Page 1

DAC5674 EVM

User’ s Gu ide

September 2003 Wireless Infrastructure Products

SWRU007

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 3

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR S TATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 4

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within an input voltage range of 0 V to 3.3 V.

Exceeding the specified input range may cause unexpected operation and/or irreversible

damage to the EVM. If there are questions concerning the input range, please contact a TI

field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or

possible permanent damage to the EVM. Please consult the EVM User’s Guide prior to

connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than

40°C. The EVM is designed to operate properly with certain components above 40°C as long

as the input and output ranges are maintained. These components include but are not limited

to linear regulators, switching transistors, pass transistors, and current sense resistors. These

types of devices can be identified using the EVM schematic located in the EVM User’s Guide.

When placing measurement probes near these devices during operation, please be aware

that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 5

Contents

Contents

1 Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Purpose 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 EVM Basic Functions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Power Requirements 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 DAC5674 EVM Operational Procedure 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 PCB Layout and Parts List 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 PCB Layout 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Parts List 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Circuit Description 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Circuit Function 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Input Clock 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Input Data 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Output Data 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Internal Reference Operation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5 External Reference Operation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6 Sleep Mode 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7 Filter Control 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.8 PLL Divider Control 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Schematics 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

2−1 DAC5674 EVM Parts List 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−1 EVM Clock Configuration 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−2 Input Connector J8 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−3 Transformer Output Configuration 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 6

Contents

Figures

2−1 Top Layer 1 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 Ground Plane 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−3 Power Plane 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−4 Bottom Layer 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 7

Chapter 1

Overview

This user’s guide document gives a general overview of the DAC5674

evaluation module (EVM) and provides a general description of the features

and functions to be considered while using this module.

Topic Page

1.1 Purpose 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 EVM Basic Functions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Power Requirements 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 DAC5674 EVM Operational Procedure 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

1-1

Page 8

Purpose

1.1 Purpose

The DAC5674 EVM provides a platform for evaluating the DAC5674

digital-to-analog converter (DAC) under various signal, reference, and supply

conditions. This document should be used in combination with the EVM

schematic diagram supplied.

1.2 EVM Basic Functions

Digital inputs to the DAC can be provided with CMOS level signals up to

200 MSPS through a 40-pin header. This enables the user to provide

high-speed digital data to the DAC5674.

The analog output from the DAC is available via SMA connectors. Because

of its flexible design, the analog output of the DAC5674 can be configured to

drive a 50- Ω terminated cable using a 4:1 or 1:1 impedance ratio transformer,

or single-ended referred to GND.

The EVM allows for different clock configurations. The user can input a

differential ECL/PECL or TTL/CMOS level signal, to be used to generate a

single-ended or differential clock source. See the clock section for proper

configuration and operation.

Power connections to the EVM are via banana jack sockets. Separate sockets

are provided for the analog, digital, PLL, and I/O supply.

In addition to the internal bandgap reference provided by the DAC5674 device,

options on the EVM allow external reference to be provided to the DAC.

1.3 Power Requirements

The demonstration board has four power inputs. The first, +3.3VA, is required

to be +3.3 Vdc at banana jack J9 with the return going to J11. This is the analog

supply for the DAC5674. The second, +1.8 VD, is required to be +1.8 Vdc at

banana jack J14 with the return to J16. This is the digital +1.8-V supply for the

DAC5674. The third, +3.3VCLK, is required to be +3.3 Vdc at banana jack J10

with the return at J13. This is the digital supply for the internal PLL circuitry. The

fourth, +1.8/3.3VD_IO, is required to be either +1.8 or +3.3 Vdc at banana jack

J12 with the return at J15. This is the supply for the digital I/Os. The EVM can

be powered using only two supplies, but powering from four separate supplies

provides higher performance.

Note: Voltage Limits

Exceeding the maximum input voltages can damage EVM components.

Undervoltage may cause improper operation of some or all of the EVM

components.

1-2

Page 9

1.4 DAC5674 EVM Operational Procedure

The DAC5674 EVM can be set up in a variety of configurations to

accommodate a specific mode of operation. Before starting evaluation, the

user should decide on the configuration and make the appropriate

connections or changes. The demonstration board comes with the following

factory-set configuration:

- Differential clock mode using transformer T2 and a clock input at J4

- Transformer coupled output using transformer T1

- The converter is set to operate with internal reference. Jumper W2 is

installed between pins 1 and 2.

DAC5674 EVM Operational Procedure

- Full-scale output current set to 20 mA through R

- The DAC5674 output is enabled (sleep mode disabled). Jumper W3 is

resistor R1

BIAS

installed between pins 1 and 2.

- Reset operation controlled through S1. Jumper W5 is installed between

pins 2 and 3.

- Internal PLL is disabled. Jumper W4 is installed between pins 1 and 2.

Overview

1-3

Page 10

1-4

Page 11

Chapter 2

PCB Layout and Parts List

This chapter describes the physical characteristics and PCB layout of the EVM

and lists the components used on the module.

Topic Page

2.1 PCB Layout 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Parts List 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCB Layout and Parts List

2-1

Page 12

PCB Layout

2.1 PCB Layout

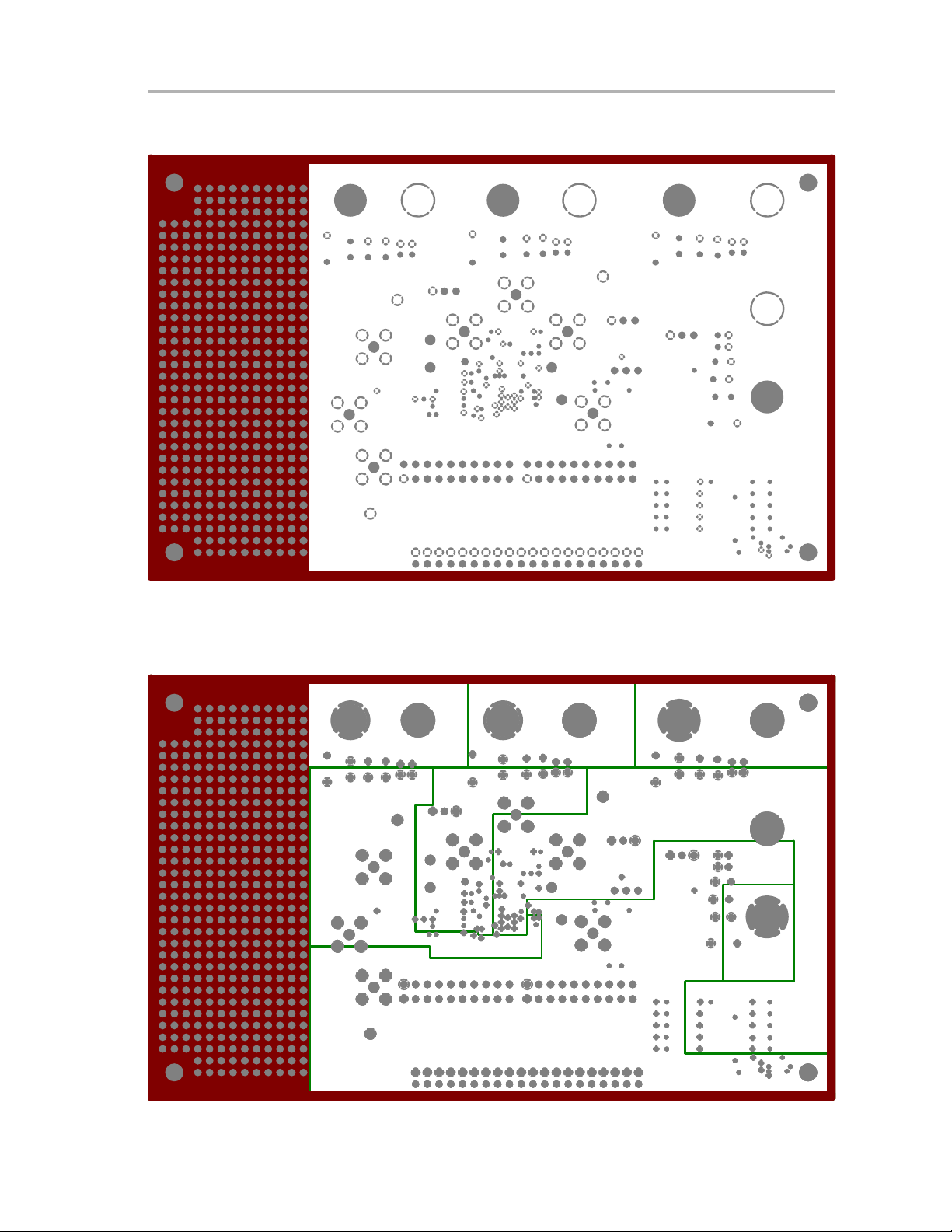

Figure 2−1.Top Layer 1

The EVM is constructed on a 4-layer, 3.3-inch × 5.75-inch, 0.062-inch thick

PCB using FR-4 material. Figure 2−1 through Figure 2−4 show the PCB layout

for the EVM.

2-2

Page 13

Figure 2−2.Layer 2, Ground Plane

PCB Layout

Figure 2−3.Layer 3, Power Plane

PCB Layout and Parts List

2-3

Page 14

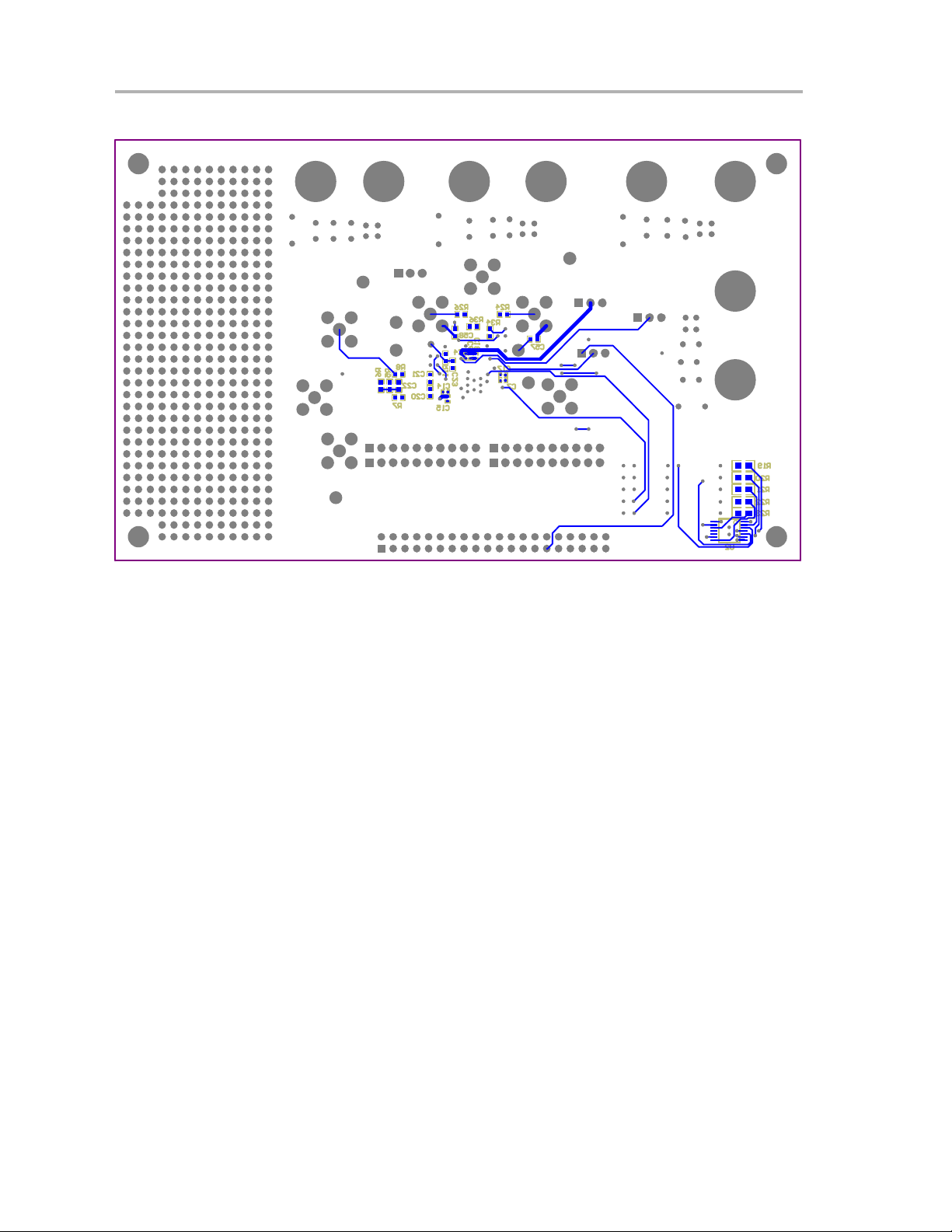

PCB Layout

Figure 2−4.Bottom Layer

2-4

Page 15

Parts List

2.2 Parts List

Table 2−1 lists the parts used in constructing the EVM.

Table 2−1.DAC5674 EVM Parts List

Ref. Des.

Description Qty. Part Number Mfg.

22-pF, 50-V, 5% capacitor 0 06035A220JAT2A AVX C20, C21

100-pF, 50-V, 5% capacitor 1 ECU-V1H101JCG Panasonic C23

0.01-µF, 16-V, 10% capacitor 2 06035A103KAT2A AVX C24, C52 C25, C55, C56

0.01-µF, 100-V, 5% capacitor 4 08055C103KAT2A AVX C42−C45

0.1-µF, 16-V, 10% capacitor 17 08055C104JAT2A AVX C1 −C7, C10,

0.1-µF, 100-V, 10% capacitor 4 ECJ-2VB1C104K Panasonic C38−C41

1-µF, 16-V, 10% capacitor 4 ECJ-3YB1C105K Panasonic C34−C37

10-µF, 10-V, 10% capacitor 4 GRM42X5R106K10 Murata C30−C33

47-µF, 10-V, 10%, tantalum

capacitor

DAC5674 1 DAC5674IDW TI U1

Ferrite bead 4 D01608C-472 Coil Craft FB1−FB4

3POS header 4 TSW-150-07-L-S Samtec W2−W5

40-pin header 1 TSW-120-07-L-D Samtec J8

Red banana jacks 4 ST-351A Allied J9, J10, J12,

Black banana jacks 4 ST-351B Allied J11, J13, J15,

Green LED 5 LN1351C-(TR) Panasonic D1−D5

0-Ω, 1/16-W, 1% resistor 1 ERJ-3EKF0R00V Panasonic R6 R5, R7−R10,

10-Ω, 1/16-W, 1% resistor 1 ERJ-3EKF10R0 Panasonic R32

49.9-Ω, 1/16-W, 1% resistor 6 ERJ-3EKF49R9V Panasonic R3, R4,

100-Ω , 1/8-W, 1% resistor 1 ERA-3YEB100 Panasonic R2

200-Ω, 1/10-W, 1% resistor 5 ERJ-6ENF2000 Panasonic R19−R23

200-Ω, 1/16-W, 0.1% resistor 2 ERA-3YEB200 Panasonic R11, R12

1-kΩ, 1/8-W, 1% resistor 0 ERJ-3EKF1001 Panasonic R35, R37

1-kΩ, 1/8-W, 1% resistor 5 ERJ-6ENF1001 Panasonic R14−R18

2-kΩ, 1/16-W, 1% resistor 1 ERJ-6ENF2001 Panasonic R1

10K-kΩ, 1/8-W, 1% resistor 2 ERJ-3EKF1002 Panasonic R13, R33

22-Ω resistor pack 2 4816P-001-220 Bourns RP1, RP2

51-Ω resistor pack 2 770-101-R51 CTS RP4, RP6 RP7, RP8

4 10TPA47M Sanyo C46−C49

Installed Not Installed

C14, C15,

C17−C19, C22,

C27, C57, C58

J14

J16

R34, R36

R24−R27

PCB Layout and Parts List

2-5

Page 16

Parts List

Table 2−1.DAC5674 EVM Parts List (Continued)

Description Qty. Part Number Mfg.

SW-PB switch 1 EVQ-PJX04M Panasonic S1

Switch 1 SD05HOSK CK S2

SMA connectors 3 713-4339

(901-144-8RFX)

SN74LVC04A 1 SN74LVC04APW TI U2

Standoff, hex (1/4 × 1”) 4 219-2063 Allied

Black test point 3 5001K Keystone TP3, TP4, TP5

Red test point 3 5000K Keystone TP1, TP2, TP6

Transformer 1 T1-1T-KK8 Mini-Circuits T1

Transformer 1 TCM4-1 Mini-Circuits T2

Allied J2, J4, J7 J1, J3, J5, J6

Installed Not Installed

Ref. Des.

2-6

Page 17

Chapter 3

Circuit Description

This chapter provides descriptions of the primary functional circuits on the

DAC5674 EVM.

Topic Page

3.1 Circuit Function 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description

3-1

Page 18

Circuit Function

3.1 Circuit Function

The following paragraphs describe the EVM circuits.

3.1.1 Input Clock

The DAC5674 EVM default operation setting is with a differential input clock

sent to the DAC5674. A 500-mV p-p, 0-V offset, 50% duty-cycle external

sinewave is applied to SMA connector J4 and converted to a d i fferential clock

input to the DAC5674 by transformer T2. This input represents a 50-Ω load to

the source. In order to preserve the specified performance of the DAC5674

converter, the clock source should feature very low jitter. Using a clock with a

50% duty cycle gives optimum dynamic performance.

3.1.1.1 Differential ECL/PECL Input Clock

The EVM can be configured for differential ECL/PECL input clock mode by

configuring the board per Table 3−1 and applying the appropriate ECL/PECL

common mode voltage at terminal E1 (VTT). Use J3 and J5 to input the

external differential ECL/PECL clock signals.

3.1.1.2 Single-Ended Input Clock

The EVM can be configured for single-ended input clock mode by configuring

the board per T able 3−1. SMA connector J3 or header J8 can be used to input

the external TTL/CMOS clock signal.

Table 3−1.EVM Clock Configuration

Clock Configuration Components Installed

Sinewave (Default) R12, T2, C52 R9, R10, R34, R35, R36, R37,

ECL or PECL R9 (0.01-µF cap.), R10 (0.01-µF

cap.)

Single ended TTL/CMOS from J3 R9, C55 R10, R12, R25, R34, R35, R37,

Single ended TTL/CMOS from J8 R34, R37, C55 R9, R10, R12, R35, T2, C56

†

All component values are per the schematic except where shown in parentheses.

†

Components Not Installed

C55, C56

R36, R12, R34, R35, R37, T2,

C55, C56

T2, C56

3.1.2 Input Data

The DAC5674 EVM can accept 3.3-V CMOS logic level data inputs through

the 40-pin header J8 per Table 3−2. The board provides 50-Ω termination to

ground and series dampening resistors to minimize digital ringing and

switching noise. J8 also provides a path for an input clock (see Table 3−1 for

proper board configuration).

3-2

Page 19

Circuit Function

Table 3−2.Input Connector J8

J8 Pin Description J8 Pin Description J8 Pin Description

1 CMOS data bit 13 (MSB) 15 CMOS data bit 6 29 Reset

2 GND 16 GND 30 GND

3 CMOS data bit 12 17 CMOS data bit 5 31

4 GND 18 GND 32 GND

5 CMOS data bit 11 19 CMOS data bit 4 33

6 GND 20 GND 34 GND

7 CMOS data bit 10 21 CMOS data bit 3 35

8 GND 22 GND 36 GND

9 CMOS data bit 9 23 CMOS data bit 2 37

10 GND 24 GND 38 GND

11 CMOS data bit 8 25 CMOS data bit 1 39 SCLK_IN

12 GND 26 GND 40 GND

13 CMOS data bit 7 27 CMOS data bit 0 (LSB)

14 GND 28 GND

3.1.3 Output Data

The DAC5674 EVM can be configured to drive a doubly terminated 50-Ω cable

or provide unbuffered differential outputs.

3.1.3.1 Transformer Coupled Signal Output

The factory-set configuration of the demonstration board provides the user

with a single-ended output signal at SMA connector J7. The DAC5674 is

configured to drive a doubly terminated 50-Ω cable using a 1:1 impedance

ratio transformer, a 100-Ω terminating resistor R2, and the center tap of T1

connected to ground per Table 3−3. When using a 4:1 impedance ratio

transformer, configure the EVM per Table 3−3. The common mode input

voltage of T1 can be adjusted by using the resistor divider network R5 and R6.

Table 3−3.Transformer Output Configuration

Configuration Components Installed

1:1 Impedance ratio transfomer R2, R3, R4, R6, C22, T1 (1:1) R5, R7, R8, C20, C21

4:1 Impedance ratio transfomer R3 (100), R4 (100), R6, C22,

T1 (4:1)

†

All component values are per the schematic except where shown in parenthesis.

3.1.3.2 Unbuffered Differential Output

†

Components Not Installed

R2, R5, R7, R8, C20, C21

To provide unbuffered differential outputs, the EVM must be configured as

follows: remove R2, C20, C21, and T1; Install R3, R4, R7, R8, J1 and J6.

Circuit Description

3-3

Page 20

Circuit Function

3.1.4 Internal Reference Operation

The full-scale output current is set by applying an external resistor (R1)

between the BIASJ pin of the DAC5674 and ground. The full-scale output

current can be adjusted from 20 mA down to 2 mA by varying R1 or changing

the externally applied reference voltage. The full-scale output current,

IOUT

, is defined as follows:

FS

IOUT

= 32 × (V

FS

EXTIO

/R1)

where V

is the voltage at pin EXTIO. This voltage is 1.2 V typical when

EXTIO

using the internally provided bandgap reference voltage source.

3.1.5 External Reference Operation

The internal reference can be disabled and overridden by an external

reference by connecting a voltage source to terminal TP2 (EXT_I/O) and

connecting EXTLO to AVDD. The specified range for external reference

voltages should be observed (see the DAC5674 data sheet (SLWS148) for

details).

3.1.6 Sleep Mode

The DAC5674 EVM provides a means of placing the DAC5674 into a

power-down mode. This mode is activated by placing jumper W3 between pins

2 and 3.

3.1.7 Filter Control

The DAC5674 has two inputs, HP1 and HP2, which control the internal

interpolation filters (FIR1 and FIR2) mode of operation. When these inputs are

set to a logic high, the filters are configured for high-pass response. When set

to a logic low, the filters are configured for low-pass response. A third input,

X4, allows the user to bypass Interpolation Filter 1. When X4 is set to a logic

low, Filter 1 is bypassed. See the data sheet (SL WS148) for more information.

3.1.8 PLL Divider Control

The DAC5674 has two inputs, DIV0 and DIV1, which control the internal PLL

prescaler divide ratio setting. These two signals, along with the three filter

control signals, are all controlled by DIP switch S2 on the EVM. All control

signals are in the logic low level when the DIP switch is in the closed position.

See the data sheet (SLWS148) for more information.

3-4

Page 21

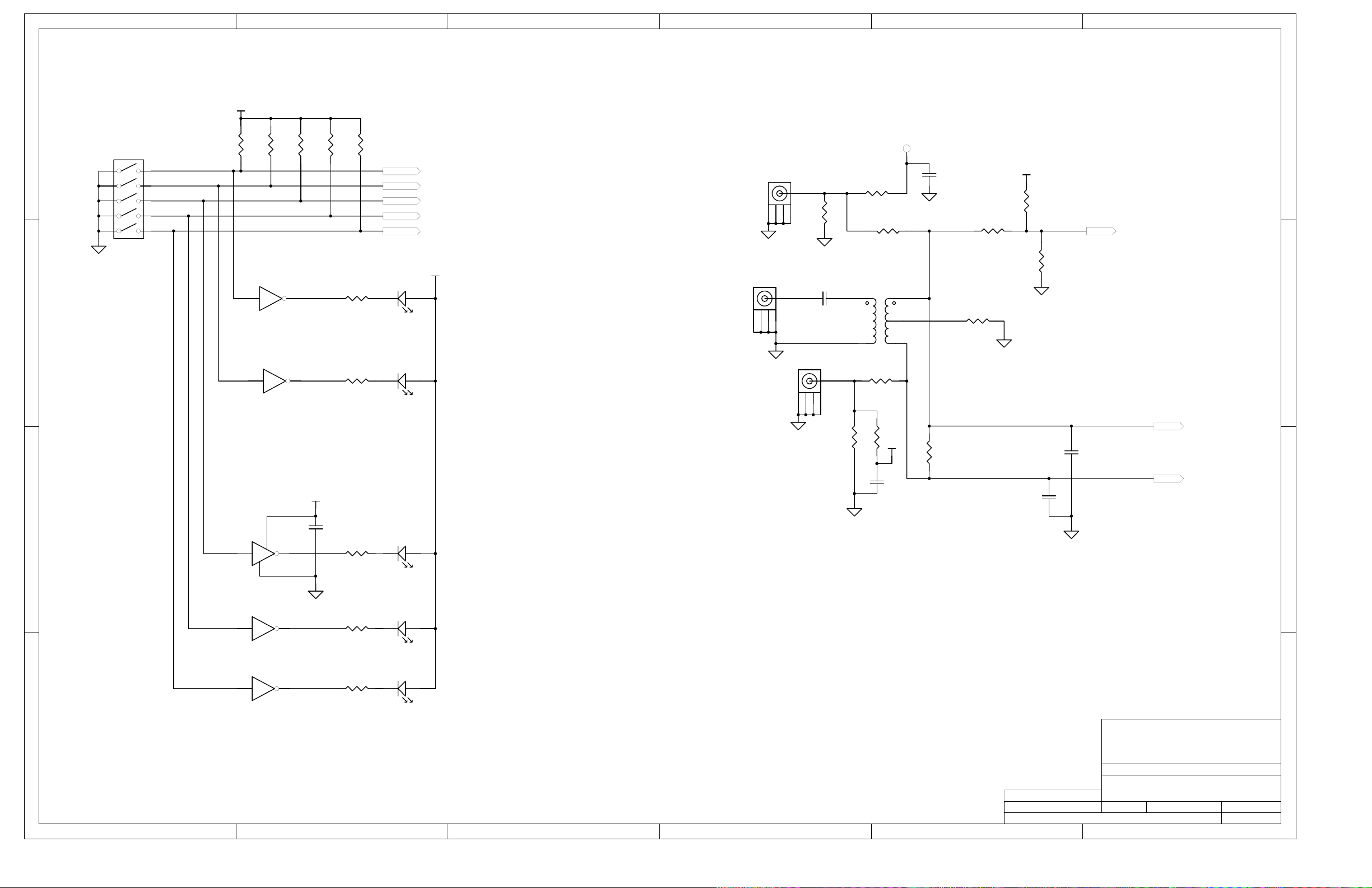

This chapter contains the EVM schematic diagrams.

Chapter 4

Schematics

Schematics

4-1

Page 22

D

SCLK

C

B

12

34

56

78

910

1112

1314

1516

1718

1920

2122

2324

2526

2728

2930

3132

3334

3536

3738

3940

40PIN_IDC

54321

REV ECN Number Approved

J6

(Note 1)

SMA

C24

.01uF

3

J2

SMA

W5

1

3 4

5

2

R7

0

(Note 1)

C22

R6

0

.1uF

+3.3VCLK

S1

3

SW-PB

.1uF

3

2

1

R8

0

1

2

C4

3 4

C10

.1uF

R13

10K

T1

T1-1T-KK81

J1

SMA

(Note 1)

5

C6

.1uF

+3.3VA

(Note 1)

R3

49.9R449.9

1

2

R33

10K

R5

0

W4

1

2

3 4

5

2

1

+1.8_3.3VD

RP7

(Note 1)

10PIN_SIP_RPACK

10

9

8

7

6

5

4

3

RP8

RP1

RP2

2

10

9

8

7

6

5

4

3

2

22

22

SCLK

1

(Sh 3)

RP4

10PIN_SIP_RPACK

2

3

4

5

6

7

8

9

10

1

1

(Note 1)

10PIN_SIP_RPACK

J8

D13_IN

D12_IN

D11_IN

D10_IN

D9_IN

D8_IN

D7_IN

D6_IN

D5_IN

D4_IN

D3_IN

D2_IN

D1_IN

D0_IN

RESET

SCLK_IN

R32

10

1 16

2 15

3 14

4 13

5 12

6 11

7 10

8 9

1 16

2 15

3 14

4 13

5 12

6 11

7 10

8 9

SCLK

.1uF

C3

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

.1uF

C1

.1uF

1

2

3

4

5

6

7

8

9

10

11

12

+3.3VA

C14

.1uF

+1.8VD

C15

48

DGND

DGND

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

HP1

HP2

X4

AVDD45AVDD46DVDD47DVDD

D313D214D115D016HP117HP218DGND19IOGND20DVDD21IODVDD22X423GND

HP1

HP2

X4

44

42

43

AGND

IOUT2

IOUT1

U1

DAC5674

(Sh 3)

(Sh 3)

(Sh 3)

(Sh 3)

C21

22pF

E2

RESET

R2

100

C23

100 pF

TP6

RED

R11

200, 1%

TP1

RED

R1

2K

+3.3VA

41

39

40

38

BIASJ

AGND

EXTIO

EXTLO

PLLLOCK

3

37

AGND

SLEEP

LPF

PLLVDD

PLLGND

CLKVDD

CLKGND

CLKC

CLK

DIV0

DIV1

RESET

24

1

2

C5

.1uF

W2

+1.8VD

36

35

34

33

32

31

30

29

28

27

26

25

TP2

RED

C2

.1uF

CLKC

CLK

DIV0

DIV1

+1.8_3.3VD

C17

.1uF

+1.8_3.3VD

W3

1

2

(Note 1) (Note 1) (Note 1)

C20

22pF

3

CLKC

CLK

DIV0

DIV1

Revision History

4

6

+3.3VCLK

+1.8_3.3VD

6

D

1

C18

.1uF

J7

3 4

I_OUT

5

2

C

B

1

A

10PIN_SIP_RPACK

RP6

2

3

4

5

6

7

8

9

10

NOTE 1. PART IS NOT INSTALLED

1 2 3 4 56

.1uF

C7

C19

.1uF

A

ti

12500 TI Boulevard. Dallas, Texas 75243

Title:

Engineer:

Drawn By:

FILE:

J. SETON

Y. DEWONCK

SIZE:

DAC5674

DATE: REV:

4-Sep-2003

SHEET: OF:

B

1

3

Page 23

54321

6

D

+3.3V ANALOG

J9

RED

J11

BLACK

C

3VA

FB1

FERRITE

+

10uF

C30

C34

1uF

C38

.1uF

1.8V / +3.3V DIGITAL

J12

3VD

RED

J15

BLACK

FB3

FERRITE

+

10uF

C32

C36

1uF

C40

.1uF

C42

.01uF

+1.8_3.3VD

C44

.01uF

+3.3VA

+

+

C46

47 uF

C48

47 uF

+3.3V CLOCK

J10

RED

J13

BLACK

+1.8VD

J14

RED

J16

BLACK

VCLK

18VD

FB2

FERRITE

FB4

FERRITE

+

10uF

+

10uF

C31

C33

C35

1uF

C37

1uF

C39

.1uF

C41

.1uF

C43

.01uF

C45

.01uF

+3.3VCLK

+

+1.8VD

+

C47

47 uF

C49

47 uF

D

C

B

TP3

BLACK

A

TP4

BLACK

TP5

BLACK

B

A

ti

12500 TI Boulevard. Dallas, Texas 75243

Title:

Engineer:

J. SETON

Drawn By:

Y. DEWONCK

FILE:

1 2 3 4 56

SIZE:

DAC5674

DATE: REV:

4-Sep-2003

SHEET: OF:

B

23

Page 24

54321

+1.8_3.3VD

D

R141KR15

S2

10_SM_SWITCH

1 10

2 9

3 8

4 7

5 6

C

B

1 2

1K

U2B

3 4

SN74LVC04A

U2C

5 6

SN74LVC04A

14

U2A

SN74LVC04A

7

+1.8_3.3VD

R16

1K

C27

.1uF

R17

1K

DIV1

DIV0

HP2

HP1

X4

R20

200

R19

200

R21

200

R18

1K

GREEN

GREEN

GREEN

D1

D2

D3

E1

VTT

R34

0

+3.3VCLK

R35

49.9

(Note 1)

(Note 1)

R37

49.9

(Note 1)

(Note 1)

SCLK

C55

.01uF

C57

.1uF

(Note 1)

6

5

4

(Note 1)

R36

0

R12

200

(Note 1)

5

J3

SMA

5

3 4

2

J5

SMA

(Note 1)

49.9

R26

R25

49.9

(Note 1)

R9

0

T2

1

3

TCM4-1

(Note 1)

R10

0

R27

49.9

VTT

C58

.1uF

1

3 4

2

1

R24

49.9

C52

.01uF

1

3 4

5

2

(Sh 1)

DIV1

(Sh 1)

DIV0

(Sh 1)

HP2

(Sh 1)

HP1

(Sh 1) (Sh 1)

X4

+3.3VCLK

J4

SMA

INPUT CLOCK

SCLK

CLK

C56

.01uF

CLKC

CLK

CLKC

6

D

C

(Sh 1)

(Sh 1)

B

U2D

9 8

SN74LVC04A

U2F

13 12

SN74LVC04A

A

R22

200

R23

200

D4

GREEN

D5

GREEN

A

ti

12500 TI Boulevard. Dallas, Texas 75243

NOTE 1. PART IS NOT INSTALLED

1 2 3 4 56

Engineer:

Drawn By:

FILE:

J. SETON

Y. DEWONCK

Title:

SIZE:

DAC5674

DATE: REV:

4-Sep-2003

SHEET: OF:

B

33

Loading...

Loading...