Page 1

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

LM4910 Output Capacitor-less Stereo 35mW Headphone

Amplifier

Check for Samples: LM4910

1

FEATURES

2

• Eliminates headphone amplifier output

coupling capacitors

• Eliminates half-supply bypass capacitor

• Advanced pop & click circuitry eliminates

noises during turn-on and turn-off

• Ultra-low current shutdown mode

• Unity-gain stable

• 2.2V - 5.5V operation

DESCRIPTION

The LM4910 is an audio power amplifier primarily designed for headphone applications in portable device

applications. It is capable of delivering 35mW of continuous average power to a 32Ω load with less than 1%

distortion (THD+N) from a 3.3VDCpower supply.

The LM4910 utilizes a new circuit topology that eliminates output coupling capacitors and half-supply bypass

capacitors. The LM4910 contains advanced pop & click circuitry which eliminates noises caused by transients

that would otherwise occur during turn-on and turn-off.

Boomer audio power amplifiers were designed specifically to provide high quality output power with a minimal

amount of external components. Since the LM4910 does not require any output coupling capacitors, half-supply

bypass capacitors, or bootstrap capacitors, it is ideally suited for low-power portable applications where minimal

space and power consumption are primary requirements.

The LM4910 features a low-power consumption shutdown mode, activated by driving the shutdown pin with logic

low. Additionally, the LM4910 features an internal thermal shutdown protection mechanism. The LM4910 is also

unity-gain stable and can be configured by external gain-setting resistors.

• Available in space-saving MSOP, LLP, and

SOIC packages

APPLICATIONS

• Mobile Phones

• PDAs

• Portable electronics devices

• Portable MP3 players

Table 1. Key Specifications

VALUE UNIT

PSRR at f = 217Hz 65 dB (typ)

Power Output at VDD= 3.3V, RL= 32Ω, and THD ≤ 1% 35 mW (typ)

Shutdown Current 0.1 µA (typ)

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2004–2007, Texas Instruments Incorporated

Page 2

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

Typical Application

www.ti.com

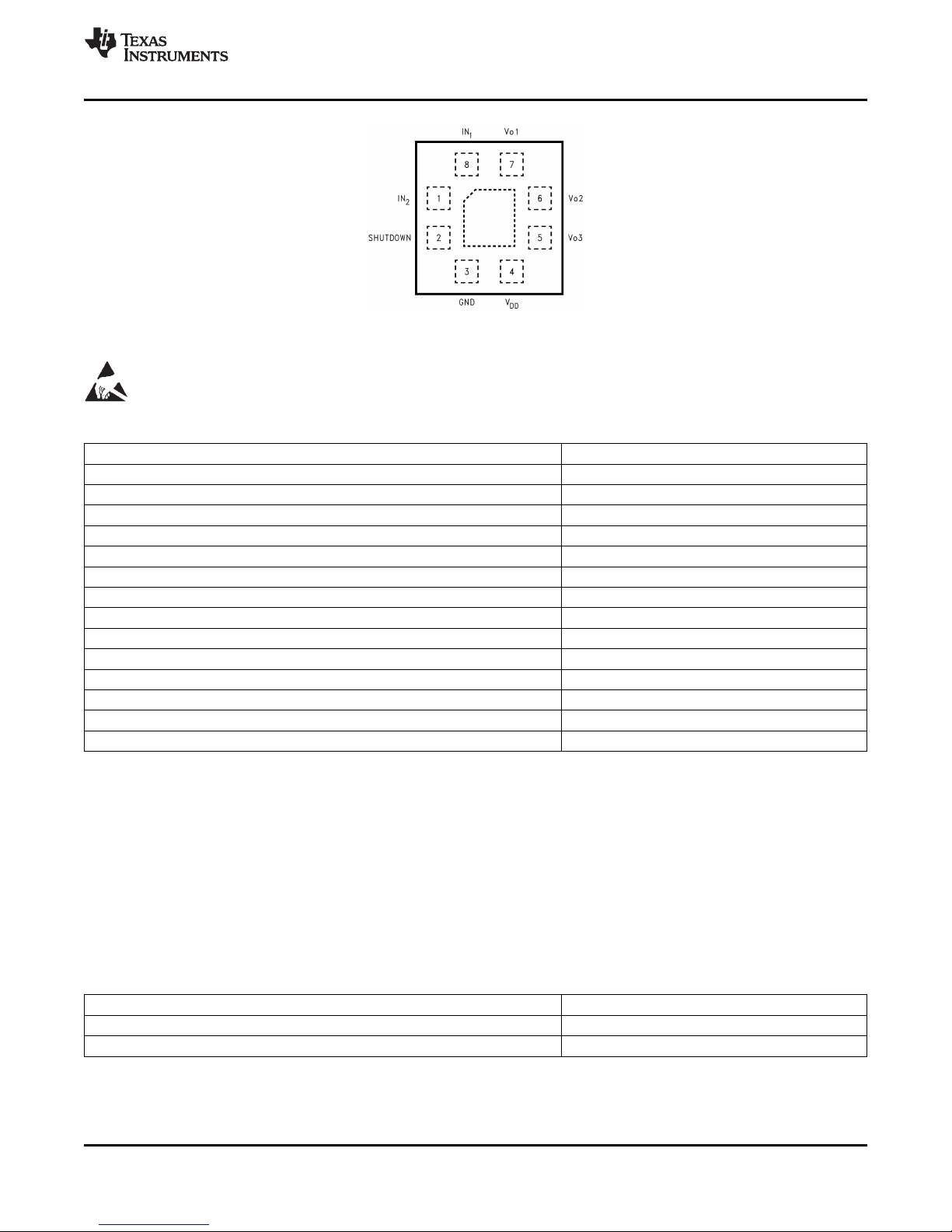

Connection Diagram

Figure 1. Typical Audio Amplifier Application Circuit

Figure 2. MSOP/SO Package Top View

Figure 3. MSOP Marking Top View

G - Boomer Family

C2 - LM4910MM

2 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Figure 4. SO Marking Top View

TT - Die Traceability

Bottom 2 lines - Part Number

Product Folder Links: LM4910

Page 3

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

Figure 5. LLP Package Top View

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

Absolute Maximum Ratings

Supply Voltage

Storage Temperature −65°C to +150°C

Input Voltage -0.3V to VDD+ 0.3V

Power Dissipation

ESD Susceptibility Pin 6

ESD Susceptibility

ESD Susceptibility

Junction Temperature 150°C

Thermal Resistance

θ

(MSOP) 56°C/W

JC

θ

(MSOP) 190°C/W

JA

θ

(SOP) 35°C/W

JC

θ

(SOP) 150°C/W

JA

θ

(LQ) 57°C/W

JC

θ

(LQ) 140°C/W

JA

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is functional but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical

specifications under particular test conditions which guarantee specific performance limits. This assumes that the device is within the

Operating Ratings. Specifications are not guaranteed for parameters where no limit is given, however, the typical value is a good

indication of device performance.

(2) If the product is in shutdown mode and VDDexceeds 6V (to a max of 8V VDD) then most of the excess current will flow through the ESD

protection circuits. If the source impedance limits the current to a max of 10ma then the part will be protected. If the part is enabled

when VDDis above 6V circuit performance will be curtailed or the part may be permanently damaged.

(3) The maximum power dissipation must be derated at elevated temperatures and is dictated by T

TA. The maximum allowable power dissipation is P

whichever is lower. For the LM4910, see power derating currents for more information.

(4) Human body model, 100pF discharged through a 1.5kΩ resistor, Pin 6 to ground.

(5) Human body model, 100pF discharged through a 1.5kΩ resistor.

(6) Machine Model, 220pF-240pF discharged through all pins.

(2)

(3)

(4)

(5)

(6)

(1)

DMAX

= (T

, θJA, and the ambient temperature,

- TA)/ θJAor the number given in Absolute Maximum Ratings,

JMAX

JMAX

6.0V

Internally Limited

10kV

2000V

200V

Operating Ratings

Temperature Range

T

≤ TA≤ T

MIN

Supply Voltage (VDD) 2.2V ≤ VCC≤ 5.5V

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 3

MAX

−40°C ≤ TA≤ 85°C

Product Folder Links: LM4910

Page 4

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

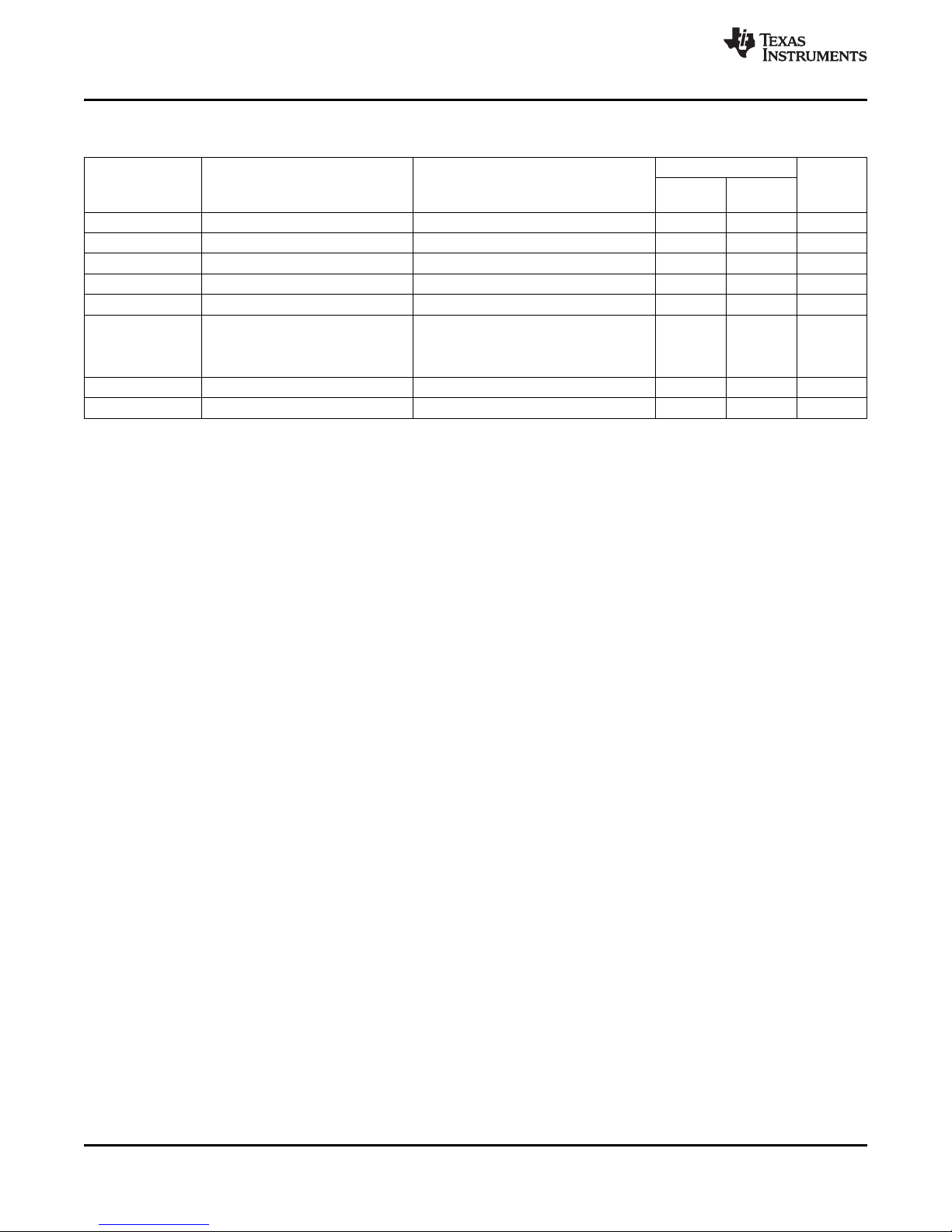

Electrical Characteristics VDD= 3.3V

(1) (2)

www.ti.com

The following specifications apply for VDD= 3.3V, AV= 1, and 32Ω load unless otherwise specified. Limits apply to TA= 25°C.

Symbol Parameter Conditions LM4910 Units

Typ Limit

(3) (4) (5)

I

DD

I

SD

V

OS

P

O

THD+N Total Harmonic Distortion + Noise PO= 30mW

Quiescent Power Supply Current VIN= 0V, 32Ω Load 3.5 6 mA (max)

Standby Current V

SHUTDOWN

= GND 0.1 1.0 µA (max)

Output Offset Voltage 5 30 mV (max)

Output Power THD = 1% (max); f = 1kHz 35 30 mW (min)

; f = 1kHz 0.3 %

rms

65 (f =

V

= 200mV

PSRR Power Supply Rejection Ratio dB

RIPPLE

Input terminated with 10Ω to ground 65 (f =

sinewave 217Hz)

p-p

1kHz)

V

IH

V

IL

Shutdown Input Voltage High 1.5 V (min)

Shutdown Input Voltage Low 0.4 V (max)

(1) All voltages are measured with respect to the GND pin unless otherwise specified.

(2) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is functional but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical

specifications under particular test conditions which guarantee specific performance limits. This assumes that the device is within the

Operating Ratings. Specifications are not guaranteed for parameters where no limit is given, however, the typical value is a good

indication of device performance.

(3) Typicals are measured at 25°C and represent the parametric norm.

(4) Limits are guaranteed to National's AOQL (Average Outgoing Quality Level).

(5) Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

(Limits)

4 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 5

LM4910

www.ti.com

Electrical Characteristics VDD= 3V

(1) (2)

SNAS151G –MAY 2004–REVISED MARCH 2007

The following specifications apply for VDD= 3V, AV= 1, and 32Ω load unless otherwise specified. Limits apply to TA= 25°C.

Symbol Parameter Conditions LM4910 Units

Typ Limit

(3) (4) (5)

I

DD

I

SD

V

OS

P

O

THD+N Total Harmonic Distortion + Noise PO= 25mW

Quiescent Power Supply Current VIN= 0V, 32Ω Load 3.3 6 mA (max)

Standby Current V

SHUTDOWN

= GND 0.1 1.0 µA (max)

Output Offset Voltage 5 30 mV (max)

Output Power THD = 1% (max); f = 1kHz 30 25 mW (min)

; f = 1kHz 0.3 %

rms

65 (f = 217

V

= 200mV

PSRR Power Supply Rejection Ratio dB

RIPPLE

Input terminated with 10Ω to ground 65 (f =

sinewave Hz)

p-p

1kHz)

V

IH

V

IL

Shutdown Input Voltage High 1.5 V (min)

Shutdown Input Voltage Low 0.4 V (max)

(1) All voltages are measured with respect to the GND pin unless otherwise specified.

(2) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is functional but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical

specifications under particular test conditions which guarantee specific performance limits. This assumes that the device is within the

Operating Ratings. Specifications are not guaranteed for parameters where no limit is given, however, the typical value is a good

indication of device performance.

(3) Typicals are measured at 25°C and represent the parametric norm.

(4) Limits are guaranteed to National's AOQL (Average Outgoing Quality Level).

(5) Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

(Limits)

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: LM4910

Page 6

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

Electrical Characteristics VDD= 2.6V

(1) (2)

www.ti.com

The following specifications apply for VDD= 2.6V, AV= 1, and 32Ω load unless otherwise specified. Limits apply to TA= 25°C.

Symbol Parameter Conditions LM4910 Units

Typ Limit

(3) (4) (5)

I

DD

I

SD

V

OS

P

O

THD+N Total Harmonic Distortion + Noise PO= 10mW

Quiescent Power Supply Current VIN= 0V, 32Ω Load 3.0 mA (max)

Standby Current V

SHUTDOWN

= GND 0.1 µA (max)

Output Offset Voltage 5 mV (max)

Output Power THD = 1% (max); f = 1kHz 13 mW

; f = 1kHz 0.3 %

rms

55 (f =

V

= 200mV

PSRR Power Supply Rejection Ratio dB

RIPPLE

Input terminated with 10Ω to ground 55 (f =

sinewave 217Hz)

p-p

1kHz)

(1) All voltages are measured with respect to the GND pin unless otherwise specified.

(2) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is functional but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical

specifications under particular test conditions which guarantee specific performance limits. This assumes that the device is within the

Operating Ratings. Specifications are not guaranteed for parameters where no limit is given, however, the typical value is a good

indication of device performance.

(3) Typicals are measured at 25°C and represent the parametric norm.

(4) Limits are guaranteed to National's AOQL (Average Outgoing Quality Level).

(5) Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

(Limits)

External Components Description

(Figure 1)

Components Functional Description

1. RIInverting input resistance which sets the closed-loop gain in conjunction with Rf. This resistor also forms a high-pass

2. CIInput coupling capacitor which blocks the DC voltage at the amplifier's input terminals. Also creates a high-pass filter

3. RfFeedback resistance which sets the closed-loop gain in conjunction with Ri.

4. CSSupply bypass capacitor which provides power supply filtering. Refer to the Power Supply Bypassing section for

filter with Ciat fc= 1/(2πRiCi).

with Riat fc= 1/(2πRiCi). Refer to the section Proper Selection of External Components, for an explanation of how to

determine the value of Ci.

information concerning proper placement and selection of the supply bypass capacitor.

6 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 7

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

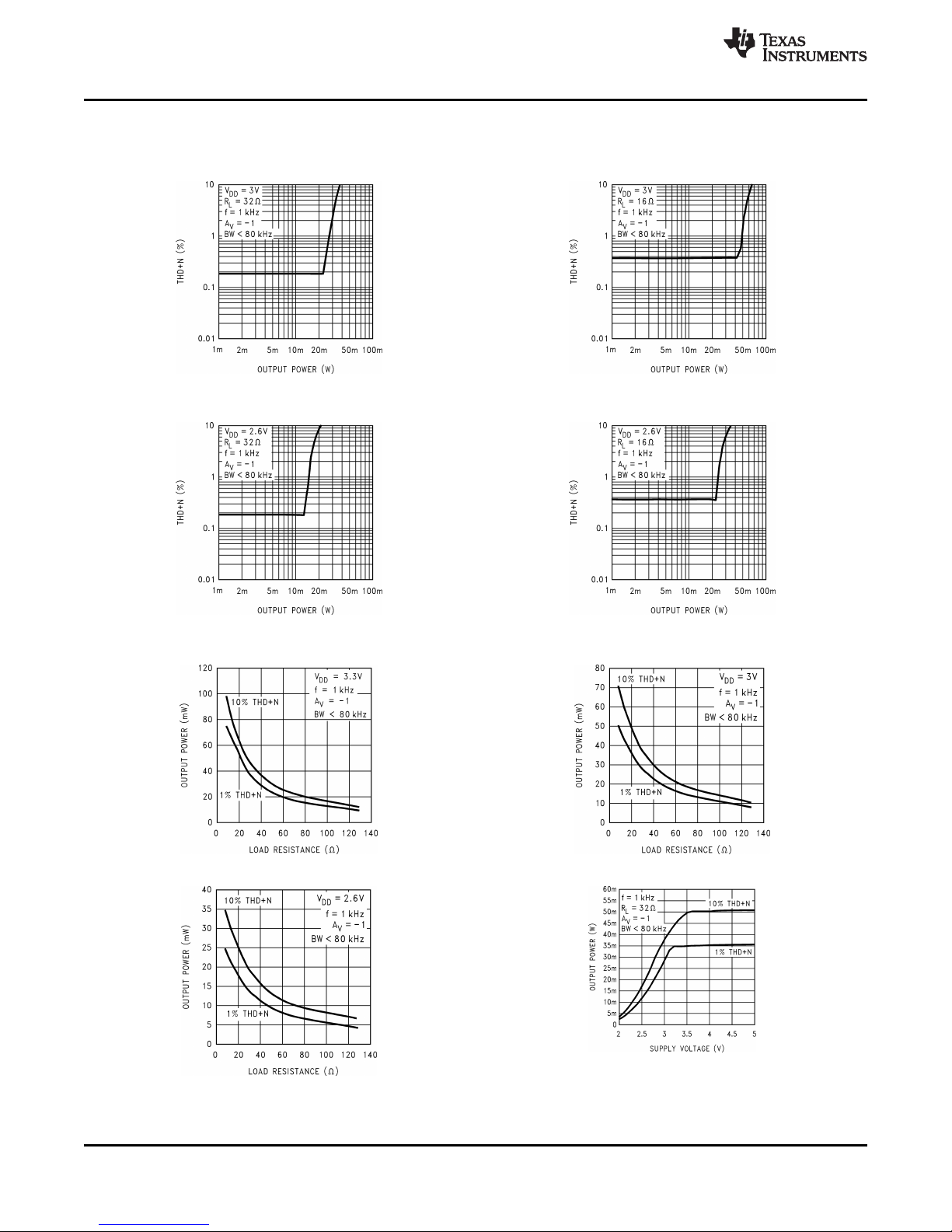

Typical Performance Characteristics

THD+N THD+N

vs vs

Frequency Frequency

THD+N THD+N

vs vs

Frequency Frequency

THD+N THD+N

vs vs

Frequency Frequency

THD+N THD+N

vs vs

Output Power Output Power

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: LM4910

Page 8

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

Typical Performance Characteristics (continued)

THD+N THD+N

vs vs

Output Power Output Power

THD+N THD+N

vs vs

Output Power Output Power

www.ti.com

Output Power

vs Output Power vs

Load Resistance Load Resistance

Output Power vs Output Power vs

Load Resistance Supply Voltage

8 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 9

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

Typical Performance Characteristics (continued)

Output Power vs Power Dissipation vs

Supply Voltage Output Power

Power Dissipation vs Power Dissipation vs

Output Power Output Power

Channel Separation Power Supply Rejection Ratio

Power Supply Rejection Ratio Power Supply Rejection Ratio

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: LM4910

Page 10

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

Typical Performance Characteristics (continued)

Open Loop Frequency Response Noise Floor

Frequency Response vs Supply Current vs

Input Capacitor Size Supply Voltage

www.ti.com

Application Information

ELIMINATING OUTPUT COUPLING CAPACITORS

Typical single-supply audio amplifiers that drive single-ended (SE) headphones use a coupling capacitor on each

SE output. This output coupling capacitor blocks the half-supply voltage to which the output amplifiers are

typically biased and couples the audio signal to the headphones. The signal return to circuit ground is through

the headphone jack's sleeve.

The LM4910 eliminates these output coupling capacitors. Amp3 is internally configured to apply a bandgap

referenced voltage (V

voltage present on the Amp1 and Amp2 outputs that drive the headphones. The headphones operate in a

manner similar to a bridge-tied-load (BTL). The same DC voltage is applied to both headphone speaker

terminals. This results in no net DC current flow through the speaker. AC current flows through a headphone

speaker as an audio signal's output amplitude increases on the speaker's terminal.

The headphone jack's sleeve is not connected to circuit ground. Using the headphone output jack as a line-level

output will place the LM4910's bandgap referenced voltage on a plug's sleeve connection. This presents no

difficulty when the external equipment uses capacitively coupled inputs. For the very small minority of equipment

that is DC-coupled, the LM4910 monitors the current supplied by the amplifier that drives the headphone jack's

sleeve. If this current exceeds 500mAPK, the amplifier is shutdown, protecting the LM4910 and the external

equipment.

ELIMINATING THE HALF-SUPPLY BYPASS CAPACITOR

Typical single-supply audio amplifers are normally biased to 1/2VDDin order to maximize the output swing of the

audio signal. This is usually achieved with a simple resistor divider network from VDDto ground that provides the

proper bias voltage to the amplifier. However, this scheme requires the use of a half-supply bypass capacitor to

improve the bias voltage's stability and the amplifier's PSRR performance.

The LM4910 utilizes an internally generated, buffered bandgap reference voltage as the amplifier's bias voltage.

This bandgap reference voltage is not a direct function of VDDand therefore is less susceptible to noise or ripple

on the power supply line. This allows for the LM4910 to have a stable bias voltage and excellent PSRR

performance even without a half-supply bypass capacitor.

= 1.58V) to a stereo headphone jack's sleeve. This voltage matches the quiescent

REF

10 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 11

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

OUTPUT TRANSIENT ('CLICK AND POPS') ELIMINATED

The LM4910 contains advanced circuitry that virtually eliminates output transients ('clicks and pops'). This

circuitry prevents all traces of transients when the supply voltage is first applied or when the part resumes

operation after coming out of shutdown mode. The LM4910 remains in a muted condition until there is sufficient

input signal magnitude (>5mV

, typ) to mask any remaining transient that may occur. Figure 2 shows the

RMS

LM4910's lack of transients in the differential signal (Trace B) across a 320 load. The LM4910's active-low

SHUTDOWN pin is driven by the logic signal shown in Trace A. Trace C is the VO1output signal and Trace D is

the VO3output signal.

To ensure optimal click and pop performance under low gain configurations (less than 0dB), it is critical to

minimize the RC combination of the feedback resistor RFand stray input capacitance at the amplifier inputs. A

more reliable way to lower gain or reduce power delivered to the load is to place a current limiting resistor in

series with the load as explained in the Minimizing Output Noise / Reducing Output Power section.

AMPLIFIER CONFIGURATION EXPLANATION

As shown in Figure 1, the LM4910 has three operational amplifiers internally. Two of the amplifier's have

externally configurable gain while the other amplifier is internally fixed at the bias point acting as a unity-gain

buffer. The closed-loop gain of the two configurable amplifiers is set by selecting the ratio of Rfto Ri.

Consequently, the gain for each channel of the IC is

AV= -(Rf/Ri) (1)

By driving the loads through outputs VO1and VO2with VO3acting as a buffered bias voltage the LM4910 does not

require output coupling capacitors. The typical single-ended amplifier configuration where one side of the load is

connected to ground requires large, expensive output coupling capacitors.

A configuration such as the one used in the LM4910 has a major advantage over single supply, single-ended

amplifiers. Since the outputs VO1, VO2, and VO3are all biased at V

= 1.58V, no net DC voltage exists across

REF

each load. This eliminates the need for output coupling capacitors that are required in a single-supply, singleended amplifier configuration. Without output coupling capacitors in a typical single-supply, single-ended

amplifier, the bias voltage is placed across the load resulting in both increased internal IC power dissipation and

possible loudspeaker damage.

POWER DISSIPATION

Power dissipation is a major concern when designing a successful amplifier. A direct consequence of the

increased power delivered to the load by a bridge amplifier is an increase in internal power dissipation. The

maximum power dissipation for a given application can be derived from the power dissipation graphs or from

Equation 1.

P

= 4(VDD)2/ (π2RL) (2)

DMAX

It is critical that the maximum junction temperature T

is for headphone operation (32Ω impedance) using a 3.3V supply the maximum power dissipation is only

138mW. Therefore, power dissipation is not a major concern.

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 11

of 150°C is not exceeded. Since the typical application

JMAX

Product Folder Links: LM4910

Page 12

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

www.ti.com

POWER SUPPLY BYPASSING

As with any amplifier, proper supply bypassing is important for low noise performance and high power supply

rejection. The capacitor location on the power supply pins should be as close to the device as possible.

Typical applications employ a 3.3V regulator with 10µF tantalum or electrolytic capacitor and a ceramic bypass

capacitor which aid in supply stability. This does not eliminate the need for bypassing the supply nodes of the

LM4910. A bypass capacitor value in the range of 0.1µF to 1µF is recommended for CS.

MICRO POWER SHUTDOWN

The voltage applied to the SHUTDOWN pin controls the LM4910's shutdown function. Activate micro-power

shutdown by applying a logic-low voltage to the SHUTDOWN pin. When active, the LM4910's micro-power

shutdown feature turns off the amplifier's bias circuitry, reducing the supply current. The trigger point is

0.4V(max) for a logic-low level, and 1.5V(min) for a logic-high level. The low 0.1µA(typ) shutdown current is

achieved by applying a voltage that is as near as ground as possible to the SHUTDOWN pin. A voltage that is

higher than ground may increase the shutdown current.

There are a few ways to control the micro-power shutdown. These include using a single-pole, single-throw

switch, a microprocessor, or a microcontroller. When using a switch, connect an external 100kΩ pull-up resistor

between the SHUTDOWN pin and VDD. Connect the switch between the SHUTDOWN pin and ground. Select

normal amplifier operation by opening the switch. Closing the switch connects the SHUTDOWN pin to ground,

activating micro-power shutdown. The switch and resistor guarantee that the SHUTDOWN pin will not float. This

prevents unwanted state changes. In a system with a microprocessor or microcontroller, use a digital output to

apply the control voltage to the SHUTDOWN pin. Driving the SHUTDOWN pin with active circuitry eliminates the

pull-up resistor.

SELECTING EXTERNAL COMPONENTS

Selecting proper external components in applications using integrated power amplifiers is critical to optimize

device and system performance. While the LM4910 is tolerant of external component combinations,

consideration to component values must be used to maximize overall system quality.

The LM4910 is unity-gain stable which gives the designer maximum system flexibility. The LM4910 should be

used in low gain configurations to minimize THD+N values, and maximize the signal to noise ratio. Low gain

configurations require large input signals to obtain a given output power. Input signals equal to or greater than

1V

are available from sources such as audio codecs. Very large values should not be used for the gain-setting

rms

resistors. Values for Riand Rfshould be less than 1MΩ. Please refer to the section, Audio Power Amplifier

Design, for a more complete explanation of proper gain selection

Besides gain, one of the major considerations is the closed-loop bandwidth of the amplifier. To a large extent, the

bandwidth is dictated by the choice of external components shown in Figure 1. The input coupling capacitor, Ci,

forms a first order high pass filter which limits low frequency response. This value should be chosen based on

needed frequency response and turn-on time.

SELECTION OF INPUT CAPACITOR SIZE

Amplifiying the lowest audio frequencies requires a high value input coupling capacitor, Ci. A high value capacitor

can be expensive and may compromise space efficiency in portable designs. In many cases, however, the

headphones used in portable systems have little ability to reproduce signals below 60Hz. Applications using

headphones with this limited frequency response reap little improvement by using a high value input capacitor.

In addition to system cost and size, turn-on time is affected by the size of the input coupling capacitor Ci. A larger

input coupling capacitor requires more charge to reach its quiescent DC voltage. This charge comes from the

output via the feedback Thus, by minimizing the capacitor size based on necessary low frequency response,

turn-on time can be minimized. A small value of Ci (in the range of 0.1µF to 0.39µF), is recommended.

12 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 13

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

USING EXTERNAL POWERED SPEAKERS

The LM4910 is designed specifically for headphone operation. Often the headphone output of a device will be

used to drive external powered speakers. The LM4910 has a differential output to eliminate the output coupling

capacitors. The result is a headphone jack sleeve that is connected to VO3instead of GND. For powered

speakers that are designed to have single-ended signals at the input, the click and pop circuitry will not be able

to eliminate the turn-on/turn-off click and pop. Unless the inputs to the powered speakers are fully differential the

turn-on/turn-off click and pop will be very large.

AUDIO POWER AMPLIFIER DESIGN

A 30mW/32Ω Audio Amplifier

Given:

Power Output 30mWrms

Load Impedance 32Ω

Input Level 1Vrms

Input Impedance 20kΩ

A designer must first determine the minimum supply rail to obtain the specified output power. By extrapolating

from the Output Power vs Supply Voltage graphs in the Typical Performance Characteristics section, the

supply rail can be easily found.

Since 3.3V is a standard supply voltage in most applications, it is chosen for the supply rail in this example. Extra

supply voltage creates headroom that allows the LM4910 to reproduce peaks in excess of 30mW without

producing audible distortion. At this time, the designer must make sure that the power supply choice along with

the output impedance does no violate the conditions explained in the Power Dissipation section.

Once the power dissipation equations have been addressed, the required differential gain can be determined

from Equation 2.

(3)

From Equation 2, the minimum AVis 0.98; use AV= 1. Since the desired input impedance is 20kΩ, and with A

equal to 1, a ratio of 1:1 results from Equation 1 for Rfto Ri. The values are chosen with Ri= 20kΩ and Rf=

20kΩ.

The last step in this design example is setting the amplifier's −3dB frequency bandwidth. To achieve the desired

±0.25dB pass band magnitude variation limit, the low frequency response must extend to at least one-fifth the

lower bandwidth limit and the high frequency response must extend to at least five times the upper bandwidth

limit. The gain variation for both response limits is 0.17dB, well within the ±0.25dB desired limit. The results are

an

fL= 100Hz/5 = 20Hz (4)

and an

fH= 20kHz x 5 = 100kHz (5)

As mentioned in the Selecting Proper External Components section, Riand Cicreate a highpass filter that

sets the amplifier's lower bandpass frequency limit. Find the coupling capacitor's value using Equation (3).

Ci≥ 1/(2πRifL) (6)

V

The result is

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: LM4910

Page 14

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

1/(2π*20kΩ*20Hz) = 0.397µF (7)

www.ti.com

Use a 0.39µF capacitor, the closest standard value.

The high frequency pole is determined by the product of the desired frequency pole, fH, and the differential gain,

AV. With an AV= 1 and fH= 100kHz, the resulting GBWP = 100kHz which is much smaller than the LM4910

GBWP of 11MHz. This figure displays that if a designer has a need to design an amplifier with higher differential

gain, the LM4910 can still be used without running into bandwidth limitations.

MINIMIZING OUTPUT NOISE / REDUCING OUTPUT POWER

Figure 6.

Output noise delivered to the load can be minimized with the use of an external resistor, R

with each load as shown in Figure 6. R

RL. As a result, output noise is attenuated by the factor RL/ (RL+ R

between output noise and R

by the factor RL/ (RL+ R

SERIES

for different loads. R

SERIES

)2. However, this may not pose a problem since most headphone applications

forms a voltage divider with the impedance of the headphone driver

SERIES

also decreases output power delivered to the load

SERIES

). Figure 7 illustrates the relationship

SERIES

require less than 10mW of output power. Figure 9 illustrates output power (@1% THD+N) vs R

, placed in series

SERIES

SERIES

for different

loads.

Figure 7 shows an optional resistor connected between the amplifier output that drives the headphone jack

sleeve and ground. This resistor provides a ground path that supressed power supply hum. This hum may occur

in applications such as notebook computers in a shutdown condition and connected to an external powered

speaker. The resistor's 100Ω value is a suggested starting point. Its final value must be determined based on the

tradeoff between the amount of noise suppression that may be needed and minimizing the additional current

drawn by the resistor (25mA for a 100Ω resistor and a 5V supply).

ESD PROTECTION

As stated in the Absolute Maximum Ratings, pin 6 (Vo3) on the LM4910 has a maximum ESD susceptibility rating

of 10kV. For higher ESD voltages, the addition of a PCDN042 dual transil (from California Micro Devices), as

shown in Figure 7, will provide additional protection.

14 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 15

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

Figure 7. The PCDN042 provides additional ESD protection beyond the 10kV shown in the Absolute

Maximum Ratings for the Vo3 output

Figure 8. Output Noise vs R

SERIES

Figure 9.

Figure 10. Output Power vs R

Figure 11.

SERIES

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: LM4910

Page 16

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

www.ti.com

HIGHER GAIN AUDIO AMPLIFIER

The LM4910 is unity-gain stable and requires no external components besides gain-setting resistors, input

coupling capacitors, and proper supply bypassing in the typical application. However, if a very large closed-loop

differential gain is required, a feedback capacitor (Cf) may be needed as shown in Figure 11 to bandwidth limit

the amplifier. This feedback capacitor creates a low pass filter that eliminates possible high frequency

oscillations. Care should be taken when calculating the -3dB frequency in that an incorrect combination of Rfand

Cfwill cause frequency response roll off before 20kHz. A typical combination of feedback resistor and capacitor

that will not produce audio band high frequency roll off is Rf = 20kΩ and Cf= 25pF. These components result in

a -3dB point of approximately 320kHz.

REFERENCE DESIGN BOARD and LAYOUT GUIDELINES MSOP & SO BOARDS

(Note: RPU2 is not required. It is used for test measurement purposes only.)

16 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 17

LM4910

www.ti.com

LM4910 SO DEMO BOARD ARTWORK

SNAS151G –MAY 2004–REVISED MARCH 2007

Figure 12. Composite View

Figure 13. Silk Screen

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: LM4910

Page 18

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

www.ti.com

Figure 14. Top Layer

Figure 15. Bottom Layer

18 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 19

LM4910

www.ti.com

LM4910 MSOP DEMO BOARD ARTWORK

Figure 16. Composite View

SNAS151G –MAY 2004–REVISED MARCH 2007

Figure 17. Silk Screen

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: LM4910

Page 20

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

www.ti.com

Figure 18. Top Layer

Figure 19. Bottom Layer

20 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 21

LM4910

www.ti.com

LM4910 LLP DEMO BOARD ARTWORK

SNAS151G –MAY 2004–REVISED MARCH 2007

Figure 20. Composite View

Figure 21. Silk Screen

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: LM4910

Page 22

LM4910

SNAS151G –MAY 2004–REVISED MARCH 2007

www.ti.com

Figure 22. Top Layer

Figure 23. Bottom Layer

LM4910 Reference Design Boards Bill of Materials

Part Description Qty Ref Designator

LM4910 Mono Reference Design Board 1

LM4910 Audio AMP 1 U1

Tantalum Cap 1µF 16V 10 1 Cs

Ceramic Cap 0.39µF 50V Z50 20 2 Ci

Resistor 20kΩ 1/10W 5 4 Ri, Rf

Resistor 100kΩ 1/10W 5 1 Rpu

Jumper Header Vertical Mount 2X1, 0.100 1 J1

PCB LAYOUT GUIDELINES

This section provides practical guidelines for mixed signal PCB layout that involves various digital/analog power

and ground traces. Designers should note that these are only "rule-of-thumb" recommendations and the actual

results will depend heavily on the final layout.

22 Submit Documentation Feedback Copyright © 2004–2007, Texas Instruments Incorporated

Product Folder Links: LM4910

Page 23

LM4910

www.ti.com

SNAS151G –MAY 2004–REVISED MARCH 2007

Minimization of THD

PCB trace impedance on the power, ground, and all output traces should be minimized to achieve optimal THD

performance. Therefore, use PCB traces that are as wide as possible for these connections. As the gain of the

amplifier is increased, the trace impedance will have an ever increasing adverse affect on THD performance. At

unity-gain (0dB) the parasitic trace impedance effect on THD performance is reduced but still a negative factor in

the THD performance of the LM4910 in a given application.

GENERAL MIXED SIGNAL LAYOUT RECOMMENDATION

Power and Ground Circuits

For two layer mixed signal design, it is important to isolate the digital power and ground trace paths from the

analog power and ground trace paths. Star trace routing techniques (bringing individual traces back to a central

point rather than daisy chaining traces together in a serial manner) can greatly enhance low level signal

performance. Star trace routing refers to using individual traces to feed power and ground to each circuit or even

device. This technique will require a greater amount of design time but will not increase the final price of the

board. The only extra parts required may be some jumpers.

Single-Point Power / Ground Connections

The analog power traces should be connected to the digital traces through a single point (link). A "PI-filter" can

be helpful in minimizing high frequency noise coupling between the analog and digital sections. Further, place

digital and analog power traces over the corresponding digital and analog ground traces to minimize noise

coupling.

Placement of Digital and Analog Components

All digital components and high-speed digital signal traces should be located as far away as possible from analog

components and circuit traces.

Avoiding Typical Design / Layout Problems

Avoid ground loops or running digital and analog traces parallel to each other (side-by-side) on the same PCB

layer. When traces must cross over each other do it at 90 degrees. Running digital and analog traces at 90

degrees to each other from the top to the bottom side as much as possible will minimize capacitive noise

coupling and cross talk.

Revision History

Rev Date Description

1.0 7/12/05 Released to the WEB.

1.1 01/16/07 Deleted the phrase “patent pending” on page

1.

Copyright © 2004–2007, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: LM4910

Page 24

PACKAGE OPTION ADDENDUM

www.ti.com

9-Aug-2013

Addendum-Page 1

PACKAGING INFORMATION

Orderable Device Status

(1)

Package Type Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

Samples

LM4910LQ/NOPB ACTIVE WQFN NGP 8 1000 Green (RoHS

& no Sb/Br)

CU SN Level-3-260C-168 HR -40 to 85 GA4

LM4910LQX/NOPB ACTIVE WQFN NGP 8 TBD Call TI Call TI -40 to 85 GA4

LM4910MM/NOPB ACTIVE VSSOP DGK 8 1000 Green (RoHS

& no Sb/Br)

CU SN Level-1-260C-UNLIM -40 to 85 GC2

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Page 25

PACKAGE OPTION ADDENDUM

www.ti.com

9-Aug-2013

Addendum-Page 2

Page 26

PACKAGE MATERIALS INFORMATION

www.ti.com 12-Aug-2013

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

LM4910LQ/NOPB WQFN NGP 8 1000 178.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM4910MM/NOPB VSSOP DGK 8 1000 178.0 12.4 5.3 3.4 1.4 8.0 12.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 27

PACKAGE MATERIALS INFORMATION

www.ti.com 12-Aug-2013

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

LM4910LQ/NOPB WQFN NGP 8 1000 213.0 191.0 55.0

LM4910MM/NOPB VSSOP DGK 8 1000 210.0 185.0 35.0

Pack Materials-Page 2

Page 28

Page 29

NGP0008A

MECHANICAL DATA

www.ti.com

LQB08A (Rev B)

Page 30

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...