPI_CLK

MCLK

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModul x IN

#

Pad Logic

P1.2/SPI_CLK/MCLK/TA0.0

PortsOn

P1IRQ.x

P1IE.x

P1IES.x Set

Q

P1IFG.x

eUSCI_B0

Bus

Keeper

www.ti.com

6.7.3 Port P1.2 Input/Output

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

P1.2/SPI_CLK/MCLK/TA0.0 2

(1) X = Don't care

(2) Module controls direction of port, depending on whether RF430 device is master or slave.

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 35

Table 6-10. Port P1 (P1.2) Pin Functions

PIN NAME (P1.x) x FUNCTION

P1.2 (I/O) I:0; O:1 0 0 0

SPI_CLK

MCLK 1 1 0 0

TA0.0 1 1 1 0

(2)

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

CONTROL BITS OR SIGNALS

P1DIR.x P1SEL1.x P1SEL0.x

1 0 1 0

(1)

RSELx/ASEL

x

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

SPI_STE

TA0.2

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModul x IN

#

Pad Logic

P1.3/SPI_STE/TA0.2/ACLK/TA0CLK

PortsOn

P1IRQ.x

P1IES.x Set

Q

P1IFG.x

eUSCI_B0

Bus

Keeper

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6.7.4 Port P1.3 Input/Output

www.ti.com

P1.3/SPI_STE/TA0.2/ACLK/TA0CLK 3 TA0.2 1 1 0 0

(1) X = Don't care

(2) Module controls direction of port, depending on whether RF430 device is master or slave.

36 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

PIN NAME (P1.x) x FUNCTION

Table 6-11. Port P1 (P1.3) Pin Functions

P1.3 (I/O) I:0; O:1 0 0 0

SPI_STE

ACLK 1 1 1 0

TA0CLK X ≠0 ≠0 X

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

CONTROL BITS OR SIGNALS

P1DIR.x P1SEL1.x P1SEL0.x

(2)

1 0 1 0

(1)

RSELx/ASE

Lx

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

RFU

TA0.1

SMCLK

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModule X IN

#

Pad Logic

P1.4/TA0.1/SMCLK/TCK /CCI0.1/CLKIN

TCK to JTAG logic

PortsOn

P1IRQ.x

P1IES.x Set

Q

P1IFG.x

Bus

Keeper

Pad Logic

to clock system

www.ti.com

6.7.5 Port P1.4 Input/Output

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

TCK/P1.4/TA0.1/SMCLK/CCI0.1 4 Reserved 1 1 1 0

(1) X = Don't care

(2) JTAG signals TMS, TCK, and TDI read as 1 when not configured as explicit JTAG terminals.

(3) JTAG overrides digital output control when configured as explicit JTAG terminals.

(4) JTAG function with enabled pullup resistors is default after power up.

PIN NAME (P1.x) x FUNCTION

Table 6-12. Port P1.4 Pin Functions

P1.4 (I/O) I:0; O:1 0 0 0

Timer_A0.1 1 0 1 0

SMCLK 1 1 0 0

Timer_A0.CCI1A 0 ≠0 ≠0 0

JTAG-TCK

CLKIN from bypass X X X 0

(2)(3)(4)

CONTROL BITS OR SIGNALS

P1DIR.x P1SEL1.x P1SEL0.x JTAG Mode

X X X 1

(1)

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 37

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

Submit Documentation Feedback

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

RFU

TA 0.2

MCLK

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModule X IN

#

Pad Logic

P1.5/TA0.2/MCLK/TDI/CCI0.1

TDI to JTAG logic

PortsOn

P1IRQ.x

P1IE.x

P1IES.x Set

Q

P1IFG.x

Bus

Keeper

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

6.7.6 Port P1.5 Input/Output

www.ti.com

Table 6-13. Port P1.5 Pin Functions

PIN NAME (P1.x) x FUNCTION

TDI/P1.5/TA0.2/MCLK/CCI0.1 5

(1) X = Don't care

(2) JTAG signals TMS, TCK, and TDI read as 1 when not configured as explicit JTAG terminals.

(3) JTAG overrides digital output control when configured as explicit JTAG terminals.

(4) JTAG function with enabled pullup resistors is default after power up.

P1.5 (I/O) I:0; O:1 0 0 0

Timer_A0.2 1 0 1 0

MCLK 1 1 0 0

Timer_A0 CCI1B 0 ≠0 ≠0 0

JTAG-TDI

(2)(3)(4)

P1DIR.x P1SEL1.x P1SEL0.x JTAG Mode

CONTROL BITS OR SIGNALS

1 1 1 0

X X X 1

(1)

38 Detailed Description Copyright © 2012–2014, Texas Instruments Incorporated

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

Submit Documentation Feedback

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x

TDO from JTAG

TA0.0

TA0.2

P1SEL0.x

P1SEL1.x

0

1Vcc

Vss

P1IN.x

EN1

EN2

DModule X IN

#

Pad Logic

TDO/P1.6/TA0.0/TA0.2/CCI0.2

from JTAG logic

PortsOn

P1IRQ.x

P1IE.x

P1IES.x

Set

Q

P1IFG.x

Bus

Keeper

www.ti.com

6.7.7 Port P1.6 Input/Output

RF430FRL152H, RF430FRL153H, RF430FRL154H

SLAS834C –NOVEMBER 2012–REVISED DECEMBER 2014

TDO/P1.6/TA0.0/TA0.2/CCI0.2 6 Timer_A0.2 1 1 0

(1) JTAG signals TMS, TCK, and TDI read as 1 when not configured as explicit JTAG terminals.

(2) JTAG overrides digital output control when configured as explicit JTAG terminals.

Table 6-14. Port P1.6 Pin Functions

PIN NAME (P1.x) x FUNCTION

P1.6 (I/O) I:0; O:1 0 0

Timer_A0.0 1 0 1

JTAG-TDO

Timer_A0 CCI2A 0 ≠0 ≠0

(1)(2)

CONTROL BITS OR SIGNALS

P1DIR.x P1SEL1.x P1SEL0.x

1 1 1

Copyright © 2012–2014, Texas Instruments Incorporated Detailed Description 39

Submit Documentation Feedback

Product Folder Links: RF430FRL152H RF430FRL153H RF430FRL154H

P1REN.x

00

01

10

11

P1DIR.x

00

01

10

11

P1OUT.x