Page 1

www.ti.com

V

SS

(1)

S0

VDD1

Y1

Y1

VDD1

VDD3

18

17

16

15

14

13

1

2

3

4

5

6

EN

VDDPECL

IN

IN

VDDPECL

VBB

24 23 22 21 20 19

7 8 9 10 11 12

S2

V

DD

0

Y0

Y0

V

DD

0

S1

V

SS

V

DD

2

Y2

Y2

V

DD

2

Y3

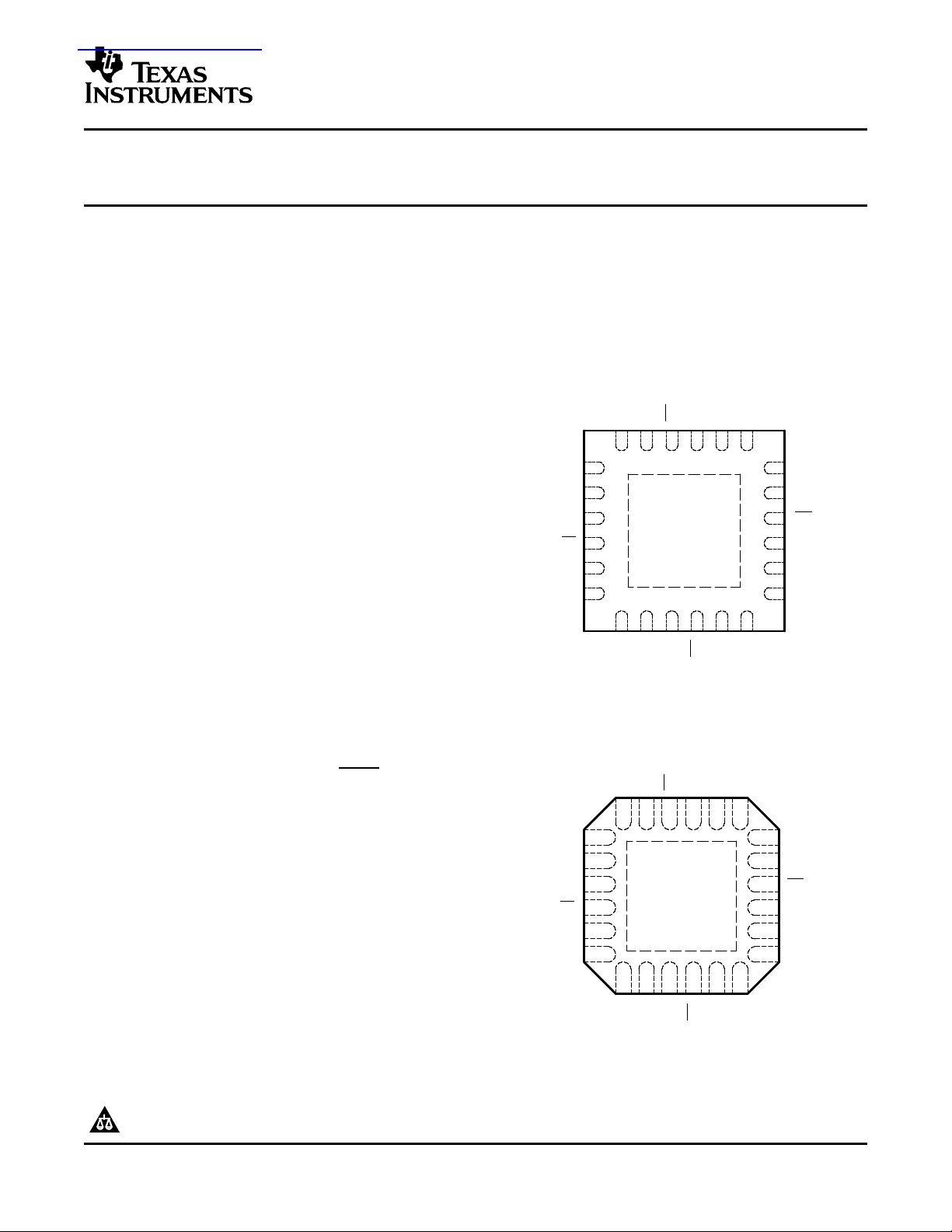

RGE PACKAGE

(TOP VIEW)

(1)

Thermal pad must be connected to VSS.

P0024-01

(1)

Thermal pad must be connected to VSS.

P0025-01

18

17

16

15

14

13

S0

VDD1

Y1

Y1

VDD1

VDD3

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

EN

VDDPECL

IN

IN

VDDPECL

VBB

S2

V

DD

0

Y0Y0V

DD

0

S1

V

SS

V

DD

2

Y2

Y2

V

DD

2

Y3

V

SS

(1)

RTH PACKAGE

(TOP VIEW)

查询CDCM1804供应商

LVCMOS OUTPUT AND PROGRAMMABLE DIVIDER

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

1:3 LVPECL CLOCK BUFFER + ADDITIONAL

FEATURES

• Distributes One Differential Clock Input to

Three LVPECL Differential Clock Outputs and

One LVCMOS Single-Ended Output

• Programmable Output Divider for Two

LVPECL Outputs and LVCMOS Output

• Low-Output Skew 15 ps (Typical) for

Clock-Distribution Applications for LVPECL

Outputs; 1.6-ns Output Skew Between

LVCMOS and LVPECL Transitions Minimizing

Noise

• V

• Signaling Rate Up to 800-MHz LVPECL and

• Differential Input Stage for Wide

• Provides VBB Bias Voltage Output for

• Receiver Input Threshold ± 75 mV

• 24-Terminal QFN Package (4 mm × 4 mm)

• Accepts Any Differential Signaling:

Range 3 V–3.6 V

CC

200-MHz LVCMOS

Common-Mode Range

Single-Ended Input Signals

LVDS, HSTL, CML, VML, SSTL-2, and

Single-Ended: LVTTL/LVCMOS

The CDCM1804 is characterized for operation from

–40 ° C to 85 ° C.

For use in single-ended driver applications, the

CDCM1804 also provides a VBB output terminal that

can be directly connected to the unused input as a

common-mode voltage reference.

DESCRIPTION

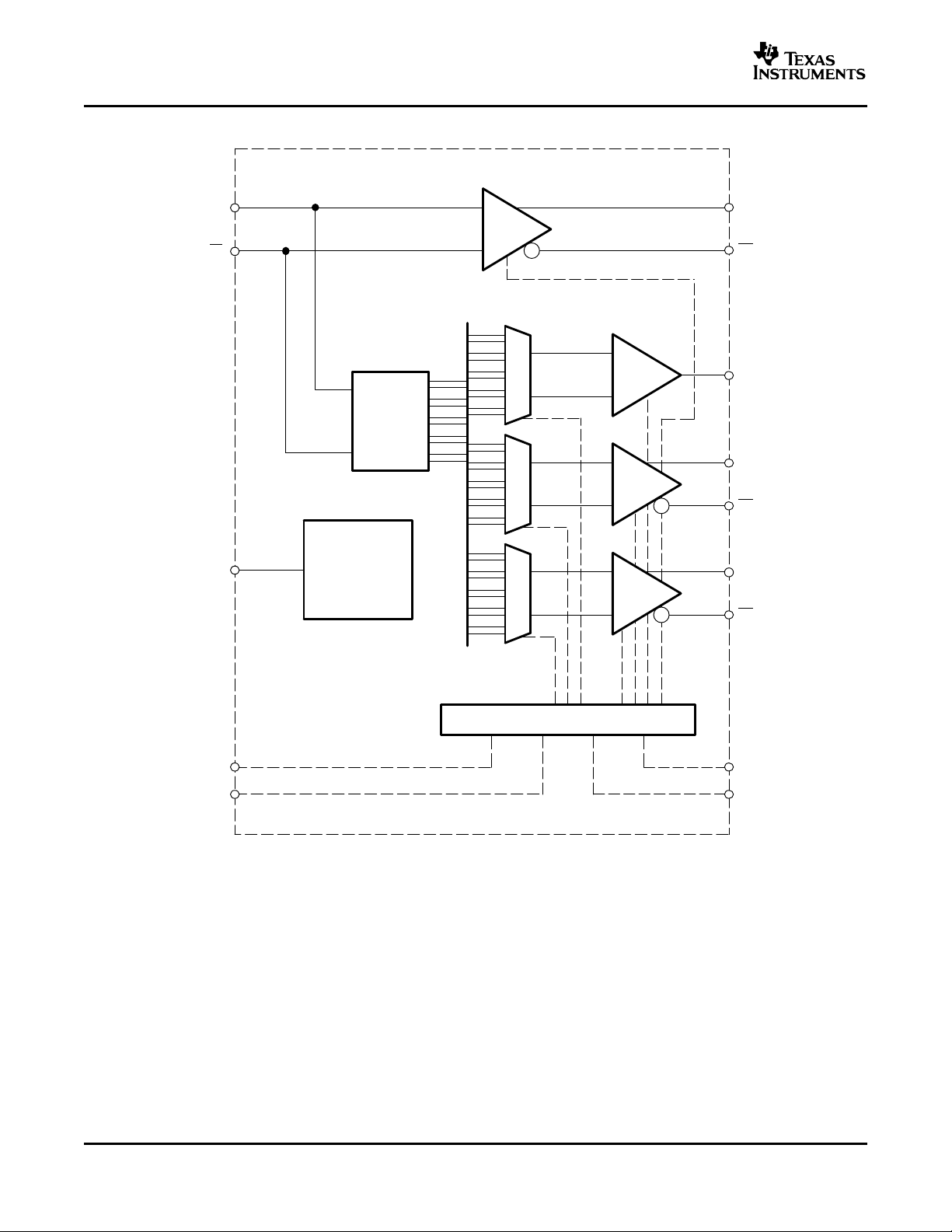

The CDCM1804 clock driver distributes one pair of

differential clock inputs to three pairs of LVPECL

differential clock outputs Y[2:0] and Y[2:0], with minimum skew for clock distribution. The CDCM1804 is

specifically designed for driving 50- Ω transmission

lines. Additionally, the CDCM1804 offers a

single-ended LVCMOS output Y3. This output is

delayed by 1.6 ns over the three LVPECL output

stages to minimize noise impact during signal transitions.

The CDCM1804 has three control terminals, S0, S1,

and S2, to select different output mode settings. The

S[2:0] terminals are 3-level inputs and therefore allow

up to 33= 27 combinations. Additionally, an enable

terminal (EN) is provided to disable or enable all

outputs simultaneously. The EN terminal is a 3-level

input as well and extends the number of settings to

2 × 27 = 54. See Table 1 for details.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2003–2005, Texas Instruments Incorporated

Page 2

www.ti.com

Control

VBB

LVPECL

Y1

Y1

LVPECL

Y2

Y2

LVPECL

Y3

LVCMOS

Y0

Y0

Div 1

Div 2

Div 4

Div 8

Div 16

Bias

Generator

VDD − 1.3 V

(I

max

< 1.5 mA)

IN

IN

S2

ENS0

S1

B0059-01

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

FUNCTIONAL BLOCK DIAGRAM

2

Page 3

www.ti.com

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

EN 1 I ENABLE: Enables or disables all outputs simultaneously. The EN terminal offers three

IN, IN 3, 4 I (differential) Differential input clock: Input stage is sensitive and has a wide common-mode range.

S[2:0] 18, 19, 24 I Select mode of operation: Defines the output configuration of Y[3:0]. Each terminal

VBB 6 O Bias voltage output to be used to bias unused complementary input IN for single-ended

V

SS

VDDPECL 2, 5 Supply Supply voltage LVPECL input + internal logic

VDD[2:0] 8, 11, 14, Supply LVPECL output supply voltage for output Y[2:0]. Each output can be disabled by pulling

VDD3 13 Supply Supply voltage LVCMOS output. The LVCMOS output can be disabled by pulling VDD3

Y[2:0] 9, 15, 21 O (LVPECL) LVPECL clock outputs. These outputs provide low-skew copies of IN or down-divided

Y[2:0] 10, 16, 22 copies of clock IN based on selected mode of operation S[2:0]. If an output is unused,

Y3 12 O LVCMOS clock output. This output provides copy of IN or down-divided copy of clock IN

7 Supply Device ground

17, 20, 23 the corresponding VDDx to GND.

I/O DESCRIPTION

(with 60-k Ω pullup) different configurations: tied to GND (logic 0), external 60-k Ω pulldown resistor (pull to

(with 60-k Ω pullup) offers three different configurations: tied to GND (logic 0), external 60-k Ω pulldown

VDD/2), or left floating (logic 1);

EN = 1: outputs on according to S[2:0] settings

EN = VDD/2: outputs on according to S[2:0] settings

EN = 0: outputs Y[3:0] off (high impedance)

See Table 1 for details.

Therefore, almost any type of differential signal can drive this input (LVPECL, LVDS,

CML, HSTL). Because the input is high-impedance, it is recommended to terminate the

PCB transmission line before the input (e.g., with 100 Ω across input). Input can also be

driven by single-ended signal if the complementary input is tied to VBB. A

more-advanced scheme for single-ended signals is given in the Application Information

section near the end of this document.

The inputs employ an ESD structure protecting the inputs in case of an input voltage

exceeding the rails by more than ~0.7 V. Reverse biasing of the IC through these inputs

is possible and must be prevented by limiting the input voltage < VDD.

resistor (pull to VDD/2), or left floating (logic 1); see Table 1 for details.

input signals.

The output voltage of VBB is V

is limited to about 1.5 mA.

CAUTION: In this mode, no voltage from outside may be forced, because internal

diodes could be forced in forward direction. Thus, it is recommended to disconnect the

output.

to GND.

CAUTION: In this mode, no voltage from outside may be forced because internal

diodes could be forced in a forward direction. Thus, it is recommended to leave Y3

unconnected, tied to GND, or terminated into GND.

the output can simply be left open to save power and minimize noise impact to the

remaining outputs.

based on selected mode of operation S[2:0]. Also, this output can be disabled when

VDD3 becomes tied to GND.

– 1.3 V. When driving a load, the output current drive

DD

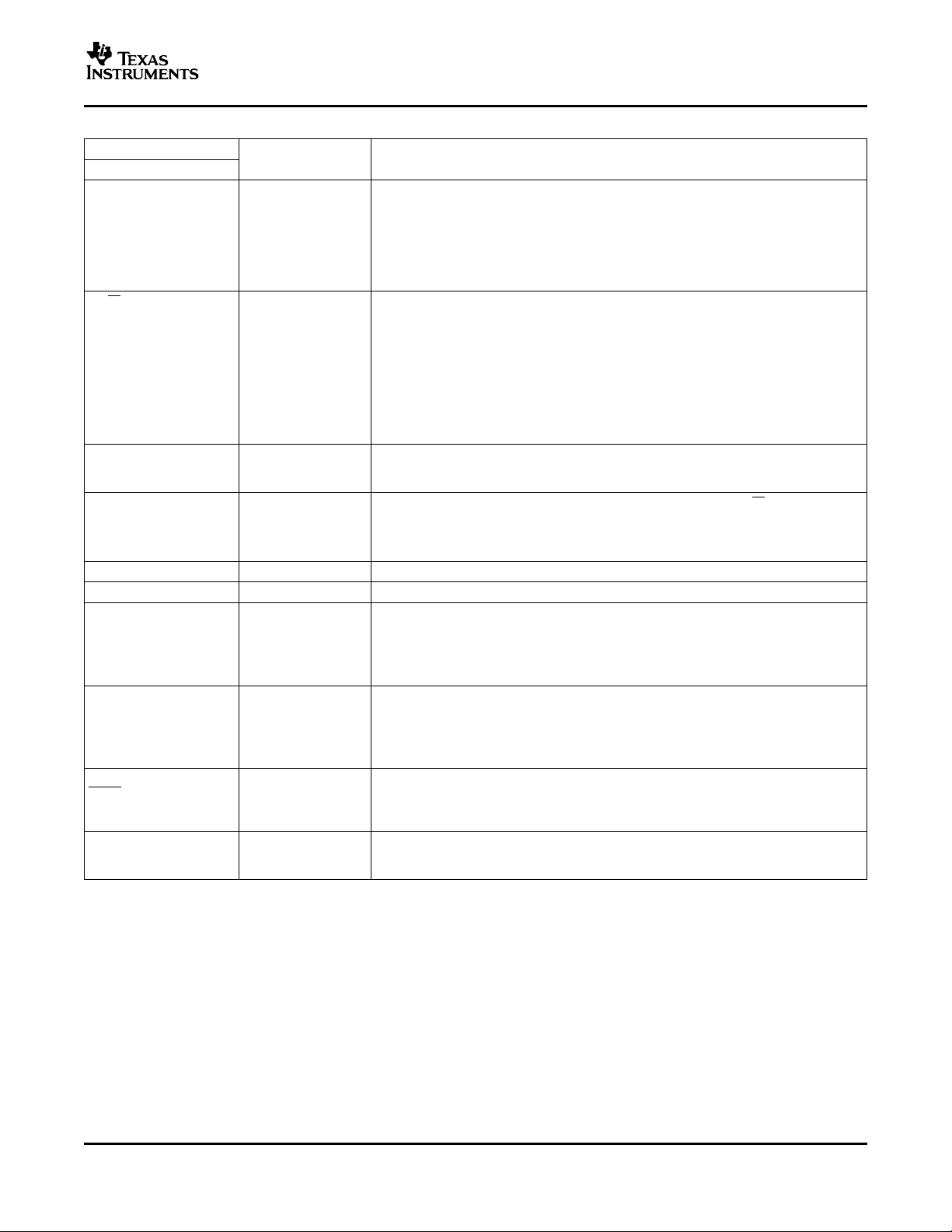

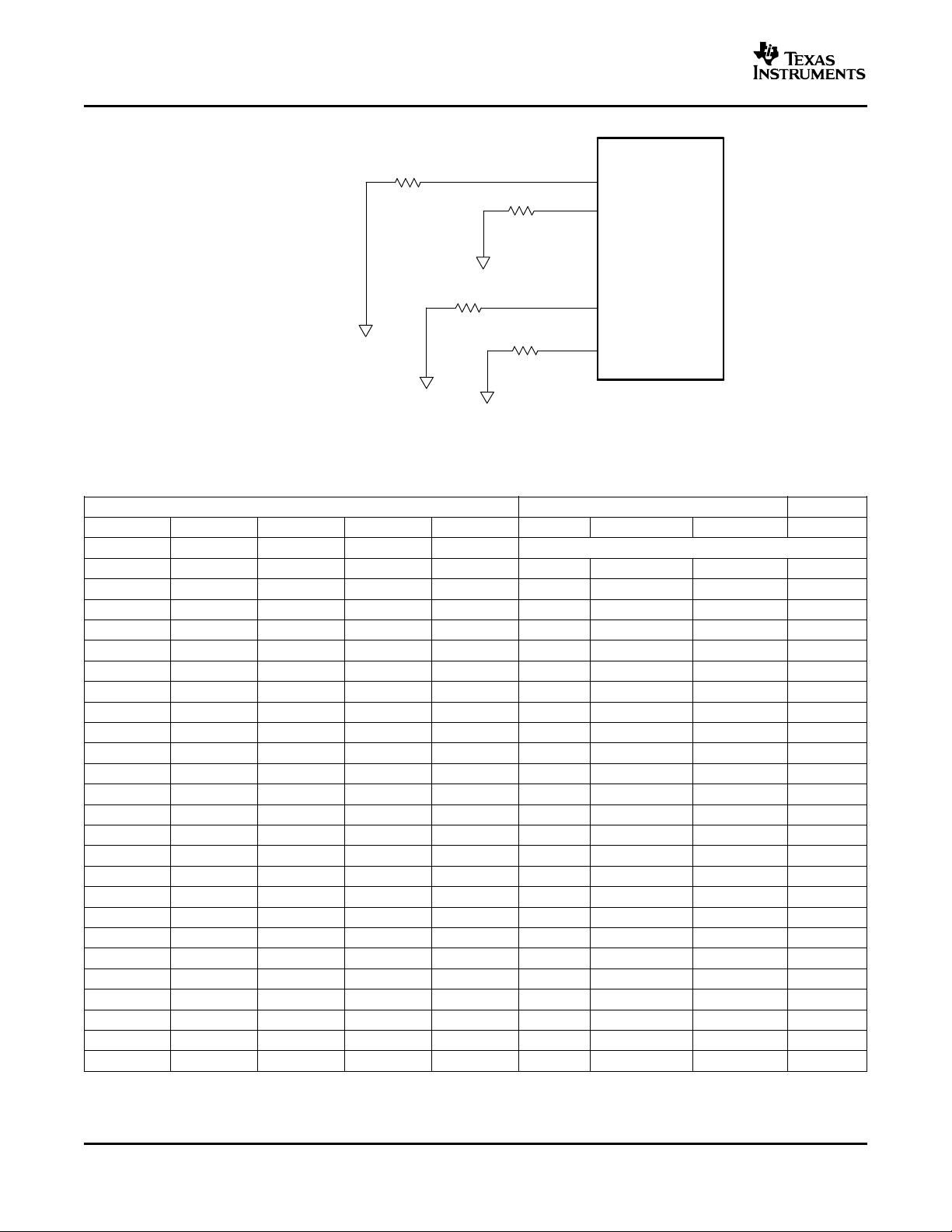

CONTROL TERMINAL SETTINGS

The CDCM1804 has three control terminals (S0, S1, and S2) and an enable terminal (EN) to select different

output mode settings. All four inputs (S0, S1, S2, and EN) are 3-level inputs offering 54 different combinations. In

addition, the EN input allows the disabling of all outputs and forcing them into a high-z (or 3-state) output state

when pulled to GND.

Each control input incorporates a 60-k Ω pullup resistor. Thus, it is easy to choose the input setting by designing

a resistor pad between the control input and GND. To choose a logic zero, the resistor value must be zero.

Setting the input high requires leaving the resistor pad empty (no resistor installed). For setting the input to

V

/2, the installed resistor must be a 60-k Ω pulldown to GND with a 10% tolerance or better.

DD

3

Page 4

www.ti.com

RS0 = 0 Ω

EN

CDCM1804

S1

S0

RS1 = 60 kΩ

REN = Open

Setting for Mode 13:

EN = 1

S2 = VDD/2

S1 = VDD/2

S0 = 0

RS2 = 60 kΩ

S2

S0084-01

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

Figure 1. Control Terminal Setting for Example

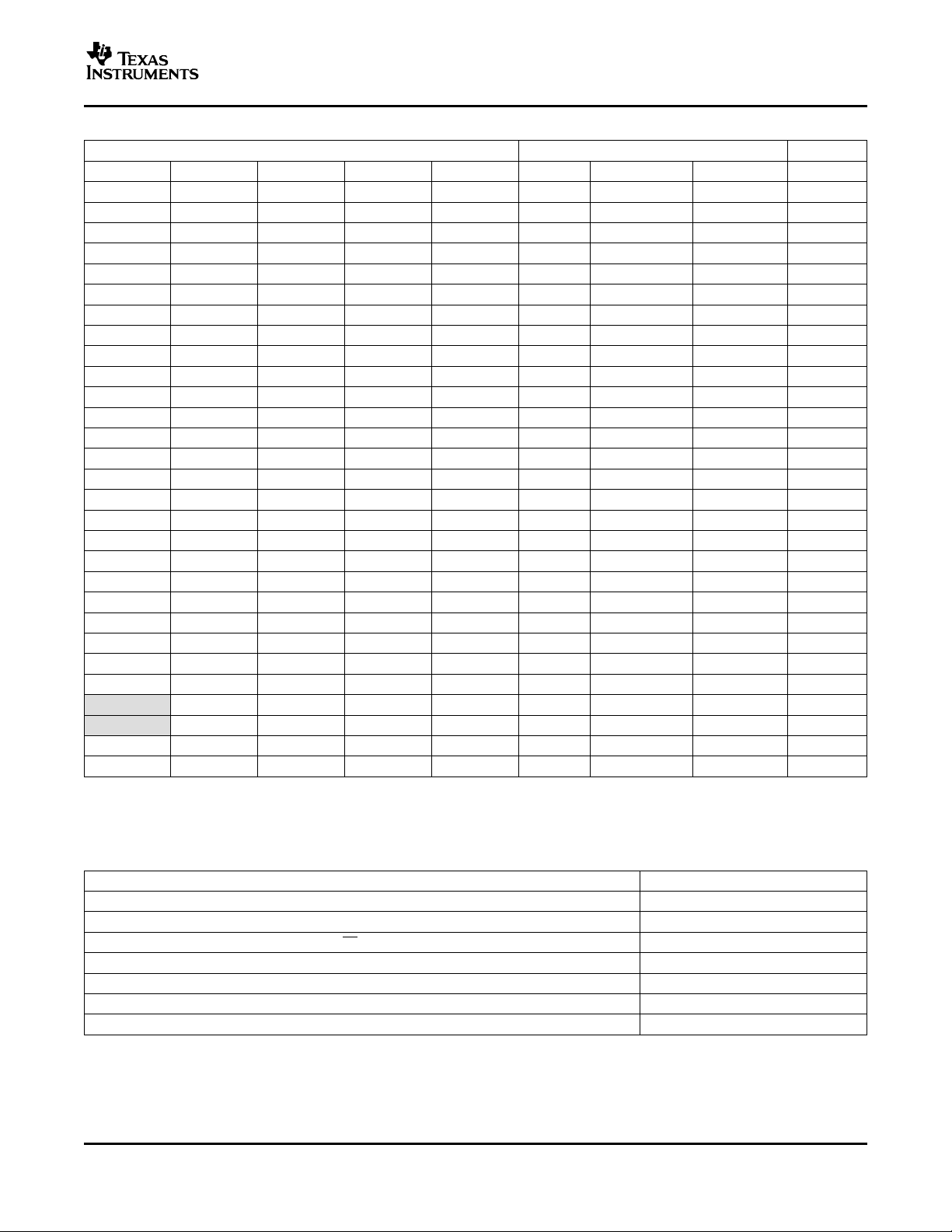

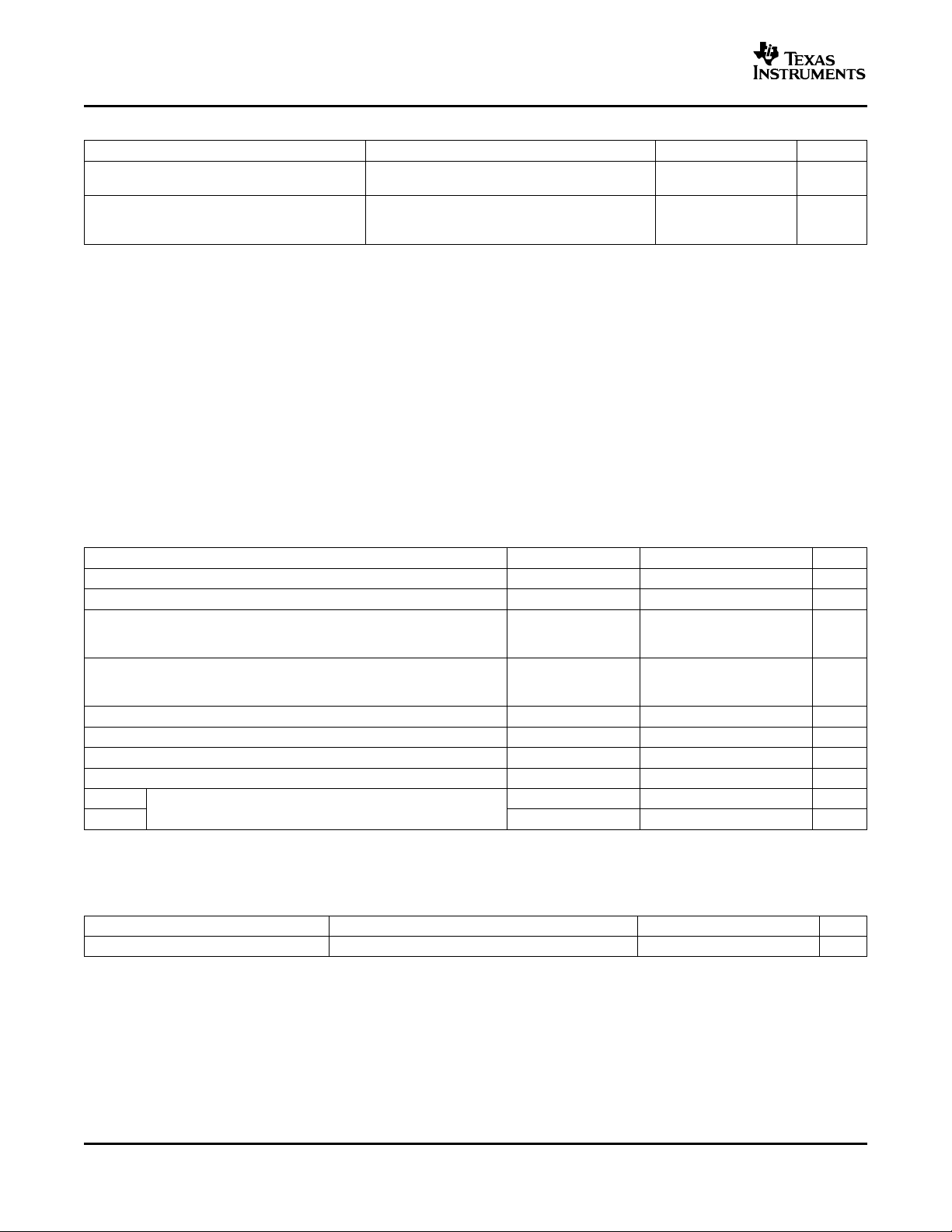

Table 1. Selection Mode Table

LVPECL

MODE EN S2 S1 S0 Y0 Y1 Y2 Y3

0 0 x x x Off (high-z)

1 1 0 0 0 ÷ 1 ÷ 1 ÷ 1 Off (high-z)

2 1 0 0 VDD/2 ÷ 1 Off (high-z) Off (high-z) ÷ 4

3 1 0 0 1 ÷ 1 ÷ 1 Off (high-z) ÷ 4

4 1 0 VDD/2 0 ÷ 1 ÷ 2 Off (high-z) ÷ 4

5 1 0 VDD/2 VDD/2 ÷ 1 ÷ 4 Off (high-z) ÷ 4

6 1 0 VDD/2 1 ÷ 1 ÷ 8 Off (high-z) ÷ 4

7 1 0 1 0 ÷ 1 Off (high-z) ÷ 1 ÷ 4

8 1 0 1 VDD/2 ÷ 1 ÷ 1 ÷ 1 ÷ 4

9 1 0 1 1 ÷ 1 ÷ 2 ÷ 1 ÷ 4

10 1 VDD/2 0 0 ÷ 1 ÷ 4 ÷ 1 ÷ 4

11 1 VDD/2 0 VDD/2 ÷ 1 ÷ 8 ÷ 1 ÷ 4

12 1 VDD/2 0 1 ÷ 1 Off (high-z) ÷ 2 ÷ 4

13 1 VDD/2 VDD/2 0 ÷ 1 ÷ 1 ÷ 2 ÷ 4

14 1 VDD/2 VDD/2 VDD/2 ÷ 1 ÷ 2 ÷ 2 ÷ 4

15 1 VDD/2 VDD/2 1 ÷ 1 ÷ 4 ÷ 2 ÷ 4

16 1 VDD/2 1 0 ÷ 1 ÷ 8 ÷ 2 ÷ 4

17 1 VDD/2 1 VDD/2 ÷ 1 Off (high-z) ÷ 4 ÷ 4

18 1 VDD/2 1 1 ÷ 1 ÷ 1 ÷ 4 ÷ 4

19 1 1 0 0 ÷ 1 ÷ 2 ÷ 4 ÷ 4

20 1 1 0 VDD/2 ÷ 1 ÷ 4 ÷ 4 ÷ 4

21 1 1 0 1 ÷ 1 ÷ 8 ÷ 4 ÷ 4

22 1 1 VDD/2 0 ÷ 1 Off (high-z) ÷ 8 ÷ 4

23 1 1 VDD/2 VDD/2 ÷ 1 ÷ 1 ÷ 8 ÷ 4

24 1 1 VDD/2 1 ÷ 1 ÷ 2 ÷ 8 ÷ 4

25 1 1 1 0 ÷ 1 ÷ 4 ÷ 8 ÷ 4

(1)

LVCMOS

(1) The LVPECL outputs are open-emitter stages. Thus, if you leave the unused LVPECL outputs Y0, Y1, or Y2 unconnected, then the

current consumption is minimized and noise impact to remaining outputs is neglectable. Also, each output can be individually disabled

by connecting the corresponding V

4

DD

input to GND.

Page 5

www.ti.com

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

Table 1. Selection Mode Table (continued)

LVPECL

MODE EN S2 S1 S0 Y0 Y1 Y2 Y3

26 1 1 1 VDD/2 ÷ 1 ÷ 8 ÷ 8 ÷ 4

27 1 1 1 1 ÷ 1 Off (high-z) ÷ 16 ÷ 4

28 VDD/2 0 0 0 ÷ 1 ÷ 1 ÷ 16 ÷ 4

29 VDD/2 0 0 VDD/2 ÷ 1 ÷ 2 ÷ 16 ÷ 4

30 VDD/2 0 0 1 ÷ 1 ÷ 4 ÷ 16 ÷ 4

31 VDD/2 0 VDD/2 0 ÷ 1 ÷ 8 ÷ 16 ÷ 4

32 VDD/2 0 VDD/2 VDD/2 ÷ 1 Off (high-z) Off (high-z) ÷ 1

33 VDD/2 0 VDD/2 1 ÷ 1 ÷ 1 Off (high-z) ÷ 1

34 VDD/2 0 1 0 ÷ 1 ÷ 2 Off (high-z) ÷ 1

35 VDD/2 0 1 VDD/2 ÷ 1 ÷ 1 Off (high-z) ÷ 2

36 VDD/2 0 1 1 ÷ 1 ÷ 2 Off (high-z) ÷ 2

37 VDD/2 VDD/2 0 0 ÷ 1 Off (high-z) Off (high-z) ÷ 2

38 VDD/2 VDD/2 0 VDD/2 ÷ 1 ÷ 1 ÷ 1 ÷ 2

39 VDD/2 VDD/2 0 1 ÷ 1 ÷ 2 ÷ 8 ÷ 2

40 VDD/2 VDD/2 VDD/2 0 ÷ 1 ÷ 2 ÷ 8 ÷ 8

41 VDD/2 VDD/2 VDD/2 VDD/2 ÷ 1 ÷ 4 Off (high-z) ÷ 1

42 VDD/2 VDD/2 VDD/2 1 ÷ 1 ÷ 8 Off (high-z) ÷ 1

43 VDD/2 VDD/2 1 0 ÷ 1 ÷ 4 Off (high-z) ÷ 2

44 VDD/2 VDD/2 1 VDD/2 ÷ 1 ÷ 8 Off (high-z) ÷ 2

45 VDD/2 VDD/2 1 1 ÷ 1 ÷ 1 ÷ 2 ÷ 2

46 VDD/2 1 0 0 ÷ 1 Off (high-z) Off (high-z) ÷ 8

47 VDD/2 1 0 VDD/2 ÷ 1 ÷ 4 Off (high-z) ÷ 8

48 VDD/2 1 0 1 ÷ 1 ÷ 4 ÷ 8 ÷ 8

49 VDD/2 1 VDD/2 0 ÷ 1 ÷ 8 Off (high-z) ÷ 8

50 VDD/2 1 VDD/2 VDD/2 ÷ 1 ÷ 2 ÷ 8 ÷ 16

Rsv VDD/2 1 VDD/2 1 Reserved Reserved Reserved Reserved

Rsv VDD/2 1 1 0 N/A Low Low Low

53 VDD/2 1 1 VDD/2 ÷ 1 ÷ 1 ÷ 1 ÷ 1

54 VDD/2 1 1 1 ÷ 1 ÷ 1 ÷ 1 ÷ 1

(1)

LVCMOS

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature (unless otherwise noted)

V

DD

V

I

V

O

T

stg

T

J

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

Supply voltage –0.3 V to 3.8 V

Input voltage –0.2 V to (V

Output voltage –0.2 V to (V

Differential short-circuit current, Yn, Yn, I

OSD

Electrostatic discharge (HBM 1.5 k Ω , 100 pF), ESD >2000 V

Moisture level 24-terminal QFN package (solder reflow temperature of 235 ° C) MSL 2

Storage temperature –65 ° C to 150 ° C

Maximum junction temperature 125 ° C

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(1)

DD

DD

Continuous

+ 0.2 V)

+ 0.2 V)

5

Page 6

www.ti.com

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

RECOMMENDED OPERATING CONDITIONS

V

DD

T

A

ELECTRICAL CHARACTERISTICS

over recommended operating free-air temperature range (unless otherwise noted)

LVPECL INPUT IN, IN

f

clk

V

CM

V

IN

I

IN

R

IN

C

I

(1) Is required to maintain ac specifications

(2) Is required to maintain device functionality

Supply voltage 3 3.3 3.6 V

Operating free-air temperature –40 85 ° C

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Input frequency 0 800 MHz

High-level input common mode 1 V

Input voltage swing between IN and IN

Input voltage swing between IN and IN

Input current VI= V

(1)

(2)

or 0 V ± 10 µ A

DD

Input impedance 300 k Ω

Input capacitance at IN, IN 1 pF

MIN TYP MAX UNIT

DD

500 1300

150 1300

– 0.3 V

mV

LVPECL OUTPUT DRIVER Y[2:0], Y[2:0]

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

clk

V

OH

V

OL

V

O

I

OZL

I

OZH

tr/t

f

t

skpecl(o)

t

Duty

t

sk(pp)

C

O

Output frequency, see Figure 4 0 800 MHz

High-level output voltage Termination with 50 Ω to V

Low-level output voltage Termination with 50 Ω to V

Output voltage swing between Y and

Y, see Figure 4 .

Output 3-state current µ A

Rise and fall time 200 350 ps

Output skew between any LVPECL

output Y[2-0] and Y[2-0]

Output duty-cycle distortion

(1)

Termination with 50 Ω to V

V

= 3.6 V, VO= 0 V 5

DD

V

= 3.6 V, VO= V

DD

20% to 80% of V

ure 9 .

DD

OUTPP

See Note A in Figure 8 . 15 30 ps

Crossing point-to-crossing point dis-

tortion

– 2 V V

DD

– 2 V V

DD

– 2 V 500 mV

DD

– 1.18 V

DD

– 1.98 V

DD

DD

DD

– 0.8 V 10

, see Fig-

–50 50 ps

– 0.81 V

– 1.55 V

Part-to-part skew Any Y, see Note B in Figure 8 . 50 ps

Output capacitance VO= V

or GND 1 pF

DD

LOAD Expected output load 50 Ω

(1) For an 800-MHz signal, the 50-ps error would result in a duty-cycle distortion of ± 4% when driven by an ideal clock input signal.

LVPECL INPUT-TO-LVPECL OUTPUT PARAMETERS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

LVPECL INPUT-TO-LVPECL OUTPUT PARAMETER

t

pd(lh)

t

pd(hl)

t

sk(p)

Propagation delay rising edge VOX to VOX 320 600 ps

Propagation delay falling edge VOX to VOX 320 600 ps

LVPECL pulse skew VOX to VOX, see Note C in Fig- 100 ps

ure 8 .

6

Page 7

www.ti.com

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

LVCMOS OUTPUT PARAMETER, Y3

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

clk

t

skLVCMOS(o)

t

sk(pp)

V

OH

V

OL

I

OH

I

OL

I

OZ

C

O

t

Duty

t

pd(lh)

t

pd(hl)

t

r

t

f

OUTPUT frequency, see Figure 5

Output skew between the LVCMOS out-

put Y3 and LVPECL outputs Y[2:0]

Part-to-part skew Y3, see Note B in Figure 8 . 300 ps

High-level output voltage V

Low-level output voltage V

High-level output current V

Low-level output current V

High-impedance-state output current V

Output capacitance V

Output duty cycle distortion

Propagation delay rising edge from IN to

Y3

Propagation delay falling edge from IN

to Y3

Output rise slew rate 20% to 80% of swing, see Figure 10 . 1.4 2.3 V/ns

Output fall slew rate 80% to 20% of swing, see Figure 10 . 1.4 2.3 V/ns

(1) Operating the CDCM1804 LVCMOS output above the maximum frequency does not cause a malfunction to the device, but the Y3

output will not achieve enough signal swing to meet the output specification. Therefore, the CDCM1804 can be operated at higher

frequencies, while the LVCMOS output Y3 becomes unusable.

(2) For a 200-MHz signal, the 150-ps error would result in a duty cycle distortion of ± 3% when driven by an ideal clock input signal.

(1)

. 0 200 MHz

VOX to VDD/2, see Figure 8 . 1.3 1.6 2.1 ns

V

= min to max IOH= –100 µ A V

DD

= 3 V IOH= –6 mA 2.4 V

DD

V

= 3 V IOH= –12 mA 2

DD

V

= min to max IOL= 100 µ A 0.1

DD

= 3 V IOL= 6 mA 0.5 V

DD

V

= 3 V IOL= 12 mA 0.8

DD

= 3.3 V VO= 1.65 V –29 mA

DD

= 3.3 V VO= 1.65 V 37 mA

DD

= 3.6 V VO= V

DD

= 3.3 V 2 pF

(2)

DD

Measured at VDD/2 –150 150 ps

or 0 V ± 5 µ A

DD

– 0.1

DD

VOX to VDD/2 load, see Figure 10 . 1.6 2.6 ns

VOX to VDD/2 load, see Figure 10 . 1.6 2.6 ns

JITTER CHARACTERISTICS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

12 kHz to 20 MHz,

f

= 250 MHz to 800 MHz, 0.15

out

t

jitterLVPECL

t

jitterLVCMOS

Additive phase jitter from input to

LVPECL output Y[2:0], see Figure 2 .

Additive phase jitter from input to

LVCMOS output Y3, see Figure 3 .

divide-by-1 mode

50 kHz to 40 MHz,

f

= 250 MHz to 800 MHz, 0.25

out

divide-by-1 mode

12 kHz to 20 MHz, f

divide-by-1 mode

50 kHz to 40 MHz, f

divide-by-1 mode

= 250 MHz,

out

= 250 MHz,

out

ps rms

0.25

ps rms

0.4

7

Page 8

www.ti.com

−160

−155

−150

−145

−140

−135

−130

−125

−120

−115

−110

VDD = 3.3 V

TA = 25°C

f = 622 MHz

÷1 Mode

Additive Phase Noise − dBc/Hz

f − Frequency Offset From Carrier − Hz

10 100 1k 100M10k 100k 10M1M

G001

−160

−155

−150

−145

−140

−135

−130

−125

−120

−115

−110

−105

−100

VDD = 3.3 V

TA = 25°C

f = 250 MHz

÷1 Mode

Additive Phase Noise − dBc/Hz

f − Frequency Offset From Carrier − Hz

10 100 1k 100M10k 100k 10M1M

G002

f − Frequency − GHz

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.1 0.3 0.5 0.7 0.9 1.1 1.3 1.5

LVPECL Output Swing − V

TA = 25°C

Load = 50 Ω to VDD − 2 V

VDD = 3.6 V

VDD = 3.3 V

VDD = 3 V

G003

f − Frequency − MHz

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

25 75 125 175 225 275 325 375 425 475

LVCMOS Output Swing − V

TA = 25°C

Load = See Figure 10

VDD3 = 3 V

VDD3 = 3.6 V

VDD = 3.3 V

G004

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

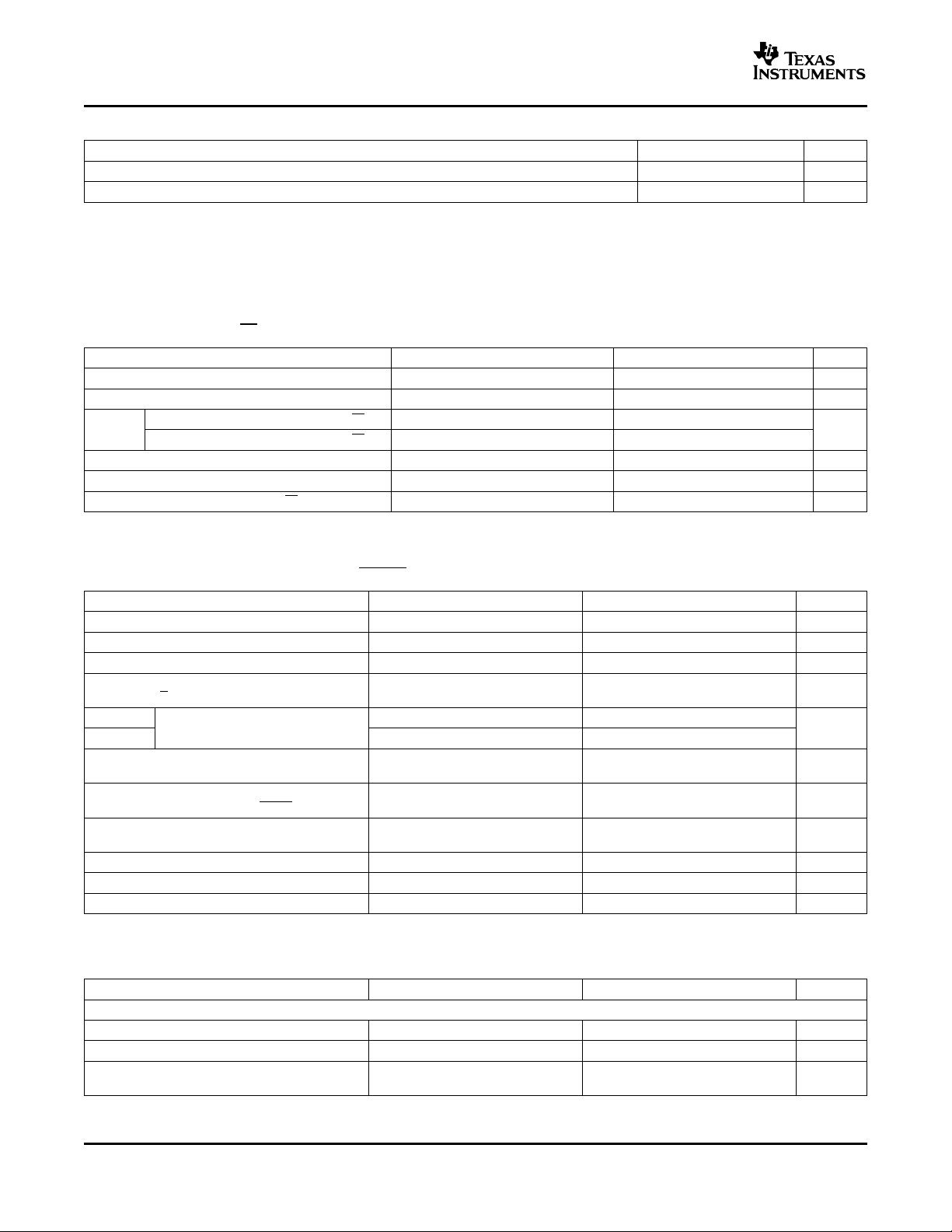

ADDITIVE PHASE NOISE ADDITIVE PHASE NOISE

vs vs

FREQUENCY OFFSET FROM CARRIER – LVPECL FREQUENCY OFFSET FROM CARRIER – LVCMOS

Figure 2. Figure 3.

LVPECL OUTPUT SWING LVCMOS OUTPUT SWING

vs vs

FREQUENCY FREQUENCY

8

Figure 4. Figure 5.

Page 9

www.ti.com

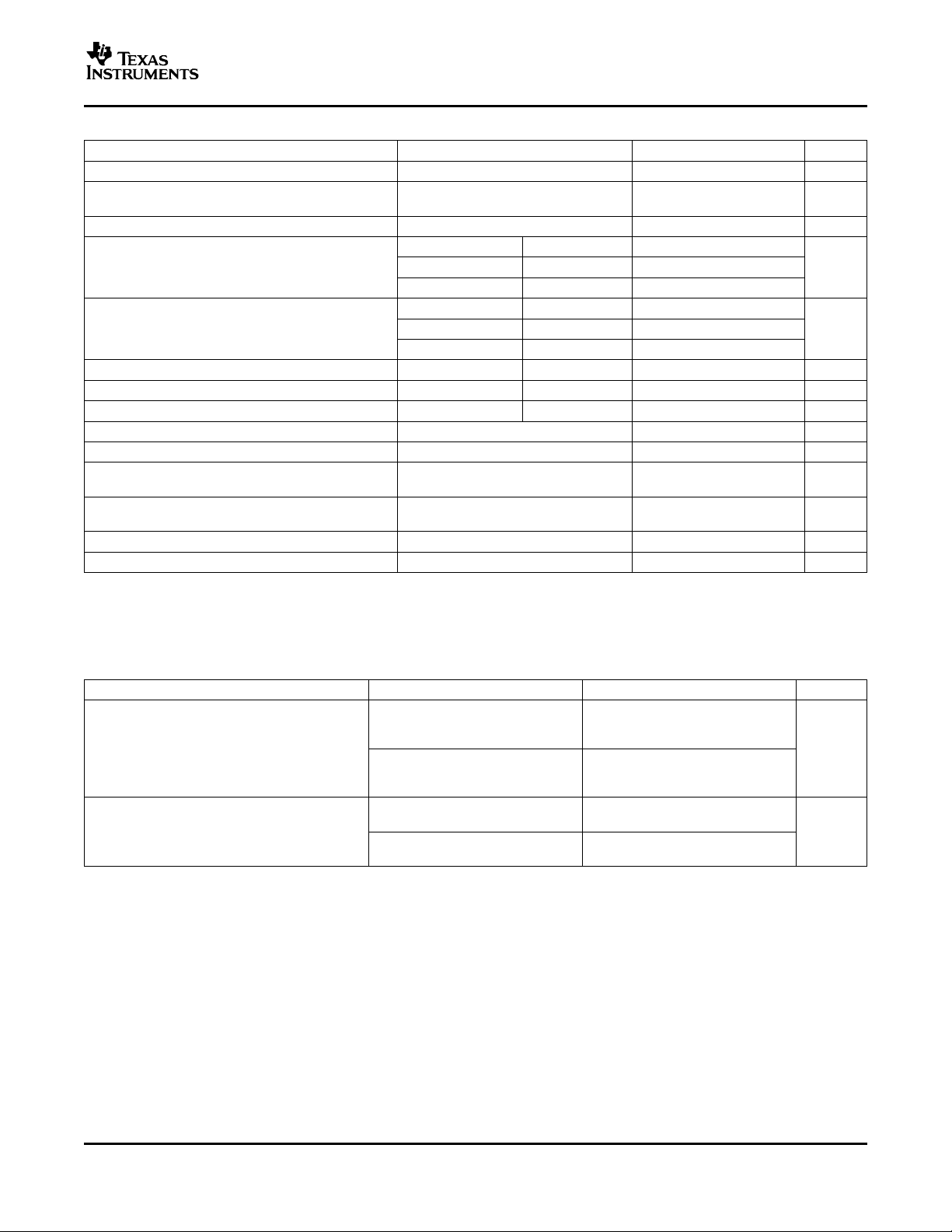

SUPPLY CURRENT ELECTRICAL CHARACTERISTICS

f − Frequency − MHz

110

120

130

140

150

160

170

180

100 300 500 700 900 1100 1300 1500

I

DD

− Supply Current − mA

VDD = 3.3 V

TA = 25°C

Load = 10 pF/1k/1k for LVCMOS

50 Ω to VDD − 2 V for LVPECL

3 LVPECL Outputs (÷1),

LVCMOS Output (÷4)

3 LVPECL Outputs (÷1)

Running, LVCMOS Output Off

2 LVPECL Outputs (÷1),

LVCMOS Output (÷4)

G005

over recommended operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

All outputs enabled and terminated with 50 Ω to

V

– 2 V on LVPECL outputs and 10 pF on LVCMOS

Full load 160

Supply current mA

I

DD

No load 110

Supply current saving per LVPECL

output stage disabled, no load

I

Supply current, 3-state Hz, 0.5 mA

DDZ

DD

output, f = 800 MHz for LVPECL outputs and 200 MHz for

LVCMOS, V

= 3.3 V

DD

Outputs enabled, no output load, f = 800 MHz for LVPECL

outputs and 200 MHz for LVCMOS, V

f = 800 MHz for LVPECL output, V

All outputs in the high-impedance state by control logic, f = 0

V

= 3.6 V

DD

SUPPLY CURRENT

vs

FREQUENCY

SCAS697E – JULY 2003 – REVISED MAY 2005

= 3.6 V

DD

= 3.3 V 10 mA

DD

CDCM1804

Figure 6.

9

Page 10

www.ti.com

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

PACKAGE THERMAL RESISTANCE

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

R

R

QFN-24 package thermal resistance

θ JA-1

QFN-24 package thermal resistance 4-layer JEDEC test board (JESD51-7) with four

with thermal vias in PCB

θ JA-2

(1)

(1) It is recommended to provide four thermal vias to connect the thermal pad of the package effectively with the PCB and ensure a good

heat sink.

Example:

Calculation of the junction-lead temperature with a 4-layer JEDEC test board using four thermal vias:

T

P

θ T

T

= 85 ° C (temperature of the chassis)

Chassis

= I

effective

Junction

Junction

max

= R

= θ T

T

die-max

Junction

= 125 ° C is not violated)

× V

θ JA-2

= 110 mA × 3.6 V = 396 mW (maximum power consumption inside the package)

max

× P

effective

+ T

Chassis

CONTROL INPUT CHARACTERISTICS

over recommended operating free-air temperature range

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

su

t

h

t

(disable)

t

(enable)

Rpullup Internal pullup resistor on S[2:0] and EN inputs 42 60 78 k Ω

V

IH(H)

V

IM(M)

V

IL(L)

I

IH

I

IL

(1) Leaving this terminal floating automatically pulls the logic level high to V

Setup time, S0, S1, S2, and EN terminals before clock IN 25 ns

Hold time, S0, S1, S2, and EN terminals after clock IN 0 ns

Time between latching the EN low transition and when all

outputs are disabled (how much time is required until the 10 ns

outputs turn off)

Time between latching the EN low-to-high transition and when

outputs are enabled based on control settings (how much time 1 µ s

passes before the outputs carry valid signals)

Three-level input high, S0, S1, S2, and EN terminals

Three-level input MID, S0, S1, S2, and EN terminals 0.3 V

Three-level input low, S0, S1, S2, and EN terminals 0.1 V

Input current, S0, S1, S2, and EN terminals

(1)

4-layer JEDEC test board (JESD51-7),

airflow = 0 ft/min

thermal vias of 22-mil diameter each, 55.4 ° C/W

airflow = 0 ft/min

= 55.45 ° C/W × 396 mW = 21.96 ° C

= 21.96 ° C + 85 ° C = 107 ° C (the maximum junction temperature of

(1)

VI= V

DD

VI= GND 38 85 µ A

through an internal pullup resistor of 60 k Ω .

DD

0.9 V

DD

DD

106.6 ° C/W

0.7 V

DD

DD

–5 µ A

V

V

V

BIAS VOLTAGE VBB

over recommended operating free-air temperature range

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VBB Output reference voltage V

10

DD

= 3 V–3.6 V, IBB= –0.2 mA V

– 1.4 V

DD

DD

– 1.2 V

Page 11

www.ti.com

I − Load − mA

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

−5 0 5 10 15 20 25 30 35

VDD = 3.3 V

V

BB

− Output Reference Voltage − V

G006

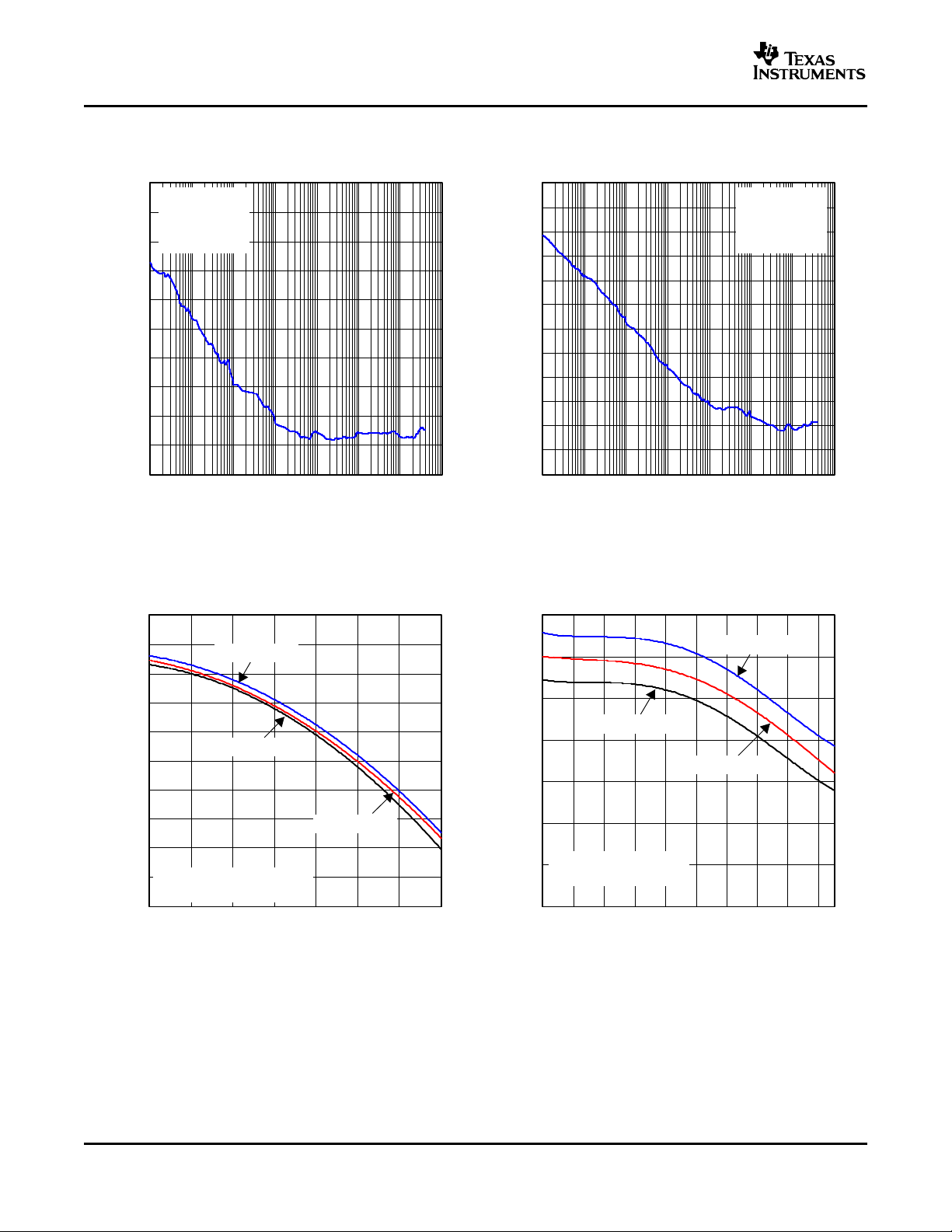

OUTPUT REFERENCE VOLTAGE (VBB)

vs

LOAD

Figure 7.

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

11

Page 12

www.ti.com

IN

IN

Y0

Y0

t

pd(LH1)

Y1

Y1

t

pd(LH2)

t

skLVCMOS(o)

Y3

0.5 × VDD3

Y2

Y2

NOTES: A. Output skew, t

sk(o)

, is calculated as the greater of:

− The difference between the fastest and the slowest t

pd(LH)n

(n = 0…2)

− The difference between the fastest and the slowest t

pd(HL)n

(n = 0…2)

B. Part-to-part skew, t

sk(pp)

, is calculated as the greater of:

− The difference between the fastest and the slowest t

pd(LH)n

(n = 0…2 for LVPECL, n = 3 for LVCMOS) across multiple devices

− The difference between the fastest and the slowest t

pd(HL)n

(n = 0…2 for LVPECL, n = 3 for LVCMOS) across multiple devices

C. Pulse skew, t

sk(p)

, is calculated as the magnitude of the absolute time difference between the high-to-low (t

pd(HL

) and the low-to-high

(t

pd(LH)

) propagation delays when a single switching input causes one or more outputs to switch, t

sk(p)

= | t

pd(HL)

− t

pd(LH)

|. Pulse skew

is sometimes referred to as pulse width distortion or duty cycle skew.

T0067-01

|YnYn|

Yn

Yn

V

OH

V

OL

80%

20%

0 V

t

r

t

f

V

OUT(pp)

T0058-02

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

PARAMETER MEASUREMENT INFORMATION

12

Figure 8. Waveforms for Calculation of t

sk(o)

Figure 9. LVPECL Differential Output Voltage and Rise/Fall Time

and t

sk(pp)

Page 13

www.ti.com

LVCMOS

10 pF

Y3

CDCM1804

1 kΩ

1 kΩ

S0079-02

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

PARAMETER MEASUREMENT INFORMATION (continued)

Figure 10. LVCMOS Output Loading During Device Test

PCB DESIGN FOR THERMAL FUNCTIONALITY

It is recommended to take special care of the PCB design for good thermal flow from the QFN-24 terminal

package to the PCB.

Due to the three LVPECL outputs, the current consumption of the CDCM1804 is fixed.

JEDEC JESD51-7 specifies thermal conductivity for standard PCB boards.

Modeling the CDCM1804 with a standard 4-layer JEDEC board results in a 67.22 ° C maximum temperature with

R

of 106.62 ° C/W for 25 ° C ambient temperature.

θ JA

When deploying four thermal vias (one per quadrant), the thermal flow improves significantly, yielding 46.94 ° C

maximum temperature with R

To ensure sufficient thermal flow, it is recommended to design with four thermal vias in applications enabling all

four outputs at once.

of 55.4 ° C/W for 25 ° C ambient temperature.

θ JA

13

Page 14

www.ti.com

Package Thermal Pad

(Underside)

Top Side

Island

Thermal Via

Dia 0.020 In.

Heat

Dissipation

VSS Copper Plane

VSS Copper Plane

M0029-01

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

PARAMETER MEASUREMENT INFORMATION (continued)

Figure 11. Recommended Thermal Via Placement

See the application reports Quad Flatpack No-Lead Logic Packages (SCBA017 ) and QFN/SON PCB Attachment

(SLUA271 ) for further package-related information.

14

Page 15

www.ti.com

IN

150 Ω

150 Ω

C

AC

C

AC

50 Ω

50 Ω

IN

CDCM1804

C

VBB

50 Ω

50 Ω

S0085-01

LVPECL

LVPECL

130 Ω

83 Ω

CDCM1804

50 Ω

50 Ω

130 Ω

83 Ω

S0086-01

IN

IN

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

APPLICATION INFORMATION

LVPECL RECEIVER INPUT TERMINATION

The input of the CDCM1804 has a high impedance and comes with a large common-mode voltage range.

For optimized noise performance, it is recommended to properly terminate the PCB trace (transmission line). If a

differential signal drives the CDCM1804, then a 100- Ω termination resistor is recommended to be placed as

close as possible across the input terminals. An even better approach is to install 2 × 50 Ω , with the center tap

connected to a capacitor (C) to terminate odd-mode noise and make up for transmission-line mismatches. The

VBB output can also be connected to the center tap to bias the input signal to (V

– 1.3 V) (see Figure 12 ).

DD

Figure 12. Recommended AC-Coupling LVPECL Receiver Input Termination

Figure 13. Recommended DC-Coupling LVPECL Receiver Input Termination

The CDCM1804 can also be driven by single-ended signals. Typically, the input signal becomes connected to

one input, while the complementary input must be properly biased to the center voltage of the incoming input

signal. For LVCMOS signals, this would be V

The best option (especially if the dc offset of the input signal might vary) is to ac-couple the input signal and then

/2, realized by a simple voltage divider (e.g., two 10-k Ω resistors).

CC

rebias the signal using the VBB reference output. See Figure 14 .

15

Page 16

www.ti.com

IN

CLK

C

AC

IN

CDCM1804

C

CT

VBB

R

dc

NOTE: CAC − AC-coupling capacitor (e.g., 10 nF)

CCT − Capacitor keeps voltage at IN constant (e.g., 10 nF)

Rdc − Load and correct duty cycle (e.g., 50 Ω)

VBB − Bias voltage output

S0087-01

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

APPLICATION INFORMATION (continued)

Figure 14. Typical Application Setting for Single-Ended Input Signals Driving the CDCM1804

DEVICE BEHAVIOR DURING RESET AND CONTROL-TERMINAL SWITCHING

Output Behavior From Enabling the Device (EN = 0 → 1)

In disable mode (EN = 0), all output drivers are switched in high-Z mode. The S[2:0] control inputs are also

switched off. In the same mode, all flip-flops are reset. The typical current consumption is below 500 µ A.

When the device is enabled again, it takes typically 1 µ s for the settling of the reference voltage and currents.

During this time, the outputs Y[2:0] and Y[2:0] drive a high signal. Y3 is unknown (could be high or low). After the

settle time, the outputs go into the low state. Due to the synchronization of each output driver signal with the

input clock, the state of the waveforms after enabling the device is as shown in Figure 15 . The inverting input

and output signal are not included. The Y:/1 waveform is the undivided output driver state.

16

Page 17

www.ti.com

High-Z

EN

IN

Y:/1 Undefined

Low

High-ZY:/2 Undefined

Low

High-ZY:/4 Undefined

Low

1 µs

Signal State After the Device is Enabled (IN = Low)

High-Z

EN

IN

Y:/1 Undefined

Low

High-ZY:/2 Undefined

Low

High-ZY:/4 Undefined

Low

1 µs

Signal State After the Device is Enabled (IN = High)

Undivided State is Valid After the First

Positive Transition of the Input Clock

T0068-01

APPLICATION INFORMATION (continued)

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

Enabling a Single Output Stage

If a single output stage becomes enabled:

• Y[2:0] is either low or high (undefined).

• Y[2:0] is the inverted signal of Y[2:0].

With the first positive clock transition, the undivided output becomes the input clock state. The divided output

states are equal to the actual internal divider. The internal divider is not reset while enabling single-output drivers.

Figure 15. Waveforms

17

Page 18

www.ti.com

High-Z

ENABLE Yx:

IN

Yx:/1

High-ZYx:/x Undefined

EnabledDisabled

Divider State

Undivided State is Valid After the First

Positive Transition of the Input Clock

Undefined

T0069-01

High-Z

ENABLE Yx:

IN

Yx:/1 Undefined

High-ZYx:/x Undefined Divider State

EnabledDisabled

Undivided State is Valid After the First

Positive Transition of the Input Clock

T0070-01

CDCM1804

SCAS697E – JULY 2003 – REVISED MAY 2005

APPLICATION INFORMATION (continued)

Figure 16. Signal State After an Output Driver Becomes Enabled While IN = 0

Figure 17. Signal State After an Output Driver Becomes Enabled While IN = 1

18

Page 19

Page 20

Page 21

Page 22

Page 23

PACKAGE OPTION ADDENDUM

www.ti.com

8-Aug-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

CDCM1804RGER ACTIVE QFN RGE 24 3000 Green (RoHS &

no Sb/Br)

CDCM1804RGERG4 ACTIVE QFN RGE 24 3000 Green (RoHS &

no Sb/Br)

CDCM1804RGET ACTIVE QFN RGE 24 250 Green (RoHS &

no Sb/Br)

CDCM1804RGETG4 ACTIVE QFN RGE 24 250 Green (RoHS &

no Sb/Br)

CDCM1804RTHR ACTIVE QFN RTH 24 3000 TBD CU SNPB Level-2-235C-1 YEAR

CDCM1804RTHT ACTIVE QFN RTH 24 250 TBD CU SNPB Level-2-235C-1 YEAR

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 24

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...