Page 1

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N July 14, 1999

Originator:

Phillip LaCroix

Effective Date:

Hardware Specification

for

LUHF Vehicle Transponder (U.S.)

RI-TRP-VUSA

PRINTED COPIES OF THIS SPECIFICATION

ARE NOT CONTROLLED DOCUMENTS.

VERIFY THEIR CORRECT REVISION BEFORE USING.

Revision: Date:

Approval: Approval: Approval:

Function: Engineering Function: Operations Function: Quality

Name: Loek D’Hont Name: Paul Angelo Name: Larry Vidal

Date: Date: Date

RI-TRP-VUSA – Hardware Specification Page 1 of 20 11-09-05-700

Page 2

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

TABLE OF CONTENTS

1. INTRODUCTION ……………………………………………………………………………..…..…...4

1.1 SCOPE..........................................................................................................................4

1.2 APPLICABLE DOCUMENTS ...............................................................................................4

1.3 DEFINITIONS, ACRONYMS AND ABBREVIATIONS.................................................................5

2. FUNCTIONAL AND OPERATIONAL REQUIREMENTS ………………………………….6

2.1 SYSTEM OVERVIEW........................................................................................................6

3. PERFORMANCE REQUIREMENTS ..……………………………………………………….8

3.1 PHYSICAL CHARACTERISTICS ..........................................................................................8

3.1.1 Dimensions...........................................................................................................8

3.1.2 Weight..................................................................................................................8

3.1.3 Housing................................................................................................................8

3.1.4 Battery..................................................................................................................8

3.1.5 Transponder Mounting..........................................................................................8

3.2 ELECTRICAL CHARACTERISTICS .......................................................................................8

3.2.1 Radio Frequency Characteristics - Downlink .........................................................8

3.2.2 Radio Frequency Characteristics - Uplink..............................................................9

3.2.3 Transponder data ...............................................................................................10

3.2.4 Processor Characteristics...................................................................................10

3.2.5 Current Consumption Characteristics..................................................................11

3.2.6 Operation at Temperature Extremes...................................................................11

4. INTERFACE REQUIREMENTS ……………………………………………………………..12

4.1 DISPENSER CONTROLLER BOARD INTERFACES ...............................................................12

4.1.1 Downlink message format (poll)..........................................................................12

4.1.2 Uplink message format (response)......................................................................12

4.2 PROGRAMMING STATION INTERFACES............................................................................12

5. ELECTROMAGNETIC INTERFERENCE REQUIREMENTS ……………………………13

5.1 GENERAL....................................................................................................................13

5.2 RADIATED EMISSION.....................................................................................................13

5.3 RADIATED SUSCEPTIBILITY............................................................................................13

5.4 ELECTRIC / MAGNETIC FIELD DAMAGE SUSCEPTIBILITY....................................................13

6. REGULATORY REQUIREMENTS ………………………………………………………….11

6.1 FCC REQUIREMENTS...................................................................................................14

7. QUALITY ASSURANCE PROVISIONS……………………………………………………..15

7.1 INSPECTION.................................................................................................................15

7.2 TESTING .....................................................................................................................15

RI-TRP-VUSA – Hardware Specification Page 2 of 20 11-09-05-700

Page 3

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

7.3 MATERIALS..................................................................................................................15

7.3.1 Toxic Products and Formulations........................................................................15

7.3.2 Workmanship......................................................................................................15

7.4 RELIABILITY REQUIREMENTS .........................................................................................16

7.4.1 Reliability Performance.......................................................................................16

7.5 ENVIRONMENTAL REQUIREMENTS ..................................................................................16

8. PREPARATION FOR DELIVERY …………………………………………………………………18

8.1 PACKING AND PACKAGING.............................................................................................18

8.2 ELECTROSTATIC (ES) PRPTECTION...............................................................................18

9. BATTERY LIFE CALCULATION …………………………………………………………...19

Revision:

RI-TRP-VUSA – Hardware Specification Page 3 of 20 11-09-05-700

Page 4

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

1. INTRODUCTION

1.1 SCOPE

This document describes the implementation of the FCC compliant Vehicle Transponder for the ARC

customer identification system. The scope of this document includes the performance requirements

for the U.S. vehicle transponder and the interface definition between the transponder and other major

assemblies in the ARC system.

If anything in this document is ambiguous or incorrect, it should be immediately reported to the

Project Managers for the ARC Team, and corrected. The document should then be approved by all

the concerned individuals on the cover page and redistributed to all parties involved.

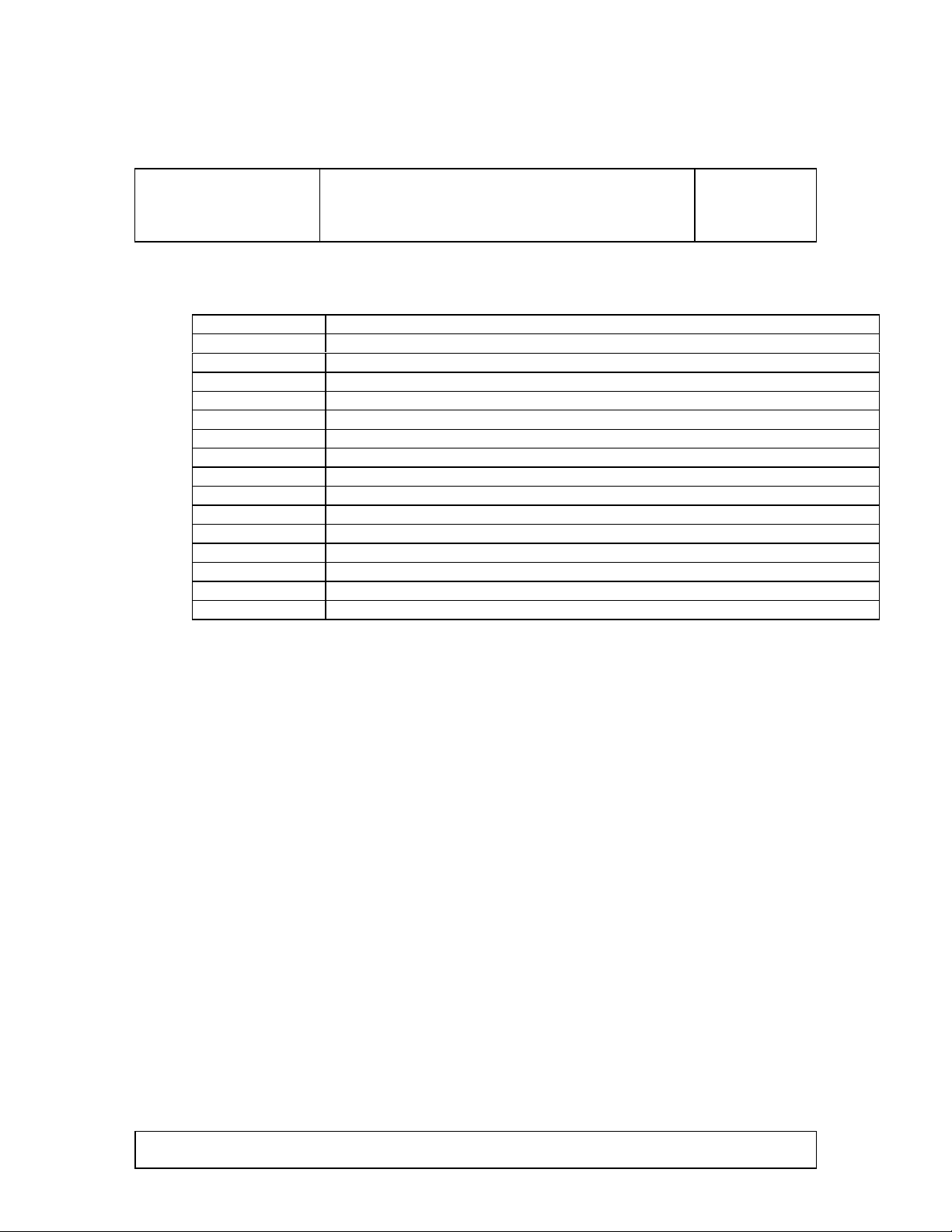

1.2 APPLICABLE DOCUMENTS

The hierarchy of documentation pertaining to the ARC system is depicted below. As this table

appears in each of the documents, it is important that revisions to any document in the family be

reflected in this table.

Document

Number

TIRIS2001 Mobil Speedpass System Customer Requirements Product Specification

06-01-02-700 ARC System Specification for Retail Fueling Applications

11-09-05-702 ARC Digital Control Board Hardware Specification - RI-CTL-DCUA

11-09-05-703 ARC UHF Receiver Daughter-Board Specification (US) - RI-RFM-HRUA

11-09-05-700 Hardware Specification for LUHF Vehicle Transponder (U.S.)

11-09-05-701 Software Specification for LUHF Vehicle Transponder (U.S.)

11-09-05-704 ARC LUHF Vehicle Transponder Programmer Specification

ARC System Qualification Test Procedure & Manufacturing / QA/QC Procedures per TQM

Standards.

FCC Part 15, Class B

Document Title

RI-TRP-VUSA – Hardware Specification Page 4 of 20 11-09-05-700

Page 5

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

1.3 DEFINITIONS, ACRONYMS, AND ABBREVIATIONS

ARC Automatic Recognition of Consumers

ASK Amplitude Shift Keying

DCB Digital Control Board

DST Digital Signature Transponder

ES Electrostatic

ETSI European Telecommunication Standards Institute

FCC Federal Communications Commission

FSK Frequency Shift Keying

IPC Interconnecting and Packaging Electronic Circuits

LF Low Frequency

MTBF Mean Time Between Failure

PLL Phase Locked Loop

POS Point of Sale

UHF Ultra High Frequency

Uplink RF Data Transmission from the Transponder to the Reader

Downlink RF Data Transmission from the Reader to the Transponder

A92FPTVEH – Attachment 2

Revision:

RI-TRP-VUSA – Hardware Specification Page 5 of 20 11-09-05-700

Page 6

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

2. FUNCTIONAL AND OPERATIONAL REQUIREMENTS

The ARC system, when installed in a fuel dispenser which offers pay-at-the-pump functionality,

provides hands-free identification of a customer and/or the customer’s vehicle. The system offers

pay-at-the-pump convenience, without requiring the insertion of a credit card or any keypad entries.

The U.S. Vehicle Transponder is the component of the system placed in the customer's vehicle. When

activated by a ARC dispenser, the transponder provides identification and authentication data via a

radio frequency link to the dispenser. An overview of the complete ARC system is provided in the

ARC System Specification, 06-01-02-700.

2.1 SYSTEM OVERVIEW

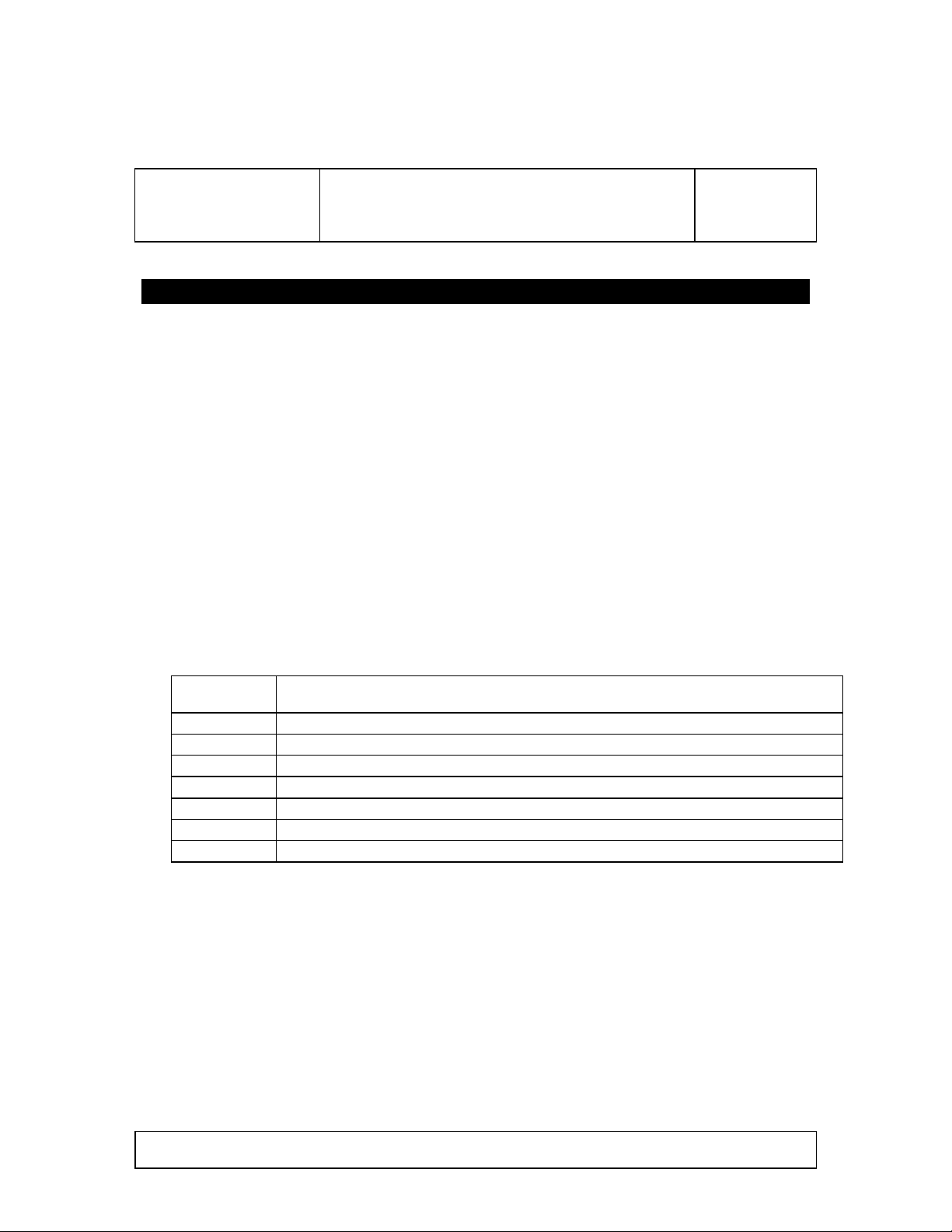

An overview of the U.S. vehicle transponder is depicted in Figure 2-1 below. The major functional

blocks of the transponder are the downlink network, the processor, and the uplink network.

RI-TRP-VUSA – Hardware Specification Page 6 of 20 11-09-05-700

Page 7

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Digital

Controller

Board

A92FPTVEH – Attachment 2

Revision:

LF

Downlink

Downlink

Network

Data Processing

and Storage

UHF

Uplink

Uplink

Network

LUHF Vehicle Transponder

Figure 2-1. U.S. Vehicle Transponder Block Diagram.

RI-TRP-VUSA – Hardware Specification Page 7 of 20 11-09-05-700

Page 8

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

3. PERFORMANCE REQUIREMENTS

Top-level customer specific system performance requirements are defined in the applicable Customer

Requirements Product Specifications detailed in Section 1.2. This section augments and clarifies

those requirements pertaining to the vehicle transponder, as appropriate.

3.1 PHYSICAL CHARACTERISTICS

3.1.1 Dimensions

The transponder shall be fully contained within a 58.mm x 44.5mm x 24.mm space. The maximum

dimensions of the transponder shall not exceed this space in any direction.

3.1.2 Weight

The transponder shall weigh no more than 0.5 lbs.

3.1.3 Housing

The transponder shall be enclosed in a plastic housing, type PC/ASA.

3.1.4 Battery

The transponder housing shall provide access to the replaceable battery. The battery is a coin cell,

type 2032. The chemistry of the battery will be Li-MnO2 or equivalent approved by Texas

Instruments to ensure compliance with this specification.

3.1.5 Transponder Mounting

The transponder shall be mounted in the lower middle of the rear window using "hook and loop" or

"ball and cup" fasteners with adhesive attachment to the window and to the transponder.

3.2 ELECTRICAL CHARACTERISTICS

3.2.1 Radio Frequency Characteristics - Downlink

The transponder shall detect and process signals, which consist of the following properties:

RI-TRP-VUSA – Hardware Specification Page 8 of 20 11-09-05-700

Page 9

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Property Requirement

Carrier Frequency 134.2 kHz +/- 100 ppm

Activation Field Strength Level (at the

transponder surface)

Max. Operating Field Strength (at the

transponder surface)

Modulation ASK

Modulation Depth > 95 %

Data Encoding FM0

Data Rate 1 kbps +/- 100 ppm

Duty Cycle of received FM0 signal 50 +/- 5%

34 mA/m +/- 7 mA/m, at the optimum transponder

orientation

At a 45° rotation from optimum, an additional 3dB

of field strength is required.

The transponder must be separated from any

metallic material by a minimum of 3 cm.

500 mA/m

A92FPTVEH – Attachment 2

Revision:

The transponder shall successfully process signals with these properties while in the operating

temperature range specified in section 7.5.

3.2.2 Radio Frequency Characteristics - Uplink

The output signals from the transponder shall conform to the following properties:

Property Requirement

Virtual Carrier Frequency 902.8 MHz

Carrier Frequency Accuracy +/- 100 ppm

Total Radiated Power -20 dBm +/- 3dB

Spurious Emissions -36 dBm maximum (250 nW)

Modulation FSK

Virtual Carrier Frequency Drift within one Transmission 10 kHz maximum

Frequency Deviation 40 kHz maximum

Digital high level encoding Positive frequency deviation

Digital low level encoding Negative frequency deviation

Data Encoding Manchester

Data Rate 20 kbps +/- 100 ppm

Duty Cycle of transmitted signal 50 +/- 10%

RI-TRP-VUSA – Hardware Specification Page 9 of 20 11-09-05-700

Page 10

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

The transponder shall transmit signals with these properties while in the operating temperature range

specified in section 7.5.

3.2.3 Transponder data

The transponder shall have the capability of storing data in non-volatile memory. Data may be loaded

into the transponder at three possible locations: the transponder manufacturing facility; the

transponder distribution center; and at Third Party locations. The following table defines the data that

shall be programmed into the transponder, and the facilities where it could be programmed.

Revision:

Data block Programmable at

Factory

Transponder Identification

Number (32 bits)

Account Data field, for fleet

identification (5 bits)

DST data, up to 32 unique keys

(40 bits each)

Key activation data, to indicate

programmed key

Any data block may be programmed one time only. The DST keys shall be stored in such a way that

they may not be read from the transponder once programmed.

3.2.4 Processor Characteristics

The transponder processor is a dedicated microcontroller capable of operating at 1 MIPS. The

processor includes a crystal clock operating at 4 MHz +/- 100 ppm over the full temperature range of

the transponder. This tolerance directly influences the accuracy of the output data rate of the uplink

data. Refer to the ARC Vehicle Transponder Software Specification, 11-09-05-701, for detailed

requirements for the transponder software.

The processor shall have two modes, Sleep and Active. The transponder shall go into its Sleep mode

after exiting a RF field with the defined RF characteristics below the maximum RF level of an

incoming data 0. In Sleep mode the transponder will consume a minimal amount of current to

enhance battery life. The transponder will wake-up and go into an Active mode upon entering a RF

field with the defined RF characteristics above the minimum RF level of an incoming Data 1. Once

activated, the transponder will attempt to acquire and respond to incoming polls or else go back into

Sleep mode if the RF field goes away.

Yes Yes No

Yes Yes Yes

Yes Yes No

Yes Yes Yes

Programmable at

Distribution Center

Programmable by

Third Party

The processor executes tasks sequentially, and will only perform half-duplex communication. For a

poll to be recognized by the processor, sufficient time must be allowed following the previous

response. The first unique DST Challenge poll will cause the processor to save the challenge data and

RI-TRP-VUSA – Hardware Specification Page 10 of 20 11-09-05-700

Page 11

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

execute the DST algorithm. While executing the DST algorithm, the processor will not respond to

any polls. The processor will response to subsequent identical DST Challenge polls using the

calculated DST Challenge Response.

3.2.5 Current Consumption Characteristics

The transponder shall achieve a minimum battery life of three years. The battery life shall be defined

through the functional temperature range with the defined number of fueling transactions per week.

Exposure to temperatures in excess of the defined functional temperature range will reduce the

battery life.

Fueling Transactions 5 per week

Battery Voltage, typical 3V (depends on battery type)

Battery Voltage, allowable

operating range

Battery Capacity ~210 mAH

Current load (Sleep) < 4 uA average over specified

Current load (Active) < 5 mA

2.5 V to 3.5 V

temperature range

Revision:

3.2.6 Operation at Temperature Extremes

The transponder may not be functional outside of the defined operating temperature range. The

transponder shall return to full functionality after returning to the operating temperature range from

the storage temperature range, provided that there is still sufficient battery capacity available after

storage. The operating and storage temperature ranges are defined in section 7.5.

RI-TRP-VUSA – Hardware Specification Page 11 of 20 11-09-05-700

Page 12

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

4. INTERFACE REQUIREMENTS

This section defines the interfaces between vehicle transponder and relevant subsystems of the ARC

system.

4.1 DIGITAL CONTROL BOARD INTERFACES

4.1.1 Downlink message format (poll)

The Dispenser Controller Board communicates with the vehicle transponder by sending poll

messages in the downlink channel. The format of the downlink poll messages are defined in the ARC

Vehicle Transponder Software Specification, 11-09-05-701.

4.1.2 Uplink message format (response)

The vehicle transponder communicates with the Dispenser Controller board by sending response

messages in the uplink channel. The format of the downlink poll messages are defined in the ARC

Vehicle Transponder Software Specification, 11-09-05-701.

4.2 PROGRAMMING STATION INTERFACES

The programming interface shall be in accordance with Vehicle Transponder Programming

Specification, 11-09-05-704.

RI-TRP-VUSA – Hardware Specification Page 12 of 20 11-09-05-700

Page 13

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

5. ELECTROMAGNETIC INTERFERENCE REQUIREMENTS

5.1 GENERAL

The design requirements for the control of the electromagnetic emission and susceptibility

characteristics of the U.S. vehicle transponder shall be in accordance with MIL-STD-461D

Requirements for Control of Electromagnetic Interference Emissions and Susceptibility.

5.2 RADIATED EMISSION

Requirement Description

RE101 Radiated Emissions, Magnetic Field, 30 Hz to 100 kHz for a Land Mobile

platform.

RE102 Radiated Emissions, Electric Field, 10 kHz to 18 GHz. Except for 903 +/-

1 MHz, where a maximum of - 10 dBm may be present for a Land Mobile

platform.

RE103 Radiated Emissions, Antenna Spurious and harmonic Output, 10 kHz to

40 GHz. Except for 903 +/- 1 MHz, where a maximum of - 10 dBm may

be present for a Land Mobile platform.

5.3 RADIATED SUSCEPTIBILITY

Requirement Description

RS101 Radiated Susceptibility, Magnetic Field, 30 Hz to 100 kHz. A maximum field

strength of 27 mA/m is allowable.

RS103 Radiated Susceptibility, Electric Field, 10 kHz to 40 GHz.. Except for 10kHz to

200 kHz, where a field strength of 2.7 mA/m is allowable.

5.4 ELECTRIC / MAGNETIC FIELD DAMAGE SUSCEPTIBILITY

The transponder shall withstand, without permanent damage, a field of 1 A/m in the band 0 - 200

kHz, excluding 133 -135 kHz, or a field of 200 V/m in any other band.

RI-TRP-VUSA – Hardware Specification Page 13 of 20 11-09-05-700

Page 14

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

6. REGULATORY REQUIREMENTS

6.1 FCC REQUIREMENTS

The vehicle transponder shall comply with FCC Regulations, Part 15, Class B.

A92FPTVEH – Attachment 2

Revision:

RI-TRP-VUSA – Hardware Specification Page 14 of 20 11-09-05-700

Page 15

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

7. QUALITY ASSURANCE PROVISIONS

The U.S. vehicle transponder shall be designed and manufactured under a quality assurance program

equivalent to ISO 9001. This does not imply that the suppliers of the design or manufacturers shall be

certified to ISO 9001 but are capable of and have withstood an external audit by an independent

auditor.

7.1 INSPECTION

The transponder shall be visually inspected by the supplier. The transponder shall be inspected for

compliance to the Institute for Interconnecting and Packaging Electronic Circuits (IPC) or equivalent

standard. This inspection shall be sufficient to assure performance to the requirements of this

specification, workmanship and electrical interface.

7.2 TESTING

The transponder shall be tested for compliance to the performance requirement of paragraphs 3

through 6. Test procedures shall be reviewed and approved prior to the acceptance of product.

7.3 MATERIALS

Materials chosen by the supplier shall be in accordance with IPC or equivalent standards and

practices, sufficient to assure performance to the requirements of this specification.

External parts, elements or coatings including marking shall be inherently non-nutrient to fungus and

do not blister, crack, outgas, soften, flow or exhibit defects that adversely affect storage, operation, or

assembly.

7.3.1 Toxic Products and Formulations

No products or formulations, which are known to be toxic or harmful, shall be used without approval

by Texas Instruments Incorporated.

7.3.2 Workmanship

Workmanship evidenced in the construction of the vehicle transponder shall be inspected for

compliance to the Institute for Interconnecting and Packaging Electronic Circuits (IPC) or equivalent,

RI-TRP-VUSA – Hardware Specification Page 15 of 20 11-09-05-700

Page 16

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

sufficient to assure performance to the requirements of this specification to the extremes of the

environments specified herein.

7.4 RELIABILITY REQUIREMENTS

7.4.1 Reliability Performance

The reliability of the transponder shall be designed to meet or exceed the design goals documented in

the table below. The reliability prediction technique shall utilize MIL-HDBK-217 or Bell Core,

Method 1, at 25 degrees C, as a guideline.

Revision:

Module

LUHF Vehicle Transponder

(excluding Battery)

Table 7-1. Reliability Requirements

* MTBF - Mean Time Between Failure which are repairable.

** MTTF - Mean Time to Failure which are non-repairable.

7.5 ENVIRONMENTAL REQUIREMENTS

The U.S. vehicle transponder is to meet applicable sections defined in the applicable Customer

Requirements Product Specifications detailed in Section 1.2.

The critical operating environmental guidelines are as follows:

- Operating temperature: Operating temperature tests in accordance with MIL-STD-202F,

method 102A, temperature cycling or equivalent, using the following parameters: -10 to +85

degrees C, duration 500 hours. Transponder may have degraded operational performance to -20

degrees C.

MTBF *

(hours, Repairable)

MTTF **

(hours, Non-

repairable)

1,000,000 .974

Survival

Probability

(3 years)

- Storage temperature (battery removed): Storage temperate tests in accordance with MIL-STD-

810D, method 502.2, using the following parameters: Low temperature - 40 degrees C 1000

hours, High temperature 104 degrees C, 1000 hours.

- Shock Environment: Shock test performed in accordance with Mil-STD-810D, Method 516.3 or

equivalent using the following parameters: 30 G's at 10 mS, half sinusoidal wave, 6 axes.

RI-TRP-VUSA – Hardware Specification Page 16 of 20 11-09-05-700

Page 17

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

- Vibration Environment: Vibration tests in accordance with MIL-STD-810E, Method 514.4 or

equivalent, using the following parameters: 10 to 500 Hz, 10 g peak, 30 minutes sweep,

logarithmic.

- Humidity Environment (battery removed): Humidity tests in accordance with MIL-STD-810D,

Method 507.2, procedure III, aggravated screening or equivalent, using the following humidity

parameters: 85 percent relative humidity, non-condensing at 85o C, duration 500 hours.

- Thermal Shock (battery removed): Thermal Shock testing in accordance with MIL-STD-810D,

Method 503.2 or equivalent, using the following thermal shock parameters: - 40 to 85 degrees C,

100 cycles duration.

- Drop: Drop from 1m onto a 1-inch thick maple block, 1 drop per side on all surfaces.

Operational functionality and structural integrity shall not be compromised. The battery cover is

allowed to fall off of the transponder as long as it is not damaged and can be replaced into the

unit.

Revision:

RI-TRP-VUSA – Hardware Specification Page 17 of 20 11-09-05-700

Page 18

A92FPTVEH – Attachment 2

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Revision:

8. PREPARATION FOR DELIVERY

8.1 PACKING AND PACKAGING

Preservation, packaging, and packing of system and subsystems to be delivered shall be to the

supplier's best commercial practice to prevent deterioration and mechanical damage in shipment and

in storage.

8.2 ELECTROSTATIC (ES) PROTECTION

The ARC system and subsystems shall meet an ES level of 2000 volts minimum using a standard

body model.

RI-TRP-VUSA – Hardware Specification Page 18 of 20 11-09-05-700

Page 19

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

9. BATTERY LIFE CALCULATION

Battery Load Conditions

* Standby Conditions

Load Current: 2 uA

Duration: 100% of time

* Active Conditions

Duration: 5 transactions / week, assuming 5 minutes / transaction

Continuous Load:1 mA

Pulsed Cycle Load: (* Additional to Continuous Load)

Cycle Time: 200 mS

A92FPTVEH – Attachment 2

Revision:

Pulse Time: 6 mS

Pulsed Load: 4 mA

* Temperature:

Range: -10C to +85C (Operational)

Hot %: 15% (+85C)

Cold %: 15% (-10C)

* Minimum Operational Voltage: 2.5V

* Battery Self Discharge: < 5% / year

* Battery Energy:210 mA-Hour

Energy Usage per Year

*Self Discharge Energy per Year: 10.50 mA-Hour

(210 mA-Hour * 5%)

*Standby Energy per Year: 17.52 mA-Hours

(2 uA * 24 Hours/Day * 365 Days/Year)

* Active Energy per Year:

RI-TRP-VUSA – Hardware Specification Page 19 of 20 11-09-05-700

Page 20

TI PROPRIETARY T E X A S I N S T R U M E N T S

INFORMATION

T I R I S

Internal Data S P E C I F I C A T I O N

Continuous: 21.67 mA-Hours

(1 mA * [(5 Min/Day)/ (60 Min/Hour)]* 5 Days/Week * 52 Weeks/Year)

Pulsed: 2.60 mA-Hours

(4 mA * [(6 mS/200 mS * 5 Min/Day)/(60 Min/Hour)] * 5 Days/Week * 52 Weeks/Year)

Calculated Life: 4.02 Years

(210 mA-Hour / 52.29 mA-Hour/Year)

A92FPTVEH – Attachment 2

Revision:

====================

Total 52.29 mA-Hours/Year

RI-TRP-VUSA – Hardware Specification Page 20 of 20 11-09-05-700

Loading...

Loading...