Page 1

User's Guide

SLUU514–July 2011

bq76925EVM Evaluation Module

This user's guide for the bq76925EVM evaluation module can assist designers in their evaluation of the

bq76925, Analog Front End for 3- to 6-Series Lithium-Ion Cells. This guide discusses setup and operation

of the module and contains schematics, bill of materials, and printed-circuit board layout.

Before designing a battery management system with the bq76925, designers are advised to read the

bq76925 data sheet (SLUSAM9).

Contents

1 Overview ..................................................................................................................... 4

1.1 Features ............................................................................................................. 4

1.2 Kit Contents ......................................................................................................... 4

1.3 Equipment Requirements ......................................................................................... 4

2 Circuit Details and Configuration .......................................................................................... 6

2.1 Connections ........................................................................................................ 6

2.2 Configuration Jumpers and Switches (J1 – J6, S2, S4) ...................................................... 8

2.3 Pushbuttons (S1, S3) ............................................................................................ 10

2.4 Test Points ........................................................................................................ 10

2.5 bq76925 ........................................................................................................... 11

2.6 MSP430F2122 .................................................................................................... 11

3 Quick-Start Demonstration ............................................................................................... 11

3.1 Evaluation Software and USB-TO-GPIO Adapter ............................................................ 11

3.2 Configuration Switches and Jumpers .......................................................................... 12

3.3 Power to the bq76925EVM ...................................................................................... 12

3.4 Connect USB-TO-GPIO Adapter ............................................................................... 12

3.5 bq76925 Evaluation Software ................................................................................... 13

4 Control Register Demonstration ......................................................................................... 16

4.1 View Control Registers .......................................................................................... 16

4.2 Control Registers Introduction .................................................................................. 18

4.3 Modifying Control Registers ..................................................................................... 19

4.4 Sleep Mode and Wake Up ...................................................................................... 19

5 Control Panel Demonstration ............................................................................................ 21

5.1 Access to the Control Panel .................................................................................... 21

5.2 Measurement Tab ................................................................................................ 22

5.3 Analog Output Section ........................................................................................... 22

5.4 VCOUT Readings ................................................................................................ 23

5.5 VIOUT Readings .................................................................................................. 23

5.6 Auto Control ....................................................................................................... 23

5.7 EEPROM Correction Registers ................................................................................. 24

5.8 Startup Config Tab ............................................................................................... 24

5.9 Configuration Control ............................................................................................ 24

5.10 Power Control ..................................................................................................... 25

5.11 Logging Tab ....................................................................................................... 25

5.12 Log File ............................................................................................................ 26

Adobe, Reader are trademarks of Adobe Systems Incorporated.

Pentium is a trademark of Intel Corporation.

Mentor Graphics, PADs are trademarks of Mentor Graphics Corporation.

Microsoft, Windows, Excel are trademarks of Microsoft Corporation.

I2C is a trademark of Philips Electronics N.V..

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

1

Page 2

www.ti.com

5.13 Log File Options .................................................................................................. 26

5.14 Enable/Disable Logging ......................................................................................... 26

5.15 Log File Example ................................................................................................. 26

5.16 Communications Tab ............................................................................................ 27

5.17 Monitor Window ................................................................................................... 27

5.18 Transactions During a Connect to Device Command ....................................................... 28

5.19 I2C .................................................................................................................. 29

5.20 I2C Register Read ................................................................................................ 29

5.21 I2C Register Write ................................................................................................ 29

5.22 I2C Communications With MSP430F2122 .................................................................... 29

5.23 Example of I2C Communications from MSP430F2122 ..................................................... 30

6 3-, 4-, and 5-Cell Operation .............................................................................................. 31

6.1 Introduction ........................................................................................................ 31

6.2 Using Onboard Cell Simulator .................................................................................. 31

6.3 Five-Cell Operation ............................................................................................... 31

6.4 Four-Cell Operation .............................................................................................. 32

6.5 Three-Cell Operation ............................................................................................. 32

7 Operation With Cells ...................................................................................................... 32

7.1 Preparing Circuit for Operation ................................................................................. 32

7.2 Battery Connection Sequence .................................................................................. 33

7.3 Six-Cell Operation ................................................................................................ 33

7.4 Five-Cell Operation ............................................................................................... 33

7.5 Four-Cell Operation .............................................................................................. 33

7.6 Three-Cell Operation ............................................................................................. 34

7.7 Battery Removal Sequence ..................................................................................... 34

8 Schematic and Bill of Materials .......................................................................................... 34

8.1 Schematics ........................................................................................................ 35

8.2 Bill of Materials .................................................................................................... 37

9 Printed-Circuit Board ...................................................................................................... 38

List of Figures

1 Home Screen of the Evaluation Software.............................................................................. 13

2 Poll Button in the Evaluation Software.................................................................................. 13

3 Poll Button in the Evaluation Software.................................................................................. 14

4 Demo With Two Power Supplies........................................................................................ 15

5 Voltage, Temperature, and Current Measurement in the Evaluation Software ................................... 15

6 Select Cell Count Set to Three Cells ................................................................................... 16

7 Volatile Control Registers Checkbox.................................................................................... 16

8 Volatile Control Registers Access....................................................................................... 17

9 Volatile Control Registers Bit Legend................................................................................... 18

10 Sleep Mode Showing 3.3-V Status...................................................................................... 20

11 Wake Up From Sleep Mode ............................................................................................. 20

12 Open Control Panel ....................................................................................................... 21

13 Control Panel Details ..................................................................................................... 21

14 Measurement Tab in the Control Panel ................................................................................ 22

15 Startup Config Tab in the Control Panel................................................................................ 24

16 Change to the Current Comparator Threshold to 175 mV at Start-Up............................................. 25

17 The Logging Tab .......................................................................................................... 26

18 Communications Tab ..................................................................................................... 27

19 Schematic – Page 1 of 4 ................................................................................................. 35

20 Schematic – Page 2 of 4 ................................................................................................. 36

21 Schematic – Page 3 of 4 ................................................................................................. 36

22 Schematic – Page 4 of 4 ................................................................................................. 37

2

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

23 Top Silkscreen Layer ..................................................................................................... 38

24 Top Copper Layer......................................................................................................... 39

25 Inner Copper Layer........................................................................................................ 39

26 Inner Copper Layer........................................................................................................ 40

27 Bottom Copper Layer ..................................................................................................... 40

28 Drill Drawing................................................................................................................ 41

1 Cell Voltage Connections.................................................................................................. 7

2 USB Interface Connection ................................................................................................. 7

3 JTAG Interface Connection................................................................................................ 8

4 Pack Status Connection.................................................................................................... 8

5 J1, BAT Pin Circuit Configuration......................................................................................... 8

6 J2, VCTL Pin Circuit Configuration ...................................................................................... 8

7 J3, V3P3 Pin Circuit Configuration ....................................................................................... 9

8 J4, V3P3 Pin Capacitor Circuit Configuration........................................................................... 9

9 J5, SENSEP Pin Circuit Configuration................................................................................... 9

10 J6, DVCC Pin Circuit Configuration ...................................................................................... 9

11 DIP Switch, S4 .............................................................................................................. 9

12 DIP Switch, S2............................................................................................................. 10

13 Test Points ................................................................................................................. 10

14 Circuit Configuration ...................................................................................................... 12

15 Default Register Values .................................................................................................. 18

16 Formulas to Convert VCOUT to either °C or mV...................................................................... 23

17 Example Log File.......................................................................................................... 26

18 Example of a Device Connect Command.............................................................................. 28

19 Data From MSP430F2122 ............................................................................................... 29

20 Example of a Device Connect Command.............................................................................. 30

21 Bill of Materials............................................................................................................. 37

List of Tables

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

3

Page 4

Overview

1 Overview

This section describes the features of the bq76925EVM and the equipment that is typically required to

demonstrate and use the EVM.

1.1 Features

A summary of the features of the bq76925EVM follows.

• One bq76925 and one MSP430F2122 device with associated support circuitry

• Support for 3-to 6-series connected cells

– Pluggable terminal block for cell connections, or

– Onboard simulation of cells for operation from a power supply

• bq76925 circuit is jumper configurable for internal or external 3.3-V source

• MSP430 application circuit includes

– JTAG connector

– Reset and SOC buttons

– Four, controllable LEDs

– I2C™ interface to bq76925 and to USB-to-GPIO

– Pack status connector

• Supports nominal 4.2-V to 26.4-V pack voltages, 30 V maximum

• 20-A continuous charge/discharge current rating

– 0.001-Ω (equivalent) shunt resistor

– High-current, stud-type connections for battery power and pack power

• Onboard thermistor for temperature measurement

• Transient voltage protection of PACK± terminals

• Connector for USB-TO-GPIO Adapter

• Test points for monitoring of cell voltages and other important circuit nets

• EVM design files in Mentor Graphics™ PADs™ 2009 format available on request

• Gerber files available on request

www.ti.com

1.2 Kit Contents

The bq76925EVM includes the PWR008 printed-circuit board (PCB). Evaluation software is downloadable

from the Texas Instruments Web site (www.ti.com).

1.3 Equipment Requirements

The bq76925EVM includes one PCB containing a bq76925 application circuit. The following equipment

and software are typically needed for operation. Some items depend on the usage case.

1.3.1 bq76925 Evaluation Software

The bq76925 Evaluation Software is the Microsoft™ Windows™ application that controls and interfaces

with the bq76925. Installation of this software on a compatible personal computer (PC) is required. The

installation file can be found on the product page for the bq76925 on the Texas Instruments Web site.

1.3.2 Microsoft Windows-Compatible Computer

The minimum requirement for the PC and operating system are as follows:

• Pentium™ III class or better processor at 1.6 GHz

• Microsoft Windows 2000, XP, or later (32-bit OS)

• 512 MB or more RAM

• 15 MB of free hard-disk space

• CD-ROM drive

• Adobe™ Reader™ 5.0 or later

4

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

• A color monitor with 1024 × 768 or better resolution

1.3.3 USB-TO-GPIO Adapter

The USB-TO-GPIO Adapter is actually an EVM available from Texas Instruments. It is used to provide the

I2C connection between the bq76925 and the PC.

The USB-TO-GPIO Adapter original firmware is 1.0.10. Firmware version

2.0.19 or later must be installed using the USB-TO-GPIO Firmware Updater

software available (free) on the TI Web site at

http://focus.ti.com/docs/toolsw/folders/print/usb2gpio-loader-sw.html.

1.3.4 Power Supply for Onboard Cell Simulator

A resistor divider network is provided on the bq76925EVM to simulate cells. This allows basic evaluation

of the bq76925 without the use of cells. In this case, a power supply connected between BATT+ and

BATT– is required to power the resistor network. A 24-V power supply with a current capability of 100 mA

is required to power the circuit .

1.3.5 Power Supply for Simulation of Current

A second power supply is used to simulate battery current. The bq76925 expects a sense resistor value of

0.001 Ω and 1 mV is equal to 1 A. A jumper (J5) allows the sense resistor to be disconnected from the

current input of the bq76925 and be replaced with a millivolt source. A power supply that can accurately

provide up to 100 mV can allow for simulated testing of up to 100 A without actually running this

dangerously high current.

Overview

CAUTION

1.3.6 Battery

Lithium-ion, rechargeable-type cells can be used with this EVM. Typical cell voltage rating is 3.3 V to 3.7 V

nominal and the pack consists of 3- to 6-series connected cells. Almost all Lithium-ion chemistries can be

used with the bq76925.

This EVM has no battery current control devices (MOSFETs) that

can stop the flow of charge or discharge current in the event that a

dangerous condition is induced through discharging or charging

of a battery. Exercise extreme caution when using a battery with

this EVM.

1.3.7 Power Supply to Charge Battery

A power supply can be connected to the PACK± terminals to provide charge current if a battery is

connected to the BATT± inputs.

WARNING

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

5

Page 6

Circuit Details and Configuration

Use caution when mating batteries with a charger power supply.

Some power supplies cannot tolerate current being fed into their

output terminals. A battery connected to a power supply can easily

cause this to happen. A properly sized blocking diode connected

to the positive output voltage of the power supply can provide

adequate protection against backfeed from the battery and into the

power supply electronics.

1.3.8 Electronic Load

An electronic load is often needed to sink current or power from the battery and through the EVM. A

constant-current load provides a good means of evaluating the performance of the bq76925 when a

battery is used. Equipment rating depends on the application. Typical criteria for electronic load selection

are a voltage rating of up to 4.5 V/cell and up to 20-A discharge capability with 10-mA resolution.

1.3.9 Digital Multimeter

One or two digital multimeters (DMM) capable of voltage, current, and temperature measurement equal to

or greater than the accuracy ratings of the bq76925 are needed for adequate evaluation. Numerous test

clips on the PCB can accept a DMM.

www.ti.com

WARNING

1.3.10 Oscilloscope

An oscilloscope may be needed if evaluation of waveforms or timing measurements is required. Typical

waveforms that a user may be interested in are the I2C signals (100 kHz), cell-balancing waveforms or

capture of the activation time of the ALERT signal after an overcurrent event may be of interest. These

signals can happen down to the 10s of microseconds time base.

2 Circuit Details and Configuration

This section highlights the important features of the EVM circuit, gives some operating instructions, and

also provides a description of the connector pin assignments. Read through this section before using the

EVM for the first time.

Do not connect the battery, power supplies, or interface at this time. Wait until

the next section.

2.1 Connections

Pin 1 on all multisignal-pin headers is indicated by a square solder pad.

2.1.1 BATT+, BATT– (CN1, CN2)

These connections connect the battery terminals to the circuit.

The positive, current-carrying connection of the battery connects to the BATT+ terminal (CN1).

The negative, current-carrying connection of the battery connects to the BATT– terminal (CN2).

The BATT± connections are single, heavy-duty screw terminals that feature a 6-32 × 1/4-in.-long screw.

This connector is rated to 30 A, maximum. Actual current is limited to a lower value (20 A) by other circuit

board components.

CAUTION

6

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

2.1.2 Cells (CN6)

The cell-sensing wires of the battery pack provide the connection for cell voltage measurement and

resistive cell balancing. If the cell count is N, the number of cell wires is N+1.

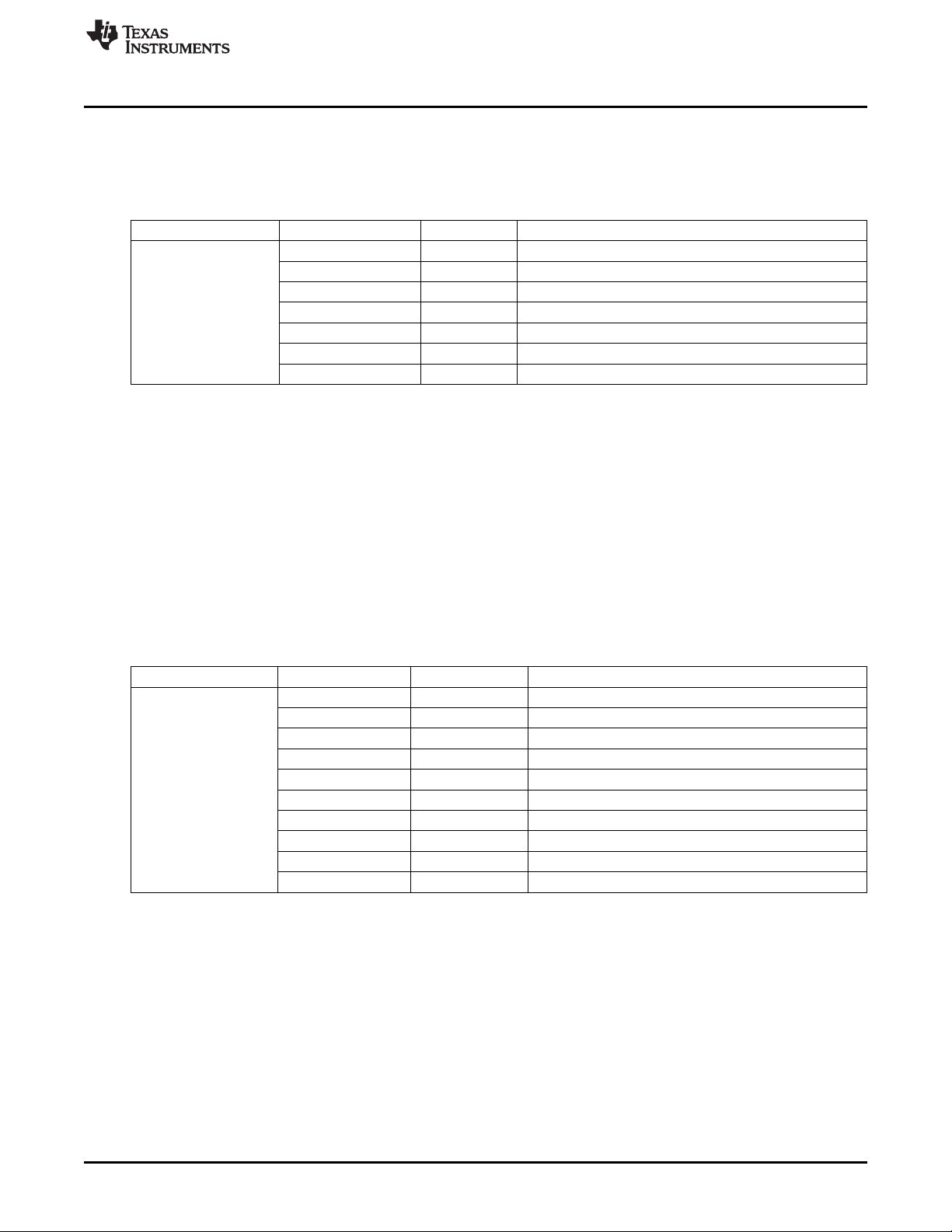

Header Name Terminal Label Purpose

CN6 4 Cell 3 Cell 3 positive terminal.

2.1.3 PACK+, PACK– (CN3, CN4)

The positive, current-carrying connection of the load or charger connects to the PACK+ terminal (CN3).

The negative, current-carrying connection of the load or charger connects to the PACK- terminal (CN4).

The PACK± connections are single, heavy-duty screw terminals that feature a 6-32 × 1/4-in. screw. This

connector is rated to 30 A, maximum. Actual current is limited to a lower value (20 A) by other circuit

board components.

Circuit Details and Configuration

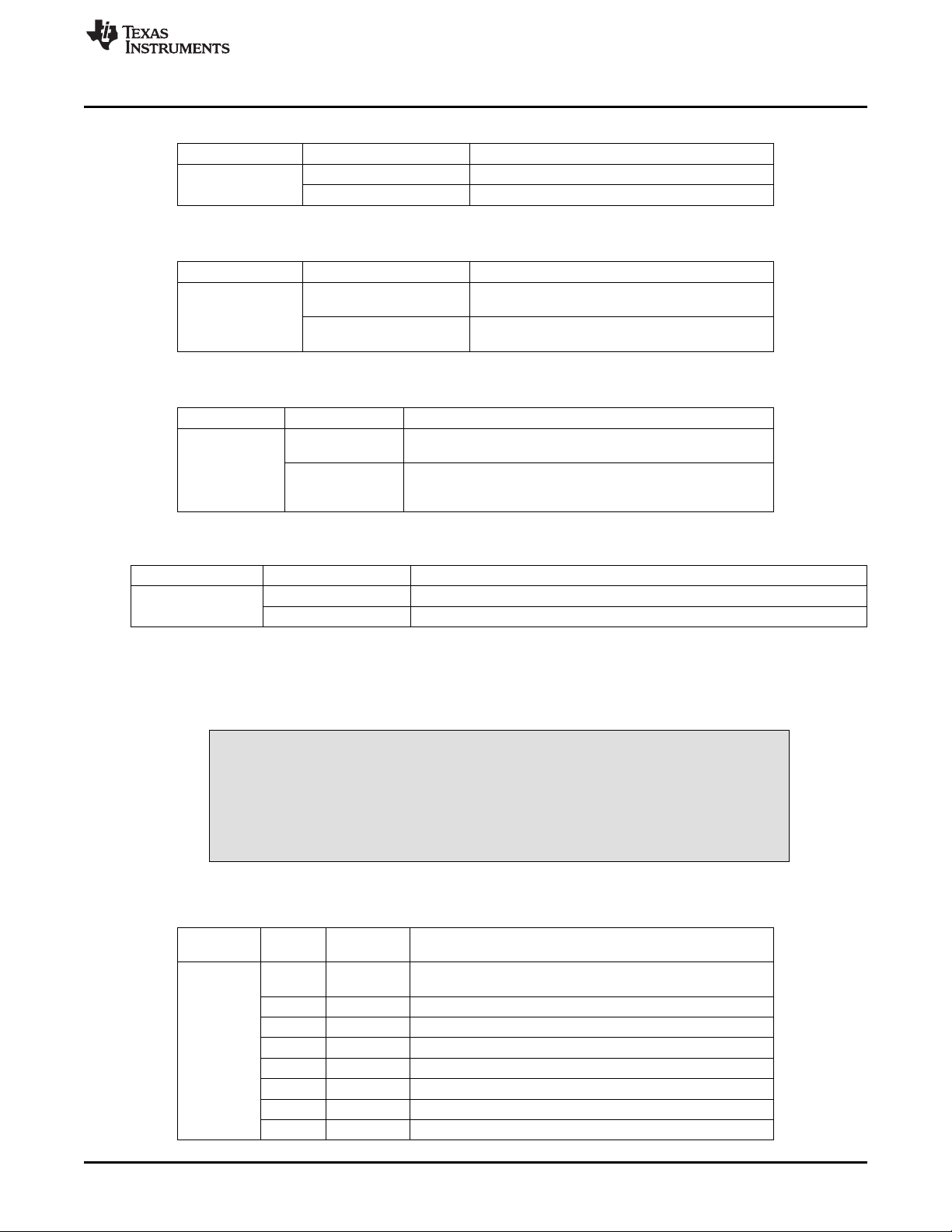

Table 1. Cell Voltage Connections

1 Cell 6 Cell 6 positive terminal.

2 Cell 5 Cell 5 positive terminal.

3 Cell 4 Cell 4 positive terminal.

5 Cell 2 Cell 2 positive terminal.

6 Cell 1 Cell 1 positive terminal.

7 Cell 0 Cell 1 negative terminal.

2.1.4 USB Interface (CN8)

The USB interface connector (CN8) is for connection to the USB-TO-GPIO Adapter. The pin assignment

is as follows:

Header Name Terminal Label Purpose

CN8 1 – V3P3 Monitor and Input

2.1.5 JTAG Interface (CN7)

The JTAG Interface connector (CN7) is for connection to an MSP430 programmer, such as the

MSP-FET430UIF. Use of this connector is not required for evaluation of the bq76925. This header is for

those users who wish to write code for the MSP430F2122 resident on the EVM. The pin assignment is as

follows:

Table 2. USB Interface Connection

2 – ALERT Output

3 – None

4 – None

5 – +3.3V Output

6 – Ground

7 – None

8 – None

9 – I2C Clock (SCL)

10 – I2C Data (SDA)

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

7

Page 8

Circuit Details and Configuration

Header Name Terminal Label Purpose

CN7 1 1 TDI/TDO

2.1.6 Pack Status (CN5)

The Pack Status header is provided as a convenience for those users desiring to develop firmware for the

MSP430. The default firmware does not use these pins. This connector can be used for GPIO or for an

SPI interface. Total current sourcing from these pins must be limited such that the current rating of the

3.3-V source of the bq76925 circuit is not exceeded. Consult the data sheet for details.

www.ti.com

Table 3. JTAG Interface Connection

2 – VCC-TOOL

3 – TDI/VPP

4 – VCC-TARGET

5 – TMS

6 – NONE

7 – TCK

8 – TEST/VPP

9 – GROUND

10 – NONE

11 – RESET

12 – NONE

13 – NONE

14 – NONE

Table 4. Pack Status Connection

Header Name Terminal Label Purpose

CN5 1 GPIO1 GPIO, RXD, SOMI

2 GPIO2 GPIO, TXD

3 GPIO3 GPIO, SCLK

4 GND Ground

(1)

Silkscreen on the board incorrectly reads RXD

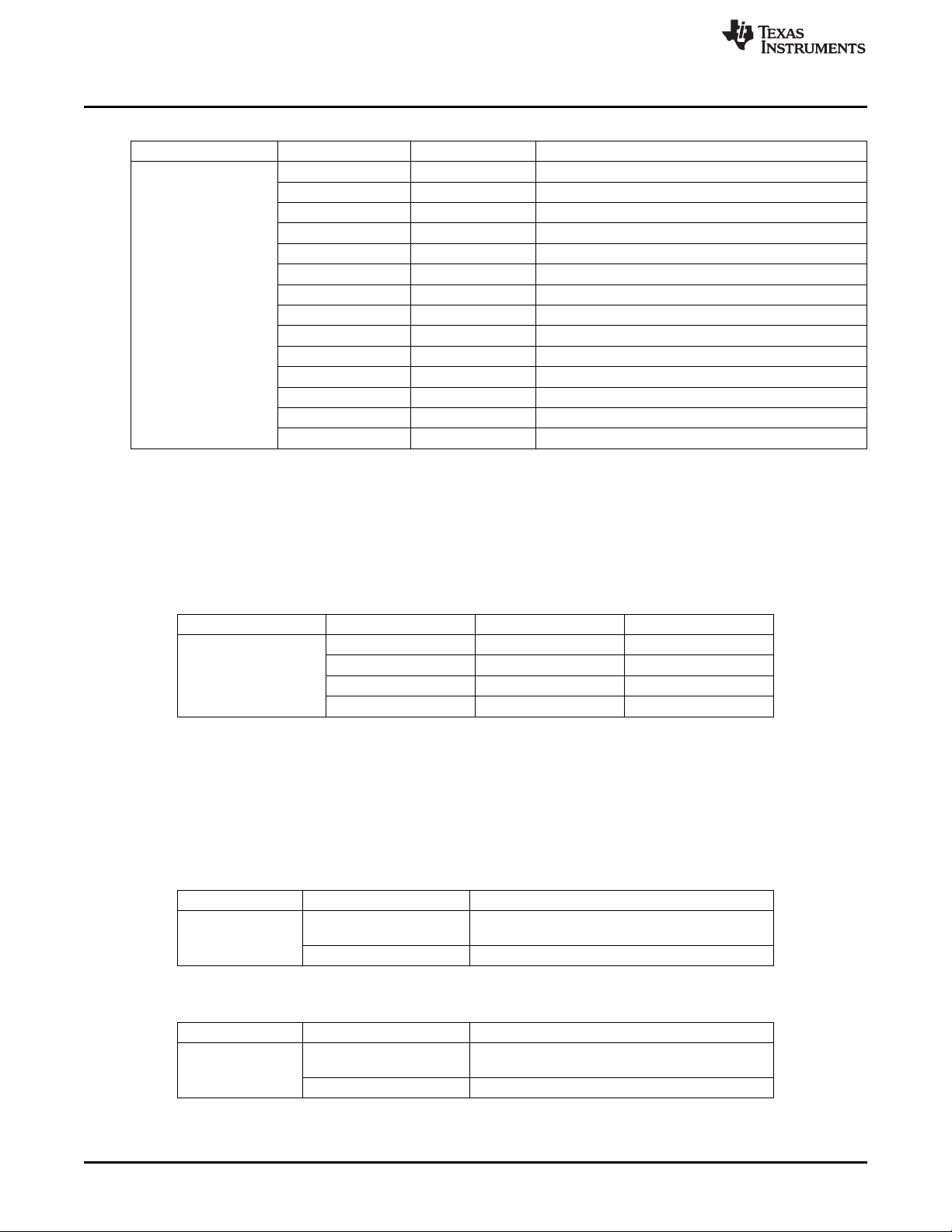

2.2 Configuration Jumpers and Switches (J1 – J6, S2, S4)

Two- and three-terminal headers allow the user to configure the operation of the EVM by installing a shunt

at the header. The description of each jumper header is shown in the following tables. Shunts are

provided with the EVM in the default position.

Table 5. J1, BAT Pin Circuit Configuration

Header Name Position Purpose

1 - 2 Zener diode and series diode in BAT pin circuit

J1

2 - 3 Only series resistor in BAT pin circuit.

Table 6. J2, VCTL Pin Circuit Configuration

Header Name Position Purpose

1 - 2 Internal V3P3 selected. Not recommended when

J2

2 - 3 External V3P3 selected. (default)

(default)

SOC LEDs are being used.

(1)

, SIMO

8

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

Table 7. J3, V3P3 Pin Circuit Configuration

Header Name Position Purpose

J3

1 - 2 External V3P3 source in circuit (default).

OFF External V3P3 source in circuit

Table 8. J4, V3P3 Pin Capacitor Circuit Configuration

Header Name Position Purpose

J4

1 - 2 External V3P3 source in circuit 1-µF + 4.7-µF

OFF Internal V3P3 source in circuit and 1-µF capacitance

capacitance used (default).

used

Table 9. J5, SENSEP Pin Circuit Configuration

Header Name Position Purpose

J5

1 - 2 SENSEP connected to sense resistor for normal operation

OFF SENSEP disconnected from sense resistor. This is a test mode

(default).

operation where a mV source is applied to J5:pin 1 for simulation

of current.

Circuit Details and Configuration

Table 10. J6, DVCC Pin Circuit Configuration

Header Name Position Purpose

J6

1 - 2 Power to MSP430 during programming is from VCC-Tool. (default)

2 - 3 Power to MSP430 during programming is from VCC-Target.

2.2.1 Cell Simulator DIP Switch (S4)

The eight-position DIP switch (S4) allows the user to simulate cell-voltage inputs to the bq76925 rather

than supply actual cell voltages. See Table 11 for details of the operation of the DIP switch.

Use silkscreen labeling and square pin 1 pad to determine orientation and

operation of the eight-position DIP switch. Ignore numbers actually printed on

the switch.

All S4 dip switches must be opened when using a battery with the EVM.

Switch Terminal Label Purpose

Name

S4 1 Battery Switch to connect power supply to resistor network. Closure

2 Cell 6 Applies simulated cell voltage to VC6.

3 Cell 5 Applies simulated cell voltage to VC5.

4 Cell 4 Applies simulated cell voltage to VC4.

5 Cell 3 Applies simulated cell voltage to VC3.

6 Cell 2 Applies simulated cell voltage to VC2.

7 Cell 1 Applies simulated cell voltage to VC1.

8 Cell 0 Applies simulated cell voltage to VC0.

CAUTION

Table 11. DIP Switch, S4

activates LED D13.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

9

Page 10

Circuit Details and Configuration

2.2.2 Circuit Isolation DIP Switch (S2)

The eight-position DIP switch (S2) allows the user to isolate the MSP430 circuit from the bq76925 circuit.

Circuit isolation may be needed to measure some performance characteristics of the bq76925 or during

MSP430 programming.

Use silkscreen labeling and square pin 1 pad to determine orientation and

operation of the eight-position DIP switch. Ignore numbers actually printed on

the switch.

Switch Name Terminal Label Purpose

S2 1 V3P3 Controls application of V3P3 from bq76925 to MSP430

2 Therm Isolates the THERM circuit when opened.

3 VCOUT Isolates the VCOUT circuit when opened.

4 VIOUT Isolates the VIOUT circuit when opened.

5 SDA Isolates the SDA circuit when opened.

6 SCL Isolates the SCL circuit when opened.

7 ALERT Isolates the ALERT circuit when opened.

8 VRef Isolates the VREF circuit when opened.

www.ti.com

CAUTION

Table 12. DIP Switch, S2

2.3 Pushbuttons (S1, S3)

The two pushbuttons on the EVM are normally open, momentary-style buttons. The pushbutton labeled

RESET (S1) is the reset button for the MSP430. Pressing this button restarts the MSP430.

The pushbutton labeled LEDs (S3) is intended to be a display control for the state of charge (SOC) display

formed by the four LEDs (D8 –D11). Pressing this button triggers an input on the MSP430 that

incrementally lights the four LEDs – despite what the actual SOC of the battery may be that is connected

to the EVM. This is the default functionality defined by the firmware. The user can choose to use the

pushbutton in another way by creating new firmware for the MSP430.

2.4 Test Points

Twenty-nine test loops are located on the EVM. Table 13 names the circuit connected to each test point.

The first 20 test points correspond one-to-one to the pin number on the bq76925.

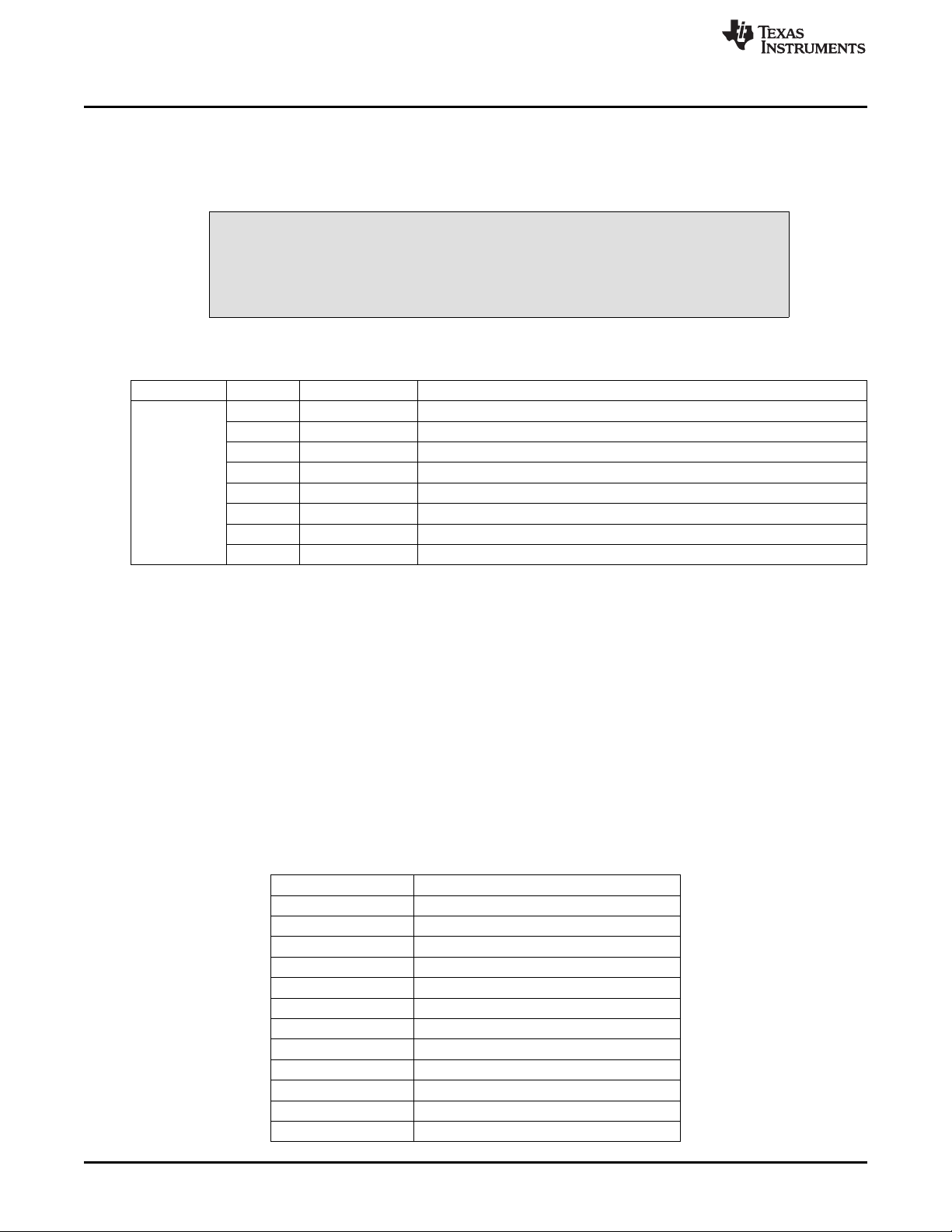

Table 13. Test Points

Label Ground Reference Test Point

TP1 VCTL

TP2 BAT

TP3 VC6

TP4 VC5

TP5 VC4

TP6 VC3

TP7 VC2

TP8 VC1

TP9 VC0

TP10 VSS

TP11 SENSEN

TP12 SENSEP

10

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

Quick-Start Demonstration

Table 13. Test Points (continued)

Label Ground Reference Test Point

TP13 ALERT

TP14 VIOUT

TP15 VCOUT

TP16 VTB

TP17 VREF

TP18 SDA

TP19 SCL

TP20 V3P3

TP21 BATT+

TP22 PACK–

TP23 P2.5 ON MSP430

TP24 P3.7 ON MSP430

TP25 P3.5 ON MSP430

TP26 P3.4 ON MSP430

TP27 P3.0 ON MSP430

TP28 VSS

TP29 VSS

2.5 bq76925

The bq76925 application circuit provided allows for complete evaluation of the device performance with 3-,

4-, 5-, or 6-cell battery packs. Cell voltages, battery current, and temperature can be monitored.

Monitoring is possible with the firmware that is preloaded into the MSP430 microcontroller and with the

bq76925 Evaluation Software provided. Alternatively, the user can develop a custom system if desired.

2.6 MSP430F2122

The MSP430F2122 application circuit is provided to read the analog signals from the bq76925 and make

them available for reading over the I2C bus by the bq76925 Evaluation Software. The MSP430 circuitry is

designed to allow the user to create custom firmware if desired.

3 Quick-Start Demonstration

This section demonstrates the measurement system of the bq76925 using the onboard cell simulator.

To quickly get the bq76925EVM up and running, follow the instructions in this section. The following

equipment and software are required:

• bq76925EVM Evaluation Module

• A 24-Vdc power supply

• Power supply capable of up to 100 mV and at least 100 mA of drive capability.

• PC with MS Windows operating system

• bq76925 Evaluation Software

• USB-TO-GPIO Adapter

3.1 Evaluation Software and USB-TO-GPIO Adapter

The bq76925 Evaluation Software and the USB-TO-GPIO Adapter must be installed and set up.

The USB-TO-GPIO Adapter is an EVM that is sold separately from the bq76925EVM. The firmware in it

must be changed to work with the bq76925 because this EVM was developed for generic applications. Go

to the TI Web site to download the firmware loader.

http://focus.ti.com/docs/toolsw/folders/print/usb2gpio-loader-sw.html

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

11

Page 12

Quick-Start Demonstration

With the USB-TO-GPIO Adapter connected to the PC, follow the instructions included with the firmware

loader software, and change the firmware version to 2.0.19. All necessary files are included with the

USB-TO-GPIO Firmware Updater.

If the firmware download fails, do not disconnect the USB-TO-GPIO Adapter.

Try to load the firmware again until it is successful. Removing power after a

failed download can permanently damage the USB-TO-GPIO Adapter.

The bq76925 Evaluation Software is free to download from the product page for the bq76925 on the TI

Web site. Follow the installation instructions in the install package.

3.2 Configuration Switches and Jumpers

Before applying any power to the board, ensure that all of the jumpers and switches are set up correctly

for this demonstration. A summary of all of the jumper and switch positions appears in Table 14.

Table 14. Circuit Configuration

Header Shunt or Switch Notes

Name Position

J1 1 – 2 Zener and blocking diode on BAT Pin

J2 2 – 3 External Pass Transistor enabled

J3 ON External Pass Transistor enabled

J4 ON 5.7- µF capacitance on V3P3 pin.

J5 ON Normal mode

J6 1 – 2 VCC from Tool

S2 ON All eight switches to the closed position.

S4 ON All eight switches to the closed position.

www.ti.com

CAUTION

3.3 Power to the bq76925EVM

Ensure that the configuration described in Table 14 has been verified.

The bq76925EVM must be powered from a power supply for this demonstration. The power supply drives

an onboard cell simulator as well as powers the bq76925 and MSP430 circuitry. No battery is required at

this point.

Connect a 24-V power supply with current drive of at least 100 mA between the BATT+ and BATT–. Turn

on the output of the power supply.

On application of power, the red LED, D13, illuminates.

A voltmeter can be used to verify that the 3.3-V output is working. Place the voltmeter between test points

TP20 and TP10.

3.4 Connect USB-TO-GPIO Adapter

Connect the USB cable provided with the USB-TO-GPIO Adapter between the PC with the Evaluation

Software installed on it and the USB-TO-GPIO Adapter.

The green LED near the USB connector illuminates to indicate that the USB-TO-GPIO Adapter is properly

connected. Because of the marginal mechanical design of the case, the USB connection can sometimes

become intermittent. The green LED is a good indication if a connection problem exists.

Connect the ribbon cable provided with the USB-TO-GPIO Adapter from it to header CN8 on the

bq76925EVM. The red LED, D12, illuminates.

12

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

3.5 bq76925 Evaluation Software

3.5.1 Open the Application

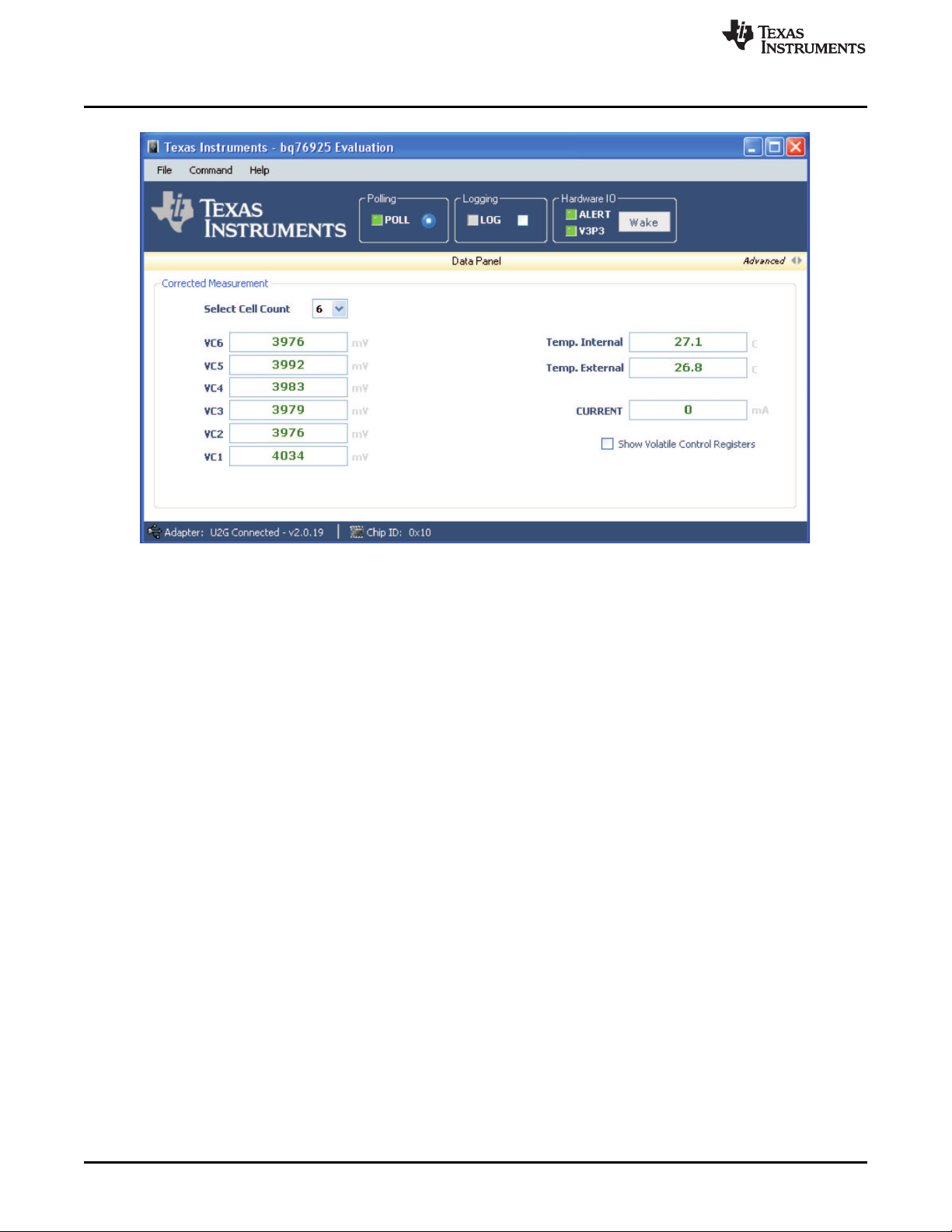

Having followed the instructions in the previous sections, open the bq76925 Evaluation Software.

The following screen appears (Figure 1). This main screen is often referred to as the home screen.

Quick-Start Demonstration

3.5.2 Start Polling Data

Data from the bq76925 can be polled and displayed in the application. To start polling, click on the Poll

button.

With polling active, the cell voltages and temperatures update on a periodic basis. The poll indicator light

next to the word POLL flashes between green and orange for each poll cycle.

Figure 1. Home Screen of the Evaluation Software

Figure 2. Poll Button in the Evaluation Software.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

13

Page 14

Quick-Start Demonstration

www.ti.com

Figure 3. Poll Button in the Evaluation Software

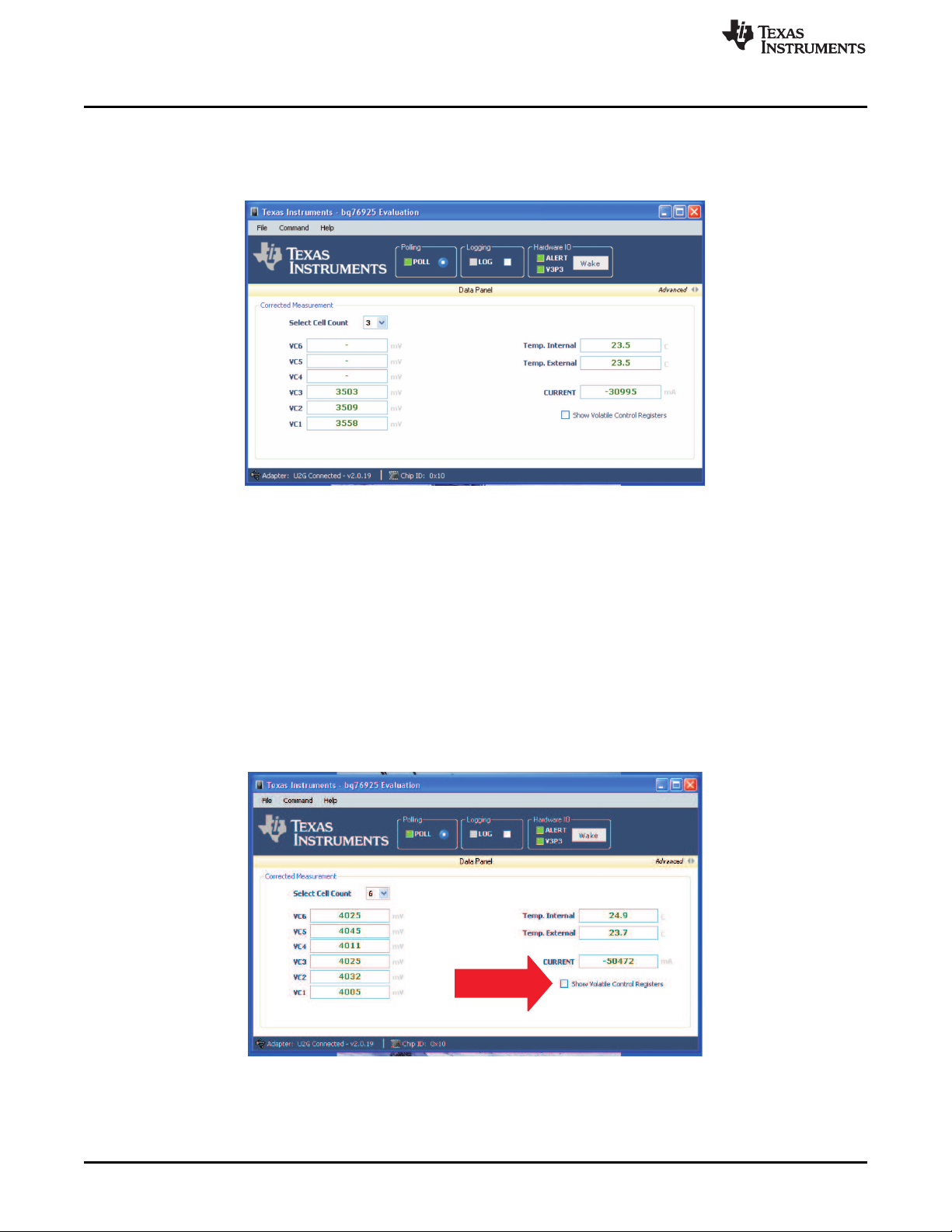

3.5.3 Add Second Power Supply to Simulate Current

One way to easily simulate battery current is to apply a millivolt source to the current-sense inputs of the

bq76925. Tens of amperes can be simulated where each 10 mV is equal to 10 amperes.

14

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

+-

24.0V 100mA

Power Supply1

50mV 100mA

Power Supply2

- +

Personal Computer

Windows XP32 Bit

with

bq76925 Evaluation

Software Installed

USB

USB-TO-

GPIO

Adapter

www.ti.com

Quick-Start Demonstration

Figure 4. Demo With Two Power Supplies

Remove the shunt from header J5. Use the second power supply to apply 50 mV between pin 1 of header

J5 and the BATT- terminal. This simulates approximately –50 A or –50,000 mA, of discharge current.

Figure 5. Voltage, Temperature, and Current Measurement in the Evaluation Software

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

15

Page 16

Control Register Demonstration

The drop-down box labeled Select Cell Count determines the number of cell voltage measurements that

are displayed: 1 to 6. This function is independent of the cell count. For example, if the user only wanted

to display 3 cells of a 6-cell pack, then the Select Cell Count box is changed to 3. This convenience

feature avoids seeing a somewhat random number being displayed for unconnected cell inputs.

www.ti.com

Figure 6. Select Cell Count Set to Three Cells

4 Control Register Demonstration

The Quick-Start demonstration from the previous section presents the fundamental measurement system

of the bq76925. The method to access and modify the Control Registers using the Evaluation Software is

presented in this section.

4.1 View Control Registers

4.1.1 Introduction

Open the Evaluation Software, if not already open, and click the checkbox marked Show Volatile Control

Registers.

16

Figure 7. Volatile Control Registers Checkbox

This expands the home window to show the six registers.

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

Control Register Demonstration

Figure 8. Volatile Control Registers Access

All of the bits that are assigned for reading and writing are shown. Bit positions that are unnamed are not

used. These bits must always be left as zero.

A legend that can be clicked explains the bit colors. A zero value for a bit is displayed as a grey

background. A one is shown as either a green background or as an orange background.

Clicking each bit toggles the bit value in real time. If a bit turns green, it is set to a 1. If a bit is white or

grey, it is a zero. Each of the STATUS bits is displayed in orange when they are a value of 1.

If the SLEEP bit is a 1, it halts communications, so that the status of this bit is unable to be displayed. The

SLEEP bit always appears to be OFF or MASKED.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

17

Page 18

Control Register Demonstration

www.ti.com

Figure 9. Volatile Control Registers Bit Legend

4.1.2 Factory-Programmed Register Values

The Control Registers are programmed at the factory to have a default value. Table 15 shows these

values.

Table 15. Default Register Values

Address Register Default Value

0x00 STATUS 0x01

0x01 CELL_CTL 0x10

0x02 BAL_CTL 0x00

0x03 CONFIG_1 0x00

0x04 CONFIG_2 0x81

0x05 PWR_CTL 0x00

4.1.3 Register Values When Polling

When the Polling button is pressed, the PWR_CTL register is forced to the value of 0x1F. This turns on all

measurement systems as well as the current comparator. This is shown in the Control Register Display.

Note that other bits are automatically updated (written) during polling but are not displayed (read). The

update rate of the bits during polling is in the 10s of milliseconds and does not make sense to display.

4.2 Control Registers Introduction

18

The Control Registers of the bq76925 are used to configure and control the device. A summary of the

read/write Control Registers follows. This user's guide, however, does not provide the necessary details

on the operation and settings of these registers that are given in the bq76925 data sheet . For those

details, see SLUSAM9.

Mousing over a bit in the Control Register section of the software displays a brief description of the bit.

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

4.2.1 STATUS: 0x00

Bit 0 is the Power On Reset Flag (POR). It is set on a each power-up and wake up from sleep.

Bit 1 is the CRC Error Status Flag (CRC_ERROR). It is updated on every I2C write packet.

Bit 2 is the Overcurrent Alert Status Flag (ALERT). This reflects the state of the overcurrent comparator.

4.2.2 CELL_CTL: 0x01

Bits 0-2 are the cell select bits (CELL_SEL) that determine which cell voltage input (VC1 – VC6) is sent to

the VCOUT pin.

Bits 4-5 are the VCOUT multiplexer selector bits (VCOUT_SEL). These bits determine the output of the

VCOUT pin: either VSS, VCn, Vref x 0.5, or Vref x 0.85.

4.2.3 BAL_CTL: 0x02

Bits 0-5 are for cell balance control (BAL_1…BAL_6).

4.2.4 CONFIG_1: 0x03

Bit 0 is the current amplifier gain select bit (I_GAIN). The gain can be set to 4 or 8.

Bit 2 is the current amplifier calibration bit (I_AMP_CAL). It is used to select the current measurement:

from SENSEN or SENSEP.

Bit 3 is the current comparator polarity select bit (I_COMP_POL). This determines the current direction

used to trip the comparator: charge or discharge.

Bits 4 – 7 determine the current comparator threshold setting (I_THRESH). Sixteen different mV levels are

available.

Control Register Demonstration

4.2.5 CONFIG_2: 0x04

Bit 0 is used to set the reference voltage level (REF_SEL). VREF has two different voltage levels.

Bit 7 is used to enable or disable the I2C CRC.

4.2.6 POWER_CTL: 0x05

Bit 0 is used to enable or disable the reference voltage (REF_EN).

Bit 1 is used to enable or disable the thermistors bias voltage (VTB_EN).

Bit 2 is used to enable or disable the cell voltage amplifier (VC_AMP_EN).

Bit 3 is used to enable or disable the current amplifier (I_AMP_EN).

Bit 4 is used to enable or disable the current comparator (ICOMP_EN).

Bit 6 is used to disable the sleep mode (SLEEP_DIS).

Bit 7 is used to enter sleep mode (SLEEP).

4.3 Modifying Control Registers

Control register bits that are writable can be modified by simply clicking on the bit that the user wishes to

change. The modification is immediately communicated by the Evaluation Software to the bq76925.

4.4 Sleep Mode and Wake Up

The bq76925 can be put into a low-power mode called Sleep. Bit 7 in the PWR_CTL register is called

SLEEP. When this bit is set to a 1, the part shuts down the V3P3 output and enters the low-power state.

To enter sleep mode, simply click the SLEEP bit in the Control Registers display.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

19

Page 20

Control Register Demonstration

The bq76925 shuts down the 3.3-V level at the V3P3 pin. The Hardware IO section shows a red light next

to V3P3 to indicate that the 3.3-V level is now zero. The Evaluation Software actually monitors the V3P3

output of the bq76925 via the USB-TO-GPIO Adapter input on pin 1.

www.ti.com

Figure 10. Sleep Mode Showing 3.3-V Status

The method to wake the part from sleep is to apply a voltage, 3.3 V in the case of the bq76925EVM, to

the ALERT pin. This is accomplished easily by clicking the Wake button in the Hardware IO Section.

20

Figure 11. Wake Up From Sleep Mode

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

5 Control Panel Demonstration

The Control Panel features of the bq76925 Evaluation Software are explained in this section. This is a

deeper look in to the software operation and the functionality of the bq76925.

5.1 Access to the Control Panel

The Control Panel is purposefully hidden from view when the software is first opened. This approach

eases the user into the complexity of the software. Access to the control panel is gained by clicking on the

small toggle switch in the top right corner of the home screen labeled Advanced.

Control Panel Demonstration

Figure 12. Open Control Panel

Figure 13. Control Panel Details

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

21

Page 22

Control Panel Demonstration

5.2 Measurement Tab

The measurement menu includes an Analog Output section and EEPROM Correction Registers section as

shown in Figure 14.

www.ti.com

Figure 14. Measurement Tab in the Control Panel

5.3 Analog Output Section

The Analog Output Section consists primarily of a display of the analog outputs of the bq76925 circuit

including VCOUT, VIOUT, VREF, and THERM.

The analog levels are measured by the onboard MSP430F2122 and then stored internally. The MSP430

updates all of the analog-to-digital converter (A/D) results on a 12-µs interval. The bq76925 software

writes to the control registers in the bq76925 to dictate how the measurement system operates. The

sequence of events is as follows:

1. Set VCOUT to Read Internal Temperature.

2. Delay 40 µs, get A/D Counts for Internal Temperature.

3. Set VCOUT to Read VC6.

4. Delay 40 µs, get A/D Counts for VC6.

5. Set VCOUT to Read VC5.

6. Delay 40 µs, get A/D Counts for VC5.

7. Set VCOUT to Read VC4.

8. Delay 40 µs, get A/D Counts for VC4.

9. Set VCOUT to Read VC3.

10. Delay 40 µs, get A/D Counts for VC3.

11. Set VCOUT to Read VC2.

22

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

1317 VCOUT

4.018

-

æ ö

ç ÷

è ø

( )

VREF

VCOUT

VC6 GC + VC6_OFFSET_CORR 0.001

1 + VC6_GAIN_CORR 0.001

G

æ ö

´ ´

´ ´

ç ÷

è ø

( )

VREF

VCOUT

VC5 GC + VC5_OFFSET_CORR 0.001

1 + VC5_GAIN_CORR 0.001

G

æ ö

´ ´

´ ´

ç ÷

è ø

( )

VREF

VCOUT

VC4 GC + VC4_OFFSET_CORR 0.001

1 + VC4_GAIN_CORR 0.001

G

æ ö

´ ´

´ ´

ç ÷

è ø

( )

VREF

VCOUT

VC3 GC + VC3_OFFSET_CORR 0.001

1 + VC3_GAIN_CORR 0.001

G

æ ö

´ ´

´ ´

ç ÷

è ø

( )

VREF

VCOUT

VC2 GC + VC2_OFFSET_CORR 0.001

1 + VC2_GAIN_CORR 0.001

G

æ ö

´ ´

´ ´

ç ÷

è ø

( )

VREF

VCOUT

VC1 GC + VC1_OFFSET_CORR 0.001

1 + VC1_GAIN_CORR 0.001

G

æ ö

´ ´

´ ´

ç ÷

è ø

( )

VREF

NOMINAL

VREF_OFFSET_CORR 0.001

GC = 1 + VREF_GAIN_CORR 0.001 +

VREF

´

´

www.ti.com

12. Delay 40 µs, get A/D Counts for VC2.

13. Set VCOUT to Read VC1.

14. Delay 40 µs, get A/D Counts for VC1.

15. Set VIOUT to read SENSEP (SENSEN for first 5 s of polling).

16. Delay 40 µs, get A/D Counts for Current.

17. Get A/D Count for THERM.

5.4 VCOUT Readings

VCOUT is a multiplexed output, and up to seven measurement results can be displayed. These millivolt

values are converted to Corrected Measurements on the home screen using the equations in Table 16.

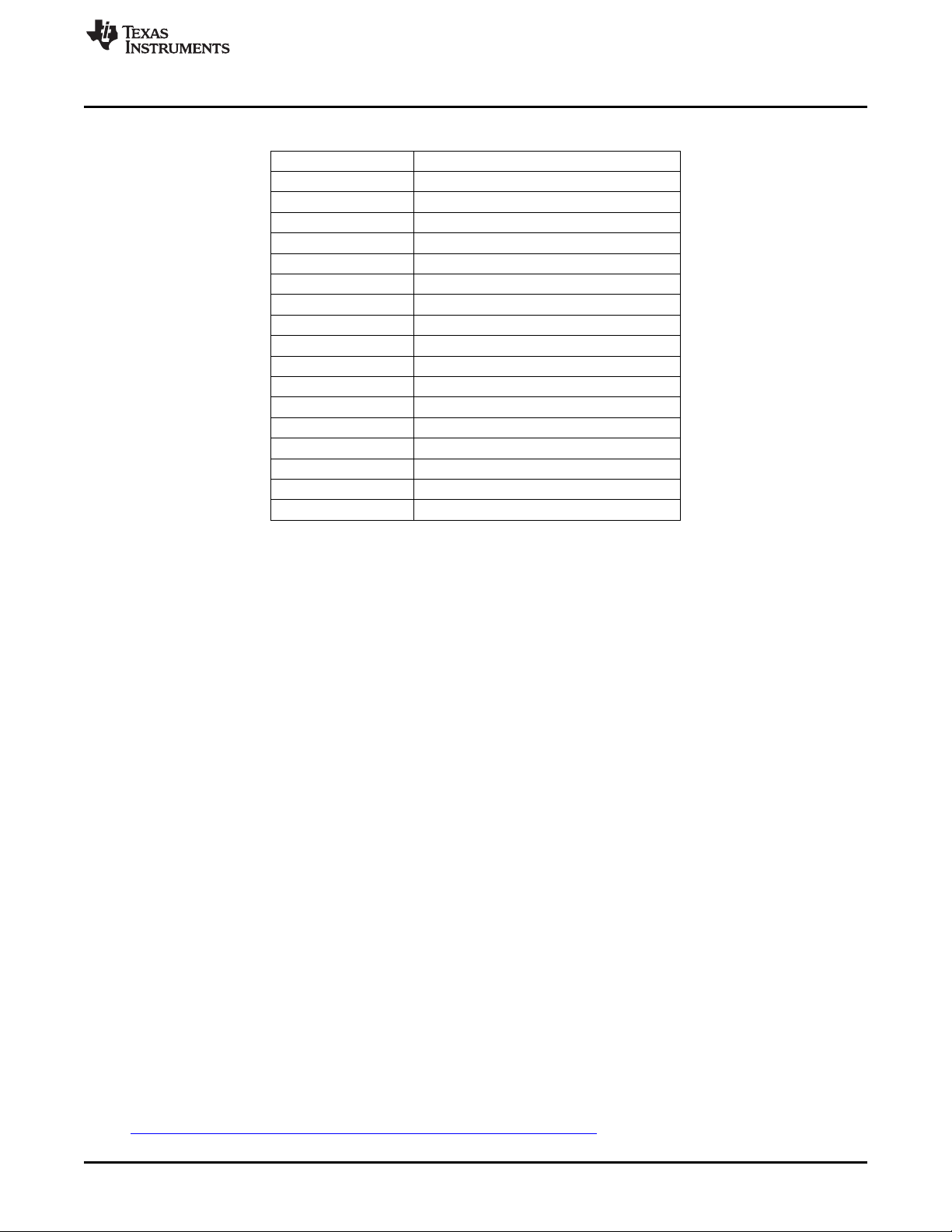

Display Function Formula to convert VCOUT reading to Cell Voltage or Temperature Units

Name

Tint Internal Temp. °C

VC6 Cell 6 mV

VC5 Cell 5 mV

Control Panel Demonstration

Table 16. Formulas to Convert VCOUT to either °C or mV

VC4 Cell 4 mV

VC3 Cell 3 mV

VC2 Cell 2 mV

VC1 Cell 1 mV

In Table 16, GC

And, G

VCOUT

REF

must be set to 0.6 for the bq76925EVM.

The VCn in Table 16 is the millivolt reading shown in the measurement window.

5.5 VIOUT Readings

The VIOUT readings are shown in millivolts and labeled as SENSEP and SENSEN. The SENSEN

readings are done with I_AMP_CAL set to zero and are only taken in the first 5 seconds of polling while

the VIOUT signal level stabilizes. After that time, SENSEN is not updated. The SENSEP readings are

done with I_AMP_CAL set to one thereafter and are done continuously until polling is stopped.

This measurement technique results in an approximate 5-s delay before the current measurement

stabilizes.

is defined as

(1)

5.6 Auto Control

Two checkboxes are in the Analog Output Section: Auto Control VCOUT during poll and Auto Control

VIOUT during poll, checked by default. The Auto Control VCOUT During Poll means that all six-cell

voltage inputs are read during polling. The Auto Control VIOUT During Poll means that the current is read

during polling. Note that these checkboxes do not turn the Voltage and Current Amplifier circuits on/off.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

23

Page 24

A

B

C

D

E

F

H

F

Control Panel Demonstration

5.7 EEPROM Correction Registers

The EEPROM Correction Registers are the seven registers in the bq76925 that store the offset and gain

values for the VCn circuits and the VREF circuit. These values can be different for each device. See the

data sheet for additional details.

Each gain value is derived from the top four bits (nibble) of the register value. This number is a signed 2’s

complement representation in the range of –8 to +7. The units are in mV.

Each offset value is derived from the bottom four bits (nibble) of the register value. This number is a

signed 2’s complement representation. The units are in 0.1%.

5.8 Startup Config Tab

The Startup Config tab is a convenience feature. It allows the user to set the way the bq76925 Evaluation

Software initializes each time it is started or when the Find Target Command is issued.

This tab specifies the settings of the Control Registers 0x00 to 0x05 when the Enable checkbox is

checked.

www.ti.com

Figure 15. Startup Config Tab in the Control Panel

5.9 Configuration Control

The Configuration Control section displays some of the options that a user may want to have preselected

each time the software starts. The features are listed by description rather than bit location and value (1 or

0). Again, this is a convenience feature, and usage of this tab is purely optional.

(A) A drop-down box for the Current Comparator threshold setting has values of 25, 50, 75, … , 375, 400

mV. These are bits 4 to 7 in the CONFIG_1 register.

(B) Two radio buttons allow the user to select the current polarity for the Current Comparator Threshold.

This is bit 3 of the CONFIG_1 register.

24

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

(C) A drop-down box for the Current Amplifier Gain is bit 0 of the CONFIG_1 register.

(D) Two radio buttons allow the user to select the current measurement polarity for the Current Amplifier.

This is bit 2 of the CONFIG_1 register.

(E) Two radio buttons allow the user to select the voltage reference (VREF). This is bit 0 of the CONFIG_2

register.

(F) The CRC Enable/Disable function has a checkbox. Check the box marked CRC Enable to turn on the

CRC feature. This is bit 7 of the CONFIG_2 register.

(G) The POR Enable/Disable function has a checkbox. Check the box marked POR Clear to turn on the

POR clear feature. This is related to bit 0 of the CONFIG_1 register.

(H) The Startup Config Functionality has a checkbox to enable/disable.

5.9.1 Configuration Control Example

As an example of how to use the Configuration Control, change the Current Comparator Threshold to 175

mV, and then press the F2 key to execute the Find Target Command. The I_THRESH bits in the

CONFIG_1 register changes to [0110].

Control Panel Demonstration

Figure 16. Change to the Current Comparator Threshold to 175 mV at Start-Up

5.10 Power Control

The Power Control section allows the user to have certain components of the measurement system

enabled at the start of the software.

When checked, five checkboxes activate the corresponding components in the bq76925. The default

setting is to have all of the components turned off.

These checkboxes correspond to bits 0 to 4 in the PWR_CTL register.

5.11 Logging Tab

The logging tab is another convenience feature. It allows the user to record the I2C transactions that take

place between the bq76925 software and the bq76925.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

25

Page 26

Control Panel Demonstration

5.12 Log File

www.ti.com

Figure 17. The Logging Tab

Three buttons specify the file to be used during logging.

1. The Browse… button opens a dialog box to let the user choose an existing log file to use to record the

logged data.

2. The Create… button opens a dialog box to let the user create an existing log file to use to record the

logged data.

3. The Export… button opens the file listed in the text box preceded by Log File: in the program assigned

to open Common Separated Value (.csv) files on the computer. Typically, this is a Microsoft Excel™

file.

5.13 Log File Options

The logging rate can be set by the drop-down box marked Log Rate. The logging rates are in seconds.

Two checkboxes offer options for how logging is done. The first checkbox labeled Overwrite File deletes

any existing data in the specified log file (.csv) each time logging is started. The second checkbox labeled

Include Uncorrected Values includes all of the uncorrected values for VCOUT and VIOUT.

5.14 Enable/Disable Logging

Logging is enabled by clicking the checkbox on the home screen of the software marked Logging. Then,

only after polling is started does the log file start to record samples of data. Logging is halted when polling

is stopped.

Editing of the Logging Tab is disabled when logging is enabled.

5.15 Log File Example

Table 17 is an example of a log file recording. This file only includes the corrected data.

Table 17. Example Log File

TimeStamp VC6 VC5 VC4 VC3 VC2 VC1 Current

6/15/2011 9:52 3953 3935 3878 3943 3949 3944 27.4 26.8 –722

6/15/2011 9:52 3953 3940 3878 3938 3949 3940 27.4 26.7 –722

26

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Int. Ext.

Temperature Temperature

Submit Documentation Feedback

Page 27

www.ti.com

Control Panel Demonstration

Table 17. Example Log File (continued)

TimeStamp VC6 VC5 VC4 VC3 VC2 VC1 Current

6/15/2011 9:52 3948 3940 3878 3938 3949 3944 27.4 26.3 –722

6/15/2011 9:52 3948 3940 3878 3938 3949 3944 27.4 26.7 –722

6/15/2011 9:52 3953 3940 3878 3938 3949 3940 27.4 26.7 –722

6/15/2011 9:52 3948 3940 3878 3938 3949 3944 27.4 26.1 –722

6/15/2011 9:52 3948 3940 3878 3943 3949 3935 27.4 26.9 –722

6/15/2011 9:52 3953 3940 3878 3943 3949 3940 27.4 26.8 –722

6/15/2011 9:52 3953 3940 3878 3938 3949 3944 28.2 26.8 –722

6/15/2011 9:52 3953 3940 3878 3938 3949 3944 27.4 26.9 –722

6/15/2011 9:52 3948 3940 3878 3938 3949 3940 27.4 26.7 –33922

6/15/2011 9:52 3943 3940 3878 3934 3949 3944 27.4 26.7 –47635

6/15/2011 9:52 3953 3940 3878 3938 3949 3944 27.4 26.8 –49800

6/15/2011 9:53 3948 3935 3878 3938 3949 3944 27.4 26.8 –49800

6/15/2011 9:53 3948 3940 3878 3943 3949 3944 27.4 26.8 –49800

6/15/2011 9:53 3953 3940 3878 3943 3949 3944 27.4 26.8 –50522

6/15/2011 9:53 3948 3940 3873 3938 3949 3940 27.4 26.9 –49800

6/15/2011 9:53 3953 3940 3878 3938 3949 3944 27.4 26.8 –49800

6/15/2011 9:53 3948 3940 3878 3938 3949 3944 27.4 26.8 –49800

6/15/2011 9:53 3948 3940 3878 3943 3949 3944 27.4 26.8 –50522

Int. Ext.

Temperature Temperature

5.16 Communications Tab

The communications tab is another convenience feature of the bq76925 Evaluation Software. It gives the

user insight into the communications happening between the Software, MSP430F2122, and the bq76925.

It also allows the user to perform manual reads and writes of the control registers of the bq76925.

The software both writes and reads to the bq76925 and just reads from the MSP430F2122.

Figure 18. Communications Tab

5.17 Monitor Window

The Monitor window can be used to monitor all of the communication traffic on the I2C bus. It records the

transaction history. The default condition of the monitor is to be off. Click on the checkbox below the

window that is labeled Enable to enable the monitor.

The Clear button erases the contents of the monitor window, if clicked.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

27

Page 28

Control Panel Demonstration

CAUTION

Be aware of a warning that reads: "Attention. The purpose of this

communications monitor is to evaluate the various commands to and from the

target device. It is not recommended for long term data capture and should be

disabled while logging is active.” This restriction is computer dependent based

on the amount of system memory. If left on for too long, the computer’s system

memory may get allocated to a point where the application performance can be

severely affected.

I2C_W is a write transaction from the software. I2C_R is a read transaction issued by the software.

5.18 Transactions During a Connect to Device Command

The typical transaction history after a Connect to Device command appears as shown in Table 18:

Table 18. Example of a Device Connect Command

Searching for I2C device...

I2C_R: 20 1 49

Device found!

Base Address: 0x20

I2C_W: 21 10 1

I2C_R: 21 10 14

I2C_R: 20 1 49

I2C_W: 23 0 25

I2C_R: 23 0 30

I2C_R: 20 1 49

I2C_W: 24 81 7D

I2C_R: 24 81 68

I2C_R: 20 1 49

I2C_W: 25 0 D9

I2C_R: 25 0 CC

I2C_R: 20 1 49

I2C_R: 20 1 49

I2C_R: 21 10 14

I2C_R: 22 0 1A

I2C_R: 23 0 30

I2C_R: 24 81 68

I2C_R: 25 0 CC

I2C_R: 27 10 E8

I2C_R: 30 3F 5D

I2C_R: 31 10 BA

I2C_R: 32 10 C4

I2C_R: 33 30 0E

I2C_R: 34 4F A2

I2C_R: 35 4E 8F

I2C_R: 36 4D F8

www.ti.com

28

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

First column is a comment. Second column is the combined device-address and register-address. Third

column is the register value. Last column is the CRC.

5.19 I2C

The I2C section shows the I2C Base Address of the bq76925 and the group address. These are 0x20 and

0x04, respectively. The base address is the group address shifted to the left by three places.

The user can use this I2C section to read and write data to the bq76925.

5.20 I2C Register Read

To read a register, select the desired register to read using the drop-down box. Refer to the product data

sheet to understand the meaning and usage of each register. Then click the Read button. The result is

displayed in the Monitor window.

For example, a read of register 0x01, CELL_CTL, appear as:

I2C_R: SPACER 22 SPACER 00 SPACER 1A.

The first number, 0x22, is the combined device address and the register number. The second number,

0x00, is the value of the register. The third number, 0x1A, is the CRC. If the CRC_EN bit in the

CONFIG_2 register is not set, the CRC value 0x1A does not appear.

5.21 I2C Register Write

To write a register, select the desired register to write using the drop-down box. See the product data

sheet to understand the meaning and usage of each register. Enter the value to be written in hexadecimal

notation. Then click the Write button. The result is displayed in the Monitor window.

If the Update GUI on write checkbox is selected, then the change to the register is updated in the Volatile

Control Registers section.

Control Panel Demonstration

5.22 I2C Communications With MSP430F2122

The I2C device address of the MSP430F2122 was assigned as 0x40 so as to not interfere with the

address structure of the bq76925.

The MSP430 reads the various analog outputs of the bq76925 and stores the results, in terms of counts,

in registers in its memory. The MSP430 A/D converter has 10 bits of resolution. The software accesses

these registers. The register map inside the MSP430 is shown in Table 19.

Table 19. Data From MSP430F2122

Byte

Number

1 Status of Alert pin: None

2 Reserved Reserved None

Name Description Units

Status of Alert pin. Bit zero indicates level

1=High, 0=Low (Overcurrent).

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

29

Page 30

Control Panel Demonstration

Table 19. Data From MSP430F2122 (continued)

Byte

Number

3 Ext Thermistor, MSB

4 Ext Thermistor, LSB

5 VCOUT, MSB

6 VCOUT, LSB

7 VIOUT1, MSB

8 VIOUT1, LSB

9 VIOUT2, MSB

10 VIOUT2, LSB

11 VREF, MSB

12 VREF, LSB

13 1/2 x DVCC, MSB

14 1/2 x DVCC, LSB

Name Description Units

Thermistor voltage

VCOUT voltage

VIOUT1 voltage (current)

VIOUT2 voltage

VREF voltage

DVCC voltage

To convert to mV, divide the 10-bit value by 1024 and multiply by the reference voltage (VREF) of 3000

mV.

5.23 Example of I2C Communications from MSP430F2122

The software continuously accesses the MSP430 registers during polling. An example of this appears in

Table 20.

www.ti.com

Counts from 10-bit A/D converter

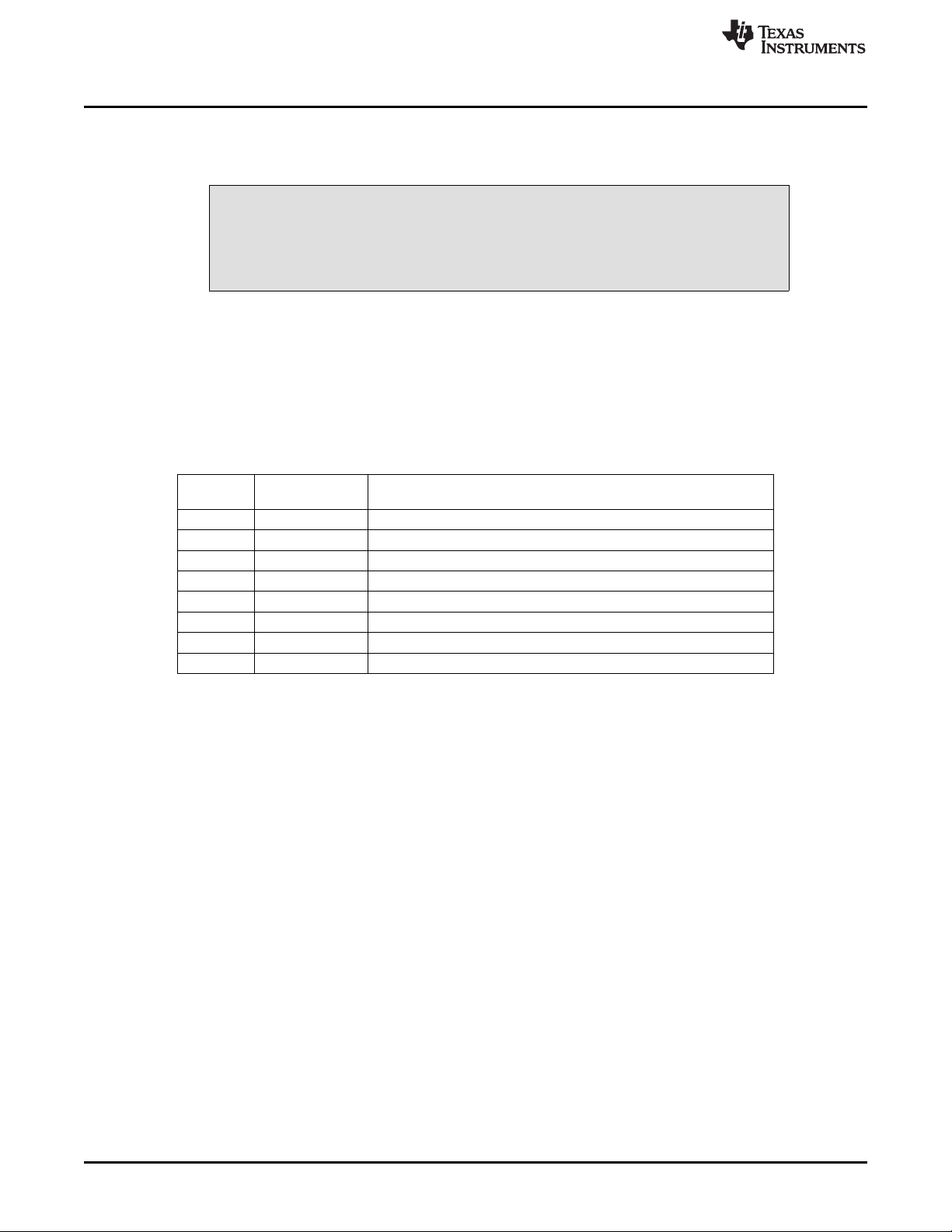

Table 20. Example of a Device Connect Command

I2C_W: 25 1F 84

I2C_R: 25 1F 91

I2C_W: 21 16 13

I2C_R: 40 0 0 2 30 1 9E 0 77 0 77 3 FF 2 2B

I2C_W: 21 15 1A

I2C_R: 40 0 0 2 30 3 36 0 AC 0 AB 3 FE 2 2F

I2C_W: 21 14 1D

I2C_R: 40 0 0 2 30 3 33 0 DB 0 DA 3 FF 2 2E

I2C_W: 21 13 8

I2C_R: 40 0 0 2 30 3 26 1 5 0 FA 3 FE 2 30

I2C_W: 21 12 0F

I2C_R: 40 0 0 2 30 3 32 1 22 1 21 3 FF 2 2F

I2C_W: 21 11 6

I2C_R: 40 0 0 2 30 3 35 1 45 1 44 3 FF 2 2E

I2C_W: 21 10 1

I2C_R: 40 0 0 2 30 3 2F 1 64 1 64 3 FE 2 30

I2C_W: 23 0 25

I2C_R: 40 0 0 2 2F 3 30 1 81 1 81 3 FF 2 2F

I2C_W: 21 16 13

I2C_R: 40 0 0 2 2F 1 9E 1 D6 1 D6 3 FF 2 2F

I2C_W: 21 15 1A

I2C_R: 40 0 0 2 30 3 36 1 E9 1 E8 3 FF 2 2F

I2C_W: 21 14 1D

I2C_R: 40 0 0 2 30 3 34 1 F9 1 F9 3 FF 2 2E

I2C_W: 21 13 8

I2C_R: 40 0 0 2 30 3 26 2 6 2 7 3 FF 2 2F

30

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

In general, polling data involves writing to the Control Registers of the bq76925 to configure the outputs

(VCOUT, VIOUT and VTB) and then reading the results from the MSP430.

3-, 4-, and 5-Cell Operation

Table 20. Example of a Device Connect Command (continued)

I2C_W: 21 12 0F

I2C_R: 40 0 0 2 30 3 32 2 15 2 15 3 FF 2 2D

I2C_W: 21 11 6

I2C_R: 40 0 0 2 30 3 35 2 21 2 21 3 FF 2 2F

I2C_W: 21 10 1

I2C_R: 40 0 0 2 30 3 2F 2 2C 2 2C 3 FF 2 2E

I2C_W: 23 0 25

I2C_R: 40 0 0 2 2F 3 2F 2 36 2 34 3 FE 2 30

I2C_W: 25 0 D9

I2C_R: 25 0 CC

I2C_W: 21 10 1

I2C_R: 40 0 0 2 30 3 2F 2 2C 2 2C 3 FF 2 2E

I2C_W: 23 0 25

I2C_R: 40 0 0 2 2F 3 2F 2 36 2 34 3 FE 2 30

I2C_W: 25 0 D9

I2C_R: 25 0 CC

6 3-, 4-, and 5-Cell Operation

This section includes instructions for setting up the bq76925EVM for operation with less than 6 cells. The

discussion considers operation with the cell simulator only.

6.1 Introduction

The bq76925 is capable of working with cell packs that have 3-, 4-, 5-, or 6-series connected cells. There

are some special considerations when operating with less than six series cells. For complete information,

consult the bq76925 data sheet.

Configure the bq76925EVM for the appropriate cell count prior to applying

power to the board.

6.2 Using Onboard Cell Simulator

The cell simulator can be set up for 3-, 4-, 5-, or 6-cell operation. The process simply involves placing a

shorting wire across the proper pins on the CN6:CELLS connector.

6.3 Five-Cell Operation

The procedure for five-cell operation with the simulation circuit is as follows:

1. Ensure that the power to the board, at BATT+/-, is removed.

2. Close all switches on S4.

3. Apply a jumper wire from pin 1 to pin 2 on connector CN6. These are the inputs marked Cell 6 and

Cell 5.

4. Set the power supply to a safe level for 5-cell operation. This is somewhere below 25 V.

5. Connect the power supply to BATT+ and BATT–.

6. Turn on the power supply.

7. Connect to the evaluation software.

CAUTION

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

31

Page 32

Operation With Cells

8. Change the Select Cell Count drop-down box on the home screen to 5.

6.4 Four-Cell Operation

The procedure for four-cell operation with the simulation circuit is as follows:

1. Ensure that the power to the board, at BATT+/–, is removed.

2. Close all switches on S4.

3. Apply a jumper wire from pin 1 to pin 2 on connector CN6. These are the inputs marked Cell 6 and

Cell 5.

4. Apply a jumper wire from pin 2 to pin 3 on connector CN6. These are the inputs marked Cell 5 and

Cell 4.

5. Set the power supply to a safe level for 4-cell operation. This is somewhere below 20 V.

6. Connect the power supply to BATT+ and BATT–.

7. Connect to the evaluation software.

8. Change the Select Cell Count drop-down box on the home screen to 4.

6.5 Three-Cell Operation

The procedure for three-cell operation with the simulation circuit is as follows:

1. Ensure that the power to the board, at BATT+/–, is removed.

2. Close all switches on S4.

3. Apply a jumper wire from pin 1 to pin 2 on connector CN6. These are the inputs marked Cell 6 and

Cell 5.

4. Apply a jumper wire from pin 2 to pin 3 on connector CN6. These are the inputs marked Cell 5 and

Cell 4.

5. Apply a jumper wire from pin 3 to pin 4 on connector CN6. These are the inputs marked Cell 4 and

Cell 3.

6. Set the power supply to a safe level for 4 cell operation. This would be somewhere below 15 V.

7. Connect the power supply to BATT+ and BATT–.

8. Connect to the evaluation software.

9. Change the Select Cell Count drop-down box on the home screen to 3.

www.ti.com

7 Operation With Cells

This section discusses operating the bq76925EVM with a real cell pack.

7.1 Preparing Circuit for Operation

Improper operation with real lithium-ion cells can cause permanent damage to

the bq76925EVM.

No battery current control devices (MOSFETs) are on this EVM that

can stop the flow of charge or discharge current in the event that a

dangerous condition is induced through discharging or charging

of a battery. Exercise extreme caution when using a battery with

this EVM.

32

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

CAUTION

WARNING

Submit Documentation Feedback

Page 33

www.ti.com

Disconnect all external electronics from the bq76925EVM prior to the connection of real cells. This

includes power supplies, electronic load, USB-TO-GPIO Adapter or MSP-FET430UIF that may be

connected.

7.2 Battery Connection Sequence

The connection of a real battery pack to the bq76925EVM requires a certain connection sequence for safe

operation.

The fundamental connection sequence is:

1. Ensure that all switches on S4 are open.

2. Connect BATT–.

3. Connect BATT+.

4. Connect CN6. The cell inputs have a specific assignment (1-1, 2-2, 3-3,etc) but no specific connection

timing sequence is required.

Remove the CN6 mating connector from the board before wiring cell connections to the terminals.

7.3 Six-Cell Operation

The procedure for six-cell operation with a cell pack is as follows:

1. Ensure that all switches on S4 are open.

2. Wire the seven-cell tap wires to the mating plug of CN6.

3. Connect BATT–.

4. Connect BATT+.

5. Connect CN6 to the EVM. The cell inputs can be connected in any order.

6. Connect to the evaluation software.

7. Change the Select Cell Count drop-down box on the home screen to 6.

Operation With Cells

7.4 Five-Cell Operation

The procedure for five-cell operation with a cell pack is as follows:

1. Ensure that all switches on S4 are open.

2. Wire the six-cell tap wires to positions 2 through 7 on the mating plug of CN6.

3. Apply a jumper wire from pin 1 to pin 2 on mating plug of CN6. (These are the inputs marked Cell 6

and Cell 5.)

4. Connect BATT–.

5. Connect BATT+.

6. Connect CN6 to the EVM. The cell inputs can be connected in any order.

7. Connect to the evaluation software.

8. Change the Select Cell Count drop-down box on the home screen to 5.

7.5 Four-Cell Operation

The procedure for four-cell operation with the simulation circuit is as follows:

1. Ensure that all switches on S4 are open.

2. Wire the five-cell tap wires to positions 3 through 7 on the mating plug of CN6.

3. Apply jumper wire from pin 1 to pin 2 on plug for CN6. These are inputs marked Cell 6 and Cell 5.

4. Apply jumper wire from pin 2 to pin 3 on plug for CN6. These are inputs marked Cell 5 and Cell 4.

5. Connect BATT–.

6. Connect BATT+.

7. Connect CN6 to the EVM. The cell inputs can be connected in any order.

8. Connect to the evaluation software.

9. Change the Select Cell Count drop-down box on the home screen to 4.

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

33

Page 34

Schematic and Bill of Materials

7.6 Three-Cell Operation

The procedure for three-cell operation with the simulation circuit is as follows:

1. Ensure that all switches on S4 are open.

2. Wire the four-cell tap wires to positions 4 through 7 on the mating plug of CN6.

3. Apply jumper wire from pin 1 to pin 2 on plug for CN6. These are inputs marked Cell 6 and Cell 5.

4. Apply jumper wire from pin 2 to pin 3 on plug for CN6. These are inputs marked Cell 5 and Cell 4.

5. Apply jumper wire from pin 3 to pin 4 on plug for CN6. These are inputs marked Cell 4 and Cell 3.

6. Connect BATT–.

7. Connect BATT+

8. Connect CN6 to the EVM. The cell inputs can be connected in any order.

9. Connect to the Evaluation Software.

10. Change the Select Cell Count drop-down box on the home screen to 4.

7.7 Battery Removal Sequence

The removal of the battery from the bq76925EVM requires a certain sequence for safe operation.

The connection removal sequence is:

1. Remove USB-TO-GPIO connector at CN8.

2. Unplug CN6 (CELLS).

3. Remove BATT+ connection.

4. Remove BATT– connection.

www.ti.com

8 Schematic and Bill of Materials

This section includes the schematic and the bill of materials for the bq76925EVM.

34

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

www.ti.com

8.1 Schematics

Schematic and Bill of Materials

Figure 19. Schematic – Page 1 of 4

SLUU514–July 2011 bq76925EVM Evaluation Module

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

35

Page 36

Schematic and Bill of Materials

www.ti.com

Figure 20. Schematic – Page 2 of 4

Figure 21. Schematic – Page 3 of 4

36

bq76925EVM Evaluation Module SLUU514– July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

www.ti.com

Schematic and Bill of Materials

Figure 22. Schematic – Page 4 of 4

8.2 Bill of Materials

Table 21. Bill of Materials

Count RefDes Value Description Size Part Number MFR

1 C9 10 µF Capacitor, Ceramic, 50V, Y5V, –20%/+80% 1210 C3225Y5V1H106Z TDK

1 C10 1.0 µF Capacitor, Ceramic, Low Inductance, 16V, X7R, 10% 0805 Standard Standard

1 C12 0.33 µF Capacitor, Leaded, Metalized 40VAC, ±10% 3.0 x 7.2 mm B32529C334K Epcos

1 C14 470 pF Capacitor, Ceramic, 50V, X7R, 10% 0805 Standard Standard

1 C15 4.7 µF Capacitor, Ceramic, 16V, X7R, 10% 0805 Standard Standard

1 C17 470 nF Capacitor, Ceramic, 50V, C0G, 5% 0805 Standard Standard

1 C19 220 pF Capacitor, Ceramic, 50V, X7R, 10% 0805 Standard Standard

1 C23 10 µF Capacitor, Ceramic, 10V, X7R, 10% 0805 Standard Standard