For assistance or to order, call (800) 531-5782

PT3100 Series

24V

Product Selector Guide

15 WATT 24V TO 5V/12V/15V

ISOLATED DC-DC CONVERTER

Application Notes

Mechanical Outline

Revised 5/15/98

• Power Density 15 Watts/in

3

• Wide Input Voltage Range

18V to 40V

• 81% Efficiency

• 500 VDC Isolation

• Small Footprint

• No External Components Required

Isolated DC-DC Converters advance the

state-of-the-art for board-mounted converters by employing high switching frequencies

greater than 650 KHz and planar magnetics

and surface-mount construction. They feature the industry’s smallest footprint, a power

density of 15 Watts/in

at 80% efficiency. They are designed for

Power Trends’ PT3104A (5V),

PT3105A (12V) and PT3106A (15V)

Telecom, Industrial, Computer, Medical,

and other distributed power applications

requiring input-to-output isolation.

Standard Application

On/Off

+Vin

1

3

PT3100

24

+Vout

5

-Vout-Vin

Specifications

Characteristics

(Ta=25°C unless noted) Symbols Conditions Min Typ Max Units

Output Current I

Current Limit I

On/Off Standby Current I

Short Circuit Current I

Inrush Current I

Input Voltage Range V

Output Voltage Tolerance ∆V

Ripple Rejection RR Over Vin range @ 120 Hz — 60 — dB

Line Regulation Reg

Load Regulation Reg

Vo Ripple/Noise V

Transient Response t

Efficiency η Vin=24V, Io=3.0A, Vo=5V — 80 — %

Switching Frequency ƒ

Recommended Operating T

Temperature Range Free air convection, (40-60LFM)

Thermal Resistance θ

Case Temperature T

Storage Temperature T

Mechanical Shock — Per Mil-STD-202F, Method 213B,

Mechanical Vibration — Per Mil-STD-202F, Method 204D,

Weight — — — 28 — grams

Isolation — — 500 — — V

Capacitance — — — 1100 — pF

Resistance — — 10 — — MΩ

Flammability — Materials meet UL 94V-0

Remote On/Off On Open or 2.5 to 7.0 VDC above -V

* See Thermal Derating Curves

o

cl

in standby

sc

ir

t

ir

in

n

tr

o

a

ja

c

s

Off Short or 0 to 0.8 VDC above -V

Over Vin range, Vo = 5V 0 — 3.0 A

Vin = 18V, Vo = 5V — 4.0 — A

Vin = 24V, Pin 1 = -V

Vin = 24V, Vo = 5V — 6.25 — A

Vin = 24V @ max I

On start-up — 1.0 5.0 mSec

Io = 0.1 to max I

Over Vin Range

o

TA= -20°C to +70°C

Over Vin range @ max I

line

10% to 100% of Io max — ±0.4 ±1.0 %V

load

Vin=24V, Io=3.0A, Vo=5V — 75 100 mV

Vin=24V, Io=1.25A, Vo=12V — 75 150 mV

Vin=24V, Io=1.25A, Vo=15V — 100 200 mV

50% load change — 125 200 µSec

Vo over/undershoot — 3.0 5.0 %V

=24V, Io=1.25A, Vo=12V — 80 — %

V

in

Vin=24V, Io=1A, Vo=15V — 81 — %

Over Vin and Io, Vo=5V 800 850 900 kHz

Vo=12V/15V 600 650 700 kHz

Vin = 24V @ max I

Free Air Convection, (40-60LFM) — 14 — °C/W

@ Thermal shutdown — — 100 °C

6mS, Half-sine, mounted to a PCB

10-500Hz, Soldered in a PCB

= 12V 0 — 1.25 A

V

o

Vo = 15V 0 — 1.0 A

V

= 12V — 1.75 — A

o

Vo = 15V — 1.4 — A

in

V

= 12V — 2.5 — A

o

Vo = 15V — 2.0 — A

o

o

o

o

PT3100 SERIES

—7 10mA

— 1.0 2.0 A

18.0 24.0 40.0 V

— ±1.0 ±2.0 %V

— ±0.2 ±1.0 %V

-20 — +70* °C

-40 — 110 °C

—50—G’s

—10—G’s

in

in

3

, and operate

Pin-Out Information

Pin Function

Remote

1

ON/OFF

2-V

in

3+V

in

4-V

out

5+V

out

6 Do not connect

o

Ordering Information

o

o

pp

pp

pp

o

Through-Hole

PT3104A = 5 Volts

PT3105A = 12 Volts

PT3106A = 15 Volts

Surface Mount

PT3104C = 5 Volts

PT3105C = 12 Volts

PT3106C = 15 Volts

(For dimensions and PC

board layout, see Package

Style 700.)

62

Power Trends, Inc. 27715 Diehl Road, Warrenville, IL 60555 (800) 531-5782 Fax: (630) 393-6902 http://www.powertrends.com

For assistance or to order, call (800) 531-5782

PT3100 Series

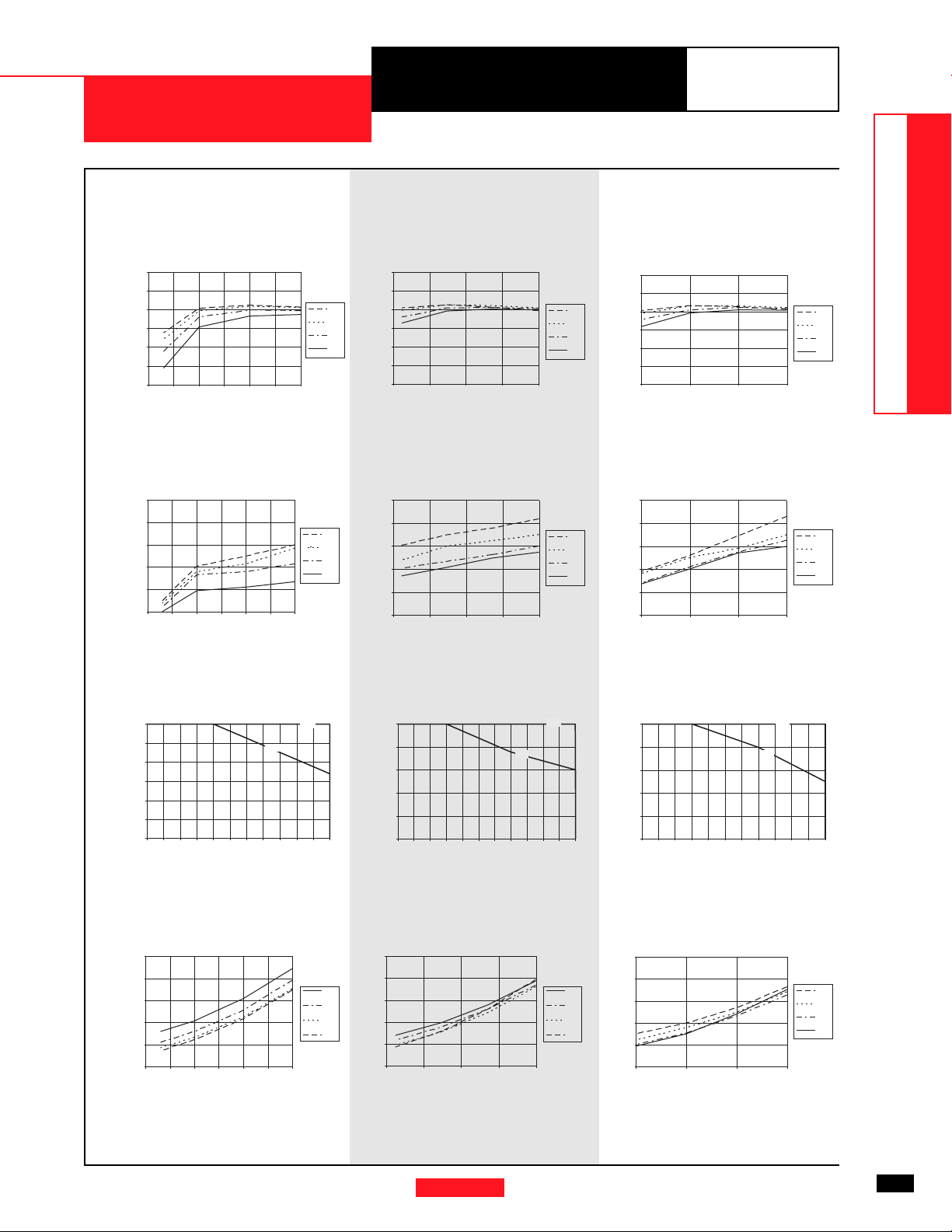

CHARACTERISTIC DATA

PT3104, 5.0 VDC

(See Note 1)

Efficiency vs Output Current Efficiency vs Output Current Efficiency vs Output Current

100

90

80

70

60

Efficiency - %Ripple-(mV)Iout-(Amps)PD-(Watts)

50

40

0 0.5 1 1.5 2 2.5 3

Vin

PT3105, 12.0 VDC

(See Note 1)

100

90

18V

24V

32V

40V

80

70

60

Efficiency - %

50

40

0.25 0.5 0.75 1 1.25

Vin

18V

24V

32V

40V

Iout-(Amps) Iout-(Amps) Iout-(Amps)

Ripple vs Output Current Ripple vs Output Current Ripple vs Output Current

110

90

70

50

30

10

0 0.5 1 1.5 2 2.5 3

Iout-(Amps) Iout-(Amps) Iout-(Amps)

Vin

40V

32V

24V

18V

110

90

70

50

Ripple-(mV)

30

10

0.25 0.5 0.75 1 1.25

Vin

40V

32V

24V

18V

PT3106, 15.0 VDC

(See Note 1)

100

90

80

70

60

Efficiency - %

50

40

0.25 0.5 0.75 1

110

90

70

50

Ripple-(mV)Iout-(Amps)

30

10

0.25 0.5 0.75 1

24V

DATA SHEETS

24V Bus Products

Vin

18V

24V

32V

40V

Vin

40V

32V

24V

18V

Thermal Derating (Ta) (See Note 2) Thermal Derating (Ta) (See Note 2)

3

2.5

2

1.5

1

0.5

0

18 20 22 24 26 28 30 32 34 36 38 40

85°C

70°C

1.25

1

0.75

0.5

Iout-(Amps)

0.25

0

18 20 22 24 26 28 30 32 34 36 38 40

70˚C

85˚C

Thermal Derating (Ta) (See Note 2)

1

0.8

0.6

0.4

0.2

0

18 20 22 24 26 28 30 32 34 36 38 40

70°C

85°C

Vin-(Volts) Vin-(Volts)Vin-(Volts)

Power Dissipation vs Output Current Power Dissipation vs Output Current Power Dissipation vs Output Current

5

4

3

2

1

0

0 0.5 1 1.5 2 2.5 3

Vin

40V

32V

24V

18V

5

4

3

2

PD-(Watts)

1

0

0.25 0.5 0.75 1 1.25

5

Vin

40V

32V

24V

18V

4

3

2

PD-(Watts)

1

0

0.25 0.5 0.75 1

Iout-(Amps) Iout-(Amps) Iout-(Amps)

Note 1: All data listed in the above graphs, except for derating data, has been developed from actual products tested at 25°C. This data is considered typical data for the DC-DC Converters.

Note 2: Thermal derating graphs are developed in free air convection cooling of 40-60 LFM.

Vin

40V

32V

24V

18V

Power Trends, Inc. 27715 Diehl Road, Warrenville, IL 60555 (800) 531-5782 Fax: (630) 393-6902 http://

www.powertrends.com

63

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...