Page 1

LM108A,LM208A,LM308A

LM108A LM208A LM308A Operational Amplifiers

Literature Number: SNOSBS6A

Page 2

LM108A/LM208A/LM308A Operational Amplifiers

Obsolete

General Description

The LM108/LM108A series are precision operational amplifiers having specifications about a factor of ten better than

FET amplifiers over their operating temperature range. In

addition to low input currents, these devices have extremely

low offset voltage, making it possible to eliminate offset adjustments, in most cases, and obtain performance approaching chopper stabilized amplifiers.

The devices operate with supply voltages from

g

18V and have sufficient supply rejection to use unregulated supplies. Although the circuit is interchangeable with and

uses the same compensation as the LM101A, an alternate

compensation scheme can be used to make it particularly

insensitive to power supply noise and to make supply bypass capacitors unnecessary.

The low current error of the LM108A series makes possible

many designs that are not practical with conventional amplifiers. In fact, it operates from 10 MX source resistances,

g

2V to

Compensation Circuits

Standard Compensation Circuit

introducing less error than devices like the 709 with 10 kX

sources. Integrators with drifts less than 500 mV/sec and

analog time delays in excess of one hour can be made using capacitors no larger than 1 mF.

The LM208A is identical to the LM108A, except that the

LM208A has its performance guaranteed over a

a

85§C temperature range, instead ofb55§Ctoa125§C.

The LM308A devices have slightly-relaxed specifications

and performances over a 0

Ctoa70§C temperature range.

§

Features

Y

Offset voltage guaranteed less than 0.5 mV

Y

Maximum input bias current of 3.0 nA over temperature

Y

Offset current less than 400 pA over temperature

Y

Supply current of only 300 mA, even in saturation

Y

Guaranteed 5 mV/§C drift

Alternate* Frequency Compensation

May 1989

b

25§Cto

LM108A/LM208A/LM308A Operational Amplifiers

R1 C

O

t

C

f

R1aR2

e

C

30 pF

O

**Bandwidth and slew rate are proportional to 1/Cf.

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

TL/H/7759

TL/H/7759– 1

Feedforward Compensation

*Improves rejection of power supply

noise by a factor of ten.

**Bandwidth and slew rate are proportional to 1/C

TL/H/7759– 3

TL/H/7759– 2

.

s

Page 3

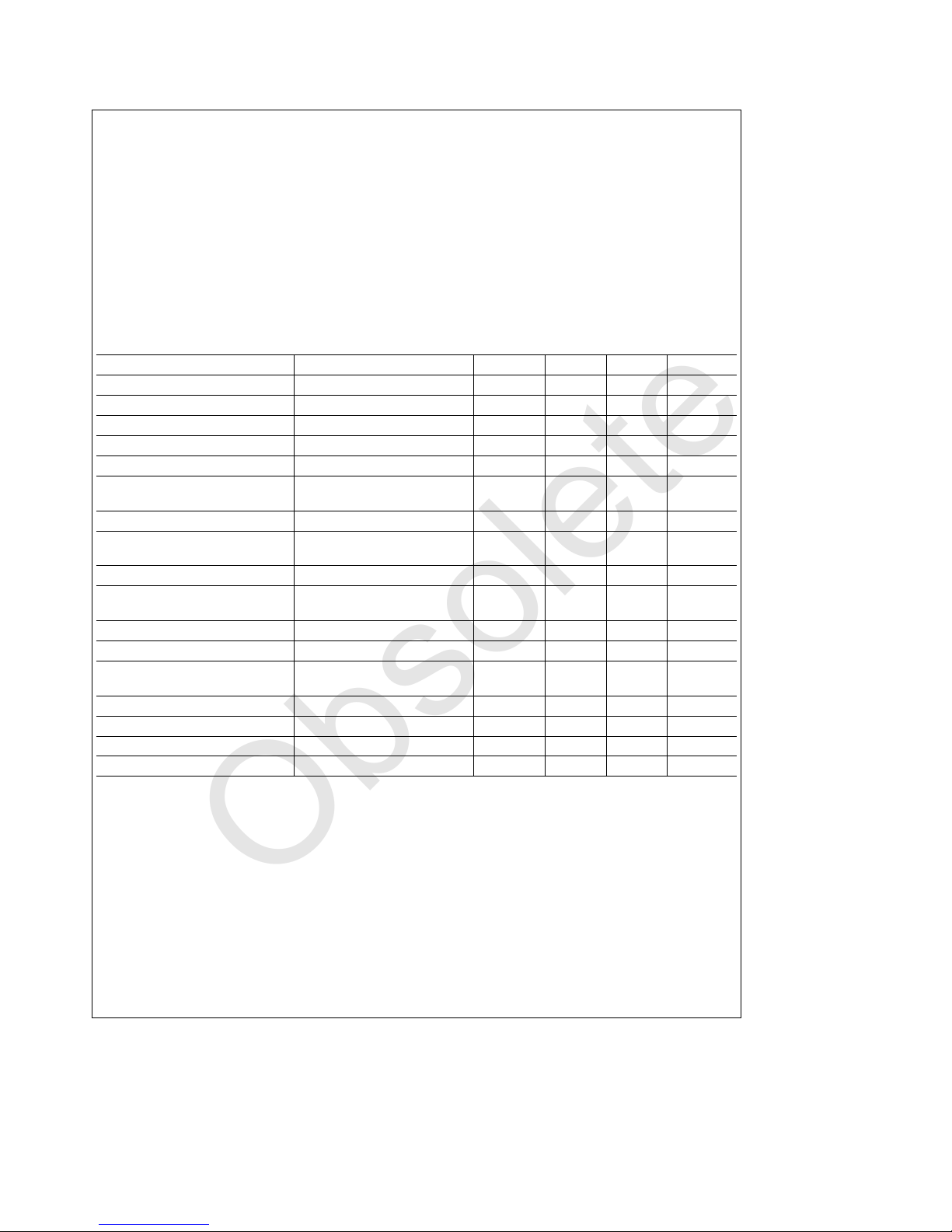

LM108A/LM208A Absolute Maximum Ratings

Obsolete

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

(Note 5)

Supply Voltage

Power Dissipation (Note 1) 500 mW

Differential Input Current (Note 2)

Input Voltage (Note 3)

Output Short-Circuit Duration Continuous

Operating Free Air Temperature Range

LM108A

LM208A

b

55§Ctoa125§C

b

g

20V

g

10 mA

g

15V

25§Ctoa85§C

Storage Temperature Range

Lead Temperature (Soldering, 10 sec.) (DIP) 260§C

Soldering Information

Dual-In-Line Package

Soldering (10 sec.) 260

Small Outline Package

Vapor Phase (60 sec.) 215

Infrared (15 sec.) 220

See An-450 ‘‘Surface Mounting Methods and Their Effect

on Product Reliability’’ for other methods of soldering surface mount devices.

ESD Tolerance (Note 6) 2000V

b

65§Ctoa150§C

Electrical Characteristics (Note 4)

Parameter Conditions Min Typ Max Units

Input Offset Voltage T

Input Offset Current T

Input Bias Current T

Input Resistance T

Supply Current T

Large Signal Voltage Gain T

Input Offset Voltage 1.0 mV

Average Temperature Coefficient

of Input Offset Voltage

Input Offset Current 0.4 nA

Average Temperature Coefficient

of Input Offset Current

Input Bias Current 3.0 nA

Supply Current T

Large Signal Voltage Gain V

Output Voltage Swing V

Input Voltage Range V

Common Mode Rejection Ratio 96 110 dB

Supply Voltage Rejection Ratio 96 110 dB

Note 1: The maximum junction temperature of the LM108A is 150§C, while that of the LM208A is 100§C. For operating at elevated temperatures, devices in the H08

package must be derated based on a thermal resistance of 160

package is 100

Note 2: The inputs are shunted with back-to-back diodes for overvoltage protection. Therefore, excessive current will flow if a differential input voltage in excess of

1V is applied between the inputs unless some limiting resistance is used.

Note 3: For supply voltages less than

Note 4: These specifications apply for

specifications are limited to

Note 5: Refer to RETS108AX for LM108AH and LM108AJ-8 military specifications.

Note 6: Human body model, 1.5 kX in series with 100 pF.

C/W, junction to ambient.

§

b

25§CsT

g

15V, the absolute maximum input voltage is equal to the supply voltage.

g

5VsV

s

85§C.

A

e

25§C 0.3 0.5 mV

A

e

25§C 0.05 0.2 nA

A

e

25§C 0.8 2.0 nA

A

e

25§C3070MX

A

e

25§C 0.3 0.6 mA

A

e

A

V

OUT

e

A

e

S

t

R

L

e

S

e

S

s

g

20V andb55§CsT

S

e

g

10V, R

g

15V,

S

t

10 kX

L

e

g

10V,

OUT

e

10 kX

L

s

125§C, unless otherwise specified. With the LM208A, however, all temperature

A

80 300 V/mV

1.0 5.0 mV/

0.5 2.5 pA/

40 V/mV

g

13

g

13.5 V

g

14 V

25§C, V

e

125§C 0.15 0.4 mA

g

15V, V

10 kX

g

15V, R

g

15V

C/W, junction to ambient, or 20§C/W, junction to case. The thermal resistance of the dual-in-line

§

§

§

C

§

C

§

C

§

C

C

2

Page 4

LM308A Absolute Maximum Ratings

Obsolete

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

g

g

18V

10 mA

g

15V

Supply Voltage

Power Dissipation (Note 1) 500 mW

Differential Input Current (Note 2)

Input Voltage (Note 3)

Output Short-Circuit Duration Continuous

Operating Temperature Range 0§Ctoa70§C

Storage Temperature Range

H-Package Lead Temperature

(Soldering, 10 sec.) 300

b

65§Ctoa150§C

§

Lead Temperature (Soldering, 10 sec.) (DIP) 260

Soldering Information

Dual-In-Line Package

Soldering (10 sec.) 260

Small Outline Package

Vapor phase (60 sec.) 215

Infrared (15 sec.) 220

See An-450 ‘‘Surface Mounting Methods and Their Effect

on Product Reliability’’ for other methods of soldering surface mount devices.

ESD rating to be determined.

C

Electrical Characteristics (Note 4)

Parameter Conditions Min Typ Max Units

Input Offset Voltage T

Input Offset Current T

Input Bias Current T

Input Resistance T

Supply Current T

Large Signal Voltage Gain T

Input Offset Voltage V

Average Temperature Coefficient V

of Input Offset Voltage

Input Offset Current 1.5 nA

Average Temperature Coefficient

of Input Offset Current

Input Bias Current 10 nA

Large Signal Voltage Gain V

Output Voltage Swing V

Input Voltage Range V

Common Mode Rejection Ratio 96 110 dB

Supply Voltage Rejection Ratio 96 110 dB

Note 1: The maximum junction temperature of the LM308A is 85§C. For operating at elevated temperatures, devices in the H08 package must be derated based on

a thermal resistance of 160

ambient.

Note 2: The inputs are shunted with back-to-back diodes for overvoltage protection. Therefore, excessive current will flow if a differential input voltage in excess of

1V is applied between the inputs unless some limiting resistance is used.

Note 3: For supply voltages less than

Note 4: These specifications apply for

C/W, junction to ambient, or 20§C/W, junction to case. The thermal resistance of the dual-in-line package is 100§C/W, junction to

§

g

15V, the absolute maximum input voltage is equal to the supply voltage.

g

5VsV

A

A

A

A

A

A

V

OUT

S

S

S

R

L

S

S

s

g

15V and 0§CsT

S

e

25§C 0.3 0.5 mV

e

25§C 0.2 1 nA

e

25§C 1.5 7 nA

e

25§C1040MX

e

e

e

e

e

t

e

e

10 kX

25§C, V

25§C, V

e

g

g

15V, R

g

15V, R

g

15V, V

g

15V, R

g

15V

e

g

15V 0.3 0.8 mA

S

e

g

15V,

S

t

10V, R

10 kX

L

e

100X 0.73 mV

S

e

100X

S

e

g

10V,

OUT

e

10 kX

L

s

a

70§C, unless otherwise specified.

A

80 300 V/mV

2.0 5.0 mV/

2.0 10 pA/

60 V/mV

g

13

g

14 V

g

14 V

C

§

C

§

C

§

C

§

C

§

C

§

3

Page 5

Typical Applications

Obsolete

Sample and Hold

²

Teflon, polyethylene or polycarbonate dielectric capacitor.

Worst case drift less than 2.5 mV/sec. TL/H/7759– 4

High Speed Amplifier with Low Drift and Low Input Current

TL/H/7759– 5

4

Page 6

Application Hints

Obsolete

A very low drift amplifier poses some uncommon application

and testing problems. Many sources of error can cause the

apparent circuit drift to be much higher than would be predicted.

Thermocouple effects caused by temperature gradient

across dissimilar metals are perhaps the worst offenders.

Only a few degrees gradient can cause hundreds of microvolts of error. The two places this shows up, generally, are

the package-to-printed circuit board interface and temperature gradients across resistors. Keeping package leads

short and the two input leads close together helps greatly.

Resistor choice as well as physical placement is important

for minimizing thermocouple effects. Carbon, oxide film and

some metal film resistors can cause large thermocouple errors. Wirewound resistors of evanohm or manganin are best

since they only generate about 2 mV/

per. Of course, keeping the resistor ends at the same temperature is important. Generally, shielding a low drift stage

electrically and thermally will yield good results.

C referenced to cop-

§

Schematic Diagram

Resistors can cause other errors besides gradient generated voltages. If the gain setting resistors do not track with

temperature a gain error will result. For example, a gain of

1000 amplifier with a constant 10 mV input will have a 10V

output. If the resistors mistrack by 0.5% over the operating

temperature range, the error at the output is 50 mV. Referred to input, this is a 50 mV error. All of the gain fixing

resistor should be the same material.

Testing low drift amplifiers is also difficult. Standard drift

testing technique such as heating the device in an oven and

having the leads available through a connector, thermoprobe, or the soldering iron methodÐdo not work. Thermal

gradients cause much greater errors than the amplifier drift.

Coupling microvolt signal through connectors is especially

bad since the temperature difference across the connector

can be 50

gain setting resistor should be isothermal.

C or more. The device under test along with the

§

TL/H/7759– 6

5

Page 7

Connection Diagrams

Obsolete

Metal Can Package

Dual-In-Line Package

Pin 4 is connected to the case.

**Unused pin (no internal connection) to allow for input anti-leakage guard

ring on printed circuit board layout.

Order Number LM108AH, LM208AH or LM208AH

See NS Package Number H08C

Physical Dimensions inches (millimeters)

TL/H/7759– 7

Top View

TL/H/7759– 8

Order Number LM108AJ-8, LM208AJ-8, LM308AJ-8,

LM308AM or LM308AN

See NS Package Number J08A, M08A or N08E

Order Number LM108AH, LM208AH or LM308AH

Metal Can Package (H)

NS Package Number H08C

6

Page 8

Physical Dimensions inches (millimeters) (Continued)

Obsolete

Order Number LM108AJ-8, LM208AJ-8 or LM308AJ-8

Ceramic Dual-In-Line Package (J)

NS Package Number J08A

S.O. Package (M)

Order Number LM308AM

NS Package Number M08A

7

Page 9

Physical Dimensions inches (millimeters) (Continued)

Obsolete

Molded Dual-In-Line Package (N)

Order Number LM308AN

NS Package Number N08E

LM108A/LM208A/LM308A Operational Amplifiers

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Page 10

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and Automotive www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...