Page 1

CC1010

SWRS047 Page 1 of 152

CC1010

Single Chip Very Low Power RF Transceiver with

8051-Compatible Microcontroller

Applications

Very low power UHF wireless data

transmitters and receivers

315 / 433 / 868 and 915 MHz ISM/SRD

band systems

Home automation and security

AMR – Automatic Meter Reading

RKE – Remote Keyless Entry with

acknowledgement

Low power telemetry

Toys

Product Description

The

CC1010

is a true single-chip UHF

transceiver with an integrated high

performance 8051 microcontroller with 32

kB of Flash program memory. The RF

transceiver can be programmed for

operation in the 300 – 1000 MHz range,

and is designed for very low power

wireless applications.

The

CC1010

together with a few external

passive components constitutes a

powerful embedded system with wireless

communication capabilities.

CC1010

is based on Chipcon’s SmartRF02

technology in 0.35 m CMOS.

Key Features

300-1000 MHz RF Transceiver

Very low current consumption (9.1

mA in RX)

High sensitivity (typically -107 dBm)

Programmable output power up to

+10 dBm

Data rate up to 76.8 kbps

Very few external components

Fast PLL settling allowing frequency

hopping protocols

RSSI

EN 300 220 and FCC CFR47 part

15 compliant

8051-Compatible Microcontroller

Typically 2.5 times the performance

of a standard 8051

32 kB Flash, 2048 + 128 Byte SRAM

3 channel 10 bit ADC, 4 timers / 2

PWMs, 2 UARTs, RTC, Watchdog,

SPI, DES encryption, 26 general I/O

pins

In-circuit interactive debugging is

supported for the Keil Vision2 IDE

through a simple serial interface.

2.7 - 3.6 V supply voltage

64-lead TQFP

Page 2

CC1010

SWRS047 Page 2 of 152

Table Of Contents

1. FEATURES..................................................................................................................... 4

2. ABSOLUTE MAXIMUM RATINGS ................................................................................ 5

3. RECOMMENDED OPERATING CONDITIONS............................................................. 5

4. DC CHARACTERISTICS ............................................................................................... 6

5. ELECTRICAL SPECIFICATIONS.................................................................................. 7

6. ADC ................................................................................................................................ 8

7. RF SECTION, GENERAL .............................................................................................. 8

8. RF TRANSMIT SECTION .............................................................................................. 9

9. RF RECEIVE SECTION ............................................................................................... 10

10. IF SECTION.................................................................................................................. 11

11. FREQUENCY SYNTHESIZER SECTION.................................................................... 12

12. PIN CONFIGURATION ................................................................................................ 13

13. PIN DESCRIPTION ...................................................................................................... 15

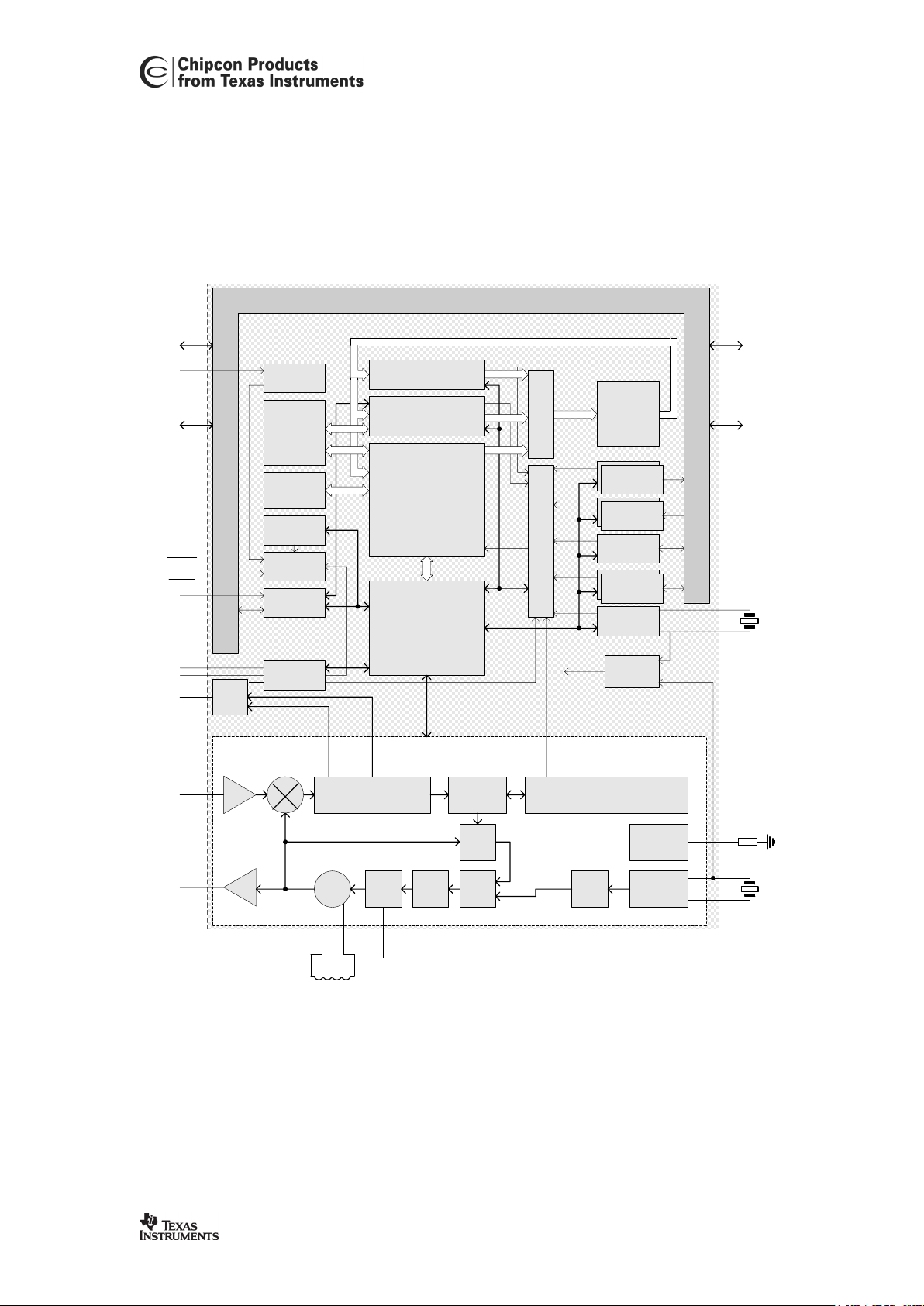

14. BLOCK DIAGRAM....................................................................................................... 18

15. 8051 CORE .................................................................................................................. 19

15.1 GENERAL DESCRIPTION............................................................................................ 19

15.2 RESET..................................................................................................................... 19

15.3 MEMORY MAP ......................................................................................................... 20

15.4 CPU REGISTERS ..................................................................................................... 23

15.5 INSTRUCTION SET SUMMARY.................................................................................... 24

15.6 INTERRUPTS ............................................................................................................ 28

15.7 EXTERNAL INTERRUPTS............................................................................................ 32

15.8 MAIN CRYSTAL OSCILLATOR..................................................................................... 32

15.9 POWER AND CLOCK MODES ..................................................................................... 34

15.10 FLASH PROGRAM MEMORY ...................................................................................... 37

15.11 SPI FLASH PROGRAMMING....................................................................................... 37

15.12 SERIAL PROGRAMMING ALGORITHM.......................................................................... 37

15.13 8051 FLASH PROGRAMMING .................................................................................... 42

15.14 FLASH POWER CONTROL ......................................................................................... 44

15.15 IN CIRCUIT DEBUGGING............................................................................................ 44

15.16 CHIP VERSION / REVISION ........................................................................................ 45

16. 8051 PERIPHERALS ................................................................................................... 47

16.1 GENERAL PURPOSE I/O ........................................................................................... 47

16.2 TIMER 0 / TIMER 1.................................................................................................... 52

16.3 TIMER 2 / 3 WITH PWM ............................................................................................ 59

16.4 POWER ON RESET (BROWN-OUT DETECTION) .......................................................... 62

16.5 WATCHDOG TIMER................................................................................................... 63

16.6 REAL-TIME CLOCK ................................................................................................... 65

16.7 SERIAL PORT 0 AND 1 .............................................................................................. 66

16.8 SPI MASTER ........................................................................................................... 71

16.9 DES ENCRYPTION / DECRYPTION ............................................................................. 75

16.10 RANDOM BIT GENERATION ....................................................................................... 78

16.11 ADC ....................................................................................................................... 79

17. RF TRANSCEIVER ...................................................................................................... 83

17.1 GENERAL DESCRIPTION............................................................................................ 83

17.2 RF TRANSCEIVER BLOCK DIAGRAM .......................................................................... 83

17.3 RF APPLICATION CIRCUIT ........................................................................................ 85

17.4 TRANSCEIVER CONFIGURATION OVERVIEW ............................................................... 88

17.5 RF TRANSCEIVER RX/TX CONTROL AND POWER MANAGEMENT ................................. 89

17.6 DATA MODEM AND DATA MODES .............................................................................. 91

17.7 BAUD RATES............................................................................................................ 94

17.8 TRANSMITTING AND RECEIVING DATA ........................................................................ 95

Page 3

CC1010

SWRS047 Page 3 of 152

17.9 DEMODULATION AND DATA DECISION......................................................................... 97

17.10 SYNCHRONIZATION AND PREAMBLE DETECTION ....................................................... 102

17.11 RECEIVER SENSITIVITY VERSUS DATA RATE AND FREQUENCY SEPARATION................ 105

17.12 FREQUENCY PROGRAMMING................................................................................... 107

17.13 LOCK INDICATION................................................................................................... 110

17.14 RECOMMENDED SETTINGS FOR ISM FREQUENCIES................................................. 111

17.15 VCO..................................................................................................................... 113

17.16 VCO AND PLL SELF-CALIBRATION .......................................................................... 113

17.17 VCO, LNA AND BUFFER CURRENT CONTROL........................................................... 118

17.18 INPUT / OUTPUT MATCHING .................................................................................... 120

17.19 OUTPUT POWER PROGRAMMING ............................................................................ 123

17.20 RSSI OUTPUT ....................................................................................................... 126

17.21 IF OUTPUT ............................................................................................................. 127

17.22 OPTIONAL LC FILTER ............................................................................................. 128

18. RESERVED REGISTERS AND TEST REGISTERS ................................................. 129

19. SYSTEM CONSIDERATIONS AND GUIDELINES ................................................... 131

19.1 SRD REGULATIONS................................................................................................ 131

19.2 LOW COST SYSTEMS .............................................................................................. 131

19.3 BATTERY OPERATED SYSTEMS................................................................................ 131

19.4 NARROW-BAND SYSTEMS ....................................................................................... 131

19.5 HIGH RELIABILITY SYSTEMS .................................................................................... 131

19.6 FREQUENCY HOPPING SPREAD SPECTRUM SYSTEMS................................................ 132

19.7 SOFTWARE ............................................................................................................ 132

19.8 DEVELOPMENT TOOLS............................................................................................ 132

19.9 PA “SPLATTERING”................................................................................................. 132

19.10 PCB LAYOUT RECOMMENDATIONS ......................................................................... 133

19.11 ANTENNA CONSIDERATIONS ................................................................................... 133

20. PACKAGE DESCRIPTION (TQFP-64)...................................................................... 135

21. SOLDERING INFORMATION.................................................................................... 136

22. PACKAGE MARKING................................................................................................ 137

22.1 STANDARD LEADED ................................................................................................ 137

22.2 ROHS COMPLIANT PB-FREE ................................................................................... 137

23. RECOMMENDED PCB FOOTPRINT ........................................................................ 138

24. PACKAGE THERMAL COEFFICIENTS.................................................................... 138

25. TRAY SPECIFICATION ............................................................................................. 139

26. CARRIER TAPE AND REEL SPECIFICATION ........................................................ 139

27. LIST OF ABBREVIATIONS ....................................................................................... 140

28. SFR SUMMARY ......................................................................................................... 141

29. ALPHABETIC REGISTER INDEX ............................................................................. 145

30. ORDERING INFORMATION...................................................................................... 148

31. GENERAL INFORMATION........................................................................................ 149

31.1 DOCUMENT HISTORY ............................................................................................. 149

31.2 PRODUCT STATUS DEFINITIONS.............................................................................. 150

31.3 DISCLAIMER........................................................................................................... 150

31.4 TRADEMARKS ........................................................................................................ 150

31.5 LIFE SUPPORT POLICY ........................................................................................... 150

32. ADDRESS INFORMATION........................................................................................ 152

Page 4

CC1010

SWRS047 Page 4 of 152

1. Features

Fully Integrated UHF RF Transceiver

Programmable frequency in the

range 300 – 1000 MHz

High sensitivity (typically -107 dBm

at 2.4 kBaud)

Programmable output power –20 to

+10 dBm

Very low current consumption (RX:

9.1 mA)

Very few external components

required and no external RF switch

or IF filter required

Single port antenna connection

Fast PLL settling allows frequency

hopping protocols

FSK modulation with a data rate of

up to 76.8 kBaud

Manchester or NRZ coding and

decoding of data performed in

hardware. Byte delineation of data

can be performed in hardware to

lessen the processor burden

RSSI output which can be sampled

by on-chip ADC

Complies with EN 300 220 and FCC

CFR47 part 15

High-Performance and Low-Power

8051-Compatible Microcontroller

Optimised 8051-core which typically

gives 2.5x the performance of a

standard 8051

Dual data pointers

Idle and sleep modes

In-circuit interactive debugging is

supported for the Keil Vision IDE

through a simple serial interface

Data and Non-volatile Program Memory

32 kB of non-volatile Flash memory

in-system programmable through a

simple SPI interface or by the 8051

core.

Typical Flash memory endurance:

20 000 write/erase cycles

Programmable read and write lock of

portions of Flash memory for software

security

2048 + 128 Byte of internal SRAM

Hardware DES Encryption / Decryption

DES supported in hardware

Output Feedback Mode or Cipher

Feedback Mode DES to avoid the

requirement that data length must

be a multiple of eight bytes

Peripheral Features

Power On Reset / Brown-Out

Detection

Three channel, max 23 kSample/s,

10 bit ADC

Programmable watchdog timer.

Real time clock with 32 kHz crystal

oscillator

Two timers / pulse counters and two

timers / pulse width modulators

Two programmable serial UARTs.

Master SPI interface

26 configurable general-purpose

I/O-pins

Random bit generator in hardware

Low Power

8051 core and peripherals can use

the RTC's 32 kHz clock

Idle and sleep modes for reduced

power consumption. System can

wake up on interrupt or when ADC

input exceeds a set threshold

Low-power fully static CMOS design

Operating Conditions

2.7 - 3.6 V supply voltage

-40 - 85 C operational temperature

3 - 24 MHz crystal (up to 50 ppm)

for the main crystal oscillator

Packaging

64-lead TQFP

Page 5

CC1010

SWRS047 Page 5 of 152

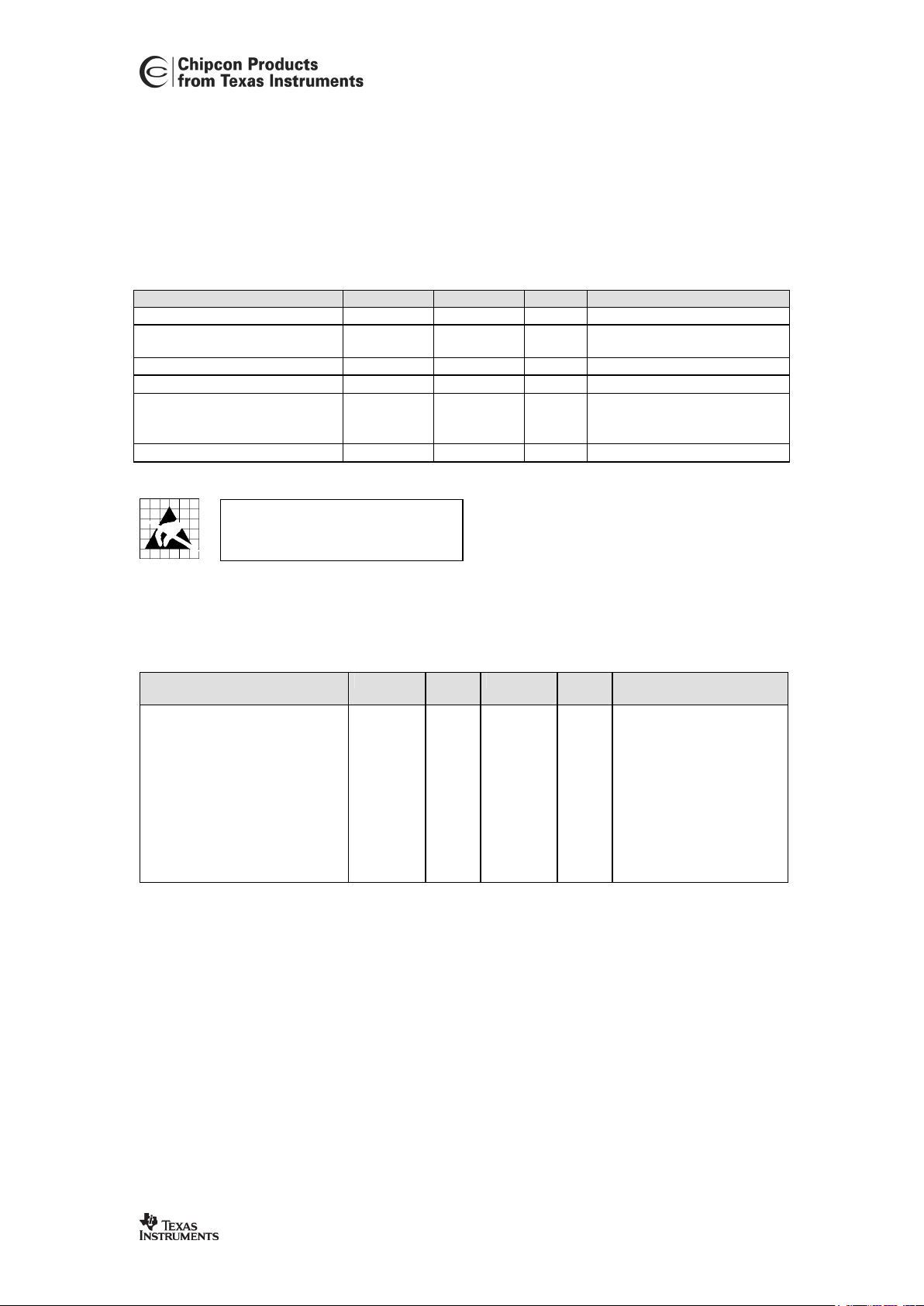

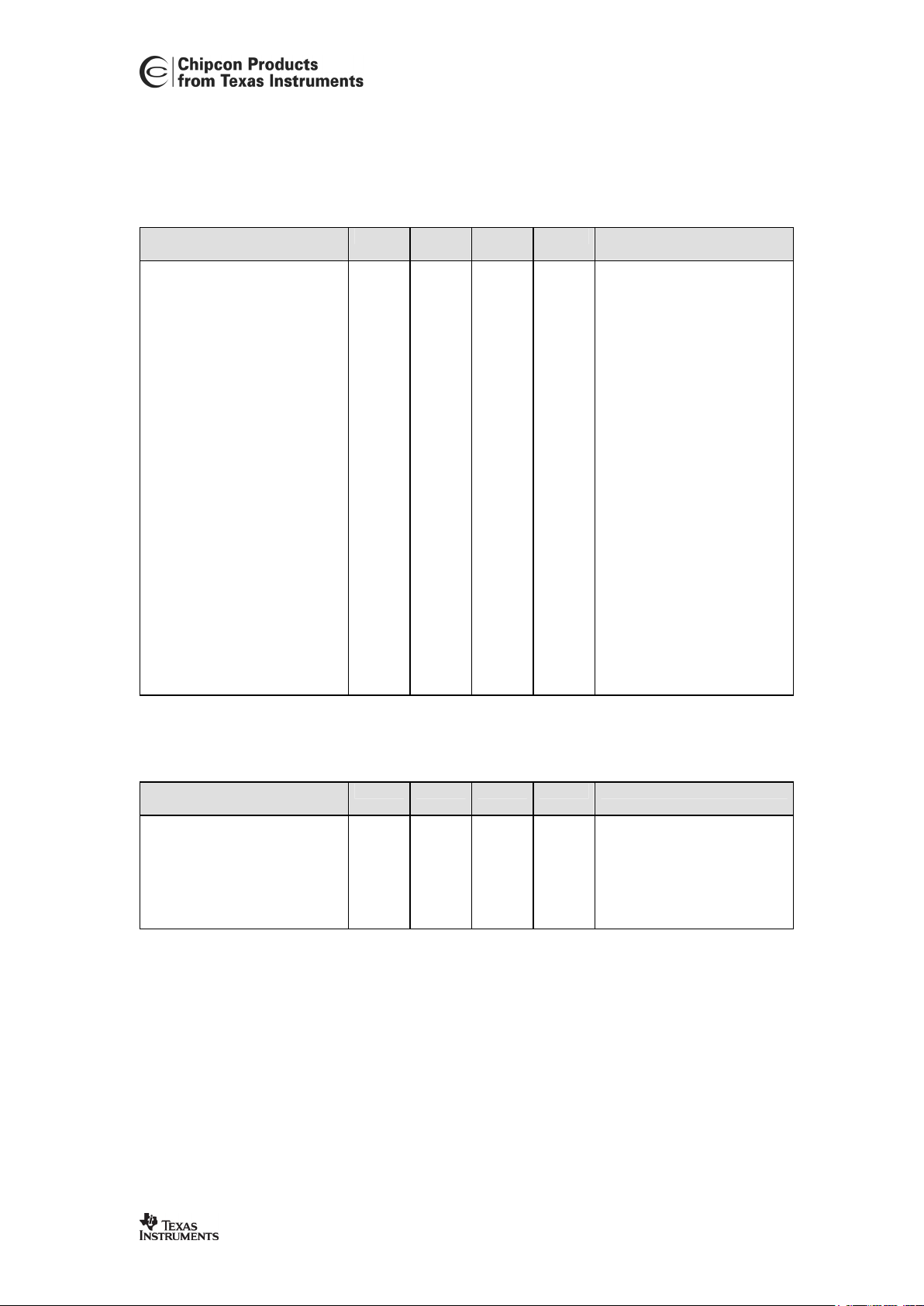

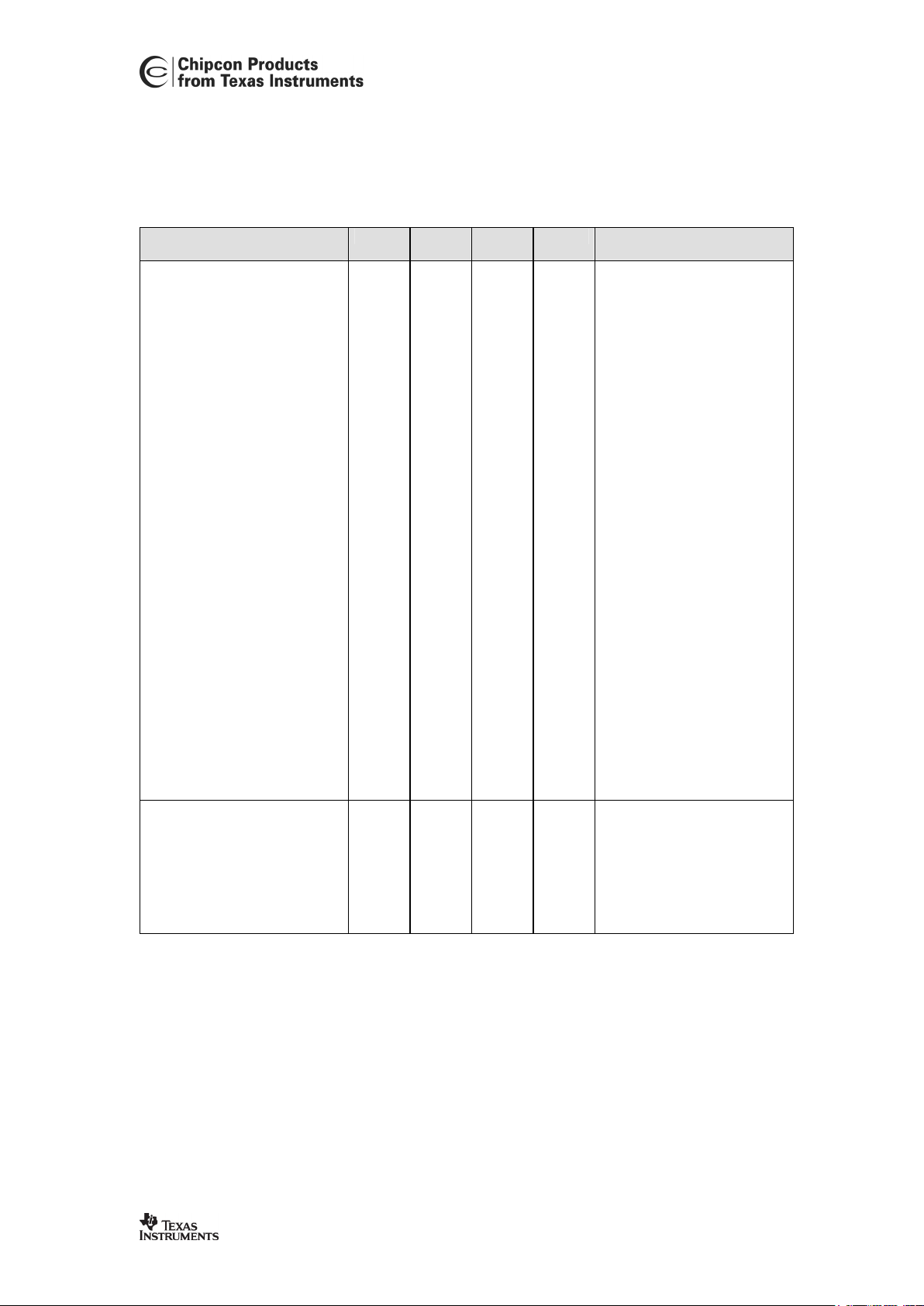

2. Absolute Maximum Ratings

Under no circumstances must the absolute maximum ratings given in Table 1 be violated.

Stress exceeding one or more of the limiting values may cause permanent damage to the

device.

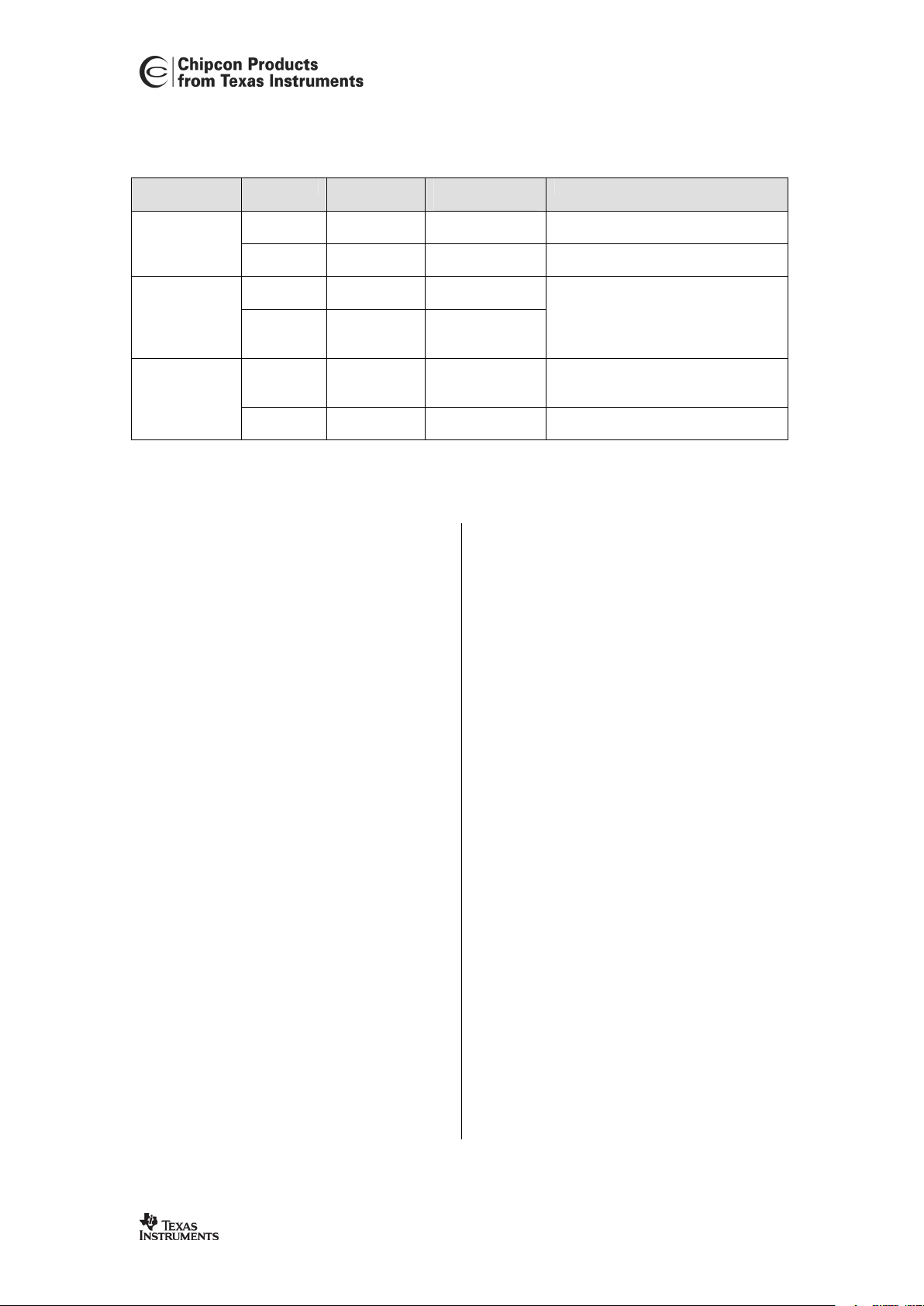

Parameter Min. Max. Units Condition

Supply voltage, VDD -0.3 5.0 V

Voltage on any pin -0.3 VDD+0.3,

max 5.0

V

Input RF level 10 dBm

Storage temperature range -50 150

C

Un-programmed device

Storage temperature range -40 125

C

Programmed device, data

retention > 0.49 years at

125C

Lead temperature 260

C

T = 10 s

Table 1. Absolute Maximum Ratings

Caution! ESD sensitive device.

Precaution should be used when handling

the device in order to prevent permanent

damage.

3. Recommended Operating Conditions

Tc = -40 to 85C, VDD = 2.7 to 3.6 V if nothing else stated

Parameter

Min Typ Max Unit Condition

Supply voltage, DVDD, AVDD 2.7 3.3 3.6 V

Supply voltage during

normal operation

Supply voltage, DVDD, AVDD 2.7 3.6 V Supply voltage during

program/erase Flash

memory

Operating temperature, free-air -40 85

C

Main oscillator frequency

3 24 MHz

RTC oscillator frequency 32768 Hz

Table 2. Recommended Operating Conditions

Page 6

CC1010

SWRS047 Page 6 of 152

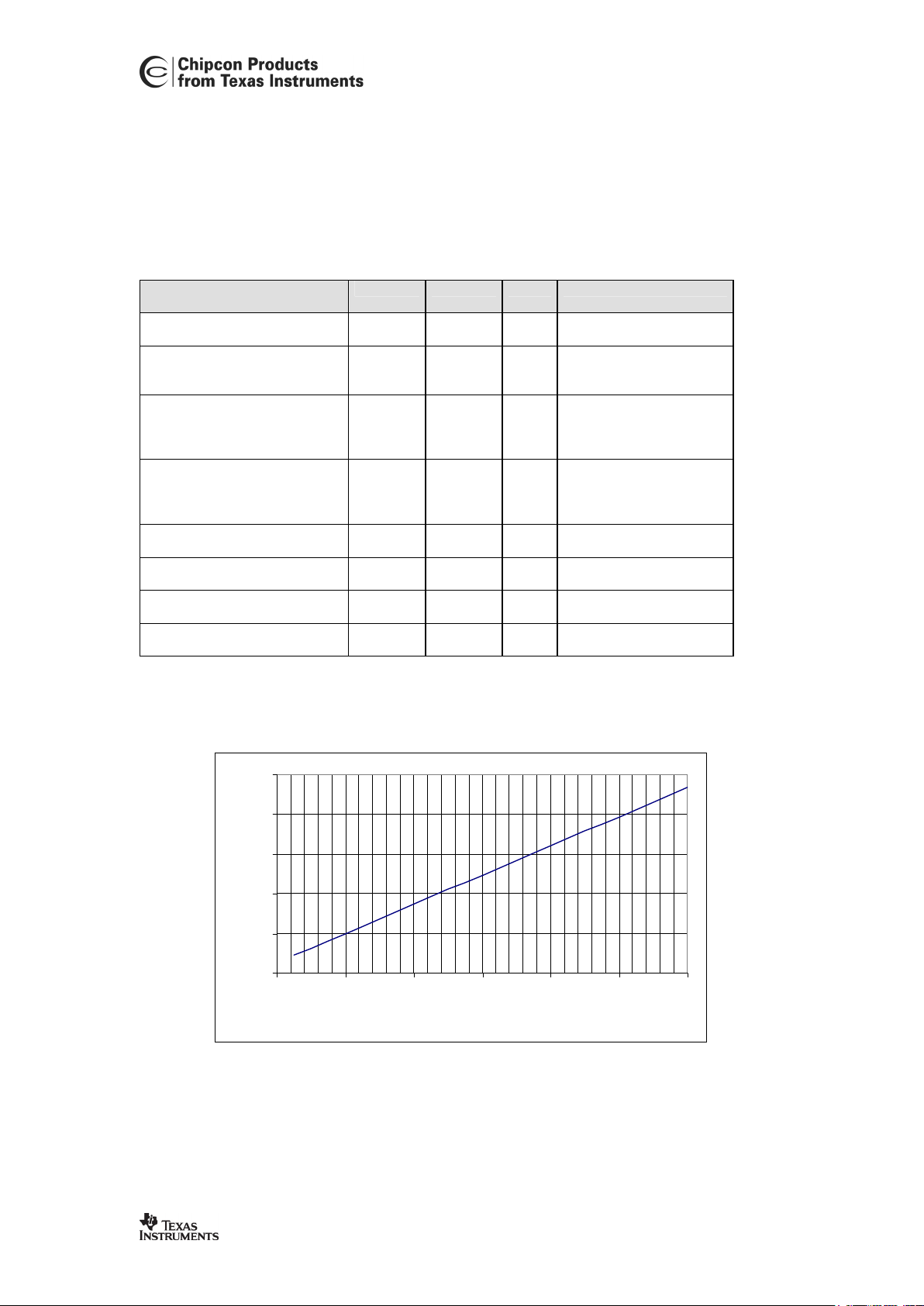

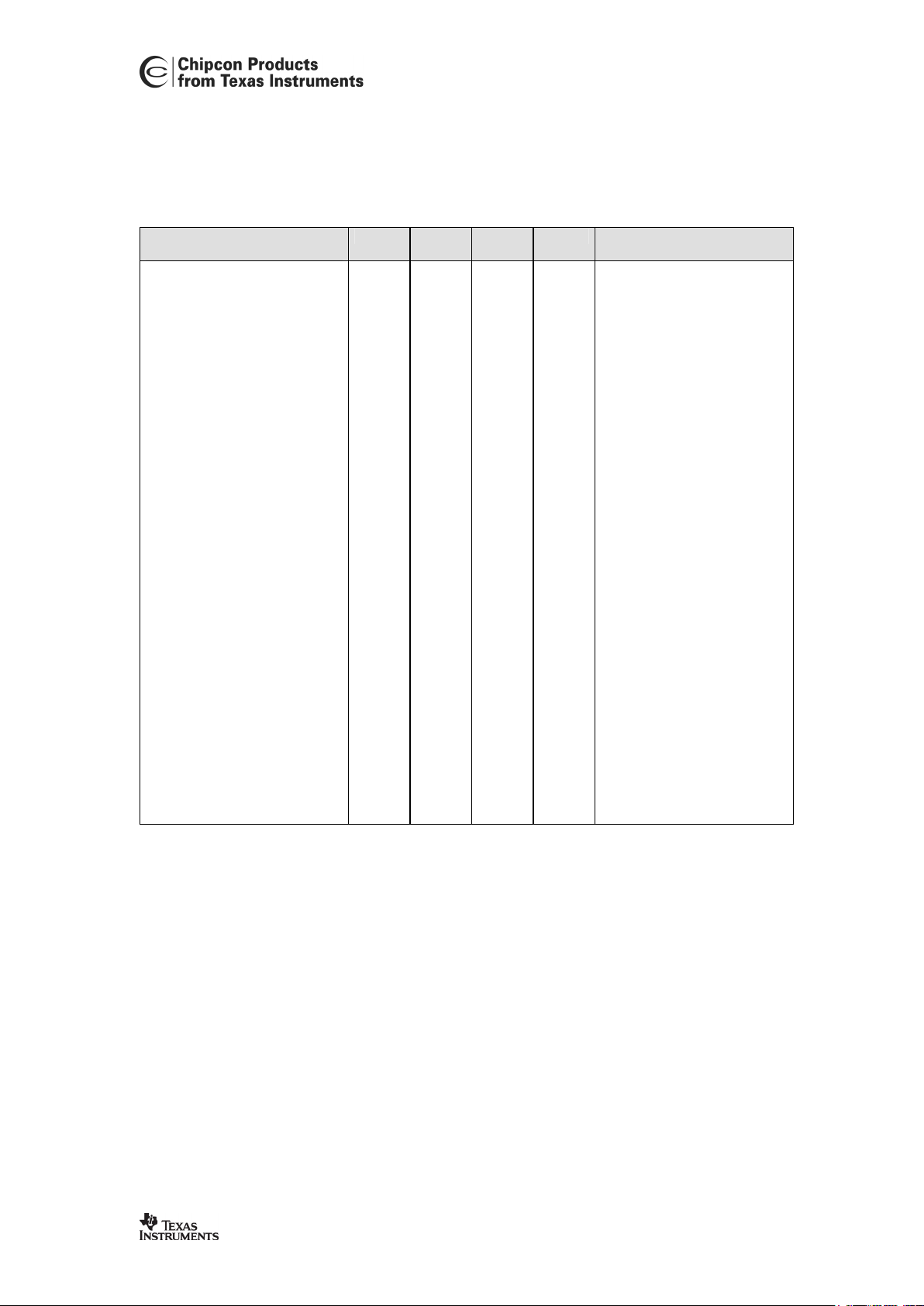

4. DC Characteristics

The DC Characteristics of

CC1010

are listed in Table 3 below.

Tc = 25C, VDD = 3.3 V if nothing else stated

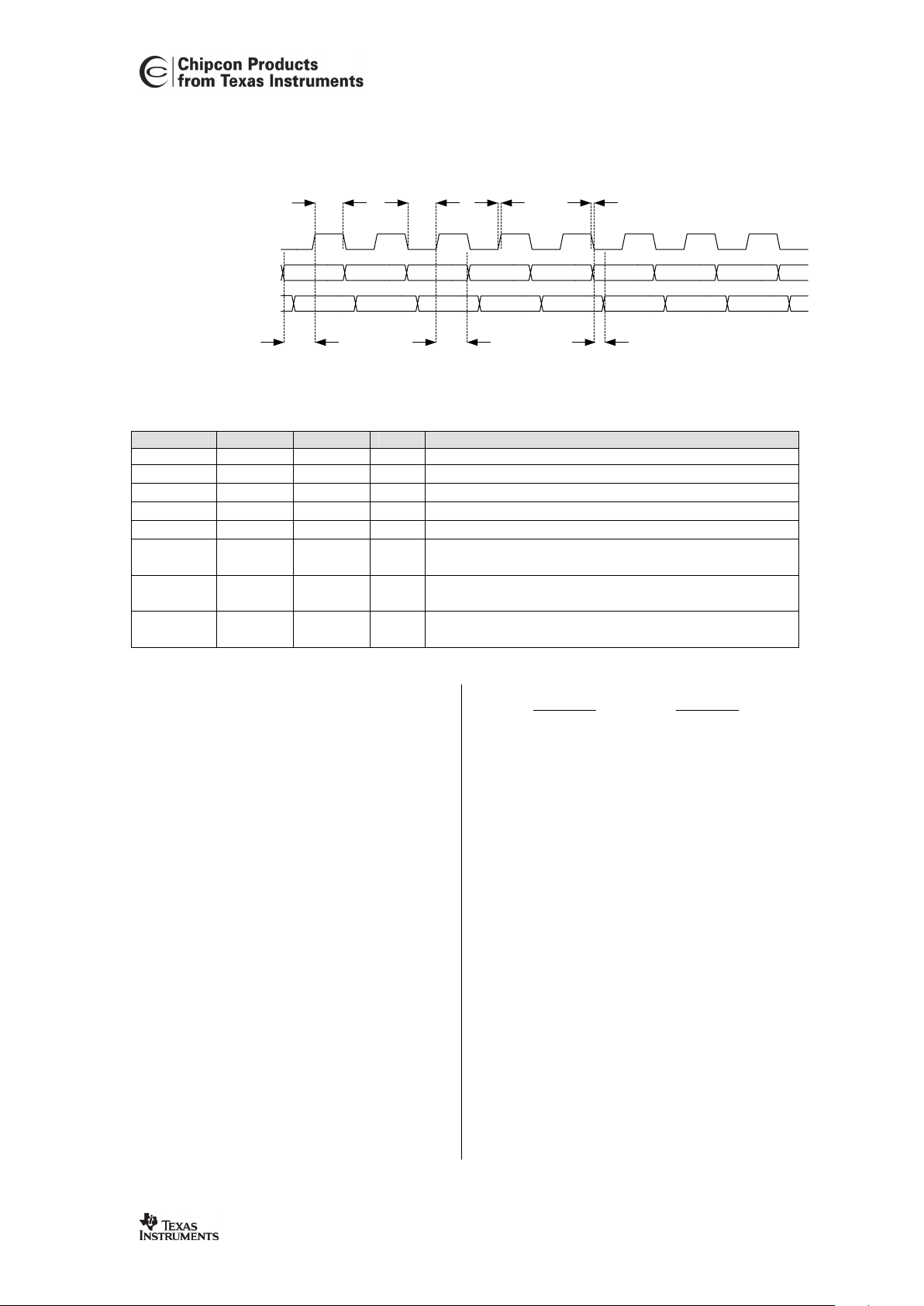

Digital Inputs/Outputs

Min Max Unit Condition

Logic "0" input voltage

0 0.3*VDD V

Logic "1" input voltage

0.7*VDD VDD V

Logic "0" output voltage 0

0.4 V Output current -2.0 mA,

ports P0.3-P0.0, P1.7P1.0, P2.7-P2.4, P2.2P2.0

Logic "1" output voltage 2.5

VDD V Output current 2.0mA,

ports P0.3-P0.0, P1.7P1.0, P2.7-P2.4, P2.2P2.0

Logic "0" output voltage 0

0.4 V Output current -8.0 mA,

port P2.3

Logic "1" output voltage 2.5

VDD V Output current 8.0mA,

port P2.3

Logic "0" input current

NA -1

A

Input signal equals GND

Logic "1" input current

NA 1

A

Input signal equals VDD

Table 3. DC Characteristics

0

5

10

15

20

25

04812162024

Frequency [MHz]

Supply current [m A]

Figure 1. Typical CPU core supply current vs. clock frequency

Page 7

CC1010

SWRS047 Page 7 of 152

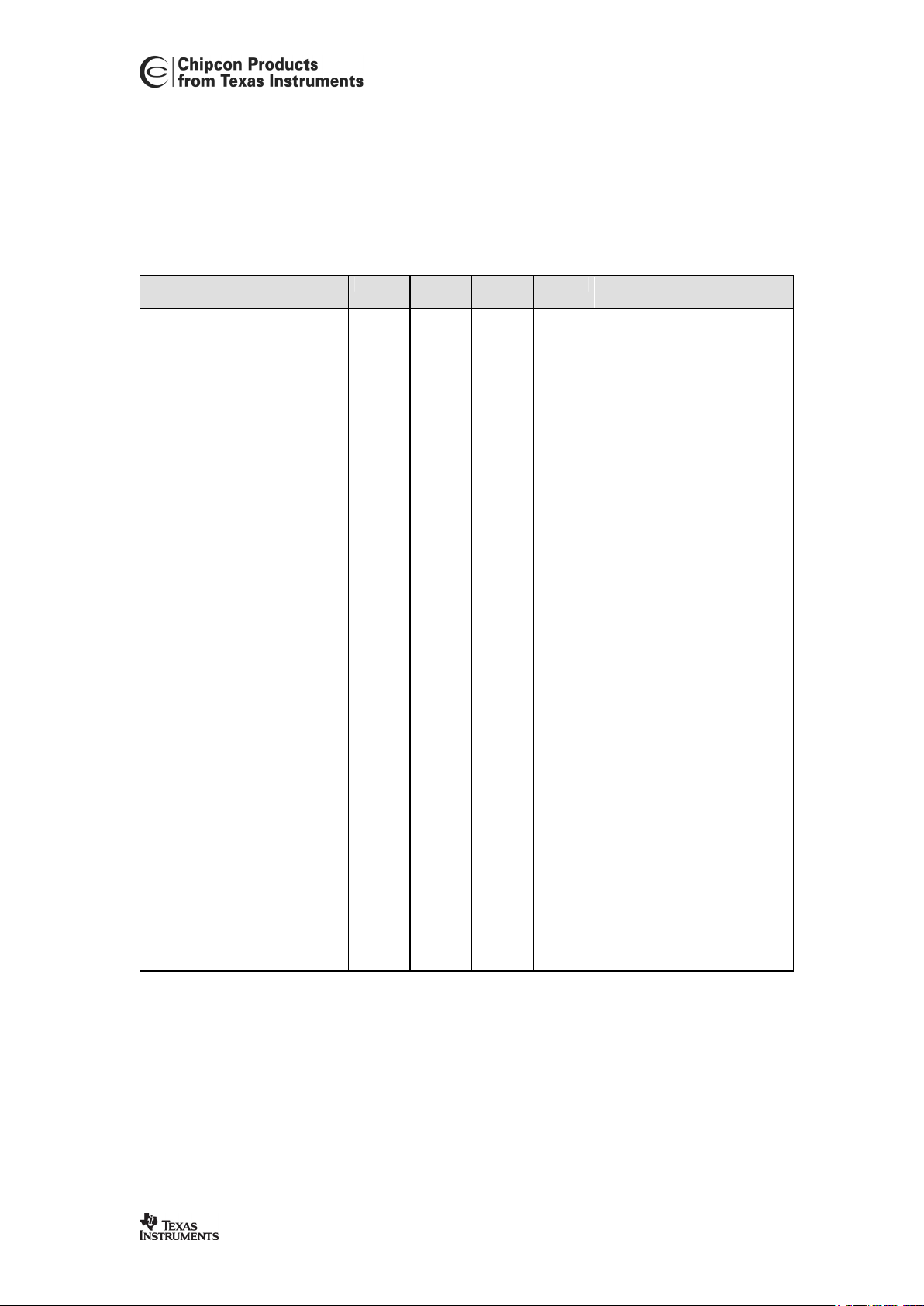

5. Electrical Specifications

Tc = 25C, VDD = 3.3 V if nothing else stated

All electrical specifications are measured on Chipcon’s CC1010EM reference design.

Parameter

Min. Typ. Max. Unit Condition

Power on reset (POR) voltage 2.7 2.9 3.1 V Tc = -40 to 85°C

Brown out voltage 2.7 2.9 3.1 V Tc = -40 to 85°C

RTC start-up time 160 ms

Current consumption MCU,

Active mode

14.8

1.3

mA

mA

14.7456 MHz, main oscillator

32 kHz, RTC oscillator

See page 33 for explanation

of modes. See Figure 1 page

6 for supply current vs. clock

frequency

Current consumption MCU, Idle

mode

12.8

29.4

mA

A

14.7456 MHz, main oscillator

32 kHz, RTC oscillator

Current consumption, Power

Down mode

0.2 1

A

Current consumption, Poweron reset circuit (when enabled)

34 uA

Current consumption Main

crystal oscillator

67 µA 14.7456 MHz crystal

Current consumption RF

Transceiver, Receive mode,

433/868 MHz

9.1/

11.9

mA Current for RF transceiver

alone

Current consumption RF

Transceiver, Transmit mode,

433/868 MHz

P=0.01 mW (-20 dBm)

P=0.3 mW (-5 dBm)

P=1 mW (0 dBm)

P=2.5 mW (4 dBm)

P=10 mW (10 dBm)

5.3/8.6

8.9/13.8

10.4/17

24.8/

23.5

26.6/NA

mA

mA

mA

mA

mA

The output power is delivered

to a single-ended 50 load,

see also page 123. Current is

for RF transceiver alone

32 kHz oscillator crystal load

capacitance

12 pF

Table 4. Electrical specifications

Page 8

CC1010

SWRS047 Page 8 of 152

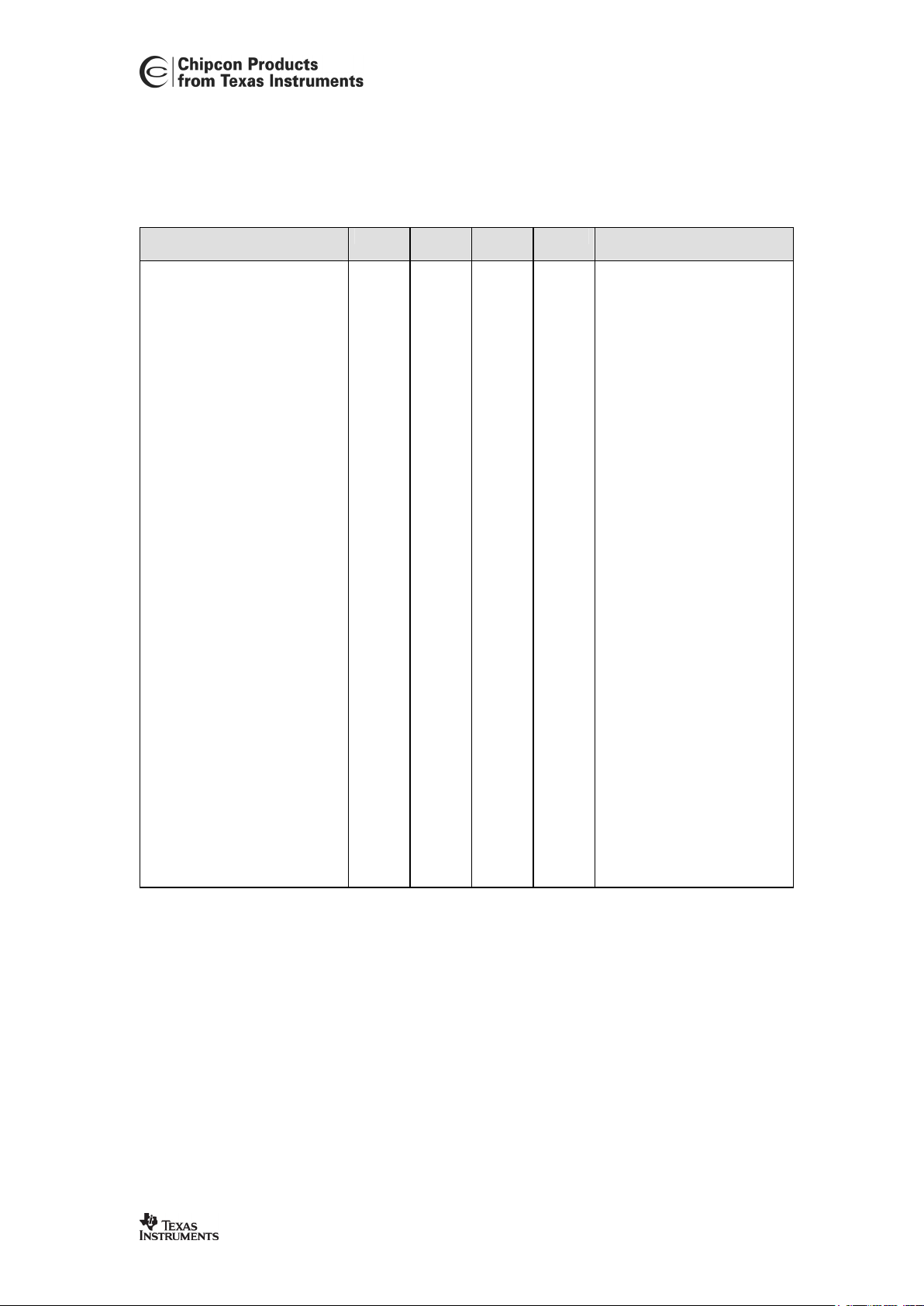

6. ADC

Parameter

Min. Typ. Max. Unit Condition

Number of bits 10 bits

Differential Nonlinearity (DNL) +/-0.2 LSB VDD is reference voltage

Integral Nonlinearity (INL)

+/-1.3 LSB VDD is reference voltage

Offset 3 LSB 7 Hz test tone

Total Harmonic Distortion

(THD)

59 dB 7 Hz test tone

SINAD 54

9

dB

bits

7 Hz test tone

Internal reference tolerance

± 10 %

Conversion time 44 µs When ADC is operated at 250

kHz

Clock frequency 32 250 250 kHz 250 kHz recommended for full

10-bit performance

External reference voltage 1.3 2.7 V External reference voltage

should never exceed 2.7 V. It

is recommended to use a

reference voltage close to 1.3

V to have the best possible

linearity.

Input voltage 0 Vref V

Table 5. ADC characteristics

7. RF section, general

Parameter

Min. Typ. Max. Unit Condition

RF Frequency Range 300

1000 MHz Programmable in steps of

< 250 Hz

Data rate

0.6 76.8 kBaud NRZ or Manchester encoding.

76.8 kBaud equals 76.8 kbps

using NRZ coding. See page

94

Table 6 General RF characteristics

Page 9

CC1010

SWRS047 Page 9 of 152

8. RF transmit section

Parameter

Min. Typ. Max. Unit Condition

Binary FSK frequency

separation

0 64 65 kHz The frequency corresponding

to the digital "0" is denoted f

0

,

while f

1

corresponds to a

digital "1".

The frequency separation is

f

1-f0

. The RF carrier

frequency, f

c

, is then given by

f

c

=(f0+f1)/2.

(The frequency deviation is

given by fd=+/-(f1-f0)/2 )

The frequency separation is

programmable in 250 Hz

steps. Separations up to 65

kHz are guaranteed at 1 MHz

reference frequency. Larger

separations can be achieved

at higher reference

frequencies

Output power

433 / 868 MHz

-20 0 10/4 dBm Delivered to single-ended 50

load.

The output power is

programmable, see page 123

RF output impedance

433 / 868 MHz

140/80

Transmit mode, optimum load

impedance. For matching

details see “Input/ output

matching” p.120

Harmonics

2

nd

harmonic, 433 / 868 MHz

3

rd

harmonic, 433 / 868 MHz

-7/-15

-27/-29

dBm

Conducted measur at

maximum output power. An

external LC filter should be

used to reduce harmonics

emission to comply with SRD

requirements. See p.128

Table 7. RF transmit characteristics

Page 10

CC1010

SWRS047 Page 10 of 152

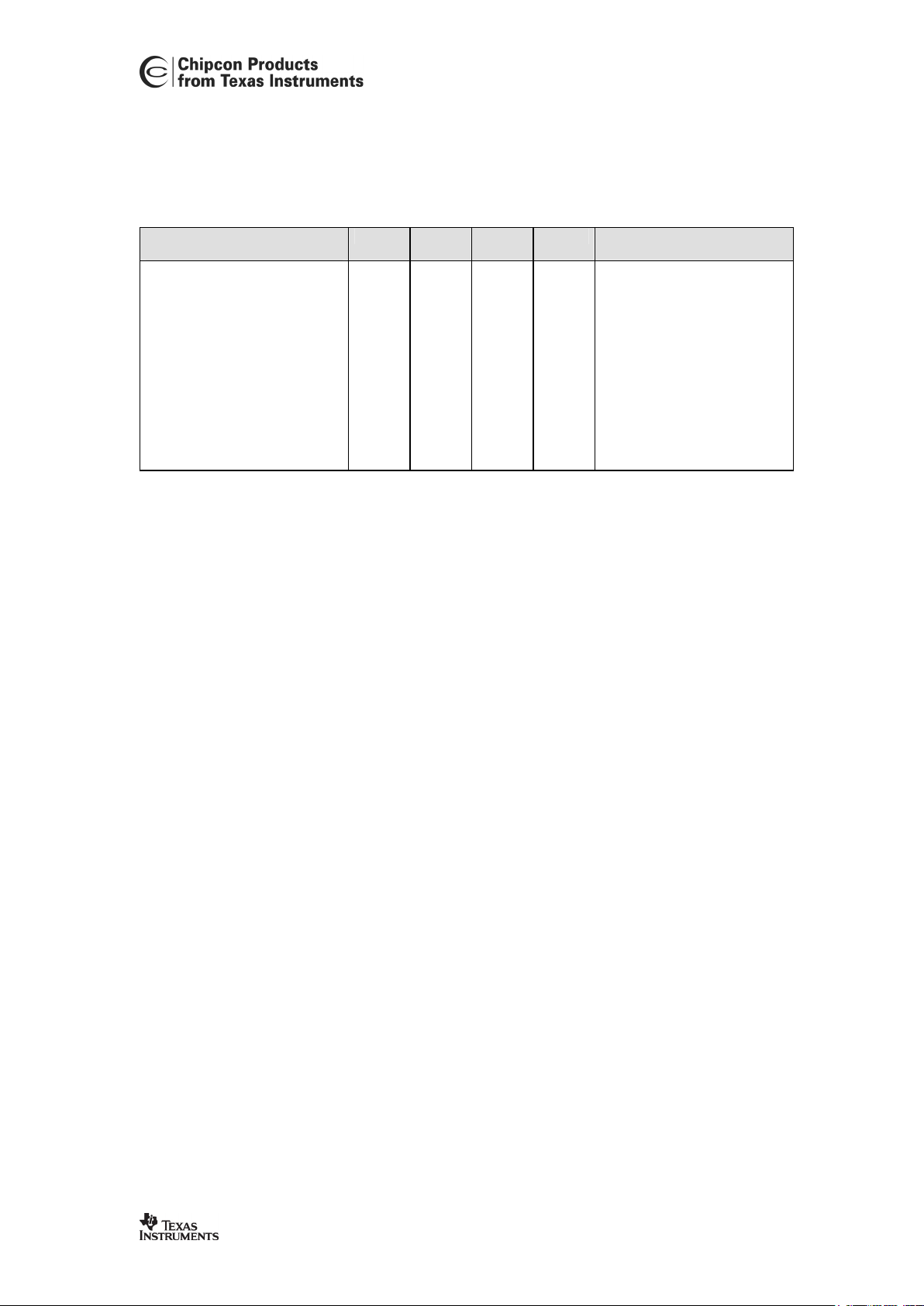

9. RF receive section

Parameter

Min. Typ. Max. Unit Condition

Receiver Sensitivity,

433 / 868 MHz

-107/

-106

dBm 2.4 kBaud, Manchester coded

data, 64 kHz frequency

separation, BER = 10-3

See Table 33 and Table

34page 105 for typical

sensitivity figures at other

data rates.

System noise bandwidth 30 kHz 2.4 kBaud, Manchester coded

data

Cascaded noise figure

433/868 MHz

12/13 dB

Saturation (maximum input

level)

10 dBm 2.4 kBaud, Manchester coded

data, BER = 10

-3

-1 dBm 76.8 kBaud NRZ, BER = 10-3

Input IP3 -26 dBm From LNA to IF output

Blocking 40 dBc At +/- 1 MHz

LO leakage -57 dBm

Input impedance

90-j13

68-j24

36-j11

36-j13

Receive mode, series

equivalent

at 315 MHz

at 433 MHz

at 868 MHz

at 915 MHz

For matching details see

“Input/ output matching” p.

120.

Turn on time 11 128 Baud The demodulator settling

time, which is programmable,

determines the turn-on time.

See page 97 for details.

Table 8. RF receive characteristics

Page 11

CC1010

SWRS047 Page 11 of 152

10. IF section

Parameter

Min. Typ. Max. Unit Condition

Intermediate frequency (IF)

433/868 MHz

150/

130

10.7

kHz

MHz

Internal IF filter

External IF filter

IF bandwidth (noise bandwidth) 175 kHz

RSSI dynamic range

-105 -60 dBm

RSSI 3-dB bandwidth 260 kHz 868 MHz CW, -70 dBm

RSSI accuracy

6

dB See p. 126 for details

RSSI linearity

2

dB

Table 9 IF characteristics

Page 12

CC1010

SWRS047 Page 12 of 152

11. Frequency synthesizer section

Parameter

Min. Typ. Max. Unit Condition

Crystal Oscillator Frequency 3 24 MHz Crystal frequency can be 3-4,

6-8 or 9-24 MHz.

Recommended frequencies

are 3.6864, 7.3728, 11.0592,

14.7456, 18.4320 and

22.1184 MHz. See page 32

for details

Crystal frequency accuracy

requirement

50

25

ppm 433 MHz

868 MHz

The crystal frequency

accuracy and drift (ageing

and temperature

dependency) will determine

the frequency accuracy of the

transmitted signal.

Crystal operation

Parallel

C171 and C181 are loading

capacitors

Crystal load capacitance 12

12

12

12

20

16

16

12

30

30

16

16

pF

pF

pF

pF

3-4 MHz, 20 pF recommended

6-8 MHz, 16 pF recommended

9-16 MHz, 16 pF recommended

16-24 MHz, 12 pF recommended

Crystal oscillator start-up time 5

1.5

2

ms

ms

ms

3.6864 MHz, 16 pF load

7.3728 MHz, 16 pF load

16 MHz, 16 pF load

Output signal phase noise

-85 dBc/Hz At 100 kHz offset from carrier

PLL lock time (RX / TX turn

time)

200

s

PLL turn-on time 250

s

Table 10. Frequency synthesizer characteristics

Page 13

CC1010

SWRS047 Page 13 of 152

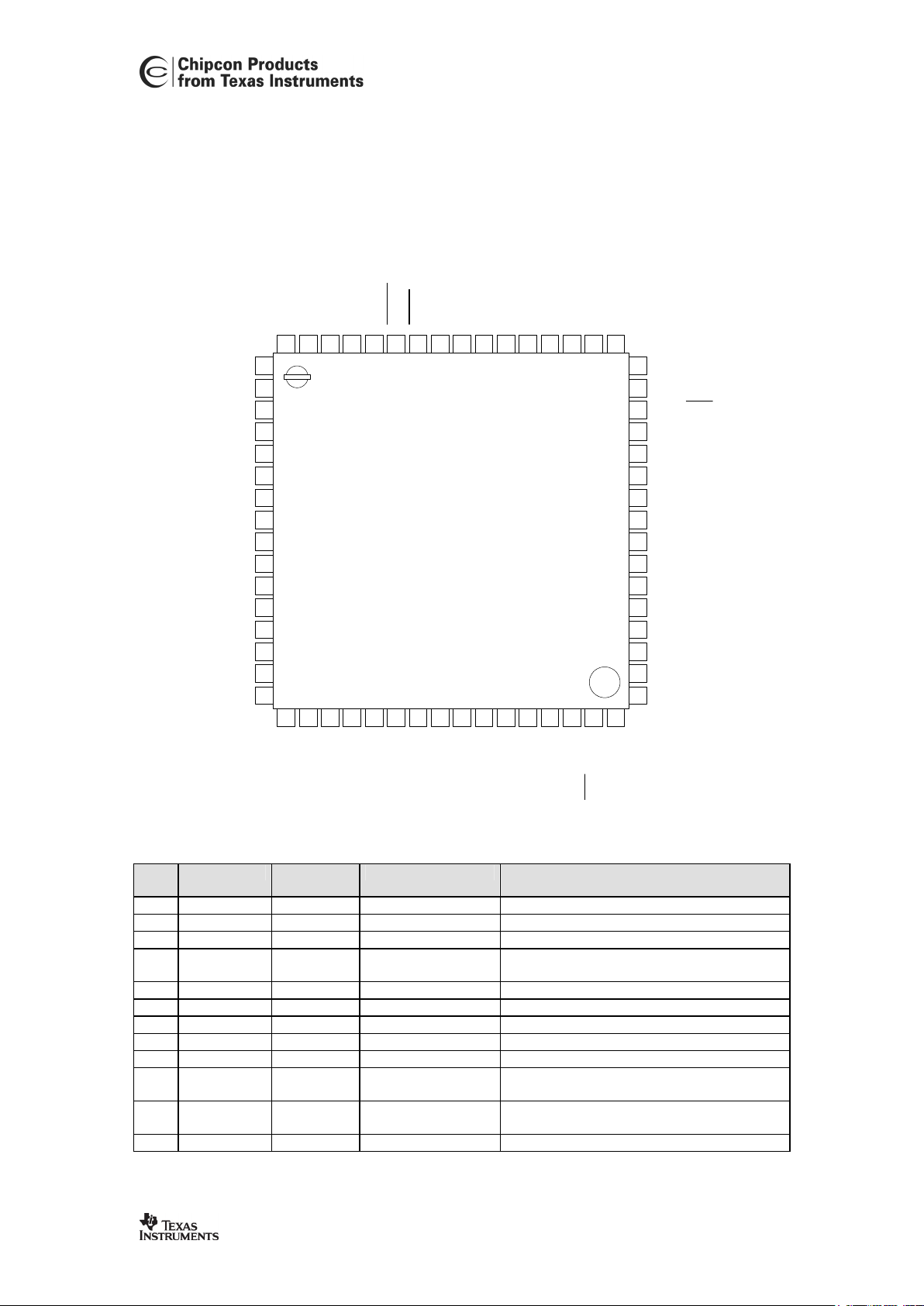

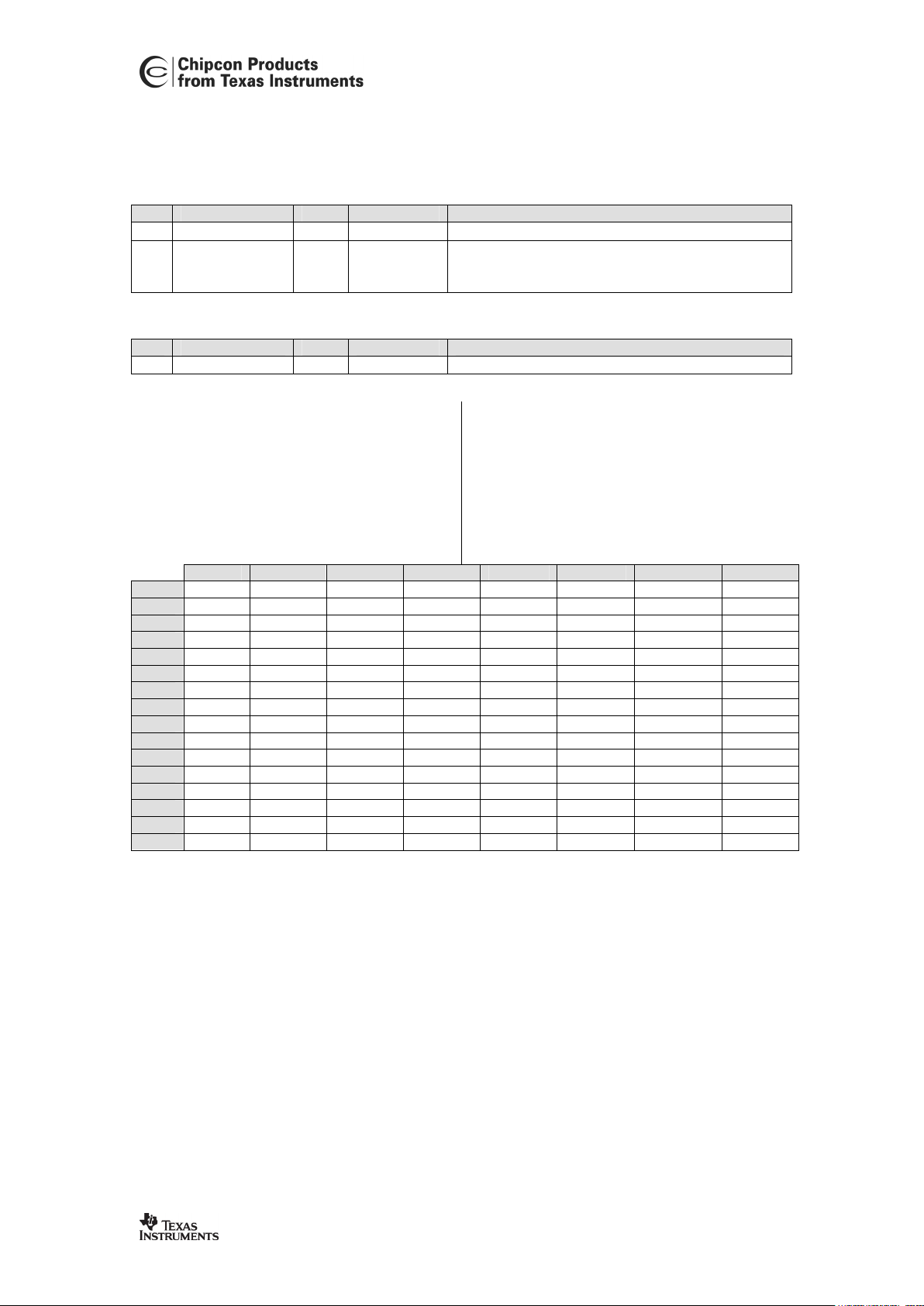

12. Pin Configuration

17

AGND

CC1010

1AVDD

2AVDD

3AGND

4RF_IN

5RF_OUT

6AVDD

7AGND

8AGND

9AGND

10L1

11L2

12AVDD

13CHP_OUT

14R_BIAS

15AVDD

16AGND

18

XOSC_Q119XOSC_Q2

20

XOSC32_Q2

21

XOSC32_Q1

22

AGND

23

DGND24DGND

25

POR_E

26

P1.0

27

(RXD1) P2.0

28

(TXD1) P2.1

29

(PWM3) P3.5

30

(PWM2) P3.4

31

(INT1) P3.3

32

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

DGND

P3.0 (RXD0)

P3.1 (TXD0)

P3.2 (INT0)

P2.5

P2.4

DVDD

P2.3

DGND

DVDD

P2.2

P1.4

P1.3

P1.2

P1.1

P0.1 (MOSI)

P0.0 (SCK)

AGND

AD2 (RSSI/IF)

AD1

AD0

DVDD

RESET

PROG

P2.7

P2.6

P1.7

P1.6

P1.5

P0.3

P0.2 (MISO)

DVDD

DGND

(Top view)

Pin

#

Pin name Alternate

function

Pin type Description

1 AVDD - Power (A) Power supply ADC

2 AVDD - Power (A) Power supply Mixer and IF

3 AGND - Power (A) Ground connection Mixer and IF

4 RF_IN - RF input RF signal input from antenna (external AC-

coupling)

5 RF_OUT - RF output RF signal output to antenna

6 AVDD - Power (A) Power supply LNA and PA

7 AGND - Power (A) Ground connection LNA and PA

8 AGND - Power (A) Ground connection PA

9 AGND - Power (A) Ground connection VCO and prescaler

10 L1 - Analog Connection #1 for external VCO tank

inductor

11 L2 - Analog Connection #2 for external VCO tank

inductor

12 AVDD - Power (A) Power supply VCO and prescaler

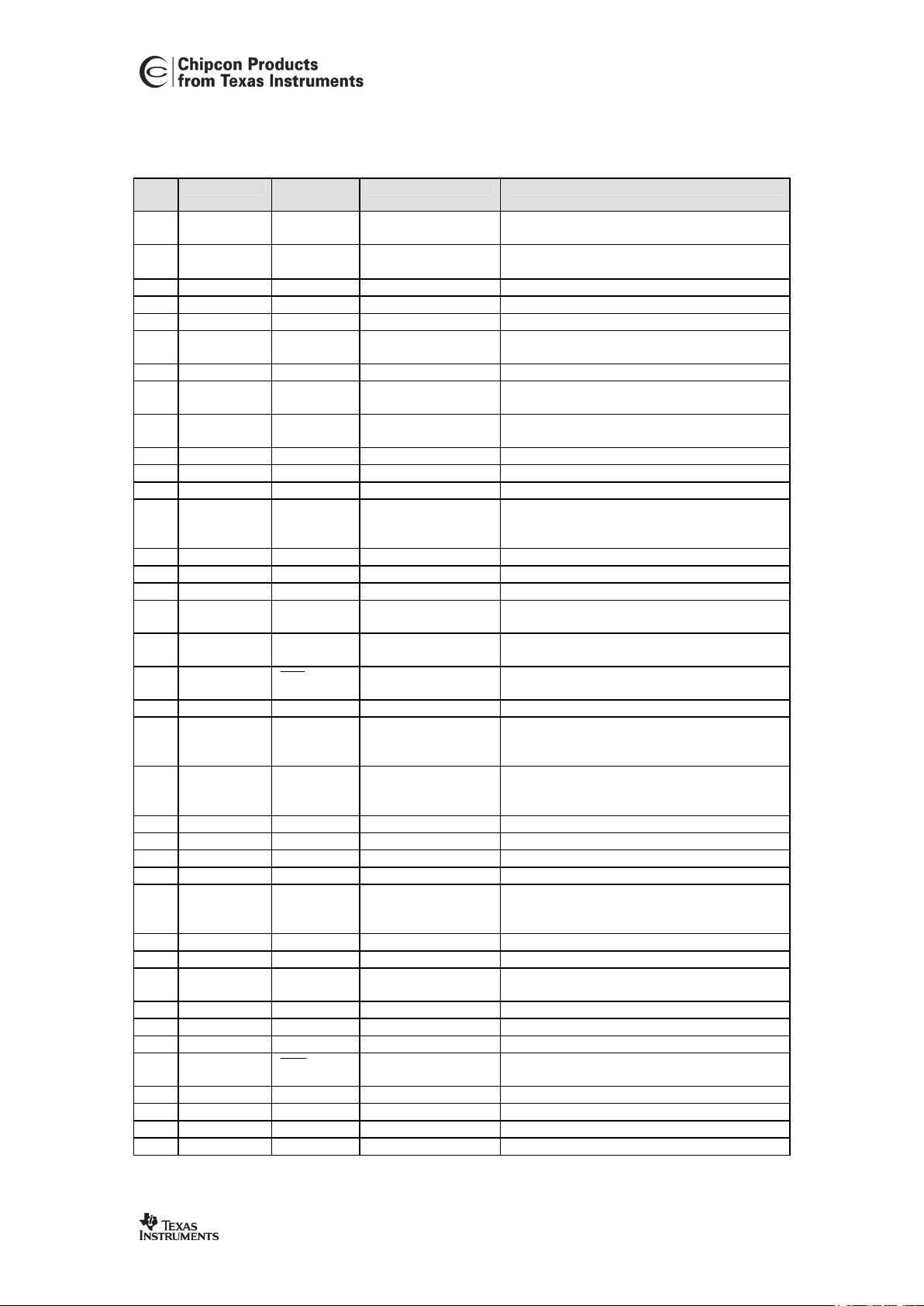

Page 14

CC1010

SWRS047 Page 14 of 152

Pin

#

Pin name Alternate

function

Pin type Description

13 CHP_OUT - Analog output Charge pump current output when external

loop filter is used

14 R_BIAS - Analog Connection for external precision bias

resistor (82 k, 1%)

15 AVDD - Power (A) Power supply misc. analog modules

16 AGND - Power (A) Ground connection misc. analog modules

17 AGND - Power (A) Analog ground connection

18 XOSC_Q1 - Analog input 3-24 MHz crystal, pin 1 or external clock

input

19 XOSC_Q2 - Analog output 3-24 MHz crystal, pin 2

20 XOSC32_Q2 - Analog output 32 kHz crystal pin2

21 XOSC32_Q1 - Analog input 32 kHz crystal pin1 or external clock input

22 AGND - Power (A) Analog ground connection

23 DGND - Power (D) Digital ground connection

24 DGND - Power (D) Digital ground connection

25 POR_E - Digital input Power-on reset enable.

0: Disable internal power-on reset module

1: Enable internal power-on reset module

26 P1.0 - Digital high-Z I/O 8051 port 1, bit 0

27 P2.0 RXD1 (I) Digital high-Z I/O 8051 port 2, bit 0 or RX of serial port 1

28 P2.1 TXD1 (O) Digital high-Z I/O 8051 port 2, bit 1 or TX of serial port 1

29 P3.5 PWM3 (O)

T1 (I)

Digital high-Z I/O 8051 port 3, bit 5 or pulse width modulator

3's output or Timer / Counter 1 external input

30 P3.4 PWM2 (O)

T0 (I)

Digital high-Z I/O 8051 port 3, bit 4 or pulse width modulator

2's output or Timer / Counter 0 external input

31 P3.3

INT1

(I)

Digital high-Z I/O 8051 port 3, bit 3 or interrupt 1 input

configurable as level or edge sensitive

32 DGND - Power (D) Ground connection digital part

33 P0.0 SCK (O)

SCK (I)

Digital high-Z I/O 8051 port 0, bit 0 or SPI master interface

serial clock output or Flash programming

SPI slave clock input.

34 P0.1 MO (O)

SI (I)

Digital high-Z I/O 8051 port 0, bit 1 or SPI interface master

output or Flash programming SPI slave

serial data input

35 P1.1 - Digital high-Z I/O 8051 port 1, bit 1

36 P1.2 - Digital high-Z I/O 8051 port 1, bit 2

37 P1.3 - Digital high-Z I/O 8051 port 1, bit 3

38 P1.4 - Digital high-Z I/O 8051 port 1, bit 4

39 P2.2 - Digital high-Z I/O

(Schmitt trigger

input)

8051 port 2, bit 2

40 DVDD - Power (D) Digital power supply

41 DGND - Power (D) Ground connection digital part

42 P2.3 - Digital high-Z I/O (8

mA)

8051 port 2, bit 3

43 DVDD - Power (D) Digital power supply

44 P2.4 - Digital high-Z I/O 8051 port 2, bit 4

45 P2.5 - Digital high-Z I/O 8051 port 2, bit 5

46 P3.2

INT0

(I)

Digital high-Z I/O 8051 port 3, bit 2 or interrupt 0 input

configurable as level or edge sensitive

47 P3.1 TXD0 (O) Digital high-Z I/O 8051 port 3, bit 1 or TX of serial port 0

48 P3.0 RXD0 (I) Digital high-Z I/O 8051 port 3, bit 0 or RX of serial port 1

49 DGND - Power (D) Digital ground connection

50 DVDD - Power (D) Digital power supply

Page 15

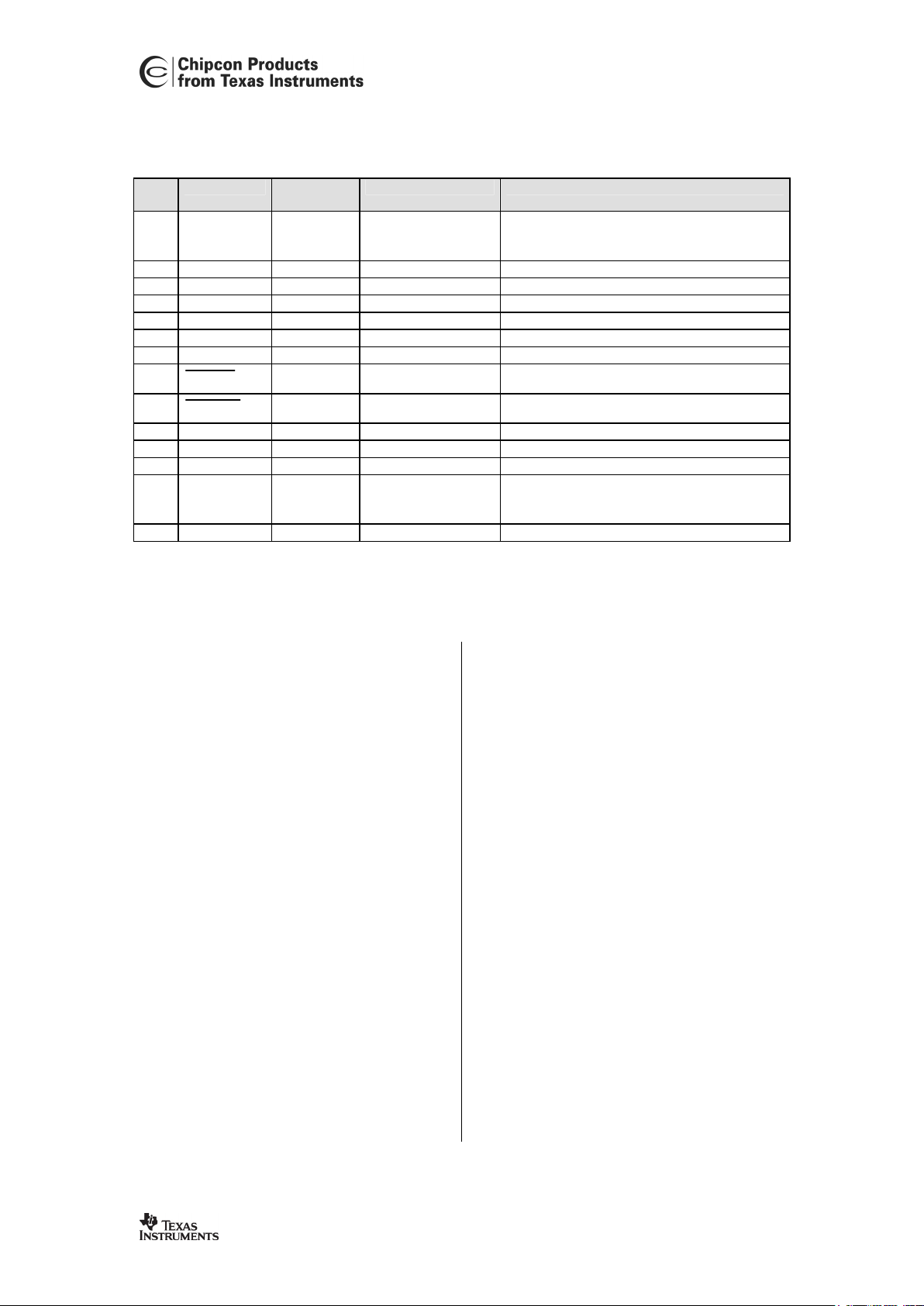

CC1010

SWRS047 Page 15 of 152

Pin

#

Pin name Alternate

function

Pin type Description

51 P0.2 MI (I)

SO (O)

Digital high-Z I/O 8051 port 0, bit 2 or SPI interface master

input or Flash programming SPI slave serial

data output

52 P0.3 - Digital high-Z I/O 8051 port 0, bit 3

53 P1.5 - Digital high-Z I/O 8051 port 1, bit 5

54 P1.6 - Digital high-Z I/O 8051 port 1, bit 6

55 P1.7 - Digital high-Z I/O 8051 port 1, bit 7

56 P2.6 - Digital high-Z I/O 8051 port 2, bit 6

57 P2.7 - Digital high-Z I/O 8051 port 2, bit 7

58

PROG

- Digital input Flash program enable pad, active low

59

RESET

- Digital input (pull-up) System reset pin, active low

60 DVDD - Power (D) Digital power supply

61 AD0 - Analog input ADC input channel 0

62 AD1 - Analog input ADC input channel 1

63 AD2 RSSI (O),

IF (O)

Analog input/output ADC input channel 2, RSSI (Receiver signal

strength indicator) output, or IF output when

using external demodulator

64 AGND - Power (A) Analog ground connection ADC

A = Analog, D = Digital, I = input, O= Output

13. Pin description

AVDD, DVDD

Supply voltages for analog and digital

modules respectively. All supply pins

should be decoupled by capacitors. In

particular, the digital and analog supply

domains should be properly decoupled

from each other (a ferrite bead can be

used to prevent high-frequency noise from

coupling from one supply domain to

another). The placement and size of

decoupling capacitors and supply filtering

are critical with respect to LO leakage and

sensitivity. Chipcon’s reference layout

designs should be used (available from

Chipcon’s website). See also page 133 for

layout recommendations.

AGND, DGND

Ground for analog and digital modules

respectively. Normally one common

ground plane is recommended. If two

separate analog and digital grounds are

used they should be interconnected in one

place, and one place only.

RFIN

This is the RF input, internally connected

to the low noise amplifier (LNA). The

signal source (antenna) should be

matched to the input impedance. A DC

ground is needed for LNA biasing.

RFOUT

This is the RF output, internally connected

to the power amplifier (PA). The external

load (antenna) should be matched to the

output impedance (optimum load

impedance). This pin must be DC coupled

to AVDD for PA biasing (open drain

output).

L1, L2

Connection to internal voltage controlled

oscillator (VCO). An inductor should be

connected between these pins. The

inductor value will determine the VCO

tuning range. The inductor should be place

very close to the pins in order to minimize

paracitic inductance.

CHP_OUT

Charge Pump output. If the RF transceiver

is configured for external loop filter this is

the current output from the charge pump.

Normally the internal loop filter should be

used and this pin should be left open (not

connected).

Page 16

CC1010

SWRS047 Page 16 of 152

RBIAS

Current output from internal band gap cell

bias generator. A precision resistor (82

k, 1%) should be connected between

this pin and ground to set the correct bias

current level.

XOSC_Q1, XOSC_Q2

These are the main oscillator connection

pins. An external crystal should be

connected between these pins, and load

capacitors should be connected between

each pin and ground. If an external

oscillator is used, the clock signal should

be connected to the XOSC_Q1 pin, and

XOSC_Q2 should be left open (not

connected).

XOSC32_Q1, XOSC32_Q2

These are the real time clock (RTC)

oscillator connection pins. An external

crystal should be connected between

these pins, and load capacitors should be

connected between each pin and ground.

If an external oscillator is used, the clock

signal should be connected to the

XOSC32_Q1 pin, and XOSC32_Q2

should be left open (not connected).

POR_E

Enable signal for the on-chip power-on

reset module. The power-on reset is

enabled when POR_E is connected to

DVDD and disabled when connected to

DGND.

PROG

Active low Flash programming enable pin.

When this signal is active (driven to DGND)

a Flash programmer can be connected to

the SPI interface. Under normal operation

it must be driven to DVDD.

RESET

Active low asynchronous system reset. It

has an internal pull-up resistor and can be

left unconnected during normal operation.

AD0, AD1

Analog inputs to A/D converter channels 0

and 1 respectively. When not used these

pins can be left open (not connected).

AD2 (RSSI/IF)

Analog input to A/D converter channel 2.

This pin can also be configured to be RSSI

output or IF output. The pin is configured

by the FREND register. When not used this

pin can be left open (not connected).

PORT 0

Port 0 is a 4-bit (P0.3-P0.0) bi-directional

CMOS I/O port with 2 mA drivers. A

direction register (P0DIR) controls whether

each pin is an output or input and the

register P0 is used to read the input or

control the logical value of the output.

Pins P0.0 - P0.2 can be configured to

become a master SPI interface in register

SPCR and will then override P0(2:0),

P0DIR(2) and P0DIR(1).

Used as SPI interface, P0.0 is SCK,

P0.1 is MOSI, and P0.2 is MISO.

PORT 1

Port 1 is an 8-bit (P1.7-P1.0) bidirectional CMOS I/O port with 2 mA

drivers. A direction register (P1DIR)

controls whether each pin is an output or

input and the register P1 is used to read

the input or control the logical value of the

output.

PORT 2

Port 2 is an 8-bit (P2.7-P2.0) bidirectional CMOS I/O port with 2 mA

drivers, except for P2.3 that has an 8 mA

output buffer. A direction register (P2DIR)

controls whether each pin is an output or

input and the register P2 is used to read

the input or control the logical value of the

output.

Pins P2.0 and P2.1 can be configured to

become the RXD1 and TXD1 pin,

respectively, of UART 1.

Pin P2.2 has a Schmitt-trigger input

stage. Note that while this pin does have

hysteresis, it will draw a large input current

(~0.5 mA) if the input voltage is close to

VDD/2.

PORT 3

Port 3 is a 6-bit (P3.5-P3.0) bi-directional

CMOS I/O port with 2 mA drivers. A

direction register (P3DIR) controls whether

each pin is an output or input. The register

P3 is used to read the input or control the

logical value of the output.

Page 17

CC1010

SWRS047 Page 17 of 152

Pins P3.0 and P3.1 can be configured to

become the RXD0 and TXD0 pin,

respectively, of UART 0.

Pins P3.2 and P3.3 are connected to the

external interrupt inputs

INT0 and

INT1

,

respectively, and can cause interrupts if

the corresponding interrupt enable flags

are set in register

IE. The interrupts inputs

can be configured to be either levelsensitive or edge-sensitive.

Pins

P3.4 and P3.5 can be configured to

become the pulse width modulator (PWM)

outputs of Timer/PWM 2 and Timer/PWM

3, respectively. When pulse width

modulation is enabled the corresponding

bits in

P3DIR and P3 are overridden.

Page 18

CC1010

SWRS047 Page 18 of 152

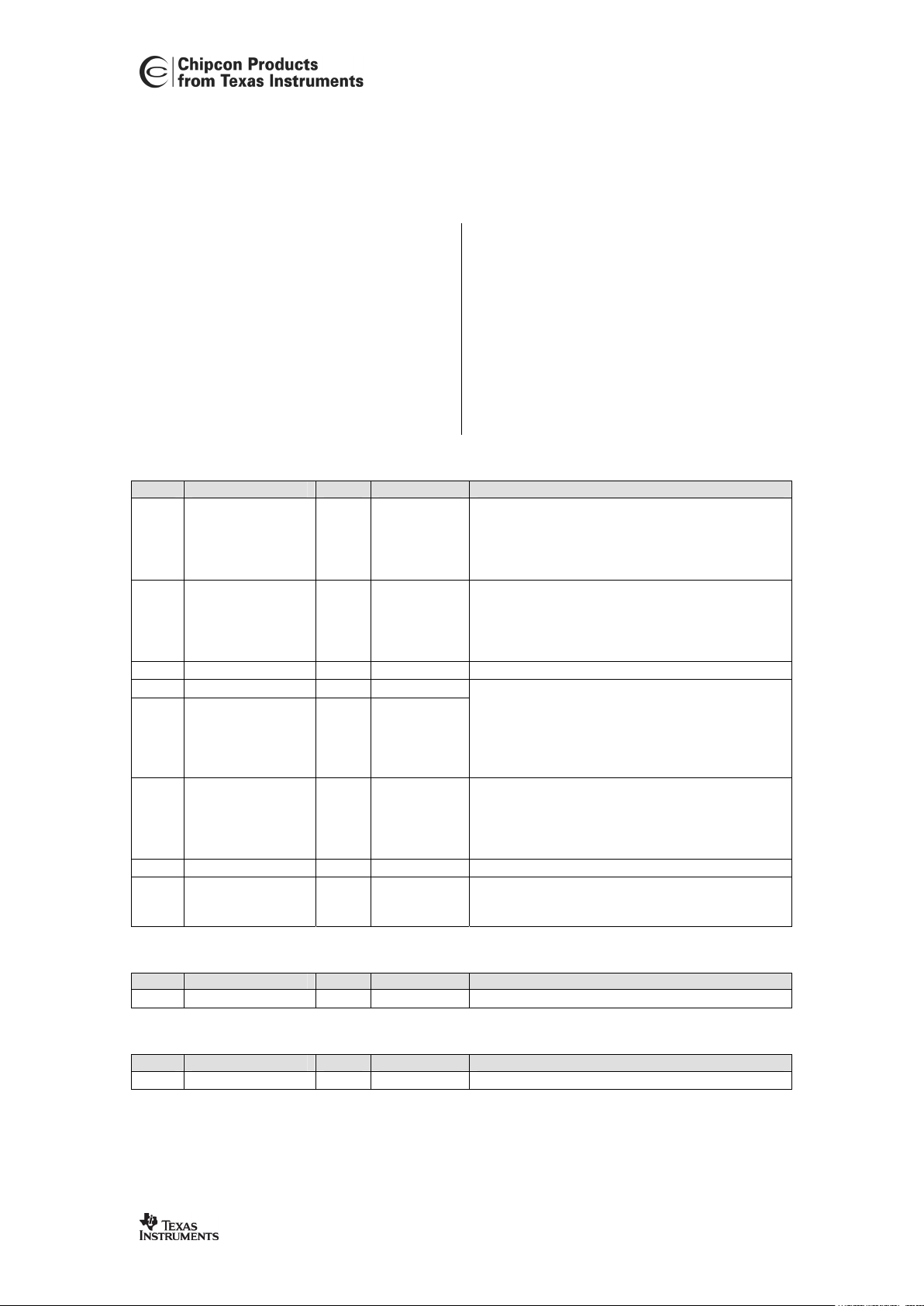

14. Block Diagram

The

CC1010

Block Diagram is shown in Figure 2 below.

Figure 2. CC1010 Block Diagram

32 kB

FLASH

128 byte

SRAM

Special Function

Registers

(SFRs)

Interrupt

Controller

Realtime

Clock

Watchdog

Timer

SPI

Timers/

Counters

Timers/

PWMs

UARTs

UARTs

General

purpose I/O

CODEC, Bit synchronizer,

Serializer/Deserializer

IF stage MODEM

RF Transceiver

8051 core

FLASH

Programming DMA

DES Module

2048 byte

SRAM

RAM Arbiter

Reset

Generation

3-24 MHz crystal

32 kHz crystal

Clock

Multiplexer

System

clock

Port 0

Port 1

Port 2

Port 3

RESET

PROG

RF_IN

ADC

Programmable I/O (General purpose or alternate function)

Power-on

reset

POR_E

Main Crystal

Oscillator

:R

:N.n

RF_OUT

LPF CHP PD

MUX

RSSIIF

Bias

Bias resistor

VCO inductor

VCO

CHP_OUT

AD2

(RSSI/IF)

AD0

AD1

PA

LNA

MIXER

L1 L2

Page 19

CC1010

SWRS047 Page 19 of 152

15. 8051 Core

15.1 General description

The

CC1010

microcontroller core is based

on the industry-standard 8051

architecture. The MCU core is 8-bit, with

program and data memory located in

separate memory spaces (Harvard

architecture). The internal registers are

organised as four banks of 8 registers

each. The instruction set supports direct,

indirect and register addressing modes.

Program memory can be addressed using

indexed addressing. The core registers

are comprised of an accumulator, a stack

pointer and dual data pointer registers in

addition to the general registers.

Data memory is split into internal and

external RAM. The name "external RAM"

is in fact misleading since in the case of

the

CC1010

all the RAM is internal to the

chip. The difference between external and

internal is that external RAM can only be

accessed by a few instructions. Therefore,

frequently-accessed variables as well as

the stack should be kept in internal RAM.

The various peripherals are controlled

through Special Function Registers

(SFRs) located in the internal RAM space.

The 8051 core is instruction set

compatible with the industry standard

8051. It also has one additional instruction,

TRAP, to enable advanced in-circuit-

debugging features. This is described on

page 44.

The instruction cycle time is 4 clock

cycles, which typically gives a 2.5X

average reduction in instruction execution

time over the original Intel 8051.

Peripheral units, including general purpose

I/O, 2 standard 8051 timers, 2 extra timers

with PWM functionality, a watchdog timer,

a real-time clock, an SPI master interface,

hardware DES encryption, a true random

bit generator and ADC are all described

from page 47 and out. Dual data pointers

are available for faster data transfer.

15.2 Reset

CC1010

must be reset at start-up. There

are several sources for reset in

CC1010

:

External reset pin, RESET

. Applying

a low signal to this pin at any time will

reset almost all registers in

CC1010

.

Exceptions can be found in Table 41

on page 144. The input is

asynchronous and is synchronised

internally, so that the reset can be

released independent of the timing of

the active clock signal. If the main

crystal oscillator is inactive, the reset

input should be held long enough for

the oscillator to start up and stabilize.

See Electrical Specifications page 7

for oscillator start-up timing.

Power On Reset (POR). The internal

POR module can generate reset upon

power-up. Special requirements for

power consumption or power supply

voltage may require an external POR

module, as described in the Power On

Reset (Brown-Out Detection) section

at page 62.

Brown-out detection reset. The POR

will also detect low supply voltage and

generate a reset.

Watchdog timer reset. The watchdog

timer can generate a reset, as

described in the section on page 63.

ADC reset. The ADC module can be

programmed to generate a reset

signal if its inputs exceed a

programmed threshold. See the ADC

section on page 79 for details.

The POR and ADC reset signals will be

held for 1024 clock periods after the signal

is released. This will ensure a safe clock

start-up if the crystal oscillator is currently

not running.

Page 20

CC1010

SWRS047 Page 20 of 152

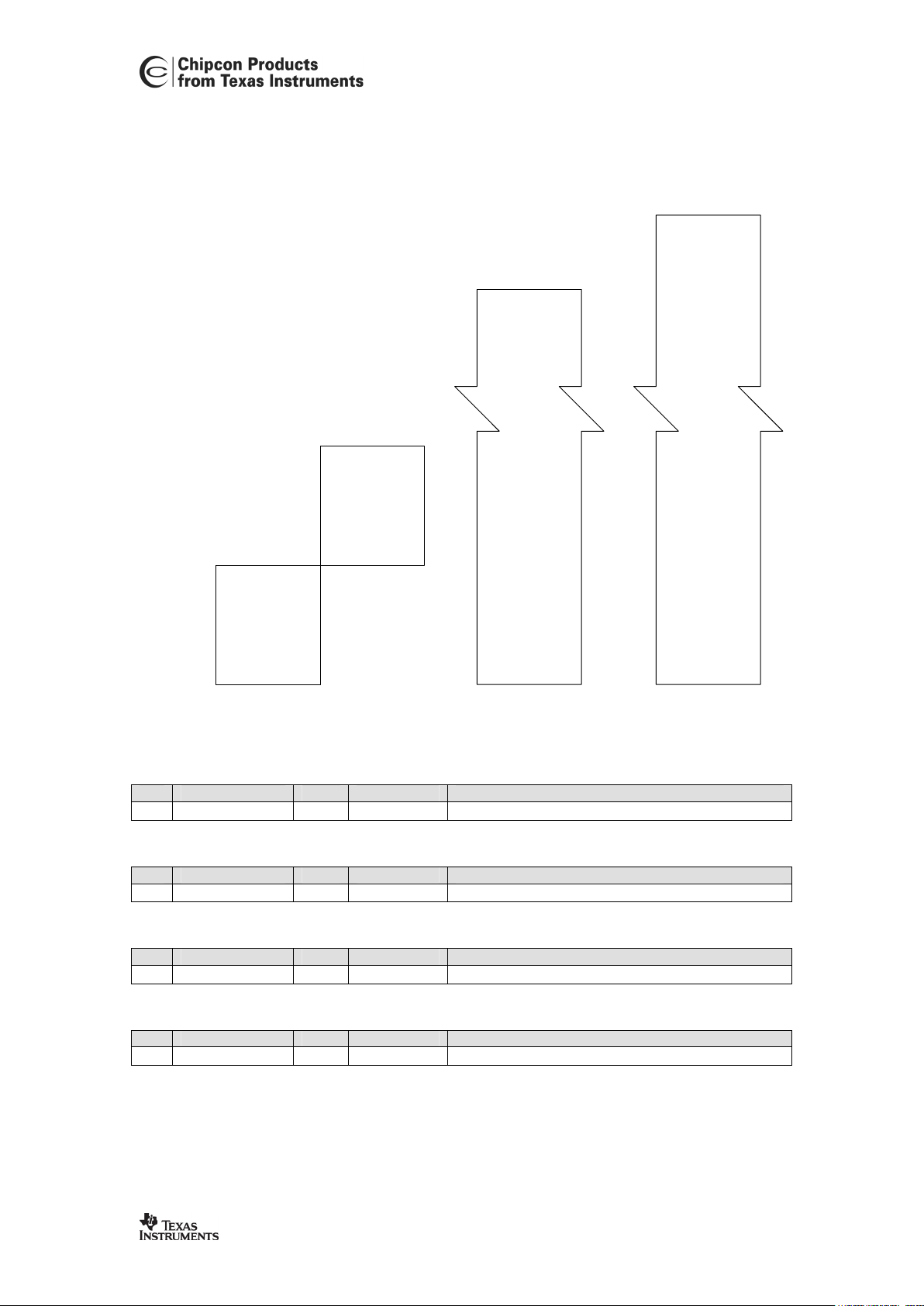

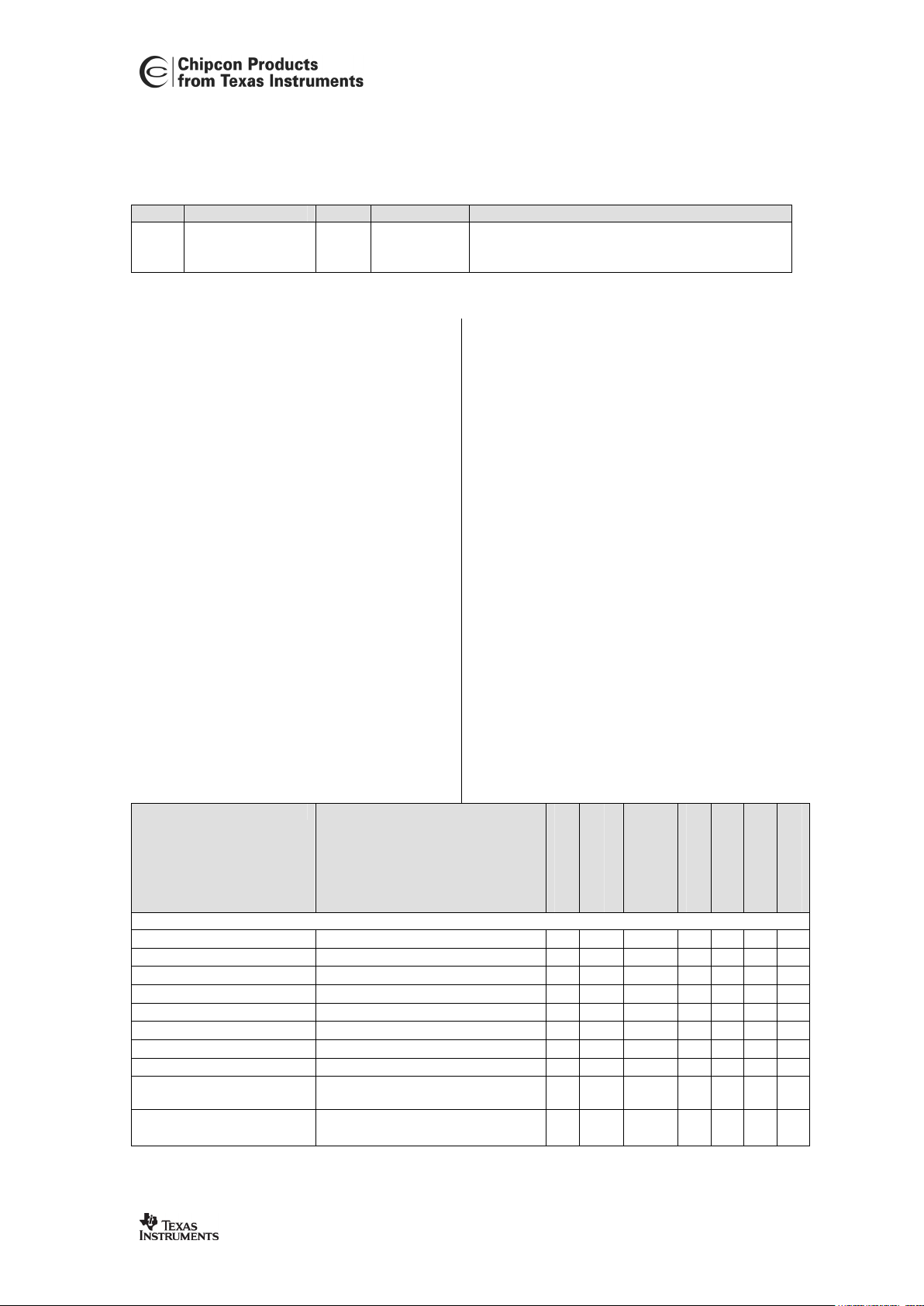

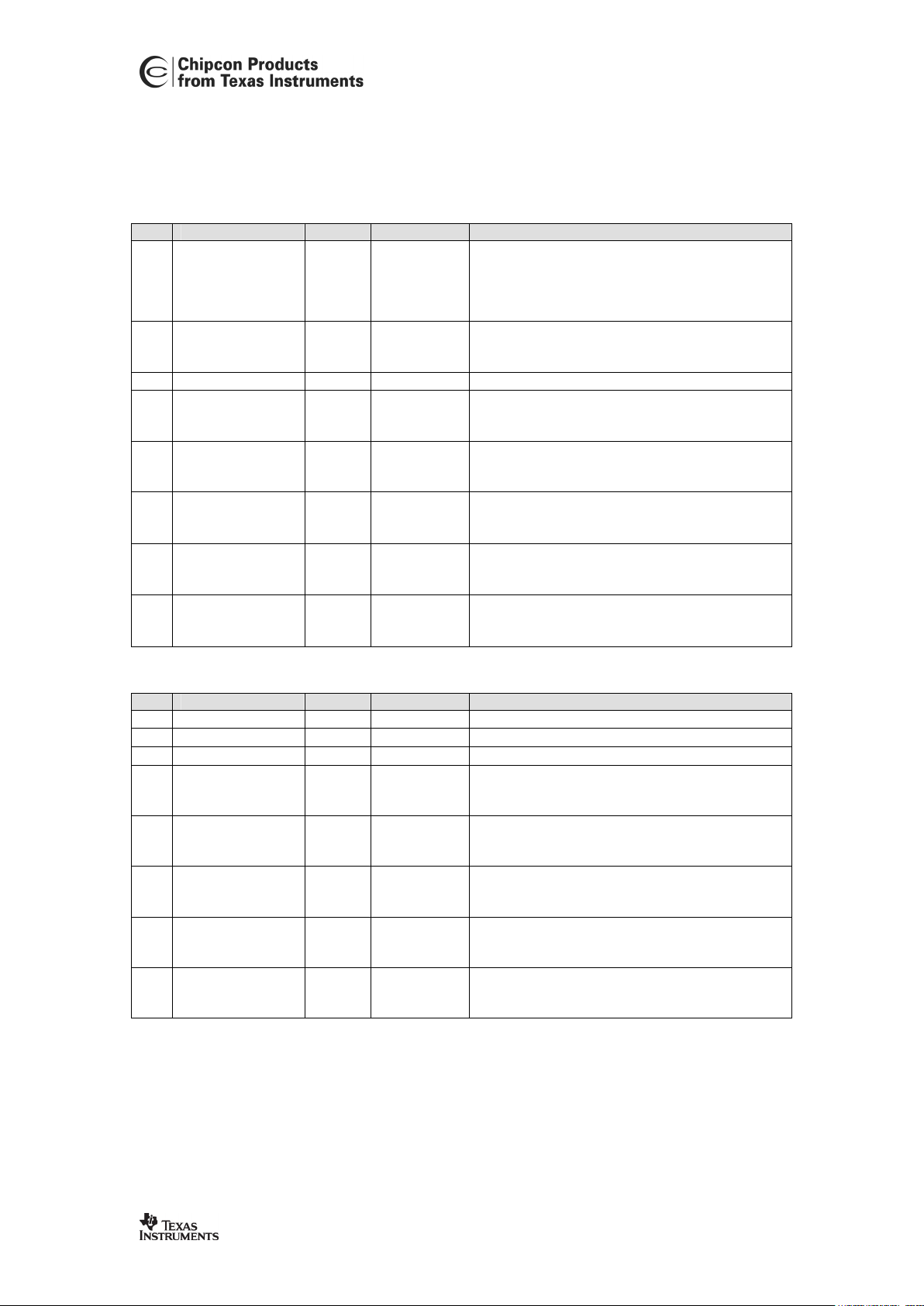

15.3 Memory Map

The

CC1010

memory map is shown in

Figure 3.

CC1010

has 2 blocks of RAM on chip. This

includes the 128 bytes Internal RAM and

the 2048 bytes External RAM. (The 2048byte RAM will be referred to as External

RAM, although it is on-chip. Direct access

to off-chip RAM is not implemented.)

Access to the internal RAM is performed

using the MOV instruction. MOV A, @Ri,

MOV @Ri, A and MOV @Ri, #data use

indirect addressing. MOV A, direct,

MOV Rn, direct, MOV direct, A,

MOV direct, Rn, MOV direct,

direct and MOV direct, #data use

direct addressing. MOV @Ri, direct

uses indirect and direct addressing.

All direct addressing instructions can also

be used to access the SFRs.

CC1010

also

implements the option to access SFRs

indirectly, as described in the In Circuit

Debugging section on page 44.

CC1010

has

dual data pointers to external RAM,

provided in the 16 bit registers

DPTR0 and

DPTR1 (SFRs DPH0, DPL0, DPH1 and

DPL1). If a high-level language compilator

is used, it should be set up to make use of

both pointers for better performance. The

data pointer is selected through

DPS.SEL.

Access to the external RAM is performed

using the MOVX instruction and indirect

addressing using either the 16 bit data

pointers or the 8 bit registers R0 or R1

together with

MPAGE. MOVX A, @DPTR

and MOVX @DPTR, A

moves data to (from) the accumulator,

from (to) the address pointed to by the

currently selected data pointer.

The instructions MOVX A, @Ri and MOVX

@Ri, A moves data to (from) the

accumulator, from (to) the address given

by the memory page address register

MPAGE and the register Ri (R0 or R1).

MPAGE gives the 8 most significant

address bits, while the register Ri gives

the 8 least significant bits. In many 8051

implementations, this type of external

RAM access is performed using

P2 to give

the most significant address bits. Existing

software may therefore have to be

adapted to make use of

MPAGE instead of

P2.

The program memory can be read using

the MOVC A, @A+DPTR and MOVC A,

@A+PC instructions, which moves a byte

from the program memory address given

by A+DPTR or A+PC respectively. The

program memory can not be written using

MOV commands, but uses the method

described in the 8051 Flash Programming

section on page 42.

CC1010

also provides a possibility to stretch

the access cycle to external RAM, through

CKCON.MD(2:0) (see page 55). The

default value for

CKCON.MD is "001". It is

recommended to set

CKCON.MD to "000"

for faster RAM access.

Page 21

CC1010

SWRS047 Page 21 of 152

Internal RAM

Accessible

through Direct

and Indirect

Addressing

0x00

0x7F

Special Function

Registers (SFR),

accessible

through Direct

Addressing

0xFF

Accesible

through indirect

addressing

0x7FF

Internal RAM / SFR

External RAM

0x00

Flash Program

Memory

0x00

Accesible

through indirect

addressing

0x7FFF

Figure 3. Memory Map

DPL0 (0x82) - Data Pointer 0, low byte

Bit Name R/W Reset value Description

7:0

DPL0(7:0)

R/W 0x00 Data Pointer 0, low byte

DPH0 (0x83) - Data Pointer 0, high byte

Bit Name R/W Reset value Description

0

DPH0(7:0)

R/W 0x00 Data Pointer 0, high byte

DPL1 (0x84) - Data Pointer 1, low byte

Bit Name R/W Reset value Description

7:0

DPL1(7:0)

R/W 0x00 Data Pointer 1, low byte

DPH1 (0x85) - Data Pointer 1, high byte

Bit Name R/W Reset value Description

7:0

DPH1(7:0)

R/W 0x00 Data Pointer 1, high byte

Page 22

CC1010

SWRS047 Page 22 of 152

DPS (0x86) - Data Pointer Select

Bit Name R/W Reset value Description

7:1

-

R0 0x00 Reserved, read as 0

0

SEL

R/W 0x00 Data Pointer Select for external RAM access

0 :

DPH0 and DPL0 are used

1 :

DPH1 and DPL1 are used

MPAGE (0x92) - Memory Page Select Register

Bit Name R/W Reset value Description

7:0

MPAGE(7:0)

R/W 0x00 Memory Page

A total of 119 Special Function Registers

(SFRs) are accessible from the

microcontroller core. The names and

addresses of all SFRs are listed in Table

11. All standard 8051 registers are

available, in addition to SFRs which are

CC1010

specific, controlling modules such

as the RF Transceiver, DES encryption,

ADC and Real-Time Clock.

All SFRs will be described in the following

sections. A more detailed overview is

provided in Table 41 on page 144, which

also includes all reset values. SFRs with

addresses ending with 0 or 8 (leftmost

column of Table 11) are bit adressable.

0/8 1/9 2/A 3/B 4/C 5/D 6/E 7/F

0xF8

EIP TEST0 TEST1 TEST2 TEST3 TEST4 TEST5 TEST6

0xF0

B FSHAPE7 FSHAPE6 FSHAPE5 FSHAPE4 FSHAPE3 FSHAPE2 FSHAPE1

0xE8

EIE FSDELAY FSEP0 FSEP1 FSCTRL RTCON FREND TESTMUX

0xE0

ACC CURRENT PA_POW PLL LOCK CAL PRESCALER RESERVED

0xD8

EICON MODEM2 MODEM1 MODEM0 MATCH FLTIM - -

0xD0

PSW X32CON WDT PDET BSYNC - - -

0xC8

RFMAIN RFBUF FREQ_0A FREQ_1A FREQ_2A FREQ_0B FREQ_1B FREQ_2B

0xC0

SCON1 SBUF1 RFCON CRPCON CRPKEY CRPDAT CRPCNT RANCON

0xB8

IP RDATA RADRL RADRH CRPINI4 CRPINI5 CRPINI6 CRPINI7

0xB0

P3 - - - CRPINI0 CRPINI1 CRPINI2 CRPINI3

0xA8

IE TCON2 T2PRE T3PRE T2 T3 FLADR FLCON

0xA0

P2 SPCR SPDR SPSR P0DIR P1DIR P2DIR P3DIR

0x98

SCON0 SBUF0 - - - - - CHVER

0x90

P1 EXIF MPAGE ADCON ADDATL ADDATH ADCON2 ADTRH

0x88

TCON TMOD TL0 TL1 TH0 TH1 CKCON -

0x80

P0 SP DPL0 DPH0 DPL1 DPH1 DPS PCON

Table 11

CC1010

SFR Overview

Page 23

CC1010

SWRS047 Page 23 of 152

15.4 CPU Registers

CC1010

provides 4 register banks of 8

registers each. These register banks are

mapped in the the internal data memory

(see the Memory section on page 33) at

addresses 0x00 - 0x07, 0x08 - 0x0F, 0x10

- 0x17 and 0x18 - 0x1F. Each register

bank contains the 8 8-bit registers R0

through R7. The different register banks

are selected through the Program Status

Word

PSW.RS(1:0) as shown below.

PSW also contains carry, overflow and

parity flags that reflect the current CPU

state.

In addition, the CPU uses the accumulator

register

A (accessed via the SFR space as

ACC), B (for multiplication and division) and

the stack pointer

SP. These registers are

shown below. Note that the hardware

stack pointer

SP is increased when

pushing and decreased when popping

data, unlike many other microcontroller

architectures.

PSW (0xD0) - Program Status Word

Bit Name R/W Reset value Description

7

CY

R/W 0 Carry Flag, set to 1 when the last arithmetic

operation resulted in a carry (during addition) or

borrow (during subtraction), otherwise cleared to

0 by all arithmetic operations.

CY is also used for

rotation instructions.

6

AC

R/W 0 Auxiliary carry flag. Set to 1 when the last

arithmetic operation resulted in a carry into

(during addition) or borrow from (during

subtraction) the high order nibble, otherwise

cleared to 0 by all arithmetic operations.

5

F0

R/W 0 Flag 0 (Available to the user for general purpose)

4

RS1

R/W 0

3

RS0

R/W 0

Register bank select.

RS1 RS0 Working register bank and address

0 0 Bank0 0x00-0x07

0 1 Bank1 0x08-0x0F

1 0 Bank2 0x10-0x17

1 1 Bank3 0x18-0x1F

2

OV

R/W 0 Overflow flag. Set to 1 when the last arithmetic

operation resulted in a carry (addition), borrow

(subtraction), or overflow (multiply or divide).

Otherwise, the bit cleared to 0 by all arithmetic

operations.

1

F1

R/W 0 Flag 1 (Available to the user for general purpose)

0

P

R/W 0 Parity flag. Set to 1 when the modulo-2 sum of

the 8 bits in the accumulator is 1 (odd parity),

cleared to 0 on even parity.

ACC (0xE0) - Accumulator Register

Bit Name R/W Reset value Description

7:0

ACC(7:0)

R/W 0x00 Accumulator

B (0xF0) - B Register

Bit Name R/W Reset value Description

7:0

B(7:0)

R/W 0x00

B is used for multiplication and division

Page 24

CC1010

SWRS047 Page 24 of 152

SP (0x81) - Stack Pointer

Bit Name R/W Reset value Description

7:0

SP(7:0)

R/W 0x07 Stack Pointer, used for pushing and poping data

to and from the stack. Note that the reset value

for

SP is 0x07

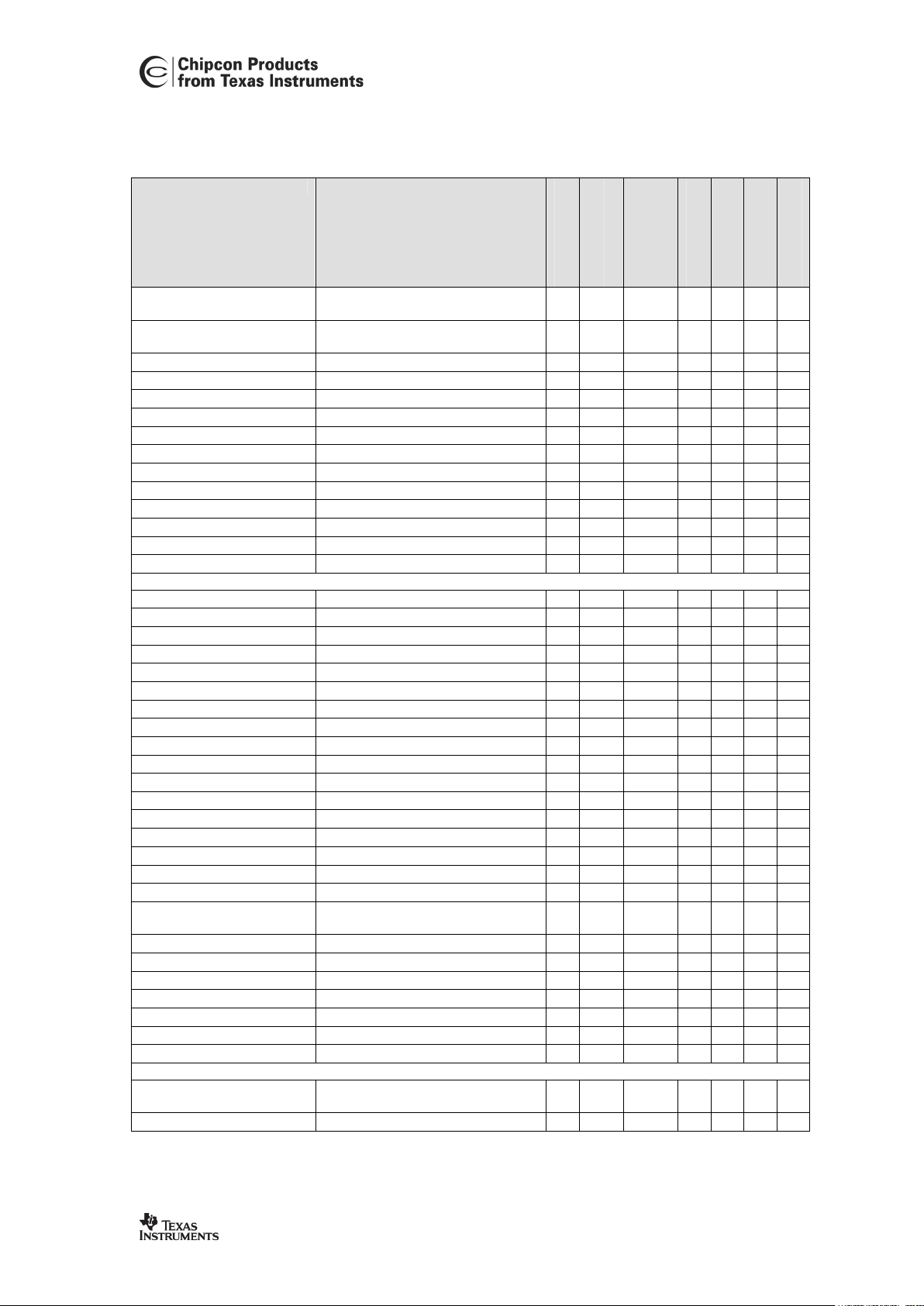

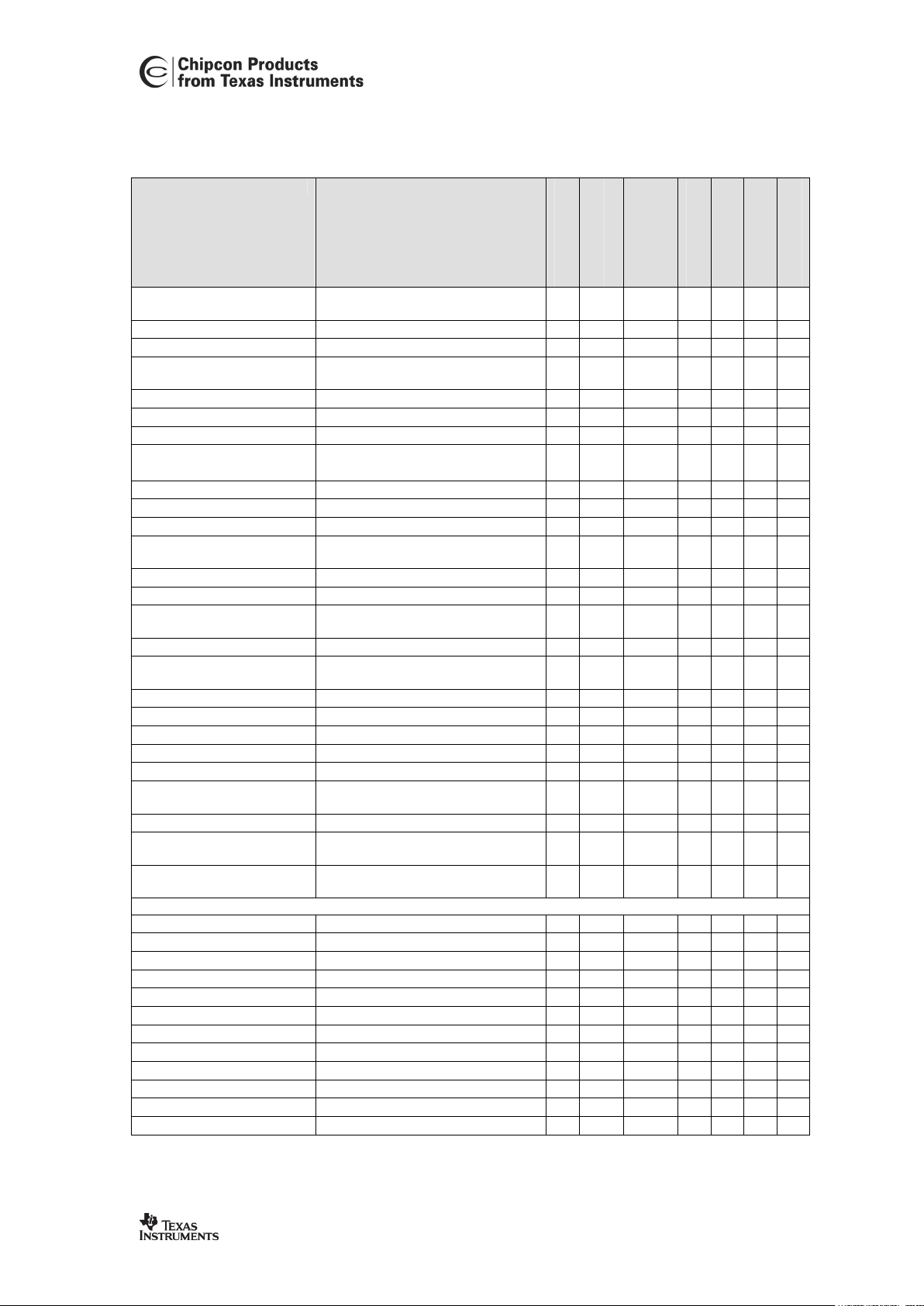

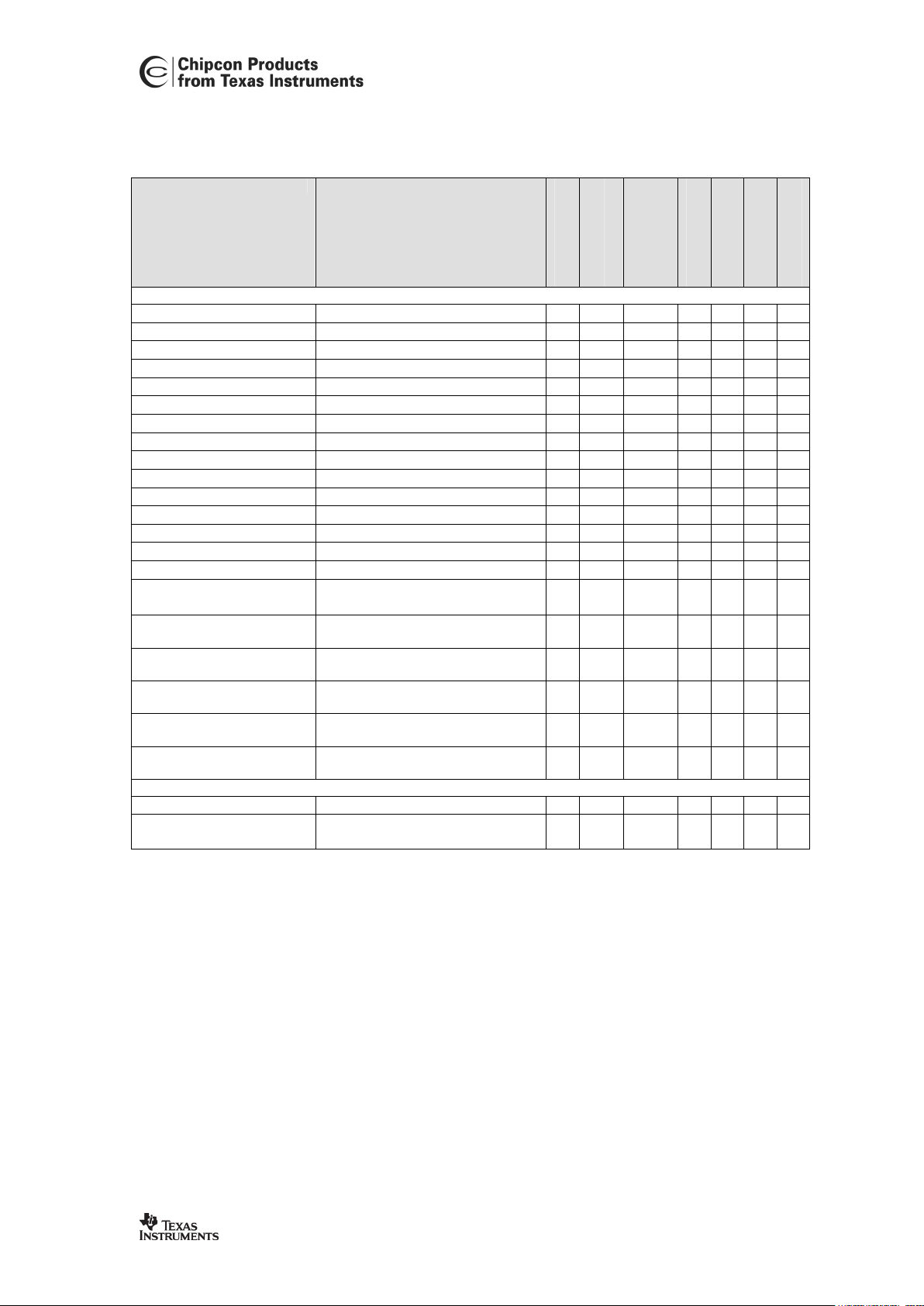

15.5 Instruction Set Summary

The 8051 instruction set is summarised in

Table 12 below. All mnemonics are

Copyright Intel Corporation 1980.

One non-standard 8051 instruction, TRAP,

with opcode 0xA5 is included to enable

setting of breakpoints. This instruction is

described in the In Circuit Debugging

section at page 44. Symbols used in the

table are:

A - Accumulator

AB - Register pair A and B

B - Multiplication register

C - Carry flag

DPTR - Data pointer

Rn - Register R0 - R7

PC - Program counter

direct - 8-bit data address (Internal

RAM 0x00 - 0x7F, SFRs 0x80-0xFF)

@Ri - Internal register pointed to by R0

or R1 (except MOVX)

rel - Two's complement offset byte

used by SJMP and conditional jumps

bit - Direct bit address

#data - 8-bit constant

#data 16 - 16-bit constant

addr 16 - 16-bit destination address

addr 11 - 11-bit destination address,

used by ACALL and AJMP. The branch

will be within the same 2 kB block of

program memory of the first byte of

the following instruction.

The ‘Bytes’ column shows the number of

bytes of Flash memory used. Further, the

number of instruction cycles is shown.

Each instruction cycle requires four clock

cycles. The 4 rightmost columns shows

which flags in the program status word

PSW (see page 23) are affected by the

instructions.

Mnemonic Description

Bytes

Instr. Cycles

Hex Opcode

CY

AC

OV

P

Arithmetic

ADD A, Rn

Add register to A 1 1 28-2F x x x x

ADD A, direct

Add direct byte to A 2 2 25 x x x x

ADD A, @Ri

Add data memory to A 1 1 26-27 x x x x

ADD A, #data

Add immediate to A 2 2 24 x x x x

ADDC A, Rn

Add register to A with carry 1 1 38-3F x x x x

ADDC A, direct

Add direct byte to A with carry 2 2 35 x x x x

ADDC A, @Ri

Add data memory to A with carry 1 1 36-37 x x x x

ADDC A, #data

Add immediate to A with carry 2 2 34 x x x x

SUBB A, Rn

Subtract register from A with

borrow

1 1 98-9F x x x x

SUBB A, direct

Subtract direct byte from A with

borrow

2 2 95 x x x x

Page 25

CC1010

SWRS047 Page 25 of 152

Mnemonic Description

Bytes

Instr. Cycles

Hex Opcode

CY

AC

OV

P

SUBB A, @Ri

Subtract data memory from A with

borrow

1 1 96-97 x x x x

SUBB A, #data

Subtract immediate from A with

borrow

2 2 94 x x x x

INC A

Increment A 1 1 04 x

INC Rn

Increment register 1 1 08-0F

INC direct

Increment direct byte 2 2 05

INC @Ri

Increment data memory 1 1 06-07

DEC A

Decrement A 1 1 14 x

DEC Rn

Decrement register 1 1 18-1F

DEC direct

Decrement direct byte 2 2 15

DEC @Ri

Decrement data memory 1 1 16-17

INC DPTR

Increment data pointer 1 3 A3

MUL AB

Multiply A by B 1 5 A4 x x x

DIV AB

Divide A by B 1 5 84 x x x

DA A

Decimal adjust A 1 1 D4 x x

Logical

ANL A, Rn

AND register to A 1 1 58-5F x

ANL A, direct

AND direct byte to A 2 2 55 x

ANL A, @Ri

AND data memory to A 1 1 56-57 x

ANL A, #data

AND immediate to A 2 2 54 x

ANL direct, A

AND A to direct byte 2 2 52

ANL direct, #data

AND immediate data to direct byte 3 3 53

ORL A, Rn

OR register to A 1 1 48-4F x

ORL A, direct

OR direct byte to A 2 2 45 x

ORL A, @Ri

OR data memory to A 1 1 46-47 x

ORL A, #data

OR immediate to A 2 2 44 x

ORL direct, A

OR A to direct byte 2 2 42

ORL direct, #data

OR immediate data to direct byte 3 3 43

XRL A, Rn

Exclusive-OR register to A 1 1 68-6F x

XRL A, direct

Exclusive-OR direct byte to A 2 2 65 x

XRL A, @Ri

Exclusive-OR data memory to A 1 1 66-67 x

XRL A, #data

Exclusive-OR immediate to A 2 2 64 x

XRL direct, A

Exclusive-OR A to direct byte 2 2 62

XRL direct, #data

Exclusive-OR immediate to direct

byte

3 3 63

CLR A

Clear A 1 1 E4 x

CPL A

Complement A 1 1 F4 x

SWAP A

Swap nibbles of A 1 1 C4

RL A

Rotate A left 1 1 23

RLC A

Rotate A left through carry 1 1 33 x x

RR A

Rotate A right 1 1 03

RRC A

Rotate A right through carry 1 1 13 x x

Data Transfer

MOV A, Rn

Move register to A 1 1 E8-

EF

x

MOV A, direct

Move direct byte to A 2 2 E5 x

Page 26

CC1010

SWRS047 Page 26 of 152

Mnemonic Description

Bytes

Instr. Cycles

Hex Opcode

CY

AC

OV

P

MOV A, @Ri

Move data memory to A 1 1 E6-

E7

x

MOV A, #data

Move immediate to A 2 2 74 x

MOV Rn, A

Move A to register 1 1 F8-FF

MOV Rn, direct

Move direct byte to register 2 2 A8-

AF

MOV Rn, #data

Move immediate to register 2 2 78-7F

MOV direct, A

Move A to direct byte 2 2 F5

MOV direct, Rn

Move register to direct byte 2 2 88-8F

MOV direct,

direct

Move direct byte to direct byte 3 3 85

MOV direct, @Ri

Move data memory to direct byte 2 2 86-87

MOV direct, #data

Move immediate to direct byte 3 3 75

MOV @Ri, A

MOV A to data memory 1 1 F6-F7

MOV @Ri, direct

Move direct byte to data memory 2 2 A6-

A7

MOV @Ri, #data

Move immediate to data memory 2 2 76-77

MOV DPTR, #data

Move immediate to data pointer 3 3 90

MOVC A, @A+DPTR

Move code byte relative DPTR to A 1 3 93 x

MOVC A, @A+PC

Move code byte relative PC to A 1 3 83 x

MOVX A, @Ri

Move external data (A8) to A 1 2-9 E2-

E3

x

MOVX A, @DPTR

Move external data (A16) to A 1 2-9 E0 x

MOVX @Ri, A

Move A to external data (A8) 1 2-9 F2-F3

MOVX @DPTR, A

Move A to external data (A16) 1 2-9 F0

PUSH direct

Push direct byte onto stack 2 2 C0

POP direct

Pop direct byte from stack 2 2 D0

XCH A, Rn

Exchange A and register 1 1 C8-

CF

x

XCH A, direct

Exchange A and direct byte 2 2 C5 x

XCH A, @Ri

Exchange A and data memory 1 1 C6-

C7

x

XCHD A, @Ri

Exchange A and data memory

nibble

1 1 D6-

D7

x

Boolean

CLR C

Clear carry 1 1 C3 x

CLR bit

Clear direct bit 2 2 C2

SETB C

Set carry 1 1 D3 x

SETB bit

Set direct bit 2 2 D2

CPL C

Complement carry 1 1 B3 x

CPL bit

Complement direct bit 2 2 B2

ANL C, bit

AND direct bit to carry 2 2 82 x

ANL C, /bit

AND direct bit inverse to carry 2 2 B0 x

ORL C, bit

OR direct bit to carry 2 2 72 x

ORL C, /bit

OR direct bit inverse to carry 2 2 A0 x

MOV C, bit

Move direct bit to carry 2 2 A2 x

MOV bit, C

Move carry to direct bit 2 2 92

Page 27

CC1010

SWRS047 Page 27 of 152

Mnemonic Description

Bytes

Instr. Cycles

Hex Opcode

CY

AC

OV

P

Branching

ACALL addr 11

Absolute call to subroutine 2 3 11-F1

LCALL addr 16

Long call to subroutine 3 4 12

RET

Return from subroutine 1 4 22

RETI

Return from interrupt 1 4 32

AJMP addr 11

Absolute jump unconditional 2 3 01-E1

LJMP addr 16

Long jump unconditional 3 4 02

SJMP rel

Short jump (relative address) 2 3 80

JC rel

Jump on carry = 1 2 3 40

JNC rel

Jump on carry = 0 2 3 50

JB bit, rel

Jump on direct bit = 1 3 4 20

JNB bit, rel

Jump on direct bit = 0 3 4 30

JBC bit, rel

Jump on direct bit = 1 and clear 3 4 10

JMP @A+DPTR

Jump indirect relative DPTR 1 3 73

JZ rel

Jump on accumulator = 0 2 3 60

JNZ rel

Jump on accumulator /= 0 2 3 70

CJNE A, direct,

rel

Compare A and direct, jump

relative if not equal

3 4 B5 x

CJNE A, #d, rel

Compare A and immediate, jump

relative if not equal

3 4 B4 x

CJNE Rn, #d, rel

Compare reg and immediate,

jump relative if not equal

3 4 B8-

BF

x

CJNE @Ri, #d, rel

Compare ind and immediate, jump

relative if not equal

3 4 B6-

B7

x

DJNZ Rn, rel

Decrement register, jump relative

if not zero

2 3 D8-

DF

DJNZ direct, rel

Decrement direct byte, jump

relative if not zero

3 4 D5

Misc.

NOP

No operation 1 1 00

TRAP

Set EICON.FDIF = 1, used for

breakpoints

1 3 A5

Table 12. Instruction Set Summary

Page 28

CC1010

SWRS047 Page 28 of 152

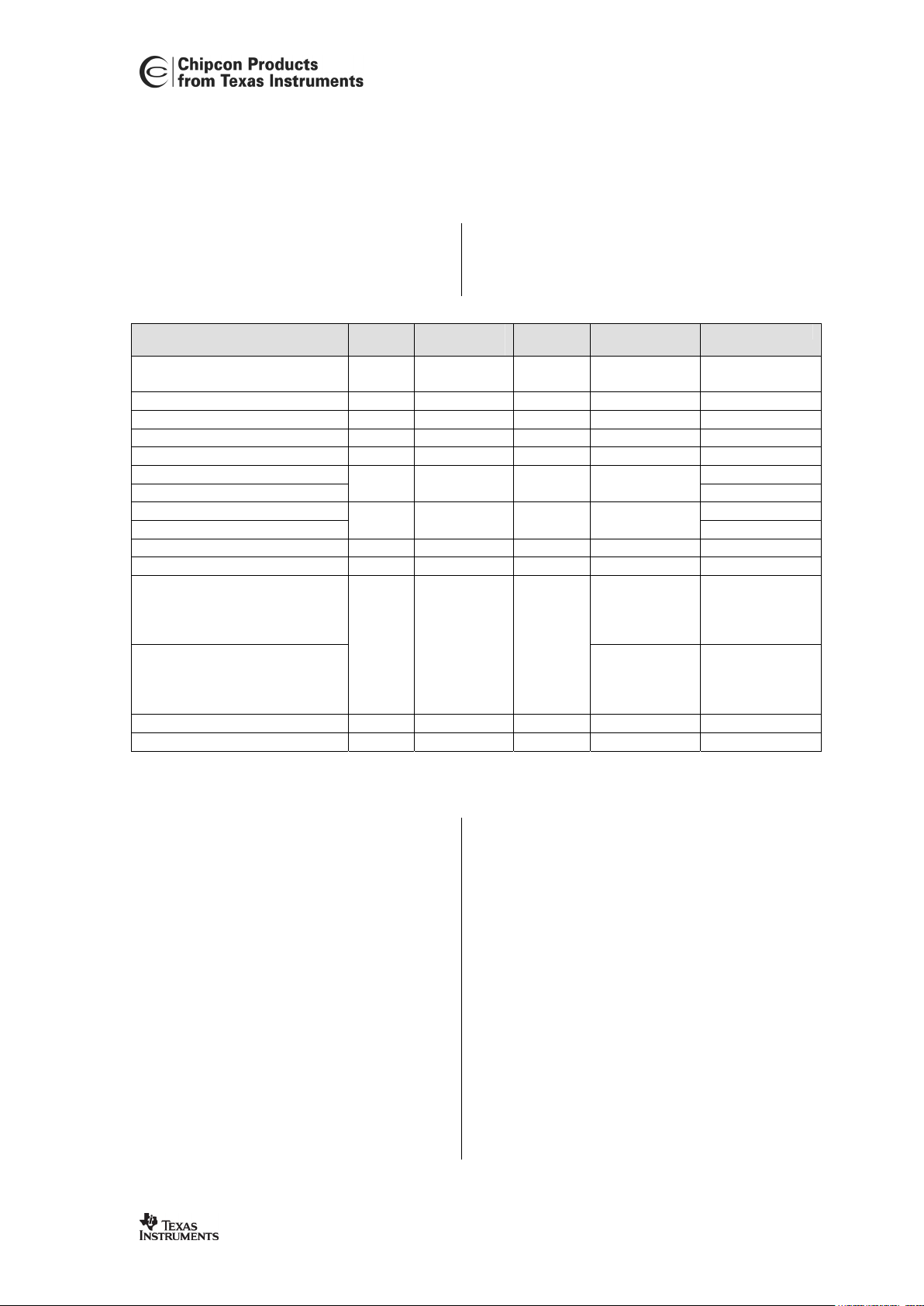

15.6 Interrupts

In

CC1010

there are a total of 15 interrupt

sources, which share 12 interrupt lines.

These are all shown in Table 13. Each

interrupt’s natural priority, interrupt vector,

interrupt enable and interrupt flag, is also

shown in the table, and will be described

below.

Interrupt Natural

Priority

Priority

Control

Interrupt

Vector

Interrupt

Enable

Interrupt Flag

Flash / Debug interrupt 0

-

0x33

EICON.

FDIE

EICON.

FDIF

External Interrupt 0 1

IP.PX0

0x03

IE.EX0 TCON.IE0

(*)

Timer 0 Interrupt 2

IP.PT0

0x0B

IE.ET0 TCON.TF0

(*)

External Interrupt 1 3

IP.PX1

0x13

IE.EX1 TCON.IE1

(*)

Timer 1 Interrupt 4

IP.PT1

0x1B

IE.ET1 TCON.TF1

(*)

Serial Port 0 Transmit Interrupt

SCON0.TI_0

Serial Port 0 Receive Interrupt

5

IP.PS0

0x23

IE.ES0

SCON0.RI_0

Serial Port 1 Transmit Interrupt

SCON1.TI_1

Serial Port 1 Receive Interrupt

6

IP.PS1

0x3B

IE.ES1

SCON1.TI_1

RF Transmit / Receive Interrupt 7

EIP.PRF

0x43

EIE.RFIE EXIF.RFIF

Timer 2 Interrupt 8

EIP.PT2

0x4B

EIE.ET2 EXIF.TF2

ADC Interrupt

EIE.ADIE

and

ADCON2.

ADCIE

EXIF.ADIF

and

ADCON2.

ADCIF

DES Encryption / Decryption

Interrupt

9

EIP.PAD

0x53

EIE.ADIE

and

CRPCON.

CRPIE

EXIF.ADIF

and

CRPCON.

CRPIF

Timer 3 Interrupt 10

EIP.PT3

0x5B

EIE.ET3 EXIF.TF3

Realtime Clock Interrupt 11

EIP.PRTC

0x63

EIE.RTCIE EICON.RTCIF

(*)

- Interrupt flag is cleared by hardware.

Table 13.

CC1010

Interrupt overview

15.6.1 Interrupt Masking

IE.EA is the global interrupt enable for all

interrupts, except the Flash / Debug

interrupt. When

IE.EA is set, each

interrupt is masked by the interrupt enable

bits listed in Table 13. When

IE.EA is

cleared, all interrupts are masked, except

the Flash / Debug interrupt, which has its

own interrupt mask bit,

EICON.FDIE.

15.6.2 Interrupt Processing

When an enabled interrupt occurs, the

CPU jumps to the address of the interrupt

service routine (ISR) associated with that

interrupt, as shown in Table 13. Most

interrupts can also be initiated by setting

the associated interrupt flag from software.

CC1010

executes the ISR to completion

unless another interrupt set at a higher

interrupt level occurs. Each ISR ends with

a RETI (return from interrupt) instruction.

After executing the RETI,

CC1010

returns

to the next instruction that would have

been executed if the interrupt had not

occurred.

CC1010

always completes the instruction in

progress before servicing an interrupt. If

the instruction in progress is RETI, or a

write access to any of the

IP, IE, EIP, or

EIE SFRs,

CC1010

completes one

additional instruction before servicing the

interrupt.

Page 29

CC1010

SWRS047 Page 29 of 152

IE (0xA8) - Interrupt Enable Register

Bit Name R/W Reset value Description

7

EA

R/W 0 Global Interrupt enable / disable

0 : All interrupts except the Flash / debug

interrupt are disabled

1 : Each interrupt is enabled by its individual

masking bit

6

ES1

R/W 0 Serial Port 1 interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

5

-

R/W 0 Reserved for future use

4

ES0

R/W 0 Serial Port 0 interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

3

ET1

R/W 0 Timer 1 interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

2

EX1

R/W 0

External interrupt 1 (from

P3.3) enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

1

ET0

R/W 0 Timer 0 interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

0

EX0

R/W 0

External interrupt 0 (from

P3.2) enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also EA is set

EIE (0xE8) - Extended Interrupt Enable Register

Bit Name R/W Reset value Description

7

-

R1 1 Reserved, read as 1

6

-

R1 1 Reserved, read as 1

5

-

R1 1 Reserved, read as 1

4

RTCIE

R/W 0 Realtime Clock interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

3

ET3

R/W 0 Timer 3 interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

2

ADIE

R/W 0 ADC / DES interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

1

ET2

R/W 0 Timer 2 interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also

EA is set

0

RFIE

R/W 0 RF Interrupt enable / disable

0 : Interrupt is disabled

1 : Interrupt is enabled, when also EA is set

Page 30

CC1010

SWRS047 Page 30 of 152

EICON (0xD8) - Extended Interrupt Control

Bit Name R/W Reset value Description

7

SMOD1

R/W 0 Serial Port 1 baud rate doubler enable / disable

0 : Serial Port 1 baud rate is normal

1 : Serial Port 1 baud rate is doubled

6

-

R1 1 Reserved, read as 1

5

FDIE

R/W 0 Flash / Debug interrupt enable

0 : Interrupt is disabled

1 : Interrupt is enabled (independent of

IE.EA)

4

FDIF

R/W 0 Flash / Debug interrupt flag

FDIF is set by hardware when an 8051-initiated write to

Flash program memory is completed or a TRAP instruction

is executed. FDIF may also be set by software. FDIF

must be cleared by software before exiting the ISR.

3

RTCIF

R/W 0 Real-time clock interrupt flag

RTCIF is set by hardware when an interrupt request is

generated from the real-time clock.

RTCIF may also be set

by software.

RTCIF must be cleared by software before

exiting the ISR.

2

-

R0 0 Reserved, read as 0

1

-

R0 0 Reserved, read as 0

0

-

R0 0 Reserved, read as 0

EXIF (0x91) - Extended Interrupt Flag

Bit Name R/W Reset value Description

7

TF3

R/W 0 Timer 3 interrupt flag.

TF3

is set by hardware when an interrupt request is

generated from Timer 3.

TF3 may also be set by software.

TF3 must be cleared by software before exiting the ISR.

6

ADIF

R/W 0 ADC / DES Interrupt flag.

ADIF is set by hardware when an interrupt request is

generated from the ADC block (

ADCON2.ADCIF) or by the

DES Encryption / Decryption block (

CRPCON.CRPIF).

These interrupts must also be enabled by setting

ADCON2.ADCIE and CRPCON.CRPIE. ADIF may also

be set by software.

ADIF must be cleared by software

before exiting the ISR

5

TF2

R/W 0 Timer 2 interrupt flag.

TF2

is set by hardware when an interrupt request is

generated from Timer 2.

TF2 may also be set by software.

TF2 must be cleared by software before exiting the ISR

4

RFIF

R/W 0 RF Transmit / receive interrupt flag.

RFIF is set by hardware when an interrupt request is

generated from the RF transceiver block.

RFIF may also

be set by software.

RFIF must be cleared by software

before exiting the ISR.

3

-

R1 1 Reserved, read as 1

2

-

R0 0 Reserved, read as 0

1

-

R0 0 Reserved, read as 0

0

-

R0 0 Reserved, read as 0

Page 31

CC1010

SWRS047 Page 31 of 152

15.6.3 Interrupt Priority

Interrupts are prioritised in two stages:

Interrupt level and natural priority. The

interrupt level (low, high or highest) takes

precedence over the natural priority.

The Flash / Debug Interrupt, if enabled,

always has the highest priority and is the

only interrupt that can have the highest

priority. All other interrupts can be

assigned either low or high priority, set by

the registers

IP and EIP listed below.

Two interrupts with the same interrupt

priority that occur simultaneously are

resolved through their natural priority. The

natural priority is shown in Table 13. The

interrupt having the lowest natural priority

will be serviced first.

Once an interrupt is being serviced, only

an interrupt of higher priority level can

interrupt the service routine of the interrupt

currently being serviced.

IP (0xB8) - Interrupt Priority Register

Bit Name R/W Reset value Description

7

-

R1 1 Reserved, read as 1

6

PS1

R/W 0 Serial Port 1 interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

5

-

R/W 0 Reserved for future use

4

PS0

R/W 0 Serial Port 0 interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

3

PT1

R/W 0 Timer 1 interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

2

PX1

R/W 0

External Interrupt 1 (from

P3.3) interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

1

PT0

R/W 0 Timer 0 interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

0

PX0

R/W 0

External Interrupt 0 (from

P3.2) interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

EIP (0xF8) - Extended Interrupt Priority Register

Bit Name R/W Reset value Description

7

-

R1 1 Reserved, read as 1

6

-

R1 1 Reserved, read as 1

5

-

R1 1 Reserved, read as 1

4

PRTC

R/W 0 Realtime Clock interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

3

PT3

R/W 0 Timer 3 interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

2

PAD

R/W 0 ADC / DES interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

1

PT2

R/W 0 Timer 2 interrupt priority control

0 : Interrupt has low priority

1 : Interrupt has high priority

0

PRF

R/W 0 0 : Interrupt has low priority

1 : Interrupt has high priority

Page 32

CC1010

SWRS047 Page 32 of 152

15.7 External interrupts

Two external interrupt pins are available in

the

CC1010

. They are located on pins P3.2

and

P3.3, and can be set up to be either

level- or edge sensitive by setting the

IT1

and

IT2 bits in the TCON register (see

page 54 for more information). When the

external interrupts are activated in the

IE

register, any pulse longer than 8 clock

cycles will always generate an interrupt.

The

CC1010

will wake up from Idle mode

when an external interrupt pin is activated,

but the external interrupt pins cannot wake

the

CC1010

from Power-Down mode.

15.8 Main Crystal Oscillator

An external clock signal or the main crystal

oscillator can be used as main frequency

reference and microcontroller clock signal.

An external clock signal should be

connected to

XOSC_Q1, while XOSC_Q2

should be left open.

The microcontroller core and main

oscillator will operate at any frequency in

the range 3 - 24 MHz. However, the

crystal frequency should be in the range 34, 6-8 or 9-24 MHz because the crystal

frequency is used as reference for the

data rate in the RF transceiver part (as

well as other internal functions). The

following frequencies are recommended

as they will provide “standard” data rates:

3.6864, 7.3728, 11.0592, 14.7456,

18.4320 and 22.1184 MHz. The selected

crystal frequency range must be set in

MODEM0.XOSC_FREQ(2:0) in order to

get the correct data rate (see page 93).

Using the main crystal oscillator, the

crystal must be connected between the

pins

XOSC_Q1 and XOSC_Q2. The

oscillator is designed for parallel mode

operation of the crystal. In addition loading

capacitors (C171 and C181) for the crystal

are required. The loading capacitor values

depend on the total load capacitance, C

L

,

specified for the crystal. The total load

capacitance seen between the crystal