Page 1

User Manual

Rev. 1.5

CC400DK Development Kit

Page 2

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 2 of 22

Table of contents

TABLE OF CONTENTS............................................................................................................ 2

INTRODUCTION ....................................................................................................................... 3

EVALUATION BOARD............................................................................................................. 3

DESCRIPTION ........................................................................................................................... 4

LAYOUT SKETCHES AND CIRCUIT DRAWINGS............................................................................... 9

BILL OF MATERIALS................................................................................................................. 15

USING THE DEVELOPMENT KIT.......................................................................................... 19

APPENDIX A........................................................................................................................... 20

A.1 FINE TUNING PROCEDURE OF LNA/PA MATCHING NETWORK.......................................... 20

Page 3

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 3 of 22

Introduction

The CC400 single chip transceiver includes many features and great flexibility which makes

the chip suitable for a very large number of applications and system requirements. The

CC400 Development Kit is designed to make it very easy for the user to evaluate transceiver

performance and in short time develop his own applications.

The Development Kit includes two evaluation boards with a complete CC400 transceiver,

voltage regulator and PC interface circuitry. Using the evaluation board connected to a PC

running the SmartRF

®

Studio software, various system parameters can be changed and

tested by key-strokes.

Technical features:

RF power up to 25mW (14dBm) programmable in 1dB steps

-112 dBm sensitivity for 10

-3

bit error rate (1.2kbps, 20kHz frequency separation)

Logic level data input/output (Manchester coded)

Selectable RF filtering (SAW or LC)

Selectable IF filtering

All set-up controlled by PC

Selectable 3V or 4-10Vunregulated voltage supply inputs

This user manual describes how to get started with the Development Kit. You will also find

detailed description of the evaluation board and advice how to develop your own applications.

For details on how to use the SmartRF

®

Studio software please refer to the SmartRF® Studio

user manual.

Your SmartRF

®

CC400DK Development Kit should contain the following items:

Evaluation circuit boards (PCB) 2 ex

CC400 single chip transceiver 5 ex

PC parallel port extension cable 2 ex 25-pin D-sub, male-female, 3m

Adapter 4 ex SMA male-BNC female

Antenna 2 ex 50Ω, λ/4 monopole, SMA male

Quick Start Instructions

SmartRF

®

CD-ROM

The evaluation board includes a significant number of components for great flexibility.

However, only a minor part of these components are required in an actual application. Check

the datasheet for a typical application circuitry.

Evaluation board

Page 4

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 4 of 22

The kit includes an evaluation circuit board (PCB) with the following items:

• CC400

• Necessary external surface mounted devices, SMD, for the chip.

• Voltage regulator 4V-10V to 3V regulated voltage.

• Possibilities to apply a 3V voltage source directly (chosen by switches or connectors

at the board).

• Voltage-level interface circuits between the CC400 (3V) and the parallel port of the

computer (5V).

• Connector for a PC parallel port cable.

• Connector for antenna and modulation data in/out.

• Edge connector for future use.

This board is designed with great flexibility so that you can evaluate the circuit performance

for several circuit configurations, and in development of your own applications. A layout

sketch of the evaluation board is shown in chapter 0.

Description

The evaluation circuit board constitutes of three main parts. These are the RF-section, the

voltage supply and the PC-interface. The PC-interface contains voltage level shift circuit,

which buffers the control lines.

Voltage supply

You can chose between applying a 4-10V non-regulated supply voltage or a 3V regulated

supply voltage by setting a switch on the board (SPDT). If a non-regulated supply voltage is

applied, an on board regulator generates a regulated 3V supply. A diode prevents damage if

wrong polarity is used for the non-regulated input. The connector has five contacts, which is

shown below. In addition to the three supply voltage contacts, there are two contacts, which

can be used to measure the DC current to the CC400 chip. A short jumper is placed between

these two contacts for the circuit to work. If you want to measure the DC current, replace the

jumper with an amperemeter (as shown in the figure below). The current range is from 0 to 70

mA.

Page 5

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 5 of 22

Figure: The power connector with an amperemeter attached.

RF-section

The RF section consists of a CC400 chip with external components. The different

components are explained below.

The loop filter

The PLL loop filter contains the components C121-C123 and R121-R123. The software

program calculates the component values. Using the calculated component values for the

loop filter will give an optimum loop bandwidth for the selected system parameters.

The component values used in the CC400EB is selected for 9.6 kbit/s data rate, but can also

be used for evaluation of lower data rates.

The transmitted frequency is FSK modulated, which means that the bits ‘0’ and ‘1’ has

different frequencies, see Frequency separation in chapter 4.1.1.5 in SmartRF

®

Studio user

manual.

Note: If you need a shorter switching time between the two frequencies, the PLL settling time

has to be shorter. To find the new component values that you need for the loop filter, the

software program can be used as a calculator. Using a higher data rate value will give you a

larger loop bandwidth, but also an increase in the side-band noise on the carrier. A warning

may appear when increasing the data rate. To get around this warning, try to set the X-tal

accuracy to zero. Do not update the device when doing this, but use Enter to calculate the

values and return to your earlier settings afterwards.

External IF filter

The evaluation board is equipped with an external 455kHz ceramic filter. Input and output

impedance to the CC400 is 1.5kΩ, and the bandwidth is approximately 30kHz.

4-10V

0V

3V

I

out

A

Page 6

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 6 of 22

The LOCK signal

A LOCK signal is connected to the parallel port interface to be monitored by the software. The

signal tells you if the synthesiser frequency is in lock. It is also available at a test pin, TP2,

and is active high.

NOTE: If Power Down mode is selected when the LOCK signal is high, the current

consumption will be approximately 23 uA. This is due to the current flowing from the LOCK

pin into the external buffer transistor (Q2). This transistor could be replaced with a MOSFET

to avoid this trickle current. Without this extra load the CC400 Power Down current is less

than 1 uA.

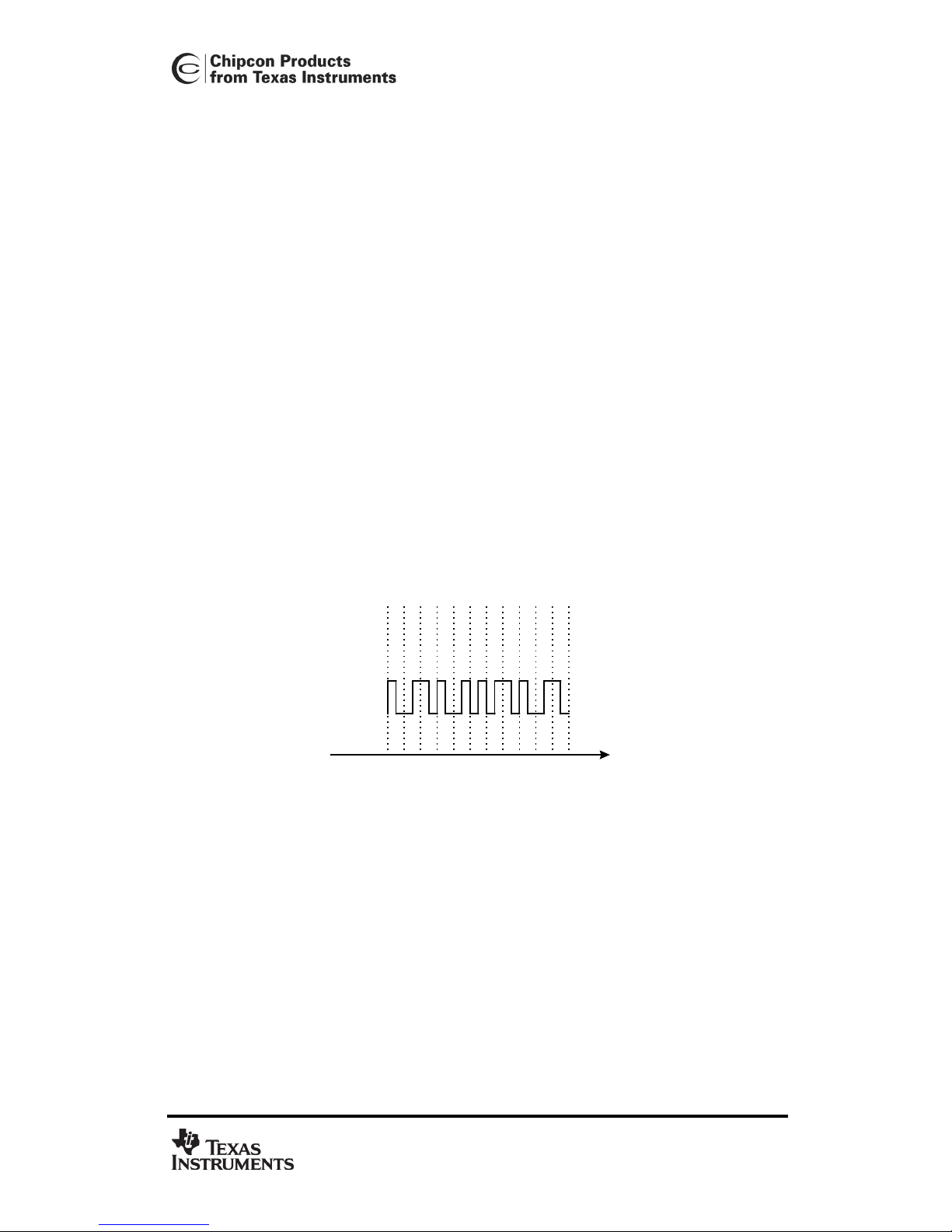

The modulation input/output

The modulation input/output (DIO) is connected to a separate connector. The connector type

is SMA female. The data to be sent has to be Manchester encoded (also known as bi-phaselevel coding). The Manchester code ensures that the signal has no DC component, which is

necessary for the FSK demodulator. The Manchester code is based on transitions; a “0” is

encoded as a low-to-high transition, a “1” is encoded as a high-to-low transition. See figure

below. Maximum data-rate is 9.6 kbit/s and is chosen in the software. To test your module

use a 3V

pp

logic level with 1-10 kHz square wave.

Time

TX

data

1 0 1 1 0 0 0 1 1 0 1

LNA/PA matching

The input/output matching network is optimised for 433.92MHz operation. The component

values are calculated in the software program, and consist of C51, C61, L51 and L61. Using

the specified component values for the input/output match will give an optimum match at the

specified operating frequency. Minor tuning of the component values may be necessary to

compensate for layout parasitics at other frequencies or other layouts. See appendix A.

Page 7

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 7 of 22

The Voltage Controlled Oscillator (VCO)

The VCO tank on the evaluation board is optimised for the 433MHz band, covering

approximately 410 – 450MHz. The tank contains the components C91, C92, C93, L91 and

the variable capacitance D2.

To operate in other frequency bands, C93 and L91 can be altered. To increase the operation

frequency C93 or L91 (or both) should be decreased (use 8.2nH for L91, and 1.5pF or 1.8pF

for C93). To decrease the operation frequency C93 or L91 (or both) should be increased (use

12nH for L91, and 2.7pF or 3.3pF for C93).

To find the tuning range for the new VCO tank, set the RF frequency to 300 MHz and 500

MHz in the software, update the device and measure the output frequency. In this way the

VCO tank will be tuned to its minimum and maximum operation frequency respectively.

For further details, please contact Chipcon.

The crystal oscillator

Crystal frequency is set to 12.000 MHz, X1. The crystal oscillator circuit has a trimmer

capacitor, CT152, which reduces the initial tolerance of the crystal to zero by careful

adjustment using a precision frequency counter. The crystal used at this board has ±10 ppm

initial tolerance and ±10 ppm drift over the –10 to +70 °C temperature range. The crystal

oscillator has an AC coupled (C153) test pin for external clock injection, TP1. Be sure to

remove the crystal when an external clock is used. The external clock should have amplitude

of 1-3V

pp

. If using other crystals they should be designed for 12pF load capacitance.

The preselector filter options

There are three preselector filter options: LC-filter, SAW filter, or no filter used. Each of the

three filter alternatives is equipped with a female SMA antenna connector. To choose

between the three filters there is a zero ohm resistor that can be moved (R61-R63).

Page 8

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 8 of 22

Unfiltered antenna output

The unfiltered antenna output has been made with an option. Two components, L71 and

C71, can be used to match the antenna if the antenna impedance is different from 50Ω. To

select this output the zero ohm resistor must be put in R61, and R62 and R63 shall not be

mounted.

LC-filtered antenna output

A LC-filter consisting of L52, C52 and C53 make up a 3dB-equal ripple low-pass filter that

prevents harmonics to be emitted from the transmitter. In receive mode the filter removes

high frequencies in order to prevent distortion and jamming of in the receiver. The filter is

designed for 50Ω termination impedance. The LC-filter is selected by placing the zero ohm

resistor in the R62 position. For operation at other frequencies, please use the formulas

below.

⎟

⎠

⎞

⎜

⎝

⎛

−⋅≈1333.01

1

RFC

ωω

,

C

L

ω

6.35

=

,

C

C

ω

067.0

=

,

where ω

C

is the cut-off frequency and ωRF is the transmitted RF frequency .

SAW filtered antenna output

To choose this output the zero ohm resistor must be put in the R63 position. The components

around the filter (F2) can be changed to match any SAW filter type. The SAW filter will

introduce additional loss, but will increase the selectivity of the receiver. The 3dB bandwidth

is approximately 200 kHz. The filter can be replaced with another SAW filter with a 3dB

bandwidth of 2 MHz if desirable.

Note: Using the SAW filter, the output power amplifier class should be A or AB and the output

power should not exceed 0 dBm. This will give approximately –5 dBm at the antenna output.

Using power settings above 0 dBm may cause stability problems.

Page 9

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 9 of 22

Layout sketches and circuit drawings

25 pin D-SUB

DIO

ANT

(LC filter)

ANT

(No filter)

ANT

(SAW filter)

4-10V

Switch

Module

slot

(future use)

4-10V

GND

3V

I_out

I_in

3V

Page 10

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 10 of 22

Page 11

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 11 of 22

Page 12

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 12 of 22

Page 13

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 13 of 22

Page 14

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 14 of 22

Page 15

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 15 of 22

Bill of materials

RF part

Reference Description Value Part

C10 Capacitor 0603 1nF C_1N0_0603_NP0_J_50

C11 Capacitor 0805 33nF C_33N_0805_X7R_J_50

C12 Capacitor 1206 4.7nF C_4N7_1206_NP0_J_50

C24 Capacitor 0603 220pF C_220P_0603_NP0_G_50

C25 Capacitor 0603 220pF C_220P_0603_NP0_G_50

C51 Capacitor 0603 220pF C_220P_0603_NP0_G_50

C52 Capacitor 0603 15pF C_15P_0603_NP0_J_50

C53 Capacitor 0603 22pF C_22P_0603_NP0_J_50

C61 Capacitor 0603 15pF C_15P_0603_NP0_G_50

C62 Capacitor 0603 220pF C_220P_0603_NP0_G_50

C63 Capacitor 0805 5.6pF C_5P6_0805_NP0_C_50

C66 Capacitor 0805 Do Not Mount

C68 Capacitor 0805 5.6pF C_5P6_0805_NP0_C_50

C71 Capacitor 0603 Do Not Mount

C91 Capacitor 0603 4.7pF C_4P7_0603_NP0_C_50

C92 Capacitor 0603 8.2pF C_8P2_0603_NP0_C_50

C93 Capacitor 0603 3.9pF C_3P9_0603_NP0_C_50

C121 Capacitor 0603 2.2nF C_2N2_0603_X7R_J_50

C122 Capacitor 0603 120pF C_120P_0603_NP0_J_50

C123 Capacitor 0603 22pF C_22P_0603_NP0_J_50

C151 Capacitor 0603 15pF C_15P_0603_NP0_G_50

C153 Capacitor 0603 1nF C_1N0_0603_NP0_J_50

C161 Capacitor 0603 15pF C_15P_0603_NP0_G_50

C210 Capacitor 0603 1nF C_1N0_0603_NP0_J_50

C211 Capacitor 0805 33nF C_33N_0805_X7R_J_50

C231 Capacitor 0603 Do Not Mount

CT152 Trimmer Capacitor C_3-10P_TRIM_NP0

D2 Varactor diode KV1832C, Toko

F1 Ceramic filter, 455kHz CFUCG455D, Murata

F2 SAW filter, 433.92MHz B3550, Siemens

Page 16

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 16 of 22

L51 Inductor 0805 39nH L_39N_0805_J

L52 Inductor 0805 8.2nH L_8N2_0805_J

L61 Inductor 0805 6.8nH L_6N8_0805_J

L64 Inductor 0805 33nH L_33N_0805_J

L67 Inductor 0805 33nH L_39N_0805_J

L71 Resistor 0805

0Ω

R_0R_0805

L91 Inductor 0805 10nH L_10N_0805_J LQN21A,

Murata

L210 EMI filter bead BLM11A102S, Murata

R24 Resistor 0805 Do Not Mount

R51 Resistor 0805 Do Not Mount

R61 Resistor 0603

0Ω

R_0R_0603

R62 Resistor 0603 Do Not Mount

R63 Resistor 0603 Do Not Mount

R65 Resistor 0805

270Ω

R_270_0805_J

R121 Resistor 0603

27kΩ

R_27K_0603_G

R122 Resistor 0603

150kΩ

R_150K_0603_J

R123 Resistor 0603

22kΩ

R_22K_0603_G

R231 Resistor 0603

0Ω

R_0R_0603

TP1 Testpoint TESTPIN

TP2 Testpoint TESTPIN

U1 Single chip transceiver CC400

X1 Crystal, HC-49-SMD X_12.000000 MHz, 12pF load

Voltage regulator

Reference Description Value Part

C1 Capacitor, tantal

3.3µF

C_3U3_TAN_B

C2 Capacitor, tantal

3.3µF

C_3U3_TAN_B

C3 Capacitor 0805 33nF C_33N_0805_X7R_J_50

D1 Diode, Si BAT254

Q1 MOSFET, P ch. SI9424DY, Siliconix

S1 SPDT switch SWITCH_SPDT

U2 Voltage regulator LP2981, 3V, National

Page 17

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 17 of 22

PC interface

Reference Description Value Part

C26 Capacitor 0805 33nF C_33N_0805_X7R_J_50

C27 Capacitor 0805 33nF C_33N_0805_X7R_J_50

Q2 BJT, Si, NPN, small signal BC846

Q3 BJT, Si, NPN, small signal BC846

Q4 BJT, Si, NPN, small signal BC846

Q5 BJT, Si, NPN, small signal BC846

R1 Resistor 0603

10kΩ

R_10K_0603_G

R2 Resistor 0603

10kΩ

R_10K_0603_G

R3 Resistor 0603

10kΩ

R_10K_0603_G

R4 Resistor 0603

10kΩ

R_10K_0603_G

R5 Resistor 0603

10kΩ

R_10K_0603_G

R6 Resistor 0603

10kΩ

R_10K_0603_G

R7 Resistor 0603

10kΩ

R_10K_0603_G

R8 Resistor 0603

10kΩ

R_10K_0603_G

R9 Resistor 0603

10kΩ

R_10K_0603_G

R10 Resistor 0603

10kΩ

R_10K_0603_G

R11 Resistor 0603

10kΩ

R_10K_0603_G

R12 Resistor 0603

10kΩ

R_10K_0603_G

R13 Resistor 0603

10kΩ

R_10K_0603_G

R14 Resistor 0603

10kΩ

R_10K_0603_G

R15 Resistor 0603

10kΩ

R_10K_0603_G

R16 Resistor 0603

10kΩ

R_10K_0603_G

R17 Resistor 0603

10kΩ

R_10K_0603_G

R18

Resistor 0603

10kΩ

R_10K_0603_G

R19 Resistor 0603

10kΩ

R_10K_0603_G

R20 Resistor 0603

100kΩ

R_100K_0603_G

R21 Resistor 0603

100kΩ

R_100K_0603_G

R22

Resistor 0603

100kΩ

R_100K_0603_G

R23 Resistor 0603

100kΩ

R_100K_0603_G

U3 Hex inverter, oc 74HC05

U4 Hex inverter, oc 74HC05

Page 18

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 18 of 22

Evaluation board

Reference Description Value Part

H1 Circuit Board Support Distance 12.5mm

H2 Circuit Board Support Distance 12.5mm

H3 Circuit Board Support Distance 12.5mm

H4 Circuit Board Support Distance 12.5mm

P1 D-Sub, 25 pin DSUB_25

P2 5 pin terminal, screw SCREW_TERM_5

P3 SMA connector SMA (Straight)

P4 SMA connector SMA (Straight)

P5 SMA connector SMA (Straight)

P6 SMA connector SMA_RA (Right angle)

P8 Edge connector, 2 x 8 pin EDGE_CONN_2X8

Page 19

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 19 of 22

Using the Development Kit

The purpose of the Development Kit is to give users of the integrated transceiver CC400

hands-on experience with the chip. A typical set-up of the evaluation board is shown below.

Each of the evaluation boards is connected to a PC to be programmed by the software.

• How to set up a transmitter.

The data signal that you want to send in transmit mode must be Manchester coded. If you

don’t have Manchester coded signals available, a square wave from a function generator can

be used instead. The signal source shall be connected to the Data I/O port (DIO) at the

evaluation board. The signal must be a square wave from 0 to 3V as shown. Do not apply a

5V signal because it can damage the CC400 chip. The signal from the function generator will

represent either zeroes or ones, and the bit rate will be 1/T, where T is the period time. For

example, when 1.2 kbit/s is used, set the function generator frequency to 1.2 kHz as this will

give a 1.2kbit/s Manchester coded bit stream.

The transmitted signal can be studied on a spectrum analyser, sent out on the antenna (see

note below) or sent to the receiver via a cable with an attenuator attached.

Figure: Equipment set-up in transmit mode.

Antenna

Circuit board

PC

4-10V

Spectrum analyser

DIO

Function generator

3V

T

Page 20

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 20 of 22

• How to set up a receiver

In receive mode a RF generator can be connected to the antenna input to give an ideal RF

signal to the circuit board for testing the receiver. Use FSK modulation with appropriate

deviation and modulation rate. If you don’t have the equipment to send FSK modulation, you

can use a RF generator with FM modulation and use an external function generator to

modulate the signal with a square wave. The RF signal can also come from the transmitter

via the antenna. An oscilloscope is used to see the Manchester coded signal that is being

received.

Figure: Equipment set-up in receive mode.

Important: The use of radio transceivers is regulated by international and national rules.

Before transmitting a RF signal out on the antenna, please contact your local

telecommunication authorities to check if you are licensed to operate the transceiver.

Appendix A

The component values to the input/output matching network are calculated in the software

program, and consist of C51, C61, L51 and L61. Using the specified component values for

the input/output match will give an optimum match at the specified operating frequency. Minor

tuning of the component values may be necessary to compensate for layout parasitics at

other frequencies or other layouts.

A.1 Fine tuning procedure of LNA/PA matching network

Follow the procedure below to fine-tune the matching network. Use the components that the

software program calculates as initial values. Set the bits F5:F3 = 000 in the Register

configuration window and update the device.

1) Receiver tuning

Oscilloscope

Circuit board

PC

4-10V

RF generator

Antenna

DIO

Page 21

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 21 of 22

Connect a Network Analyser to the unfiltered antenna output as shown in the figure, and

measure the impedance at the output.

Figure: Equipment set-up.

Set the CC400 transceiver in RX mode with the software program and adjust L51 and C61

until you measure approximately 50Ω impedance at the antenna output.

2) Transmitter tuning

Connect a Spectrum Analyser to the unfiltered antenna output in the same way as you did for

the RX tuning and measure output power. Set the CC400 transceiver in TX mode and adjust

C61 until you measure the highest output power.

3) Setting the Register bits

Choose the Register configuration window in the software.

1) If the optimum value of C61 found in RX mode is larger than C61 found in TX

mode:

Set bit F2 to 0 and increase bits F5 to F3 by an amount following the formula below

and update the device.

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

=

pF

CC

roundFF

TXRX

25.1

6161

3:5

Choose the value of C61 that you got from the TX tuning (C61

TX

).

Circuit board

PC

4-10V

Network analyser

Page 22

CC400DK Development kit (rev. 1.5) 2002-09-17 Page 22 of 22

Example: If C61TX = 12pF and C61RX = 15pF the bits F5:F3 = 010.

2) If the optimum value of C61 found in TX mode is larger than C61 found in RX

mode:

Set bit F2 to 1 and increase bits F5 to F3 by an amount following the formula below

and update the device.

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

=

pF

CC

roundFF

RXTX

25.1

6161

3:5

Choose the value of C61 that you got from the RX tuning (C61

RX

).

General Information

Chipcon AS believes the furnished information is correct and accurate at the time of this

printing. However, Chipcon AS reserves the right to make changes to this product without

notice. Chipcon AS does not assume any responsibility for the use of the described product.

Please refer to Chipcon’s web site for the latest update.

SmartRF

®

is a registered trademark of Chipcon AS. SmartRF® is Chipcon's RF technology

platform with RF library cells, modules and design expertise. Based on SmartRF

®

Chipcon

develops standard component RF-circuits as well as full custom ASICs based on customers'

requirements.

Loading...

Loading...