Page 1

CDT370

Addendum to the TMS370 Family C Source Debugger

User' s Guide

Addendum

1993 Microprocessor Development Systems

Page 2

Printed in U.S.A., October 1993; reprinted July 1995

265691 1–9761 revision B

SPNU133

Page 3

CDT370 Addendum

to the TMS370 Family

C Source Debugger

User's Guide

SPRU133

July 1995

Printed on Recycled Paper

Page 4

IMPORTANT NOTICE

T exas Instruments (TI) reserves the right to make changes to its products or to discontinue any

semiconductor product or service without notice, and advises its customers to obtain the latest

version of relevant information to verify , before placing orders, that the information being relied

on is current.

TI warrants performance of its semiconductor products and related software to the specifications

applicable at the time of sale in accordance with TI’s standard warranty . T esting and other quality

control techniques are utilized to the extent TI deems necessary to support this warranty.

Specific testing of all parameters of each device is not necessarily performed, except those

mandated by government requirements.

Certain applications using semiconductor products may involve potential risks of death,

personal injury , or severe property or environmental damage (“Critical Applications”).

TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES

OR SYSTEMS OR OTHER CRITICAL APPLICATIONS.

Inclusion of TI products in such applications is understood to be fully at the risk of the customer.

Use of TI products in such applications requires the written approval of an appropriate TI officer .

Questions concerning potential risk applications should be directed to TI through a local SC

sales office.

In order to minimize risks associated with the customer’s applications, adequate design and

operating safeguards should be provided by the customer to minimize inherent or procedural

hazards.

TI assumes no liability for applications assistance, customer product design, software

performance, or infringement of patents or services described herein. Nor does TI warrant or

represent that any license, either express or implied, is granted under any patent right, copyright,

mask work right, or other intellectual property right of TI covering or relating to any combination,

machine, or process in which such semiconductor products or services might be or are used.

Copyright 1995, Texas Instruments Incorporated

Page 5

About This Manual

This book tells you how to install and use the CDT370 (Compact Development

T ool) and explains the similarities and differences between the debugger used

with the CDT370 and the debugger that is described in the

Source Debugger User’s Guide

Information About Cautions

This book contains cautions.

This is an example of a caution statement.

A caution statement describes a situation that could potentially

damage your software or equipment.

Read This First

TMS370 Family C

.

The information in a caution is provided for your protection. Please read each

caution carefully.

FCC Warning

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which

case the user at his own expense will be required to take whatever measures

may be required to correct this interference.

Read This First

iii

Page 6

Trademarks

Trademarks

PC-DOS is a trademark of International Business Machines.

MS-DOS and Windows are trademarks of Microsoft Corporation.

iv

Page 7

Contents

Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About the CDT370 Board 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 About the Target Cable Set 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Getting Started 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 System Hardware Requirements 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 System Software Requirements 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Unpacking The CDT370 Board 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Add-On PC Connection 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Serial RS-232 Connection 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Software Installation 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Using the Debugger With Microsoft Windows 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Power-Up Procedure 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Invoking the Debugger 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 Exiting the Debugger 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Trace 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Trace and Timing 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Trace Commands 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Differences Between XDS/22 BTT and CDT370 Trace 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Programming 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Programming a Device (the P Command) 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Action Selection 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Memory Type Selection 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Validation Dialog Box 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Messages 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Autotest 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Clock Source 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Defining a Memory Map 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Memory Mapping Introduction 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Memory Mapping 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Copying Data Within the On-Board RAM 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

v

Page 8

Contents

8 Target Cables 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Target Cables Description 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Switches Description 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Installing the Target Cable in the Emulator 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Connecting the Target Cable to the Target System 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 How to Use the Target Cable 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 CDT370 Repair Guide 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 The Debugger Menu Doesn’t Display 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 The CDT370 Does Not Function 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 The Target System Doesn’t Respond 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Additional Notes 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 9

Running Title—Attribute Reference

Figures

2–1. Configuration Switches 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. DOS Command Setup for the Debugger 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1. Modify Address Dialog Box 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2. Select Action Dialog Box 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3. Select Memory Type Dialog Box 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4. Validation Dialog Box 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–1. PLCC Target Cable Termination 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–2. Switch Positions 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–3. Connecting the Target Cable to the CDT370 Board 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

vii

Page 10

Running Title—Attribute Reference

Tables

2–1. On-Board Switches 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. RS-232 Pin and Signal Assignments 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3. Summary of the Debugger Options 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4. Screen Size Options (for Use With the –b Option) 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5. Serial Port and Add-On Address Options 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1. Displayed Trace Samples 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–1. Available Target Cables 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–2. Switch Signals 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–3. Connections for CDT370/Target Cables 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10–1. Predefined Constants for Use With Conditional Commands 10-1. . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 11

Introduction

Chapter 1

Introduction

The CDT370 (Compact Development Tool) offers a low-cost but highly efficient route to TMS370 family development. In addition, the CDT370 supports

programming of the new Field Programmable Microcontroller (FPM) family

members. Features such as a new interactive windowed CDT370 debugger,

real-time emulation, and an integrated EPROM and EEPROM programmer all

contribute to enhanced user productivity and, consequently , a shorter design

cycle.

The CDT370 is composed of:

-

CDT370 emulator board

-

Interactive windowed CDT370 C-source debugger

-

Assembler and linker

-

Complete support documentation

The CDT370 debugger is a screen-oriented, interactive program that aids in

the development of applications for TMS370 family microcontrollers. The debugger is used with a hardware unit called an emulator, which provides realtime, in-circuit emulation of the TMS370 microcontroller. The debugger runs

under the MS-DOS operating system on an IBM or compatible and connects

to the emulator through an add-on PC connection or RS-232 serial communications link.

Topic Page

1.1 About The CDT370 Board 1-2

1.2 About The Target Cable Set 1-3

Introduction

1-1

Page 12

About the CDT370 Board

1.1 About the CDT370 Board

Once the CDT370 is unpacked, you can begin code development immediately .

Everything required to emulate or program TMS370 devices is provided. The

CDT370 supports the following devices:

-

TMS370Cx1x

-

TMS370Cx2x

-

TMS370Cx4x

-

TMS370Cx5x

Use the

XDS22 Extended Development System

to develop code for

TMS370Cx3x PACT devices.

The CDT370 emulator hardware is a single board that can be connected in two

different ways:

-

The CDT370 board is designed to plug into the expansion chassis of any

IBM XT/AT or compatible

-

The CDT370 can be connected to the PC through an RS-232 serial link

The CDT370 on-board hardware provides:

-

Serial/parallel communication interface

-

Real-time TMS370 emulation logic (up to 20 MHz)

-

Real-time TMS370 data EEPROM emulation logic

-

Real-time trace circular buffer (up to 2048 program steps)

-

Real-time 24-bit cycle counter

-

Integrated EPROM and EEPROM device programmer

1-2

Page 13

1.2 About the Target Cable Set

Each emulator can have a target cable with a connector on one end that has

the same pinout as the device being emulated. This connector plugs directly

into the socket on the application system (also referred to as the

circuit board that would normally hold the TMS370 device. This allows direct,

in-circuit emulation. Each target cable also has an easy-extract socket that

allows you to program the devices.

In the supported TMS370 family, there are five different packages:

-

28DIL

-

28LCC

-

40DIL

-

44LCC

-

68LCC

There are seven different target cables to support these packages because

the 40-pin DIL and the 44-pin LCC TMS370Cx2x devices have different pinouts than the 40-pin DIL and 44-pin LCC TMS370Cx4x devices. As a result,

the emulator target cables for the devices are different and not interchangeable. The seven target cable sets are listed below along with the devices they

support:

About the Target Cable Set

target system

)

-

x1x devices in 28-pin DIL socket 28-pin DIL target cable. . . . . . . . . . . . .

-

x1x devices in 28-pin LCC socket 28-pin LCC target cable. . . . . . . . . . .

-

x2x devices in 40-pin DIL socket 40-pin DIL target cable. . . . . . . . . . . . .

-

x2x devices in 44-pin LCC socket 44-pin LCC target cable. . . . . . . . . . .

-

x4x devices in 40-pin DIL socket 40-pin DIL target cable. . . . . . . . . . . . .

-

x4x devices in 44-pin LCC socket 44-pin LCC target cable. . . . . . . . . . .

-

x5x devices in 68-pin LCC socket 68-pin LCC target cable. . . . . . . . . . .

Introduction

1-3

Page 14

1-4

Page 15

Running Title—Attribute Reference

Chapter 2

Getting Started

This chapter includes the proper procedures to set up the CDT370.

The following topics are covered:

Topic Page

2.1 System Hardware Requirements 2-2

2.2 System Software Requirements 2-3

2.3 Unpacking the CDT370 Board 2-4

2.4 Add-On PC Connection 2-5

2.5 Serial RS-232 Connection 2-7

2.6 Software Installation 2-9

2.7 Using the Debugger With Microsoft Windows 2-15

2.8 Power-Up Procedure 2-17

2.9 Invoking the Debugger 2-18

2.10 Exiting the Debugger 2-21

Chapter Title—Attribute Reference

2-1

Page 16

System Hardware Requirements

2.1 System Hardware Requirements

Host An IBM PC XT/A T or 100% compatible PC with a hard-disk system,

a serial port or a free full-length internal slot, and a 1.2-Mbyte 5-1/4”

floppy-disk drive.

Memory A minimum of 640K bytes of main memory is needed, but extended

(minimum 256K bytes) memory is also needed when you run the debugger under Windows.

Display A monochrome screen can be used, but a color screen (EGA or

VGA) is recommended.

Cable A target cable is required to connect the CDT370 board to the target,

but it is not needed when the emulator runs in stand-alone mode.

Options A Microsoft-compatible mouse.

An EGA- or VGA-compatible graphics display card and a large

monitor.

The debugger has two options that allow you to change the overall

size of the debugger display.

To use a larger screen size, you must invoke the debugger with the

appropriate option. For more information about options, refer to

Section 2.9,

Miscellaneous Blank, formatted disks.

Invoking the Debugger

.

2-2

Note: Firmware Version

Make sure you are using a CDT370 board with firmware version 3.0 or later.

Page 17

2.2 System Software Requirements

Operating System MS-DOS or PC-DOS (version 3.0 or later)

Optional: Microsoft Windows (version 3.0 or later)

Software Tools TMS370 C compiler, assembler (version 5.06 or later), and linker.

If you have a program that you assembled with an earlier version of

the assembler, be sure to update it.

Optional Files

†

init.cmd is a file that contains debugger commands. The version of

this file that’s shipped with the debugger defines a ’370 memory

map. If this file isn’t present when you first invoke the debugger, then

all memory is invalid at first. When you first start using the debugger,

this memory map should be sufficient for your needs.

Later, you may want to define your own memory map. For information about setting up your own memory map, refer to Section 7.2,

Memory Mapping

ily C Source Debugger User’s Guide

In addition to init.cmd, there are several other .cmd files in the maps

directory. These .cmd files define memory maps for standard ’370

devices. If you want to emulate a specific device, copy the appropriate .cmd file into your init.cmd file.

init.clr is a general-purpose screen configuration file. If this file isn’t

present when you invoke the debugger, the debugger uses the default screen configuration.

The default configuration file (.clr extension) is for color monitors;

another file (.mon extension) can be used with monochrome monitors. Several of each type of screen configuration file are included

in your screens directory. When you first invoke the debugger, the

default screen configuration should be sufficient for your needs. Later, you may want to define your own custom configuration.

and

Defining a Memory Map

System Software Requirements

, in the

TMS370 Fam-

.

†

For information about these files and about setting up your own

screen configuration, refer to

TMS370 Family C Source Debugger User’s Guide

the

Customizing the Debugger Display

.

, in

Due to the 640K-byte memory limitation under DOS, it may not be

possible to load and/or debug large applications with the DOS version of the debugger. The Windows version of the debugger will

make use of any extended memory available on the PC.

Included as part of the debugger package, these files are available on the C-source debugger

product disk but have not been copied by the installation process.

Getting Started

2-3

Page 18

Unpacking the CDT370 Board

2.3 Unpacking the CDT370 Board

Before you unpack the CDT370 board, decide if you want to plug the board into

an expansion slot inside your PC or connect it to an RS-232 cable outside your

PC. Placing the board inside your computer’s case is preferable, but if you

have no empty slots or if the internal mount makes it awkward to access the

target system, the RS-232 link can be used.

Remove the CDT370 board from its antistatic protection sheath.

To avoid damage to the board, do not touch the board directly,

except at a static-free workstation.

Do not connect any electric motors or fluorescent lights to the

CDT370 power circuit. Noise and/or voltage spikes from these

devices could affect operation.

Do not plug the CDT board into a slot next to an Ethernet card. The

target cables are not shielded.

2-4

Page 19

2.4 Add-On PC Connection

The CDT370 board can be plugged into any IBM PC XT/AT or compatible.

There are two different areas of jumpers on the board:

-

CONF with two possible positions

-

COM PORT with 4 possible positions

The shipping position is: Add-on PC link / Address 318h, IRQ4.

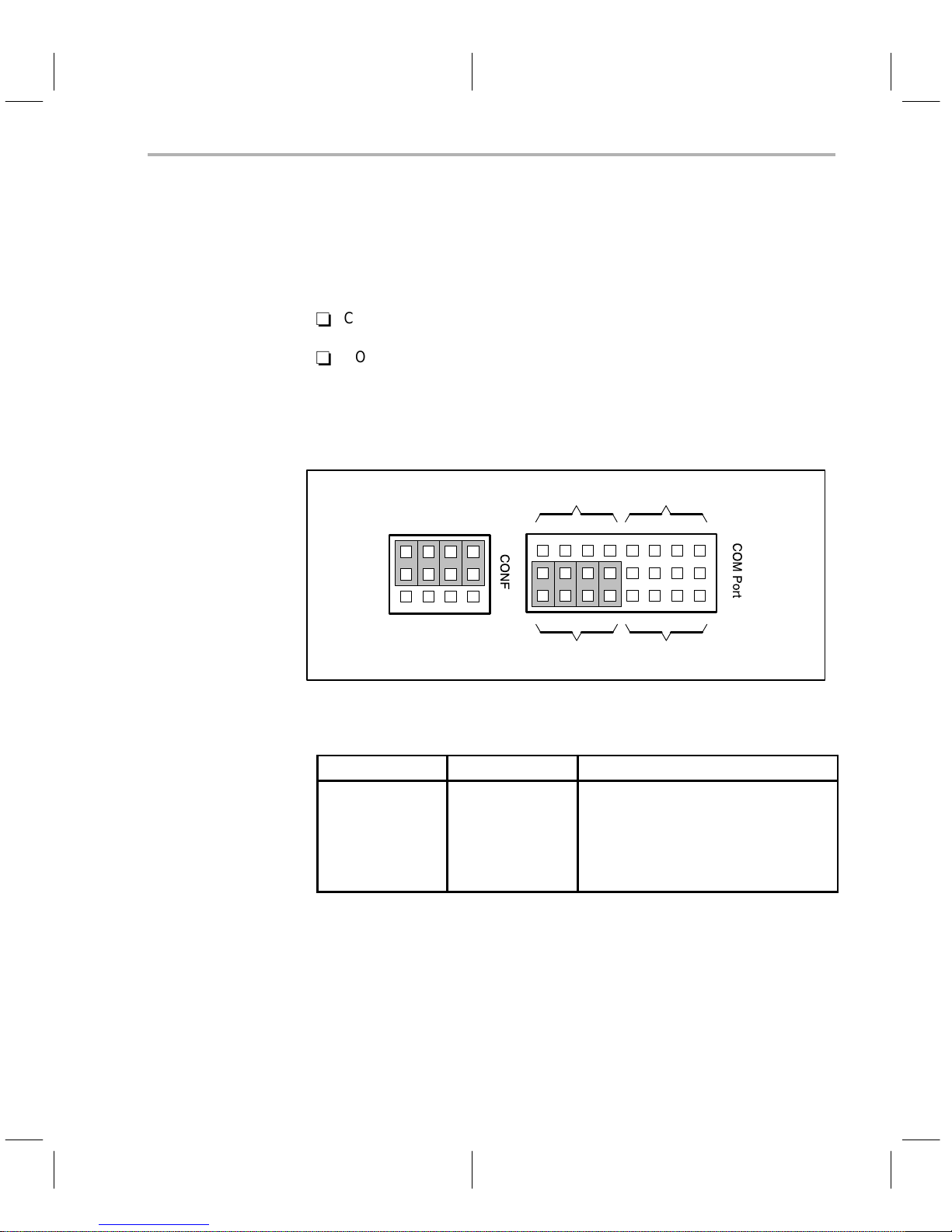

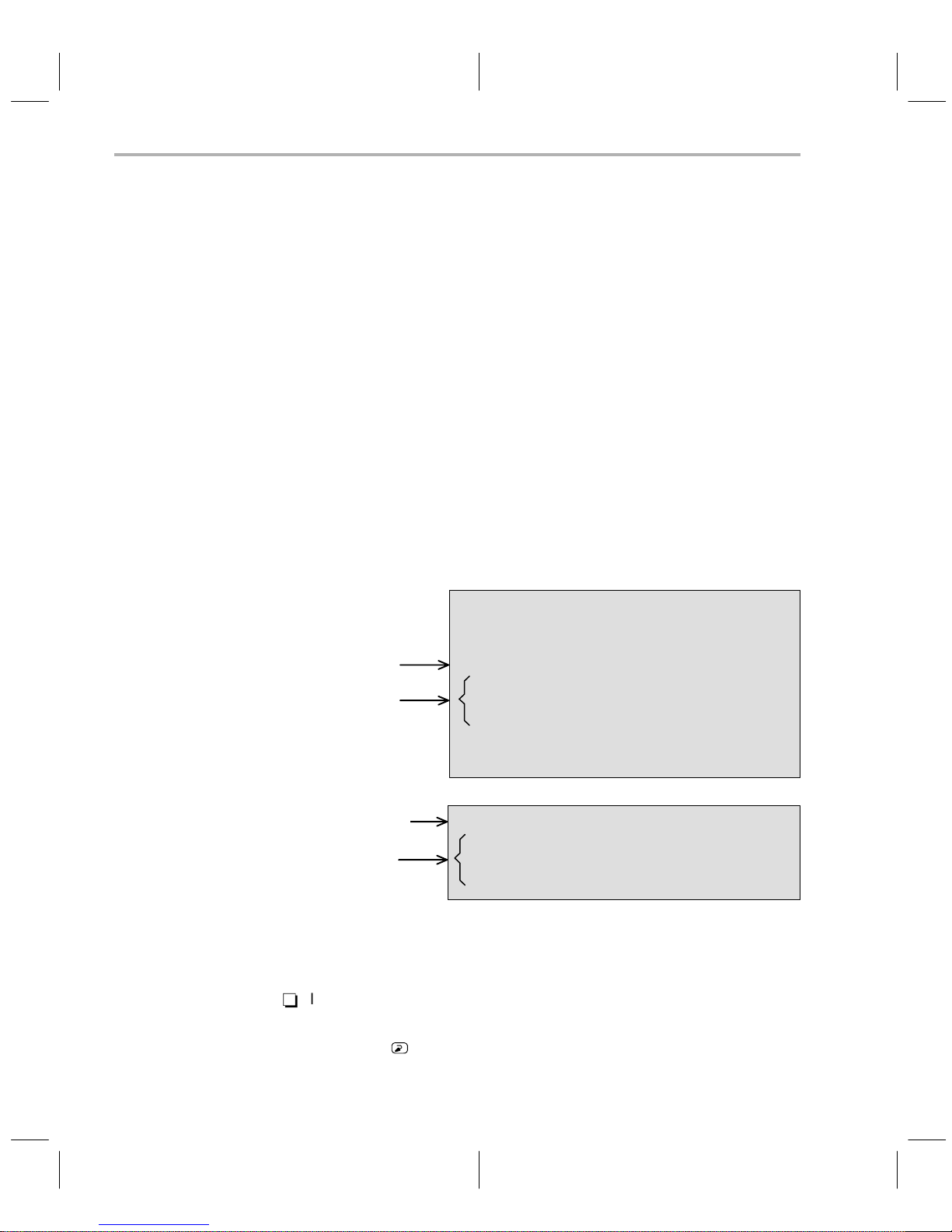

Figure 2–1.Configuration Switches

Add-On PC Connection

COM2 COM4

Add-On

Table 2–1.On-Board Switches

CONF COM Port Comments

ADD-ON

ADD-ON

ADD-ON

ADD-ON

RS-232

RS-232

Step 1: The CONF jumper must be set to the ADD-ON position, and the com

Step 2: Switch off your IBM PC XT/A T or compatible and remove the cover.

RS232

COM1 COM3

COM1

COM2

COM3

COM4

X

X

Add-on PC link / 318h, IRQ4

Add-on PC link / 358h, IRQ2

Add-on PC link / 338h, IRQ3

Add-on PC link / 398h, IRQ7

RS-232 link / serial com port 1

RS-232 link / serial com port 2

PORT jumper must be set to one of the four positions that are

referred to as COM1 through com 4.

Then, carefully plug the properly configured CDT370 board into an

empty slot.

Getting Started

2-5

Page 20

Add-On PC Connection

Step 3: To use the CDT370 to perform in-circuit emulation on your target

device or device programming, plug the target cable dedicated to the

TMS370 family member you are working with into the CDT370 board

before closing the cover.

For target cable connection, refer to Chapter 8,

T arget Connectors

Step 4: Close the cover of your PC and turn the power on.

.

2-6

Page 21

2.5 Serial RS-232 Connection

This section discusses connecting the debugger’s host machine to the

CDT370 board with a serial RS-232 communication link.

In addition to what is supplied with the CDT370 board, you must supply a 5-volt

regulated power supply (Icdt max = 1.8 A. Standard 5-V , 3-A power supply recommended) and an RS-232 serial cable type DB-9.

Do not connect the system to a power source at this time. Wait until

all installation checks are complete.

Check to make sure that there are no metal objects beneath the

CDT370 board that might short the V

Step 1: The CONF jumper must be set to the position RS232.

When the CONF jumper is set to RS232, the com PORT area’s jumper is not relevant, and any position is allowed.

Serial RS-232 Connection

, ground, or other signals.

cc

Step 2: Connect the external regulated power supply to the CDT370 board

through the dedicated connector. Make sure that the polarity is set

correctly.

Step 3: Connect the RS-232 cable of the host to the DB-9 pin connector of

the CDT370 according to the cable description (Table 2–2).

Step 4: If you want to perform in-circuit emulation or device programming

with the CDT370, install the target cable dedicated to the TMS370

family member you are working with.

For target cable connections, refer to Chapter 8,

T arget Connectors

Step 5: Turn the CDT370 board on before you turn on the application hard-

ware.

.

Getting Started

2-7

Page 22

Serial RS-232 Connection

The CDT370 uses 8 of the 9 signals on a DB9 connector to communicate with

the host. The pin and signal assignments for the emulator and host computer

are listed in Table 2–2.

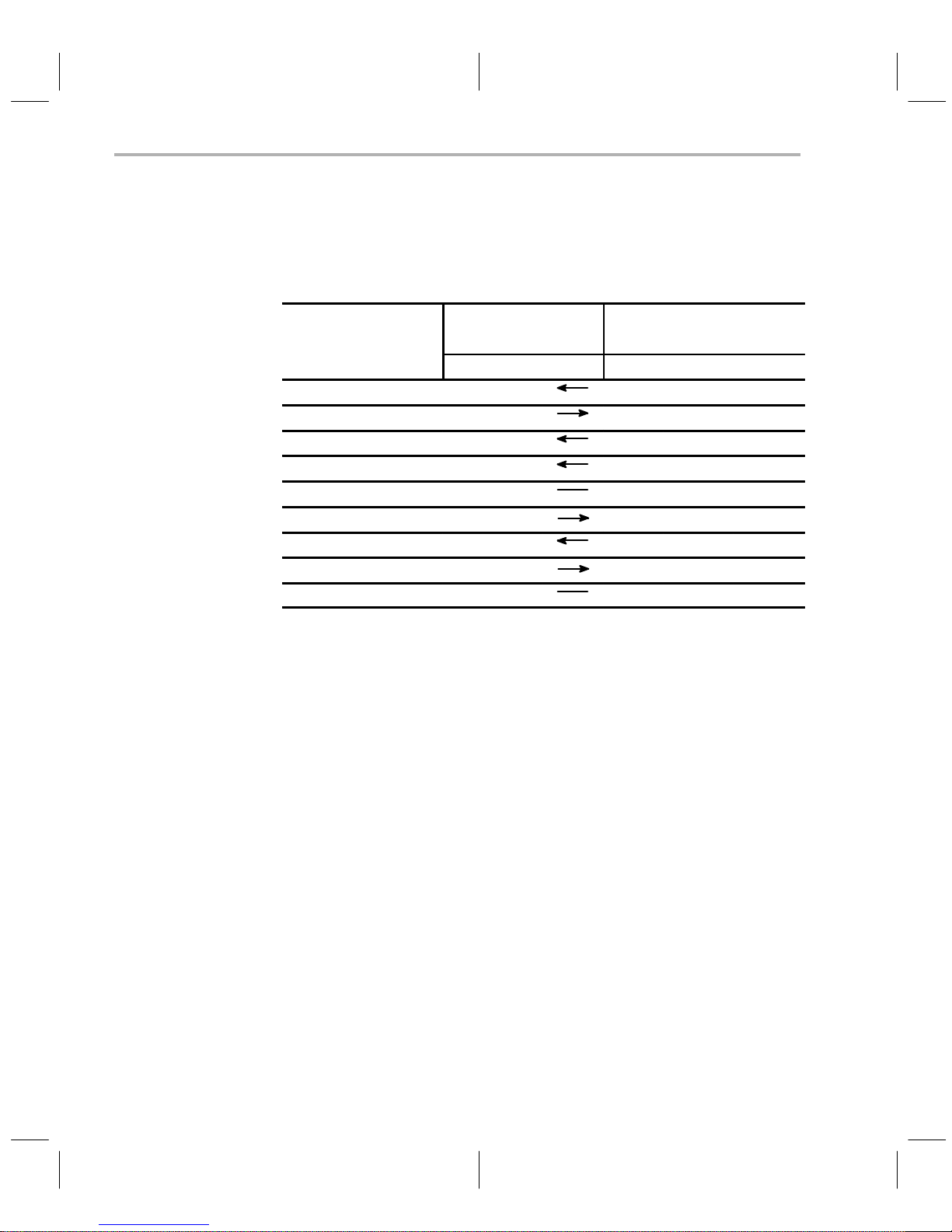

Table 2–2.RS-232

Pin and Signal Assignments

CDT370 HOST

Function

Female DB-9 DB-25 DB-9

Pin

Signal Signal Pin/XT Pin/AT

Connect Established 1 DCD DCD 8 1

Data to Host 2 TX RX 3 2

Data to Emulator 3 RX TX 2 3

Terminal Ready 4 DTR DTR 20 4

Signal Ground 5 GND GND 7 5

Emulator Ready 6 DSR DSR 6 6

Attention to Emulator 7 CTS RTS 4 7

Attention to Host 8 RTS CTS 5 8

Not used 9 RI RI 22 9

2-8

Page 23

2.6 Software Installation

This section explains the process of installing the debugger software on a

hard-disk system:

1) Make a backup copy of each product disk. Refer to a DOS manual, if necessary, to complete this step.

2) On your hard disk or system disk, create a directory named 370TOOLS.

This directory will contain the debugger software.

md c:\370TOOLS

3) Insert a product disk into drive A. Copy the debugger software onto the

hard disk or system disk.

copy a:\*.* c:\370TOOLS\*.* /v

Repeat this step for each product diskette.

4) If you don’t plan to use both the DOS and the Windows versions of the

debugger, you may want to delete the one you’re not using.

To delete the DOS executable file, enter:

del cdt370.exe

To delete the Windows executable file, enter:

del cdt370w.exe

Software Installation

Modifying your config.sys file

When using the debugger, you can have only twenty files open or active at the

same time. To tell the system not to allow more than twenty active files, you

must add the following line to your config.sys file:

FILES = 20

Once you have edited your config.sys file and added the line, invoke the file

by turning off the PC’s power and turning it on again.

Setting up the debugger environment

To ensure that your debugger works correctly, you must:

-

Modify the PATH statement to identify the 370TOOLS directory.

-

Define environment variables so that the debugger can find the files it

needs.

Not only must you do these things before you invoke the debugger for the first

you must do them any time you power up or reboot the system

time,

Getting Started

.

2-9

Page 24

Software Installation

You can accomplish these tasks by entering individual DOS commands, but

it’s simpler to put the commands in a batch file.

Y ou can edit your system’s autoexec.bat file; however , in some cases, modifying the autoexec.bat file may interfere with other applications running on your

PC. So, if you prefer, you can create a separate batch file that performs these

tasks.

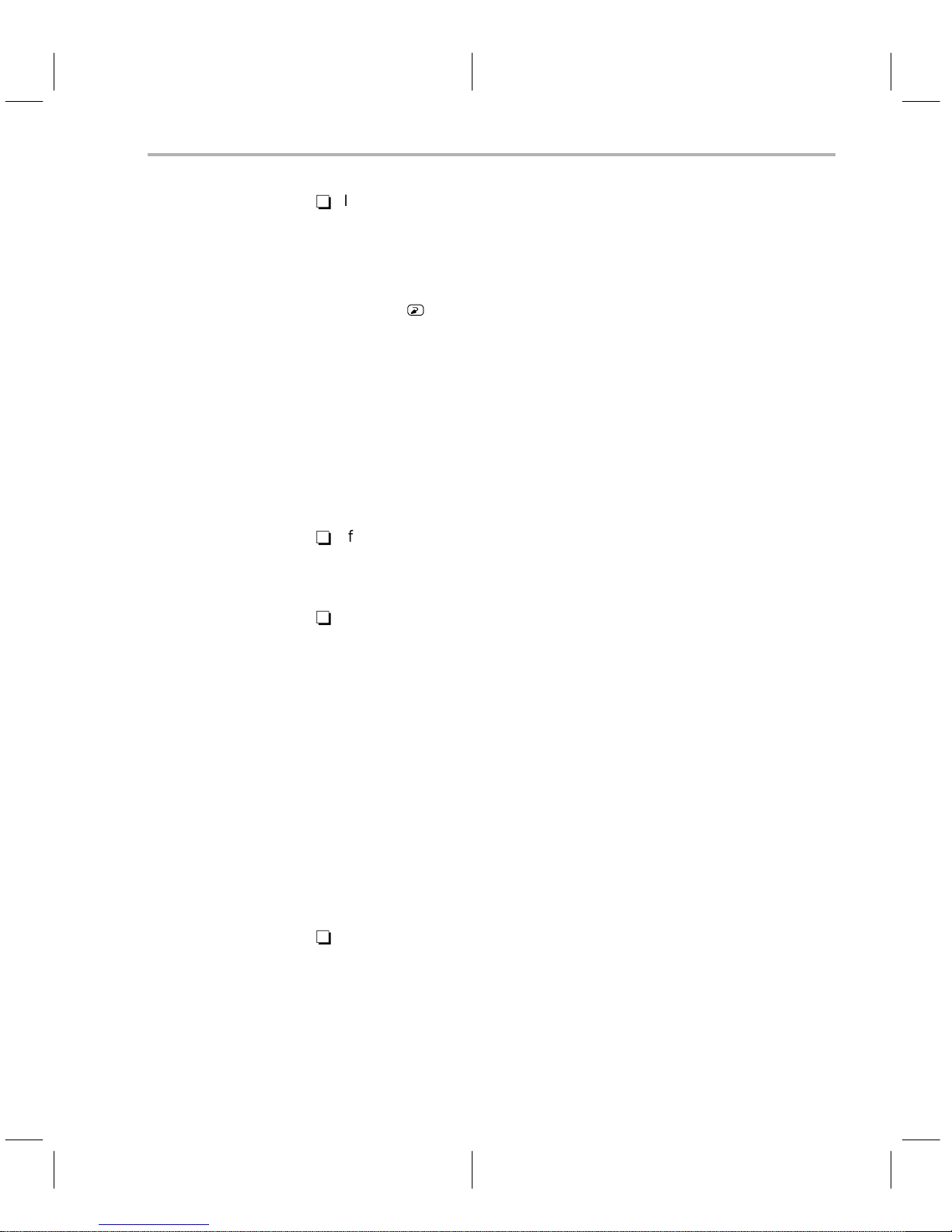

Figure 2–2 (a) shows an example of an autoexec.bat file that contains the suggested modifications (highlighted in bold type).

Figure 2–2 (b) shows a sample batch file that you could create instead of editing the autoexec.bat file. (For the purpose of discussion, assume that this sample file is named initdb.bat). The subsections following the figure explain these

modifications.

Figure 2–2.DOS Command Setup for the Debugger

(a) Sample autoexec.bat file

P ATH statement

Environment

variables and

I/O space

(b) Sample initdb.bat file

P ATH statement

Environment

variables and

I/O space

Invoking the new or modified batch file

-

If you modify the autoexec.bat file, be sure to invoke it before invoking the

debugger for the first time. To invoke this file, enter:

autoexec

DATE

TIME

ECHO OFF

PATH=c:\dos;c:\370tools

SET D_DIR=c:\370tools

SET D_SRC=;c:\csource

SET D_OPTIONS=–p2 –b

SET C_DIR=c:\370tools

CLS

PATH=C:\370tools;%path%

SET D_DIR=c:\370tools

SET D_SRC=c:\csource

SET D_OPTIONS=–p2 –b

2-10

Page 25

-

If you create an initdb.bat file, you must invoke it before invoking the debugger for the first time. If you are using Microsoft Windows, invoke

initdb.bat

to invoke initdb.bat any time that you power up or reboot your PC. To do

so, enter:

initdb

Modifying the path statement

Define a path to the debugger directory. The general format for doing this is:

Software Installation

before

entering the Windows environment. After that, you’ll need

PATH = C:\370TOOLS;

This allows you to invoke the debugger without specifying the name of the directory that contains the debugger executable file.

-

If you are modifying your autoexec.bat file and it already contains a P A TH

statement, simply include ;C:\370TOOLS at the end of the statement, as

shown in Figure 2–2 (a).

-

If you are creating an initdb.bat file, use a different format for the PATH

statement:

PATH=C:\370TOOLS;%path%

The addition of ;%path% ensures that this P ATH statement won’t undo the

PATH statements in other batch files (including the autoexec.bat file).

Setting up the environment variables

An environment variable is a special system symbol that the debugger uses

for finding or obtaining certain types of information. The debugger uses three

environment variables named D_DIR, D_SRC, and D_OPTIONS. The next

three steps tell you how to set up these environment variables. The format for

doing this is the same for both the autoexec.bat and initdb.bat files.

pathname2;pathname3

;...

-

Set up the D_DIR environment variable to identify the 370TOOLS directory:

SET D_DIR=C:\370TOOLS;

pathname2

;....

(Be careful not to precede the equal sign with a space).

This directory contains auxiliary files (init.cmd) that the debugger needs.

Getting Started

2-1 1

Page 26

Software Installation

-

Set up the D_SRC environment variable to identify any directories that

contain program source files that you will want to look at while you’re debugging code. The general format is:

SET D_SRC=

pathname1;pathname2

;...

(Be careful not to precede the equal sign with a space).

For example, if your ’370 programs reside in a directory named

CSOURCES, the D_SRC setup would be:

SET D_SRC=C:\CSOURCES

-

Y ou can use several options when you invoke the debugger. If you use the

same options over and over, it’s convenient to specify them with D_OPTIONS. The general format for doing this is:

SET D_OPTIONS=[

object filename][debugger options

(Be careful not to precede the equal sign with a space).

This tells the debugger to load the specified object file and use the se-

lected options each time you invoke the debugger.

These are the options that you can identify with D_OPTIONS:

]

Verifying the installation

To ensure that you have correctly installed the emulator and debugger software, enter this command at the system prompt:

CDT370 C:\370TOOLS\sample –p

or

CDT370 C:\370TOOLS\sample –a

–b –bb –i

–a

add-on address

–t

filename

–profile –s

–v

pathname

–p

serial port

Note that the –p and –a options cannot be used at the same time. Also, you

can override D_OPTIONS by invoking the debugger with the –x option.

For more information about options, refer to Section 2.9,

Debugger

.

serial port

add_on address

Invoking the

2-12

Page 27

Software Installation

If you are using Microsoft Windows, use cdt370w to invoke the debugger.

Please refer to Section 2.7 for information on running under Microsoft Windows. After invoking the debugger, you should see a display similar to this:

Load Break Watch Memory

DISASSEMBLY

7185 88 c_into0: MOVW #02883h,R021

7189 98 MOVW R021,R01F

718c 52 MOV #022h,B

718e fd LDSP

718f 8e CALL 7199h

7192 8e CALL main

7195 8e CALL exit

7198 fa RTI

7199 88 MOVW #0723Ah,R0F

719d 00 JMP 71BFh

719f f4 MOV 3(R0F),A

71a3 d0 MOV A,R0D

71a5 f4 MOV 2(R0F),A

71a9 d0 MOV A,R0C

71ab 70 INCW #4,R0F

71ae 00 JMP 71BAh

COMMAND

(c)Copyright 1992, Texas Instruments

Silicon Revision 2

Emulator Revision 1

Loading sample.out

Done

>>>

-

If you see a display similar to this one, you have correctly installed your

MoDe Run=F5 Step=F8 Next=F10Color

BTT

MEMORY

0000 87 00 cb 01 00 00 28 e5 00 00 00 00

000c 28 81 72 44 00 00 00 00 00 00 00 00

0018 00 00 00 00 00 00 28 87 28 8f 00 70

0024 40 00 00 00 00 00 00 00 00 00 00 00

0030 00 00 00 00 00 00 00 00 00 00 00 00

CPU

PC 7185

A87

B00

ST 40

SP 22

emulator and debugger.

-

If you don’t see a display, then your debugger or cables may not be

installed properly. Go back through the installation instructions and be

sure that you have followed each step correctly; then reenter the command.

Installation error messages

If the following message appears on your screen:

One of several conditions may be the cause.

Check these items:

-

CANNOT INITIALIZE TARGET SYSTEM ! !

– Check I/O configuration

– Check cabling and target power

If the target cable is installed on the target board, is the target board powered?

Getting Started

2-13

Page 28

Software Installation

-

If the target cable is not installed on the target, is it isolated from any conductive surfaces, including conductive foam or bags?

-

Is the emulator board installed properly and powered?

-

Are you using the correct host communication port?

-

If an RS-232 link is used, is the cable properly connected and wired?

-

Is your serial port or add-on address set correctly?

2-14

Page 29

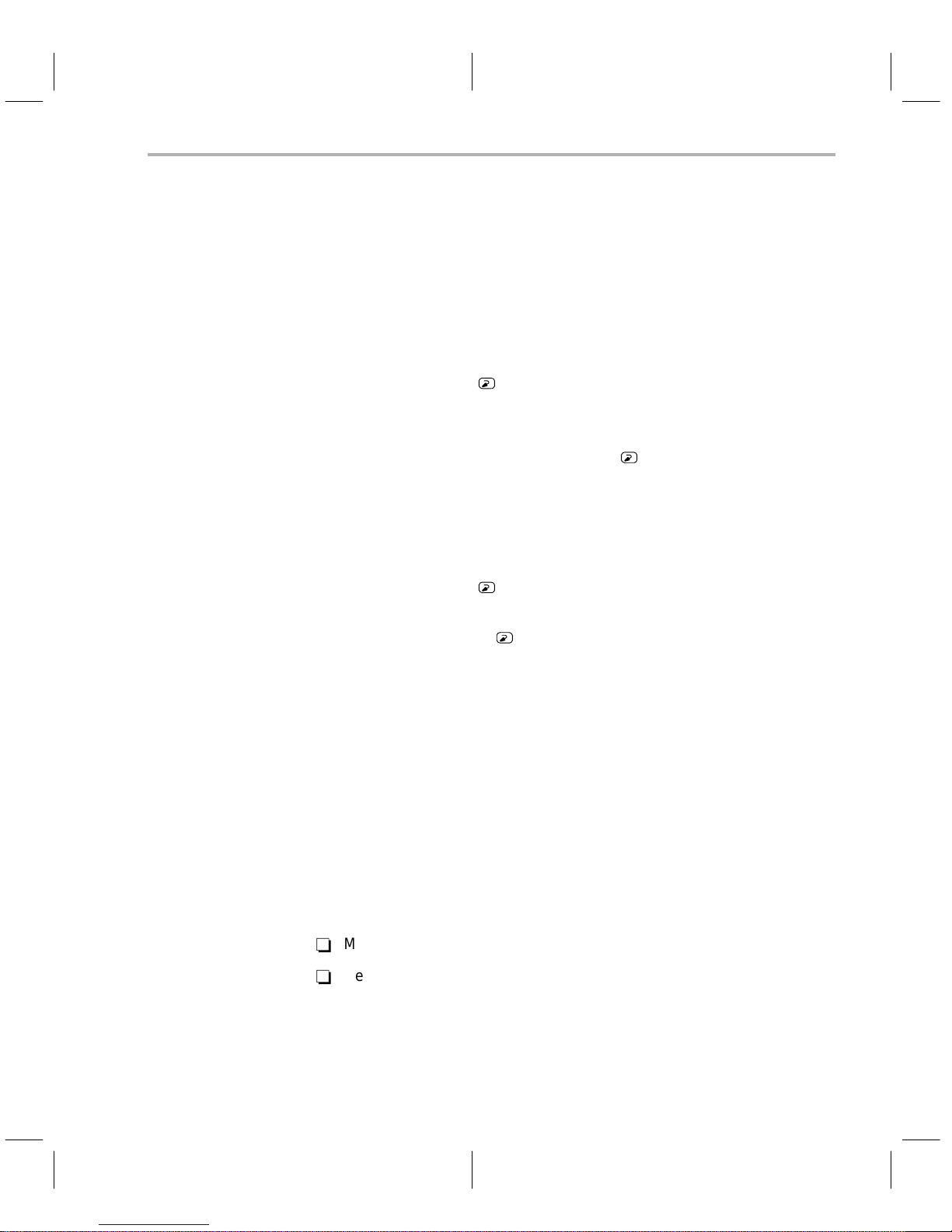

Using the Debugger With Microsoft Windows

2.7 Using the Debugger With Microsoft Windows

When using the debugger under Windows, you must configure a communication port:

-

Serial Connection: The debugger will communicate with Windows

through Windows com port 1 if you have connected the CDT370 to com

port 1, and Windows com port 2 if you have connected the CDT370 to com

port 2. The standard communication settings (baud rate, data bits, parity ,

stop bits, and flow control) are configured directly by the debugger software without your intervention and can therefore be ignored.

The advanced settings should be configured by your Windows program to

correspond to your hardware setup. You can verify this by checking the

advanced communications settings of the com port you are using; open

the Control Panel window, select the Ports icon, and compare the

advanced settings for the port you are using (COM1 or COM2) against

your hardware manual.

-

Add-On PC Connection: Regardless of how you set the com port jumper

on the CDT370 board, the debugger software will always communicate

with Windows through Windows com port 3. The standard communication

settings (baud rate, data bits, parity , stop bits, and flow control) are configured directly by the debugger software without your intervention and can

therefore be ignored. Y ou must set the advanced settings, however (base

I/O port address and interrupt request line (IRQ)).

To configure the port, open the Control Panel window and choose the

Ports icon. The Ports dialog box appears, showing icons for the four possible serial ports. Double-click on the COM3: icon. The Settings dialog box

appears. Choose the Advanced button. The Advanced Settings dialog box

appears. Type the correct value into the Base I/O Port Address; then open

the Interrupt Request Line list and select the proper IRQ number. These

values are determined by the way you have positioned the com port

jumper on the CDT370 board and are shown in Table 2–1 on page 2-5.

Choose the OK button and restart Windows by choosing the Restart Now

button.

Getting Started

2-15

Page 30

Using the Debugger With Microsoft Windows

Example 2–1.Examples of Windows COM Port Configuration for Add-on Connections

1) Add-on connection with jumper position COM2

0358

2

2) Add-on connection with jumper position COM3

0338

3

Invoking the debugger with Microsoft Windows

Y ou may want to create an icon to make it easier to invoke the debugger from

within the Microsoft Windows environment. To install the debugger software

in Microsoft Windows, create a new program item. (Please refer to your Microsoft Windows manual for details.) While creating a new program item, type

cdt370w.exe at the command line and include any additional parameters you

want. If you plan on using the profiler, be sure to include the

–profile

option.

If you prefer, you can also execute the DOS version from Windows by entering

cdt370.exe at the command line. If you are going to be switching frequently

between the basic debugger and the profiler, it might be more convenient for

you to create separate program items for each.

Using Microsoft Windows, you can freely move or resize the debugger display

on the screen. If the resized display is bigger than the debugger requires, the

extra space is not used. If the resized display is smaller than required, the display is clipped. Note that when the display is clipped, it can’t be scrolled.

When running Microsoft Windows, you should run it in either the standard

mode or the 386 enhanced mode to get the best results.

2-16

Page 31

2.8 Power-Up Procedure

If a target system is used, replace the TMS370 microprocessor in the target

system with the target connector of the CDT370. See Section 8.4,

the Target Cable to the Target System

correct.

Note: Pin 1 is marked with an open dot ( f ).

Always ensure that the power of the CDT370 is off before

connecting or disconnecting the target connectors.

Power-Up Procedure

Connecting

. Make sure that the pin orientation is

Getting Started

2-17

Page 32

Invoking the Debugger

2.9 Invoking the Debugger

Before invoking the debugger, check that the emulator is properly configured

and that the cable from the emulator to the PC host (if used) is properly connected. The debugger will not operate unless the emulator is correctly connected and turned on.

Here’s the basic format for the commands that invoke the debugger:

cdt370 [

filename

] [

–options

cdt370 is the command that invokes the debugger. If you are using

Microsoft Windows, use cdt370w to invoke the debugger.

filename

is an optional parameter that names an object file that the

debugger will load into memory during invocation. The

debugger looks for the file in the current directory; if the file

isn’t in the current directory , you must supply the entire pathname. If you don’t supply an extension for the filename, the

debugger assumes that the extension is .out.

–options

supply the debugger with additional information (Table 2–3

summarizes the available options).

You can also specify filename and option information with the D_OPTIONS

environment variable (see

2-1 1). T able 2–3 lists the debugger options; the subsections following the table

describe the options.

Table 2–3.Summary of the Debugger Options

Option Brief description

–b[b] Selects the screen size

–i

pathname

address

–a

–p

serial port

–profile Enter the profile environment (Windows version only)

–s Load the symbol table only

–t

filename

–v Load without the symbol table

–x

]

Setting up the environment variables

Identify additional directories

Identify the add-on address

Identify the serial port

Identify a new initialization file

Ignore D_OPTIONS

on page

Selecting the screen size (–b option)

By default, the debugger uses an 80-character-by-25-line screen. Y ou can use

one of the options in Table 2–4 to specify a different screen size.

2-18

Page 33

Table 2–4.Screen Size Options (for Use With the –b Option)

Option Description Notes

none

–b 80 characters by 43 lines Any EGA or VGA display

–bb 80 characters by 50 lines VGA only

Note:

80 characters by 25 lines Default display

Invoking the Debugger

Using the –b options overrides the

init.clr

file.

Identifying additional directories (–i option)

The –i option identifies additional directories that contain your source files. Re-

place

pathname

with an appropriate directory name. Y ou can specify several

pathnames; use the –i option as many times as necessary. For example:

CDT370 –i

path1

–i

path2

–i

path3

...

Using –i is similar to using the D_SRC environment variable.

Setting up the environment variables

(See

in 2.4.3)

If you name directories with both –i and D_SRC, the debugger first searches

through directories named with –i. The debugger can track a cumulative total

of 20 paths (including paths specified with –i,D_SRC, and the debugger USE

command).

Identifying the serial port (–p option )or the add-on address (–a option)

The –p or –a option identifies the serial port or the add-on address that the

debugger uses for communicating with the emulator. The default value, –a1,

corresponds to the CDT370 board shipping position (Add-on PC link, Address

318h, IRQ4). Depending on your configuration, use one of these values:

Table 2–5.Serial Port and Add-On Address Options

Option CONF COM PORT Comments

–a1

–a2 ADD-ON COM2 Add-on PC link 358h IRQ2

–a3 ADD-ON COM3 Add-on PC link 338h IRQ3

–a4 ADD-ON COM4 Add-on PC link 398h IRQ7

–p1 RS-232 X RS232 link serial com port 1

–p2

ADD-ON COM1 Add-on PC link 318h IRQ4

RS-232 X RS232 link serial com port 2

Getting Started

2-19

Page 34

Invoking the Debugger

Note: You Cannot Use the –a and –p Options at the Same Time

the –a and –p options are mutually exclusive; only one can be used (according to your hardware configuration)

If you used a wrong setting, you’ll see this error message when you try to invoke the debugger:

CANNOT INITIALIZE TARGET SYSTEM ! !

– Check I/O configuration

– Check cabling and target power

Entering the profiling environment (–profile option)

The –profile option allows you to bring up the debugger in a profiling environ-

ment so that you can collect statistics about code execution. Note that only a

subset of the base debugger features is available in the profiling environment.

Loading the symbol table only (–s option)

.

If you supply a filename when you invoke the debugger, you can use the –s

option to tell the debugger to load only the file’s symbol table (without the file’s

object code). This is similar to the debugger’s SLOAD command.

Identifying a new initialization file (–t option)

The –t option allows you to specify an initialization command file that will be

used instead of init.cmd. If –t is present on the command line, the file specified

by filename will be invoked as the command file instead of init.cmd.

Loading without the symbol table (–v option)

The –v option prevents the debugger from loading the entire symbol table

when you load an object file. The debugger loads only the global symbols and

later loads local symbols as it needs them. This speeds up the loading time and

consumes less memory space.

The –v option affects all loads, including those performed when you invoke the

debugger and those performed with the LOAD command within the debugger

environment.

Ignoring D_OPTIONS (–x option)

The –x option tells the debugger to ignore any information supplied with the

D_OPTIONS. For more information about D_OPTIONS, please refer to

ting up the environment variables

Set-

in Section 2.6.

2-20

Page 35

2.10 Exiting the Debugger

To exit any version of the debugger and return to the operating system, enter

this command:

quit

You don’t need to worry about where the cursor is or which window is

active—just type. If a program is running, press

before you quit the debugger.

If you are running the debugger under Microsoft Windows, you can also exit

the debugger by selecting the exit option from the Microsoft Windows menu

bar.

Exiting the Debugger

ESC

to halt program execution

Getting Started

2-21

Page 36

2-22

Page 37

Running Title—Attribute Reference

Chapter 3

Trace

This chapter explains how to use the circular trace buffer that exists on the

CDT370 board. With the trace buffer and the trace and timing commands, you

can monitor and collect statistics on the CPU as it runs. This chapter also covers the differences between the CDT370 trace functions and the breakpoint/

trace/timing (BTT) board described in the

User’s Guide.

Topic Page

3.1 Trace and T iming 3-2

3.2 Trace Commands 3-5

3.3 Differences Between XDS/22 BTT and CDT370 Trace 3-7

TMS370 Family C Source Debugger

Chapter Title—Attribute Reference

3-1

Page 38

Trace and Timing

3.1 Trace and Timing

There is a 2K x 16-bit trace circular buffer on the CDT370 board. The TMS370

internal address bus is stored each time an opcode fetch is detected. When

you want to display the contents of this buffer , the debugger reconstitutes all

the opcodes executed by the TMS370.

This trace feature is fully real time because the CPU is not halted. The sample

capture begins when you start the CPU and ends when you halt it, either with

a breakpoint or halt command.

A 24-bit-wide on-board counter is incremented by the CPU’s clock, so the total

number of cycles can be measured between two defined instructions (referenced by two breakpoints).

The capacity of this counter is up to 16 777 216 cycles; at 20 MHz, that means

a total time of 3.35 seconds.

Trace Feature

The trace feature is used to display trace samples that have been collected,

as well as the value of the timer.

Trace Samples

When you select Trace from the menu bar , a pull-down menu is opened, where

you can open the Inspect window, position the frame to display within the Inspect window, or save the trace buffer to a file.

Most of the inspect window consists of space for the trace samples. In the bottom corner, the value of the on-board timer is displayed. You can move and

scroll through trace samples in the same way as with other windows.

Trace samples are snapshots of bus cycle activity that are collected and stored

by the on-board trace logic when the CDT370 is running.

The trace buffer is a circular buffer that can hold 2048 samples. If more samples than this are collected, the buffer wraps around, and new samples overwrite the old ones. Each sample is 16 bits wide and contains the value of the

address bus of the CPU when an opcode fetch is detected.

Each trace sample is referred to by its index in the trace buffer, starting from

0. Trace samples with lower indices are chronologically older than samples

with higher indices. Thus, if the buffer is full, sample 2046 is always the most

recent sample taken.

3-2

Page 39

When trace samples are displayed on the screen, they include the information

shown in Table 3.1 identified by a heading displayed on top of the screen.

Table 3–1.Displayed Trace Samples

Field Description

SAMPLE Index in trace buffer

ADDRESS 16-bit value of address bus

REVERSE ASM

Note: The first trace sample is never taken, but the runtime value is accurate. After target reset, trace buffer content are irrelevant.

Timer Value

On the bottom of the screen, the value of the on-board counter is displayed.

This counter is incremented by the CPU’s clock in run mode. When you enter

the RUN command (F5 key), this timer is automatically reset before the CPU

runs, and automatically disabled when the CPU is halted (manually or by a

breakpoint). As a result, you can measure the number of cycles spent during

the whole run mode. The major purpose of this counter is to measure the number of cycles spent between defined addresses. You simply need to define

breakpoints before executing the RUN command; Each time a breakpoint is

reached, the number of cycles spent since the last breakpoint is displayed.

Trace and Timing

Disassembled code

This counter is 24 bits wide, so it overflows at 16 777 216 cycles.

A time information can be obtained by applying the following formula :

TIME_SPENT (ms)

ACCURACY (ms)

4 COUNTER_VALUE

+

FREQUENCY_USED (MHz)

+

FREQUENCY_USED (MHz)

4

For example, if the frequency is 16 MHz, and the counter value is 42 400, the

time spent and accuracy are:

TIME_SPENT (ms)

ACCURACY (ms)

4 42400

+

+

16 MHz

16 MHz

4

+

+

10600ms+10.6 ms

4

+

16

0.25ms

+

250 ns

At the maximum allowed frequency of 20 MHz, the maximum time measurable

is about 3. 355 433 seconds with an accuracy of 200 ns.

Trace

3-3

Page 40

Trace and Timing

Benchmarking

Code benchmarking, as explained in the

User’s Guide

, is also available in the CDT370. The value of the pseudoregister

TMS370 Family C Source Debugger

CLK is valid after a RUN or a RUNB command that is terminated by a software

breakpoint.

3-4

Page 41

3.2 Trace Commands

Trace Commands

T o access the T race , simply hit

opens a trace pull-down menu in which you can select or click the following

commands:

-

Inspect

-

Position

-

Save

Inspect frames (the I command)

When Inspect is selected, the debugger checks the emulator to determine how

many trace samples have been collected. If the emulator has no trace samples, a blank window appears on the screen. Otherwise, the debugger reads

a screenful of the most recent trace samples and displays them. The Inspect

window looks as follows.

(This is given as an example only and assumes that the trace has collected something)

Inspect

Sample ADDR Reverse ASM

0007

0008 7043 CALL INIT_INIT

0009 7090 RTS

0010 7046 CALL SPI_INIT

... ... ...

... ... ...

... ... ...

ALT T

7042 LDSP

, or click Trace from the menu bar . This

Sample is the frame number within the trace buffer, ADDR is the program

counter of the traced instruction, and Reverse ASM is the recreated mnemonic

of the instruction.

Position at an index (the P command)

When Position is selected by pressing

mouse, the following dialog box is opened.

ALT P

Position

Sample Number [...............................]

or by clicking the P with the

<Bottom>

<Top>

<<OK>> <Cancel>

Trace

3-5

Page 42

Trace Commands

To select the frame to display within the Inspect window, enter an adequate

frame number, select the Bottom frame (with the

it with the mouse), or select the T op frame (with the

it with the mouse). Once the choice is made, simply quit the Position window

ALT O

with the

(for OK) or

be updated accordingly.

T (T op Samples) positions the screen at the top of the trace buf fer . The oldest

samples in the buffer are displayed, starting with index 0.

B (Bottom Samples) positions the screen at the bottom of the trace buffer . The

most recent samples in the buffer are displayed. If the buffer is full, the highest

index is 2046. Otherwise, the highest index is one less than the total.

Saving trace information (the S command)

When the Save Command is invoked, the following dialog box is opened:

Save trace buffer

File name [................................................................]

Start [.....] to End [.....]

ALT B

keys or by clicking

ALT T

keys or by clicking

ALT A

(for Cancel). The Trace Window will then

The Save command saves trace samples to a disk file for later inspection. Any

number of samples can be saved, up to the number that were recorded. Just

type in the filename of the file where you want to store the trace information

and hit the enter key or click the O (for O. K.) with the mouse.

Enter the indices of the first and last samples if you want specific frames to be

saved.

The default start index is 0, and the default end index is the last sample taken;

using both defaults causes the whole trace buffer to be saved. The specified

trace samples are read from the emulator, formatted just as they would be for

display on the screen, and written to the file. If many samples are saved, this

process can be somewhat lengthy. For example, saving a full trace buffer of

2048 samples may take approximately 30 seconds.

Execute from the trace screen

Y ou can execute code while you are viewing the trace screen. You use the F8

or F10 command from the trace menu. After the code executes, the debugger

will update the trace screen by reading the new trace samples from the emulator and displaying the most recent ones.

<<OK>> <Cancel>

3-6

Page 43

Differences Between XDS/22 BTT and CDT370 Trace

3.3 Differences Between XDS/22 BTT and CDT370 Trace

The BTT command, which is specific to the XDS/22 BTT, is not available with

the CDT370.

The

TMS370 Family C Source Debugger User’s Guide

that are not applicable to the CDT370 debugger:

and

Using Hardware Breakpoint, Trace, and Timing Features

The following commands are available:

-

INSP Open INSPECT Window

-

TSAVE Store and Save the Trace Buffer

-

RUNF Run Free

-

RRUNF Reset and Run Free

-

WRUNF Wait and Run Free

-

HALT Halt Target System

T utorial: Using BTT Features

includes two chapters

.

Please refer to the

Family C Source Debugger User’s Guide

Summary of Commands and Special Keys

for a description of these commands.

in the

TMS370

Since the CDT370 does not have a BTT , you remain in control of the command

ESC

line; that is, you do not have to press

to regain control after entering a

RUNF, RRUNF, or WRUNF command.

Trace

3-7

Page 44

3-8

Page 45

With the debugger, it is possible to:

-

Program an EPROM device (FPM)

-

Program data EEPROM

-

Blank Check a device

-

Verify a device

-

Upload the contents of a device to RAM

Running Title—Attribute Reference

Chapter 4

Programming

These features use the emulator’s memory. First, you must configure the emulator memory map to match the device you are emulating. Second, you must

load your code into the emulator’s memory in the same locations where the

code will ultimately reside on the device. For information on memory mapping,

please refer to Section 7.2,

in the

TMS370 Family C Source Debugger User’s Guide.

Memory Mapping

, and to

Defining a Memory Map

Topic Page

4.1 Programming a Device (the P Command) 4-2

4.2 Action Selection 4-3

4.3 Memory T ype Selection 4-4

4.4 Validation Dialog Box 4-5

4.5 Messages 4-6

Chapter Title—Attribute Reference

4-1

Page 46

Programming a Device (the P Command)

4.1 Programming a Device (the P Command)

The P (programming) command is used to program the device that you will

plug into the target connector’s easy-extract socket. When you type

or click the P on the menu bar with the mouse, the Device Programming window is displayed and a dialog box is opened as shown in Figure 4–1.

Figure 4–1.Modify Address Dialog Box

DEVICE PROGRAMMING

Data EEPROM start address :0x1E00

Data EEPROM end address :0x1FFF

Program EPROM start address :0x4000

Program EPROM end address :0x7FFF

Warning:

1) Disconnect emulation cable from target system

2) Ensure target switches are set to ’EMU’ & install device in socket

3) Set all 3 switches on target connector to ’PROG’

A warning at the bottom of the window reminds you that you must disconnect

the emulation cable from the target system, ensure that target switches are set

to EMUL, install the device to be programmed into the socket, and finally set

all 3 switches on target connector to PROG.

Modify Address

Data EEprom start : [0x1E00]

Data EEprom end : [0x1FFF]

Program Eprom start : [0x4000]

Program Eprom end : [0x7FFF]

<<OK>> <Cancel>

ALT P

,

4-2

If you want to modify the start and end address of each memory block, click

with the mouse, or position the cursor (with the keyboard cursor keys) on the

address to modify, then enter the proper value for each memory type.

Remember to load your object code in the emulator RAM at these address

ranges before entering the Programming mode if you intend to program or

verify your device.

When the values are right for your application, click on OK with the mouse or

activate it with the

ALT O

keys. The debugger will then load progv3.obj, the

device programming utility (DPU), and open the Select Action dialog box.

Note: Effects of Loading the DPU

Loading the Device Programming Utility erases the current debugger symbol

table.

To go back, or to cancel the P Command, simply click the A with the mouse

ALT A

or use the

keys to activate the cancel command. When you specify this

commmand, the debugger will return to the menu bar.

ESC

Press the

to return to the previous window.

Page 47

4.2 Action Selection

Once the address ranges convenient for the application are selected, the

Select Action dialog box is opened as shown in Figure 4–2.

Figure 4–2.Select Action Dialog Box

Data EEPROM start address : 0x1F00

Data EEPROM end address : 0x1FFF

Program EPROM start address : 0x6000

Program EPROM end address : 0x7FFF

Warning:

1) Disconnect emulation cable from target system

2) Ensure target switches are set to ’EMU’ & install device in socket

3) Set all 3 switches on target connector to ’PROG’

You can select one of following actions:

-

Program to program the device

DEVICE PROGRAMMING

Select Action

<<Program>>

<Blanck Check>

<Verify>

<Upload>

Action Selection

<Cancel>

Program

Blank Check

Verify

Upload

-

Blank Check to check that the device has no program

-

Verify to check the contents of the device against the CDT’s content

-

Upload to upload the contents of the device into the CDT’s memory

Program is the default selection. The action selected will be applied to the

memory address ranges selected previously.

This action programs the contents of the CDT370 RAM into the device (byte

per byte copy , at the same addresses). The program is automatically verified.

This action checks whether a device has already been programmed or not.

Each EPROM or EEPROM memory location is compared to FFh.

This action verifies that the contents of the device memory perfectly match the

contents of the CDT370 RAM.

This action loads the contents of the device memory into the CDT370 RAM.

Programming

4-3

Page 48

Memory T ype Selection

4.3 Memory Type Selection

Once you have selected an action, select the type of memory you want to access.

The dialog box looks like:

Figure 4–3.Select Memory Type Dialog Box

Data EEPROM start address : 1F00

Data EEPROM end address : 1FFF

Program EPROM start address : 6000

Program EPROM end address : 7FFF

Warning:

1) Disconnect emulation cable from target system

2) Ensure target switches are set to ’EMU’ & install device in socket

3) Set all 3 switches on target connector to ’PROG’

DEVICE PROGRAMMING

Selected Action

<<Program Eprom>>

<Data EEprom>

<Both Eprom + EEprom>

<Cancel>

You can apply the selected action (Program, Blank Check, Verify or Upload)

to:

-

the Program EPROM only,

-

the Data EEPROM only,

-

or Both EPROM and EEPROM.

Program EPROM is the default selection.

4-4

Page 49

4.4 Validation Dialog Box

After selecting the memory type, the V alidation dialog box allows you to start

or cancel the operation.

Figure 4–4.Validation Dialog Box

Data EEPROM start address : 1F00

Data EEPROM end address : 1FFF

Program EPROM start address : 6000

Program EPROM end address : 7FFF

PROG Prog Eprom

Warning:

1) Disconnect emulation cable from target system

2) Ensure target switches are set to ’EMU’ & install device in socket

3) Set all 3 switches on target connector to ’PROG’

Make sure that all three target connector switches are set to PROG before

starting the operation. To abort the process once it has been started, press

ESC

.

Validation Dialog Box

DEVICE PROGRAMMING

Selected Action Selected Memory Type

<<START>>

<Cancel>

Once the operation has completed, a warning message at the bottom of the

window reminds you that, to avoid damage to the device, you must return all

3 target switches to EMUL before removing the device from the programming

socket; a completion message is displayed in the command window. You can

then repeat the same operation to the same device or a different one, or cancel

and go back to Action Selection.

Programming

4-5

Page 50

Messages

4.5 Messages

Depending on the action selected, the following messages can be displayed:

Action Message

Program Device programmed and checked

Programmation failed

Verification failed

Blank Check Device is blank

Device is not blank

Verify Device programmed and checked

Verification failed

Upload Device upload completed

All

Fault condition ... Operation failed

4-6

Page 51

Running Title—Attribute Reference

Chapter 5

Autotest

The Autotest command, from the Load pull-down menu, provides a quick technical check of the CDT370 board functionality . When you select this function,

the debugger loads the Autotest and a TMS370C756 memory map required

to perform the test. When started, the Autotest software displays the message:

AUTOTEST IN PROGRESS.

At the end of the Autotest (a few seconds), the completion message is displayed as:

AUTOTEST SUCCESSFUL or AUTOTEST FAILED.

and the original memory map is restored. The autotest program can be run

from the command line of the Command window or in a batch file.

The Autotest software must be run with

No connection to a target system and

No device in the easy extract socket of the target cable.

The Autotest software is not exhaustive.

See Chapter 9,

fails.

Note: Autotest Restores the Memory Map, but not Memory

Running the Autotest command erases the symbol table and the CDT370

memory contents.

Repair Guide,

for information about what to do if the Autotest

Autotest

5-1

Page 52

5-2

Page 53

Running Title—Attribute Reference

Chapter 6

Clock Source

Y ou can select an alternate clock setting through the Configuration dialog box

in the Load menu. Please refer to

C Source Debugger User’s Guide

CDT370.

The choices are:

-

OSCILLATOR: If you select OSCILLATOR from the menu, the debugger

will reset the TMS370 device with Osc 2 as the clock. If there is not a

usable clock signal at Osc 2, the device will use Osc 1. The CDT370 20

MHz oscillator (location Osc 1) is used to generate the default clock. Y ou

can also plug in another oscillator at Osc 2, to work at any allowed frequency. Osc 2 is the highest priority device.

Setting Up The Clock

. The crystal option is not available on the

in the

TMS370 Family

-

TARGET: If you select T ARGET , the CPU expects the clock input from the

target system. A clock buffer circuitry is found in the target cable head, so

the external clock can be a crystal.

As a result, the target clock source can be:

1) A crystal connected between low and high input lead on the target connector (the crystal driver of the target connector will generate the clock for the

CDT370 board).

2) An oscillator driving low input lead on the target connector.

If you change the clock source, the debugger tries to reset the TMS370 device

with the new clock source. If the emulator detects that the device is not operating properly , it rejects the new clock source and resets the chip again, restoring

the old clock.

When this occurs, an error message is displayed:

source

not available for clock

source

is the clock source you tried to select.

Chapter Title—Attribute Reference

6-1

Page 54

6-2

Page 55

Running Title—Attribute Reference

Chapter 7

Defining a Memory Map

Before you begin using the debugger, you must supply the debugger with a

memory map. The memory map tells the debugger which areas of memory it

can access and how those areas are accessed.

Topic Page

7.1 Memory Mapping Introduction 7-2

7.2 Memory Mapping 7-3

7.3 Copying Data Within the On-Board RAM 7-6

Chapter Title—Attribute Reference

7-1

Page 56

Memory Mapping Introduction

7.1 Memory Mapping Introduction

The memory mapping capability of the TMS370 debugger allows you to specify exactly how the CPU is allowed to access various memory ranges. The

TMS370 device provides significant flexibility in the memory map, with its various configurations of internal memory and external addressing capability. In

addition, the emulator has 64K bytes of high-speed emulation RAM, which can

be used to functionally emulate target system memory . The debugger memory

mapping system allows you to take advantage of the hardware’s flexibility.

Specifying the memory map is accomplished by dividing the 64K address

space into ranges. Each range starts and ends on a 16-byte boundary and has

a type that determines how addresses in the range are accessed. The type

determines:

-

what class of memory the range falls into, such as RAM, program ROM,

EEPROM, etc... (the type for a given range is determined by the architecture of the particular TMS370 device being emulated),

-

whether the memory is to be accessed internally on the chip, from external

target memory, or from emulator RAM, and

-

the protection that allows you to prevent the CPU from reading and/or writing to the given address range.

Please refer to

bugger User’s Guide

Defining a Memory Map

for more information.

in the

TMS370 Family C source De-

Any address that is not covered by a specified range in the debugger memory

map is considered to be “unconfigured”. All unconfigured memory is protected

against both read and write operations so that if the CPU tries to access an

unconfigured location, an access violation occurs, and the CPU halts.

7-2

Page 57

7.2 Memory Mapping

The emulator board contains 64K bytes of RAM reserved for emulation.

Memory references from the TMS370 can be satisfied in one of three ways:

-

-

-

The 64K-byte address range of the microcontroller is divided into 16-byte

areas called frames. The memory mapping scheme of the debugger and emulator allows you to specify , for each 16-byte frame of the address space, where

memory references to that frame are to be satisfied. References to the register

file (addresses 000h to 0FFh) are always satisfied internally. Sixteen-byte

frames in the peripheral register file (addresses 1000h to 10FFh) can be

mapped either internally or to an optional user-supplied peripheral expansion

board on the emulator.

In addition to mapping various parts of the address space to different parts of

the physical memory , you can protect areas of memory from certain types of

access. Protection can be on read cycles, write cycles, both, or none. If the

CPU tries to execute a memory cycle on an address that is protected for that

cycle, a trap occurs, and the CPU is halted. Thus, you can use memory as

ROM by write protecting it, and you can treat it as nonexistent by both read and

write protecting it. Any memory that you don’t explicitly map is fully protected

in this way so that any attempt to access an address outside configured

memory causes a trap and halts the CPU.

Memory Mapping

Internally from the TMS370 device,

Externally from target system memory, or

Externally from emulator RAM.

The CDT370 emulates ROM by write-protecting the ROM area of emulator

memory.

The CDT370 emulates data EEPROM with on-board hardware that allows the

use of every feature of the data EEPROM module:

-

Control frame access

-

Write-protect registers

-

Write-protect override

-

Write ones, write zeros

-

Array programming

-

Programming time of 10 ms (20 ms for array programming)

Y ou access emulated data EEPROM on the CDT370 in the same way as you

would access EEPROM on a TMS370 chip.

For more information, refer to

Data Manual

.

Data EEPROM Modules

Defining a Memory Map

in the

TMS370 Family

7-3

Page 58

Memory Mapping

Register File Memory

Description Locations are part of the TMS370 on-chip register file.

Mapping Attributes It should be mapped as IRAM for location 0x00 to 0x7F

or 0xFF, depending on the device to emulate.

Peripheral Frame Memory

Description This type is used for 16-byte ranges in the peripheral register file.

Program ROM/EPROM Memory

Description This memory type is used for addresses that fall in the range of

the on-chip mask ROM. Program ROM and program EPROM are emulated

using the high-speed RAM in the emulator.

Mapping Attributes Program ROM should be mapped as emulator ROM,

and program EPROM should always be mapped as PEPROM. This means

that whenever internal memory is enabled on the device, memory accesses

in this range are satisfied by the emulator (just as if the memory were actually

on the chip).

You must not define any EPROM control frame (EPCTL) when you define

PEPROM. You can define only one PEPROM.

Protection Attributes Program ROM is, by default, write protected. Write

cycles to addresses in a range of this type cause an access violation trap to

occur. W rites to external target memory cause a trap, but the write operation

cannot be prevented.

Note: Unsupported EPROMS

Data EPROM (DEPROM) and Custom EPROM (CEPROM) are not supported.

Data EEPROM Memory

Description The data EEPROM type is used for addresses that fall in the

range of the chip data EEPROM. Some devices have no memory of this type

in the memory map. Data EEPROM is emulated using the RAM in the emulator

and a special interface logic that allows you to use all the data EEPROM module features found in any TMS370 devices:

-

-

-

-

-

Control frame access

Write protection registers

Write protect override mode

Array programming

Minimum programming time criteria

7-4

Page 59

Memory Mapping

When a programming operation is started, it must be finished; the EXE bit must

be reset at least 10 or 20 ms (depending on the operation) after its rising edge.

Otherwise, the CPU is halted and an the following error message is displayed:

EEPROM VIOL

Since the data EEPROM memory is emulated through a simple RAM, all written data are retained as long as the CDT370 is powered; they are lost when

it is switched-off.

In all other respects, the CDT370 behaves exactly as if you were programming

actual data EEPROM with a TMS370 device. Refer to

EEPROM

in the

TMS370 Family Data Manual

for complete instructions.

Programming the Data

Mapping Attributes Data EEPROM memory must always be mapped as

DEEPROM; you can define only one DEEPROM. You must not define any

EPROM control frame (EPCTL) when you define a DEEPROM. An EPCTL is

automatically created (address 0x1010, length 0x10); any frame that may

have existed at this address must be deleted first. The EPCTL is automatically

deleted when the DEEPROM is deleted.

Note: Unsupported EEPROMS

Program EEPROM (PEEPROM) and Custom EEPROM (CEEPROM) are

not supported.

Defining a Memory Map

7-5

Page 60

Copying Data Within the On-Board RAM

7.3 Copying Data Within the On-Board RAM

You can use the MEMCOPY command to copy data from one location in the

on-board RAM to another. The syntax for the command is:

memcopy

-

The

source, destination, length

source

parameter identifies the starting address of the range that you

want to copy . This parameter can be an absolute address, a C expression,

the name of a C function, or an assembly language label.

-

destination

The

parameter identifies the location in RAM where you want

the data to go. This parameter can be an absolute address, a C expression, the name of a C function, or an assembly language label.

length

-

The

parameter defines the length of the range. This parameter can

be any C expression.

If you select Memcopy from the Memory menu, or if you enter MEMCOPY without any parameters, the debugger displays a dialog box for you to enter the

source, destination, and length.

7-6

Page 61

Running Title—Attribute Reference

Chapter 8

Target Cables

T arget cables allow you to emulate and program TMS370 devices. This chapter describes the target cables and their installation.

The following sections are included:

Topic Page