Page 1

DAC8574 Evaluation Module

User’ s Gu ide

June 2003 Data Acquisition - Digital/Analog Converters

SLAU109

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products & application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Secruity www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 3

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR S TATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 4

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input and output voltage ranges described in the

EVM user’s guide.

Exceeding the specified input range may cause unexpected operation and/or irreversible

damage to the EVM. If there are questions concerning the input range, please contact a TI

field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or

possible permanent damage to the EVM. Please consult the EVM User’s Guide prior to

connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than

60°C. The EVM is designed to operate properly with certain components above 60°C as long

as the input and output ranges are maintained. These components include but are not limited

to linear regulators, switching transistors, pass transistors, and current sense resistors. These

types of devices can be identified using the EVM schematic located in the EVM User’s Guide.

When placing measurement probes near these devices during operation, please be aware

that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 5

About This Manual

Information About Cautions and Warnings

Preface

Read This First

This user’s guide describes the characteristics, operation, and the use of the

DAC8574 evaluation module. It covers all pertinent areas involved to properly

use this EVM board along with the devices that it supports. The physical PCB

layout, schematic diagram and circuit descriptions are included.

How to Use This Manual

This document contains the following chapters:

Chapter 1 —EVM Overview

Chapter 2—PCB Design and Performance

Chapter 3—EVM Operation

Information About Cautions and Warnings

This book may contain cautions and warnings.

The information in a caution or a warning is provided for your protection. Read

each caution and warning carefully.

This is an example of a caution statement.

A caution statement describes a situation that could potentially

damage your software or equipment.

This is an example of a warning statement.

A warning statement describes a situation that could potentially

cause harm to you

.

iii

Page 6

Trademarks

Related Documentation From Texas Instruments

To obtain a copy of any of the following TI documents, call the Texas

Instruments Literature Response Center (PIC) at (800) 477- 8924 or the

Product Information Center (PIC) at (972) 644-5580. When ordering, identify

this manual by its title and literature number. Updated documents can also be

obtained through our website at www.ti.com.

Data Sheets: Literature Number:

DAC8574 SLAS377A

REF02 SBVS-003A

OPA627 PDS-998H

OPA2132 PDS-1309B

Questions about this or other Data Converter EVM’s?

If you have questions about this or other Texas Instruments Data Converter

evaluation modules, feel free to e-mail the Data Converter Application Team

at dataconvapps@list.ti.com. Inlcude in the subject heading the product you

have questions or concerns with.

FCC Warning

Trademarks

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which

case the user at his own expense will be required to take whatever measures

may be required to correct this interference.

TI Logo is a trademark of Texdas Instruments Incorporated.

2

I

C is a trademark of Phillips Corporation.

iv

Page 7

Contents

Contents

1 EVM Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Features 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Power Requirements 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Supply Voltage 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Reference Voltage 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 EVM Basic Functions 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 PCB Design and Performance 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 PCB Layout 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 EVM Performance 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Bill of Materials 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 EVM Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Factory Default Setting 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Host Processor Interface 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 EVM Stacking 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 The Output Op-Amp 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Unity Gain Output 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Output Gain of Two 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Capacitive Load Drive 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Optional Signal Conditioning Op-Amp (U8B) 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Jumper Setting 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Schematic 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 8

Contents

Figures

1-1 EVM Block Diagram 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Top Silkscreen 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Layer 1 (Top Signal Plane) 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Layer 2 (Ground Plane) 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Layer 3 (Power Plane) 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Layer 4 (Bottom Signal Plane) 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Bottom Silkscreen 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Drill Drawing 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 DAC8574 EVM Test Parameters and Results 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 INL and DNL Characterization Graph of DAC A 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 INL and DNL Characterization Graph of DAC B 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 INL and DNL Characterization Graph of DAC C 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12 INL and DNL Characterization Graph of DAC D 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

2-1 Parts List 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Factory Default Jumper Setting 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 DAC Output Channel Mapping 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Unity Gain Output Jumper Settings 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Gain of Two Output Jumper Settings 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Capacitive Load Drive Output Jumper Settings 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Jumper Setting Functions 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 9

Chapter 1

EVM Overview

This chapter gives a general overview of the DAC8574 evaluation module

(EVM), and describes some of the factors that must be considered in using this

module.

Topic Page

1.1 Features 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Power Requirements 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 EVM Basic Functions 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVM Overview

1-1

Page 10

Features

1.1 Features

This EVM features the DAC8574 digital-to-analog converter (DAC). The

DAC8574 EVM is a simple evaluation module designed for a quick and easy

way to evaluate the functionality and performance of the high resolution,

quad-channel, and serial I

interface to communicate with any host microprocessor or TI DSP base

system.

1.2 Power Requirements

The following sections describe the power requirements of this EVM.

1.2.1 Supply Voltage

The dc power supply requirement for the digital section (VDD) of this EVM is

typically 5 V connected to the J5-1 or via J6-10 terminal (when plugged in with

another EVM board or interface card) and is referenced to ground through the

J5 -2 and J6 - 5 terminal. The dc power supply requirements for the analog

section of this EVM are as follows; the V

- 15.75 V maximum and connects through J1 - 3 and J1 -1 respectively, or

through J6-1 and J6-2 terminals. The 5 VA connects through J5-3 or J6-3

and the 3.3 VA connects through J6-8. All of the analog power supplies are

referenced to analog ground through J1-2 and J6-6 terminals.

2

C input DAC. This EVM features a serial I2C

and VSS ranges from 15.75 V to

CC

The device under test, U1, analog power supply can be powered by either 5 VA

or 3.3 VA by selecting the proper position of jumper W1. This allows the

DAC8574 analog section to operate in either supply power while the I/O and

digital section is powered by 5 V, V

The V

supply source is mainly used to provide the positive rail of the external

CC

DD

.

output op-amp, U2, the reference chip, U3 and the reference buffer, U8. The

negative rail of the output op-amp, U2, can be selected between V

SS

and

AGND via W5 jumper. The external op-amp is installed as an option to provide

output signal conditioning or boost capacitive load drive and for other output

mode requirement desired.

Caution

To avoid potential damage to the EVM board, make sure that the

correct cables are connected to their respective terminals as

labeled on the EVM board.

Stresses above the maximum listed voltage ratings may cause

permanent damage to the device.

1-2

Page 11

1.2.2 Reference Voltage

The 5-V precision voltage reference is provided to supply the external voltage

reference for the DAC through REF02, U3, via jumper W4 by shorting pins 1

and 2. The reference voltage goes through an adjustable 100 kΩ

potentiometer, R11, in series with 20 kΩ, R10, to allow the user to adjust the

reference voltage to its desired settings. The voltage reference is then

buffered through U8A as seen by the device under test. The test points TP1,

TP2 and TP5 are also provided, as well as J4-18 and J4-20, to allow the user

to connect other external reference source if the onboard reference circuit is

not desired. The external voltage reference should not exceed 5-V dc.

EVM Basic Functions

The REF02 precision reference is powered by V

J6-1 terminal.

Caution

When applying an external voltage reference through TP1 or J4-20,

make sure that it does not exceed 5 V maximum. Otherwise, this

can permanently damage the DAC8574, U1, device under test.

1.3 EVM Basic Functions

The DAC8574 EVM is designed primarily as a functional evaluation platform

to test certain functional characteristics of the DAC8574 DAC. Functional

evaluation of the DAC device can be accomplished with the use of any

microprocessor, TI DSP, or some sort of a waveform generator.

The headers J2 and P2 are the connectors provided to allow the control signals

and data required to interface a host processor or waveform generator to the

DAC8574 EVM using a custom built cable.

A specific adapter interface card is also available for most of TI’s DSP starter

kit (DSK) and the card model depend on the type of the TI DSP starter kit to

be used. Make sure to specify the DSP that is used to interface with to acquire

the right adapter interface card. In addition, there is also an MSP430 based

platform (HPA449) that uses the MSP430F449 microprocessor, which this

EVM can connect to and interface with. For more details or information

regarding the adapter interface card or the HPA449 platform, please call T exas

Instruments Inc. or email us at dataconvapps@list.ti.com.

(15 V) through J1 -3 or

CC

The DAC outputs can be monitored through the selected pins of J4 header

connector. All the outputs can be switched through their respective jumpers

W2, W1 1, W12 and W13, for the reason of stacking. Stacking allows a total of

eight DAC channels to be used provided that the I

each EVM board stacked.

In addition, the option of selecting one DAC output that can be fed to the

noninverting side of the output op-amp, U2, is also possible by using a jumper

across the selected pins of J4. The output op-amp, U2, must first be configured

correctly for the desired waveform characteristic, refer to Section 3 of this

user’s guide.

2

C address is unique for

EVM Overview

1-3

Page 12

EVM Basic Functions

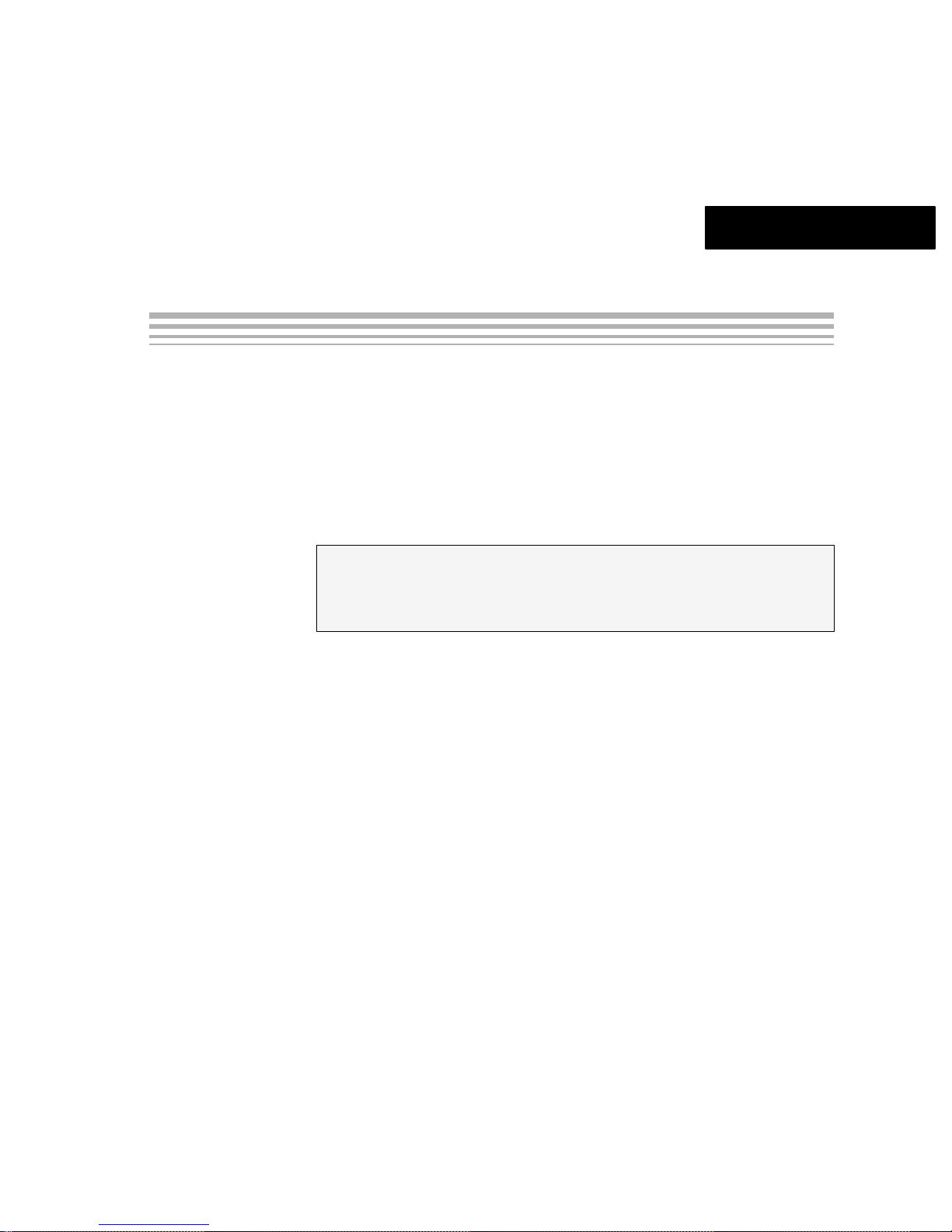

A block diagram of the EVM is shown in Figure 1-1.

Figure 1-1. EVM Block Diagram

DAC Out

TP3

Module

Buffer

Output

W5

VSS

(J4)

(P4)

W3

V

W15

8 CH

REF

VCC

VDD

5 VA

(J1)

(J5)

(J6)

(P6)

(J2)

(P2)

L

TP5

VSS

3.3 VA

External

Reference

Module

TP1

W2

W11

W12

W13

H

4 CH

TP2

W4

V

H

REF

DAC Module

A0 A2

A1

W9W7

W8

A3

V

W10

REF

W6

VCC

GND

VSS

GND

VDD

A0

A1

A2

A3

SDA

SCL

LDAC

1-4

Page 13

Chapter 2

PCB Design and Performance

This chapter describes the layout design of the PCB, thereby, describing the

physical and mechanical characteristics of the EVM. This section also shows

the resulting performance of the EVM, which can be compared to the device

specification listed in the data sheet. The list of components used on the

module is also included in this section.

Topic Page

2.1 PCB Layout 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 EVM Performance 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Bill of Materials 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCB Design and Performance

2-1

Page 14

PCB Layout

2.1 PCB Layout

The DAC8574 EVM is designed to preserve the performance quality of the

DAC, device under test, as specified in the data sheet. Carefully analyzing the

EVM’s physical restrictions and the given or known elements that contributes

to the EVM’s performance degradation is the key to a successful design

implementation. These obvious attributes that diminish the performance of the

EVM can be taken care of during the schematic design phase, by properly

selecting the right components and building the circuit correctly. The circuit

must include adequate bypassing, identifying and managing the analog, and

digital signals and knowing or understanding the components mechanical

attributes.

The obscure part of the design is the layout process where lack of knowledge

and inexperience can easily present a problem. The main concern here is

primarily with the placement of components and the proper routing of signals.

The bypass capacitors should be placed as close as possible to the pins and

the analog and digital signals should be properly separated from each other.

The power and ground plane is very important and must be carefully

considered in the layout process. A solid plane is ideally preferred but

sometimes impractical, so when solid planes are not possible, a split plane can

do the job as well. When considering a split plane design, analyze the

component placement and carefully split the board into its analog and digital

sections starting from the device under test. The ground plane plays an

important role in controlling the noise and other effects that otherwise

contributes to the error of the DAC output. To ensure that the return currents

are handled properly, route the appropriate signals only in their respective

sections, meaning the analog traces should only lay directly above or below

the analog section and the digital traces in the digital section. Minimize the

length of the traces, but use the biggest possible trace width allowable in the

design. These design practices discussed can be seen in the following figures

presented on the following pages.

2-2

The DAC8574 EVM board is constructed on a four-layer printed-circuit board

using a copper-clad FR-4 laminate material. The printed-circuit board has a

dimension of 43,1800 mm (1.7000 inch) X 82,5500 mm (3.2500 inch), and the

board thickness is 1,5748 mm (0.0620 inch). Figures 2-1 through 2-6 show

the individual artwork layers.

Page 15

Figure 2-1. Top Silkscreen

Figure 2-2. Layer 1 (Top Signal Plane)

PCB Layout

Figure 2-3. Layer 2 (Ground Plane)

PCB Design and Performance

2-3

Page 16

PCB Layout

Figure 2-4.Layer 3 (Power Plane)

Figure 2-5. Layer 4 (Bottom Signal Plane)

Figure 2-6. Bottom Silkscreen

2-4

Page 17

Figure 2-7.Drill Drawing

PCB Layout

PCB Design and Performance

2-5

Page 18

EVM Performance

2.2 EVM Performance

The EVM performance test is performed using a high density DAC bench test

board, an Agilent 3458A digital multimeter, and a PC running the LABVIEW

software. The EVM board is tested for all codes of 65535 and the device under

test (DUT) is allowed to settle for 1ms before the meter is read. This process

is repeated for all codes to generate the measurements for INL and DNL

results and is shown in Figure 2-9.

The parameters and results of the DAC8574 EVM characterization test can be

seen in Figure 2-8.

Figure 2-8. DAC8574 EVM Test Parameters and Results

2-6

Page 19

Figure 2-9. INL and DNL Characterization Graph of DAC A

EVM Performance

PCB Design and Performance

2-7

Page 20

EVM Performance

Figure 2-10. INL and DNL Characterization Graph of DAC B

2-8

Page 21

Figure 2-11. INL and DNL Characterization Graph of DAC C

EVM Performance

PCB Design and Performance

2-9

Page 22

EVM Performance

Figure 2-12. INL and DNL Characterization Graph of DAC D

2-10

Page 23

2.3 Bill of Materials

Table 2-1.Parts List

Bill of Materials

Item #

1 2 C9 C10 Panasonic ECUV1H105JCH 1 µF, 1206 Multilayer ceramic

2 4 C1 C2 C3 C7 Panasonic ECJ3VB1C104K 0.1 µF, 1206 Multilayer ceramic

3 1 C12 Panasonic ECUV1H102JCH 1 nF, 1206 Multilayer ceramic

4 3 C5 C6 C11 Kemet C1210C106K8PAC 10 µF, 1210 Multilayer ceramic

5 17 R8 R17 R25 R26

6 2 R15 R16 Panasonic ERJ-8GEYJ431V 430 Ω, 1/4W 1206 Chip resistor

7 1 R13 Panasonic ERJ-8GEYJ101V 100 Ω, 1/4W 1206 Chip resistor

8 1 R10 Panasonic ERJ-8ENF2002V 20 kΩ, 1/4W 1206 Chip resistor

9 6 R1 R2 R3 R4 R5R7Panasonic ERJ-8GEYJ302V 3 kΩ, 1/4W 1206 Chip resistor

10 3 R6 R12 R14 Panasonic ERJ-8ENF1002V 10 kΩ, 1/4W 1206 Chip resistor

11 1 R9 Bourns 3214W-203E 20 kΩ, BOURNS_32X4W Series

12 1 R11 Bourns 3214W-104E 100 kΩ, BOURNS_32X4W Series

13 1 J6 Samtec TSM-105-01-T-DV 5X2X0.1, 10-pin 3A isolated power

14 2 J2 J4 Samtec TSM-110-01-S-DV-M 10X2X.1, 20 pin 0.025”sq SMT

15 2 J1 J5 On-Shore

16 1 U1 Texas Instruments DAC8574IPW 16 Bit, quad voltage output, serial

17 1 U2 Texas Instruments OPA627AU 8-SOP(D) precision op amp

18 1 U3 Texas Instruments REF02AU +5V, 8-SOP(D) precision voltage

19 1 U8 Texas Instruments OPA2132UA 8-SOP(D) dual precision op amp

20 7 TP1 TP2 TP3 TP4

21 2 P2 P4 (see Note) Samtec SSW-110-22-S-D-VS-P 20 Pin 0.025”sq SMT terminal

22 1 P6 (see Note) Samtec SSW-105-F-D-VS-K 3A Isolated 10-pin power header

23 6 W3 W7 W8 W9

24 8 W1 W2 W4 W5

Note: P2, P4 & P6 parts are not shown in the schematic diagram. All the P designated parts are installed in the bottom side of the

PC Board opposite the J designated counterpart. Example, J2 is installed on the topside while P2 is installed in the bottom

side opposite of J2.

Designator Manufacturer Part Number Description

Qty

R27 R28 R29 R30

R31 R32 R33 R34

R35 R36 R37 R38

R39

TP5 TP6 TP7

W10 W15

W6 W11 W12

W13

Panasonic ERJ-8GEY0R00V 0 Ω, 1/4W 1206 Chip resistor

ED555/3DS 3-Pin terminal connector

Technology

Mill-max 2348-2-01-00-00-07-0 Turret terminal test point

Molex 22-03-2021 2 Position jumper_ 0.1” spacing

Molex 22-03-2031 3 Position Jumper_ 0.1” spacing

capacitor

capacitor

capacitor

X5R capacitor

5T Pot

5T Pot

socket

socket

2

input I

C DAC, TSSOP-16

reference

strips

PCB Design and Performance

2-11

Page 24

2-12

Page 25

Chapter 3

EVM Operation

This chapter covers in detail the operation of the EVM to provide guidance to

the user in evaluating the onboard DAC and how to interface the EVM to a

specific host processor.

Refer to the DAC8574 data sheet (SLAS377A), for information about its serial

interface and other related topics.

The EVM board is factory tested and configured to operate in the bipolar output

mode.

Topic Page

3.1 Factory Default Setting 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Host Processor Interface 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 EVM Stacking 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 The Output Op Amp 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Optional Signal Conditioning Op Amp (U8B) 3-5. . . . . . . . . . . . . . . . . . . .

3.6 Jumper Setting 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Schematic 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVM Operation

3-1

Page 26

Factory Default Setting

3.1 Factory Default Setting

The EVM board is set to its default configuration from the factory as described

in Table 3 - 1 to operate in gain of 2 configuration (0 V to +10-V) mode of

operation.

Table 3-1.Factory Default Jumper Setting

Jumper

Reference

W1 1-2 Analog supply for the DAC8574 is +5VA.

W2 1-2 DAC output A (V

W3 OPEN V

W4 1-2 Onboard external buffered reference U3 is routed to V

W5 1-2 Negative supply rail of U2 op-amp is supplied with VSS.

W6 1-2 V

W7 CLOSE A0 pin is tied to DGND.

W8 CLOSE A1 pin is tied to DGND.

W9 CLOSE A3 pin is tied to DGND.

W10 CLOSE A2 pin is tied to DGND.

W11 1-2 DAC output B (V

W12 1-2 DAC output C (V

W13 1-2 DAC output D (V

W15 CLOSE Output op amp, U2, is configured for a gain of 2.

J4 1-2 DAC output A (V

Position

A) is routed to J4-2.

OUT

H is not routed to the inverting input of the op amp.

REF

L is tied to AGND.

REF

B) is routed to J4-4.

OUT

C) is routed to J4-6.

OUT

D) is routed to J4-8.

OUT

A) is connected to the noninverting input of the output op-amp, U2.

OUT

Function

REF

H.

3.2 Host Processor Interface

The host processor basically drives the DAC, so the DAC’s proper operation

depends on the successful configuration between the host processor and the

EVM board. In addition, a properly written code is also required to operate the

DAC.

A custom cable can be made specific to the host interface platform. The EVM

allows interface to the host processor through J2 header connector for the

serial control signals and the serial data input. The output can be monitored

through the J4 header connector.

An interface adapter card is also available for the specific TI DSP starter kit as

well as an MSP430 based microprocessor as mentioned in chapter 1 of this

manual. Using the interface card alleviates the tedious task of building

customize cables and allows easy configuration of a simple evaluation

system.

The DAC8574 interfaces with any host processor capable of handling I

protocols or the popular TI DSP. For more information regarding the DAC8574

data interface, refer to the data sheet (SLAS377A).

2

C

3-2

Page 27

3.3 EVM Stacking

The stacking of EVMs is possible if there is a need to evaluate two DAC8574s

to yield a total of eight channel outputs. A maximum of two EVMs are allowed

since the output terminal, J4, dictates the number of DAC channels that can

be connected without colliding. Table 3-2 shows how the DAC output

channels are mapped into the output terminal, J4, with respect to the jumper

position of W2, W11, W12 and W13.

Table 3-2.DAC Output Channel Mapping

Reference Jumper Position Function

W2

W11

W12

W13

1-2 DAC output A (V

2-3 DAC output A (V

1-2 DAC output B (V

2-3 DAC output B (V

1-2 DAC output C (V

2-3 DAC output C (V

1-2 DAC output D (V

2-3 DAC output D (V

A) is routed to J4-2.

OUT

A) is routed to J4-10.

OUT

B) is routed to J4-4.

OUT

B) is routed to J4-12.

OUT

C) is routed to J4-6.

OUT

C) is routed to J4-14.

OUT

D) is routed to J4-8.

OUT

D) is routed to J4-16.

OUT

EVM Stacking

In order to allow exclusive control of each EVM that are stacked together, each

DAC8574 EVM must have its own unique I

by configuring the address jumpers W7 through W10 (refer to the data sheet

2

C addressing).

for I

The LDAC signal can be shared to have a synchronous DAC output update

and is hardware driven by GPIO0. If controlling the LDAC through software is

desired, the GPIO0 signal must be set low through software or the J2 pin 2 can

be pin strapped to DGND.

3.4 The Output Op-Amp

The EVM includes an optional signal conditioning circuit for the DAC output

through an external operational amplifier, U2. Only one DAC output channel

can be monitored at any given time for evaluation since the odd numbered pins

(J4 - 1 to J4 -15) are tied together. The output op-amp is set to a gain of 2

configuration by default. Nevertheless, the raw outputs of the DAC can be

probed through the even pins of J4, the output terminal, which also provides

mechanical stability when stacking or plugging into any interface card. In

addition, it provides easy access for monitoring up to eight DAC channels

when stacking two EVMs together, refer to Section 3.3 above.

The following sections describe the different configurations of the output

amplifier, U2.

2

C address. This is accomplished

EVM Operation

3-3

Page 28

The Output Op-Amp

3.4.1 Unity Gain Output

The buffered output configuration can be used to prevent loading the

DAC8574, though it may present some slight distortion because of the

feedback resistor and capacitor . Users can tailor the feedback circuit to closely

match their desired wave shape by simply desoldering R7 and C11 and

replacing it with the desired values. You can also simply get rid of R7 and C11

altogether, and just solder a 0-Ω resistor in replacement of R7, if desired.

Table 3-3 shows the jumper setting for the unity gain configuration of the DAC

external output buffer in unipolar or bipolar mode.

Table 3-3.Unity Gain Output Jumper Settings

Reference

W3 OPEN OPEN Disconnect V

W5 2-3 1-2 Supplies VSS to the negative rail of op-amp or ties it to AGND.

W15 OPEN OPEN Disconnect negative input of op-amp from AGND.

Jumper Setting

Unipolar Bipolar

Function

H from the inverting input of the op-amp.

REF

3.4.2 Output Gain of Two

There are two types of configurations that yield a gain of two output depending

on the setup of the jumpers W3 and W15. These configurations allow the user

to choose whether the DAC output has V

H as an offset or not.

REF

Table 3-4 shows the proper jumper settings of the EVM for the 2× gain output

of the DAC.

Table 3-4.Gain of Two Output Jumper Settings

Reference

W3

W5 2-3 1-2

W15

Jumper Setting

Unipolar Bipolar

Close Close

Open Open

Close Close

Open Open

Function

Inverting input of the output op-amp, U2, is connected to V

as its offset voltage with a gain of 2. W15 jumper must be open.

V

H is disconnected from the inverting input of the output op-amp,

REF

U2. W15 jumper must be close.

Supplies power, VSS, to the negative rail of op-amp, U2, for bipolar

mode, or ties it to AGND for unipolar mode.

Configures op-amp, U2, for a gain of 2 output without a voltage offset.

W3 jumper must be open.

Inverting input of the op-amp, U2, is disconnected from AGND. W3

jumper must be close.

REF

H for use

3.4.3 Capacitive Load Drive

Another output configuration option is to drive a wide range of capacitive load

requirement. However, all op-amps under certain conditions may become

unstable depending on the op-amp configuration, gain, and load value. These

are just few factors that can affect op-amps stability performance and must be

considered when implementing.

3-4

Page 29

Optional Signal Conditioning Op-Amp (U8B)

In unity gain, the OPA627 op-amp, U2, performs very well with very large

capacitive loads. Increasing the gain enhances the amplifier’s ability to drive

even more capacitance, and adding a load resistor would even improve the

capacitive load drive capability.

Table 3-5 shows the jumper setting configuration for a capacitive load drive.

Table 3-5.Capacitive Load Drive Output Jumper Settings

Reference

W3 Close Close

W5 2-3 1-2

W15 Close Open

Jumper Setting

Unipolar Bipolar

V

H is disconnected from the inverting input of the output op-amp,

REF

U2.

Supplies power, VSS, to the negative rail of op-amp, U2, for bipolar

mode, or ties it to AGND for unipolar mode.

Capacitive load drive output of DAC is routed to pin 1 of W15 jumper and

maybe used as the output terminal.

3.5 Optional Signal Conditioning Op-Amp (U8B)

One part of the dual package op-amp, OPA2132 (U8), is used for reference

buffering (U8A) while the other is unused. This unused op-amp (U8B) is left

for whatever op-amp circuit application the user desires to implement. The

1206 footprint for the resistors and capacitors surrounding the U8B op-amp

are not populated and made available for easy configuration. TP6 and TP7 test

points are not installed either so it is up to the user on how to connect the ± input

signals to this op-amp. No test point has been made available for the output

due to space restriction, but a wire can be simply soldered to the output of the

op-amp via unused component pads that connects to it.

Function

Once the op-amp circuit is realized the configuration becomes easy by simply

populating the corresponding components that matches the circuit designed

and leaving all other unused component footprints unpopulated.

EVM Operation

3-5

Page 30

Jumper Setting

3.6 Jumper Setting

Table 3-6 shows the function of each specific jumper setting of the EVM.

Table 3-6.Jumper Setting Functions

Reference

W1

W2

W3

W4

W5

W6

W7

Jumper

Setting

1 3

1 3

1 3

1 3

1 3

1 3

1 3

1 3

1 3

1 3

Function

+5-V analog supply is selected for AVDD.

+3.3-V analog supply is selected for AVDD.

Routes V

Routes V

Disconnects V

Connects V

Routes the adjustable, buffered, onboard +5-V reference to the V

A to J4-2.

OUT

A to J4-10.

OUT

H to the inverting input of the output op-amp, U2

REF

H to the inverting input of the output op-amp, U2

REF

H input of the

REF

DAC8574.

Routes the user supplied reference from TP1 or J4 - 20 to the V

H input of the

REF

DAC8574.

Negative supply rail of the output op-amp, U2, is powered by VSS for bipolar operation.

Negative supply rail of the output op-amp, U2, is tied to AGND for unipolar operation.

V

L is tied to AGND.

REF

Routes the user supplied negative reference from TP2 or J4-18 to the V

of the DAC8574. This voltage should be within the range of 0V to V

REF

H.

REF

L input

A0 pin is set high through pullup resistor, R4. A0 can be driven by GPIO5.

A0 pin is set low.

A1 pin is set high through pullup resistor, R3. A1 can be driven by GPIO4.

W8

A1 pin is set low.

A3 pin is set high through pullup resistor, R2. A3 can be driven by GPIO1.

W9

LDAC pin is set low and DAC update is accomplished via software.

A2 pin is set high through pullup resistor, R1. A2 can be driven by GPIO3.

W10

A2 pin is set low.

W11

1 3

1 3

Routes V

Routes V

3-6

B to J4-4.

OUT

B to J4-12.

OUT

Page 31

Schematic

Reference Function

W12

W13

Jumper

Setting

1 3

1 3

1 3

1 3

Routes V

Routes V

Routes V

Routes V

C to J4-6.

OUT

C to J4-14.

OUT

D to J4-8.

OUT

D to J4-16.

OUT

Disconnects the inverting input of the output op amp, U2, from AGND.

W15

Connects the inverting input of the output op amp, U2, to AGND for gain of 2.

Legend: Indicates the corresponding pins that are shorted or closed.

3.7 Schematic

The schematic is located on the following page.

EVM Operation

3-7

Page 32

1 2 3 4 56

A

B

C

D

6

54321

D

C

B

A

ti

12500 TI Boulevard. Dallas, Texas 75243

Title:

SHEET: OF:

FILE: SIZE:

DATE:

REV:

13-Jun-2003

Drawn By:

Engineer:

Revision History

REV ECN Number Approved

DAC8534 RevA.Sch

DOCUMENTCONTROL #

C1

0.1µF

C2

0.1µF

+5VA

SCLK

R6

10K

VSS

2

3

6

4

71

5

U2

Op Amp

VCC

C10

1µF

C9

1µF

R12

10K

C12

1nF

W5

R8

0

GND

4

TRIM

5

NC

1

NC

7

NC

8

TEMP

3

OUT

6

V+

2

U3

REF02AU(8)

C11

10µF

C3

0.1µF

VCC

1

3

TP1

TP2

EXTERNAL

REFERENCE

1

2

3

R11

100K

R10

20K

1

2

3

R9

20K

VCC VDD

VDD

W4

12

34

56

78

910

1112

1314

1516

1718

1920

J4

OUTPUT HEADER

VrefH

FSX

C6

10µF

C5

10µF

DAC8534_74 EVM

A

J. PARGUIAN

W7

W10

W8

VSS

+REFin

+REFin

W9

Tantalum

1

SDI

CLKX

DX

CLKR

FSR

DR

VoutB

2

IO_V/DVDD

12

A3/LDAC

16

A1

14

GND

6

VrefH

3

VrefL

5

VoutA

1

A2/EN

15

A0

13

VoutD

8

SDA/Din

11

SCL/SCLK

10

LDAC/SYNC

9

AVDD

4

VoutC

7

U1

DAC7574/8534/8574

VDD

R15 440/0

R16 440/0

R53KR7

3K

R1

10KR210KR310KR410K

-REFin

W2

OUT_A1

OUT_C1

OUT_B1

OUT_D1

OUT_A2

OUT_B2

OUT_C2

OUT_D2

OUT_A

OUT_B

OUT_C

OUT_D

2

3

1

84

U8A

OPA2227UA

5

6

7

U8B

OPA2227UA

R17

0

TP5

-REFin

VrefH

R14

10K

VrefH

VCC

C7

0.1µF

TP3

VOUT

U2_+IN

U2_-IN

U2_OUT

VrefL

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

201719

18

J2

Serial Header

W6

VrefL

TP4

R23

NI

R22

NI

R21

NI

R20

NI

R24

NI

C13

NI

C8

NI

R19

NI

R18

NI

VCC = +15V Analog

VDD = +2.7V to +5.0V Digital

VSS = 0V to -15V Analog

TP6

+Vin

TP7

-Vin

123

J1

123

J5

+5VA

NOTE: Voltage range of -REFin input should not exceed

0 - VrefH.

VCC

1 2

3 4

5 6

7 8

9 10

J6

VSS+5VA -5VA VDD+3.3VD+1.8VD +3.3VA

GPIO0

GPIO1

SCL

SDA

R25

0

R26

0

GPIO2

GPIO3

GPIO0

GPIO1

GPIO2

GPIO3

R27

0

R28

0

GPIO4

GPIO5

GPIO4

GPIO5

R31

0

R32

0

R33

0

R29

0

R30

0

FSX

GPIO0

(LDAC)

(LDAC)

(SYNC)

(A3)

(EN)

(A2)

(A1)

(A0)

(LDAC)

(A3)

(EN)

(A2)

(A1)

(A0)

R34

0

R35

0

SCLK

SDI

R36

0

R37

0

DX

CLKX

R38

0

R39

0

W1

+3.3VA

AVDD

W11

W12

W13

6447711

R13

100

W15

W3

Page 33

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

DAC8574EVM

Loading...

Loading...