Page 1

User's Guide

SBOU100–April 2011

BUF20800/20820EVM User Guide and Software Tutorial

This user's guide describes the characteristics, operation, and use of the BUF20800/20820EVM

evaluation board. It discusses how to set up and configure the software and hardware, and reviews

various aspects of the program operation. Throughout this document, the terms evaluation board,

evaluation module, and EVM are synonymous with the BUF20800/20820EVM. This document also

includes information regarding operating procedures and input/output connections, an electrical schematic,

printed circuit board (PCB) layout drawings, and a parts list for the EVM.

Contents

1 Overview ..................................................................................................................... 2

2 BUF20800/20820EVM Hardware Setup ................................................................................. 4

3 BUF20800/20820EVM Hardware Overview ............................................................................. 7

4 BUF20800/20820EVM Software ......................................................................................... 15

5 BUF20800/20820EVM Software Overview ............................................................................ 17

6 BUF20800/20820EVM Documentation ................................................................................. 27

List of Figures

1 Hardware Included with BUF20800/20820EVM Kit .................................................................... 3

2 BUF20800/20820EVM Hardware Setup ................................................................................. 4

3 BUF20800/20820EVM Board Block Diagram........................................................................... 5

4 USB_DIG_Platform Block Diagram....................................................................................... 7

5 Typical Hardware Connections for BUF20800/20820EVM............................................................ 8

6 Connecting External Power to the EVM ................................................................................. 9

7 Connecting the USB Cable to the USB_DIG_Platform............................................................... 10

8 Confirmation of USB_DIG_Platform Driver Installation............................................................... 10

9 BUF20800/20820EVM Default Jumper Settings ...................................................................... 11

10 BUF20800/20820EVM Software Installation........................................................................... 16

11 BUF20800/20820EVM License Agreements........................................................................... 16

12 BUF20800/20820EVM Software Installation Progress ............................................................... 17

13 BUF20800/20820EVM Software About Button ........................................................................ 17

14 BUF20800/20820EVM Software Interface ............................................................................. 18

15 BUF20800/20820EVM Software: Communication Error with the USB_DIG_Platform ........................... 19

16 Software Setting for JMP6 Low.......................................................................................... 19

17 Software Setting for JMP6 High ......................................................................................... 19

18 Measuring and Entering Power-Supply Voltage....................................................................... 20

19 Auto Write Feature Enabled ............................................................................................. 21

20 Save to File Dialog Box Button and Window .......................................................................... 22

21 File Format of Saved Data ............................................................................................... 22

22 Load From File Button and Window .................................................................................... 23

23 Run Batch Dialog Button and Window.................................................................................. 24

PowerPAD is a trademark of Texas Instruments.

Microsoft, Windows are registered trademarks of Microsoft Corporation.

I2C is a trademark of NXP Semiconductors.

WinZIP is a registered trademark of WinZip International LLC.

All other trademarks are the property of their respective owners.

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

1

Page 2

Overview

24 Control Panel Button and Window ...................................................................................... 25

25 Program OTP All Channels (BUF20820 DUT Only) .................................................................. 26

26 BUF20800/20820EVM Schematic....................................................................................... 27

27 BUF20800/20820EVM PCB Top Layer (Component Side).......................................................... 28

1 BUF20800/20820EVM Kit Contents...................................................................................... 3

2 Signal Definition of J1 (25-Pin Male DSUB) on BUF20800/20820EVM Board ..................................... 6

3 BUF20800/20820EVM Test Board Jumper Functions................................................................ 12

4 USB_DIG_Platform Jumper Functions ................................................................................. 13

5 Bill of Materials ............................................................................................................ 29

1 Overview

www.ti.com

List of Tables

The BUF20800 and BUF2082 are programmable gamma-voltage generators and V

BUF20800 offers two banks of 18 programmable gamma channels and two programmable V

calibrators. The

COM

COM

channels,

making it ideal for 10-bit source TFT-LCD reference drivers. The BUF20820 also features programmable

OTP memory that allows the user to store the gamma voltages on-chip, which eliminates the need for an

external EEPROM. The BUF20800/20820EVM is a platform for evaluating the performance of either the

BUF20800 or BUF20820 under various signal, reference, and supply conditions. This document gives a

general overview of the BUF20800/20820EVM, and provides a general description of the features and

functions to be considered while using this evaluation module. Unless otherwise noted, all references to

the device under test (DUT) apply to both the BUF20800 and the BUF20820.

2

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

© 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

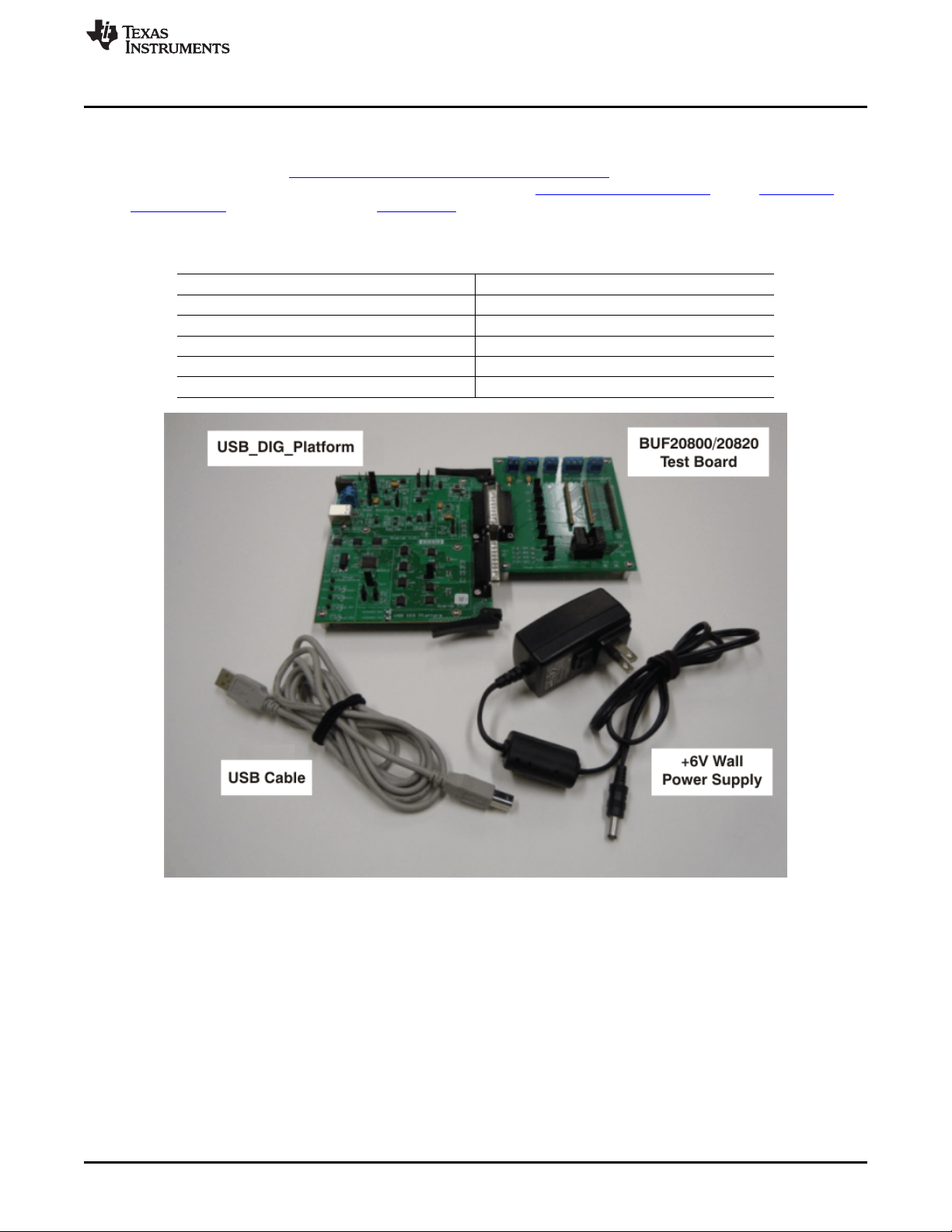

1.1 BUF20800/20820EVM Kit Contents

Table 1 summarizes the contents of the BUF20800/20820EVM kit. Figure 1 shows all of the included

hardware. Contact the Texas Instruments Product Information Center nearest you if any component is

missing. It is highly recommended that you also check the BUF20800 product folder or the BUF20820

product folder on the TI web site at www.ti.com to verify that you have the latest versions of the related

software.

Table 1. BUF20800/20820EVM Kit Contents

Item Quantity

BUF20800/20820 PCB Test Board 1

USB_DIG_Platform PCB 1

USB Cable 1

+6V Power Supply 1

User’s Guide CD-ROM 1

Overview

Figure 1. Hardware Included with BUF20800/20820EVM Kit

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

3

Page 4

+6V dc wall

supply

BUF20800/20820

Test Board

BUF20800/20820

Analog Supply

USB Dig Platform

Outputs

Measurement

Device

BUF20800/20820EVM Hardware Setup

1.2 Related Documentation from Texas Instruments

The following documents provide information regarding Texas Instruments' integrated circuits used in the

assembly of the BUF20800/20820EVM. This user's guide is available from the TI web site under literature

number SBOU100. Any letter appended to the literature number corresponds to the document revision

that is current at the time of the writing of this document. Newer revisions may be available from the TI

web site, or call the Texas Instruments' Literature Response Center at (800) 477-8924 or the Product

Information Center at (972) 644-5580. When ordering, identify the document by both title and literature

number.

Related Documentation

Document Literature Number

BUF20800/20820 Product Data SBOS329

Sheet

USB_DIG_Platform User Guide SBOU058

2 BUF20800/20820EVM Hardware Setup

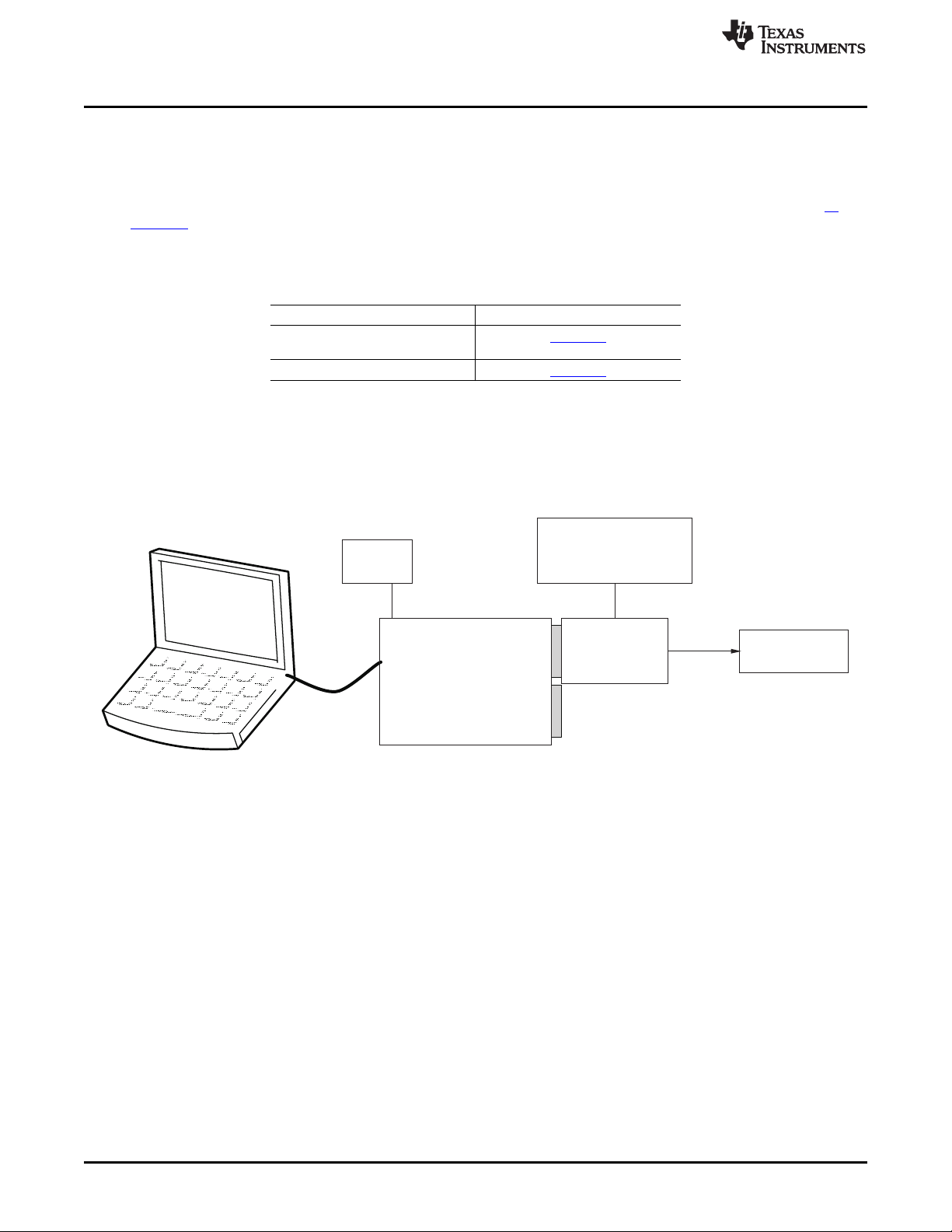

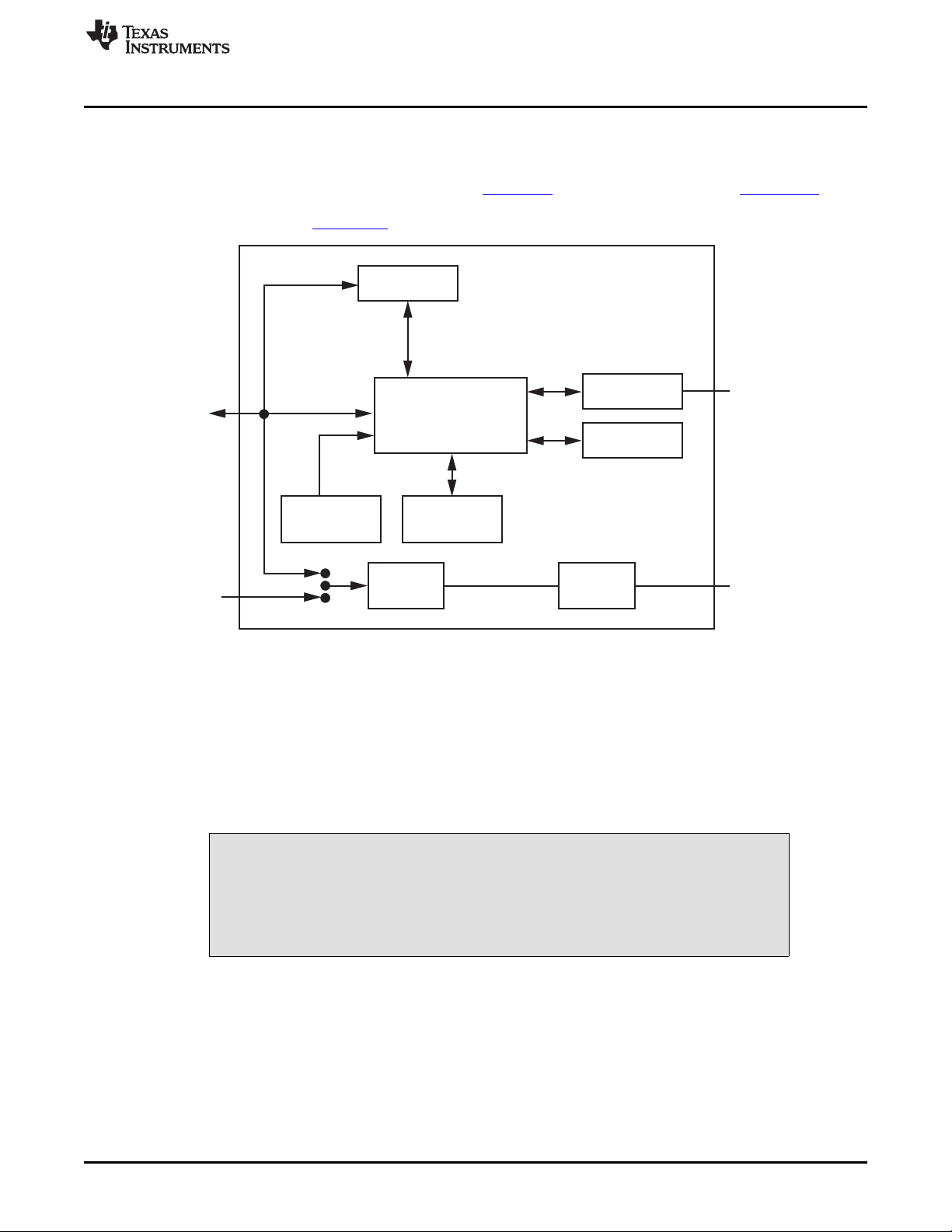

Figure 2 shows the system setup for the BUF20800/20820EVM. The PC runs software that communicates

with the USB_DIG_Platform. The USB_DIG_Platform generates the analog and digital signals used to

communicate with the BUF20800/20820 board. Connectors on the BUF20800/20820 allow the user to

connect to the system under test conditions where the power, current, and voltage are monitored.

www.ti.com

Figure 2. BUF20800/20820EVM Hardware Setup

4

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

© 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

BUF20800/

BUF20820

J1

T4

TPG1

V Supply

(AV Power Supply)

DUT

DD

I C Interface

2

Test Outputs

I C A0 Address

Jumper

2

External BUF20800/20820

Analog Power Supply

Test Point

Header

25-Pin Male

DSUB

www.ti.com

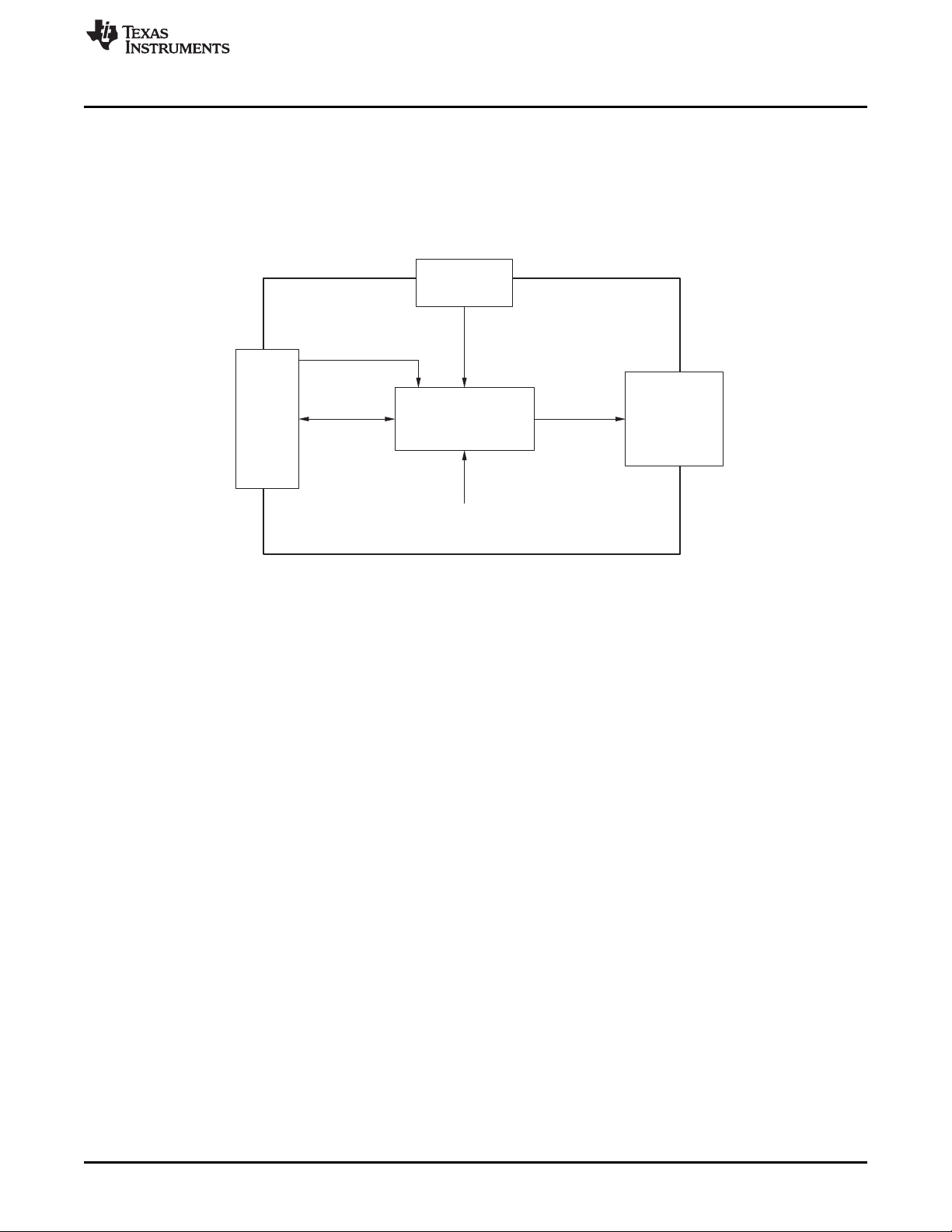

2.1 Theory of Operation for BUF20800/20820 Hardware

A block diagram of the BUF20800/20820 test board hardware setup is shown in Figure 3. The functionality

of the PCB is such that it provides connections to the I2C™ interface and general-purpose inputs/outputs

(GPIOs) on the USB_DIG_Platform board. It also provides connection points for external connections of

the shunt voltage, bus voltage, and ground.

BUF20800/20820EVM Hardware Setup

Figure 3. BUF20800/20820EVM Board Block Diagram

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

5

Page 6

BUF20800/20820EVM Hardware Setup

2.2 Signal Definitions of J1 (25-Pin Male DSUB)

Table 2 lists the different signals connected to J1 on the BUF20800/20820EVM test board.

Table 2. Signal Definition of J1 (25-Pin Male DSUB) on BUF20800/20820EVM

Board

Pin on J1 Signal BUF20800/20820 Pin

1 N/C No connection

2 N/C No connection

3 N/C No connection

4 N/C No connection

5 N/C No connection

6 N/C No connection

7 N/C No connection

8 N/C No connection

9 I2C_SCK No connection

10 I2C_SDA2 No connection

11 N/C No connection

12 I2C_SCK_ISO

13 I2C_SDA_ISO

14 N/C No connection

15 N/C No connection

16 N/C No connection

17 V

18 V

19 N/C No connection

20 N/C No connection

21 GND Common ground connection

22 SPI_SCK No connection

23 SPI_CS1 No connection

24 SPI_DOUT1 No connection

25 SPI_DIN1 No connection

DUT

CC

www.ti.com

I2C clock signal (SCL) channel 1; can be

disconnected using a switch

I2C data signal (SDA) channel 1; can be

disconnected using a switch

Switched 3V/5V power. Note that when

power is switched off, digital I/O is also

switched off.

No connection

6

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

© 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

Adjustable

Regulator

TUSB3210

8052 Cm

with USB Interface

and UART

3.3V

Regulator

8K byte

EEPROM

V

CC

(2.7V to 5.5V)

V Cm

S

3.3V

V

USB

5V

V

DUT

(2.7V to 5.5V)

Reset Button and

Power-On Reset

Buffers and

Latches

Calibration

EEPROM

USB DIG Platform

Power

Switching

Switched

Power

External

Power

(6V dc)

USB Bus

from

Computer

I C/SPI

2

Control and

Measure Bits

www.ti.com

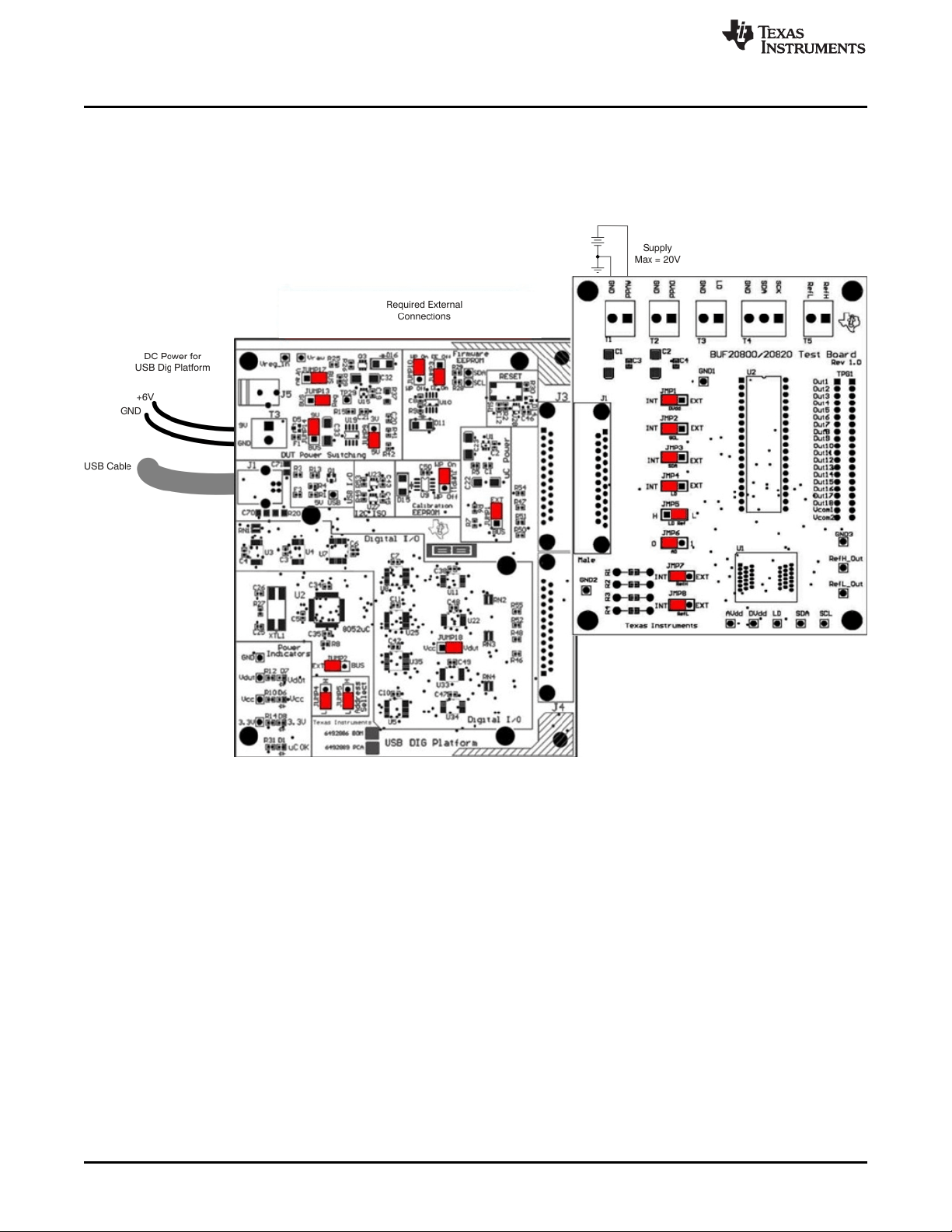

2.2.1 Theory of Operation for USB_DIG_Platform

Figure 4 shows the block diagram for the USB_DIG_Platform. This platform is a general-purpose data

acquisition system that is used on several different Texas Instruments evaluation modules. The details of

its operation are included in a separate document, SBOU058 (available for download at www.ti.com). The

block diagram shown in Figure 4 gives a brief overview of the platform. The primary control device on the

USB_DIG_Platform is the TUSB3210.

BUF20800/20820EVM Hardware Overview

Figure 4. USB_DIG_Platform Block Diagram

3 BUF20800/20820EVM Hardware Overview

The BUF20800/20820EVM hardware overview involves connecting the two PCBs of the EVM together,

applying power, connecting the USB cable, and setting the jumpers. This section presents the details of

this procedure.

3.1 Electrostatic Discharge Warning

Many of the components on the BUF20800/20820EVM are susceptible to

damage by electrostatic discharge (ESD). Customers are advised to observe

proper ESD handling precautions when unpacking and handling the EVM,

including the use of a grounded wrist strap at an approved ESD workstation.

CAUTION

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

7

Page 8

BUF20800/20820EVM Hardware Overview

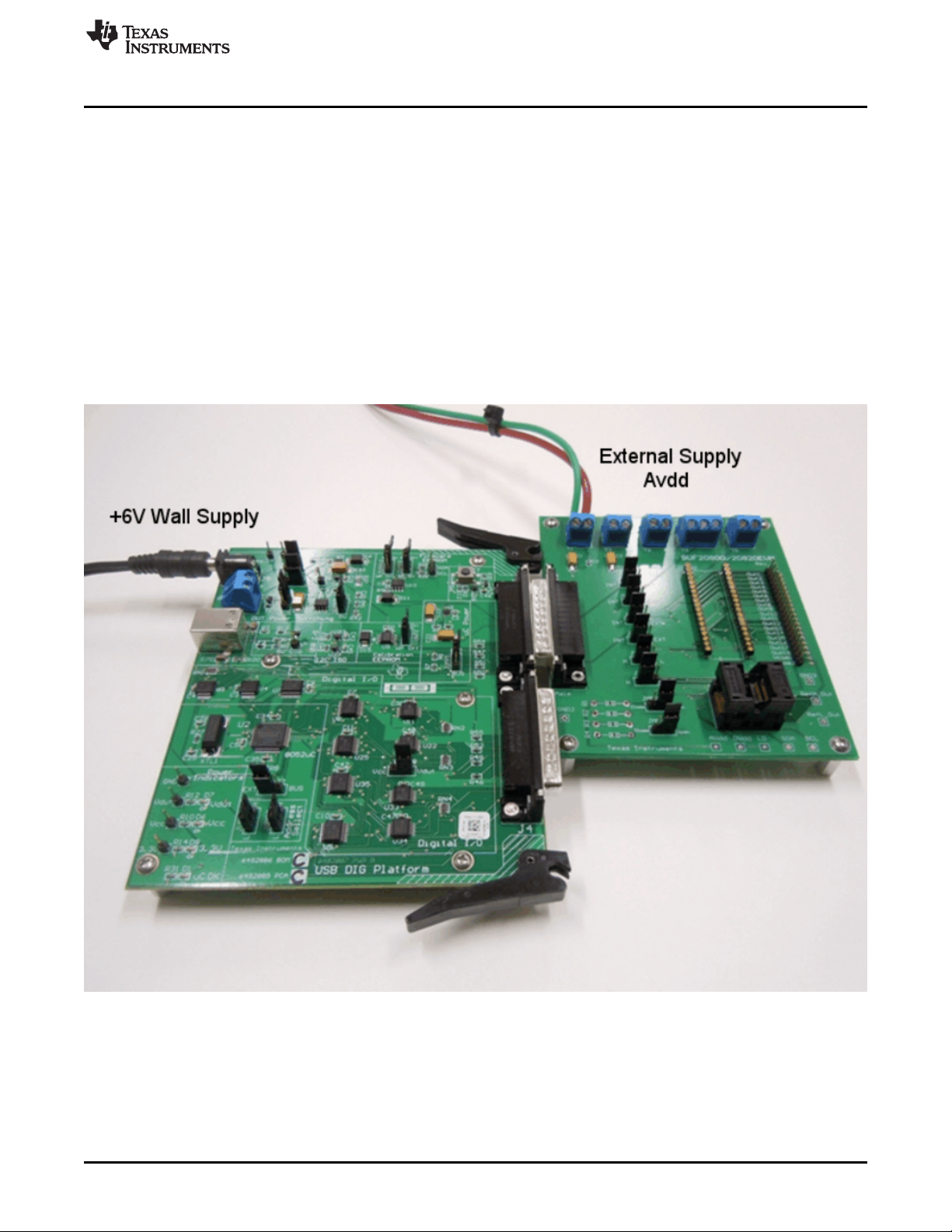

3.2 Typical Hardware Connections

To set up the BUF20800/20820EVM hardware, connect the two PCBs of the EVM together, and apply a

power source to the BUF20800/20820EVM test board. The external connections may be the real-world

system that the BUF20800 or BUF20820 will be incorporated into. Figure 5 illustrates the typical hardware

connections.

www.ti.com

Figure 5. Typical Hardware Connections for BUF20800/20820EVM

8

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

© 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

3.3 Connecting the Hardware

To connect the two PCBs of the BUF20800/20820EVM together, gently push on both sides of the DSUB

connectors (as shown in Figure 6). Note that the USB_DIG_Platform board has two DSUB connectors;

either may be used. Make sure that the two connectors are completely pushed together; loose

connections may cause intermittent operation.

3.4 Connecting Power

After the two parts of the BUF20800/20820EVM are conjoined, connect a +6V wall supply to the

USB_DIG_Platform board, as Figure 6 shows. Always connect power before connecting the USB cable. If

you connect the USB cable before connecting the power, the computer will attempt to communicate with

an unpowered device that will not be able to respond.

In addition, the BUF20800/20820EVM also requires an external power source. This source is not included

with the kit. Its voltage may differ depending on your testing needs, and it will be connected to the terminal

T1.

BUF20800/20820EVM Hardware Overview

Figure 6. Connecting External Power to the EVM

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

9

Page 10

BUF20800/20820EVM Hardware Overview

3.5 Connecting the USB Cable to the BUF20800/20820EVM

Once power is connected, the USB cable must be connected to the USB_DIG_Platform, as shown in

Figure 7. Note that the BUF20800/20820EVM test board and the USB_DIG_Platform board must each be

powered on before connecting the USB cable. Typically, the computer will respond with a Found New

Hardware, USB Device pop-up dialog. The pop-up window typically changes to Found New Hardware,

USB Human Interface Device. This pop-up indicates that the device is ready to be used. The

USB_DIG_Platform uses the human interface device drivers that are part of the Microsoft®Windows

operating system.

www.ti.com

®

10

Figure 7. Connecting the USB Cable to the USB_DIG_Platform

In some cases, the Windows Add Hardware Wizard may pop up. If this prompt appears, allow the system

device manager to install the human interface drivers by clicking Yes when requested to install drivers.

Windows will confirm installation of the drivers with the message shown in Figure 8.

Figure 8. Confirmation of USB_DIG_Platform Driver Installation

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 11

www.ti.com

3.6 BUF20800/20820EVM Default Jumper Settings

Figure 9 shows the default jumpers configuration for the BUF20800/20820EVM. In general, the jumper

settings of the USB_DIG_Platform will not need to be changed. You may want to change some of the

jumpers on the BUF20800/20820EVM board to match your specific configuration. For instance, you may

wish to set a specific I2C address on the DUT.

BUF20800/20820EVM Hardware Overview

Figure 9. BUF20800/20820EVM Default Jumper Settings

Jumpers 1 through 4 on the BUF20800/20820EVM are all typically set to the same position. When set to

the INT position, the signals from the digital supply (JMP1) and the digital communication lines

(JMP2-JMP4) are generated and controlled from the USB_DIG_Platform or by the onboard bank select

switch. When these jumpers are set the EXT position, the signals from JMP1-JPM4 connect to the

terminal strips T2, T3, and T4. Jumper 6 controls the I2C address pin for the BUF20800/20820; this jumper

can set the address for A0 to either high or low. Jumper 5 can be set to low or high to hard set the LD

signal to the BUF20800/20820 as long as JMP4 is configured correctly.

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

11

Page 12

BUF20800/20820EVM Hardware Overview

Table 3 summarizes the function of the BUF20800/20820EVM board jumpers. For most application,

Jumpers 2 through 5 are all set to the default positions.

Table 3. BUF20800/20820EVM Test Board Jumper Functions

Jumper Default Purpose

JMP1 INT This jumper selects whether the DVDDdigital supply pin on the

JMP2 INT This jumper selects whether the SCL pin on the BU20800 or

JMP3 INT This jumper selects whether the SDA pin on the BUF20800 or

JMP4 INT This jumper selects whether the LD pin on the BUF20800 or

JMP5 L This jumper selection depends on the configuration of JMP4. In

JMP6 0 This jumper selects the I2C A0 address selection. Two separate

JMP7 INT This jumper selects whether or not the RefH pin on the

JMP8 INT This jumper selects whether or not the RefL pin on the

www.ti.com

BUF20800 or BUF20820 is connected to the V

generated from the USB_DIG_Platform or whether DVDDis

DUT

signal

connected to terminal T2 to allow for an external supply to power

the digital circuitry. The default INT position connects the DV

pin to the V

control signal

DUT

DD

BUF20820 is connected to the I2C_SCK_ISO signal generated

from the USB_DIG_Platform or whether the SCL pin is

connected to terminal T4 to allow for an external source to

control the I2C clock line. The default INT position connects the

SCL pin to the I2C_SCK_ISO control signal.

BUF20820 is connected to the I2C_SDA_ISO signal generated

from the USB_DIG_Platform or whether the SDA pin is

connected to terminal T4 to allow for an external source to

control the I2C data line. The default INT position connects the

SDA pin to the I2C_SDA_ISO control signal.

BUF20820 is connected to jumper JMP5 or whether the LD pin

is connected to terminal T3 to allow for an external source to

control the latch pin. The default INT position connects the LD

pin to jumper JMP5.

the event that JMP4 is set to INT, JMP5 is used to select

whether or not the LD pin on the BUF20800 or BUF20820 is

connected to the DVDDdigital supply or whether the LD pin is

connected to ground. The default LOW position connects the LD

pin to ground. If JMP4 is set to the EXT position, JMP4 is not

used.

I2C addresses can be selected depending on whether JMP6 is

set high or low.

BUF20800 is connected or BUF20820 to the AVDDsignal

generated by the external analog power-supply input at terminal

T1, or whether the RefH pin is connected to a user-designated

reference, which is set using an external input at terminal T5 as

well as resistors R1 and R2. The default INT position connects

the RefH pin to the external power-supply input at terminal T1.

BUF20800 is connected to ground or whether the RefL pin is

connected to a user-designated reference, which is set using an

external input at terminal T5 as well as resistors R3 and R4. The

default INT position connects the RefL pin to ground.

12

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 13

www.ti.com

Table 4 summarizes the function of the USB_DIG_Platform jumpers. For most applications, the default

jumper position should be used. A separate document (SBOU058) gives details regarding the operation

and design of the USB_DIG_Platform.

BUF20800/20820EVM Hardware Overview

Table 4. USB_DIG_Platform Jumper Functions

Jumper Default Purpose

This jumper selects external power or bus power.

JUMP1 EXT

JUMP2 EXT Same as JUMP1.

JUMP3 EE ON

JUMP4, JUMP5 L, L The only reason to change from the default setting

JUMP9 5V

JUMP10 WP ON This write protects the firmware EEPROM.

JUMP11 WP ON This write protects the calibration EEPROM.

JUMP13 REG supply. The USB bus can be used as the V

JUMP14 9V

JUMP17 BUS

JUMP18 V

(1)

CAUTION: Adjusting outside of this range will damage the EVM.

DUT

External power is applied on J5 or T3 (9V dc). Bus

power is 5V from the USB bus. External power is

typically used because the USB Bus power is noisy.

This jumper determines where the TUSB3210 will

load the USB_DIG_Platform firmware upon

power-up or reset. The EE Off position is used for

development for development or firmware update.

This jumper sets the address for the USB board.

is if multiple boards are being used.

This jumper selects the voltage of the device under

test supply (V

typically the only jumper that is changed for most

applications.

Uses the regulator output to generate the V

supply.

Uses the external power (9V as opposed to the

bus).

While in the BUS position V

While in the V

connected to an external source. This configuration

allows for any value of V

Connects the pull-up on GPIO to the V

the VCCsupply.

= 5V or 3V). This jumper is

DUT

operation is normal.

position the V

RAW

DUT

DUT

between 3V and 5V.

DUT

supply is

DUT

DUT

DUT

(1)

supply or

3.7 BUF20800/20820EVM Features

This section describes some of the hardware features present on the BUF20800/20820 test board.

3.7.1 JMP1: DVDDControl Setting

Jumper JMP1 selects where the BUF20800 or BUF20820 digital supply pin is connected. If JMP1 is set to

the INT position, the DVDDpin is connected to the switchable V

USB_DIG_Platform. This voltage can be set to either +3.3V or +5V depending on how JMP9 on the

USB_DIG_Platform is set. While JMP1 is set to the INT position, the DVDDPower button in the

BUF20800/20820 software is able to control whether the V

DUT

When JMP1 is set in the EXT position, an external supply connected to terminal T1 can be used to

provide the digital supply voltage for the BUF20800 or BUF20820.

3.7.2 JMP2: I2C SCL Control Setting

Jumper JMP2 selects where the BUF20800 or BUF20820 I2C SCL pin is connected. If JMP2 is set to the

INT position, the I2C clock signal is generated from the I2C_SCK_ISO signal from the USB_DIG_Platform.

When JMP2 is set to the EXT position, an external source connected to SCL pin of terminal T4 can be

used to provide the I2C SCK signal for the BUF20800 or BUF20820.

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

signal generated from the

DUT

supply voltage is turned on or off.

13

Page 14

RefH = V

SUP_H

R2

R1 + R2

(

(

BUF20800/20820EVM Hardware Overview

3.7.3 JMP3: I2C SDA Control Setting

Jumper JMP3 selects where the BUF20800 or BUF20820 I2C SDA pin is connected. If JMP4 is set in the

INT position, the I2C data signal is generated from the I2C_SDA_ISO signal from the USB_DIG_Platform.

When JMP3 is set in the EXT position, an external source connected to SDA pin of terminal T4 can be

used to provide the I2C SDA signal for the BUF20800 or BUF20820.

3.7.4 JMP4: LD Control Setting

Jumper JMP4 selects which input the LD latch pin of the BUF20800 or BUF20820 is connected to. If

JMP4 is set in the INT position, it is routed through the JMP5 jumper where the reference voltage can be

set high or low (see Section 3.7.5).

When JMP4 is set to the EXT position, an external source connected to the LD pin of terminal T3 can be

used to provide a reference voltage for the latch pin, which dictates the method by which the DAC output

voltage is updated.

3.7.5 JMP5: LD Reference Setting

Jumper JMP5 is used to select the reference voltage that is connected to the LD latch pin. It is used only

when jumper JMP4 is set to INT. If JMP5 is set to H, the latch pin is connected to the DVDDsupply

voltage, which allows all DAC output voltages to retain the respective values during data transfer until LD

sees a low reference (such as when JMP5 is set to the L position).

When JMP5 is set to the L position, the LD latch pin is connected to ground, which then updates each

DAC output voltage whenever its corresponding register is updated.

www.ti.com

3.7.6 JMP6: I2C Address Hardware Setting

Jumper JMP6 is used to set the hardware setting for the A0 I2C address pin on the BUF20800 or

BUF20820. Using JMP6, the A0 address can be set to either logic '1' or logic '0' to allow for two unique I2C

addresses. See Section 5.2.1 on how to configure the BUF20800/20820EVM software to match the JMP6

hardware setting.

3.7.7 JMP7: RefH Control Setting

Jumper JMP7 selects where the BUF20800 or BUF20820 high reference supply pin RefH is connected. If

JMP7 is set to the INT position, RefH is connected to AVDD, the external analog supply input at terminal

T1.

When JMP7 is set to the EXT position, the reference voltage is then designated by using the RefH pin of

terminal T5 along with resistors R1 and R2. An external power supply is connected to the RefH pin of

terminal T5, and R1 and R2 act as a voltage-divider circuit; the user sets the values of R1 and R2 to

achieve the desired reference voltage using Equation 1:

Where V

is the input supply voltage seen at the RefH pin of terminal T5.

SUP_H

(1)

14

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 15

RefL = V

SUP_L

R4

R3 + R4

(

(

www.ti.com

3.7.8 JMP8: RefL Control Setting

Jumper JMP8 selects where the BUF20800 or BUF20820 low reference supply pin RefL is connected. If

JMP8 is set to the INT position, RefL is connected to ground.

When JMP8 is set to the EXT position, the reference voltage is then designated by using the RefL pin of

terminal T5 along with resistors R3 and R4. An external power supply is connected to the RefH pin of

terminal T5, and R3 and R4 act as a voltage-divider circuit; the user sets the values of R3 and R4 to

achieve the desired reference voltage using Equation 2:

Where V

is the input supply voltage seen at the RefL pin of terminal T5.

SUP_L

3.7.9 BUF20800/20820 Device Placement

The BUF20800/20820EVM offers the user two separate locations on the PCB where the BUF20800 of

BUF20820 test device can be installed. The U1 location on the BUF20800/20820EVM test board is a

38-pin, QFN/MLF test socket that allows the user to evaluate and program many devices very quickly.

One drawback to this socket is that there is no connection to the PowerPAD™ of the BUF20800 or

BUF20820 DUT. Because of this limitation, while in this socket, the BUF20800/20820 device cannot

operate at its full output capability as a result of thermal dissipation restrictions.

The U2 location allows for a BUF20800 or BUF20820 device that is soldered down on a DIP adapter

board to be installed on the BUF20800/20820EVM test board. The output capability of the BUF20800 or

BUF20820 device that is soldered on this adapter board can be fully evaluated. The PowerPAD of this

soldered BUF20800/20820 unit is connected correctly, allowing the device to dissipate the necessary

power while being evaluated.

BUF20800/20820EVM Software

(2)

Only one location should be populated at a time. The use of both locations

simultaneously will damage one or both of the devices being tested.

3.7.10 Terminal Strip TPG1

Terminal strip TPG1 provides the individual output signals on a single row of headers as well as a row of

vias. This footprint provides the user with multiple options regarding how to interface the output signals of

the BUF20800 or BUF20820 with the available display panel. Users can develop a custom cable to

connect the headers to their respective panels directly, or to solder directly to the individual vias.

4 BUF20800/20820EVM Software

4.1 Hardware Requirements

The BUF20800/20820EVM software has been tested on Microsoft®Windows®XP, Vista, and Windows 7

operating systems (OS) with United States and European regional settings.

4.2 Software Installation

The BUF20800/20820EVM software is included on the CD that is shipped with the EVM kit. It is also

available through the BUF20800/20820EVM product folder on the TI web site. To install the software to a

computer, insert the disc into an available CD-ROM drive. Navigate to the drive contents and open the

BUF20800/20820EVM software folder. Locate the compressed file (BUF20800/20820EVM.zip) and open it

using WinZIP®or a similar file compression program; extract the BUF20800/20820EVM files into a specific

BUF20800/20820EVM folder (for example, C:\BUF20800/20820EVM) on your hard drive.

CAUTION

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

15

Page 16

BUF20800/20820EVM Software

Once the files are extracted, navigate to the BUF20800/20820EVM folder you created on the hard drive.

Locate the setup.exe file and execute it to start the installation, as shown in Figure 10.

www.ti.com

Figure 10. BUF20800/20820EVM Software Installation

After the installation process initializes, the user is given the choice of selecting the directory in which to

install the program; the default location is C:\Program Files\BUF208xx\ and C:\Program Files\National

Instruments\. Following this option, two license agreements are presented that must be accepted, as

shown in Figure 11. After accepting the Texas Instruments and National Instruments license agreements,

the progress bar opens and shows the installation of the software, as Figure 12 illustrates. Once the

installation process is completed, click Finish.

16

Figure 11. BUF20800/20820EVM License Agreements

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 17

www.ti.com

BUF20800/20820EVM Software Overview

Figure 12. BUF20800/20820EVM Software Installation Progress

4.3 Software Description and Set-Up

The BUF20800/20820EVM software allows the user to read and write to all registers in the

BUF20800/20820 gamma correction buffer. Furthermore, it allows programming of the OTP register on the

BUF20820. The software also permits the user to select either I2C address. Press the About button, as

shown in Figure 13, to verify that you have the latest version of the software.

Figure 13. BUF20800/20820EVM Software About Button

5 BUF20800/20820EVM Software Overview

This section discusses how to use the BUF20800/20820EVM software.

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

17

Page 18

BUF20800/20820EVM Software Overview

5.1 Starting the BUF20800/20820EVM Software

The BUF20800/20820 software can be operated through the Windows Start menu. From Start, select All

Programs; then select the BUF20800/20820EVM program. Figure 14 illustrates how the software should

appear if the BUF20800/20820EVM is functioning properly.

www.ti.com

18

Figure 14. BUF20800/20820EVM Software Interface

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 19

www.ti.com

Figure 15 shows an error that pops up if the computer cannot communicate with the EVM. If you receive

this error, first check to see that the USB cable is properly connected on both ends. This error can also

occur if you connect the USB cable before the USB_DIG_Platform power source. Another possible source

for this error is a problem with your PC USB Human Interface Device driver. Make sure that the device is

recognized when the USB cable is plugged in; recognition is indicated by a Windows-generated

confirmation sound.

Figure 15. BUF20800/20820EVM Software: Communication Error with the USB_DIG_Platform

5.2 Using the BUF20800/20820 Software

5.2.1 I2C Address Selection

As mentioned previously in the BUF20800/20820EVM Features section (see Section 3.7), jumper JMP6 is

used to set the I2C address pin of the BUF20800/20820 . Figure 16 shows how the hardware and software

must both be set to allow for communication between the BUF20800/20820EVM and the software.

Without jumper JMP6 and the software address button configured correctly, the software will not be able

to communicate with the BUF20800/20820 device.

BUF20800/20820EVM Software Overview

Figure 16. Software Setting for JMP6 Low

When JMP6 is set high and the software is set as shown in Figure 17, the second I2C address can be

configured.

Figure 17. Software Setting for JMP6 High

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

19

Page 20

V

OUT

=

V V

1024

REFH REFL

-

? Decimal Value of Code + V

REFL

V

OUT

=

15 0

1024

-

? 68 + 0 =

1020

1024

= 0.996

BUF20800/20820EVM Software Overview

5.2.2 Measuring the Power Supply

You must measure the power supply (VS) with respect to the GND on the BUF20800/20820EVM board

and enter it in the V

field located in the top section of the software interface, as shown in Figure 18.

SUP

Figure 18. Measuring and Entering Power-Supply Voltage

www.ti.com

The voltage out of each DAC is calculated according to the V

These values exist as a window for maximum and minimum levels that the voltage can achieve. These

maximum and minimum levels are then multiplied by the decimal code to determine the DAC voltage. The

calculation is performed according to Equation 3.

For example, changing the value in the channel 6 cell, with V

immediately changes the output of channel 6 to 0.996V.

Example: Channel 6: Code 44 (hexadecimal) = 68 (decimal)

5.2.3 Read DAC Button

By pressing the Read DAC button in the BUF20800/20820EVM software, all of the BUF20800/20820

DAC/V

registers are read to obtain the respective current register contents. Once the read procedure is

COM

complete, all of the corresponding text boxes are updated to show the current values present in the

DAC/V

COM

registers.

REFH

REFH

and the V

and V

REFL

scaled values entered.

REFL

connected internally,

(3)

20

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

© 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

5.2.4 Write DAC Button

The method used to write the values in the DAC/V

feature is enabled. The BUF20800/20820 has two methods of writing information into the DAC/V

registers. The first method allows for the output voltage to change immediately after the writing to the DAC

register. In the BUF20800/20820EVM software, this mode is configured by enabling the Auto Write feature

found in the Buffer Menu dropdown menu. In this mode, as an individual channel is written to, the output

voltage changes as soon as the user moves to a different text box in the software. The second method of

writing to the DAC/V

output voltages change at the same time, rather than each channel voltage changing as soon as it is

written to.

Disabling the Auto Write feature in the software allows the user to enter all of the values desired for all of

the channels and then press the Write DAC button to change all of the output voltage of all of the

channels at one time. When the Auto Write feature is enabled, no change occurs to the output voltages

when the Write DAC button is pressed. No change occurs because after the text box for a given channel

has been updated, as soon as another item in the software is clicked, the Auto Write feature automatically

performs a write command to the updated channel that then updates the output voltage. When in the Auto

Write enabled mode, the Write DAC button cannot be pressed with different data in the corresponding

channel text boxes than the values already stored in the DAC/V

Figure 19 shows the location in the Buffer Menu showing the Auto Write feature enabled. Clicking on the

Auto Write feature again enables/disables the feature, depending on its current state.

BUF20800/20820EVM Software Overview

registers is based on whether or not the Auto Write

COM

registers allows for the user to write multiple channels and then have all of the

COM

register; thus, no change occurs.

COM

COM

5.2.5 Reset Button

Pressing the Reset button in the BUF20800/20820EVM software performs two functions. The first function

is to call a General-Call Reset for the BUF20800 or BUF20820. The status of the DAC/V

this General-Call Reset has been used depends on the DUT on the EVM.

If the BUF20800 is in the test board, the channel registers default to 1000000000, or mid-supply.

If the BUF20820 is in the test board, the status of the DAC/V

depends on whether or not the OTP has been programmed. If the OTP has been programmed, the

channel registers are loaded with the last values programmed into the OTP memory. If the OTP memory

has not been programmed, the channel registers will default to 1000000000, or mid-supply.

The second function performed after the reset button is pressed is that a Read DAC call is made to

update the corresponding channel text boxes to the current value for each channel. This function is valid

for both the BUF20800 and the BUF20820 device.

Figure 19. Auto Write Feature Enabled

registers after this General-Call Reset

COM

registers after

COM

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

21

Page 22

BUF20800/20820EVM Software Overview

5.2.6 Save to File Button

The register configurations of the BUF20800/20820 DACs are displayed in both analog voltage and in

hexadecimal. The DAC codes (that is, gamma voltages) can be saved into a text file using the Save to

File button.

Pressing the Save to File button opens a file-save dialog box similar to that shown in Figure 20. Pressing

the folder icon creates a new folder on your PC. It is a good idea to create a directory exclusively for

BUF20800/20820 DAC code (that is, gamma voltage) files. Enter a unique file name in the File name field

to store your BUF20800/20820 register information. Press the OK button to save the file.

Figure 20. Save to File Dialog Box Button and Window

Saved BUF20800/20820 DAC codes (gamma voltages) exist in a text file that can be opened in a text

editor, as Figure 21 illustrates.

www.ti.com

22

Figure 21. File Format of Saved Data

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 23

www.ti.com

5.2.7 Load From File Button

The BUF20800/20820EVM software is also able to load data saved from previous evaluations. A saved

register configuration can be loaded into the BUF20800/20820 using the Load From File button, as

shown in Figure 22. The program remembers where you saved the last register configuration. Simply

select the desired configuration and press Open.

BUF20800/20820EVM Software Overview

5.2.8 Changing the DAC/V

The voltage of any of the DAC or V

the voltage by entering the desired voltage directly in the voltage text box. In order to be able to manually

type the voltage into the text box, you must first click on the cell to be edited. Click a second time and the

cell turns from blue to black, and allows the user to type the updated voltage in the cell. The hexadecimal

DAC codes can be entered in the Code column in the same manner.

Another method of changing the voltage of a DAC or V

main software window. There is only a single slider that is used for all channels. In order to use the slider

to adjust the voltage of a particular channel, that channel must first be selected. To select a channel, click

on either the channel number, voltage, or code of a particular channel. The entire channel row highlights

in blue to show the user that the channel is selected. Adjusting the slider bar then only updates the

highlighted channel.

The final method to change DAC/V

software window. These buttons allow for fine and coarse adjustments, respectively, to the highlighted

channel, giving the user the ability to quickly step the channel output up or down as needed without

having to manually enter the changes in the Code column.

Figure 22. Load From File Button and Window

Analog Voltage

COM

channels can be adjusted in several ways. First, you can change

COM

channel is through the use of the slider on the

COM

voltages is through the ±1 Code and ±5 Code buttons on the main

COM

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

23

Page 24

BUF20800/20820EVM Software Overview

5.2.9 Run Batch Button

The Run Batch button (as highlighted in Figure 23) enables the user to configure the BUF20800 of

BUF20820 to cycle through different register configurations in a continuous loop. When connected to the

end application, this feature can be used to cycle through different gamma settings to determine what the

optimal settings must be for a given application.

When the Run Batch button is pressed, a new dialog box displays as Figure 23 shows. The delay time is

the amount of time allowed between loading new configurations into the BUF20800/20820 DUT.

Use the Single Step Up and Single Step Down buttons to step through the selected files manually. The

currently-selected file name is displayed in the lower left corner area of the dialog box. Double-click on the

file names to select them. Once a series of filenames have been selected, the check box turns dark.

Double-click on a filename again to unselect it from the batch run.

www.ti.com

24

Figure 23. Run Batch Dialog Button and Window

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 25

www.ti.com

5.2.10 Control Panel Button

Pressing the Control Panel button brings up a display panel that allows you to adjust each channel using

a set of graphical sliders, as shown in Figure 24. Simply drag the slider to adjust the desired channel

output. The DAC code and corresponding output value of each channel change automatically. This

function is similar to the slider present on the primary BUF20800/20820EVM software window that

changes based on the channel that highlighted (as discussed in the above section).

BUF20800/20820EVM Software Overview

Figure 24. Control Panel Button and Window

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

25

Page 26

BUF20800/20820EVM Software Overview

5.2.11 Program OTP All Channels Button (BUF20820 DUT Only)

To configure the BUF20820 Program OTP function, make sure the device inserted into the

BUF20800/20820 test board is the BUF20820. Also, be sure the BUF20820 is selected from the Buffer

Model menu. As Figure 25 shows, pressing the Program OTP All Channels button allows you to program

a gamma curve into the nonvolatile memory of the BUF20820. All 18 channels (including the V

channels) are then programmed simultaneously. The values are stored in the memory bank.

www.ti.com

COM

26

Figure 25. Program OTP All Channels (BUF20820 DUT Only)

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 27

www.ti.com

6 BUF20800/20820EVM Documentation

This section contains the complete bill of materials and schematic diagram for the BUF20800/20820EVM.

Documentation information for the USB_DIG_Platform can be found in the USB_DIG_Platform User’s

Guide, SBOU058, available at the TI web site at http://www.ti.com.

6.1 Schematic

Figure 26 shows the schematic for the BUF20800/20820EVM.

BUF20800/20820EVM Documentation

Figure 26. BUF20800/20820EVM Schematic

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

27

Page 28

BUF20800/20820EVM Documentation

6.2 PCB Layouts

Figure 27 shows the PCB component layout of the BUF20800/20820EVM.

www.ti.com

28

Figure 27. BUF20800/20820EVM PCB Top Layer (Component Side)

BUF20800/20820EVM User Guide and Software Tutorial SBOU100–April 2011

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

Page 29

www.ti.com

BUF20800/20820EVM Documentation

6.3 Bill of Materials

Table 5 lists the bill of materials for this EVM.

Table 5. Bill of Materials

Item No Count Value RefDes Description Part Number Mfr

1 4 R1-R4 Resistor, 1/16W .5% 0603 SMD Varies SusumuCo Ltd

2 2 4.7μF C1, C2 Capacitor, Tantalum 4.7μF 35V 10% 293D475X9035C2TE3 Vishay/Sprague

3 2 1μF C3, C4 Capacitor, Ceramic 1μF 25V Y5V 0603 GRM188F51E105ZA12D Murata Electronics North

4 6 0.1μF C5-C10 Capacitor, .10μF 25V Ceramic Y5V 0603 C0603C104Z3VACTU Kemet

5 1 U1 Socket, TSSOP 38-Pin ZIF OTS-38(28)-0.65-01 ENPLAS

6 2 U2 Connector, Rcpt .100" 19-Position Gold SS-119-G-2 Samtec

7 1 DSUB25M J1 Connector, D-SUB plug R/A 25-Position 5747842-4 AMP/Tyco Electronics

8 4 T1, T2, T3, T5 Terminal Block 5MM 2-Position ED300/2 On-Shore Technology Inc

9 1 T4 Terminal Block 5MM 3-Position ED300/3 On-Shore Technology Inc

10 1 Strip cut to TPG1 Connector, Header 20-Position .100" TSW-120-07-G-S Samtec

size SGL Gold

11 10 TP cut to Test Points, All Connector, Header 1-Position .100" SGL TSW-101-07-G-S Samtec

size Gold

12 4 Standoff None Standoffs, Hex , 4-40 Threaded, 0.500" 2203 Keystone

13 4 Screw None Screw Machine Phillips 4-40 × 1/4 SS PMSSS 440 0025 PH B & F Fastener Supply

14 8 Strip cut to JMP1- JMP8 Connector, Header 3-Position .100" SGL TSW-103-07-G-S Samtec

size Gold

15 8 Jumper JMP1- JMP8 LP W/Handle 2-Position 881545-2 AMP/Tyco Electronics

SMD

America

T/H

30 Gold (with threaded inserts and board

locks)

length, 0.250" OD, Aluminum Iridite

Finish

SBOU100–April 2011 BUF20800/20820EVM User Guide and Software Tutorial

Submit Documentation Feedback

© 2011, Texas Instruments Incorporated

29

Page 30

Evaluation Board/Kit Important Notice

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the

product(s) must have electronics training and observe good engineering practice standards. As such, the goods being provided are

not intended to be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations,

including product safety and environmental measures typically found in end products that incorporate such semiconductor

components or circuit boards. This evaluation board/kit does not fall within the scope of the European Union directives regarding

electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC, CE or UL, and therefore may not meet the

technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30

days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY

SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all

claims arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to

take any and all appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of

patents or services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the

product. This notice contains important safety information about temperatures and voltages. For additional information on TI’s

environmental and/or safety programs, please contact the TI application engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and

can radiate radio frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15

of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this

equipment in other environments may cause interference with radio communications, in which case the user at his own expense

will be required to take whatever measures may be required to correct this interference.

EVM Warnings and Restrictions

It is important to operate this EVM within the input voltage range of 7V (min) to 18V (max) and the output voltage range of 7V (min)

to 18V (max).

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are

questions concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the

EVM. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load

specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than +25°C. The EVM is designed to

operate properly with certain components above +25°C as long as the input and output ranges are maintained. These components

include but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of

devices can be identified using the EVM schematic located in the EVM User's Guide. When placing measurement probes near

these devices during operation, please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Page 31

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com Wireless www.ti.com/wireless-apps

RF/IF and ZigBee® Solutions www.ti.com/lprf

TI E2E Community Home Page e2e.ti.com

Automotive

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...