Page 1

User’s Guide

March 2012

LMK00308EVM User’s Guide

1. General Description

This user guide describes how to set up and operate the LMK00308 evaluation module (EVM). The

LMK00308 is a 3-GHz, 8-output differential clock buffer intended for high frequency, low additive jitter clock

distribution and level translation. The EVM allows the user to verify the functionality and performance

specifications of the device. Refer to the LMK00308 datasheet for the functional description and

specifications.

2. Features

Low-noise clock fan-out via two banks of four differential outputs and one LVCMOS output

Selectable differential output type (LVPECL, LVDS, HCSL, or Hi-Z)

3:1 input multiplexer with two universal input buffers and one crystal oscillator interface

DIP switch control of device configuration

3.3 V core and 3 independent 3.3 V/2.5 V output supplies (one per output bank) using external supply

inputs or optional LP3878-ADJ LDO or LMZ10500 switching regulator on board

AC- or DC-coupled input & output interface with low-skew, controlled-impedance traces and edge SMA

connectors

Figure 1: LMK00308EVM Board Photo

March 2012 SNAU117 LMK00308EVM User’s Guide 1

Page 2

1. General Description ................................................................................................... 1

2. Features ...................................................................................................................... 1

CONTENTS ........................................................................................................................ 2

LIST OF FIGURES ............................................................................................................. 3

LIST OF TABLES ............................................................................................................... 3

3. Quick Setup ................................................................................................................ 4

4. Signal Path and Control Switches ........................................................................... 5

CONTENTS

5. Power Supplies .......................................................................................................... 6

5.1. Independent Output Supply Voltages................................................................... 6

6. Clock Inputs ............................................................................................................... 7

6.1. Configuring CLKinX+ for a Single Ended Input ................................................... 7

7. Crystal Oscillator Interface ....................................................................................... 7

7.1. Configuring OSCin for a Single Ended Input ....................................................... 7

8. Clock Outputs ............................................................................................................ 8

8.1. LVPECL and LVCMOS with 2.5 V Vcco ................................................................ 8

9. Schematics ................................................................................................................. 9

10. Board Layout .......................................................................................................... 12

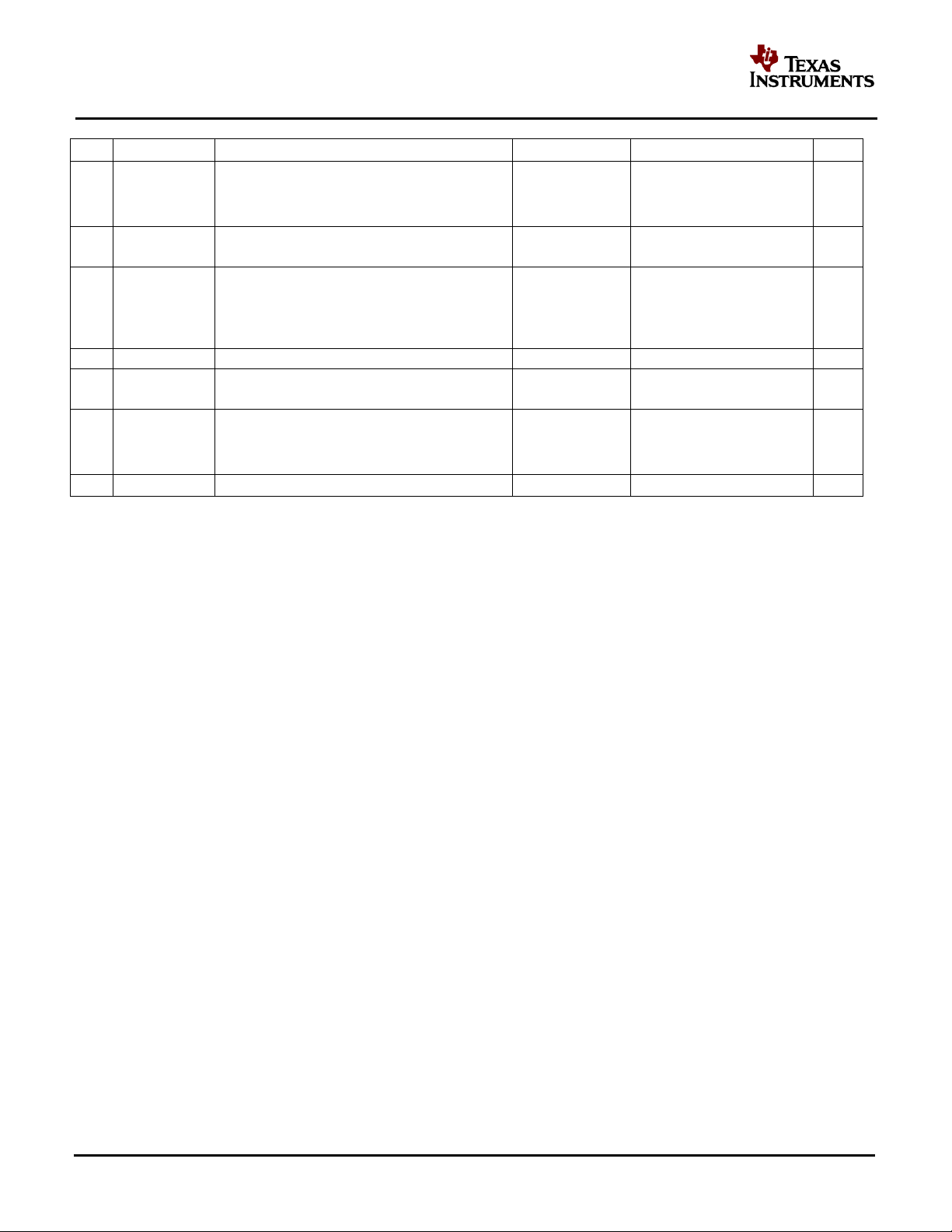

11. Bill of Materials ...................................................................................................... 16

2 LMK00308EVM User’s Guide March 2012

Page 3

LIST OF FIGURES

Figure 1: LMK00308EVM Board Photo ........................................................................... 1

Figure 2: LMK00308 Evaluation Board Quick Start Setup ............................................ 4

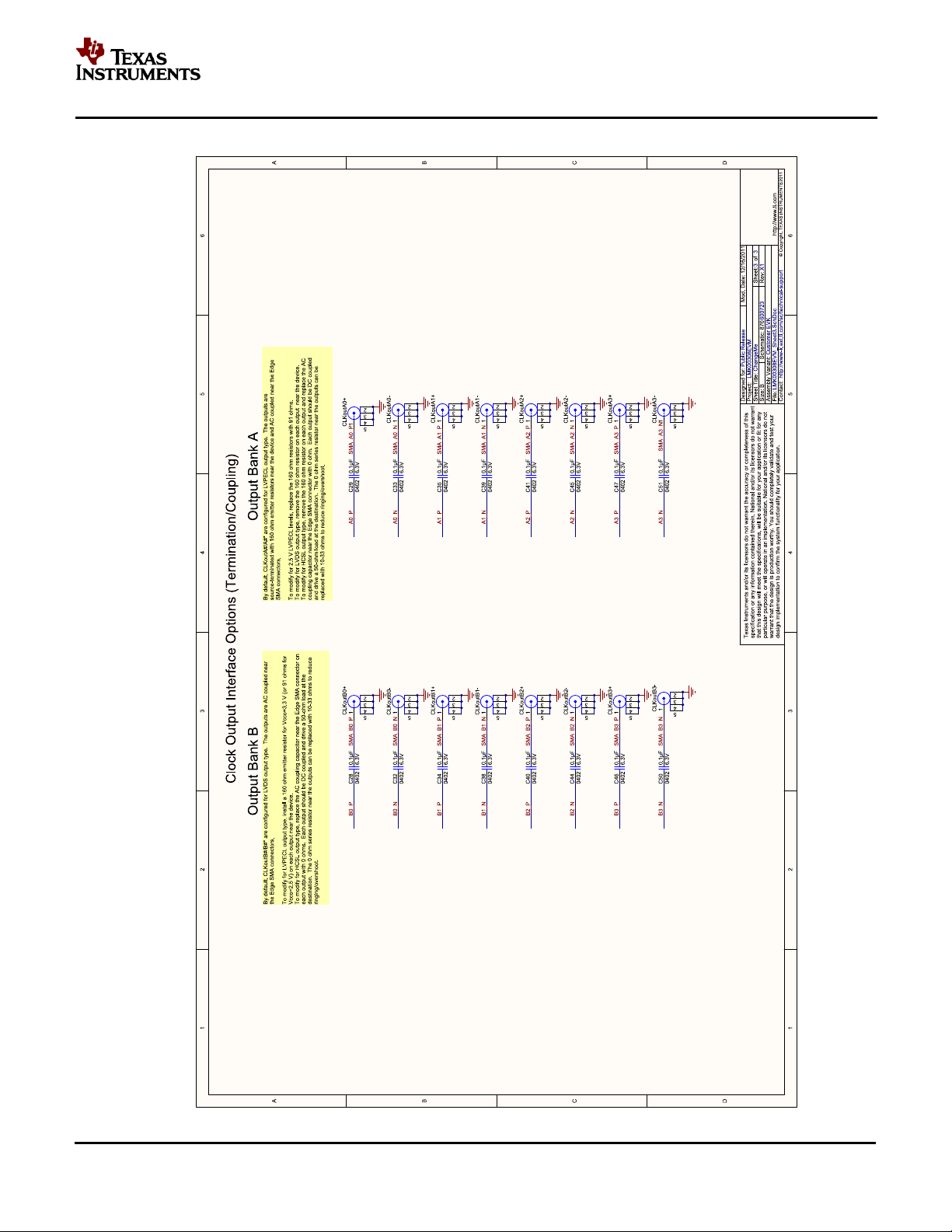

Figure 3: Schematic Sheet #1 .......................................................................................... 9

Figure 4: Schematic Sheet #2 ........................................................................................ 10

Figure 5: Schematic Sheet #3 ........................................................................................ 11

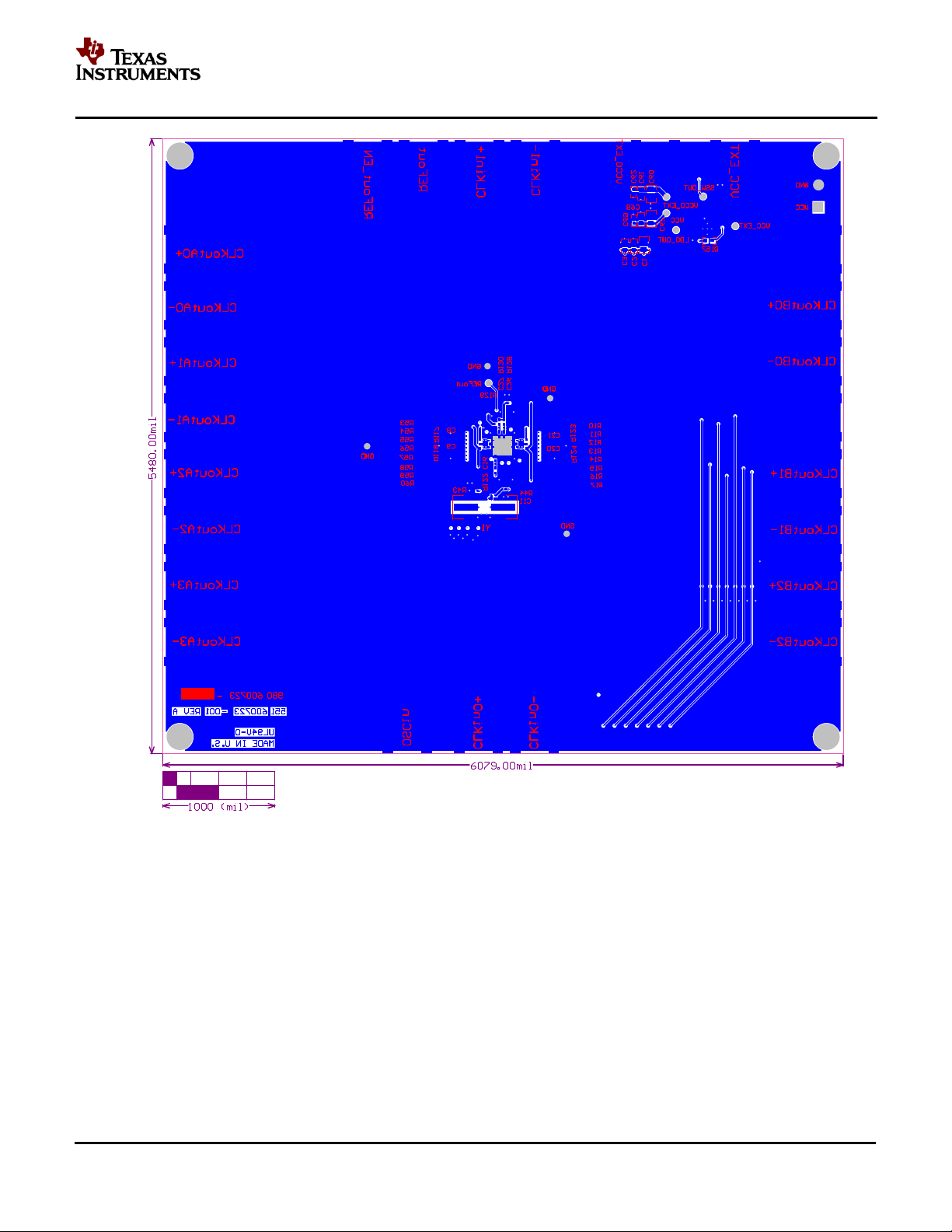

Figure 6: Top Side, Layer #1 (Not to scale) .................................................................. 12

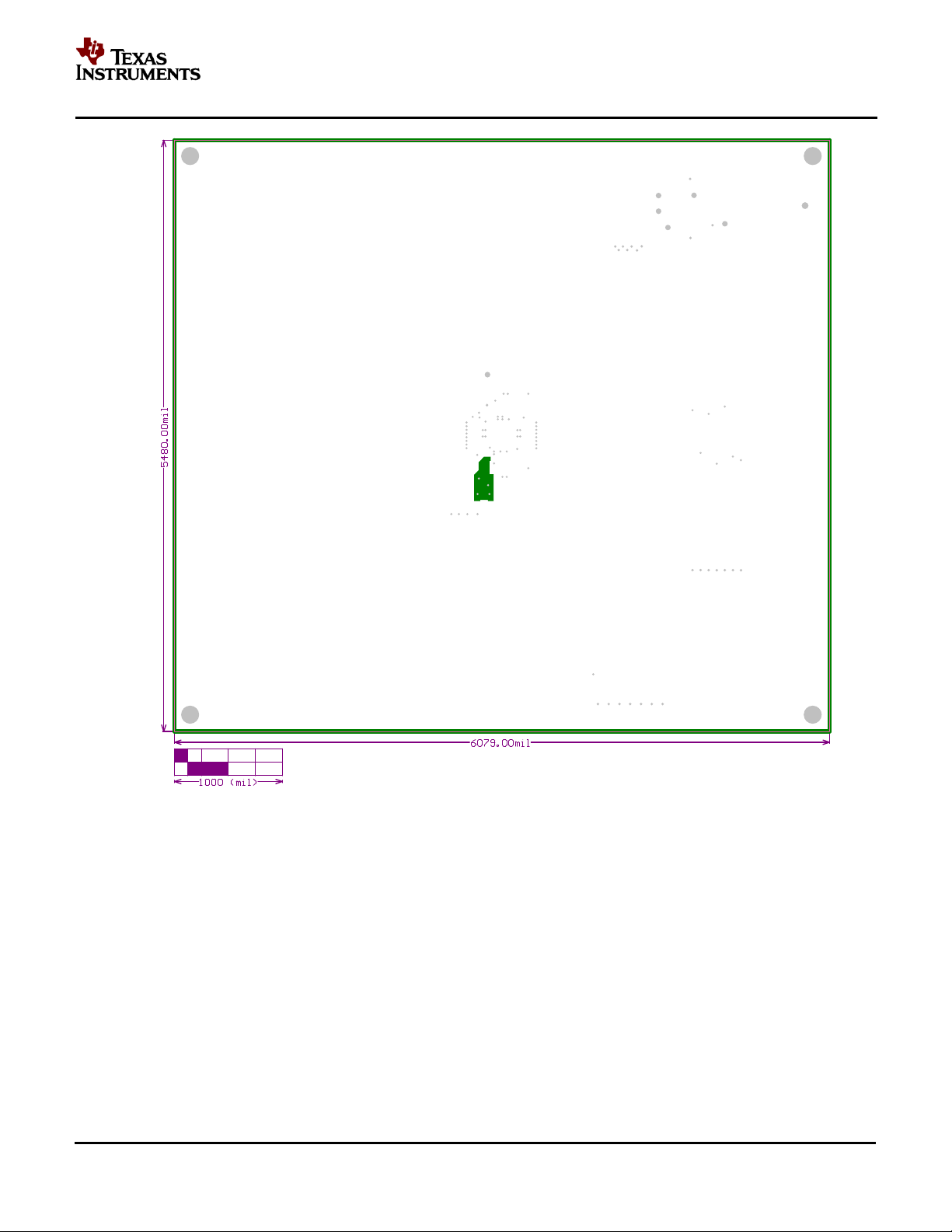

Figure 7: Internal Ground Plane, Layer #2 (Layer Inverted, Not to scale) ................. 13

Figure 8: Internal Power Plane, Layer #3 (Not to scale) .............................................. 14

Figure 9: Bottom Side, Layer #4 (Top view, Not to scale) .......................................... 15

LIST OF TABLES

Table 1: Default Clock Output Modes ............................................................................. 4

Table 2: Input Selection.................................................................................................... 5

Table 3: Bank A Output Mode Selection......................................................................... 5

Table 4: Bank B Output Mode Selection......................................................................... 5

Table 5: REFout Enable Selection ................................................................................... 5

Table 6: EVM Power Supply Configuration Options ..................................................... 6

March 2012 LMK00308EVM User’s Guide 3

Page 4

LMK0030x

EVALUATION

MODULE

CLKinX

CLKinX*

VCC_EXT

GND

Bank A Outputs

(LVPECL default)

REFout

(LVCMOS)

Bank B Outputs

(LVPECL default)

Bottom side:

25 MHz Crystal

(Default Input)

CLKoutBn

CLKoutBn*

CLKoutAn

CLKoutAn*

O-SCOPE

(50W inputs)

50W TERM

50W TERM

Note: Terminate unused

output traces (or disconnect

from output pin on PCB)

CLOCK

SOURCE

(OPTIONAL)

50W TERM

4-6 V

GND

POWER

SUPPLY

SW Position/Name

SW State

Default Clock Output Modes

S1[1] / CLKoutB_Type1

OFF

Bank B outputs are LVDS

S1[2] / CLKoutB_Type0

ON

S1[3] / CLKoutB_Type1

OFF

Bank A outputs are LVPECL

S1[4] / CLKoutB_Type0

OFF

S1[5] / REFout_EN

ON

REFout (CMOS) enabled

3. Quick Setup

To quickly set up and operate the board with basic equipment, refer to the setup procedure below and test

setup shown in Figure 2.

Figure 2: LMK00308 Evaluation Board Quick Start Setup

1. Verify the output mode control switches, S1[1:5], match the states shown in Table 1 to reflect the default

output clock interfaces configured on the EVM.

Table 1: Default Clock Output Modes

2. Connect a 4 – 6 V power supply to VCC_EXT and GND terminals of the power block labeled J2. This powers

the on-board LDO regulator to supply 3.3 V to the VCC and VCCO rails of the IC. Both VCC & VCCO status

LEDs should be lit green when ON.

3. Set the desired clock input using the input selection control switches, S1[6:7], per Table 2. The onboard 25

MHz crystal (Y1) can be selected, so an external clock source is not required. A differential clock source can

be connected to SMAs labeled CLKin0/0* or CLKin1/1*. By default, these differential inputs are AC coupled

and terminated near the device with 100 ohms differential. To configure the EVM for a single-ended input,

refer to the Clock Inputs section.

4 LMK00308EVM User’s Guide March 2012

Page 5

Selected Input

Default Input Mode

S1[6] CLKin_Sel1 State

S1[7] CLKin_Sel0 State

CLKin0/0*

Differential clock

OFF

OFF

CLKin1/1*

Differential clock

OFF

ON

OSCin

25 MHz XTAL onboard

ON

Don’t care

Bank A Output Mode

S1[3] CLKoutA_Type1 State

S1[4] CLKoutA_Type0 State

LVPECL

OFF

OFF

LVDS

OFF

ON

HCSL

ON

OFF

Disabled/Hi-Z

ON

ON

Bank B Output Mode

S1[1] CLKoutB_Type1 State

S1[2] CLKoutB_Type0 State

LVPECL

OFF

OFF

LVDS

OFF

ON

HCSL

ON

OFF

Disabled/Hi-Z

ON

ON

REFout Enable Mode

S1[5] REFout_EN State

Disabled/Hi-Z

OFF

Enabled

ON

Table 2: Input Selection

4. Connect and measure any clock output SMA labeled CLKoutA#/A#*, CLKoutB#/B#*, or REFout to an

oscilloscope or other test instrument using SMA cable(s). The output clock will be a level-translated/buffered

copy of the selected clock input or crystal oscillator. Note: All output clocks are AC-coupled to the SMA

connectors to ensure safe use with RF instruments.

Note: Any active output trace(s) without proper load termination can cause signal reflections on the board,

which can couple onto nearby outputs and degrade signal quality and measurement accuracy. To minimize

these effects, be sure to properly terminate any unused output trace with a 50-ohm SMA load, or else

disconnect any unused output trace from the device output pin by removing the series 0-ohm resistor. An

unused output or output bank may also be disabled using the output mode control switch.

4. Signal Path and Control Switches

The LMK00308 supports single-ended or differential clocks on CLKin0 and CLKin1. A third input, OSCin, has

an integrated crystal oscillator interface that supports a fundamental mode, AT-cut crystal or an external

single-ended clock. To achieve the maximum operating frequency and lowest additive jitter, it is

recommended to use a differential input clock with high slew rate (>3 V/ns) on either CLKin0 or CLKin1 port.

The device provides up to 8 differential outputs with pin-selectable output mode (LVPECL, LVDS, HCSL, or

Hi-Z). An additional output, REFout, has a fixed LVCMOS buffer with output enable input.

All control pins are configured with the control DIP switch, S1. The input selection logic is shown in Table 2.

The output mode selection logic for Bank A and Bank B are shown in Table 3 and Table 4. The REFout

enable logic is shown in Table 5.

Table 3: Bank A Output Mode Selection

Table 4: Bank B Output Mode Selection

Table 5: REFout Enable Selection

March 2012 LMK00308EVM User’s Guide 5

Page 6

LP3878 LDO

Regulator (U3)

3.3 V (DEFAULT)

LMZ10500

Switcher (U2)

3.3 V

Single

Direct Supply

3.3 V

Dual

Direct Supplies

3.3 V & 2.5 V

VCC_EXT port

(J2 or SMA)

Apply 4 V – 6 V

Apply 4 V – 5.5 V

Apply 3.3 V ± 5%

Apply 3.3 V ± 5%

VCCO_EXT port

(SMA)

Not used

Not used

Not used

Apply 2.5 V ± 5%

U2 Vout

Not used

3.3 V (VCC & VCCO)

Not used

Not used

U3 Vout

3.3 V (VCC & VCCO)

Not used

Not used

Not used

R131

OPEN

OPEN

OPEN

0

R132 0 0 0 0

R134

OPEN

0

OPEN

OPEN

R145

OPEN

0

OPEN

OPEN

R153

OPEN

OPEN 0 0

R155

0

OPEN

OPEN

OPEN

R156

0

OPEN

OPEN

OPEN

5. Power Supplies

The power supply section on the EVM provides flexibility to power the device using the onboard regulator(s)

or direct supply input(s). A combination of 0-ohm resistor options allows the user to modify the EVM power

supply configuration, if desired.

By default, 3.3 V is supplied to both VCC and VCCO rails by the onboard LDO regulator, U3. To power the

regulator, connect a 4 V – 6 V input voltage and ground from an external power source to the terminal block,

J2, or SMA input labeled VCC_EXT.

To modify the EVM with a different power supply configuration, populate the resistor options as shown in

Table 6. Then, apply the appropriate voltage(s) to the EVM power input(s).

If the EVM is configured for dual direct supplies, connect the 3.3 V supply and ground to VCC_EXT and the

2.5 V supply and ground to the SMA input labeled VCCO_EXT.

Decoupling capacitors and 0-ohm resistor footprints, which can accommodate ferrite beads, can be used to

isolate the EVM power input(s) from the device power pins.

Table 6: EVM Power Supply Configuration Options

5.1. Independent Output Supply Voltages

On the bottom side of the EVM, resistor options provide flexibility to power each of the three individual output

supply pins (VCCOA, VCCOB, and VCCOC) from either VCC or VCCO rail. This is useful when 3.3 V and

2.5 V are both needed for separate output supplies.

For example, if Bank A outputs require 3.3 V LVPECL levels, Bank B outputs require 2.5 V LVPECL levels,

and REFout requires 2.5 V LVCMOS, then VCCOA can be connected to VCC (3.3 V) and VCCOB and

VCCOC can be connected to VCCO (2.5 V).

The EVM power supply needs to be modified to get 2.5 V on the VCCO rail, either using the VCCO_EXT

input or LMZ10500 switcher, per Table 6. To configure LMZ10500 with 2.5 V output, set R138 to 150k and

R139 to 118k.

Note: When the LMZ10500 switcher is used to power the DUT and an ultra-low-noise clock source is used,

the higher output noise voltage of the switcher (compared to the LP3878-ADJ) can cause an slight increase

6 LMK00308EVM User’s Guide March 2012

Page 7

in the output phase noise floor at low offset frequencies as well as low-level spurs. The high PSRR of the

device helps to minimize supply-induced jitter.

6. Clock Inputs

The SMA inputs labeled CLKin0 & CLKin0* and CLKin1 & CLKin1* can be configured to receive a differential

clock or single-ended clock. Best performance is achieved with a differential input clock, which is the default

configuration for both CLKin ports.

Both CLKin0 and CLKin1 paths include footprint options to provide the user with flexibility in configuring the

termination, biasing, and coupling for the device inputs.

6.1. Configuring CLKinX+ for a Single Ended Input

To configure an AC-coupled or DC-coupled single-ended clock input on CLKin0, follow the steps below.

CLKin1 can be modified similarly.

1. Remove R24 (100 ohm differential termination).

2. Terminate CLKin0 (driven input) by installing 51 ohms on R30.

3. Install 0.1 uF on C10 as a bypass capacitor.

4. Modify for AC or DC coupled input:

a. AC-coupled input:

i. Install 0 ohms on R23, so CLKin0* input pin is AC coupled to ground via C17.

b. DC-coupled input:

i. Replace R22 and R28 with 0 ohms to DC couple the input path.

ii. Bias CLKin0*(non-driven input) with a reference voltage near the common-mode voltage of

the DC-coupled input signal (on CLKin0) using R21 and R23 to form a voltage divider from

VCC.

For example, if CLKin0 will be driven by a single-ended, DC-coupled LVCMOS signal with a common-mode

voltage of 1.65 V, then 1 kohm resistors can be installed on R21 and R23 to bias CLKin0* to VCC/2.

7. Crystal Oscillator Interface

The LMK00308 has an integrated crystal oscillator interface (OSCin/OSCout) that supports a fundamental

mode, AT-cut crystal. If the crystal input is selected, the onboard XTAL on either footprint Y1 or Y2 will startup and the oscillator clock can be measured on any enabled output.

By default, a 25.000 MHz XTAL is populated on Y1, which uses a HC49 footprint on the bottom side of the

PCB. Alternatively, a 3.2 x 2.5 mm XTAL or 3.3 V XO (3.3 V CMOS or clipped sinewave) can be populated

on Y2, located on the top side. Only one XTAL footprint should be used at a time.

When using a XTAL, the external load capacitor values of C18 and C22 (C

capacitance (C

PCB stray capacitance (C

equal external load capacitor values for optimum symmetry, C

) for the crystal, as well as the device’s OSCin input capacitance (C

L

~ 1 pF). The selected 25 MHz crystal is specified for CL of 18 pF. Assuming

STRAY

can be calculated as follows:

EXT

) depend on the specified load

EXT

= 1 pF typical) and the

IN

C

= (CL – CIN – C

EXT

C

= (18 pF – 1 pF – 1 pF) * 2

EXT

C

~ 33 pF (nearest standard value)

EXT

STRAY

) * 2

To limit crystal power dissipation, a 1 kohm resistor is placed between the OSCout pin and the crystal.

7.1. Configuring OSCin for a Single Ended Input

To configure a single-ended clock input on OSCin, remove R34 and R37 to disconnect the crystal. Install 0.1

uF on C24 to provide an AC-coupled path from the SMA input labeled OSCin to the device input, which has

internal biasing. Note that the OSCin path includes a 51-ohm termination on R42.

March 2012 LMK00308EVM User’s Guide 7

Page 8

8. Clock Outputs

By default, Bank A outputs are configured for LVPECL mode, source-terminated with 160 ohm resistors, and

AC coupled to the SMA connectors labeled CLKoutA#+ / CLKoutA#-. Bank B outputs are configured for

LVDS and AC coupled to SMA connectors labeled CLKoutB#+ / CLKoutB#-. To modify the output interface

for a different output mode, refer to the modifications noted in the Schematics section.

REFout is a LVCMOS output and is AC coupled to its SMA connector.

As noted before, active output traces should be properly terminated; otherwise any unused output pin can be

disconnected from the output trace by removing the 0-ohm series resistor.

8.1. LVPECL and LVCMOS with 2.5 V Vcco

The LVPECL and LVCMOS output levels depend on the output driver’s respective Vcco supply as specified

in the datasheet.

When an output bank is configured for LVPECL and its Vcco supply is 2.5 V, it is suggested to replace the

160-ohm -termination resistor to ground with a lower value, such as 91 ohms, to maintain proper DC

bias current on each output.

8 LMK00308EVM User’s Guide March 2012

Page 9

9. Schematics

Figure 3: Schematic Sheet #1

March 2012 LMK00308EVM User’s Guide 9

Page 10

Figure 4: Schematic Sheet #2

10 LMK00308EVM User’s Guide March 2012

Page 11

Figure 5: Schematic Sheet #3

March 2012 LMK00308EVM User’s Guide

11

Page 12

10. Board Layout

Figure 6: Top Side, Layer #1 (Not to scale)

12 LMK00308EVM User’s Guide March 2012

Page 13

Figure 7: Internal Ground Plane, Layer #2 (Layer Inverted, Not to scale)

March 2012 LMK00308EVM User’s Guide

13

Page 14

Figure 8: Internal Power Plane, Layer #3 (Not to scale)

14 LMK00308EVM User’s Guide March 2012

Page 15

Figure 9: Bottom Side, Layer #4 (Top view, Not to scale)

March 2012 LMK00308EVM User’s Guide

15

Page 16

#

Designator

Description

Manufacturer

Part Number

Qty

1

AA1

Printed Circuit Board

551600723-001 REV A

1

2

C1, C4, C60,

C64, C65,

C67, C71,

C72

CAP, CERM, 10uF, 10V, +/-10%, X5R, 0805

MuRata

GRM21BR61A106KE19L

8

3

C2, C5, C61,

C68

CAP, CERM, 1uF, 16V, +/-10%, X7R, 0603

TDK

C1608X7R1C105K

4

4

C3, C6

CAP, CERM, 0.1uF, 16V, +/-10%, X7R, 0603

TDK

C1608X7R1C104K

2

5

C23, C28,

C29, C32,

C33, C34,

C35, C38,

C39, C40,

C41, C44,

C45, C46,

C47, C50,

C51, R22,

R27, R28,

R33

CAP, CERM, 0.1uF, 6.3V, +/-10%, X5R,

0402

TDK

C1005X5R0J104K

21

6

C8, C9, C16,

C20, C21,

C26, C27,

C62, C69

CAP, CERM, 0.01uF, 16V, +/-10%, X7R,

0402

TDK

C1005X7R1C103K

9

7

C18, C22

CAP, CERM, 33pF, 50V, +/-5%, C0G/NP0,

0603

Kemet

C0603C330J5GACTU

2

8

C63

CAP, CERM, 470pF, 50V, +/-10%, X7R,

0603

TDK

C1608X7R1H471K

1

9

C70

CAP, CERM, 2200pF, 100V, +/-5%, X7R,

0603

AVX

06031C222JAT2A

1

10

C73

CAP, CERM, 0.01uF, 25V, +/-5%, C0G/NP0,

0603

TDK

C1608C0G1E103J

1

11

CLKin0+,

CLKin0-,

CLKin1+,

CLKin1-,

CLKoutA0+,

CLKoutA0-,

CLKoutA1+,

CLKoutA1-,

CLKoutA2+,

CLKoutA2-,

CLKoutA3+,

CLKoutA3-,

CLKoutB0+,

CLKoutB0-,

CLKoutB1+,

CLKoutB1-,

CLKoutB2+,

CLKoutB2-,

CLKoutB3+,

CLKoutB3-,

OSCin,

REFout,

REFout_EN,

VCC_EXT,

VCCO_EXT

Connector, SMT, End launch SMA 50 ohm

Emerson

Network Power

142-0701-806

25

11. Bill of Materials

16 LMK00308EVM User’s Guide March 2012

Page 17

#

Designator

Description

Manufacturer

Part Number

Qty

12

D1, D2

LED 2.8X3.2MM 565NM GRN CLR SMD

Lumex

Opto/Compone

nts Inc.

SML-LX2832GC

2

13

J1

Low Profile Vertical Header 2x5 0.100"

FCI

52601-G10-8LF

1

14

J2

CONN TERM BLK PCB 5.08MM 2POS OR

Weidmuller

1594540000

1

15

C7, C12,

C14, C17,

R1, R2, R3,

R4, R5, R6,

R7, R8, R18,

R36, R41,

R45, R46,

R47, R48,

R49, R50,

R51, R52,

R117, R122,

R123, R128,

R129

RES, 0 ohm, 5%, 0.063W, 0402

Panasonic

ERJ-2GE0R00X

28

16

R24, R31

RES, 100 ohm, 1%, 0.063W, 0402

Vishay-Dale

CRCW0402100RFKED

2

17

R34

RES, 1.0k ohm, 5%, 0.1W, 0603

Vishay-Dale

CRCW06031K00JNEA

1

18

R37, R132,

R155, R156

RES, 0 ohm, 5%, 0.1W, 0603

Vishay-Dale

CRCW06030000Z0EA

4

19

R42

RES, 51 ohm, 5%, 0.063W, 0402

Vishay-Dale

CRCW040251R0JNED

1

20

R53, R54,

R55, R56,

R57, R58,

R59, R60

RES, 160 ohm, 5%, 0.063W, 0402

Vishay-Dale

CRCW0402160RJNED

8

21

R133, R154

RES, 270 ohm, 5%, 0.1W, 0603

Vishay-Dale

CRCW0603270RJNEA

2

22

R135, R136,

R137, R140,

R141, R142,

R143

RES, 2.0k ohm, 5%, 0.1W, 0603

Vishay-Dale

CRCW06032K00JNEA

7

23

R138

RES, 118k ohm, 1%, 0.1W, 0603

Vishay-Dale

CRCW0603118KFKEA

1

24

R139

RES, 150k ohm, 1%, 0.1W, 0603

Vishay-Dale

CRCW0603150KFKEA

1

25

R157

RES, 51k ohm, 5%, 0.1W, 0603

Vishay-Dale

CRCW060351K0JNEA

1

26

R158

RES, 2.00k ohm, 1%, 0.1W, 0603

Vishay-Dale

CRCW06032K00FKEA

1

27

R159

RES, 866 ohm, 1%, 0.1W, 0603

Vishay-Dale

CRCW0603866RFKEA

1

28

S1

SWITCH DIP ROCKER 8POS SMD

Tyco

GDR08S04

1

29

SO1, SO2,

SO3, SO4

0.875" Standoff

VOLTREX

SPCS-14

4

30

U1

High-Performance Differential Fanout Buffer

National

Semiconductor

LMK00308

1

31

U2

IC DC-DC NANO MODULE

NSC

LMZ10500SEE/NOPB

1

32

U3

Micropower 800mA Low Noise 'Ceramic

Stable' Adjustable Voltage Regulator for 1V

to 5V Applications, 8-pin LLP

National

Semiconductor

LP3878SD-ADJ

1

33

Y1

CRYSTAL 25.000 MHZ 18PF SMD

Abracon

Corporation

ABLS-25.000MHZ-B4-F-T

1

34

C10, C13,

C15, C19,

C24

DNP

0

35

C11

DNP

0

36

C25

DNP

0

37

R9

DNP

0

March 2012 LMK00308EVM User’s Guide

17

Page 18

#

Designator

Description

Manufacturer

Part Number

Qty

38

R10, R11,

R12, R13,

R14, R15,

R16, R17

DNP

0

39

R19, R118,

R124, R130

DNP

0

40

R21, R23,

R25, R26,

R29, R30,

R32, R35,

R39, R40

DNP

0

41

R43, R44

DNP

0

42

R131, R134,

R145, R153

DNP

0

43

R146, R147,

R148, R149,

R150, R151,

R152

DNP

0

44

Y2

DNP

0

18 LMK00308EVM User’s Guide March 2012

Page 19

EVALUATION BOARD/KIT/MODULE (EVM) ADDITIONAL TERMS

Texas Instruments (TI) provides the enclosed Evaluation Board/Kit/Module (EVM) under the following conditions:

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all

claims arising from the handling or use of the goods.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/ kit may be returned within 30

days from the date of delivery for a full refund. THE FOREGOING LIMITED WARRANTY IS THE EXCLUSIVE WARRANTY MADE

BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE

EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Please read the User's Guide and, specifically, the Warnings and Restrictions notice in the User's Guide prior to handling the

product. This notice contains important safety information about temperatures and voltages. For additional information on TI's

environmental and/or safety programs, please visit www.ti.com/esh or contact TI.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used. TI currently deals with a variety of customers for products,

and therefore our arrangement with the user is not exclusive. TI assumes no liability for applications assistance, customer product

design, software performance, or infringement of patents or services described herein.

REGULATORY COMPLIANCE INFORMATION

As noted in the EVM User’s Guide and/or EVM itself, this EVM and/or accompanying hardware may or may not be subject to the

Federal Communications Commission (FCC) and Industry Canada (IC) rules.

For EVMs not subject to the above rules, this evaluation board/kit/module is intended for use for ENGINEERING DEVELOPMENT,

DEMONSTRATION OR EVALUATION PURPOSES ONLY and is not considered by TI to be a finished end product fit for general

consumer use. It generates, uses, and can radiate radio frequency energy and has not been tested for compliance with the limits of

computing devices pursuant to part 15 of FCC or ICES-003 rules, which are designed to provide reasonable protection against

radio frequency interference. Operation of the equipment may cause interference with radio communications, in which case the

user at his own expense will be required to take whatever measures may be required to correct this interference.

General Statement for EVMs including a radio

User Power/Frequency Use Obligations: This radio is intended for development/professional use only in legally allocated frequency

and power limits. Any use of radio frequencies and/or power availability of this EVM and its development application(s) must

comply with local laws governing radio spectrum allocation and power limits for this evaluation module. It is the user’s sole

responsibility to only operate this radio in legally acceptable frequency space and within legally mandated power limitations. Any

exceptions to this is strictly prohibited and unauthorized by Texas Instruments unless user has obtained appropriate

experimental/development licenses from local regulatory authorities, which is responsibility of user including its acceptable

authorization.

For EVMs annotated as FCC – FEDERAL COMMUNICATIONS COMMISSION Part 15 Compliant

Caution

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate

the equipment.

FCC Interference Statement for Class A EVM devices

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his

own expense.

Page 20

FCC Interference Statement for Class B EVM devices

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

For EVMs annotated as IC – INDUSTRY CANADA Compliant

This Class A or B digital apparatus complies with Canadian ICES-003.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate

the equipment.

Concerning EVMs including radio transmitters

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause

undesired operation of the device.

Concerning EVMs including detachable antennas

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser)

gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and

its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful

communication.

This radio transmitter has been approved by Industry Canada to operate with the antenna types listed in the user guide with the

maximum permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this

list, having a gain greater than the maximum gain indicated for that type, are strictly prohibited for use with this device.

Cet appareil numérique de la classe A ou B est conforme à la norme NMB-003 du Canada.

Les changements ou les modifications pas expressément approuvés par la partie responsable de la conformité ont pu vider

l’autorité de l'utilisateur pour actionner l'équipement.

Concernant les EVMs avec appareils radio

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation

est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit

accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Concernant les EVMs avec antennes détachables

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d'un type et

d'un gain maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage

radioélectrique à l'intention des autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la puissance isotrope

rayonnée équivalente (p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication satisfaisante.

Le présent émetteur radio a été approuvé par Industrie Canada pour fonctionner avec les types d'antenne énumérés dans le

manuel d’usage et ayant un gain admissible maximal et l'impédance requise pour chaque type d'antenne. Les types d'antenne non

inclus dans cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour l'exploitation de

l'émetteur.

REGULATORY COMPLIANCE INFORMATION (continued)

Page 21

【Important Notice for Users of this Product in Japan】

This development kit is NOT certified as Confirming to Technical Regulations of Radio Law of Japan

If you use this product in Japan, you are required by Radio Law of Japan to follow the instructions below with respect to this

product:

1. Use this product in a shielded room or any other test facility as defined in the notification #173 issued by Ministry of Internal Affairs

and Communications on March 28, 2006, based on Sub-section 1.1 of Article 6 of the Ministry’s Rule for Enforcement of Radio Law of

Japan,

2. Use this product only after you obtained the license of Test Radio Station as provided in Radio Law of Japan with respect to this

product, or

3. Use of this product only after you obtained the Technical Regulations Conformity Certification as provided in Radio Law of Japan with

respect to this product. Also, please do not transfer this product, unless you give the same notice above to the transferee. Please note

that if you could not follow the instructions above, you will be subject to penalties of Radio Law of Japan.

Texas Instruments Japan Limited

(address) 24-1, Nishi-Shinjuku 6 chome, Shinjukku-ku, Tokyo, Japan

http://www.tij.co.jp

【ご使用にあたっての注】

本開発キットは技術基準適合証明を受けておりません。

本製品のご使用に際しては、電波法遵守のため、以下のいずれかの措置を取っていただく必要がありますのでご注意ください。

1. 電波法施行規則第6条第1項第1号に基づく平成18年3月28日総務省告示第173号で定められた電波暗室等の試験設備でご使用い

ただく。

2. 実験局の免許を取得後ご使用いただく。

3. 技術基準適合証明を取得後ご使用いただく。

なお、本製品は、上記の「ご使用にあたっての注意」を譲渡先、移転先に通知しない限り、譲渡、移転できないものとします。

上記を遵守頂けない場合は、電波法の罰則が適用される可能性があることをご留意ください。

日本テキサス・インスツルメンツ株式会社

東京都新宿区西新宿6丁目24番1号

西新宿三井ビル

http://www.tij.co.jp

SPACER

Page 22

EVALUATION BOARD/KIT/MODULE (EVM)

For Feasibility Evaluation Only, in Laboratory/Development Environments. Unless otherwise indicated, this EVM is not a

finished electrical equipment and not intended for consumer use. It is intended solely for use for preliminary feasibility evaluation in

laboratory/development environments by technically qualified electronics experts who are familiar with the dangers and application

risks associated with handling electrical mechanical components, systems and subsystems. It should not be used as all or part of a

finished end product.

Your Sole Responsibility and Risk. You acknowledge, represent and agree t that :

1. You have unique knowledge concerning Federal, State and local regulatory requirements (including but not limited to Food and Drug

Administration regulations, if applicable) which relate to your products and which relate to your use (and/or that of your employees,

affiliates, contractors or designees) of the EVM for evaluation, testing and other purposes.

2. You have full and exclusive responsibility to assure the safety and compliance of your products with all such laws and other applicable

regulatory requirements, and also to assure the safety of any activities to be conducted by you and/or your employees, affiliates,

contractors or designees, using the EVM. Further, you are responsible to assure that any interfaces (electronic and/or mechanical)

between the EVM and any human body are designed with suitable isolation and means to safely limit accessible leakage currents to

minimize the risk of electrical shock hazard.

3. You will employ reasonable safeguards to ensure that your use of the EVM will not result in any property damage, injury or death,

even if the EVM should fail to perform as described or expected.

4. You will take care of proper disposal and recycling of the EVM’s electronic components and packing materials.

Certain Instructions, It is important to operate this EVM within TI’s recommended specifications and environmental considerations

per the user guidelines. Exceeding the specified EVM ratings (including but not limited to input and output voltage, current, power,

and environmental ranges) may cause property damage, personal injury or death. If there are questions concerning these ratings

please contact a TI field representative prior to connecting interface electronics including input power and intended loads. Any

loads applied outside of the specified output range may result in unintended and/or inaccurate operation and/or possible permanent

damage to the EVM and/or interface electronics. Please consult the EVM User's Guide prior to connecting any load to the EVM

output. If there is uncertainty as to the load specification, please contact a TI field representative. During normal operation, some

circuit components may have case temperatures greater than 60°C as long as the input and output are maintained at a normal

ambient operating temperature. These components include but are not limited to linear regulators, switching transistors, pass

transistors, and current sense resistors which can be identified using the EVM schematic located in the EVM User's Guide. When

placing measurement probes near these devices during normal operation, please be aware that these devices may be very warm

to the touch. As with all electronic evaluation tools, only qualified personnel knowledgeable in electronic measurement and

diagnostics normally found in development environments should use these EVMs.

Agreement to Defend, Indemnify and Hold Harmless. You agree to defend, indemnify and hold TI, its licensors and their

representatives harmless from and against any and all claims, damages, losses, expenses, costs and liabilities (collectively,

"Claims") arising out of or in connection with any use of the EVM that is not in accordance with the terms of the agreement. This

obligation shall apply whether Claims arise under law of tort or contract or any other legal theory, and even if the EVM fails to

perform as described or expected.

Safety-Critical or Life-Critical Applications. If you intend to evaluate the components for possible use in safety critical

applications (such as life support) where a failure of the TI product would reasonably be expected to cause severe personal injury

or death, such as devices which are classified as FDA Class III or similar classification, then you must specifically notify TI of such

intent and enter into a separate Assurance and Indemnity Agreement.

Special Instructions.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

WARNINGS, RESTRICTIONS AND DISCLAIMERS

Copyright © 2012, Texas Instruments Incorporated

Page 23

NOTES

Page 24

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue any

product or service without notice. Customers should obtain the latest relevant information before placing orders and

should verify that such information is current and complete. All products are sold subject to TI’s terms and conditions

of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance

with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by government requirements, testing of all parameters of each

product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their

products and applications using TI components. To minimize the risks associated with customer products and

applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process in

which TI products or services are used. Information published by TI regarding third-party products or services does

not constitute a license from TI to use such products or services or a warranty or endorsement thereof. Use of such

information may require a license from a third party under the patents or other intellectual property of the third party,

or a license from TI under the patents or other intellectual property of TI. Reproduction of information in TI data

books or data sheets is permissible only if reproduction is without alteration and is accompanied by all associated

warranties, conditions, limitations, and notices.

Reproduction of this information with alteration is an unfair and deceptive business practice. TI is not responsible or

liable for such altered documentation. Resale of TI products or services with statements different from or beyond the

parameters stated by TI for that product or service voids all express and any implied warranties for the associated TI

product or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such

statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI

product would reasonably be expected to cause severe personal injury or death, unless officers of the parties have

executed an agreement specifically governing such use. Buyers represent that they have all necessary expertise in

the safety and regulatory ramifications of their applications, and acknowledge and agree that they are solely

responsible for all legal, regulatory and safety-related requirements concerning their products and any use of TI

products in such safety-critical applications, notwithstanding any applications-related information or support that may

be provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of

the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the

TI products are specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI

as military-grade meet military specifications. Buyers acknowledge and agree that any such use of TI products which

TI has not designated as military-grade is solely at the Buyer's risk, and that they are solely responsible for

compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific

TI products are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree

that, if they use any non-designated products in automotive applications, TI will not be responsible for any failure to

meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

IMPORTANT NOTICE

Copyright © 2007, Texas Instruments Incorporated

Page 25

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

LMK00308EVM/NOPB

Loading...

Loading...