Page 1

CC3100 and CC3200 SimpleLink™ Wi-Fi®and

Internet of Things Solution Layout Guidelines

User's Guide

Literature Number: SWRU370B

June 2014–Revised August 2018

Page 2

Contents

1 Trademarks......................................................................................................................... 4

2 Device Overview ................................................................................................................. 5

3 PCB Specification ................................................................................................................ 5

3.1 PCB Stack-Up ............................................................................................................ 5

3.2 PCB Design Rules ....................................................................................................... 6

3.3 Layer Information......................................................................................................... 6

4 Layout Information............................................................................................................... 7

4.1 Placement of Components.............................................................................................. 7

4.2 Layer Information......................................................................................................... 8

5 Layout Guidelines .............................................................................................................. 12

5.1 RF......................................................................................................................... 12

5.2 Power..................................................................................................................... 16

5.3 Clock ..................................................................................................................... 17

5.4 Digital I/O ................................................................................................................ 17

5.5 QFN Ground............................................................................................................. 18

5.6 Recommended Footprint .............................................................................................. 19

6 Summary........................................................................................................................... 20

7 Additional References......................................................................................................... 20

Revision History.......................................................................................................................... 21

2

Table of Contents

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 3

www.ti.com

1 Example Stack-up ........................................................................................................... 5

2 CC3100BOOST 3.3-A Placement Diagram .............................................................................. 7

3 Layer-1 ........................................................................................................................ 8

4 Layer-2 ........................................................................................................................ 9

5 Layer-3....................................................................................................................... 10

6 Layer-4....................................................................................................................... 11

7 RF Section Layout ......................................................................................................... 12

8 Filter Routing................................................................................................................ 14

9 Coplanar Waveguide (Cross Section) With GND and via Stitching ................................................. 15

10 CPW With GND (Top View)............................................................................................... 15

11 7x7 Ground Vias on Ground Pad ........................................................................................ 18

12 Split Solder Paste Into Smaller Blocks .................................................................................. 18

13 Recommended Footprint .................................................................................................. 19

1 PCB Design Rules........................................................................................................... 6

2 4 Layer PCB.................................................................................................................. 6

3 Inductors ...................................................................................................................... 7

4 Antenna Guidelines........................................................................................................ 13

5 Recommended Components ............................................................................................. 13

6 Characteristic of Recommended Antenna .............................................................................. 13

7 Filter Guidelines ............................................................................................................ 14

8 Characteristic of Recommended Filter .................................................................................. 15

9 Recommended Values for the PCB...................................................................................... 16

10 Power Management........................................................................................................ 16

11 Characteristic of Recommended 32K XTAL............................................................................ 17

12 Characteristic of Recommended 40M XTAL............................................................................ 17

List of Figures

List of Tables

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

List of Figures

3

Page 4

User's Guide

SWRU370B–June 2014–Revised August 2018

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of

Things Solution Layout Guidelines

..................................................................................................... Embedded Processing Applications

ABSTRACT

This document provides the design guidelines of a 4-layer PCB board, for the CC31xx and CC32xx

SimpleLink™ Wi-Fi®family of devices. The CC31xx and CC32xx are easy to lay-out, QFN-packaged

devices. Optimize the board’s performance by following these suggestions during the board’s design. The

first section is a brief overview of the SimpleLink Wi-Fi family of devices. The second section focuses on

the PCB specification; the third section addresses components placement, and board layer information.

The last section, on layout guidelines, covers the board’s main sections such as RF, power, clock, digital

I/O, and the ground. Each section can be read independently.

In addition to this document, TI recommends verifying the schematic board design with the associated

schematic checklist.

1 Trademarks

SimpleLink, Internet-on-a-chip, E2E are trademarks of Texas Instruments.

ARM, Cortex are registered trademarks of ARM Limited.

Wi-Fi is a registered trademark of Wi-Fi Alliance.

All other trademarks are the property of their respective owners.

4

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 5

Type Layer Height(um)

Mask 25

Copper L1 35

FR-4 255

Copper L2 35

FR-4 350

Copper L3 35

FR-4 255

Copper L4 35

Mask 25

Total 1050

Total thickness ~ 1.1mm (+/- 10%)

www.ti.com

2 Device Overview

Start the design with the industry’s first Internet-on-a-chip™. Created for the Internet of Things (IoT), the

SimpleLink Wi-Fi family has several variants. The CC3100 SimpleLink Wi-Fi and IoT solution dramatically

simplifies the implementation of Internet connectivity. This product integrates all protocols for Wi-Fi and

Internet, which greatly minimizes host microcontroller (MCU) software requirements. CC3200 device is a

wireless MCU that integrates a high-performance ARM®Cortex®-M4 MCU with the CC3100 network

processor subsystem, allowing customers to develop an entire application with a single IC. With on-chip

Wi-Fi, Internet, and robust security protocols, no prior Wi-Fi experience is needed for faster development.

SimpleLink Wi-Fi is a complete platform solution, including various tools and software, sample

applications, user and programming guides, reference designs, and the TI E2E™ support community. The

devices are available in an easy to lay-out QFN package. The layout for both devices are similar, with a

higher number of IOs routed for the CC3200.

3 PCB Specification

3.1 PCB Stack-Up

An example stack-up is shown in Figure 1, used for the construction of the CC3100BOOST Rev3.3-A. The

user can alter the layer stack-up based on their requirements, but the impedance of the 50-Ω lines should

be recalculated. Having the L1-L2 distance reduced helps improve the grounding and the RF decoupling.

TI recommends keeping the L1-L2 distance similar to the recommended value.

Device Overview

Figure 1. Example Stack-up

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

5

Page 6

PCB Specification

3.2 PCB Design Rules

Parameter Value Comments

Number of layers 4

Thickness 1.1 mm ±

Size of PCB 2.0” x 1.7”

Solder mask Red Can be replaced with any color

Dielectric FR4

Silk White Can be replaced with any color

Surface finish ENIG

Min track width 6 mils Min track width can be reduced but cost would be higher

Min spacing 6 mils Min spacing can be reduced but the cost would be higher

Mid drill diameter 8 mils 12-mil diameter drill is used on the Rev 3.3-A board

Copper thickness 1 oz

Lead free / ROHS Yes

Impedance control Yes 50-Ω controlled impedance trace of 18-mils width on L1 w.r.t L2 (GND).

Impedance variation 5%

www.ti.com

Table 1. PCB Design Rules

For greater thickness increase the distance between L2 and L3

10%

Air gap = 15 mils

Note: The above calculations are based on CPW-G (NOT microstrip).

3.3 Layer Information

The 4-layer PCB is used with the configuration, as shown in Table 2.

Layer Usage Notes

1 Signal + RF RF trace is a CPW on L1 w.r.t. L2 ground

2 GND Reference plane for RF

3 Power + signal The power planes for the power amplifier (PA), analog blocks and the main input supply are routed on

4 Power + signal

Table 2. 4 Layer PCB

this layer

6

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 7

www.ti.com

4 Layout Information

The complete layout package is available for download on the TI website at http://www.ti.com/tool/cc3200-

launchxl-rd and http://www.ti.com/tool/cc3100boost-rd. TI recommends that the customers copy the exact

layout of the engine area to ensure optimum performance as measured on the CC3x00 reference boards.

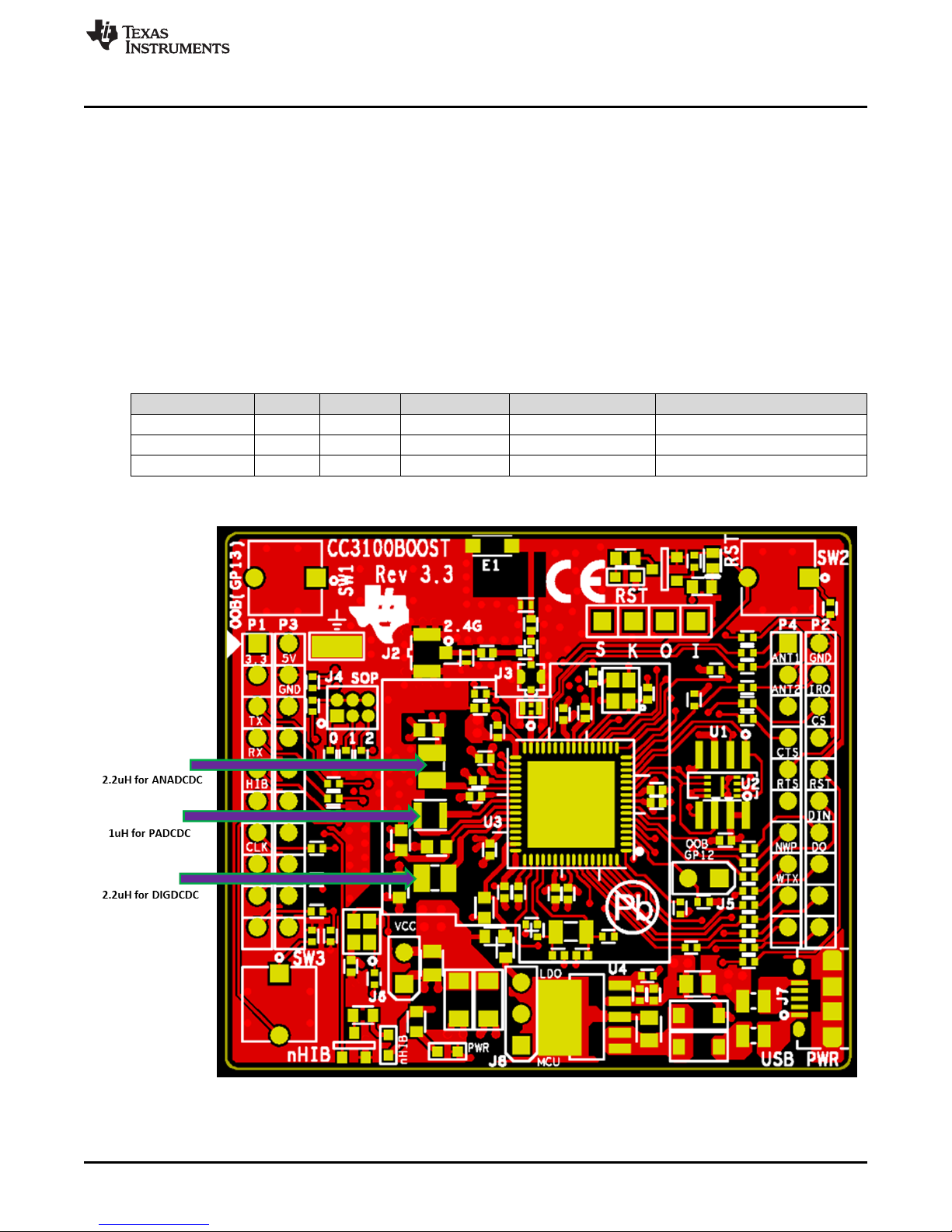

4.1 Placement of Components

The components placement on the CC3100 BoosterPack is provided in Figure 2. This placement provides

optimum performance of the device. Great care must be taken for the power inductors components to

ensure reduced emissions and optimum EVM and mask performance. The power inductors should be

placed close to the device, and the power traces should be minimized. The CC3x00 device is sensitive to

the layout of the DC-DC converter, which can impact the performance of the device. For the main

inductors at the analog, power amplifier, and digital DC-DC output, see Table 3.

Inductor @ Value Size Current Rating Recommended PN Description

ANA DCDC OUT 2.2 µH 1008 1.3A LQM2HPN2R2MG0L INDUCTOR 2.2UH 20% 1008

PA DCDC OUT 1 µH 1008 1.5A LQM2HPN1R0MJ0L INDUCTOR 1UH 20% 1008

DIG DCDC OUT 2.2 µH 1008 1.3A LQM2HPN2R2MG0L INDUCTOR 2.2UH 20% 1008

Figure 2. CC3100BOOST 3.3-A Placement Diagram

Layout Information

Table 3. Inductors

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

7

Page 8

Layout Information

4.2 Layer Information

4.2.1 Layer-1

Most of the routing is performed on Layer-1 to avoid vias on the board (see Figure 3). The trace widths

are maximized for high-current pins and minimized for signal pins. For example, the signal pins can be

routed with 6 mils (4 mils, if possible) and the power pins with 12 mils and above.

www.ti.com

Figure 3. Layer-1

8

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 9

www.ti.com

4.2.2 Layer-2

Layer-2 is primary ground plane for the board reference (see Figure 4). It has a void for the antenna

section, which is per the antenna guidelines. This return current path for the input de-coupling capacitors

(C11, C13, and C18) is routed on L2 using thick traces to isolate RF ground from a noisy supply ground.

This is also required to meet the IEEE spectral mask specifications.

Layout Information

Figure 4. Layer-2

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

9

Page 10

Layout Information

4.2.3 Layer-3

Layer-3 is used to route the power lines to the device (see Figure 5). Power planes are necessary for the

power amplifier (PA) and the main supply input to the device. More details are available in subsequent

sections.

www.ti.com

Figure 5. Layer-3

10

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 11

www.ti.com

4.2.4 Layer-4

Layer-4 is used for routing the power and the signal lines on the board (see Figure 6). It is also the main

power dissipation GND layer for the QFN package. The bottom GND plane must be maximized for the

best thermal performance. The solder mask has been kept open below the QFN device to improve heat

dissipation and yield.

Layout Information

Figure 6. Layer-4

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

11

Page 12

Chip

Antenna

Feed

Void space

on all layers

Antenna

match

Filter

U.FL

conn

Murata

Conn

Layout Guidelines

5 Layout Guidelines

5.1 RF

As a wireless device, the RF section gets the top priority in terms of layout (see Figure 7). It is very

important for the RF section to be laid out correctly to get the optimum performance from the device. A

poor layout can cause performance degradation for the output power, the error vector magnitude (EVM),

the sensitivity, and the spectral mask.

www.ti.com

Figure 7. RF Section Layout

12

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 13

www.ti.com

5.1.1 Antenna Placement and Routing

The antenna is the element used to convert the guided waves on the PCB traces to the free-space

electromagnetic radiation. The placement and layout of the antenna is key to increased range and data

rates.

The guidelines in Table 4 must be observed for the antenna.

Sr No Guidelines

1 Place the antenna on an edge or corner of the PCB.

2 Ensure that no signals are routed across the antenna elements on all the layers of the PCB.

3 Most antennas, including the chip antenna used on the BoosterPack, require ground clearance on all the layers of the

PCB. Ensure that the ground is cleared on the inner layers as well.

4 Ensure that there is provision to place matching components for the antenna. These must be tuned for best return loss

once the complete board is assembled.

Any plastics or casing should also be mounted while tuning the antenna, as this can impact the impedance.

5 Ensure that the antenna impedance is 50 Ω, as the device is rated to work only with a 50-Ω system.

6 In case of printed antenna, ensure that the simulation is performed with the solder mask in consideration.

7 Ensure that the antenna has a near omni-directional pattern.

8 The return loss measured at the filter out (looking into the device) should be better than -10 dB. To ease the FCC, CE, and

ETSI certification, the antenna used should be of the same gain or lesser.

Table 5. Recommended Components

Layout Guidelines

Table 4. Antenna Guidelines

Choice Part Number Manufacturer Notes

1 AH316M245001-T Taiyo Yuden Can be placed on the edge of the PCB and uses less PCB space

2 RFANT5220110A2T Walsim Must be placed on the corner of the PCB

Table 6. Characteristic of Recommended Antenna

Parameter Spec

Frequency bandwidth 2.4G to 2.5G

Typical peak gain +1.9 dBi

Average gain at OMNI plane 0 dBi

Efficiency (typical) –1.3 dB (73%)

VSWR 3

5.1.2 Filter Placement and Routing

The RF filter used on the board performs the important function of attenuating the out-of-band emissions

from the device. The recommended filter is DEA202450BT-1294C1. The datasheet for the filter can be

accessed at http://www.tdk.co.jp/tefe02/rf_bpf_dea202450bt-1294c1-h_en.pdf.

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

13

Page 14

Filter

Layout Guidelines

www.ti.com

Figure 8. Filter Routing

Table 7. Filter Guidelines

Sr No Guidelines Notes

1 Route the RF lines at the input and output of the filter using a coplanar

waveguide (CPW) with ground structure. This structure offers the best

isolation between input and output due to reduced field fringing.

2 Use via stitching along the RF trace to reduce emissions and keep the fields

confined to the trace boundary.

3 Use a Zo of 50 Ω only with a tolerance of 10%. Use the stack-up and the

trace width provided for reference in the PCB design rules.

4 Add multiple ground vias for the filter ground pads as close as possible.

Minimum of 2 per GND pad is recommended.

5 To achieve the specifications of the filter attenuation, the minimum isolation

between input and output ports of the filter must be at least 60 dB. (Measured

without filter)

6 In case a conducted test is required on the PCB, TI recommends adding a

U.FL connector or a Murata switch type connector (MM8030 series).

CPW with GND and via stitching can be

accurately simulated using 3D EM tools

like EESOF.

14

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Page 15

w

s

e

r

S W S

h

www.ti.com

Parameter Frequency (MHz) Spec

Return loss 2412-2484 10 dB (min)

Insertion loss 2412-2484 1.5 dB (max)

Attenuation

Reference impedance 2412-2484 50 Ω

Filter type Band pass

5.1.3 Transmission Line

The RF signal from the device is routed to the antenna using a coplanar waveguide with ground (CPW-G)

structure. This structure offers the maximum isolation across filter gap and the best possible shielding to

the RF lines. In addition to the ground on the L1 layer, placing GND vias along the line also provides

additional shielding.

Layout Guidelines

Table 8. Characteristic of Recommended Filter

800-830 30 dB (min)

1600-1670 20 dB (min)

3200-3300 30 dB (min)

4000-4150 45 dB (min)

4800-5000 20 dB (min)

5600- 5800 20 dB (min)

6400-6600 20 dB (min)

7200-7500 35 dB (min)

7500-10000 20 dB (min)

Figure 9. Coplanar Waveguide (Cross Section) With GND and via Stitching

Figure 10. CPW With GND (Top View)

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

15

Page 16

Layout Guidelines

The recommended values for the PCB are provided in Table 9.

(1)

Er is assumed to be of an FR-4 substrate.

5.2 Power

• All of the input de-coupling capacitors (C11, C13, and C18) should be routed on L2 using thick traces

to isolate RF ground from a noisy supply ground. This is also required to meet the IEEE spectral mask

specifications.

• Maintain the thickness of power traces to be higher than 12 mils. Special care should be taken for

power amplifier supply lines (pin 33, 40, 41, and 42) and all input supply pins (pin 37, 39, and 44).

• Ensure shortest grounding loop for PLL supply de-coupling capacitor (pin 24)

• Place all de-coupling capacitors as close as possible to the respective pins.

• Power budget: The CC3X00 device can consume up to 450 mA for 3.3 V, 670 mA for 2.1 V, and 700

mA for 1.85 V for 24 msec during the calibration cycle. Ensure that the power supply is designed to

source this current without any issues. The complete calibration (TX and RX) can take up to 17 mJ of

energy from the battery over a time of 24 ms.

• There are many high-current input pins on the CC3X00 device. Ensure the trace feeding these pins is

capable of handling the following currents:

– PA DCDC input : pin 39. Max 1A

– ANA DCDC input : pin 37 : Max 600 mA

– Dig DCDC input : pin 44: Max 500 mA

– PA DCDC switching nodes : pin 40/41 , Max 1A

– PA DCDC output node: pin 42, Max 1A

– ANA DCDC switching node: pin 38: Max 600 mA

– Dig DCDC switching node: pin 43 : Max 500 mA

– PA supply : pin 33: Max 500mA

Table 9. Recommended Values for the PCB

Parameter Value Units

W 18 mils

S 15 mils

H 10 mils

(1)

Er

3.9

www.ti.com

5.2.1 Inductors for Power Management

The components used in the power management section of the design are critical to achieve the required

performance. These should be chosen based on the recommendations in Table 10.

Inductors Value ESR

PA DC-DC 1 uH TBD 1.5 TBD 20%

ANA, DIG DC-DC 2.2 uH TBD 1.3 TBD 20%

16

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Table 10. Power Management

(mOhm) Rated Current (A)

min

Copyright © 2014–2018, Texas Instruments Incorporated

Saturation

Current I

SWRU370B–June 2014–Revised August 2018

sat

Submit Documentation Feedback

Tolerance

Page 17

www.ti.com

5.3 Clock

5.3.1 32K RTC

The 32.768K XTAL should be placed close to the QFN package. Ensure the load capacitance is tuned

based on board parasitic, so that the frequency tolerance is within ±150 ppm.

Tolerance with temperature and aging ±150 ppm

5.3.2 40M XTAL

The 40M XTAL should be placed close to the QFN package. Ensure the load capacitance is tuned based

on board parasitic, so that the frequency tolerance is within ±20 ppm. The frequency tolerance for the

XTAL across temperature and with aging should be ±25 ppm. In addition, ensure no high frequency lines

are routed closer to the XTAL routing, to avoid any phase noise degradation.

Tolerance with temperature and aging ±25 ppm

Layout Guidelines

Table 11. Characteristic of Recommended 32K XTAL

Parameter Spec

Nominal frequency 32.768 kHz

Table 12. Characteristic of Recommended 40M XTAL

Parameter Spec

Nominal frequency 40 MHz

Tolerance ±20 ppm

Load capacitance 8 pF

5.4 Digital I/O

Route serial peripheral interface (SPI) and universal asynchronous receiver/transmitter (UART) lines away

from any RF traces, as these digital I/O lines are high-frequency lines and can cause interference to the

RF signal.

Keep the length of the high-speed lines as short as possible to avoid transmission line effects. Keep the

line lower than 1/10th of the rise time of the signal to ignore transmission line effects. This is required only

if the traces cannot be kept short. The resistor should be placed at the source end, closer to the device

driving the signal.

Add series-terminating resistors for each high-speed line (for example, SPI_CLK, SPI_DATA) to match the

driver impedance to the line. Typical terminating resistor values range from 27 to 36 Ω for a 50-Ω line

impedance.

Route high-speed lines with a ground reference plane continuously below it to offer good impedance

throughout, and help shield the trace against EMI interference.

Avoid stubs on high speed lines to minimize the reflections. If the line needs to be routed to multiple

locations, use a separate line driver for each line.

If the lines are longer compared to the rise time, add series-terminating resistors near the driver for each

high-speed line (for example, SPI_CLK, SPI_DATA) to match the driver impedance to the line. Typical

terminating resistor values range from 27 to 36 Ω for a 50-Ω line impedance.

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

17

Page 18

Layout Guidelines

5.5 QFN Ground

1. Ensure 7x7 ground vias are placed on the ground pad for optimal thermal dissipation (see Figure 11).

The via drill size can be between 8 mils to 12 mils.

www.ti.com

Figure 11. 7x7 Ground Vias on Ground Pad

2. Open the solder mask on L4 for better soldering yield.

3. Split solder paste into smaller blocks (see Figure 12) to avoid component lifting while soldering or reflow.

Figure 12. Split Solder Paste Into Smaller Blocks

4. Solder paste should cover at-least 75% of the ground tab of the QFN.

18

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 19

www.ti.com

5.6 Recommended Footprint

Layout Guidelines

Figure 13. Recommended Footprint

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Copyright © 2014–2018, Texas Instruments Incorporated

Layout Guidelines

19

Page 20

Summary

6 Summary

This document presents an introduction to designing a 4-layer PCB board for the CC3100/CC3200

SimpleLink Wi-Fi easy-to-layout QFN packaged family of devices. In addition to the recommendations

presented here, see the CC3100 SimpleLink Wi-Fi and IoT Solution BoosterPack design files located at

http://www.ti.com/lit/zip/swrc288 and the CC3200 SimpleLink Wi-Fi and IoT Solution With MCU

LaunchPad board design files located at http://www.ti.com/lit/zip/swrc289.

7 Additional References

1. CC31xx and CC32xx main landing page.

2. The CC3100 SimpleLink™ Wi-Fi® and IoT Solution for MCU Applications data sheet (SWAS031)

3. The CC3200 SimpleLink™ Wi-Fi® and IoT Solution, a Single Chip Wireless MCU data sheet

(SWAS032)

www.ti.com

20

CC3100 and CC3200 SimpleLink™ Wi-Fi®and Internet of Things Solution

Layout Guidelines

Copyright © 2014–2018, Texas Instruments Incorporated

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Page 21

www.ti.com

Revision History

Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from A Revision (September 2014) to B Revision .......................................................................................... Page

• Updated Schematic Checklist link....................................................................................................... 4

• Updated References..................................................................................................................... 20

SWRU370B–June 2014–Revised August 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Revision History

21

Page 22

IMPORTANT NOTICE FOR TI DESIGN INFORMATION AND RESOURCES

Texas Instruments Incorporated (‘TI”) technical, application or other design advice, services or information, including, but not limited to,

reference designs and materials relating to evaluation modules, (collectively, “TI Resources”) are intended to assist designers who are

developing applications that incorporate TI products; by downloading, accessing or using any particular TI Resource in any way, you

(individually or, if you are acting on behalf of a company, your company) agree to use it solely for this purpose and subject to the terms of

this Notice.

TI’s provision of TI Resources does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI

products, and no additional obligations or liabilities arise from TI providing such TI Resources. TI reserves the right to make corrections,

enhancements, improvements and other changes to its TI Resources.

You understand and agree that you remain responsible for using your independent analysis, evaluation and judgment in designing your

applications and that you have full and exclusive responsibility to assure the safety of your applications and compliance of your applications

(and of all TI products used in or for your applications) with all applicable regulations, laws and other applicable requirements. You

represent that, with respect to your applications, you have all the necessary expertise to create and implement safeguards that (1)

anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that

might cause harm and take appropriate actions. You agree that prior to using or distributing any applications that include TI products, you

will thoroughly test such applications and the functionality of such TI products as used in such applications. TI has not conducted any

testing other than that specifically described in the published documentation for a particular TI Resource.

You are authorized to use, copy and modify any individual TI Resource only in connection with the development of applications that include

the TI product(s) identified in such TI Resource. NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO

ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY

RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or

endorsement thereof. Use of TI Resources may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

TI RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR

REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING TI RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED TO

ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL

PROPERTY RIGHTS.

TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY YOU AGAINST ANY CLAIM, INCLUDING BUT NOT

LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS EVEN IF

DESCRIBED IN TI RESOURCES OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL,

COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR

ARISING OUT OF TI RESOURCES OR USE THEREOF, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

You agree to fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of your noncompliance with the terms and provisions of this Notice.

This Notice applies to TI Resources. Additional terms apply to the use and purchase of certain types of materials, TI products and services.

These include; without limitation, TI’s standard terms for semiconductor products http://www.ti.com/sc/docs/stdterms.htm), evaluation

modules, and samples (http://www.ti.com/sc/docs/sampterms.htm).

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2018, Texas Instruments Incorporated

Loading...

Loading...