Page 1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询DDC118供应商

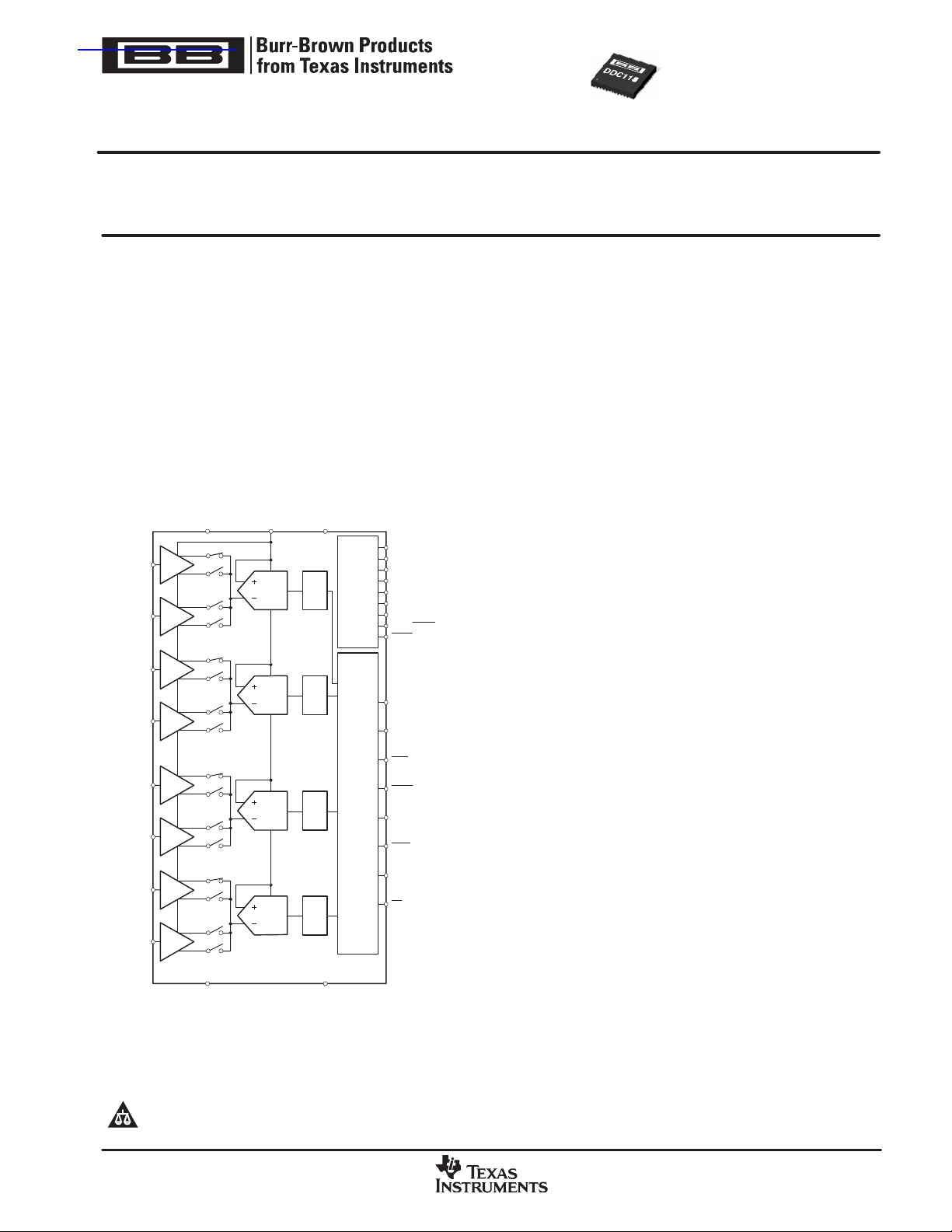

DDC118

SBAS325A − JUNE 2004 − REVISED JUNE 2005

Octal Current Input 20-Bit

Analog-To-Digital Converter

FEATURES

D SINGLE-CHIP SOLUTION TO DIRECTLY

MEASURE EIGHT LOW-LEVEL CURRENTS

D HIGH PRECISION, TRUE INTEGRATING

FUNCTION

D INTEGRAL LINEARITY:

±0.01% of Reading ±0.5ppm of FSR

D VERY LOW NOISE: 5.2ppm of FSR

D LOW POWE R: 13.5mW/channel

D ADJUSTABLE DATA RATE: Up to 3.125kSPS

D PROGRAMMABLE FULL SCALE

D DAISY-CHAINABLE SERIAL INTERFACE

VREF DVDDAVDD

CLK

Control

Digital

CONV

RANGE0

RANGE1

RANGE2

TEST

CLK_4X

HISPD/LOPWR

RESET

FORMAT

DCLK

DCLK

DVALID

DOUT

DOUT

DIN

DIN

IN1

IN3

IN2

IN4

IN5

IN7

IN6

IN8

Dual

Switched

Integrator

Dual

Switched

Integrato r

Dual

Switched

Integrator

Dual

Switched

Integrator

Dual

Switched

Integrator

Dual

Switched

Integrato r

Dual

Switched

Integrator

Dual

Switched

Integrator

∆Σ

Modulator

∆Σ

Modulator

∆Σ

Modulator

∆Σ

Modulator

Digital

Filter

Digital

Filter

Digital

Filter

Digital

Filter

Input/Output

DGNDAGND

APPLICATIONS

D CT SCANNER DAS

D PHOTODIODE SENSORS

D INFRARED PYROMETER

D LIQUID/GAS CHROMATOGRAPHY

Protected b y U S Patent #5841310

DESCRIPTION

The DDC118 is a 20-bit octal channel, current-input

analog-to-digital (A/D) converter. It combines both

current-to-voltage and A/D conversion so that eight

low-level current output devices, such as photodiodes, can

be directly connected to its inputs and digitized.

For each of the eight inputs, the DDC118 provides a

dual-switched integrator front-end. This design allows for

continuous current integration: while one integrator is

being digitized by the onboard A/D converter, the other is

integrating the input current. Adjustable full-scale ranges

from 12pC to 350pC and adjustable integration times from

50µs to 1s allow currents from fAs to µAs to be measured

with outstanding precision. Low-level linearity is ±0.5ppm

of the full-scale range and noise is 5.2ppm of the full-scale

range.

Two modes of operation are provided. In Low-Power

mode, total power dissipation is only 13.5mW per channel

with a maximum data rate of 2.5kSPS. High-Speed mode

supports data rates up to 3.125kSPS with a corresponding

dissipation of 18mW per channel.

The DDC118 has a serial interface designed for

daisy-chaining in multi-device systems. Simply connect

the output of one device to the input of the next to create

the chain. Common clocking feeds all the devices in the

chain so that the digital overhead in a multi-DDC118

system is minimal.

The DDC118 is a single-supply device using a +5V analog

supply and supporting a +2.7V to +5.25V digital supply.

Operating over the industrial temperature range of −40°C

to 85°C, the DDC118 is offered in a QFN-48 package.

semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

! !

www.ti.com

Copyright 2002−2005, Texas Instruments Incorporated

Page 2

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

ABSOLUTE MAXIMUM RATINGS

Analog Input Current 750µA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AVDD to DVDD −0.3V to +6V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AVDD to AGND −0.3V to +6V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DVDD to DGND −0.3V to +6V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGND to DGND ±0.2V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VREF Input to AGND 2.0V to AVDD + 0.3V. . . . . . . . . . . . . . . . . .

Analog Input to AGND −0.3V to +0.7V. . . . . . . . . . . . . . . . . . . . . . .

Digital Input Voltage to DGND −0.3V to DVDD + 0.3V. . . . . . . . . . .

Digital Output Voltage to DGND −0.3V to AVDD + 0.3V. . . . . . . . .

Operating Temperature −40°C to +85°C. . . . . . . . . . . . . . . . . . . . . .

Storage Temperature −60°C to +150°C. . . . . . . . . . . . . . . . . . . . . . .

Junction Temperature (TJ) +150°C. . . . . . . . . . . . . . . . . . . . . . . . . . .

(1)

Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only , an d

functional operation of the device at these or any other conditions

beyond those specified is not implied.

(1)

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

ORDERING INFORMATION

For package and ordering information, see the Package

Option Addendum located at the end of this data sheet.

2

Page 3

""#

Integration Time, T

Integral Linearity Error

(6)

Resolution

www.ti.com

SBAS325A − JUNE 2004 − REVISED JUNE 2005

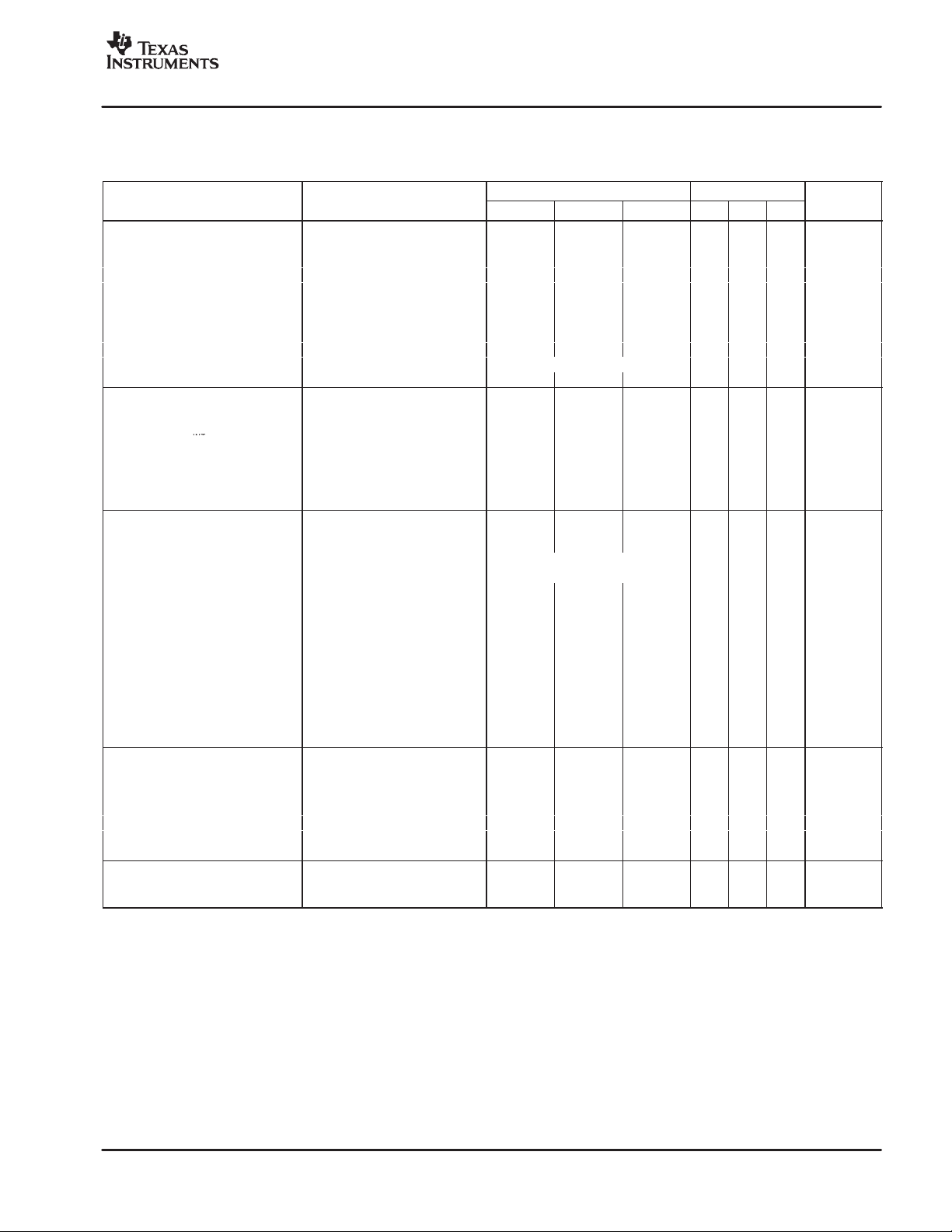

ELECTRICAL CHARACTERISTICS

At TA = +25°C, AVDD = +5V, DVDD = 3V, VREF = +4.096V, Range 5 (250pC), and continuous mode operation, unless otherwise noted.

Low-Power Mode: T

PARAMETER TEST CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

ANALOG INPUT RANGE

Range 0 10.2 12 13.8 ∗

Range 1 47.5 50 52.5 ∗ ∗ ∗ pC

Range 2 95 100 105 ∗ ∗ ∗ pC

Range 3 142.5 150 157.5 ∗ ∗ ∗ pC

Range 4 190 200 210 ∗ ∗ ∗ pC

Range 5 237.5 250 262.5 ∗ ∗ ∗ pC

Range 6 285 300 315 ∗ ∗ ∗ pC

Range 7 332.5 350 367.5 ∗ ∗ ∗ pC

Negative Full-Scale Range −0.4% of Positive Full-Scale Range ∗ pC

Input Current

DYNAMIC CHARACTERISTICS

Data Rate 2.5 3.125 kSPS

System Clock Input (CLK)

Data Clock (DCLK) 16 ∗ MHz

ACCURACY

Noise, Low-Level Input

Resolution FORMAT = 1 20 ∗ Bits

Input Bias Current 0.1 10 ∗ ∗ pA

Range Error Match

Range Sensitivity to VREF V

Offset Error Range 5 (250pC) ±400 ±1000 ∗ ∗ ppm of FSR

Offset Error Match

DC Bias Voltage

Power-Supply Rejection Ratio at dc ±25 ±200 ∗ ∗ ppm of FSR/V

Internal Test Signal 11 ∗ pC

Internal Test Accuracy ±10 ∗ %

PERFORMANCE OVER TEMPERATURE

Offset Drift ±0.5 ±3

Offset Drift Stability ±0.2 ±1

DC Bias Voltage Drift

Input Bias Current Drift TA = +25°C to +45°C 0.01 1

Range Drift

REFERENCE

Voltage 4.000 4.096 4.200 ∗ ∗ ∗ V

Input Current

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(2)

CLK_4X = 0 4 4.8 MHz

CLK_4X = 1 16 19.2 MHz

(9)

(10)

(11)

∗ indicates that specification is the same as Low-Power Mode.

Exceeding maximum input current specification may damage device.

Input is less than 1% of full scale.

C

FSR is Full-Scale Range.

A best-fit line is used in measuring nonlinearity.

Matching between side A and side B of the same input.

Ensured by design, not production tested.

Voltage produced by the DDC118 at its input which is applied to the sensor.

Range drift does not include external reference drift.

Input reference current decreases with increasing T

Data format is Straight Binary with a small offset. The number of bits in the output word is controlled by the FORMAT pin (see text).

is the capacitance seen at the DDC118 inputs from wiring, photodiode, etc.

SENSOR

= 400µs and CLK = 4MHz; High-Speed Mode: T

INT

INT

(3)

(7)

(7)

(9)

Continuous Mode 400 1,000,000 320 ∗ µS

Non-continuous Mode, Range 1 to 7 50 ∗ µS

(4)

C

= 50pF, Range 5 (250pC) 5.2 6.5 5.5 7

SENSOR

FORMAT = 0 16 ∗ Bits

All Ranges 0.1 0.5 ∗ ∗ % of FSR

= 4.096 ± 0.1V 1:1 ∗

REF

Low-Level Input (< 1% FSR) ±0.05 ±2 ∗ ∗ mV

Average Value 150 190 µA

(see the Voltage Reference section, page 11).

INT

= 320µs and CLK = 4.8MHz.

INT

Low-Power Mode High-Speed Mode

(1)

750 ∗ µA

±0.01% Reading ± 0.5ppm FSR, typ ∗

±0.025% Reading ± 1.0ppm FSR, max ∗

±100 ∗ ppm of FSR

(8)

(8)

3 ∗ µV/°C

25 ∗ ppm/°C

(8)

∗ ∗ pC

ppm of

(5)

FSR

∗ ∗

∗ ∗

ppm of

FSR/°C

ppm of FSR/

minute

∗ ∗ pA/°C

, rms

3

Page 4

""#

www.ti.com

SBAS325A − JUNE 2004 − REVISED JUNE 2005

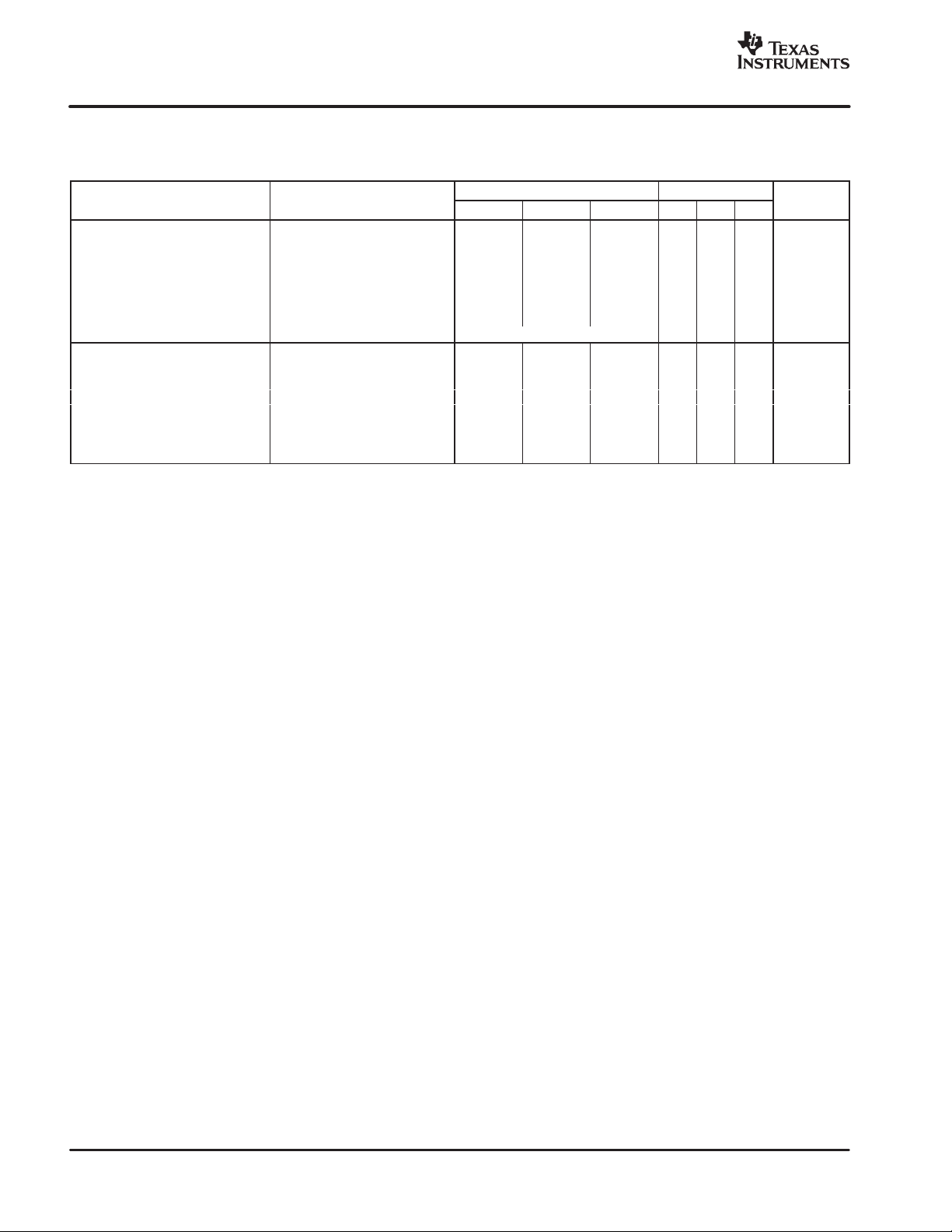

ELECTRICAL CHARACTERISTICS (continued)

At TA = +25°C, AVDD = +5V, DVDD = 3V, VREF = +4.096V, Range 5 (250pC), and continuous mode operation, unless otherwise noted.

Low-Power Mode: T

PARAMETER UNITSMAXTYPMINMAXTYPMINTEST CONDITIONS

DIGITAL INPUT/OUTPUT

Logic Levels

V

IH

V

IL

V

OH

V

OL

Input Current (IIN) 0 < VIN < DVDD ±10 ∗ µA

Data Format

POWER-SUPPLY REQUIREMENTS

Analog Power-Supply Voltage (AVDD) 4.75 5.25 ∗ ∗ V

Digital Power-Supply Voltage (DVDD) 2.7 5.25 ∗ ∗ V

Supply Current

Total Power Dissipation DVDD = +3V 108 150 144 200 mW

Total Power Dissipation per Channel DVDD = +3V 13.5 18.75 18 25 mW

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(12)

Total Analog Current 21 28 mA

Total Digital Current DVDD = +3V 1 1.34 mA

∗ indicates that specification is the same as Low-Power Mode.

Exceeding maximum input current specification may damage device.

Input is less than 1% of full scale.

C

FSR is Full-Scale Range.

A best-fit line is used in measuring nonlinearity.

Matching between side A and side B of the same input.

Ensured by design, not production tested.

Voltage produced by the DDC118 at its input which is applied to the sensor.

Range drift does not include external reference drift.

Input reference current decreases with increasing T

Data format is Straight Binary with a small offset. The number of bits in the output word is controlled by the FORMAT pin (see text).

is the capacitance seen at the DDC118 inputs from wiring, photodiode, etc.

SENSOR

= 400µs and CLK = 4MHz; High-Speed Mode: T

INT

IOH = −500µA DVDD − 0.4 V

IOL = 500µA 0.4 ∗ V

(see the Voltage Reference section, page 11).

INT

= 320µs and CLK = 4.8MHz.

INT

High-Speed ModeLow-Power Mode

0.8DVDD DVDD + 0.1 ∗ ∗ V

− 0.1 0.2DVDD ∗ ∗ V

Straight Binary ∗

4

Page 5

""#

www.ti.com

SBAS325A − JUNE 2004 − REVISED JUNE 2005

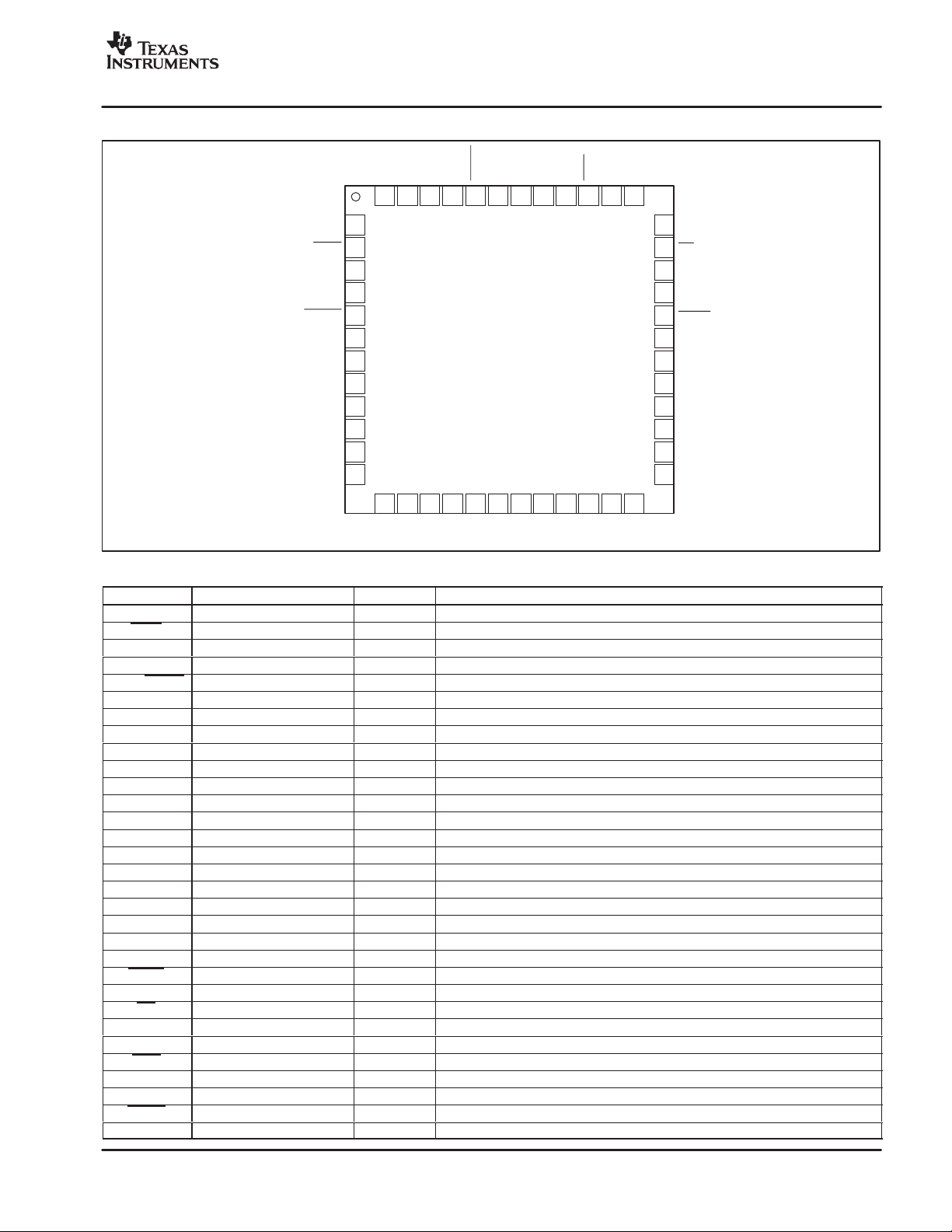

PIN CONFIGURATION

Top View QFN

DGND

DGND

CONV

DGND

DVA LID

DGND

CLK

DGND

DCLK

DCLK

DGND

DVDD

48 47 46 45 44 43 42

41 40 39 38

DOUT

DOUT

CLK_4X

FOR MA T

HISPD/LOPWR

RANG E0

RANG E1

RANG E2

AGND

VREF

AGND

AGND

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 233724

AIN8

AIN4

AGND

AIN7

DDC118

AIN3

AGND

AIN6

AGND

AIN2

AIN5

36

DIN

35

DIN

34

NC

33

NC

32

RESET

31

TEST

30

DGND

29

DGND

28

AGND

27

AVDD

26

AGND

25

AGND

AIN1

AGND

PIN DESCRIPTIONS

PIN NUMBER FUNCTION DESCRIPTION

DOUT 1 Digital Output Serial Data Output

DOUT 2 Digital Output Serial Data Output: Complementary Signal (optional, see text on page 13)

CLK_4X 3 Digital Input Master Clock Divider Control: 0 = divide by 1, 1 = divide by 4

FORMAT 4 Digital Input Digital Output Word Format: 0 = 16 Bits, 1 = 20 Bits

HISPD/LOPWR 5 Digital Input Mode Control: 0 = Low-Power, 1 = High-Speed

RANGE0 6 Digital Input Range Control 0 (least significant bit)

RANGE1 7 Digital Input Range Control 1

RANGE2 8 Digital Input Range Control 2 (most significant bit)

AGND 9, 11-13, 18, 19, 24-26, 28 Analog Analog Ground

VREF 10 Analog Input External Voltage Reference Input, 4.096V Nominal

AIN8 14 Analog Input Analog Input 8

AIN7 16 Analog Input Analog Input 7

AIN6 20 Analog Input Analog Input 6

AIN5 22 Analog Input Analog Input 5

AIN4 15 Analog Input Analog Input 4

AIN3 17 Analog Input Analog Input 3

AIN2 21 Analog Input Analog Input 2

AIN1 23 Analog Input Analog Input 1

AVDD 27 Analog Analog Power Supply, 5V Nominal

DGND 29, 30, 38, 41, 43, 45, 47, 48 Digital Digital Ground

TEST 31 Digital Input Test Mode Control

RESET 32 Digital Input Resets the Digital Circuitry, Active Low

NC 33, 34 — No connection. These pins must be left unconnected.

DIN 35 Digital Input Serial Data Input: Complementary Signal (optional, see text on page 13)

DIN 36 Digital Input Serial Data Input

DVDD 37 Digital Digital Power Supply, 3V Nominal

DCLK 39 Digital Input Serial Data Clock Input: Complementary Signal (optional, see text on page 13)

DCLK 40 Digital Input Serial Data Clock Input

CLK 42 Digital Input Master Clock Input

DVALID 44 Digital Output Data Valid Output, Active Low

CONV 46 Digital Input Conversion Control Input: 0 = Integrate on Side B, 1 = Integrate on Side A

5

Page 6

""#

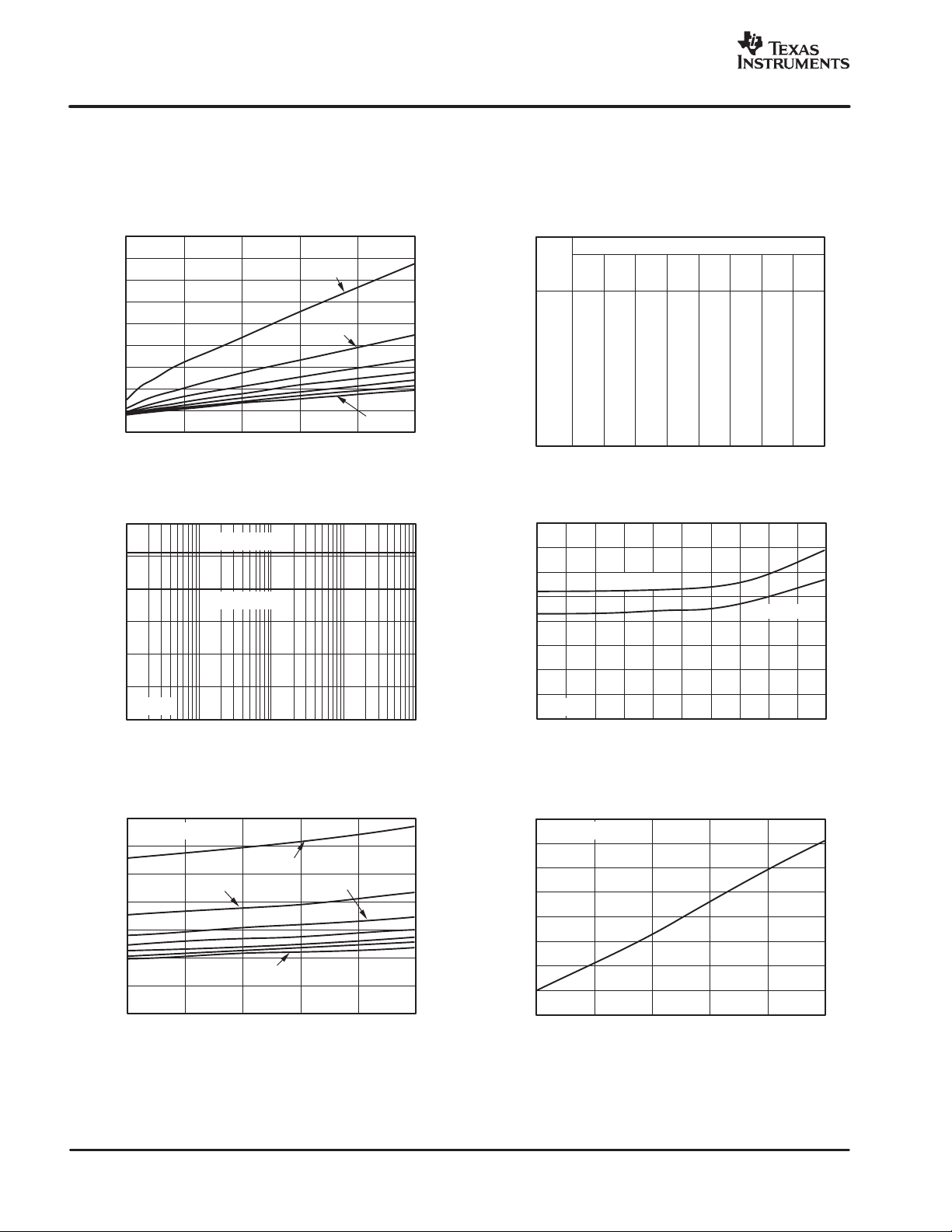

NOISE vs C

Range Drift (ppm)

SBAS325A − JUNE 2004 − REVISED JUNE 2005

TYPICAL CHARACTERISTICS

At TA = +25°C, characterization done with Range 5 (250pC), AVDD = +5V, DVDD = 3V, VREF = +4.096V, and Low-Power Mode: T

unless otherwise noted.

www.ti.com

= 400µs and CLK = 4MHz,

INT

45

NOISE vs C

40

35

30

25

20

15

10

Noise(ppmofFSR,rms)

5

0

100 4000 500300200

C

SENSOR

NOISE vs T

6

5

4

C

SENSOR

3

2

Noise (ppm of FSR, rms)

1

Range 5

0

1 10000.1 10010

C

SENSOR

= 50pF

T

=0pF

(ms)

INT

SENSOR

(pF)

INT

Range 1

Range 2

Range 7

SENSOR

Noise (ppmof FSR, rms)

C

SENSOR

(pF)

24

50

75

100

150

200

300

500

Range

Range

Range

5.2

6.7

8.2

8.9

10.0

11.9

13.5

16.3

22.4

Range

2

3

4.4

5.5

6.5

7.2

8.0

9.2

10.2

12.5

16.6

0

1

0

23.6

7.3

30.8

10.4

36.3

12.3

41.3

14.4

46.1

16.0

57.0

18.8

68.1

21.7

89.3

27.7

134.0

38.9

Range

4

4.2

4.9

5.6

6.0

6.7

7.8

8.6

10.6

13.5

Range

5

4.0

4.5

5.1

5.4

5.9

6.8

7.6

9.0

11.7

Range

6

3.8

4.3

4.8

5.1

5.4

6.1

6.8

8.1

10.4

Range

7

3.7

4.1

4.4

4.7

5.0

5.7

6.4

7.4

9.5

NOISE vs INPUT LEVEL

8

7

6

5

4

C

SENSOR

= 50pF

C

SENSOR

= 0pF

3

2

Noise (ppm of FSR, rms)

1

Range 5

0

20 3010 800 10060 70 9040 50

Input Level (% of Full−Scale)

14

C

=50pF

SENSOR

12

10

Range 2

Range 1

Range 3

8

2000

1500

1000

500

All Ranges

NOISE vs TEMPERATURE

RANGE DRIFT vs TEMPERATURE

0

6

4

Noise (ppm of FSR, rms)

2

Range 7

0

−

40

−

15 10 35 60 85

Temperature (_C)

−

−

−

−

500

1000

1500

2000

−

40

−

15 10 35 60 85

Temperature (_C)

6

Page 7

www.ti.com

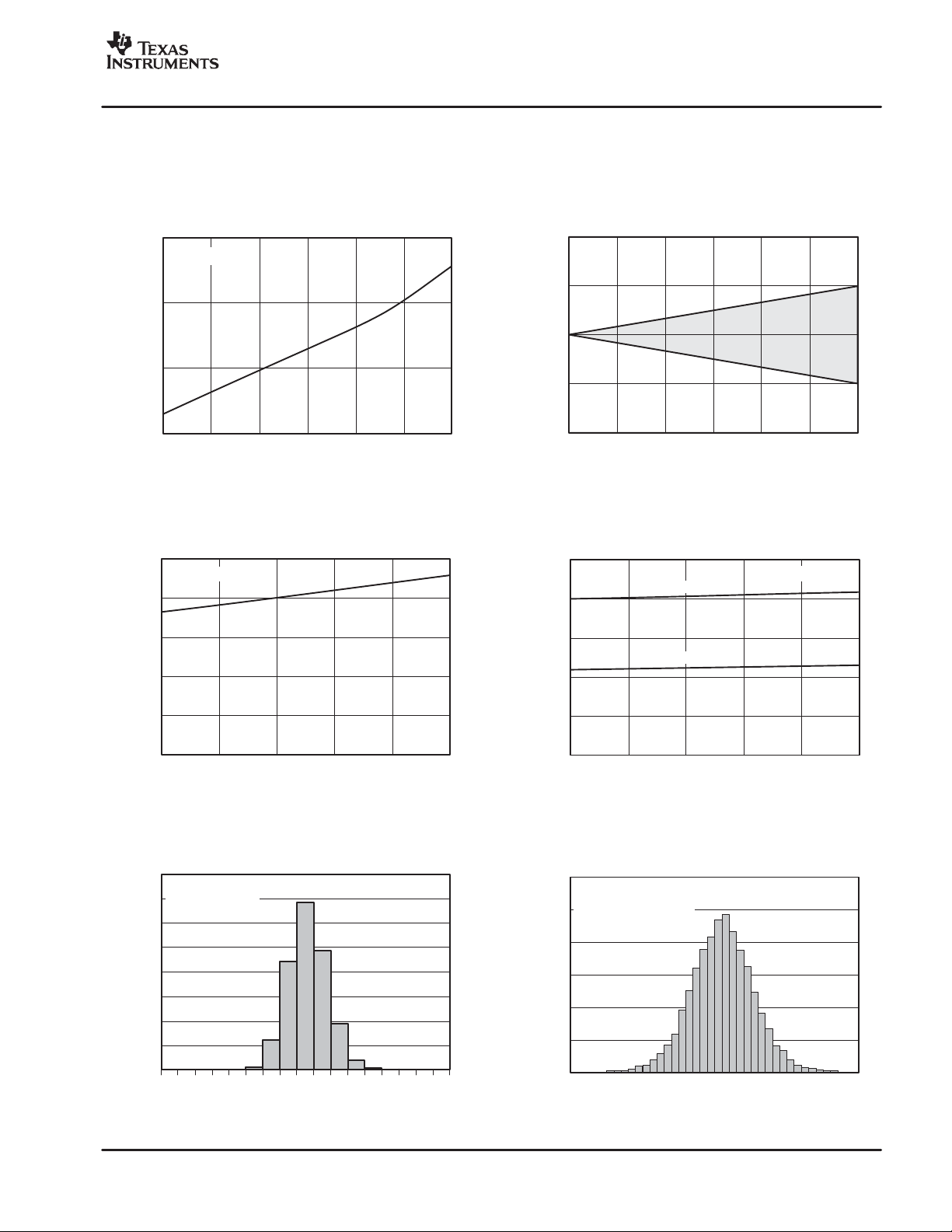

IBvs TEMPERATURE

ANALOG SUPPLY CURRENTvs TEMPERATURE

POWER CONSUMPTION HISTOGRAM

OFFSET DRIFT vs TEMPERATURE

SBAS325A − JUNE 2004 − REVISED JUNE 2005

TYPICAL CHARACTERISTICS (continued)

At TA = +25°C, characterization done with Range 5 (250pC), AVDD = +5V, DVDD = 3V, VREF = +4.096V, and Low-Power Mode: T

unless otherwise noted.

""#

= 400µs and CLK = 4MHz,

INT

10

All Ranges

1

(pA)

B

I

0.1

0.01

25 35 45 55 65 75 85

Temperature (_C)

25

Low−Power Mode

20

15

10

Current (mA)

100

50

0

−

50

Offset Drift (ppm of FSR)

−

100

25 35 45 55 65 75 85

Temperature (_C)

2.5

2.0

1.5

1.0

Current (mA)

DIGITAL SUPPLY CURRENT vsTEMPERATURE

Low−Power Mode

DVDD= 5V

DVDD = 3V

5

0

−

40

40

35

30

25

20

15

Occurences(%)

10

5

0

−

15 10 35 60 85

Data collected

from multiple lots.

12.00

12.25

12.50

12.75

Temperature (_C)

13.00

13.25

13.50

13.75

14.00

Power per Channel (mW)

Low−Power Mode

14.25

14.50

14.75

15.00

15.25

15.50

15.75

16.00

Occurences

0.5

0

1200

1000

800

600

400

200

−

40

0

−

1.0

−

15 10 35 60 85

Temperature (_C)

OFFSET DRIFT HISTOGRAM AT ROOM TEMPERATURE

Repeated measurement

of offset drift over a

one minute interval.

−

0.6

−

0.2 0.2 0.6 1.0

Offset Drift (ppm of FSR/minute)

Range 5

7

Page 8

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

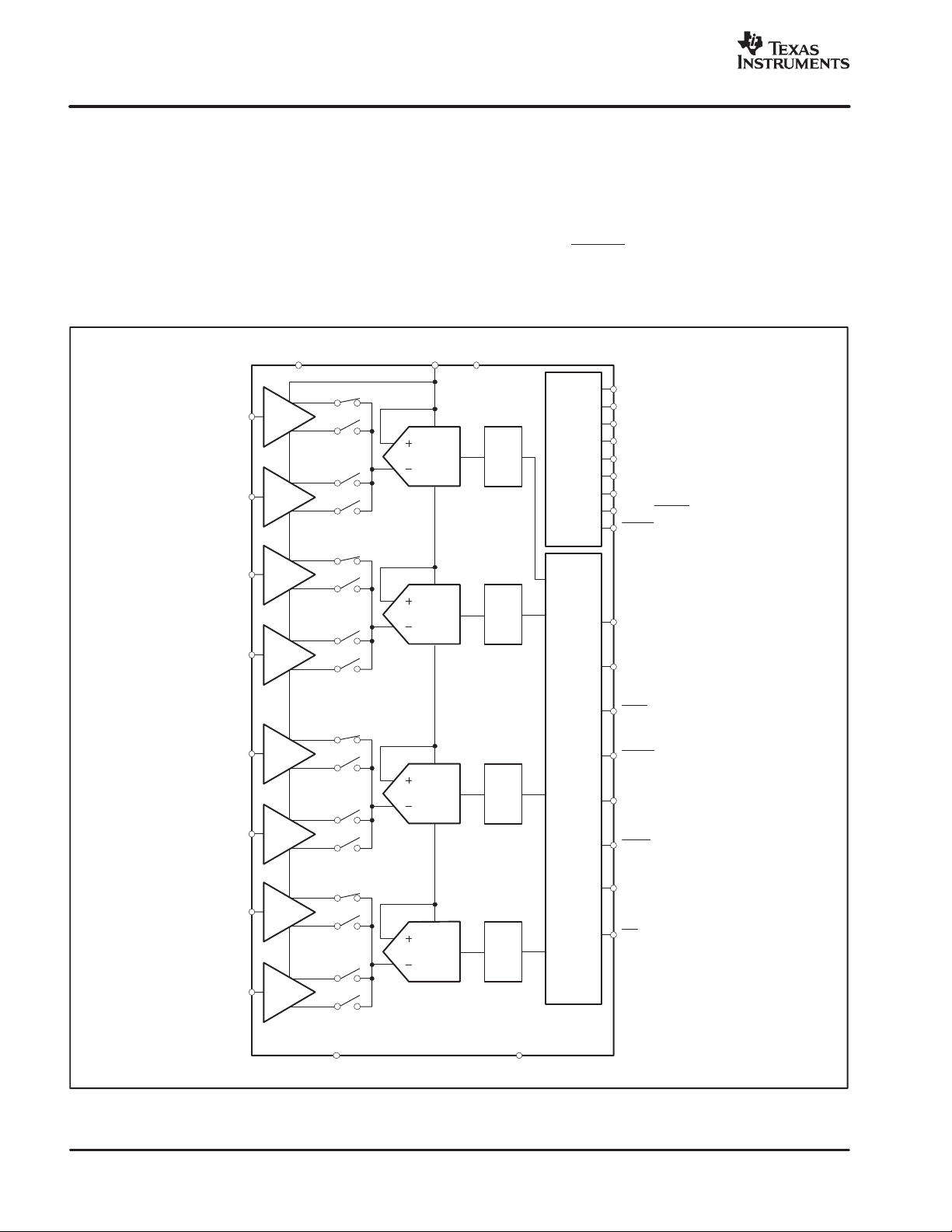

THEORY OF OPERATION

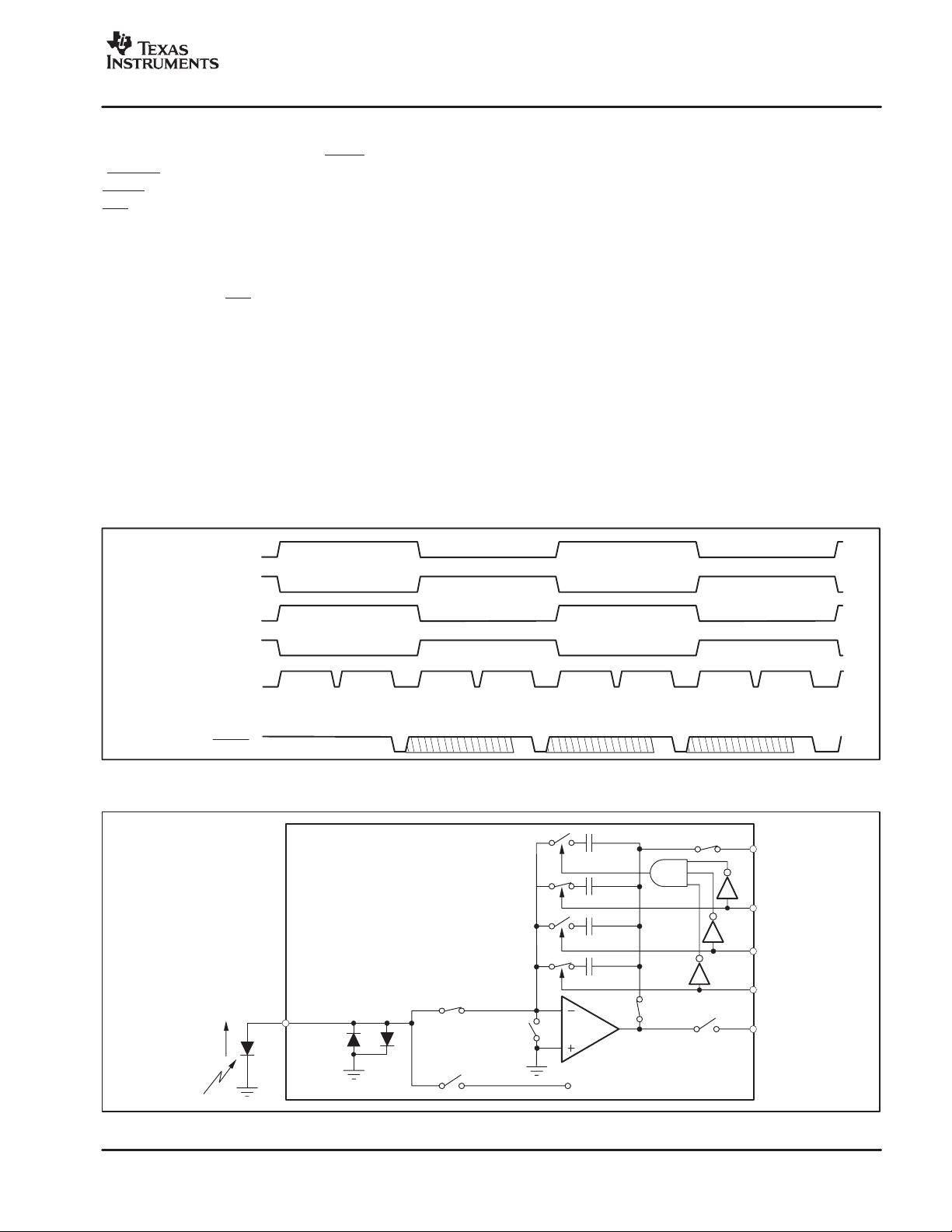

The block diagram of the DDC118 is shown in Figure 1.

The device contains eight identical input channels that

perform the function of current-to-voltage integration

followed by a multiplexed A/D conversion. Each input has

two integrators so that the current-to-voltage integration

can be continuous in time. The output of the sixteen

integrators are switched to four delta-sigma (∆Σ)

converters via four four-input multiplexers. With the

VREF

Modulator

Modulator

IN1

IN3

IN2

AVDD

Switched

Integrator

Switched

Integrator

Switched

Integrator

Dual

Dual

Dual

DDC118 in the continuous integration mode, the output of

the integrators from one side of the inputs will be digitized

while the other eight integrators are in the integration

mode, as illustrated in the timing diagram in Figure 2. This

integration and A/D conversion process is controlled by

the system clock, CLK. The results from side A and side

B of each signal input are stored in a serial output shift

register. The DVALID

output goes low when the shift

register contains valid data.

DVDD

CLK

CONV

RANGE0

∆Σ

∆Σ

Digital

Filter

Digital

Filter

Control

RANGE1

RANGE2

TEST

CLK_4X

HISPD/LOPWR

RESET

FORMAT

IN4

IN5

IN7

IN6

IN8

Dual

Switched

Integrator

Dual

Switched

Integrator

Dual

Switched

Integrator

Dual

Switched

Integrator

Dual

Switched

Integrator

AGND

∆Σ

Modulator

∆Σ

Modulator

Digital

Filter

Digital

Filter

DCLK

DCLK

DVALID

Digital

Input/Output

DOUT

DOUT

DIN

DIN

DGND

Figure 1. DDC118 Block Diagram

8

Page 9

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

The digital interface of the DDC118 provides the digital

results via a synchronous serial interface consisting of

differential data clocks (DCLK and DCLK), a valid data pin

(DVALID

DOUT

DIN

), differential serial data output pins (DOUT and

), and differential serial data input pins (DIN and

). The DDC118 contains only four A/D converters, so

the conversion process is interleaved (see Figure 2). The

integration and conversion process is fundamentally

independent of the data retrieval process. Consequently,

the CLK frequency and DCLK frequencies need not be the

same. DIN and DIN

are only used when multiple

converters are cascaded and should be tied to DGND and

DVDD otherwise.

DEVICE OPERATION

Basic Integration Cycle

The topology of the front end of the DDC118 is an analog

integrator as shown in Figure 3. In this diagram, only Input

IN1 is shown. This representation of the input stage

consists of an operational amplifier, a selectable feedback

capacitor network (C

IN1, IN2, IN5, and IN6,

IN1, IN2, IN5, and IN6,

IN3, IN4, IN7, and IN8,

IN3, IN4, IN7, and IN8,

Conversion in Progress

Integrator A

Integrator B

Integrator A

Integrator B

DVALID

), and several switches that

F

Integrate

Integrate

IN1B

IN2B

IN5B

IN6B

IN3B

IN4B

IN7B

IN8B

IN1A

IN2A

IN5A

IN6A

implement the integration cycle. The timing relationships

of all of the switches shown in Figure 3 are illustrated in

Figure 4. Figure 4 is used to conceptualize the operation

of the integrator input stage of the DDC118 and should not

be used as an exact timing tool for design. See Figure 5 for

the block diagrams of the reset, integrate, wait and convert

states of the integrator section of the DDC118. This

internal switching network is controlled externally with the

convert pin (CONV), range selection pins

(RANGE0-RANGE2), and the system clock (CLK). For the

best noise performance, CONV must be synchronized

with the rising edge of CLK. It is recommended that CONV

toggle within ±10ns of the rising edge of CLK.

The noninverting inputs of the integrators are connected to

ground. Consequently, the DDC118 analog ground should

be as clean as possible. The range switches, along with

the internal and external capacitors (C

), are shown in

F

parallel between the inverting input and output of the

operational amplifier. At the beginning of a conversion, the

switches S

A/D

, S

INTA

, S

INTB

, S

REF1

, S

REF2

are set (see Figure 4).

Integrate

IN1A

IN2A

IN5A

IN6A

Integrate

Integrate

IN3A

IN4A

IN7A

IN8A

Integrate

Integrate

IN3A

IN4A

IN7A

IN8A

IN1B

IN2B

IN5B

IN6B

Integrate

IN3B

IN4B

IN7B

IN8B

, and S

RESET

Figure 2. Basic Integration and Conversion Timing for the DDC118 (continuous mode)

S

Photodiode

Input

Current

IN1

ESD

Protection

Diodes

REF1

3pF

50pF

25pF

12.5pF

S

INTA

S

RESET

S

INTB

Integrator A

IntegratorB (same asA)

S

S

REF2

A/D1A

VREF

RANGE2

RANGE1

RANGE0

To Converter

Figure 3. Basic Integration Configuration for Input 1, shown with a 250pC (CF = 62.5pF) Input Range

9

Page 10

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

CONV

CLK

S

INTA

S

INTB

S

REF1

S

REF2

S

RESET

S

A/D1A

www.ti.com

Configuration of

Integrator A

VREF

Integrator A

Voltage Output

S

INT

IN

S

RESET

a) Reset Configuration

S

INT

IN

S

RESET

c) Integrate Configuration

WaitConvert WaitConvertIntegrate

Wait

Reset

Figure 4. Basic Integration Timing Diagram (as shown in Figure 3)

S

S

REF2

REF2

S

S

S

S

REF1

A/D

REF1

A/D

VREF

To Converter

VREF

To Converter

S

INT

IN

S

RESET

b) Wait Configuration

S

INT

IN

S

RESET

S

S

S

REF2

REF2

C

F

C

F

C

F

C

F

REF1

S

S

S

A/D

REF1

A/D

Wait

Reset

VREF

To Converter

VREF

To Converter

10

d) Convert Configuration

Figure 5. Diagrams for the Four Configurations of the Front End Integrators of the DDC118

Page 11

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

At the completion of an A/D conversion, the charge on the

integration capacitor (C

) is reset with S

F

REF1

and S

RESET

(see Figure 4 and Figure 5a). In this manner, the selected

capacitor is charged to the reference voltage, VREF. Once

the integration capacitor is charged, S

REF1

and S

RESET

are switched so that VREF is no longer connected to the

amplifier circuit while it waits to begin integrating (see

Figure 5b). With the rising edge of CONV, S

INTA

closes,

which begins the integration of side A. This process puts

the integrator stage into its integrate mode (see Figure 5c).

Charge from the input signal is collected on the integration

capacitor, causing the voltage output of the amplifier to

decrease. The falling edge of CONV stops the integration

by switching the input signal from side A to side B (S

and S

). Prior to the falling edge of CONV, the signal on

INTB

INTA

side B was converted by the A/D converter and reset

during the time that side A was integrating. With the falling

edge of CONV, side B starts integrating the input signal.

Now the output voltage of the side A operational amplifier

is presented to the input of the ∆Σ A/D converter (see

Figure 5d).

Integration Capacitors

There are eight different capacitors available on-chip for

both sides of every channel in the DDC118. These internal

capacitors are trimmed in production to achieve the

specified performance for range error of the DDC118. The

range control pins (RANGE0-RANGE2) change the

capacitor value for all four integrators. Consequently, all

inputs and both sides of each input will always have the

same full-scale range. Table 1 shows the capacitor value

selected for each range selection.

Table 1. Range Selection of the DDC118

C

RANGE2 RANGE1 RANGE0

0 0 0 3 −0.048 to 12

0 0 1 12.5 –0.2 to 50

0 1 0 25 –0.4 to 100

0 1 1 37.5 –0.6 to 150

1 0 0 50 –0.8 to 200

1 0 1 62.5 –0.1 to 250

1 1 0 75 –1.2 to 300

1 1 1 87.5 –1.4 to 350

F

(pF, typ)

INPUT RANGE

(pC, typ)

Voltage Reference

The external voltage reference is used to reset the

integration capacitors before an integration cycle begins.

It is also used by the ∆Σ converter while the converter is

measuring the voltage stored on the integrators after an

integration cycle ends. During this sampling, the external

reference must supply the charge needed by the ∆Σ

converter. For an integration time of 400µs, this charge

translates to an average VREF current of approximately

150µA. The amount of charge needed by the ∆Σ converter

is independent of the integration time; therefore,

increasing the integration time lowers the average current.

For example, an integration time of 800µs lowers the

average VREF current to 75µA.

It is critical that VREF be stable during the different modes

of operation (see Figure 5). The ∆Σ converter measures

the voltage on the integrator with respect to VREF. Since

the integrator capacitors are initially reset to VREF, any

drop in VREF from the time the capacitors are reset to the

time when the converter measures the integrator output

will introduce an offset. It is also important that VREF be

stable over longer periods of time because changes in

VREF correspond directly to changes in the full-scale

range. Finally, VREF should introduce as little additional

noise as possible.

For these reasons, it is strongly recommended that the

external reference source be buffered with an operational

amplifier, as shown in Figure 6. In this circuit, the voltage

reference is generated by a 4.096V reference.

A low-pass

filter to reduce noise connects the reference to an

operational amplifier configured as a buffer . This amplifier

should have low noise, and input/output common-mode

ranges that support VREF. Following the buffer are

capacitors placed close to the DDC118 VREF pin. Even

though the circuit in Figure 6 might appear to be unstable

because of the large output capacitors, it works well for

most operational amplifiers. It is NOT recommended that

series resistance be placed in the output lead to improve

stability since this can cause a drop in VREF, which

producing large offsets.

2

3

+5V

0.10µF

7

OPA350

4

6

+

10µF

To VREF

Pin10of

the DDC118

0.1µF

0.47µF

REF3140

+5V

1

Ω

10k

2

+

3

10µF

0.10µF

Figure 6. Recommended External Voltage Reference Circuit for Best Low-Noise Operation with the DDC118

11

Page 12

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

DDC118 Frequency Response

The frequency response of the DDC118 is set by the front

end integrators and is that of a traditional continuous time

integrator, as shown in Figure 7. By adjusting T

INT

, the

user can change the 3dB bandwidth and the location of the

notches in the response. The frequency response of the

∆Σ converter that follows the front end integrator is of no

consequence because the converter samples a held

signal from the integrators. That is, the input to the ∆Σ

converter is always a DC signal. Since the output of the

front end integrators are sampled, aliasing can occur.

Whenever the frequency of the input signal exceeds

one-half of the sampling rate, the signal will fold back down

to lower frequencies.

0

−

10

−

20

−

30

Gain (dB)

−

40

Test Mode

When Test Mode is used, the inputs (IN1, IN2, IN3, IN4,

IN5, IN6, IN7, and IN8) are disconnected from the DDC1 18

integrators to enable the user to measure a zero input

signal regardless of the current supplied to the inputs. In

addition, packets of charge can be transferred to the

integrators in 11pC intervals to measure non-zero values.

The test mode works with both the continuous and

non-continuous modes. The timing diagram for the test

mode is shown in Figure 8 with the timing specifications

given in Table 2.

To enter Test Mode, hold TEST high while CONV

transitions. If TEST is held high during the entire

integration period, the integrators measure a zero value.

This mode can be used to help debug a design or perform

diagnostic tests. To apply packets of charge during Test

Mode, simply strobe TEST low then high before the next

CONV transition. Each rising edge of TEST causes

approximately 11pC of charge to be transferred to the

integrators. This charge transfer is independent of the

integration time. Data retrieval during Test Mode is

identical to normal operation. To exit Test Mode, take

TEST low and allow several cycles after exiting before

using the data.

−

50

0.1

T

INT

T

1

INT

Frequency

10

T

INT

100

T

INT

Figure 7. Frequency Response of the DDC118

Action

CONV

TEST

Test Mode D isabled

Integrate B Integrate A

0pC into B 11pC into A 22pC into B 33pC into A

t

4

t

1

t

3

t

6

t

5

Test Mode DisabledTest Mode Enabled: Inputs Disconnected

Integrate B Integrate A

t

2

t

4

Figure 8. Timing Diagram of the Test Mode of the DDC118

Table 2. Timing for the DDC118 in the Test Mode

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

1

t

2

t

3

t

4

t

5

t

6

From Rising Edge of TEST to the Edge of CONV while Test Mode

Setup Time for Test Mode Enable 100 ns

Setup Time for Test Mode Disable 100 ns

Hold Time for Test Mode Enable 100 ns

Enabled

Falling Edge to Rising Edge of TEST 1 µs

Rising Edge to Falling Edge of TEST 1 µs

1 µs

12

Page 13

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

DIGITAL INTERFACE

The digital interface of the DDC118 provides the digital

results via a synchronous serial interface consisting of

differential data clocks (DCLK and DCLK), a valid data pin

(DVALID

DOUT

DIN

the conversion process is interleaved (see Figure 2,

page 9). The integration and conversion processes are

independent of the data retrieval process. Consequently,

the CLK frequency and DCLK frequencies need not be the

same. DIN and DIN

cascaded. Cascading or daisy-chaining greatly simplifies

the interconnection and routing of the digital outputs in

cases where a large number of converters are needed.

Refer to the Cascading Multiple Converters section of this

data sheet for more detail.

Complementary Signals (DCLK, DIN, and DOUT)

The DDC118 provides optional complementary inputs

(DCLK

inputs. If using these inputs, connect a complementary

signal to each. If these inputs are not connected on the

DDC118, they should be tied to DGND. DOUT

complementary output designed to drive DIN

DOUT

System and Data Clocks (CLK and CONV)

The system clock is supplied to CLK and the data clock is

supplied to DCLK. Make sure the clock signals are

clean—avoid overshoot or ringing. For best performance,

generate both clocks from the same clock source. DCLK

should be disabled by taking it low after the data has been

shifted out or while CONV is transitioning.

When using multiple DDC118s, pay close attention to the

DCLK distribution on the printed circuit board (PCB). In

particular, make sure to minimize skew in the DCLK signal

as this can lead to timing violations in the serial interface

specifications. See the Cascading Multiple Converters

section for more details.

), differential serial data output pins (DOUT and

), and differential serial data input pins (DIN and

). The DDC118 contains only four A/D converters, so

are used when multiple converters are

, DIN) to help reduce digital coupling to the analog

is a

. If not using

, leave it floating.

High-Speed and Low-Power Modes

(HISPD/LOPWR

)

The HISPD/LOPWR input controls the power dissipation

and in turn, the maximum allowable CLK frequency and

data rate, as shown in Table 4. With HISPD/LOPWR

= 0,

the Low-Power Mode is selected with a typical 13.5mW/

channel and a maximum data rate of 2.5kSPS. Setting

HISPD/LOPWR

= 1 selects the High-Speed Mode, which

supports a maximum data rate of 3.125kSPS with a corresponding typical power of 18.0mW/channel.

Table 4. HISPD/LOPWR Pin Operation

HISPD/

LOPWR

0 Low-Power 13.5mW/ch 4.0MHz 2.5kSPS

1 High-Speed 18.0mW/ch 4.8MHz 3.125kSPS

MODE

TYPICAL

POWER/

CHANNEL

MAXIMUM

CLK FREQUENCY

(CLK_4X = 0)

MAXIMUM

DATA

RATE

Data Valid (DVALID)

The DVALID signal indicates that data is ready. Data

retrieval may begin after DVALID

goes low. This signal is

generated using an internal clock divided down from the

system clock CLK. The phase relationship between this

internal clock and CLK is set when power is first applied

and is random. Since the user must synchronize CONV

with CLK, the DVALID

relationship with CONV. This uncertainty is ± 1/f

Polling DVALID

signal will have a random phase

CLK

eliminates any concern about this

relationship. If data read back is timed from CONV, wait the

maximum value of t

or t8 to insure data is valid.

7

Reset (RESET)

The DDC118 is reset asynchronously by taking the

RESET

input low, as shown in Figure 9. Make sure the

reset pulse is at least 50µs wide. After resetting the

DDC118, wait at least four conversions before using the

data. It is very important to make sure the RESET

free to avoid unintended resets. The RESET

is glitch

pin is used

during power-up; see the Power-Up Sequence section for

more details.

.

System Clock Divider (CLK_4X)

The CLK_4X input enables an internal divider on the

system clock as shown in Table 3. When CLK_4X = 1, the

system clock is divided by four. This allows a 4X faster

system clock, which in turn provides a finer quantization of

the integration time as the CONV signal needs to be

synchronized with the system clock for the best

performance.

Table 3. CLK_4X Pin Operation

CLK_4X

PIN

0 1 4MHz 4MHz

1 4 16MHz 4MHz

CLK DIVIDER

VALUE

TYPICAL CLK

FREQUENCY

INTERNAL CLOCK

FREQUENCY

RESET

>50µs

Figure 9. Reset Timing

Convert (CONV)

CONV controls the integration time (T

). For optimum

INT

analog performance, make sure CONV is synchronized to

CLK.

This recommendation implies that while SPEED is low,

needs to be adjusted in steps of 250ns if CLK_4X is

T

INT

low and CLK = 4MHz. If CLK_4X is high and CLK =

16MHz, this allows T

to be adjusted in steps of 62.5ns.

INT

13

Page 14

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

Conversion Rate

The conversion rate of the DDC118 is set by a combination

of the integration time (determined by the user) and the

speed of the A/D conversion process. The A/D conversion

time is primarily a function of the system clock (CLK)

speed. One A/D conversion cycle encompasses the

conversion of two signals (one side of each dual integrator

feeding the modulator) and the reset time for each of the

integrators involved in the two conversions. In most

situations, the A/D conversion time is shorter than the

integration time. If this condition exists, the DDC118 will

operate in the continuous mode. When the DDC118 is in

the continuous mode, the sensor output is continuously

integrated by one of the two sides of each input.

CONV× mbsy

IntB/Meas A

1

Ncont

4

Cont

CONV|mbsy

CONV

CONV × mbsy

3

Int A

Cont

CONV× mbsy

CONV× mbsy

www.ti.com

2

Ncont

CONV

5

Int A/Meas B

Cont

In the event that the A/D conversion takes longer than the

integration time, the DDC118 will switch into a

non-continuous mode. In non-continuous mode, the A/D

converter is not able to keep pace with the speed of the

integration process. Consequently, the integration

process is periodically halted until the digitizing process

catches up. These two basic modes of operation for the

DDC118—continuous and non-continuous modes—are

described below.

Continuous and Non-Continuous Operational

Modes

Figure 10 shows the state diagram of the DDC118. In all,

there are eight states. Table 5 provides a brief explanation

of each state.

Table 5. State Descriptions

STATE MODE DESCRIPTION

1 Ncont Complete m/r/az of side A, then side B (if previous

state is state 4). Initial power-up state when CONV

is initially held HIGH.

2 Ncont Prepare side A for integration.

3 Cont Integrate on side A.

4 Cont Integrate on side B; m/r/az on side A.

5 Cont Integrate on side A; m/r/az on side B.

6 Cont Integrate on side B.

7 Ncont Prepare side B for integration.

8 Ncont Complete m/r/az of side B, then side A (if previous

state is state 5). Initial power-up state when CONV

is initially held LOW.

Four signals are used to control progression around the

state diagram: CONV, mbsy, and their complements. The

state machine uses the level as opposed to the edges of

CONV to control the progression. mbsy is an internallygenerated signal not available to the user. It is active

whenever a measurement/reset/auto-zero (m/r/az) cycle

is in progress.

CONV

CONV × mbsy

8

Ncont

CONV|mbsy

7

Ncont

6

Int B

Cont

CONV

CONV × mbsy

Figure 10. Integrate/Measure State Diagram

During the cont mode, mbsy is not active when CONV

toggles. The non-integrating side is always ready to begin

integrating when the other side finishes its integration.

Consequently, monitoring the current status of CONV is all

that is needed to know the current state. Cont mode

operation corresponds to states 3-6. Two of the states, 3

and 6, only perform an integration (no m/r/az cycle).

mbsy becomes important when operating in the ncont

mode, states 1, 2, 7, and 8. Whenever CONV is toggled

while mbsy is active, the DDC118 will enter or remain in

either ncont state 1 (or 8). After mbsy goes inactive, state

2 (or 7) is entered. This state prepares the appropriate side

for integration. In the ncont states, the inputs to the

DDC118 are grounded.

One interesting observation from the state diagram is that

the integrations always alternate between sides A and B.

This relationship holds for any CONV pattern and is

independent of the mode. States 2 and 7 insure this

relationship during the ncont mode.

When power is first applied to the DDC118, the beginning

state is either 1 or 8, depending on the initial level of CONV.

For CONV held high at power-up, the beginning state is 1.

Conversely, for CONV held low at power-up, the beginning

state is 8. In general, there is a symmetry in the state

diagram between states 1-8, 2-7, 3-6, and 4-5. Inverting

CONV results in the states progressing through their

symmetrical match.

14

Page 15

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

TIMING EXAMPLES

Cont Mode

A few timing diagrams help illustrate the operation of the

state machine. These diagrams are shown in Figure 11

through Figure 19. Table 6 gives generalized timing

specifications in units of CLK periods for CLK_4X = 0. If

CLK_4X = 1, these values increase by a factor of four

because of the internal clock divider. Values (in µs) for

Table 6 can be easily found for a given CLK. For example,

if CLK = 4MHz, then a CLK period = 0.25µs. t

would then be 367.50 ± 0.125µs.

Table 6. Timing Specifications Generalized in

CLK Periods

SYMBOL DESCRIPTION

t

Cont mode m/r/az cycle 1470 ± 0.5

6

t

Cont mode data ready 1380 ± 0.5

7

t

1st ncont mode data ready 1379 ± 1

8

t

2nd ncont mode data ready 1450

9

t

Ncont mode m/r/az cycle 2901 ± 1

10

VALUE

(CLK periods with CLK_4X = 0)

Figure 11 shows a few integration cycles beginning with

initial power-up for a cont mode example. The top signal

is CONV and is supplied by the user. The next line

indicates the current state in the state diagram. The

following two traces show when integrations and

in Table 6

6

measurement cycles are underway. The internal signal

mbsy is shown next. Finally, DVALID

is given. DVALID

goes active low when data is ready to be retrieved from the

DDC118. It stays low until DCLK is taken high and then

back low by the user. The text below the DVALID

pulse

indicates the side of the data available to be read, and

arrows help match the data to the corresponding

integration. The signals illustrated in Figure 11 through

Figure 19 are drawn at approximately the same scale.

In Figure 11, the first state is ncont state 8. The DDC118

always powers up in the ncont mode. In this case, the first

state is 8 because CONV is initially low. After the first two

states, cont mode operation is reached and the states

begin toggling between 4 and 5. From now on, the input is

being continuously integrated, either on side A or side B.

The time needed for the m/r/az cycle, or t

, is the same time

6

that determines the boundary between the cont and ncont

modes described earlier in the Overview section. DVALID

goes low after CONV toggles in time t7, indicating that data

is ready to be retrieved. As shown in Figure 11, there are

two values for t

and t7. The reason for this is discussed in

6

the Special Considerations section.

See Figure 12 for the timing diagram of the internal

operations occurring during continuous mode operation.

Table 7 gives the timing specifications in the continuous

mode.

CONV

State

Integration

Status

m/r/az

Status

mbsy

DVALID

t=0

Power− Up

SYMBOL DESCRIPTION VALUE (CLK = 4MHz, CLK_4X = 0) VALUE (CLK = 4.8MHz, CLK_4X = 0)

t

6

t

7

Cont Mode m/r/az Cycle 367.50 ± 0.125µs 306.25 ± 0.104µs

Cont Mode Data Ready 345.00 ± 0.125µs 287.5 ± 0.104µs

5678 45

Integrate AIntegrate B Integrate B Integrate A

m/r/az B m/r/az A m/r/az B

t

6

t

7

Side B

Data

Side A

Data

Side B

Data

Figure 11. Continuous Mode Timing

15

Page 16

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

Inputs 1, 2, 5, and 6(Internal)

A/D Conversion

A/D Conversion

Inputs 3, 4, 7, and 8(Internal)

Figure 12. Timing Diagram of the Internal Operation in Continuous Mode of the DDC118

SYMBOL DESCRIPTION

T

Integration Period (continuous mode) 400 1,000,000 320 1,000,000 µs

INT

t

A/D Conversion Time (internally controlled) 169.5 141.25 µs

12

t

A/D Conversion Reset Time (internally controlled) 4 3.333 µs

13

Integrator and A/D Conversion Reset Time

t

14

(internally controlled)

EndIntegrationSide A

Start Integration Side B

CONV

Side A

t

12

t

T

INT

SideA

t

13

End Integration Side B

Start Integration Side A

12

T

INT

Side B

t

13

t

14

SideB

DVALID

Side A

Data Ready

Side B

Data Ready

Table 7. Timing for the Internal Operation in Continuous Mode

CLK = 4MHz, CLK_4X = 0 CLK = 4.8MHz, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

23 19.167 µs

End Integration Side A

Start Integration Side B

t

14

SideA

UNITS

16

Page 17

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

Ncont Mode

Non-continuous mode of operation is intended for Ranges

1 to 7. It is not recommended to use Range 0 when

operating in non-continuous mode. Figure 13 illustrates

operation in the ncont mode. The integrations come in

pairs (that is, sides A/B or sides B/A) followed by a time

during which no integrations occur. During that time, the

previous integrations are being measured, reset and

auto-zeroed. Before the DDC1 18 can advance to states 3

or 6, both sides A and B must be finished with the m/r/az

cycle which takes time t

completed, time t

is needed to prepare the next side for

11

. When the m/r/az cycles are

10

integration. This time is required for the ncont mode

because the m/r/az cycle of the ncont mode is slightly

different from that of the cont mode. After the first

CONV

State

Integration

Status

integration ends, DV ALID

goes low in time t8. This time is

the same as in the cont mode. The second data will be

ready in time t9 after the first data is ready . One res ult o f the

naming convention used in this data sheet is that when the

DDC118 is operating in the ncont mode, it passes through

both ncont mode states and cont mode states. For

example, in Figure 13, the state pattern is 3, 4, 1, 2, 3, 4,

1, 2, 3, 4 ... where 3 and 4 are cont mode states. Ncont

mode, by definition, means that for some portion of the

time, neither side A nor B is integrating. States that perform

an integration are labeled cont mode states, while those

that do not are called ncont mode states. Since

integrations are performed in the ncont mode, just not

continuously, some cont mode states must be used in a

ncont mode state pattern.

23134 4 1 2

t

11

Int BInt AInt BInt A

m/r/az

Status

mbsy

DVALID

t

8

Side A

Data

SYMBOL DESCRIPTION VALUE (CLK = 4MHz, CLK_4X = 0) VALUE (CLK = 4.8MHz, CLK_4X = 0)

t

8

t

9

t

10

t

11

1st ncont Mode Data Ready 344.75 ± 0.25µs 287.292 ± 0.208µs

2nd ncont Mode Data Ready 362.5µs 302.083µs

ncont Mode m/r/az Cycle 725.25 ± 0.25µs 604.375 ± 0.208µs

Prepare Side for Integration ≥ 18µs ≥ 15µs

m/r/az Bm/r/az A

t

10

t

9

Side B

Data

m/r/az A m/r/az B

Side A

Data

SideB

Data

Figure 13. Non-Continuous Mode Timing

17

Page 18

""#

SYMBOL

DESCRIPTION

UNITS

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

CONV

A/D Conversion

Inputs 1, 2, 5, and 6

Start Integration Side A

End Integration Side A

StartIntegration Side B

T

INT

End Integration Side B

WaitState

T

INT

t

12

t

16

Start Integration Side A

Release

State

t

17

A/D Conversion

Inputs 3, 4, 7, and 8

t

13

t

12

t

15

DVALID

Side A

Data Ready

Side B

Data Ready

Figure 14. Conversion Detail for the Internal Operation of Non-Continuous Mode with Side A Integrated

First

Table 8. Internal Timing for the DDC118 in Non-Continuous Mode

CLK = 4MHz, CLK_4X = 0 CLK = 4.8MHz, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

T

Integration Time (non-continuous mode) 400 1,000,000 320 1,000,000 µs

INT

t

A/D Conversion Time (internally controlled) 169.5 141.25 µs

12

t

A/D Conversion Reset Time (internally controlled) 4 3.333 µs

13

Integrator and A/D Conversion Reset Time

t

15

(internally controlled)

t

Total A/D Conversion and Reset Time (internally controlled) 725.25 ± 0.25 604.375 ± 0.208 µs

16

t

Release Time 18 15 µs

17

19.5 16.25 µs

CONV

A/D Conversion

Inputs 1, 2, 5, and 6

Start Integration Side A

End Integration Side A

StartIntegration Side B

T

INT

End Integration Side B

WaitState

T

INT

t

12

t

16

Start Integration Side A

Release

State

t

17

A/D Conversion

Inputs 3, 4, 7, and 8

t

13

t

12

t

15

DVALID

Side A

Data Ready

Side B

Data Ready

Figure 15. Internal Operation Timing Diagram of Non-Continuous Mode with Side B Integrated First

18

Page 19

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

Looking at the state diagram, one can see that the CONV

pattern needed to generate a given state progression is not

unique. Upon entering states 1 or 8, the DDC1 18 remains

in those states until mbsy goes low, independent of CONV.

As long as the m/r/az cycle is underway , the state machine

ignores CONV (see Figure 10, page 14). The top two

signals in Figure 16 are different CONV patterns that

produce the same state. This feature allows flexibility in

generating ncont mode CONV patterns. For example, the

DDC118 Evaluation Fixture operates in the ncont mode by

generating a square wave with pulse width < t

. Figure 17

6

illustrates operation in the ncont mode using a 50% duty

CONV1

CONV2

mbsy

State

cycle CONV signal with T

= 512 CLK periods. Care

INT

must be exercised when using a square wave to generate

CONV. There are certain integration times that must be

avoided since they produce very short intervals for state 2

(or state 7 if CONV is inverted). As seen in the state

diagram, the state progresses from 2 to 3 as soon as

CONV is high. The state machine does not insure that the

duration of state 2 is long enough to properly prepare the

next side for integration (t

). This must be done by the

11

user with proper timing of CONV. For example, if CONV is

a square wave with T

only be 9 CLK periods long; therefore, t

23134 4 1 2

= 970 CLK periods, state 2 will

INT

will not be met.

11

CONV

State

Integration

Status

mbsy

DVALID

Figure 16. Equivalent CONV Signals in Non-Continuous Mode

23134 41

IntA

SideA

Data

Side B

Data

Int BInt AIntB

Figure 17. Non-Continuous Mode Timing with a 50% Duty Cycle CONV Signal

Side A

Data

19

Page 20

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

Changing Between Modes

Changing from the cont to ncont mode occurs whenever

< t6. Figure 18 shows an example of this transition.

T

INT

In this figure, the cont mode is entered when the integration

on side A is completed before the m/r/az cycle on side B

is complete. The DDC118 completes the measurement on

sides B and A during states 8 and 7 with the input signal

shorted to ground. Ncont integration begins with state 6.

CONV

State

Integration

Status

m/r/az

Status

5 65

Continuous Non−Continuous

Integrate A Integrate B Int AInt A Int B

m/r/az B m/r/az A m/r/az B m/r/az A m/r/az B

Changing from the ncont to cont mode occurs when T

is increased so that T

is always ≥ t6, as shown in

INT

INT

Figure 19 (see also Figure 14 and Table 8, page 18). With

a longer T

, the m/r/az cycle has enough time to finish

INT

before the next integration begins and continuous

integration of the input signal is possible. For the special

case of the very first integration when changing to the cont

mode, T

no simultaneous

can be < t6. This is allowed because there is

INT

m/r/az cycle on the side B during state

3—there is no n e e d t o w a i t f or it to fi n ish before ending the

integration on side A.

8745

CONV

State

Integration

Status

m/r/az

Status

mbsy

mbsy

Figure 18. Changing from Continuous Mode to Non-Continuous Mode

33

Non−Continuous Continuous

Int BInt A Integrate A Integrate B

m/r/az A m/r/az B m/r/az A

Figure 19. Changing from Non-Continuous Mode to Continuous Mode

4214

20

Page 21

www.ti.com

SYMBOL

DESCRIPTION

UNITS

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

DATA FORMAT (FORMAT)

The serial output data is provided in an offset binary code

as shown in Table 9. The digital input pin FORMAT selects

how many bits are used in the output word. When

FORMAT is high (1), 20 bits are used. When FORMAT is

low (0), the lower 4 bits are truncated so that only 16 bits

are used. Note that the LSB size is 16 times bigger when

FORMAT = 0. An offset is included in the output to allow

slightly negative inputs, from board leakages for example,

from clipping the reading. This offset is approximately

0.4% of the positive full-scale.

Table 9. Ideal Output Code

INPUT

SIGNAL

≥ 100% FS 1111 1111 1111 1111 1111 1111 1111 1111 1111

0.001531% FS 0000 0001 0000 0001 0000 0000 0001 0000 0001

0.001436% FS 0000 0001 0000 0000 1111 0000 0001 0000 0000

0.000191% FS 0000 0001 0000 0000 0010 0000 0001 0000 0000

0.000096% FS 0000 0001 0000 0000 0001 0000 0001 0000 0000

0% FS 0000 0001 0000 0000 0000 0000 0001 0000 0000

−0.3955% FS 0000 0000 0000 0000 0000 0000 0000 0000 0000

(1)

Excludes the effects of noise, INL, offset, and gain errors.

IDEAL OUTPUT CODE

FORMAT = HIGH (1)

(1)

vs Input Signal

IDEAL OUTPUT CODE

FORMAT = LOW (0)

DATA RETRIEVAL

In both the continuous and non-continuous modes of

operation, the data from the last conversion is available for

retrieval on the falling edge of DVALID

Table 10). Data is shifted out on the falling edge of the data

clock, DCLK. Make sure not to retrieve data while CONV

changes as this can introduce noise. Stop activity on

DCLK at least 10µs before or after a CONV transition.

Setting the FORMAT pin = 0 (16-bit output word) reduces

the time needed to retrieve data by 20%, since there are

fewer bits to shift out. This time reduction can be useful in

multichannel systems requiring only 16 bits of resolution.

(see Figure 20 and

CLK

t

18

DVA LID

t

DCLK

DOUT

20

Input 8

MSB

t

19

t

21

Input 8

LSB

Input 7

MSB

Input 5

LSB

Figure 20. Digital Interface Timing Diagram for Data Retrieval From a Single DDC118

Table 10. Timing for the DDC118 Data Retrieval

t

Propagation Delay from Falling Edge of CLK to DVALID LOW 5 5 ns

18

t

Propagation Delay from Falling Edge of DCLK to DVALID HIGH 5 5 ns

19

t

Hold Time that DOUT is Valid Before the Falling Edge of DVALID 1.75 1.458 µs

20

t

Hold Time that DOUT is V alid After Falling Edge of DCLK 5 5 ns

21

(1)

t

21A

(1)

With a maximum load of one DDC118 (4pF typical) with an additional load of (5pF).

Propagation Delay from Falling Edge of DCLK to Valid DOUT 10 10 ns

Input 4

MSB

CLK = 4MHz, CLK_4X = 0 CLK = 4.8MHz, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

Input 2

LSB

Input 1

MSB

Input 1

LSB

t

20

Input 8

MSB

21

Page 22

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

SPECIAL CONSIDERATIONS

Cascading Multiple Converters

Multiple DDC118 units can be connected in serial

configuration, as illustrated in Figure 21.

DOUT can be used with DIN to daisy-chain several

DCLK

DCLK

DVALID

Data Retrieval

Outputs

DOUT

DDC118

DOUT

IN8

IN7BIN6CIN5DIN4EIN3FIN2GIN1

ASensor

DIN

DIN

DOUT

DOUT

IN8IIN7JIN6KIN5LIN4MIN3NIN2OIN1

H

DDC118 devices together to minimize wiring. In this mode

of operation, the serial data output is shifted through

multiple DDC118s, as illustrated in Figure 21.

See Figure 22 for the timing diagram when the DIN input

is used to daisy-chain several devices. Table 11 gives the

timing specification for data retrieval using DIN.

Data Clock

DCLK

DCLK

DVALID

DDC118 DDC118

DIN

DIN

P

DOUT

DOUT

IN8QIN7RIN6SIN5TIN4UIN3VIN2WIN1

DCLK

DCLK

DVALID

DIN

DIN

X

CLK

DVA LID

DCLK

DIN

DOUT

Figure 21. Daisy-Chained DDC118s

t

18

t

20

Input A

MSB

t

19

t

23

Input W

LSB

Input X

MSB

Input A

LSB

t

21

Input B

MSB

t

22

Input L

LSB

Input M

MSB

Figure 22. Timing Diagram When Using the DIN Function of the DDC118

Input X

LSB

t

20

Input A

MSB

Table 11. Timing for the DDC118 Data Retrieval Using DIN

SYMBOL DESCRIPTION MIN TYP MAX UNITS

22

t

22

t

23

Set-Up Time From DIN to Falling Edge of DCLK 5 ns

Hold Time For DIN After Falling Edge of DCLK 4 ns

Page 23

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

RETRIEVAL BEFORE CONV TOGGLES

(CONTINUOUS MODE)

Date retrieval before CONV toggles is the most

straightforward method. Data retrieval begins soon after

DVALID

shown in Figure 23. For best performance, data retrieval

must stop t28 before CONV toggles. This method is most

appropriate for longer integration times. The maximum

time available for readback is T

10MHz and CLK = 4MHz, the maximum number of

DDC118s that can be daisy-chained together (FORMAT =

high) is calculated by Equation 1:

goes low and finishes before CONV toggles, as

– t27 – t28. For DCLK =

INT

T

* 355.125ms

INT

160t

CONV

DVALID

DCLK

DOUT

DCLK

T

INT

t

27

(1)

Side B

Data

NOTE: 128τ

where τ

if T

DCLK

= 1000µs and DCLK = 10MHz, the maximum

INT

is used for FORMAT = low.

DCLK

is the period of the data clock. For example,

number of DDC118s (FORMAT = high) is shown in

Equation 2:

1000ms * 355.125ms

(

160)(100ns

+ 40.30 ³ 40DDC118s

)

(or 50 for FORMAT = low).

T

INT

t

28

……

……

Side A

Data

(2)

SYMBOL DESCRIPTION

t

27

t

28

Cont Mode Data Ready 345.00 ± 0.125 287.5 ± 0.104 µs

Data Retrieval Shutdown Before Edge of CONV 10 10 µs

CLK = 4MHz, CLK_4X = 0 CLK = 4.8MHz, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

Figure 23. Readback Before CONV Toggles

UNITS

23

Page 24

""#

SYMBOL

DESCRIPTION

UNITS

SBAS325A − JUNE 2004 − REVISED JUNE 2005

www.ti.com

RETRIEVAL AFTER CONV TOGGLES

(CONTINUOUS MODE)

For shorter integration times, more time is available if data

retrieval begins after CONV toggles and ends before the

new data is ready. Data retrieval must wait t

toggles before beginning. See Figure 24 for an example of

this. The maximum time available for retrieval is

t

27−t29

CLK = 4MHz), regardless of T

– t26 (344.875µs – 10µs – 1.75µs for

. The maximum number

INT

CONV

DVALID

DCLK

DOUT

t

Hold Time that DOUT is Valid Before Falling Edge of DVALID 1.75 1.458 µs

26

t

Cont Mode Data Ready 345.00 ± 0.125 287.5 ± 0.104 µs

27

t

Data Retrieval Start-Up After Edge of CONV 10 10 µs

29

after CONV

29

T

INT

t

27

t

29

t

26

………

………

Side A

Data

of DDC1 18s that can be daisy-chained together (FORMAT

= high) is calculated by Equation 3:

333.125ms

160t

DCLK

NOTE: 128τ

is used for FORMAT = low.

DCLK

For DCLK = 10MHz, the maximum number of DDC118s is

20 (or 26 for FORMAT = low).

T

INT

Side B

Data

CLK = 4MHz, CLK_4X = 0 CLK = 4.8MHz, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

SideA

Data

T

INT

(3)

Figure 24. Readback After CONV Toggles

24

Page 25

www.ti.com

SYMBOL

DESCRIPTION

UNITS

SYMBOL

DESCRIPTION

UNITS

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

RETRIEVAL BEFORE AND AFTER CONV

TOGGLES (CONTINUOUS MODE)

For the absolute maximum time for data retrieval, data can

be retrieved before and after CONV toggles. Nearly all of

T

is available for data retrieval. Figure 25 illustrates

INT

how this is done by combining the two previous methods.

Retrieval during CONV toggling to prevent digital noise, as

discussed previously, and finished before the next data is

ready. The maximum number of DDC118s that can be

daisy-chained together (FORMAT = high) is:

T

* 20ms * 1.75ms

INT

160t

DCLK

NOTE: 128τ

For T

= 400µs and DCLK = 10MHz, the maximum

INT

number of DDC118s is 23 (or 29 for FORMAT = low).

CONV

DVALID

DCLK

is used for FORMAT = low.

DCLK

T

INT

………… … …

t

29

t

28

RETRIEVAL: NONCONTINUOUS MODE

Retrieving in noncontinuous mode is slightly different,

compared to the continuous mode. As illustrated in

Figure 26, DVALID

integration completes. If T

of t

is available to retrieve data before the other side data

31

is ready. For T

before the second integration completes. Data retrieval

must be delayed until the second integration completes,

leaving less time available for retrieval. The time available

is t

– (T

31

– t30). The second integration’s data must be

INT

retrieved before the next round of integration begins. This

time is highly dependent on the pattern used to generate

CONV. As with the continuous mode, data retrieval must

halt before and after CONV toggles (t

completed before new data is ready (t

T

INT

t

26

goes low in time t30 after the first

is shorter than this time, all

INT

> t30, the first integration data is ready

INT

, t29) and be

28

).

26

T

INT

DOUT

t

Hold Time that DOUT is Valid Before Falling Edge of DVALID 1.75 1.458 µs

26

t

Data Retrieval Shutdown Before Edge of CONV 10 10 µs

28

t

Data Retrieval Start-Up After Edge of CONV 10 10 µs

29

………

Side B

Data

CLK = 4MHZ, CLK_4X = 0 CLK = 4.8MHZ, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

… … …

SideA

Data

Figure 25. Readback Before and After CONV Toggles

T

CONV

DVALID

DCLK

DOUT

t

1st ncont Mode Data Ready 344.75 ± 0.25 287.292 ± 0.208 µs

30

t

2nd ncont Mode Data Ready 362.500 302.083 µs

31

T

INT

INT

t

30

t

31

……

……

Side A

Data

CLK = 4MHz, CLK_4X = 0 CLK = 4.8MHz, CLK_4X = 0

MIN TYP MAX MIN TYP MAX

Side B

Data

T

T

INT

INT

Figure 26. Readback in Non-Continuous Mode

25

Page 26

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

POWER-UP SEQUENCING

Prior to power-up, all digital and analog inputs must be low .

After the power supplies have settled, release RESET

after time t32. (See Figure 28 and Table 12.) Wait for time

t

to begin applying the digital signals CONV and CLK.

33

The first CONV pulse will complete the release state and

begin integration.

VA

10µF

VD

0.1µF

AVDD

www.ti.com

AGND

DDC118

LAYOUT

POWER SUPPLIES AND GROUNDING

Both AVDD and DVDD should be as quiet as possible. It

is particularly important to eliminate noise from AVDD that

is non-synchronous with the DDC118 operation. Figure 27

illustrates two acceptable ways to supply power to the

DDC118. The first case shows two separate +5V supplies

for A VDD and DVDD. In this case, each +5V supply of the

DDC118 should be bypassed with 10µF solid tantalum

capacitors and 0.1µF ceramic capacitors. The second

case shows the DVDD power supply derived from the

AVDD supply with a < 10Ω isolation resistor. In both cases,

the 0.1µF capacitors should be placed as close to the

DDC118 package as possible. It is recommended that

both the analog and digital grounds (AGND and DGND) be

connected to a single ground plane on the printed circuit

board (PCB).

THERMAL PAD

It is strongly recommended that the thermal pad on the

DDC118 be connected to ground on the PCB. No PCB

traces should be routed underneath the thermal pad.

+5V

10µF

<10

DVDD

10µF

Ω

0.1µF

Separate Supplies

AVDD

0.1µF

DVDD

0.1µF

One +5V Supply

DGND

AGND

DDC118

DGND

Figure 27. Power-Supply Connection Options

AVDD

DVDD

RESET

CONV

CLK

t

32

Release State

t

33

t

34

…

Start Integration

Integrate Side B

Figure 28. Timing Diagram at Power-Up of the DDC118

Table 12. Timing for the DDC118 Power-Up Sequence

SYMBOL DESCRIPTION MIN TYP MAX UNITS

26

t

32

t

33

t

34

Power Supplies Settled to RESET Release 10 ms

RESET Release to CONV, CLK Begin 50 µs

First CONV Pulse Width 50 µs

Page 27

www.ti.com

""#

SBAS325A − JUNE 2004 − REVISED JUNE 2005

Shielding Analog Signal Paths

As with any precision circuit, careful PCB layout ensures

the best performance. It is essential to make short, direct

interconnections and avoid stray wiring

capacitance—particularly at the analog input pins. Digital

signals should be kept as far from the analog input signals

as possible on the PCB.

Input shielding practices should be taken into

consideration when designing the circuit layout for the

DDC118. The inputs to the DDC118 are high impedance

and extremely sensitive to extraneous noise. Leakage

Digital I/O and Digital Power

48 47 46 45 44 43 42 41 40 39 38

1

2

3

4

5

6

7

8

9

10

11

12

currents between the PCB traces can exceed the input

bias current of the DDC1 18 if shielding is not implemented.

Figure 29 illustrates an acceptable approach to this

problem. A PC ground plane is placed around the inputs

of the DDC118. This shield helps minimize coupled noise

into the input pins.

This approach reduces leakage effects by surrounding

these sensitive pins with a low impedance analog ground.

Leakage currents from other portions of the circuit will flow

harmlessly to the low impedance analog ground rather

than into the analog input stage of the DDC118.

37

36

35

34

33

32

DDC118

31

30

29

28

27

26

25

AnalogPower

13 14 15 16 17 18 19 20 21 22 23

Analog

Ground

IN7IN8 IN5IN6

IN4 IN3

Analog

Ground

IN2 IN1

24

Analog

Ground

Figure 29. Recommended Shield for DDC118 Layout Design

27

Page 28

PACKAGE OPTION ADDENDUM

www.ti.com

1-Jul-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

DDC118IRTCR ACTIVE QFN RTC 48 2500 Green (RoHS &

no Sb/Br)

DDC118IRTCT ACTIVE QFN RTC 48 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.