Page 1

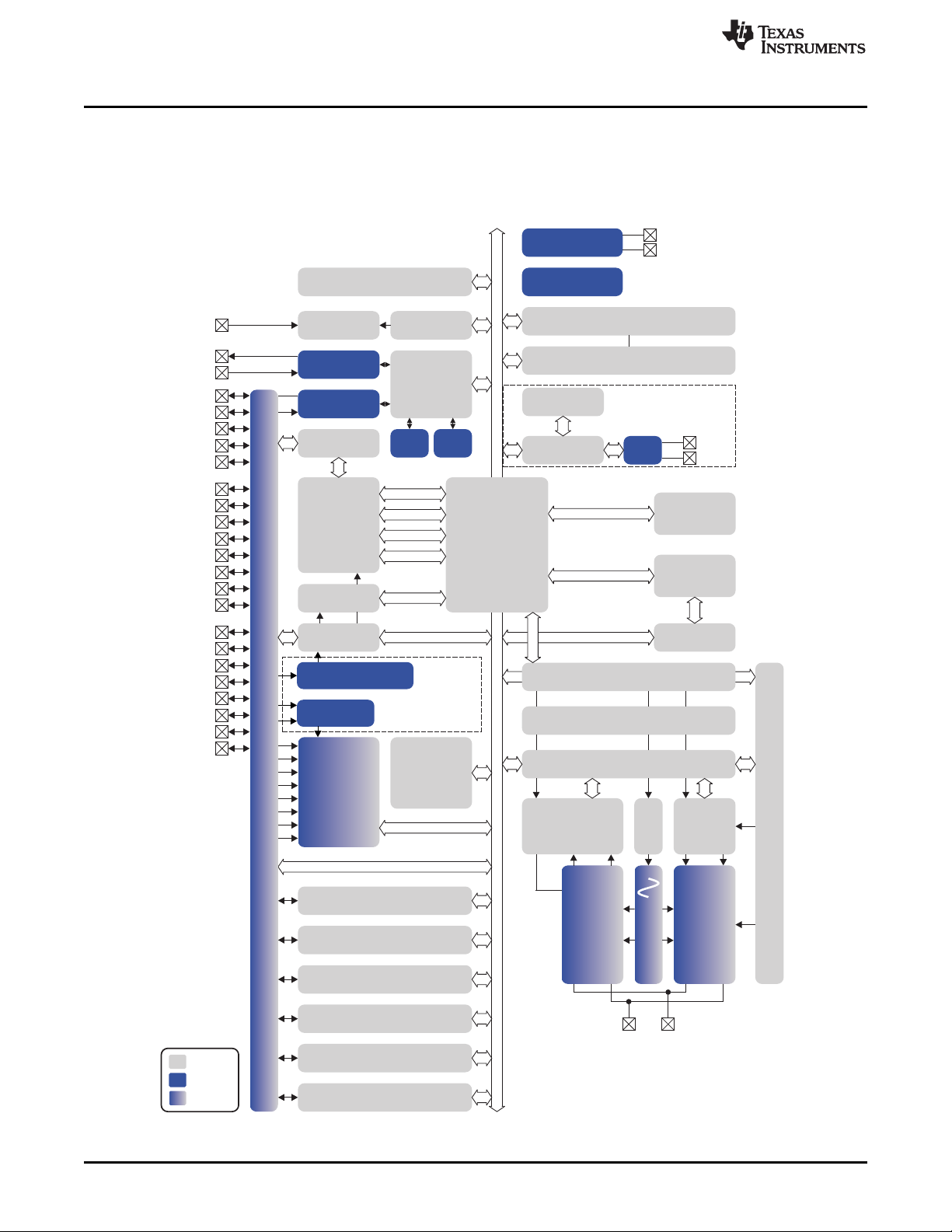

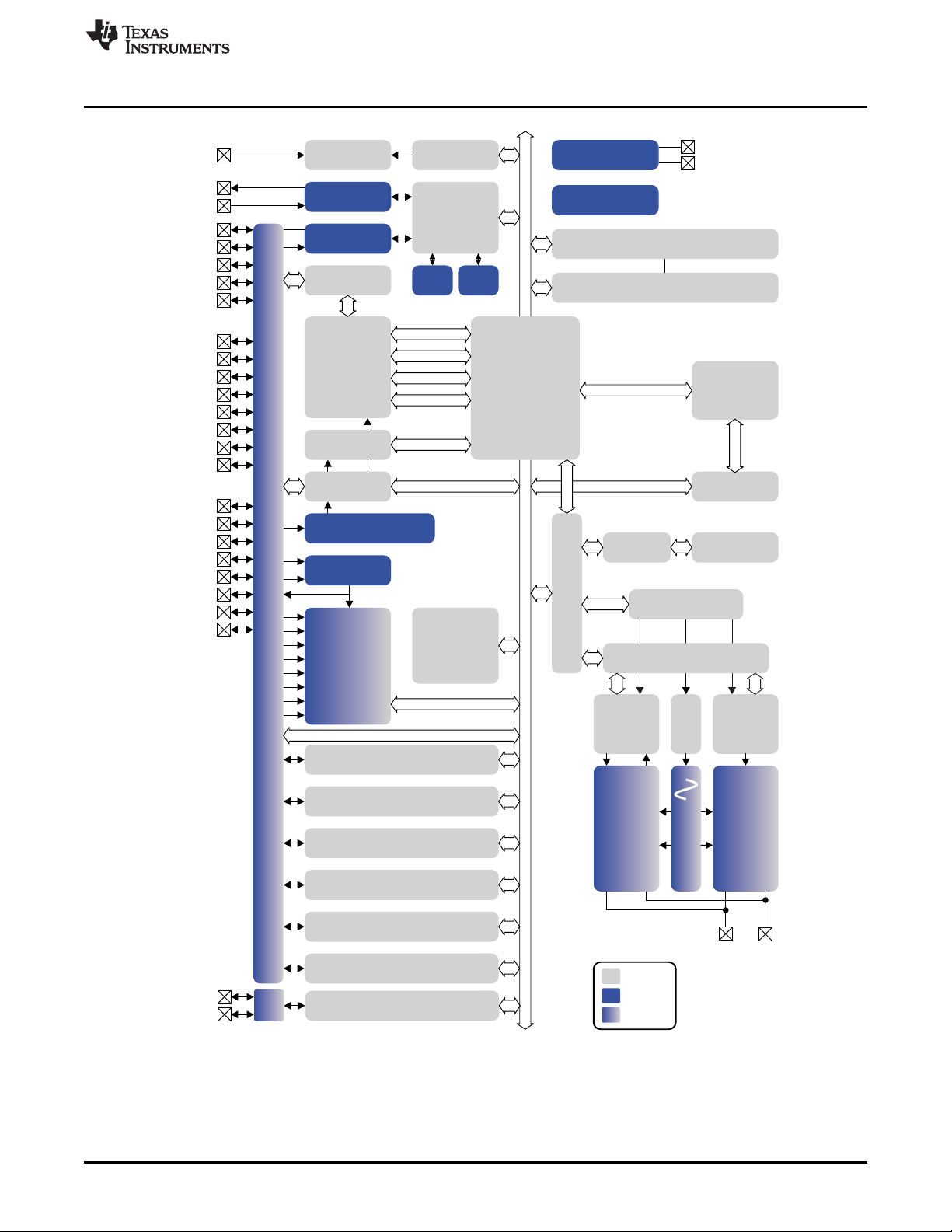

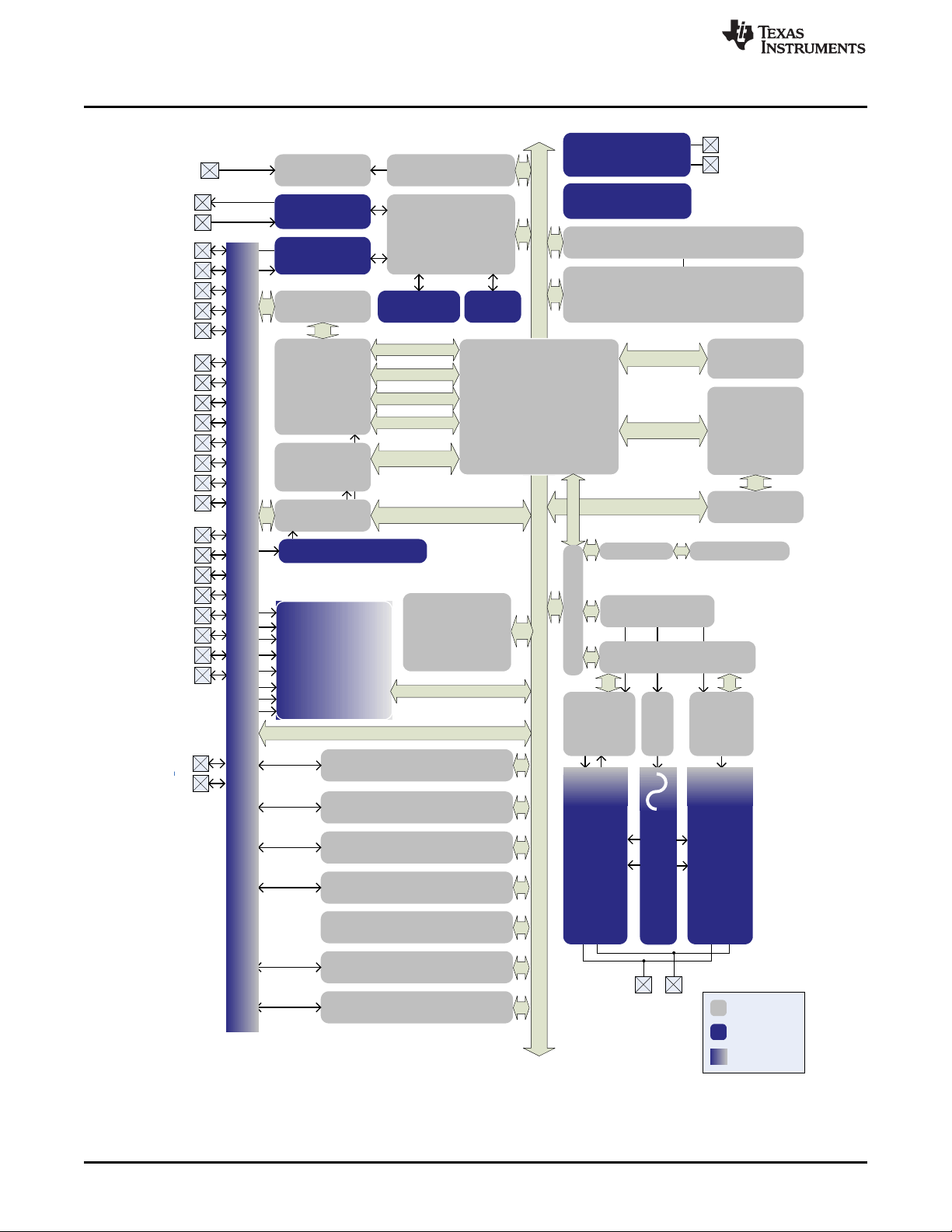

CC253x System-on-Chip Solution for 2.4-GHz

IEEE 802.15.4 and ZigBee®Applications

A

CC2540/41 System-on-Chip Solution for 2.4GHz Bluetooth®low energy Applications

User's Guide

Literature Number: SWRU191F

April 2009–Revised April 2014

Page 2

Contents

Preface....................................................................................................................................... 14

1 Introduction....................................................................................................................... 17

1.1 Overview..................................................................................................................... 18

1.1.1 CPU and Memory ................................................................................................. 21

1.1.2 Clocks and Power Management ................................................................................ 21

1.1.3 Peripherals ......................................................................................................... 21

1.1.4 Radio................................................................................................................ 23

1.2 Applications ................................................................................................................. 23

2 8051 CPU........................................................................................................................... 24

2.1 8051 CPU Introduction .................................................................................................... 25

2.2 Memory...................................................................................................................... 25

2.2.1 Memory Map....................................................................................................... 25

2.2.2 CPU Memory Space .............................................................................................. 27

2.2.3 Physical Memory .................................................................................................. 28

2.2.4 XDATA Memory Access.......................................................................................... 33

2.2.5 Memory Arbiter .................................................................................................... 33

2.3 CPU Registers.............................................................................................................. 34

2.3.1 Data Pointers ...................................................................................................... 34

2.3.2 Registers R0–R7 .................................................................................................. 35

2.3.3 Program Status Word............................................................................................. 35

2.3.4 Accumulator........................................................................................................ 36

2.3.5 B Register .......................................................................................................... 36

2.3.6 Stack Pointer....................................................................................................... 36

2.4 Instruction Set Summary .................................................................................................. 36

2.5 Interrupts .................................................................................................................... 40

2.5.1 Interrupt Masking.................................................................................................. 41

2.5.2 Interrupt Processing............................................................................................... 45

2.5.3 Interrupt Priority.................................................................................................... 47

3 Debug Interface.................................................................................................................. 50

3.1 Debug Mode ................................................................................................................ 51

3.2 Debug Communication .................................................................................................... 51

3.3 Debug Commands ......................................................................................................... 53

3.3.1 Debug Configuration.............................................................................................. 55

3.3.2 Debug Status ...................................................................................................... 55

3.3.3 Hardware Breakpoints ............................................................................................ 56

3.4 Flash Programming ........................................................................................................ 57

3.4.1 Lock Bits............................................................................................................ 57

3.5 Debug Interface and Power Modes...................................................................................... 57

3.6 Registers .................................................................................................................... 59

4 Power Management and Clocks ........................................................................................... 60

4.1 Power Management Introduction......................................................................................... 61

4.1.1 Active and Idle Modes............................................................................................ 62

4.1.2 PM1 ................................................................................................................. 62

4.1.3 PM2 ................................................................................................................. 62

2

Contents SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

4.1.4 PM3 ................................................................................................................. 62

4.2 Power-Management Control.............................................................................................. 62

4.3 Power-Management Registers ........................................................................................... 63

4.4 Oscillators and Clocks ..................................................................................................... 66

4.4.1 Oscillators .......................................................................................................... 66

4.4.2 System Clock ...................................................................................................... 66

4.4.3 32-kHz Oscillators................................................................................................. 67

4.4.4 Oscillator and Clock Registers .................................................................................. 67

4.5 Timer Tick Generation ..................................................................................................... 69

4.6 Data Retention.............................................................................................................. 69

5 Reset ................................................................................................................................ 70

5.1 Power-On Reset and Brownout Detector ............................................................................... 71

5.2 Clock-Loss Detector ....................................................................................................... 71

6 Flash Controller ................................................................................................................. 72

6.1 Flash Memory Organization............................................................................................... 73

6.2 Flash Write .................................................................................................................. 73

6.2.1 Flash-Write Procedure............................................................................................ 73

6.2.2 Writing Multiple Times to a Word ............................................................................... 74

6.2.3 DMA Flash Write .................................................................................................. 74

6.2.4 CPU Flash Write................................................................................................... 75

6.3 Flash Page Erase .......................................................................................................... 75

6.3.1 Performing Flash Erase From Flash Memory ................................................................. 76

6.3.2 Different Flash Page Size on CC2533 ......................................................................... 76

6.4 Flash DMA Trigger ......................................................................................................... 76

6.5 Flash Controller Registers ................................................................................................ 76

7 I/O Ports............................................................................................................................ 78

7.1 Unused I/O Pins ............................................................................................................ 79

7.2 Low I/O Supply Voltage ................................................................................................... 79

7.3 General-Purpose I/O....................................................................................................... 79

7.4 General-Purpose I/O Interrupts........................................................................................... 79

7.5 General-Purpose I/O DMA ................................................................................................ 80

7.6 Peripheral I/O ............................................................................................................... 80

7.6.1 Timer 1.............................................................................................................. 81

7.6.2 Timer 3.............................................................................................................. 81

7.6.3 Timer 4.............................................................................................................. 82

7.6.4 USART 0 ........................................................................................................... 82

7.6.5 USART 1 ........................................................................................................... 82

7.6.6 ADC................................................................................................................. 83

7.6.7 Operational Amplifier and Analog Comparator................................................................ 83

7.7 Debug Interface............................................................................................................. 83

7.8 32-kHz XOSC Input ........................................................................................................ 83

7.9 Radio Test Output Signals................................................................................................ 84

7.10 Power-Down Signal MUX (PMUX)....................................................................................... 84

7.11 I/O Registers................................................................................................................ 84

8 DMA Controller .................................................................................................................. 92

8.1 DMA Operation ............................................................................................................. 93

8.2 DMA Configuration Parameters .......................................................................................... 95

8.2.1 Source Address.................................................................................................... 95

8.2.2 Destination Address............................................................................................... 95

8.2.3 Transfer Count..................................................................................................... 95

8.2.4 VLEN Setting....................................................................................................... 96

8.2.5 Trigger Event....................................................................................................... 96

SWRU191F–April 2009–Revised April 2014 Contents

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

3

Page 4

www.ti.com

8.2.6 Source and Destination Increment.............................................................................. 96

8.2.7 DMA Transfer Mode .............................................................................................. 97

8.2.8 DMA Priority........................................................................................................ 97

8.2.9 Byte or Word Transfers........................................................................................... 97

8.2.10 Interrupt Mask .................................................................................................... 97

8.2.11 Mode 8 Setting ................................................................................................... 97

8.3 DMA Configuration Setup ................................................................................................. 97

8.4 Stopping DMA Transfers .................................................................................................. 98

8.5 DMA Interrupts.............................................................................................................. 98

8.6 DMA Configuration-Data Structure....................................................................................... 98

8.7 DMA Memory Access...................................................................................................... 98

8.8 DMA Registers ............................................................................................................ 101

9 Timer 1 (16-Bit Timer)........................................................................................................ 103

9.1 16-Bit Counter............................................................................................................. 104

9.2 Timer 1 Operation ........................................................................................................ 104

9.3 Free-Running Mode ...................................................................................................... 104

9.4 Modulo Mode.............................................................................................................. 105

9.5 Up-and-Down Mode ...................................................................................................... 105

9.6 Channel-Mode Control ................................................................................................... 105

9.7 Input Capture Mode ...................................................................................................... 106

9.8 Output Compare Mode................................................................................................... 106

9.9 IR Signal Generation and Learning .................................................................................... 111

9.9.1 Introduction ....................................................................................................... 111

9.9.2 Modulated Codes ................................................................................................ 111

9.9.3 Non-Modulated Codes .......................................................................................... 112

9.9.4 Learning........................................................................................................... 113

9.9.5 Other Considerations............................................................................................ 113

9.10 Timer 1 Interrupts......................................................................................................... 113

9.11 Timer 1 DMA Triggers.................................................................................................... 113

9.12 Timer 1 Registers......................................................................................................... 114

9.13 Accessing Timer 1 Registers as Array ................................................................................ 119

10 Timer 3 and Timer 4 (8-Bit Timers)...................................................................................... 120

10.1 8-Bit Timer Counter....................................................................................................... 121

10.2 Timer 3 and Timer 4 Mode Control..................................................................................... 121

10.2.1 Free-Running Mode ............................................................................................ 121

10.2.2 Down Mode...................................................................................................... 121

10.2.3 Modulo Mode.................................................................................................... 121

10.2.4 Up-and-Down Mode ............................................................................................ 121

10.3 Channel Mode Control ................................................................................................... 121

10.4 Input Capture Mode ...................................................................................................... 122

10.5 Output Compare Mode................................................................................................... 122

10.6 Timer 3 and Timer 4 Interrupts.......................................................................................... 122

10.7 Timer 3 and Timer 4 DMA Triggers .................................................................................... 123

10.8 Timer 3 and Timer 4 Registers.......................................................................................... 123

11 Sleep Timer...................................................................................................................... 128

11.1 General..................................................................................................................... 129

11.2 Timer Compare ........................................................................................................... 129

11.3 Timer Capture............................................................................................................. 129

11.4 Sleep Timer Registers ................................................................................................... 130

12 ADC ................................................................................................................................ 132

12.1 ADC Introduction.......................................................................................................... 133

12.2 ADC Operation............................................................................................................ 133

4

Contents SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

12.2.1 ADC Inputs ...................................................................................................... 133

12.2.2 ADC Conversion Sequences.................................................................................. 134

12.2.3 Single ADC Conversion........................................................................................ 134

12.2.4 ADC Operating Modes......................................................................................... 134

12.2.5 ADC Conversion Results ...................................................................................... 135

12.2.6 ADC Reference Voltage ....................................................................................... 135

12.2.7 ADC Conversion Timing ....................................................................................... 135

12.2.8 ADC Interrupts .................................................................................................. 135

12.2.9 ADC DMA Triggers............................................................................................. 135

12.2.10 ADC Registers................................................................................................. 136

13 Battery Monitor ................................................................................................................ 139

13.1 Functionality and Usage of the Battery Monitor ...................................................................... 140

13.2 Using the Battery Monitor for Temperature Monitoring.............................................................. 140

13.3 Battery Monitor Registers ............................................................................................... 141

14 Random-Number Generator ............................................................................................... 143

14.1 Introduction ................................................................................................................ 144

14.2 Random-Number-Generator Operation................................................................................ 144

14.2.1 Pseudorandom Sequence Generation....................................................................... 144

14.2.2 Seeding .......................................................................................................... 144

14.2.3 CRC16 ........................................................................................................... 144

14.3 Random-Number-Generator Registers ................................................................................ 145

15 AES Coprocessor ............................................................................................................. 146

15.1 AES Operation ............................................................................................................ 147

15.2 Key and IV ................................................................................................................. 147

15.3 Padding of Input Data.................................................................................................... 147

15.4 Interface to CPU .......................................................................................................... 147

15.5 Modes of Operation ...................................................................................................... 147

15.6 CBC-MAC.................................................................................................................. 147

15.7 CCM Mode................................................................................................................. 148

15.8 AES Interrupts............................................................................................................. 150

15.9 AES DMA Triggers ....................................................................................................... 150

15.10 AES Registers ............................................................................................................ 150

16 Watchdog Timer ............................................................................................................... 152

16.1 Watchdog Mode........................................................................................................... 153

16.2 Timer Mode................................................................................................................ 153

16.3 Watchdog Timer Register................................................................................................ 153

17 USART ............................................................................................................................ 155

17.1 UART Mode ............................................................................................................... 156

17.1.1 UART Transmit.................................................................................................. 156

17.1.2 UART Receive .................................................................................................. 156

17.1.3 UART Hardware Flow Control ................................................................................ 156

17.1.4 UART Character Format....................................................................................... 157

17.2 SPI Mode .................................................................................................................. 157

17.2.1 SPI Master Operation .......................................................................................... 157

17.2.2 SPI Slave Operation............................................................................................ 158

17.3 SSN Slave-Select Pin .................................................................................................... 158

17.4 Baud-Rate Generation ................................................................................................... 158

17.5 USART Flushing .......................................................................................................... 159

17.6 USART Interrupts......................................................................................................... 159

17.7 USART DMA Triggers.................................................................................................... 159

17.8 USART Registers......................................................................................................... 159

18 Operational Amplifier ........................................................................................................ 164

SWRU191F–April 2009–Revised April 2014 Contents

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

5

Page 6

www.ti.com

18.1 Description................................................................................................................. 165

18.2 Calibration ................................................................................................................. 165

18.3 Clock Source .............................................................................................................. 165

18.4 Registers................................................................................................................... 165

19 Analog Comparator........................................................................................................... 166

19.1 Description................................................................................................................. 167

19.2 Register .................................................................................................................... 167

20 I

2

C................................................................................................................................... 168

20.1 Operation .................................................................................................................. 169

20.1.1 I

20.1.2 I

20.1.3 I

20.1.4 I

20.1.5 I

2

C Initialization and Reset..................................................................................... 170

2

C Serial Data .................................................................................................. 170

2

C Addressing Modes ......................................................................................... 171

2

C Module Operating Modes ................................................................................. 171

2

C Clock Generation and Synchronization.................................................................. 177

20.1.6 Bus Error......................................................................................................... 178

2

C Interrupt...................................................................................................... 178

2

C Pins........................................................................................................... 178

20.2 I

20.1.7 I

20.1.8 I

2

C Registers............................................................................................................... 178

21 USB Controller ................................................................................................................. 181

21.1 USB Introduction.......................................................................................................... 182

21.2 USB Enable................................................................................................................ 182

21.3 48-MHz USB PLL......................................................................................................... 182

21.4 USB Interrupts............................................................................................................. 183

21.5 Endpoint 0 ................................................................................................................. 183

21.6 Endpoint-0 Interrupts ..................................................................................................... 183

21.6.1 Error Conditions................................................................................................. 184

21.6.2 SETUP Transactions (IDLE State) ........................................................................... 184

21.6.3 IN Transactions (TX State) .................................................................................... 184

21.6.4 OUT Transactions (RX State)................................................................................. 185

21.7 Endpoints 1–5............................................................................................................. 185

21.7.1 FIFO Management ............................................................................................. 185

21.7.2 Double Buffering ................................................................................................ 186

21.7.3 FIFO Access..................................................................................................... 187

21.7.4 Endpoint 1–5 Interrupts ........................................................................................ 187

21.7.5 Bulk or Interrupt IN Endpoint.................................................................................. 188

21.7.6 Isochronous IN Endpoint....................................................................................... 188

21.7.7 Bulk or Interrupt OUT Endpoint............................................................................... 188

21.7.8 Isochronous OUT Endpoint.................................................................................... 188

21.8 DMA ........................................................................................................................ 189

21.9 USB Reset................................................................................................................. 189

21.10 Suspend and Resume ................................................................................................... 189

21.11 Remote Wake-Up ........................................................................................................ 189

21.12 USB Registers ............................................................................................................ 190

22 Timer 2 (MAC Timer) ......................................................................................................... 197

22.1 Timer Operation........................................................................................................... 198

22.1.1 General........................................................................................................... 198

22.1.2 Up Counter ...................................................................................................... 198

22.1.3 Timer Overflow.................................................................................................. 198

22.1.4 Timer Delta Increment ......................................................................................... 198

22.1.5 Timer Compare ................................................................................................. 198

22.1.6 Overflow Count.................................................................................................. 198

22.1.7 Overflow-Count Update........................................................................................ 199

6

Contents SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

22.1.8 Overflow-Count Overflow ...................................................................................... 199

22.1.9 Overflow-Count Compare...................................................................................... 199

22.1.10 Capture Input .................................................................................................. 199

22.1.11 Long Compare (CC2541 Only).............................................................................. 199

22.2 Interrupts................................................................................................................... 199

22.3 Event Outputs (DMA Trigger and Radio Events)..................................................................... 200

22.4 Timer Start-and-Stop Synchronization ................................................................................. 200

22.4.1 General........................................................................................................... 200

22.4.2 Timer Synchronous Stop ...................................................................................... 200

22.4.3 Timer Synchronous Start ...................................................................................... 201

22.5 Timer 2 Registers......................................................................................................... 202

23 CC253x Radio................................................................................................................... 208

23.1 RF Core .................................................................................................................... 209

23.1.1 Interrupts......................................................................................................... 209

23.1.2 Interrupt Registers.............................................................................................. 209

23.2 FIFO Access............................................................................................................... 213

23.3 DMA ........................................................................................................................ 213

23.4 Memory Map .............................................................................................................. 213

23.4.1 RXFIFO .......................................................................................................... 214

23.4.2 TXFIFO........................................................................................................... 214

23.4.3 Frame-Filtering and Source-Matching Memory Map....................................................... 214

23.5 Frequency and Channel Programming ................................................................................ 215

23.6 IEEE 802.15.4-2006 Modulation Format............................................................................... 215

23.7 IEEE 802.15.4-2006 Frame Format.................................................................................... 217

23.7.1 PHY Layer ....................................................................................................... 217

23.7.2 MAC Layer....................................................................................................... 217

23.8 Transmit Mode ............................................................................................................ 218

23.8.1 TX Control ....................................................................................................... 218

23.8.2 TX State Timing................................................................................................. 218

23.8.3 TXFIFO Access ................................................................................................. 218

23.8.4 Retransmission.................................................................................................. 219

23.8.5 Error Conditions................................................................................................. 219

23.8.6 TX Flow Diagram ............................................................................................... 219

23.8.7 Transmitted Frame Processing ............................................................................... 221

23.8.8 Synchronization Header ....................................................................................... 221

23.8.9 Frame-Length Field............................................................................................. 221

23.8.10 Frame Check Sequence ..................................................................................... 221

23.8.11 Interrupts ....................................................................................................... 222

23.8.12 Clear-Channel Assessment.................................................................................. 222

23.8.13 Output Power Programming................................................................................. 222

23.8.14 Tips and Tricks ................................................................................................ 222

23.9 Receive Mode ............................................................................................................ 222

23.9.1 RX Control....................................................................................................... 222

23.9.2 RX State Timing ................................................................................................ 223

23.9.3 Received-Frame Processing .................................................................................. 223

23.9.4 Synchronization Header and Frame-Length Fields ........................................................ 224

23.9.5 Frame Filtering .................................................................................................. 224

23.9.6 Source Address Matching ..................................................................................... 227

23.9.7 Frame-Check Sequence....................................................................................... 230

23.9.8 Acknowledgement Transmission ............................................................................. 230

23.10 RXFIFO Access........................................................................................................... 232

23.10.1 Using the FIFO and FIFOP .................................................................................. 232

23.10.2 Error Conditions ............................................................................................... 233

SWRU191F–April 2009–Revised April 2014 Contents

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

7

Page 8

www.ti.com

23.10.3 RSSI ............................................................................................................ 233

23.10.4 Link Quality Indication ........................................................................................ 234

23.11 Radio-Control State Machine ........................................................................................... 234

23.12 Random-Number Generation ........................................................................................... 236

23.13 Packet Sniffing and Radio Test Output Signals...................................................................... 237

23.14 Command Strobe Processor............................................................................................ 238

23.14.1 Instruction Memory............................................................................................ 238

23.14.2 Data Registers................................................................................................. 239

23.14.3 Program Execution............................................................................................ 239

23.14.4 Interrupt Requests ............................................................................................ 239

23.14.5 Random Number Instruction................................................................................. 239

23.14.6 Running CSP Programs...................................................................................... 239

23.14.7 Registers ....................................................................................................... 240

23.14.8 Instruction Set Summary..................................................................................... 241

23.14.9 Instruction Set Definition ..................................................................................... 243

23.15 Registers................................................................................................................... 255

23.15.1 Register Settings Update..................................................................................... 256

23.15.2 Register Access Modes ...................................................................................... 256

23.15.3 Register Descriptions ......................................................................................... 257

24 CC2540 and CC2541 Bluetooth low energy Radio .................................................................. 275

24.1 Registers................................................................................................................... 276

25 CC2541 Proprietary Mode Radio......................................................................................... 278

25.1 RF Core .................................................................................................................... 279

25.2 Interrupts................................................................................................................... 279

25.2.1 Interrupt Registers.............................................................................................. 279

25.3 RF Core Data Memory................................................................................................... 280

25.3.1 FIFOs............................................................................................................. 281

25.3.2 DMA .............................................................................................................. 284

25.3.3 RAM-Based Registers ......................................................................................... 285

25.3.4 Variables in RAM Page 5...................................................................................... 291

25.4 Bit-Stream Processor..................................................................................................... 291

25.4.1 Whitening ........................................................................................................ 291

25.4.2 CC2500-Compatible PN9 Whitening......................................................................... 292

25.4.3 CRC .............................................................................................................. 293

25.4.4 Coprocessor Mode ............................................................................................. 295

25.5 Frequency and Channel Programming ................................................................................ 296

25.6 Modulation Formats ...................................................................................................... 296

25.7 Receiver.................................................................................................................... 296

25.8 Packet Format............................................................................................................. 297

25.8.1 RX FIFO Packet Organization ................................................................................ 299

25.8.2 TX FIFO Packet Organization................................................................................. 300

25.8.3 TX Buffers for ACK Payload................................................................................... 300

25.9 Link Layer Engine......................................................................................................... 301

25.9.1 Command Register............................................................................................. 302

25.9.2 Radio Tasks ..................................................................................................... 302

25.9.3 RF Test Commands............................................................................................ 317

25.10 Random Number Generation ........................................................................................... 318

25.11 Packet Sniffing............................................................................................................ 319

25.12 Registers................................................................................................................... 320

25.12.1 Register Overview............................................................................................. 320

25.12.2 Register Settings Update..................................................................................... 321

25.12.3 SFR Register Descriptions................................................................................... 322

26 Voltage Regulator ............................................................................................................. 342

8

Contents SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

27 Available Software ............................................................................................................ 343

27.1 SmartRF™ Software for Evaluation (www.ti.com/smartrfstudio) ................................................... 344

27.2 RemoTI™ Network Protocol (www.ti.com/remoti).................................................................... 344

27.3 SimpliciTI™ Network Protocol (www.ti.com/simpliciti) ............................................................... 345

27.4 TIMAC Software (www.ti.com/timac)................................................................................... 345

27.5 Z-Stack™ Software (www.ti.com/z-stack) ............................................................................. 346

27.6 BLE Stack Software ...................................................................................................... 346

A Abbreviations................................................................................................................... 347

B Additional Information....................................................................................................... 350

B.1 Texas Instruments Low-Power RF Web Site ......................................................................... 351

B.2 Low-Power RF Online Community ..................................................................................... 351

B.3 Texas Instruments Low-Power RF Developer Network.............................................................. 351

B.4 Low-Power RF eNewsletter ............................................................................................. 351

C References....................................................................................................................... 352

Revision History ........................................................................................................................ 353

SWRU191F–April 2009–Revised April 2014 Contents

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

9

Page 10

www.ti.com

List of Figures

1-1. CC253x Block Diagram.................................................................................................... 18

1-2. CC2540 Block Diagram ................................................................................................... 19

1-3. CC2541 Block Diagram ................................................................................................... 20

2-1. XDATA Memory Space (Showing SFR and DATA Mapping) ........................................................ 26

2-2. CODE Memory Space ..................................................................................................... 26

2-3. CODE Memory Space for Running Code From SRAM ............................................................... 26

2-4. Interrupt Overview.......................................................................................................... 43

3-1. External Debug Interface Timing......................................................................................... 51

3-2. Transmission of One Byte................................................................................................. 51

3-3. Typical Command Sequence—No Extra Wait for Response......................................................... 52

3-4. Typical Command Sequence. Wait for Response ..................................................................... 53

3-5. Burst Write Command (First 2 Bytes) ................................................................................... 55

4-1. Clock System Overview ................................................................................................... 65

6-1. Flash Write Using DMA.................................................................................................... 75

8-1. DMA Operation ............................................................................................................. 94

8-2. Variable Length (VLEN) Transfer Options .............................................................................. 96

9-1. Free-Running Mode ...................................................................................................... 104

9-2. Modulo Mode.............................................................................................................. 105

9-3. Up-and-Down Mode ...................................................................................................... 105

9-4. Output Compare Modes, Timer Free-Running Mode ................................................................ 108

9-5. Output Compare Modes, Timer Modulo Mode........................................................................ 109

9-6. Output Compare Modes, Timer Up-and-Down Mode................................................................ 110

9-7. Block Diagram of Timers in IR-Generation Mode .................................................................... 112

9-8. Modulated Waveform Example ......................................................................................... 112

9-9. IR Learning Board Diagram ............................................................................................. 113

11-1. Sleep Timer Capture (Example Using Rising Edge on P0_0)...................................................... 130

12-1. ADC Block Diagram ...................................................................................................... 133

14-1. Basic Structure of the Random-Number Generator.................................................................. 144

15-1. Message Authentication Phase Block B0 ............................................................................. 148

15-2. Authentication Flag Byte................................................................................................. 148

15-3. Message Encryption Phase Block...................................................................................... 149

15-4. Encryption Flag Byte ..................................................................................................... 149

19-1. Analog Comparator....................................................................................................... 167

20-1. Block Diagram of the I

20-2. I

20-3. I

2

C Bus Connection Diagram............................................................................................ 170

2

C Module Data Transfer................................................................................................ 170

20-4. Bit Transfer on I

20-5. I

20-6. I

2

C Module 7-Bit Addressing Format ................................................................................... 171

2

C Module Addressing Format With Repeated START Condition................................................. 171

20-7. Arbitration Procedure Between Two Master Transmitters........................................................... 177

20-8. Synchronization of Two I

21-1. USB Controller Block Diagram.......................................................................................... 182

21-2. IN and OUT FIFOs ....................................................................................................... 186

23-1. Modulation................................................................................................................. 216

23-2. I/Q Phases When Transmitting a Zero-Symbol Chip Sequence, t

23-3. Schematic View of the IEEE 802.15.4 Frame Format [1] ........................................................... 217

23-4. Format of the Frame Control Field (FCF) ............................................................................. 217

2

C Module ....................................................................................... 169

2

C Bus................................................................................................... 171

2

C Clock Generators During Arbitration .................................................. 177

= 0.5 μs ..................................... 216

C

10

List of Figures SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

23-5. Frame Data Written to the TXFIFO..................................................................................... 219

23-6. TX Flow .................................................................................................................... 220

23-7. Single Transmitted Frame............................................................................................... 221

23-8. Transmitted Synchronization Header .................................................................................. 221

23-9. FCS Hardware Implementation......................................................................................... 222

23-10. Single Received Frame and Transmitted Acknowledgment Frame................................................ 223

23-11. SFD Signal Timing........................................................................................................ 224

23-12. Filtering Scenarios (Exceptions Generated During Reception)..................................................... 226

23-13. Matching Algorithm for Short and Extended Addresses............................................................. 228

23-14. Interrupts Generated by Source Address Matching.................................................................. 229

23-15. Data in RXFIFO for Different Settings ................................................................................. 230

23-16. Acknowledge Frame Format ............................................................................................ 230

23-17. Acknowledgment Timing................................................................................................. 231

23-18. Command Strobe Timing ................................................................................................ 231

23-19. Behavior of FIFO and FIFOP Signals.................................................................................. 233

23-20. Main FSM.................................................................................................................. 235

23-21. FFT of the Random Bytes ............................................................................................... 236

23-22. Histogram of 20 Million Bytes Generated With the RANDOM Instruction......................................... 236

23-23. Running a CSP Program ................................................................................................ 240

23-24. Example Hardware Structure for the R* Register Access Mode ................................................... 256

25-1. Mapping of Radio Memory to MCU XDATA Memory Space........................................................ 281

25-2. FIFO Pointers ............................................................................................................. 281

25-3. PN7 Whitening ............................................................................................................ 292

25-4. CC2500-Compatible Whitening ......................................................................................... 293

25-5. CRC Module............................................................................................................... 294

25-6. Air Interface Packet Format for Basic Mode .......................................................................... 297

25-7. Air Interface Packet Format for Auto Mode ........................................................................... 298

25-8. Bits of 9-Bit Header....................................................................................................... 298

25-9. Bits of 10-Bit Header ..................................................................................................... 298

25-10. Structure of Packets in the RX FIFO................................................................................... 299

25-11. Structure of Packets in the TX FIFO ................................................................................... 300

25-12. Timing of Packets in RX Tasks ......................................................................................... 316

25-13. Timing of Packets in TX Tasks.......................................................................................... 317

25-14. Complete Appended Packet............................................................................................. 319

SWRU191F–April 2009–Revised April 2014 List of Figures

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

11

Page 12

www.ti.com

List of Tables

0-1. CC253x Family Overview ................................................................................................. 15

0-2. Register Bit Conventions .................................................................................................. 16

2-1. SFR Overview .............................................................................................................. 29

2-2. Overview of XREG Registers............................................................................................. 32

2-3. Instruction Set Summary .................................................................................................. 37

2-4. Instructions That Affect Flag Settings ................................................................................... 40

2-5. Interrupts Overview ........................................................................................................ 41

2-6. Priority Level Setting....................................................................................................... 48

2-7. Interrupt Priority Groups................................................................................................... 48

2-8. Interrupt Polling Sequence................................................................................................ 49

3-1. Debug Commands ......................................................................................................... 53

3-2. Debug Configuration....................................................................................................... 55

3-3. Debug Status ............................................................................................................... 55

3-4. Relation Between PCON_IDLE and PM_ACTIVE.......................................................................... 56

3-5. Flash Lock-Protection Bit Structure Definition.......................................................................... 57

4-1. Power Modes ............................................................................................................... 61

6-1. Example Write Sequence ................................................................................................. 74

7-1. Peripheral I/O Pin Mapping ............................................................................................... 81

8-1. DMA Trigger Sources...................................................................................................... 98

8-2. DMA Configuration-Data Structure....................................................................................... 99

9-1. Initial Compare Output Values (Compare Mode)..................................................................... 107

9-2. Frequency Error Calculation for 38-kHz Carrier ...................................................................... 111

10-1. Initial Compare Output Values (Compare Mode)..................................................................... 122

13-1. Values Showing How Different Temperatures Relate to BATTMON_VOLTAGE for a Typical Device........ 140

13-2. Values for A and B (for a Typical Device) When Using the Battery monitor for Temperature Monitoring .... 141

17-1. Commonly Used Baud-Rate Settings for 32 MHz System Clock................................................... 158

20-1. Slave Transmitter Mode.................................................................................................. 172

20-2. Slave Receiver Mode..................................................................................................... 173

20-3. Master Transmitter Mode................................................................................................ 175

20-4. Master Receiver Mode................................................................................................... 176

20-5. Miscellaneous States..................................................................................................... 178

20-6. Clock Rates Defined at 32 MHz ........................................................................................ 179

21-1. USB Interrupt Flags Interrupt-Enable Mask Registers............................................................... 183

21-2. FIFO Sizes for EP 1–5 ................................................................................................... 186

22-1. Internal Registers ......................................................................................................... 203

23-1. Frame Filtering and Source Matching Memory Map ................................................................. 214

23-2. IEEE 802.15.4-2006 Symbol-to-Chip Mapping ....................................................................... 216

23-3. FSM State Mapping ...................................................................................................... 236

23-4. Instruction Set Summary................................................................................................. 242

23-5. Register Overview ........................................................................................................ 255

23-6. Registers That Require Update From Their Default Value.......................................................... 256

23-7. Register-Bit Access Modes.............................................................................................. 256

25-1. Radio RAM Pages........................................................................................................ 280

25-2. Commands to FIFO via RFST Register ............................................................................... 283

25-3. Access to FIFO Registers ............................................................................................... 283

25-4. RAM-Based Registers.................................................................................................... 285

25-5. Address Structure for Auto Mode....................................................................................... 289

12

List of Tables SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

25-6. Address Structure for Basic Mode...................................................................................... 290

25-7. RAM-Based Registers in RAM Page 5 ................................................................................ 291

25-8. Register Settings for Different CRCs................................................................................... 294

25-9. Register Settings for Some Commonly Used CRCs, Assuming Initialization With All 1s....................... 295

25-10. Supported Modulation Formats, Data Rates, and Deviations....................................................... 296

25-11. Segments for Holding ACK Payload for Each Address Entry....................................................... 300

25-12. Commands From MCU to LL Engine via RFST Register ........................................................... 302

25-13. Timer 2 Capture Settings ................................................................................................ 304

25-14. End-of-Task Causes...................................................................................................... 304

25-15. Recommended RAM Register Settings for Start Tone .............................................................. 306

25-16. Interrupt and Counter Operation for Received Messages........................................................... 307

25-17. Interrupt and Counter Operation for Received Messages........................................................... 308

25-18. End-of-Receive Tasks.................................................................................................... 310

25-19. Interrupt and Counter Operation for Received ACK Packets....................................................... 312

25-20. End-of-Transmit Tasks................................................................................................... 313

25-21. Additional Reasons for End-of-Transmit on Clear-Channel Tasks................................................. 315

25-22. Packet-Sniffer Modes of Operation..................................................................................... 319

25-23. XREG Register Overview................................................................................................ 320

25-24. Registers That Should Be Updated From Their Default Value, Bit Rates 1 Mbps and Lower ................. 321

25-25. Registers That Should Be Updated From Their Default Value, Bit Rate 2 Mbps ................................ 321

SWRU191F–April 2009–Revised April 2014 List of Tables

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

13

Page 14

About This Manual

The CC2540 and CC2541 are cost-effective, low-power, and true system-on-chip (SoC) solutions for

Bluetooth low energy applications. They enable robust BLE master or slave nodes to be built with very low

total bill-of-material costs. The CC2540 and CC2541 combine the excellent performance of a leading RF

transceiver with an industry-standard enhanced 8051 MCU, in-system programmable flash memory, 8-KB

RAM, and many other powerful supporting features and peripherals. The CC2540 and CC2541 are suited

for systems where very low power consumption is required. Very low-power sleep modes are available.

Short transition times between operating modes further enable low power consumption.

The CC2540 comes in two different versions: CC2540F128 and CC2540F256, with 128 KB and 256 KB of

flash memory, respectively.

The CC2541 comes in two different versions: CC2541F128 and CC2541F256, with 128 KB and 256 KB of

flash memory, respectively.

The CC2541F128/F256 comes in two different versions: CC2541F128/F256, with 128 and 256 KB of flash

memory, respectively.

Combined with the Bluetooth low-energy protocol stack from Texas Instruments, the

CC2540F128/CC2540F256 and CC2541F128/CC2541F256 constitute the market’s most comprehensive

single-mode Bluetooth low energy solution.

The CC253x System-on-Chip solution for 2.4 GHz is suitable for a wide range of applications. These can

easily be built on top of the IEEE 802.15.4 based standard protocols (RemoTI™ network protocol, TIMAC

software, and Z-Stack™ software for ZigBee®compliant solutions) or on top of the proprietary SimpliciTI™

network protocol. The usage is, however, not limited to these protocols alone. The CC253x family is, for

example, also suitable for 6LoWPAN and Wireless HART implementations.

Each chapter of this manual describes details of a module or peripheral; however, not all features are

present on all devices. To see the differences regarding features, see Table 0-1 in the Devices section.

For detailed technical numbers, such as power consumption and RF performance, see the device-specific

data sheet (Appendix C).

Preface

SWRU191F–April 2009–Revised April 2014

Read This First

Related Documentation and Software From Texas Instruments

Related documentation (for example, the CC2530 data sheet http://www-s.ti.com/sc/techlit/swrs081 and

CC2540 data sheet http://www-s.ti.com/sc/techlit/swrs084) can be found in Appendix C.

For more information regarding software that can be used with the CC253x, CC2540, or CC2541 Systemon-Chip solution (for example, SmartRF™ software for radio performance and functionality evaluation),

see Chapter 27, which also contains more information regarding the RemoTI network protocol, the

SimpliciTI network protocol, the TIMAC software, the Z-Stack software, and the BLE stack software.

SmartRF, RemoTI, SimpliciTI, Z-Stack are trademarks of Texas Instruments.

Bluetooth is a registered trademark of Bluetooth SIG, Inc.

Microsoft, Windows are trademarks of Microsoft Corporation.

ZigBee is a registered trademark of ZigBee Alliance.

14

Read This First SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

FCC Warning

This equipment generates, uses, and can radiate radio frequency energy and has not been tested for

compliance with the limits of computing devices pursuant to subpart J of part 15 of FCC rules, which are

designed to provide reasonable protection against radio frequency interference. Operation of this

equipment in other environments may cause interference with radio communications, in which case the

user at his own expense will be required to take whatever measures may be required to correct this

interference.

If You Need Assistance

All technical support is channeled through the TI Product Information Centers (PIC) - www.ti.com/support.

To send an E-mail request, please enter your contact information, along with your request at the following

link – PIC request form.

Also visit the Low Power RF, ZigBee, and Bluetooth low energy sections of the TI E2E Community

(www.ti.com/lprf-forum), where you can easily get in touch with other CC253x, CC2540, and CC2541

users and find FAQs, Design Notes, Application Notes, Videos, and so forth.

Glossary

Abbreviations used in this user guide can be found in Appendix A.

Devices

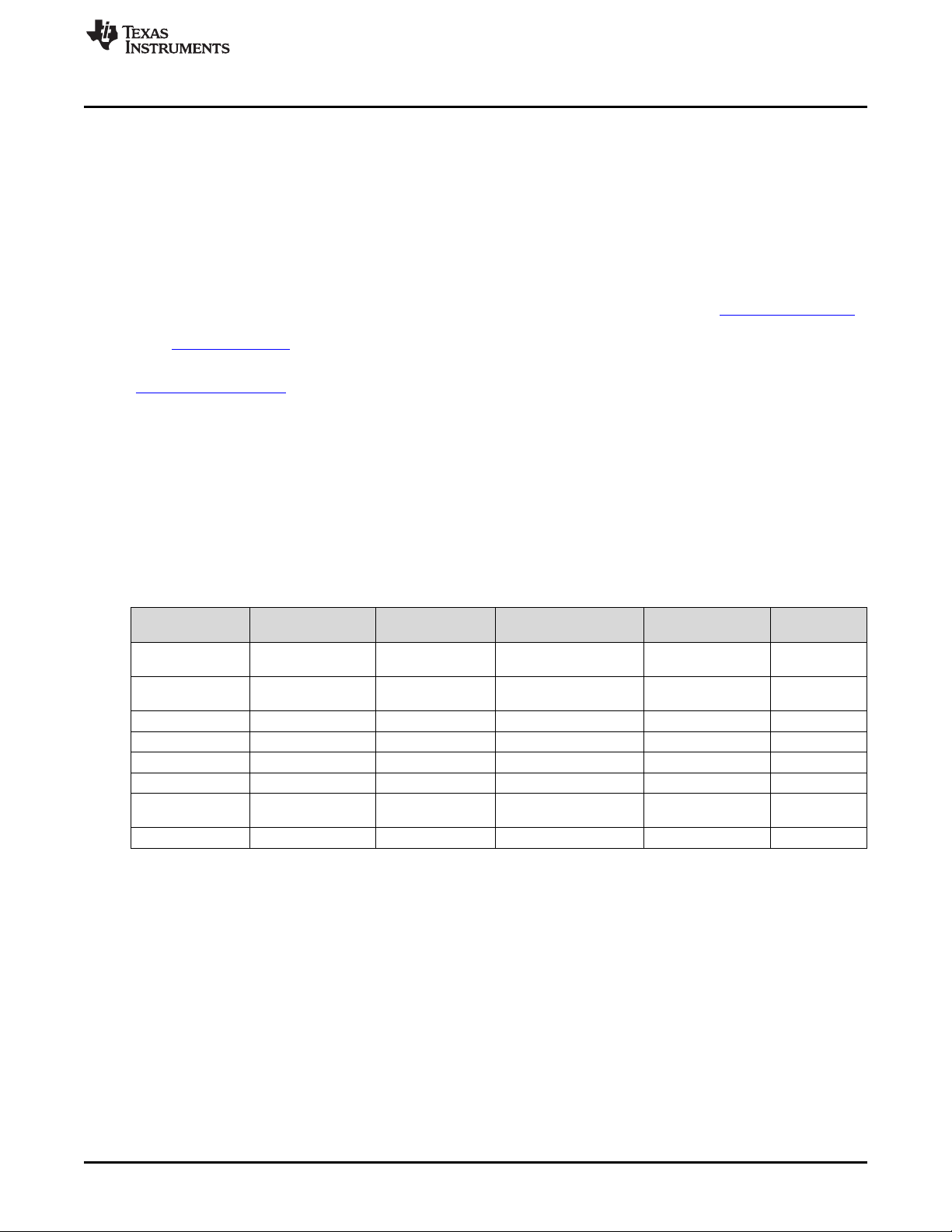

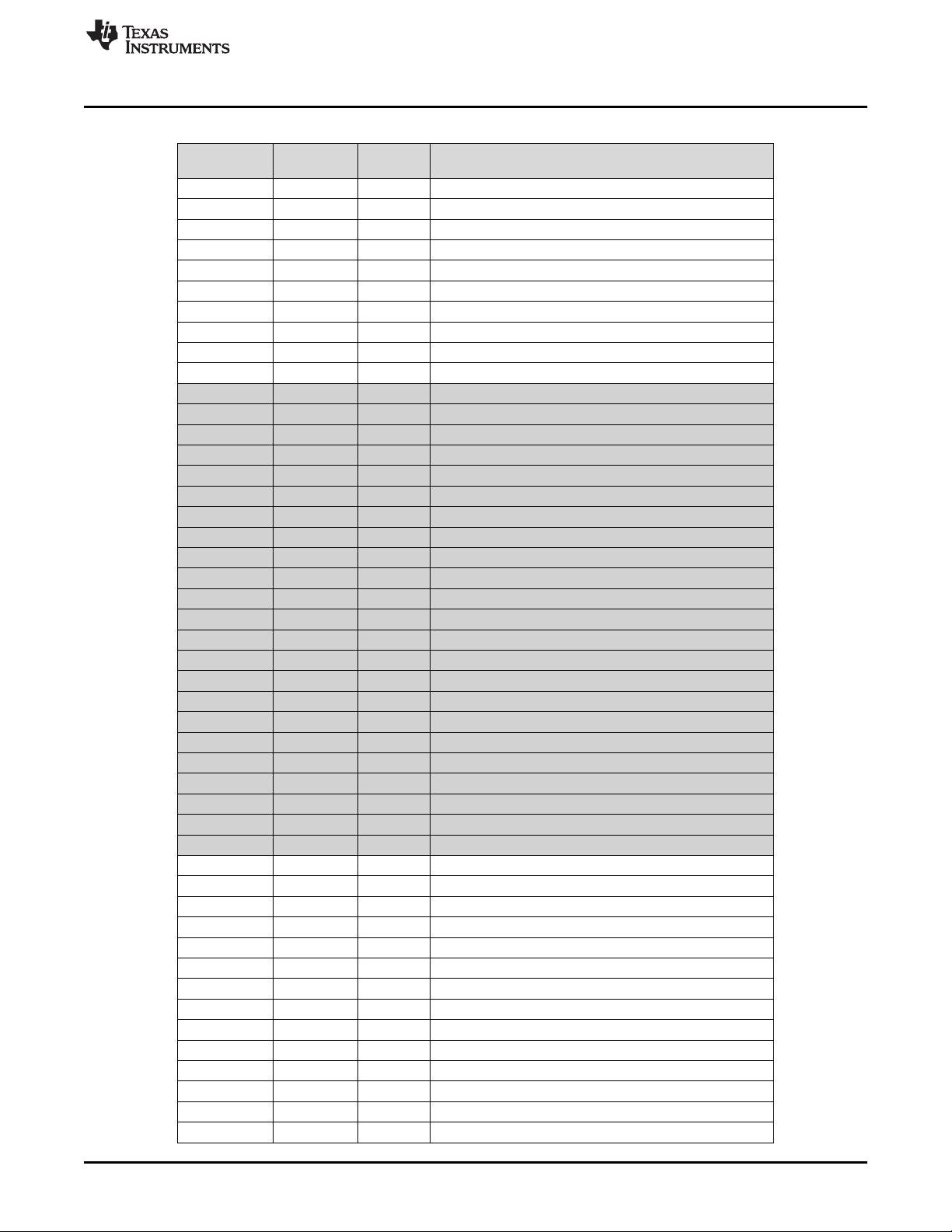

The CC253x System-on-Chip solution family consists of several devices. The following table provides a

device overview and points out the differences regarding memory sizes and peripherals. For a complete

feature list of any of the devices, see the corresponding data sheet (Appendix C).

FCC Warning

Table 0-1. CC253x Family Overview

Feature

FLASH_SIZE 128 KB, 256 KB 32 KB, 64 KB, 96 KB 128 KB, 256 KB

SRAM_SIZE 8 KB, 8 KB 4 KB, 4 KB, 6 KB 8 KB 8 KB

USB Not included Included Not included Included Not included

ADC Included Included Not included Included Included

Battery monitor Not included Not included Included Not included Not included

I2C Not included Not included Included Not included Included

Operational

amplifier

Analog comparator Included Included Not included Included Included

CC2530F32, -F64, CC2531F128, CC2533F32, CC2540F128, CC2541F128,

-F128/, -F256 CC2531F256 -F64, -F96 -F256 -F256

32 KB, 64 KB, 128 KB,

128 KB, 256 KB 256 KB

8 KB, 8 KB, 8 KB,

8 KB

Included Included Not included Included Not included

Legend:

FLASH_SIZE – The size of the flash

SRAM_SIZE – The size of the SRAM

SWRU191F–April 2009–Revised April 2014 Read This First

Submit Documentation Feedback

Copyright © 2009–2014, Texas Instruments Incorporated

15

Page 16

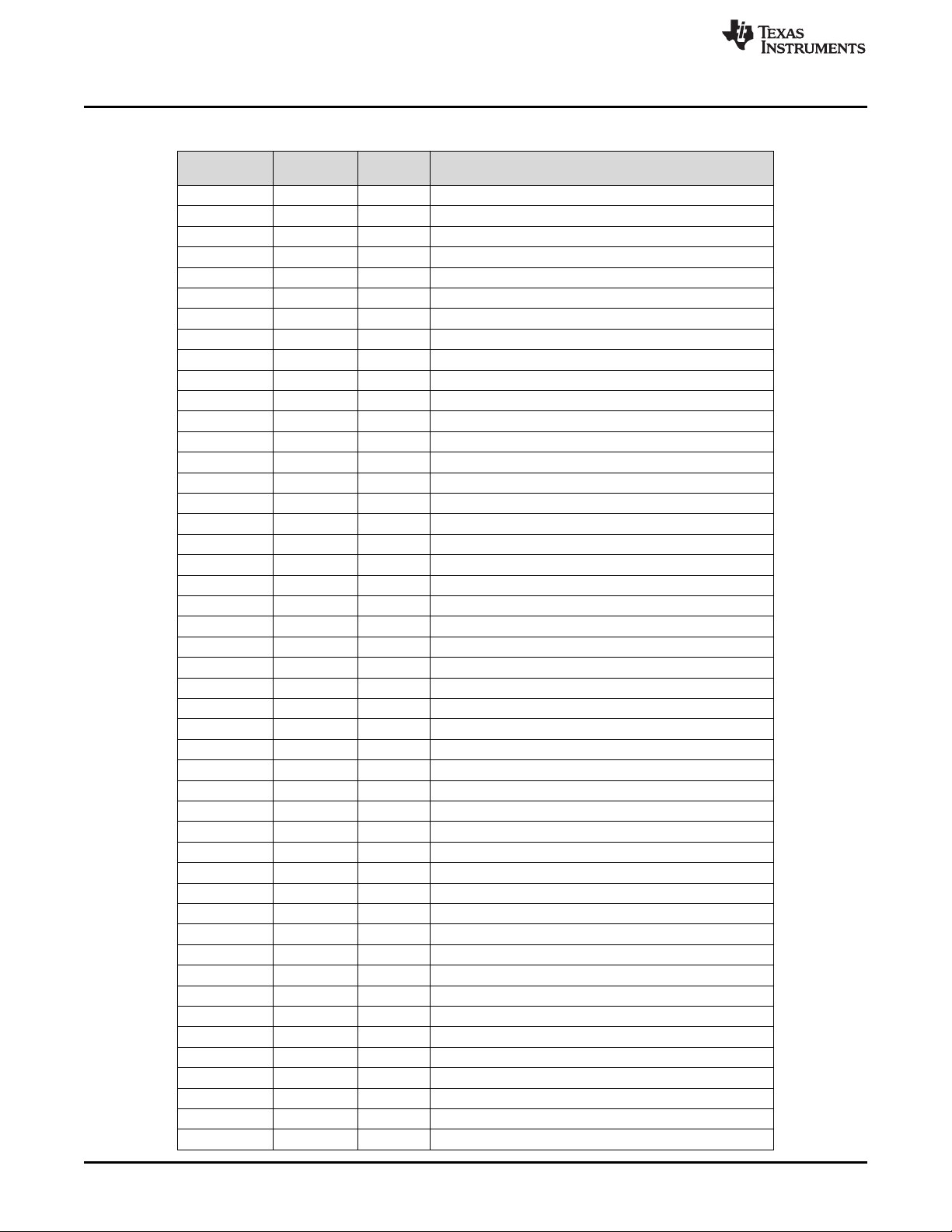

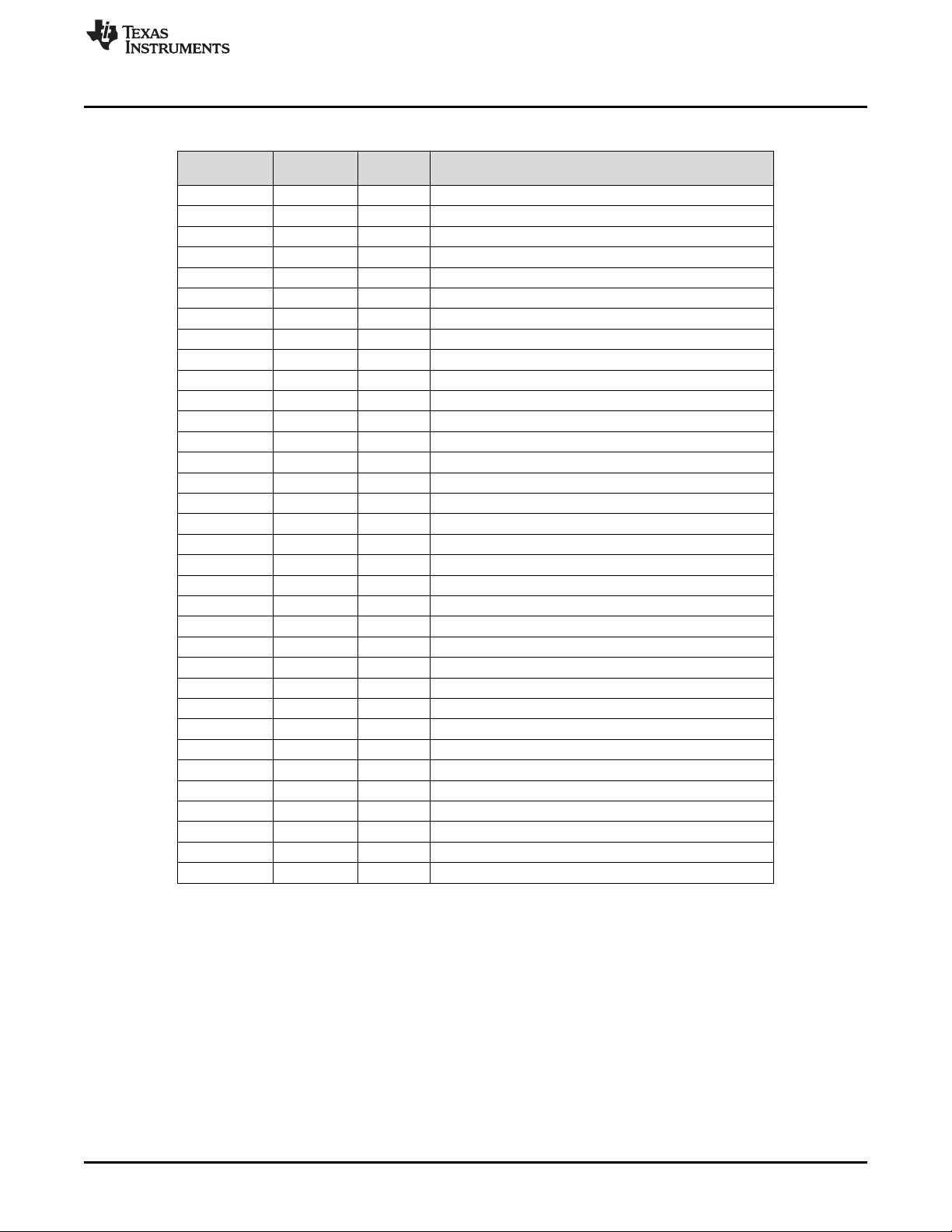

Register Conventions

Register Conventions

Each SFR and XREG register is described in a separate table, where each table title contains the

following information in the format indicated:

For SFR registers: REGISTER NAME (SFR address) – register description

For XREG registers: REGISTER NAME (XDATA address) – register description

Each table has five columns to describe the different register fields as described in the following:

Column 1 – Bit: Denotes which bits of the register are described and addressed in the specific row

Column 2 – Name: Specific name of the register field

Column 3 – Reset: Reset or initial value of the register field

Column 4 – R/W: Key indicating the accessibility of the bits in the field (see Table 0-2 for more details)

Column 5 – Description: More details about the register field, and often a description of the functions of

the different values

In the register descriptions, each register field is shown with a symbol (R/W) indicating the access mode of

the register field. The register values are always given in binary notation unless prefixed by 0x, which

indicates hexadecimal notation.

www.ti.com

Table 0-2. Register Bit Conventions

SYMBOL ACCESS MODE

R/W Read and write

R Read-only

R0 Read as 0

R1 Read as 1

W Write-only

W0 Write as 0

W1 Write as 1

H0 Hardware clear

H1 Hardware set

16

Read This First SWRU191F–April 2009–Revised April 2014

Copyright © 2009–2014, Texas Instruments Incorporated

Submit Documentation Feedback