Page 1

CC1000

CC1000

Single Chip Very Low Power RF Transceiver

Applications

• Very low power UHF wireless data

transmitters and receivers

• 315 / 433 / 868 and 915 MHz ISM/SRD

band systems

• RKE – Two-way Remote Keyless Entry

Product Description

CC1000

ceiver designed for very low power and

very low voltage wireless applications. The

circuit is mainly intended for the ISM

(Industrial, Scientific and Medical) and

SRD (Short Range Device) frequency

bands at 315, 433, 868 and 915 MHz, but

can easily be programmed for operation at

other frequencies in the 300-1000 MHz

range.

The main operating parameters of

can be programmed via a serial bus, thus

making

use transceiver. In a typical system

CC1000

microcontroller and a few external passive

components.

is a true single-chip UHF trans-

CC1000

CC1000

will be used together with a

a very flexible and easy to

• Home automation

• Wireless alarm and security systems

• AMR – Automatic Meter Reading

• Low power telemetry

• Game Controllers and advanced toys

CC1000

technology in 0.35 µm CMOS.

is based on Chipcon’s SmartRF®

Features

• True single chip UHF RF transceiver

• Very low current consumption

• Frequency range 300 – 1000 MHz

• Integrated bit synchroniser

• High sensitivity (typical -110 dBm at 2.4

kBaud)

• Programmable output power –20 to

10 dBm

• Small size (TSSOP-28 or UltraCSP™

package)

• Low supply voltage (2.1 V to 3.6 V)

• Very few external components required

• No external RF switch / IF filter

required

• RSSI output

• Single port antenna connection

• FSK data rate up to 76.8 kBaud

• Complies with EN 300 220 and FCC

CFR47 part 15

• Programmable frequency in 250 Hz

steps makes crystal temperature drift

compensation possible without TCXO

• Suitable for frequency hopping

protocols

• Development kit available

• Easy-to-use software for generating the

CC1000

SWRS048 Page 1 of 53

configuration data

Page 2

CC1000

Table of Contents

1. Absolute Maximum Ratings................................................................................... 4

2. Operating Conditions ............................................................................................. 4

3. Electrical Specifications......................................................................................... 4

4. Pin Assignment.......................................................................................................8

5. Circuit Description..................................................................................................9

6. Application Circuit ................................................................................................ 10

6.1 Input / output matching............................................................................................... 10

6.2 VCO inductor.............................................................................................................. 10

6.3 Additional filtering.......................................................................................................10

6.4 Power supply decoupling ........................................................................................... 10

7. Configuration Overview ....................................................................................... 12

8. Configuration Software ........................................................................................ 12

9. 3-wire Serial Configuration Interface ..................................................................13

10. Microcontroller Interface.................................................................................... 15

10.1 Connecting the microcontroller ................................................................................ 15

11. Signal interface ................................................................................................... 16

11.1 Manchester encoding and decoding ........................................................................ 16

12. Bit synchroniser and data decision ..................................................................19

13. Receiver sensitivity versus data rate and frequency separation.................... 22

14. Frequency programming.................................................................................... 23

15. Recommended RX settings for ISM frequencies .............................................24

16. VCO ...................................................................................................................... 25

17. VCO and PLL self-calibration............................................................................. 25

18. VCO and LNA current control ............................................................................ 28

19. Power management ............................................................................................ 28

20. Input / Output Matching...................................................................................... 31

21. Output power programming .............................................................................. 32

22. RSSI output ........................................................................................................33

SWRS048 Page 2 of 53

Page 3

CC1000

23. IF output ............................................................................................................. 34

24. Crystal oscillator.................................................................................................35

25. Optional LC Filter................................................................................................36

26. System Considerations and Guidelines............................................................ 37

26.1 SRD regulations ....................................................................................................... 37

26.2 Low cost systems..................................................................................................... 37

26.3 Battery operated systems......................................................................................... 37

26.4 Crystal drift compensation........................................................................................ 37

26.5 High reliability systems............................................................................................. 37

26.6 Frequency hopping spread spectrum systems......................................................... 37

27. PCB Layout Recommendations......................................................................... 38

28. Antenna Considerations..................................................................................... 38

29. Configuration registers ...................................................................................... 39

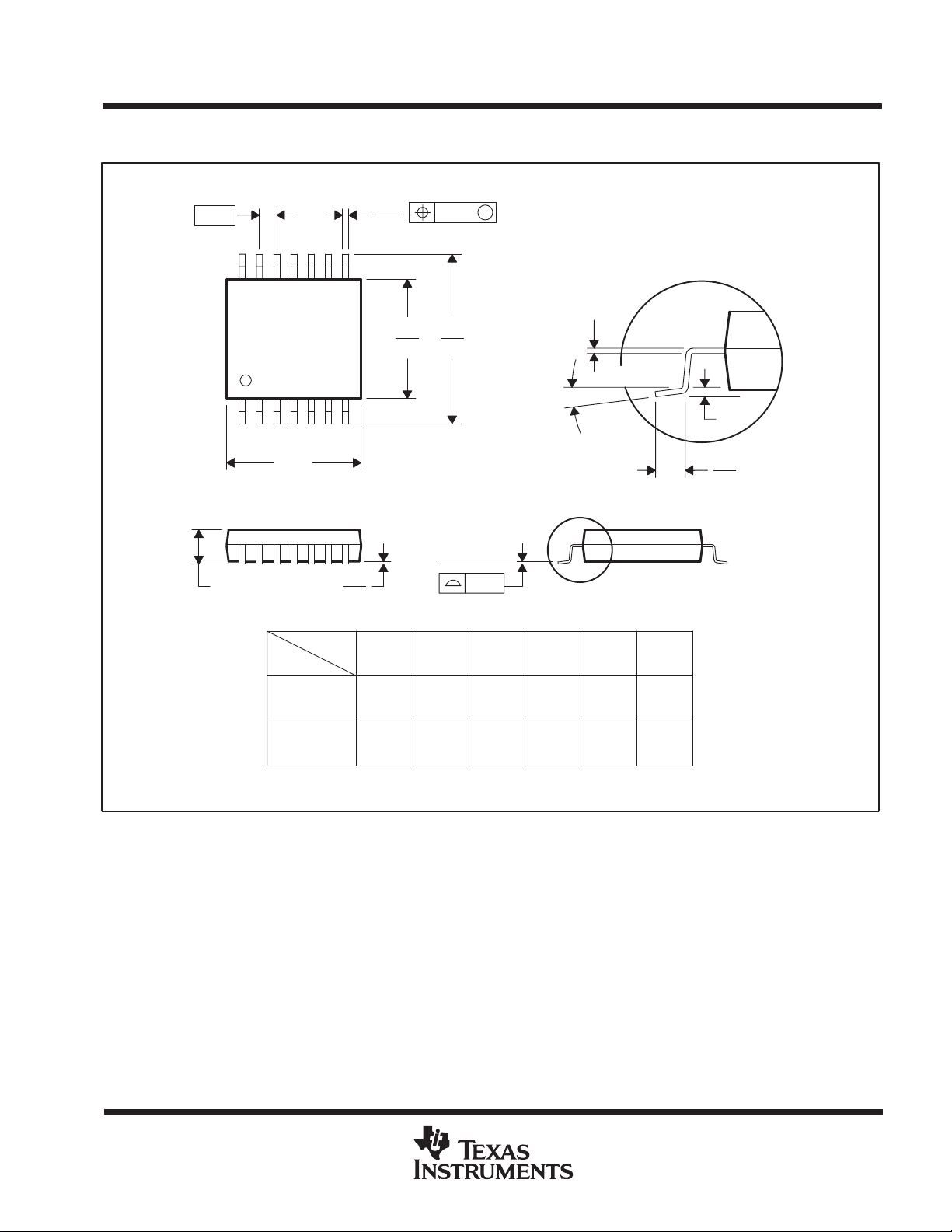

30. Package Description (TSSOP-28) ...................................................................... 48

31. Package Description (UltraCSP™) .................................................................... 49

32. Plastic Tube Specification ................................................................................. 51

33. Carrier Tape and Reel Specification.................................................................. 51

34. Ordering Information .......................................................................................... 52

35. General Information............................................................................................ 52

36. Address Information........................................................................................... 53

SWRS048 Page 3 of 53

Page 4

CC1000

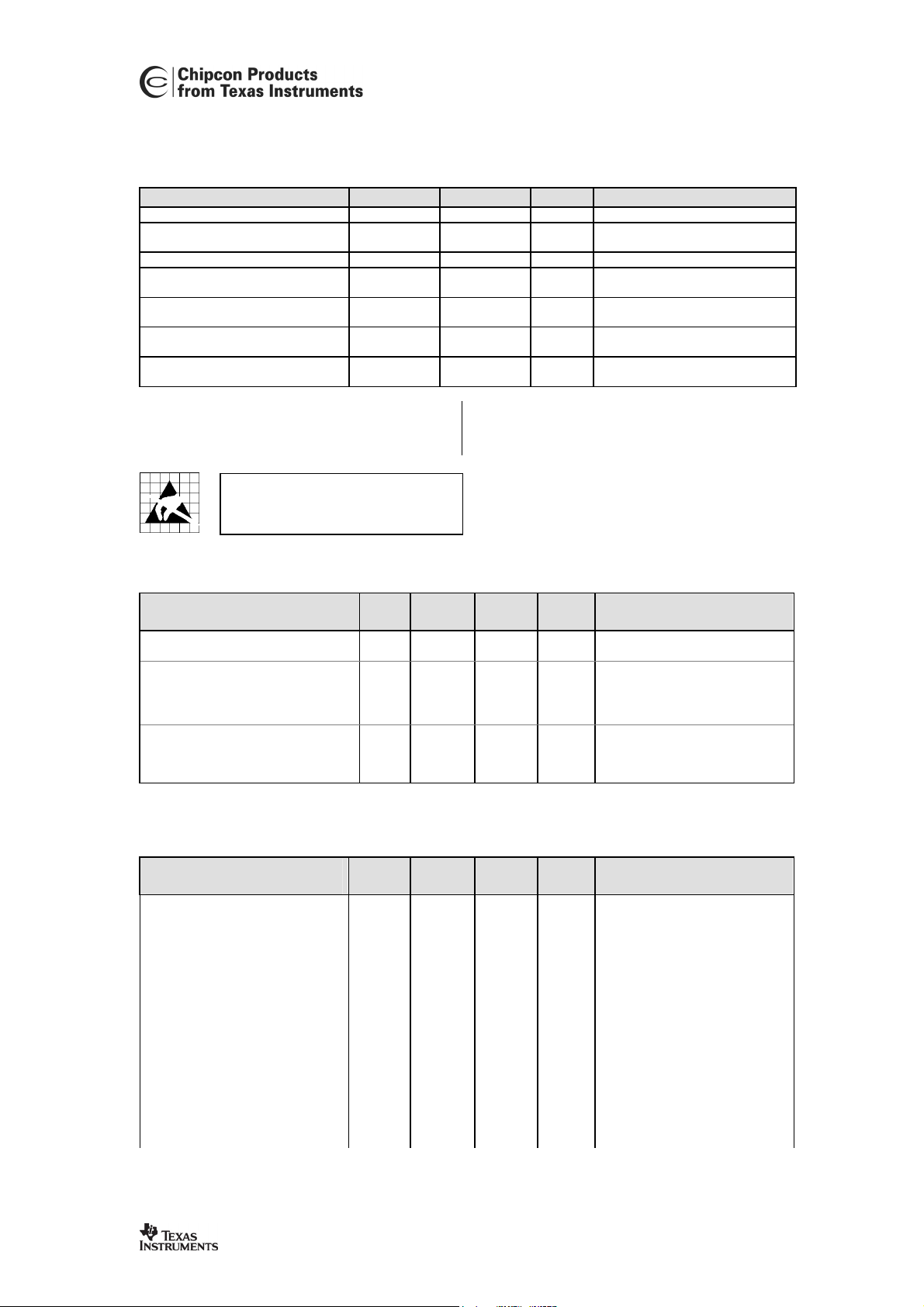

1. Absolute Maximum Ratings

Parameter Min. Max. Units Condition

Supply voltage, VDD -0.3 5.0 V

Voltage on any pin -0.3 VDD+0.3,

Input RF level 10 dBm

Storage temperature range

(TSSOP)

Shelf life (UltraCSP™) 1 year Room temperature and oxygen

Reflow soldering temperature

(TSSOP)

Peak reflow soldering temperature

(UltraCSP™)

-50 150

260

251

Under no circumstances the absolute

maximum ratings given above should be

violated. Stress exceeding one or more of

max 5.0

the limiting values may cause permanent

damage to the device.

Caution! ESD sensitive device.

Precaution should be used when handling

the device in order to prevent permanent

damage.

2. Operating Conditions

Parameter

RF Frequency Range 300

Operating ambient temperature range -40 85

Min. Typ. Max. Unit Condition / Note

1000 MHz Programmable in steps of 250 Hz

V

°C

°C

°C

°C

IPC/JEDEC J-STD-020B

IPC/JEDEC J-STD-020A

free cabinet

Supply voltage

2.1 3.0 3.6 V

3. Electrical Specifications

Tc = 25°C, VDD = 3.0 V if nothing else stated

Parameter

Transmit Section

Transmit data rate

Binary FSK frequency separation

Min. Typ. Max. Unit Condition / Note

0.6 76.8 kBaud NRZ or Manchester encoding.

0 65 kHz

Note: The same supply voltage

should be used for digital (DVDD)

and analogue (AVDD) power.

76.8 kBaud equals 76.8 kbit/s

using NRZ coding. See page 16.

The frequency separation is

programmable in 250 Hz steps.

65 kHz is the maximum

guaranteed separation at 1 MHz

reference frequency. Larger

separations can be achieved at

higher reference frequencies.

SWRS048 Page 4 of 53

Page 5

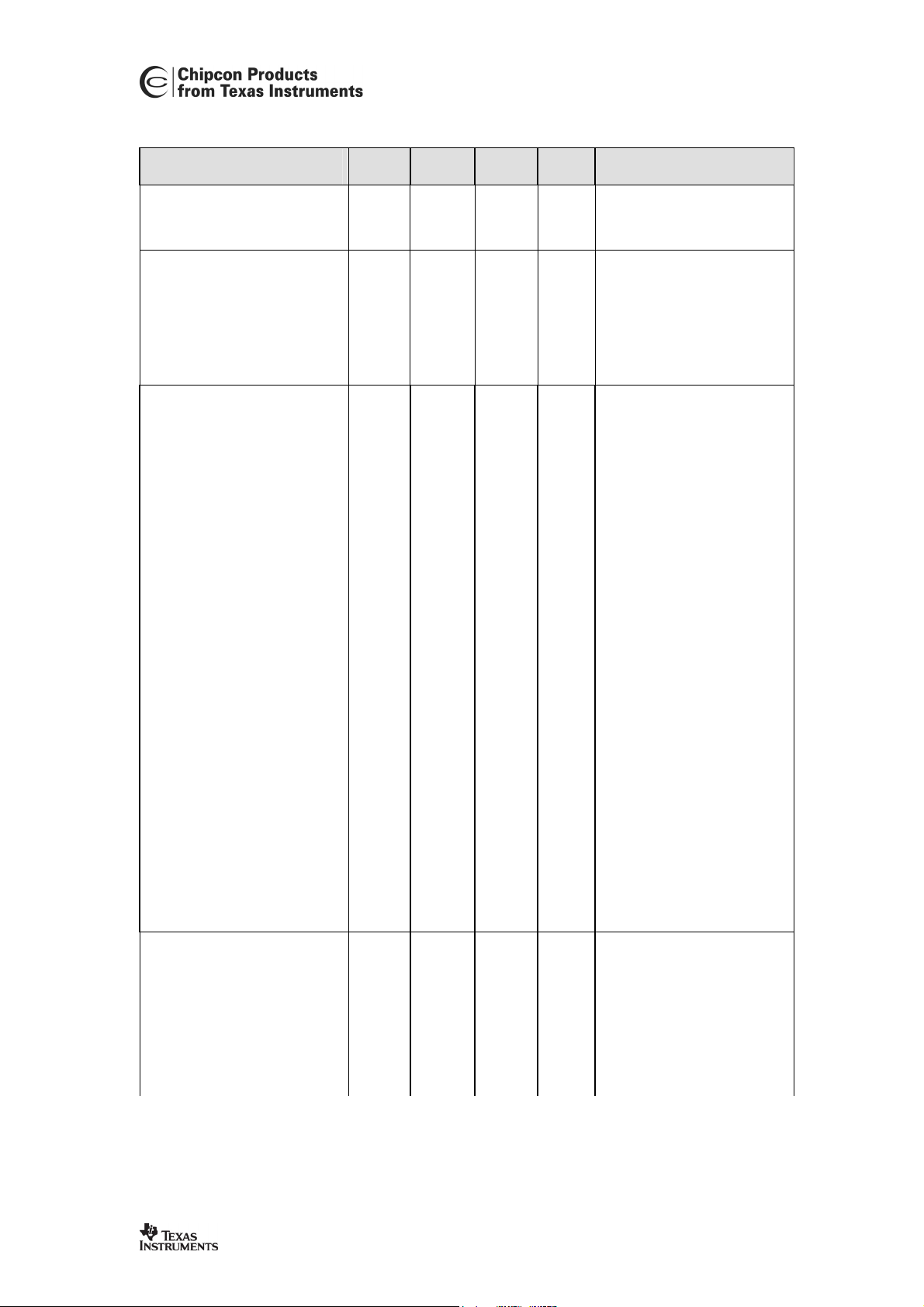

CC1000

Parameter

Output power

433 MHz

868 MHz

RF output impedance

433/868 MHz

Harmonics

Receive Section

Receiver Sensitivity, 433 MHz

Optimum sensitivity (9.3 mA)

Low current consumption (7.4 mA)

Receiver Sensitivity, 868 MHz

Optimum sensitivity (11.8 mA)

Low current consumption (9.6 mA)

System noise bandwidth 30 kHz 2.4 kBaud, Manchester coded

Cascaded noise figure

433/868 MHz

Saturation

Input IP3

Blocking

LO leakage -57 dBm

Input impedance

Turn on time 11 128 Baud The turn-on time is determined by

IF Section

Intermediate frequency (IF)

IF bandwidth

RSSI dynamic range

RSSI accuracy

Min. Typ. Max. Unit Condition / Note

-20

-20

140 / 80

-20 dBc An external LC or SAW filter

12/13 dB

10 dBm 2.4 kBaud, Manchester coded

-18 dBm From LNA to IF output

40 dBc At +/- 1 MHz

150

175 kHz

-105 -50 dBm

-110

-109

-107

-105

88-j26

70-j26

52-j7

52-j4

± 6

10

5

10.7

dB See p.33 for details

dBm

dBm

Ω

dBm

dBm

dBm

dBm

Ω

Ω

Ω

Ω

kHz

MHz

Delivered to 50 Ω load.

The output power is

programmable.

Transmit mode. For matching

details see “Input/ output

matching” p.31.

should be used to reduce

harmonics emission to comply

with SRD requirements. See

p.36.

2.4 kBaud, Manchester coded

data, 64 kHz frequency

separation, BER = 10

See Table 6 and Table 7 page 22

for typical sensitivity figures at

other data rates.

data

data, BER = 10

Receive mode, series equivalent

at 315 MHz

at 433 MHz

at 868 MHz.

At 915 MHz

For matching details see “Input/

output matching” p. 31.

the demodulator settling time,

which is programmable. See p.

19

Internal IF filter

External IF filter

-3

-3

SWRS048 Page 5 of 53

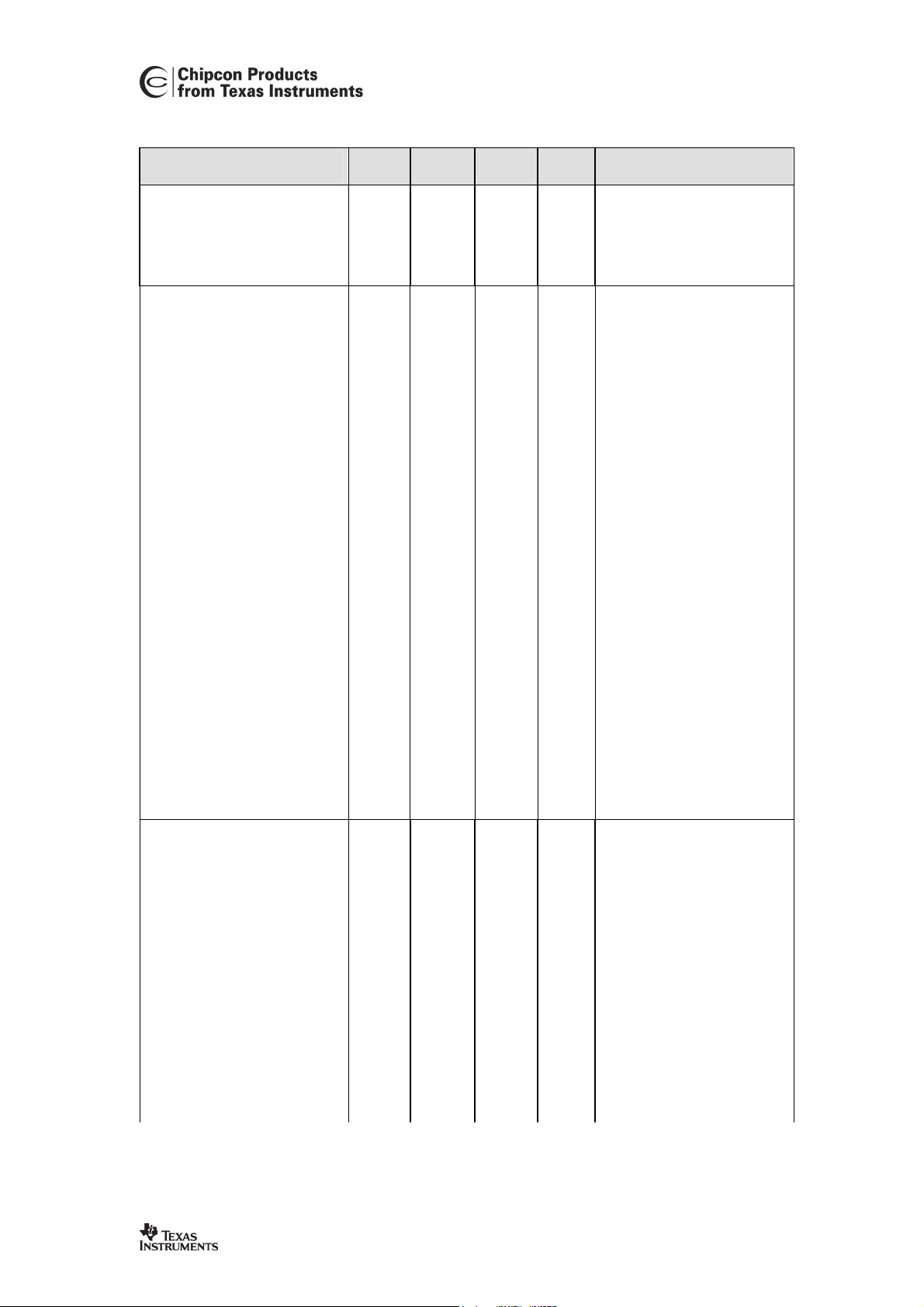

Page 6

Parameter

RSSI linearity

Frequency Synthesiser

Section

Crystal Oscillator Frequency

Crystal frequency accuracy

requirement

Crystal operation

Crystal load capacitance

Crystal oscillator start-up time 5

Output signal phase noise

PLL lock time (RX / TX turn time)

PLL turn-on time, crystal oscillator

on in power down mode

Min. Typ. Max. Unit Condition / Note

3 16 MHz Crystal frequency can be 3-4, 6-8

Parallel C171 and C181 are loading

12

12

12

-85 dBc/Hz At 100 kHz offset from carrier

200

250

± 2

± 50

± 25

22

16

16

1.5

2

dB

ppm 433 MHz

30

30

16

ms

or 9-16 MHz. Recommended

frequencies are 3.6864, 7.3728,

11.0592 and 14.7456. See page

35 for details.

868 MHz

The crystal frequency accuracy

and drift (ageing and

temperature dependency) will

determine the frequency accuracy

of the transmitted signal.

capacitors, see page 35

pF

3-4 MHz, 22 pF recommended

pF

6-8 MHz, 16 pF recommended

pF

9-16 MHz, 16 pF recommended

3.6864 MHz, 16 pF load

ms

7.3728 MHz, 16 pF load

ms

16 MHz, 16 pF load

Up to 1 MHz frequency step

µs

Crystal oscillator running

µs

CC1000

Digital Inputs/Outputs

Logic “0” input voltage

Logic ”1” input voltage

Logic “0” output voltage

Logic “1” output voltage

Logic “0” input current

Logic “1” input current

DIO setup time

0 0.3*VDD V

0.7*VDD VDD V

0

2.5

NA -1

NA 1

20 ns TX mode, minimum time DIO

0.4 V Output current -2.5 mA,

VDD V Output current 2.5 mA,

SWRS048 Page 6 of 53

3.0 V supply voltage

3.0 V supply voltage

Input signal equals GND

µA

Input signal equals VDD

µA

must be ready before the positive

edge of DCLK

Page 7

Parameter

DIO hold time

Serial interface (PCLK, PDATA and

PALE) timing specification

Current Consumption

Power Down mode

Current Consumption,

receive mode 433/868 MHz

Current Consumption,

average in receive mode using

polling 433/868 MHz

Current Consumption,

transmit mode 433/868 MHz:

P=0.01mW (-20 dBm)

P=0.3 mW (-5 dBm)

P=1 mW (0 dBm)

P=3 mW (5 dBm)

P=10 mW (10 dBm)

Current Consumption, crystal osc.

Current Consumption, crystal osc.

And bias

Current Consumption, crystal osc.,

bias and synthesiser, RX/TX

Min. Typ. Max. Unit Condition / Note

10 ns TX mode, minimum time DIO

See Table 2 page 14

0.2 1

7.4/9.6 mA Current is programmable and can

74/96

5.3/8.6

8.9/13.8

10.4/16.5

14.8/25.4

26.7/NA

30

80

105

860

4/5

5/6

must be held after the positive

edge of DCLK

Oscillator core off

µA

be increased for improved

sensitivity

Polling controlled by micro-

µA

controller using 1:100 receive to

power down ratio

mA

The ouput power is delivered to a

50Ω load, see also p. 32

mA

mA

mA

mA

3-8 MHz, 16 pF load

µA

9-14 MHz, 12 pF load

µA

14-16 MHz, 16 pF load

µA

µA

< 500 MHz

mA

> 500 MHz

mA

CC1000

SWRS048 Page 7 of 53

Page 8

CC1000

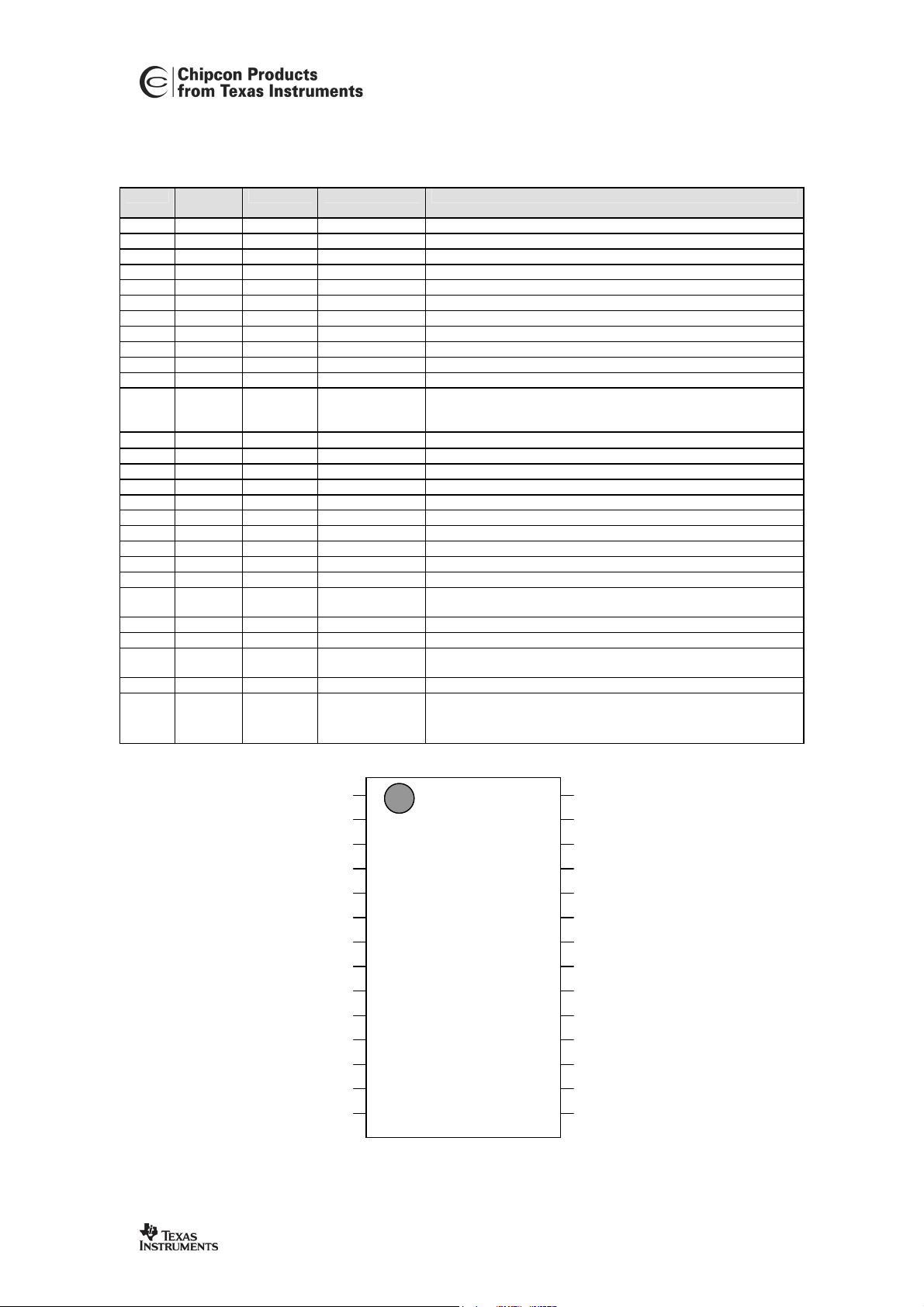

4. Pin Assignment

Pin no. UltraCSP

pin no.

1 G3 AVDD Power (A) Power supply (3 V) for analog modules (mixer and IF)

2 F2 AGND Ground (A) Ground connection (0 V) for analog modules (mixer and IF)

3 G2 RF_IN RF Input RF signal input from antenna

4 G1 RF_OUT RF output RF signal output to antenna

5 F1 AVDD Power (A) Power supply (3 V) for analog modules (LNA and PA)

6 E2 AGND Ground (A) Ground connection (0 V) for analog modules (LNA and PA)

7 E1 AGND Ground (A) Ground connection (0 V) for analog modules (PA)

8 D1 AGND Ground (A) Ground connection (0 V) for analog modules (VCO and prescaler)

9 C1 AVDD Power (A) Power supply (3 V) for analog modules (VCO and prescaler)

10 B1 L1 Analog input Connection no 1 for external VCO tank inductor

11 A1 L2 Analog input Connection no 2 for external VCO tank inductor

12 B2 CHP_OUT

13 C2 R_BIAS Analog output

14 F3 AGND Ground (A) Ground connection (0 V) for analog modules (backplane)

15 A2 AVDD Power (A) Power supply (3 V) for analog modules (general)

16 B3 AGND Ground (A) Ground connection (0 V) for analog modules (general)

17 A3 XOSC_Q2 Analog output Crystal, pin 2

18 A4 XOSC_Q1 Analog input Crystal, pin 1, or external clock input

19 B4 AGND Ground (A) Ground connection (0 V) for analog modules (guard)

20 C3 DGND Ground (D) Ground connection (0 V) for digital modules (substrate)

21 C4 DVDD Power (D) Power supply (3 V) for digital modules

22 D4 DGND Ground (D) Ground connection (0 V) for digital modules

23 E4 DIO Digital

24 F4 DCLK Digital output Data clock for data in both receive and transmit mode

25 G4 PCLK Digital input Programming clock for 3-wire bus

26 D3 PDATA Digital

27 D2 PALE Digital input Programming address latch enable for 3-wire bus. Internal pull-up.

28 E3 RSSI/IF Analog output The pin can be used as RSSI or 10.7 MHz IF output to optional

A=Analog, D=Digital

Pin name Pin type Description

Analog output Charge pump current output

(LOCK)

The pin can also be used as PLL Lock indicator. Output is high

when PLL is in lock.

Connection for external precision bias resistor (82 kΩ, ± 1%)

Data input/output. Data input in transmit mode. Data output in

input/output

receive mode

Programming data for 3-wire bus. Programming data input for

input/output

write operation, programming data output for read operation

external IF and demodulator. If not used, the pin should be left

open (not connected).

(Top View)

1

AVDD

AVDD

AGND

AGND

RF_IN

RF_IN

RF_OUT

RF_OUT

AVDD

AVDD

AGND

AGND

AGND

AGND

AGND

AGND

AVDD

AVDD

L1

L1

L2

L2

CHP_OUT

CHP_OUT

R_BIAS

R_BIAS

AGND

AGND

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14 15

14 15

CC1000

CC1000

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

RSSI/IF

RSSI/IF

RSSI/IF

PALE

PALE

PALE

PDATA

PDATA

PDATA

PCLK

PCLK

PCLK

DCLK

DCLK

DCLK

DIO

DIO

DIO

DGND

DGND

DGND

DVDD

DVDD

DVDD

DGND

DGND

DGND

AGND

AGND

AGND

XOSC_Q1

XOSC_Q1

XOSC_Q1

XOSC_Q2

XOSC_Q2

XOSC_Q2

AGND

AGND

AGND

AVDD

AVDD

AVDD

SWRS048 Page 8 of 53

Page 9

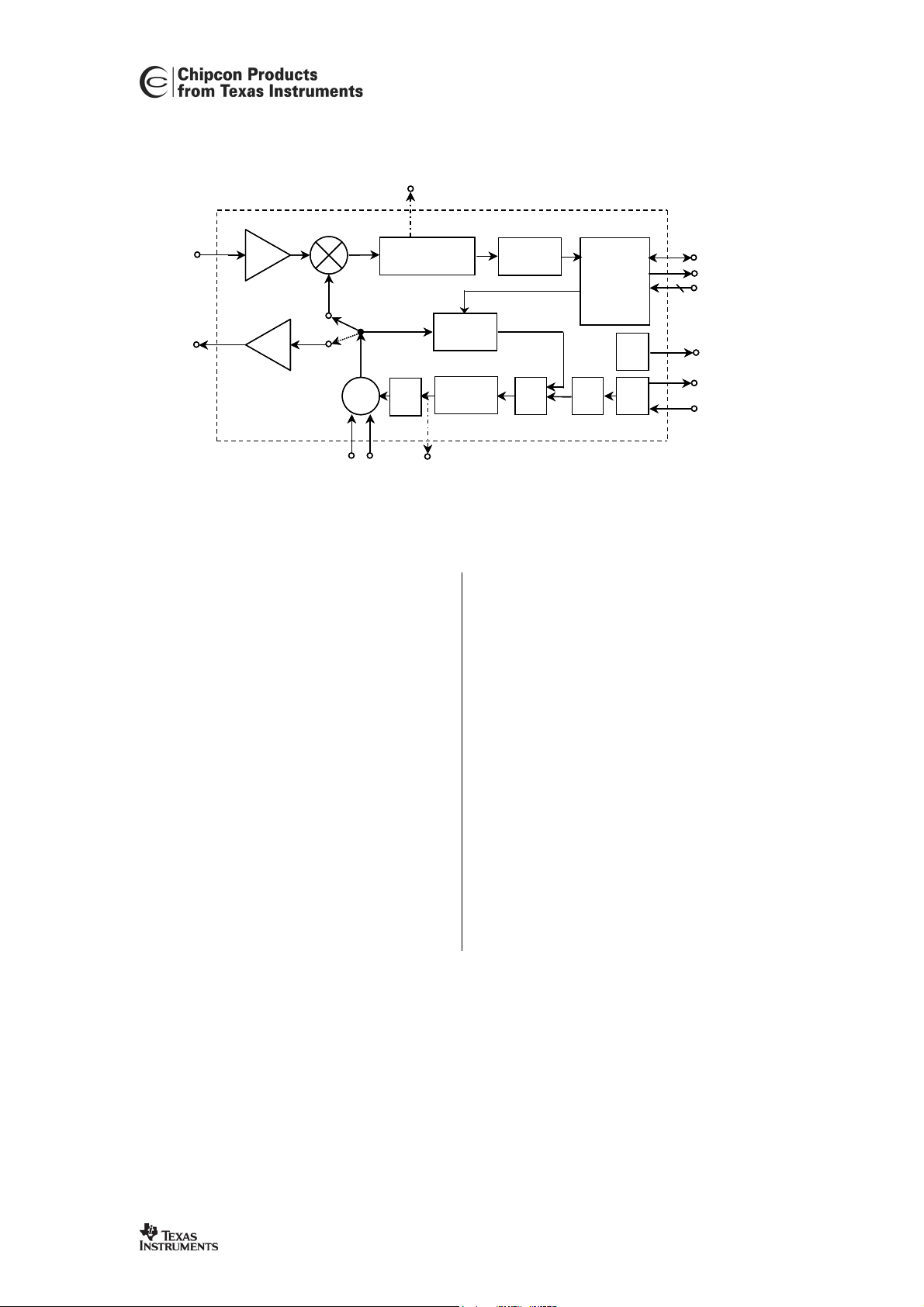

5. Circuit Description

MIXER

MIXER

RF_IN

RF_IN

RF_OUT

RF_OUT

LNA

LNA

PA

PA

VCO

VCO

RSSI/IF

RSSI/IF

DEMOD

/N

/N

DEMOD

~

~

L1

L1

L2

L2

IF STAGE

IF STAGE

LPF

LPF

CHP_OUT

CHP_OUT

CHARGE

CHARGE

PUMP

PUMP

CONTROL

CONTROL

BIAS

BIAS

PD OSC

PD OSC

/R

/R

CC1000

DIO

DIO

DCLK

DCLK

PDATA, PCLK, PALE

PDATA, PCLK, PALE

3

3

R_BIAS

R_BIAS

XOSC_Q2

XOSC_Q2

XOSC_Q1

XOSC_Q1

Figure 1. Simplified block diagram of the

A simplified block diagram of

CC1000

is

shown in Figure 1. Only signal pins are

shown.

In receive mode

CC1000

is configured as a

traditional superheterodyne receiver. The

RF input signal is amplified by the lownoise amplifier (LNA) and converted down

to the intermediate frequency (IF) by the

mixer (MIXER). In the intermediate

frequency stage (IF STAGE) this

downconverted signal is amplified and

filtered before being fed to the

demodulator (DEMOD). As an option a

RSSI signal, or the IF signal after the

mixer is available at the RSSI/IF pin. After

demodulation

CC1000

outputs the digital

demodulated data on the pin DIO.

Synchronisation is done on-chip providing

data clock at DCLK.

CC1000

In transmit mode the voltage controlled

oscillator (VCO) output signal is fed

directly to the power amplifier (PA). The

RF output is frequency shift keyed (FSK)

by the digital bit stream fed to the pin DIO.

The internal T/R switch circuitry makes the

antenna interface and matching very easy.

The frequency synthesiser generates the

local oscillator signal which is fed to the

MIXER in receive mode and to the PA in

transmit mode. The frequency synthesiser

consists of a crystal oscillator (XOSC),

phase detector (PD), charge pump

(CHARGE PUMP), VCO, and frequency

dividers (/R and /N). An external crystal

must be connected to XOSC, and only an

external inductor is required for the VCO.

The 3-wire digital serial interface

(CONTROL) is used for configuration.

SWRS048 Page 9 of 53

Page 10

6. Application Circuit

Very few external components are

required for the operation of

typical application circuit is shown in

Figure 2. Component values are shown in

Table 1.

6.1 Input / output matching

C31/L32 is the input match for the

receiver. L32 is also a DC choke for

biasing. C41, L41 and C42 are used to

match the transmitter to 50 Ω. An internal

T/R switch circuit makes it possible to

connect the input and output together and

match the

TX mode. See “Input/output matching”

p.31 for details.

6.2 VCO inductor

The VCO is completely integrated except

for the inductor L101.

CC1000

to 50 Ω in both RX and

CC1000

. A

CC1000

Component values for the matching

network and VCO inductor are easily

calculated using the SmartRF® Studio

software.

6.3 Additional filtering

Additional external components (e.g. RF

LC or SAW-filter) may be used in order to

improve the performance in specific

applications. See also “Optional LC filter”

p.36 for further information.

6.4 Power supply decoupling

Power supply decoupling and filtering

must be used (not shown in the

application circuit). The placement and

size of the decoupling capacitors and the

power supply filtering are very important to

achieve the optimum performance.

Chipcon provides reference designs

(CC1000PP and CC1000uCSP_EM) that

should be followed very closely.

Figure 2. Typical

CC1000

application circuit (power supply decoupling not shown)

SWRS048 Page 10 of 53

Page 11

CC1000

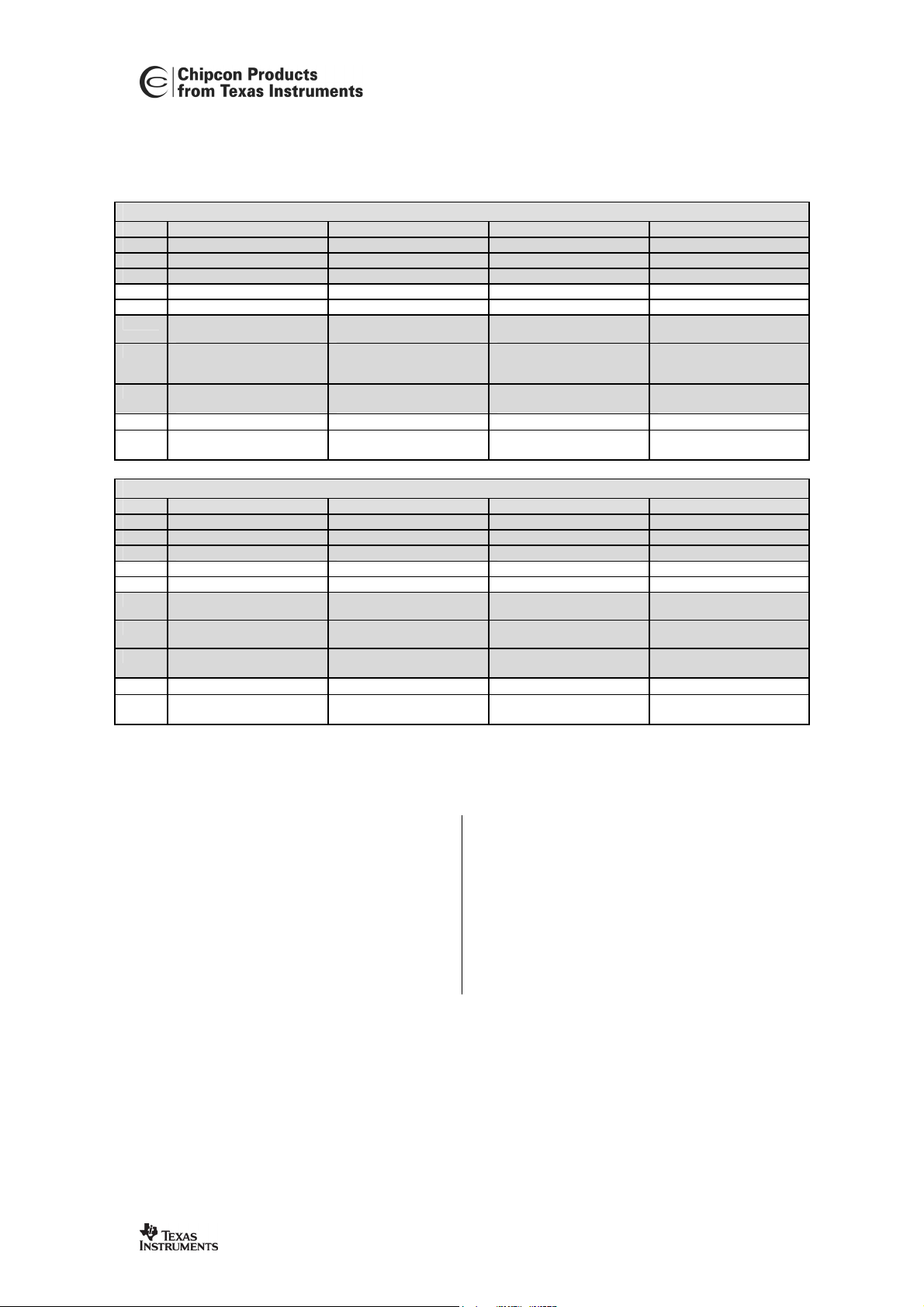

CC1000 TSSOP package

Item 315 MHz 433 MHz 868 MHz 915 MHz

C31 8.2 pF, 5%, C0G, 0603 15 pF, 5%, C0G, 0603 10 pF, 5%, C0G, 0603 10 pF, 5%, C0G, 0603

C41 2.2 pF, 5%, C0G, 0603 8.2 pF, 5%, C0G, 0603 Not used Not used

C42 5.6 pF, 5%, C0G, 0603 5.6 pF, 5%, C0G, 0603 4.7 pF, 5%, C0G, 0603 4.7 pF, 5%, C0G, 0603

C171 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603

C181 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603

L32 39 nH, 10%, 0805

L41 20 nH, 10%, 0805

L101 56 nH, 5%, 0805

R131

XTAL 14.7456 MHz crystal,

(Coilcraft 0805CS-390XKBC)

(Coilcraft 0805HQ20NXKBC)

(Koa KL732ATE56NJ)

82 kΩ, 1%, 0603 82 kΩ, 1%, 0603 82 kΩ, 1%, 0603 82 kΩ, 1%, 0603

16 pF load

Item 315 MHz 433 MHz 868 MHz 915 MHz

C31 8.2 pF, 5%, C0G, 0402 15 pF, 5%, C0G, 0402 10 pF, 5%, C0G, 0402 10 pF, 5%, C0G, 0402

C41 Not used Not used Not used Not used

C42 4.7 pF, 5%, C0G, 0402 4.7 pF, 5%, C0G, 0402 6.8 pF, 5%, C0G, 0402 6.8 pF, 5%, C0G, 0402

C171 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402

C181 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402

L32 39 nH, 5%, 0402

L41 22 nH, 5%, 0402

L101 56 nH, 5%, 0402

R131

XTAL 14.7456 MHz crystal,

(Ceramic multilayer)

(Ceramic multilayer)

(Thin film inductor)

82 kΩ, 1%, 0402 82 kΩ, 1%, 0402 82 kΩ, 1%, 0402 82 kΩ, 1%, 0402

16 pF load

Note: Items shaded are different for different frequencies

68 nH, 10%, 0805

(Coilcraft 0805CS-680XKBC)

6.2 nH, 10%, 0805

(Coilcraft 0805HQ6N2XKBC)

33 nH, 5%, 0805

(Koa KL732ATE33NJ)

14.7456 MHz crystal,

16 pF load

120 nH, 10%, 0805

(Coilcraft 0805CS-121XKBC)

2.5 nH, 10%, 0805

(Coilcraft 0805HQ2N5XKBC)

4.7 nH, 5%, 0805

(Koa KL732ATE4N7C)

14.7456 MHz crystal,

16 pF load

CC1000 UltraCSP™ package

68 nH, 5%, 0402

(Ceramic multilayer)

15 nH, 5%, 0402

(Ceramic multilayer)

33 nH, 5%, 0402

(Thin film inductor)

14.7456 MHz crystal,

16 pF load

120 nH, 5%, 0402

(Ceramic multilayer)

2.7 nH, 5%, 0402

(Ceramic multilayer)

7.5 nH, 5%, 0402

(Thin film inductor)

14.7456 MHz crystal,

16 pF load

120 nH, 10%, 0805

(Coilcraft 0805CS-121XKBC)

2.5 nH, 10%, 0805

(Coilcraft 0805HQ2N5XKBC)

4.7 nH, 5%, 0805

(Koa KL732ATE4N7C)

14.7456 MHz crystal,

16 pF load

120 nH, 5%, 0402

(Ceramic multilayer)

2.7 nH, 5%, 0402

(Ceramic multilayer)

7.5 nH, 5%, 0402

(Thin film inductor)

14.7456 MHz crystal,

16 pF load

Table 1. Bill of materials for the application circuit

Note that the component values for

868/915 MHz can be the same. However,

it is important the layout is optimised for

the selected VCO inductor in order to

centre the tuning range around the

operating frequency to account for

inductor tolerance. The VCO inductor

must be placed very close and

symmetrical with respect to the pins (L1

and L2).

Chipcon provide reference layouts that

should be followed very closely in order to

achieve the best performance. The

reference design can be downloaded from

the Chipcon website.

SWRS048 Page 11 of 53

Page 12

7. Configuration Overview

CC1000

best performance for different

applications. Through the programmable

configuration registers the following key

parameters can be programmed:

• Receive / transmit mode

• RF output power

• Frequency synthesiser key

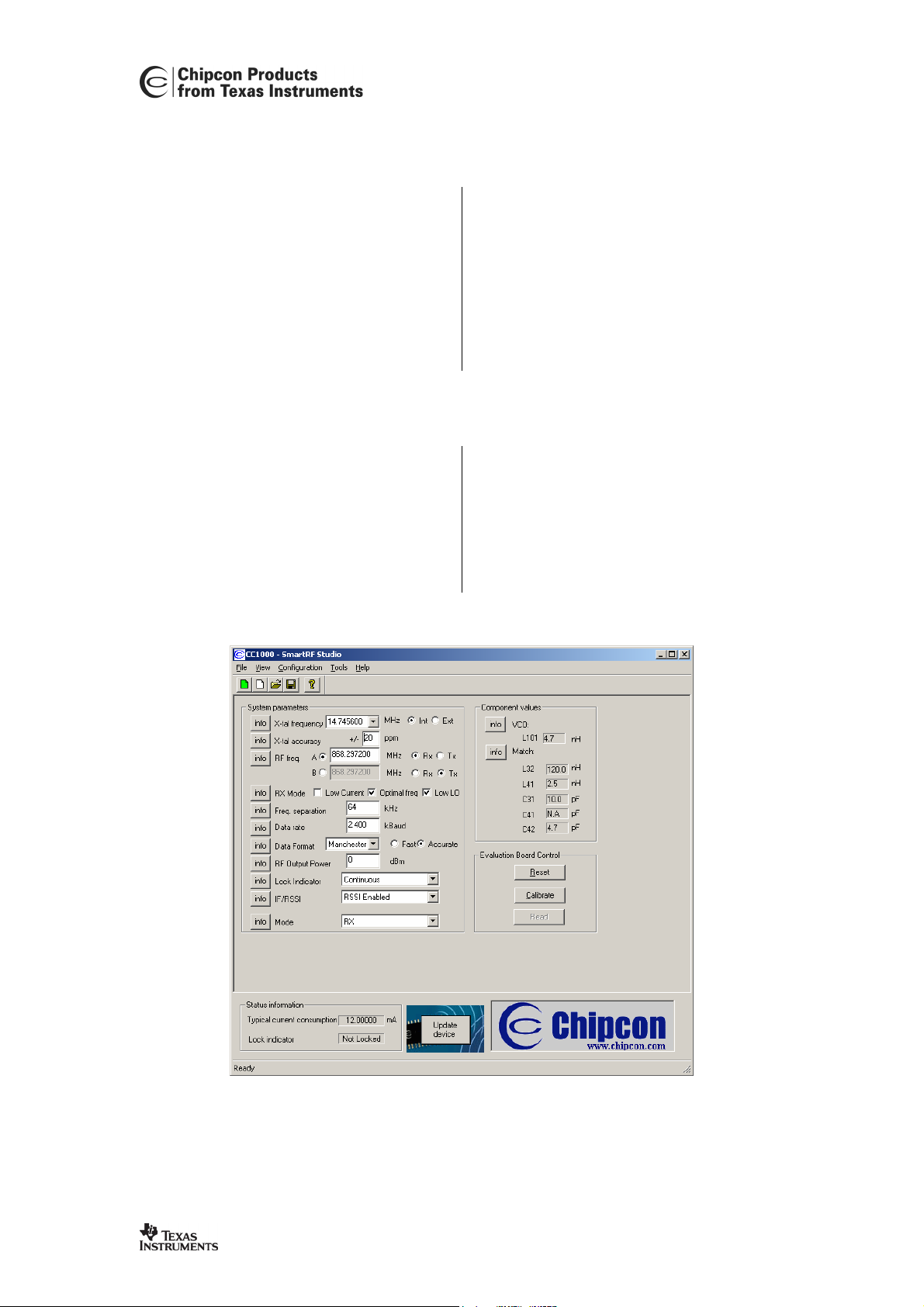

8. Configuration Software

Chipcon provides users of

software program, SmartRF® Studio

(Windows interface) that generates all

necessary

based on the user’s selections of various

parameters. These hexadecimal numbers

will then be the necessary input to the

microcontroller for the configuration of

can be configured to achieve the

parameters: RF output frequency, FSK

CC1000

CC1000

configuration data

with a

CC1000

frequency separation (deviation),

crystal oscillator reference frequency

• Power-down / power-up mode

• Crystal oscillator power-up / power

down

• Data rate and data format (NRZ,

Manchester coded or UART interface)

• Synthesiser lock indicator mode

• Optional RSSI or external IF

CC1000

provide the user with the component

values needed for the input/output

matching circuit and the VCO inductor.

Figure 3 shows the user interface of the

CC1000

. In addition the program will

configuration software.

Figure 3. SmartRF® Studio user interface

SWRS048 Page 12 of 53

Page 13

9. 3-wire Serial Configuration Interface

CC1000

interface (PDATA, PCLK and PALE).

There are 28 8-bit configuration registers,

each addressed by a 7-bit address. A

Read/Write bit initiates a read or write

operation. A full configuration of

requires sending 22 data frames of 16 bits

each (7 address bits, R/W bit and 8 data

bits). The time needed for a full

configuration depend on the PCLK

frequency. With a PCLK frequency of 10

MHz the full configuration is done in less

than 46 µs. Setting the device in power

down mode requires sending one frame

only and will in this case take less than 2

µs. All registers are also readable.

In each write-cycle 16 bits are sent on the

PDATA-line. The seven most significant

bits of each data frame (A6:0) are the

address-bits. A6 is the MSB (Most

Significant Bit) of the address and is sent

as the first bit. The next bit is the R/W bit

(high for write, low for read). During

address and R/W bit transfer the PALE

(Program Address Latch Enable) must be

kept low. The 8 data-bits are then

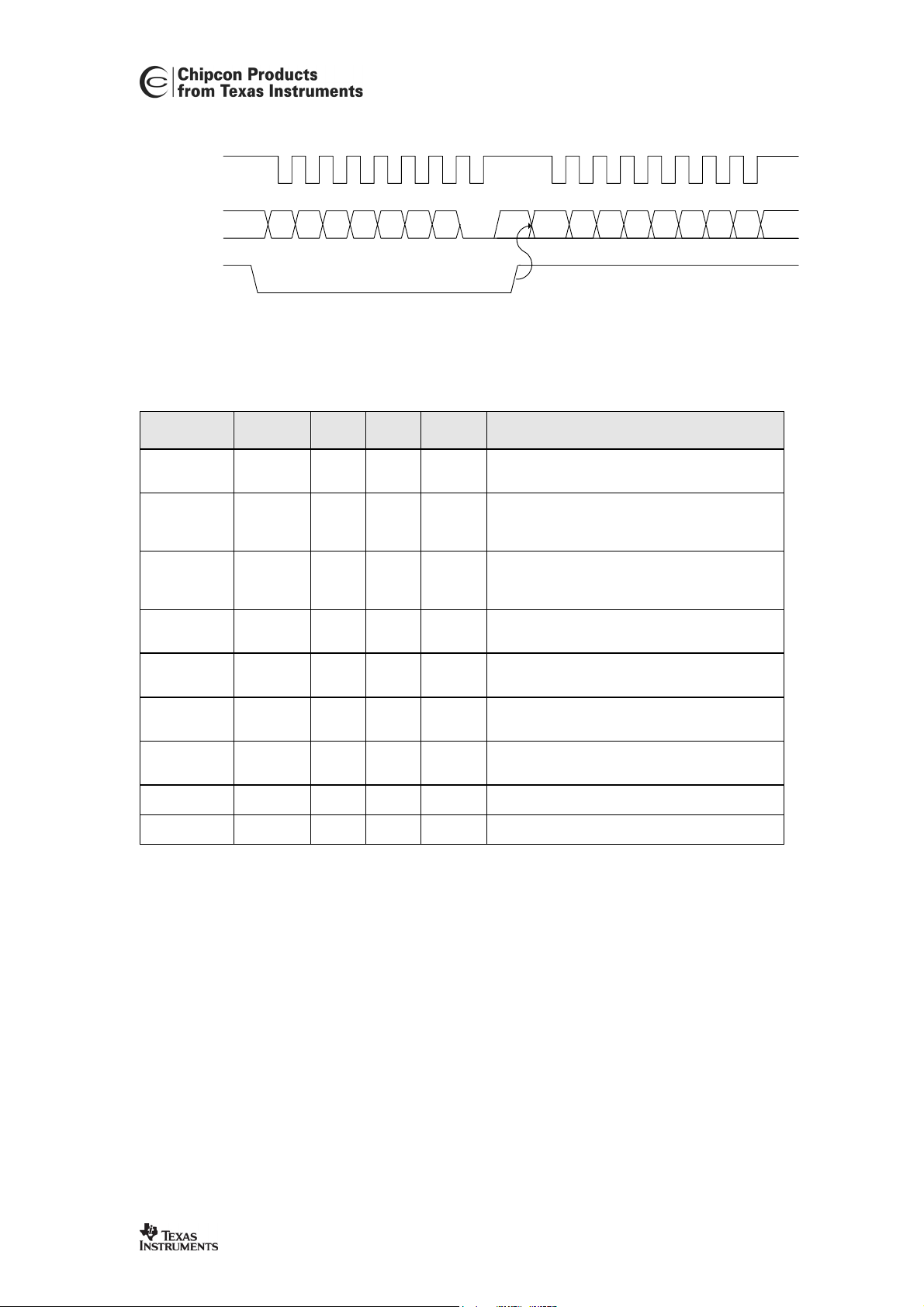

transferred (D7:0). See Figure 4.

is configured via a simple 3-wire

CC1000

T

SA

CC1000

The timing for the programming is also

shown in Figure 4 with reference to Table

2. The clocking of the data on PDATA is

done on the negative edge of PCLK.

When the last bit, D0, of the 8 data-bits

has been loaded, the data word is loaded

in the internal configuration register.

The configuration data is stored in internal

RAM. The data is retained during powerdown mode, but not when the powersupply is turned off. The registers can be

programmed in any order.

The configuration registers can also be

read by the microcontroller via the same

configuration interface. The seven address

bits are sent first, then the R/W bit set low

to initiate the data read-back.

CC1000

returns the data from the addressed

register. PDATA is in this case used as an

output and must be tri-stated (or set high n

the case of an open collector pin) by the

microcontroller during the data read-back

(D7:0). The read operation is illustrated in

Figure 5.

T

HA

then

PCLK

PDATA

PALE

T

CH,min

Address Write mode

6543210

T

CL,min

Figure 4. Configuration registers write operation

T

SA

W

7 6 5 4 3 2 1 0

T

HD

Data byte

T

SD

SWRS048 Page 13 of 53

Page 14

CC1000

PCLK

Address Read mode

PDATA

6543210

R 7 6 5 4 3 2 1 0

PALE

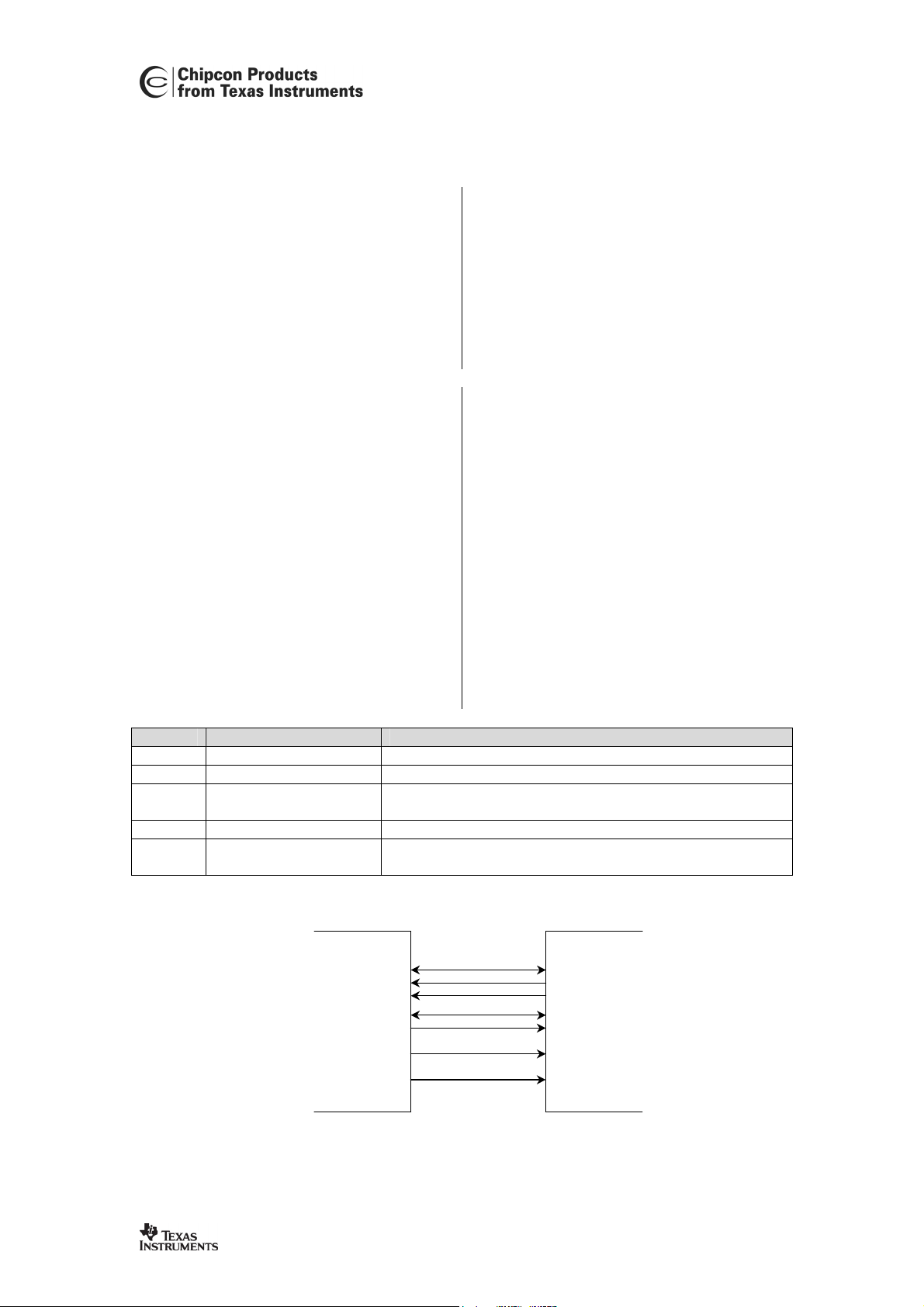

Figure 5. Configuration registers read operation

Parameter Symbol Min Max Units Conditions

PCLK, clock

frequency

PCLK low

pulse

duration

PCLK high

pulse

duration

PALE setup

time

PALE hold

time

PDATA setup

time

PDATA hold

time

Rise time T

Fall time T

F

CLOCK

50 ns The minimum time PCLK must be low.

T

CL,min

50 ns The minimum time PCLK must be high.

T

CH,min

T

SA

THA 10 - ns The minimum time PALE must be held low after

T

SD

10 - ns The minimum time data must be held at PDATA,

T

HD

100 ns The maximum rise time for PCLK and PALE

rise

100 ns The maximum fall time for PCLK and PALE

fall

Note: The set-up- and hold-times refer to 50% of VDD.

- 10 MHz

10 - ns The minimum time PALE must be low before

negative edge of PCLK.

the positive edge of PCLK.

10 - ns The minimum time data on PDATA must be ready

before the negative edge of PCLK.

after the negative edge of PCLK.

Data byte

Table 2. Serial interface, timing specification

SWRS048 Page 14 of 53

Page 15

10. Microcontroller Interface

Used in a typical system,

interface to a microcontroller. This

microcontroller must be able to:

• Program

via the 3-wire serial configuration

interface (PDATA, PCLK and PALE).

• Interface to the bi-directional

synchronous data signal interface

(DIO and DCLK).

10.1 Connecting the microcontroller

The microcontroller uses 3 output pins for

the configuration interface (PDATA, PCLK

and PALE). PDATA should be a bidirectional pin for data read-back. A bidirectional pin is used for data (DIO) to be

transmitted and data received. DCLK

providing the data timing should be

connected to a microcontroller input.

Optionally another pin can be used to

monitor the LOCK signal (available at the

CHP_OUT pin). This signal is logic level

high when the PLL is in lock. See Figure

6.

Also the RSSI signal can be connected to

the microcontroller if it has an analogue

ADC input.

Pin Pin state Note

PDATA Input Should be driven high or low

PCLK Input Should be driven high or low

PALE Input with internal pull-

DIO Input Should be driven high or low

DCLK High-impedance

CC1000

up resistor

output

into different modes

CC1000

will

Should be driven high or high-impedance to minimize

power consumption

• Optionally the microcontroller can do

data encoding / decoding.

• Optionally the microcontroller can

monitor the frequency lock status from

pin CHP_OUT (LOCK).

• Optionally the microcontroller can

monitor the RSSI output for signal

strength acquisition.

The microcontroller pins connected to

PDATA and PCLK can be used for other

purposes when the configuration interface

is not used. PDATA and PCLK are high

impedance inputs as long as PALE is

high.

PALE has an internal pull-up resistor and

should be left open (tri-stated by the

microcontroller) or set to a high level

during power down mode in order to

prevent a trickle current flowing in the pullup. The pin state in power down mode is

summarized in Table 3.

CC1000

Table 3. CC1000 pins in power-down mode

PDATA

CC1000

PCLK

PALE

DIO

DCLK

CHP_OUT

(LOCK)

RSSI/IF

Figure 6. Microcontroller interface

(Optional)

(Optional)

SWRS048 Page 15 of 53

Microcontroller

ADC

Page 16

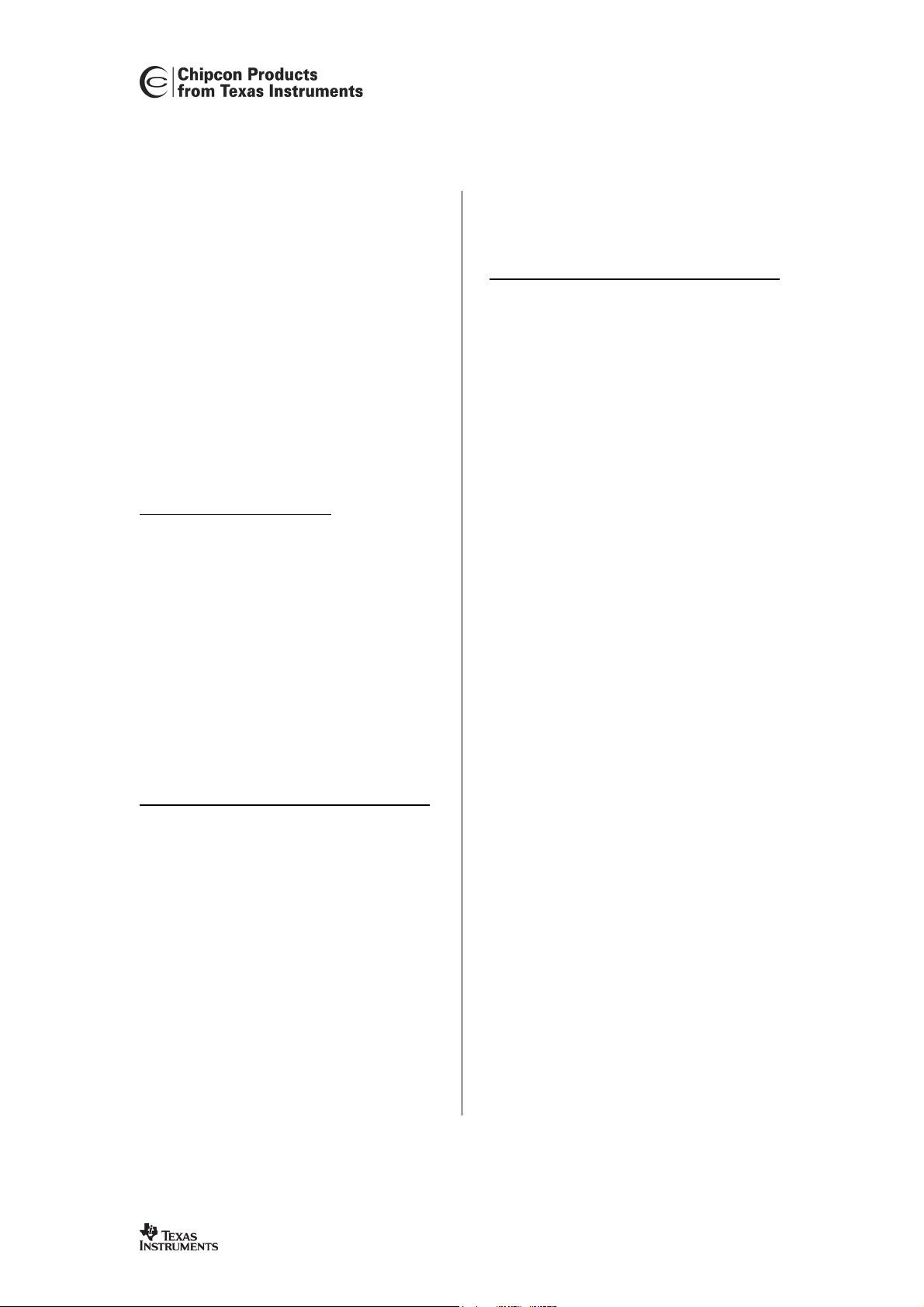

11. Signal interface

The signal interface consists of DIO and

DCLK and is used for the data to be

transmitted and data received. DIO is the

bi-directional data line and DCLK provides

a synchronous clock both during data

transmission and data reception.

CC1000

The

Return-to-Zero) data or Manchester (also

known as bi-phase-level) encoded data.

CC1000

the demodulator and provide the data

clock at DCLK.

CC1000

different data formats:

Synchronous NRZ mode

mode

DCLK, and DIO is used as data input.

Data is clocked into

edge of DCLK. The data is modulated at

RF without encoding.

configured for the data rates 0.6, 1.2, 2.4,

4.8, 9.6, 19.2, 38.4 or 76.8 kbit/s. For 38.4

and 76.8 kbit/s a crystal frequency of

14.7456 MHz must be used. In receive

mode

and provides received data clock at DCLK

and data at DIO. The data should be

clocked into the interfacing circuit at the

rising edge of DCLK. See Figure 7.

Synchronous Manchester encoded mode

In transmit mode

clock at DCLK, and DIO is used as data

input. Data is clocked into

rising edge of DCLK and should be in NRZ

format. The data is modulated at RF with

Manchester code. The encoding is done

CC1000

by

configured for the data rates 0.3, 0.6, 1.2,

2.4, 4.8, 9.6, 19.2 or 38.4 kbit/s. The 38.4

kbit/s rate corresponds to the maximum

76.8 kBaud due to the Manchester

encoding. For 38.4 and 76.8 kBaud a

crystal frequency of 14.7456 MHz must be

used. In receive mode

synchronisation and provides received

data clock at DCLK and data at DIO.

CC1000

can be used with NRZ (Non-

can also synchronise the data from

can be configured for three

. In transmit

CC1000

does the decoding and NRZ data

provides the data clock at

CC1000

CC1000

CC1000

does the synchronisation

CC1000

provides the data

CC1000

. In this mode

CC1000

CC1000

at the rising

can be

.

at the

can be

does the

CC1000

is presented at DIO. The data should be

clocked into the interfacing circuit at the

rising edge of DCLK. See Figure 8.

CC1000

.

Transparent Asynchronous UART mode

In transmit mode DIO is used as data

input. The data is modulated at RF without

synchronisation or encoding. In receive

mode the raw data signal from the

demodulator is sent to the output. No

synchronisation or decoding of the signal

is done in

the interfacing circuit. The DCLK pin is

used as data output in this mode. Data

rates in the range from 0.6 to 76.8 kBaud

can be used. For 38.4 and 76.8 kBaud a

crystal frequency of 14.7456 MHz must be

used. See Figure 9.

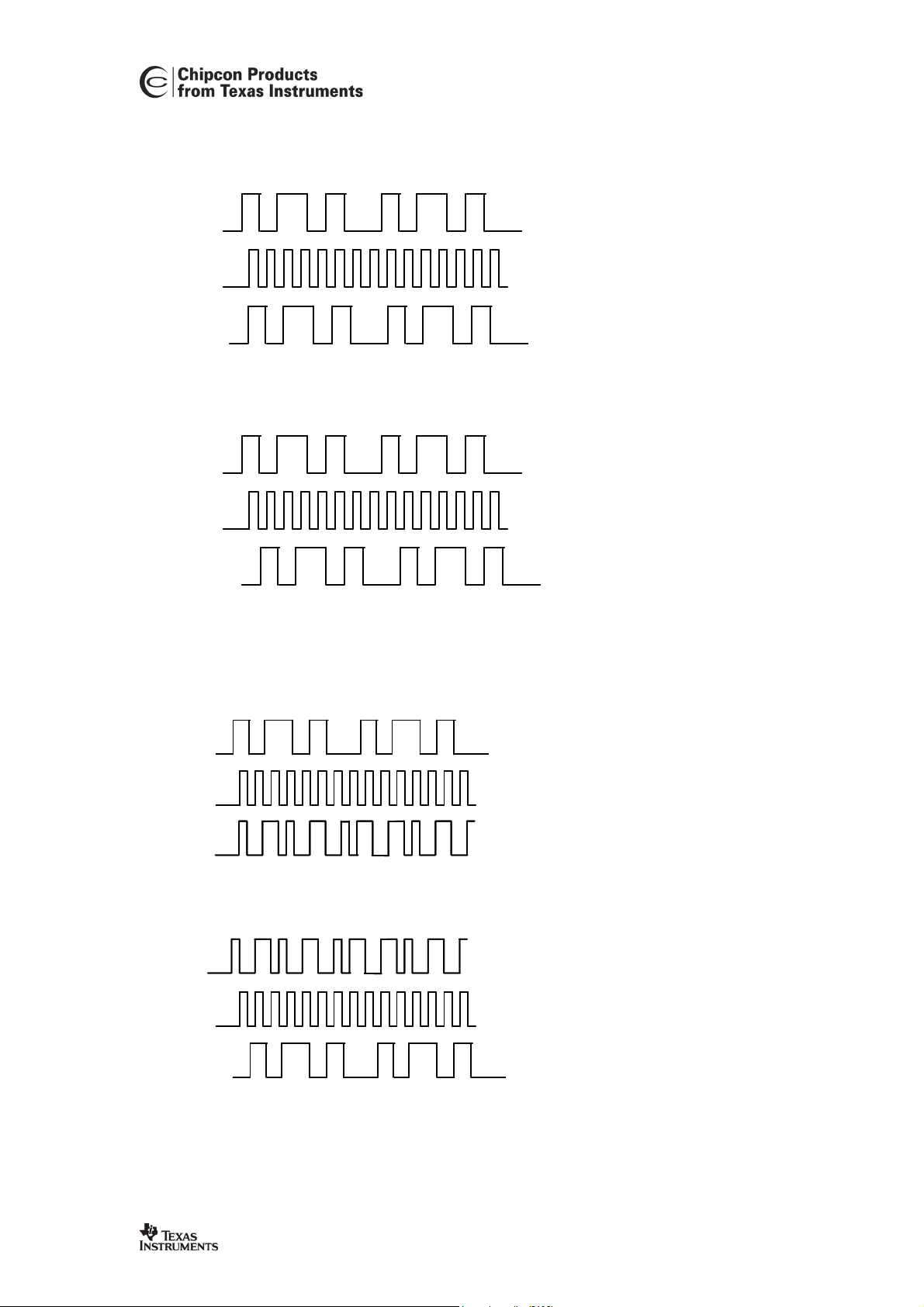

11.1 Manchester encoding and decoding

In the Synchronous Manchester encoded

mode

when modulating the data. The

also performs the data decoding and

synchronisation. The Manchester code is

based on transitions; a “0” is encoded as a

low-to-high transition, a “1” is encoded as

a high-to-low transition. See Figure 10.

The

decoding violation and will set a

Manchester Violation Flag when such a

violation is detected in the incoming

signal. The threshold limit for the

Manchester Violation can be set in the

MODEM1 register. The Manchester

Violation Flag can be monitored at the

CHP_OUT (LOCK) pin, configured in the

LOCK register.

The Manchester code ensures that the

signal has a constant DC component,

which is necessary in some FSK

demodulators. Using this mode also

ensures compatibility with CC400/CC900

designs.

CC1000

CC1000

CC1000

and should be done by

uses Manchester coding

can detect a Manchester

SWRS048 Page 16 of 53

Page 17

Transmitter side:

Transmitter side:

CC1000

DIO

DIO

DCLK

DCLK

“RF”

“RF”

Receiver side:

Receiver side:

“RF”

“RF”

DCLK

DCLK

DIO

DIO

Transmitter side:

Transmitter side:

Data provided by microcontroller

Data provided by microcontroller

Clock provided by CC1000

Clock provided by CC1000

FSK modulating signal (NRZ),

FSK modulating signal (NRZ),

internal in CC1000

internal in CC1000

Demodulated signal (NRZ),

Demodulated signal (NRZ),

internal in CC1000

internal in CC1000

Clock provided by CC1000

Clock provided by CC1000

Data provided by CC1000

Data provided by CC1000

Figure 7. Synchronous NRZ mode

DIO

DIO

DCLK

DCLK

“RF”

“RF”

Receiver side:

Receiver side:

“RF”

“RF”

DCLK

DCLK

DIO

DIO

Figure 8. Synchronous Manchester encoded mode

Data provided by microcontroller (NRZ)

Data provided by microcontroller (NRZ)

Clock provided by CC1000

Clock provided by CC1000

FSK modulating signal (Manchester encoded),

FSK modulating signal (Manchester encoded),

internal in CC1000

internal in CC1000

Demodulated signal (Manchester encoded),

Demodulated signal (Manchester encoded),

internal in CC1000

internal in CC1000

Clock provided by CC1000

Clock provided by CC1000

Data provided by CC1000 (NRZ)

Data provided by CC1000 (NRZ)

SWRS048 Page 17 of 53

Page 18

Transmitter side:

Transmitter side:

CC1000

DIO

DIO

DCLK

DCLK

“RF”

“RF”

Receiver side:

Receiver side:

“RF”

“RF”

DIO

DIO

DCLK

DCLK

Data provided by UART (TXD)

Data provided by UART (TXD)

DCLK is not used in transmit mode.

DCLK is not used in transmit mode.

Used as data output in receive mode.

Used as data output in receive mode.

FSK modulating signal,

FSK modulating signal,

internal in CC1000

internal in CC1000

Demodulated signal,

Demodulated signal,

internal in CC1000

internal in CC1000

DIO is not used in receive mode. Used only

DIO is not used in receive mode. Used only

as data input in transmit mode.

as data input in transmit mode.

Data output provided by CC1000.

Data output provided by CC1000.

Connect to UART (RXD).

Connect to UART (RXD).

Figure 9. Transparent Asynchronous UART mode

1 0 1 1 0 0 0 1 1 0 1

1 0 1 1 0 0 0 1 1 0 1

TX

TX

data

data

Time

Time

Figure 10. Manchester encoding

SWRS048 Page 18 of 53

Page 19

12. Bit synchroniser and data decision

Average

filter

CC1000

Sampler

Frequency

detector

Decimator

Data

filter

Figure 11. Demodulator block diagram

A block diagram of the digital demodulator

is shown in Figure 11. The IF signal is

sampled and its instantaneous frequency

is detected. The result is decimated and

filtered. In the data slicer the data filter

output is compared to the average filter

output to generate the data output.

The averaging filter is used to find the

average value of the incoming data. While

the averaging filter is running and

acquiring samples, it is important that the

number of high and low bits received is

equal (e.g. Manchester code or a

balanced preamble).

Therefore all modes, also synchronous

NRZ mode, need a DC balanced

preamble for the internal data slicer to

acquire correct comparison level from the

averaging filter. The suggested preamble

is a ‘010101…’ bit pattern. The same bit

pattern should also be used in Manchester

mode, giving a ‘011001100110…chip

pattern. This is necessary for the bit

synchronizer to synchronize correctly.

The averaging filter must be locked before

any NRZ data can be received. If the

averaging filter is locked

(MODEM1.LOCK_AVG_MODE=’1’), the

Data slicer

comparator

acquired value will be kept also after

Power Down or Transmit mode. After a

modem reset

(MODEM1.MODEM_RESET_N), or a

main reset (using any of the standard

reset sources), the averaging filter is reset.

In a polled receiver system the automatic

locking can be used. This is illustrated in

Figure 12. If the receiver is operated

continuously and searching for a

preamble, the averaging filter should be

locked manually as soon as the preamble

is detected. This is shown in Figure 13. If

the data is Manchester coded there is no

need to lock the averaging filter

(MODEM1.LOCK_AVG_IN=’0’), as shown

in Figure 14.

The minimum length of the preamble

depends on the acquisition mode selected

and the settling time. Table 4 gives the

minimum recommended number of chips

for the preamble in NRZ and UART

modes. In this context ‘chips’ refer to the

data coding. Using Manchester coding

every bit consists of two ‘chips’. For

Manchester mode the minimum

recommended number of chips is shown

in Table 5.

SWRS048 Page 19 of 53

Page 20

CC1000

Manual Lock Automatic Lock Settling

MODEM1.

SETTLING

(1:0)

00 14 11 16 16

01 25 22 32 32

10 46 43 64 64

11 89 86 128 128

Notes:

** The averaging filter is locked when MODEM1.LOCK_AVG_IN is set to 1

*** X = Do not care. The timer for the automatic lock is started when RX mode is set in the

register

Also please note that in addition to the number of bits required to lock the filter, you need to add the

number of bits needed for the preamble detector. See the next section for more information.

Table 4. Minimum preamble bits for locking the averaging filter, NRZ and UART mode

NRZ mode

MODEM1.LOCK_

AVG_MODE=’1’

MODEM1.LOCK_

AVG_IN=’0’=→’1’**

UART mode

MODEM1.LOCK_

AVG_MODE=’1’

MODEM1.LOCK_

AVG_IN=’0’=→’1’**

Settling

MODEM1.

SETTLING

(1:0)

Free-running

Manchester mode

MODEM1.LOCK_

AVG_MODE=’1’

MODEM1.LOCK_

NRZ mode

MODEM1.LOCK_

AVG_MODE=’0’

MODEM1.LOCK_

AVG_IN=’X’***

AVG_IN=’0’

00 23

01 34

10 55

11 98

UART mode

MODEM1.LOCK_

AVG_MODE=’0’

MODEM1.LOCK_

AVG_IN=’X’***

RFMAIN

Table 5. Minimum number preamble chips for averaging filter, Manchester mode

SWRS048 Page 20 of 53

Page 21

CC1000

Data package to be received

Data package to be received

Averaging filter

Averaging filter

free-running / not used

free-running / not used

Noise

Noise

RX

PD

PD

Averaging filter free-running

Averaging filter free-running

RX

Noise

Noise

RX

RX

Automatically locked after a short period depending on “SETTLING”

Automatically locked after a short period depending on “SETTLING”

Preamble NRZ data

Preamble NRZ data

RXPD

RXPD

Averaging filter locked

Averaging filter locked

Figure 12. Automatic locking of the averaging filter

Data package to be received

Data package to be received

Preamble NRZ data

Preamble NRZ data

Averaging filter locked

Averaging filter locked

Noise

Noise

Noise

Noise

Noise

Noise

RX

PD

PD

Averaging filter always free-running

Averaging filter always free-running

RX

Manually locked after preamble is detected

Manually locked after preamble is detected

Figure 13. Manual locking of the averaging filter

Data package to be received

Data package to be received

Preamble Manchester encoded data

Figure 14. Free-running averaging filter

SWRS048 Page 21 of 53

NoisePreamble Manchester encoded data

Noise

Page 22

CC1000

13. Receiver sensitivity versus data rate and frequency separation

The receiver sensitivity depends on the

data rate, the data format, FSK frequency

separation and the RF frequency. Typical

figures for the receiver sensitivity (BER =

-3

10

) are shown in Table 6 for 64 kHz

frequency separations and Table 7 for 20

kHz separations. Optimised sensitivity

[kBaud]

0.6 64 -113 -114 -113 -110 -111 -110

1.2 64 -111 -112 -111 -108 -109 -108

2.4 64 -109 -110 -109 -106 -107 -106

4.8 64 -107 -108 -107 -104 -105 -104

9.6 64 -105 -106 -105 -102 -103 -102

19.2 64 -103 -104 -103 -100 -101 -100

38.4 64 -102 -103 -102 -98 -99 -98

76.8 64 -100 -101 -100 -97 -98 -97

Average current

Separation

[kHz]

consumption

NRZ

mode

433 MHz 868 MHz Data rate

Manchester

mode

9.3 mA

configurations are used. For best

performance the frequency separation

should be as high as possible especially at

high data rates. Table 8 shows the

sensitivity for low current settings. See

page 28 for how to program different

current consumption.

UART

mode

NRZ

mode

Manchester

mode

11.8 mA

UART mode

Table 6. Receiver sensitivity as a function of data rate at 433 and 868 MHz, BER = 10-3,

frequency separation 64 kHz, normal current settings

[kBaud]

0.6 20 -109 -111 -109 -106 -108 -106

1.2 20 -108 -110 -108 -104 -106 -104

2.4 20 -106 -108 -106 -103 -105 -103

4.8 20 -104 -106 -104 -101 -103 -101

9.6 20 -103 -104 -103 -100 -101 -100

19.2 20 -102 -103 -102 -99 -100 -99

38.4 20 -98 -100 -98 -98 -99 -98

76.8 20 -94 -98 -94 -94 -96 -94

Average current

Separation

[kHz]

consumption

NRZ

mode

433 MHz 868 MHz Data rate

Manchester

mode

9.3 mA

UART

mode

NRZ

mode

Manchester

mode

11.8 mA

UART mode

Table 7. Receiver sensitivity as a function of data rate at 433 and 868 MHz, BER = 10-3,

frequency separation 20 kHz, normal current settings

[kBaud]

0.6 64 -111 -113 -111 -107 -109 -107

1.2 64 -110 -111 -110 -106 -107 -106

2.4 64 -108 -109 -108 -104 -105 -104

4.8 64 -106 -107 -106 -102 -103 -102

9.6 64 -104 -105 -104 -100 -101 -100

19.2 64 -102 -103 -102 -98 -99 -98

38.4 64 -101 -102 -101 -96 -97 -96

76.8 64 -99 -100 -99 -95 -96 -95

Average current

Separation

[kHz]

consumption

NRZ

mode

433 MHz 868 MHz Data rate

Manchester

mode

7.4 mA

UART

mode

NRZ

mode

Manchester

mode

9.6 mA

UART mode

Table 8. Receiver sensitivity as a function of data rate at 433 and 868 MHz, BER = 10-3,

frequency separation 64 kHz , low current settings

SWRS048 Page 22 of 53

Page 23

R

V

14. Frequency programming

RX mode:

CC1000

f

(low-side) fLO (high-side)

f

LO

TX mode:

f

IF

f

0

(Lower FSK

frequency)

Figure 15. Relation between f

RF

(Receive frequency)

f

RF

(Center frequency)

f

sep

f

IF

f

(Upper FSK

frequency)

, fif, and LO frequency

vco

The frequency synthesiser (PLL) is

controlled by the frequency word in the

configuration registers. There are two

frequency words, A and B, which can be

programmed to two different frequencies.

The reference frequency f

oscillator clock divided by PLL.REFDIV, a

number between 2 and 14 that should be

chosen such that:

One of the frequency words can be used

for RX (local oscillator frequency) and the

other for TX (transmitting frequency, f

).

0

This makes it possible to switch very fast

Thus, the reference frequency f

between RX mode and TX mode. They

can also be used for RX (or TX) on two

different channels. The MAIN.F_REG

control bit performs selection of frequency

word A or B.

The frequency word, FREQ, is 24 bits (3

bytes) located in

FREQ_2A:FREQ_1A:FREQ_0A and

FREQ_2B:FREQ_1B:FREQ_0B for the A

and B word, respectively.

The frequency word FREQ can be

calculated from:

⋅=

ff

refVCO

TXDATAFSEPFREQ

16384

8192+⋅+

,

where TXDATA is 0 or 1 in transmit mode

depending on the data bit to be

f

is the Local Oscillator (LO) frequency

VCO

in receive mode, and the f

transmit mode (lower FSK frequency). The

LO frequency must be f

giving low-side or high side LO injection

respectively. Note that the data on DIO will

be inverted if high-side LO is used.

The upper FSK transmit frequency is

given by:

where the frequency separation f

by the 11 bit separation word

(FSEP1:FSEP0):

transmitted on DIO. In receive mode

TXDATA is always 0.

SWRS048 Page 23 of 53

1

1.0 MHz ≤ f

f

ref

=

f

= f0 + f

1

f

vco

f

vco

ref

≤ 2.46 MHz

ref

f

xosc

EFDI

– fIF or fRF + fIF

RF

,

sep

FSEP

⋅=

ff

refsep

16384

is the crystal

is:

ref

frequency in

0

is set

sep

Page 24

CC1000

Clearing PLL.ALARM_DISABLE will

enable generation of the frequency alarm

bits PLL.ALARM_H and PLL.ALARM_L.

These bits indicate that the frequency

synthesis PLL is near the limit of generate

the frequency requested, and the PLL

should be recalibrated.

15. Recommended RX settings for ISM frequencies

Shown in Table 9 are the recommended RX frequency synthesiser settings for a few

operating frequencies in the popular ISM bands. These settings ensure optimum

configuration of the synthesiser in receive mode for best sensitivity. For some settings of the

synthesiser (combinations of RF frequencies and reference frequency), the receiver

sensitivity is degraded. The FSK frequency separation is set to 64 kHz. The SmartRF®

Studio can be used to generate optimised configuration data as well. Also an application note

(AN011) and a spreadsheet are available from Chipcon generating configuration data for any

frequency giving optimum sensitivity.

ISM

Frequency

[MHz]

315 315.037200 3.6864 High-side 3 4194304 400000

7.3728 6 4194304 400000

11.0592 9 4194304 400000

14.7456 12 4194304 400000

433.3 433.302000 3.6864 Low-side 3 5775168 580000

7.3728 6 5775168 580000

11.0592 9 5775168 580000

14.7456 12 5775168 580000

433.9 433.916400 3.6864 Low-side 3 5775360 582000

7.3728 6 5775360 582000

11.0592 9 5775360 582000

14.7456 12 5775360 582000

434.5 434.530800 3.6864 Low-side 3 5783552 584000

7.3728 6 5783552 584000

11.0592 9 5783552 584000

14.7456 12 5783552 584000

868.3 868.297200 3.6864 Low-side 2 7708672 75A000

7.3728 4 7708672 75A000

11.0592 6 7708672 75A000

14.7456 8 7708672 75A000

868.95 868.918800 3.6864 High-side 2 7716864 75C000

7.3728 4 7716864 75C000

11.0592 6 7716864 75C000

14.7456 7716864 75C000

869.525 869.526000 3.6864 Low-side 3 11583488 B0C000

7.3728 6 11583488 B0C000

11.0592 9 11583488 B0C000

14.7456 12 11583488 B0C000

869.85 869.840400 3.6864 High-side 2 7725056 75E000

7.3728 4 7725056 75E000

11.0592 6 7725056 75E000

14.7456 8 7725056 75E000

915 914.998800 3.6864 High-side 2 8126464 7C0000

7.3728 4 8126464 7C0000

11.0592 6 8126464 7C0000

14.7456 8 8126464 7C0000

*Note: When using high-side LO injection the data at DIO will be inverted.

Actual

frequency

[MHz]

Crystal

frequency

[MHz]

Low-side /

high- side

LO*

It is recommended that the

LOCK_CONTINOUS bit in the LOCK

register is checked when changing

frequencies and when changing between

RX and TX mode. If lock is not achieved, a

calibration should be performed.

Reference

divider

REFDIV

(decimal)

Frequency word

RX mode

FREQ

(decimal)

Frequency word

RX mode

FREQ

(hex)

Table 9. Recommended settings for ISM frequencies

SWRS048 Page 24 of 53

Page 25

16. VCO

Only one external inductor (L101) is

required for the VCO. The inductor will

determine the operating frequency range

of the circuit. It is important to place the

inductor as close to the pins as possible in

order to reduce stray inductance. It is

recommended to use a high Q, low

tolerance inductor for best performance.

17. VCO and PLL self-calibration

To compensate for supply voltage,

temperature and process variations the

VCO and PLL must be calibrated. The

calibration is done automatically and sets

maximum VCO tuning range and optimum

charge pump current for PLL stability.

After setting up the device at the operating

frequency, the self-calibration can be

initiated by setting the CAL_START bit.

The calibration result is stored internally in

the chip, and is valid as long as power is

not turned off. If large supply voltage

variations (more than 0.5 V) or

temperature variations (more than 40

degrees) occur after calibration, a new

calibration should be performed.

The self-calibration is controlled through

the CAL register (see configuration

registers description p. 39). The

CAL_COMPLETE bit indicates complete

calibration. The user can poll this bit, or

simply wait for 34 ms (calibration wait time

when CAL_WAIT = 1). The wait time is

proportional to the internal PLL reference

frequency. The lowest permitted reference

frequency (1 MHz) gives 34 ms wait time,

which is therefore the worst case.

Reference

frequency [MHz]

2.4 14

2.0 17

1.5 23

1.0 34

The CAL_COMPLETE bit can also be

monitored at the CHP_OUT (LOCK) pin

(configured by LOCK_SELECT[3:0]) and

used as an interrupt input to the

microcontroller.

The CAL_START bit must be set to 0 by

the microcontroller after the calibration is

done.

Calibration time

[ms]

CC1000

Typical tuning range for the integrated

varactor is 20-25%.

Component values for various frequencies

are given in Table 1. Component values

for other frequencies can be found using

the SmartRF® Studio software.

There are separate calibration values for

the two frequency registers. If the two

frequencies, A and B, differ more than 1

MHz, or different VCO currents are used

(VCO_CURRENT[3:0] in the CURRENT

register) the calibration should be done

separately. When using a 10.7 MHz

external IF the LO is 10.7 MHz

below/above the transmit frequency,

hence separate calibration must be done.

The CAL_DUAL bit in the CAL register

controls dual or separate calibration.

The single calibration algorithm, using

separate calibration for RX and TX

frequency, is illustrated in Figure 16.

In Figure 17 the dual calibration algorithm

is shown for two RX frequencies. It could

also be used for two TX frequencies, or

even for one RX and one TX frequency if

the same VCO current is used.

In multi-channel and frequency hopping

applications the PLL calibration values

may be read and stored for later use. By

reading back calibration values and

frequency change can be done without

doing a re-calibration which could take up

to 34 ms. The calibration value is stored in

the TEST0 and TEST2 registers after a

calibration is completed. Note that when

using single calibration, calibration values

are stored separately for frequency

registers A and B. This means that the

TEST0 and TEST2 registers will contain

calibration settings for the currently

selected frequency register (selected by

F_REG in the MAIN register). The

calibration value can later be written into

TEST5 and TEST 6 to bypass the

calibration. Note that you must set

VCO_OVERRIDE=1 in TEST5 and

CHP_OVERRIDE=1 in the TEST6

register.

SWRS048 Page 25 of 53

Page 26

Start single calibration

Start single calibration

Write FREQ_A, FREQ_B

Write FREQ_A, FREQ_B

If DR>=9.6kBd then write TEST4: L2KIO=3Fh

If DR>=9.6kBd then write TEST4: L2KIO=3Fh

Write CAL: CAL_DUAL = 0

Write CAL: CAL_DUAL = 0

Write MAIN:

Write MAIN:

RXTX = 0; F_REG = 0

RXTX = 0; F_REG = 0

RX_PD = 0; TX_PD = 1; FS_PD = 0

RX_PD = 0; TX_PD = 1; FS_PD = 0

CORE_PD = 0; BIAS_PD = 0; RESET_N=1

CORE_PD = 0; BIAS_PD = 0; RESET_N=1

Write CURRENT = RX current

Write CURRENT = RX current

Write PLL = RX pll

Write PLL = RX pll

Write CAL:

Write CAL:

CAL_START=1

CAL_START=1

Frequency register A is used for

Frequency register A is used for

RX mode, register B for TX

RX mode, register B for TX

RX frequency register A is calibrated first

RX frequency register A is calibrated first

Update CURRENT and PLL for RX mode

Update CURRENT and PLL for RX mode

Calibration is performed in RX mode,

Calibration is performed in RX mode,

Result is stored in TEST0 and TEST2,

Result is stored in TEST0 and TEST2,

RX register

RX register

CC1000

Wait for maximum 34 ms, or

Wait for maximum 34 ms, or

Read CAL and wait until

Read CAL and wait until

CAL_COMPLETE=1

CAL_COMPLETE=1

Write CAL:

Write CAL:

CAL_START=0

CAL_START=0

Write MAIN:

Write MAIN:

RXTX = 1; F_REG = 1

RXTX = 1; F_REG = 1

RX_PD = 1; TX_PD = 0; FS_PD = 0

RX_PD = 1; TX_PD = 0; FS_PD = 0

CORE_PD = 0; BIAS_PD = 0; RESET_N=1

CORE_PD = 0; BIAS_PD = 0; RESET_N=1

Write CURRENT = TX current

Write CURRENT = TX current

Write PLL = TX pll

Write PLL = TX pll

Write PA_POW = 00h

Write PA_POW = 00h

Write CAL:

Write CAL:

CAL_START=1

CAL_START=1

Wait for 34 ms, or

Wait for 34 ms, or

Read CAL and wait until

Read CAL and wait until

CAL_COMPLETE=1

CAL_COMPLETE=1

Write CAL:

Write CAL:

CAL_START=0

CAL_START=0

Calibration time depend on the reference

Calibration time depend on the reference

frequency, see text.

frequency, see text.

TX frequency register B is calibrated second

TX frequency register B is calibrated second

Update CURRENT and PLL for TX mode

Update CURRENT and PLL for TX mode

PA is turned off to prevent spurious emission

PA is turned off to prevent spurious emission

Calibration is performed in TX mode,

Calibration is performed in TX mode,

Result is stored in TEST0 and TEST2,

Result is stored in TEST0 and TEST2,

TX registers

TX registers

End of calibration

End of calibration

Figure 16. Single calibration algorithm for RX and TX

SWRS048 Page 26 of 53

Page 27

Start dual calibration

Start dual calibration

Write FREQ_A, FREQ_B

Write FREQ_A, FREQ_B

If DR>=38kBd then write TEST4: L2KIO=3Fh

If DR>=38kBd then write TEST4: L2KIO=3Fh

Write CAL: CAL_DUAL = 1

Write CAL: CAL_DUAL = 1

Write MAIN:

Write MAIN:

RXTX = 0; F_REG = 0

RXTX = 0; F_REG = 0

RX_PD = 0; TX_PD = 1; FS_PD = 0

RX_PD = 0; TX_PD = 1; FS_PD = 0

CORE_PD = 0; BIAS_PD = 0; RESET_N=1

CORE_PD = 0; BIAS_PD = 0; RESET_N=1

Write CURRENT= RX current

Write CURRENT= RX current

Write PLL= RX pll

Write PLL= RX pll

CC1000

Frequency registers A and B are both used

Frequency registers A and B are both used

for RX mode

for RX mode

Either frequency register A or B is selected

Either frequency register A or B is selected

Update CURRENT and PLL for RX mode

Update CURRENT and PLL for RX mode

Dual calibration is performed.

Write CAL:

Write CAL:

CAL_START=1

CAL_START=1

Wait for maximum 34 ms, or

Wait for maximum 34 ms, or

Read CAL and wait until

Read CAL and wait until

CAL_COMPLETE=1

CAL_COMPLETE=1

Write CAL:

Write CAL:

CAL_START=0

CAL_START=0

End of calibration

End of calibration

Figure 17. Dual calibration algorithm for RX mode

Dual calibration is performed.

Result is stored in TEST0 and TEST2,

Result is stored in TEST0 and TEST2,

for both frequency A and B registers

for both frequency A and B registers

Calibration time depend on the reference

Calibration time depend on the reference

frequency, see text.

frequency, see text.

SWRS048 Page 27 of 53

Page 28

CC1000

18. VCO and LNA current control

The VCO current is programmable and

should be set according to operating

frequency RX/TX mode and output power.

Recommended settings for the

VCO_CURRENT bits in the CURRENT

register are shown in the tables on page

41.

uency

[MHz]

433 9.3 -110 0100 01 00 0 10

433 7.4 -109 0100 00 00 0 00

868 11.8 -107 1000 11 00 1 10

868 9.6 -105 1000 10 00 0 00

Note: Current consumption and sensitivity are typical figures at 2.4 kBaud Manchester encoded data, BER 10-3

Current

consumption

[mA]

Sensitivity

[dBm]

VCO_

CURRENT

[3:0]

Table 10. Receiver sensitivity as function of current consumption

The bias current for the LNA, and the LO

and PA buffers are also programmable.

Table 10 shows the current consumption

and receiver sensitivity for different

settings (2.4 kBaud Manchester encoded

data).

CURRENT register FRONT_END register RF freq-

LO_DRIVE

[1:0]

PA_DRIVE

[1:0]

BUF_CUR

RENT

LNA_CUR RENT[1:0]

19. Power management

CC1000

management in order to meet strict power

consumption requirements in battery

operated applications. Power Down mode

is controlled through the MAIN register.

There are separate bits to control the RX

part, the TX part, the frequency

synthesiser and the crystal oscillator (see

page 39). This individual control can be

used to optimise for lowest possible

current consumption in a certain

application.

offers great flexibility for power

A typical power-on and initialising

sequence for minimum power

consumption is shown in Figure 18 and

Figure 19.

PALE should be tri-stated or set to a high

level during power down mode in order to

prevent a trickle current from flowing in the

internal pull-up resistor.

PA_POW should be set to 00h before

power down mode to ensure lowest

possible leakage current.

SWRS048 Page 28 of 53

Page 29

CC1000

Power Off

Power Off

Power turned on

Power turned on

Initialise and reset CC1000

Initialise and reset CC1000

Reset and turning on the

MAIN:

MAIN:

RXTX = 0

RXTX = 0

F_REG = 0

F_REG = 0

RX_PD = 1

RX_PD = 1

TX_PD = 1

TX_PD = 1

FS_PD = 1

FS_PD = 1

CORE_PD = 0

CORE_PD = 0

BIAS_PD = 1

BIAS_PD = 1

RESET_N = 0

RESET_N = 0

MAIN: RESET_N = 1

MAIN: RESET_N = 1

Wait 2 ms*

Wait 2 ms*

Reset and turning on the

crystal oscillator core

crystal oscillator core

*Time to wait depends on the crystal frequency

*Time to wait depends on the crystal frequency

and the load capacitance

and the load capacitance

Program all registers except MAIN

Program all registers except MAIN

Calibrate VCO and PLL

Calibrate VCO and PLL

MAIN: RX_PD = 1, TX_PD = 1, FS_PD = 1,

MAIN: RX_PD = 1, TX_PD = 1, FS_PD = 1,

CORE_PD = 1, BIAS_PD = 1

CORE_PD = 1, BIAS_PD = 1

PA_POW = 00h

PA_POW = 00h

Power Down

Power Down

Figure 18. Initializing sequence

Frequency register A is used for

Frequency register A is used for

RX mode, register B for TX

RX mode, register B for TX

Calibration is performed according

Calibration is performed according

to single calibration algorithm for both

to single calibration algorithm for both

RX and TX mode

RX and TX mode

SWRS048 Page 29 of 53

Page 30

CC1000

Power Down

Turn on crystal oscillator core

MAIN: CORE_PD = 0

Wait 2 ms*

Turn on bias generator

BIAS_PD = 0

Wait 200 µs

RX TX

RX or TX?

*Time to wait depends on the crystal frequency

and the load capacitance

Turn on RX:

MAIN: RXTX = 0, F_REG = 0

RX_PD = 0, FS_PD = 0

CURRENT = ‘RX current’

PLL = ’RX pll’

Wait 250 µs

RX mode

Turn off RX:

MAIN: RX_PD = 1, FS_PD = 1,

CORE_PD=1, BIAS_PD=1

Power Down

Turn on TX:

PA_POW = 00h

MAIN: RXTX = 1, F_REG = 1

TX_PD = 0, FS_PD = 0

CURRENT = ‘TX current’

PLL = ’RX pll’

Wait 250 µs

PA_POW = ‘Output power’

Wait 20 µs

TX mode

Turn off TX:

MAIN: TX_PD = 1, FS_PD = 1,

CORE_PD=1, BIAS_PD=1

PA_POW = 00h

Power Down

Figure 19. Sequence for activating RX or TX mode

SWRS048 Page 30 of 53

Page 31

20. Input / Output Matching

A few passive external components

combined with the internal T/R switch

circuitry ensures match in both RX and TX

mode. The matching network is shown in

Figure 20.

C31

C31

C31

C31

TO ANTENNA

TO ANTENNA

TO ANTENNA

TO ANTENNA

C42

C42

C42

C42

CC1000

Component values for various frequencies

are given in Table 1. Component values

for other frequencies can be found using

the configuration software.

RF_IN

RF_IN

RF_IN

RF_IN

RF_OUT

RF_OUT

RF_OUT

RF_OUT

CC1000

CC1000

CC1000

CC1000

L41C41

L41C41

L41C41

L41C41

AVDD=3V

AVDD=3V

AVDD=3V

AVDD=3V

Figure 20. Input/output matching network

L32

L32

L32

L32

SWRS048 Page 31 of 53

Page 32

CC1000

21. Output power programming

The RF output power is programmable

and controlled by the PA_POW register.

Table 11 shows the closest programmable

value for output powers in steps of 1 dB.

The typical current consumption is also

shown.

[dBm]

-20 01 6.9 02 8.6

-19 01 6.9 02 8.8

-18 02 7.1 03 9.0

-17 02 7.1 03 9.0

-16 02 7.1 04 9.1

-15 03 7.4 05 9.3

-14 03 7.4 05 9.3

-13 03 7.4 06 9.5

-12 04 7.6 07 9.7

-11 04 7.6 08 9.9

-10 05 7.9 09 10.1

-9 05 7.9 0B 10.4

-8 06 8.2 0C 10.6

-7 07 8.4 0D 10.8

-6 08 8.7 0F 11.1

-5 09 8.9 40 13.8

-4 0A 9.6 50 14.5

-3 0B 9.4 50 14.5

-2 0C 9.7 60 15.1

-1 0E 10.2 70 15.8

0 0F 10.4 80 16.8

1 40 11.8 90 17.2

2 50 12.8 B0 18.5

3 50 12.8 C0 19.2

4 60 13.8 F0 21.3

5 70 14.8 FF 25.4

6 80 15.8

7 90 16.8

8 C0 20.0

9 E0 22.1

10 FF 26.7

RF frequency 433 MHz RF frequency 868 MHz Output power

PA_POW

[hex]

Current consumption,

typ. [mA]

In power down mode the PA_POW should

be set to 00h for minimum leakage

current.

PA_POW

[hex]

Current consumption,

typ. [mA]

Table 11. Output power settings and typical current consumption

SWRS048 Page 32 of 53

Page 33

22. RSSI output

CC1000

Signal Strength Indicator) giving an

analogue output signal at the RSSI/IF pin.

The IF_RSSI bits in the FRONT_END

register enable the RSSI. When the RSSI

function is enabled, the output current of

this pin is inversely

input signal level. The output should be

terminated in a resistor to convert the

current output into a voltage. A capacitor

is used in order to low-pass filter the

signal.

The RSSI voltage range from 0 – 1.2 V

when using a 27 kΩ terminating resistor,

giving approximately 50 dB/V. This RSSI

voltage can be measured by an A/D

converter. Note that a higher voltage

means a lower input signal.

has a built-in RSSI (Received

proportional to the

CC1000

The RSSI measures the power referred to

the RF_IN pin. The input power can be

calculated using the following equations:

P = -51.3 V

P = -50.0 V

The external network for RSSI operation is

shown in Figure 21. R281 = 27 kΩ, C281

= 1nF.

A typical plot of RSSI voltage as function

of input power is shown in Figure 22.

– 49.2 [dBm] at 433 MHz

RSSI

– 45.5 [dBm] at 868 MHz

RSSI

CC1000

CC1000

RSSI/IF

RSSI/IF

Figure 21. RSSI circuit

R281C281

R281C281

TO ADC

TO ADC

1.3

1.2

1.1

1

0.9

0.8

0.7

0.6

Voltage

0.5

0.4

0.3

0.2

0.1

0

-105 -100 -95 -90 -85 -80 -75 -70 -65 -60 -55 -50

dBm

433Mhz

868Mhz

Figure 22. RSSI voltage vs. input power

SWRS048 Page 33 of 53

Page 34

23. IF output

CC1000

buffer. This buffer could be applied in

narrowband applications with

requirements on mirror image filtering.

The system is then built with

10.7 MHz ceramic filter and an external

10.7 MHz demodulator. The external

network for IF output operation is shown in

Figure 23. R281 = 470 Ω, C281 = 3.3nF.

has a built-in 10.7 MHz IF output

CC1000

, a

CC1000

The external network provides 330 Ω

source impedance for the 10.7 MHz

ceramic filter.

RSSI/IF

RSSI/IF

CC1000

CC1000

C281

C281

R281

R281

Figure 23. IF output circuit

To 10.7MHz filter

To 10.7MHz filter

and demodulator

and demodulator

SWRS048 Page 34 of 53

Page 35

24. Crystal oscillator

CC1000

regulated crystal oscillator. A high current

is used to start up the oscillations. When

the amplitude builds up, the current is

reduced to what is necessary to maintain

a 600 mVpp amplitude. This ensures a

fast start-up, keeps the current

consumption as well as the drive level to a

minimum and makes the oscillator

insensitive to ESR variations.

An external clock signal or the internal

crystal oscillator can be used as main

frequency reference. An external clock

signal should be connected to XOSC_Q1,

while XOSC_Q2 should be left open. The

XOSC_BYPASS bit in the FRONT_END

register should be set when an external

clock signal is used.

The crystal frequency should be in the

range 3-4, 6-8 or 9-16 MHz. Because the

crystal frequency is used as reference for

the data rate (as well as other internal

functions), the following frequencies are

recommended: 3.6864, 7.3728, 11.0592

or 14.7456 MHz. These frequencies will

give accurate data rates. The crystal

frequency range is selected by

XOSC_FREQ1:0 in the MODEM0 register.

To operate in synchronous mode at data

rates different from the standards at 1.2,

2.4, 4.8 kBaud and so on, the crystal

frequency can be scaled. The data rate

(DR) will change proportionally to the new

crystal frequency (f). To calculate the new

crystal frequency:

has an advanced amplitude

DR

DR

new

XOSC_Q1 XOSC_Q2

XOSC_Q1 XOSC_Q2

Figure 24. Crystal oscillator circuit

ff

=

_

xtalnewxtal

CC1000

Using the internal crystal oscillator, the

crystal must be connected between

XOSC_Q1 and XOSC_Q2. The oscillator

is designed for parallel mode operation of

the crystal. In addition loading capacitors

(C171 and C181) for the crystal are

required. The loading capacitor values

depend on the total load capacitance, C

specified for the crystal. The total load