Page 1

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

300-MHz Differential Clock Source for

Direct RAMBUS Memory Systems for an

600-MHz Data Transfer Rate

D

Synchronizes the Clock Domains of the

Rambus Channel With an External System

or Processor Clock

D

Three Power Operating Modes to Minimize

Power for Mobile and Other

Power-Sensitive Applications

D

Operates From a Single 3.3-V Supply and

120-mW at 300 MHz (Typ)

D

Packaged in a Shrink Small-Outline

Package (DBQ)

D

Wide Phase-Lock Input Frequency Range

33 MHz to 100 MHz

D

No External Components Required for PLL

D

Supports Independent Channel Clocking

D

Spread Spectrum Clocking Tracking

Capability to Reduce EMI

D

Designed For Use With TI’s 133-MHz Clock

Synthesizers CDC925, CDC924, CDC922

and CDC921

description

The Direct Rambus clock generator (DRCG) provides the necessary clock signals to support a Direct Rambus

memory subsystem. It includes signals to synchronize the Direct Rambus channel clock to an external system

or processor clock. It is designed to support Direct Rambus memory on desktop, workstation, server and mobile

PC motherboards. DRCG also provides an off-the-shelf solution for a broad range of Direct Rambus memory

applications.

The DRCG provides clock multiplication and phase alignment for a Direct Rambus memory subsystem to

enable synchronous communication between the Rambus channel and ASIC clock domains. In a Direct

Rambus memory subsystem, a system clock source provides the REFCLK and PCLK clock references to the

DRCG and memory controller, respectively. The DRCG multiplies REFCLK and drives a high-speed BUSCLK

to RDRAMs and the memory controller. Gear ratio logic in the memory controller divides the PCLK and BUSCLK

frequencies by ratios M and N such that PCLK/M = SYNCLK/N, where SYNCLK = BUSCLK/4. The DRCG

detects the phase difference between PCLK/M and SYNCLK/N and adjusts the phase of BUSCLK such that

the skew between PCLK/M and SYNCLK/N is minimized. This allows data to be transferred across the

SYNCLK/PCLK boundary without incurring additional latency.

User control is provided by multiply and mode selection terminals. The multiply terminals provide selection of

one of four clock frequency multiply ratios, generating BUSCLK frequencies ranging from 267 MHz to 400 MHz

with clock references ranging from 33 MHz to 100 MHz. The CDCR81 meets Rambus Clock Generator,

Revision 1.0 specification up to 300 MHz. The mode select terminals can be used to select a bypass mode

where the frequency multiplied reference clock is directly output to the Rambus channel for systems where

synchronization between the Rambus clock and a system clock is not required. Test modes are provided to

bypass the PLL and output REFCLK on the Rambus channel and to place the outputs in a high-impedance state

for board testing.

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Direct Rambus and Rambus are trademarks of Rambus Inc.

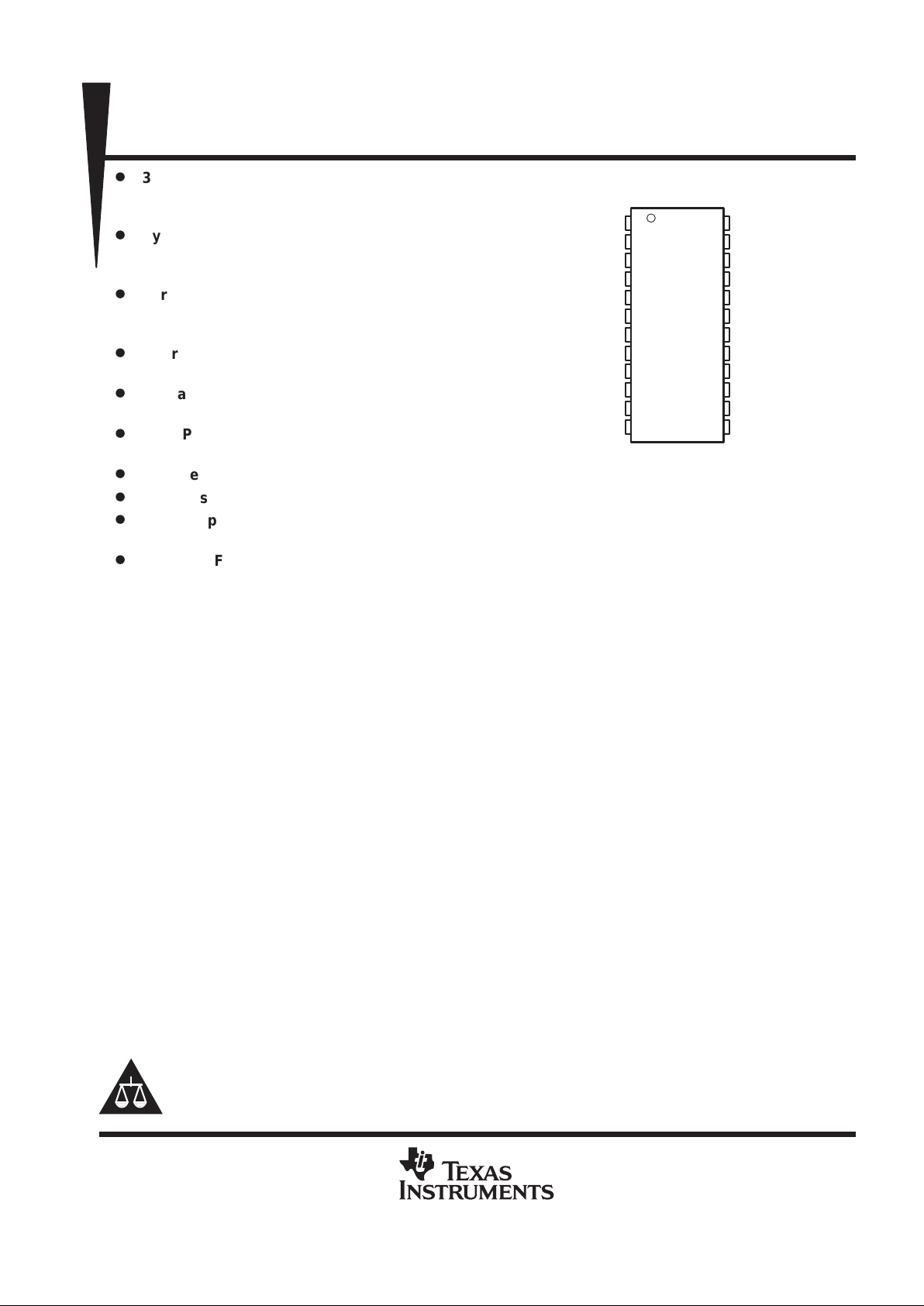

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

VDDIR

REFCLK

V

DD

P

GNDP

GNDI

PCLKM

SYNCLKN

GNDC

V

DD

C

V

DD

IPD

STOPB

PWRDNB

S0

S1

V

DD

O

GNDO

CLK

NC

CLKB

GNDO

V

DD

O

MULT0

MULT1

S2

DBQ PACKAGE

(TOP VIEW)

NC – No internal connection

Page 2

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

description (continued)

The CDCR81 is characterized for operation over free-air temperatures of 0°C to 85°C.

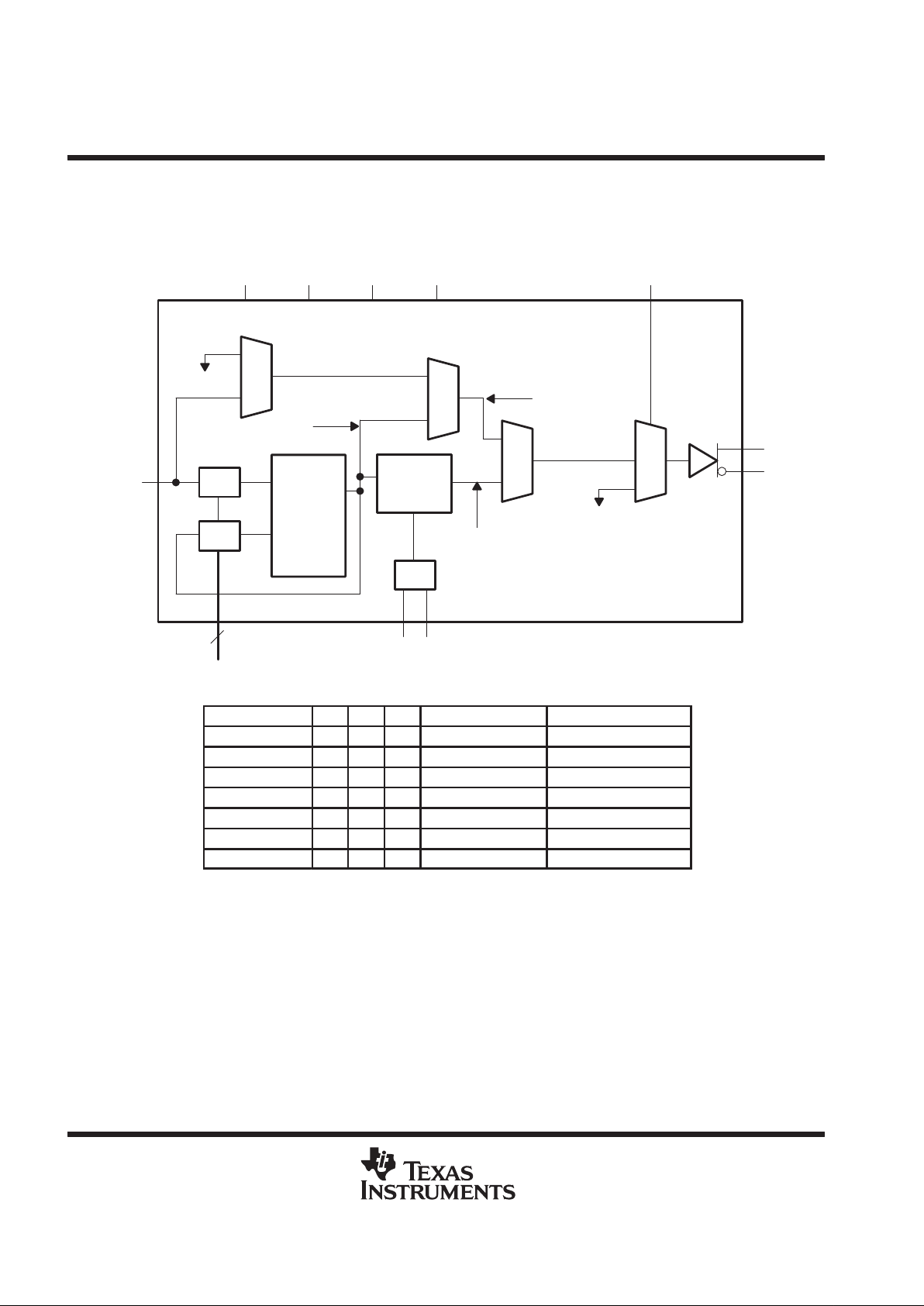

functional block diagram

Bypass MUX

Test MUX

B

A

PLL

Phase

Aligner

PACLK

PLLCLK

ByPCLK

CLK

CLKB

REFCLK

φ

D

SYNCLKNPCLKM

MULT0

MULT1

2

PWRDWNB S0 S1 S2 STOPB

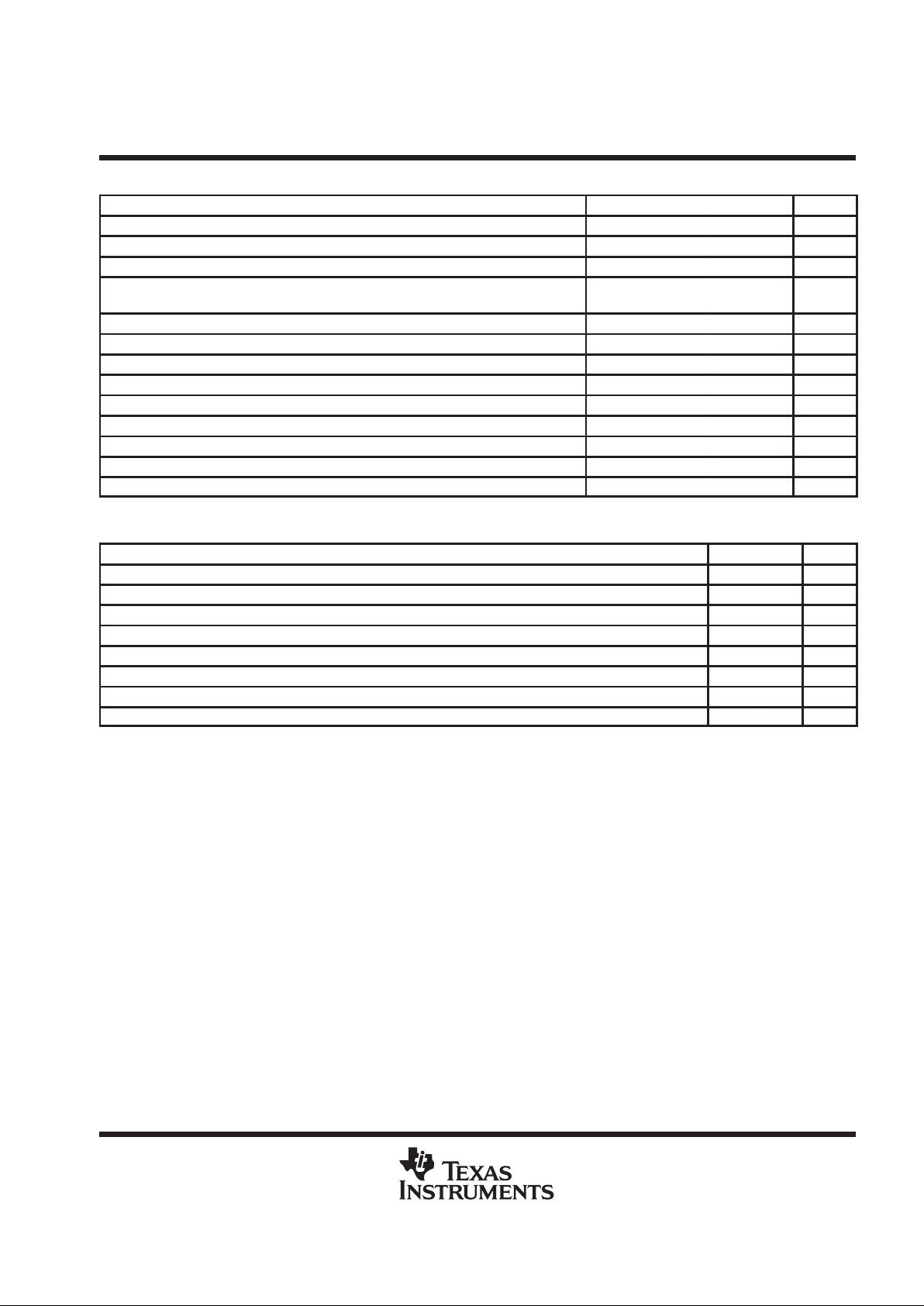

FUNCTION TABLE

†

MODE

S0 S1 S2 CLK CLKB

Normal 0 0 0 Phase aligned clock Phase aligned clock B

Bypass 1 0 0 PLLCLK PLLCLKB

Test 1 1 0 REFCLK REFCLKB

Output test (OE) 0 1 X Hi-Z Hi-Z

Reserved 0 0 1 — —

Reserved 1 0 1 — —

Reserved 1 1 1 Hi-Z Hi-Z

†

X = don’t care, Hi-Z = high impedance

Page 3

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

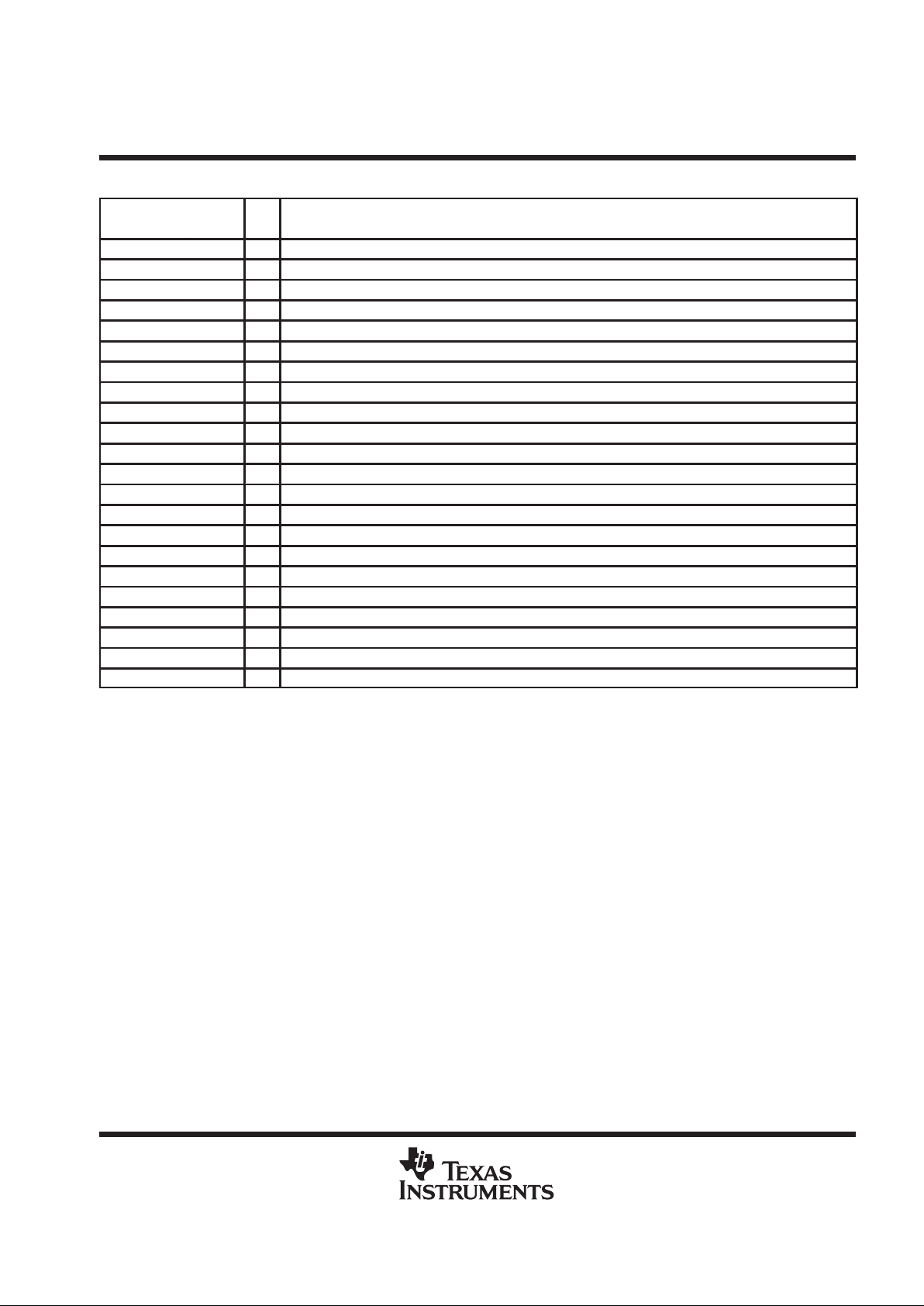

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

CLK 20 O Output clock

CLKB 18 O Output clock (complement)

GNDC 8 GND for phase aligner

GNDI 5 GND for control inputs

GNDO 17, 21 GND for clock outputs

GNDP 4 GND for PLL

MULT0 15 I PLL multiplier select

MULT1 14 I PLL multiplier select

NC 19 Not used

PCLKM 6 I Phase detector input

PWRDNB 12 I Active low power down

REFCLK 2 I Reference clock

S0 24 I Mode control

S1 23 I Mode control

S2 13 I Mode control

STOPB 11 I Active low output disable

SYNCLKN 7 I Phase detector input

VDDC 9 VDD for phase aligner

VDDIPD 10 Reference voltage for phase detector inputs and STOPB

VDDIR 1 Reference voltage for REFCLK

VDDO 16, 22 VDD for clock outputs

VDDP 3 VDD for PLL

Page 4

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

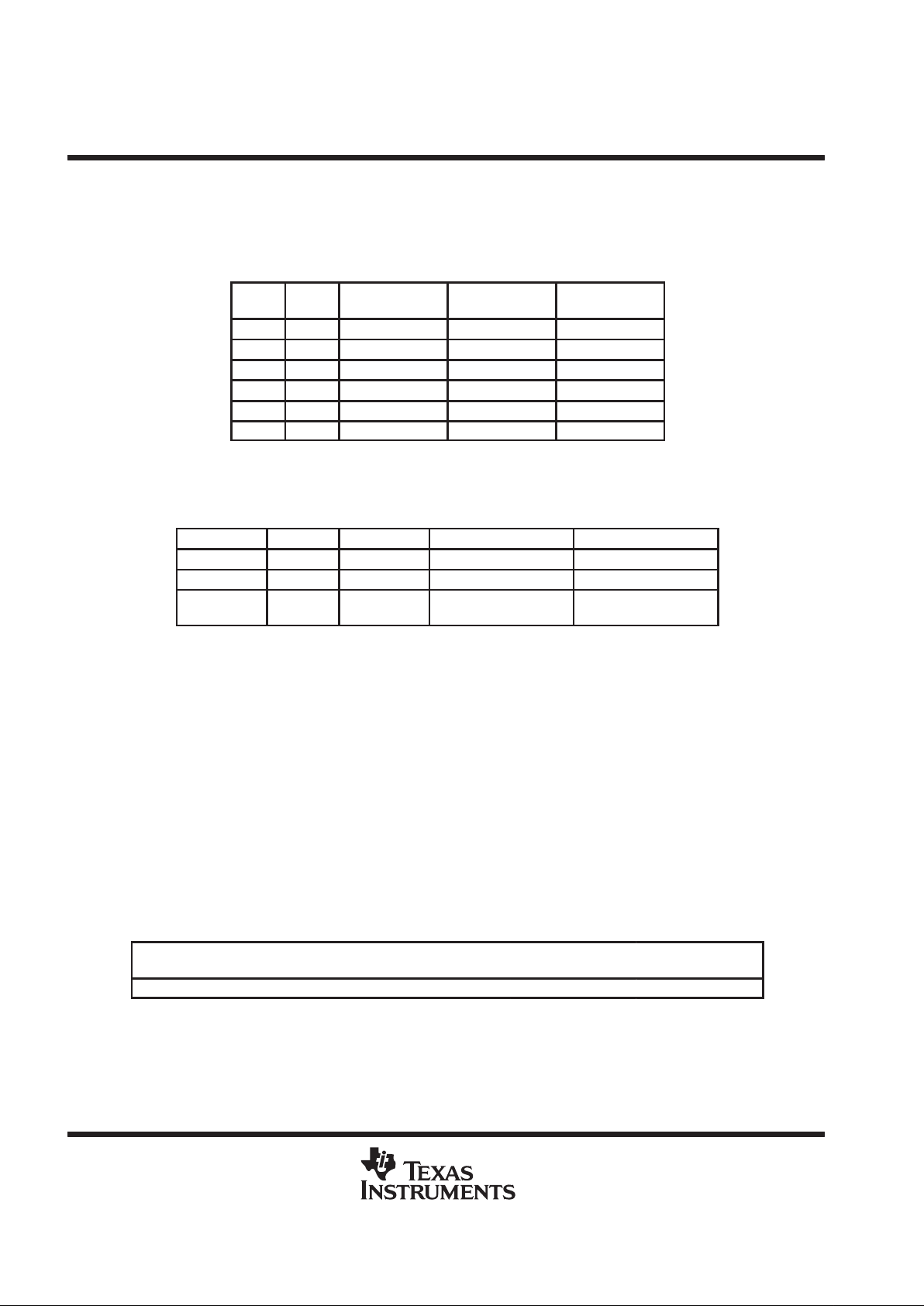

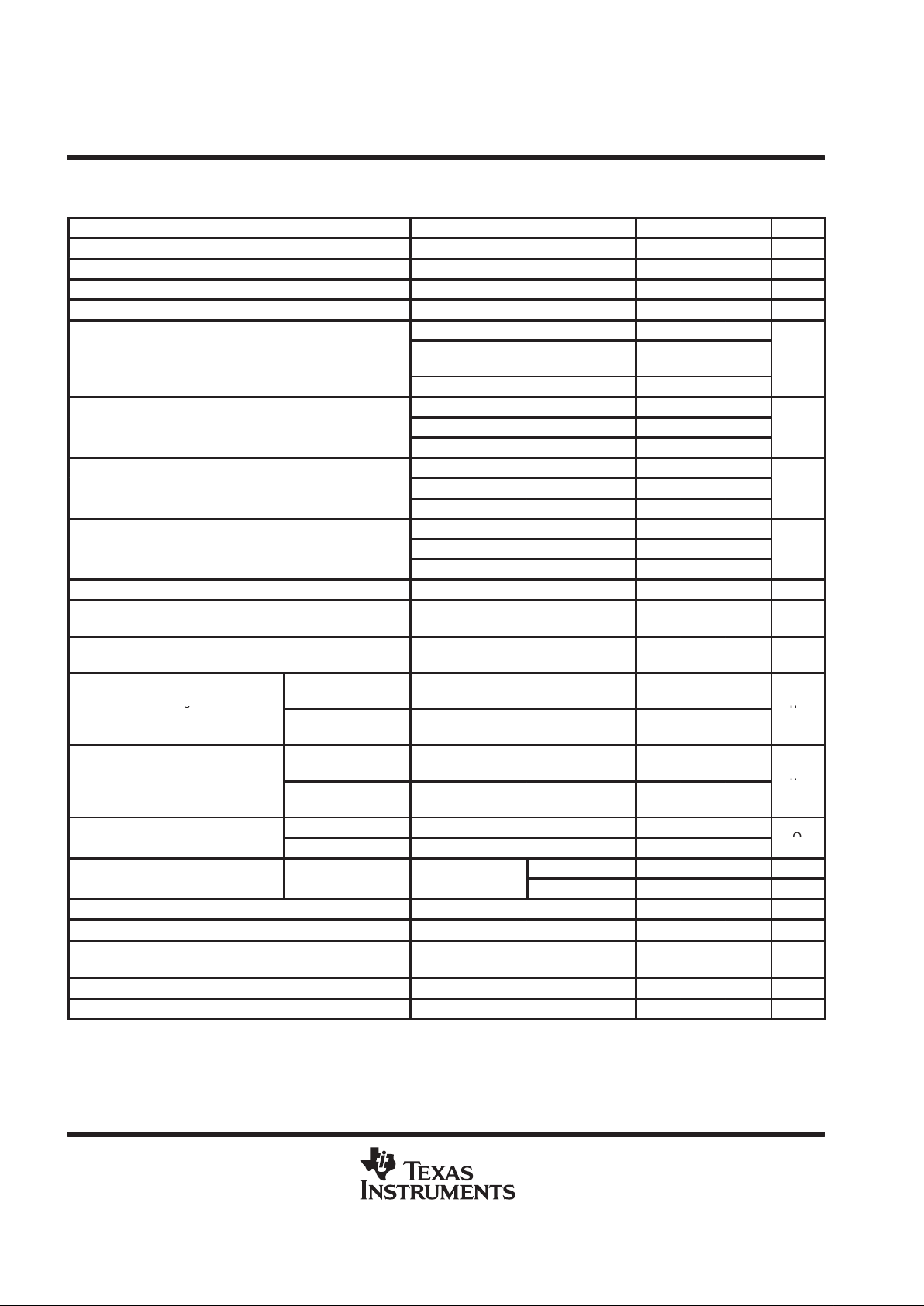

PLL divider selection

Table 1 lists the supported REFCLK and BUSCLK frequencies. Other REFCLK frequencies are permitted,

provided that (267 MHz < BUSCLK < 400 MHz) and (33 MHz < REFCLK < 100 MHz).

Table 1. REFCLK and BUSCLK Frequencies

MULT0 MULT1

REFCLK

(MHz)

MULTIPLY

RATIO

BUSCLK

(MHz)

0 0 67 4 267

0 1 50 6 300

0 1 67 6 400

1 1 33 8 267

1 1 50 8 400

1 0 100 8/3 267

clock output driver states

Table 2. Clock Output Driver States

STATE PWRDNB STOPB CLK CLKB

Powerdown 0 X GND GND

CLK stop 1 0 VX,

STOP

VX,

STOP

Normal 1 1

PACLK/PLLCLK/

REFCLK

†

PACLKB/PLLCLKB/

REFCLKB

†

Depending on the state of S0, S1, and S2.

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†

Supply voltage range, VDD (see Note 1) –0.5 V to 4 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage range, VO, at any output terminal –0.5 V to V

DD

+ 0.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range,VI, at any input terminal –0.5 V to VDD + 0.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD rating TBD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation see Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

0°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to the GND terminals.

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

‡

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

DBQ 1400 mW 11 mW/°C 905 mW 740 mW

‡

This is the inverse of the junction-to-ambient thermal resistance when board-mounted and with no air flow.

Page 5

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

DD

3.135 3.3 3.465 V

High-level input voltage, VIH (CMOS) 0.7×V

DD

V

Low-level input voltage, VIL (CMOS) 0.3×V

DD

V

Initial phase error at phase detector inputs

(required range for phase aligner)

–0.5×t

c(PD)

0.5×t

c(PD)

REFCLK low-level input voltage, V

IL

0.3×VDDIR V

REFCLK high-level input voltage, V

IH

0.7×VDDIR V

Input signal low voltage, VIL (STOPB) 0.3×VDDIPD V

Input signal high voltage, VIH (STOPB) 0.7×VDDIPD V

Input reference voltage for (REFCLK) (VDDIR) 1.235 3.465 V

Input reference voltage for (PCLKM and SYSCLKN) (VDDIPD) 1.235 3.465 V

High-level output current, I

OH

–16 mA

Low-level output current, I

OL

16 mA

Operating free-air temperature, T

A

0 85 °C

timing requirements

MIN MAX UNIT

Input cycle time, t

c(in)

10 40 ns

Input cycle-to-cycle jitter 250 ps

Input duty cycle over 10,000 cycles 40% 60%

Input frequency modulation, f

mod

30 33 kHz

Modulation index, non-linear maximum 0.5% 0.6%

Phase detector input cycle time (PCLKM and SYNCLKN) 30 100 ns

Input slew rate, SR 1 4 V/ns

Input duty cycle (PCLKM and SYNCLKN) 25% 75%

Page 6

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range (unless

otherwise noted)

PARAMETER TEST CONDITIONS

†

MIN TYP‡MAX UNIT

V

O(STOP)

Output voltage during CLK Stop (StopB=0) See Figure 1 1.1 2

V

O(X)

Output crossing-point voltage See Figures 1 and 6 1.3 1.8 V

V

O

Output voltage swing See Figure 1 0.4 0.6 V

V

IK

Input clamp voltage VDD = 3.135 V , II = –18 mA –1.2 V

See Figure 1 2

V

OH

High-level output voltage

VDD = min to max,

IOH = –1 mA

VDD–

0.1 V

V

VDD = 3.135 V , IOH = –16 mA 2.4

See Figure 1 1

V

OL

Low-level output voltage

VDD = min to max,

IOL = 1 mA 0.1

V

VDD = 3.135 V , IOL = 16 mA 0.5

VDD = 3.135 V , VO = 1 V –32 –52

I

OH

High-level output current

VDD = 3.3 V,

VO = 1.65 V –51

mA

VDD = 3.465 V , VO = 3.135 V –14.5 –21

VDD = 3.135 V , VO = 1.95 V 43 61.5

I

OL

Low-level output current

VDD = 3.3 V,

VO = 1.65 V 65

mA

VDD = 3.465 V , VO = 0.4 V 25.5 36

I

OZ

High-impedance-state output current S0 = 0, S1 = 1 ±10 µA

I

OZ(STOP)

High-impedance-state output current

during CLK stop

Stop= 0, VO = GND or V

DD

±100 µA

I

OZ(PD)

High-impedance-state output current in

powerdown state

PWDNB= 0,

VO = GND or V

DD

–10 100 µA

High-level input

REFCLK, PCLKM,

SYNCLKN, STOPB

VDD = 3.465 V , VI = V

DD

10

I

IH

g

current

PWRDNB, S0, S1,

S2, MULT0, MULT1

VDD = 3.465 V , VI = V

DD

10

µ

A

Low-level input

REFCLK, PCLKM,

SYNCLKN, STOPB

VDD = 3.465 V , VI = 0 –10

I

IL

current

PWRDNB, S0, S1,

S2, MULT0, MULT1

VDD = 3.465 V , VI = 0 –10

µ

A

p

p

High state RI at IO –14.5 mA to –16.5 mA 15 26 40

ZOOutput impedance

Low state RI at IO 14.5 mA to 16.5 mA 11 17 35

Ω

PWRDNB = 0 50 µA

Reference current

VDDIR, VDDIPD

V

DD

= 3.

465 V

,

PWRDNB = 1 0.5 mA

C

I

Input capacitance VI = VDD or GND 1.8 pF

C

O

Output capacitance VO = VDD or GND 3.1 pF

I

DD(PD)

Supply current in powerdown state

REFCLK = 0 MHz to 100 MHz,

PWDNB = 0, STOPB = 1

200 µA

I

DD(CLKSTOP)

Supply current in CLK stop state BUSCLK configured for 400 MHz 30 mA

I

DD(NORMAL)

Supply current in normal state BUSCLK = 400 MHz 70 mA

†

VDD refers to any of the following; VDD, VDDIPD, VDDIR, VDDO, VDDC, and VDDP

‡

All typical values are at VDD = 3.3 V, TA = 25°C.

Page 7

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

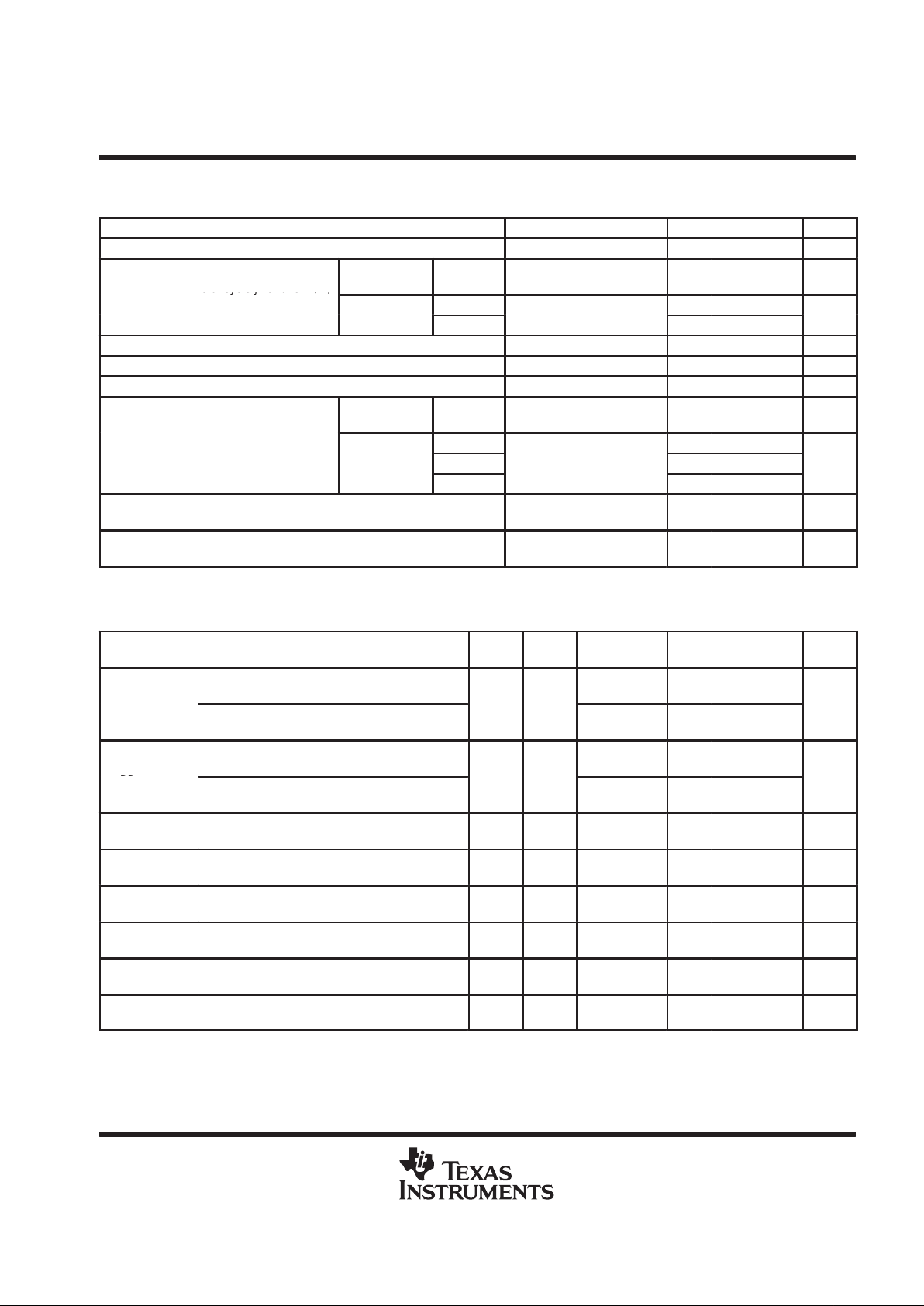

switching characteristics over recommended operating free-air temperature range (unless

otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP†MAX UNIT

t

c(out) Clock output cycle time

2.5 3.75 ns

Total cycle jitter over 1, 2

,

Stopped phase

alignment

267 MHz –

400 MHz

See Figure 3 60 ps

t

(jitter)

Total cycle jitter over 1, 2,

3, 4, 5, or 6 clock cycles

Infinite phase

267 MHz

80

p

alignment

300 MHz

See Figure 3

70

ps

t

(phase)

Phase detector phase error for distributed loop Static phase error –50 50 ps

t

(phase, SSC)

PLL output phase error when tracking SSC Dynamic phase error –100 100 ps

t

(DC)

Output duty cycle over 10,000 cycles See Figure 4 45% 55%

Stopped phase

alignment

267 MHz –

400 MHz

See Figure 5 50 ps

t

Output cycle-to-cycle

267 MHz 70

(DC,err)

duty cycle error

Infinite phase

300 MHz

See Figure 5

80

ps

alignment

400 MHz 90

tr, t

f

Output rise and fall times (measured at 20%-80% of

output voltage)

See Figure 7 200 450 ps

∆t

Difference between rise and fall times on a single device

(20%–80%) |tf – tr|

See Figure 7 100 ps

†

All typical values are at VDD = 3.3 V, TA = 25°C.

state transition latency specifications

PARAMETER FROM TO

TEST

CONDITIONS

MIN TYP†MAX UNIT

Delay time, PWRDNB↑ to CLK/CLKB output

settled (excluding t

(DISTLOCK)

)

Power-

See Figure 8 3

t

(powerup)

Delay time, PWRDNB↑ to internal PLL and

clock are on and settled

down

Normal3ms

Delay time, powerup to CLK/CLKB output

settled

See Figure 8 3

t

(VDDpowerup)

Delay time, powerup to internal PLL and clock

are on and settled

VDDNormal3ms

t

(MULT)

MULT0 and MULT1 change to CLK/CLKB

output resettled (excluding t

(DISTLOCK)

)

Normal Normal See Figure 9 1 ms

t

(CLKON)

STOPB↑ to CLK/CLKB glitch-free clock edges

CLK

Stop

Normal See Figure 10 10 ns

t

(CLKSETL)

STOPB↑ to CLK/CLKB output settled to within

50 ps of the phase before STOPB was disabled

CLK

Stop

Normal See Figure 10 20 cycles

t

(CLKOFF)

STOPB↑ to CLK/CLKB output disabled Normal

CLK

Stop

See Figure 10 5 ns

t

(powerdown)

Delay time, PWRDNB↓ to the device in powerdown mode

STOPB

Powerdown

1 ms

t

(STOP)

Maximum time in CLKSTOP (STOPB = 0)

before re-entering normal mode (STOPB = 1)

STOPB Normal 100 µs

Page 8

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

state transition latency specifications (continued)

PARAMETER FROM TO

TEST

CONDITIONS

MIN TYP†MAX UNIT

t

(ON)

Minimum time in normal mode (STOPB = 1)

before re-entering CLKSTOP (STOPB = 0)

Normal

CLK

stop

100 ms

t

(DISTLOCK)

Time from when CLK/CLKB output is settled to

when the phase error between SYNCLKN and

PCLKM falls within t

(ERR-PD)

Un-

locked

Locked 5 ms

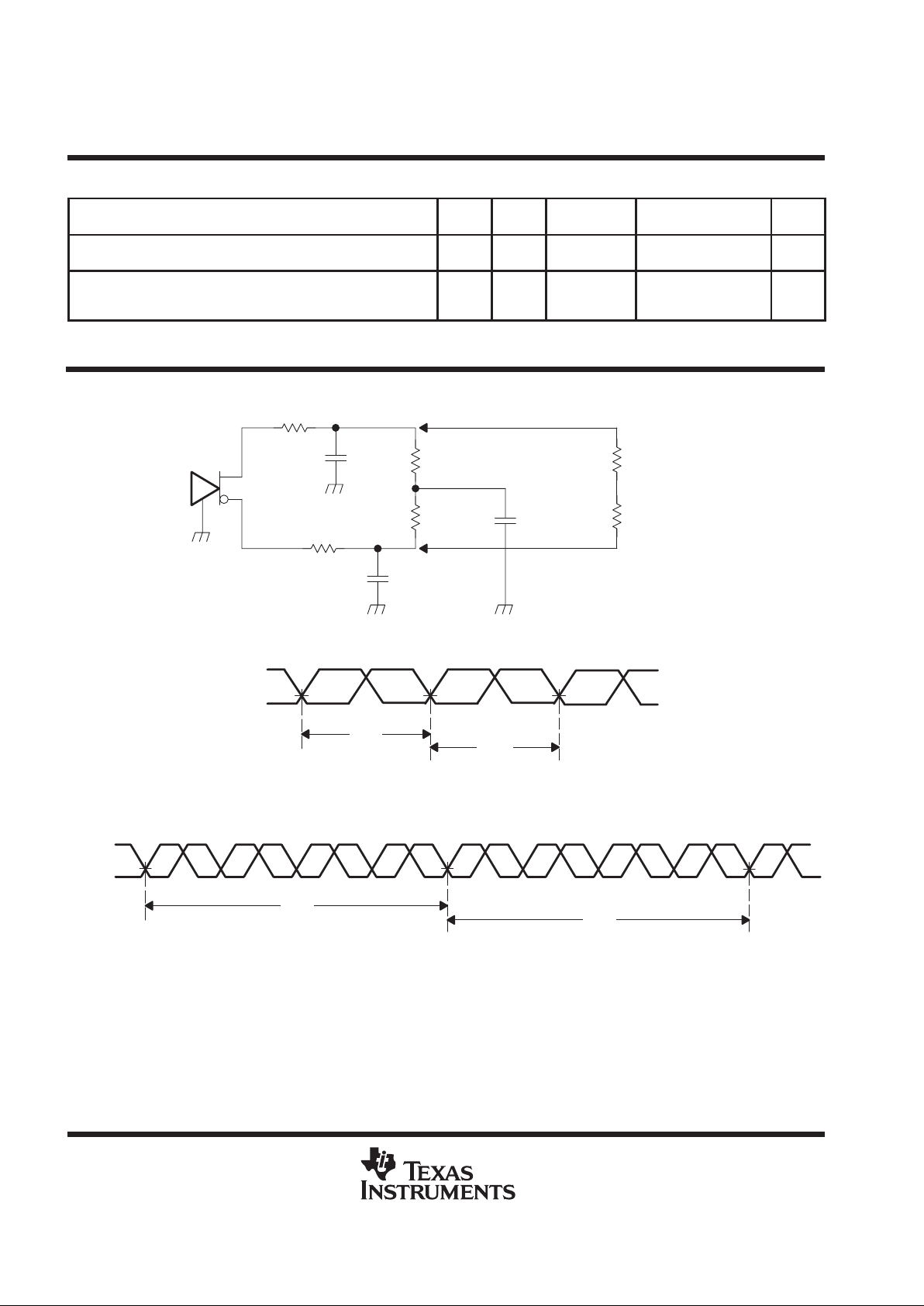

PARAMETER MEASUREMENT INFORMATION

39 Ω, ±5%

68 Ω, ±5%

68 Ω, ±5%

10 pF

100 pF

39 Ω, ±5%

10 pF

RT = 28 Ω

RT = 28 Ω

Figure 1. Test Load and Voltage Definitions (V

O(STOP)

, V

O(X)

, VO, VOH, VOL)

CLK

CLKB

t

c1

t

c2

Cycle-to-cycle jitter = | tc1 – tc2| over 10000 consecutive cycles

Figure 2. Cycle-to-Cycle Jitter

CLK

CLKB

t

c3

Cycle-to-cycle jitter = | tc3 – tc4| over 10000 consecutive cycles

t

c4

Figure 3. Short Term Cycle-to-Cycle Jitter over 4 Cycles

Page 9

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

CLK

CLKB

t

pd1

t

c5

Duty cycle = (t

Pd1/tc5

)

Figure 4. Output Duty Cycle

CLK

CLKB

t

pd2

t

c6

Duty cycle error = t

pd2

– t

pd3

t

pd3

t

c7

Figure 5. Duty Cycle Error (Cycle-to-Cycle)

CLK

CLKB

V

O(X)+

V

O(X), nom

V

O(X)–

Figure 6. Crossing-Point Voltage

80%

t

f

t

r

20%

V

OL

V

OH

Figure 7. Voltage Waveforms

ООООООО

PWRDNB

CLK/CLKB

t

powerdown

t

powerup

Figure 8. PWRDNB Transition Timings

Page 10

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

MULT0 and/or

MULT1

CLK/CLKB

t

MULT

Figure 9. MULT Transition Timings

STOPB

t

CLKOFF

(see Note A)

t

ON

t

STOP

t

CLKSETL

t

CLKON

(see Note A)

Clock output settled

within 50 ps of the

phase before disabled

Clock enabled

and glitch free

Output clock

not specified

glitches ok

CLK/CLKB

NOTE A: V

ref

= VO ±200 mV

Figure 10. STOPB Transition Timings

Page 11

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

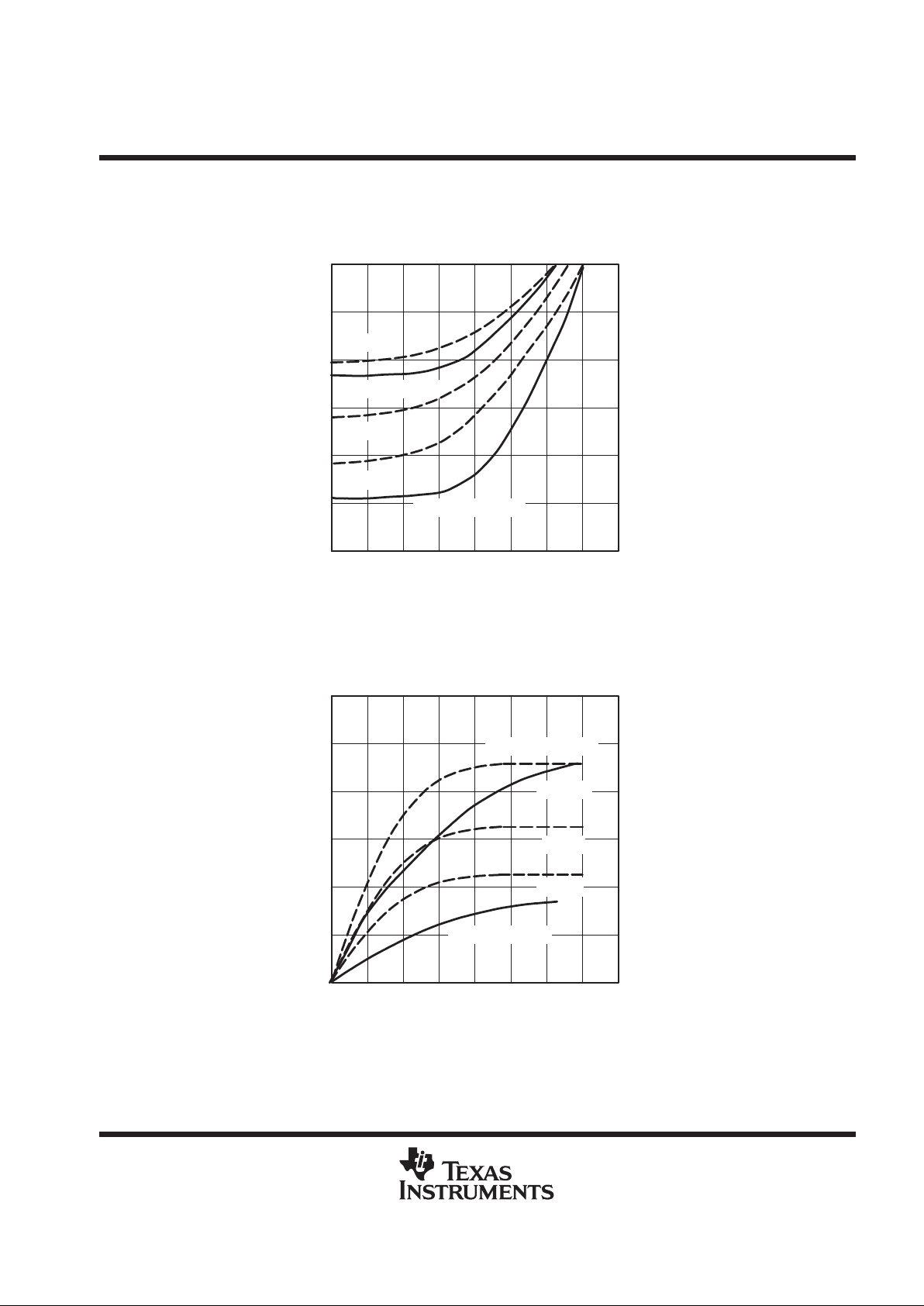

VOH – High-Level Output Voltage – V

HIGH-LEVEL OUTPUT CURRENT

vs

HIGH-LEVEL OUTPUT VOLTAGE

0

–0.04

–0.08

–0.12

0.5 1.5

–0.02

–0.06

–0.1

120

2.5 3 3.5 4

I

OH

– High-Level Output Current – A

Strong

Weak

Nom

Rambus (min)

Rambus (max)

Figure 11. Pullup IBIS I/V Chart

VOL – Low-Level Output Voltage – V

LOW-LEVEL OUTPUT CURRENT

vs

LOW-LEVEL OUTPUT VOLTAGE

0.12

0.08

0.04

0

0.5 1.5

0.1

0.06

0.02

120

2.5 3 3.5 4

I

OL

– Low-Level Output Current – A

Strong

Weak

Nom

Rambus (min)

Rambus (max)

Figure 12. Pulldown IBIS I/V Chart

Page 12

CDCR81

DIRECT RAMBUS CLOCK GENERATOR

SCAS606B – NOVEMBER 1998 – REVISED NOVEMBER 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DBQ (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

Gage Plane

0.008 (0,20) NOM

0.010 (0,25)

0.016 (0,40)

0.035 (0,89)

2420

Seating Plane

(8,74)

(8,56)

0.3370.337

(8,56)

(8,74)

0.344 0.344

4073301/C 02/97

13

0.150 (3,81)

0.157 (3,99)

0.012 (0,30)

0.008 (0,20)

12

A

24–PIN SHOWN

1

24

16

DIM

PINS **

A MIN

A MAX

0.004 (0,10)

0.010 (0,25)

0.069 (1,75) MAX

0.244 (6,20)

0.228 (5,80)

0.197

(5,00)

(4,78)

0.188

0.004 (0,10)

M

0.005 (0,13)

0.025 (0,64)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Falls within JEDEC MO-137

Page 13

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...