Page 1

Sub-1GHz 6LoWPAN Development kit

User’s Guide

Literature Number: SWRU298

September 2011

Page 2

CC-6LOWPAN-DK-868

Page 2 of 61

Abbreviations

Abbreviations used in this data sheet are described below.

6LoWPAN

IPv6 over Low Power Wireless Personal Area

Networks

IPv6

Internet Protocol version 6

ICMP

Internet Control Message Protocol

UDP

User Datagram Protocol

RS

Router Solicitation

RA

Router Advertisement

NS

Neighbor Solicitation

NA

Neighbor Advertisement

SLLAO

Source Link Layer Addressing Object

PIO

Prefix Information Object

ABRO

ARO DODAG

Destination Oriented Directed Acyclic Graph

DIS

DODAG Information Solicitation

DIO

DODAG Information Object

DAO

Destination Advertisement Object

DAO-ack

DAO acknowledge

ER

Edge Router

Page 3

CC-6LOWPAN-DK-868

Page 3 of 61

Table of Contents

TABLE OF CONTENTS ......................................................................................................................... 3

LIST OF FIGURES ................................................................................................................................. 4

LIST OF TABLES ................................................................................................................................... 5

1 6LOWPAN KIT OVERVIEW ........................................................................................................ 6

1.1 FEATURES ...................................................................................................................................... 7

1.2 WHAT‟S INCLUDED IN THE KIT? ........................................................................................................ 8

2 GETTING STARTED ................................................................................................................... 9

2.1 SETTING UP IPV6 ON YOUR PC ....................................................................................................... 9

2.2 IPV6 AND 6LOWPAN BASICS ....................................................................................................... 10

2.2.1 IPv6 Introduction ......................................................................................................................................................... 11

2.2.2 6LoWPAN Introduction ................................................................................................................................................ 11

2.3 EDGE ROUTER BOOTSTRAP PROSESS ........................................................................................... 11

2.4 NODEVIEW 2.0 ............................................................................................................................. 11

2.5 NETWORK ANALYZER APPLICATION ............................................................................................... 13

3 SOFTWARE ............................................................................................................................... 14

3.1 SENSINODE NAPSOCKET AND NANOSOCKET INTERFACE ............................................................... 14

3.2 SENSINODE NANOSTACK 2.0 LITE ................................................................................................. 15

3.2.1 Bootstrap process........................................................................................................................................................ 16

3.2.2 Synchronization ........................................................................................................................................................... 16

3.2.3 Neighbour Discovery and Router Solicitation ............................................................................................................... 17

3.2.4 RPL: IPv6 Routing Protocol for Low power and Lossy Networks ................................................................................. 17

3.2.5 Periodic processes ................................ ...................................................................................................................... 19

3.2.6 Error situations ............................................................................................................................................................ 19

3.3 CC-6LOWPAN-DK-868 SOFTWARE PROJECTS ........................................................................... 20

3.3.1 IDE installation ............................................................................................................................................................ 20

3.3.2 NanoHost Example (Network Analyzer) ....................................................................................................................... 21

3.3.3 NAPSocket Library ...................................................................................................................................................... 22

3.3.4 CC430F5137 Library Model (Network Analyzer) .......................................................................................................... 22

3.3.5 Programming the boards ................................................................ ............................................................................. 24

3.4 SENSINODE NAPSOCKET API ....................................................................................................... 25

3.4.1 Sensinode NAP Protocol API....................................................................................................................................... 26

3.5 SENSINODE NANOSOCKET API ..................................................................................................... 26

3.6 SENSINODE RF DYNAMIC CONFIGURATION API ............................................................................. 27

3.6.1 NanoSocket ................................................................................................................................................................. 27

3.6.2 NAPSocket .................................................................................................................................................................. 28

3.6.3 Node View 2.0 ............................................................................................................................................................. 28

3.7 SENSINODE NANOBOOT API ......................................................................................................... 29

3.7.1 Sensinode NanoBoot host tool .................................................................................................................................... 29

3.8 SENSINODE NODEVIEW 2.0 CUSTOM TABS .................................................................................... 29

3.8.1 Developing applications to run in custom tabs in NodeView 2.0 ................................................................................... 30

3.8.2 Exporting custom tabs to run as stand alone ............................................................................................................... 31

3.9 EDGE ROUTER (OMAP-L138) SOFTWARE ..................................................................................... 32

3.9.1 Sensinode NanoRouter 2.0 ......................................................................................................................................... 32

3.9.2 Startup scripts ............................................................................................................................................................. 32

3.9.3 Linux folder structure ................................................................................................................................................... 33

3.9.4 Sensinode NanoBoot host tool .................................................................................................................................... 33

3.9.5 Debug/console interface .............................................................................................................................................. 33

4 HARDWARE .............................................................................................................................. 33

4.1 EM430F5137RF900 ................................................................................................................... 33

4.1.1 Programming/Reprogramming the EM430F5137RF900 .............................................................................................. 34

4.1.2 Debug Interface using UART ....................................................................................................................................... 34

4.1.3 Schematics, BOM and Layout ..................................................................................................................................... 34

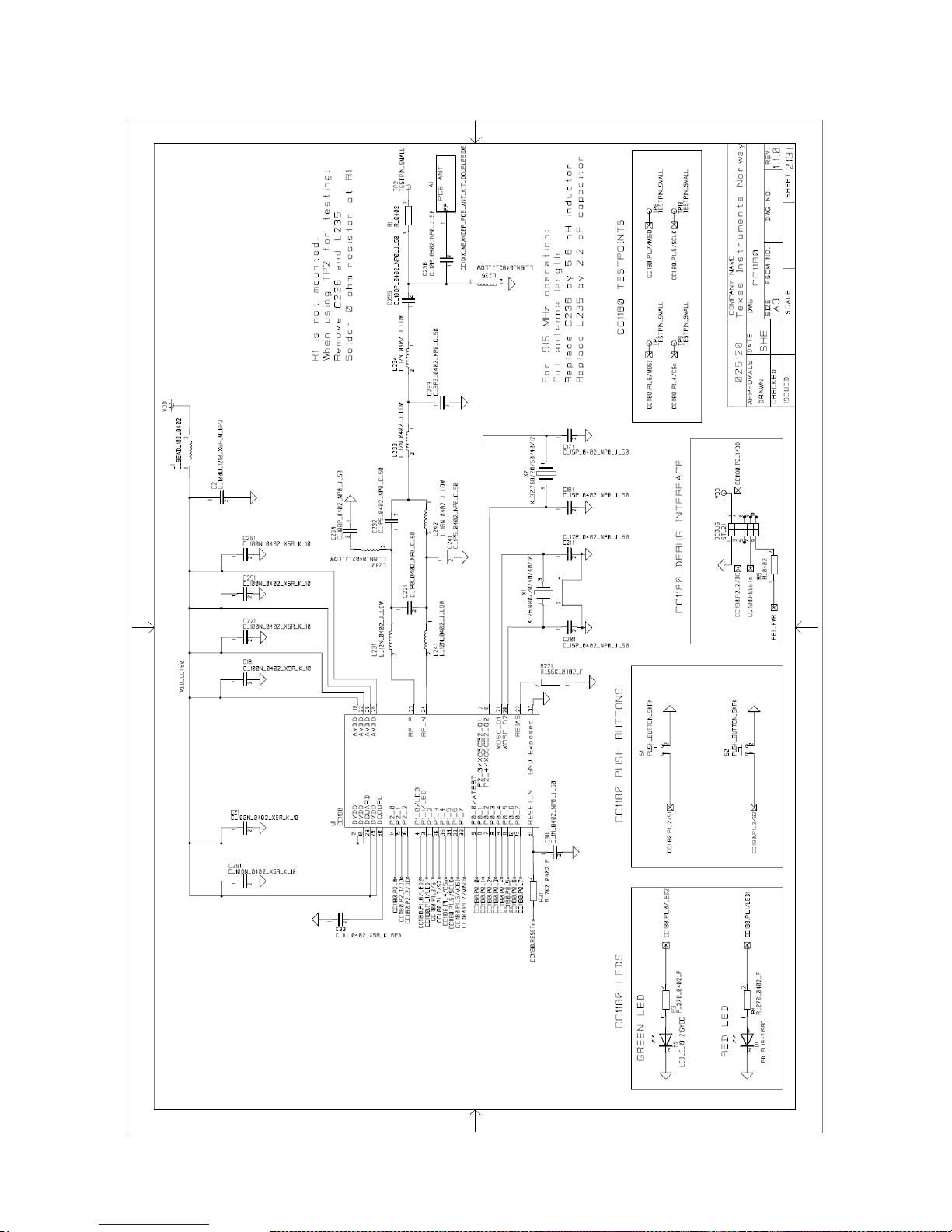

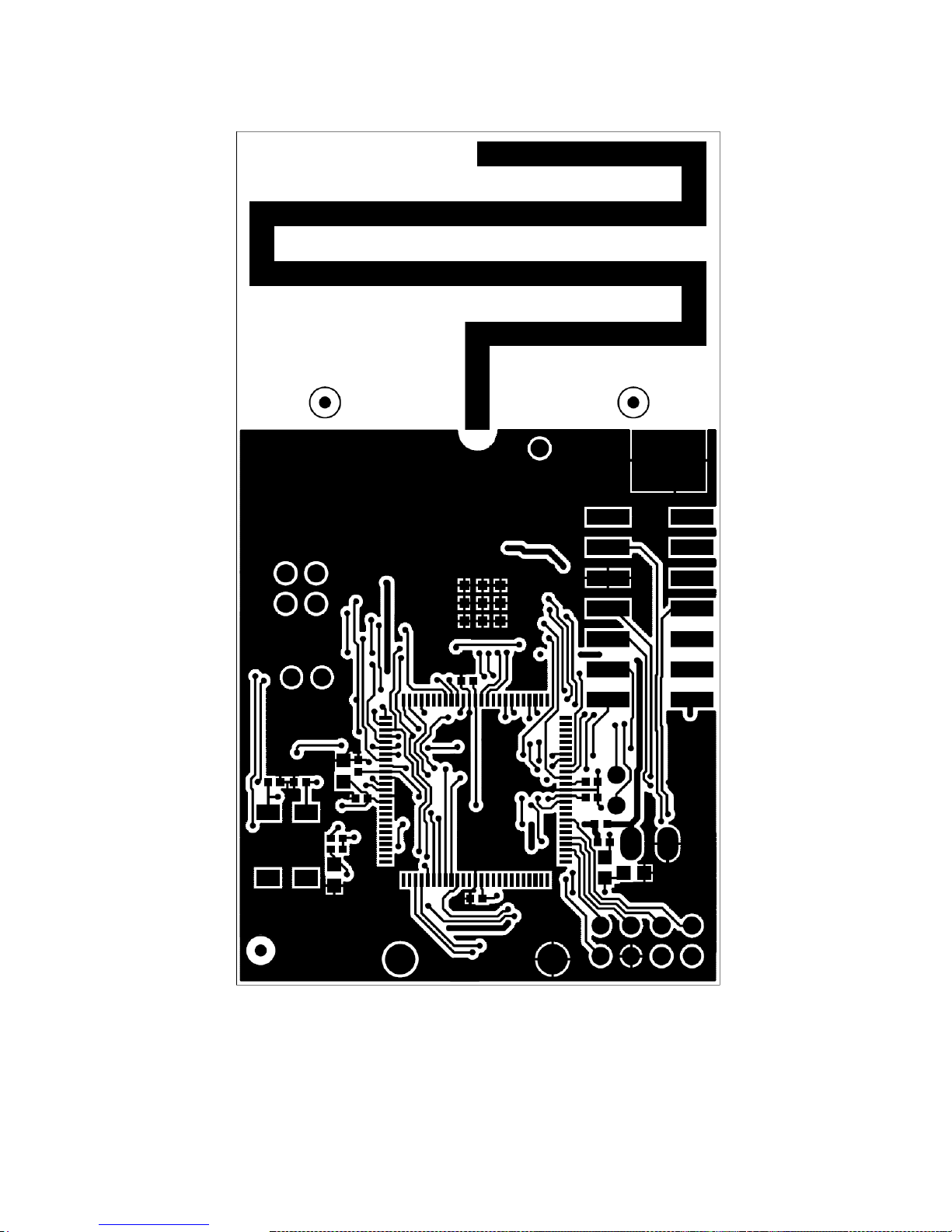

4.2 CC1180DB ................................................................................................................................. 40

4.2.1 Programming/Reprogramming the CC1180DB ............................................................................................................ 41

4.2.2 Schematics, BOM and Layout ..................................................................................................................................... 41

4.3 EDGE ROUTER, OMAP-L138 EXPERIMENTERS BOARD .................................................................. 50

4.3.1 Adapter Board ............................................................................................................................................................. 51

4.3.2 CC1180EM .................................................................................................................................................................. 55

5 FAQ ............................................................................................................................................ 60

5.1 SEND UDP PACKETS FROM PC ..................................................................................................... 60

Page 4

CC-6LOWPAN-DK-868

Page 4 of 61

5.2 TOO MUCH CODE ......................................................................................................................... 60

5.3 LINUX KERNEL AND FILE SYSTEM ................................................................................................... 60

6 REFERENCES ........................................................................................................................... 61

7 DEVELOPMENT KIT ORDERING INFORMATION .................................................................. 61

8 GENERAL INFORMATION ....................................................................................................... 61

8.1 DOCUMENT HISTORY .................................................................................................................... 61

List of Figures

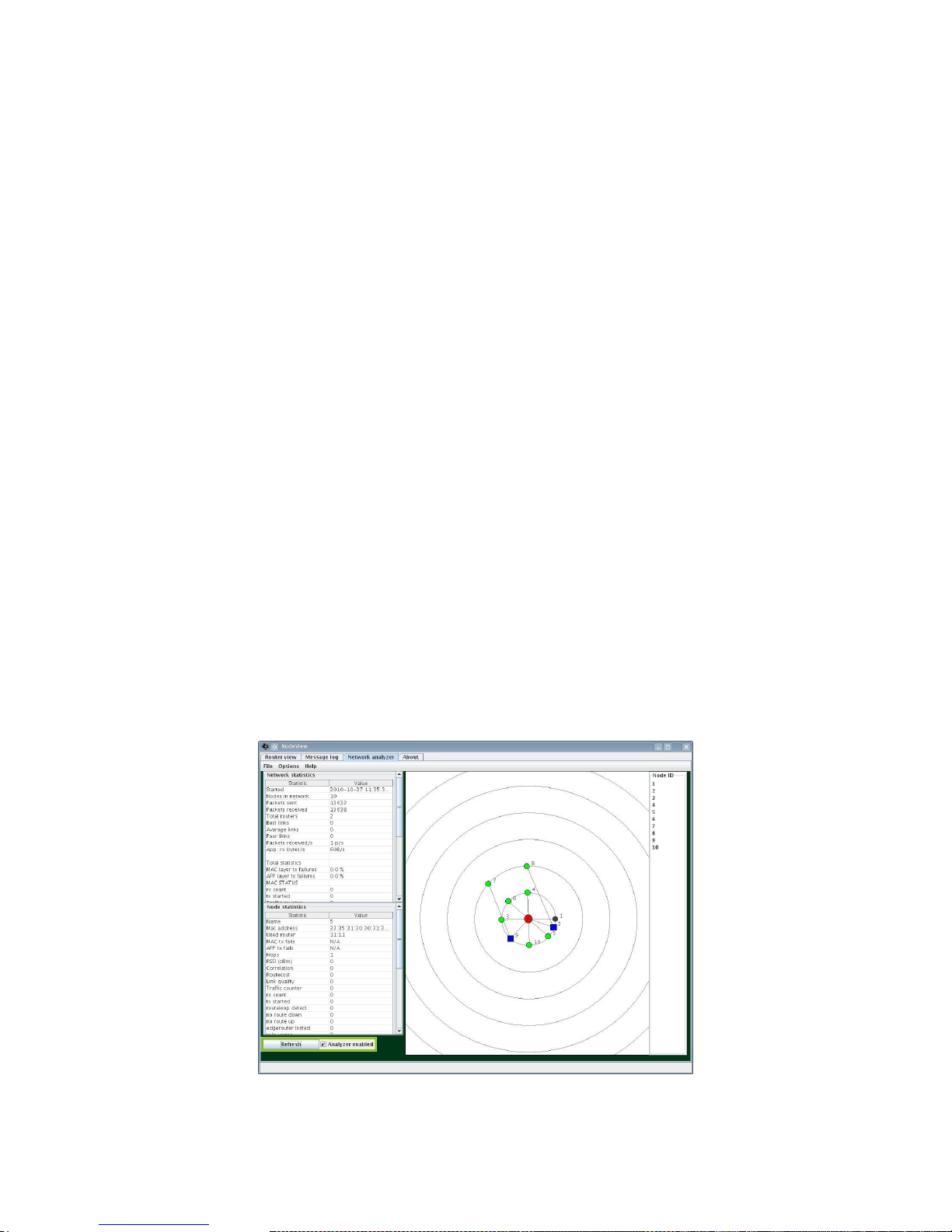

Figure 1. Sensinode NodeView Network Analyzer tool .......................................................... 6

Figure 2. CC-6LOPWAN-DK-868 kit ..................................................................................... 8

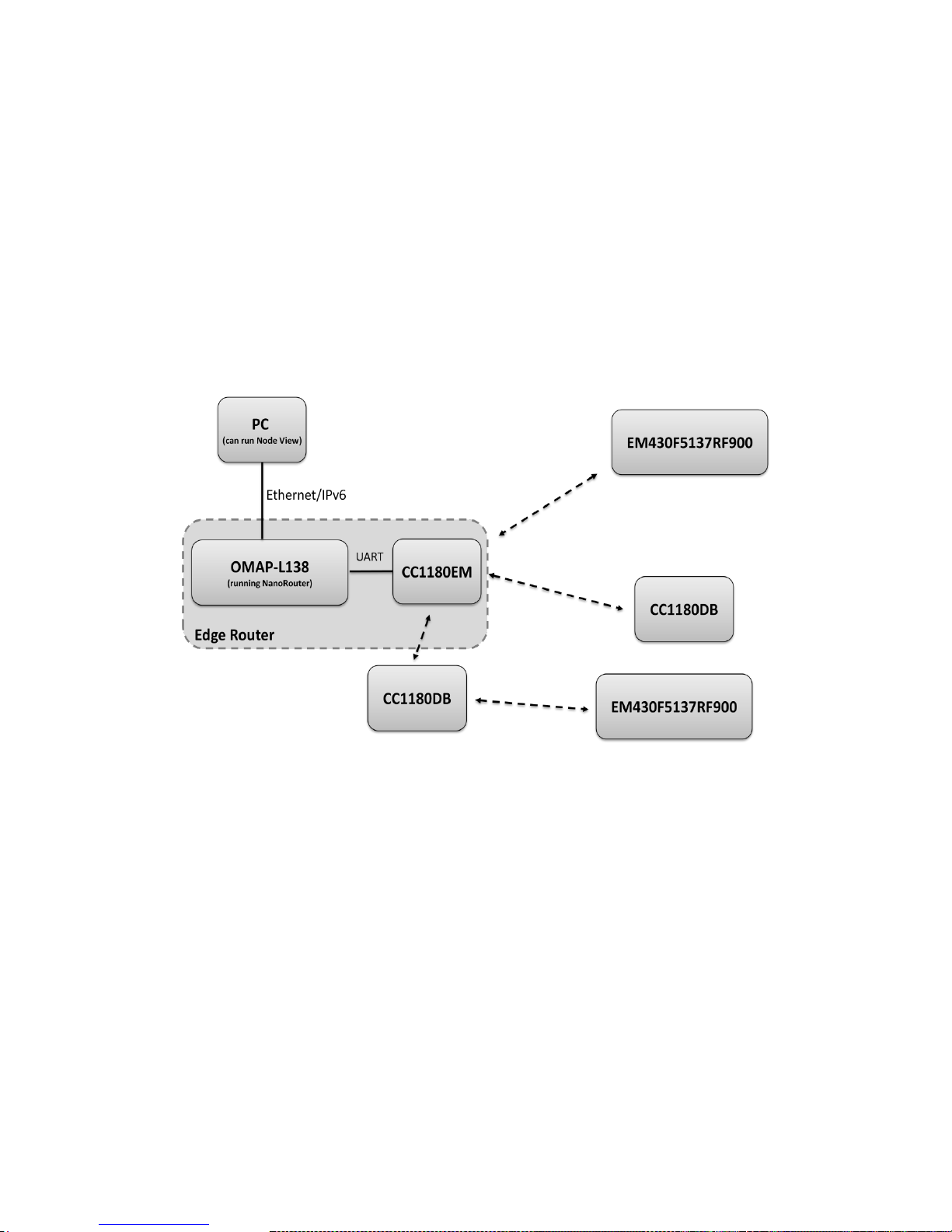

Figure 3. Kit System Overview .............................................................................................. 9

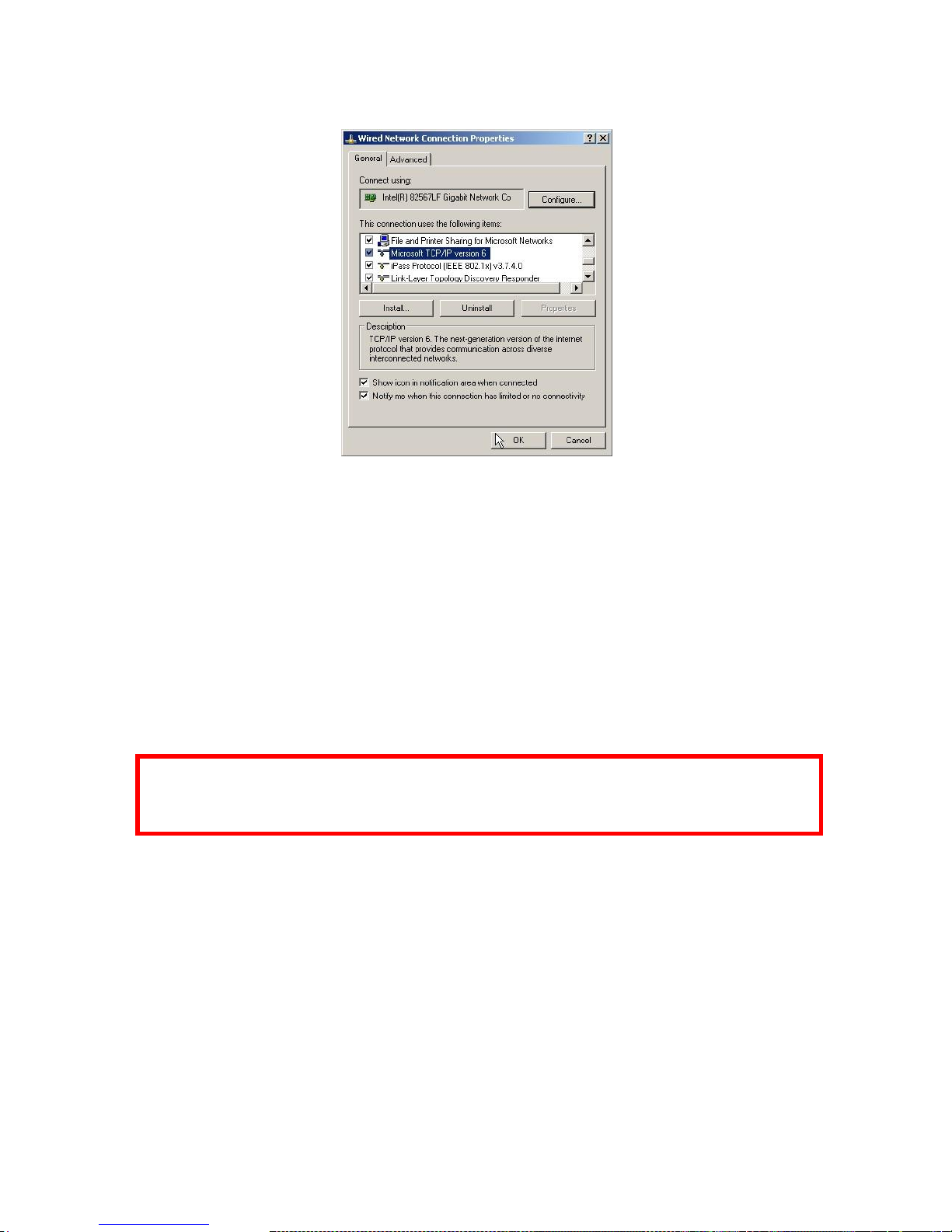

Figure 4. IPv6 enabled for Windows XP .............................................................................. 10

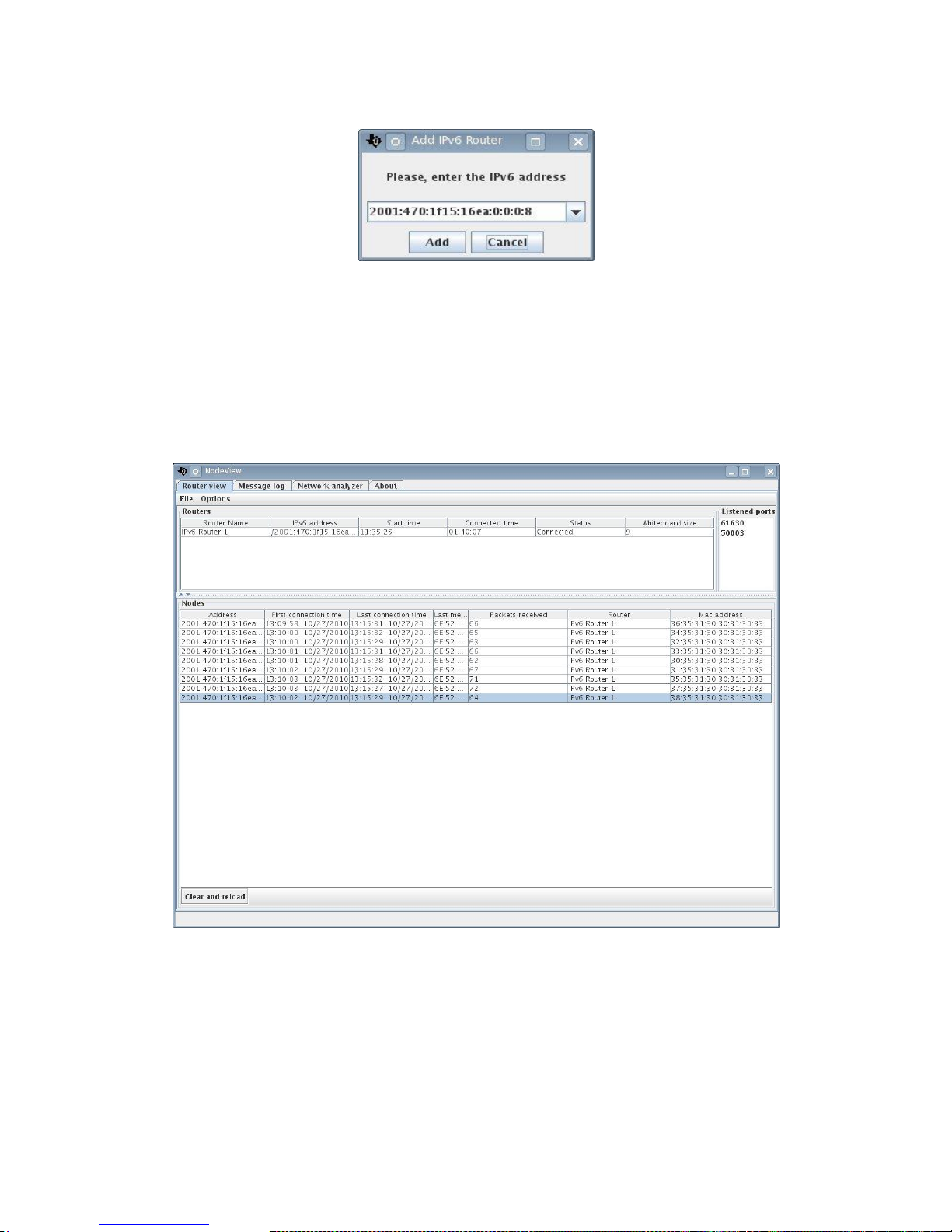

Figure 5. Adding an Edge Router. ....................................................................................... 12

Figure 6. NanoRouter Router View details. ......................................................................... 12

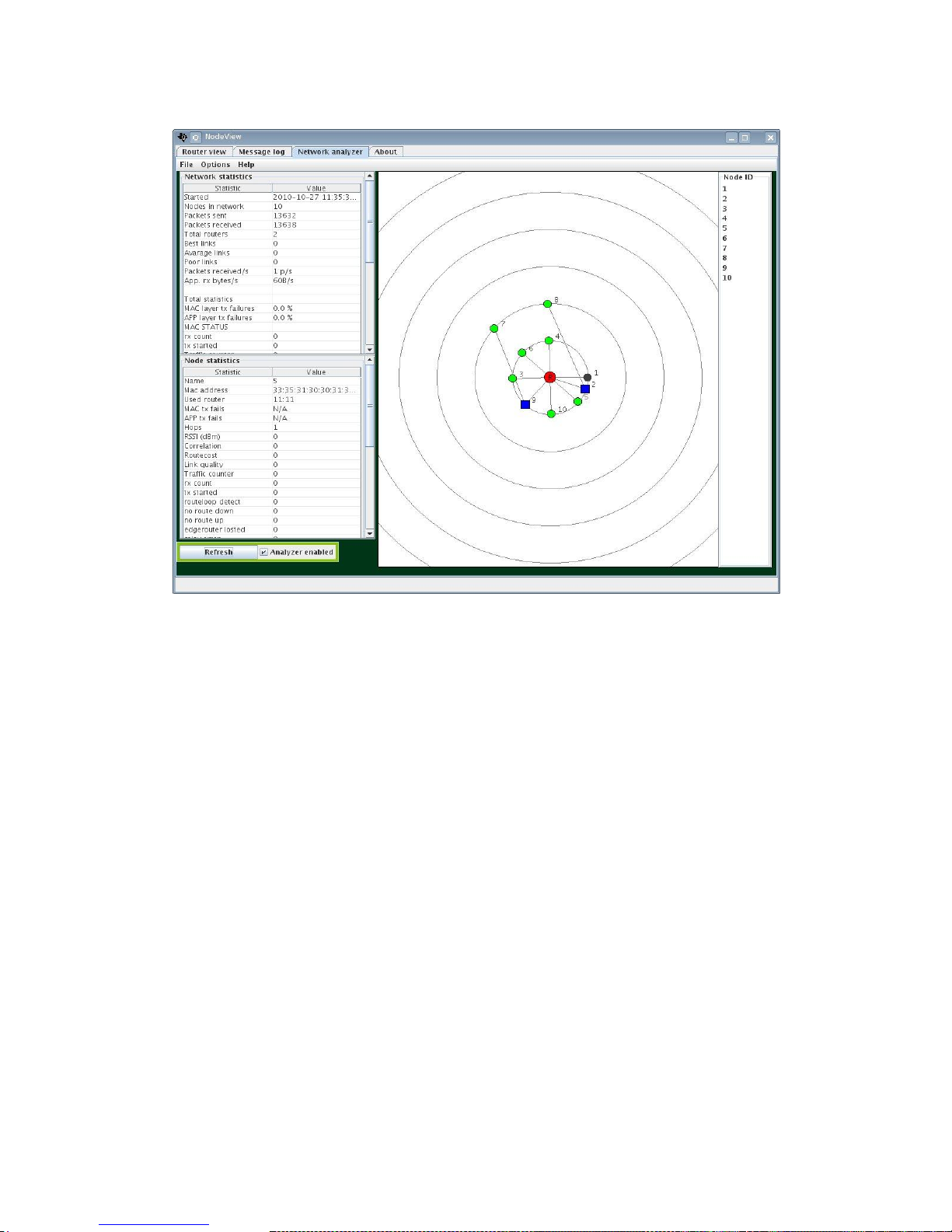

Figure 7. NodeView Network Analyzer tab. ......................................................................... 13

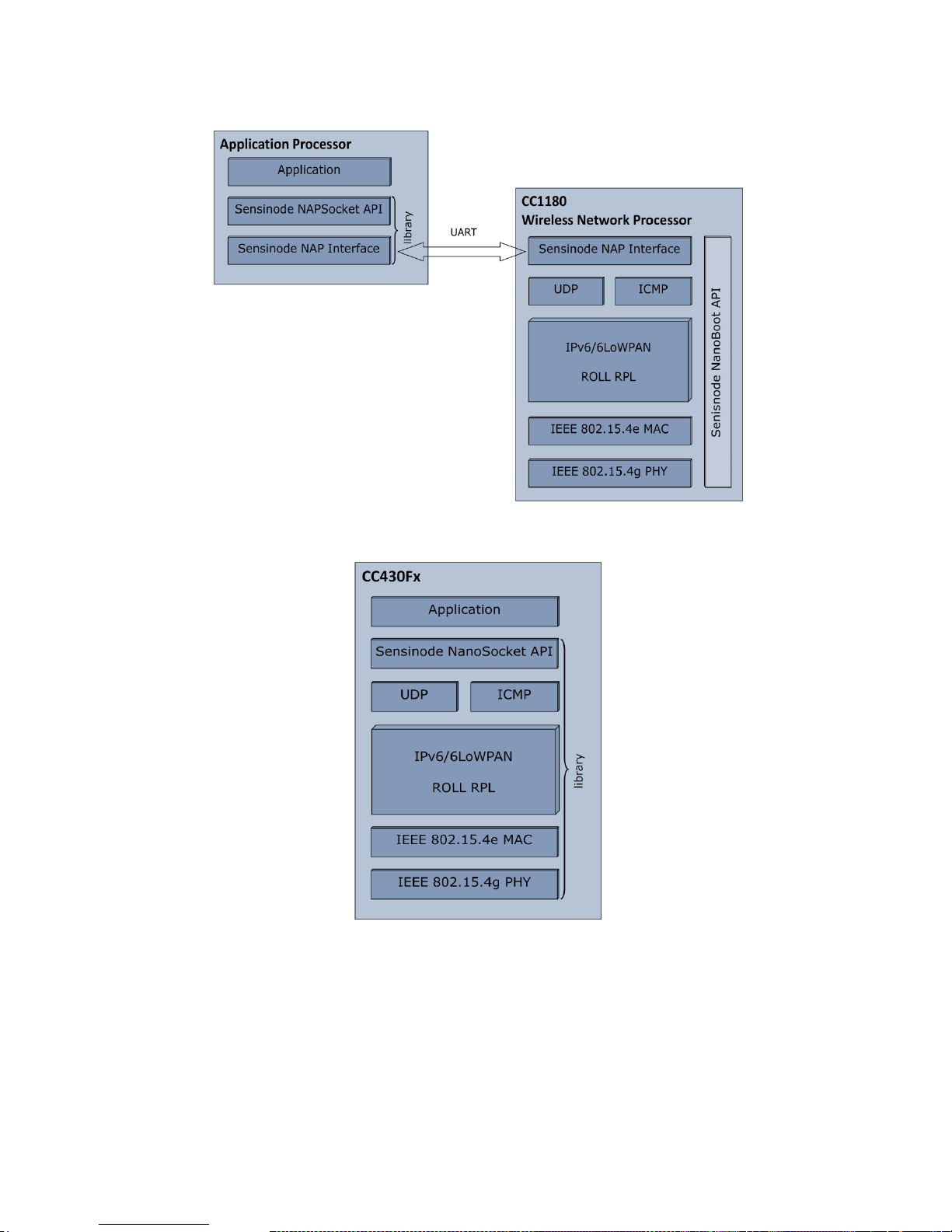

Figure 8. Stack overview CC1180 based system, using NAPSocket API ............................ 15

Figure 9. Stack Overview CC430 based system, using NanoSocket API ............................ 15

Figure 10. NanoHost Example project ................................................................................. 22

Figure 11. NAPSocket library project .................................................................................. 22

Figure 12. NanoSocket Example project ............................................................................. 23

Figure 13. Enabling the NanoSocket Debug Interface ......................................................... 23

Figure 14. Sensinode NAPSocket library ................................................................ ............ 26

Figure 15. Sensinode NanoSocket API ............................................................................... 27

Figure 16. Setting RF Configuration on Edge Router .......................................................... 28

Figure 17. Creating Eclipse project for NodeView 2.0 custom tab ....................................... 30

Figure 18. Folder structure for custom tabs ......................................................................... 30

Figure 19. tabConfig.txt file ................................................................................................. 31

Figure 20. EM430F5137RF900, Logical Description ........................................................... 34

Figure 21. EM430F5137RF900, PCB Components Top Layer ............................................ 36

Figure 22. EM430F5137RF900, PCB Components Bottom Layer ....................................... 36

Figure 23. EM430F5137RF900, Layout Top Layer ............................................................. 37

Figure 24. EM430F5137RF900, Layout Layer 2.................................................................. 37

Figure 25. EM430F5137RF900, Layout Layer 3.................................................................. 38

Figure 26. EM430F5137RF900, Layout Bottom Layer ........................................................ 38

Figure 27. CC1180DB, Logical Description ......................................................................... 40

Figure 28. CC1180DB, PCB Components Top Layer .......................................................... 45

Figure 29. CC1180DB, PCB Components Bottom Layer ..................................................... 46

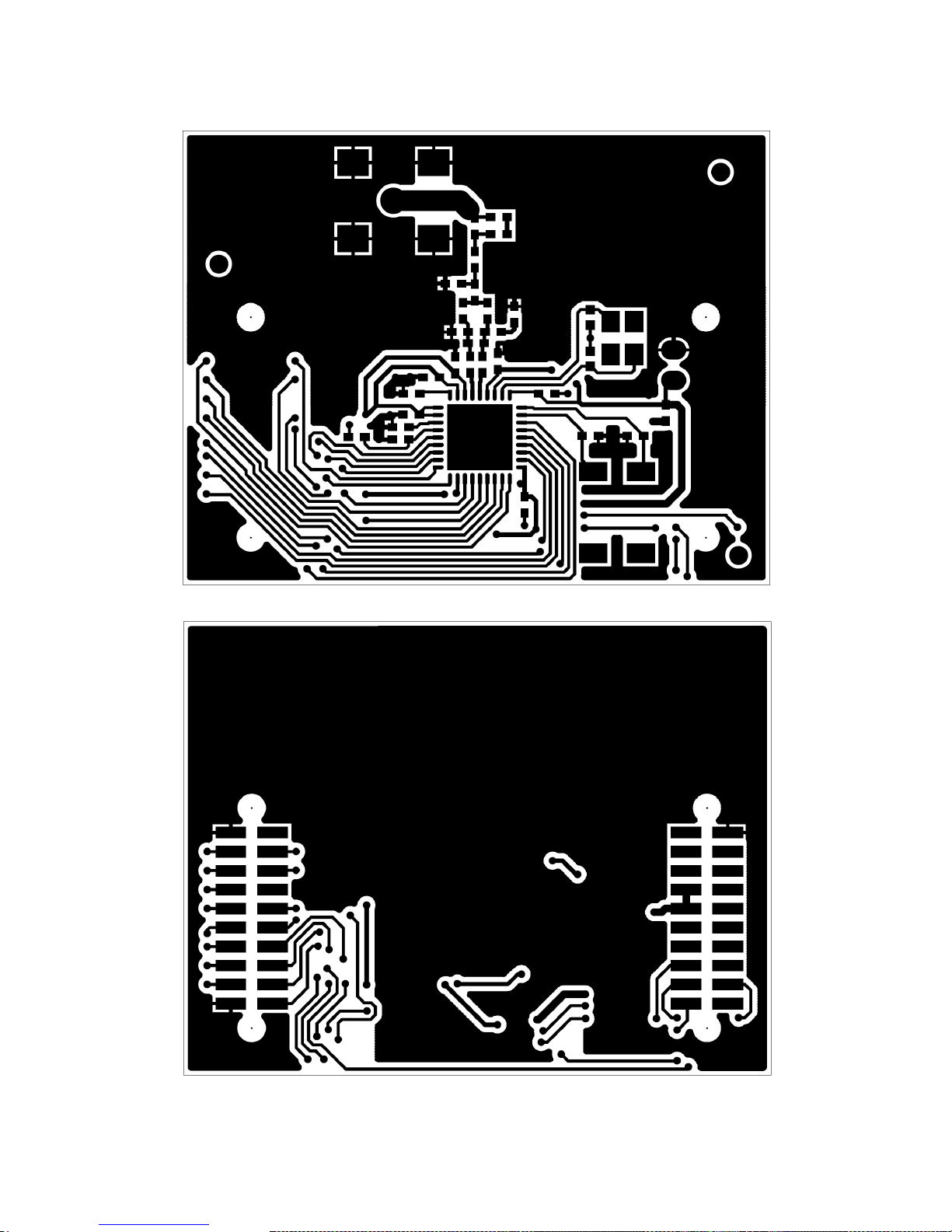

Figure 30. CC1180DB, Layout Top Layer ........................................................................... 47

Figure 31. CC1180DB, Layout Bottom Layer ...................................................................... 48

Figure 32. OMAP-L138 Experimenter's Board Overview ..................................................... 50

Figure 33. Adapter Board, PCB Components Top Layer ..................................................... 53

Figure 34. Adapter Board, PCB Components Bottom Layer ................................................ 53

Figure 35. Adapter Board, Layout Top layer ........................................................................ 54

Figure 36. Adapter Board, Layout Bottom Layer ................................................................. 54

Figure 37. CC1180EM, PCB Components Top Layer ......................................................... 57

Figure 38. CC1180EM, PCB Components Bottom Layer .................................................... 57

Figure 39. CC1180EM, Layout Top Layer ........................................................................... 58

Figure 40. CC1180EM, Layout Bottom Layer ...................................................................... 58

Page 5

CC-6LOWPAN-DK-868

Page 5 of 61

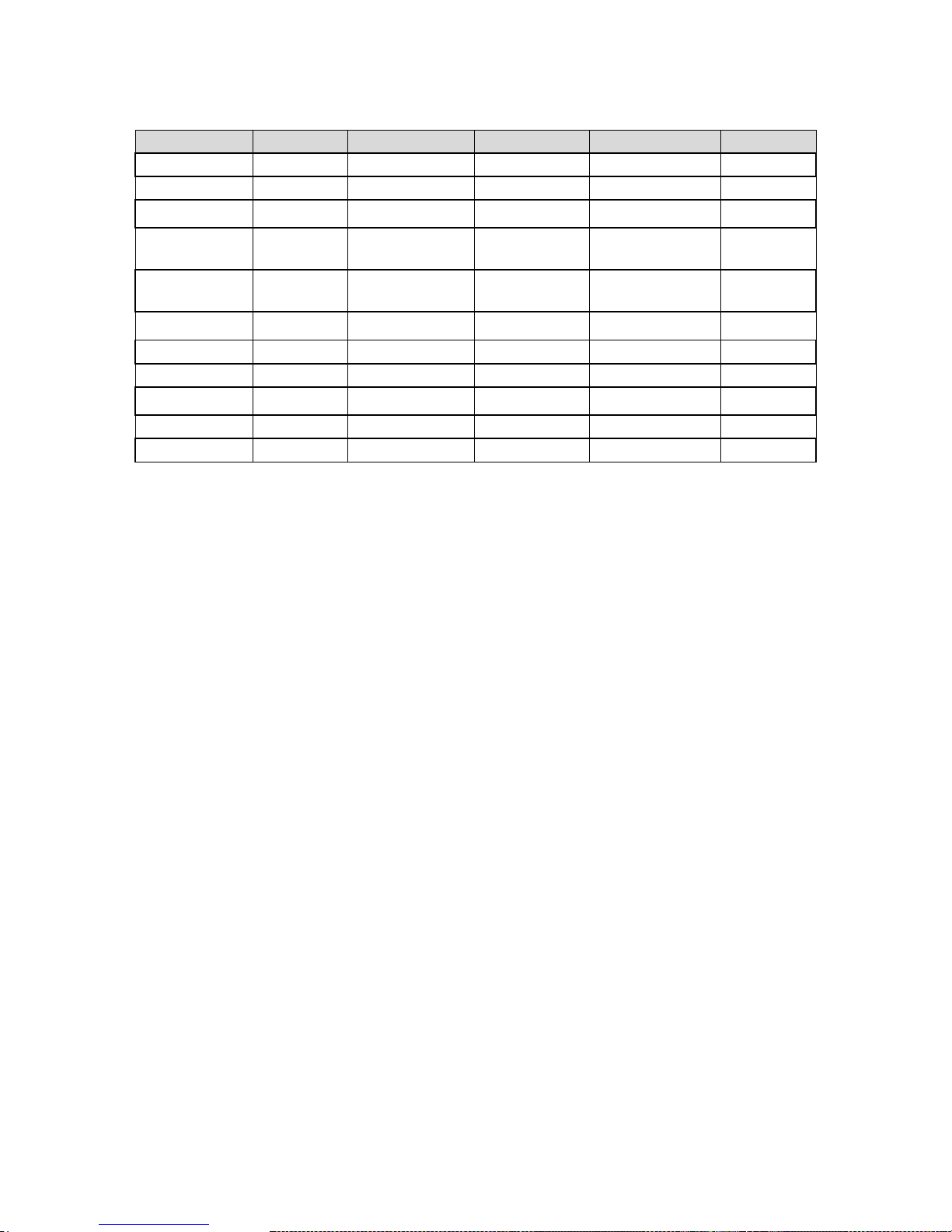

List of Tables

Table 1. CC1180 controlled LED (D1 and D2) behavior. ..................................................... 14

Table 2. MSP4305438A controlled LED (D3 and D4) behavior. .......................................... 14

Table 3. Sensinode 6LoWPAN Stack Layer Definitions. ...................................................... 16

Table 4. Beacon payload. ................................................................................................... 16

Table 5. Fixed Neighbor Discovery packet formats. ............................................................ 17

Table 6. RPL control messages .......................................................................................... 18

Table 7. Fixed formats of RPL control messages. ............................................................... 18

Table 8. RPL Objective Code Point. .................................................................................... 18

Table 9. RPL Metric container format. ................................................................................. 19

Table 10. DODAG configuration parameters. ...................................................................... 19

Table 11. EM430F5137RF900, Bill of Material .................................................................... 40

Table 12. CC1180DB, Bill of Material .................................................................................. 50

Table 13. Adapter Board LED functionality .......................................................................... 51

Table 14. Adapter Board, Bill of Material ............................................................................. 55

Table 15. CC1180EM, Bill of Material ................................................................................. 59

Table 16. Development Kit Ordering Information ................................................................. 61

Table 17. Document History ................................................................................................ 61

Page 6

CC-6LOWPAN-DK-868

Page 6 of 61

1 6LoWPAN Kit Overview

This document describes the TI 6LoWPAN evaluation kit for use in the 868/915MHz bands. The kit is

based on hardware from TI and 6LoWPAN software (NanoStack) from TI third party Sensinode Ltd.

The CC-6LOWPAN-DK-868 kit provides easy way for users to start developing their own wireless

sensor network applications based on 6LoWPAN technology. There are two different APIs for

communicating with the NanoStack, based on if you use CC1180 Network Processor or the CC430

SoC. The API used for CC1180 is called NAPSocket, while the API for CC430 is called NanoSocket.

The kit contains a 6LoWPAN Edge Router (access point/gateway to IPv6) based on TI‟s OMAP-L138

processor. The Edge Router (ER) uses a CC1180EM as radio interface. The Edge Router is running

Sensinode Ltd NanoRouter 2.0 software and can connect wireless sensor nodes running Sensinode

Ltd NanoStack 2.0 lite. The evaluation version of NanoRouter 2.0 included in the kit is limited to 10

nodes per Edge Router.

Included in the kit are two EM430F5137RF900 Rev 3.2 boards and two CC1180DB boards. The

EM430F5137RF900 and CC1180DB boards are used as wireless sensor devices in the kit. CC430

comes with library support for Sensinode NanoStack 2.0 lite (NanoSocket [8]). This library model

allows easy implementation of user applications, built directly on top of the NanoSocket library.

The CC1180DB contains a Wireless Network Processor (WNP), CC1180, which handles all

6LoWPAN network communication. Connected to the WNP is a host processor (MPS430F5438A)

running the user application. The hardware interface between the network processor and the host

processor is UART. The software interface between the network processor and the host MCU is

Sensinode NAPSocket API [12]. The NAPSocket API acts as a wrapper library to parse Sensinode

NAP protocol messages [9].

The kit provides Edge Router (NanoRouter) control and testing software (Sensinode NodeView 2.0

[10]). NodeView 2.0 can be used to control NanoRouter software running on the Edge Router in real

time and provides e.g. address information of the connected nodes. The control protocol is based on

Sensinode proprietary UDP communication. The NodeView 2.0 tool also provides a simple way to

create user‟s own java applications that are included in the NodeView 2.0 GUI in the form own

separate tabs.

All nodes can act as routers inside the 6LoWPAN network. The radio transceivers on the nodes are

thus always on, which makes the system less suitable for battery-powered devices.

This documentation gives detailed information of the kit contents and behavior, its configuration and

how the different 6LoWPAN standards are implemented.

Figure 1. Sensinode NodeView Network Analyzer tool

Page 7

CC-6LOWPAN-DK-868

Page 7 of 61

1.1 Features

IP-based networking, enabling the “Internet of Things”

CC1180 Over-Network Download (OTA), future proofs:

o Device applications and network upgrades

Low memory footprint;

o CC1180 6LoWPAN stack is less than 32kB

o CC430 6LoWPAN stack is about 17kB

Sensinode 6LoWPAN software can run on all frequencies that CC1180 and CC430 support,

providing a sub-GHz mesh solution. Note: The kit hardware is for use in the 868/915 MHz

bands.

Low development complexity, customers used to IP programming will be up and running in no

time with the simple socket API approach.

Configurable RF interface:

o Output power: -30dBm to +10dBm

o Date rates: 50, 100, 150 and 200kbit/s

o RX Attenuation, for close-in systems

o AES-CCM* secured IEEE802.15.4e payloads, using network-wide key.

Coordinated mesh networking (modified RPL)

IEEE802.15.4g/e PHY and MAC

Compressed IPv6 headers (subset of IP header compression)

ICMPv6 Neighbor Discovery (subset of ND)

User application uses User Datagram Protocol (UDP) to send data

Short address link-layer communication (based on allocated two byte address, unique under

a simple 6LoWPAN, allocation coordinated by a single Edge Router)

Fully automatic bootstrap process, automatic route discovery

Self-healing mesh

Each node replies to ICMPv6 echo requests

P2P communication

Synchronous frequency hopping possible, using 50 FHSS channels

Page 8

CC-6LOWPAN-DK-868

Page 8 of 61

Figure 2. CC-6LOPWAN-DK-868 kit

1.2 What’s included in the kit?

2 CC1180DB nodes (CC1180 NWP plus MSP4305438A host MCU)

2 EM430F5137900 (CC430 SoC) nodes

1 OMAP-L138 based Edge Router Board (Gateway, running Linux)

1 Adapter board, for connection of CC1180EM to OMAP-L138 board

1 CC1180EM (radio interface to OMAP-L138 board)

MSP-FET430UIF Debugger, used to debug and download code to nodes.

Ethernet Cable (Crossover, for direct connection to PC)

RS-232 NULL modem cable (used for Linux debug console)

Power supply for OMAP-L138 board, incl. cables

USB cable for MSP-FET430UIF Debugger

Antennas, for 868/915 MHz band

Batteries (incl. holders for CC430 boards)

Quick Start Guide

Sensinode NodeView 2.0 Network Analyzer PC SW

Software application examples

Page 9

CC-6LOWPAN-DK-868

Page 9 of 61

2 Getting Started

This chapter gives the user a quick start to using the kit. The 6LoWPAN network is completely self

healing and self organizing. The only thing the user needs to do in order to get the network up and

running is to set up the Edge Router, verify that the Edge Router has Ethernet connection with IPv6

support and start it. When the NanoRouter application on the Edge Router board boots up, automatic

scripts configures the NanoRouter software and starts advertising the network over the radio

interface. For a more detailed procedure please see the Quick Start Guide [14].

If the pre-programmed nodes from the kit are powered up, they will automatically search for and join

to available network, allocate IPv6 addresses and are ready to go with no user input needed at all.

The following chapter provides more detailed information what happens behind the scenes. The

below picture describes an architectural overview for the complete system. Note that the 6LoWPAN

stack handles exactly which node connects to which node automatically, hence forming a fully

automatic 6LoWPAN network.

Figure 3. Kit System Overview

2.1 Setting up IPv6 on your PC

Most Internet hosts are still using IPv4 only a few are using the new IPv6 protocol. The Sensinode

NanoStack 2.0 is using IPv6, so you need to have your PC ready also. For Microsoft Windows Vista

and 7 IPv6 is supported natively. If you are running Windows XP, make sure that you have the

Service Pack 3 installed. In addition, when you have Windows XP Service Pack 3 installed, you also

need to check to make sure that the IPv6 protocol is installed in your system. You can verify that this

is installed by looking at the properties of any Network Connection on your computer (Start Menu > Network Connections). As you see from the below screenshot, if you call the properties for any

connection, you should have an option called Internet Protocol Version 6 (TCP/IPv6).

Page 10

CC-6LOWPAN-DK-868

Page 10 of 61

Figure 4. IPv6 enabled for Windows XP

Follow the below steps to install IPv6 for Windows XP if you do not have it installed.

Open a command prompt and write:

ipv6 install

To be able to communicate with the devices using IPv6 your PC needs to be assigned an IPv6

address. Assigning an IPv6 address and a default route is described for Windows XP, Vista, 7 and for

Linux in the steps below.

Assign an IPv6 address to the PC using the command prompt (Run in administrator mode in Windows

7). This example adds the IPv6 address 2001::22 to your PC:

netsh interface ipv6 add address “Local Area Connection” 2001::22

Set up a default route using the command prompt: (Run in administrator mode in Windows 7)

netsh interface ipv6 add route ::/0 “Local Area Connection”

Note! You must change “Local Area Connection” to the actual name of the Ethernet connection you

want to use. You can get it from Windows Network Connections. The IPv6 address (2001::22 in this

example) has to be unique on your network.

For Linux the following commands to add IPv6 address and default route can be used:

ifconfig eth0 inet6 add 2001::22/64

route -A inet6 add 2001::/0 dev eth0

Note that some antivirus software blocks all incoming IPv6 traffic.

2.2 IPv6 and 6LoWPAN Basics

To fully benefit from the CC-6LOWPAN-DK-868 kit a basic understanding of both IPv6 and 6LoWPAN

is needed. This section makes the user familiar with basic IPv6 and 6LoWPAN technologies.

TI's third party Sensinode Ltd. 6LoWPAN solution provides an easy way of passing messages around

in a 6LoWPAN network, using a socket approach to both sending and receiving data as well as

controlling the network parameters. In small RF networks, i.e. a sensor network, sending data inside

the network is usually straight forward. Problems arise when one wants to send data to the internet or

intranet. This would normally include either specialized software on devices connected to the network,

Page 11

CC-6LOWPAN-DK-868

Page 11 of 61

or translating the RF protocol to a network protocol, i.e. using a proxy. CC-6LOWPAN-DK-868 is

therefore based on IPv6 and 6LoWPAN, eliminating such need for application layer gateways.

2.2.1 IPv6 Introduction

Internet Protocol (IP) is used in the world‟s largest networks. Nearly every desktop computer supports

IP, which makes IP ideal to use when one wants to hook up a wireless sensor network to a larger

backbone network. Setting up a wireless sensor network can even be managed by the IT department

on a company, without any knowledge of RF networks at all.

IP is not optimized for low-power, low-cost sensor networks. But since it's a very flexible protocol it

can fairly easy be adapted to make a perfect fit for a wireless sensor network, which is exactly what

6LoWPAN does.

2.2.1.1 Addressing

The most obvious difference between IPv4 and IPv6 is the number of supported addresses. IPv4

supports 232 addresses, while IPv6 supports 2

128

addresses.

A typical IPv6 address might look like this: 2001:0000:0000:0000:0000:00FF:FE00:0301. All

leading zeros can be omitted, leaving the address to look like: 2001:0:0:0:0:FF:FE00:301.

Finally zeros in the middle can be replaced by a double colon, leaving the address

to: 2001::FF:FE00:301

All IPv6 networks have a prefix. All devices in the same network have the same prefix. The prefix is

written like this: 2001:0:0:0:0:FF:FE00:301/64, meaning that the prefix is 64 bits long. Thus the

prefix for this example is: 2001:0000:0000:0000

Every interface also has a local link address associated with it. The link-local address is only valid

within the network and cannot be routed to another network. A link local address start with FE80::

2.2.2 6LoWPAN Introduction

Since the IPv6 header alone is 40 bytes, and the Maximum Transmission Unit (MTU) of IP is 1280

bytes, frames to be sent over a low power RF network based on IEEE 802.15.4 has to be

compressed in some way. IEEE 802.15.4 has a maximum packet size of 127 bytes, so a 40 byte IPv6

header would take up more than 30% of the packet. The 6LoWPAN adaptation layer bridges those

two technologies together, without the need of any application gateways.

Each node in a 6LoWPAN network has a unique IPv6 address, as described in the previous chapter.

In addition to the IPv6 address all nodes also has a unique 8 byte IEEE address. The IEEE address is

stored in flash memory of the devices. For CC430 based devices the IEEE address is stored on flash

address 0xFF70 (MSB on address 0xFF70). On the CC1180 the IEEE address is read and written

with a Sensinode bootloader utility called NanoBoot host. NanoBoot host is available for standard

Linux platforms and the OMAP platform. On all nodes in the CC-6LOWPAN-DK-868 the preloaded

IEEE address are printed on a sticker on each node.

2.3 Edge Router Bootstrap Prosess

The Edge Router board requires an Ethernet cable and main power. Also verify that the CC1180EM

radio module is properly connected to the OMAP J30 connector with the adapter board and has an

antenna. To start the Edge Router simply power up the board. On the board there is an automatic

script which will launch the NanoRouter 2.0 software during Linux kernel boot process. The time for

the Linux boot process is about 45 seconds. NanoRouter software status can be easily checked by

initiating a NodeView connection to the board IPv6 address, which is described in the next chapter.

2.4 NodeView 2.0

NodeView can be used to control and communicate with the NanoRouter software running on an

Edge Router. The NodeView software is a java based cross platform tool designed for 6LoWPAN

testing and evaluating purposes. When NodeView is started, it opens the „Router View‟ tab. The

„Router View‟ tab contains 'File' and 'Options' toolbars. To connect NodeView to an Edge Router

choose File->Add NanoRouter IPv6 from the menu.

Page 12

CC-6LOWPAN-DK-868

Page 12 of 61

Figure 5. Adding an Edge Router.

The address must be given in a basic IPv6 format seen in the figure above. To connect to the

standard Edge Router delivered with the CC-6LOWPAN-DK-868 kit simply enter 2001::11. After the

Edge Router is added, the details can be seen from the NodeView „router View‟ tab if the connection

was successfully established. When a sensor node joins the network, it can be observed in the Nodes

list shown in Figure 2Figure 6. The list is updated based on the Edge Router whiteboard information

or by pressing 'Clear and Reload' button. The whiteboard of the Edge Router contains information of

all connected nodes.

Figure 6. NanoRouter Router View details.

As described earlier in this document nodes automatically scans for and joins available 6LoWPAN

networks. When a node has joined a network a Network Analyzer application is launched on the

node. The Network Analyzer application sends data about the network to the NodeView tool. The start

is trigged by a message from NodeView, the activation message is sent automatically every time

when the whiteboard information changes or when user press the „Clear and Reload‟ button.

Page 13

CC-6LOWPAN-DK-868

Page 13 of 61

Figure 7. NodeView Network Analyzer tab.

In Figure 7, the green node indicates a normal node, while the blue color indicates a routing node.

The black/grey color indicates a node that has no longer connectivity to the NodeView. The red color

indicates a configured Edge Router. The circles describe a logical position of a node in the network in

hops. 'File', 'Options' and 'Help' contains useful information and configurations that can be useful. The

set Global Transmit Interval found in Options can be used to change how often the nodes are set to

send their network analyzer data to the Edge Router, the default value is 40s. Pay attention when

setting this value, since setting it too low in a large network can degrade the network overall

performance. One feature that can be useful when analyzing routing paths is the ability to have a

background image in NodeView. To enable this feature place your background image (must be in .jpg

format) in the same folder as NodeView, the go to Options->Use background. More information on

how to use NodeView 2.0 can be found in [10].

2.5 Network Analyzer Application

All sensor nodes come with a pre-programmed Network Analyzer firmware. The network analyzer

application is used to gather information about the network such as RSSI on different links, network

topology and application layer data traffic etc. This section describes behavior of the LEDs and

buttons that user may use on the nodes. The network analyzer application software for the nodes is

described in detail later in this document.

CC1180DB and CC430F5137 both have a green and a red led. The CC1180DB also has LEDs that

are controlled by the MSP4305438A host MCU. Radio LEDs (D1 and D2) are located in left bottom

corner when holding CC1180DB with jumpers and buttons pointing upwards. The CC1180 contains a

bootloader, Sensinode NanoBoot 1.0, and a NanoStack 2.0 Wireless Network Processor firmware.

The user can control which state (mode) that CC1180 is in, either bootloader mode or application

mode.

When the NanoBoot mode is chosen, both LEDs are on. The mode can be switched by pressing the

button S1. This will cause a falling edge interrupt to the CC1180 chip (grounding P1.2). Both LEDs will

be now disabled until a network connection is established (indicated with green LED). If the red LED

Page 14

CC-6LOWPAN-DK-868

Page 14 of 61

blinks with 1 second interval the network is disabled. The red LED also blink very rapidly during any

RF event but mainly remains inactive. Please note that the connection will not be established if the

MSP4305438A host MCU doesn‟t send a networking enable message or there is no active

NanoRouter available within the range with correct RF settings.

When the connection is established, green LED remains active and the red LED blinks on every RF

event.

Green LED active,

red LED disabled but

blinking

Red LED blinking with 1

second interval

Green LED inactive, red LED

blinking rapidly.

Both LEDs are

active

Network connection

established

Networking is not enabled

Scanning for network

Bootloader mode

Table 1. CC1180 controlled LED (D1 and D2) behavior.

Table 1 applies also for the CC430F5137 LEDs except for the bootloader LED usage, since there is

no NanoBoot 1.0 in use in CC430F5137). The MSP4305438A host MCU has a Network Analyzer

application programmed by default as describe earlier in this document. The RSSI for the node is

displayed using the LEDs. The LED control of the Network Analyzer application is defined in Table 2.

Red LED

toggling with

1 second

interval

Both LEDs

disabled

Green

LED

active, red

LED

disabled

Both LEDs remains active

Red LED remains active,

green LED disabled

3 concurrent

reply

messages

missed or

Analyzer is not

activated

Reply

message

measured

RSSI level

above -40

dBm.

Reply

message

measured

RSSI level

between 40 and -65

dBm

Reply message measured

RSSI level between -65 and 90 dBm.

RSSI reading below -90 dBm.

Table 2. MSP4305438A controlled LED (D3 and D4) behavior.

3 Software

Sensinode NanoStack 2.0 lite operating system core is event based, all the peripherals such as

timers, trigger events are executed in the main program. Interrupt service routines are used by

hardware drivers which may trigger events.

3.1 Sensinode NAPSocket and NanoSocket interface

There are, as described earlier, two different APIs for using Sensinode NanoStack 2.0 lite. Network

Processor (NAPSocket API [12]) and the library model (NanoSocket API [8]) provide easy-to-use

interfaces. NanoStack 2.0 lite networking must be initialized properly, networking is off by default.

User is provided an interface which allows enabling of networking; e.g. polling connectivity and

configuring the RF interface setup for user needs. For the Network Processor, NAPSocket library [12]

is an interface library running on a host MCU controlling the Network Processor (CC1180). The library

model of NanoStack 2.0 lite uses a function call interface which allows direct access to configure

networking features as well as other configurations, e.g. RF configuration. This interface system is

called NanoSocket API [8]. NanoSocket API is linked into user IAR application project and it contains

a .lib file of NanoStack 2.0 lite and a few header files. Both interfaces encapsulate UDP

communication into a simple socket system, making RF easy! The Sensinode NAPSocket and

NanoSocket APIs are described in detail below.

Page 15

CC-6LOWPAN-DK-868

Page 15 of 61

Figure 8. Stack overview CC1180 based system, using NAPSocket API

Figure 9. Stack Overview CC430 based system, using NanoSocket API

3.2 Sensinode NanoStack 2.0 lite

Sensinode NanoStack 2.0 lite is an embedded operating system and a 6LoWPAN protocol stack

designed especially for low power and cheap wireless sensor devices.

The protocol stack is designed to comply with a set of standards mostly provided by IETF 6LoWPAN

working group. Table 3 describes the layer structure of the protocol stack and the used standards for

each protocol layer.

Page 16

CC-6LOWPAN-DK-868

Page 16 of 61

Layer

Standard

Description

PHY

802.15.4g [4]

Link layer communication

-GFSK modulation

-FHSS support

-Single band in EU

MAC

802.15.4e [5]

Link layer communication

-Addressing modes (16 bit

addressing mode)

-AES-128 bit CCM* support

IP

draft-ietf-6lowpan-hc-13 [1]

Network layer communication,

routing

-Addressing modes (128 bit,

multicast group 2, link local)

Neighbour Discovery

draft-ietf-6lowpan-nd-13 [2]

Network layer communication,

address registration, network

scan. Neighbour resolution.

Routing method

Draft-ietf-roll-rpl-13 [3]

Network layer communication,

coordinator controlled routing.

Table 3. Sensinode 6LoWPAN Stack Layer Definitions.

3.2.1 Bootstrap process

When a node is powered up and set to search for network, it activates the MAC and PHY radio

operations automatically, providing a fully automatic bootstrap process.

3.2.2 Synchronization

All nodes must synchronize to a simple 6LoWPAN Edge Router since the radio PHY supports

frequency hopping system. When the synchronization is established, each node will start hopping on

the predefined channels. Each node remains in a channel for 350 ms, this time period is called an

active period. After each active period, a new channel is chosen and nodes remain in a guard period

for 50ms. During that period, radio receivers are disabled and no communication is performed. Each

50ms slot in the active period and the guard period is called a superframe. Each superframe consists

of 330 microsecond slots. Each superframe causes an interrupt for the radio module. This interrupt is

served by a crystal; the crystal must follow tolerances stated in the respective datasheet in order to

keep up the synchronization. Note that the synchronization is established even if the system is of

single channel type. During the active period, RF receiver is active and MCU is running. (In

CC430F5137 CPU sleeps if no other operations are performed in order to keep the power

consumption at a minimum).

The synchronization process is described here. First, a powered and activated node scans for the

beacon by broadcasting a beacon request periodically. Each node which is already joined to the

network will reply with a unicast beacon to the originator of the beacon requests. The beacon contains

timing information of the superframe. The beacon payload is described in Table 4.

Byte 1 2 3 4

5

Value

'S'

'F'

Remaining slots

in superframe

Superframe ID

Next channel

table index

Table 4. Beacon payload.

Here, the 'S' and the 'F' are header bytes to discard beacons of other systems. The remaining slots

field in the superframe message describe how many 330 us slots are left in a current superframe. The

superframe ID describes the number of the current superframe. Superframes are numbered from 0 to

7; where 1 to 7 is the active period superframes and superframe 0 indicates the guard period.

Beacons and beacon requests are built according to IEEE802.15.4e specification [5]. After

synchronization is performed, it is updated with ~10 second interval by sending unicast beacon

request to the node that responded to the beacon.

Page 17

CC-6LOWPAN-DK-868

Page 17 of 61

3.2.3 Neighbour Discovery and Router Solicitation

When a node is synchronized, the ICMP (Internet Control Message Protocol) layer is activated. The

ICMP layer scans for suitable routing nodes or Edge Routers by broadcasting a Router Solicitation

(RS) message. On reception of a RS, a routing node responds by sending a link local (unicast) Router

Advertisement (RA) to the scanning node.

On reception of a RA, the joining node receives the IPv6 prefix of the network. The prefix is used to

communicate within a simple 6LoWPAN network. Here, the prefix is defined to be 8 first bytes of the

IPv6 address that the NanoRouter advertises. After the prefix information is solicited, the node sends

a Neighbour Solicitation (NS) message. The NS message is used to solicit neighbour information of

the network. Here, a neighbour cache size is zero and therefore contains no entries. The NS also

contains a header field to register an allocated 16-bit short address. As a response to the NS, a

Neighbour Advertisement (NA) is sent. The NA message contains information of advertising node and

status fields if the address allocation was successfully performed.

The NS is sent first to a routing node which then delivers it to the Edge Router using RPL routing, if

the scanning node cannot reach the Edge Router directly. The NA message is sent from the Edge

Router to the routing node, which then sends it to the registrating node by using the link local unicast.

More detailed information can be found from Draft-ietf-6lowpan-nd-13 (draft-ietf-6lowpan-nd-13) [2].

3.2.3.1 Fixed packet formats

In order to achieve a very lightweight 6LoWPAN stack, some packet formats need to be fixed to avoid

unnecessary packet processing. In this section fixed packet formats are described. Table 5 describes

fixed packet formats of Neighbour Discovery messages.

Message

Format

Router Solicitation (RS)

SLLAO

Router Advertisement (RA)

PIO, ABRO, SLLAO

Neighbour Solicitation (NS)

ARO, SLLAO

Neighbour Advertisement (NA)

ARO, SLLAO

Table 5. Fixed Neighbor Discovery packet formats.

If other packet formats of Neighbour Discovery messages are received, they are discarded silently.

Detailed explanation of SLLAO, PIO, ABRO and ARO can be found from [2].

3.2.4 RPL: IPv6 Routing Protocol for Low power and Lossy Networks

In order to achieve a lightweight 6LoWPAN stack, routing is based on RPL control messages (DIS,

DIO, DAO and DAO-ACK). The routing is coordinated by the NanoRouter 2.0 software running on the

Edge Router, which keeps record of routing tables as well as whiteboards over time.

Nodes form topological paths extending from the access point. Each node „knows‟ their RPL parent.

Each node allows an unlimited amount of child nodes, but only one child may continue routing. This is

controlled by RPL poisoning and by sharing DIO message information required for routing. Each node

is registered into the Edge Router (NS, DAO), so the Edge Router can form a whole path into a single

node by summarizing all the registration data. Finally, the Edge Router knows the destination

address, path and depth in a network and therefore is able to route data to the destination. Forwarded

messages are also having a flag (RPL hop-by-hop option header) which indicates the direction of

forwarded data (up and down).

In routing systems where flow paths are used, each „knot‟-node can become a problem. As a flow

spreads into separate flows, routing becomes impossible. Each node can have only one routing child,

but unlimited amount of non-routing child nodes. Therefore routing is allowed only in a node which

was connected to a routing node as the first child. This logic is controlled by a timer, by keeping the

first child addressing information in memory and by restricting routing using RPL control message

(DIO).

Draft-ietf-roll-rpl-13 [3] defines the used routing protocol. It contains a few ICMP layer messages

called RPL control messages. These messages contain information of routing nodes and hosts. The

information is gathered to the Edge Router and routing configurations are sent all over the simple

6LoWPAN network. Table 6 illustrates a basic description of each message type.

Page 18

CC-6LOWPAN-DK-868

Page 18 of 61

Message type

Description

Addressing options

DIS

Used to scan for RPL DODAG.

Multicast, unicast

DIO

Used to advertise RPL DODAG.

Multicast, unicast

DAO

Contains routing information from source to

the next hop parent.

Unicast

DAO-ACK

Acknowledge message for DAO.

Unicast

Table 6. RPL control messages

When the node has accomplished Neighbour Discovery, the RPL routing protocol takes place. A

joining node scans for a Destination Oriented Directed Acyclic Graph (DODAG) Information Object

(DIO) by broadcasting a DODAG Information Solicitation (DIS) message. When a routing node

receives the DIS message, it sends the DIO as a response. The DIO may, or may not, contain

DODAG information. All details of this functionality are described in [3].

The DIO message also contains address information of the parent and a RPL root which is the Edge

Router. On reception of the DIO, a Destination Advertisement Object (DAO) is sent to the RPL root

after a predefined time. The DAO contains route information from the RPL host to the RPL parent.

Here, this information represents one logical interconnection within the simple 6LoWPAN network.

When the root receives the DAO, it gathers route information of the DAOs to a routing table. The

routing table can be used to build a whole path from the root to the destination node. This allows the

root to send data to any registered and joined node within a RPL DODAG. As a response to the DAO,

a DAO-ack is sent if requested.

In order to achieve a lightweight 6LoWPAN stack, P2P data (data going from node to node) has to be

delivered to the Edge Router and then routed from the Edge Router to the destination node. More

detailed information of each packet format can be found from [3]. It is however possible to send data

directly from one node to another by using the multicast feature, given that the nodes are within the

same physical RF range.

3.2.4.1 Fixed packet formats

Draft-ietf-roll-rpl-13 [3] defines multiple formats for RPL control messages and their options. Table 7

describes fixed packet formats for each RPL control message.

RPL control message

Options

DIS

No options

DIO

DODAG configuration, metric container or only metric

container

DAO

RPL target, transit information

DAO-ack

No options

Table 7. Fixed formats of RPL control messages.

Any other formats of RPL control messages are discarded silently.

3.2.4.2 DODAG configuration option

This CC-6LOWPAN-DK-868 kit uses a custom RPL objective function, please see [3] for more

information. Here, an Objective Code Point (defined in a DODAG configuration in [3]) is defined to be:

MSB byte

LSB Byte

's'

'n'

Table 8. RPL Objective Code Point.

Page 19

CC-6LOWPAN-DK-868

Page 19 of 61

The Objective Code Point indicates a used objective function. The Objective Function requires a

metric container. The metric container has the following format:

Byte 1

Byte 2

Byte 3

Byte 3

Type = 2

Length = 2

's'

Hop count

Table 9. RPL Metric container format.

The metric container must be included within a DIO and if it not exists, the DIO is discarded silently. A

node that doesn't receive DODAG configuration must advertise its rank as INFINITE_RANK (0xffff).

3.2.4.3 Sensinode custom Objective Function

The used Objective Function is based on a link quality metric where the received signal strength

indicator is graded from 1 to 8, where 1 is the best possible link and 8 is the worst link. The rank used

in RPL control messages is then calculated on the reception of a DIO message. The calculated link

quality grade is added to the received rank. The calculated rank is then divided by a hop count within

the metric container and is compared to the current rank divided with current hop count. If the new

rank is smaller than the old rank, a topology change is made. Therefore a DODAG configuration

defines minimal rank increase of 255*1 and maximum rank increase of 8*255. For platforms not

supporting RSSI calculation, default rank increase of 3 can be used. Table 10 summarizes these

definitions.

Definition

Value

Minimum rank increase

255*1

Maximum rank increase

255*8

Default rank increase

255*3

Table 10. DODAG configuration parameters.

A more detailed explanation of these parameters can be read from [3]

3.2.5 Periodic processes

This section describes the periodic messaging within a simple 6LoWPAN network. In order to update

the routing information, the RPL protocol sends messages periodically to maintain and update routes.

The period is mainly controlled by Edge Router (NanoRouter) but may change dynamically due to RF

events within a network.

In order to verify the connectivity and avoid duplicate address allocation, also the Neighbour

Discovery process is performed periodically. The period may change depending on failure events

within a network.

The synchronization is also updated periodically as explained in 3.2.2. Timings may also change due

to RF errors and accepted beacons.

3.2.6 Error situations

Users of the kit need to be aware of and fully understand the limits of the radio range of the used

devices. If the node doesn't have a network within its radio range, it is not able to join the network. If

default firmware (Network Analyzer application) are used, the LEDs will indicate (via RSSI) this kind of

a communication problem as explained in Table 1.

As the routes are maintained based on periodic scans and advertisements, the network do not

support a high grade of mobility. There will be communication losses if a node has been joined to an

existing network but then is moved to a different location within the network. This is due to the fact

that the nodes cannot realize the change in topology very fast. However, the network is able to do

self-healing in these situations by listening to advertisements all the time.

Page 20

CC-6LOWPAN-DK-868

Page 20 of 61

3.3 CC-6LOWPAN-DK-868 Software Projects

Included in the kit are example projects to be used with IAR Embedded Workbench. This section

describes the setup, use of, and installation of those projects.

3.3.1 IDE installation

The projects included in the kit are for the IAR Embedded Workbench IDE 5.20 for MSP. It is possible

to use the "Kick-start" version of the IAR Embedded Workbench to build the application examples for

CC1180DB. The IAR “Kick-start” version allows the user to build applications not exceeding 8kB. The

demo application (Network Analyzer) for CC1180DB in the kit is using the NAPSocket library, and the

build size is about 4kB of Flash and 2kB of RAM (including the NAPSocket library).

To be able to build a CC430 application one must use the full version of IAR Embedded Workbench,

due to the size of the 6LoWPAN CC430 NanoSocket library. The build size for the CC430 demo

application (including 6LoWPAN stack) is about 19kB of Flash and 3kB of RAM. This leaves 13kB of

flash and about 1kB of RAM to the user application.

For software development and modification of the preprogrammed firmware (Network Analyzer) the

following steps are needed:

1. Install IAR Embedded Workbench for MSP, all versions can be found here: IAR Embedded

Workbench

2. Download the CC-6LOWPAN-DK-868 Application Example zip files from

http://www.ti.com/6lowpan and unzip the files.

3. Download the NAP Socket library source from http://www.ti.com/6lowpan; this is needed to

get the .lib file that the CC1180 example application is using. It is also needed if you want to

run/port the application in/to another host MCU.

Make sure to extract the NAP Socket library and Example Application into the same folder, in order to

not have to change the settings in the IAR projects.

For more information on the different IDE options and details please visit http://www.iar.com

The examples are all configured as IAR workspaces, one workspace for CC430 and one for

MSP430F45438A (to be used on the CC1180DB). The workspace for CC430 is called

CC430NetworkAnalyzer.eww and the workspace for MSP430 (for use on the CC1180DB) is called

NanoHOEX.eww.

The files are organized into folders corresponding to their location in the file structure, e.g.:

Libraries - this contains used library file. Either CC430 NanoSocket library or Sensinode NAP

Socket library for MSP430 (for CC1180DB).

Applications - the sample applications.

Platform - this contains miscellaneous utilities, such as ADC driver for temperature/battery

level measurements.

IAR automatically creates an additional directory, Output, that contains any debug or list files.

The project configurations are all fairly simple to ease the transition to other platforms. Changes to the

default project configuration are the following (can be found under project Options-> Project: Options)

CC430 project:

General Options: Target - change Device to CC430F5137. Library Configuration - CLIB.

Library options - Change to Large Printf formatter. Change to Large Scanf formatter.

Stack/Heap - Override default and set Stack size: 256, Data16 heap size: 256.

C/C++ Compiler: Language tick multifile comp. Preprocessor - Under "Additional include

directories" the relative paths for all files are added. Otherwise IAR will display a warning if

the project directory changes, since IAR by default uses absolute paths in its project

configuration. Under Defined symbols: add NS_DEBUG=1 (if debug interface shall be

enabled) and MSPCORETYPE=5137.

Page 21

CC-6LOWPAN-DK-868

Page 21 of 61

Linker: Extra Output - Check Generate Extra Output. Output file: Check override default and

name the file *.hex

MSP430 project:

General Options: Target - change Device to MSP430F5438A. Library Configuration - CLIB.

Stack/Heap - Override default and set Stack size: 512, Data16 heap size: 512.

C/C++ Compiler: Preprocessor : Under "Additional include directories" the relative paths for

all files are added. Otherwise IAR will display a warning if the project directory changes, since

IAR by default uses absolute paths in its project configuration. Defined symbols: USE_IAR=1

Linker: Extra Output: Check Generate Extra Output. Output file: Check override default and

name the file *.hex

3.3.2 NanoHost Example (Network Analyzer)

The nodes included in the kit come preloaded with an application to monitor the 6LoWPAN network

topology and to provide link quality data to the user. The Network Analyzer Demo Application on the

nodes is used in conjunction with the PC software NodeView 2.0 to monitor and analyze the

6LoWPAN network. NodeView 2.0 software on the PC sends out a message containing information to

the nodes on how often they are supposed to report their status to NodeView 2.0. This value is set in

NodeView 2.0 and can be changed under "Network Analyzer tab -> Options -> Set Global Interval"

Default is 40s.

The Network Analyzer program sequence is this:

1. Node View sends out a "start" message to the connected nodes.

2. Nodes reply with a message containing data such as; short address, parent address, number

of hops away from Edge Router and RF signal info. The payload length of this packet is 31

Bytes.

3. Node View sends an ACK message to the node. The payload length of this packet is 9 Bytes.

4. Data is shown in Node View.

5. Nodes keep sending data to Node View with the defined interval.

As is described in chapter 3.4 the NanoHost example project uses the Sensinode NAPSocket library

as a parser library to handle the communication between the host MCU (MSP430F5438A) and the

network processor (CC1180) on the CC1180DB board.

The files in the IAR project for CC1180 have the following file structure:

Applications - The network Analyzer application source files.

Libraries - The NAP Socket library file, which is the API to NAPSocket.

Platform - Contains platform (i.e. MSP430F5438A) specific files.

Output - The output .hex file is put here.

You'll also notice that the IAR project has the includes defined in Project Options. These definitions

($PROJ_DIR$/something etc) are there to make the examples portable since IAR by default uses

absolute paths. Otherwise when you open the examples you would get an error if your file structure

doesn‟t exactly match the provided.

The NanoHost example is described in detail in [11].

3.3.2.1 Getting started with application development for CC1180 (NAPSocket)

1. Open IAR Embedded Workbench for MSP

2. Open workspace NanoHOEX.eww

3. Connect CC1180DB via MSP-FET430UIF Debugger to your PC

4. Select Debug or Release, depending on if you want to debug or just download the hex file to

CC1180DB (MSP430F5438A) from the workspace panel.

5. Click Download and Debug in the menu, or use Ctrl-D

Page 22

CC-6LOWPAN-DK-868

Page 22 of 61

Figure 10. NanoHost Example project

3.3.3 NAPSocket Library

The NAPSocket library is provided in source code in order to be able to port the library to other

platforms. The NanoHost example application is using the NAPSocket library to send and receive

data from the CC1180 Network Processor.

The NAPSocket library is described in detail in the Sensinode document [12].

Figure 11. NAPSocket library project

3.3.4 CC430F5137 Library Model (Network Analyzer)

The program flow and logic are exactly the same as for the CC1180DB version described in 3.3.2.

The files in the IAR project for CC430 have the following file structure:

main.c- The Network Analyzer application source file.

*.lib - The NanoSocket library file, which is the API to NanoSocket.

Output - The output .hex file is put here.

You'll also notice that the IAR project has the include files defined in Project Options. These

definitions ($PROJ_DIR$/something etc) are there to make the examples portable since IAR by

default uses absolute paths. Otherwise when you open the examples you would get an error if your

file structure doesn‟t exactly match the provided.

Page 23

CC-6LOWPAN-DK-868

Page 23 of 61

Figure 12. NanoSocket Example project

3.3.4.1 MCU Resources in use by NanoStack 2.0 lite on CC430

The following hardware resources are occupied by the library CC430F5137_NanoStack20lite and

therefore not available for user application.

All timer modules

Watchdog

DMA interrupt

The UART is occupied if application is compiled with NS_DEBUG defined (CC430 provides

one UART, UCA0)

CC1101 radio interface

LEDS according to EM430F5137RF900 schematic are in use. However,

DISABLE_AUTOMATIC_LEDS() function can be used to allow user defined led functionality

AES engine and CRC engine

Unified clock system:

UCSCTL4 |= SELA_0;

UCSCTL4 |= SELS_5; // Set SMCLK = XT2CLK (26MHz same crystal as radio core)

UCSCTL4 |= SELM_5; // Set MCLK = XT2CLK (26MHz same crystal as radio core)

UCSCTL6 &= ~XT2OFF; // Set XT2CLK on

UCSCTL5 |= DIVS_1; // SMCLK-divider = 2 (26/2 MHz)

Core voltage level must be 3.

Application must not disable interrupts.

3.3.4.2 NanoSocket Debug Interface

The NanoSocket library provides a debug interface that can print out debug information on the CC430

UART to display on a terminal program on a PC. The NanoSocket Debug Interface is enabled by

compiling the CC430 project with NS_DEBUG enabled, see Figure 13. By not including the

NS_DEBUG during compile time the UART is free to use for the user application. The UART settings

for the Debug Interface are 115200, 8N1, no flow control.

Figure 13. Enabling the NanoSocket Debug Interface

An example of a debug printout is shown below.

Page 24

CC-6LOWPAN-DK-868

Page 24 of 61

APP: RF MAC is:

0x00:0x12:0x4B:0x00:0x00:0x0E:0x20:0x17

APP: INIT OK!

Looking for access point...

Connection information:

-----------------------

HWaddr:00124B00000E2017

inet6: 2001000000000000000000FFFE004227

parent:2001000000000000000000FFFE00D734

Access point:2001000000000000000000FFFE000000

hop: 2

-----------------------

Hello world!

It is also possible to send data to the CC430 node via the debug interface. Sending „h‟ to the CC430

Network Analyzer example application will print out “Hello World!” on the debug interface. For more

information and details on using the debug interface see the Network Analyzer example application

IAR project for CC430.

3.3.4.3 Getting started with application development for CC430 (NanoSocket)

1. Open IAR Embedded Workbench for MSP

2. Open workspace CC430NetworkAnalyzer.eww

3. Connect EM430F5137RF900 via MSP-FET430UIF Debugger to your PC

4. Select Debug or Release, depending on if you want to debug or just download the hex file to the

CC430 based board from the workspace panel.

5. Click Download and Debug in the menu, or use Ctrl-D

6. Click start, or F5.

Note: Debug using breakpoints when running a 6LoWPAN network is not possible, since the

6LoWPAN stack is implemented as a real time OS and the nodes are time synchronized. However

debug can be used before stack is initialized. Use the debug interface described in 3.3.4.2 to print

debug information when NanoStack is running.

3.3.5 Programming the boards

This section describes two alternatives on how to program the different boards. The boards can either

be programmed directly from IAR EW, alternatively if the hex files already exist, the TI Flash

Programmer tool can be used. In either case the node (either CC430 or CC1180DB) will have to be

connected to the PC via the MSP-FET430UIF Debugger with a USB connection. The following

section describes the steps needed to build the projects and download hex files to the hardware using

IAR EW.

3.3.5.1 IAR Embedded Workbench (Can only be used on CC1180DB)

1. Open IAR Embedded Workbench for MSP

2. Open the workspace file NanoHOEX.eww with IAR. This file is found in the subfolder

\Sources in the folder where you unpacked the CC-6LOWPAN-DK-868 Applications

Examples zip file.

3. There are two different configurations for the IAR project; Release and Debug. Use Debug for

debugging your source code and release to build smaller hex files without debug information

in it.

4. Select Project->Rebuild All. This will perform a full rebuild on the selected project.

5. Connect the CC1180DB board to program to the MSP-FET430UIF Debugger.

Page 25

CC-6LOWPAN-DK-868

Page 25 of 61

6. Connect the MSP-FET430UIF Debugger to the PC with a USB cable.

7. Select Project->Debug to program the MSP430 (application (host) processor on the

CC1180DB).

8. Stop the debugger by selecting Debug -> Stop Debugging.

9. Repeat steps 7 to 8 to program additional boards.

3.3.5.2 TI Smart RF Flash Programmer (Can be used on CC430 and CC1180 host MCU)

This procedure is needed since all nodes have an IEEE (i.e. MAC) address that needs to be unique

within the 6LoWPAN network. All CC1180 chips has that pre-programmed from TI, however for the

CC430 the nodes have the IEEE address stored in the Flash memory at location 0xFF70. Thus the

IEEE address has to be written to that flash address in order for the nodes to be able to function.

There are several ways of doing this; one way is to use this line of code in the CC430 software:

__root __code const uint8_t hard_coded_mac[8] @ 0xff70 = {0x01, 0x02, 0x03,

0x04, 0x05, 0x06, 0x07, 0x08};

This will place the value 0x0102030405060708 at flash address 0xFF70.

Another (more complex) way is to modify the .hex file before it is downloaded to flash on CC430. This

is described here, this example adds the IEEE address 00:12:4B:00:00:0E:20:16 to the hex file. You

will have to change the IEEE address to your node specific address, for the kit the IEEE address can

be found on a sticker on the node.

Open CC430NetworkAnalyzer.hex e.g. in Notepad.

Insert :08FF700000124B00000E2016E8 on the 5th line from the bottom. Do not erase any

line, simple add this line to the hex file.

Save file as e.g. CC430NetworkAnalyzer_N2016.hex and close Notepad.

Connect the EM-CC430F5137-900 board to MSP-FET430UIF Debugger

Use Smart RF Flash Programmer to download the hex file

CC430NetworkAnalyzer_N2016.hex to the CC430 board.

To add the address 00:12:4B:00:00:0E:17 you would add the line:

:08FF700000124B00000E2017E7

Hint; if you increase the IEEE address by one you decrease the CRC (last byte) with one.

The hex file is constructed like this:

:08FF700000124B00000E2017E7

Start code

Byte count

Address

Record type

Data (in this case the IEEE/MAC address)

CRC

3.4 Sensinode NAPSocket API

This API is used on a host processor that communicates with the CC1180 network processor via a

UART interface. The main goal for the NAPSocket library is to provide a simple way for users to work

with NanoStack 2.0 lite CC1180 Network Processor. The user is able to use NAP protocol

configuration commands via a simple command interface. Since the NAP protocol also provides

transmissions of 6LoWPAN messages, the interface introduces a socket interface to be use with the

library. The user is able to send data packets through the socket interface the library converts

messages to the NAP protocol format. The library is a parser library, which means that it‟s the user‟s

responsibility to create suitable drivers and operating system for the chosen platform.

Page 26

CC-6LOWPAN-DK-868

Page 26 of 61

All details on the NAPSocket API are found in the Sensinode documentation [12].

Figure 14. Sensinode NAPSocket library

3.4.1 Sensinode NAP Protocol API

The Sensinode NAP interface protocol is used to access the functionality provided by the CC1180

Network Processor with Sensinode NanoStack 2.0 lite. The NAP protocol has been specifically

designed to be used over UART. The NAP protocol has been designed to be an easy-to-parse, lowoverhead serial protocol that has enough flexibility and extendibility for the Sensinode NanoStack 2.0

Network Processors. The potentially limited serial port data rates have imposed the need for a very

low overhead compared to the actual payload data. The NAP protocol defines two main types of

packets

· Config for all configuration messages (request and replies) and status queries & answers

· Data for all data communication

The Sensinode NAP protocol can be used directly without NAPSocket library to communicate with the

CC1180.

All information about the NAP Protocol API can be found in the Sensinode document [9].

3.5 Sensinode NanoSocket API

This API is used on a CC430 device running both the Sensinode 6LoWPAN stack and the user

application. The user is able to use configuration commands via a simple command interface. A

socket interface provides transmissions of 6LoWPAN messages. The library contains a sophisticated

operating system called NanoStack 2.0, which means that user doesn't need to implement drivers and

operating system for the chosen platform.

Page 27

CC-6LOWPAN-DK-868

Page 27 of 61

Figure 15. Sensinode NanoSocket API

The NanoSocket API is described in the Sensinode document [8].

3.6 Sensinode RF Dynamic Configuration API

To change RF configuration settings the Dynamic RF Configuration API is used. The API is basically

the same both for CC1180 NWP and for CC430 SOC, with minor differences.

Using the API one can make set the following:

Data rate; 50, 100, 150 and 200kbit/s

Channel spacing, Frequency spacing between two adjacent channels can be set to 200 or

400 kHz. Only used in FHSS systems.

Modulation Index, this setting changes the deviation used in GFSK modulation. Possible

values for the modulation Index is 0.5 and 1. The deviation is calculated by:

Base Frequency, for single band system this sets the used channel. For multi band (FHSS)

systems this sets the leftmost frequency.

TX Power level, PA_TABLE0 setting for CC1180 and CC430.

RX Attenuation, set RX attenuation levels in order to avoid saturation.

Frequency hopping, Enabled / Disable FHSS. Enables 50 channels FHSS mode. In FHSS

mode the base frequency sets the lowest frequency used (leftmost). If FHSS is disabled the

base frequency sets the used operating channel.

The RF Dynamic Configuration API is described in [13].

3.6.1 NanoSocket

This section describes how to use the Dynamic RF Configuration API in the NanoSocket on CC430

nodes.

//default settings for RF interface

Page 28

CC-6LOWPAN-DK-868

Page 28 of 61

static rf_conf_settings_t rf_configurations = {DATA_RATE_50, CHANNEL_SPACING_200,

MODULATION_INDEX_10, 0x21,0x65,0x6a, 0xc3, RX_ATTENUATION_0dbm};

rf_conf_set_params(&rf_configurations); //Set RF Config for CC430

The data rate parameter can have the following values: DATA_RATE_50, DATA_RATE_100, DATA_RATE_150

and DATA_RATE_200.

The channel spacing parameter can be either CHANNEL_SPACING_200 or CHANNEL_SPACING_400.

Modulation index parameter can be set to MODULATION_INDEX_10 or MODULATION_INDEX_05.

The values 0x21, 0x65, 0x6a in the above example, give the used frequency. The values correspond

to the FREQ2, FREQ1 and FREQ0 registers. The values can be obtained from the SmartRF Studio

tool, see ti.com for download.

The value 0xc3 in the example above, gives the output power. 0xc3 corresponds to 10dBm output

power, use values from data sheet for CC430.

In order to enable FHSS, the function net_enable_fhss() is called. Please see CC430F5137 Library

Model Network Analyzer Example project for details.

3.6.2 NAPSocket

This section describes how to use the Dynamic RF Configuration API in the NanoSocket on CC1180

nodes.

//rf configurations to load...

static rf_conf_settings_t rf_config = {DATA_RATE_50, CHANNEL_SPACING_200, MODULATION_INDEX_10,

0x21, 0x65, 0x6a, 0xc2, RX_ATTENUATION_0dbm, FHSS_DISABLED};

rf_conf_set_params(&rf_config);

Please see NanoSocket section for a complete description of the API. The only difference is that

FHSS can be enabled and disabled using the FHSS_DISABLED parameter. See the CC1110 data sheet

SWRS033.pdf, for configuration of the output power parameter.

3.6.3 Node View 2.0

This section describes how to change RF Configurations for the Edge Router using the Sensinode

Node View 2.0 tool.

1. Double click on the Router whose RF configuration you want to change in the Router View

tab.

2. Click on the button “Remove Interface”

3. Click on the button “Create Interface”

4. Fill in the setting you want and click “Add”

Figure 16. Setting RF Configuration on Edge Router

The NanoRouter software running on the Edge Router saves the RF configuration settings in the file

/last/configFiles/rf_configuration_ttyS1.conf

Page 29

CC-6LOWPAN-DK-868

Page 29 of 61

An example of this file is shown below.

root@da850-omapl138-evm:~/last/configFiles# cat rf_configuration_ttyS1.conf

Interface Id=0

Crystal=26

Data rate=50

Channel spacing=200

Modulation index=10

Base frequency=2180332

TX power=194

RX attenuation=0

Freq. hopping=0

3.7 Sensinode NanoBoot API

Loading the Sensinode NanoStack 2.0 lite 6LoWPAN stack to CC1180 is performed using Sensinode

NanoBoot API. The CC1180 contains a bootloader called Sensinode NanoBoot, which is used to load

the stack and to perform other tasks such as setting and getting the MAC address and toggle

between application and bootloader mode.

All details are found in [15].

3.7.1 Sensinode NanoBoot host tool

One example application to perform stack update/download and interact with the NanoBoot is

provided by Sensinode, the application is called Sensinode NanoBoot_host. The application is

available for standard Linux environment and the OMAP-L138 Edge Router board.

The application is located in the /tools folder on the Edge Router and can be started on the Edge

Router board by:

root@da850-omapl138-evm:~/tools# ./NanoBoot_host_10_8552 /dev/ttyS1 ENCRYPTED_CC

1180_AP_FW.hex

When the application is started one has to make sure that the CC1180 is in bootloader mode,

otherwise it won‟t be able to interact with the NanoBoot_host tool. Press 1 [ENTER] and then 6

[ENTER] to toggle mode. The present mode is e.g. identified by the LED on the Adapter Board for

OMAP-L138, see Table 1 and [15].

Below is the user interface for the Sensinode NanoBoot_host tool.

NanoBoot 1.0

Firmware version info: 01 10 01 00 23 93

1

Select packet type:

0. Check mac address (sanity check)

1. Write binary ENCRYPTED_CC1180_AP_FW.hex

2. Set MAC address.

3. Switch to application mode

4. Firmware versions

6. Toggle GPIO line (For mode change).

3.8 Sensinode NodeView 2.0 Custom tabs

The network analyzer tool Sensinode NodeView 2.0 can be extended with custom tabs that can run

user applications. This is a very powerful feature since it enables users to quickly develop applications

that can communicate with the nodes in a 6LoWPAN network without writing the application from the