Page 1

User Manual

Rev. 1.1

CC2400DK Development Kit

SWRU050 Page 1 of 35

Page 2

Table of contents

INTRODUCTION.......................................................................................................................3

EVALUATION MODULE........................................................................................................... 4

CIRCUIT DESCRIPTION .............................................................................................................. 4

PCB LAYOUT ........................................................................................................................... 4

SCHEMATIC ............................................................................................................................ 10

EVALUATION BOARD...........................................................................................................12

POWER SUPPLY SECTION ........................................................................................................ 12

USB INTERFACE..................................................................................................................... 14

RS-232 INTERFACE................................................................................................................ 14

JUMPERS ............................................................................................................................... 14

MICROCONTROLLER AND FPGA.............................................................................................. 15

CONNECTORS ........................................................................................................................ 16

PCB LAYOUT ......................................................................................................................... 17

SCHEMATICS, CC2400EB ...................................................................................................... 20

BILL OF MATERIALS, CC2400EB ............................................................................................ 25

USING THE DEVELOPMENT KIT.......................................................................................... 31

CC2400 RF EVALUATION USING SMARTRF

USING THE CC2400DK FOR PROTOTYPING ............................................................................. 32

TROUBLESHOOTING............................................................................................................33

IT DOES NOT WORK................................................................................................................. 33

SMARTRF

®

STUDIO DOES NOT RECOGNIZE THE CC2400EB .................................................... 33

®

STUDIO............................................................... 31

SWRU050 Page 2 of 35

Page 3

Introduction

The CC2400 single-chip RF transceiver provides a highly integrated, flexible low-cost solution

for applications using the worldwide unlicensed 2.4 GHz frequency band. The CC2400DK

development kit is a powerful and flexible tool specifically designed to make it easy for the

user to evaluate the RF performance of the CC2400 and to minimize the time spent on

evaluation.

The Development Kit includes two Evaluation Boards and two Evaluation Modules. The

Evaluation Modules contain the CC2400 chip and required external components.

The Evaluation Board serves as a motherboard for the Evaluation Modules. The Evaluation

Board provides a USB port, a serial port, buttons, LEDs, voltage regulator, configuration

jumpers and connectors to make it easy to interface the CC2400 with the SmartRF

software and various test equipment.

®

This User Manual describes how to use the Development Kit. SmartRF

Studio is

documented in its own user manual.

®

Your SmartRF

CC2400DK Development Kit should contain the following items:

Kit contents

Item Number of articles

Evaluation Board (CC2400EB) 2

Evaluation Module (CC2400EM) 2

Quick Start instructions 1

Antenna, 50Ω quarter-wave monopole, SMA male connector

2

SMA to BNC adapters 4

USB cable 2

CC2400 sample kit 1

®

Studio

SWRU050 Page 3 of 35

Page 4

Evaluation Module

The Evaluation Module contains the CC2400 chip together with the needed external circuitry

for operation. Not all components are needed in an actual application. Please see the

datasheet for a typical application circuit.

The CC2400 operates in the 2.4 GHz frequency band. Although this frequency band is

usually described as “world-wide”, some countries do not allow unlicensed operation in this

band. Please refer to application note AN001 for more information about applicable

regulations.

Important: Contact your local telecommunication authorities before transmitting an RF signal.

Circuit description

The CC2400 RF section includes all the necessary components for correct operation.

The CC2400 is connected to a 16 MHz crystal.

The Evaluation Module can be plugged into the Evaluation Board. Two 2x10 pin pin row

connectors with 0.050-inch pitch are used for this purpose.

Figure 1: CC2400EM Evaluation Module

PCB layout

RF circuits operating at high frequencies are sensitive to the physical layout of the PCB.

Chipcon has carefully optimized the layout of the CC2400EM evaluation module and we

therefore recommend that the user copies it when making own PCB designs.

The PCB is of a 4-layer type in order to provide a well-defined ground plane as well as

adequate routing space. The laminate used is standard FR-4 board material. The PCB is

1.0mm thick, with layer 1 on the top side, layers 2 and 3 are internal layers and layer 4 is on

the bottom side. Layers 1 and 4 are used for routing, while layer 2 is a ground plane and layer

3 is used for power routing. All areas not utilized for routing are filled with copper connected

to ground to provide RF shielding. The ground planes on all layers are stitched together with

closely spaced vias.

SWRU050 Page 4 of 35

Page 5

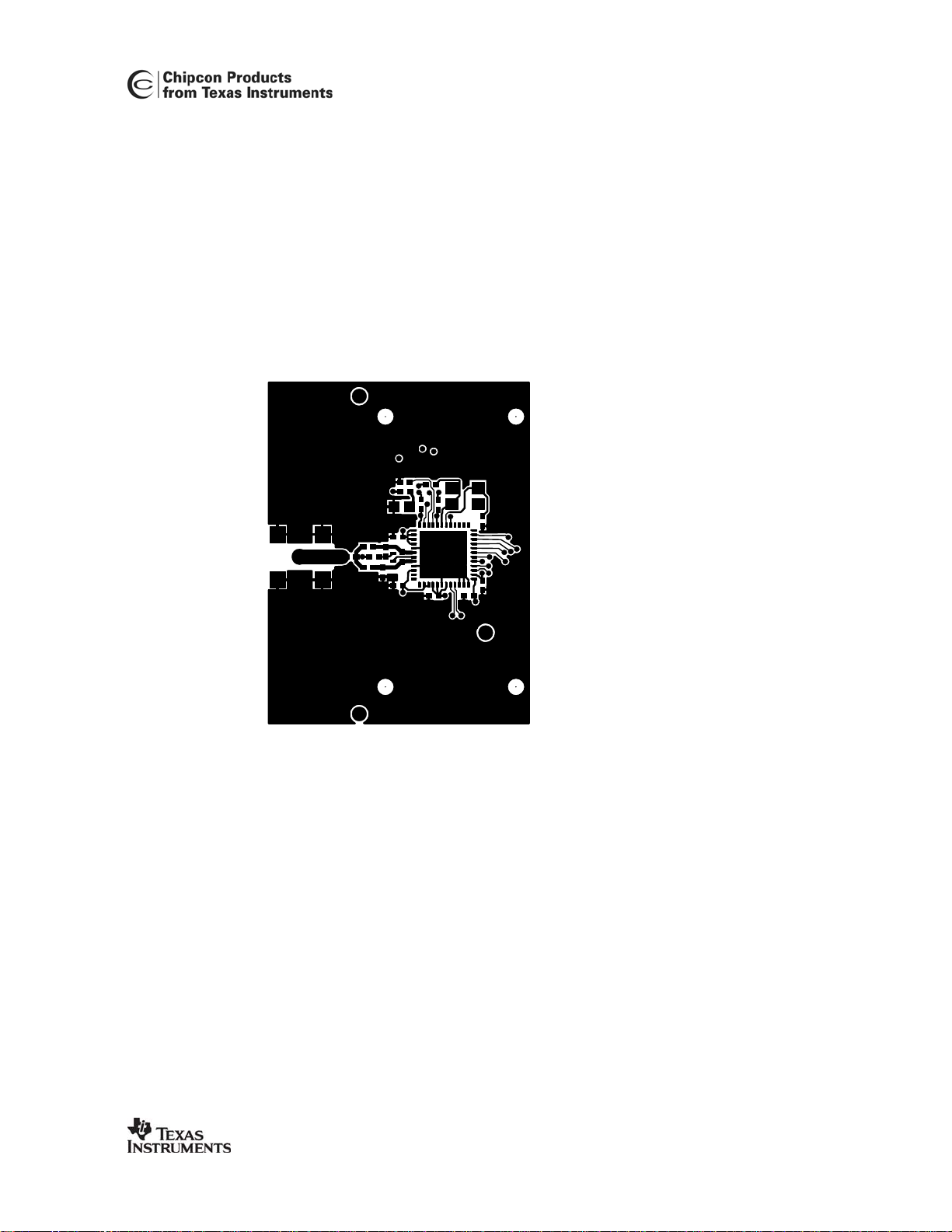

Figure 2: CC2400EM PCB layout, layer 1

SWRU050 Page 5 of 35

Page 6

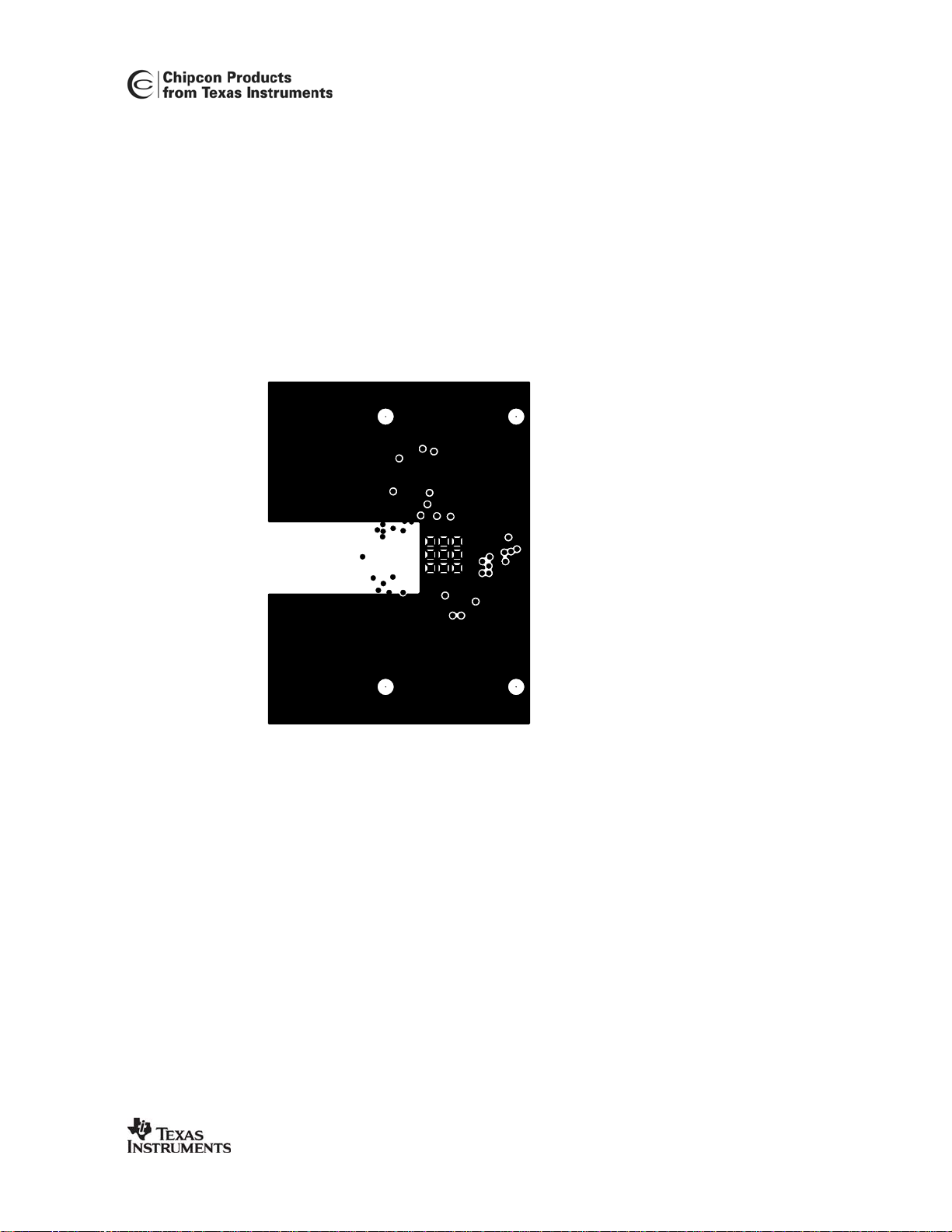

Figure 3: CC2400EM PCB layout, layer 2

SWRU050 Page 6 of 35

Page 7

Figure 4: CC2400 PCB layout, layer 3

SWRU050 Page 7 of 35

Page 8

Figure 5: CC2400EM PCB layout, layer 4

SWRU050 Page 8 of 35

Page 9

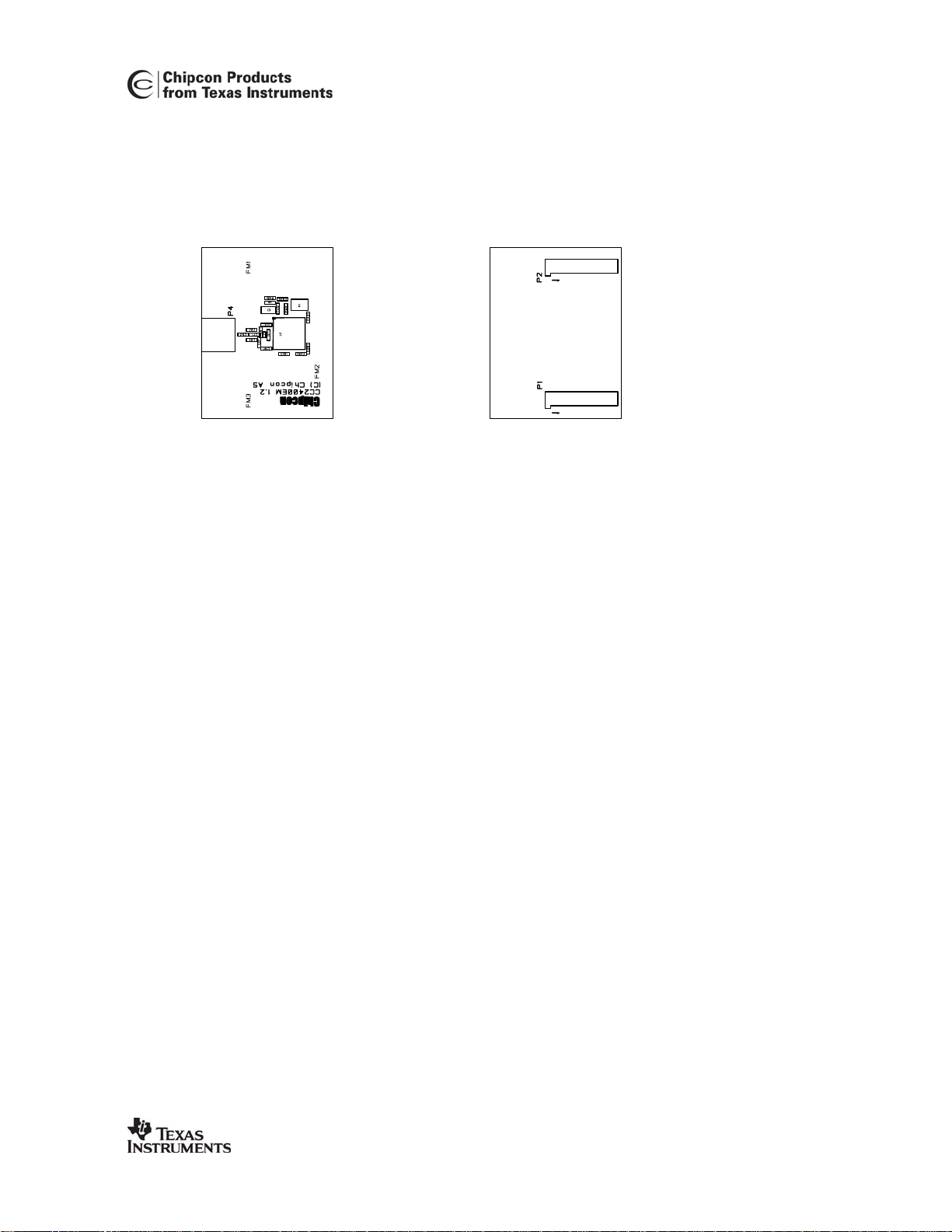

Figure 6: CC2400EM component placement, top side (left) and bottom side (right)

SWRU050 Page 9 of 35

Page 10

Schematic

SWRU050 Page 10 of 35

Page 11

Bill of materials, CC2400EM

Bill of materials, CC2400EM

Reference Description Value Part

C1 Capacitor 0603 2.2 µF, 10% C_2U2_0603_X5R_K_10

C11 Capacitor 0402 100 nF, 10% C_100N_0402_X5R_J_10

C61 Capacitor 0402 0.5 pF, ± 0.25 pF C_0P5_0402_NP0_C_50

C62 Capacitor 0402 5.6 pF, ± 0.25 pF C_5P6_0402_NP0_C_50

C71 Capacitor 0402 100 nF, 10% C_100N_0402_X5R_J_10

C81 Capacitor 0402 0.5 pF, ± 0.25 pF C_0P5_0402_NP0_C_50

C101 Capacitor 0402 10 nF, 10% C_10N_0402_X7R_K_25

C161 Capacitor 0402 68 pF, 5% C_68P_0402_NP0_J_50

C251 Capacitor 0402 100 nF, 10% C_100N_0402_X5R_K_10

C261 Capacitor 0402 100 nF, 10% C_100N_0402_X5R_K_10

C411 Capacitor 0402 68 pF, 5% C_68P_0402_NP0_J_50

C421 Capacitor 0402 27 pF, 5% C_27P_0402_NP0_J_50

C431 Capacitor 0402 27 pF, 5% C_27P_0402_NP0_J_50

C481 Capacitor 0402 68 pF, 5% C_68P_0402_NP0_J_50

L61 Inductor 0402 7.5 nH, 5% L_7N5_0402_J

L62 Inductor 0402 5.6 nH, 5% L_5N6_0402_J

L71 Inductor 0402 27 nH, 5% L_27N_0402_J

L81 Inductor 0402 7.5 nH, 5% L_7N5_0402_J

P1 SMD pinrow socket SMD_SOCKET_2x10 (Samtec

SFM-110-02-S-D-A-K-TR)

P2 SMD pinrow socket SMD_SOCKET_2x10 (Samtec

SFM-110-02-S-D-A-K-TR)

P4 Surface-mount

SMA_SMD

SMA, straight

R1 Resistor 0402 2.2 Ω, 5% R2R2_0402_J

R451 Resistor 0402 43 kΩ, 1% R_43K_0402_F

U1 Single-chip

CC2400

transceiver

X1 Crystal, ceramic

SMD 4x25mm

X_16.000/10/10/10/16 (Toyocom

TSX-10A 16M 16pF)

Note: The crystal X1 mounted on the EM board is a 16.000 MHz crystal, with ±10 ppm initial

tolerance, ± 10 ppm drift over temperature and a temperature range of -10˚ C to +60˚ C. The

crystal is designed for 16 pF load capacitance. In an actual application, the tolerance, drift

and temperature range of the crystal must be considered with application requirements in

mind. Please consult the data sheet and SmartRF

®

Studio for more information. It is possible

to choose a larger crystal package to save cost. The crystal should have an ESR of 60 Ω or

less.

SWRU050 Page 11 of 35

Page 12

DC jack

Evaluation Board

The Evaluation Board is used as a motherboard for the Evaluation Modules and provides

power and external connections.

Power

Jumpers

connections

Sockets for EM

Buttons

LEDs

Serial port

USB port

Power supply section

The power supply section is configured by moving the jumpers located on the board. There

are three voltage regulators on the board, one for use by the FPGA, a 3.3 V regulator for

general use and a 1.8 V regulator for powering the CC2400. The voltage regulator for the

FPGA is turned on under software control when the USB controller has been properly

configured.

A diode prevents permanent damage if wrong polarity is applied to the non-regulated input.

There are two power connectors; a 3.5mm DC jack-type connector allows you to connect an

unregulated battery eliminator easily (the positive supply is on the center pin), and two 5-pin

terminal blocks can be used to connect either an unregulated or regulated power supply.

An amperemeter can also be connected in order to measure the DC current drawn by the

CC2400. Since the CC2400 has two voltage supplies (Core and I/O), there are separate

SMA connectors

Test port

Reset button

Figure 7: CC2400EB Evaluation Board

SWRU050 Page 12 of 35

Page 13

current measurement loops for these two supplies. If you are not going to measure the

currents, short-circuit jumpers must be connected between the terminals, otherwise the

Evaluation Module will not be supplied with power.

IOC

A

A

IIC

ExtC

0V

0V

IOI

ExtI

0V

4-7V

P2

III

P3

Figure 8: Power terminal block with amperemeters attached

Table 1: Power connector connections

Connector and pin Marking Description

P3 pin 1 4-7V Unregulated voltage in. Input to voltage regulators.

Equivalent with the DC jack input.

P3 pin 2 0V Circuit ground.

P3 pin 3 ExtI External I/O voltage. An externally applied voltage will

drive the I/O supply of the CC2400 (and the associated

FPGA pins) if the jumpers are set correctly.

P3 pin 4 III I/O supply current input. Insert an amperemeter

between this pin and the IOI pin to measure the current

drawn by the I/O supply of the CC2400.

P3 pin 5 IOI I/O supply current output. Insert an amperemeter

between this pin and the III pin to measure the current

drawn by the I/O supply of the CC2400.

P2 pin 1 0V Circuit ground.

P2 pin 2 0V Circuit ground.

P2 pin 3 Ext C External core voltage. An externally applied voltage

that will drive the core supply of the CC2400 if the

jumpers are set correctly.

P2 pin 4 IIC Core voltage current input. Insert an amperemeter

between this pin and the IOC pin to measure the

current drawn by the core supply of the CC2400.

P2 pin 5 IOC Core voltage current output. Insert an amperemeter

between this pin and the IIC pin to measure the current

drawn by the core supply of the CC2400.

SWRU050 Page 13 of 35

Page 14

USB interface

®

The CC2400EB connects to a PC via a USB interface. SmartRF

Studio uses the USB

interface to control the CC2400EB. The USB interface can be used both to configure the

CC2400 and transfer data. Chipcon provides a Windows driver that is installed as part of the

SmartRF

®

Studio installation process. This driver must be present for SmartRF® Studio to

communicate with the CC2400EB.

Because USB is used, the CC2400DK will only function with PCs running Windows 98,

Windows ME, Windows 2000, Windows XP or newer. Windows NT and Windows 95 cannot

be used since they do not support USB.

RS-232 interface

A serial port is included on the CC2400EB. This is intended for debugging purposes, and

cannot be used to connect the Evaluation Board to SmartRF

®

Studio.

Jumpers

The jumpers are used to configure the Evaluation Board. The factory default settings are

shown below, please return to these settings if you are experiencing any problems.

Figure 9 Default jumper settings

SWRU050 Page 14 of 35

Page 15

Jumpers

Name Default setting Description

VIO Between pins

6 and 8

Determines how the I/O supply of the CC2400 is supplied

with power. If the jumper is connected between pins 8 and

6, the 1.8V supply is used. If the jumper is connected

between pins 8 and 10, the 3.3V supply is used. If the

jumper is connected between pins 8 and 7, the I/O supply is

driven by the external voltage present on the ExtI pin on the

power connector.

VC Between pins

3 and 5

Determines how the core supply of the CC2400 is supplied

with power. If the jumper is connected between pins 3 and

5, power is supplied by the 1.8V regulator. If the jumper is

connected between pins 3 and 1, the core supply is driven

by the external voltage present on the ExtC pin on the

power connector.

V Between pins

4 and 6

Determines how power is supplied to the board. If the

jumper is connected between pins 4 and 6, the EB is

powered from the power connected to the power connector

or the power jack. If the jumper is connected between pins

6 and 8, the EB is powered from the USB bus. In this case,

the USB port the EB is connected to must be able to supply

500 mA current.

EEPROM

En.

Present Determines if USB configuration information is loaded from

EEPROM memory. If removed, the CC2400EB will report

itself as a default USB device. This jumper should always

be present during normal operation.

Microcontroller and FPGA

The CC2400EB has been built around a Cypress USB microcontroller and a Xilinx Spartan II

200E FPGA. This has been done to ensure maximum flexibility and is not representative for a

low-cost CC2400 application.

Both the microcontroller and the FPGA are RAM-based devices, and their configuration is

loaded via the USB interface on power-up. The CC2400EB must therefore be connected to a

PC to function properly.

Four LEDs and two buttons are included on the board for user interface purposes. The LEDs

are driven by the FPGA, while the buttons are connected to both the FPGA and the

microcontroller.

A reset button is provided, which will reset both the microcontroller and the USB interface.

®

The LEDs are used to indicate status when the CC2400EB is used together with SmartRF

Studio.

SWRU050 Page 15 of 35

Page 16

Connectors

The Evaluation Board is furnished with many connectors for easy access to various signals.

Test Port 1 (P17) and Test Port 2 (P5) are 2x10 pin pin-row connectors that are connected to

the FPGA and can be used to monitor various signals, including all the CC2400 signals. The

pin-out of these connectors is compatible with logic analyzer probes from Agilent.

The DTEST1 (P6) and DTEST2 (P7) SMA connectors are also connected to the FPGA and

can be used to output or input signals from/to the CC2400, respectively.

The ATEST1 (P9) and ATEST2 (P8) provide access to analog test signals from the CC2400.

®

The selection of what signals are available at the different connectors is done in SmartRF

Studio.

SWRU050 Page 16 of 35

Page 17

PCB layout

The Evaluation Board is a 4-layer, 1.6 mm thick FR-4 PCB. Four layers are used because of

the routing requirements. Layers 1 and 4 are used for signal routing, layer 2 is a ground plane

and layer 3 is used for power routing. The majority of the components are mounted on the top

side of the PCB, while a few decoupling capacitors were put on the bottom side.

Figure 10: CC2400EB PCB layout, layer 1 (top left), layer 2 (top right), layer 3 (bottom left)

and layer 4 (bottom right)

SWRU050 Page 17 of 35

Page 18

Figure 11: CC2400EB component placement, top side

SWRU050 Page 18 of 35

Page 19

Figure 12: CC2400EB component placement, bottom side

SWRU050 Page 19 of 35

Page 20

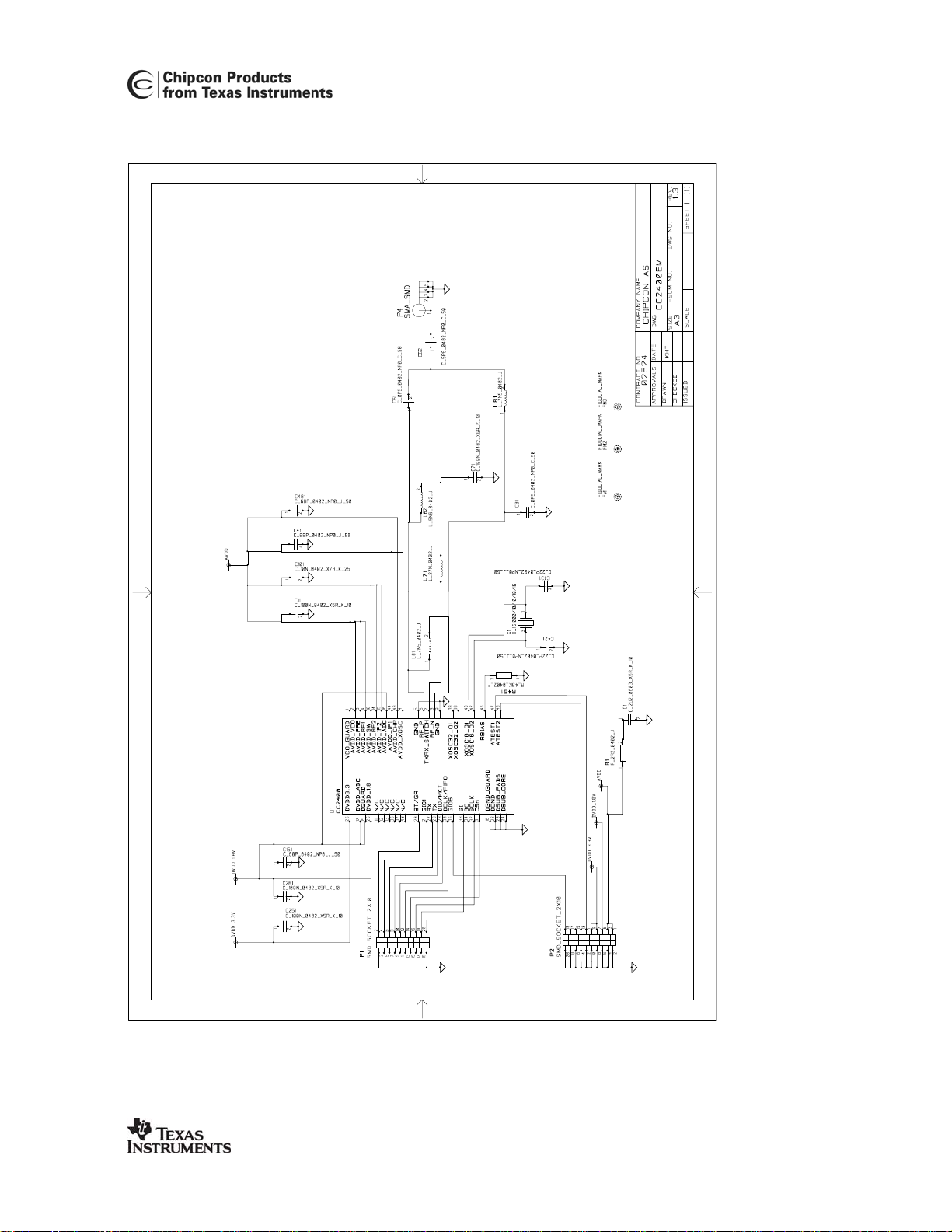

Schematics, CC2400EB

SWRU050 Page 20 of 35

Page 21

SWRU050 Page 21 of 35

Page 22

SWRU050 Page 22 of 35

Page 23

SWRU050 Page 23 of 35

Page 24

SWRU050 Page 24 of 35

Page 25

Bill of Materials, CC2400EB

Bill of materials, CC2400EB Evaluation Board

Reference Description Value Part

C1 Capacitor 1206 2.2 µF, 10% C_2U2_1206_X7R_K_10

C2 Capacitor 0603 27 pF, 5% C_27P_0603_NP0_J_50

C3 Capacitor 0603 27 pF, 5% C_27P_0603_NP0_J_50

C4 Capacitor, tantal 3.3 µF C_3U3_TAN_B

C5 Capacitor 1206 2.2 µF, 10% C_2U2_1206_X7R_K_10

C6 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C14 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C15 Capacitor, tantal 3.3 uF C_3U3_TAN_B

C16 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C17 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C18 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C19 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C20 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C21 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C22 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C23 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C24 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C25 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C26 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C27 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C28 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C29 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C30 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C31 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C32 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C33 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C34 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C35 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C36 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C37 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C38 Capacitor, tantal 47 µF C_47U_TAN_D

C39 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C40 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C41 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

Comment [C1]:

SWRU050 Page 25 of 35

Page 26

Bill of materials, CC2400EB Evaluation Board

Reference Description Value Part

C42 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C43 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C44 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C45 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C46 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C47 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C48 Capacitor, tantal 47 µF C_47U_TAN_D

C49 Capacitor, tantal 47 µF C_47U_TAN_D

C50 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C51 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C52 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C53 Capacitor, tantal 47 µF C_47U_TAN_D

C54 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C55 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C56 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C57 Capacitor, tantal 47 µF C_47U_TAN_D

C58 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C59 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C60 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C61 Capacitor, tantal 47 µF C_47U_TAN_D

C62 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C63 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C64 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C65 Capacitor, tantal 47 µF C_47U_TAN_D

C66 Capacitor, tantal, low

ESR

100 µF C_100U_TAN_D_KEMET (Kemet

T494D107M010AS)

C67 Capacitor, tantal 47 µF C_47U_TAN_D

C68 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C69 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C70 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C71 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C100 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C101 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C102 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C103 Capacitor low

impedance

SWRU050 Page 26 of 35

470 µF,

electrolytic

C_470U_8_CVAX (Sanyo CV-AX

8x10,2)

Page 27

Bill of materials, CC2400EB Evaluation Board

Reference Description Value Part

C104 Capacitor 0603 100 nF, 10% C_100N_0603_X7R_K_50

C105 Capacitor 0603 33 nF, 10% C_33N_0603_X7R_K_25

C106 Capacitor 1206 2.2 µF, 10% C_2U2_1206_X7R_K_10

D1 Schottky diode, 2A 20BQ030, International Rectifier

D2 LED, green, SMD LED_CL150GCD, Citizen

D3 LED, red, SMD LED_CL150URCD, Citizen

D4 LED, yellow, SMD LED_CL150YCD, Citizen

D5 LED, blue, SMD LED_EL15-21UBC, Everlight

H1 Circuit board support Distance 12.5mm

H2 Circuit board support Distance 12.5mm

H3 Circuit board support Distance 12.5mm

H4 Circuit board support Distance 12.5mm

P1 D-SUB, 9 pin, female DSUB_9F

P2 5-pin terminal, screw SCREW_TERM_5

P3 5-pin terminal, screw SCREW_TERM_5

P4 DC jack, 2.5mm center

DC_JACK_2.5

pin

P5 Pin row connector,

PINROW_2_10

2x10

P6 SMA connector SMA (Right angle)

P7 SMA connector SMA (Right angle)

P8 SMA connector SMA (Right angle)

P9 SMA connector SMA (Right angle)

P10 Pin row connector, 2x5 PINROW_2X5

P11 Pin row connector, 2x5 PINROW_2X5

P12 Pin row connector, 2x5 PINROW_2X5

P13 SMD pinrow header SMD_HEADER_2x10 (Samtec TFM-

110-02-S-D-A-K-TR)

P14 SMD pinrow header SMD_HEADER_2x10 (Samtec TFM-

110-02-S-D-A-K-TR)

P15 USB B-type connector USB_B (AMP 787780-1)

P16 Low-profile pin row

connector, 1x6

P17 Pin row connector,

CON6_FEMALE_LP (Preci-DIP 801-

91-006-10-012)

PINROW_2X10

2x10

P18 Low-profile pin row

connector, 1x6

CON6_FEMALE_LP (Preci-DIP 801-

91-006-10-012)

Comment [C2]:

SWRU050 Page 27 of 35

Page 28

Bill of materials, CC2400EB Evaluation Board

Reference Description Value Part

P19 Do not mount DNM

P20 Low-profile pin row

connector, 1x6

CON6_FEMALE_LP (Preci-DIP 801-

91-006-10-012)

Q1 PNP, general-purpose BC857B (Philips)

Q2 NPN, small-signal BC846B (Philips)

R1 Resistor 0603 10 kΩ, 2% R_10K_0603_G

R2 Resistor 0603 22 Ω, 2% R_22_0603_G

R3 Resistor 0603 22 Ω, 2% R_22_0603_G

R4 Resistor 0603 1.5 kΩ, 2% R_1K5_0603_G

R5 Resistor 0603 1 MΩ, 5% R_1M0_0603_J

R6 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R7 Resistor 0603

47kΩ, 2%

R_47K_0603_G

R8 Resistor 0603 0 Ω R_0_0603

R9 Resistor 0603 0 Ω R_0_0603

R10 Do Not Mount DNM

R11 Do Not Mount DNM

R12 Resistor 0603

R13 Resistor 0603

47kΩ, 2%

47kΩ, 2%

R_47K_0603_G

R_47K_0603_G

R14 Resistor 0603 0 Ω R_0_0603

R15 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R16 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R17 Do Not Mount DNM

R18 Resistor 0603

47kΩ, 2%

R_47K_0603_G

R19 Do Not Mount DNM

R20 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R21 Do Not Mount DNM

R22 Resistor 0603 1 kΩ, 5% R_1K0_0605_J

R23 Resistor 0805

270 Ω, 5%

R_270_0805_J

R24 Resistor 0805 330 Ω, 5% R_330_0805_J

R25 Resistor 0805 270 Ω, 5% R_270_0805_J

R26 Resistor 0805 270 Ω, 5% R_270_0805_J

R27 Resistor 0603 1 kΩ, 5% R_1K0_0605_J

R28 Resistor 0603 1 kΩ, 5% R_1K0_0605_J

R29 Resistor 0603 0 Ω R_0_0603

R30 Do Not Mount DNM

SWRU050 Page 28 of 35

Page 29

Bill of materials, CC2400EB Evaluation Board

Reference Description Value Part

R31 Resistor 0603 0 Ω R_0_0603

R32 Do Not Mount DNM

R33 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R34 Do Not Mount DNM

R35 Do Not Mount DNM

R36 Do Not Mount DNM

R37 Do Not Mount DNM

R38 Do Not Mount DNM

R39 Do Not Mount DNM

R40 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R41 Resistor 0603 0 Ω R_0_0603

R42 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R43 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R44 Resistor 0603 47 kΩ, 2% R_47K_0603_G

R45 Resistor 0603 1 kΩ, 5% R_1K0_0605_J

R46 Resistor 0603 10 kΩ, 2% R_10K_0603_G

R47 Resistor 0603 0 Ω R_0_0603

R100 Resistor 0603 0 Ω R_0_0603

R101 Resistor 0603 0 Ω R_0_0603

S1 Push button, SMD SKHUAF, Alps

S2 Push button, SMD SKHUAF, Alps

S3 Push button, SMD SKHUAF, Alps

TP1 Test point TESTPIN

TP2 Test point TESTPIN

TP3 Test point TESTPIN

TP4 Test point TESTPIN

TP5 Test point TESTPIN

TP6 Test point TESTPIN

TP7 Test point TESTPIN

TP8 Test point TESTPIN

U1 EZ-USB MCU CY7C64613-128NC, Cypress

U2 Spartan IIE FPGA XC2S200E-6FT256I, Xilinx

U3 Do Not Mount DNM

U4 3.3 V low drop-out

regulator

LP2981AIM5-3.3, National

Semiconductor

SWRU050 Page 29 of 35

Page 30

Bill of materials, CC2400EB Evaluation Board

Reference Description Value Part

U5 32 kB SRAM IDT71V256SA20YI, IDT

U6 1.8 V low drop-out

XC6204B182MR, Torex

regulator

U7 1.8 V low drop-out

regulator, 800 mA

LP3961ES-1.8, National

Semiconductor

U8 16 byte I2C EEPROM 24LC00I/SN, Microchip

U9 Do Not Mount DNM

U10 Do Not Mount DNM

U11 Quad NAND gate 74HC00D, Philips

U100 RS-232 Transceiver,

MAX3243EEWI, Maxim

3-5V

X1 12 MHz crystal, HC-

X_12.000/50/50/10/12

49SMD, 50/50 ppm,

12 pF

SWRU050 Page 30 of 35

Page 31

Using the Development Kit

The Development Kit is useful for providing hands-on experience with the CC2400 for both

software and hardware developers. The plug-in Evaluation Module provides flexibility; it can

operate both in a stand-alone fashion and together with the Evaluation Board. Using the

Evaluation Board, it is easy to interface the CC2400 with both test equipment and additional

application circuitry without having to make a PCB from scratch. Below we will highlight the

most useful setups.

®

CC2400 RF Evaluation using SmartRF

PC running

SmartRF Studio

Studio

Spectrum

analyzer / RF

Signal generator

CC2400

EM

CC2400

Evaulation Board

Oscilloscope /

Function

generator

®

Figure 13: RF Evaluation using SmartRF

Studio

Using the setup shown in Figure 13, the RF performance of the CC2400 can be evaluated.

Use the supplied cable to connect the USB port of the CC2400EB to the USB port of a PC

running SmartRF

®

Studio. You can then use SmartRF® Studio to control all the RF

parameters of the CC2400.

®

SmartRF

two CC2400EBs, it is possible to send data from one PC to another. It is also possible to test

a frequency-hopping link in the same fashion. Please refer to the SmartRF

Studio can be used to perform a wide variety of RF tests, including link tests. Using

®

Studio

documentation for more information.

When the CC2400EB board is connected to a PC, the PC will load the USB driver for the

board (SmartRF

update the FPGA and microcontroller, and the LEDs will start flashing. The LED flashing will

stop if one of the buttons on the board is pressed, or when SmartRF

®

Studio must be installed on the PC). Once the driver has loaded, it will

®

Studio is started.

When SmartRF Studio is running, the LEDs are used to indicate the FH network ID for the

board. The ID is shown as a binary number, with the red LED representing the least

significant bit (LSB), the yellow LED representing bit 1, and the green LED representing the

most significant bit (MSB). When FH network is active, the blue LED toggles each time the

status is read from the PC.

Important: The use of radio transceivers is regulated by international and na tional rules.

Before transmitting an RF signal on an antenna, please contact your local teleco mmunication

authorities to make sure that you are licensed to operate the transceiver.

SWRU050 Page 31 of 35

Page 32

Using the CC2400DK for prototyping

The CC2400EM module contains the CC2400 and all external components required. All

CC2400 signals are available at the SMD connectors on the bottom side of the module. The

modules can be easily plugged into a prototype PCB containing the rest of the system. The

SMD connectors used on the CC2400EM are manufactured by Samtec

(http://www.samtec.com/

), please refer to the CC2400EB bill of materials for the part number

of the connector that will interface with the connectors on the EM.

It is also possible to do prototyping by connecting any microcontroller development kit to the

CC2400EB through Test Port 1. The FPGA must then be programmed using the SmartRF

Studio “Load FPGA Configuration” function at startup. The

“fpga_cc2400_uc_prototyping_1_0.bin” FPGA file is downloadable from the Chipcon website.

All LEDs will be turned off after programming this FPGA. The FPGA will give access to all

CC2400 digital pins on Test Port 1, as shown below.

Test Port 1 Pin Number Test Port 1 (to / from uC)

1 N/C

2 N/C

3 N/C

4 DIO/PKT (to uC)

5 HighZ

6 HighZ

7 HighZ

8 DCLK/FIFO (to uC)

9 HighZ

10 HighZ

11 HighZ

12 CSn (from uC)

13 SCLK (from uC)

14 SI (from uC)

15 SO (to uC)

16 GIO1 (to uC)

17 GIO6 (to uC)

18 TX (from uC)

19 RX (from uC)

20 GND

Test Port 2 contains the same pins, except these are all outputs from the FPGA. Test Port 2

may be connected to a Logic Analyzer for software debugging purposes.

It should be noted that when using a ribbon cable from Test Port 1 to the MCU, one can

experience that some of the signals are interfering with each other.

A solution would be to use single wires instead, or use some form of shielded ribbon cable.

SWRU050 Page 32 of 35

Page 33

Troubleshooting

It does not work

• Make sure that either a jumper or an amperemeter is connected between the IOI and

II terminals and the IIC and IOC terminals on the power connector.

• Make sure that the power supply is connected to the correct pins on the power

connector.

• Is the supply voltage correctly polarized? If not, the protection diode will prevent any

current from flowing. + and – are indicated on the PCB. On the DC jack, the tip is +

and the ring is –.

• Please note that the CC2400EB must be connected to a PC for proper operation. The

FPGA and microcontroller are RAM-based, and firmware must be loaded from a PC

when power is applied to the board.

• If the USB driver is loaded correctly, you should see the LEDs on the CC2400EB

flash. The LEDs will stop flashing when one of the buttons on the CC2400EB is

pressed or when SmartRF

®

Studio is started.

SmartRF

®

Studio does not recognize the CC2400EB

• Make sure that you have installed SmartRF

®

Studio using the installation program.

• Make sure that the USB port on your computer is installed correctly (try another USB

device with the same port). Also note that USB only works correctly with Windows 98,

ME, 2000, XP or newer.

®

• Please note that SmartRF

Studio can only communicate with the CC2400EB via the

USB port. The serial port cannot be used to communicate with the CC2400EB.

Document History

Revision Date Description/Changes

1.0 2003-10-01 Initial release.

1.1 2004-04-19 Added information about FPGA configuration for prototyping with an

external microcontroller.

Minor corrections.

C421 and C431 changed to 27 pF.

SWRU050 Page 33 of 35

Page 34

Disclaimer

Chipcon AS believes the information contained herein is correct and accurate at the time of this printing. However,

Chipcon AS reserves the right to make changes to this product without notice. Chipcon AS does not assume any

responsibility for the use of the described product.; neither does it convey any license under its patent rights, or the

rights of others. The latest updates are available at the Chipcon website or by contacting Chipcon directly.

As far as possible, major changes of product specifications and functionality will be stated in product specific Errata

Notes published at the Chipcon website. Customers are encouraged to sign up for the Developer’s Newsletter in

order to receive the most recent updates on products and support tools.

When a product is discontinued this will be done according to Chipcon’s procedure for obsolete products as

described in Chipcon’s Quality Manual. This includes informing about last-time-buy options. The Quality Manual can

be downloaded from Chipcon’s website.

Trademarks

SmartRF

cells, modules and design expertise. Based on SmartRF

circuits as well as full custom ASICs based on customer requirements and this technology.

All other trademarks, registered trademarks and product names are the sole property of their respective owners.

© 2003, Chipcon AS. All rights reserved.

®

is a registered trademark of Chipcon AS. SmartRF® is Chipcon's RF technology platform with RF library

®

technology Chipcon develops standard component RF

SWRU050 Page 34 of 35

Page 35

Address Information

Web site: http://www.chipcon.com

E-mail: wireless@chipcon.com

Technical Support Email: support@chipcon.com

Technical Support Hotline: +47 22 95 85 45

Headquarters:

Chipcon AS

Gaustadalléen 21

NO-0349 Oslo

NORWAY

Tel: +47 22 95 85 44

Fax: +47 22 95 85 46

E-mail: wireless@chipcon.com

US Offices:

Chipcon Inc., Western US Sales Office

19925 Stevens Creek Blvd.

Cupertino, CA 95014-2358

USA

Tel: +1 408 973 7845

Fax: +1 408 973 7257

Email: USsales@chipcon.com

Sales Office Germany:

Chipcon AS

Riedberghof 3

D-74379 Ingersheim

GERMANY

Tel: +49 7142 9156815

Fax: +49 7142 9156818

Email: Germanysales@chipcon.com

Sales Office Asia :

Chipcon Asia Pacific

37F, Asem Tower

159-1 Samsung-dong, Kangnam-ku

Seoul 135-798 Korea

Tel: +82 2 6001 3888

Fax: +82 2 6001 3711

Email: Asiasales@chipcon.com

Chipcon Inc., Eastern US Sales Office

35 Pinehurst Avenue

Nashua, New Hampshire, 03062

USA

Tel: +1 603 888 1326

Fax: +1 603 888 4239

Email: eastUSsales@chipcon.com

Strategic Automotive Center:

Chipcon AS

Hechtseestrasse 16

D-83022 Rosenheim

GERMANY

Tel: +49 8031 2227 660

Fax: +49 8031 2227 661

Email: automotive@chipcon.com

SWRU050 Page 35 of 35

Page 36

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

CC2400DK

Loading...

Loading...