查询CDCV857A供应商

D

Phase-Lock Loop Clock Driver for Double

Data-Rate Synchronous DRAM

Applications

D

Spread Spectrum Clock Compatible

D

Operating Frequency: 60 to 180 MHz

D

Low Jitter (cyc–cyc): ±50 ps

D

Distributes One Differential Clock Input to

Ten Differential Outputs

description

The CDCV857A is a high-performance, low-skew, low-jitter zero delay buf fer that distributes a differential clock

input pair (CLK, CLK

clock output (FBOUT, FBOUT

clocks (FBIN, FBIN

and frequency with CLK. When PWRDWN

and the PLL is shut down (low power mode). The device also enters this low power mode when the input

frequency falls below a suggested detection frequency that is below 20 MHz (typical 10 MHz). An input

frequency detection circuit will detect the low frequency condition and after applying a >20 MHz input signal this

detection circuit turns on the PLL again and enables the outputs.

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

D

Three-State Outputs When the Input

Differential Clocks Are <20 MHz

D

Operates From Dual 2.5-V Supplies

D

Available in a 48-Pin TSSOP Package or

56-Ball MicroStar Junior BGA Package

D

Consumes < 200-µA Quiescent Current

D

External Feedback PIN (FBIN, FBIN) Are

Used to Synchronize the Outputs to the

Input Clocks

) to ten differential pairs of clock outputs (Y[0:9], Y[0:9]) and one differential pair of feedback

). The clock outputs are controlled by the clock inputs (CLK, CLK), the feedback

), and the analog power input (A VDD). When PWRDWN is high, the outputs switch in phase

is low, all outputs are disabled to high impedance state (3-state),

When A V

is strapped low, the PLL is turned of f and bypassed for test purposes. The CDCV857A is also able

DD

to track spread spectrum clocking for reduced EMI.

Since the CDCV857A is based on PLL circuitry , it requires a stabilization time to achieve phase-lock of the PLL.

This stabilization time is required following power up. The CDCV857A is characterized for operation from 0°C

to 85°C.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

MicroStar Junior is a trademark of Texas Instruments Incorporated.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 2002, Texas Instruments Incorporated

1

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

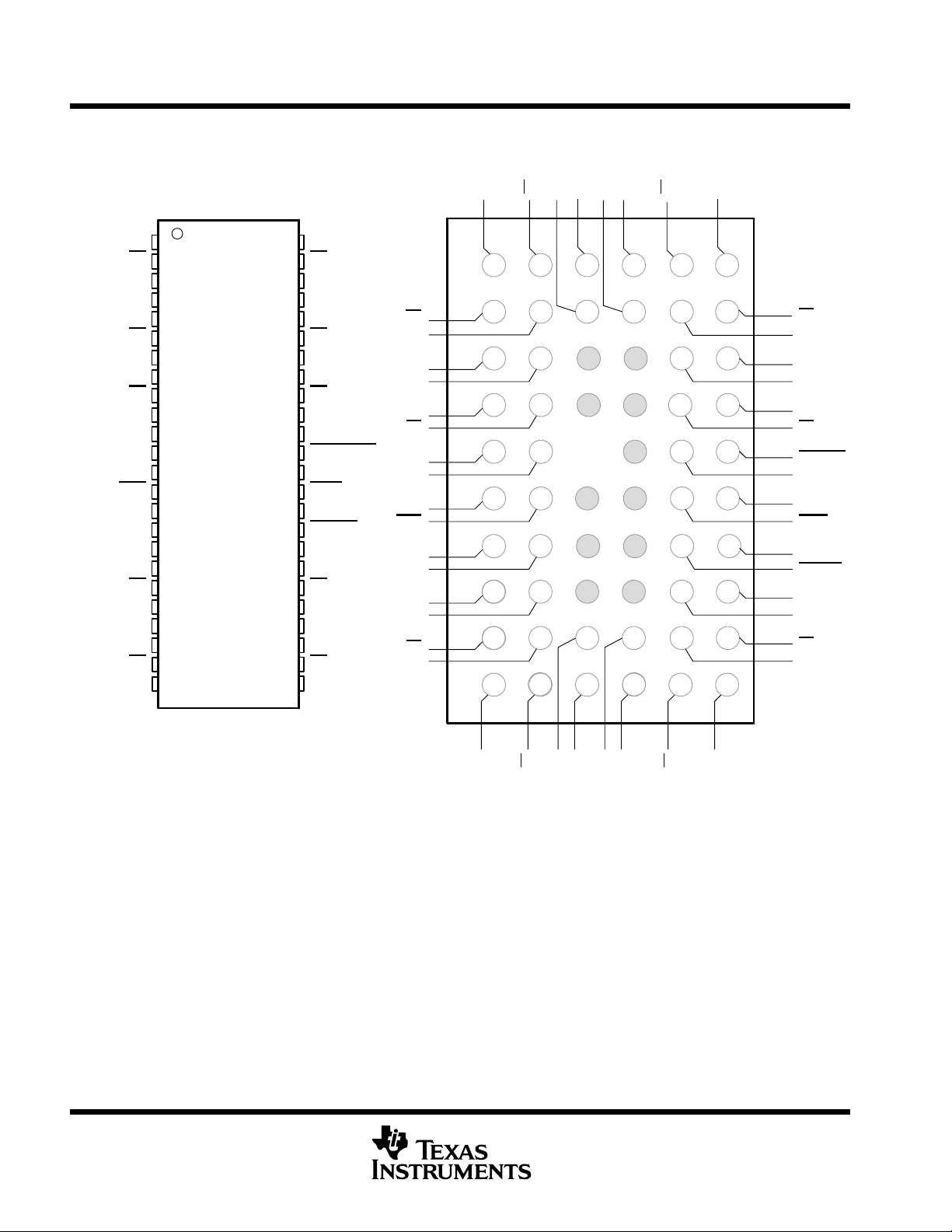

GND

Y0

Y0

V

DDQ

Y1

Y1

GND

GND

Y2

Y2

V

DDQ

V

DDQ

CLK

CLK

V

DDQ

AV

DD

AGND

GND

Y3

Y3

V

DDQ

Y4

Y4

GND

DGG PACKAGE

(TOP VIEW)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

GND

Y5

Y5

V

DDQ

Y6

Y6

GND

GND

Y7

Y7

V

DDQ

PWRDWN

FBIN

FBIN

V

DDQ

FBOUT

FBOUT

GND

Y8

Y8

V

DDQ

Y9

Y9

GND

Y1

Y1

GND

GND

Y2

Y2

V

DDQ

V

DDQ

CLK

CLK

V

DDQ

AV

DD

AGND

GND

Y3

Y3

MicroStarJunior (GQL) Package

Y0

A

B

C

D

E

F

G

H

J

K

DDQVDDQ

V

Y0

(TOP VIEW)

GND

321

NC

NC

NC NC

NC NC

NC

GND

4

NC

NC

NC

NC

Y5

Y5

65

Y6

Y6

GND

GND

Y7

Y7

PWRDN

V

DDQ

FBIN

FBIN

V

DDQ

FBOUT

FBOUT

GND

Y8

Y8

Y4

Y4

DDQ

DDQ

GND

V

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

GND

V

Y9

Y9

AV

DD

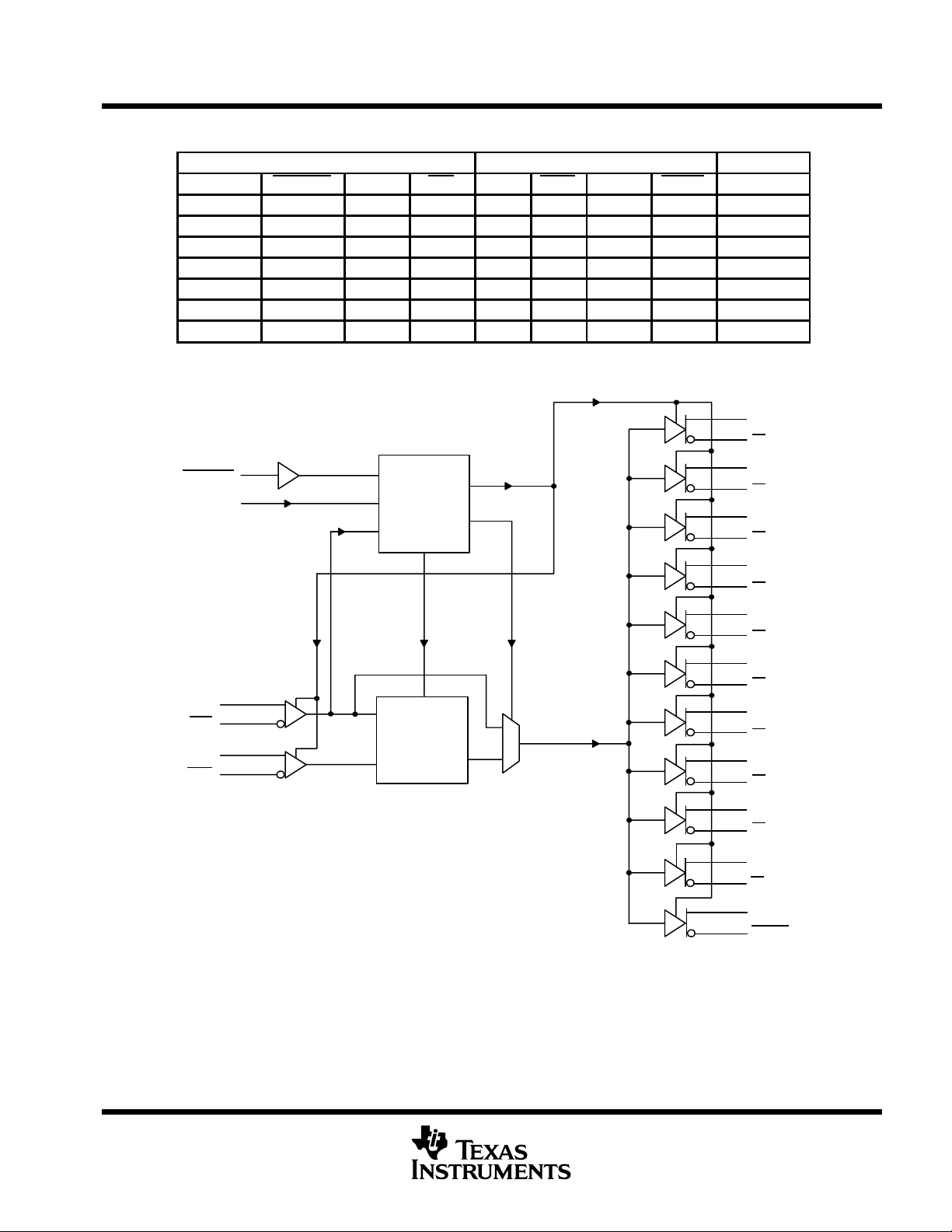

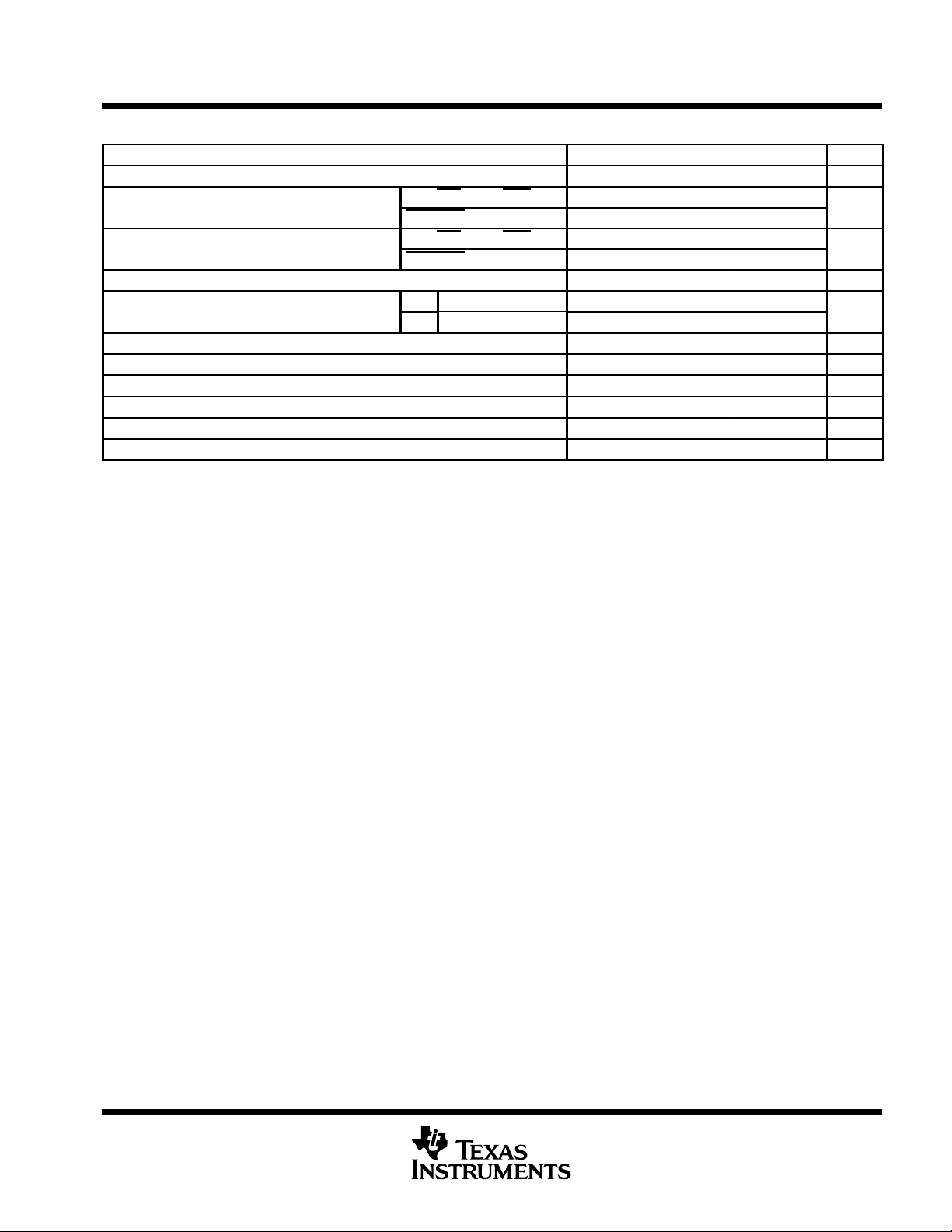

GND H L H L H L H Bypassed/Off

GND H H L H L H L Bypassed/Off

X L L H Z Z Z Z Off

X L H L Z Z Z Z Off

2.5 V (nom) H L H L H L H On

2.5 V (nom) H H L H L H L On

2.5 V (nom) X <20 MHz <20 MHz Z Z Z Z Off

functional block diagram

PWRDWN CLK CLK Y[0:9] Y[0:9] FBOUT FBOUT

INPUTS

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

FUNCTION TABLE

(Select Functions)

OUTPUTS PLL

Y0

Y0

PWRDWN

AV

DD

CLK

CLK

FBIN

FBIN

Powerdown

and Test

Logic

PLL

Y1

Y1

Y2

Y2

Y3

Y3

Y4

Y4

Y5

Y5

Y6

Y6

Y7

Y7

Y8

Y8

Y9

Y9

FBOUT

FBOUT

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

CDCV857A

DESCRIPTION

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

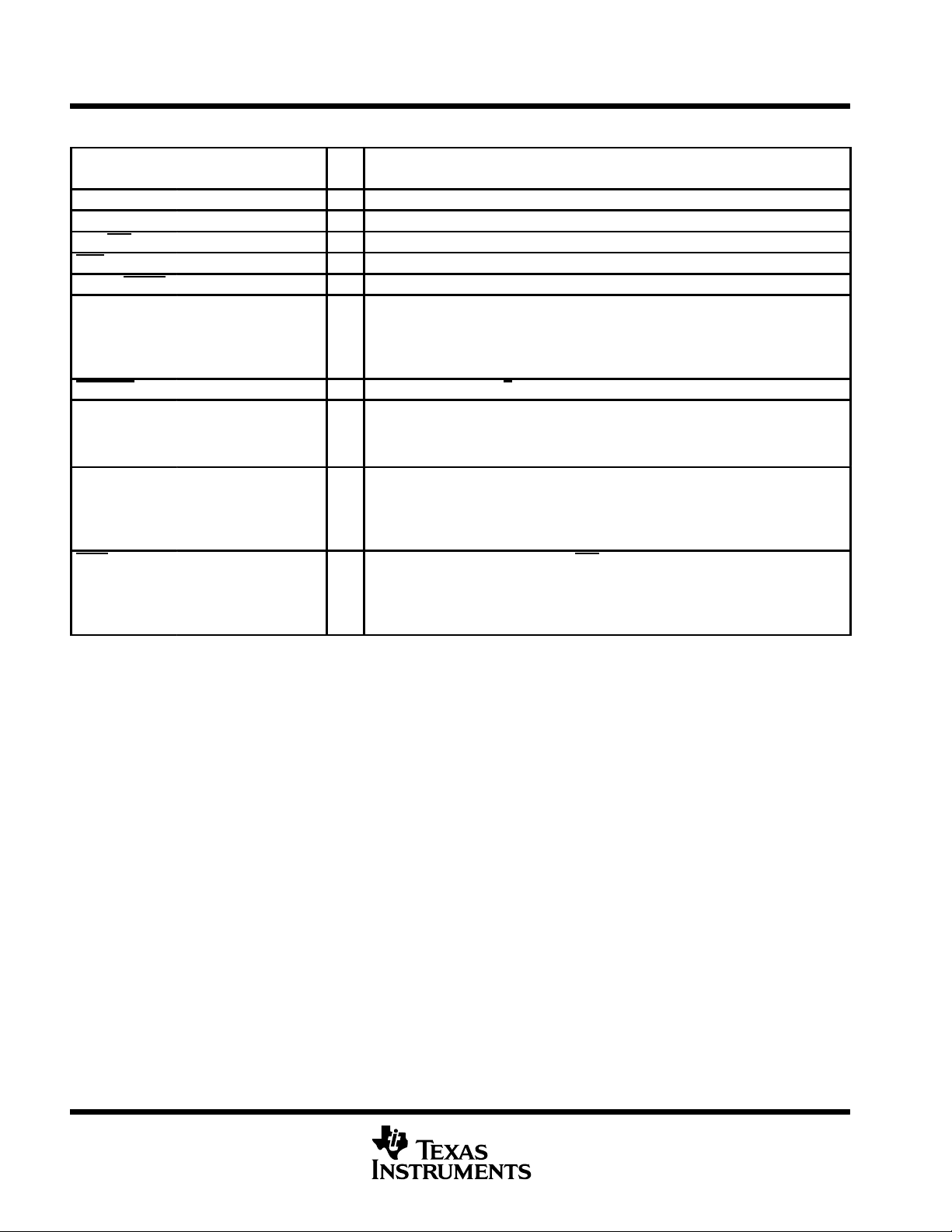

Terminal Functions

TERMINAL

NAME DGG GQL

AGND 17 H1 Ground for 2.5-V analog supply

AV

DD

CLK, CLK 13, 14 F1, F2 I Differential clock input

FBIN, FBIN 35, 36 F5, F6 I Feedback differential clock input

FBOUT, FBOUT 32, 33 H6, G5 O Feedback dif ferential clock output

GND 1, 7, 8, 18,

PWRDWN 37 E6 I Output enable for Y and Y

V

DDQ

Y[0:9] 3, 5, 10,

Y[0:9] 2, 6, 9, 19,

16 G2 2.5-V Analog supply

24, 25, 31,

41, 42, 48

4, 11, 12,

15, 21, 28,

34, 38, 45

20, 22, 27,

29, 39, 44,

46

23, 26, 30,

40, 43, 47

A3, A4,

C1, C2,

C5, C6,

H2, H5,

K3, K4

B3, B4,

E1, E2,

E5, G1,

G6, J3, J4

A1, B2,

D1, J2,

K1, A6,

B5, D6,

J5, K6

A2, B1,

D2, J1,

K2, A5,

B6, D5,

J6, K5

Ground

2.5-V Supply

O Buffered output copies of input clock, CLK

O Buffered output copies of input clock, CLK

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

Supply voltage range, V

Input voltage range, V

I

Output voltage range, V

Input clamp current, I

IK

Output clamp current, I

Continuous output current, I

Continuous current to GND or V

Package thermal impedance, θ

AVDD 0.5 V to 3.6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

,

DDQ

(see Notes 1 and 2) –0.5 V to V

(see Notes 1 and 2) –0.5 V to V

O

(VI < 0 or V

(VO < 0 or VO > V

OK

O

> V

I

(VO = 0 to V

±100 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DDQ

(see Note 3): DGG package 89°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JA

) ±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DDQ

DDQ

) ±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DDQ

) ±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

DDQ

DDQ

0.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GQL package 137.6°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. The input and output negative voltage ratings may be exceeded if the input and output clamp-current ratings are observed.

2. This value is limited to 3.6 V maximum.

3. The package thermal impedance is calculated in accordance with JESD 51.

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Low level input voltage, V

V

High level input voltage, V

V

Differential input signal voltage, V

(see Note 6)

V

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

recommended operating conditions (see Note 4)

MIN TYP MAX UNIT

Supply voltage, V

p

p

DC input signal voltage (see Note 5) –0.3 V

p

Output differential cross-voltage, VOX (see Note 7) V

Input differential pair cross-voltage, VIX (see Note 7) V

High-level output current, I

Low-level output current, I

Input slew rate, SR 1 4 V/ns

Operating free-air temperature, T

NOTES: 4. Unused inputs must be held high or low to prevent them from floating.

5. DC input signal voltage specifies the allowable dc execution of differential input.

6. Differential input signal voltage specifies the differential voltage |VTR – VCP| required for switching, where VTR is the true input level

and VCP is the complementary input level.

7. Differential cross-point voltage is expected to track variations of VCC and is the voltage at which the differential signals must be

crossing.

DDQ,

AV

IL

DD

IH

OH

OL

2.3 2.7 V

CLK, CLK, FBIN, FBIN V

PWRDWN –0.3 0.7

CLK, CLK, FBIN, FBIN V

PWRDWN 1.7 V

ID

A

DC CLK, FBIN 0.36 V

AC

CLK, FBIN 0.7 V

/2 + 0.18

DDQ

/2 – 0.2 V

DDQ

/2 – 0.2 V

DDQ

0 85 °C

DDQ

/2 V

DDQ

DDQ

DDQ

/2 – 0.18

DDQ

DDQ

DDQ

+ 0.3

DDQ

+ 0.6

+ 0.6

/2 + 0.2 V

/2 + 0.2 V

–12 mA

12 mA

V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

CDCV857A

VOHHigh-level output voltage

V

VOLLow-level output voltage

V

Differential outputs are terminated with

t

ith

IDDDynamic current on V

mA

t

ith

AIDDSupply current on AV

mA

f

60

180

MHz

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

electrical characteristics over recommended operating free-air temperature range (unless

otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP

V

IK

I

OH

I

OL

V

O

V

OX

I

I

I

OZ

I

DDPD

C

I

C

O

†

All typical values are at respective nominal V

‡

The value of VOC is expected to be |VTR + VCP|/2. In case of each clock directly terminated by a 120-Ω resistor, where VTR is the true input

signal voltage and VCP is the complementary input signal voltage.

§

Differential cross-point voltage is expected to track variations of VDDQ and is the voltage at which the differential signals must be crossing.

Input voltage All inputs V

p

p

High-level output current V

Low-level output current V

Output voltage swing

Output differential

cross-voltage

Input current V

High-impedance-state

output current

Power down current on

V

DDQ

pp

Input capacitance VCC = 2.5 V VI = VCC or GND 2 2.5 3 pF

Output capacitance VCC = 2.5 V VO = VCC or GND 2.5 3 3.5 pF

+ AV

w

DD

DDQ

DD

= 2.3 V, II = –18 mA –1.2 V

DDQ

V

= min to max, IOH = –1 mA V

DDQ

V

= 2.3 V, IOH = –12 mA 1.7

DDQ

V

= min to max, IOL = 1 mA 0.1

DDQ

V

= 2.3 V, IOL = 12 mA 0.6

DDQ

= 2.3 V, VO = 1 V –18 –32 mA

DDQ

= 2.3 V, VO = 1.2 V 26 35 mA

DDQ

120 Ω

DDQ

V

DDQ

CLK and CLK = 0 MHz; PWRDWN = Low;

Σ of IDD and AI

Differential outputs

erminated w

120 Ω/CL = 14 pF

Differential outputs

erminated w

120 Ω/CL = 0 pF

fO = 180 MHz 10 12

fO = 167 MHz

DDQ

p

V

= 2.7 V, VI = 0 V to 2.7 V ±10 µA

= 2.7 V, VO= V

DD

fO = 180 MHz 275 330

fO = 167 MHz 250 300

fO = 180 MHz 225 275

fO = 167 MHz 210 250

.

or GND ±10 µA

DDQ

DDQ

/2 – 0.2 V

DDQ

– 0.1

1.1 V

†

/2 V

DDQ

100 200 µA

8 10

DDQ

DDQ

MAX UNIT

– 0.4

/2 + 0.2

V

timing requirements over recomme nd ed ran ge s of supply voltage and operating free-air

temperature

CLK

¶

Time required for the integrated PLL circuit to obtain phase lock of its feedback signal to its reference signal. For phase lock to be obtained, a

fixed-frequency , fixed-phase reference signal must be present at CLK. Until phase lock is obtained, the specifications for propagation delay, skew ,

and jitter parameters given in the switching characteristics table are not applicable. This parameter does not apply for input modulation under

SSC application.

6

Operating clock frequency

Application clock frequency

Input clock duty cycle 40% 60%

Stabilization timeW (PLL mode) 10 µs

Stabilization timeW (Bypass mode) 30 ns

MIN MAX UNIT

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

t

w

Jitter (period), See Figure 6

t

w

Jitter (cycle-to-cycle), See Figure 3

ps

t

w

Half-period jitter, See Figure 7

ps

t

w

y(j),

ps

t

Static phase offset, See Figure 4(a)

ps

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

switching characteristics

PARAMETER TEST CONDITIONS MIN

}

t

PLH

}

t

PHL

jit(per)

jit(cc)

jit(hper)

t

slr(i)

t

slr(o)

d(Ø)

(Ø)

tsk

(o)

tr, tf Output rise and fall times (20% – 80%) Load: 120 Ω/14 pF 650 900 ps

†

All typical values are at a respective nominal V

‡

Refers to transition of noninverting output.

§

This parameter is assured by design but can not be 100% production tested.

¶

All differential output pins are terminated with 120 Ω/14 pF.

Low to high level propagation delay time Test mode/CLK to any output 4.5 ns

High-to low level propagation delay time Test mode/CLK to any output 4.5 ns

p

p

Input clock slew rate, See Figure 8 1 4 V/ns

Output clock slew rate, See Figure 8 1 2 V/ns

Dynamic phase offset (this includes jitter), See

Figure 4(b)

p

W

Output skew, See Figure 5 75 ps

.

DDQ

66 MHz –55 55 ps

100/133/167/180 MHz –35 35 ps

66 MHz –60 60

100/133/167/180 MHz –50 50

66 MHz –100 100

100/133/167/180 MHz –75 75

66 MHz –180 180

SSC off

SSC on

66 MHz –150 150

100/133/167/180 MHz –100 100

100/133 MHz –130 130

167/180 MHz –90 90

66 MHz –230 230

100/133 MHz –170 170

167/180 MHz –100 100

TYP

{

MAX UNIT

p

p

p

p

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

PARAMETER MEASUREMENT INFORMATION

V

DD

V

(CLK)

R = 60 Ω

CDCV857

GND

V

(CLK)

R = 60 Ω

VDD/2

Figure 1. IBIS Model Output Load (used for slew rate measurement)

VDD/2

CDCV857A

Z = 60 Ω

Z = 60 Ω

C = 14 pF

R = 10 Ω

C = 14 pF

–VDD/2

Z = 50 ΩR = 10 Ω

Z = 50 Ω

SCOPE

V

(TT)

V

(TT)

R = 50 Ω

R = 50 Ω

–VDD/2

–VDD/2

NOTE: V

(TT)

= GND

Figure 2. Output Load Test Circuit

Yx, FBOUT

Yx, FBOUT

t

c(n)

t

jit(cc)

= t

c(n)

– t

c(n+1)

t

c(n+1)

Figure 3. Cycle-to-Cycle Jitter

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

PARAMETER MEASUREMENT INFORMATION

CLK

CLK

FBIN

FBIN

CLK

CLK

FBIN

FBIN

t

( ) n

t

( )

(N is a large number of samples)

(a) Static Phase Offset

t

( )

t

d

( )

t

d

( )

(b)

Dynamic Phase Offset

n = N

∑

=

t

1

( ) n

N

t

d

( )

t

( ) n+1

t

( )

t

d

( )

Figure 4. Phase Offset

Yx

Yx

Yx, FBOUT

Yx, FBOUT

t

sk(o)

Figure 5. Output Skew

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

PARAMETER MEASUREMENT INFORMATION

Yx, FBOUT

Yx, FBOUT

Yx, FBOUT

Yx, FBOUT

t

Figure 6. Period Jitter

Yx

, FBOUT

jit(per)

t

c(n)

1

f

o

= tcn –

1

f

o

Yx, FBOUT

Clock Inputs

and Outputs

t

(hper_n)

t

jit(hper)

= t

t

1

f

o

(hper_n) –

(hper_n+1)

2xf

Figure 7. Half-Period Jitter

80%

20%

t

slrr(i)

, t

slrr(o)

t

slrf(i)

Figure 8. Input and Output Slew Rates

1

o

80%

VID, V

OD

20%

, t

slrf(o)

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

MECHANICAL DATA

DGG (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

48 PINS SHOWN

0,50

48

1

1,20 MAX

0,27

0,17

25

24

A

0,15

0,05

0,08

M

8,30

6,20

7,90

6,00

Seating Plane

0,10

0,15 NOM

Gage Plane

0,25

0°–8°

0,75

0,50

DIM

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

PINS **

A MAX

A MIN

48

12,60

12,40

56

14,10

13,90

64

17,10

16,90

4040078/F 12/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

CDCV857A

2.5-V PHASE LOCK LOOP CLOCK DRIVER

SCAS667A – APRIL 2001 – REVISED AUGUST 2002

MECHANICAL DATA

GQL (R-PBGA-N56) PLASTIC BALL GRID ARRAY

7,10

6,90

4,60

4,40

A1 Corner

3X Via Hole

Without

Ball

Missing Via

Hole Indicates

Pin A1

Quadrant

0,65

K

J

H

G

F

E

D

C

B

A

123 645

Bottom View

3,25

0,325

0,65

5,85

0,325

1,00 MAX

0,45

56×∅

0,35

M

0,05

NOTES: A. All linear dimensions are in millimeters.

MicroStar Junior is a trademark of Texas Instruments.

B. This drawing is subject to change without notice.

C. MicroStar Junior BGA configuration

D. Falls within JEDEC MO-225 variation BA.

E. This package is tin-lead (SnPb). Refer to the 56 ZQL package (drawing 4204437) for lead-free.

0,08

Seating Plane

0,25

0,15

4200583/D 06/2002

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PACKAGE OPTION ADDENDUM

www.ti.com

4-Mar-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

CDCV857ADGG ACTIVE TSSOP DGG 48 40 Pb-Free

CDCV857ADGGR ACTIVE TSSOP DGG 48 2000 Pb-Free

CDCV857AGQLR ACTIVE VFBGA GQL 56 1000 None Call TI Level-2A-220C-4 WKS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - May not be currently available - please check http://www.ti.com/productcontent for the latest availability information and additional

product content details.

None: Not yet available Lead (Pb-Free).

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean "Pb-Free" and in addition, uses package materials that do not contain halogens,

including bromine (Br) or antimony (Sb) above 0.1% of total product weight.

(RoHS)

(RoHS)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-250C-UNLIM

CU NIPDAU Level-1-250C-UNLIM

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDECindustry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...