Page 1

User's Guide

SLVU924B–March 2014–Revised April 2014

bq76920 Evaluation Module User's Guide

The bq76920EVM evaluation module (EVM) is a complete evaluation system for the bq76920, a 3-cell to

5-cell Li-Ion battery analog front end (AFE) integrated circuit. The EVM consists of a bq76920 circuit

module which is used for simple evaluation of the bq76920 functions. The circuit module includes one

bq76920 integrated circuit (IC), sense resistor, power FETs, and all other onboard components necessary

to protect the cells from overcharge, over discharge, short circuit, and overcurrent discharge in a 5-series

cell Li-Ion or Li-Polymer battery pack. The circuit module connects directly across the cells in a battery.

With a compatible interface board and Microsoft®Windows®based PC graphical user interface (GUI)

software, the user can view the bq76920 registers, adjust protection limits and enable FET control outputs.

Contents

1 Features....................................................................................................................... 2

1.1 Kit Contents.......................................................................................................... 2

1.2 Ordering Information ............................................................................................... 2

1.3 bq76920 Circuit Module Performance Specification Summary............................................... 3

1.4 Required Equipment................................................................................................ 3

2 bq76920 EVM Quick Start Guide.......................................................................................... 3

2.1 Before You Begin................................................................................................... 3

2.2 Quick Start........................................................................................................... 4

3 bq76940/bq76930/bq76920 Software .................................................................................... 5

3.1 System Requirements.............................................................................................. 5

3.2 Installing the bq76940/bq76930/bq76920 Software ........................................................... 5

3.3 Interface Adapter.................................................................................................... 5

3.4 Software Operation................................................................................................. 6

4 bq76920 Circuit Module Use.............................................................................................. 11

4.1 Cell Simulator...................................................................................................... 11

4.2 Evaluating with Simulated Current.............................................................................. 11

4.3 Reducing the Cell Count ......................................................................................... 12

4.4 Connecting Cells .................................................................................................. 13

4.5 Connecting to a Host ............................................................................................. 13

4.6 Gauge Circuits..................................................................................................... 13

4.7 Unused Components ............................................................................................. 13

5 bq76920EVM Circuit Module Physical Construction................................................................... 15

5.1 Board Layout....................................................................................................... 15

5.2 Bill of Materials .................................................................................................... 23

6 Related Documents From Texas Instruments.......................................................................... 29

1 EVM Connection for Basic Operation..................................................................................... 5

2 bq76940/bq76930/bq76920 Evaluation Software Display.............................................................. 6

3 Registers View ............................................................................................................... 8

4 I2C Pro View ................................................................................................................. 9

5 Sequence View............................................................................................................. 10

6 Simulating Current Setup.................................................................................................. 12

7 Top Silk Screen............................................................................................................. 15

8 Top Assembly............................................................................................................... 16

Microsoft, Windows are registered trademarks of Microsoft Corporation.

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

List of Figures

1

Copyright © 2014, Texas Instruments Incorporated

Page 2

Features

9 Top Layer.................................................................................................................... 17

10 Layer 2....................................................................................................................... 18

11 Layer 3....................................................................................................................... 19

12 Bottom Layer................................................................................................................ 20

13 Bottom Silk Screen......................................................................................................... 21

14 Bottom Assembly........................................................................................................... 22

15 Schematic Diagram AFE .................................................................................................. 26

16 Schematic Diagram Gauge .............................................................................................. 27

17 Schematic Diagram Cell Simulator ...................................................................................... 28

1 Ordering Information ........................................................................................................ 2

2 Performance Specification Summary ..................................................................................... 3

3 Reducing cell count ........................................................................................................ 12

4 bq76920 Circuit Module Bill of Materials................................................................................ 23

1 Features

• Complete evaluation system for the bq76920 3-cell to 5-cell Li-Ion and Li-Polymer battery AFE

• Populated circuit module for 5-cell configuration for quick setup

• Power connections available on banana jacks

• Communication signals available on 4-pin connector

• Resistor cell simulator for quick setup with only a power supply

• PC software available for configuration

www.ti.com

List of Tables

1.1 Kit Contents

• bq76920 circuit module

• Cable to connect the EVM to an EV2400 or EV2300 interface board

1.2 Ordering Information

For complete ordering information, refer to the product folder at www.ti.com.

EVM Part Number Chemistry Configuration Capacity

bq76920EVM Li-Ion 5 cells Any

NOTE: Although capacity is shown as Any, practical limits of the physical construction of the module

typically limits the operation of the EVM to a 1P or 2P battery construction. Refer to the

physical construction section for board details.

Table 1. Ordering Information

2

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

!

www.ti.com

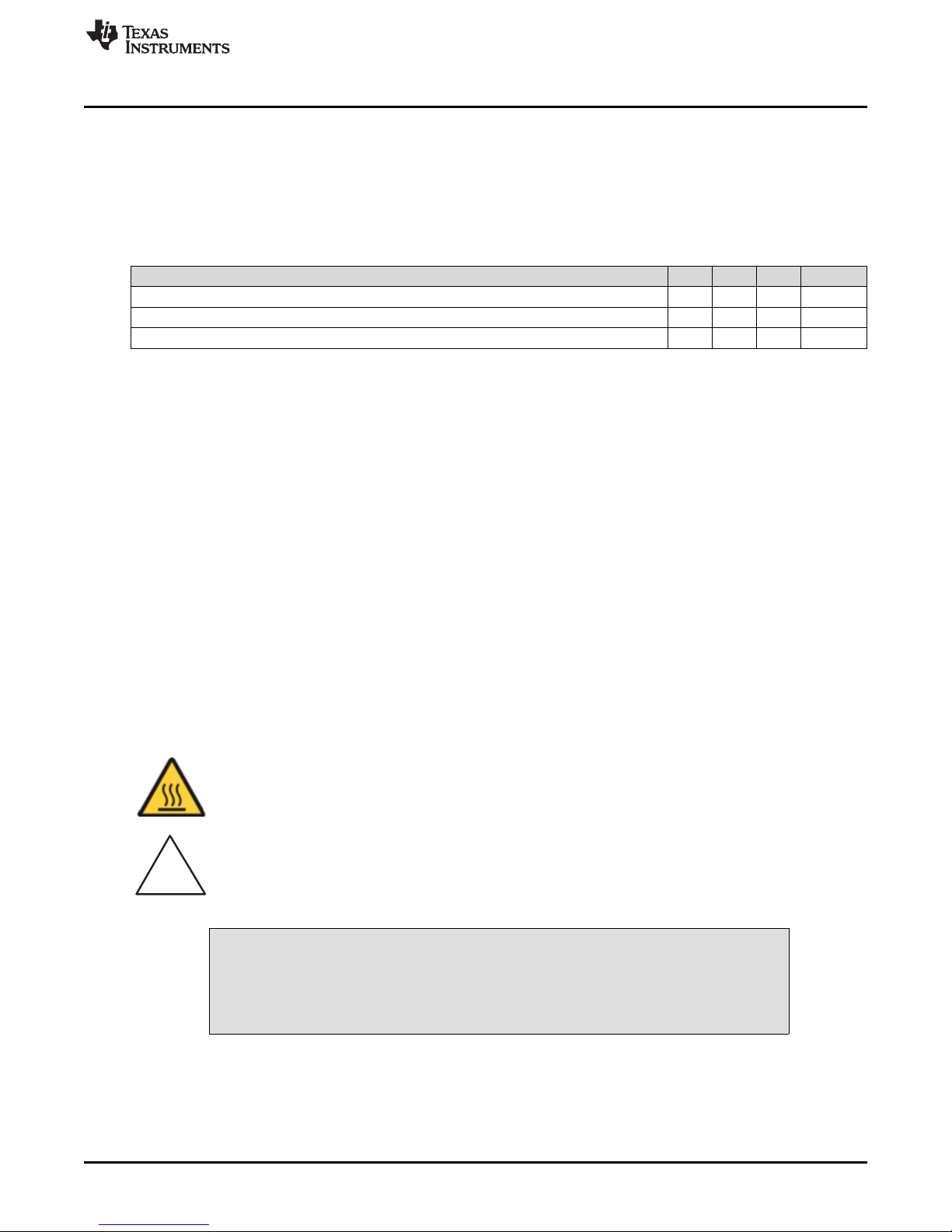

1.3 bq76920 Circuit Module Performance Specification Summary

This section summarizes the performance specifications of the bq76920 circuit module in its default 5-cell

parallel FET configuration.

Typical voltage depends on the number of cells configured. Typical current depends on the application.

Board cooling may be required for continuous operation at or below maximum current.

Table 2. Performance Specification Summary

Specification Min Typ Max Unit

Input voltage BATT+ with respect to BATT– 6 – 25 V

Continuous charge or discharge current 0 – 15 A

Operating temperature range 20 25 30 °C

1.4 Required Equipment

The following equipment is required to operate the bq76920 EVM in a simple demonstration:

• DC power supply, 0–25 V at 0.5 A

• DC voltmeter

• TI EV2300 or EV2400 interface board

• Computer with USB port and compatible Windows operating system and access to the internet

• TI bq76940/bq76930/bq76920 Evaluation Software (see Section 3)

• Test leads to connect equipment

• Electronic load or assorted resistors

Additional equipment may be desired to operate the bq76920 with a more extensive demonstration.

Features

2 bq76920 EVM Quick Start Guide

2.1 Before You Begin

The following warnings and cautions are noted for the safety of anyone using or working close to the

bq76920 EVM. Observe all safety precautions.

Warning The bq76920EVM circuit module may become hot during

Caution Do not leave the EVM powered when unattended.

The circuit module has signal traces, components, and component leads on the

bottom of the board. This may result in exposed voltages, hot surfaces or sharp

edges. Do not reach under the board during operation.

operation due to dissipation of heat. Avoid contact with the

board. Follow all applicable safety procedures applicable to

your laboratory.

CAUTION

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

3

Copyright © 2014, Texas Instruments Incorporated

Page 4

bq76920 EVM Quick Start Guide

The circuit module may be damaged by over temperature. To avoid damage,

monitor the temperature during evaluation and provide cooling, as needed, for

your system environment.

Some power supplies can be damaged by application of external voltages. If

using more than 1 power supply, check your equipment requirements and use

blocking diodes or other isolation techniques, as needed, to prevent damage to

your equipment.

The communication interface is not isolated on the EVM. Be sure no ground

potential exists between the computer and the EVM. Also be aware that the

computer is referenced to the Battery- potential of the EVM.

2.2 Quick Start

These steps describe quick connection of the bq76920 EVM to demonstrate operation of the AFE portion

of the EVM. For more detailed descriptions, refer to other sections of the user guide.

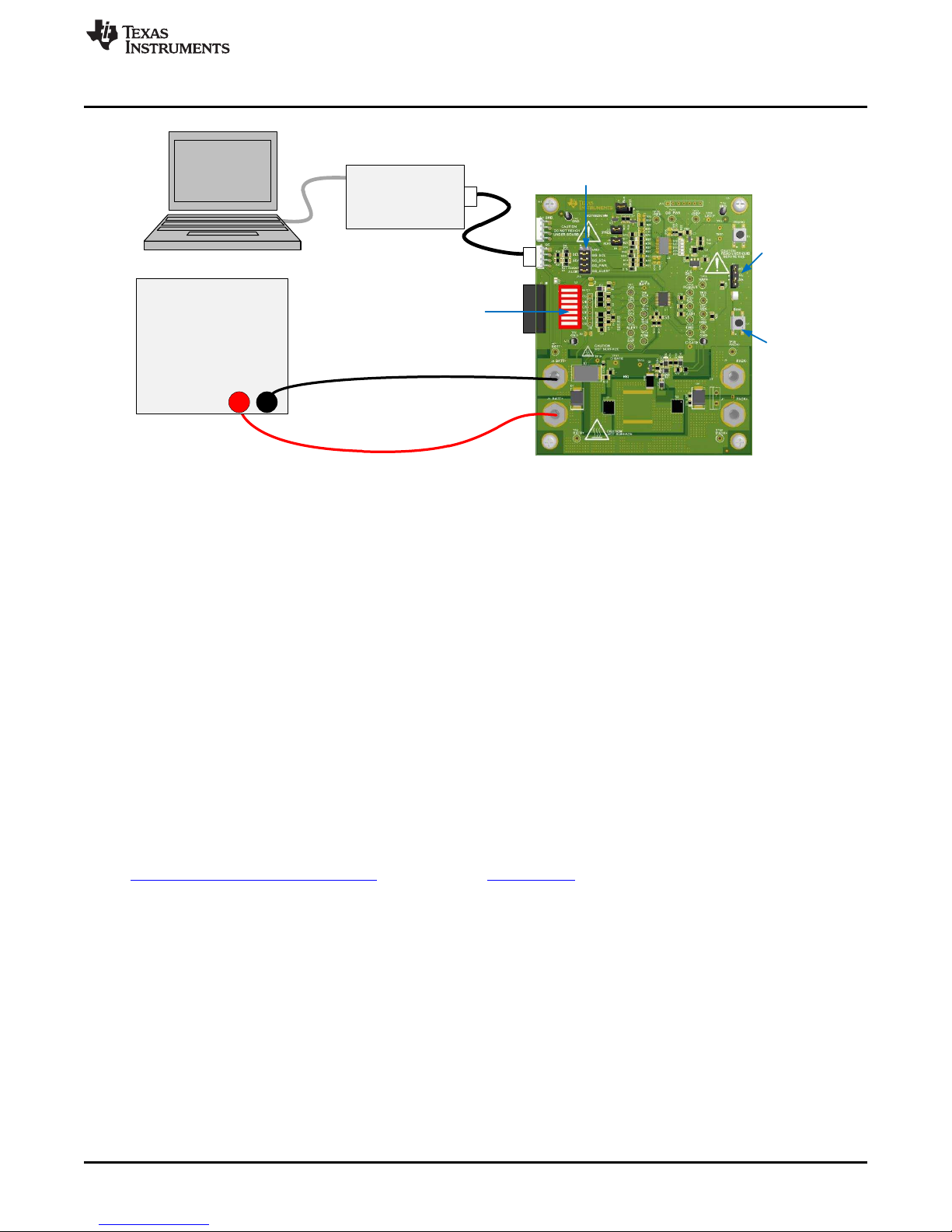

Refer to Figure 1 for the following steps.

1. Install the bq76940/bq76930/bq76920 evaluation software. Software is obtained from www.ti.com.

Install drivers for the EV2300, if necessary.

2. Remove shunts from headers connecting the AFE to the gauge.

3. If the EV2300 is used, install shunts on the SCL and SDA pull-up headers. Remove any pull-up shunts

when using the EV2400.

4. Close all dip switch positions (default is closed).

5. Attach the interface board communication adapter to the PC using USB cable. The EV2400 is

recommended, the EV2300 works if it is available and drivers are installed.

6. Attach the interface board I2C connector to the EVM I2C connector using the 4-pin cable.

7. Connect a 0-V DC power supply capable of 250 mA minimum to the “BATT” terminals and adjust to

approximately 18 V.

8. Press and release the BOOT switch.

9. Start the bq769X0 evaluation software. The GUI should display. Click on the Scan box to enable

repeated update of the display. The power supply may be adjusted within range of the part to observe

voltage changes in the GUI display Stack V/T/I section.

10. Set the voltage to approximately 18 V or a mid-range operating level. Clear any faults present by

clicking on the Clear Faults button of the All Read/Write Registers section of the GUI.

11. Click on the Continuous button in the GUI Coulomb Counter section. Enable the CHG_ON and

DSG_ON bits by clicking on the bit and commit the changes. Apply a load to the PACK terminals. Load

current must be within the capability of the supply and the components installed or 15 A, whichever is

lower. Observe the Coulomb Counter value change in the GUI display Stack V/T/I section.

12. Make other adjustments as desired, for evaluation.

Refer to other sections of this user guide for additional details.

www.ti.com

CAUTION

CAUTION

CAUTION

4

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

DC Power Supply

+ -

Boot

switch

EV2300/

EV2400

I2C

SMB

Pull-ups

for

EV2300

Remove

for

EV2400

Remove gauge

shunts

Cell simulator

switches on for

power supply

www.ti.com

Figure 1. EVM Connection for Basic Operation

3 bq76940/bq76930/bq76920 Software

This section describes how to install and use the bq76940/bq76930/bq76920 software for the EVM.

The bq76940/bq76930/bq76920 software supports the bq76920 AFE I2C communication. This software is

intended to demonstrate register control and operation of the bq769x0 family of AFEs in the absence of a

gauge or MCU. This software is not intended to operate on a bus with another master. The AFE does not

turn on the protection FETs without control, the bq76940/bq76930/bq76920 software provides that control

from the GUI.

The software may also be identified as bq76940 or bq769X0 in menus or windows as space permits.

bq76940/bq76930/bq76920 Software

3.1 System Requirements

The bq76940/bq76930/bq76920 software requires a Windows 7, or later operating system. The computer

must also have Microsoft®.NET connection software version 4.0, or higher, installed. The examples in this

document are from Windows 7.

3.2 Installing the bq76940/bq76930/bq76920 Software

Find the latest software version in the software section of the EVM tool folder

http://www.ti.com/tool/bq76920EVM or search from power.ti.com. Check periodically for software updates.

Use the following steps to install the bq76940/bq76930/bq76920 software:

1. Copy the archive file to a directory of your choice, extract all files and run the setup.exe application.

2. Follow the instructions and make selections as required on the setup windows selecting Next, as

required. TI recommends installing the software in the default location.

3. On the last window, select Close to complete the bq76940/bq76930/bq76920 software installation.

3.3 Interface Adapter

The bq76940/bq76930/bq76920 evaluation software supports either the TI EV2300 or EV2400 interface

board to provide communication with the EVM board from the computer. Drivers must be installed for the

EV2300. The EV2400 uses operating system drivers and no separate installation is required. Do not

connect the EV2300 interface board to the computer until after the drivers are installed.

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

5

Copyright © 2014, Texas Instruments Incorporated

Page 6

bq76940/bq76930/bq76920 Software

If you have used an EV2300 with your computer previously, no additional installation is required. EV2300

drivers are included in the installation package and are found in the installation directory after installing the

software, typically at c:\Program Files (x86)\Texas Instruments\bq76940. Drivers are found at

http://e2e.ti.com/support/power_management/battery_management/m/videos__files/458983.aspx or

http://www.ti.com/tool/ev2300. Install the drivers by following these steps:

1. Navigate to the installation directory, typically C:\Program Files (x86)\Texas Instruments\bq76940

2. Run the file InstallEV2300Drivers.exe

The interface adapter should not be connected to the I2C connector if a gauge or MCU is connected to

the bus. Board pull-up shunts must be installed for the EV2300 and removed for the EV2400

3.4 Software Operation

This section describes connection of the communication interface to the EVM and operation of the

software.

Although the software runs without connection to a powered device, it is recommended to have the device

on when starting the software. Follow the directions in the quick start section. Figure 1 shows connections

for operation with the GUI software.

Start the software from the desktop shortcut bq769X0 Evaluation Software or the menu Start → All

Programs → Texas Instruments → bq769X0 Eval Software.

When started, the software looks for the communication interface and the device. If either is not found, a

popup window appears and must be acknowledged. When communication is established with the device,

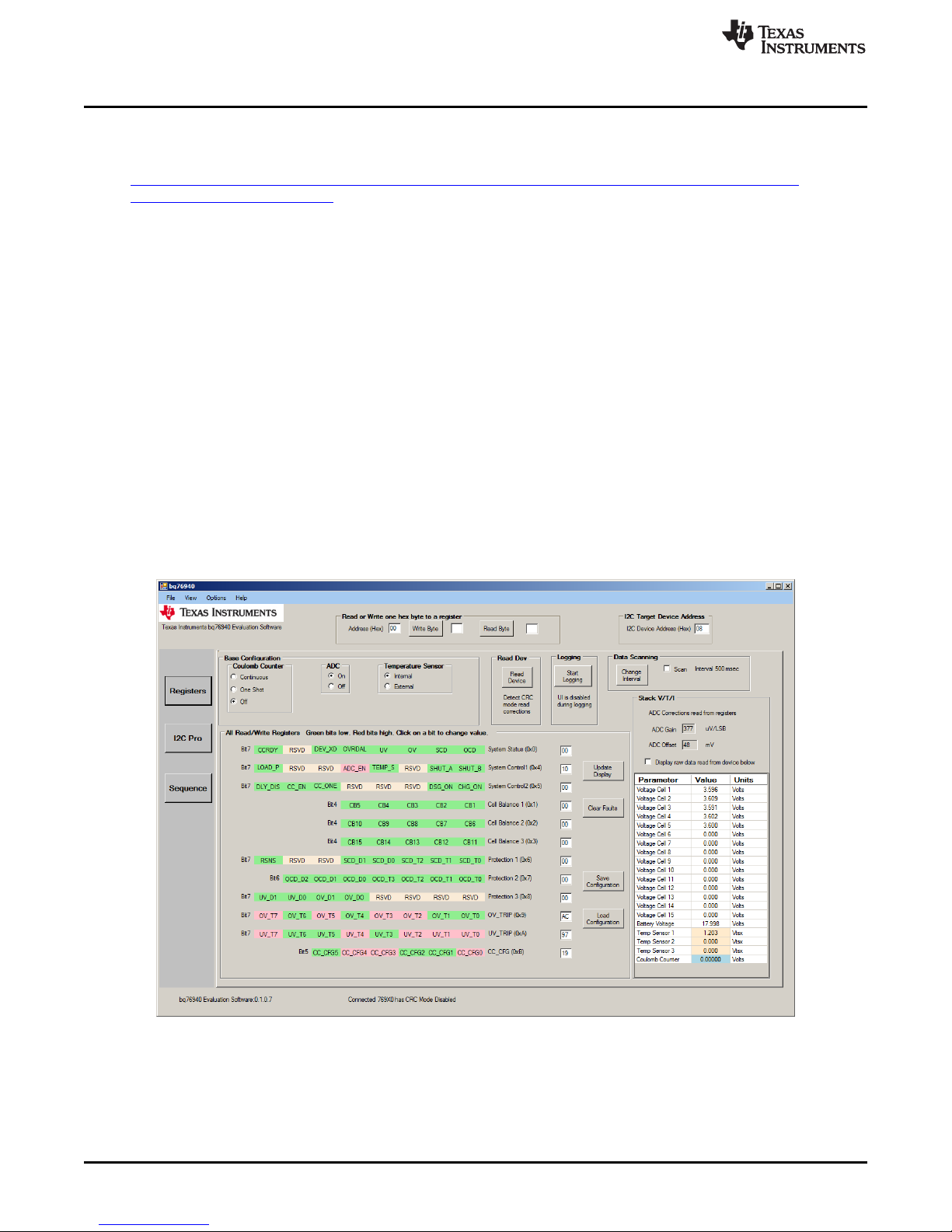

the main window appears as shown in Figure 2.

The bq76940/bq76930/bq76920 software uses popup help tips on many of the control features.

www.ti.com

Figure 2. bq76940/bq76930/bq76920 Evaluation Software Display

The software window contains a menu bar and 3 sections. The top section is an I2C tool. The middle

section has 3 selectable views. The bottom section is a status section. Details are described in following

sections.

6

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

3.4.1 Status Section

The bottom section displays the software name and version, the CRC mode and the communication

status. The CRC mode is automatically detected and the software communicates to the IC appropriately.

To the right of the CRC mode is a communication status area which may display information about the

communication with the device. Common displays and actions may include the following:

• Data channel name is invalid. Check the USB connection to the interface board. Exit and restart the

software

• No acknowledge from device. Check that the 4 pin cable is connected, the EVM is powered and boot

the device, then try to read the device.

• CRC read from device does not match calculated CRC. Check that the Read Device button was used

to detect the device. Check the connection of the 4 pin cable or its routing near high noise sources.

• Not able to find a free communication adapter. Check the connection of the USB cable to the

communication adapter.

• USB adapter timeout. Unplug and re-connect the USB cable and try to read from the device again.

• When the status area is blank, the last communication with the device was successful

3.4.2 I2C Section

The top section of the window below the menu bar has the I2C address and a byte communication tool.

The I2C address must be entered, the tool does not automatically detect the address. The default address

is 0x08 which is the default address for the device on the EVM. If the AFE on the EVM has been changed

to a different address, the address must be entered. The value is the 7 bit address and is shifted left 1 bit

position when observed on the bus.

The byte communication tool is useful to read or write a register. It is present with all views.

bq76940/bq76930/bq76920 Software

3.4.3 Menu Commands

The Help > About menu selection displays version information about the program. Other selections may

provide additional help or links to documentation.

The Options > Verify Writes selection allows selection of a readback of the registers once they are written.

The View menu allows selection of the center window display. Options are the Registers, I2C Pro or

Sequence views. Views can also be selected with buttons on the left side of the window.

Exit the program with the File menu.

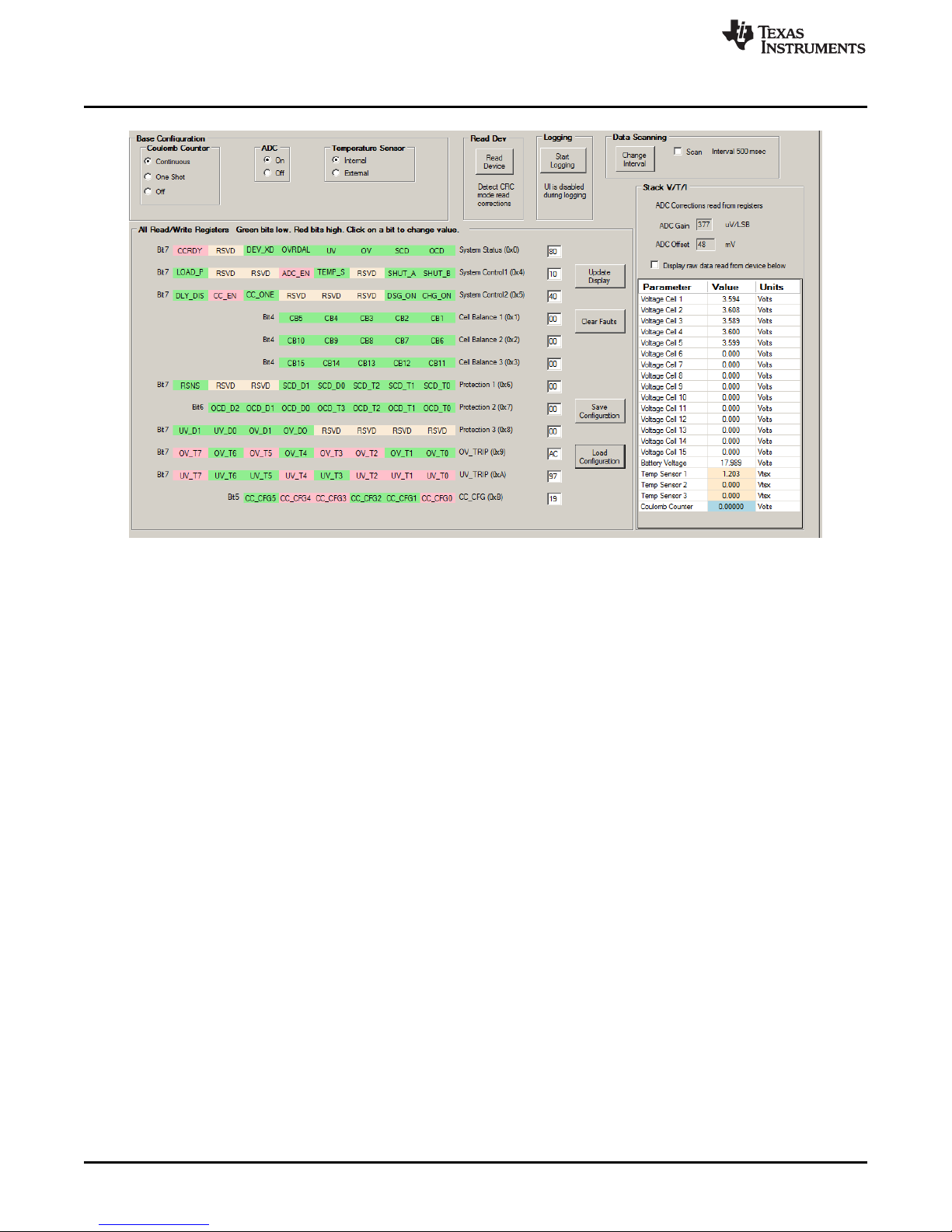

3.4.4 Registers View

The registers view is the default display in the middle of the window when the software is started, see

Figure 3. It shows the control register values. If another view is displayed it is selected using the

Registers button on the left side of the window or from the menu.

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

7

Copyright © 2014, Texas Instruments Incorporated

Page 8

bq76940/bq76930/bq76920 Software

www.ti.com

Figure 3. Registers View

The Read Device button at the top of the Registers view provides important setup of the

bq76940/bq76930/bq76920 software and the IC. The software reads the factory gain and offset data from

the device and populates these in the Stack V/T/I section for use in calculating display values. The

software writes the CC_CFG register to its proper value and also detects the CRC mode of the device and

sets the software appropriately.

The control registers are shown in the center of the display in the All Read/Write Registers section. Bits

are color coded as described in the section. Bits may be changed by clicking on the bit and selecting

Commit button in the Change value pop-up window. The default for the pop up window is to change the

polarity of the bit. Since clearing status bits requires a write of 1, the Set bit high needs to be checked in

the Change value pop-up window when clearing status register bits. A bit value change is displayed if the

Options menu Verify Writes is selected.

Control registers can also be changed as register values by writing in the value box to the right of the

value box. Scan must be disabled to enter values. Register values may also be changed using the I2C

byte write tool at the top of the window. Register changes are visible if the Verify Writes option is enabled.

The display may also be updated using the Update Display button or selecting Scan.

The All Read/Write Registers section contains 4 buttons to the right of the register display:

• Update Display: This button reads all control and value registers and updates the values, bit breakout

fields and control features.

• Clear Faults: This button clears the status register.

• Save Configuration: This button allows saving the displayed values of the control register to a file. A

pop-up box allows selection of the file name. The default file location is C:\Users\<accountname>\Documents\Texas Instruments\bq76940.

• Load configuration: This button allows loading the control register values from a file. A pop-up box

allows selection of the file, another pop up box lets you select whether to write the values to the

device. If faults are not set in the status register value in the file, they are not cleared by the write.

The Base Configuration section shown above the register detail provides convenient control of the

Coulomb Counter, ADC and Temperature Sensor selection as functional controls without locating the

control bits.

8

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

The Data Scanning section allows periodic read of the device and display of the register values. The Scan

check box enables the read when checked. The update interval is displayed and can be changed with the

Change Interval button.

The Logging section has the Start Logging button. The values read from the device can be saved to a

file. Selecting the Start Logging button opens a bq76940 Logging popup window to enter the file name,

comments and to select the data groups to be logged. The file name must be entered with the pop up

window's Browse button. The scan interval can be changed, and the logging is actually started in the pop

up window. When logging is active, the registers user interface cannot be used and the button changes to

Stop Logging. Selecting the button stops the logging. Scan is not necessary before logging, it will start

with logging and cannot be disabled during logging.

The Stack V/T/I section is on the right side of the Registers view (Figure 3). The ADC Gain and Offset

boxes show the values that are used for converting the register data into values. These value boxes are

read only, they are updated by the values read from the device with the Read Device button. The Display

raw data read from device below check box allows display of the hex register values rather than converted

values. The V/T/I values are updated by the Read Device button, the Update Display button, or the Scan

option.

3.4.5 I2C Pro View

Figure 4 shows the I2C Pro view of the GUI. The I2C Pro view is useful to read or write several sequential

registers. If another view is displayed, it can be selected using the I2C PRO button on the left side of the

window or from the menu. The I2C Command box for each section specifies the starting register address

for the transaction.

bq76940/bq76930/bq76920 Software

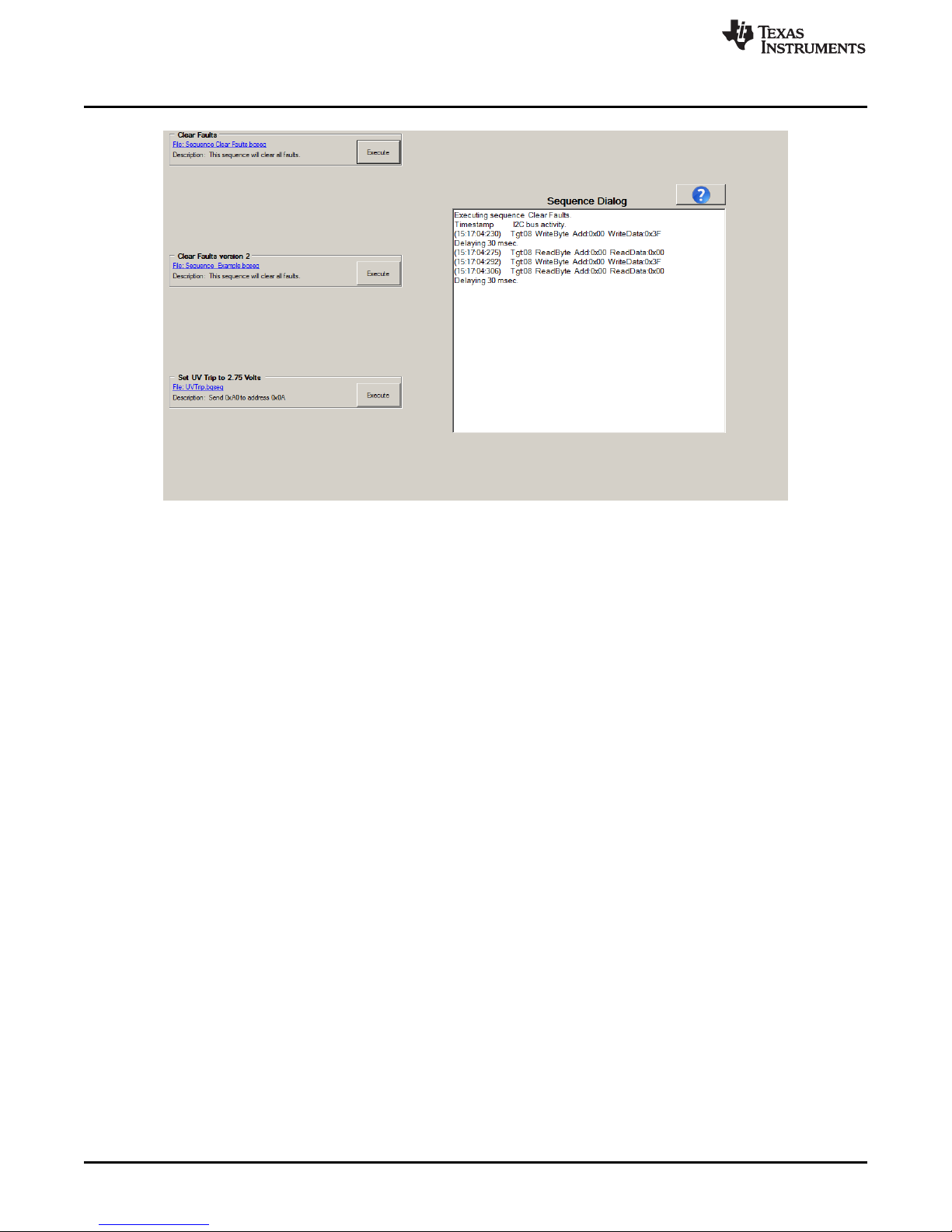

3.4.6 Sequence View

Figure 5 illustrates the Sequence view of the GUI. This is useful to send timed sequences of register

reads or writes to the device. It can be selected using the SEQUENCE button on the left side of the

window or from the menu. A sequence is run by selecting its Execute button. The results of the sequence

are shown in the Sequence Dialog section. Edit the sequence by selecting the file name under the

sequence name in the window.

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Figure 4. I2C Pro View

9

Copyright © 2014, Texas Instruments Incorporated

Page 10

bq76940/bq76930/bq76920 Software

www.ti.com

Figure 5. Sequence View

The installation comes with 3 sequence files. The Clear Faults files contain descriptions for requirements

for a sequence file. The Set UV Trip... file shows an example of a simpler format. Sequence files are

installed to: C:\Users\<account-name>\Documents\Texas Instruments\bq76940\sequence. Sequences are

loaded from this location when the program starts. Create new sequences with a text editor and save

them with the .bqseq extension. Up to 8 sequences can be stored, move other sequences to another

directory or change the extension. The sequences Sequence_Example.bqseq, Sequence Clear

Faults.bqseq, and UVTrip.bqseq are required, do not move them from the directory.

Typical uses of a sequence might include:

• Reading and clearing faults, then enabling CHG and DSG outputs

• Setting ship mode

• Setting a balance pattern

• Any repetitive multiple-register write used in evaluation

While sequences can be executed during logging, the logging is paused while the sequence executes.

Long sequences leave gaps in the log data.

3.4.7 Typical Operation of Software

Typical operation of the software involves the following steps, much like described in quick start section:

• Connect the EVM and related equipment

• Power the EVM

• Boot the EVM

• Start the software

• Read and change registers, as desired

If the board is powered off during the evaluation process:

• Power the EVM

• Boot the EVM

• Select the Read Device button

• Read and change registers, as desired

10

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

If the interface board is connected to a system already in operation and the software has not been exited:

• Select the Read Device button

• Read and change registers, as desired

3.4.8 Operation with Other interfaces or Hosts

The bq76940/bq76930/bq76920 software does not support other interface boards or adapters other than

the EV2300 and EV2400. The software does not operate in a multi-master environment. If operated with

another host on the line, data collisions can occur. Also be aware that the EV2400 has internal pull-up

resistors to 3.3 V, connecting to some shared busses could damage devices on that bus if the bus voltage

differs.

4 bq76920 Circuit Module Use

The bq76920 circuit module contains the bq76920 IC and related circuitry to demonstrate the features of

the IC. Surface mount FETs are provided for the high current path. A thermistor provides temperature

sensing on the board. Other components provide support for the IC and connections to the board. Basic

operation is described in the quick start guide. For details of the circuit, refer to the physical construction

section.

4.1 Cell Simulator

The EVM includes a resistive cell simulator made up of 200-Ω series resistors. The top section of the S3

switch connects the BATT+ node to the top of the resistor string. The bottom of the resistor string is

connected to BATT-. The individual cell taps are connected to the cell monitor signals by other sections of

the dip switch. When operating with a power supply all switch sections should be closed. When operating

with cells, all the dip switch sections should be open to prevent loading the cells and discharging the

battery. The cell simulator resistors are located on the bottom of the board and may become warm during

operation. The orange LED near the dip switch indicates the cell simulator has power.

bq76920 Circuit Module Use

4.2 Evaluating with Simulated Current

The quick start guide describes connection for basic operation. Providing more than recognizable current

in that configuration can require a power supply with a significant power rating. Applying a charge current

can damage some power supplies. Figure 6 shows a method to force current through the control path

without a high wattage power supply or special equipment. The load power supply should be set at a low

voltage in a constant current mode. Polarity can be reversed on the load supply to simulate a charge

current. The battery simulation supply should never be reversed.

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

11

Copyright © 2014, Texas Instruments Incorporated

Page 12

DC Power Supply

+ -

EV2300/

EV2400

I2C

SMB

DC Power Supply

+ -

(Load)

bq76920 Circuit Module Use

www.ti.com

4.3 Reducing the Cell Count

Cell count can be reduced for basic evaluation by shorting unused cells at the input terminal block. Follow

the recommendations in the datasheet for which cells to short. This works for both operation with the cell

simulator and cells, but can have some side effects in transient tests because it parallels the shorted

resistors to the cell IC where the capacitor provides a signal path to the used input. For the best

evaluation with reduced cells in a transient environment, short the VCx pins at the capacitor or VCx test

points and remove the unused input resistor. When using the cell simulator, shorting the unused cell

resistor is still required to eliminate the simulated cell voltage. Shorting the cell inputs at the terminal block

screw terminals is suggested since it should be apparent if the board is re-used for a different cell count.

(Numbered from Bottom Cell 1)

Figure 6. Simulating Current Setup

Table 3. Reducing cell count

Unused Cell

Cell 4 C4 to C3 R5 VC4 to VC3

Cell 3 C3 to C2 R6 VC3 to VC2

Short Cell Terminals Input Resistor to Remove Short AFE Inputs

12

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

4.4 Connecting Cells

The EVM is constructed to sense the cell voltages at the cells. Separate wires are required from the

bottom of the battery stack to the C0 connection at the terminal block for sensing voltage and from the

bottom of the battery stack to the BATT- terminal to carry the load current. The AFE IC VSS is referenced

to the BATT- connection. Similarly, separate wires are required from the top of the battery stack to the top

cell input of the terminal block and from the top of the battery stack to the BATT+ terminal to carry the

load current. The top cell sense connection also powers the AFE IC. To move the sense connections from

the cells to the board, populate R1 and R2. The bottom cell simulator switch can be closed to connect C0

to BATT-.

The cell simulator provides resistors between the cell inputs. These resistors can help divide the voltage

as cells are connected. If desired, the cell simulator switches can be closed during cell connection and

opened after cell connection. The switches must be opened after connection of cells or the cells will be

discharged by the constant drain of the cell simulator. If the orange LED is on when cells are connected,

open the dip switch sections to remove the load.

Cell connection is generally considered safest from the bottom up. This minimizes the step size of the

voltage applied to the board. Recommended connection sequence for the EVM when connecting wires

individually is bottom up:

1. Connect BATT-

2. Connect cells bottom up; C0, C1, C2 ...

3. Connect BATT+

4. Open the cell simulator switches, if needed

When the top and bottom cells are connected on the board:

1. Connect BATT- (includes C0)

2. Connect cells bottom up; C1, C2, C3...

3. Connect BATT+ (includes top cell)

4. Open the cell simulator switches, if needed

When cells are mated with a connector:

1. Connect BATT- or the node which connects VSS of the AFE, if separate

2. Mate the connector

3. Connect the BATT+. if separate

4. Open the cell simulator switches, if needed

When using external balancing with P-channel MOSFETs, such as on the bq76930 and bq76940 EVMs,

the inrush current for a cell can momentarily turn on the balance FET causing the next cell input below to

rise. This can continue down the stack. Connecting C0 on the board by closing the C0 dip switch during

cell connection can reduce stress on the VC0 input of the AFE. Open the switch after cell connection for

sensing at the cell.

bq76920 Circuit Module Use

4.5 Connecting to a Host

After initial operation with the bq76940/bq76930/bq76920 software, it may be desirable to operate the

board connected to a microcontroller board. J12 could be used to connect to the microcontroller board. No

voltages should be applied to the gauge terminals. Alternately, the microcontroller is connected to the

signal test points or J8 and the ALERT test point. The interface voltage for the installed AFE IC is 2.5 V.

4.6 Gauge Circuits

The EVM contains a gauge circuit consisting of U2 and an SMBus interface connector, J14. These circuits

are reserved for future use. Only connect these circuits should only be connected to a 2.5-V output AFE

IC.

4.7 Unused Components

The EVM contains a number of component patterns which may be useful for evaluation.

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

13

Copyright © 2014, Texas Instruments Incorporated

Page 14

bq76920 Circuit Module Use

Test points are not typically populated. The patterns may be used as probe points or wires or test points

could be soldered to provide probing, if desired.

Normally the power filter R14 and C13 keeps the supply voltage for the AFE in a safe operating range. For

situations with large transients, D3 provides a clamp for the supply voltage to the AFE, if needed. The

pattern is large and it is easy to fit other component sizes. Be aware that if the system transients are large

enough that a clamp is needed at D3, the cell inputs should also be inspected for excessive voltages and

an improved filter or clamp be added there, if needed.

The ALERT line switches high and low in normal operation as status bits are asserted and cleared. A

large load is not desired since it consumes power. If it is useful to slow the transition, the pattern C10 is

available. C10 should not be large in order to avoid current and slowing the edge to where the bq76920

would see the ALERT high as an input and set the OVRD_ALERT condition.

When the charge FET turns on with a large charger voltage present, a large voltage could be impressed

on the gate of the charge FET. With the voltages typically used on the bq76920EVM, this should not be

high enough to damage the charge FET. If special circumstances require, the D5 pattern is available for a

clamp diode.

D6 is a flyback diode to prevent PACK- from rising significantly above PACK+. The D7 pattern provides a

place to mount a higher current diode or other transient suppression component.

HS1 is a position to mount a suitable heatsink, if needed. Other heatsink options may be available in the

evaluation environment.

www.ti.com

14

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

5 bq76920EVM Circuit Module Physical Construction

This section contains the PCB layout, bill of materials, and schematic of the bq76920EVM circuit module.

The bq76920EVM consists of one circuit module assembly, PWR523.

5.1 Board Layout

The bq76920EVM circuit module is a 4.0-inch × 4.805-inch 4-layer circuit card assembly. It is designed for

easy assembly with cell connections on the left side to a terminal block and high current terminals through

banana jacks. Control connections are on the left top. Pack terminals are on the right side using banana

jacks. Wide trace areas are used reducing voltage drops on the high current paths. The EVM layout and

construction allows easy understanding of the connections and access to the test points for evaluation, but

the connector area and programming features result in a large board.

See additional information in the configuration and operation sections of this document. Figure 7 to

Figure 14 show the board layout.

bq76920EVM Circuit Module Physical Construction

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Figure 7. Top Silk Screen

15

Copyright © 2014, Texas Instruments Incorporated

Page 16

bq76920EVM Circuit Module Physical Construction

www.ti.com

16

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Figure 8. Top Assembly

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

bq76920EVM Circuit Module Physical Construction

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Figure 9. Top Layer

17

Copyright © 2014, Texas Instruments Incorporated

Page 18

bq76920EVM Circuit Module Physical Construction

www.ti.com

18

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Figure 10. Layer 2

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

bq76920EVM Circuit Module Physical Construction

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Figure 11. Layer 3

19

Copyright © 2014, Texas Instruments Incorporated

Page 20

bq76920EVM Circuit Module Physical Construction

www.ti.com

20

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Figure 12. Bottom Layer

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

bq76920EVM Circuit Module Physical Construction

SLVU924B–March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Figure 13. Bottom Silk Screen

21

Copyright © 2014, Texas Instruments Incorporated

Page 22

bq76920EVM Circuit Module Physical Construction

www.ti.com

22

bq76920 Evaluation Module User's Guide SLVU924B–March 2014–Revised April 2014

Figure 14. Bottom Assembly

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

bq76920EVM Circuit Module Physical Construction

5.2 Bill of Materials

The bill of materials for the circuit module is shown in Table 4. Substitute parts may be used in the manufacturing of the assembly.

Table 4. bq76920 Circuit Module Bill of Materials

Designator Qty Value Description PackageReference Part Number MFG Alternate Alternate

Part Number MFG

PCB1 1 Printed Circuit Board PWR523 Any - C1, C2, C3, C4, C5, C6, C14 7 1uF CAP, CERM, 1uF, 16V, +/-10%, X7R, 0805 0805 GRM21BR71C105KA01L MuRata

C7, C8, C9, C11, C12, C17, C18, 10 0.1uF CAP, CERM, 0.1uF, 50V, +/-10%, X7R, 0603 0603 GCM188R71H104KA57B MuRata

C21, C22, C23

C13 1 2.2uF CAP, CERM, 2.2uF, 50V, +/-10%, X5R, 1206 1206 GRM31CR61H225KA88L MuRata

C15 1 4700pF CAP,CERM, 4700pF, 50V, +/-10%, X7R, 0805 0805 08055C472KAT2A AVX

C16 1 4.7uF CAP, CERM, 4.7uF, 10V, +/-10%, X7R, 0805 0805 GRM21BR71A475KA73L MuRata

C20 1 3300pF CAP,CERM, 3300pF, 25V, +/-10%, X7R, 0603 0603 GRM188R71E332KA01D MuRata

D1 1 28V Diode, TVS, Uni, 28V, 1500W, SMC SMC SMCJ28A Fairchild Semiconductor

D2, D4, D12 3 1.25V Diode, Ultrafast, 100V, 0.15A, SOD-123 SOD-123 1N4148W-7-F Diodes Inc.

D6 1 600V Diode, Ultrafast, 600V, 3A, SMC SMC MURS360T3G ON Semiconductor

D8, D9, D10, D11, D19, D20 6 5.6V Diode, Zener, 5.6V, 200mW, SOD-323 SOD-323 MMSZ5232BS-7-F Diodes Inc.

D13 1 16V Diode, Zener, 16V, 500mW, SOD-123 SOD-123 MMSZ5246B-7-F Diodes Inc.

D14, D15, D16, D17, D18 5 Green LED, Green, SMD 1.6x0.8x0.8mm LTST-C190GKT Lite-On

D21 1 Orange LED, Orange, SMD 1.6x0.8x0.8mm LTST-C190KFKT Lite-On

H1, H2, H5, H6 4 Machine Screw, Round, #4-40 x 1/4, Nylon, Philips panhead Screw NY PMS 440 0025 PH B&FFastener Supply - H3, H4, H7, H8 4 Standoff, Hex, 0.5"L #4-40 Nylon Standoff 1902C Keystone - J1 1 Receptacle, 3.5mm 6x1, R/A, TH Header, 6x1 R/A 395021006 Molex

J2, J3, J6, J7 4 Standard Banana Jack, Uninsulated, 15A Banana Jack 108-0740-001 Emerson Network Power

J4, J5, J9, J10 4 Header, 100mil, 2x1, Tin plated, TH Header, 2 PIN, 100mil, Tin PEC02SAAN Sullins Connector Solutions

J8, J14 2 Header, 100mil, 4x1, R/A, TH 4x1 R/A Header 22-05-3041 Molex

J12 1 Header, 100mil, 5x2, Tin plated, TH Header,5x2, 100mil, Tin PEC05DAAN Sullins Connector Solutions

J13 1 Header, 100mil, 3x1, Tin plated, TH Header,3 PIN, 100mil, Tin PEC03SAAN Sullins Connector Solutions

P1 1 CONN TERM BLOCK 3.5MM 6POS R/A Term Block Plug 39500-0006 Molex - Q1, Q2 2 30V MOSFET, N-CH, 30V, 100A, SON 5x6mm SON 5x6mm CSD17501Q5A Texas Instruments None

Q3, Q4 2 -50V MOSFET, P-CH, -50V, -0.13A, SOT-323 SOT-323 BSS84W-7-F Diodes Inc. None

Q5, Q6, Q8 3 50V MOSFET, N-CH, 50V, 0.22A, SOT-23 SOT-23 BSS138 Fairchild Semiconductor None

Q7 1 0.25V Transistor, PNP, 40V, 0.2A, SOT-23 SOT-23 MMBT3906 Fairchild Semiconductor None None

Q9 1 0.5V Transistor, NPN, 80V, 1A, SOT-89 SOT-89 BCX5616TA Diodes Inc.

R3, R21, R23, R51, R55 5 10.0k RES, 10.0k ohm, 1%, 0.125W, 0805 0805 CRCW080510K0FKEA Vishay-Dale

R4, R5, R6, R7, R8, R9 6 100 RES, 100 ohm, 1%, 0.25W, 1206 1206 CRCW1206100RFKEA Vishay-Dale

R10, R12, R14, R24, R25, R26, R27, 15 100 RES, 100 ohm, 1%, 0.125W, 0805 0805 CRCW0805100RFKEA Vishay-Dale

R31, R32, R36, R37, R57, R58, R61,

R62

R11 1 0.001 RES, 0.001 ohm, 1%, 2W, 4527 4527 WSR21L000FEA Vishay-Dale

R13 1 499k RES, 499k ohm, 1%, 0.125W, 0805 0805 CRCW0805499KFKEA Vishay-Dale

R15, R18, R19, R47, R54, R59, R60 7 1.00Meg RES, 1.00Meg ohm, 1%, 0.125W, 0805 0805 CRCW08051M00FKEA Vishay-Dale

23

SLVU924B– March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 24

bq76920EVM Circuit Module Physical Construction

www.ti.com

Table 4. bq76920 Circuit Module Bill of Materials (continued)

Designator Qty Value Description PackageReference Part Number MFG Alternate Alternate

Part Number MFG

R16, R30 2 0 RES, 0 ohm, 5%, 0.125W, 0805 0805 CRCW08050000Z0EA Vishay-Dale

R17 1 1.00k RES, 1.00k ohm, 1%, 0.125W, 0805 0805 CRCW08051K00FKEA Vishay-Dale

R20 1 10.0k Thermistor NTC, 10.0k ohm, 1%, Disc, 5x8.4 mm Disc, 5x8.4 mm 103AT-2 SEMITEC Corporation

ohm

R22 1 3.01k RES, 3.01k ohm, 1%, 0.125W, 0805 0805 CRCW08053K01FKEA Vishay-Dale

R38 1 300k RES, 300k ohm, 0.1%, 0.1W, 0603 0603 RG1608P-304-B-T5 Susumu Co Ltd

R39, R43 2 13.7k RES, 13.7k ohm, 0.1%, 0.1W, 0603 0603 RG1608P-1372-B-T5 Susumu Co Ltd

R44, R45, R50, R52 4 100k RES, 100k ohm, 1%, 0.125W, 0805 0805 CRCW0805100KFKEA Vishay-Dale

R46 1 0 RES, 0 ohm, 5%, 0.25W, 1206 1206 CRCW12060000Z0EA Vishay-Dale

R48 1 1.0k RES, 1.0k ohm, 5%, 1W, 2512 2512 ERJ-1TYJ102U Panasonic

R49 1 196k RES, 196k ohm, 1%, 0.125W, 0805 0805 CRCW0805196KFKEA Vishay-Dale

R53 1 49.9k RES, 49.9k ohm, 1%, 0.125W, 0805 0805 CRCW080549K9FKEA Vishay-Dale

R63 1 221k RES, 221k ohm, 1%, 0.125W, 0805 0805 CRCW0805221KFKEA Vishay-Dale

R64, R65 2 1.00k RES, 1.00k ohm, 1%, 0.25W, 1206 1206 CRCW12061K00FKEA Vishay-Dale

R66, R67, R68, R69, R70 5 200 RES, 200 ohm, 1%, 0.125W, 0805 0805 CRCW0805200RFKEA Vishay-Dale

S1, S2 2 Switch, Tactile, SPST-NO, 0.05A, 12V, SMT SW,SPST 6x6 mm 4-1437565-1 TE Connectivity

S3 1 Switch, SPST 7Pos, Rocker, TH 9.65X8X19.8mm 76SB07ST Grayhill

SH-J4, SH-J5, SH-J9, SH-J10, SH- 9 1x2 Shunt, 100mil, Gold plated, Black Shunt 969102-0000-DA 3M SNT-100-BK-G Samtec

J12-3, SH-J12-5, SH-J12-7, SH-J129, SH-J13-3

TP3, TP4, TP5, TP6 4 Black Test Point, TH, Multipurpose, Black Keystone5011 5011 Keystone

U1 1 µC-Controlled AFE Family for 5/10/15-Series Cell Lithium-Ion PW0020A BQ7692000PW Texas Instruments None

and Phosphate Battery Pack Applications, PW0020A

U2 1 CEDV Fuel Gauge and Battery Management Controller DBT0030A BQ78350DBT Texas Instruments None

Companion to the bq769x0 AFE, DBT0030A

W1 1 Cable assembly, 4 pin Assembly CBL002 Texas Instruments - C10 0 470pF CAP, CERM, 470pF, 50V, +/-10%, X7R, 0805 0805 08055C471KAT2A AVX

C19 0 3300pF CAP,CERM, 3300pF, 25V, +/-10%, X7R, 0603 0603 GRM188R71E332KA01D MuRata

D3 0 30V Diode, TVS, Uni, 30V, 600W, SMB SMB SMBJ30A-13-F Diodes Inc.

D5 0 16V Diode, Zener, 16V, 500mW, SOD-123 SOD-123 MMSZ5246B-7-F Diodes Inc.

D7 0 600V Diode, Ultrafast, 600V, 8A, TH TO-220AC MUR860G ON Semiconductor

FID1, FID2, FID3 0 Fiducial mark. There is nothing to buy or mount. Fiducial N/A N/A

HS1 0 Heatsink, DDPAK/TO-263, SMT Heatsink, DDPAk 573300D00010G Aavid

J11 0 Header, TH, 100mil, 7x1, Gold plated, 230 mil above 7x1 Header TSW-107-07-G-S Samtec

insulator

J15 0 Header, TH, 100mil, 6x1, Gold plated, 230 mil above TSW-106-07-G-S TSW-106-07-G-S Samtec, Inc.

insulator

R1, R2 0 0 RES, 0 ohm, 5%, 0.125W, 0805 0805 CRCW08050000Z0EA Vishay-Dale

R28, R29, R40, R41, R56 0 1.00k RES, 1.00k ohm, 1%, 0.125W, 0805 0805 CRCW08051K00FKEA Vishay-Dale

R33 0 300k RES, 300k ohm, 0.1%, 0.1W, 0603 0603 RG1608P-304-B-T5 Susumu Co Ltd

R34, R35, R42 0 1.00Meg RES, 1.00Meg ohm, 1%, 0.125W, 0805 0805 CRCW08051M00FKEA Vishay-Dale

TP1 0 Black Test Point, TH, Multipurpose, Black Keystone5011 5011 Keystone

24

bq76920 Evaluation Module User's Guide SLVU924B– March 2014–Revised April 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 25

www.ti.com

bq76920EVM Circuit Module Physical Construction

Table 4. bq76920 Circuit Module Bill of Materials (continued)

Designator Qty Value Description PackageReference Part Number MFG Alternate Alternate

Part Number MFG

TP2, TP29 0 Red Test Point, TH, Multipurpose, Red Keystone5010 5010 Keystone

TP7, TP8, TP9, TP10, TP11, TP12, 0 White Test Point, TH, Multipurpose, White Keystone5012 5012 Keystone

TP13, TP14, TP15, TP18, TP20,

TP21, TP22, TP24, TP25, TP26,

TP27, TP28, TP33, TP34, TP35,

TP37

25

SLVU924B– March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 26

DSG

1

CHG

2

VSS

3

SDA

4

SCL

5

TS1

6

CAP1

7

REGOUT

8

REGSRC

9

BAT

10

NC

11

VC5

12

VC4

13

VC3

14

VC2

15

VC1

16

VC0

17

SRP

18

SRN

19

ALERT

20

U1

BQ7692000PW

1µF

C1

100

R5

5

4

1

2

3

6

J1

395021006

1µF

C2

1µF

C3

1µF

C4

1µF

C5

1µF

C6

100

R4

100

R6

100

R7

100

R8

100

R9

4.7µF

C16

2.2µF

C13

1.25V

D2

J2

108-0740-001

0.001

R11

100

R10

100

R12

0.1µF

C8

0.1µF

C9

0.1µF

C7

TP10

DNP

TP12

DNP

TP15

DNP

TP8

DNP

TP21

DNP

TP17

TP20

DNP

TP23

DNP

30V

D3

SMBJ30A-13-F

DNP

100

R14

100

R24

100

R25

499k

R13

4

1

2

3

J8

22-05-3041

10.0k

R23

10.0k

R21

TP19

1

2

J5

PEC02SAAN

1

2

J4

PEC02SAAN

J3

108-0740-001

600V

D7

MUR860G

DNP

4

7,8

1,2,3

5,6,

30V

Q1

CSD17501Q5A

4

7,8

1,2,3

5,6,

30V

Q2

CSD17501Q5A

600V

D6

MURS360T3G

1.00Meg

R19

1.00Meg

R15

GND GND

GND

GND

GND

J6

108-0740-001

J7

108-0740-001

0.1µF

C11

0.1µF

C12

0.1µF

C17

0.1µF

C18

1µF

C14

0

R16

1.00k

R17

1.00Meg

R18

-50V

Q3

BSS84W-7-F

16V

D5

MMSZ5246B-7-F

DNP

1.25V

D4

GND

10.0k Ω

t°

R20

4700pF

C15

GND

GND

TP9

DNP

TP11

DNP

TP13

DNP

TP14

DNP

TP7

DNP

TP18

DNP

TP24

DNP

TP27

DNP

TP26

DNP

TP25

DNP

TP22

DNP

NT1

Net-Tie

BATT– GND

BATT-

E2 E4

E3

E1

BATT–

123

4

S1

4-1437565-1

3.01k

R22

5.6V

D8

5.6V

D9

HS1

573300D00010G

DNP

TP3 TP4 TP5 TP6

TP1

DNP

TP2

DNP

TP29

DNP

TP28

DNP

GND

0

R2

DNP

0

R1

DNP

C5

C4

C3

C2

C1

C0

BATR

SCL pull up

SDA pull up

BATT+

10.0k

R3

–

Input voltage 0 - 25 V

0 - 15 A

+

–

Output voltage 0 - 25 V

0 - 15 A

+

28V

D1

SMCJ28A

100

R26

100

R27

ALERT

470pF

C10

DNP

DSG

CHG

CAP1 SDA

SCL

REGOUT

C1

C0

C1

C2

C3

C4

C5

BATT+

BATT+

PFD

PACK–

I C

2

BOOT

TP16

bq76920EVM Circuit Module Physical Construction

www.ti.com

Figure 15 through Figure 17 illustrate the schematics.

Figure 15. Schematic Diagram AFE

26

bq76920 Evaluation Module User's Guide SLVU924B– March 2014–Revised April 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 27

NC

1

ALERT

2

SDA

3

SCL

4

PRECHG

5

VAUX

6

BAT

7

PRES

8

KEYIN

9

SAFE

10

SMBD

11

VEN

12

SMBC

13

DISP

14

PWRM

15

LED1

16

LED2

17

LED3

18

LED4

19

LED5

20

VSS

21

VSS

22

VSS

23

MRST

24

VSS

25

VCC

26

RBI

27

NC

28

ADREN

29

SMBA

30

U2

BQ78350DBT

50V

Q6

BSS138

1.00Meg

R54

1.0k

R48

100

R58

100

R61

100

R57

100

R62

4

1

2

3

J14

22-05-3041

GND

BATT–

E7 E8

BATT–

1.00Meg

R60

1.00Meg

R59

GND

GND

123

4

S2

4-1437565-1

1

2

J10

PEC02SAAN

100

R31

100

R36

100

R32

100

R37

BATT-

1

2

J9

PEC02SAAN

50V

Q8

BSS138

MMBT3906

Q7

10.0k

R51

1.25V

D12

GND

0.1µF

C22

10.0k

R55

TP34

DNP

TP35

DNP

TP32

196k

R49

49.9k

R53

100k

R52

Green

D17

Green

D16

Green

D15

Green

D14

Green

D18

221k

R63

GND

GND

GND

GND

GND

0.1µF

C21

1

2

3

J13

PEC03SAAN

GND

1.00Meg

R34

DNP

1.00Meg

R35

DNP

GND

ALT

16/17

Addr select

GG_PWR

GG_SCL

GG_SDA

GG_ALERT

GG_/KEYIN

GG_/PRES

SMBA

16V

D13

MMSZ5246B-7-F

5.6V

D11

5.6V

D10

5.6V

D20

5.6V

D19

TP37

TP33

DNP

/KEYIN

/PRES

1 2

3 4

5 6

7 8

9 10

J12

PEC05DAAN

GND

GG_PWR

0

R30

TP36

AFE-GG

BCX5616TA

1

3

2,4

Q9

SMB

0.1µF

C23

GND

DISPLAY

100k

R50E6E5

SCL

SDA

REGOUT

ALERT

C5

CAP1

PFD PACK–

1.00k

R40

DNP

1.00k

R41

DNP

300k

25 ppm/C

R38

13.7k

25 ppm/C

R43

50V

Q5

BSS138

-50V

Q4

BSS84W-7-F

100k

R45

TP30 TP31

100k

R44

5

4

1

2

3

6

7

J11

TSW-107-07-G-S

DNP

13.7k

25 ppm/C

R39

GND GND GND

3300pF

C20

3300pF

C19

DNP

GND

300k

25 ppm/C

R33

DNP

1.00k

R28

DNP

1.00k

R29

DNP

CHG

DSG

1.00k

R56

DNP

EDSG

ECHG

EPM

EVEN

EVAUX

0

R46

1.00Meg

R42

DNP

1.00Meg

R47

EPCHG

DNP

www.ti.com

bq76920EVM Circuit Module Physical Construction

Figure 16. Schematic Diagram Gauge

27

SLVU924B– March 2014–Revised April 2014 bq76920 Evaluation Module User's Guide

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 28

200

R66

200

R67

200

R68

200

R69

200

R70

1.00k

R65

1

2

3

4

5

6

13

14

7

12

10

11

8

9

S3

76SB07ST

Orange

D21

GND

5

4

1

2

3

6

J15

DNP

BATT–

Test points

BATT+

C5

C4

C3

C2

C1

C0

1.00k

R64

bq76920EVM Circuit Module Physical Construction

www.ti.com

Figure 17. Schematic Diagram Cell Simulator

28

bq76920 Evaluation Module User's Guide SLVU924B– March 2014–Revised April 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 29

www.ti.com

Related Documents From Texas Instruments

6 Related Documents From Texas Instruments

Document Literature

Number

bq76920, bq76930, bq76940 μC-Controlled AFE Family for 5-, 10-, and 15-Series SLUSBK2

Cell Lithium-Ion and Phosphate Battery Pack Applications Data Sheet

Revision History

Changes from Original (March 2014) to A Revision ....................................................................................................... Page

• Changed software display image........................................................................................................ 6

• Changed registers view image........................................................................................................... 8

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Revision History

Changes from A Revision (April 2014) to B Revision .................................................................................................... Page

• Changed software title to bq76940/bq76930/bq76920 Evaluation Software in step one of the Quick Start section and

globally throughout document. .......................................................................................................... 4

• Added clarification about device identifiers in menus or windows in the bq76940/bq76930/bq76920 Software section.... 5

• Changed path name to ...'\bq76940' in second paragraph of Interface Adapter section......................................... 6

• Added sentence about how to start the software in the Software Operation section............................................. 6

• Changed Evaluation Software Display image. ........................................................................................ 6

• Added Sequence_Example.bqseq to paragraph below Sequence View image................................................. 10

• Changed content in the BOM in rows containing U1 and U2 in the Designator column. ...................................... 23

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

SLVU924B–March 2014–Revised April 2014 Revision History

Submit Documentation Feedback

29

Copyright © 2014, Texas Instruments Incorporated

Page 30

ADDITIONAL TERMS AND CONDITIONS, WARNINGS, RESTRICTIONS, AND DISCLAIMERS FOR

EVALUATION MODULES

Texas Instruments Incorporated (TI) markets, sells, and loans all evaluation boards, kits, and/or modules (EVMs) pursuant to, and user

expressly acknowledges, represents, and agrees, and takes sole responsibility and risk with respect to, the following:

1. User agrees and acknowledges that EVMs are intended to be handled and used for feasibility evaluation only in laboratory and/or

development environments. Notwithstanding the foregoing, in certain instances, TI makes certain EVMs available to users that do not

handle and use EVMs solely for feasibility evaluation only in laboratory and/or development environments, but may use EVMs in a

hobbyist environment. All EVMs made available to hobbyist users are FCC certified, as applicable. Hobbyist users acknowledge, agree,

and shall comply with all applicable terms, conditions, warnings, and restrictions in this document and are subject to the disclaimer and

indemnity provisions included in this document.

2. Unless otherwise indicated, EVMs are not finished products and not intended for consumer use. EVMs are intended solely for use by

technically qualified electronics experts who are familiar with the dangers and application risks associated with handling electrical

mechanical components, systems, and subsystems.

3. User agrees that EVMs shall not be used as, or incorporated into, all or any part of a finished product.

4. User agrees and acknowledges that certain EVMs may not be designed or manufactured by TI.

5. User must read the user's guide and all other documentation accompanying EVMs, including without limitation any warning or

restriction notices, prior to handling and/or using EVMs. Such notices contain important safety information related to, for example,

temperatures and voltages. For additional information on TI's environmental and/or safety programs, please visit www.ti.com/esh or

contact TI.

6. User assumes all responsibility, obligation, and any corresponding liability for proper and safe handling and use of EVMs.

7. Should any EVM not meet the specifications indicated in the user’s guide or other documentation accompanying such EVM, the EVM

may be returned to TI within 30 days from the date of delivery for a full refund. THE FOREGOING LIMITED WARRANTY IS THE

EXCLUSIVE WARRANTY MADE BY TI TO USER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR

STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. TI SHALL

NOT BE LIABLE TO USER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES RELATED TO THE

HANDLING OR USE OF ANY EVM.

8. No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which EVMs might be or are used. TI currently deals with a variety of customers, and therefore TI’s arrangement with

the user is not exclusive. TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services with respect to the handling or use of EVMs.

9. User assumes sole responsibility to determine whether EVMs may be subject to any applicable federal, state, or local laws and

regulatory requirements (including but not limited to U.S. Food and Drug Administration regulations, if applicable) related to its handling

and use of EVMs and, if applicable, compliance in all respects with such laws and regulations.

10. User has sole responsibility to ensure the safety of any activities to be conducted by it and its employees, affiliates, contractors or

designees, with respect to handling and using EVMs. Further, user is responsible to ensure that any interfaces (electronic and/or

mechanical) between EVMs and any human body are designed with suitable isolation and means to safely limit accessible leakage

currents to minimize the risk of electrical shock hazard.

11. User shall employ reasonable safeguards to ensure that user’s use of EVMs will not result in any property damage, injury or death,

even if EVMs should fail to perform as described or expected.

12. User shall be solely responsible for proper disposal and recycling of EVMs consistent with all applicable federal, state, and local

requirements.

Certain Instructions. User shall operate EVMs within TI’s recommended specifications and environmental considerations per the user’s

guide, accompanying documentation, and any other applicable requirements. Exceeding the specified ratings (including but not limited to

input and output voltage, current, power, and environmental ranges) for EVMs may cause property damage, personal injury or death. If

there are questions concerning these ratings, user should contact a TI field representative prior to connecting interface electronics including

input power and intended loads. Any loads applied outside of the specified output range may result in unintended and/or inaccurate

operation and/or possible permanent damage to the EVM and/or interface electronics. Please consult the applicable EVM user's guide prior

to connecting any load to the EVM output. If there is uncertainty as to the load specification, please contact a TI field representative. During

normal operation, some circuit components may have case temperatures greater than 60°C as long as the input and output are maintained

at a normal ambient operating temperature. These components include but are not limited to linear regulators, switching transistors, pass

transistors, and current sense resistors which can be identified using EVMs’ schematics located in the applicable EVM user's guide. When

placing measurement probes near EVMs during normal operation, please be aware that EVMs may become very warm. As with all

electronic evaluation tools, only qualified personnel knowledgeable in electronic measurement and diagnostics normally found in

development environments should use EVMs.

Agreement to Defend, Indemnify and Hold Harmless. User agrees to defend, indemnify, and hold TI, its directors, officers, employees,

agents, representatives, affiliates, licensors and their representatives harmless from and against any and all claims, damages, losses,

expenses, costs and liabilities (collectively, "Claims") arising out of, or in connection with, any handling and/or use of EVMs. User’s

indemnity shall apply whether Claims arise under law of tort or contract or any other legal theory, and even if EVMs fail to perform as

described or expected.

Safety-Critical or Life-Critical Applications. If user intends to use EVMs in evaluations of safety critical applications (such as life support),

and a failure of a TI product considered for purchase by user for use in user’s product would reasonably be expected to cause severe

personal injury or death such as devices which are classified as FDA Class III or similar classification, then user must specifically notify TI

of such intent and enter into a separate Assurance and Indemnity Agreement.

Page 31

RADIO FREQUENCY REGULATORY COMPLIANCE INFORMATION FOR EVALUATION MODULES

Texas Instruments Incorporated (TI) evaluation boards, kits, and/or modules (EVMs) and/or accompanying hardware that is marketed, sold,

or loaned to users may or may not be subject to radio frequency regulations in specific countries.

General Statement for EVMs Not Including a Radio

For EVMs not including a radio and not subject to the U.S. Federal Communications Commission (FCC) or Industry Canada (IC)

regulations, TI intends EVMs to be used only for engineering development, demonstration, or evaluation purposes. EVMs are not finished

products typically fit for general consumer use. EVMs may nonetheless generate, use, or radiate radio frequency energy, but have not been

tested for compliance with the limits of computing devices pursuant to part 15 of FCC or the ICES-003 rules. Operation of such EVMs may

cause interference with radio communications, in which case the user at his own expense will be required to take whatever measures may

be required to correct this interference.

General Statement for EVMs including a radio

User Power/Frequency Use Obligations: For EVMs including a radio, the radio included in such EVMs is intended for development and/or

professional use only in legally allocated frequency and power limits. Any use of radio frequencies and/or power availability in such EVMs

and their development application(s) must comply with local laws governing radio spectrum allocation and power limits for such EVMs. It is

the user’s sole responsibility to only operate this radio in legally acceptable frequency space and within legally mandated power limitations.

Any exceptions to this are strictly prohibited and unauthorized by TI unless user has obtained appropriate experimental and/or development

licenses from local regulatory authorities, which is the sole responsibility of the user, including its acceptable authorization.

U.S. Federal Communications Commission Compliance

For EVMs Annotated as FCC – FEDERAL COMMUNICATIONS COMMISSION Part 15 Compliant

Caution

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Changes or modifications could void the user's authority to operate the equipment.

FCC Interference Statement for Class A EVM devices

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at its own expense.

FCC Interference Statement for Class B EVM devices

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Industry Canada Compliance (English)

For EVMs Annotated as IC – INDUSTRY CANADA Compliant:

This Class A or B digital apparatus complies with Canadian ICES-003.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

Concerning EVMs Including Radio Transmitters

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired

operation of the device.

Concerning EVMs Including Detachable Antennas

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

This radio transmitter has been approved by Industry Canada to operate with the antenna types listed in the user guide with the maximum

permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this list, having a gain

greater than the maximum gain indicated for that type, are strictly prohibited for use with this device.

Page 32

Canada Industry Canada Compliance (French)

Cet appareil numérique de la classe A ou B est conforme à la norme NMB-003 du Canada

Les changements ou les modifications pas expressément approuvés par la partie responsable de la conformité ont pu vider l’autorité de

l'utilisateur pour actionner l'équipement.

Concernant les EVMs avec appareils radio

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Concernant les EVMs avec antennes détachables

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d'un type et d'un gain

maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à

l'intention des autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication satisfaisante.

Le présent émetteur radio a été approuvé par Industrie Canada pour fonctionner avec les types d'antenne énumérés dans le manuel

d’usage et ayant un gain admissible maximal et l'impédance requise pour chaque type d'antenne. Les types d'antenne non inclus dans

cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour l'exploitation de l'émetteur.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

spacer

Important Notice for Users of EVMs Considered “Radio Frequency Products” in Japan

EVMs entering Japan are NOT certified by TI as conforming to Technical Regulations of Radio Law of Japan.

If user uses EVMs in Japan, user is required by Radio Law of Japan to follow the instructions below with respect to EVMs:

1. Use EVMs in a shielded room or any other test facility as defined in the notification #173 issued by Ministry of Internal Affairs and

Communications on March 28, 2006, based on Sub-section 1.1 of Article 6 of the Ministry’s Rule for Enforcement of Radio Law of

Japan,

2. Use EVMs only after user obtains the license of Test Radio Station as provided in Radio Law of Japan with respect to EVMs, or

3. Use of EVMs only after user obtains the Technical Regulations Conformity Certification as provided in Radio Law of Japan with respect

to EVMs. Also, do not transfer EVMs, unless user gives the same notice above to the transferee. Please note that if user does not

follow the instructions above, user will be subject to penalties of Radio Law of Japan.

http://www.tij.co.jp

【無線電波を送信する製品の開発キットをお使いになる際の注意事項】 本開発キットは技術基準適合証明を受けておりません。 本製品の

ご使用に際しては、電波法遵守のため、以下のいずれかの措置を取っていただく必要がありますのでご注意ください。

1. 電波法施行規則第6条第1項第1号に基づく平成18年3月28日総務省告示第173号で定められた電波暗室等の試験設備でご使用いただく。

2. 実験局の免許を取得後ご使用いただく。

3. 技術基準適合証明を取得後ご使用いただく。。

なお、本製品は、上記の「ご使用にあたっての注意」を譲渡先、移転先に通知しない限り、譲渡、移転できないものとします

上記を遵守頂けない場合は、電波法の罰則が適用される可能性があることをご留意ください。

日本テキサス・インスツルメンツ株式会社

東京都新宿区西新宿6丁目24番1号

西新宿三井ビル

http://www.tij.co.jp

Texas Instruments Japan Limited

(address) 24-1, Nishi-Shinjuku 6 chome, Shinjuku-ku, Tokyo, Japan

Page 33

IMPORTANT NOTICE