Page 1

User's Guide

SBAU248–November 2016

DAC8775EVM User’s Guide

This user’s guide describes the characteristics and use of the DAC8775 evaluation board (EVM). It also

discusses how to setup and configure the software and hardware for proper operation. Throughout this

document, the terms DAC8775EVM, evaluation board, evaluation module, and EVM are synonymous with

the DAC8775EVM.

Contents

1 Overview...................................................................................................................... 2

2 EVM Hardware Overview................................................................................................... 3

3 EVM Software Setup....................................................................................................... 10

4 EVM Software Overview .................................................................................................. 12

5 EVM Documentation....................................................................................................... 15

List of Figures

1 DAC8775EVM Hardware Setup ........................................................................................... 3

2 DAC8775EVM Block Diagram ............................................................................................. 3

3 PVDD/AVDD, AVSS, and DVDD Supply Connections ................................................................. 6

4 Digital Communication Test Points........................................................................................ 7

5 Onboard Reference Supply Connections................................................................................. 8

6 Output Terminal Block Connections and Load Jumpers ............................................................... 9

7 SM-USB-DIG Connection................................................................................................... 9

8 DAC8775EVM Installer.................................................................................................... 10

9 DAC8775EVM Install Path................................................................................................ 11

10 DAC8775EVM Software License Agreements ......................................................................... 11

11 EVM GUI – Front Panel ................................................................................................... 12

12 Device Schematic .......................................................................................................... 15

13 DC-DC Schematic.......................................................................................................... 16

14 Outputs Schematic......................................................................................................... 16

15 DAC8775EVM PCB Components Layout............................................................................... 17

1 Contents of DAC8775EVM Kit ............................................................................................. 2

2 Related Documentation ..................................................................................................... 2

3 EVM Jumper Summary ..................................................................................................... 4

4 SM-USB-DIG Connector .................................................................................................. 10

5 EVM Board Bill of Materials............................................................................................... 18

SBAU248–November 2016

Submit Documentation Feedback

List of Tables

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

1

Page 2

Overview

Trademarks

Windows XP, Windows 7 are registered trademarks of Microsoft.

1 Overview

The DAC8775 is a four-channel (quad) 16-bit precision digital-to-analog converter (DAC). Each output can

be configured to produce a current in output ranges of 0 to 20 mA, 0 to 24 mA, 3.5 to 23.5 mA, or ±24 mA.

Each channel can also be configured for voltage output in ranges of 0 to 5 V, 0 to 6 V, 0 to 10 V, 0 to 12

V, ±5 V, ±6 V, ±10 V, or ±12 V. The DAC8775 includes integrated buck-boost converters for each channel

to generate all necessary power supplies from a single external supply. The buck-boost converter features

various operating modes that can be used to enhance power dissipation and thermal performance. The

DAC8775 features additional peripherals including: HART input pins for coupling of FSK HART Voltage

signals, slew-rate control for the analog outputs, and reliability features such as CRC, watchdog timer, and

conditional alarms.

1.1 EVM Kit Contents

Table 1 details the contents of the EVM kit. Contact the nearest Texas Instruments Product Information

Center or visit the Texas Instruments E2E Community (http://E2E.ti.com) if any component is missing.

ITEM NO ITEM QTY DESCRIPTION OR USE

1 DAC8775EVM PCB 1 EVM hardware

2 USB Extension Cable 1 Connects PC USB port to SM-USB-DIG USB connector

3 SM-USB-DIG Platform 1 Platform used for digital communication from PC to EVM

www.ti.com

Table 1. Contents of DAC8775EVM Kit

1.2 Related Documentation From Texas Instruments

The following documents provide information regarding Texas Instruments integrated circuits used in the

assembly of the DAC8775EVM. This user’s guide is available from the TI website under the literature

number SBAU248. Any letter appended to the literature number corresponds to the document revision that

is current at the time of the writing of this document. Newer revisions may be available from the TI website

at http://www.ti.com/, or by calling the Texas Instruments Literature Response Center at 1-800-477-8924

or the Product Information Center at 1-972-644-5580. When ordering identify the document by both title

and literature number.

Table 2. Related Documentation

ITEM NO LITERATURE NUMBER

DAC8775 product data sheet SLVSBY7

REF5050 product data sheet SBOS410

SM-USB-DIG platform user’s guide SBOU098

2

DAC8775EVM User’s Guide

Copyright © 2016, Texas Instruments Incorporated

SBAU248–November 2016

Submit Documentation Feedback

Page 3

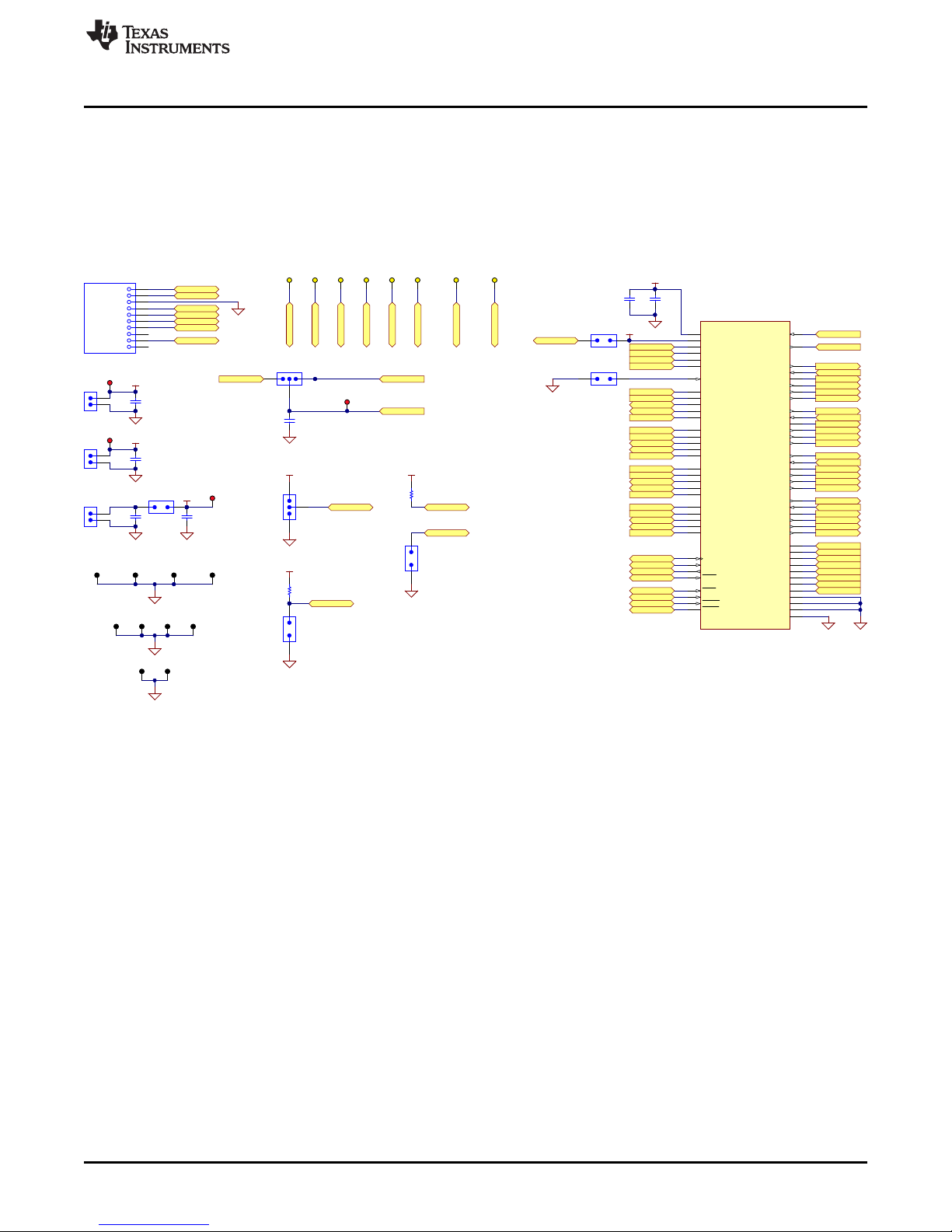

Copyright © 2016, Texas Instruments Incorporated

DAC8775

PVDD/AVDD

Power Supply

VOUT

A

IOUT

A

VOUT

D

IOUT

D

...

...

HARTIN

X

IEC61000-4 Protection Circuit

Placeholder

External Supplies

SM-USB-DIG

VPOSX/VNEG

X

Internal Buck-Boost

External V

REF

REF5050

Internal V

REF

V

REF

SPI

Computer

SM-USB-DIG

Platform

DAC8775EVM

Power Supply

USB 10-Pin Connector

Single-supply for use with buck-boost converter

Multi-supply for use without buck-boost converter

www.ti.com

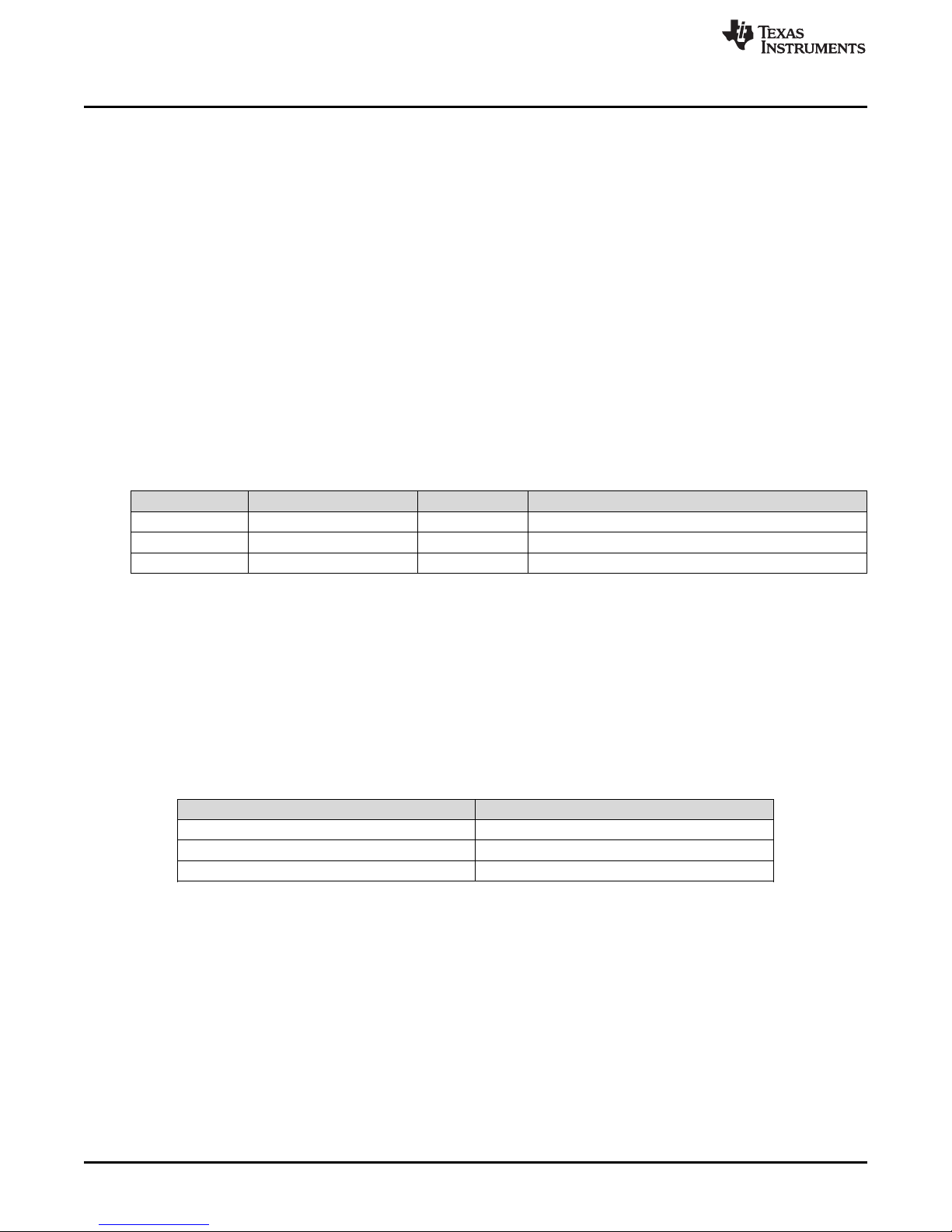

2 EVM Hardware Overview

This section discusses the overall system setup for the EVM. A personal computer (PC) runs the software

that communicates with the SM-USB-DIG platform, which provides the power and digital signals used to

communicate with the EVM board. Connectors on the EVM board allow the user to connect the required

external power supplies for the configuration under test. The SM-USB-DIG must be connected to the

DAC8775EVM with the Texas Instruments logo facing up.

Figure 1. DAC8775EVM Hardware Setup

2.1 EVM Board Block Diagram

A block diagram of the EVM board setup is shown in Figure 2. This board provides test points for the SPI,

power, reference, ground, analog outputs, !LDAC, CLR, ALARM, and RESET signals. The EVM allows the

user to select the internal buck-boost converter or external power supplies as sources for each channel’s

positive and negative supplies rails. The EVM also allows the user to select the internal reference,

onboard REF5050 reference, or external reference to provide the reference voltage to the DAC8775.

EVM Hardware Overview

SBAU248–November 2016

Submit Documentation Feedback

Figure 2. DAC8775EVM Block Diagram

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

3

Page 4

EVM Hardware Overview

2.2 Electrostatic Discharge Warning

Many of the components on the EVM are susceptible to damage by electrostatic discharge (ESD). Users

are advised to observe proper ESD handling precautions when unpacking and handling the EVM,

including the use of a grounded wrist strap at an approved ESD workstation.

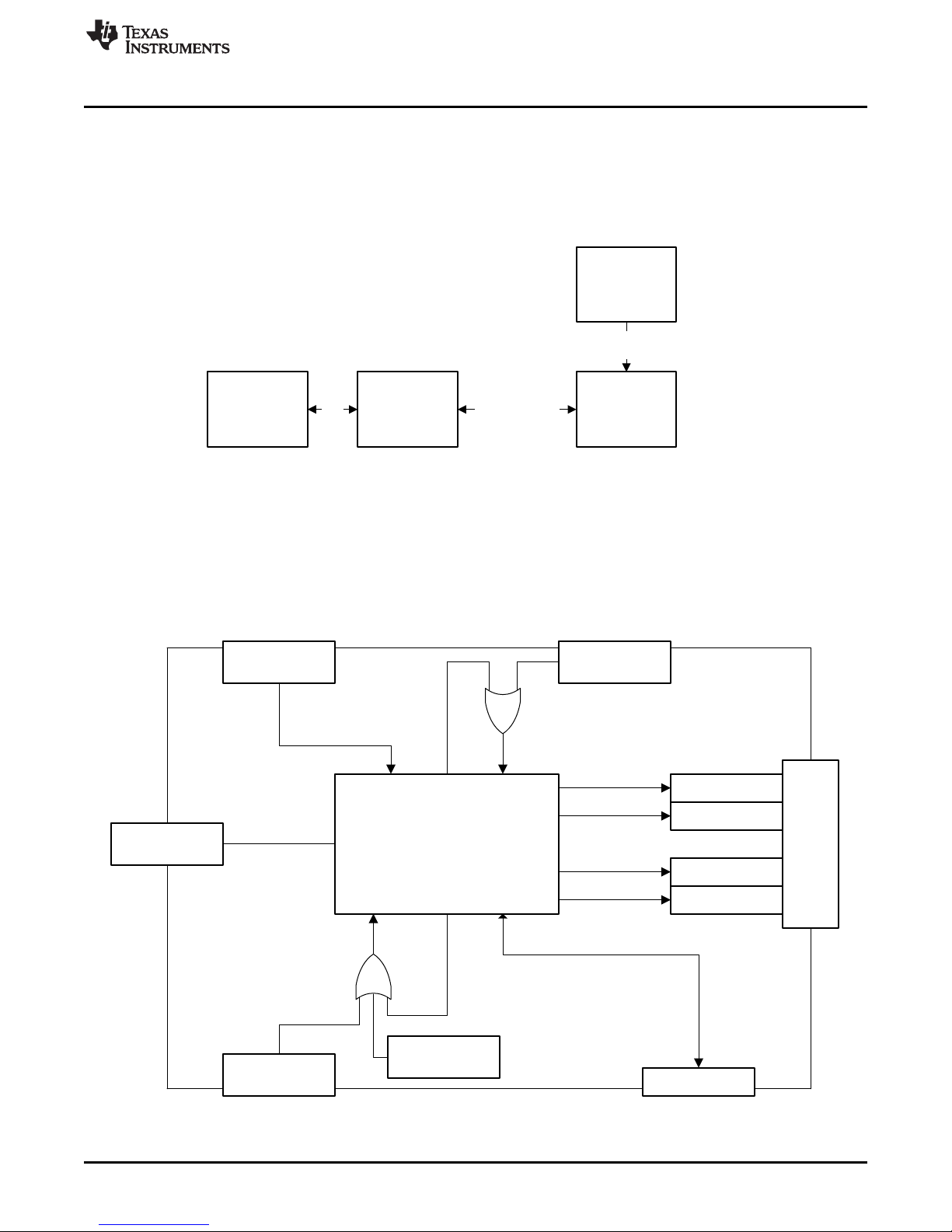

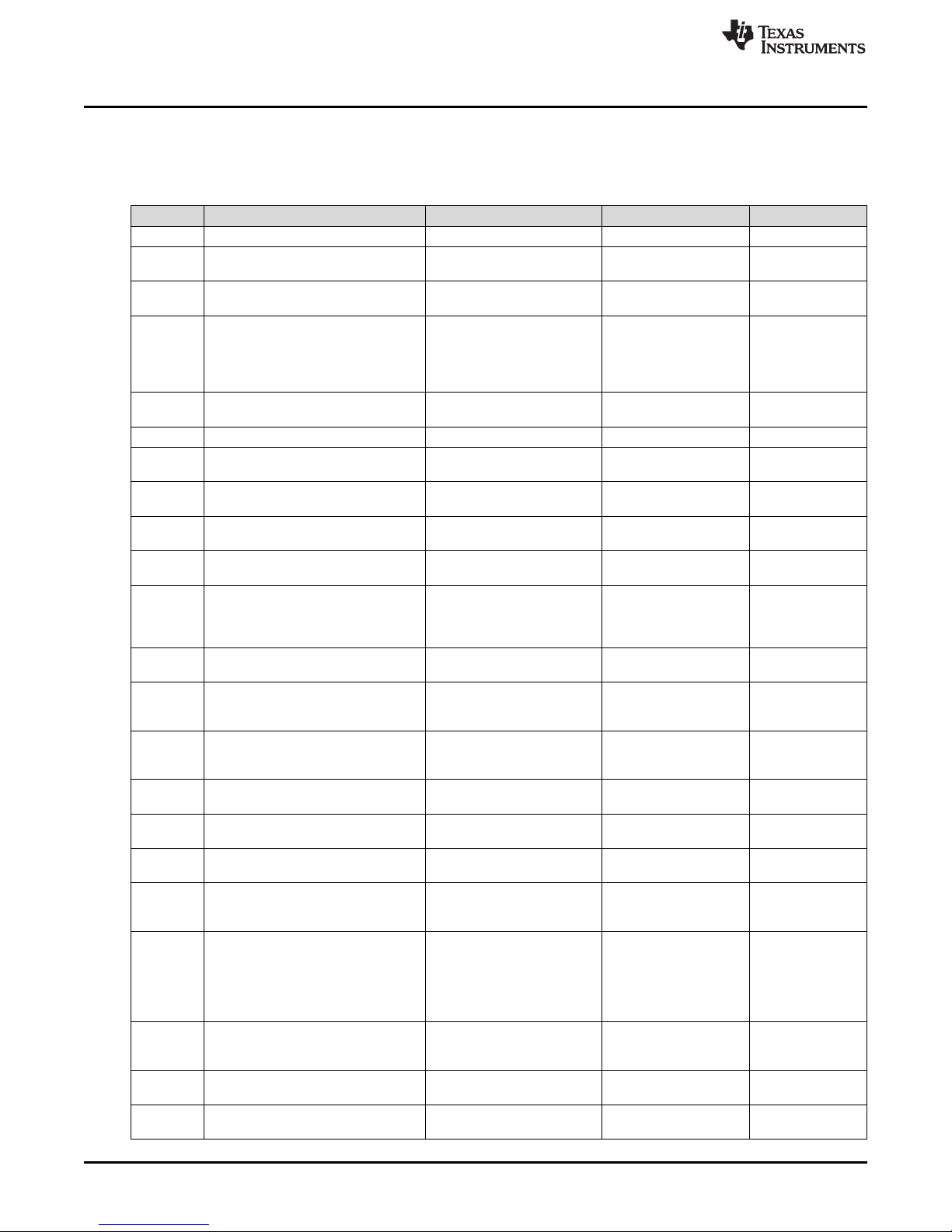

2.3 Jumper Summary

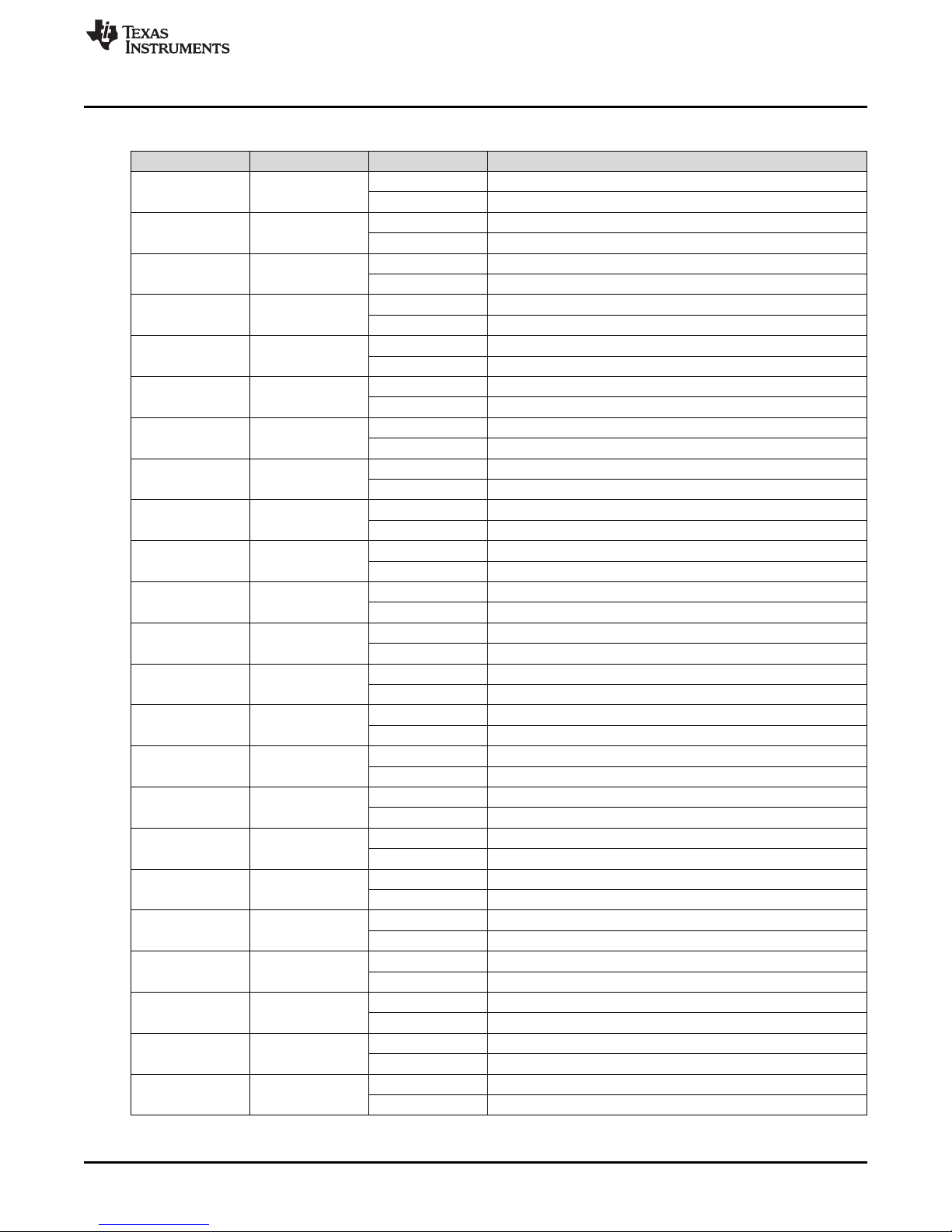

Table 3 summarizes all of the EVM jumper functionality.

JUMPER LABEL DEFAULT POSITION FUNCTION

JP1 1-2

JP2 1-2

JP3 1-2

JP4 1-2

JP5 1-2

JP6 1-2

JP7 1-2

JP8 1-2

JP9 Not installed

JP10 1-2

JP11 Not installed

JP12 2-3

JP13 Not installed

JP14 Not installed

JP15 Installed

JP16 Installed

JP17 Installed

JP18 Not installed

JP19 Installed

JP20 Not installed

www.ti.com

Table 3. EVM Jumper Summary

1-2 Selects DC/DC Channel A to supply VPOSA

2-3 Selects PVDD/AVDD to supply VPOSA

1-2 Selects DC/DC Channel A to supply VNEGA

2-3 Selects AVSS to supply VNEGA

1-2 Selects DC/DC Channel B to supply VPOSB

2-3 Selects PVDD/AVDD to supply VPOSB

1-2 Selects DC/DC Channel B to supply VNEGB

2-3 Selects AVSS to supply VNEGB

1-2 Selects DC/DC Channel C to supply VPOSC

2-3 Selects PVDD/AVDD to supply VPOSC

1-2 Selects DC/DC Channel C to supply VNEGC

2-3 Selects AVSS to supply VNEGC

1-2 Selects DC/DC Channel D to supply VPOSD

2-3 Selects PVDD/AVDD to supply VPOSD

1-2 Selects DC/DC Channel D to supply VNEGD

2-3 Selects AVSS to supply VNEGD

Installed Connects the SM-USB-DIG supply to DVDD

Not installed Disconnects the SM-USB-DIG supply from DVDD

1-2 Selects the DAC8775 internal reference

2-3 Selects the REF5050 external reference

Installed Disables internal DVDD LDO

Not installed Enables internal DVDD LDO

1-2 Issues a clear command to the DAC8775

2-3 No operation

Installed Selects the external DVDD

Not installed Disconnects the external DVDD

Installed Issues a hardware reset to the DAC8775

Not installed No operation

Installed Select asynchronous update mode

Not installed Select synchronous update mode

Installed VSENSEPA is shorted to VOUTA on-board

Not installed VSENSEPA is shorted to VOUTA off-board

Installed VSENSEPB is shorted to VOUTB onboard

Not installed VSENSEPB is shorted to VOUTB off-board

Installed Loads VOUTA/IOUTA with a short to GND

Not installed Unloads VOUTA/IOUTA of the short to GND

Installed Loads VOUTA/IOUTA with a 250-Ω resistor

Not installed Unloads VOUTA/IOUTA of the 250-Ω resistor

Installed Loads VOUTA/IOUTA with a 625-Ω resistor

Not installed Unloads VOUTA/IOUTA of the 625-Ω resistor

4

DAC8775EVM User’s Guide

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Page 5

www.ti.com

Table 3. EVM Jumper Summary (continued)

JUMPER LABEL DEFAULT POSITION FUNCTION

JP21 Not installed

JP22 Not installed

JP23 Not installed

JP24 Not installed

JP25 Not installed

JP26 Installed

JP27 Installed

JP28 Installed

JP29 Installed

JP30 Installed

JP31 Installed

JP32 Not installed

JP33 Not installed

JP34 Not installed

JP35 Not installed

JP36 Not installed

JP37 Not installed

JP38 Not installed

JP39 Not installed

JP40 Installed

JP41 Installed

JP42 Installed

JP43 Installed

Installed Loads VOUTA/IOUTA with a 1-kΩ resistor

Not installed Unloads VOUTA/IOUTA the 1-kΩ resistor

Installed Loads VOUTB/IOUTB with a short to GND

Not installed Unloads VOUTB/IOUTB of the short to GND

Installed Loads VOUTB/IOUTB with a 250-Ω resistor

Not installed Unloads VOUTB/IOUTB of the 250-Ω resistor

Installed Loads VOUTB/IOUTB with a 625-Ω resistor

Not installed Unloads VOUTB/IOUTB of the 625-Ω resistor

Installed Loads VOUTB/IOUTB with a 1-kΩ resistor

Not installed Unloads VOUTB/IOUTB the 1-kΩ resistor

Installed VSENSENA is shorted to GND onboard

Not installed VSENSENA is shorted to GND off-board

Installed VSENSENB is shorted to GND onboard

Not installed VSENSENB is shorted to GND off-board

Installed When HARTIN_A is not in use, AC couple to GND

Not installed When HARTIN_A is in use, disconnect from GND

Installed When HARTIN_B is not in use, AC couple to GND

Not installed When HARTIN_B is in use, disconnect from GND

Installed VSENSEPC is shorted to VOUTA onboard

Not installed VSENSEPC is shorted to VOUTA off-board

Installed VSENSEPD is shorted to VOUTB onboard

Not installed VSENSEPD is shorted to VOUTB off-board

Installed Loads VOUTC/IOUTC with a short to GND

Not installed Unloads VOUTC/IOUTC of the short to GND

Installed Loads VOUTC/IOUTC with a 250-Ω resistor

Not installed Unloads VOUTC/IOUTC of the 250-Ω resistor

Installed Loads VOUTC/IOUTC with a 625-Ω resistor

Not installed Unloads VOUTC/IOUTC of the 625-Ω resistor

Installed Loads VOUTC/IOUTC with a 1-kΩ resistor

Not installed Unloads VOUTC/IOUTC the 1-kΩ resistor

Installed Loads VOUTD/IOUTD with a short to GND

Not installed Unloads VOUTD/IOUTD of the short to GND

Installed Loads VOUTD/IOUTD with a 250-Ω resistor

Not installed Unloads VOUTD/IOUTD of the 250-Ω resistor

Installed Loads VOUTD/IOUTD with a 625-Ω resistor

Not installed Unloads VOUTD/IOUTD of the 625-Ω resistor

Installed Loads VOUTD/IOUTD with a 1-kΩ resistor

Not installed Unloads VOUTD/IOUTD the 1-kΩ resistor

Installed VSENSENC is shorted to GND onboard

Not installed VSENSENC is shorted to GND off-board

Installed VSENSEND is shorted to GND onboard

Not installed VSENSEND is shorted to GND off-board

Installed When HARTIN_C is not in use, AC couple to GND

Not installed When HARTIN_C is in use, disconnect from GND

Installed When HARTIN_D is not in use, AC couple to GND

Not installed When HARTIN_D is in use, disconnect from GND

EVM Hardware Overview

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

5

Page 6

PVDD/AVDD

GND

AVSS

GND

GND

DVDD

EVM Hardware Overview

2.4 Powering the EVM

This section describes the various power configurations that can be used by the EVM.

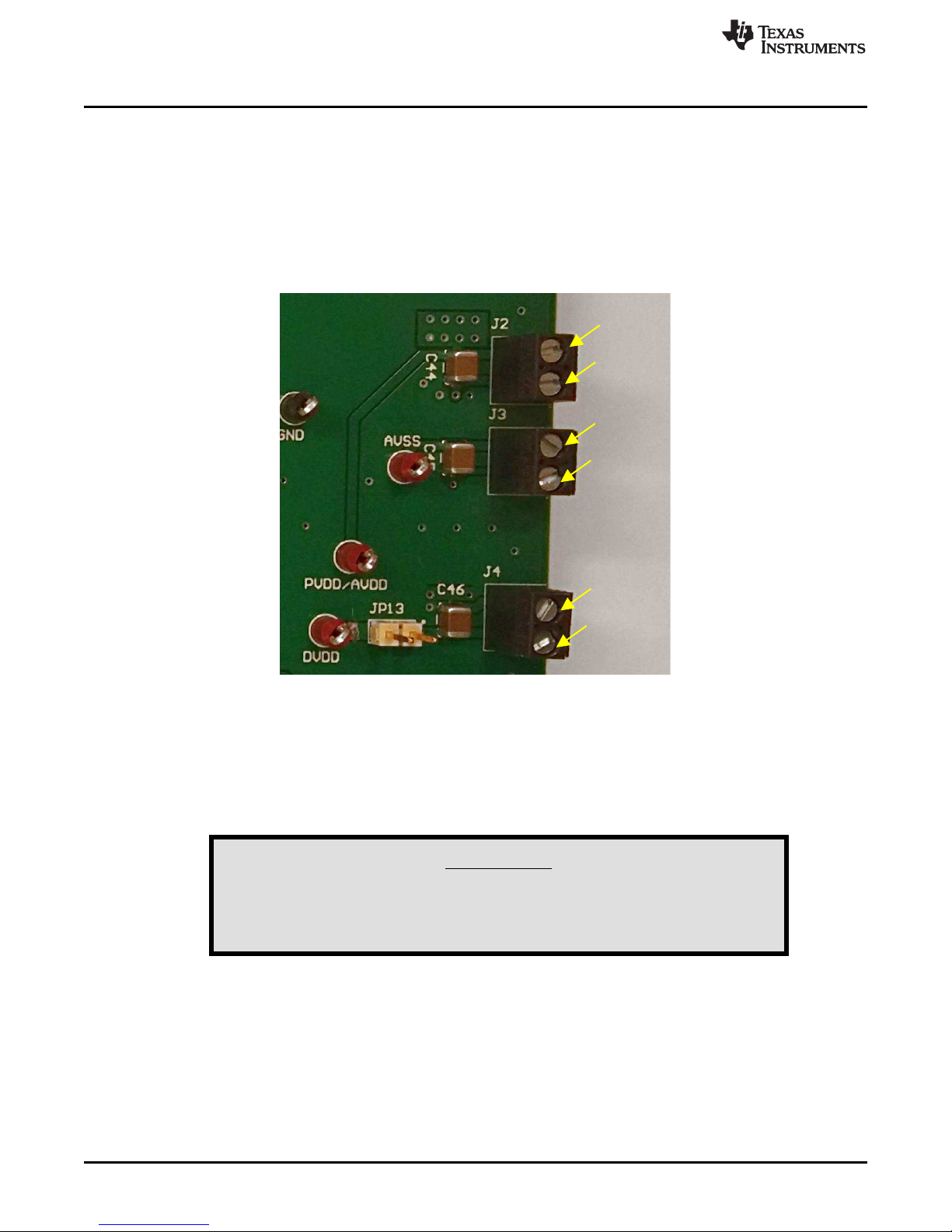

2.4.1 PVDD_X/AVDD Supply

The PVDD_X, the buck-boost converter supplies, and AVDD, the analog supply, of the DAC8775 are

connected to the same power net labeled PVDD/AVDD on the DAC8775EVM. Terminal block J2, shown

in Figure 3, allows for external voltage sources to be connected to the PVDD/AVDD supply. The

PVDD/AVDD supply must be provided regardless of whether the buck-boost converter is in use or not.

www.ti.com

Figure 3. PVDD/AVDD, AVSS, and DVDD Supply Connections

2.4.2 VPOS_X and VNEG_X Supplies

VPOS_X, the positive supply for the output signal chain, and VNEG_X, the negative supply for the output

signal chain, may be powered by the DAC8775 internal buck-boost converters or by off-board supply

voltages.

Permanent device damage may occur if externally supplying

VPOS_X or VNEG_X while the internal buck-boost supply is

enabled.

When using the DAC8775 internal buck-boost converters to supply VPOS_X and VNEG_X, install JP1

through JP8 (or the two jumpers that correspond to the channel of interest) in the 1-2 position, or "inside"

position, as indicated by Table 3.

When using external equipment to supply VPOS_X and VNEG_X, install JP1 through JP8 (or the two

jumpers that correspond to the channel of interest) in the 2-3 position, or "outside" position, as indicated

by Table 3. In this configuration, the VPOS_X supplies are connected to the PVDD/AVDD net and the

VNEG_X supplies are connected to the AVSS net. If bipolar supplies are used, connect an appropriate

negative supply voltage to AVSS through terminal block J3, as shown in Figure 3. If unipolar supplies are

used, connect AVSS to ground through terminal block J3.

WARNING

6

DAC8775EVM User’s Guide

Copyright © 2016, Texas Instruments Incorporated

SBAU248–November 2016

Submit Documentation Feedback

Page 7

www.ti.com

2.4.3 DVDD Supply

DVDD, the digital supply voltage, of the DAC8775 can be supplied by the SM-USB-DIG VDUT supply (pin

6 of J1), an external supply voltage through J4 (illustrated in Figure 3), or by the DAC8775 internal DVDD

LDO. When using the SM-USB-DIG as the DVDD supply, uninstall jumper JP13 and install jumpers JP9

and JP11. To use an external supply voltage as the DVDD supply, install jumpers JP13 and JP11 and

uninstall JP9. To use the DAC8775 internal LDO as the DVDD supply, uninstall jumpers JP9, JP13, and

JP11.

In each DVDD supply configuration, take care to ensure that digital logic thresholds of the host and

DAC8775 match and that the absolute maximum ratings of the DAC8775 are not violated.

2.5 EVM Features

This section describes some of the hardware features present on the EVM board.

2.5.1 Communication Test Points

The EVM board features test points for monitoring the communication between the SM-USB-DIG and the

DAC8775. Test points are provided for the !LDAC, CLR, ALARM, RESET, SDIN, SCLK, !SYNC, and SDO

pins of the DAC8775.

EVM Hardware Overview

Figure 4. Digital Communication Test Points

The EVM design also allows external signals to be connected through these communication test points if

the EVM is integrated into a custom evaluation setup or application specific prototype. Note that if the SMUSB-DIG platform is not used, DVDD must be configured to use the DAC8775 internal DVDD LDO or

external supplies as described in Section 2.4.3.

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

7

Page 8

+

5

V

GND

EVM Hardware Overview

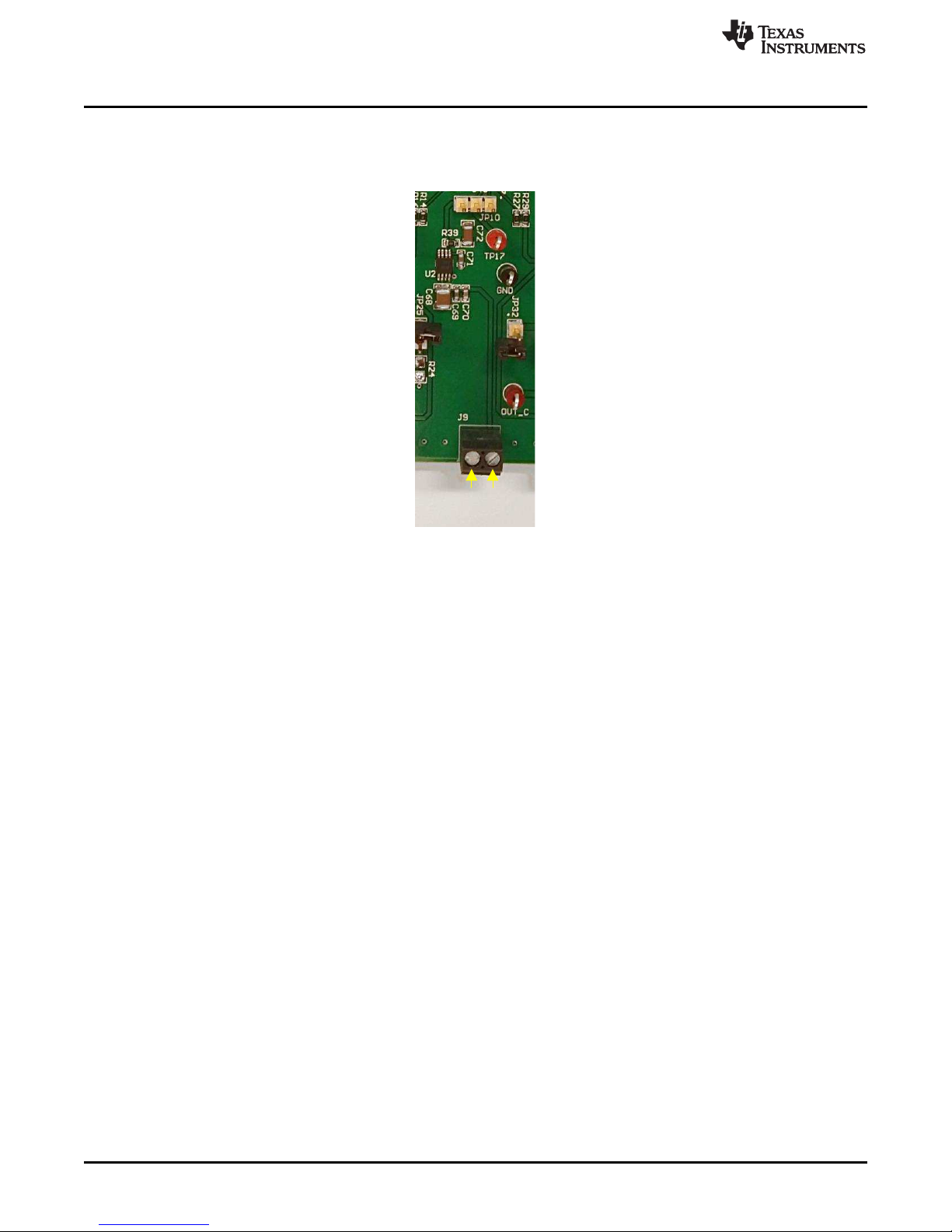

2.5.2 Reference Voltage

The DAC8775 reference voltage can be supplied by the internal voltage reference, by the onboard

REF5050, or by an external reference voltage.

www.ti.com

Figure 5. Onboard Reference Supply Connections

To use the internal reference voltage, place JP10 in the 1-2 position. To use the REF5050 reference

voltage, place JP10 in the 2-3 position and connect a supply voltage for the REF5050 to J9, as shown in

Figure 5. To use an external reference voltage, remove JP10 and the reference can be connected to the

DAC8775EVM through the center post of JP10.

2.5.3 VOUT_X, VSENSEP_X, and VSENSEN_X

The VOUT_X pins can be access on terminal blocks J5, J6, J7, and J8 or by the OUT_A, OUT_B,

OUT_C, or OUT_D test points. The VSENSEP_X and VSENSEN_X sense connections may be provided

onboard or externally closer to the point of load through terminal blocks J5, J6, J7, or J8. To provide the

VSENSEP_X connections onboard, install JP16, JP17, JP30, or JP31 based on the channel of interest.

Similarly, to provide VSENSEN_X connections onboard, install JP26, JP27, JP40, or JP41. Removing

these jumpers requires that the sense connections are made external to the EVM board. Figure 6 shows

the arrangement of the output terminal blocks.

2.5.4 IOUT_X

The IOUT_X pins can be accessed on terminal blocks J5, J6, J7, or J8 or by the test points OUT_A,

OUT_B, OUT_C, or OUT_D.

2.5.5 Onboard Output Loads

Four load choices are installed on the EVM board to evaluate the voltage and current outputs as well as

the adaptive power management performance of the DAC8775. JP18, JP22, JP32, or JP36 are available

to provide a short-circuit condition on the outputs. JP19, JP23, JP33, or JP37 provide a 250-Ω load on the

outputs. JP20, JP24, JP34, or JP38 are available to provide a 625-Ω on the outputs. JP21, JP25, JP35, or

JP39 provides a 1-kΩ load on the outputs.

8

DAC8775EVM User’s Guide

Copyright © 2016, Texas Instruments Incorporated

SBAU248–November 2016

Submit Documentation Feedback

Page 9

Load

Jumpers

GND

VSENSEN

_

A

VOUT

/

IOUT

_

A

VSENSEP

_

A

GND

VSENSEN

_B

VOUT

/

IOUT

_

B

VSENSEP

_

B

GND

VSENSEN

_

C

VOUT

/

IOUT

_

C

VSENSEP

_

C

GND

VSENSEN_

D

VOUT

/

IOUT

_

D

VSENSEP

_

D

www.ti.com

Figure 6. Output Terminal Block Connections and Load Jumpers

2.5.6 Applying HART Signals

JP28, JP29, JP42, and JP43 are available to couple external HART FSK communication signals onto the

current outputs. When injecting the HART signal, remove JP28, JP29, JP42, or JP43 and apply the HART

signal to pin 1. When a HART signal is not being injected, install JP28, JP29, JP42, or JP43, with AC

coupling the HART pins to ground.

EVM Hardware Overview

2.6 Connecting the SM-USB-DIG

To connect the EVM board and the SM-USB-DIG platform together, firmly slide the male and female ends

of the 10-pin connectors together with the Texas Instruments logo of the SM-USB-DIG facing up as shown

in Figure 7. Make sure that the two connectors are completely pushed together as loose connections may

cause intermittent operation.

SBAU248–November 2016

Submit Documentation Feedback

Figure 7. SM-USB-DIG Connection

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

9

Page 10

EVM Hardware Overview

2.7 Signal Definitions of J1 (10-Pin SM-USB-DIG Connector)

Table 4 shows the pin-out for the 10-pin connector used to communicate between the EVM and the SM-

USB-DIG. Note that the I2C communication lines (I2C_SCL and I2C_SDA1) are not used.

Table 4. SM-USB-DIG Connector

PIN ON J1 SIGNAL DESCRIPTION

1 I2C_SCL I2C clock signal (SCL)

2 CTRL/MEAS4 GPIO: Control output or measure input

3 I2C_SDA1 I2C data signal (SDA)

4 CTRL/MEAS5 GPIO: Control output or measure input

5 SPI_DOUT1 SPI data output (MOSI)

6 VDUT

7 SPI_CLK SPI clock signal (SCLK)

8 GND Power return (GND)

9 SPI_CS1 SPI chip-select signal (!CS)

10 SPI_DIN1 SPI data input (MISO)

Switchable DUT power supply: 3.3 V, 5 V, Hi-Z (disconnected).

Note: When VDUT is Hi-Z, all digital I/Os are Hi-Z as well

3 EVM Software Setup

This section discusses how to install the EVM software.

www.ti.com

3.1 Operating Systems for EVM Software

The EVM software has been tested on the Windows XP®and Windows 7®operating systems with United

States and European regional settings. The software should also function on other Windows operating

systems.

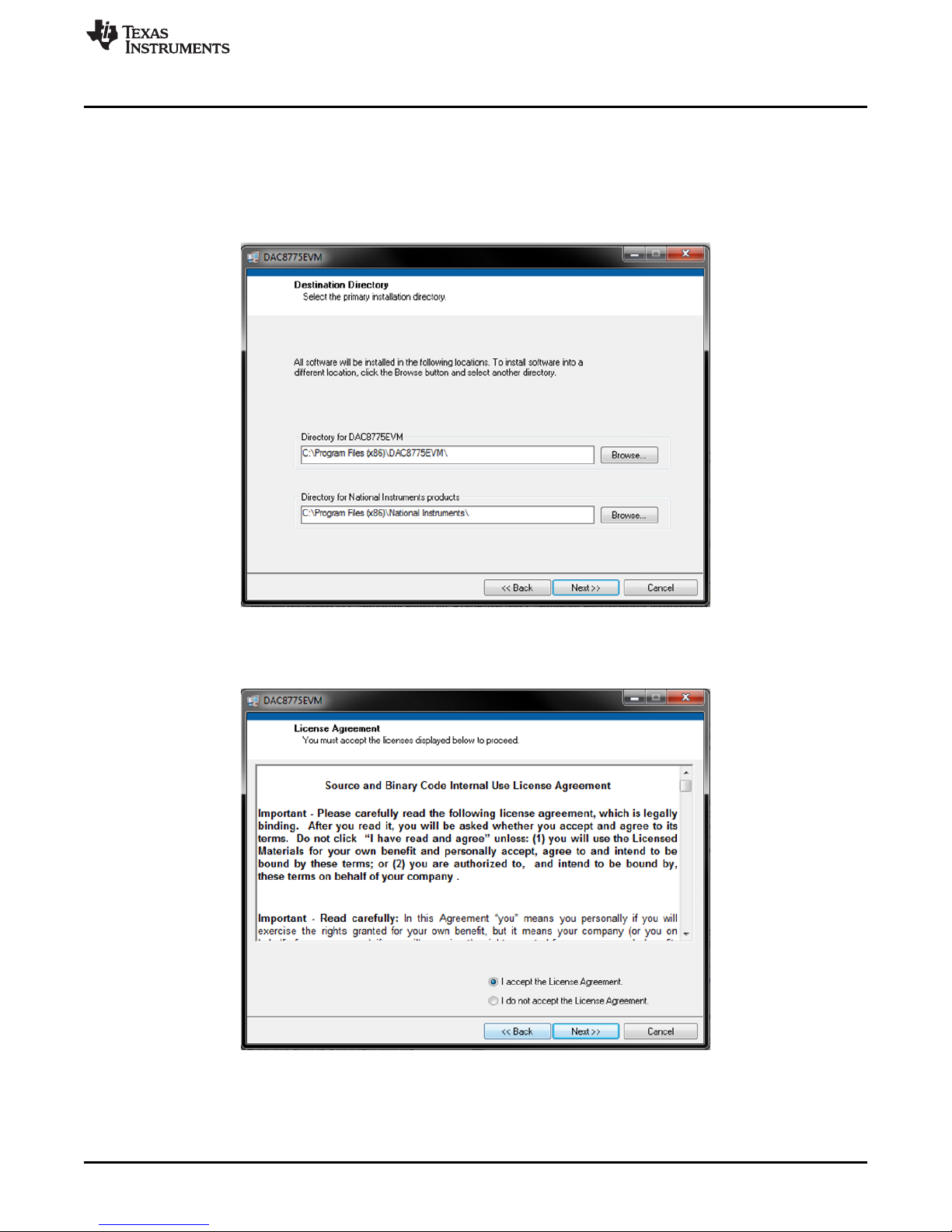

3.2 EVM Software Installation

The EVM software may be downloaded by following the instructions provided external to this document.

To install the software, locate and extract the file named DAC8775.zip to a specific folder (for example,

C:\DAC8775\) on the hard drive.

10

DAC8775EVM User’s Guide

Figure 8. DAC8775EVM Installer

Copyright © 2016, Texas Instruments Incorporated

SBAU248–November 2016

Submit Documentation Feedback

Page 11

www.ti.com

After the files are extracted, navigate to the folder created on the hard drive. Locate and execute the

setup.exe file to start the installation. The DAC8775 software installer file then opens to begin the

installation process.

After the installation process initializes, the user is given a choice of selecting the installation directory,

usually defaulting to C:\Program Files(x86)\DAC8775EVM\ and C:\Program Files(x86)\National

Instruments\.

EVM Software Setup

Figure 9. DAC8775EVM Install Path

After selecting the installation directory, two license agreements are presented that must be accepted.

Figure 10. DAC8775EVM Software License Agreements

After accepting the Texas Instruments and National Instruments license agreements, the progress bar

opens and shows the installation of the software. Once the installation process is completed, click Finish.

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

11

Page 12

EVM Software Overview

4 EVM Software Overview

This section describes the use of the EVM software. Figure 11 shows the front panel of the EVM GUI.

www.ti.com

4.1 Starting the EVM Software

The EVM software can be operated through the Windows start menu. From the start menu, select All

Programs, and then select DAC8775EVM.

An error will appear if the PC cannot communicate with the EVM. If this error happens, first ensure that

the USB cable is properly connected on both ends. This error can also occur if the USB cable is

connected before the SM-USB-DIG platform power source. Another possible source for this error is a

problem with the USB human interface driver on the PC. Make sure the device is recognized when the

USB cable is plugged in, as indicated by a Windows-generated confirmation sound.

4.2 Reading From and Writing to Registers

The EVM software automatically reads from the DAC8775 when a reset or clear command is issued. To

read from the device in other situations, press the READ ALL button on the EVM GUI. Write actions are

carried out automatically when the value of any element on the GUI is changed.

12

DAC8775EVM User’s Guide

Figure 11. EVM GUI – Front Panel

Copyright © 2016, Texas Instruments Incorporated

SBAU248–November 2016

Submit Documentation Feedback

Page 13

www.ti.com

4.3 Device Controls

This section describes the GUI controls for the internal reference, power-on conditions, clear, software

reset, and DAC broadcast functionality.

4.3.1 Internal Reference

The internal reference can be enabled or disabled using the internal reference control on the EVM GUI. By

default, the internal reference is disabled.

4.3.2 Power-On Condition

By default the power-on state of the current output is Hi-Z and the voltage output is 30 kΩ to ground after

a clear or reset command. The power-on condition GUI control allows control of the voltage output poweron condition as either 30 kΩ to ground or Hi-Z.

4.3.3 Software Reset

The RESET button on the GUI issues a software reset to the DAC8775, restoring the default power-on

register contents. The GUI immediately reads all of the registers of the device to synchronize the GUI and

hardware. A hardware reset can be issued through JP14. If a hardware issue is issued the READ ALL

button should be pressed to synchronize the GUI and hardware.

4.3.4 Software Clear

The CLEAR button on the GUI issues a clear command to the DAC8775, restoring the DAC data registers

to full-scale or zero-scale based on each channel’s clear select settings and clear enable settings. After a

clear command is issued the GUI immediately reads the data registers of the device to synchronize the

GUI and hardware. A hardware clear command can be issued through JP12. If a hardware clear is issued

the READ ALL button should be pressed to synchronize the GUI and hardware.

EVM Software Overview

4.4 DAC Controls

4.4.1 DAC Outputs

The DACs can be configured for voltage or current outputs of various spans through the Output Mode

control on the GUI. The DAC output can be set to active or inactive by checking or removing the check

from the Output Enable Boolean control on the GUI. Once an output range is selected and the output is

enabled, the DAC output value can be controlled by writing values to the DAC Data control. The DAC

Data control expects hexadecimal input formats. The small indicator on the left side of the DAC Data

control can be used to change the input data format.

Output current drive can be programmatically limited for each of the voltage output modes through the

V

Current Limit control on the GUI. Take note that the actual current limit will be compliant to the values

OUT

specified in the DAC8775 electrical characteristics table.

4.4.2 Clear Functionality

Each DAC output has a Clear Enable Boolean that is AND’d with the CLEAR command. If the Clear

Enable Boolean is checked, the output channel will respond to a clear event; conversely, if the Boolean is

unchecked, the output channel will not respond to a clear event. Each DAC can be programmed to clear

to either zero-scale or full-scale. This behavior can be controlled by the Clear Select control on the GUI.

4.4.3 HART Inputs

The enable HART signals to be coupled to the current outputs through the onboard coupling path the

HART-Enable Boolean control must be checked.

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

13

Page 14

EVM Software Overview

4.5 DAC Calibration Controls

Each DAC may use digital calibration to reduce offset and gain errors at each channel’s output. By default

the calibration features are disabled. To enable the calibration features, the Calibration Enable Boolean

control must be checked. When the control is checked, offset and gain calibration may be controlled by

the values written to each channels Offset Calibration and Gain Calibration controls, respectively, on the

EVM GUI. For more information concerning the calibration features, please refer to the DAC8775

datasheet.

4.6 Slew-Rate Controls

The slew-rate of each channel may be controlled by the slew control registers for each channel. By default

the slew-rate control features are disabled. To enable the slew-rate control features the Slew-Rate Ctl

Enable Boolean control must be checked. When the control is checked, slew-rate step size and clock

registers may be used to control the output’s slew-rate through the Slew-Rate Ctl Step Size and SlewRate Ctl Clock respectively.

4.7 Buck-Boost Converter Controls

Each buck-boost converter can be configured through the EVM GUI. The Buck-Boost Mode control is

used to select the operating mode of the buck-boost converter and the Buck-Boost Enable control is used

to enable the positive, negative, or both arms of the buck-boost converter. When Buck-Boost Mode is set

to Clamp Mode, the positive clamp and negative clamp controls are used to set each arm’s output clamp.

www.ti.com

14

DAC8775EVM User’s Guide

Copyright © 2016, Texas Instruments Incorporated

SBAU248–November 2016

Submit Documentation Feedback

Page 15

VSENSEP_A

CCOMP_A

VOUT_A

IOUT_A

VSENSEN_A

HART_IN_A

VSENSEP_B

CCOMP_B

VOUT_B

IOUT_B

VSENSEN_B

HART_IN_B

VSENSEP_C

CCOMP_C

VOUT_C

IOUT_C

VSENSEN_C

HART_IN_C

VSENSEP_D

CCOMP_D

VOUT_D

IOUT_D

VSENSEN_D

HART_IN_D

1

2

3

JP10

5

4

1

2

3

6

7

8

9

10

SPI_DIN

SPI_CS

GND

SPI_CLK

VDUT

SPI_DOUT

CTRL/MEAS5

I2C_SDA

CTRL/MEAS4

I2C_SCK

J1

SUPER MINI DIG FEMALE

SPI_MISO

SPI_SCLK

SPI_CS

SPI_MOSI

RESET

DIG_DVDD

SPI_CS

SPI_MOSI

SPI_MISO

SPI_LDAC

SPI_SCLK

0.1µF

C43

EXT_VREF

12

JP9

12

JP11

DIG_DVDD

PVDD/AVDD

AGND_A

PVSS_A

PVDD_A

VPOS_IN_A

LN_A

LP_A

VNEG_IN_A

VNEG_IN_A

VPOS_IN_B

LN_B

LP_B

VNEG_IN_B

VNEG_IN_B

AGND_B

PVSS_B

PVDD_B

AGND_C

PVSS_C

PVDD_C

VPOS_IN_C

LN_C

LP_C

VNEG_IN_C

VNEG_IN_C

VPOS_IN_D

LN_D

LP_D

VNEG_IN_D

VNEG_IN_D

AGND_D

PVSS_D

PVDD_D

0.1µF

C41

LDAC CS MOSI MISO SCLK

SPI_CS

SPI_MOSI

SPI_MISO

SPI_LDAC

SPI_SCLK

ALARM

ALARM

ALARM

ALARM

DVDD

DVDD

1

2

JP14

10k

R10

1

2

J2

PVDD/AVDD

PVDD/AVDD

1

2

J3

AVSS

AVSS

GNDGND

GNDGNDGNDGND

GNDGNDGNDGND

AVSS

PVDD/AVDD

VREF_IN

10µF

C44

10µF

C45

10µF

C46

1µF

C42

1 2

JP13 DVDD

200pF

C47

DVDD

10k

R9

RESET

RESET

RESET

1

2

3

JP12

DVDD

CLR

CLR

CLR

1

2

JP15

DVDD

PVDD_D

1

LP_D

2

PVSS_D

3

LN_D

4

PVDD_C

5

LP_C

6

PVSS_C

7

LN_C

8

AGND_B

9

LN_B

10

PVSS_B

11

LP_B

12

PVDD_B

13

LN_A

14

PVSS_A

15

LP_A

16

PVDD_A

17

AGND_A

18

VNEG_IN_A

19

VNEG_IN_B

20

SCLK

21

SDIN

22

LDAC

23

SDO

24

SYNC

25

CLR

26

HARTIN_B

27

CCOMP_B

28

HARTIN_A

29

CCOMP_A

30

VSENSEP_B

31

VSENSEN_B

32

VSENSEP_A

33

VSENSEN_A

34

AGND2

35

VNEG_IN_A

36

IOUT_A

37

VPOS_IN_A

38

VOUT_A

39

VNEG_IN_B

40

IOUT_B

41

VPOS_IN_B

42

VOUT_B

43

AVDD

44

AGND3

45

REFIN

46

REFOUT

47

VOUT_C

48

VPOS_IN_C

49

IOUT_C

50

VNEG_IN_C

51

VOUT_D

52

VPOS_IN_D

53

IOUT_D

54

VNEG_IN_D

55

AGND1

56

VSENSEN_D

57

VSENSEP_D

58

VSENSEN_C

59

VSENSEP_C

60

CCOMP_D

61

HARTIN_D

62

CCOMP_C

63

HARTIN_C

64

DVDD_EN

65

DVDD

66

ALARM

67

RESET

68

AGND_D

69

VNEG_IN_C

70

VNEG_IN_D

71

AGND_C

72

EP

73

U1

DAC8775RMP

ALARM

RESET

CLR

SPI_LDAC

REFOUT

REFIN

REFIN

REFOUT

1

2

J4

DVDD

GND

GND

GND GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND GND

GND

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

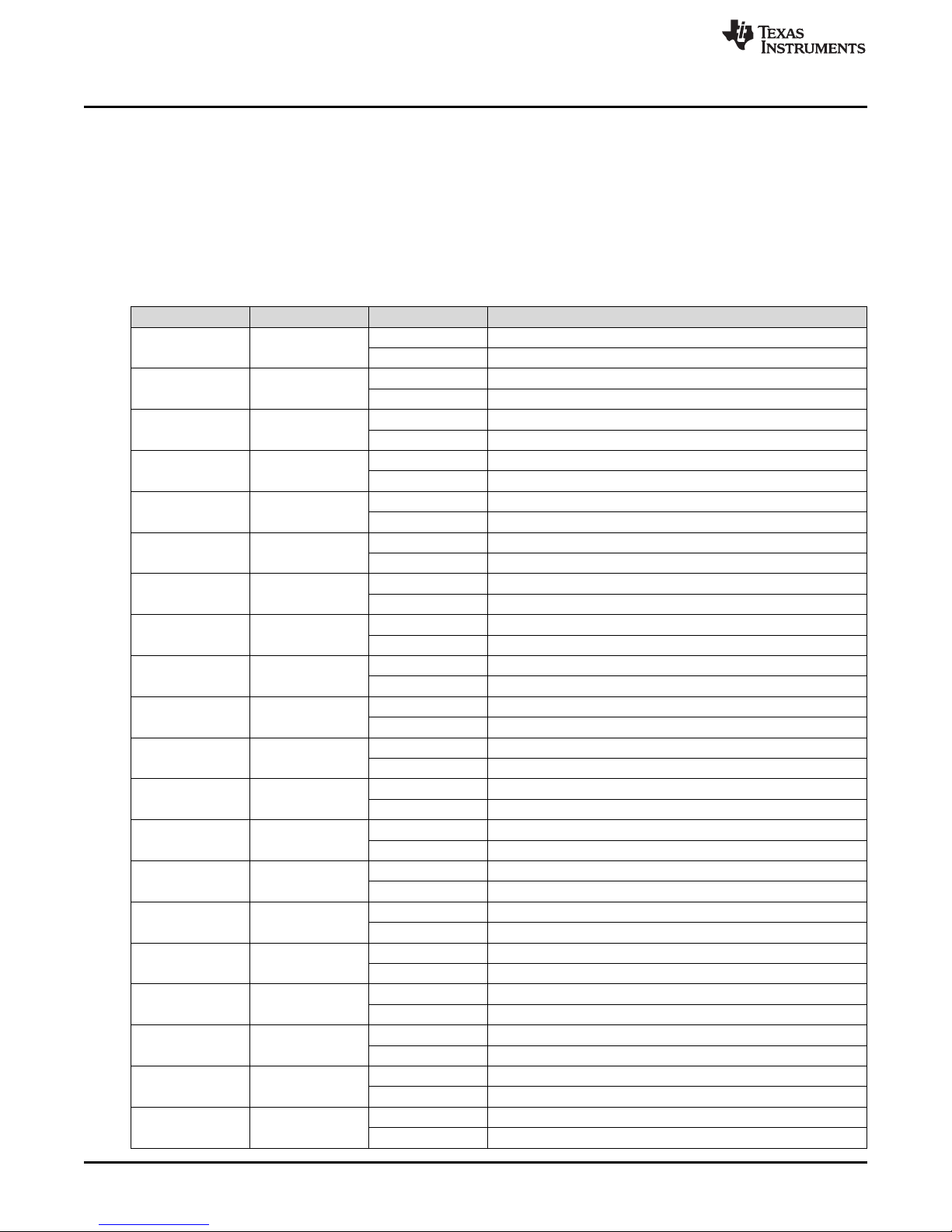

5 EVM Documentation

This section contains the complete bill of materials and schematic diagram for the DAC8775EVM.

Documentation information for the SDM-USB-DIG Platform can be found in the SDM-USB-DIG Platform

User’s Guide (SBOU136) available at www.TI.com.

5.1 EVM Board Schematic

Figure 12, Figure 13, and Figure 14 illustrate the DAC8775EVM board schematics.

EVM Documentation

SBAU248–November 2016

Submit Documentation Feedback

Figure 12. Device Schematic

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

15

Page 16

VSENSEP_A

CCOMP_A

VOUT_A

IOUT_A

VSENSEN_A

HART_IN_A

VSENSEP_B

CCOMP_B

VOUT_B

IOUT_B

VSENSEN_B

HART_IN_B

VSENSEP_C

CCOMP_C

VOUT_C

IOUT_C

VSENSEN_C

HART_IN_C

VSENSEP_D

CCOMP_D

VOUT_D

IOUT_D

VSENSEN_D

HART_IN_D

12

JP16

15

R11

C48

DNI

15

R13

15

R15

12

JP26

4

1

2

3

J5

ED555/4DS

VPOS_A

75V

1

3

2

D17

BAV99-7-F

0.1µF

C54

1

2

JP18

1

2

JP19

1

2

JP20

12

JP17

15

R12

C49

DNI

15

R14

15

R16

12

JP27

4

1

2

3

J6

ED555/4DS

VPOS_B

75V

1

3

2

D18

BAV99-7-F

0.1µF

C55

VNEG_A VNEG_B

12

JP30

15

R25

C58

DNI

15

R27

15

R29

12

JP40

4

1

2

3

J7

ED555/4DS

VPOS_C

75V

1

3

2

D21

BAV99-7-F

0.1µF

C64

VNEG_C

12

JP31

15

R26

C59

DNI

15

R28

15

R30

12

JP41

4

1

2

3

J8

ED555/4DS

VPOS_D

75V

1

3

2

D22

BAV99-7-F

0.1µF

C65

VNEG_D

DNC

1

VIN

2

TEMP

3

GND

4

TRIM/NR

5

VOUT

6

NC

7

DNC

8

U2

REF5050IDGK

1

2

J9

VREFSUPPLY

10uF

C68

0.1µF

C70

1.50

R39

47µF

C72

EXT_VREF

OUT_A OUT_B

OUT_C OUT_D

1µF

C69

1µF

C60

1µF

C61

1µF

C52

1µF

C53

1µF

C62

1µF

C63

1µF

C71

1µF

C51

1µF

C50

1

2

JP21

0.022µF

C56

0.022µF

C66

0.022µF

C57

0.022µF

C67

1

2

JP22

1

2

JP23

1

2

JP24

1

2

JP25

1

2

JP36

1

2

JP37

1

2

JP38

1

2

JP39

1

2

JP32

1

2

JP33

1

2

JP34

1

2

JP35

600 ohm

FB9

600 ohm

FB10

600 ohm

FB11

600 ohm

FB12

300

R17

300

R18

300

R32

300

R31

324

R23

324

R34

324

R37

324

R20

249

R19

249

R22

249

R33

249

R36

1.00k

R21

1.00k

R24

1.00k

R35

1.00k

R38

36V

D19

36V

D20

36V

D23

36V

D24

1

2

JP28

1

2

JP42

1

2

JP43

1

2

JP29

GND

GND GND GND

GND

GND

GND GND

GND

GND

GND GND

GND GND

GND

GND

GND

GND GND GND

GND

GND

GNDGND

GND

GND

GND GND

GND GND

GND

GND

GND GND GND

Copyright © 2016, Texas Instruments Incorporated

PVDD/AVDD

100µH

L1

AGND_A

PVSS_A

PVDD_A

VPOS_IN_A

LN_A

LP_A

VNEG_IN_A

VNEG_IN_A

2k ohm

FB1

2k ohm

FB2

0.1µF

C5

1

2

3

JP1

1

2

3

JP2PVDD/AVDD AVSS

VPOS_A VNEG_A

0.1µF

C6

VPOS_IN_B

LN_B

LP_B

VNEG_IN_B

VNEG_IN_B

AGND_B

PVSS_B

PVDD_B

AGND_C

PVSS_C

PVDD_C

VPOS_IN_C

LN_C

LP_C

VNEG_IN_C

VNEG_IN_C

VPOS_IN_D

LN_D

LP_D

VNEG_IN_D

VNEG_IN_D

AGND_D

PVSS_D

PVDD_D

PVDD/AVDD

100µH

L2

2k ohm

FB3

2k ohm

FB4

0.1µF

C7

1

2

3

JP3

1

2

3

JP4PVDD/AVDD AVSS

VPOS_B VNEG_B

0.1µF

C8

PVDD/AVDD

100µH

L3

2k ohm

FB5

2k ohm

FB6

0.1µF

C25

1

2

3

JP5

1

2

3

JP6PVDD/AVDD AVSS

VPOS_C VNEG_C

0.1µF

C26

PVDD/AVDD

100µH

L4

2k ohm

FB7

2k ohm

FB8

0.1µF

C27

1

2

3

JP7

1

2

3

JP8PVDD/AVDD AVSS

VPOS_D VNEG_D

0.1µF

C28

VPOS_A VNEG_A VPOS_B VNEG_B

VPOS_D VNEG_DVPOS_C VNEG_C

10µFC310µF

C4

10µF

C16

10µF

C23

10µF

C24

10µF

C36

10µF

C35

10µF

C15

10µFC110µF

C2

10µF

C21

10µF

C22

1µF

C9

1µF

C10

1µF

C17

1µF

C18

1µF

C13

1µF

C19

1µF

C11

1µF

C12

1µF

C14

1µF

C20

1µF

C37

1µF

C38

1µF

C33

1µF

C30

1µF

C29

1µF

C39

1µF

C31

1µF

C32

1µF

C34

1µF

C40

10.0

R1

10.0

R2

10.0

R3

10.0

R4

10.0

R5

10.0

R6

10.0

R7

10.0

R8

D1

D3

D2

D4

D9

D11

D10

D12

36V

D5

36V

D6

36V

D7

36V

D8

36V

D13

36V

D14

36V

D15

36V

D16

GND

GND GND

GND

GNDGNDGNDGND

GND

GND

GND GND

GND

GNDGNDGNDGND

GND

GND

GND GND GND GND

GND

GNDGND

GND

GND

GND GND GND GND

GND

GNDGND

GND

Copyright © 2016, Texas Instruments Incorporated

EVM Documentation

www.ti.com

16

DAC8775EVM User’s Guide

Figure 13. DC-DC Schematic

Copyright © 2016, Texas Instruments Incorporated

Figure 14. Outputs Schematic

SBAU248–November 2016

Submit Documentation Feedback

Page 17

www.ti.com

5.2 EVM PCB Components Layout

Figure 15 shows the layout of the components for the EVM board.

EVM Documentation

Figure 15. DAC8775EVM PCB Components Layout

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

17

Page 18

EVM Documentation

5.3 EVM Board Bill of Materials

Table 5 lists the EVM board bill of materials.

QTY DESIGNATOR DESCRIPTION PARTNUMBER MANUFACTURER

1 !PCB1 Printed Circuit Board PA005 Any

15

15

31

12

10

33

C1, C2, C3, C4, C15, C16, C21, C22,

C23, C24, C35, C36, C44, C45, C46

C5, C6, C7, C8, C25, C26, C27, C28,

C41, C43, C54, C55, C64, C65, C70

C9, C10, C11, C12, C13, C14, C17,

C18, C19, C20, C29, C30, C31, C32,

C33, C34, C37, C38, C39, C40, C42,

C50, C51, C52, C53, C60, C61, C62,

C63, C69, C71

1 C47

4 C48, C49, C58, C59 DNI

4 C56, C57, C66, C67

1 C68

1 C72

8 D1, D2, D3, D4, D9, D10, D11, D12

D5, D6, D7, D8, D13, D14, D15, D16,

D19, D20, D23, D24

4 D17, D18, D21, D22

FB1, FB2, FB3, FB4, FB5, FB6, FB7,

8

FB8

4 FB9, FB10, FB11, FB12

1 J1

4 J2, J3, J4, J9

4 J5, J6, J7, J8

JP1, JP2, JP3, JP4, JP5, JP6, JP7,

JP8, JP10, JP12

JP9, JP11, JP13, JP14, JP15, JP16,

JP17, JP18, JP19, JP20, JP21, JP22,

JP23, JP24, JP25, JP26, JP27, JP28,

JP29, JP30, JP31, JP32, JP33, JP34,

JP35, JP36, JP37, JP38, JP39, JP40,

JP41, JP42, JP43

4 L1, L2, L3, L4

8 R1, R2, R3, R4, R5, R6, R7, R8

2 R9, R10

Table 5. EVM Board Bill of Materials

CAP, CERM, 10uF, 50V, +/10%, X7R, 1210 (H=2.5mm)

CAP, CERM, 0.1uF, 50V, +/10%, X7R, 0603

CAP, CERM, 1uF, 50V, +/10%, X7R, 0603

CAP, CERM, 200pF, 50V, +/5%, C0G/NP0, 0603

CAP, CERM, 0.022uF, 50V,

+/-10%, X7R, 0603

CAP CER 10UF 50V 20%

X7R 1210

CAP, CERM, 47uF, 25V, +/20%, X5R, 1206

Diode, Schottky, 60V, 1A,

SOD-123

Diode, TVS, Bi, 36V, 400W,

SOD323, 2-Leads, Body

1.9x1.45mm, No Polarity

Mark

Diode, Switching, 75V, 0.3A,

SOT-23

Ferrite Bead, 2000 ohm @

100MHz, 1.2A, 1210

(H=2.5mm)

Ferrite Bead, 600 ohm @

100MHz, 3A, 1210

(H=2.5mm)

Receptacle, 50mil 10x1, R/A,

TH

Terminal Block, 6A, 3.5mm

Pitch, 2-Pos, TH

Terminal Block, 6A, 3.5mm

Pitch, 4-Pos, TH

Header, TH, 100mil, 3x1,

Gold plated, 230 mil above

insulator

Header, TH, 100mil, 2x1,

Gold plated, 230 mil above

insulator

Inductor, Shielded Drum

Core, Ferrite, 100uH, 0.52A,

0.77 ohm, SMD

RES, 10.0 ohm, 1%, 0.1W,

0603

RES, 10k ohm, 5%, 0.1W,

0603

UMK325AB7106KM-T Taiyo Yuden

GRM188R71H104KA93

D

UMK107AB7105KA-T Taiyo Yuden

GRM1885C1H201JA01

D

C1608X7R1H223K TDK

UMK325AB7106MM-T Taiyo Yuden

C3216X5R1E476M160A

C

MBRX160-TP

CDSOD323-T36SC Bourns

BAV99-7-F Diodes Inc.

FB MH3225HM202NT Taiyo Yuden

FBMH3225HM601NT Taiyo Yuden

851-43-010-20-001000 Mill-Max

ED555/2DS

ED555/4DS

TSW-103-07-G-S Samtec, Inc.

TSW-102-07-G-S Samtec

74408943101

CRCW060310R0FKEA Vishay-Dale

CRCW060310K0JNEA Vishay-Dale

www.ti.com

MuRata

MuRata

TDK

Micro Commercial

Components

On-Shore

Technology

On-Shore

Technology

Wurth Elektronik

eiSos

18

DAC8775EVM User’s Guide

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Page 19

www.ti.com

EVM Documentation

Table 5. EVM Board Bill of Materials (continued)

QTY DESIGNATOR DESCRIPTION PARTNUMBER MANUFACTURER

12

16

10

R11, R12, R13, R14, R15, R16, R25,

R26, R27, R28, R29, R30

4 R17, R18, R31, R32

4 R19, R22, R33, R36

4 R20, R23, R34, R37

4 R21, R24, R35, R38

1 R39

TP1, TP2, TP3, TP4, TP5, TP6, TP7,

TP8, TP17, TP18, TP19, TP20, TP31,

TP32, TP33, TP34

TP9, TP10, TP11, TP12, TP13, TP14,

8

TP15, TP16

TP21, TP22, TP23, TP24, TP25,

TP26, TP27, TP28, TP29, TP30

1 U1

1 U2

1 U2

RES, 15 ohm, 5%, 0.1W,

0603

RES, 300, 0.1%, 0.25 W,

1206

RES, 249, 0.1%, 0.25 W,

1206

RES, 324, 0.1%, 0.25 W,

1206

RES, 1.00 k, 0.1%, 1 W, 1206

resistor

RES, 1.50 ohm, 1%, 0.1W,

0603

Test Point, Compact, Red, TH 5005 Keystone

Test Point, Compact, Yellow,

TH

Test Point, Compact, Black,

TH

Quad-Channel, 16-Bit

Programmable Current

Output and Voltage Output

Digital-to-Analog Converter

with Adaptive Power

Management, RMP0072A

Low-Noise, Very Low Drift,

Precision Voltage Reference,

DGK0008A

Low-Noise, Very Low Drift,

Precision Voltage Reference,

DGK0008A

CRCW060315R0JNEA Vishay-Dale

ERA-8AEB301V Panasonic

TNPW1206249RBEEA Vishay-Dale

ERA-8AEB3240V Panasonic

PHP01206E1001BST5 Vishay-Dale

CRCW06031R50FKEA Vishay-Dale

5009 Keystone

5006 Keystone

DAC8775RMP Texas Instruments

REF5050IDGK Texas Instruments

REF5050IDGK Texas Instruments

SBAU248–November 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

DAC8775EVM User’s Guide

19

Page 20

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2016, Texas Instruments Incorporated

Loading...

Loading...